Method and apparatus for granulating by mixing powder and liquid continuously

A technology of mixing granulation and powder, which is applied in the direction of mixing methods, liquid and solid mixing, mixers, etc., can solve the problems of increasing the cost of water-soluble polysaccharide powder products, so as to be suitable for mass production and promote The effect of forming and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (Manufacturing example of humidified powder of α-starch)

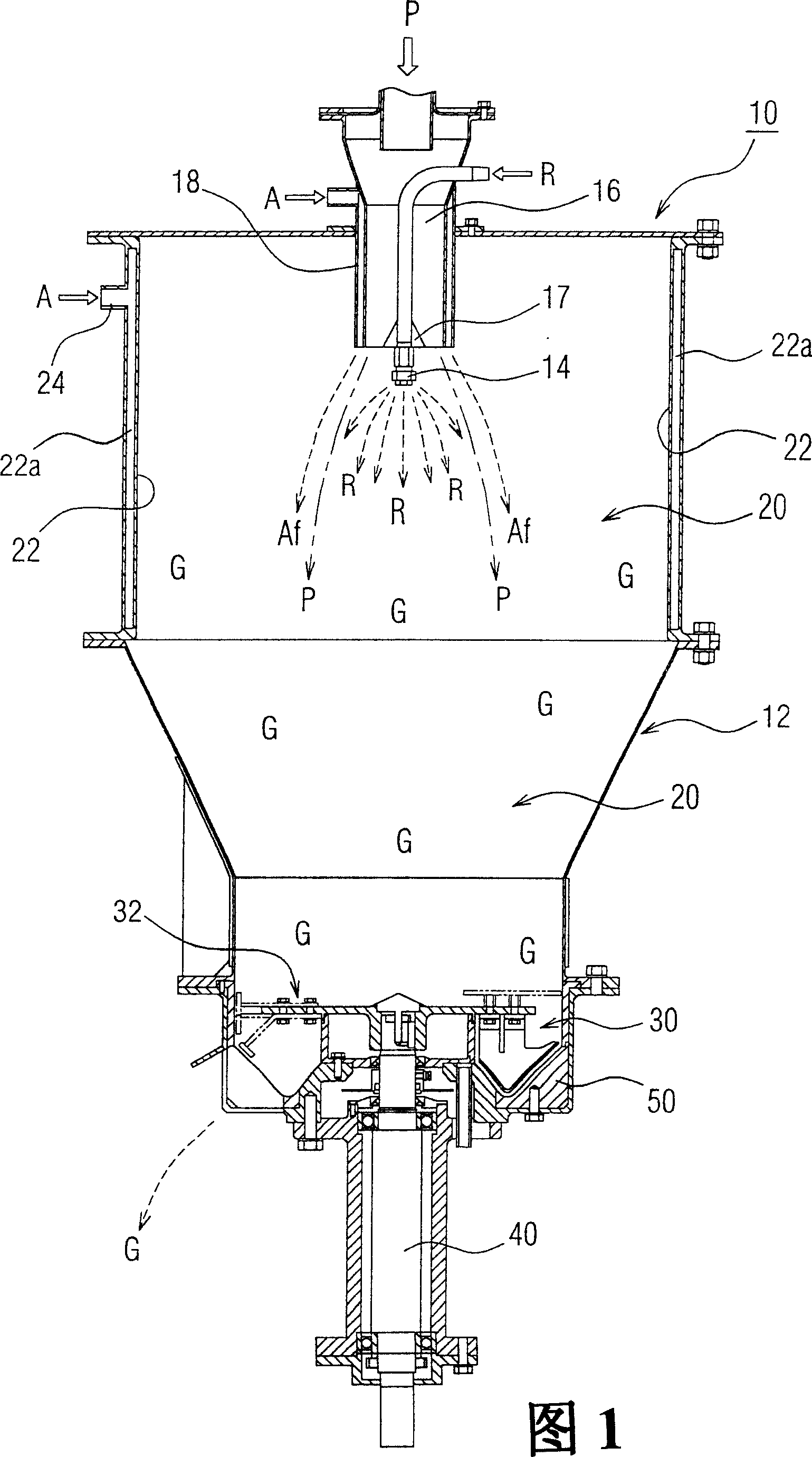

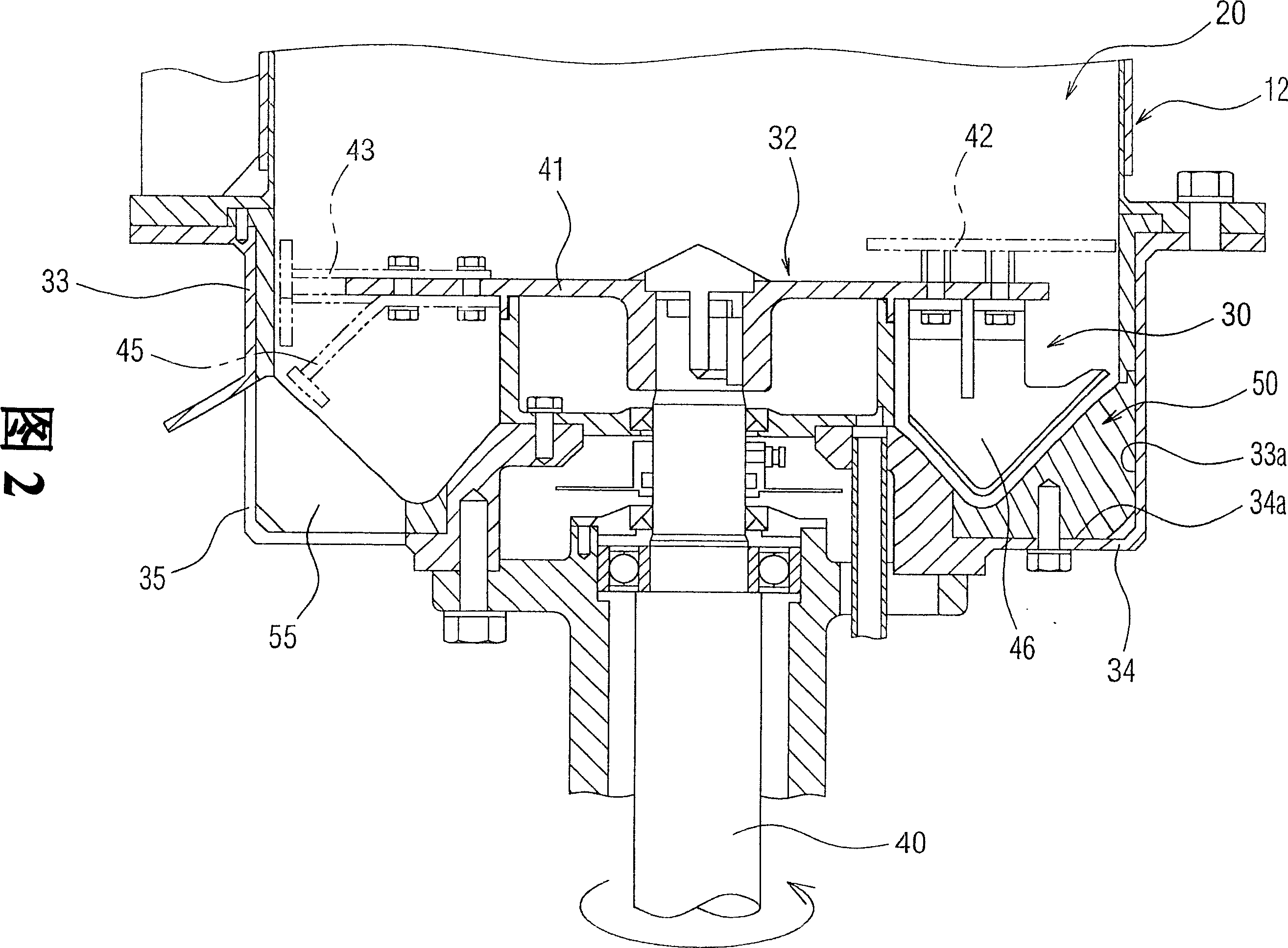

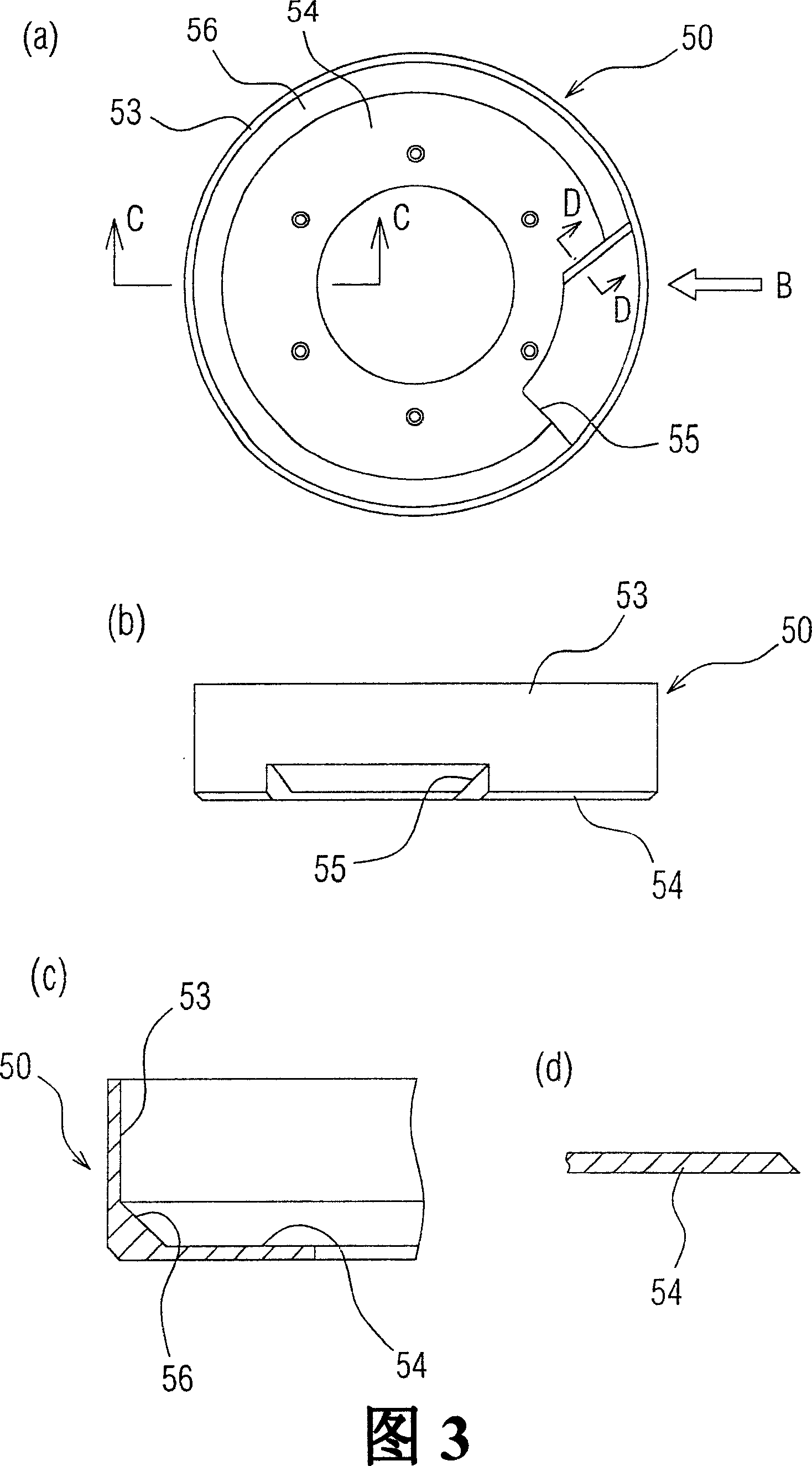

[0062] At the top of the mixing granulation chamber 12, spray 64cm continuously by the spray nozzle 14 3 / min of clear water, and at the same time, 3.63kg / min of gelatinized starch is supplied from the powder supply port 16, and then compressed air is supplied from the air supply nozzle 18. Simultaneously, at the bottom of the mixing and granulating chamber 12 , while rotating the rotary mixing and stirring disk 32 at 1000 rpm, the humidified powder of gelatinized starch was continuously produced. As a result, pregelatinized starch excellent in water solubility and composed of 10% to 13% humidified powder having a uniform particle size can be produced with a high yield of about 100%.

Embodiment 2

[0064] (Manufacturing example of polymer water-absorbing agent)

[0065] At the top of the mixing granulation chamber 12, spray 225cm continuously by the spray nozzle 14 3 / min of clear water, while supplying 4.5kg / min of polyvinyl alcohol powder from the powder supply port 16, and then supplying compressed air from the air supply nozzle 18. Simultaneously, at the bottom of the mixing and granulation chamber 12, a humidified powder of polyvinyl alcohol was continuously produced while the rotary mixing and stirring disk 32 was rotated at 1000 rpm. As a result, a high-molecular water-absorbing agent composed of 3% to 5% humidifying powder having a uniform particle size and excellent water-absorbing properties can be produced with a high yield of about 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com