Disk granulator

A disc granulator, granulation technology, applied in the direction of granulation, fertilizer mixture, fertilizer form, etc. Product quality and production efficiency, high granulation quality, and the effect of meeting the needs of granulation production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

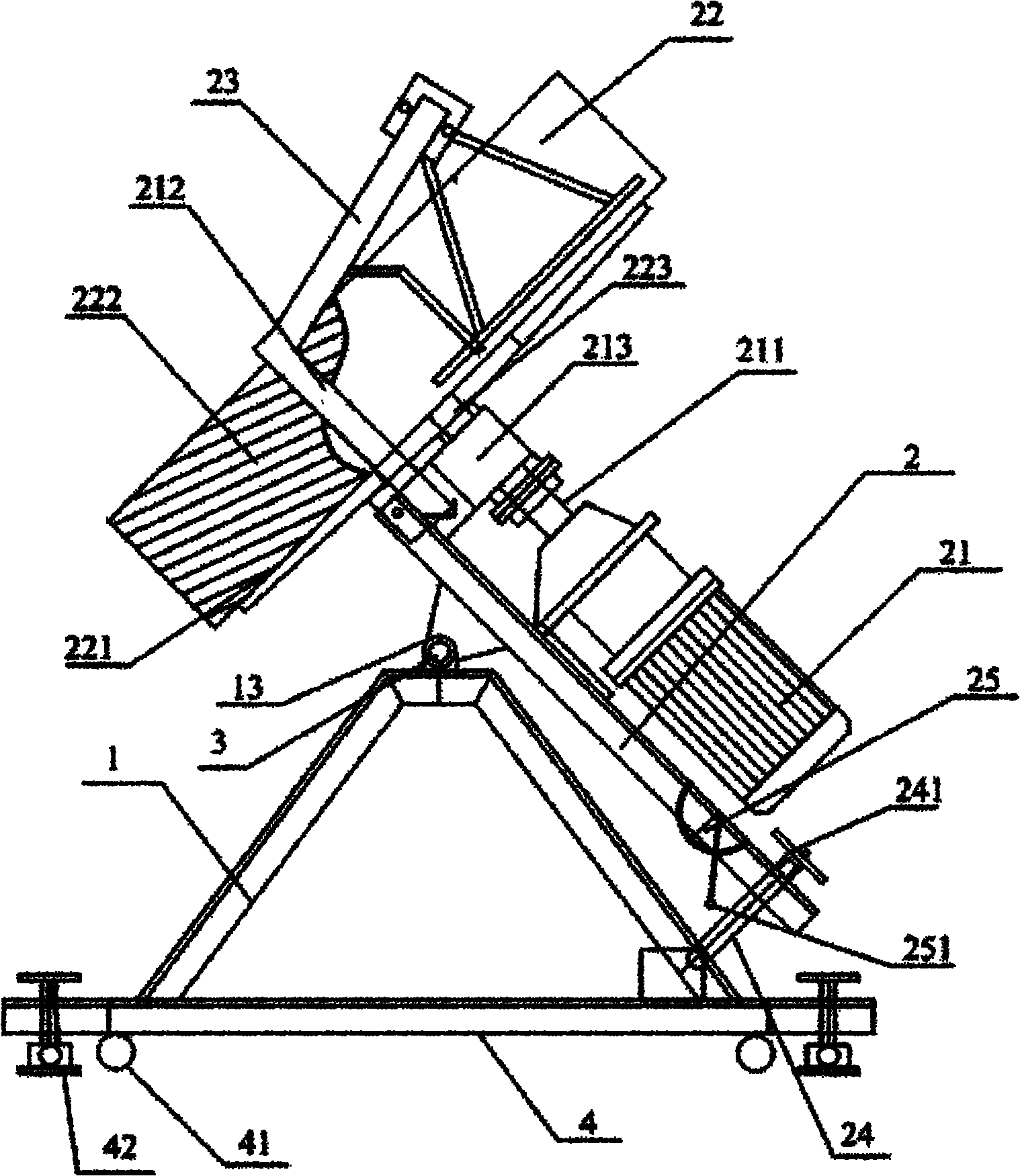

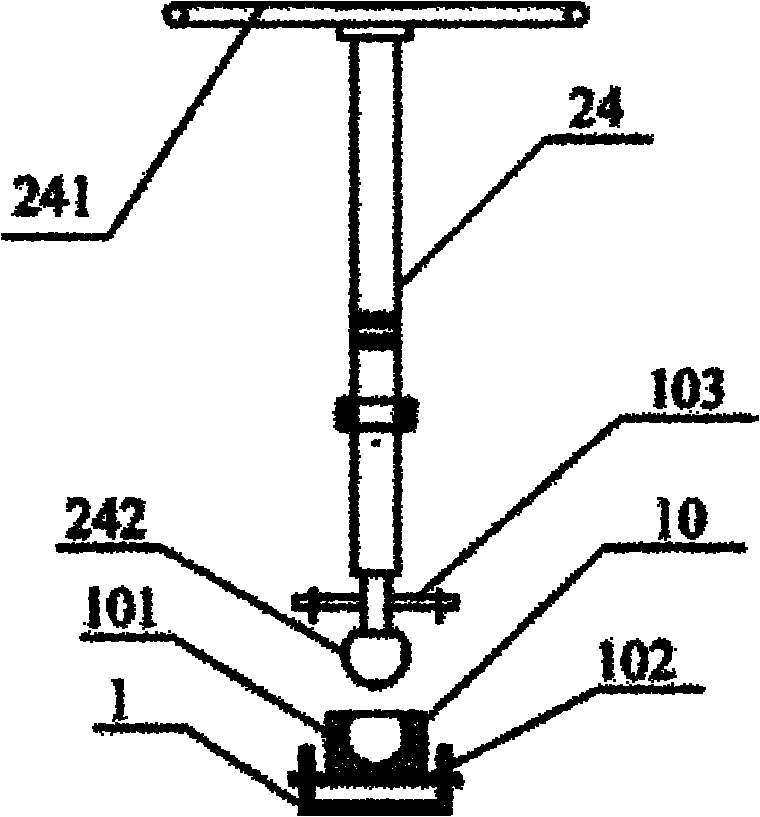

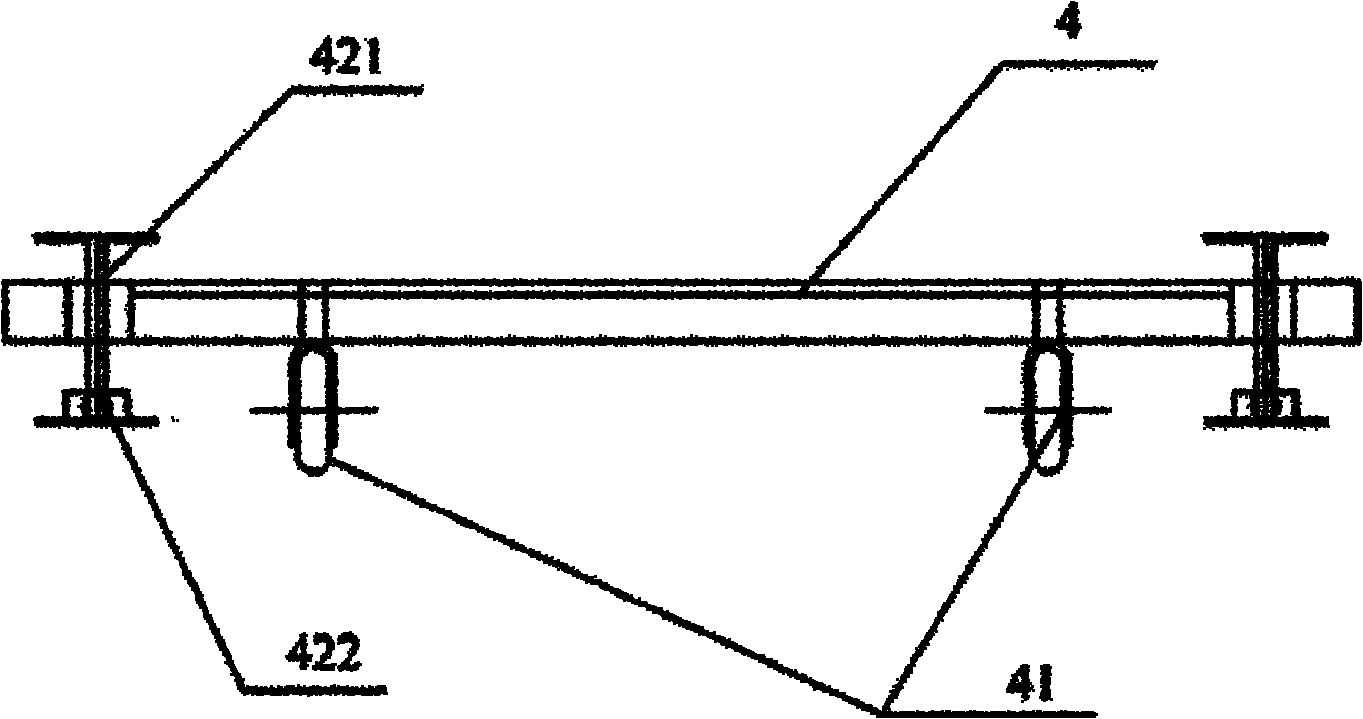

[0027] figure 1 It is a structural diagram of an embodiment of the disc granulator of the present invention. figure 2 yes figure 1 Schematic diagram of the installation relationship between the adjusting screw and the ball seat. Please also refer to figure 1 and figure 2 , the disc granulator provided in this embodiment includes: a main frame 1, a power frame 2 arranged above the main frame 1, a driving device 21 fixedly arranged on the power frame 2, connected with an output shaft 211 of the driving device 21 And the granulation disk 22 that is arranged perpendicular to the power frame 2, and the cleaning device 23 positioned above the opening of the granulation disk 22, and the cleaning device 23 is fixedly connected to the power frame 2 by an inclined beam 212; The main frame 1 is hinged; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com