Patents

Literature

302results about "Granulation in rotating dishes/pans" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

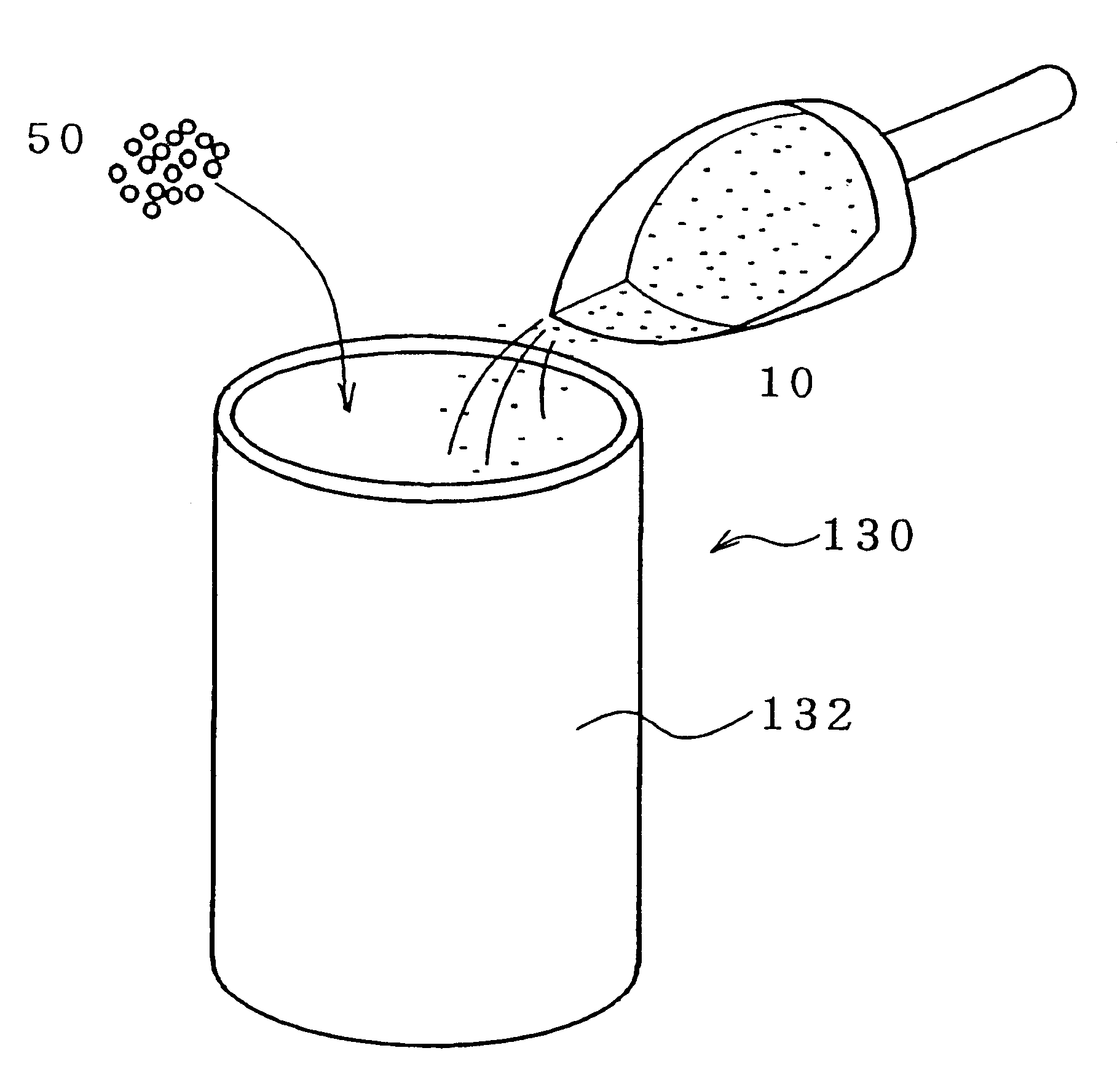

Spherical single-substance particles, medicines and foodstuffs containing the particles, and method of production thereof

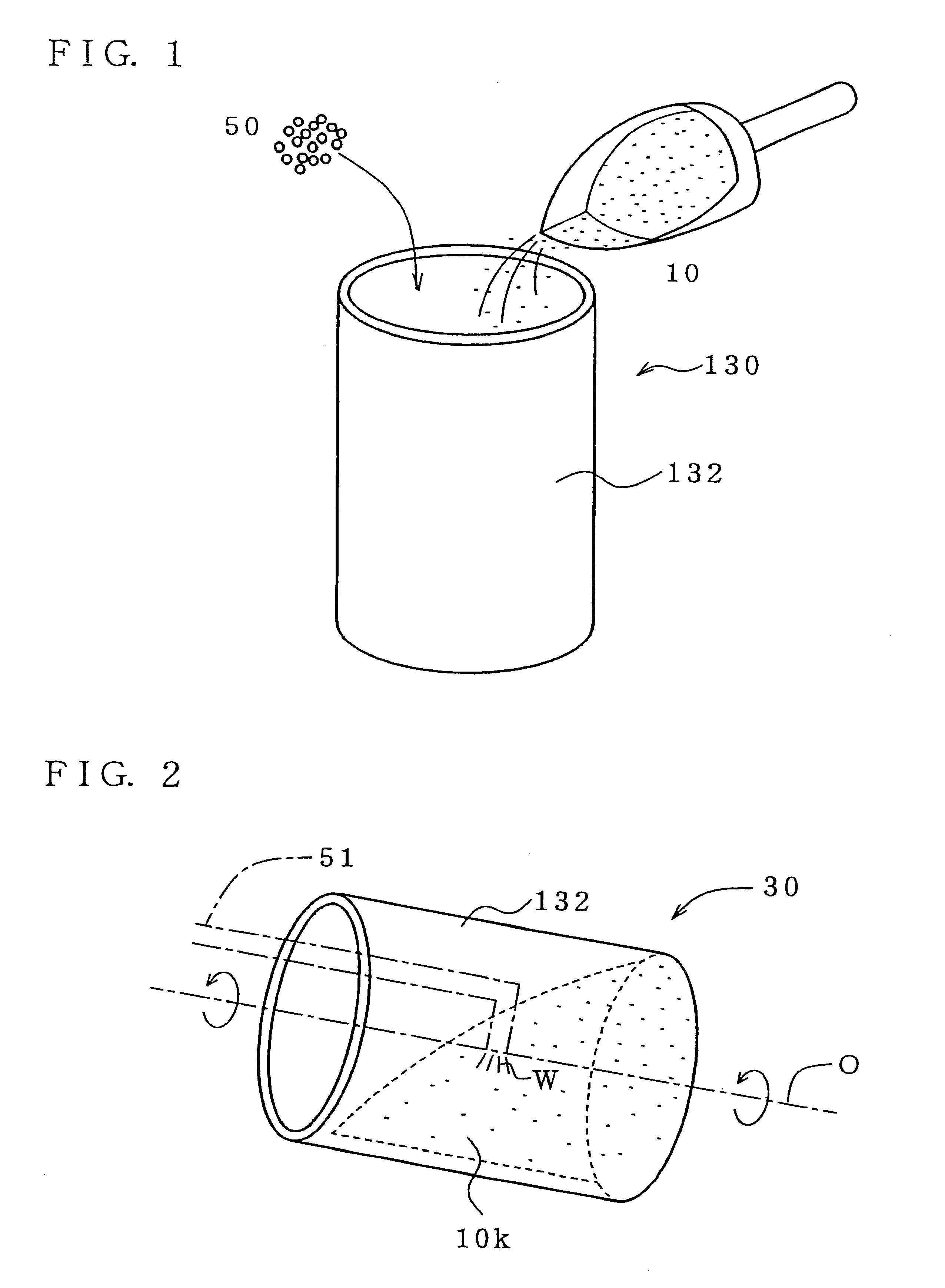

The present invention relates to a process for producing a spherical particle comprising an aggregate of particles containing at least 95% of a water-soluble single substance having a viscosity of 10 mPa.s or less as determined in the form of a saturated aqueous solution, the process comprising: preparing moist spherical particles of the single substance by charging, as cores, crystalline particles or granulated particles of the single substance on a rotary disc in a processing vessel of a centrifugal tumbling granulating apparatus, wherein the granulated particles are prepared by granulating a powder of the single substance, and dispersing over the cores a powder of the single substance and simultaneously spraying on the cores a liquid such as water or the like while supplying slit air to provide a fluidized condition; and then fixation treating the moist spherical particles by drying them while spraying an aqueous solution of the single substance or the like on the spherical particles in a fluidized bed apparatus; to the spherical particle produced by the process; and to a pharmaceutical preparation and a food containing the spherical particle.

Owner:FREUNT IND +1

Highly available particulate controlled release nitrogen fertilizer

InactiveUS6048378ASpeed up the conversion processImprove efficiencyBiocideGranulation in rotating dishes/pansParticulatesWater insoluble

A method preparing controlled release nitrogen in particulate fertilizers which exhibit single growing season availabilities to plants of about 80 percent or higher. The method utilizes relatively low urea and ammonia to formaldehyde mol ratios of about 1.7 urea to 0.1 ammonia to 1 formaldehyde to assure high conversions to controlled release nitrogen with low free ureas, and carefully controlled elevated temperatures, acid dehydration condensation catalyst concentrations and short dehydration reaction times of about 2-4 minutes to provide effective conversion of hydroxymethyl nitrogen compounds by dehydration condensation reaction to controlled release methylene nitrogen compounds. Quick neutralization of the dehydration catalyst in a turbulent mixing reactor minimizes the formation of undesirable methylene nitrogen polymers which are hot water insoluble and unavailable to plants in a single growing season.

Owner:AGRINUTRIENTS TECH GRP INC

Soil conditioning agglomerates containing calcium

InactiveUS6936087B2High mechanical strengthGood curative effectBiocideCalcareous fertilisersParticulatesWater soluble

Mechanically strong, water-disintegrable agglomerates made from a particulate calcium source, a water-soluble binder and optionally containing a primary plant nutrient source and / or micronutrient source and a process for forming such agglomerates are disclosed. The agglomerates may be used as a soil liming agent and for introducing nutrient values into cultivated soil. Also disclosed is a method for introducing nutrient values into cultivated soil so as to inhibit leaching of the nutrient values from the soil and improve utilization of the nutrient values by plants grown in the soil.

Owner:MAGIC GREEN CORP

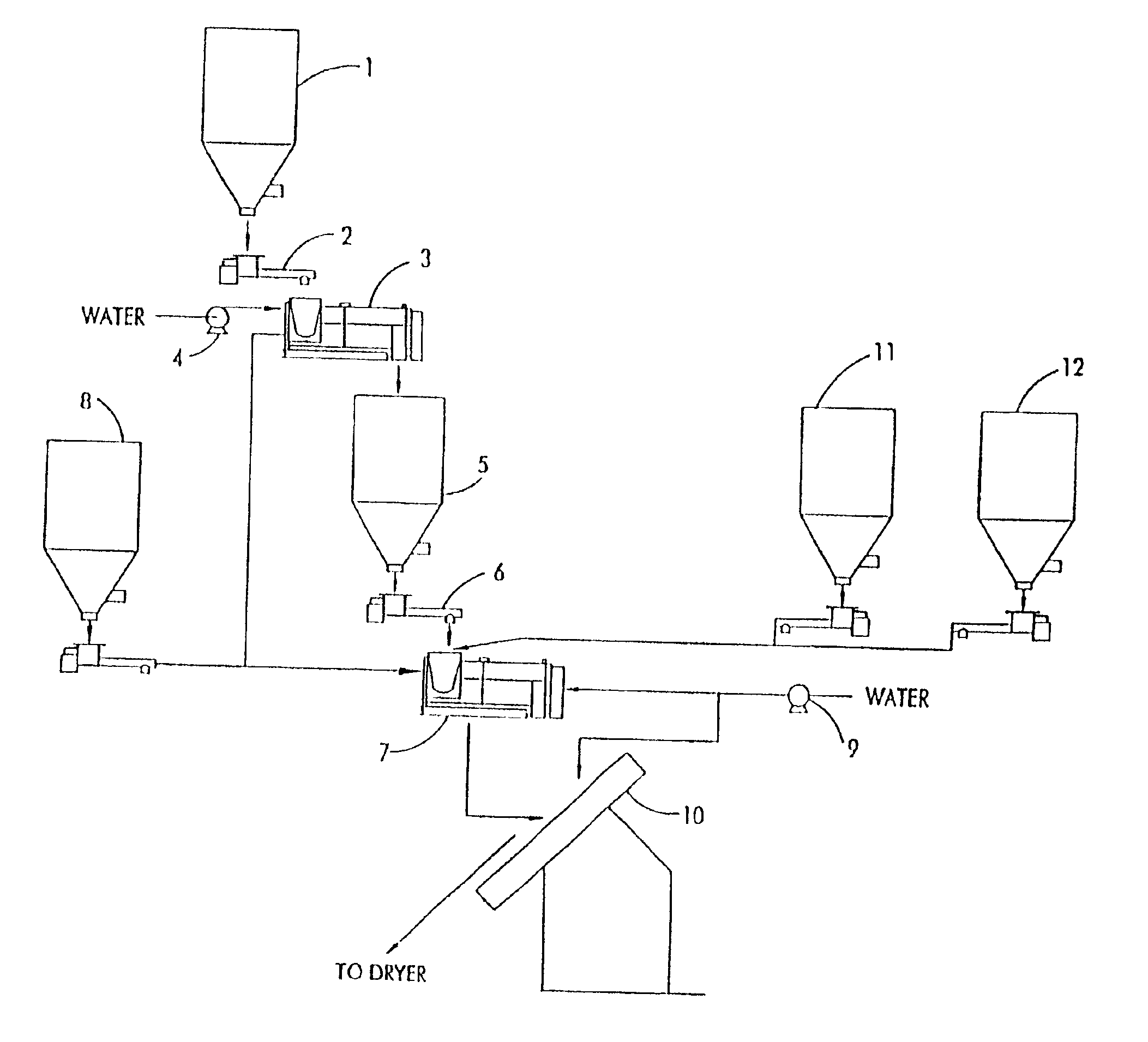

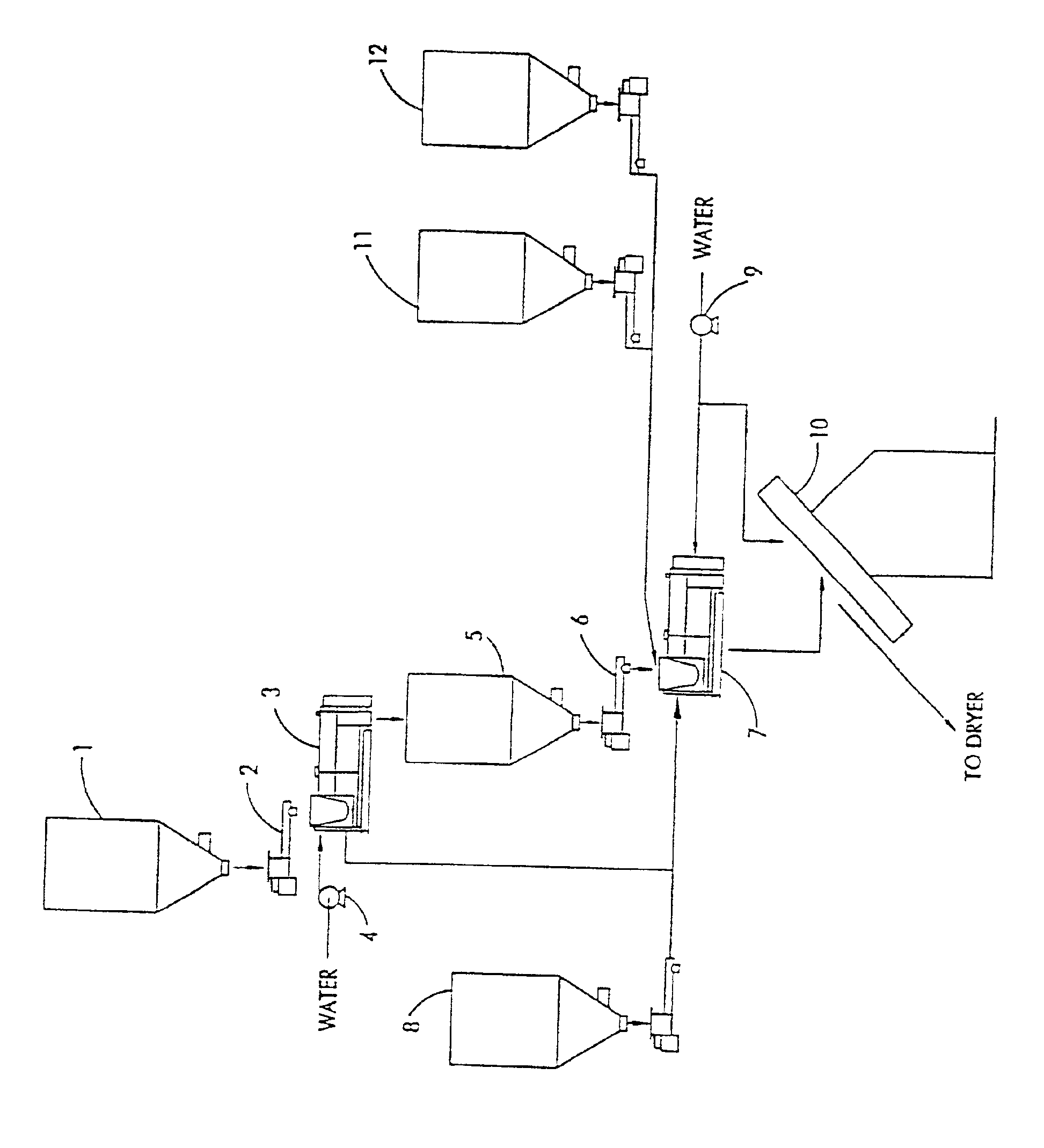

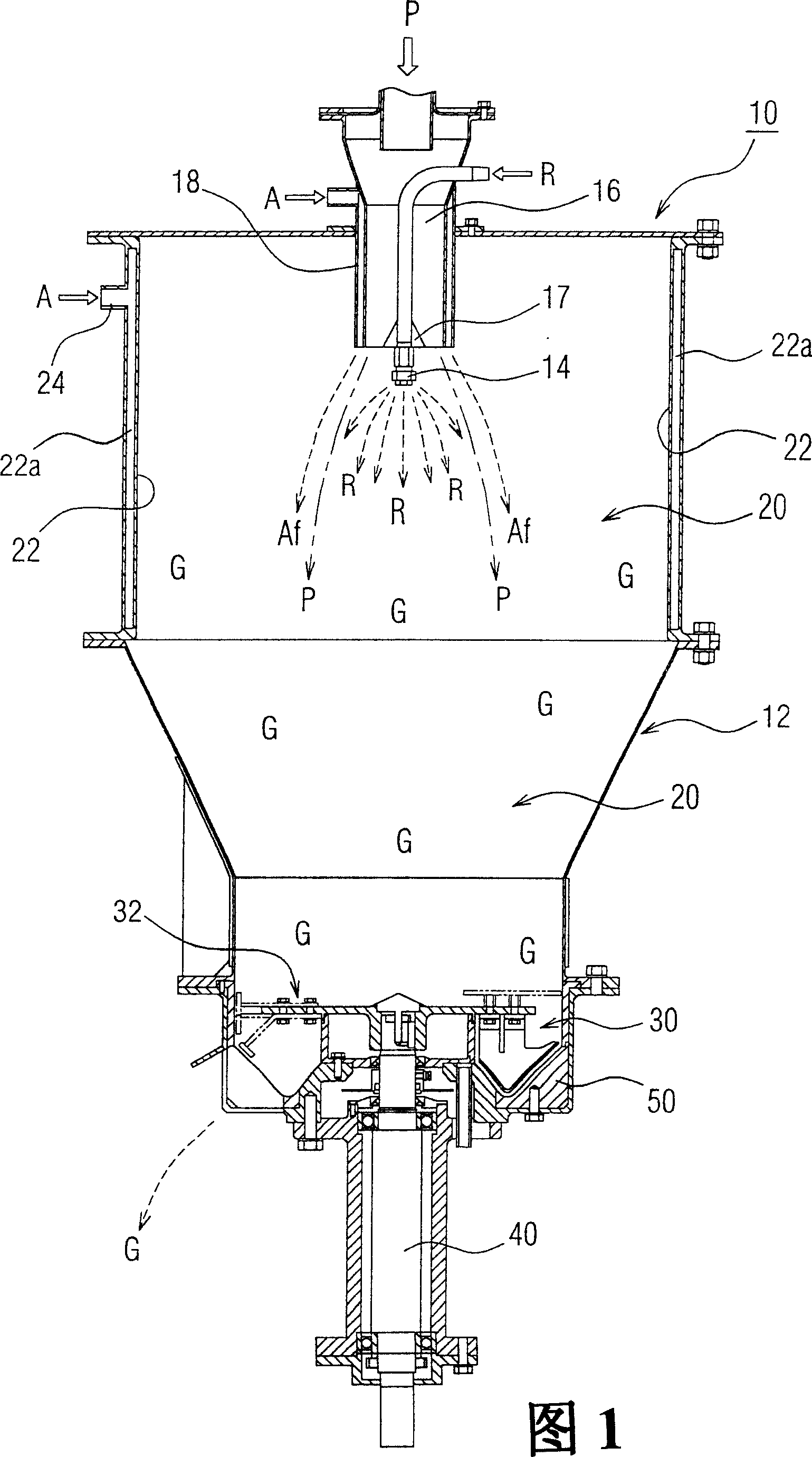

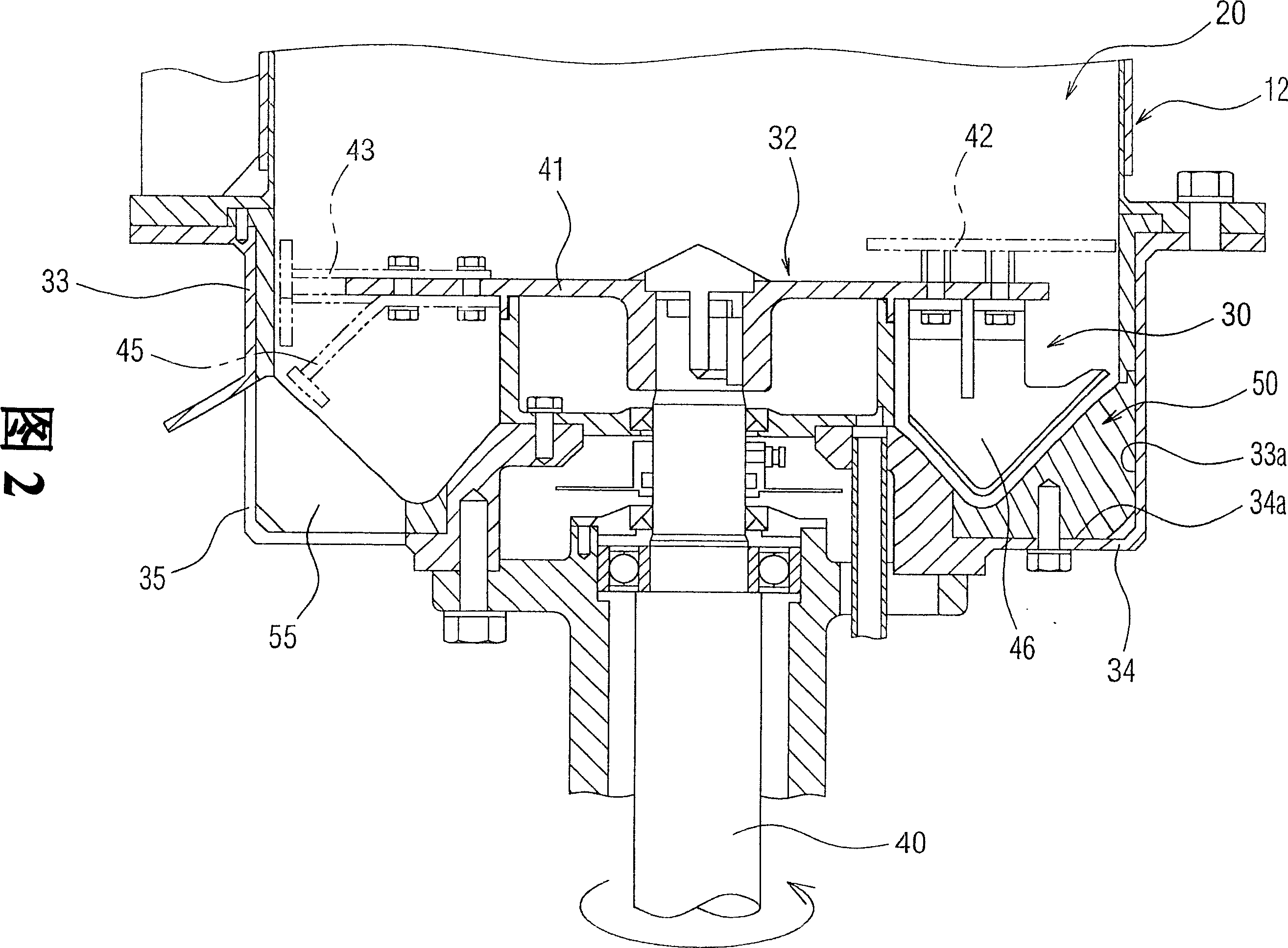

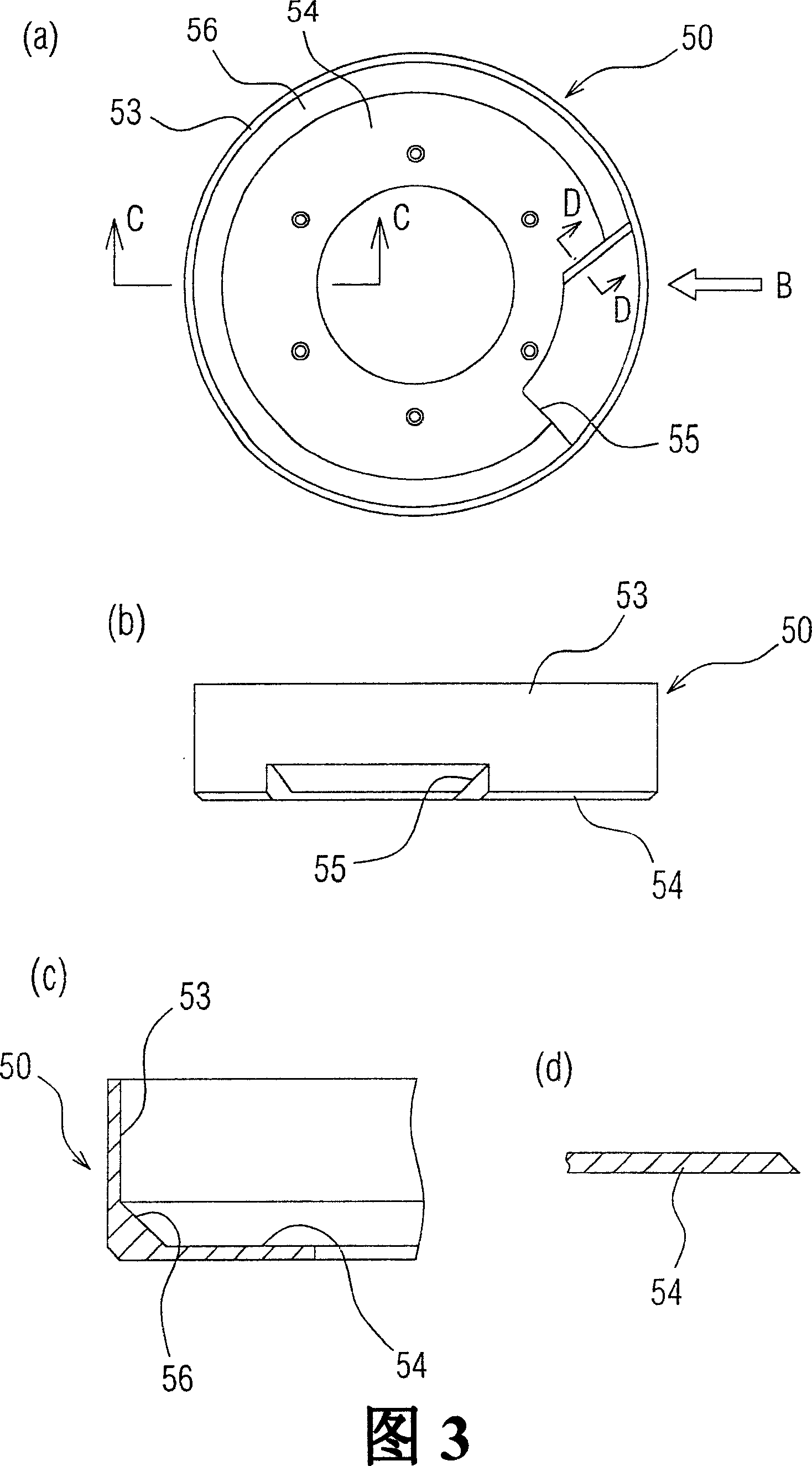

Method and apparatus for granulating by mixing powder and liquid continuously

ActiveCN1927437AImprove yieldWide applicabilityFlow mixersGranulation in rotating dishes/pansManufacturing cost reductionEngineering

The invention relates to a method of powder / liquid continuous mixing particle production. Wherein, said method comprises that sealing the top of hopper mixed particle producing room (12); the center at the top uses ejector (14) to continuously eject liquid downwards; the powder outlet (16) at the circumference of ejector disperses the atomized liquid to the powder; and the gas ejector (18) at the circumference of powder outlet feeds gas as the protective air film (Af) that avoiding dispersing the fed powder; therefore, the powder and liquid can continuously contact to form mixed particle (G); and the bottom of room (12) via the rotation of mixing disc (32) can make the air passive pressure, to generate eddy flow, to accelerate the particle (G) generation, and shear or mix the particle (G), to form and discharge uniform particles (G).

Owner:FUNKEN POWTECHS

Method for making fluid emitter orifice

InactiveUS20050130075A1Granulation in rotating dishes/pansPhotomechanical exposure apparatusResistNuclear medicine

A method of forming a depression in a surface of a layer of photo-resist comprises exposing a first portion of a layer of photo-resist with a first dose of radiant energy. A second portion of the layer is exposed with a second dose of radiant energy. The second dose is less than the first dose. The layer is baked.

Owner:HEWLETT PACKARD DEV CO LP

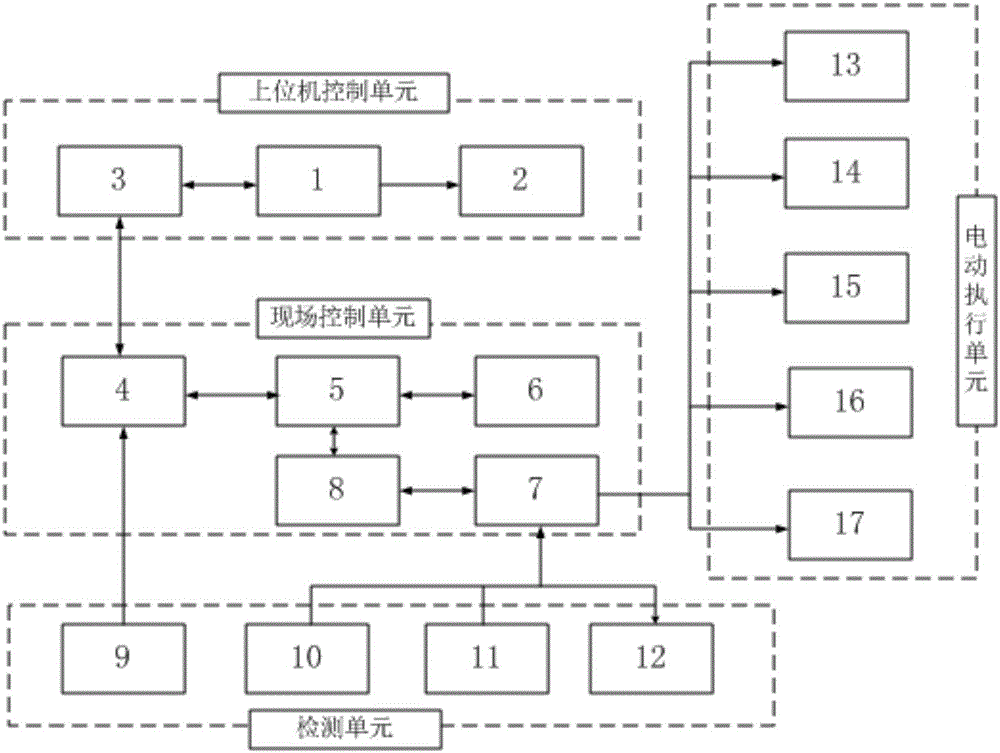

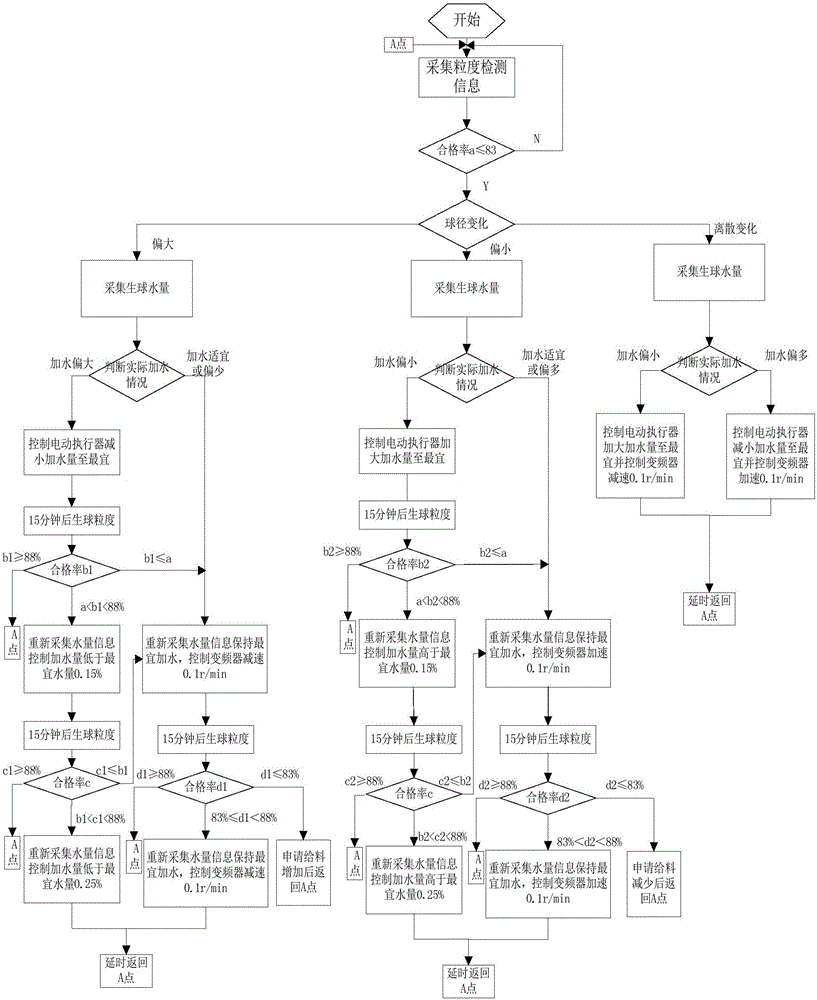

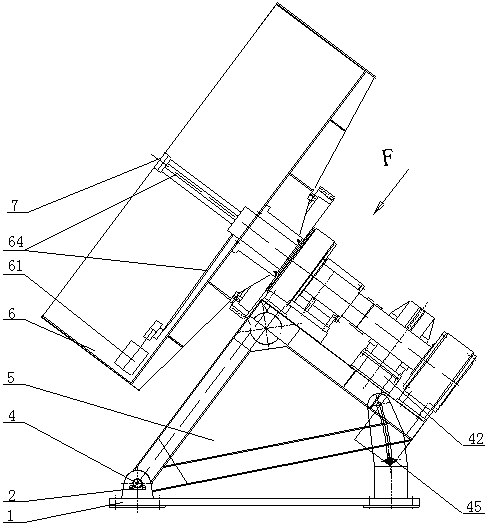

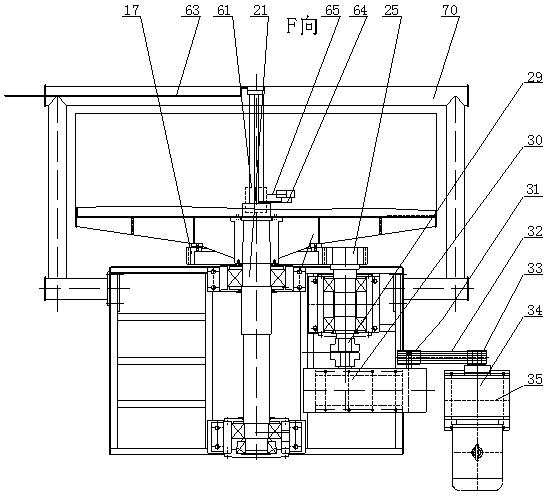

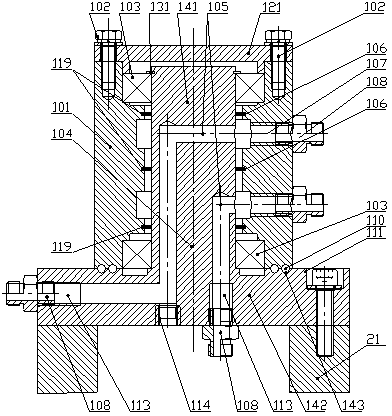

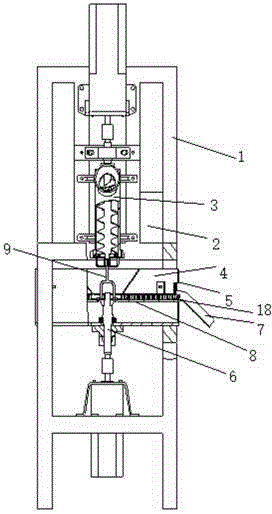

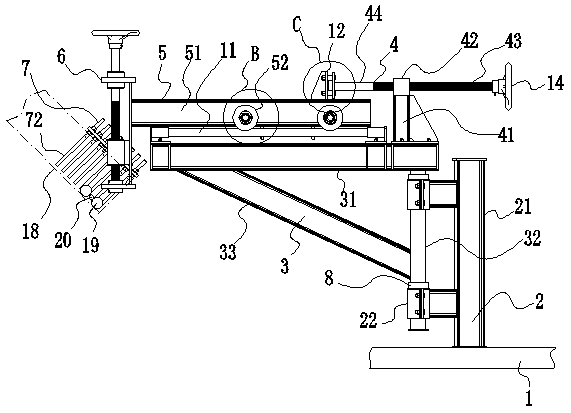

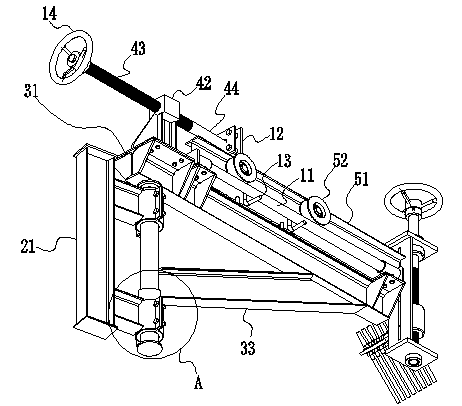

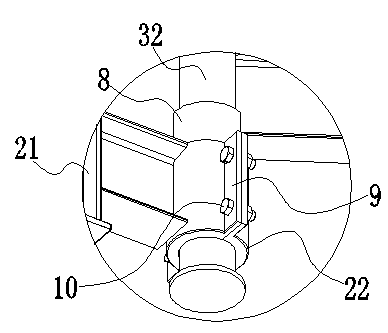

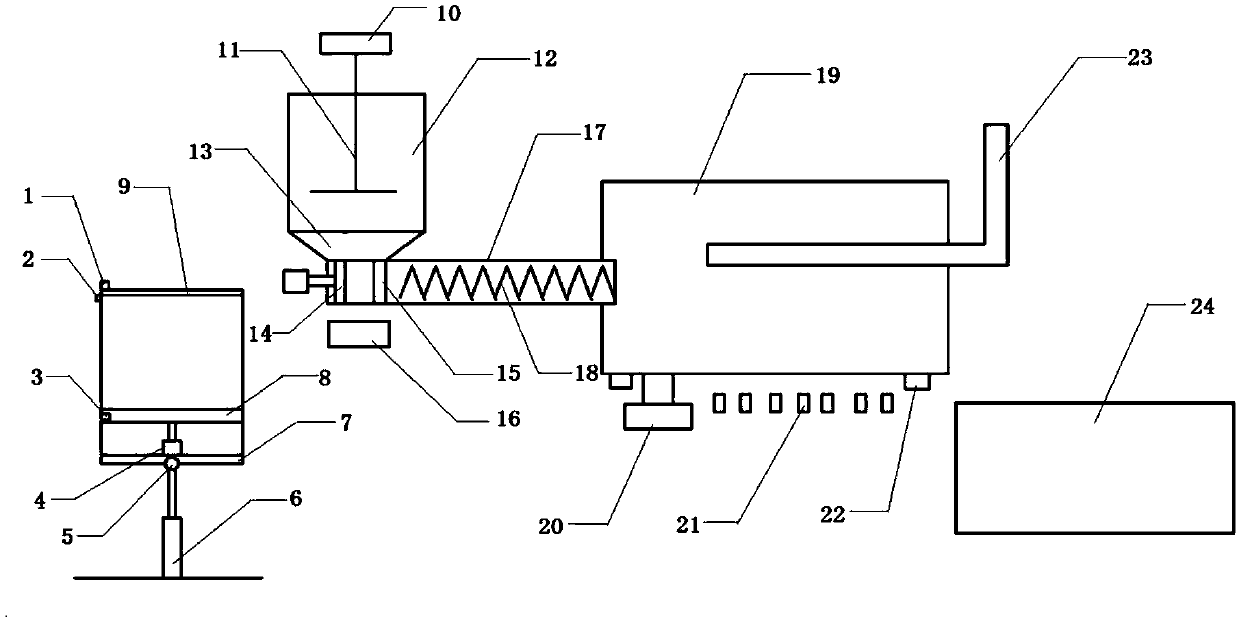

Disc pelletizing intelligent production system and control method thereof

ActiveCN106647663ATimely intelligent adjustmentRealize intelligent adjustmentGranulation in rotating dishes/pansTotal factory controlProgrammable logic controllerControl system

The invention discloses a disc pelletizing intelligent production system and a control method thereof, and the control system comprises an upper computer control unit, a field control unit, a detection unit, and an electric execution unit. The control system cooperates with the control method, carries out the processing of data and the setting of preset values through the upper computer control unit, and then transmits the data to the field control unit for production control. The detection unit is used for collecting a plurality of practical technological values related with the pelletizing qualified rate in a field disc pelletizing process, and transmitting a detection result to the field control unit for logic criterion in real time. According to the invention, the detection unit serves a data input unit of a production control system, and the electric execution unit serves as a data output unit. The system achieves the adjustment of the production technological parameters of a disc pelletizing device through a programmable logic controller, achieves a purpose of controlling the pelletizing qualified rate in a preset qualified range, and improves the product quality.

Owner:天津市三特电子有限公司

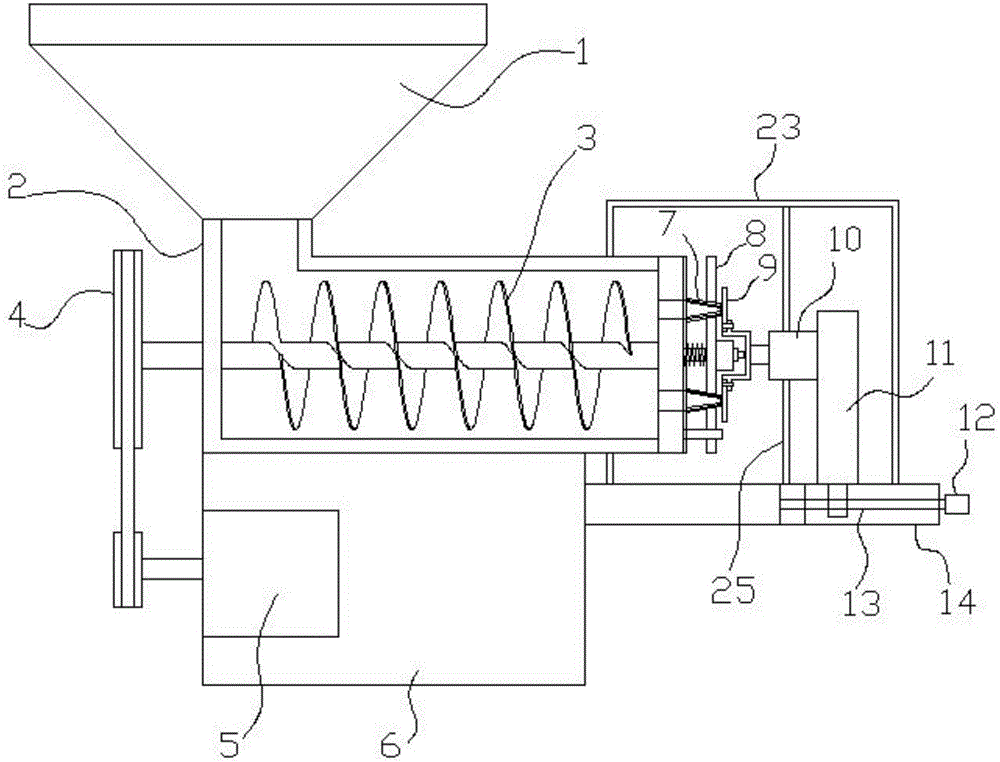

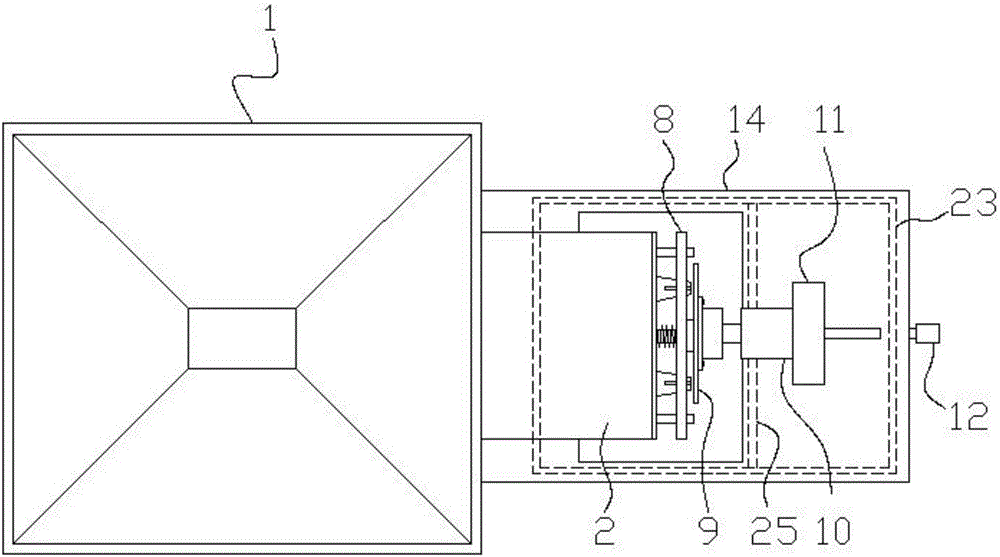

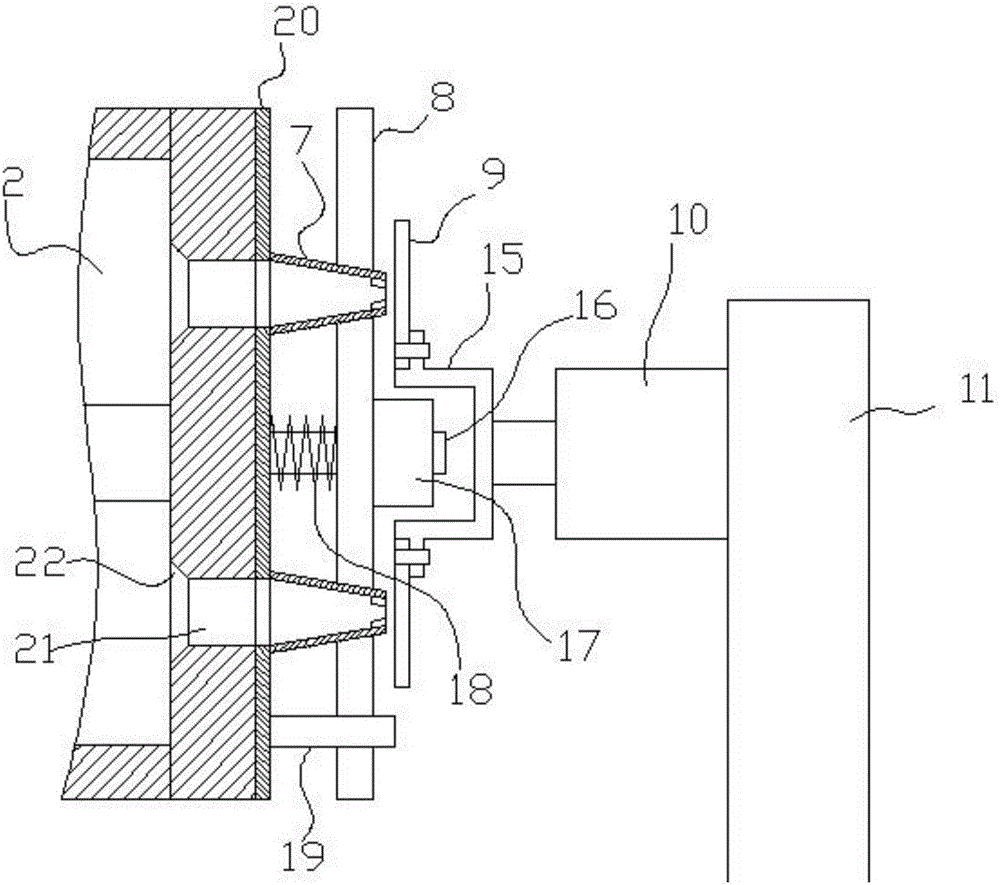

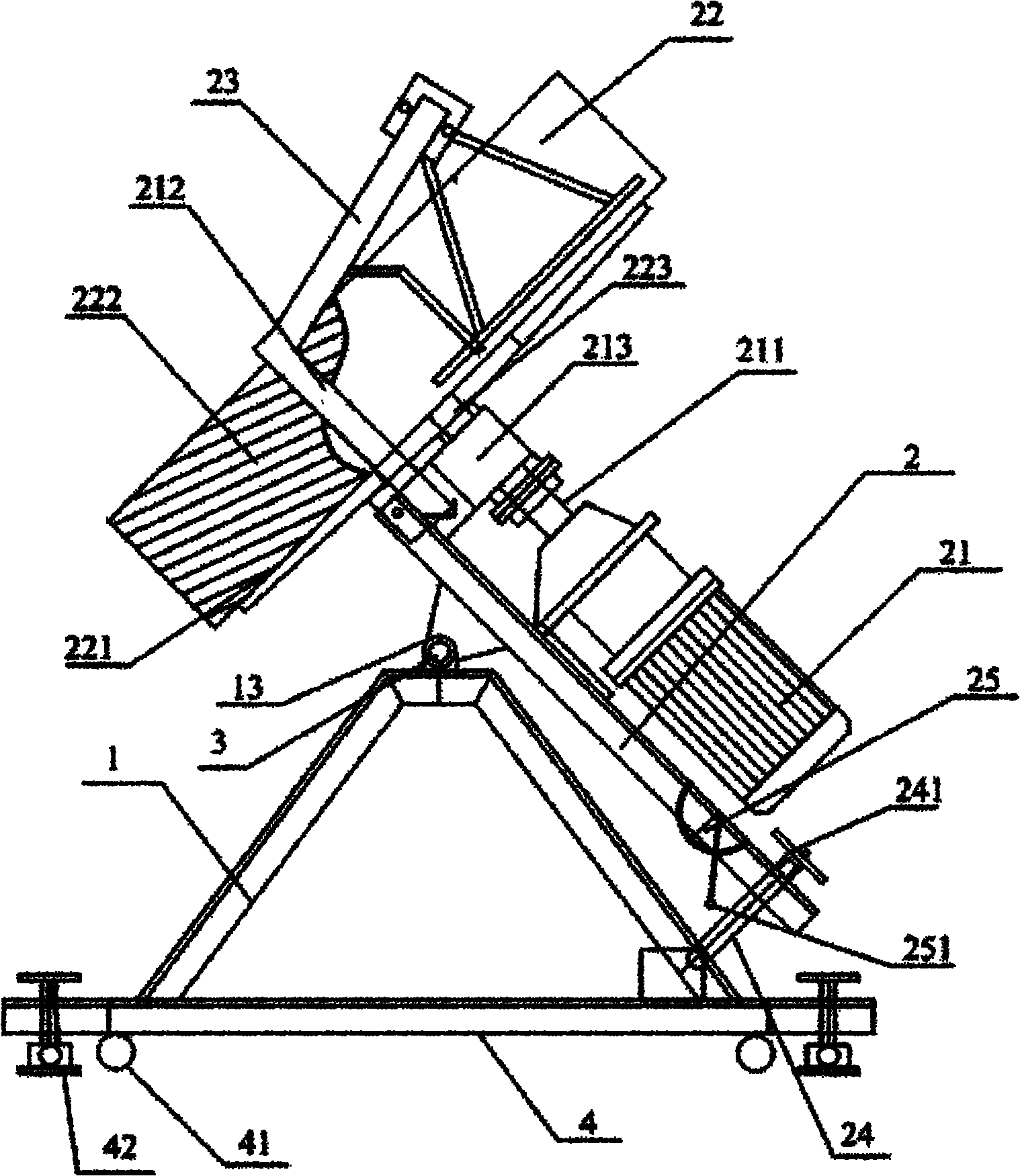

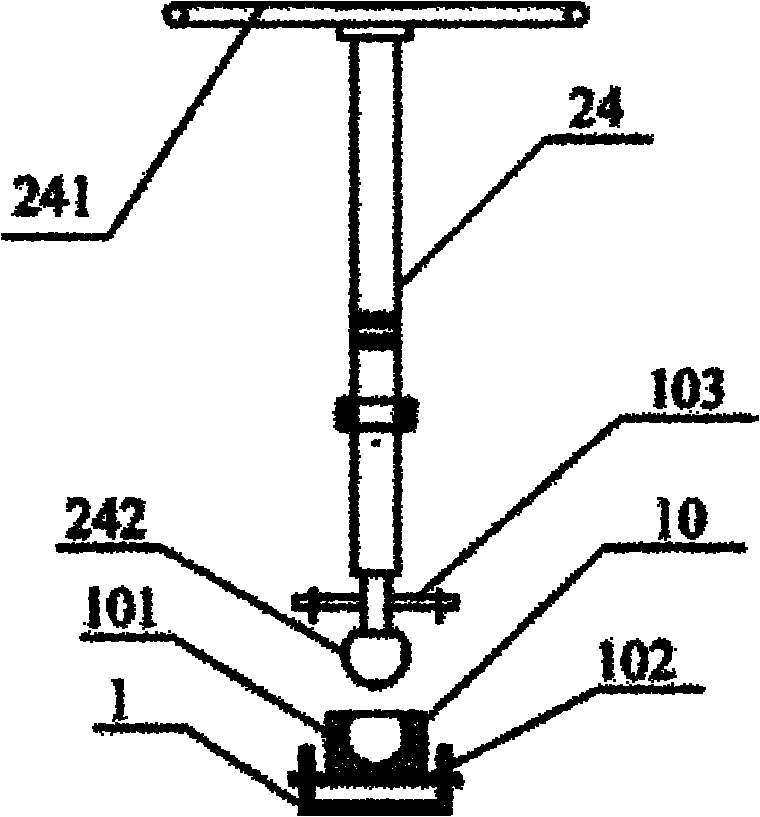

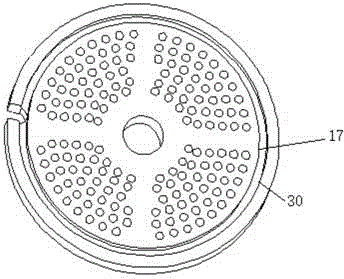

Extrusion cutting type multi-particle size adjustable granulating machine

ActiveCN106622022ALarge adjustment rangeEasy to adjustGranulation in rotating dishes/pansGranulation by material expressionPropellerAgricultural engineering

The invention discloses an extrusion cutting type multi-particle size adjustable granulating machine. The extrusion cutting type multi-particle size adjustable granulating machine comprises a stirring cylinder, wherein the stirring cylinder is arranged on a base, a spiral propeller is arranged in the stirring cylinder, and a material inlet hopper is arranged at the upper end of the stirring cylinder; the spiral propeller is connected with a propelling motor; a granulating disc is arranged at the front end of the stirring cylinder; conical granulating sleeves are uniformly arranged on the granulating disc, and are sheathed on an adjusting disc; a cutting tool disc is arranged at the front end of each conical granulating sleeve, and is fixedly arranged on a fixed disc; the fixed disc is connected with a cutting motor, and the cutting motor is arranged on a slide base; the slide base is connected with a screw rod in a bracket, and the bracket is connected with the base; an adjusting rotary button is arranged at the front end of the screw rod; each conical granulating sleeve is in a conical sleeve shape, and adjusting grooves are uniformly arranged at the front end of each conical granulating sleeve; mounting grooves are arranged on the inner walls of both sides of each adjusting groove; an arc-shaped movable plate is arranged in each mounting groove; outlet tool blades are uniformly arranged on the inner wall of the front end of each conical granulating sleeve. The extrusion cutting type multi-particle size adjustable granulating machine has the advantages that the quick and high-efficiency granulating function is realized, the granulating size can be adjusted, the adjusting range is wide, and the flexibility and convenience in use are realized.

Owner:湖南康易达绿茵科技有限公司

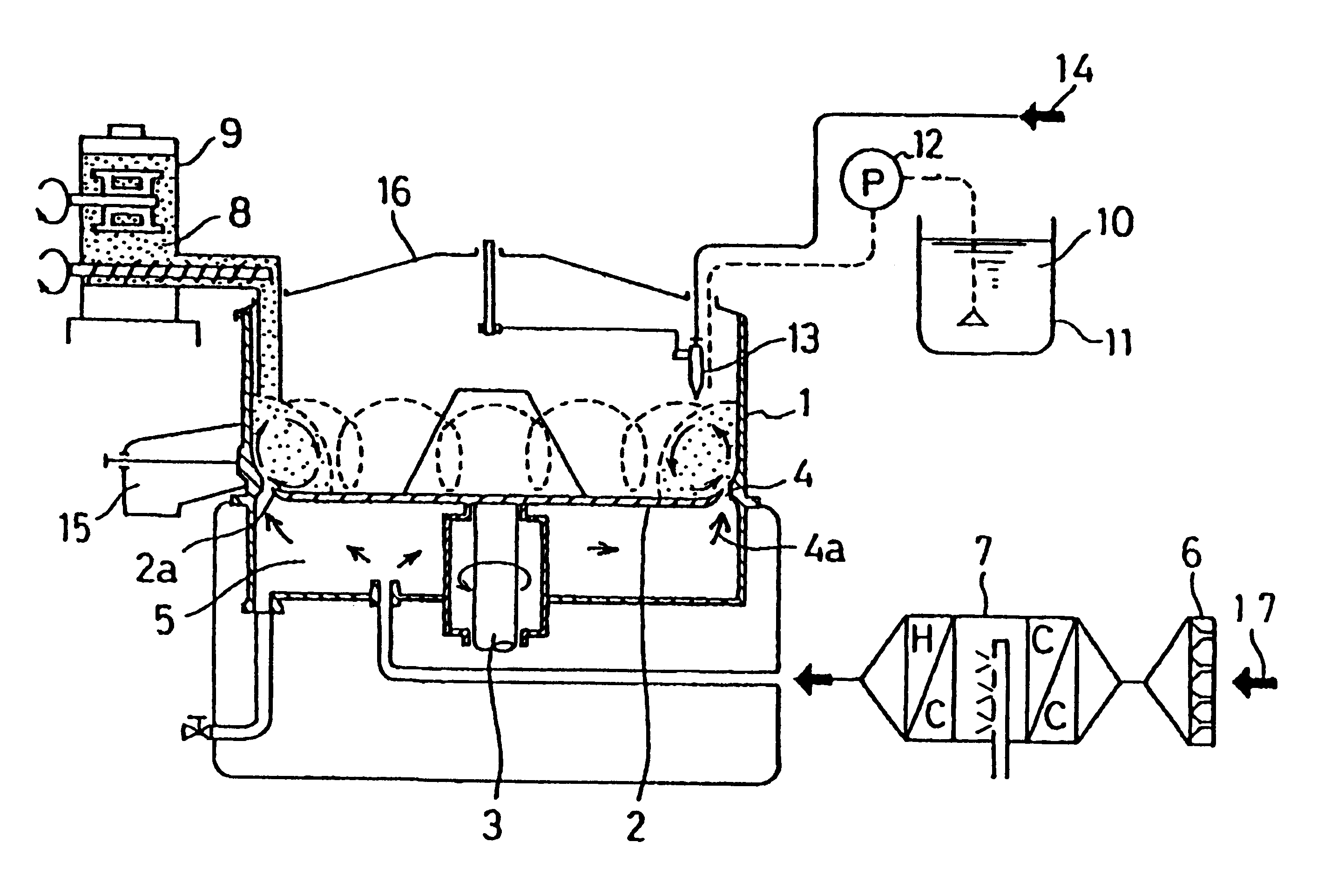

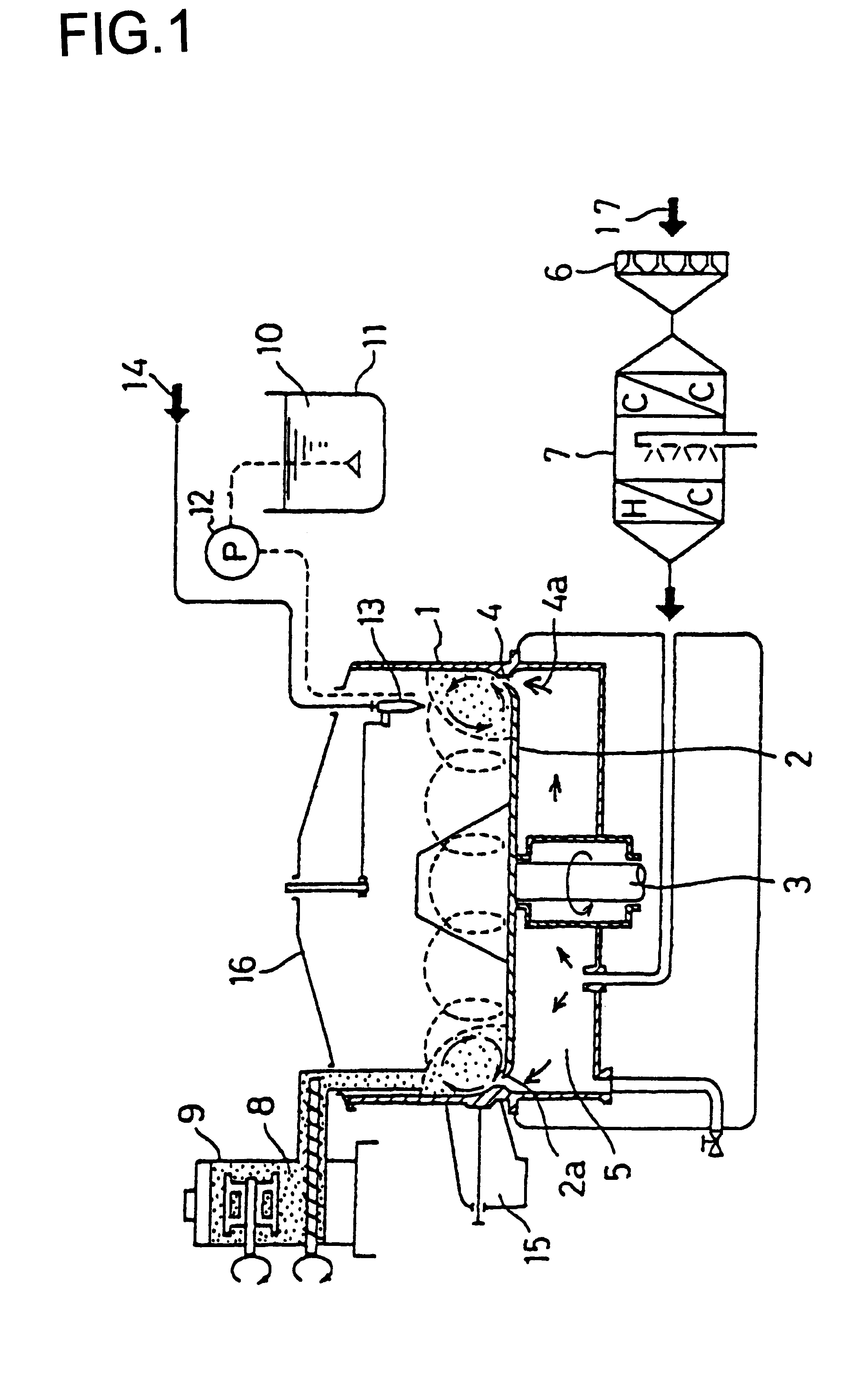

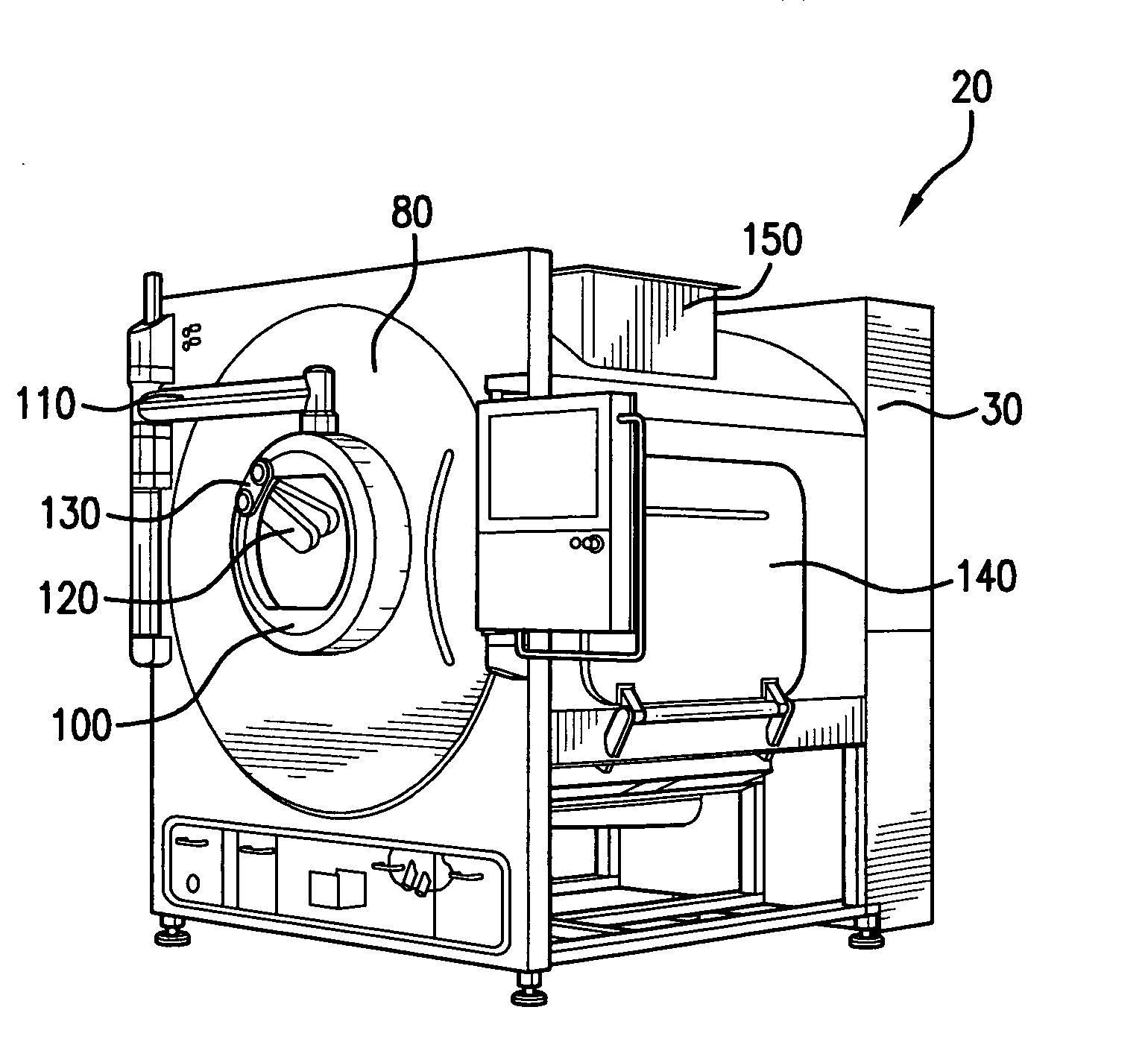

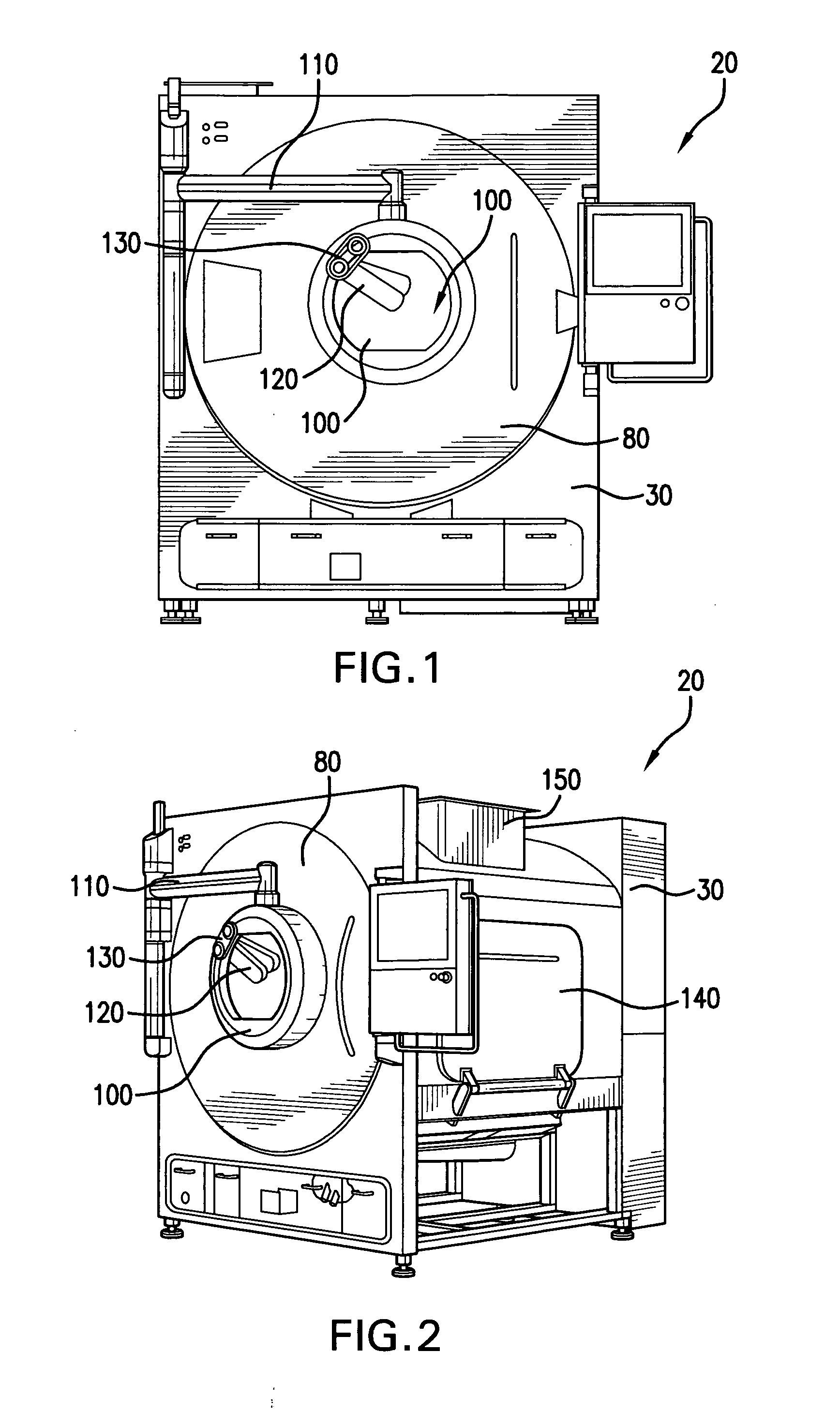

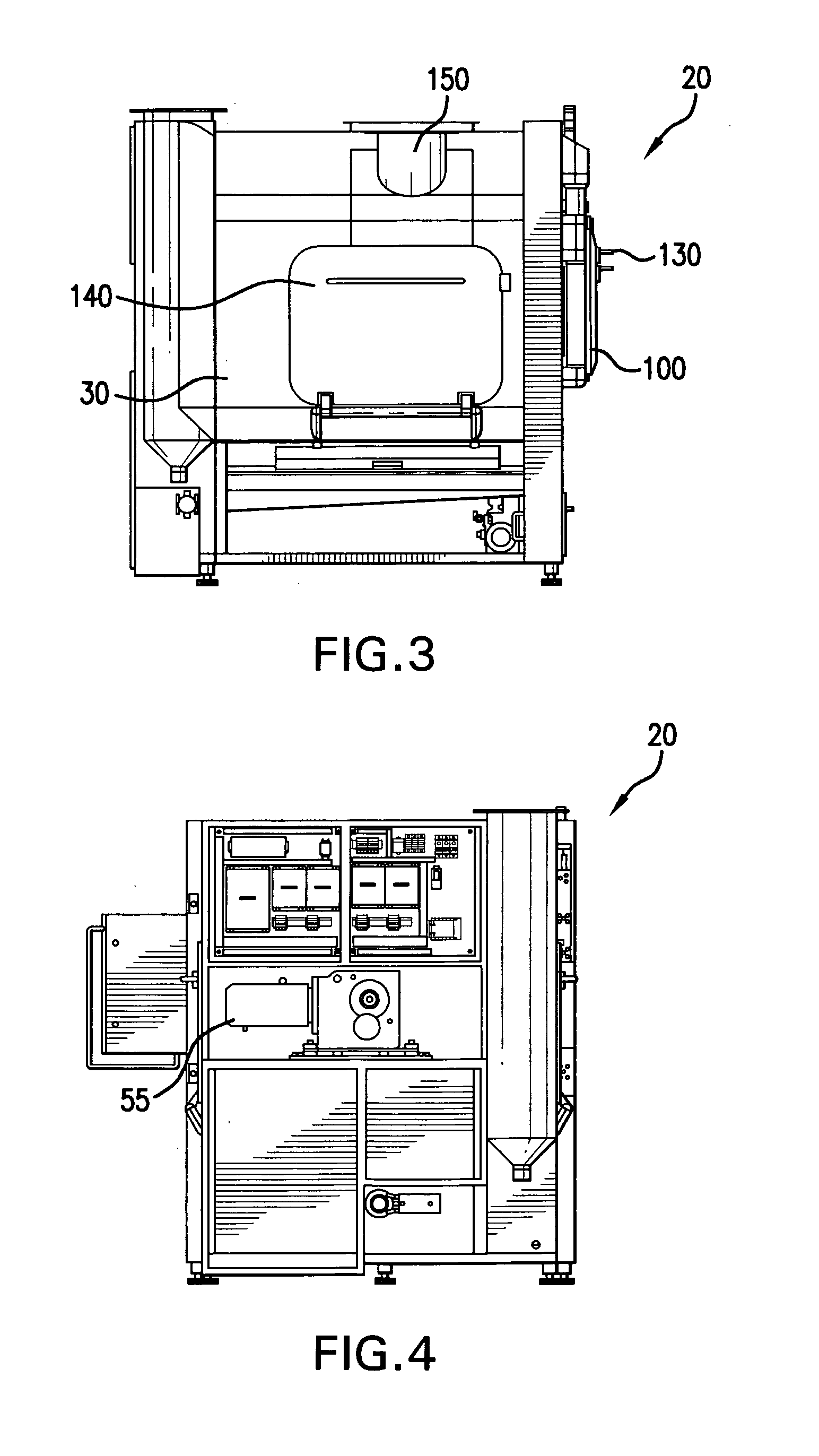

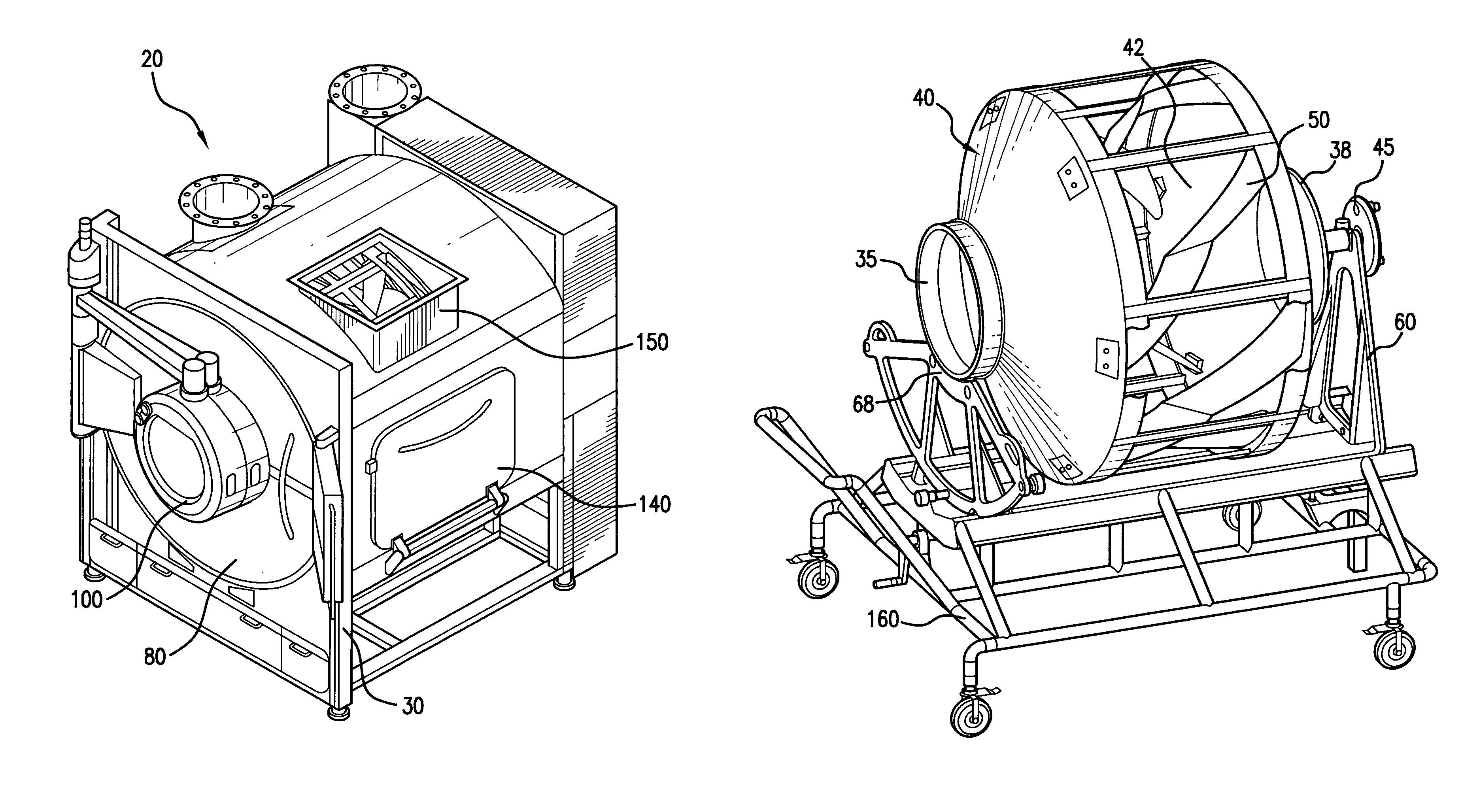

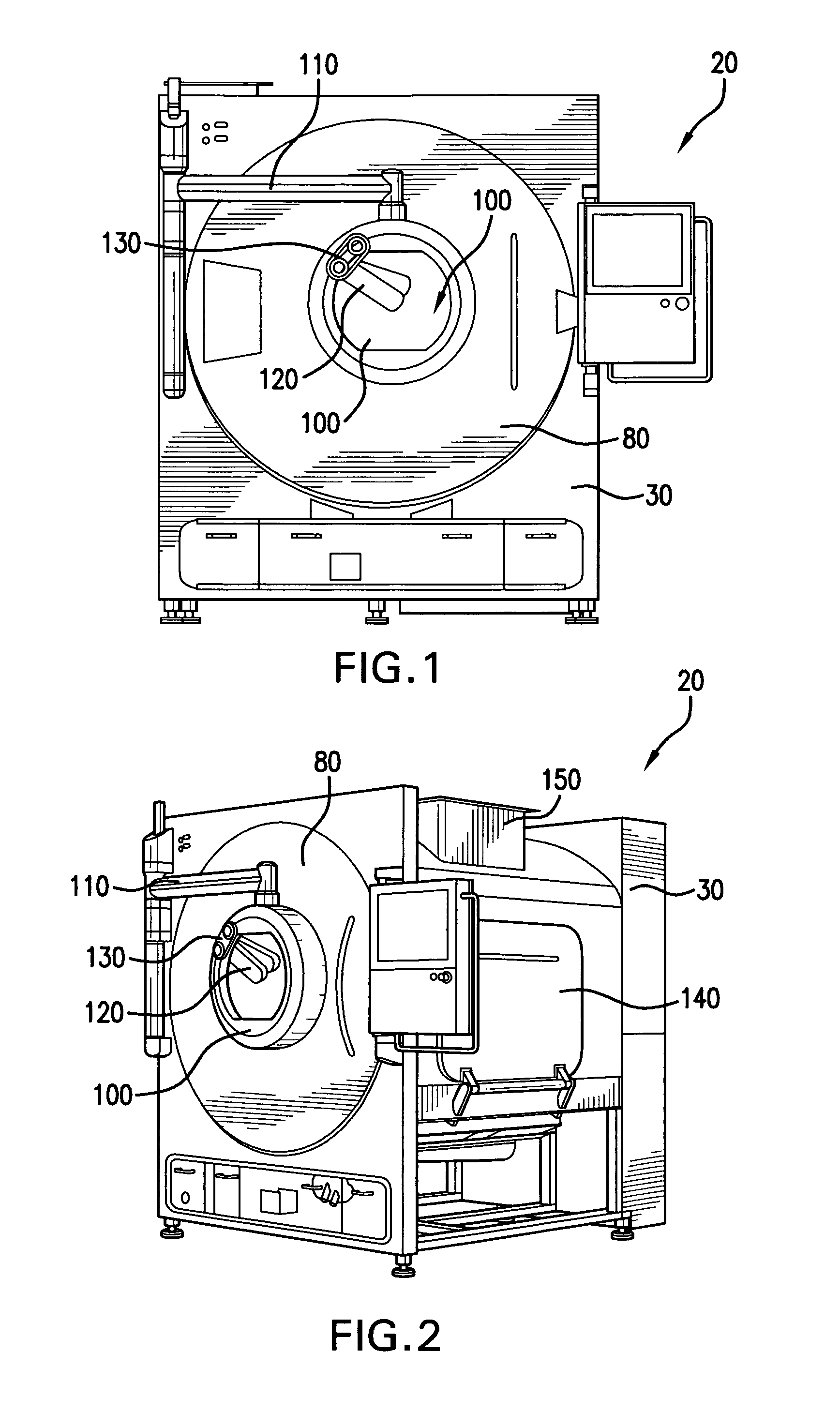

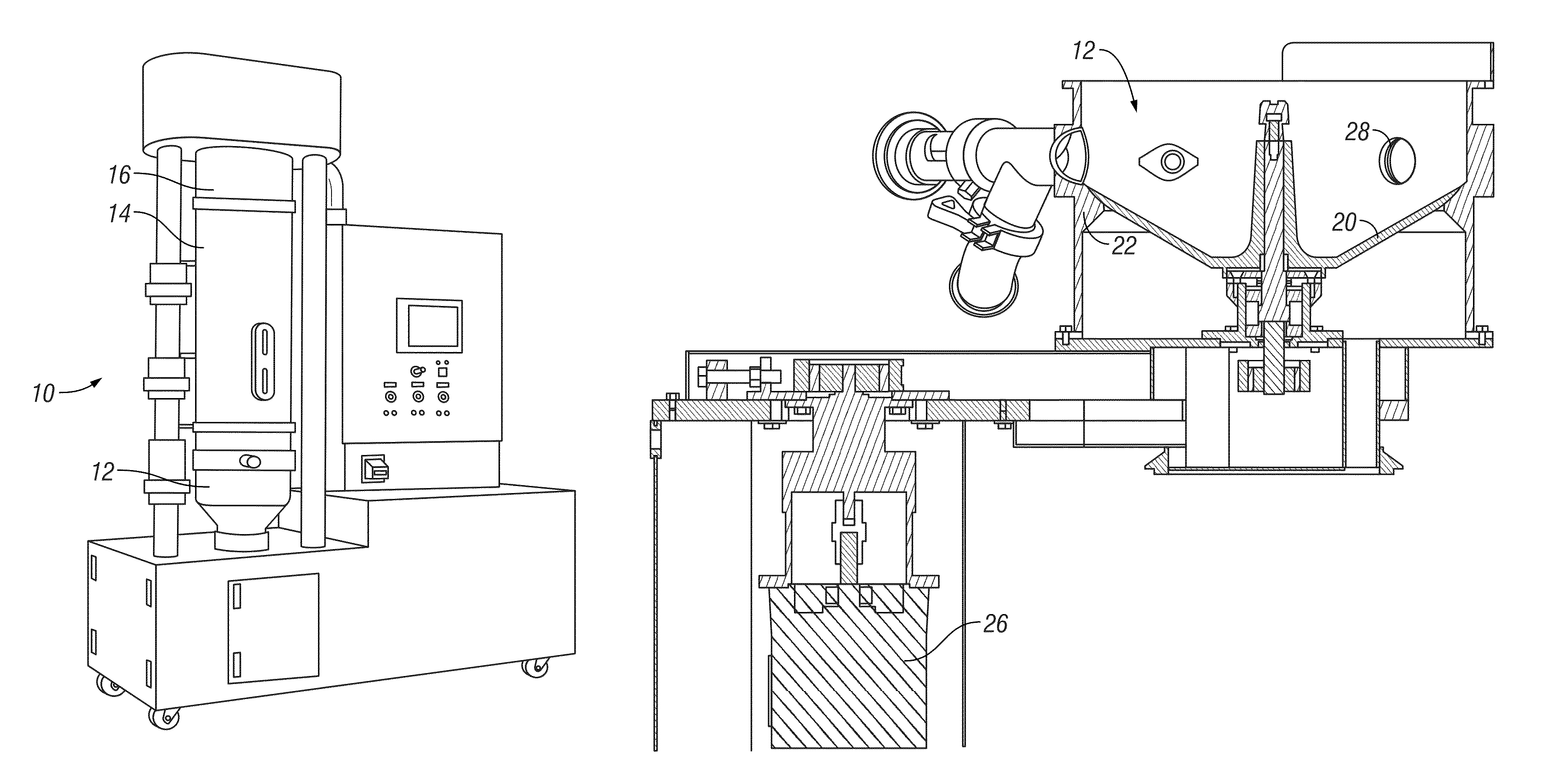

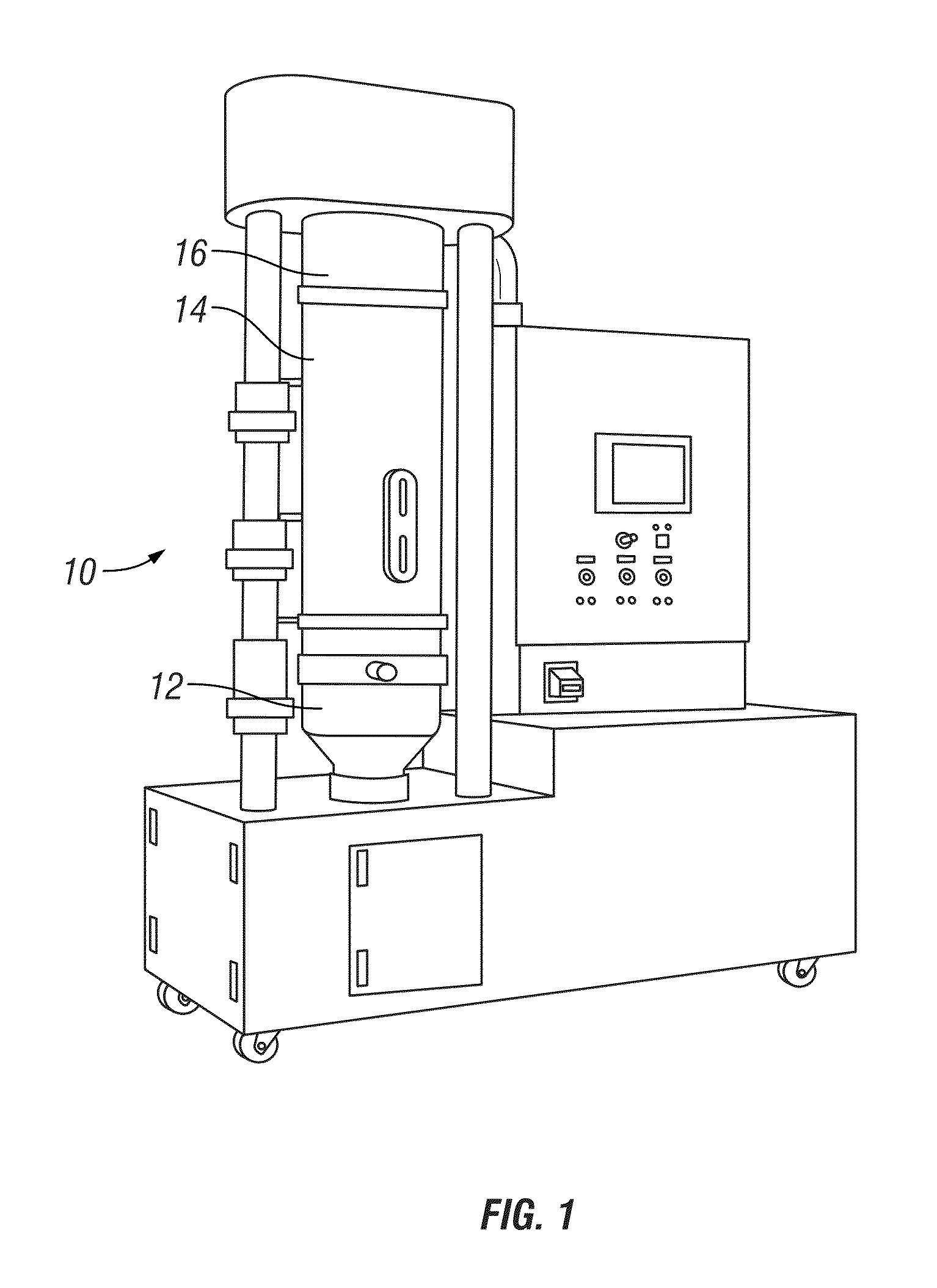

Production coater with exchangeable drums

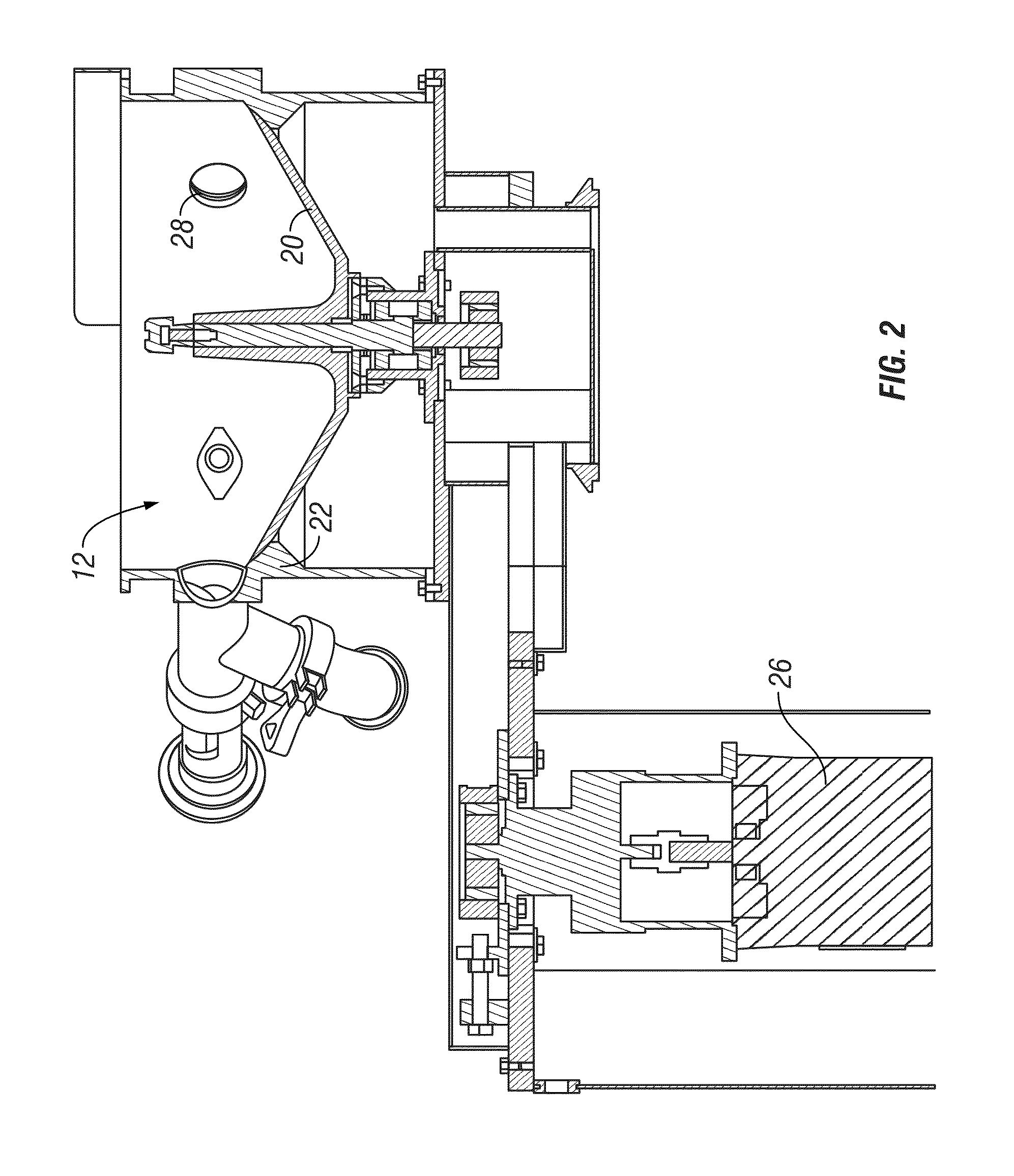

A coater for coating a material with a solution or a suspension includes an access door and a process port separately openable within a housing. A rotating coating drum is removably connected with respect to the coater and the coater is configured for exchange of drums having a wide range of production capacities.

Owner:THOMAS LLC

Production coater with exchangeable drums

A coater for coating a material with a solution or a suspension includes an access door and a process port separately openable within a housing. A rotating coating drum is removably connected with respect to the coater and the coater is configured for exchange of drums having a wide range of production capacities.

Owner:THOMAS LLC

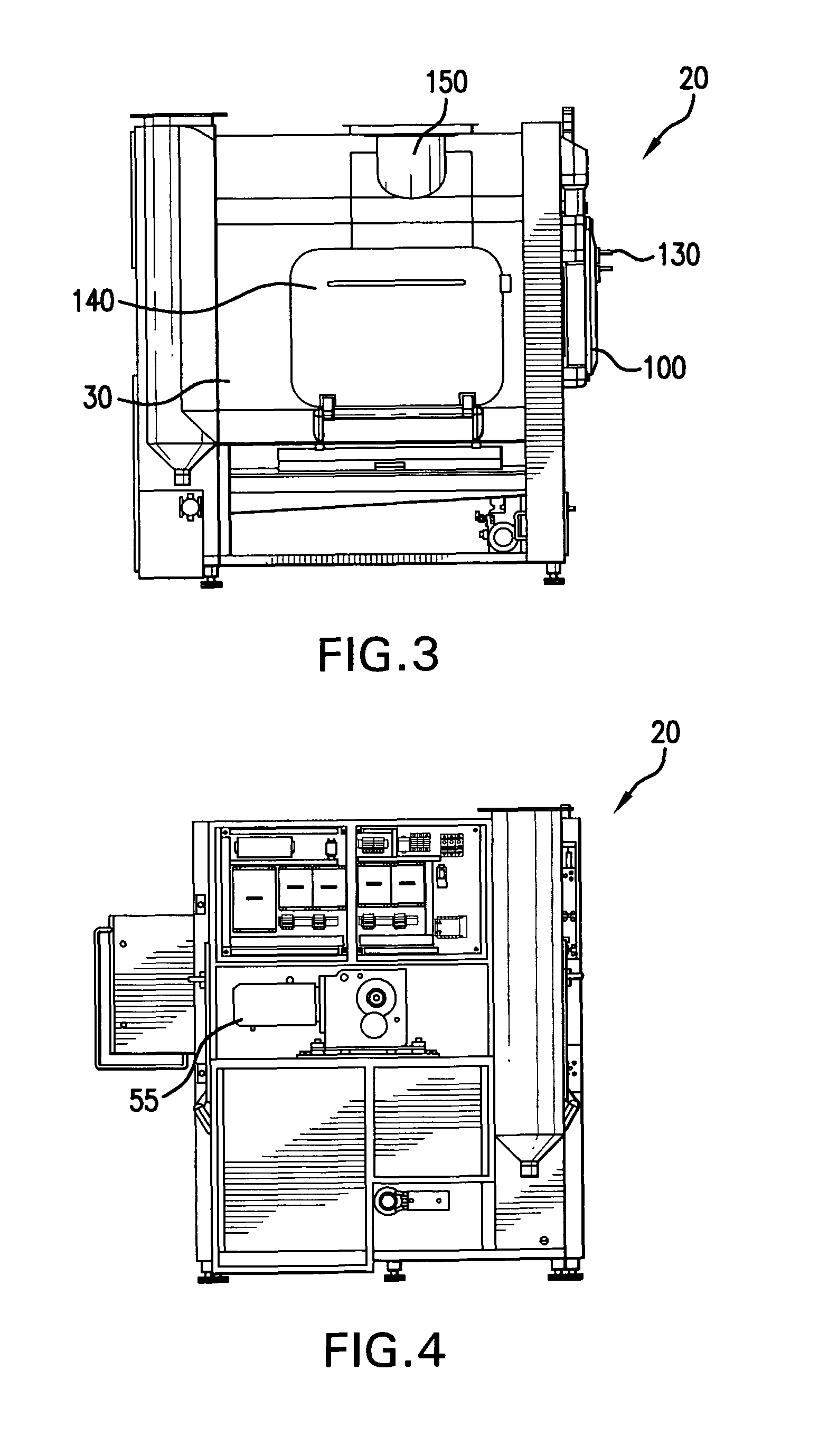

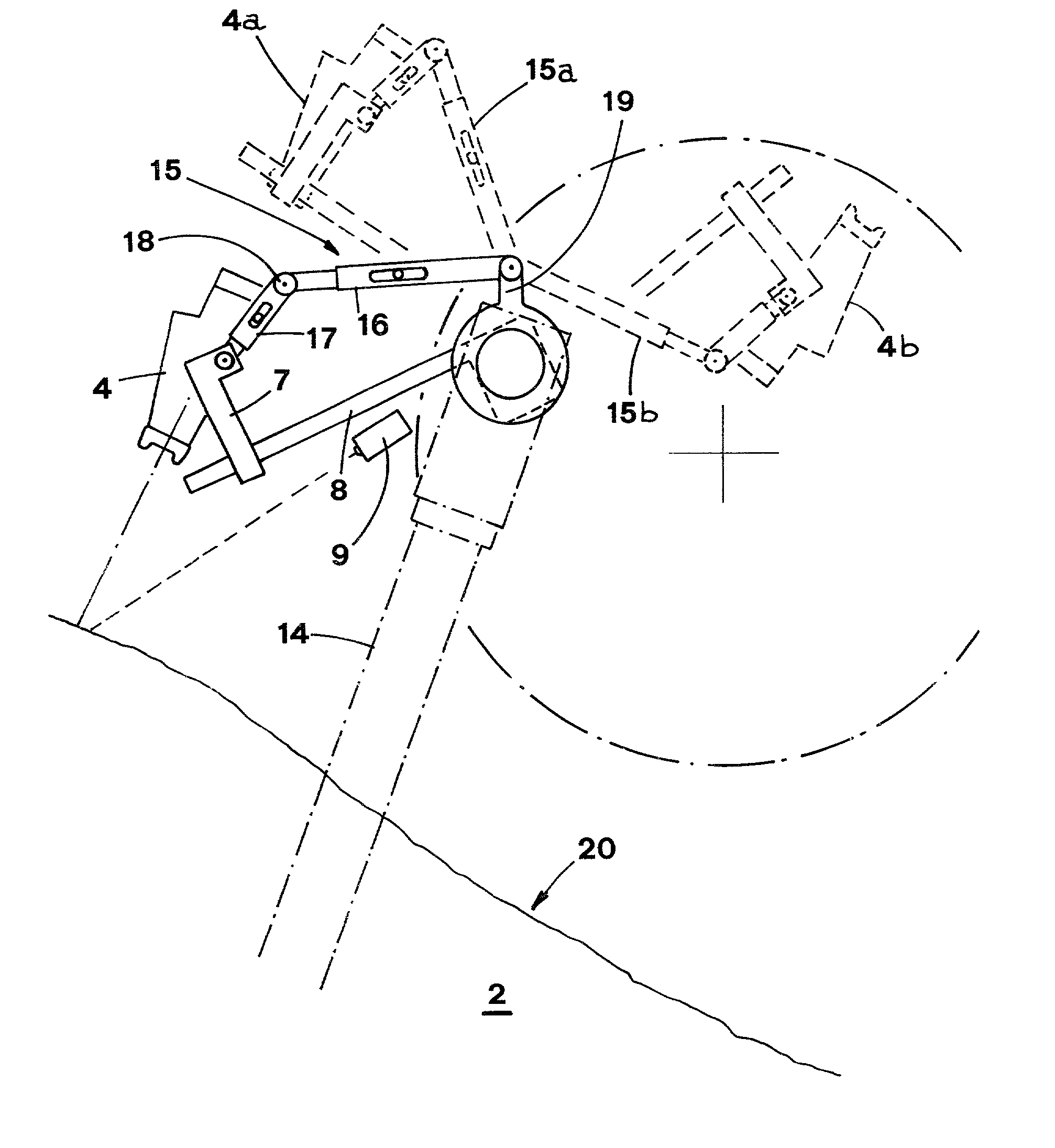

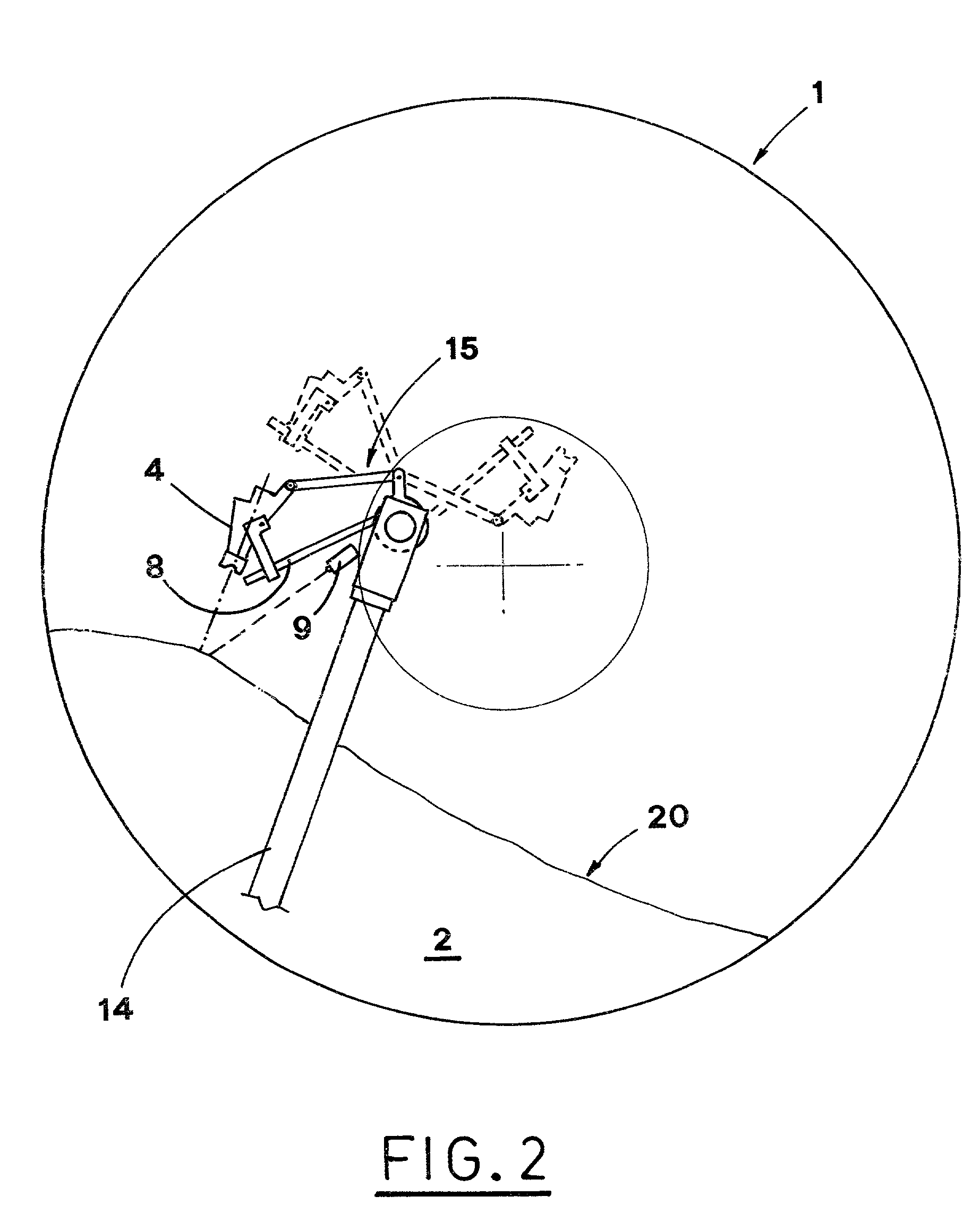

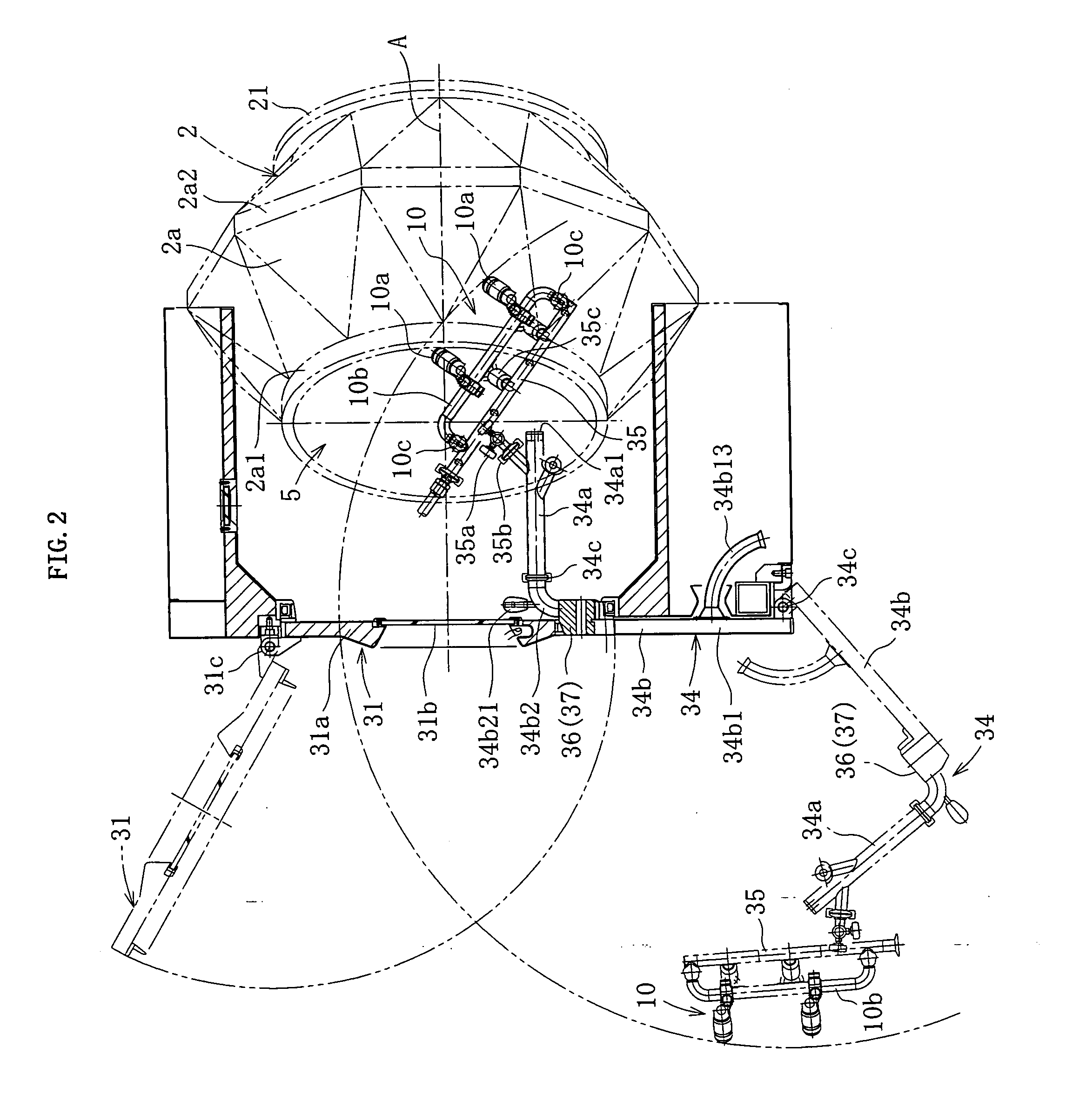

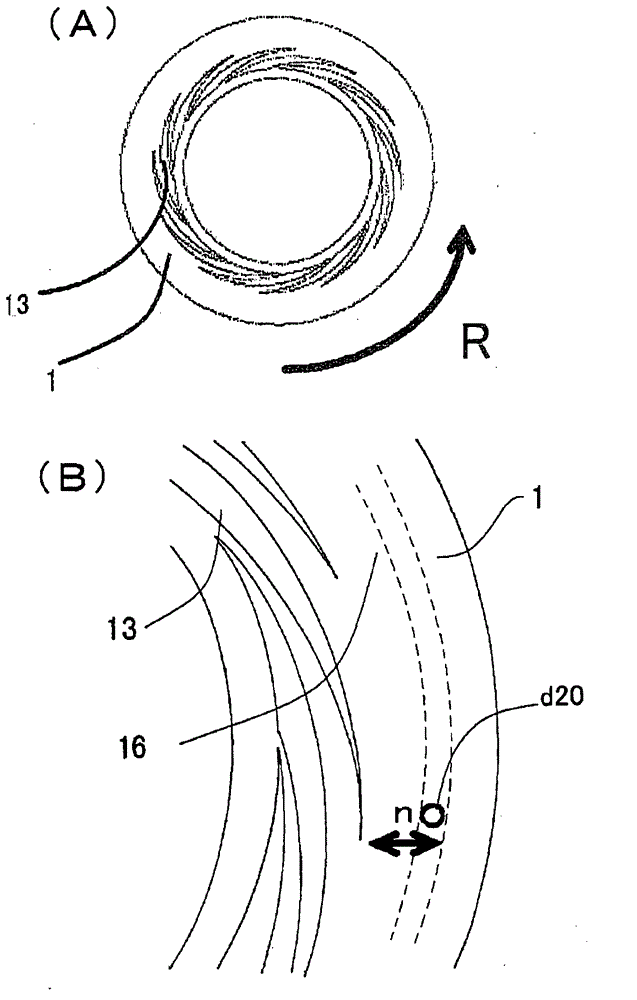

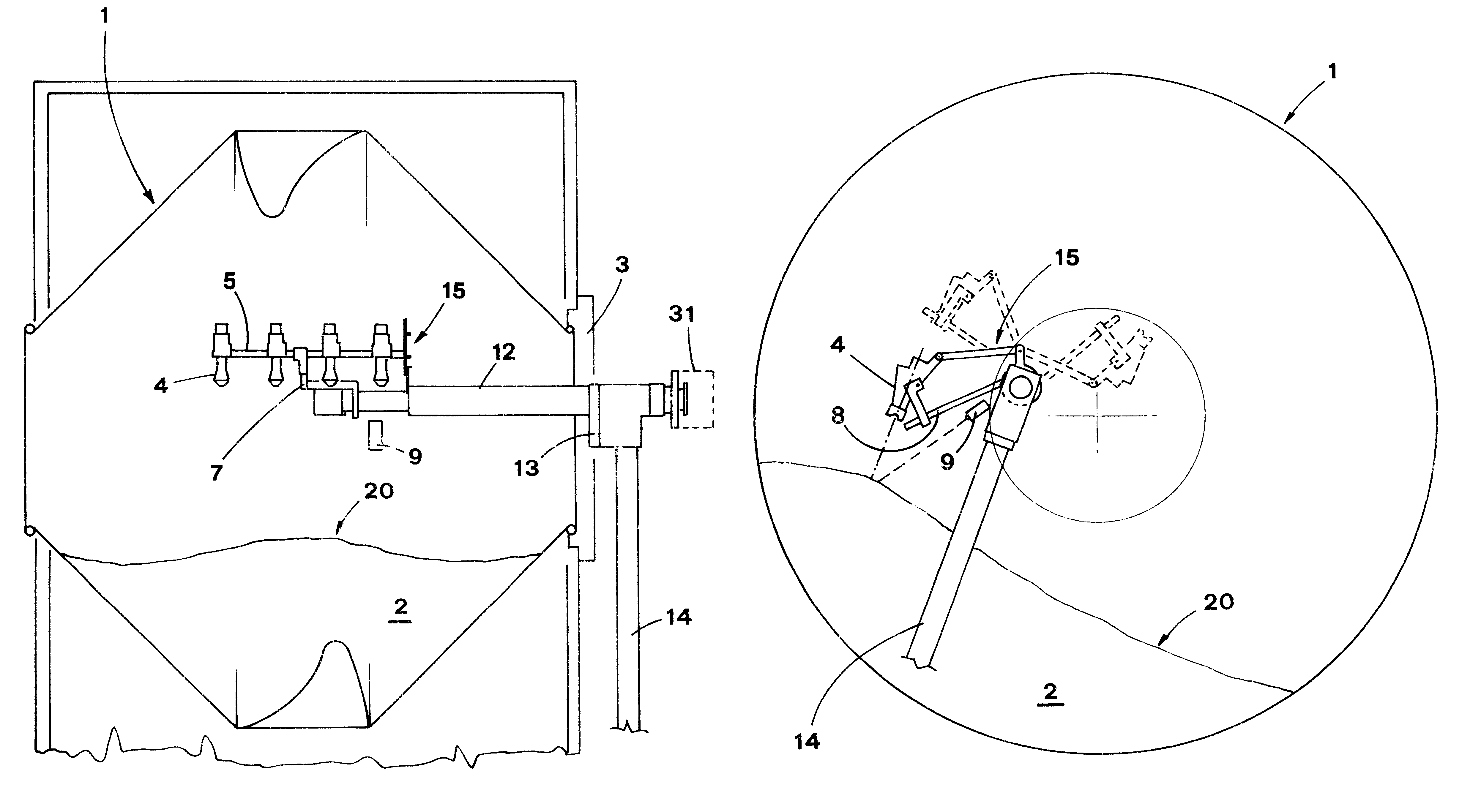

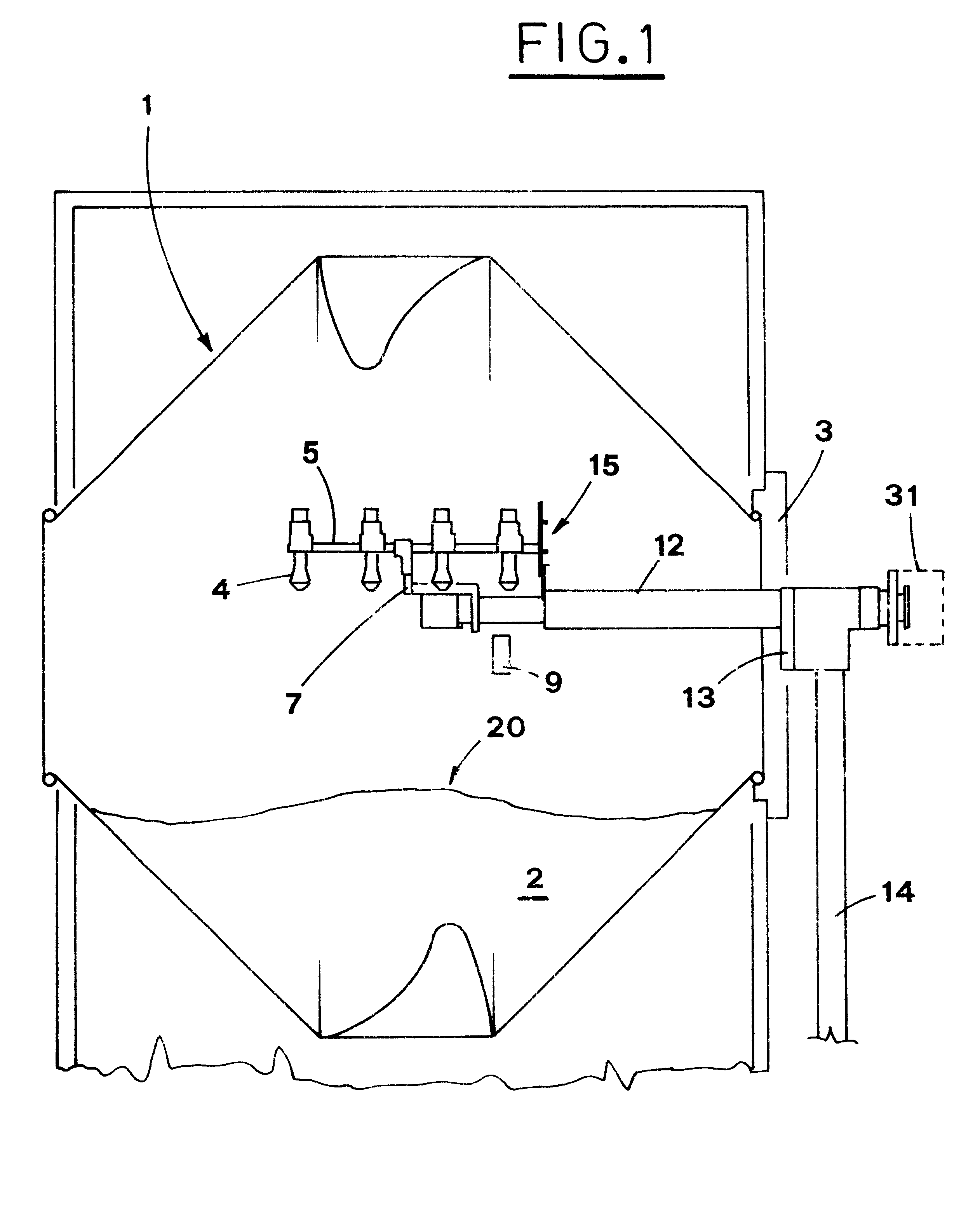

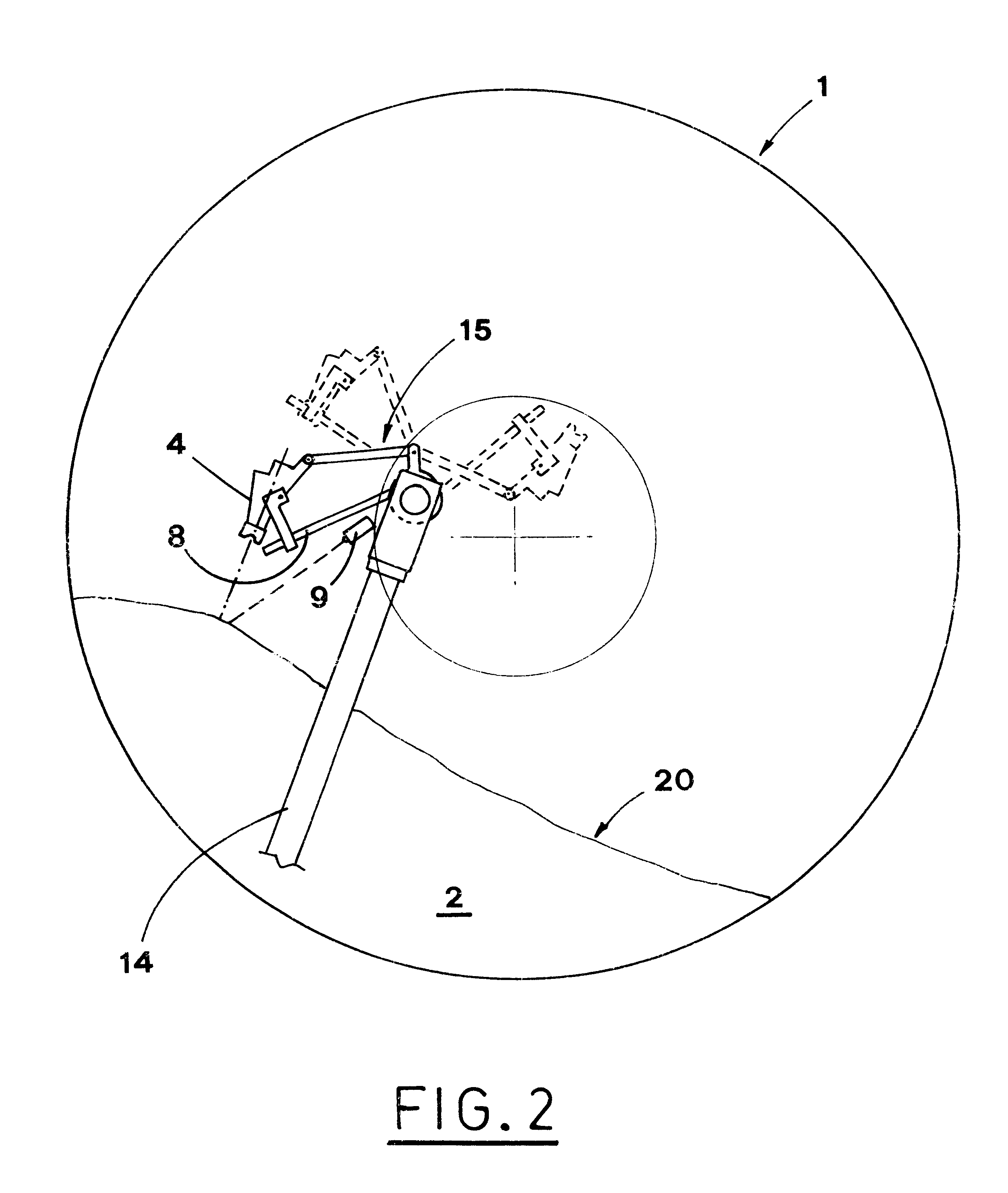

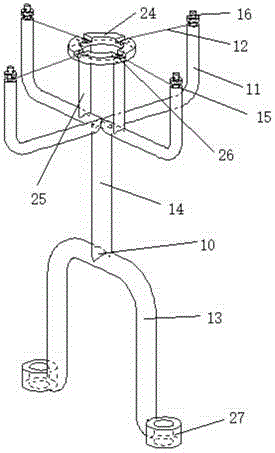

Device for moving and orienting spraying nozzles in a coating pan

InactiveUS20020134303A1Function increaseLiquid surface applicatorsGranule coatingHorizontal axisSpray nozzle

A device moves and orients spraying nozzles (4) inside a coating pan (1). The spraying nozzles (4) are carried, arranged in a line, by a shaft (5), which rotates on a horizontal axis parallel to the axis of the rotating drum (1). The shaft (5) is supported by a support frame (7), which is fastened to a bar (10), which is rotated to adjust the distance between the spraying nozzles (4) and the free surface (20) of said mass of articles (2) being treated. The shaft (5) is fastened to the lever mechanism (16,17) of a positioning member (15) for changing the inclination of the spraying nozzles (4), so as to maintain constant their orientation with respect to said free surface (20) of the mass of articles (2).

Owner:G S S R L COATING SYST

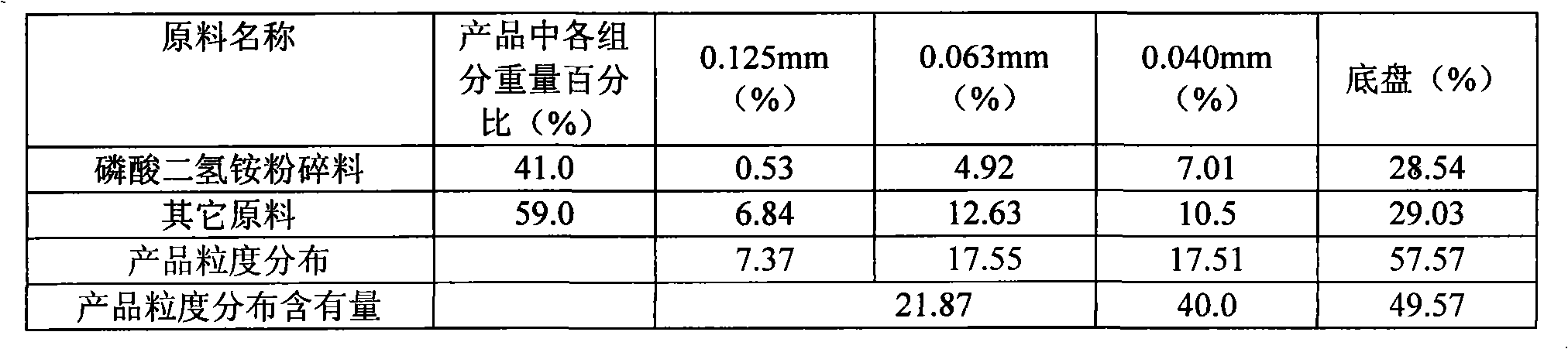

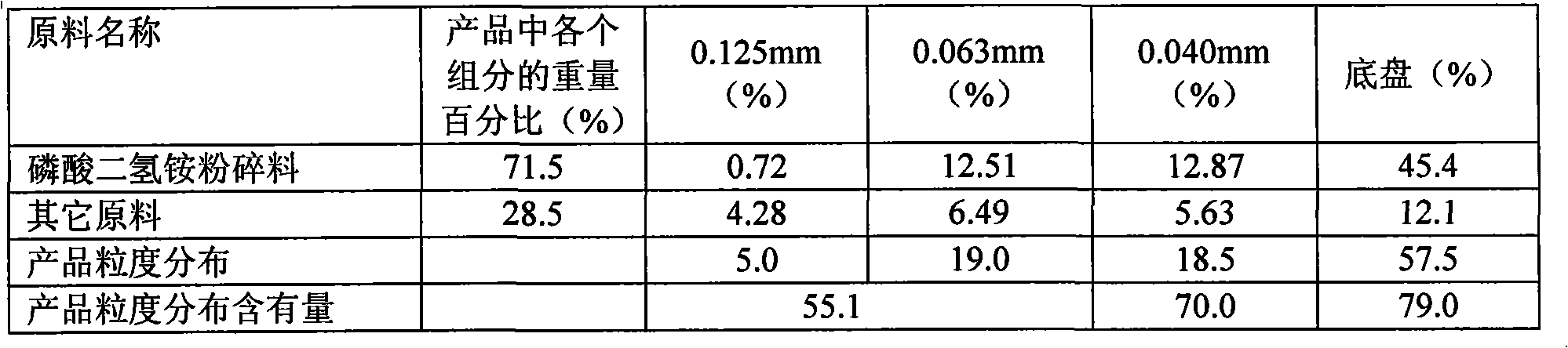

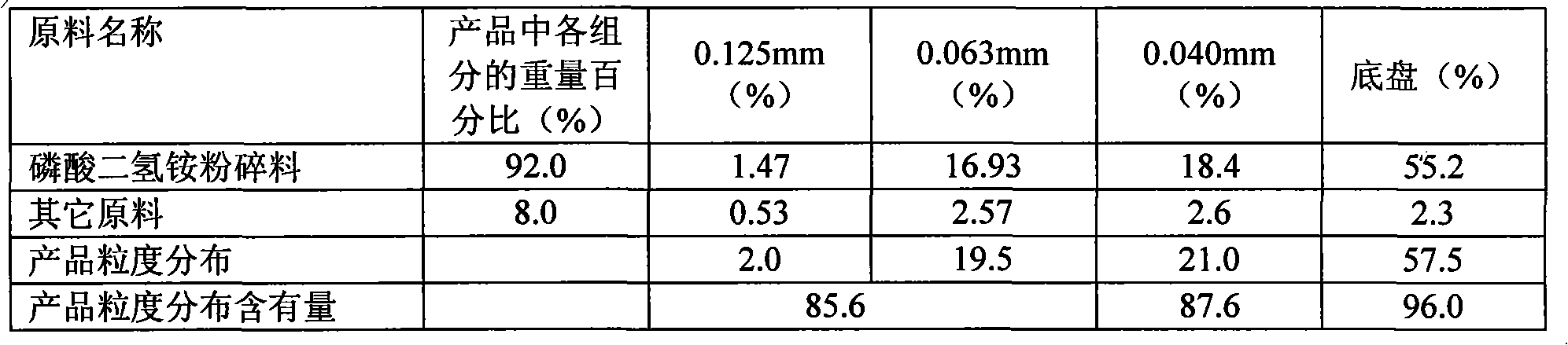

Control method of ABC dry powder grain size distribution content

ActiveCN101491722AGuaranteed fire extinguishing performanceEliminate the human factorPhosphatesGranulation in rotating dishes/pansDiammonium phosphateParticle-size distribution

The invention discloses a method for controlling the particle size distribution and content of an ABC powder extinguishing agent, which comprises the following steps of: (1) firstly, crushing diammonium phosphate with an LF concealed and stepped super micro mill and controlling the 'particle size distribution' of the diammonium phosphate; secondly, controlling the 'particle size distribution' of other materials in 0.125 millimeter, 0.063 millimeter and 0.040 millimeter sieves and an underpan; and finally, controlling the 'particle size distribution' and 'content' of the product. The ABC powder extinguishing agent prepared by the method can effectively extinguish class A, B and C fires and electric equipment fires, has a class A, B, C fire extinguishing efficiency which is 1 to 3 times of that of the prior ABC powder extinguishing agent, saves raw material cost, improves extinguishing efficiency and can match products made in advanced countries across the world in performance.

Owner:NINGBO NENGLIN FIRE FIGHTING EQUIP

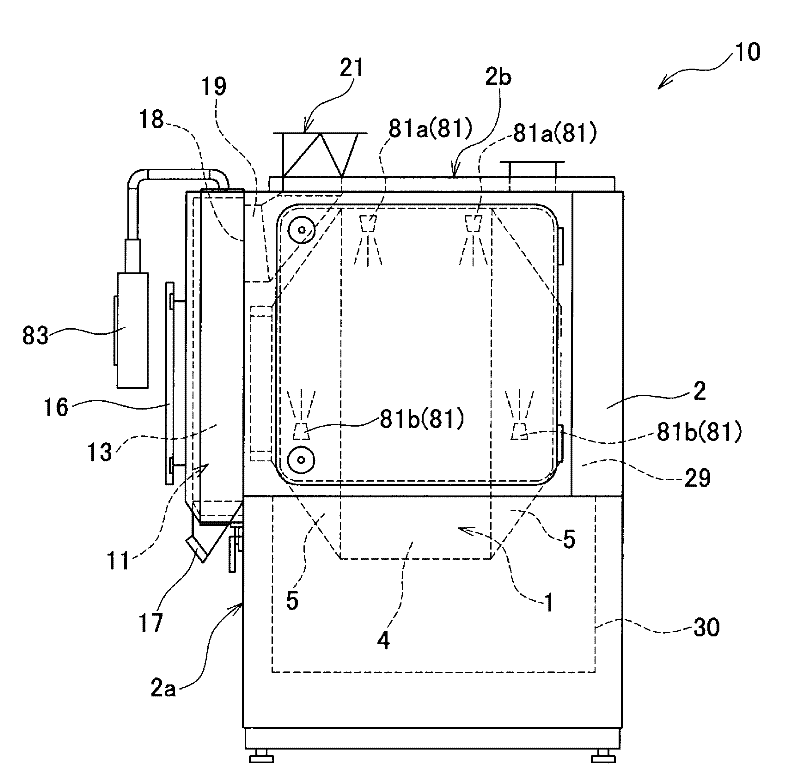

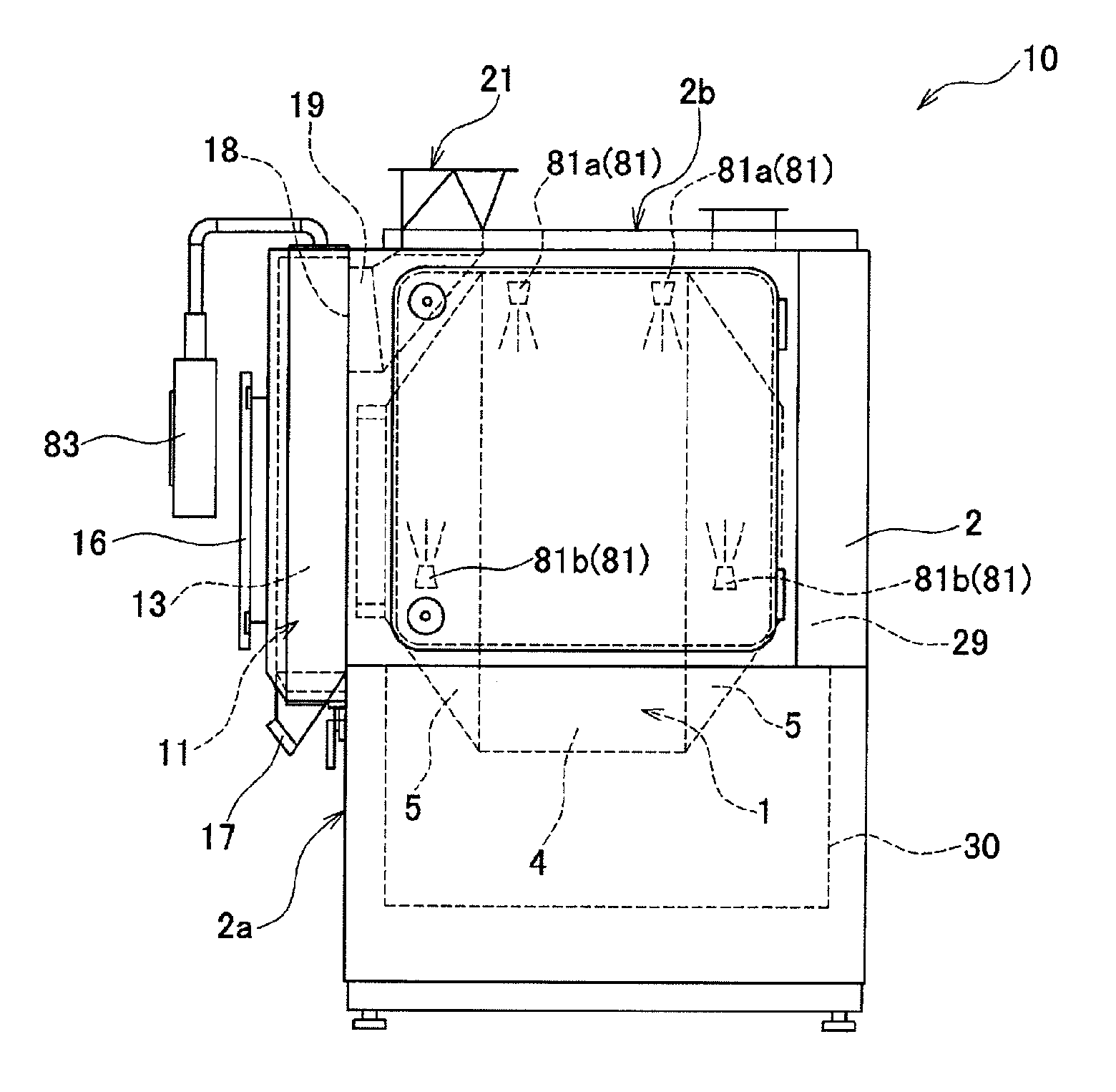

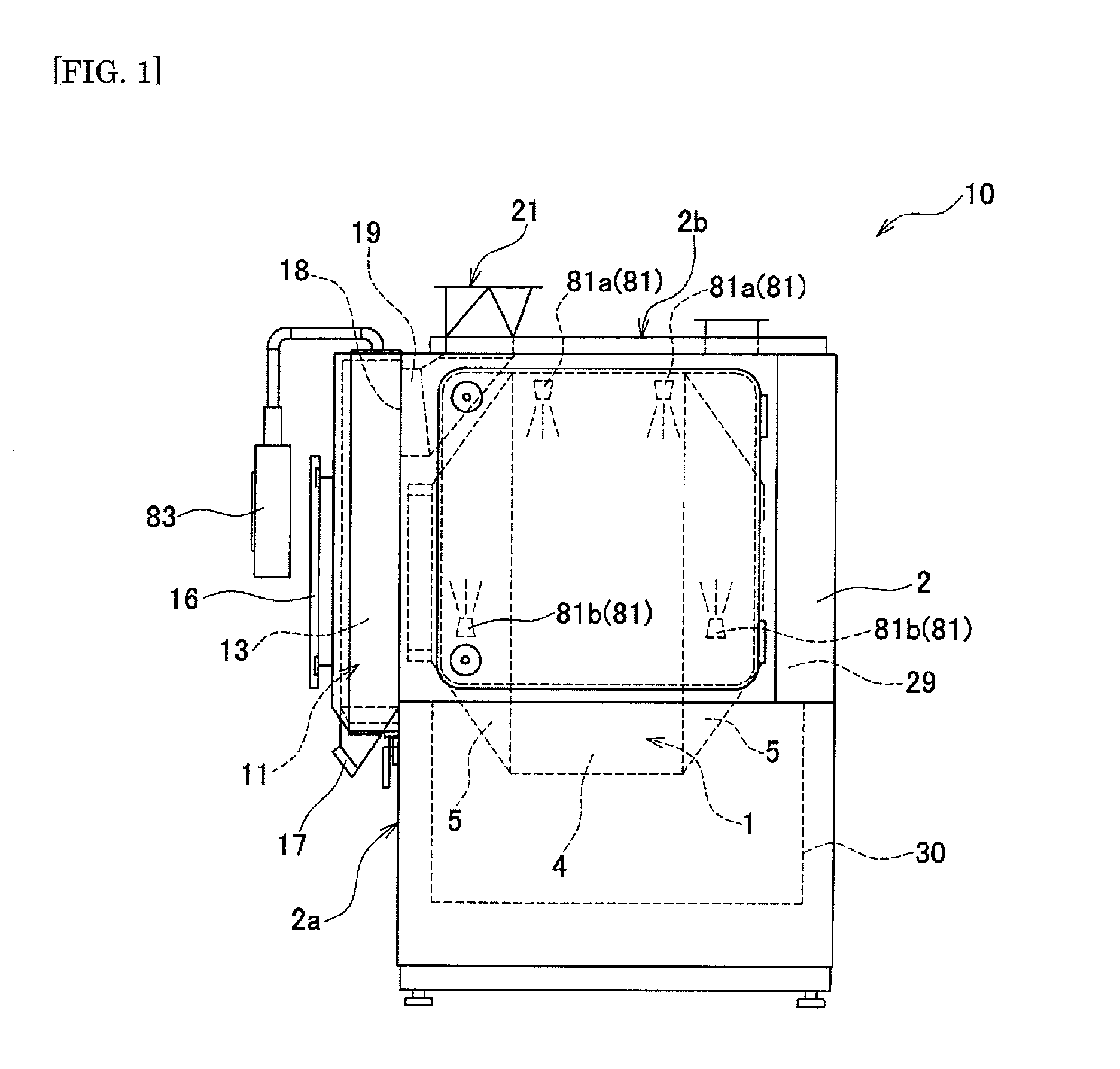

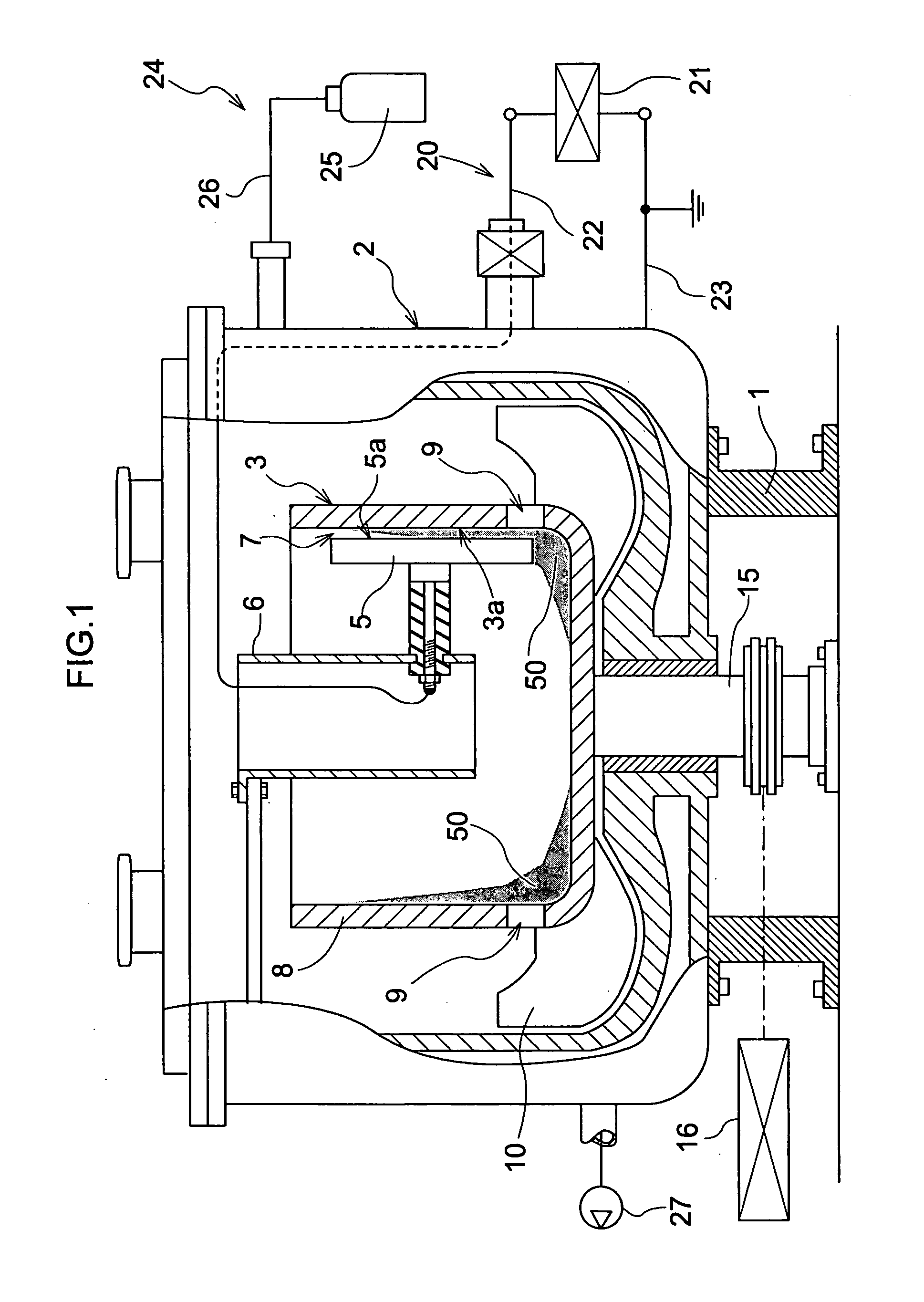

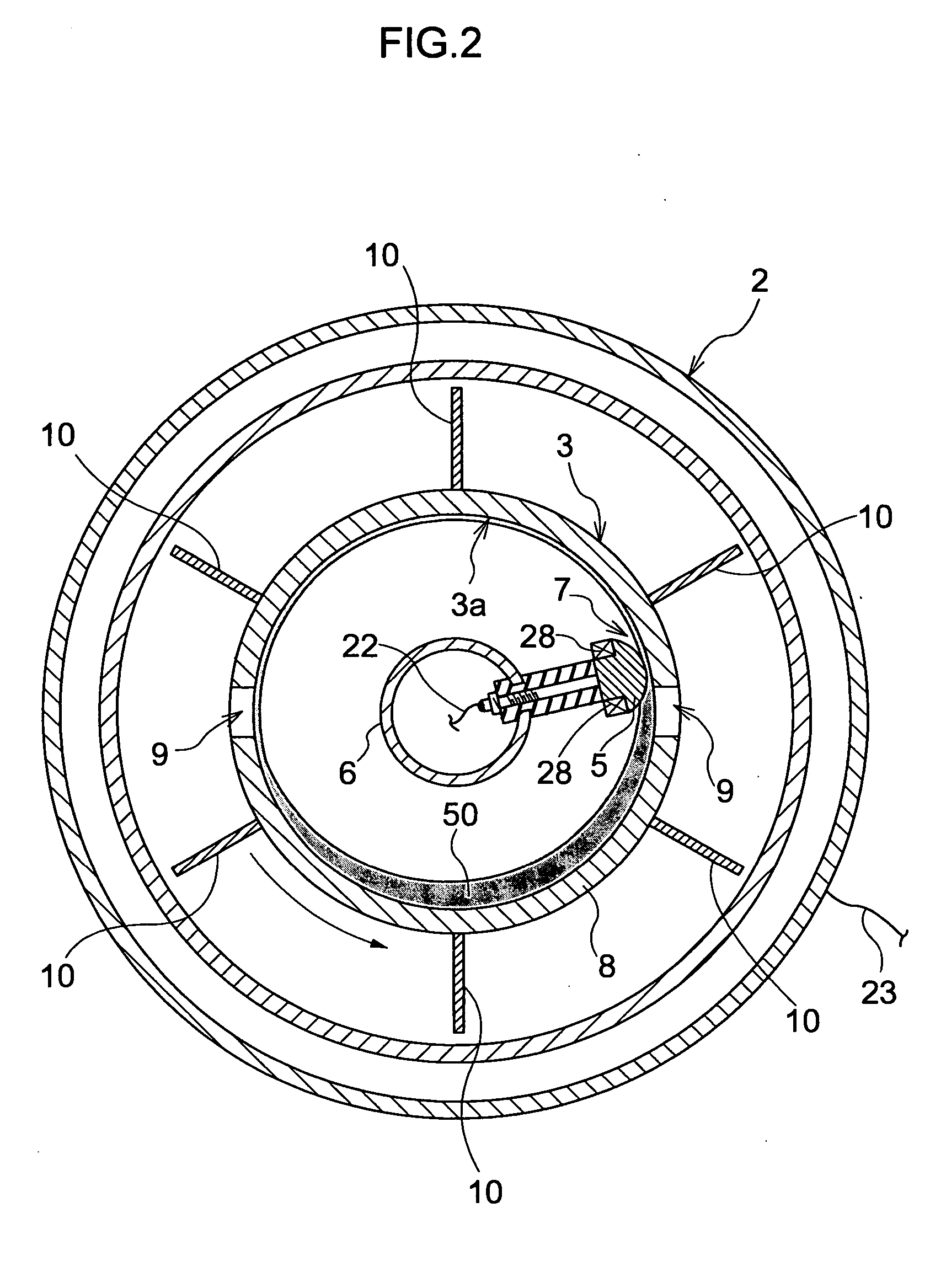

Pan coating device

ActiveCN102202778AReduce cleanup workloadReduce flow rateMaterial granulation and coatingLiquid surface applicatorsStable stateRotational axis

In a pan coating device (10) provided with a rotating drum (1) which rotates about a horizontal rotational axis line (O), an air supply chamber (13) with a larger cross-sectional area than that of an opening (7) in the front surface of the rotating drum is provided at the preceding stage of the opening (7). The air supply chamber (13) is formed inside a chamber door (11) attached to the front of a housing (2) with one end thereof communicating with the opening (7) and the other end thereof connected to an air supply duct (19) via an air supply hole (18). Air flowing into the air supply chamber (13) from the air supply duct (19) is reduced in flow velocity in the air supply chamber (13) and supplied from the opening (7) into the rotating drum (1) with the current thereof in a stable state.

Owner:FREUNT IND

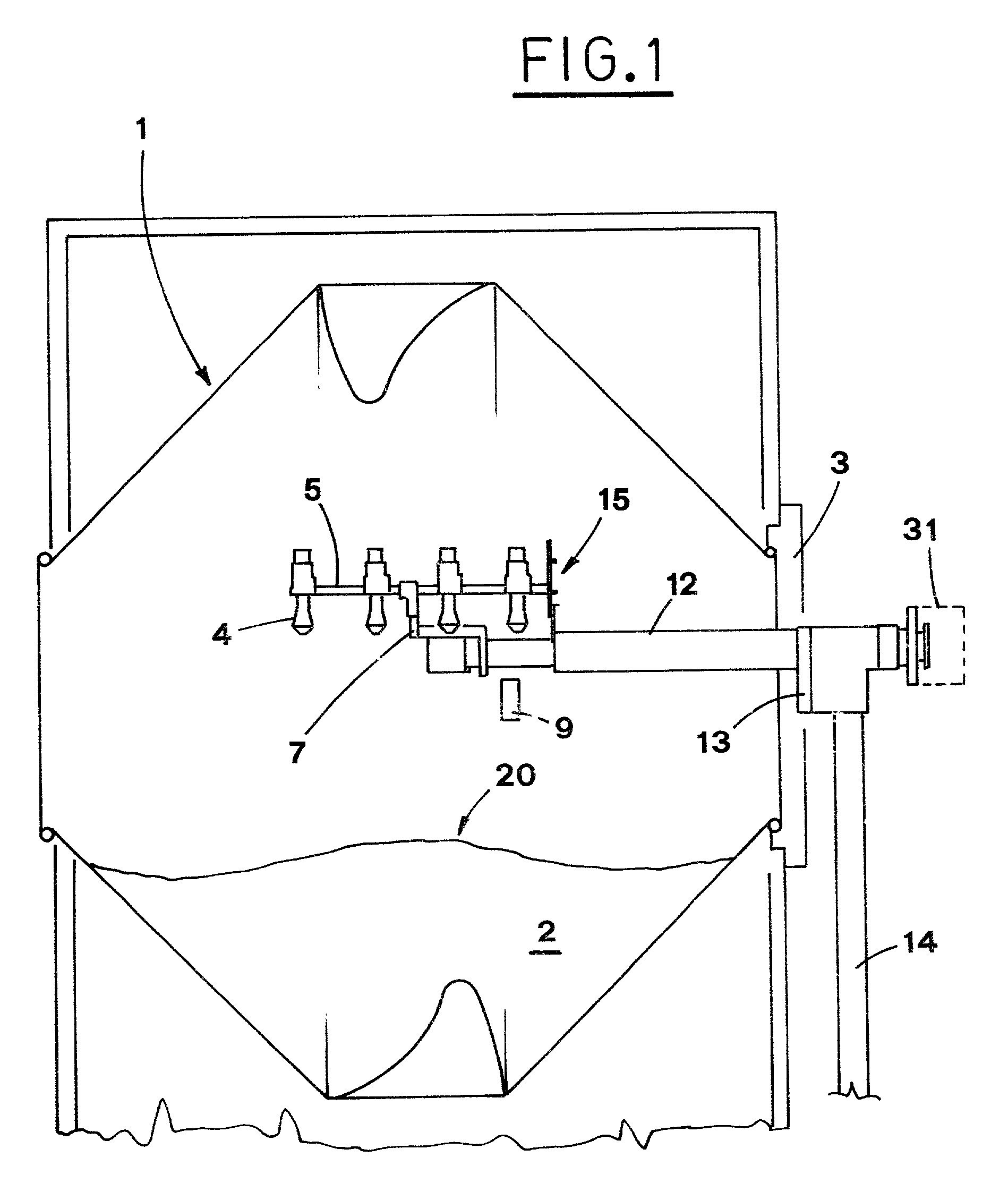

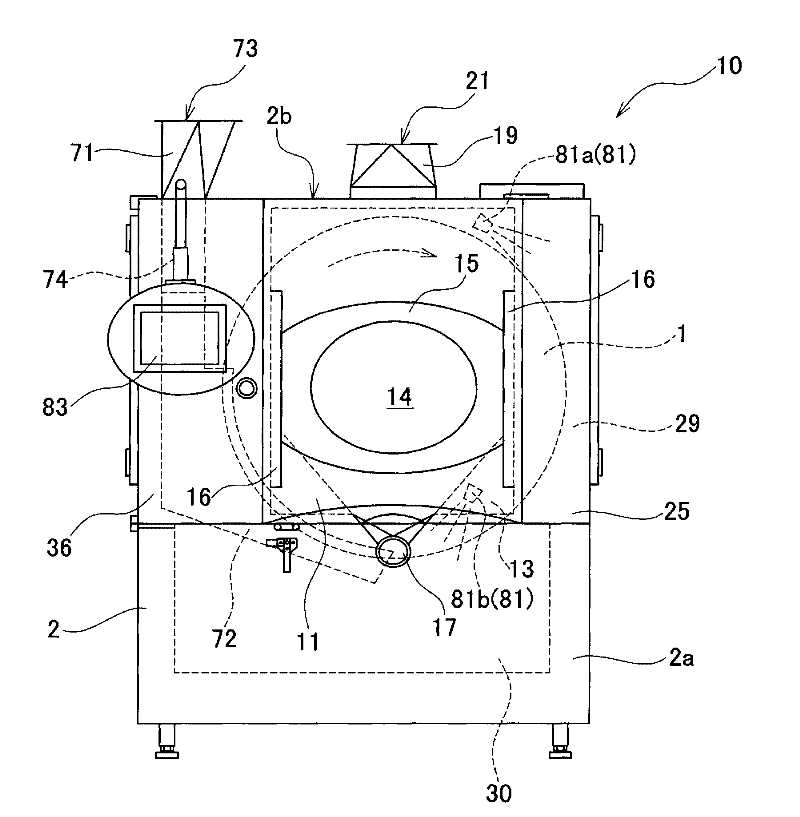

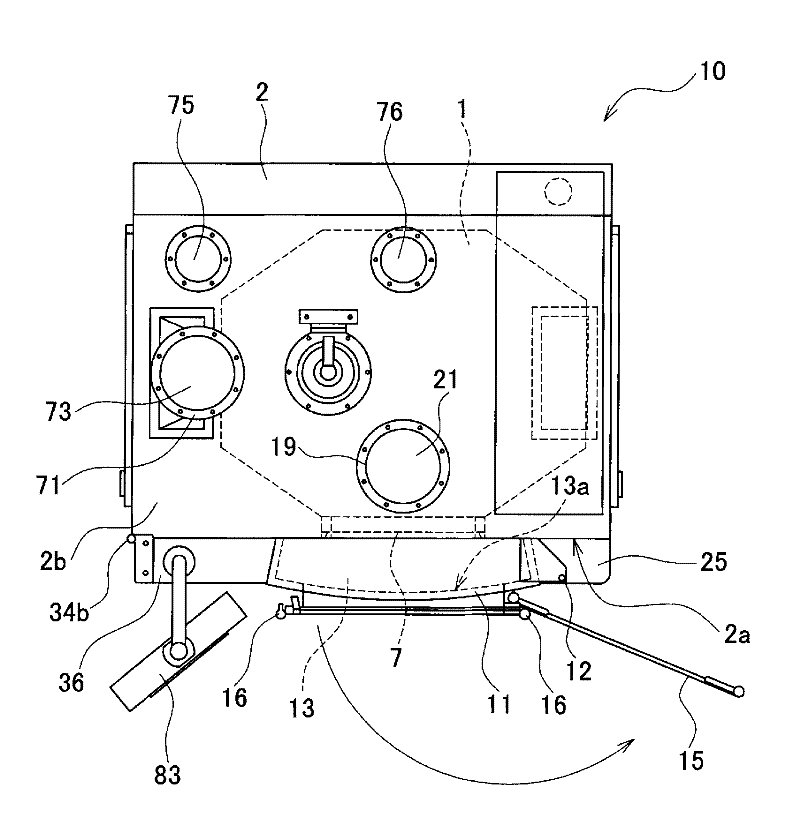

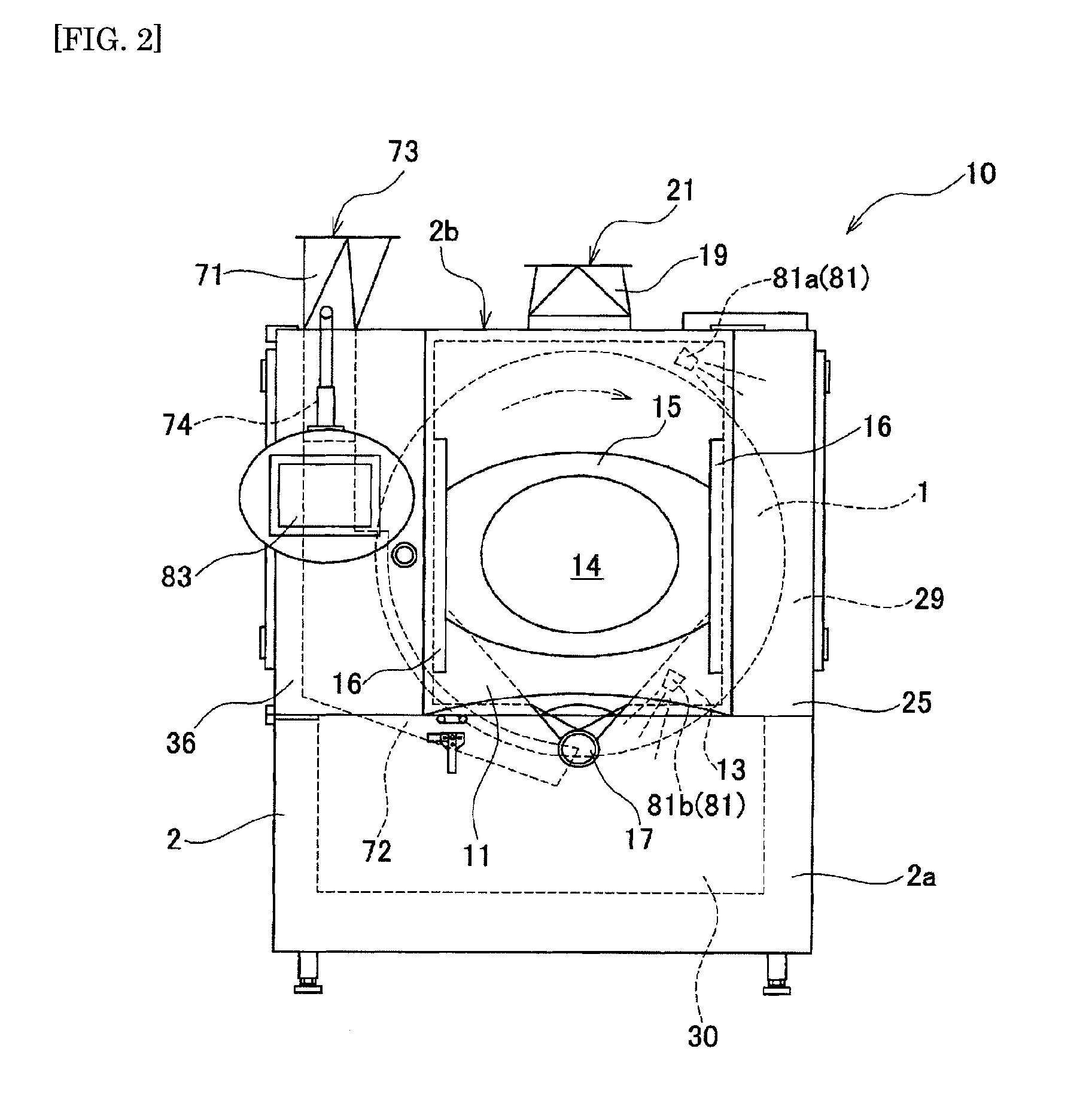

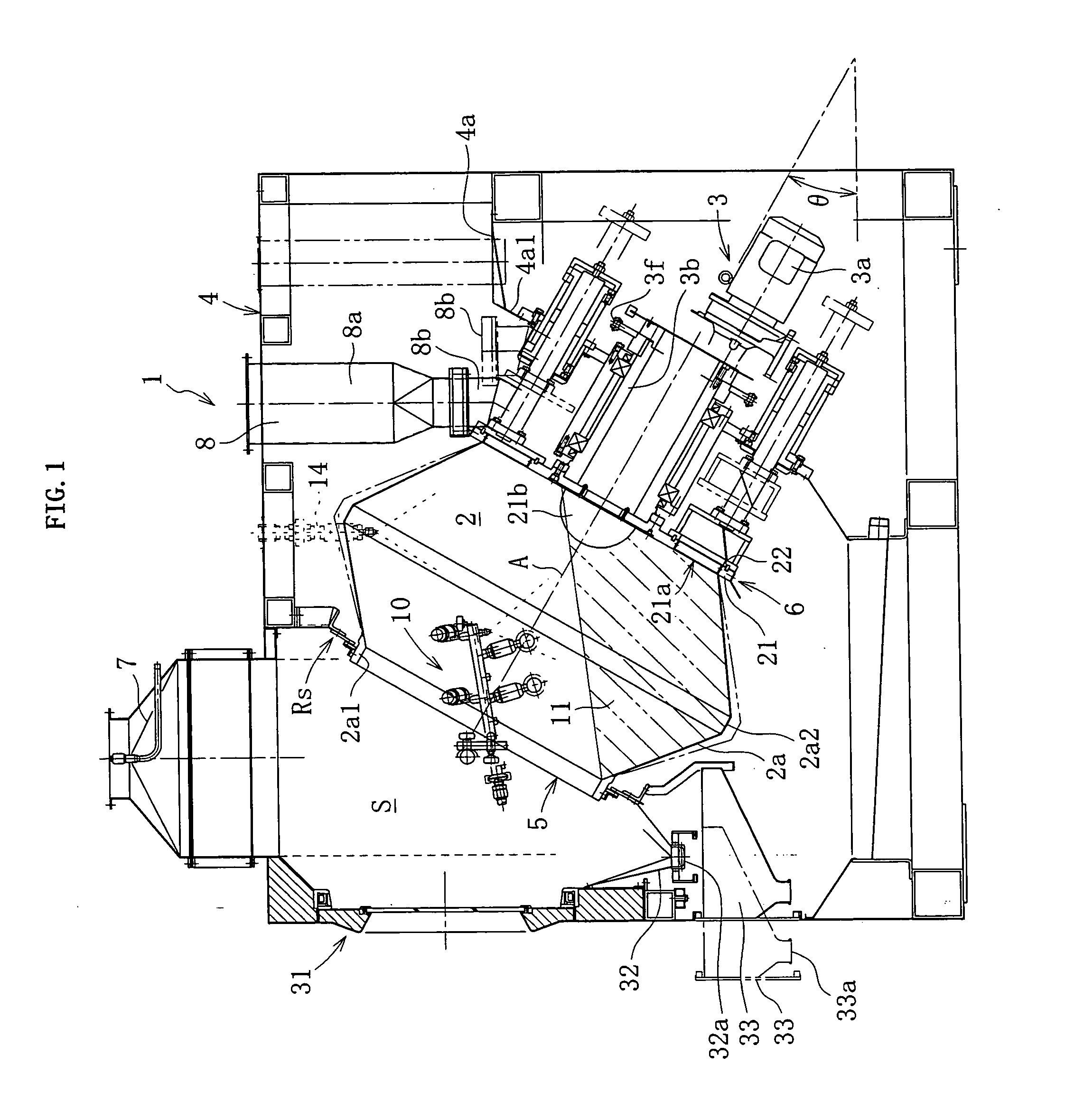

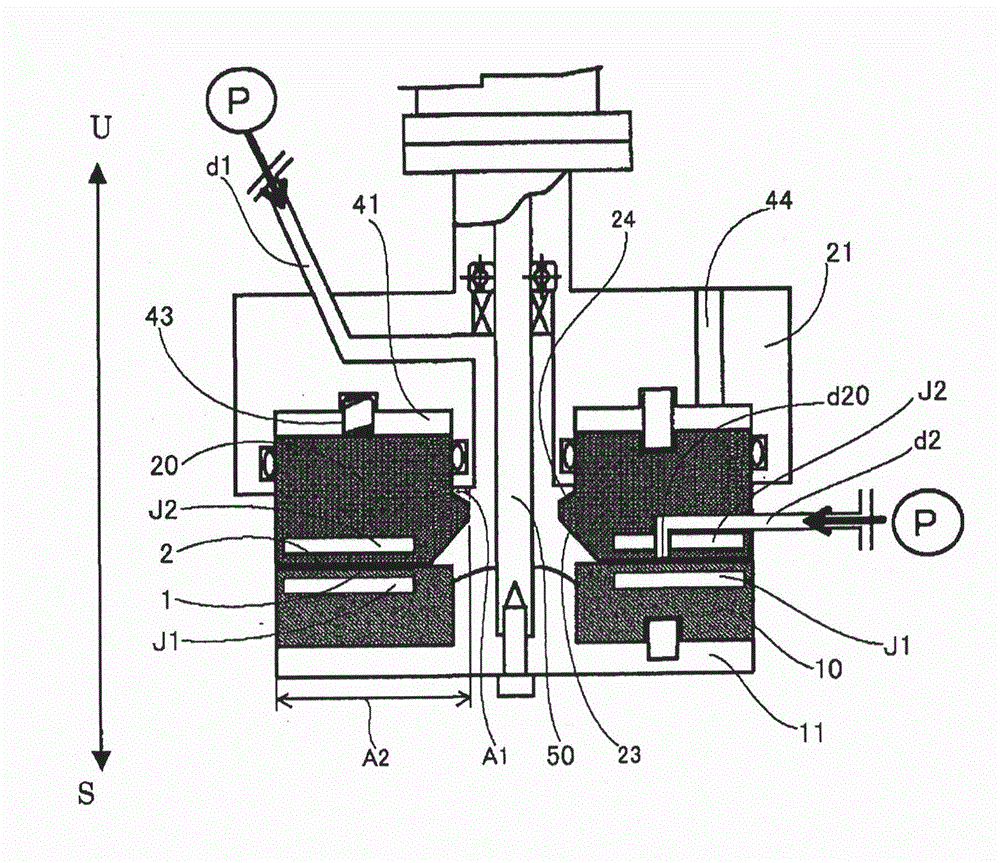

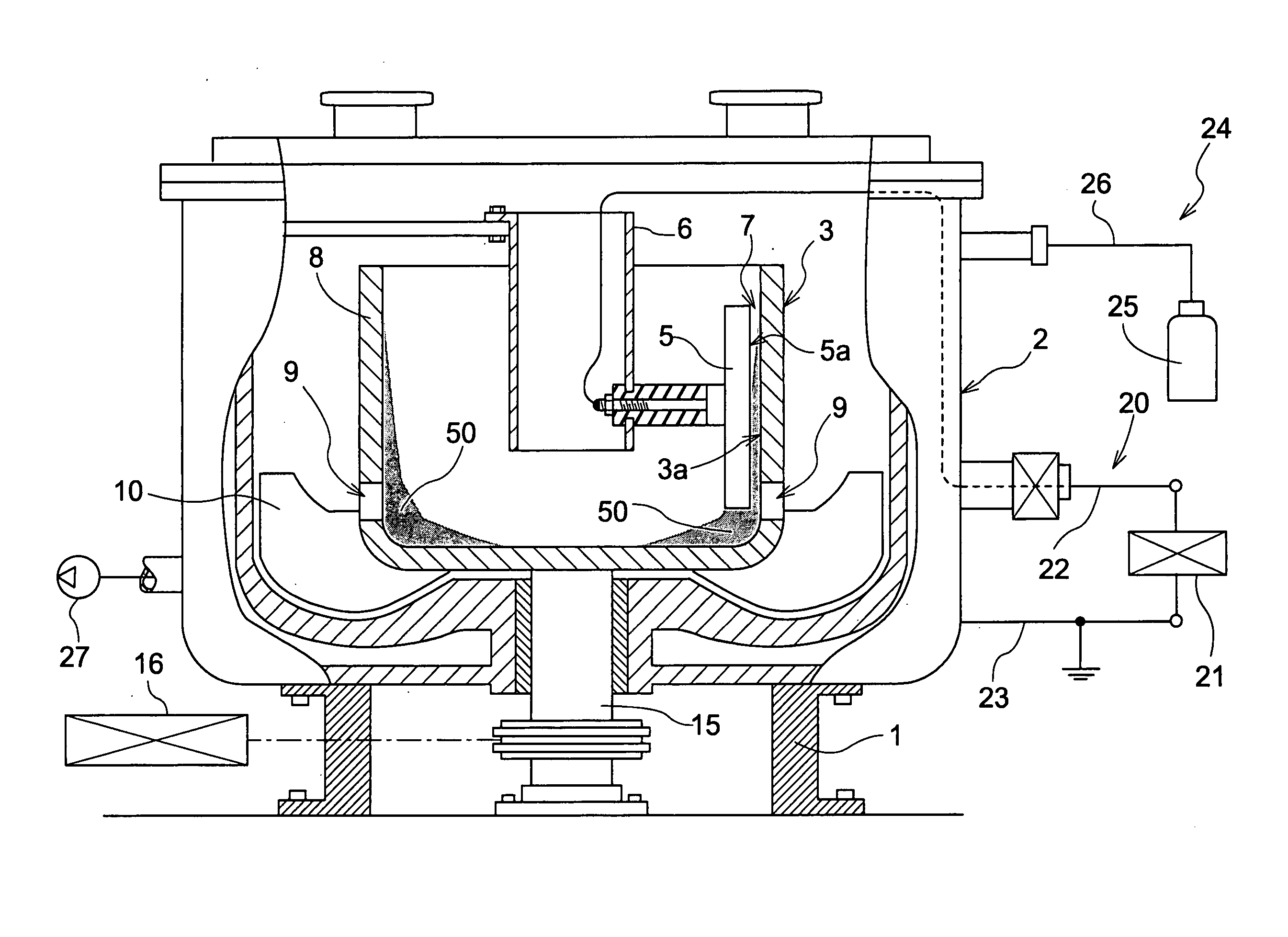

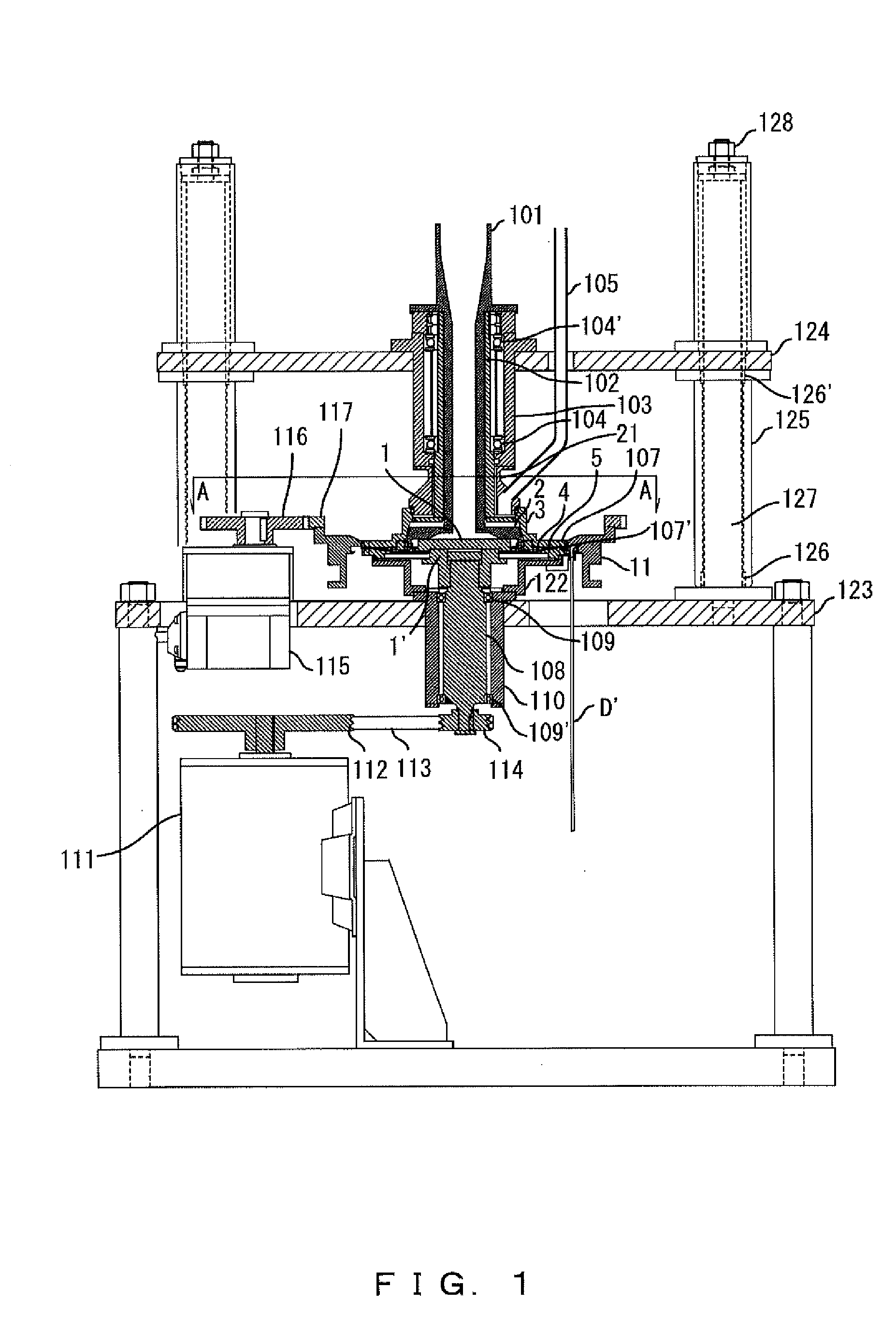

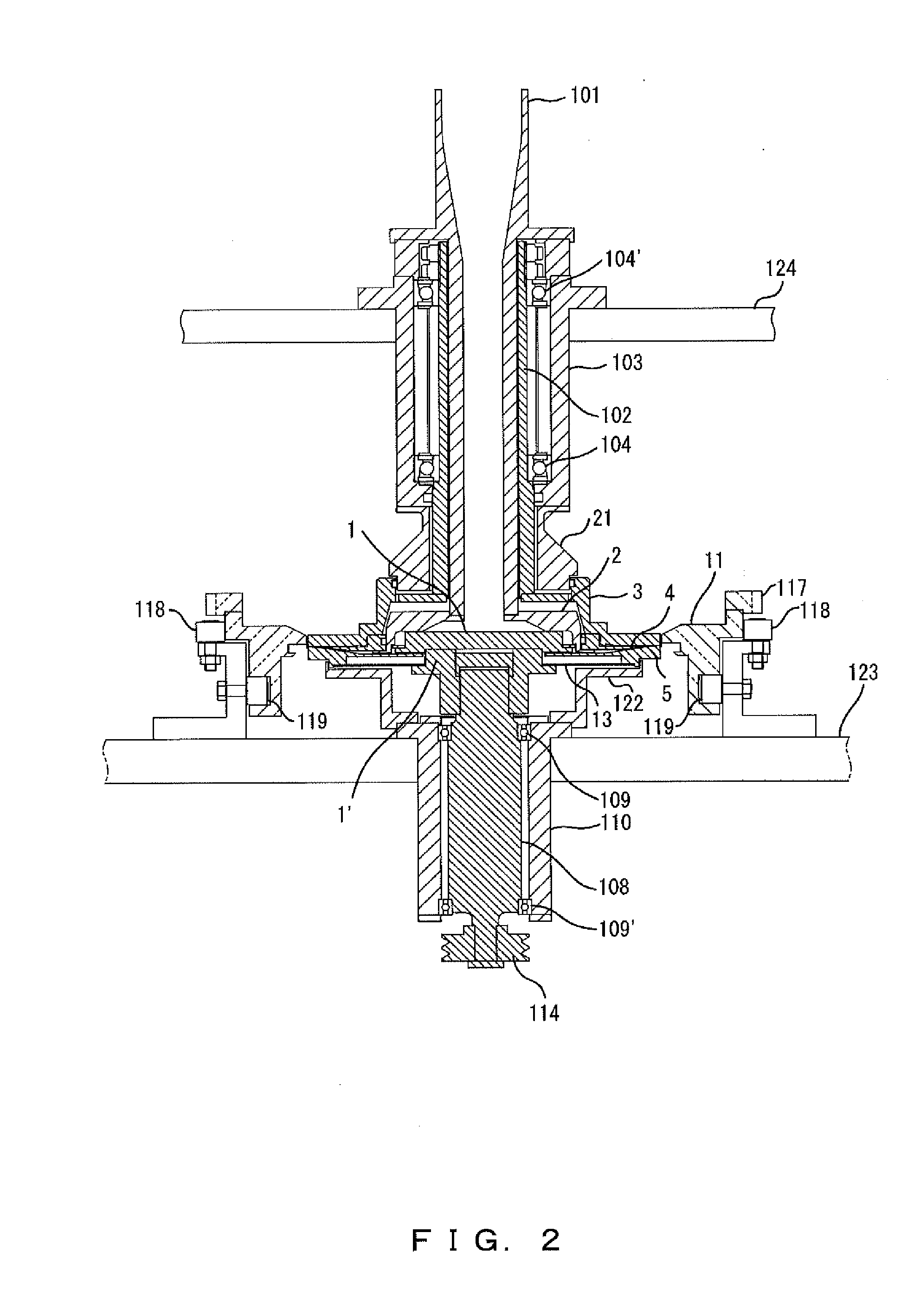

Pan coating apparatus

InactiveUS20110197810A1Increase freedomEasy to adjustConfectioneryChewing gumPerpendicular directionMechanical engineering

A spray gun (31) is attached to a multi-function unit (32) movable in a horizontal direction and a perpendicular direction. The spray gun (31) is mounted to a support holder (33), and the support holder (33) is connected to a support arm (35) of the multi-function unit (32). The support arm (35) is attached to a unit cover (36) which is openable / closable with respect to a casing (2). The support holder (33) and the support arm (35) can hide and house a liquid hose and an air hose therein so that the hoses and the like are arranged in an apparatus in such a state as to be completely free from being exposed. An installation position of the spray gun (31) can be finely adjusted by the multi-function unit (32) during a coating process, thereby enabling a control for keeping constant distances between tablet surfaces and the spray gun (31).

Owner:FREUNT IND

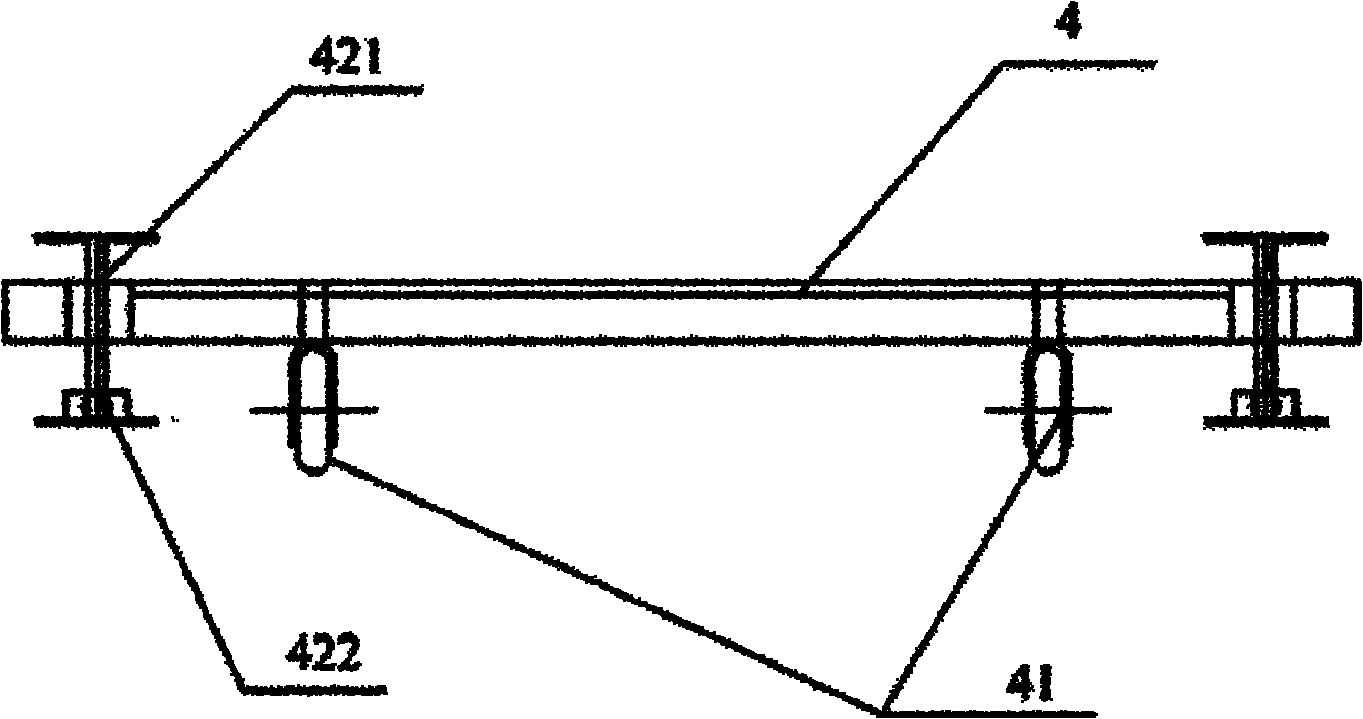

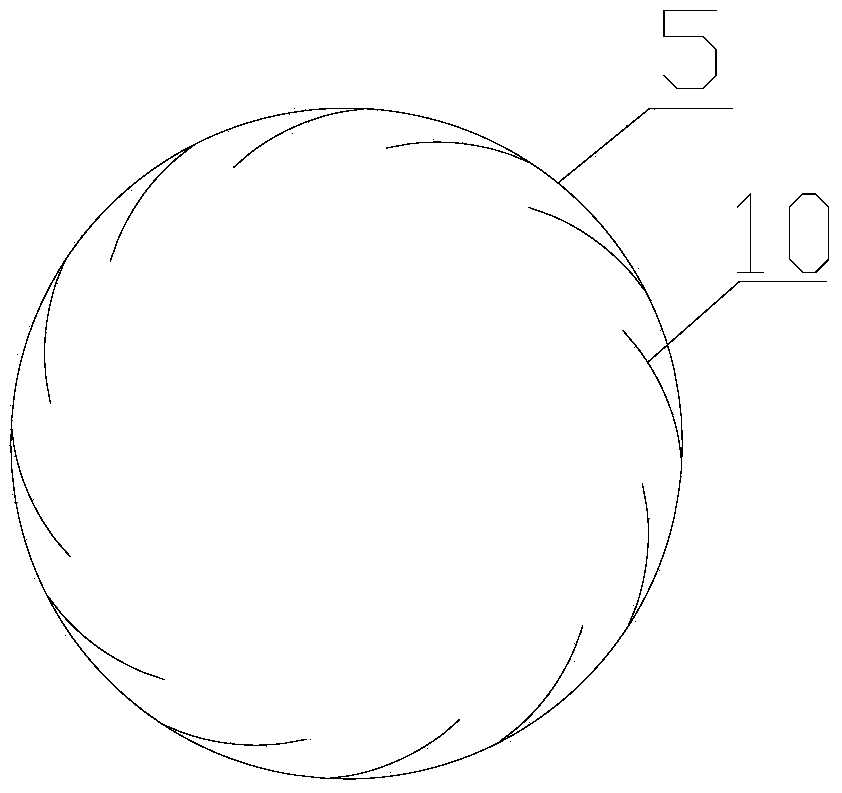

Disk granulator

InactiveCN102179203AImprove granulation qualityImprove quality and efficiencyGranulation in rotating dishes/pansFertiliser formsCircular discAdditive ingredient

Owner:CHINA AGRI UNIV

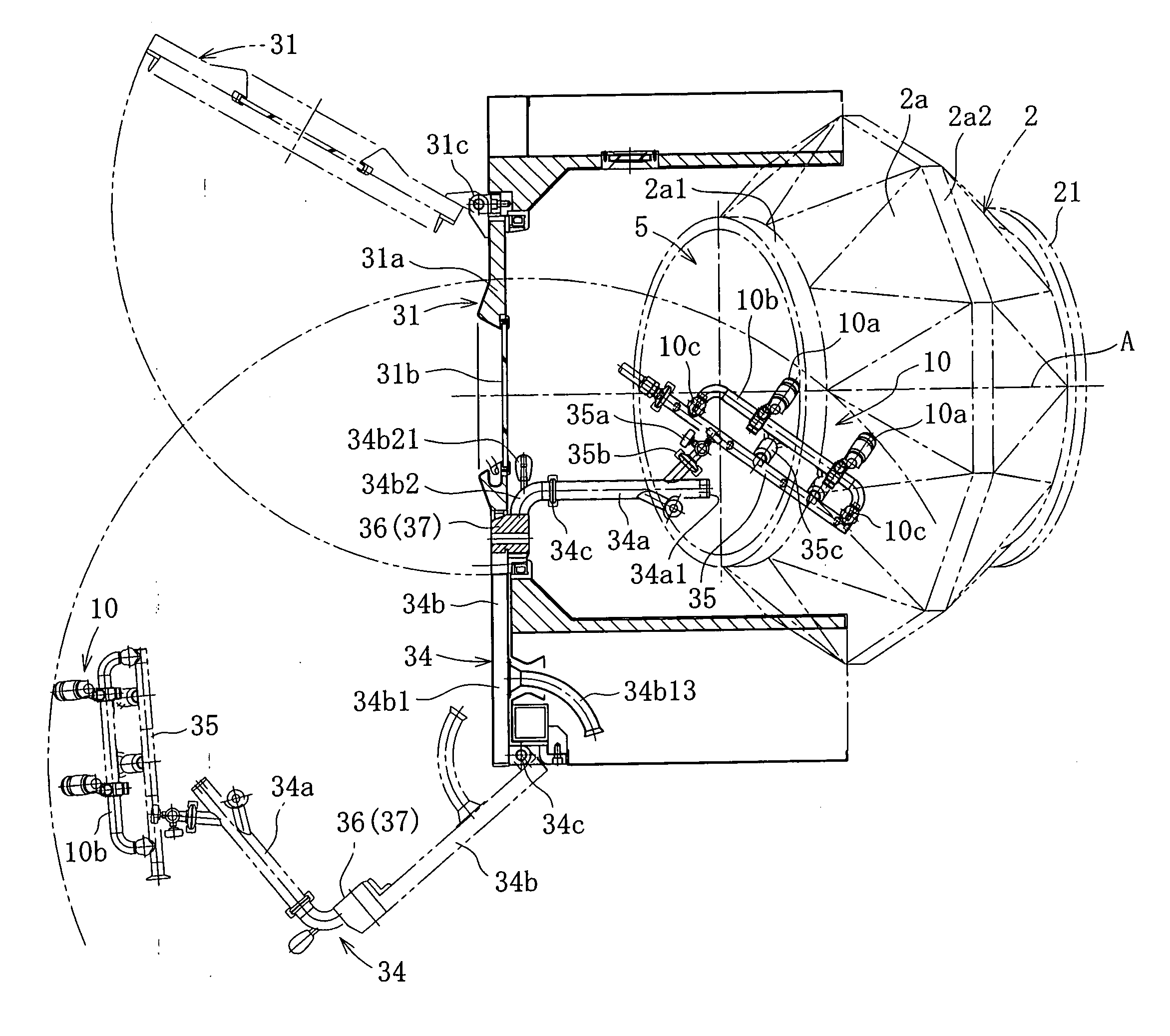

Coating Apparatus

InactiveUS20070261634A1Easy to slideEasy to operateLiquid surface applicatorsGranule coatingSpray nozzleEngineering

Provided is a coating apparatus, which has satisfactory operability at a time of installing or exchanging a spray nozzle, is not complicated in structure, and is advantageous in terms of layout. A rotary drum (2) is rotated around an axis (A) inclined with respect to a horizontal line, and has an opening (5) at one end on an inclination upper side. A spray nozzle unit (10) is removably attached to a swing arm (34), and the swing arm (34) can swing with respect to a swing axis (34c). Owing to the swing operation of the swing arm (34), the swing nozzle unit (10) can be moved between the inside and the outside of the rotary drum (2).

Owner:POWREX

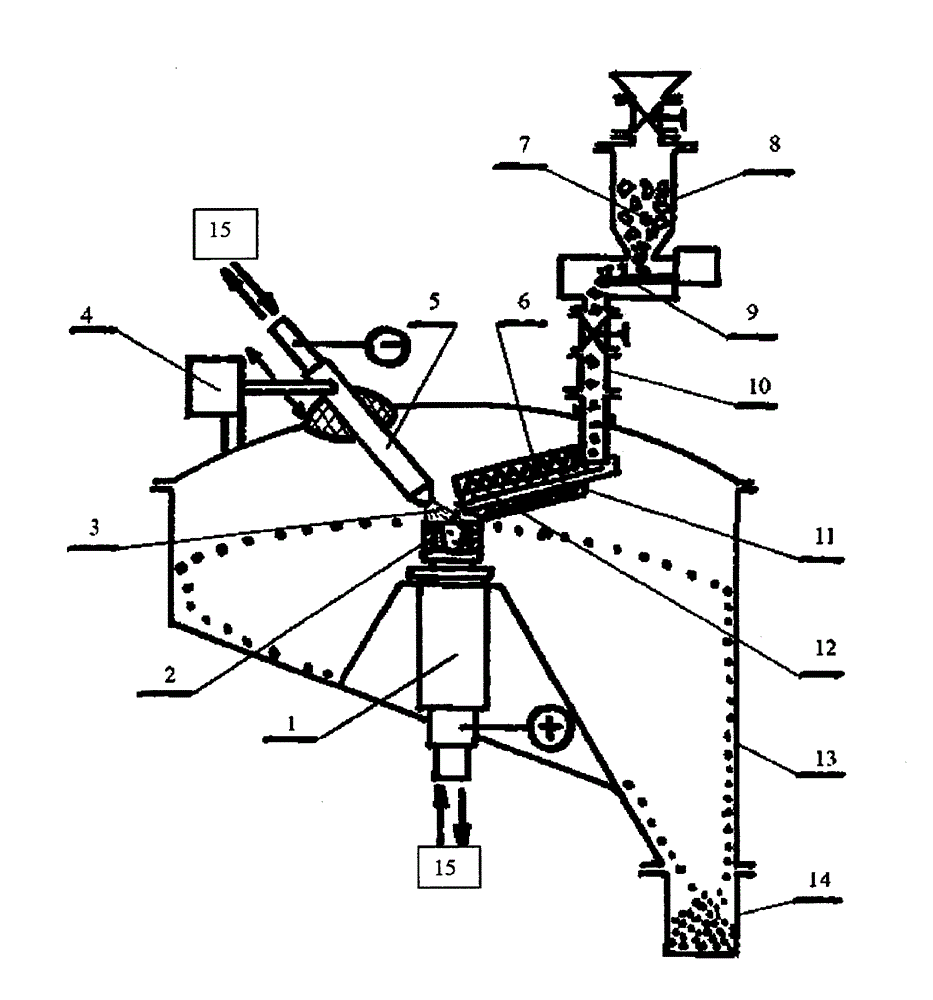

A manufacturing method of a high-strength small-size mill ball

ActiveCN104607102AHigh strengthSuitable for industrial applicationOther chemical processesGranulation in rotating dishes/pansHigh intensityUltimate tensile strength

The invention discloses a novel process for manufacturing a high-strength small-size mill ball by using a large-scale ball rolling machine as a forming device and through granulation by using a mother nucleus and powder material grading optimization. Firstly, granulation is performed by adopting one or more of raw materials as the mother nucleus, the large-scale ball rolling machine is used, and the optimized grading raw materials are added according to a certain material water ratio, and forming is performed by rolling. Finally, parameters of the ball rolling machine are adjusted, surface levelling of a ball blank is achieved, and after sintering, the small-size mill ball having a high degree of sphericity, high strength and low abrasion is obtained.

Owner:江苏金石研磨有限公司

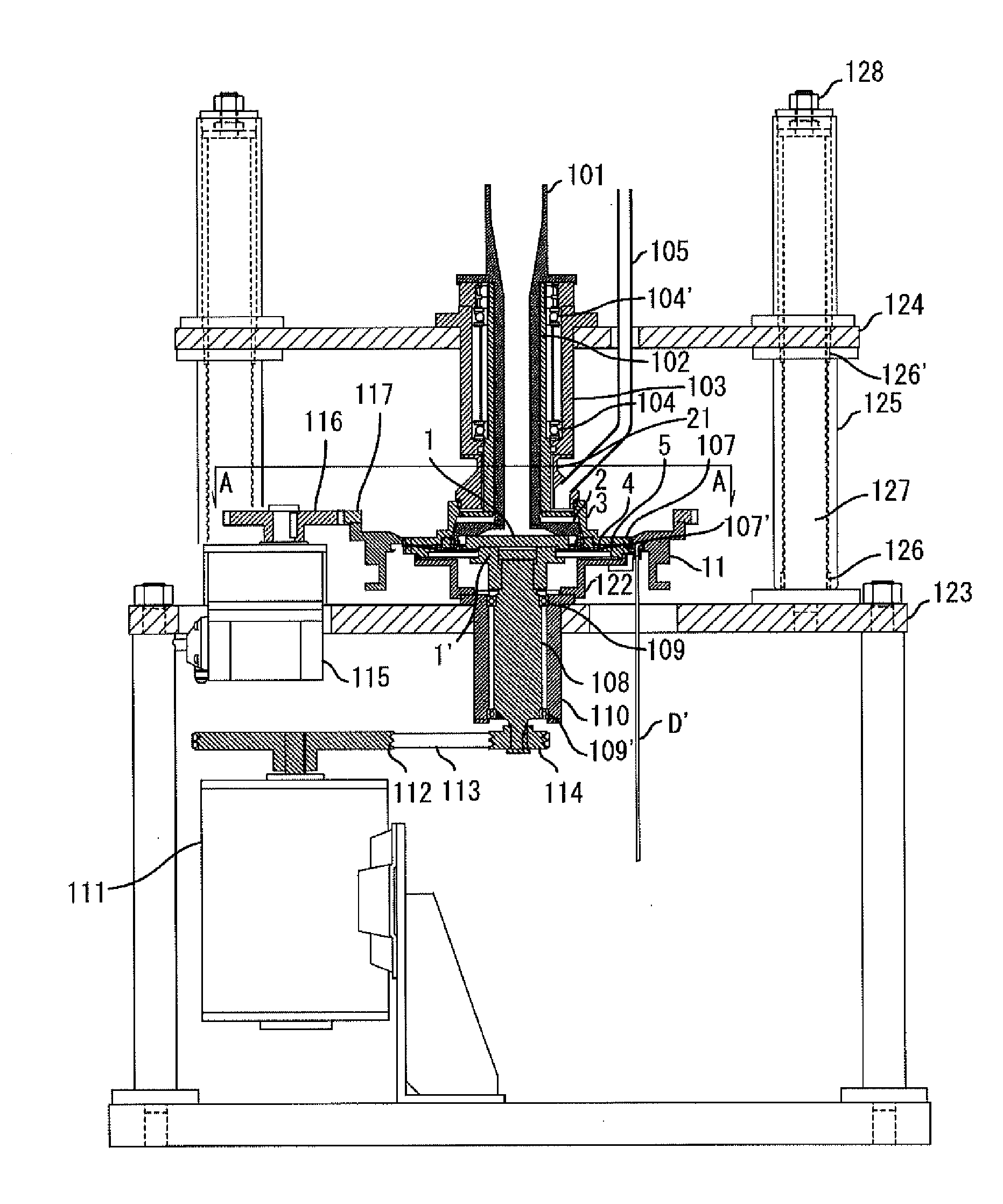

Method for manufacturing metal microparticles

ActiveCN104411429ACheap and stableLow costTransportation and packagingMetal-working apparatusMicroparticleSULFATE ION

Provided is a method for manufacturing metal microparticles in which the ratio of crystallite diameter to the particle diameter of the metal microparticles is controlled. At least two types of process fluid are used, including a metal fluid in which a metal or a metal compound is dissolved in a solvent, and a reducing agent fluid which includes a reducing agent. Sulfate ions are included in one or both of the metal fluid and the reducing agent fluid. The process fluid is mixed in a fluid thin film formed between at least two processing surfaces, at least one of which rotates relative to the other, and which are disposed facing each other and capable of approaching and separating from each other, and metal microparticles are precipitated. The present invention is characterized in that at this time, the ratio (d / D) of the crystallite diameter (d) of the metal microparticles to the particle diameter (D) of the metal microparticles is controlled by controlling the mole ratio of metal and sulfate ions in the mixed process fluid.

Owner:M TECHN

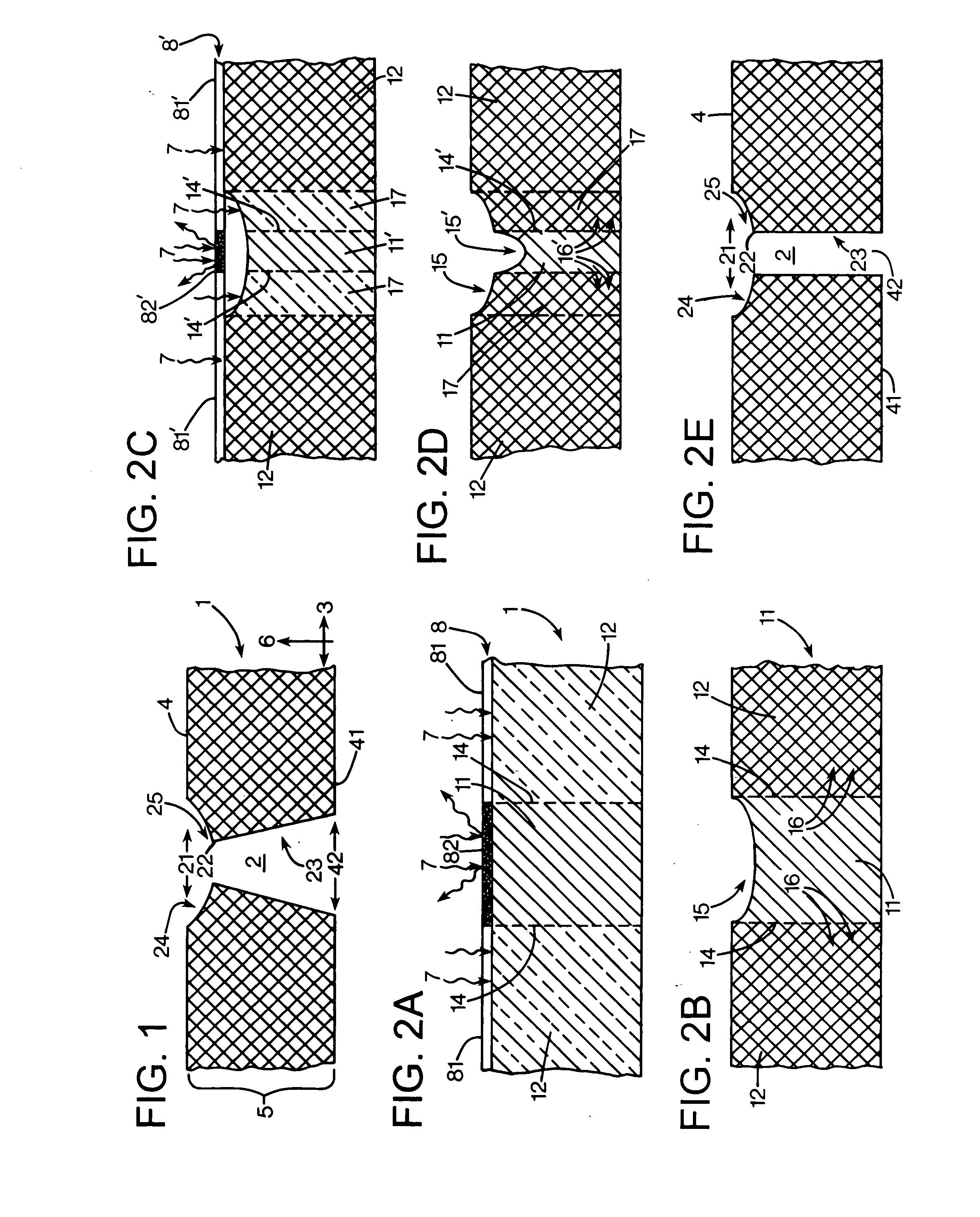

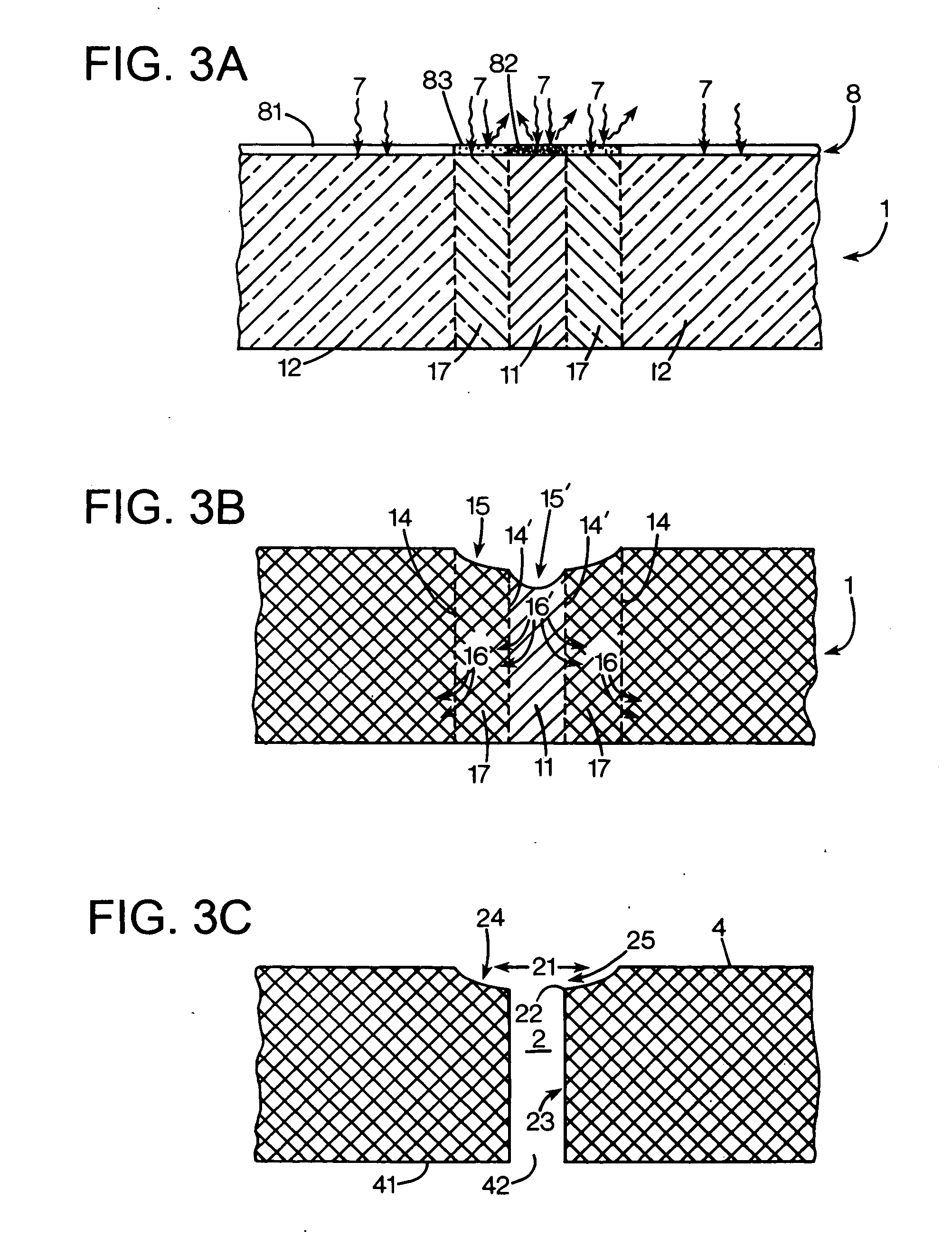

Method of manufacturing spherical bodies by rotation, spherical bodies made by the method and a powder composition for use in the method

InactiveUS6464906B1Low costInexpensive and efficient to manufactureNitrogen compoundsShaftsSolventSpherical form

A method of making spherical bodies from powder, which comprises (1) preparing an adjusted powder so as to have at least one powder characteristic selected from the group consisting of an average particle size, a powder particle size distribution and a BET specific surface area, (2) preparing nuclei having a particle size larger than that of the adjusted powder, (3) rotating the nuclei, and (4) adding the adjusted powder and a solvent to the rotating nuclei so that particles of the adjusted powder accumulate on the nuclei to form granular bodies. Also disclosed is a spherical body having a core or nucleus formed in the spherical body, an adjusted powder composition for forming a spherical body, and a method for manufacturing spherical sintered bodies of silicon nitride.

Owner:NGK SPARK PLUG CO LTD

Disk pelletizer

ActiveCN103252194ASolve the problem of low output efficiencyGranulation in rotating dishes/pansDischarge efficiencyCircular disc

The invention provides a disk pelletizer. The disk pelletizer comprises a driving device, a bracket, a main shaft, a rotary disk, a rotary oil distributor, discharge doors and a hydraulic system, and is characterized in that the driving device provides power for the rotary disk through the main shaft; the axle of the main shaft is coincided with the central line of the rotary disk, and forms a certain angle with the horizontal direction; the upper extending end of the main shaft is fixedly connected with the bottom surface of the rotary disk, and passes through the bottom surface of the rotary disk; the rotary oil distributor is arranged at the upper tail end of the main shaft; a plurality of discharge doors driven by a hydraulic cylinder are arranged at the lowest position of the side surface of the rotary disk; and the hydraulic system consists of an inner hydraulic system and an outer hydraulic system which are connected with oil passages through the rotary oil distributor. Compared with the prior art, the disk pelletizer has the advantages that hydraulic automatic switch discharge doors are arranged on the side wall of the rotary disk; and through the installation and arrangement design of the rotary oil passages, the problem of an existing disk pelletizer such as low discharge efficiency caused by necessary shutdown during discharging is effectively solved.

Owner:滁州华冶机电科技有限公司

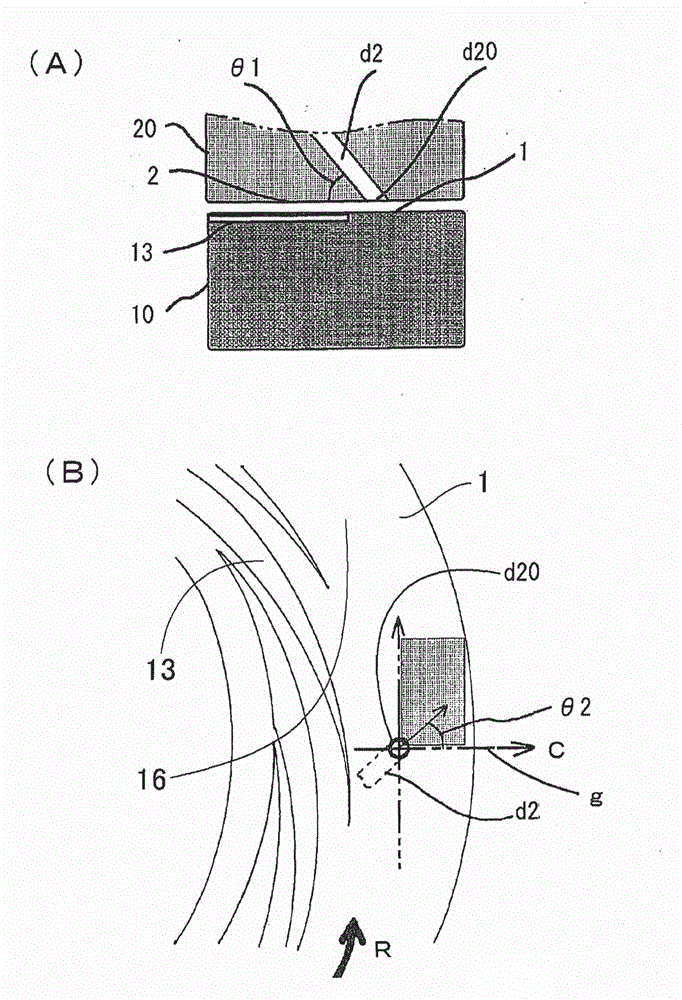

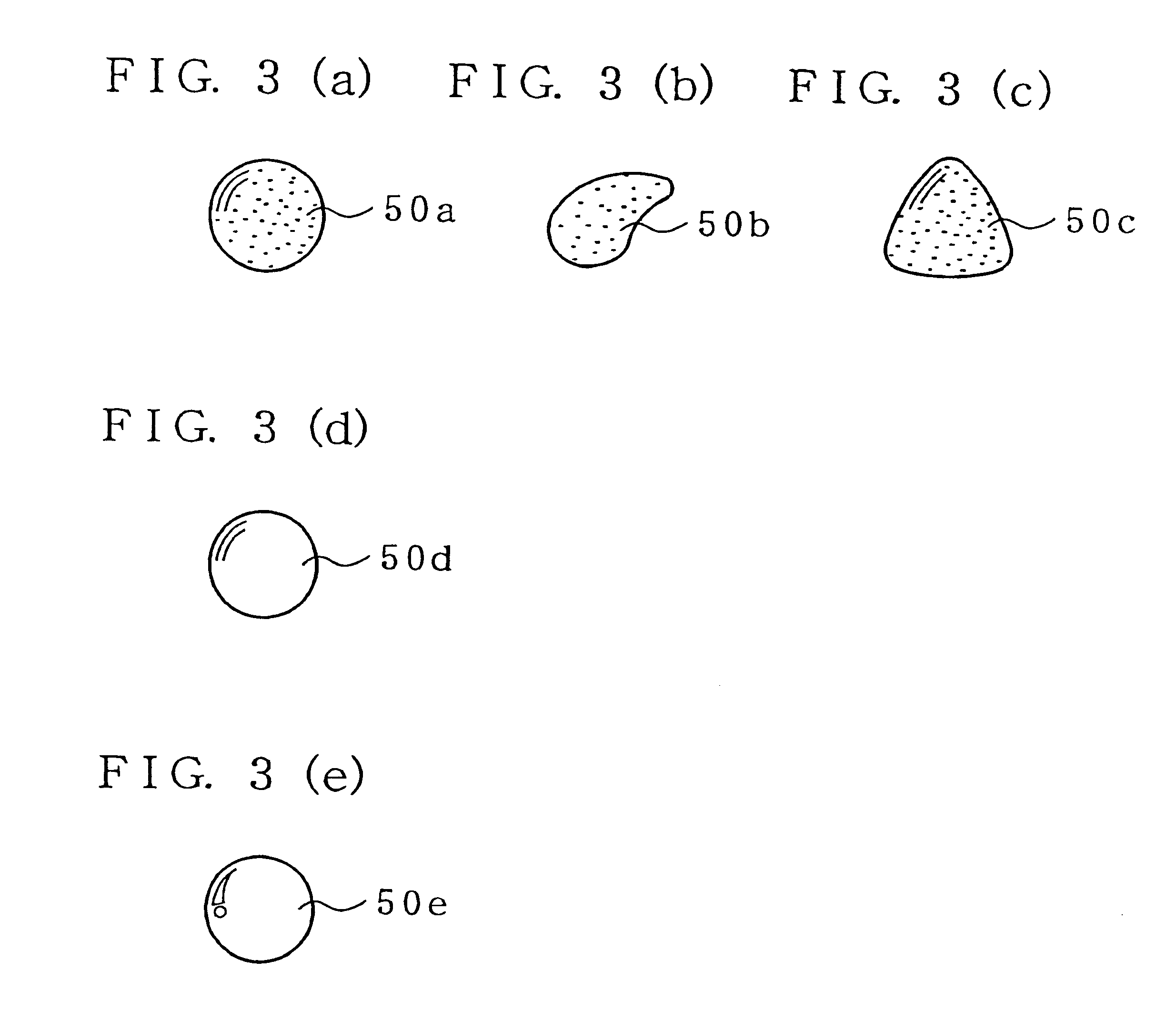

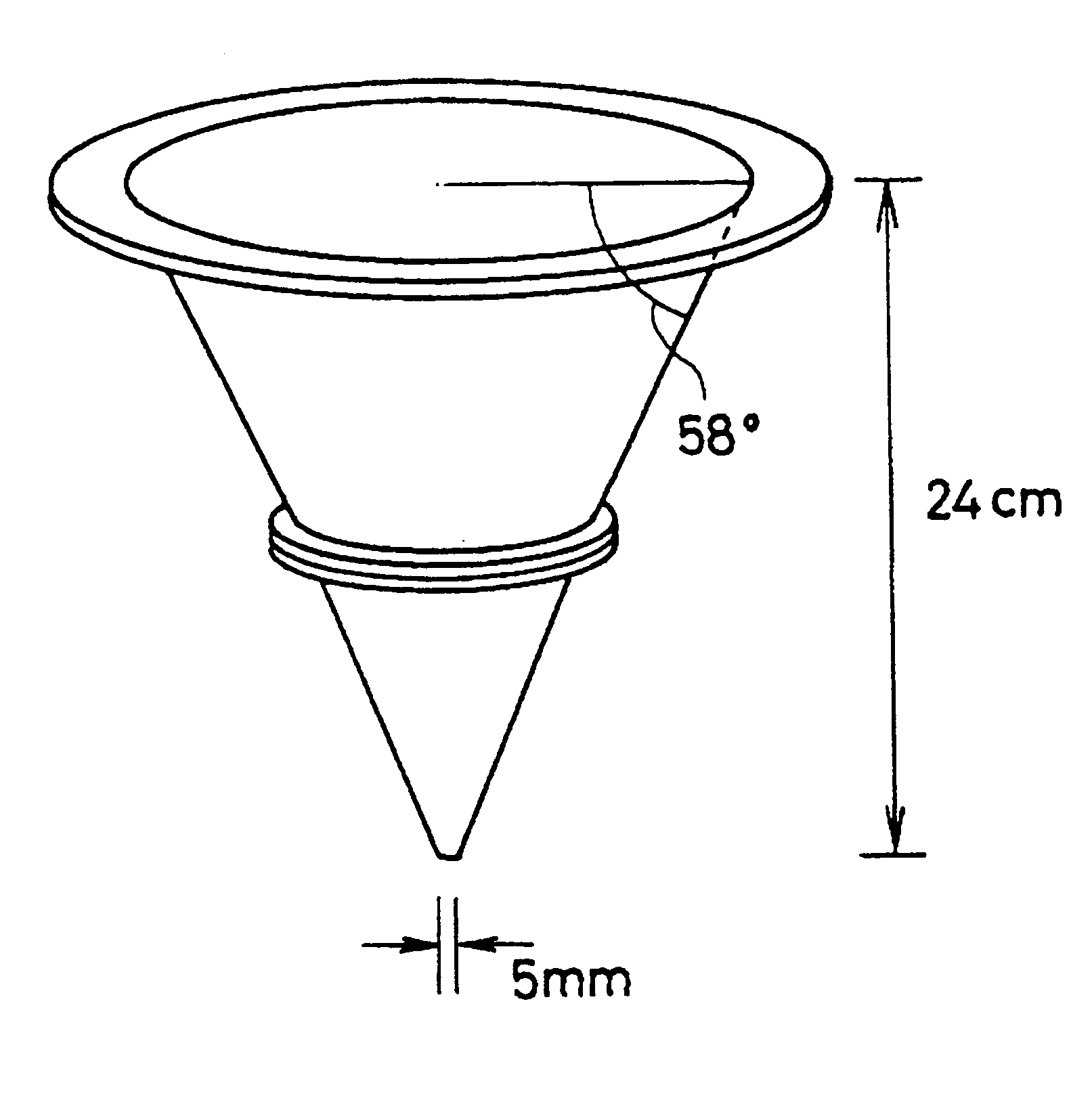

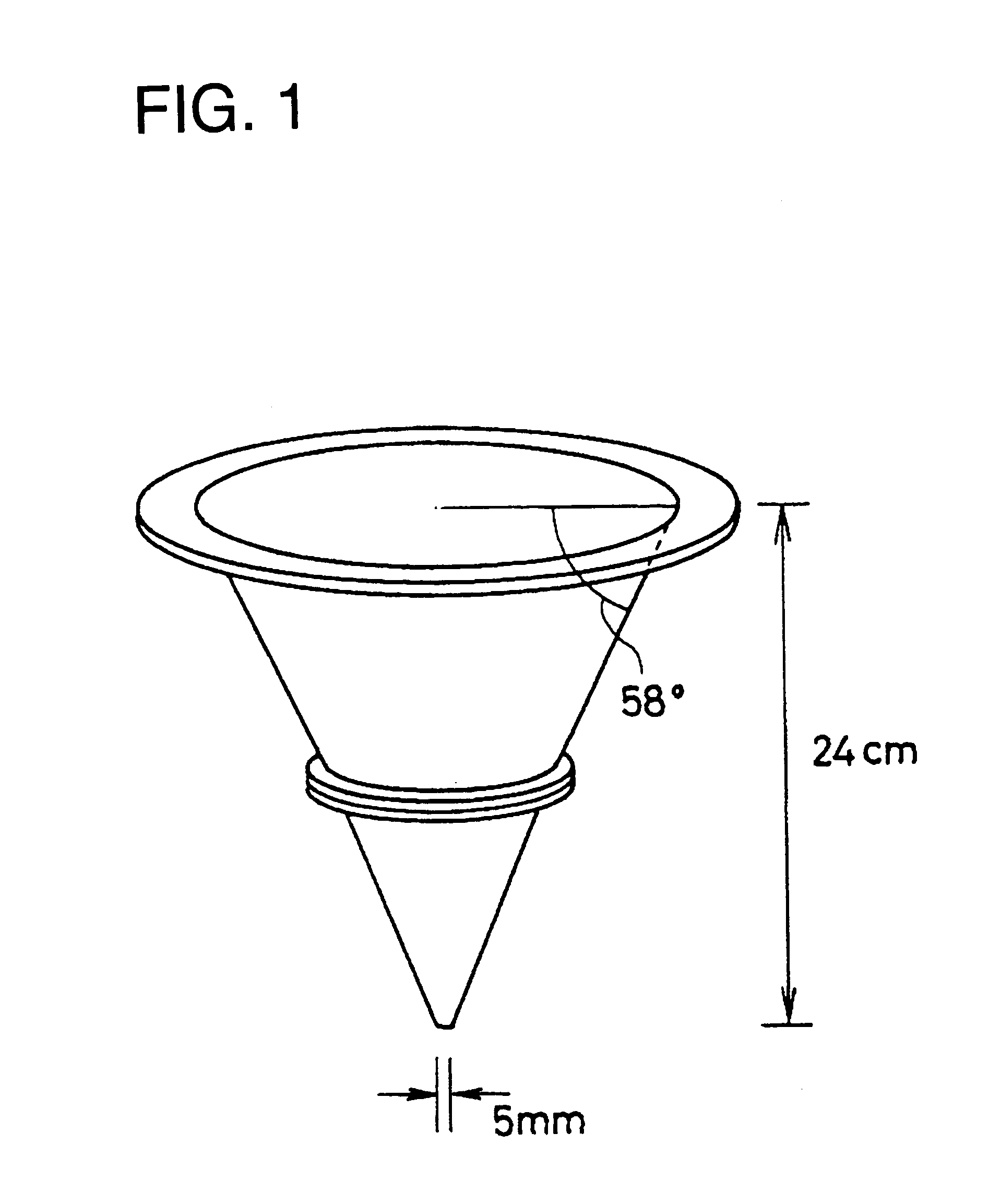

Spherical granule, process for producing the same, and spherical granule preparations using the same

InactiveUS6171619B1Less variationEasy to swallowPowder deliveryPharmaceutical product form changeSpherical granuleVolumetric Mass Density

The invention relates to spherical granules having a uniform grain size and a uniform density which are suitable for a controlled-release preparation, a process for producing the same, and a spherical granule preparation using the same. Specifically, the invention relates to a process for producing spherical granules comprising the steps of: wetting powder materials comprising one or more kinds of pharmaceutical substances and have a mean particle size of from 1 to 100 .mu.m; charging the wet powder materials into a centrifugal fluidized granulating apparatus; spraying a liquid to the wet powder materials at a rate of less than 3% based on the plastic limit of the powder materials per min. while rotating the rotary disk of the centrifugal fluidized granulating apparatus until the liquid content of the powder materials reaches 75 to 120% based on the plastic limit of the powder materials, and drying the sprayed product to give spherical granules; spherical granules having a mean grain size of 100-1000 .mu.m, in which at least 90% by weight of the total amount of the spherical granules has such a grain size distribution that the maximum grain size is not larger than 1.2 times the minimum grain size, and the difference in density between the individual spherical granules is less than 0.05 g / cm.sup.3 ; and a spherical granule preparation comprising the spherical granules.

Owner:FREUNT IND

Device for moving and orienting spraying nozzles in a coating pan

InactiveUS6557486B2Function increaseLiquid surface applicatorsGranule coatingRotational axisClassical mechanics

Owner:G S S R L COATING SYST

Rotor processor for dry powders

The improved rotor processor of the present invention includes a stator with a rotatable rotor defining a rotor chamber in which particles are circulated for coating or layering. A spray gun mounted to the stator adjacent the rotor directs liquid into the rotor chamber, while a powder feed system mounted in the stator adjacent the rotor directs dry powder into the rotor chamber. The spray gun and powder feed system are spaced apart circumferentially so as to define a spray zone and a separate powder zone through which the circulating particles repeatedly and sequentially pass. The powder feed system includes a feed screw conveyor, an eductor, and a flexible conduit for delivering micronized powders, such as polymers or glidants, to the rotor chamber.

Owner:VECTOR CORP

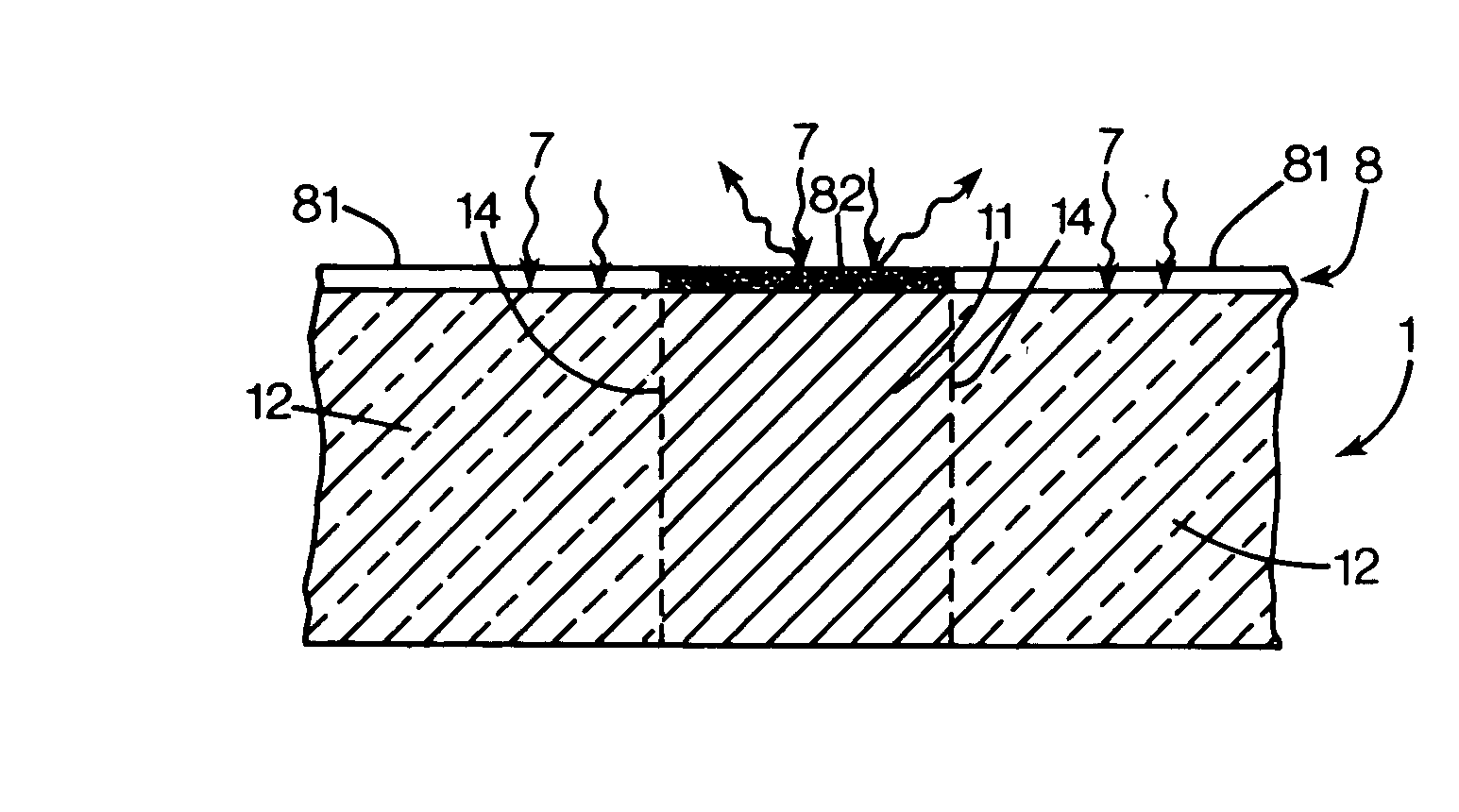

Method and Apparatus for Processing Powder and Method of Manufacturing Porous Granulated Substance

InactiveUS20070228201A1Effective controlLow thermal conductivitySolid waste disposalGranulation in rotating drumsEnergy supplyMaterials science

In order to manufacture the compound powder or the porous granulated substance in an efficient manner, a powder processing apparatus has an accumulating face on which the processing target powder is to be accumulated and a processing face disposed in opposition to the accumulating face and convexly curved, and a moving means for moving the accumulating face and the processing face along the accumulating face relative to each other. The apparatus comprises an excitement treatment means capable of applying an excitation energy to the processing target powder accumulated on the accumulating face from an excitation energy supplying portion disposed in opposition to the accumulating face or an oscillation means for oscillating the accumulating face or the processing face in a direction intersecting the accumulating face.

Owner:HOSOKAWA MICRON CORP

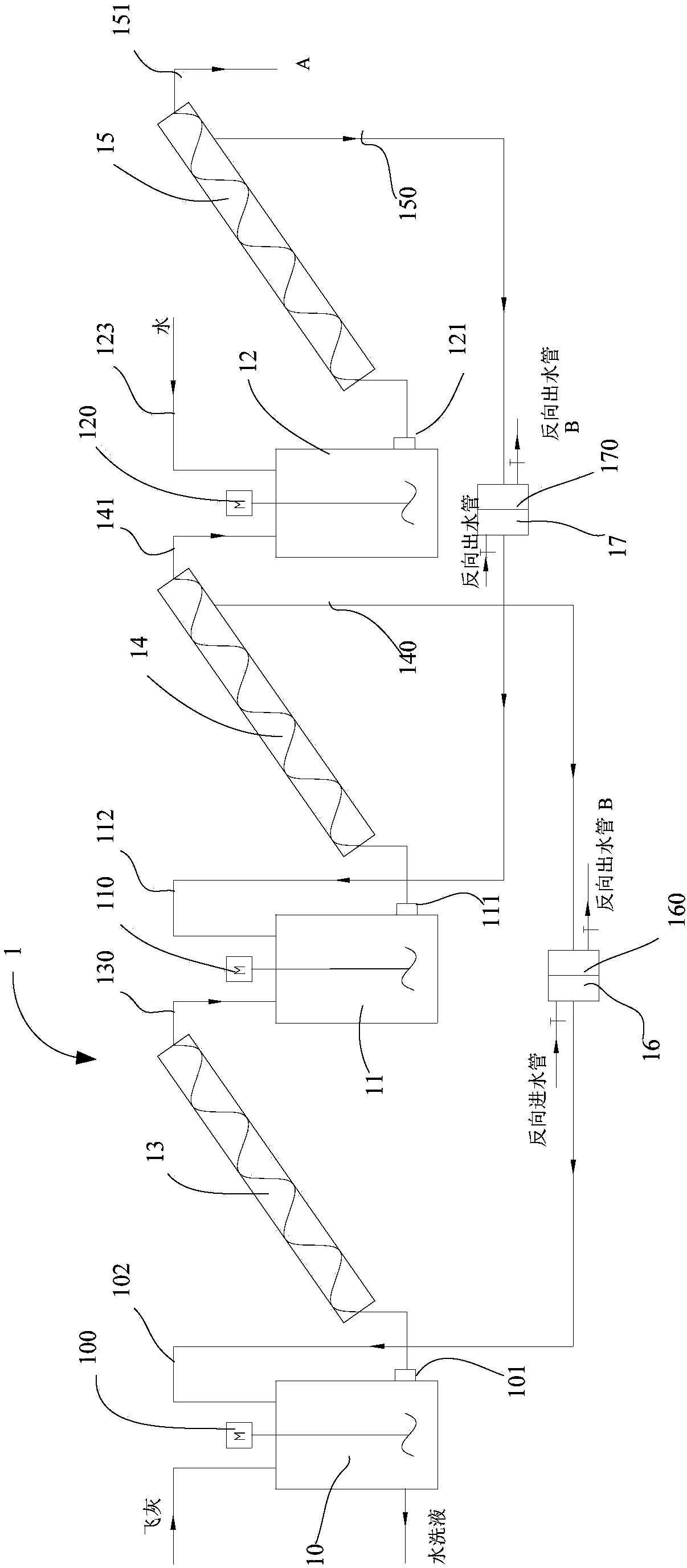

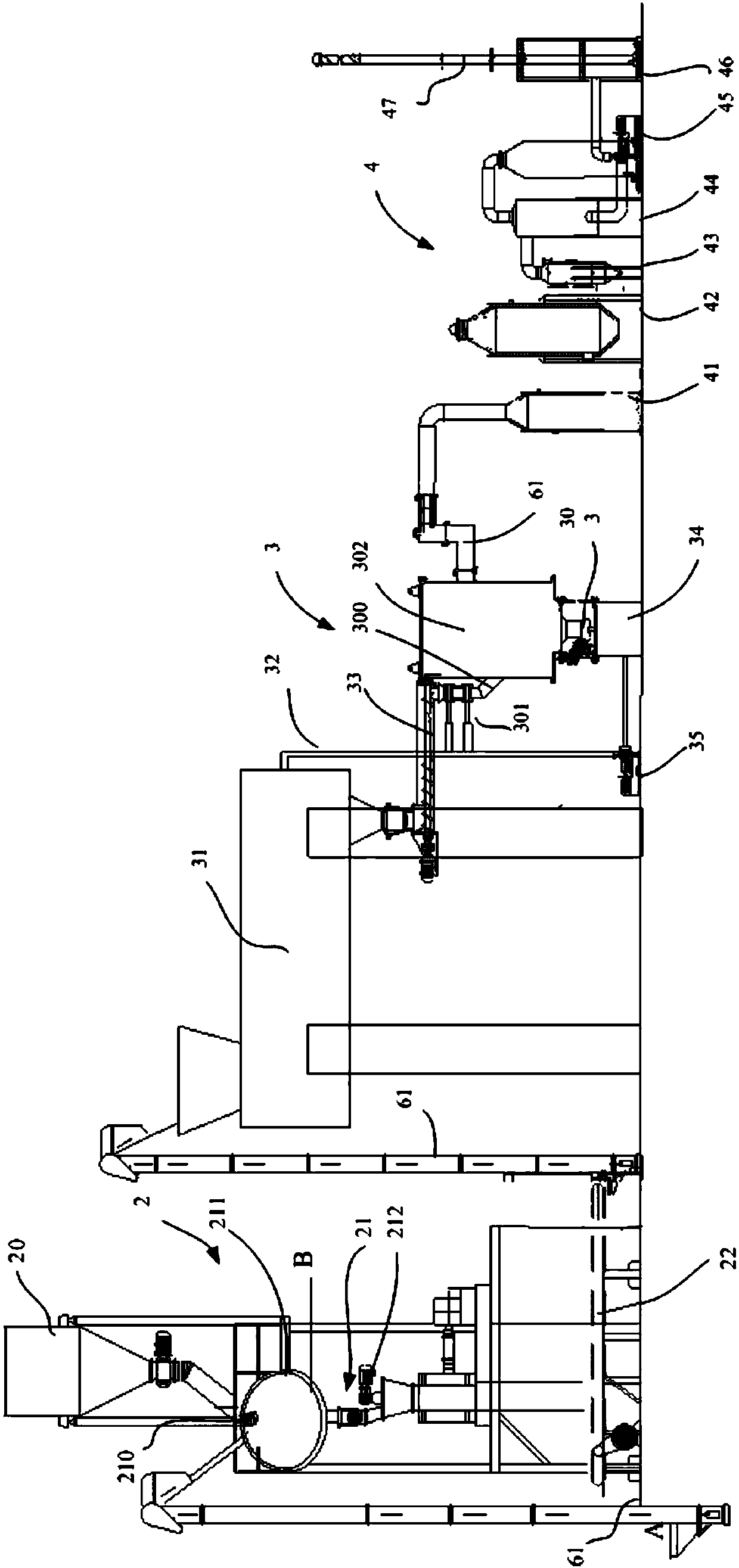

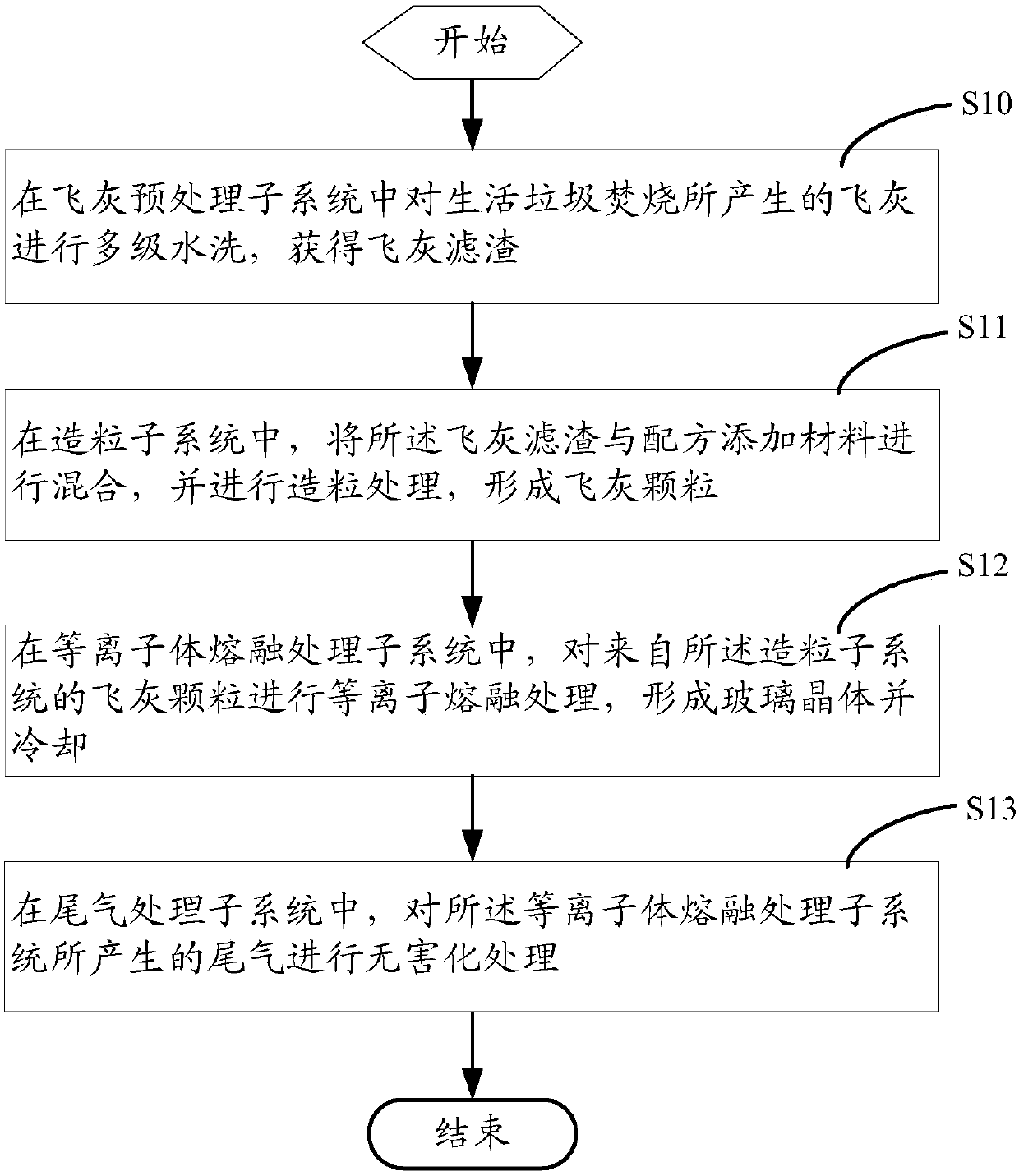

Innocent treatment system and method for household garbage incineration fly ash

PendingCN108043859AFully washedReduce corrosion rateSolid waste disposalTransportation and packagingLitterFly ash

The invention discloses an innocent treatment system for household garbage incineration fly ash at least comprising a fly ash pretreatment subsystem, a pelleting subsystem, a plasma melting treatmentsubsystem, and an exhaust gas treatment subsystem; the fly ash pretreatment subsystem is used for multi-stage washing fly ash produced by household garbage incineration, and fly ash residues are obtained; the pelleting subsystem is used for mixing the fly ash residues with formula additive materials, and pelleting treatment is carried out to form fly ash particles; the plasma melting treatment subsystem is used for performing plasma melting treatment for the fly ash particles from the pelleting subsystem, and glass crystals are formed and cooled; and the exhaust gas treatment subsystem is usedfor performing innocent treatment for exhaust gas produced by the plasma melting treatment subsystem. The invention also discloses a corresponding method. The implementation of the innocent treatmentsystem and the method for household garbage incineration fly ash can realize disposal of harness, stabilization and recycling of the incineration fly ash.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

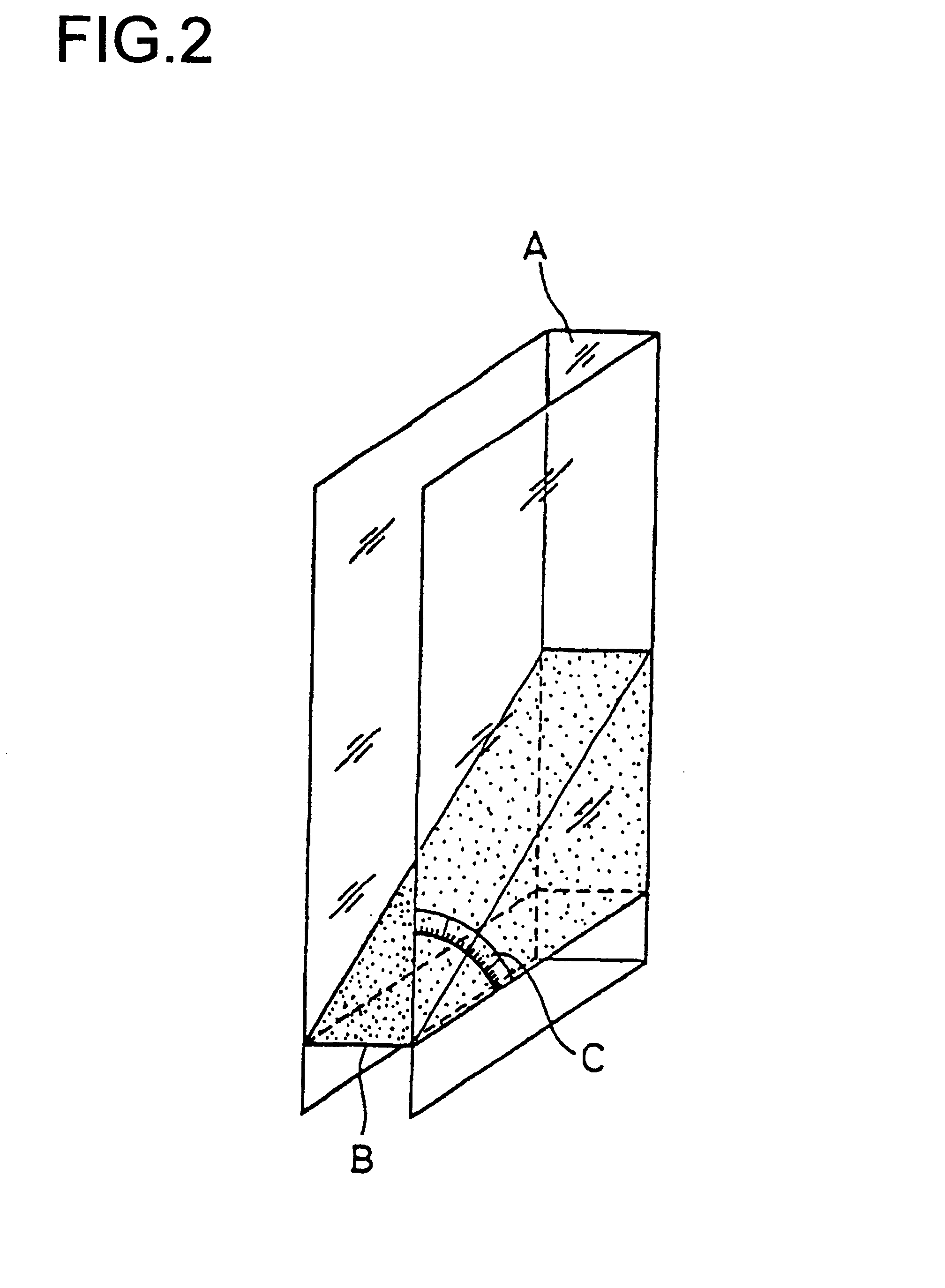

Mixing apparatus for powder raw material and liquid raw material and method for manufacturing mixture using same

A mixing apparatus is provided that evenly mixes a powder raw material and a liquid raw material. The powder raw material is supplied to and spread out on a rotating disk to form a thin layer of dispersed particle swarms close to the periphery of the rotating disk. A rotary atomizer that synchronously rotates on the same axis is provided above the rotating disk. The liquid raw material is supplied to an inside surface of the rotary atomizer. Then, the liquid raw material is conducted to an atomizing head where the liquid raw material is atomized, and droplet swarms are horizontally radiated. The dispersed particle swarms and the droplet swarms are merged and condensed within a tapered wedge-shaped space, with the result that these swarms change into a fine and homogeneous mixture. The mixture is then radiated from the periphery.

Owner:TOHKAI GIKEN

Extrusion-spheronization integrated granulating machine

InactiveCN104549045AReduce areaSmall footprintGranulation in rotating dishes/pansGranulation by material expressionEngineeringSmall footprint

The invention discloses an extrusion-spheronization integrated granulating machine. A support cutter mechanism is arranged between a screw extruder and a spheronizator of the granulating machine; the support cutter mechanism at least comprises a filament propping rod, a filament and a base support; filament winding slots are formed at two ends of each filament propping rod, the filament is fixed on the filament propping rod by the filament winding slot, two ends of each filament propping rod are in clearance fitting with grooves of a pore plate by pins, a spheronization disc cover is arranged above a spheronization disc and is in clearance fitting with the spheronization disc; a spheronization feeding hole, a lifting lug and a single-screw guide groove are respectively formed in and arranged on the spheronization disc cover; the spheronization disc cover is fixed on a spheronization barrel by the lifting lug; the spheronization feeding hole and the single-screw guide groove are arranged on the outer surface and the inner surface of the spheronization disc cover respectively, the spheronization feeding hole is communicated with a through hole, the inlet and the outlet of the single-screw guide groove are communicated with the through hole and a discharge hole respectively, friction lines are formed on the upper end surface of the spheronization disc, and the base support is arranged on the spheronization disc. The extrusion-spheronization integrated granulating machine is small in occupied area, high in granulating efficiency, short in time and good in granulating effect.

Owner:HUAZHONG AGRI UNIV

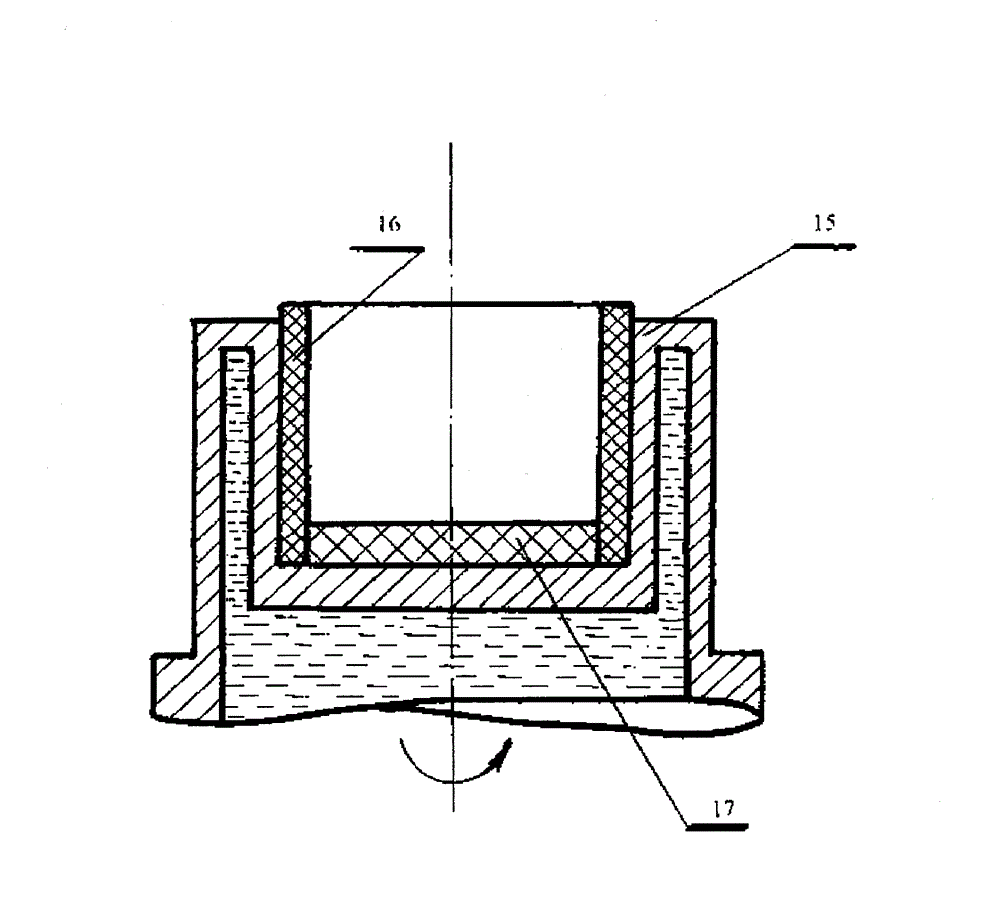

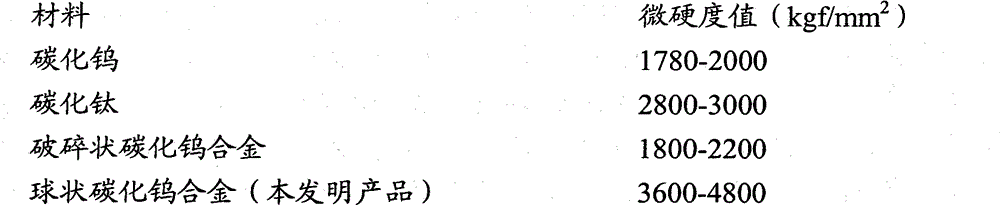

Spherical powder and its preparation

InactiveCN103068731ASmall currentStable temperatureGranulation in rotating dishes/pansGranulation by liquid drop formationApparent densityCrucible

A spherical tungsten carbide powder is characterized by that the material has a microhardness higher than 3600 kgf / mm2, and that the powder has an apparent density from 9.80 to 11.56 g / cm3. A method for the manufacture of a powder comprises the steps: a) providing a chamber comprising a rotatable crucible, b) adding material into said rotatable crucible, c) melting the material using a plasma arc discharge, d) rotating the crucible to atomize the molten material to form liquid droplets, with subsequent cooling of the droplets to obtain a powder, wherein the material added into said rotatable crucible is heated to a temperature above 40% of the melting temperature of the material before it enters the crucible. It is possible to reduce the current required for melting the stock. Heat losses are decreased, and the spherical powder obtained during atomization becomes more homogeneous in its composition and structure. The cost is reduced.

Owner:美塔斯菲尔技术公司

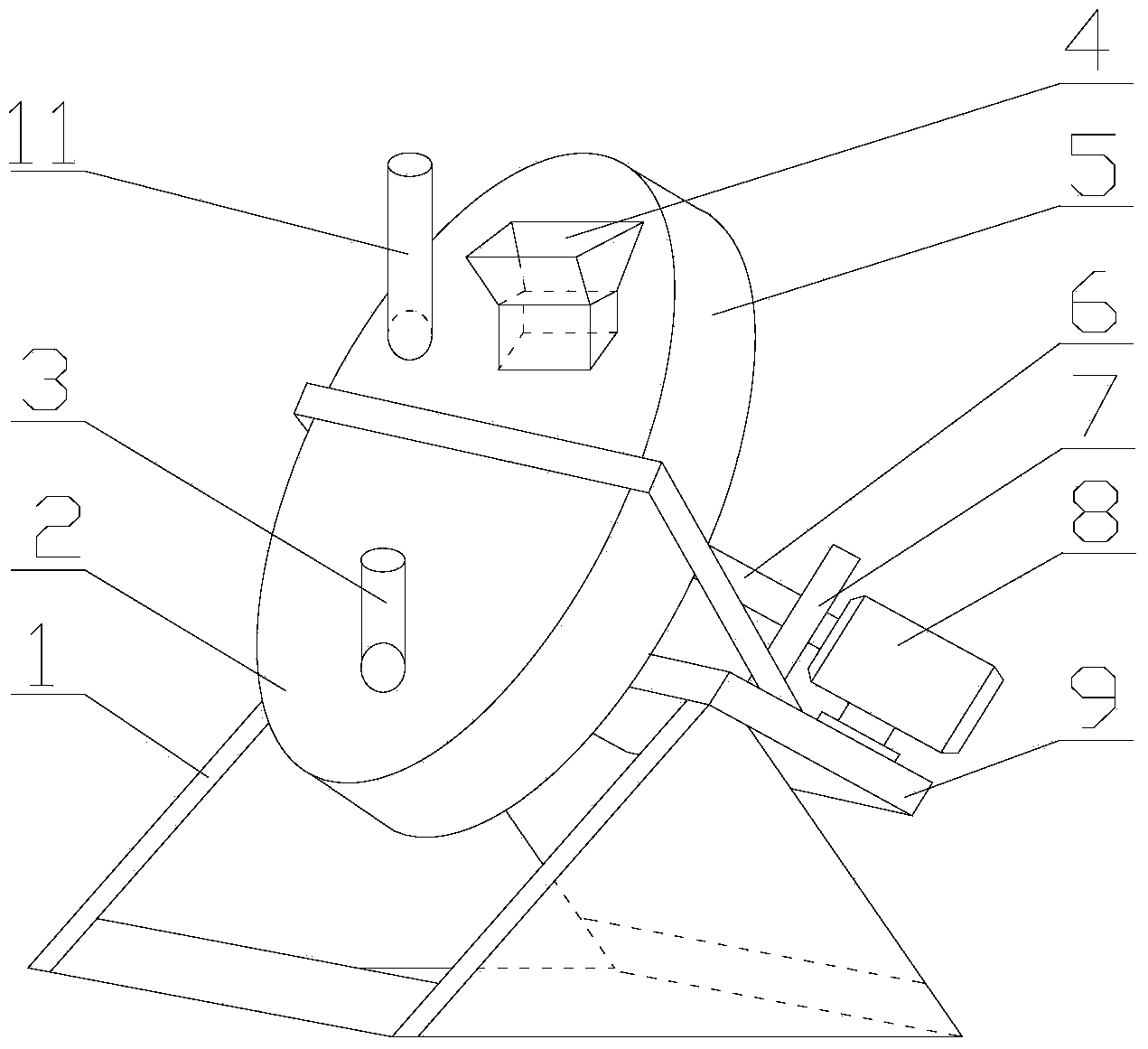

Method for inhibiting generation of large pellets and suitable for being used in disk pelletizer

ActiveCN103861523AImprove securityAvoid being broken by mistakeGranulation in rotating dishes/pansCircular discEngineering

The invention discloses a method for inhibiting the generation of large pellets and suitable for being used in a disk pelletizer. The unqualified large pellets are crushed by equipment for inhibiting the generation of the large pellets and arranged adjacent to a pelletizer disk by adjusting the position of an inhibiting rod device of the equipment for inhibiting the generation of the large pellets according to the actual positions of the unqualified large pellets generated in the pelletizer disk, blocking the inhibiting rod device on the lower half part of the pelletizer disk and the positions opposite to those of the unqualified large pellets and driving the unqualified large pellets to impact onto the inhibiting rod device through the rotary pelletizer disk. According to the method, the unqualified large pellets are crushed according to the actual positions of the unqualified large pellets generated in the pelletizer disk. The method is high in crushing efficiency and safety and strong in practicability.

Owner:ZHUZHOU SUNER HEAVY MACHINERY

Closed type disk grain making machine

InactiveCN104028169AImprove granulation effectReduce workloadGranulation in rotating dishes/pansReducerComputer engineering

A closed type disk grain making machine comprises a disk, a disk cover, lifting boards, a feed inlet, a hot air inlet, an air outlet, a motor, a speed reducer, a rotary shaft, a support and a bracket, wherein the lifting boards are evenly distributed on the inner wall of the disk, the feed inlet and the air outlet are arranged in the upper end of the disk cover, the hot air inlet is formed in the lower end of the disk cover, the support is hinged to the bracket, the speed reducer is connected with the motor, the motor is fixed to the bracket, and the portion, at the bottom of the disk, of the rotary shaft is in transmission connection with the speed reducer. By means of the closed type disk grain making machine, grains are primarily dried while being made, workloads of the later drying link are reduced, and production efficiency is improved. Meanwhile, by means of the lifting boards, corrosion and abrasion to the disk from the grains are reduced, and the service life of the closed type disk grain making machine is prolonged.

Owner:GUANGXI UNIV

Organic fertilizer drying and shaping equipment

ActiveCN107763997AEasy to operateEasy to dryDrying gas arrangementsGranulation in rotating dishes/pansAgricultural engineeringOrganic fertilizer

The invention discloses organic fertilizer drying and shaping equipment. The organic fertilizer drying and shaping equipment comprises a feeding device, a smashing and pushing device, a drying device,a controller and a disk granulating machine. The feeding device comprises a power-driven lifting rod, a feeding bin and a power-driven lifting rod, wherein the power-driven lifting rod is perpendicularly arranged on the ground, the top of the power-driven lifting rod is rotationally connected with a retainer plate, an overturning motor is arranged between the retainer plate and the power-driven lifting rod, the outer wall of the overturning motor is fixed to the top end of the power-driven lifting rod, a rotating shaft of the overturning motor and the ground keep horizontal, the rotating shaft of the overturning motor is fixedly connected with the side wall of the retainer plate, and the feeding bin is arranged on the upper surface of the retainer plate. The smashing and pushing device for grinding fertilizers is arranged above the feeding device, the smashing and pushing device stretches into one end of the drying device, and the other end of the drying device leads to the disk granulating machine. The organic fertilizer drying and shaping equipment is simple in structure and high in production efficiency, and the processing quality of organic fertilizers is effectively improved.

Owner:ANHUI RUIHU BIO FERTILIZER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com