Patents

Literature

135results about How to "Improve granulation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

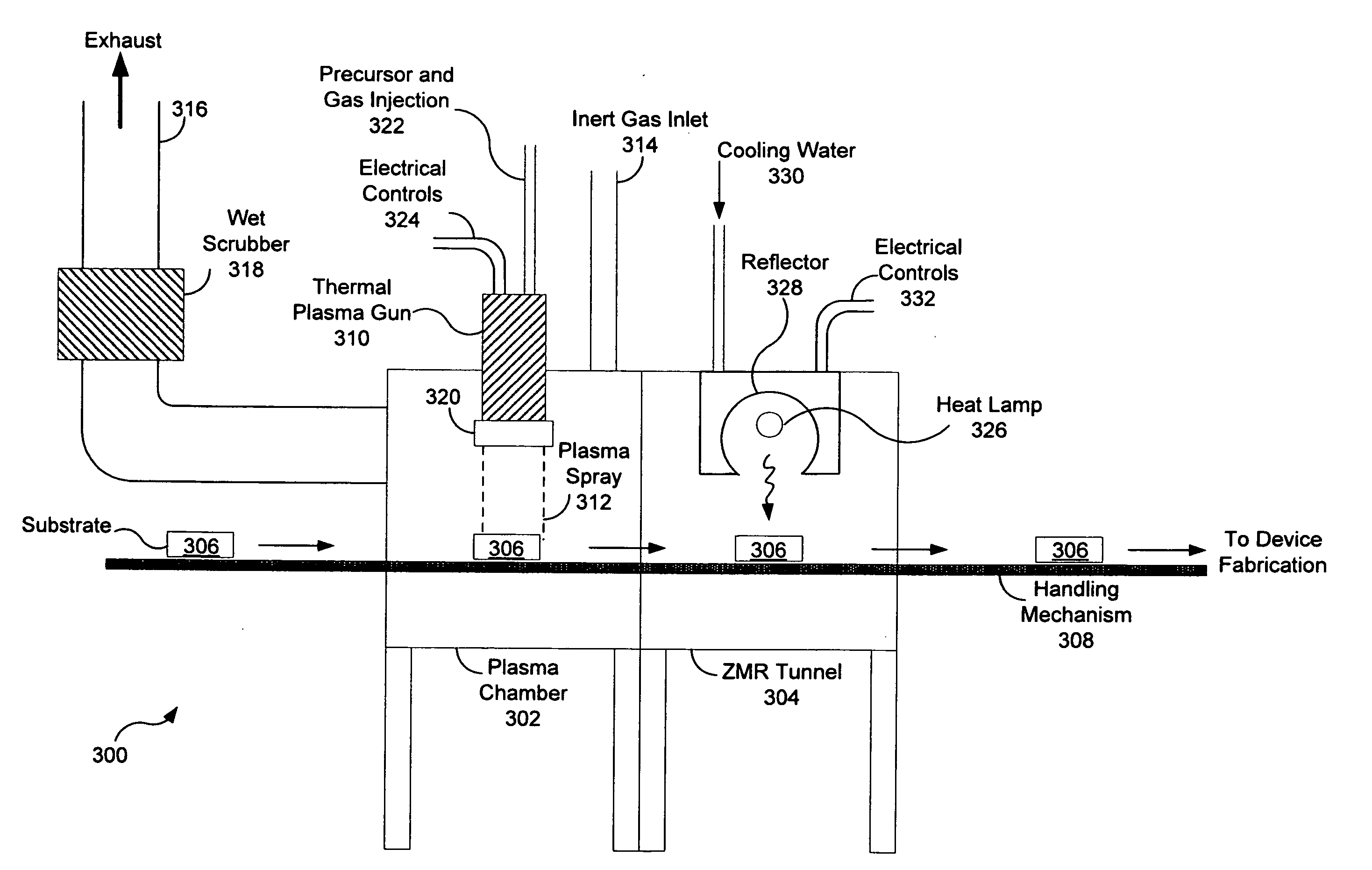

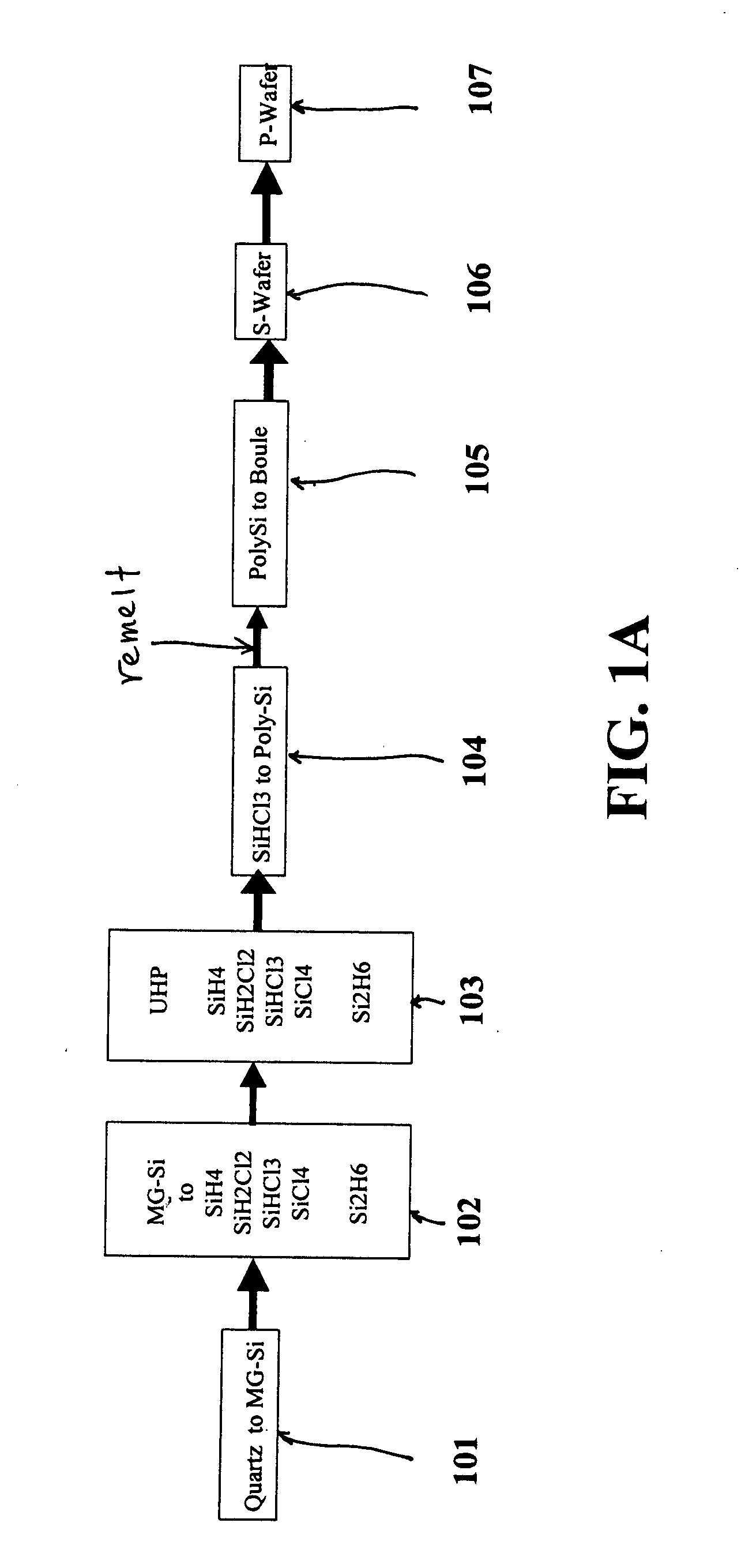

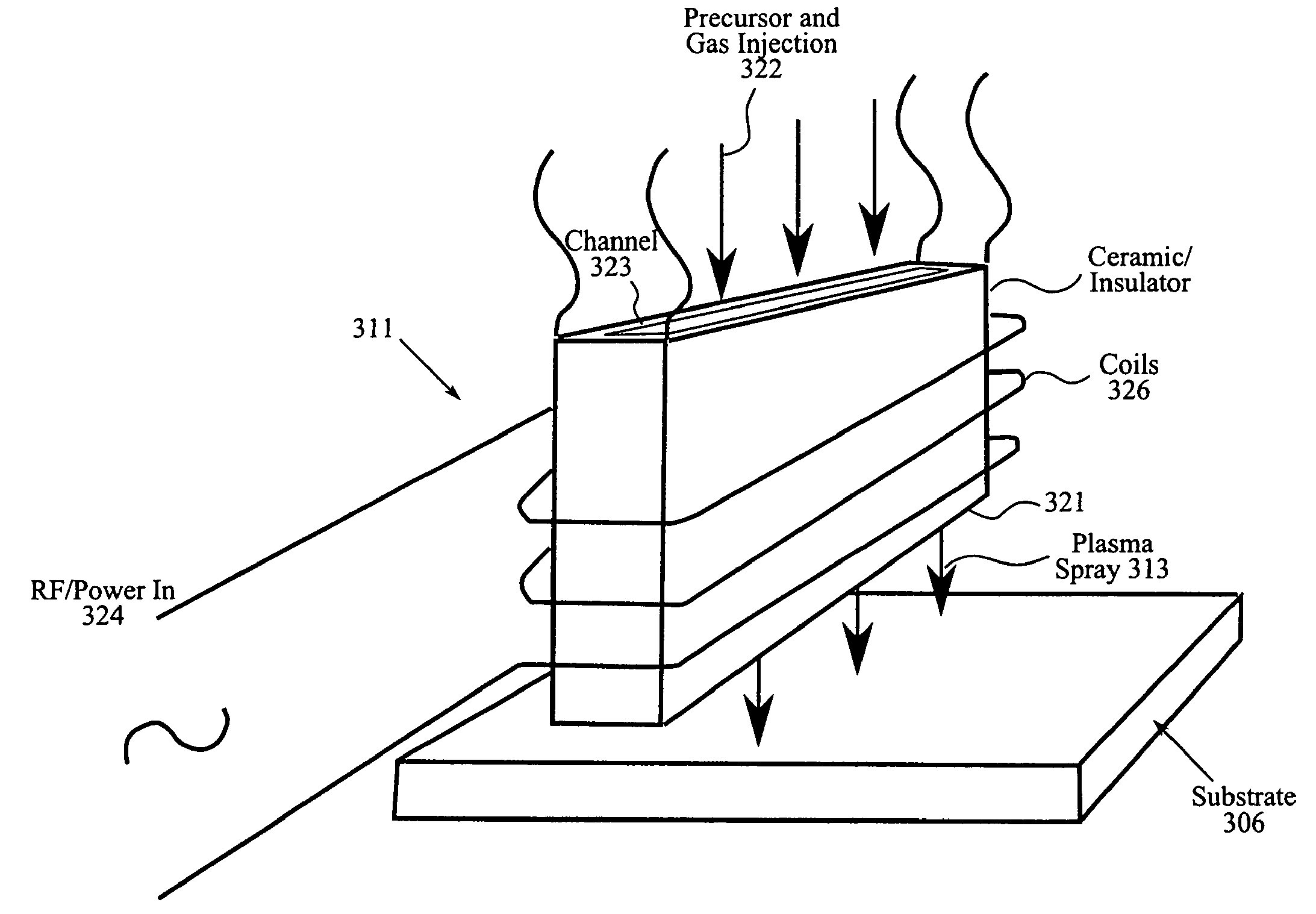

Methods and systems for manufacturing polycrystalline silicon and silicon-germanium solar cells

InactiveUS20080023070A1Low costPromoting acceptanceMolten spray coatingFinal product manufactureGas phaseSolar cell

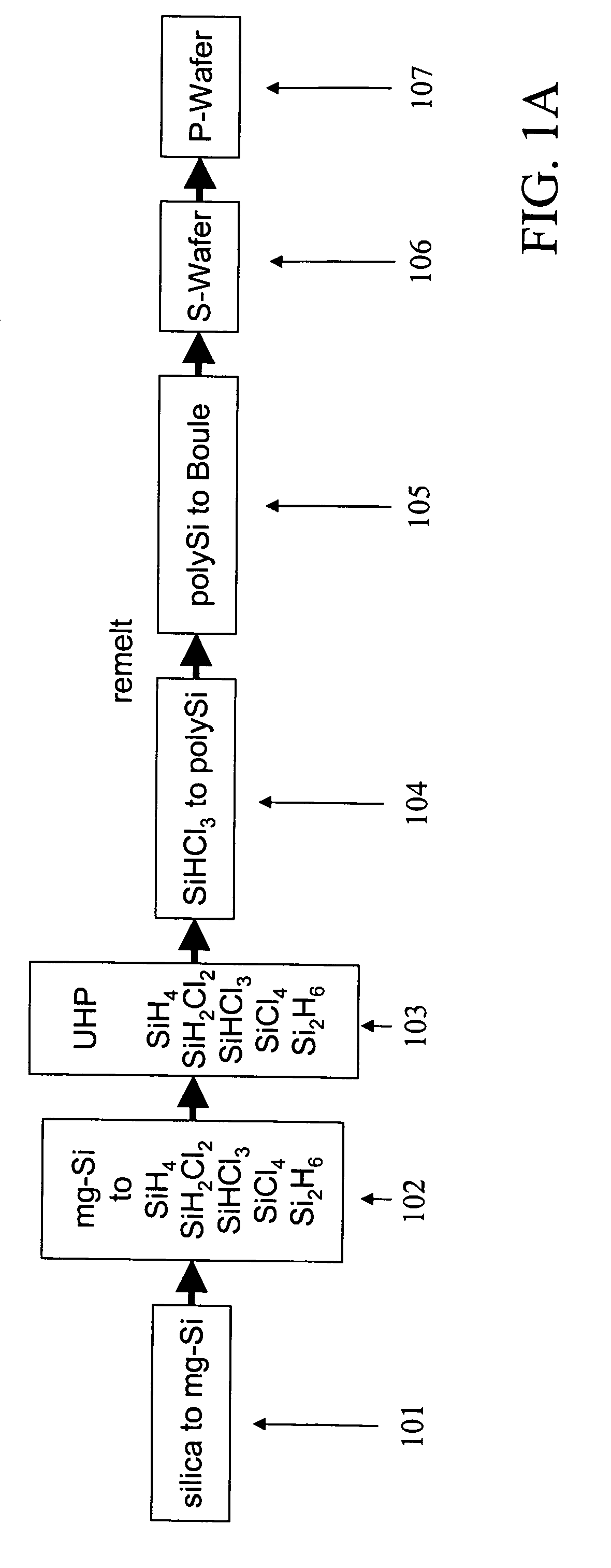

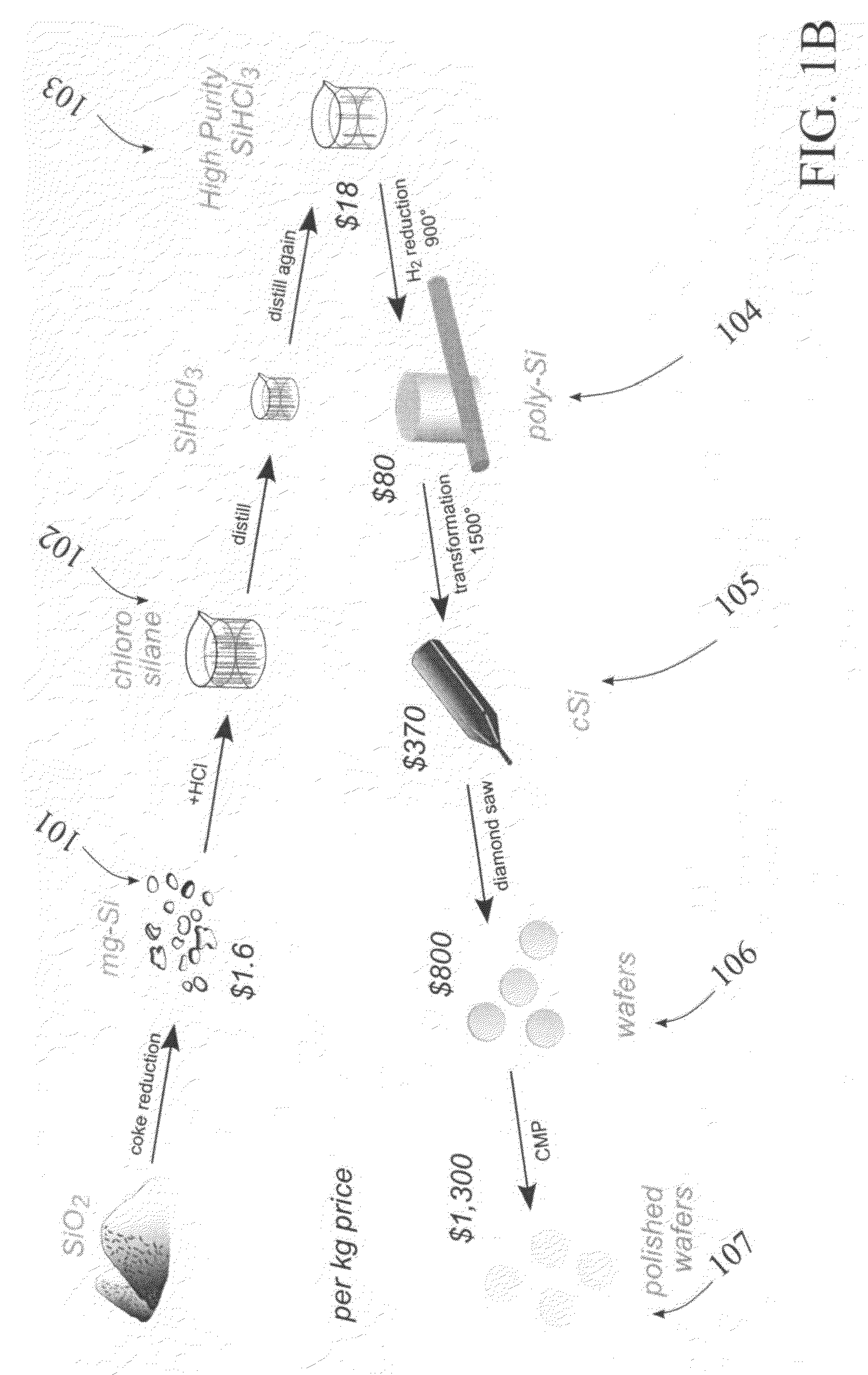

The present invention relates to a novel, unconventional methods and systems for the fabrication of silicon or silicon-germanium photovoltaic cell applications. In some embodiments high purity gaseous and / or liquid intermediate compounds of silicon (or silicon germanium) are converted directly to polycrystalline films by a thermal plasma chemical vapor deposition process or by a thermal plasma spraying technique. The intermediate compounds of silicon (or silicon germanium) are injected into the thermal plasma source where temperatures range from 2000 K to about 20,000 K. The compounds dissociate and silicon (or silicon germanium) is deposited onto substrates. Polycrystalline films having densities approaching the bulk value are obtained on cooling. PN junction photovoltaic cells can be directly prepared by spraying, or doped films after heat treatment are subsequently transformed to viable photovoltaic cells having high efficiency, low cost at a high throughput. In some embodiments a roll-to-roll or a cluster-tool type automated, continuous system is provided.

Owner:SENERGEN DEVICES

Wheat variety 25R30

ActiveUS8389831B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationTriticeaeMutagenic Process

A wheat variety designated 25R30, the plants and seeds of wheat variety 25R30, methods for producing a wheat plant produced by crossing the variety 25R30 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety 25R30 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety 25R30. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety 25R30 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

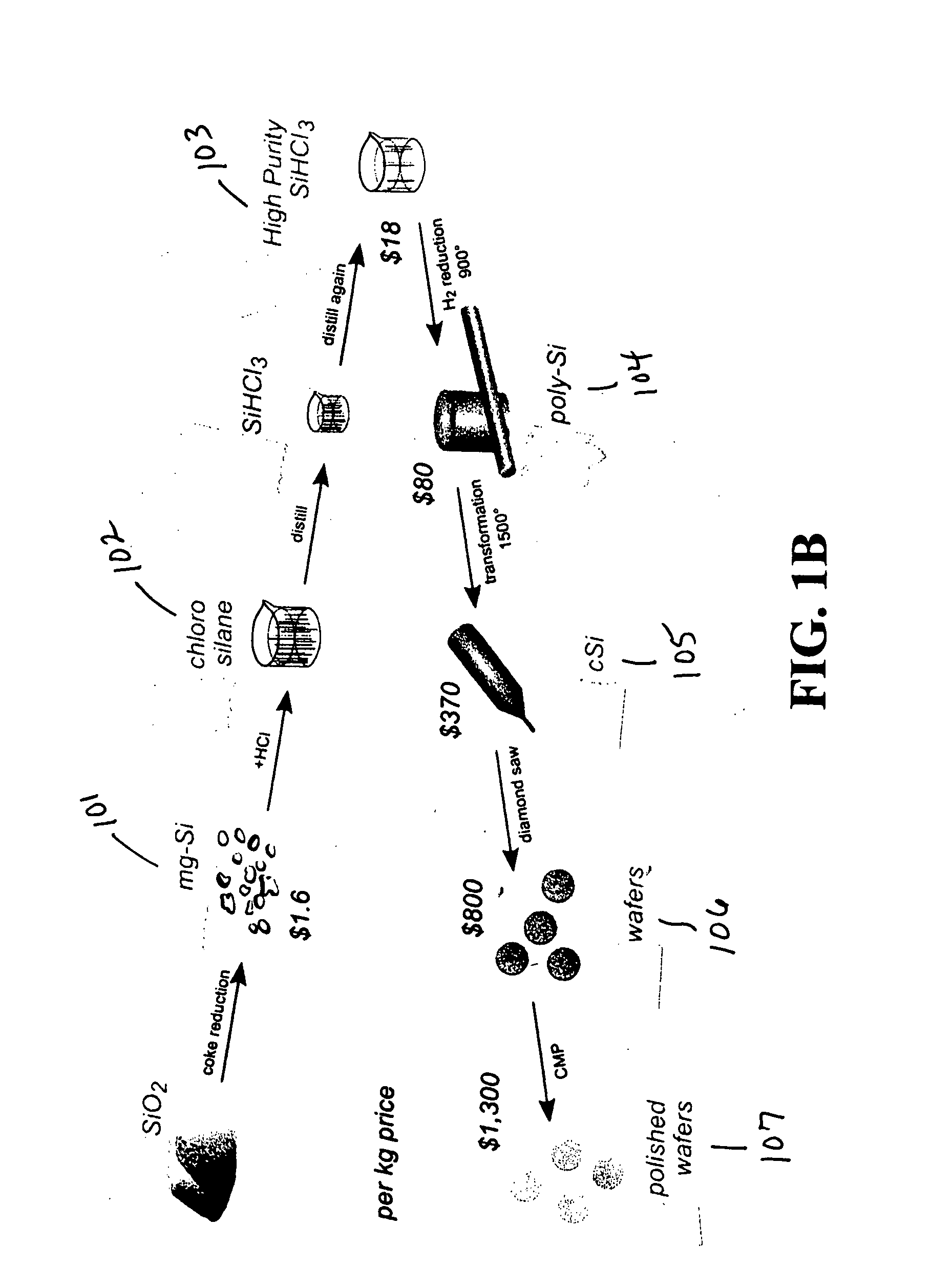

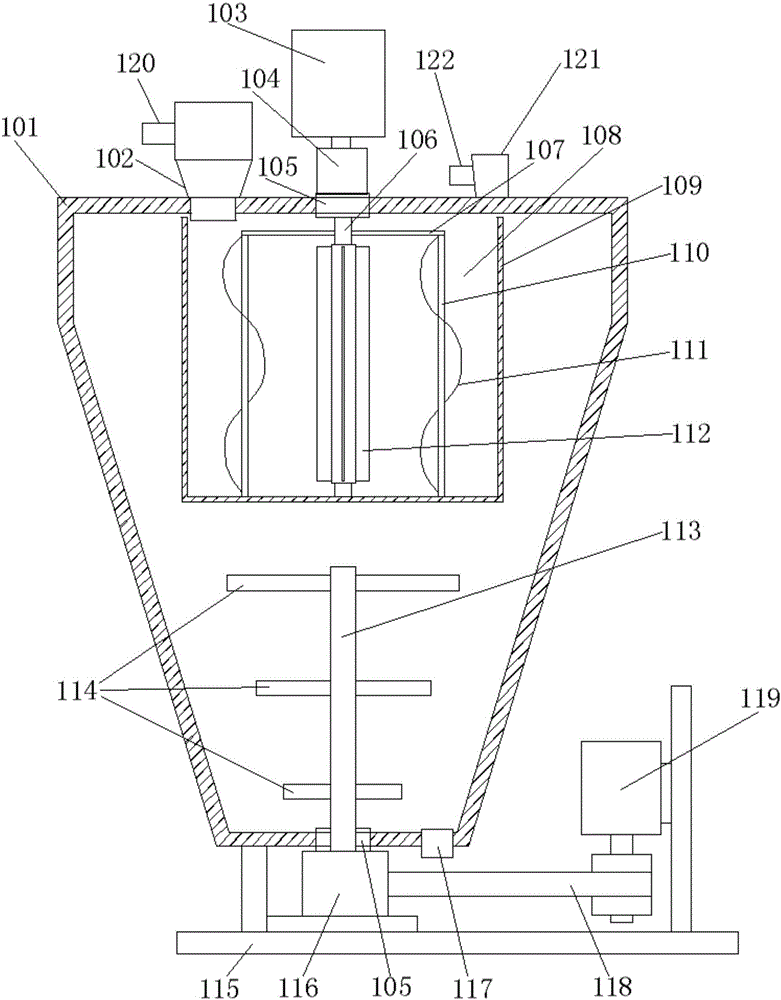

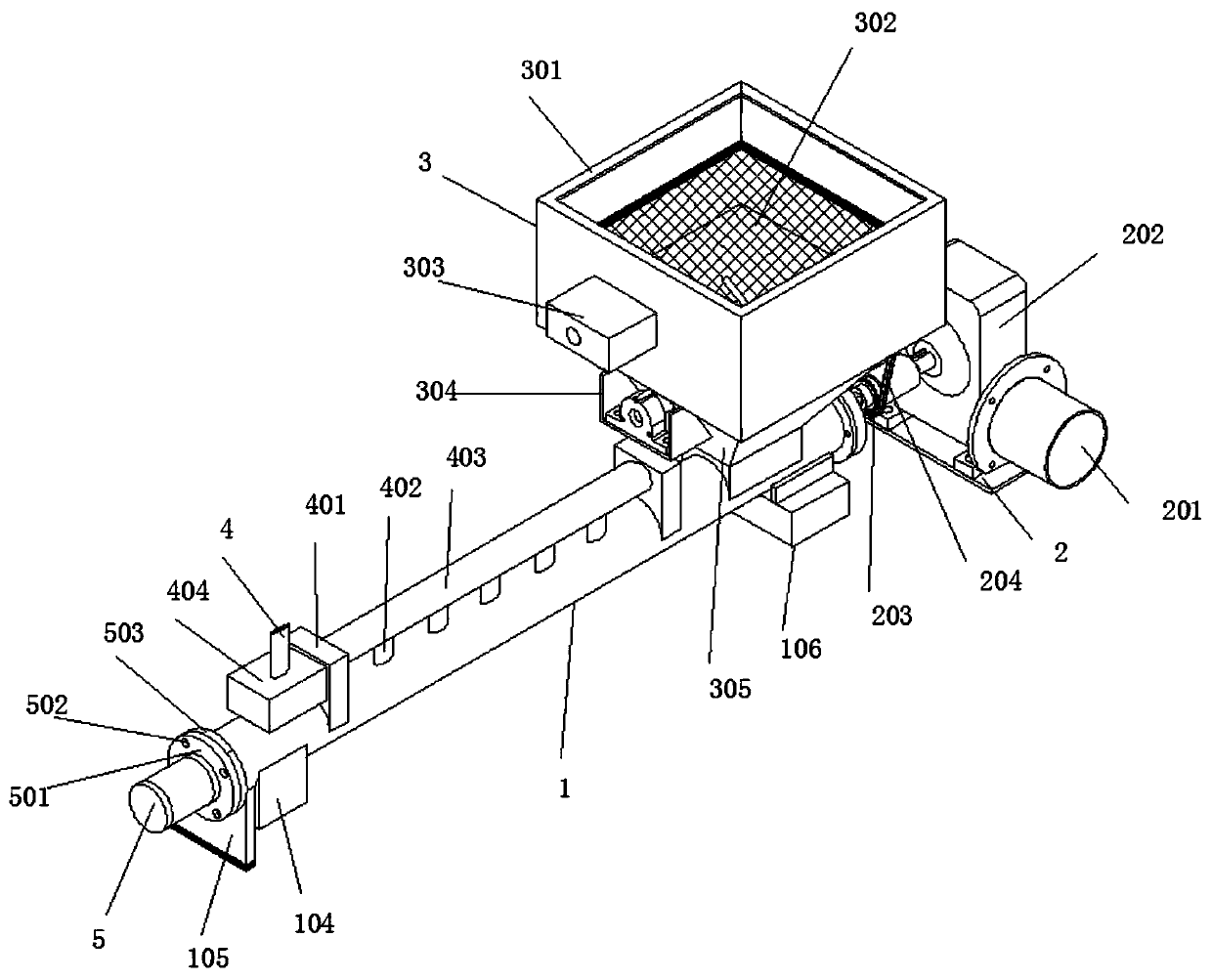

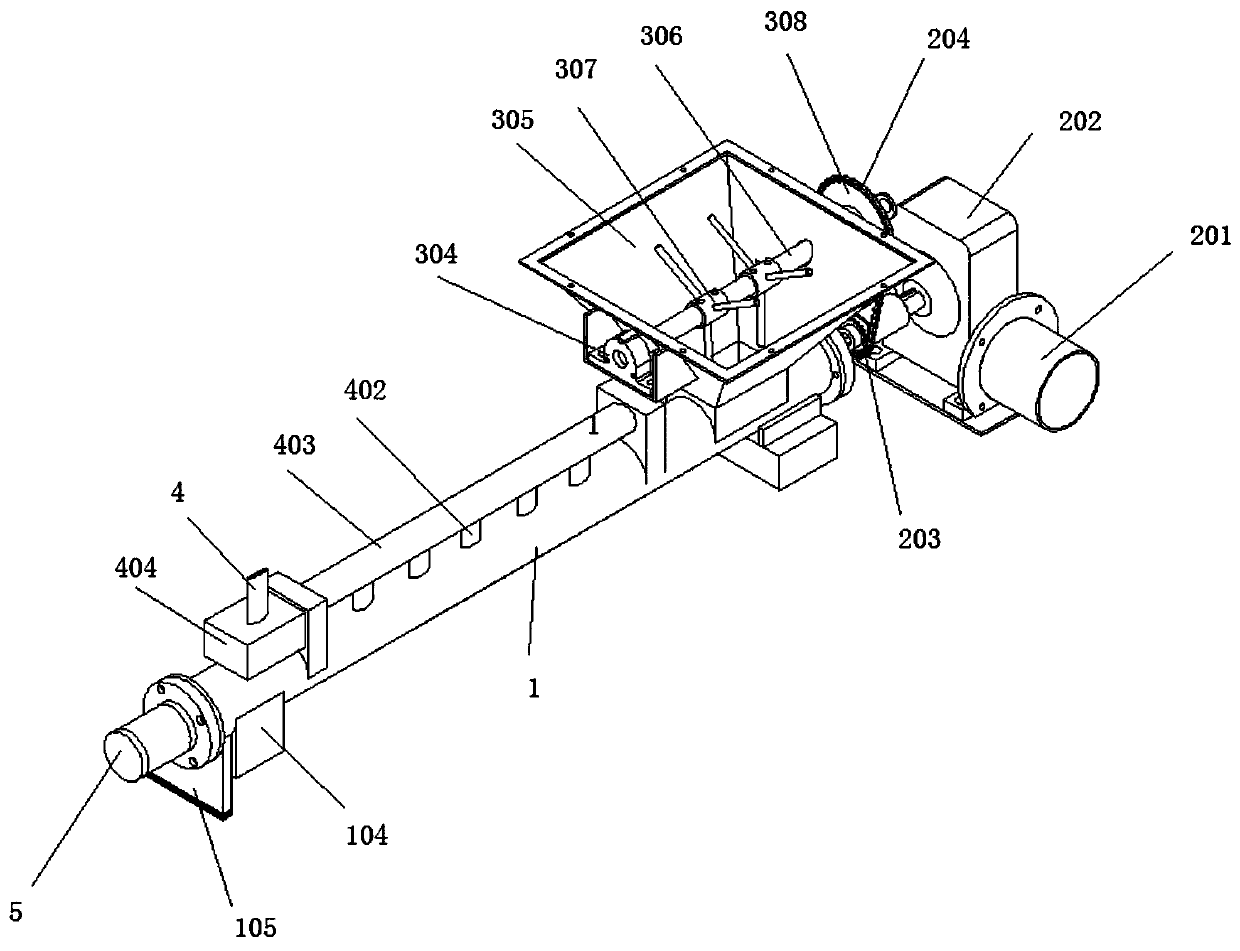

Granulation production line for composite material machining

InactiveCN106273042AAccurate and reliable measurementAccurate outputCoatingsProduction lineMixed materials

The invention discloses a granulation production line for composite material machining. The granulation production line for composite material machining comprises a mixing module for mixing materials, a kneader module for kneading the mixed materials, and a granulator module for granulating the kneaded materials; a mixing discharge port of the mixing module is connected to a kneader feed port of the kneader module through a pumping pipeline; a feeding pump is mounted on the pumping pipeline; a kneader discharge port of the kneader module is connected to a granulator feed port of the granulator module through a blanking pipeline; the mixing module includes a first feed port and a second feed port; a first weighing machine and a second weighing machine are respectively arranged on the first feed port and the second feed port; a first batching tank and a second batching tank are respectively connected to the first feed port and the second feed port through feeding pipelines; and a feed port weighing machine is arranged on the kneader feed port of the kneader module.

Owner:广东银圭新材料科技有限公司

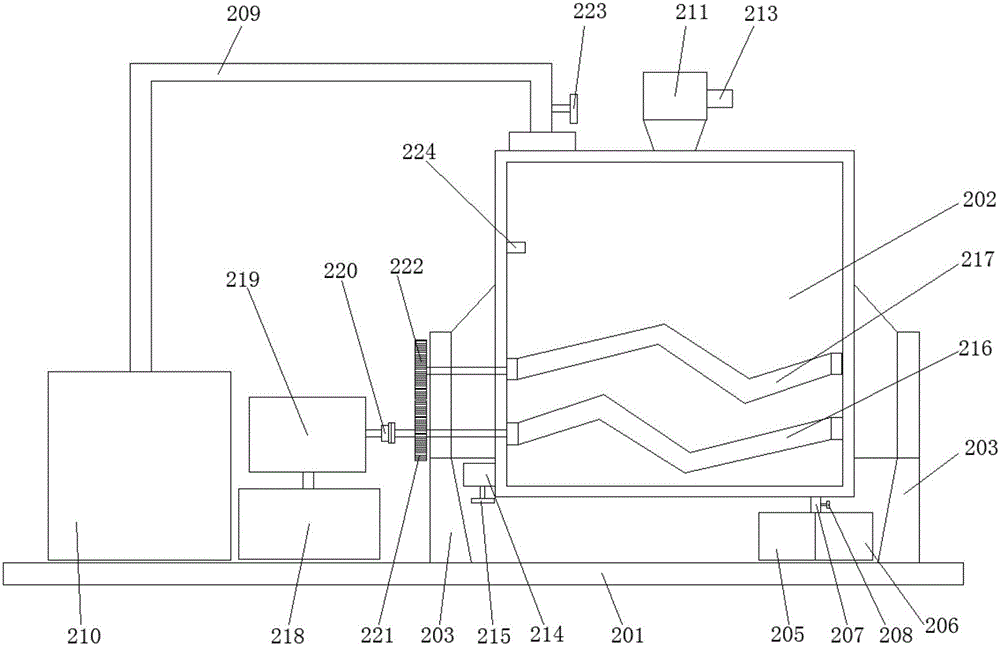

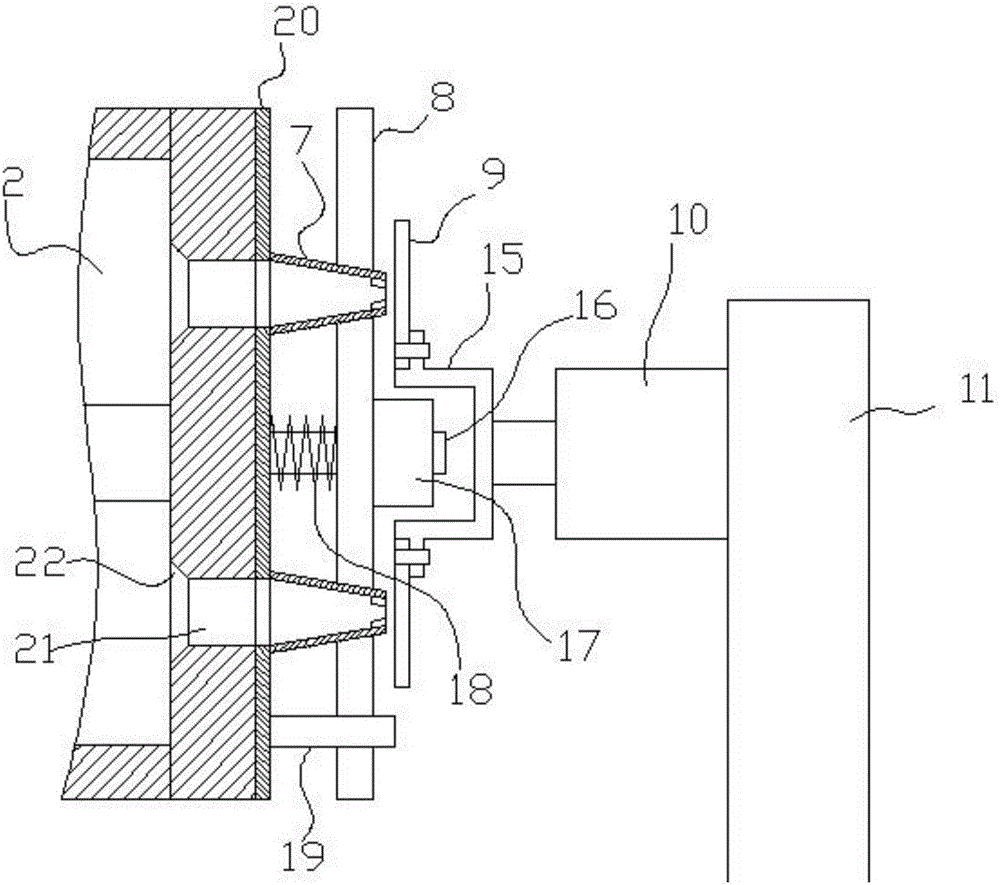

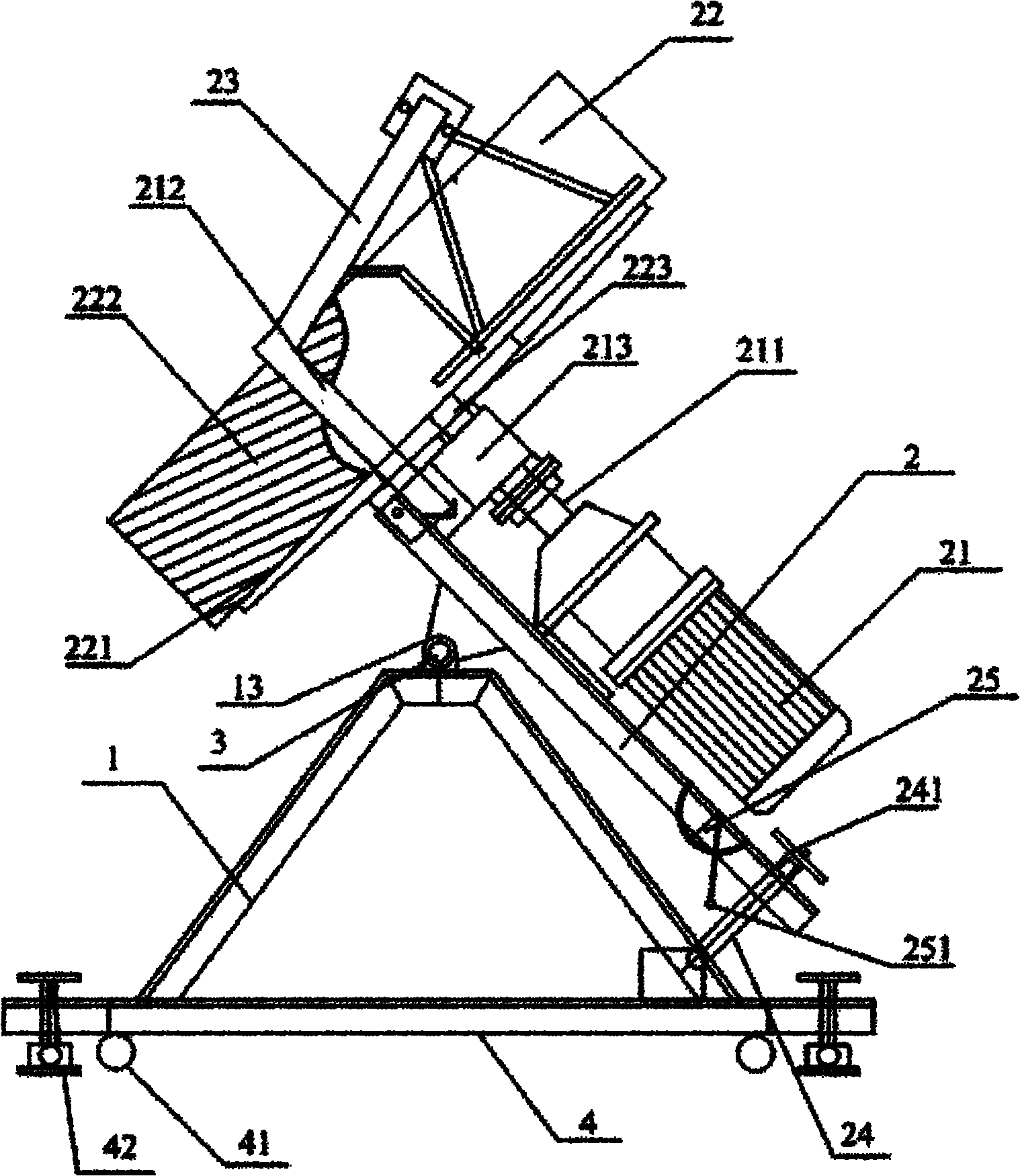

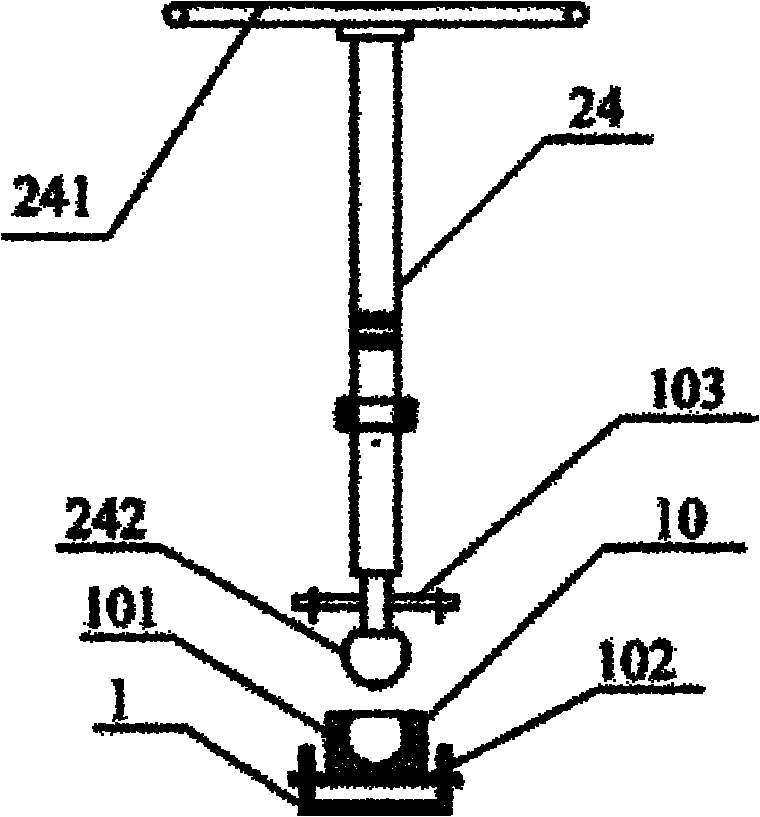

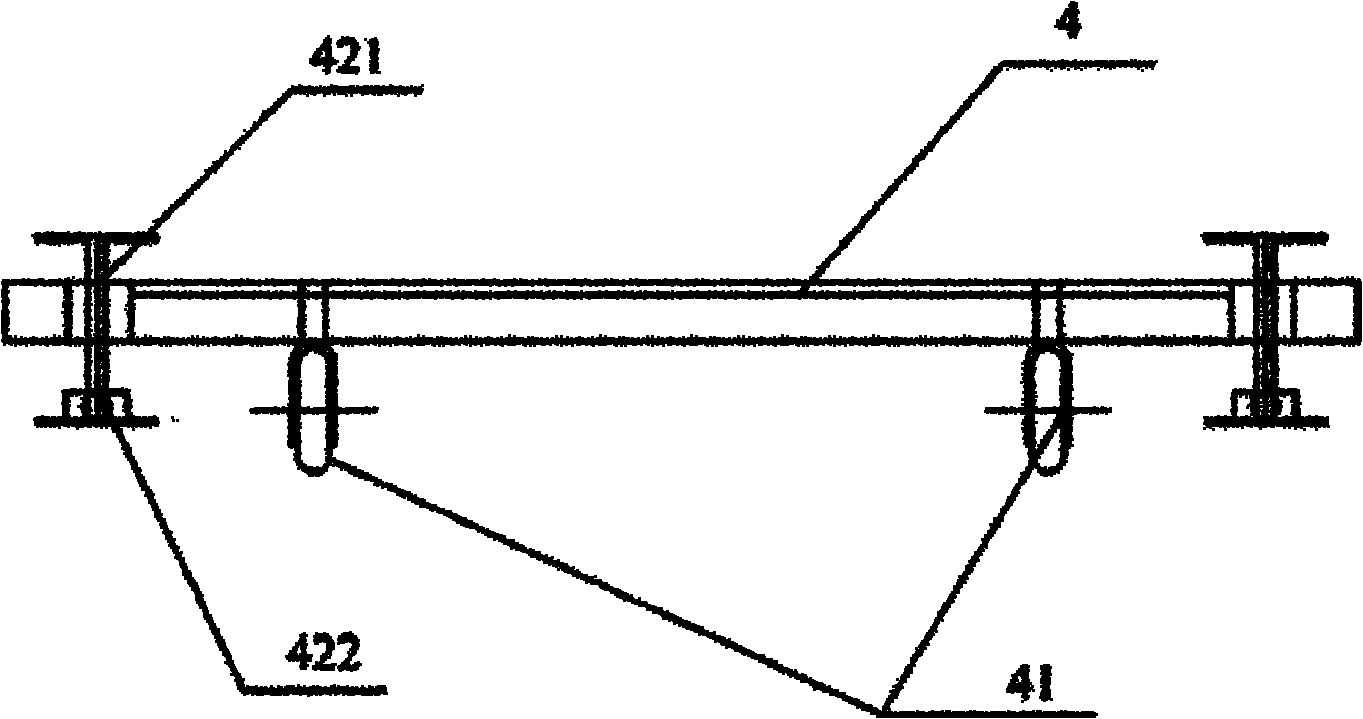

Extrusion cutting type multi-particle size adjustable granulating machine

ActiveCN106622022ALarge adjustment rangeEasy to adjustGranulation in rotating dishes/pansGranulation by material expressionPropellerAgricultural engineering

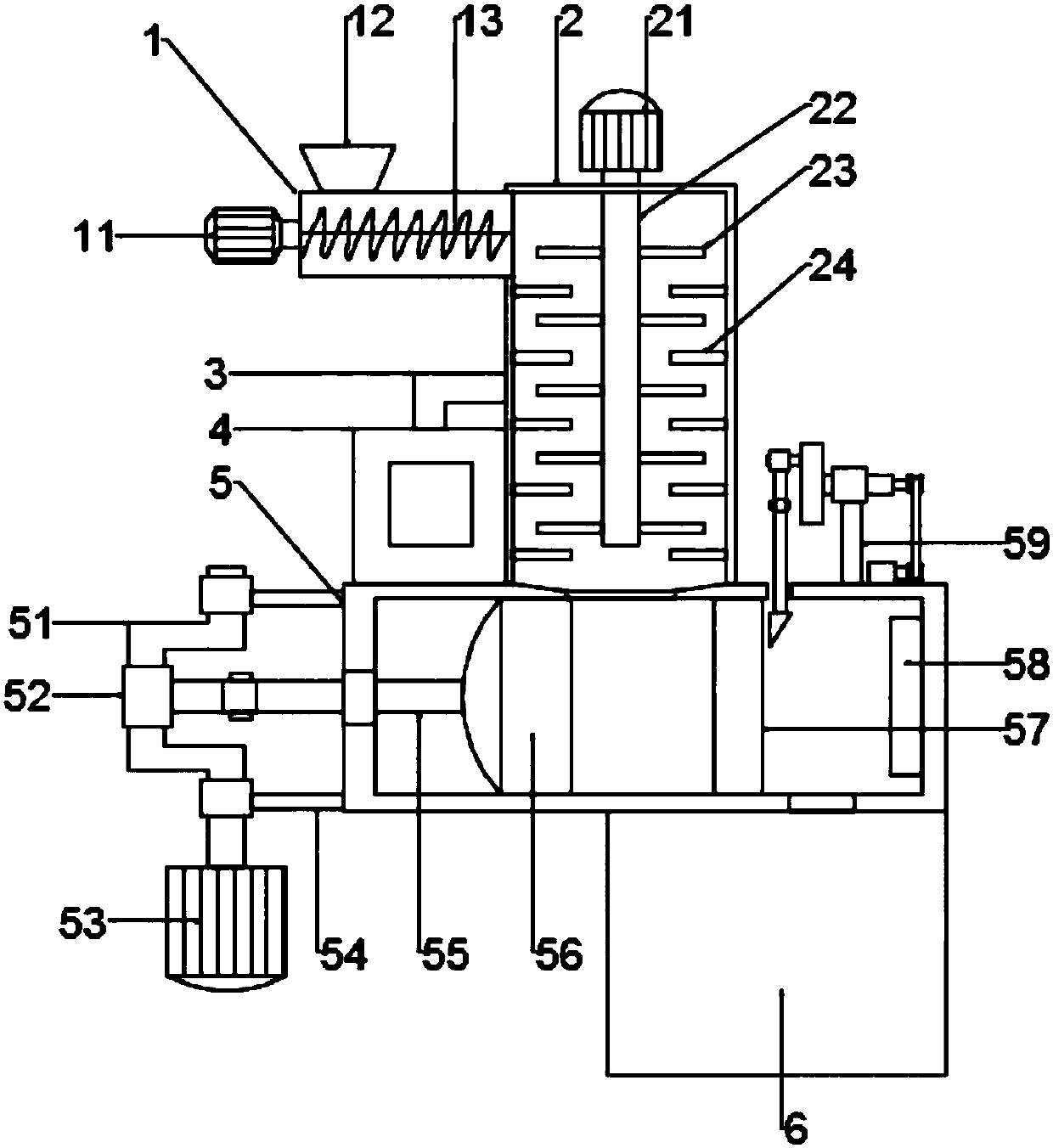

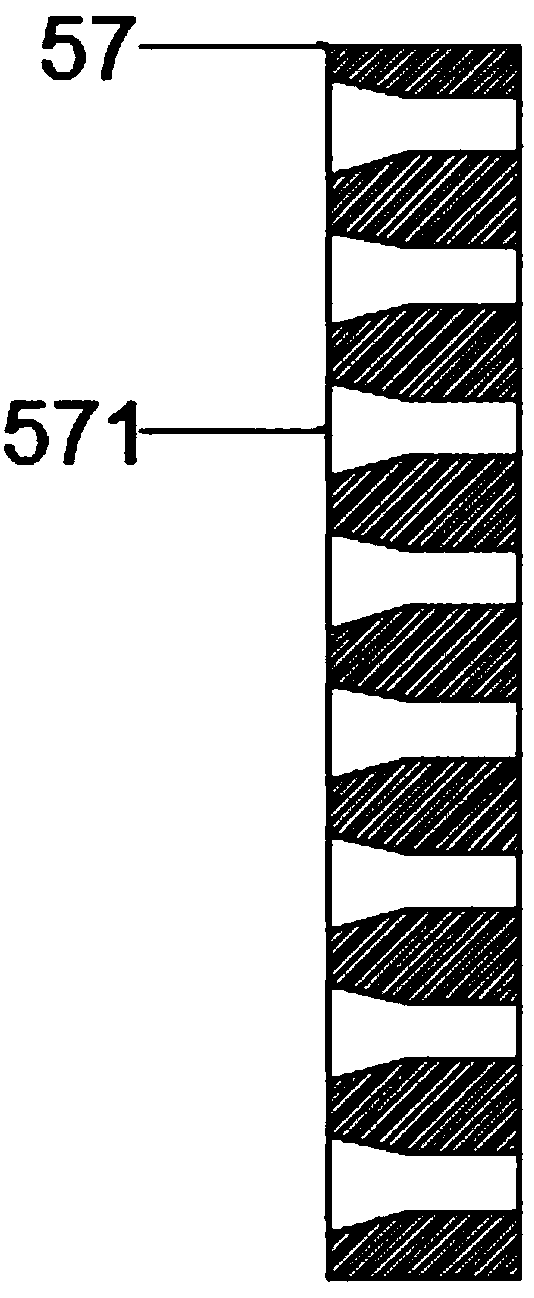

The invention discloses an extrusion cutting type multi-particle size adjustable granulating machine. The extrusion cutting type multi-particle size adjustable granulating machine comprises a stirring cylinder, wherein the stirring cylinder is arranged on a base, a spiral propeller is arranged in the stirring cylinder, and a material inlet hopper is arranged at the upper end of the stirring cylinder; the spiral propeller is connected with a propelling motor; a granulating disc is arranged at the front end of the stirring cylinder; conical granulating sleeves are uniformly arranged on the granulating disc, and are sheathed on an adjusting disc; a cutting tool disc is arranged at the front end of each conical granulating sleeve, and is fixedly arranged on a fixed disc; the fixed disc is connected with a cutting motor, and the cutting motor is arranged on a slide base; the slide base is connected with a screw rod in a bracket, and the bracket is connected with the base; an adjusting rotary button is arranged at the front end of the screw rod; each conical granulating sleeve is in a conical sleeve shape, and adjusting grooves are uniformly arranged at the front end of each conical granulating sleeve; mounting grooves are arranged on the inner walls of both sides of each adjusting groove; an arc-shaped movable plate is arranged in each mounting groove; outlet tool blades are uniformly arranged on the inner wall of the front end of each conical granulating sleeve. The extrusion cutting type multi-particle size adjustable granulating machine has the advantages that the quick and high-efficiency granulating function is realized, the granulating size can be adjusted, the adjusting range is wide, and the flexibility and convenience in use are realized.

Owner:湖南康易达绿茵科技有限公司

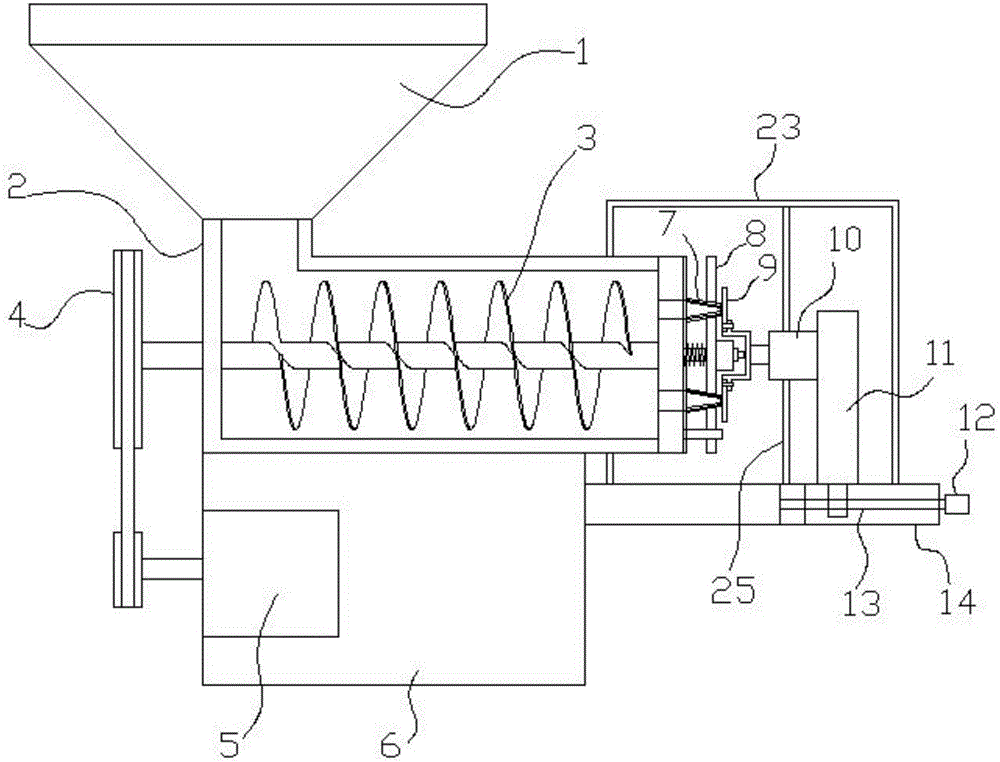

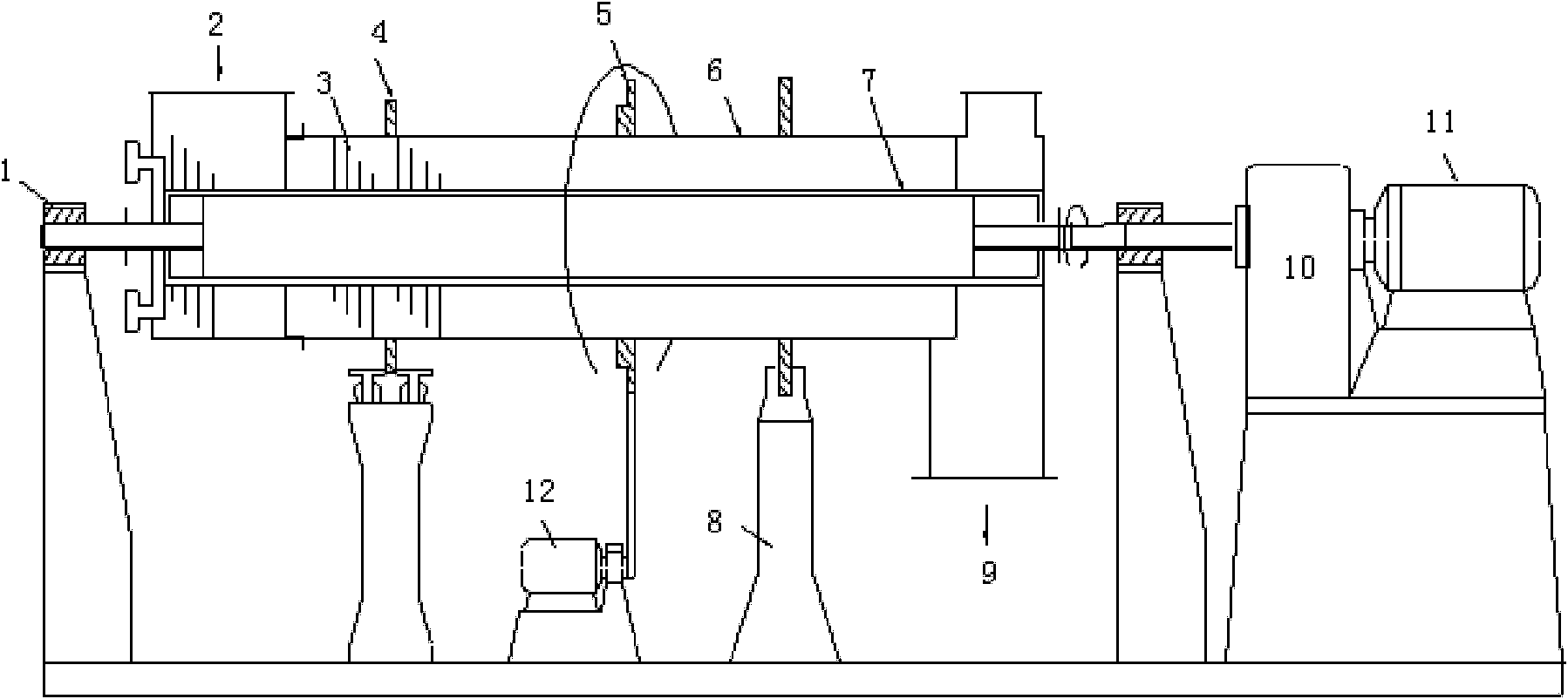

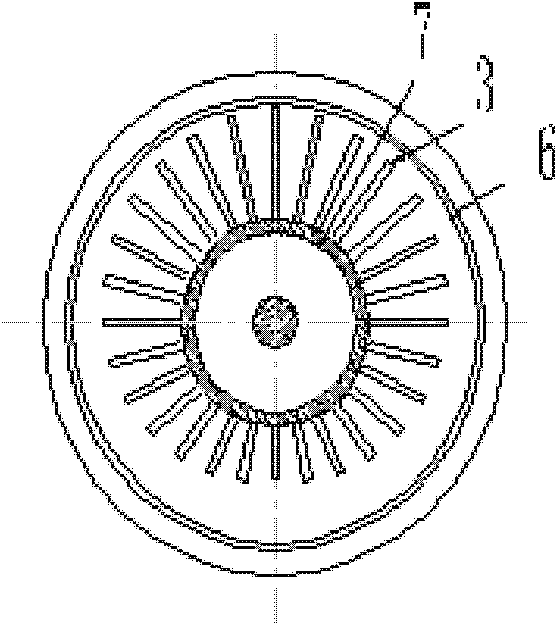

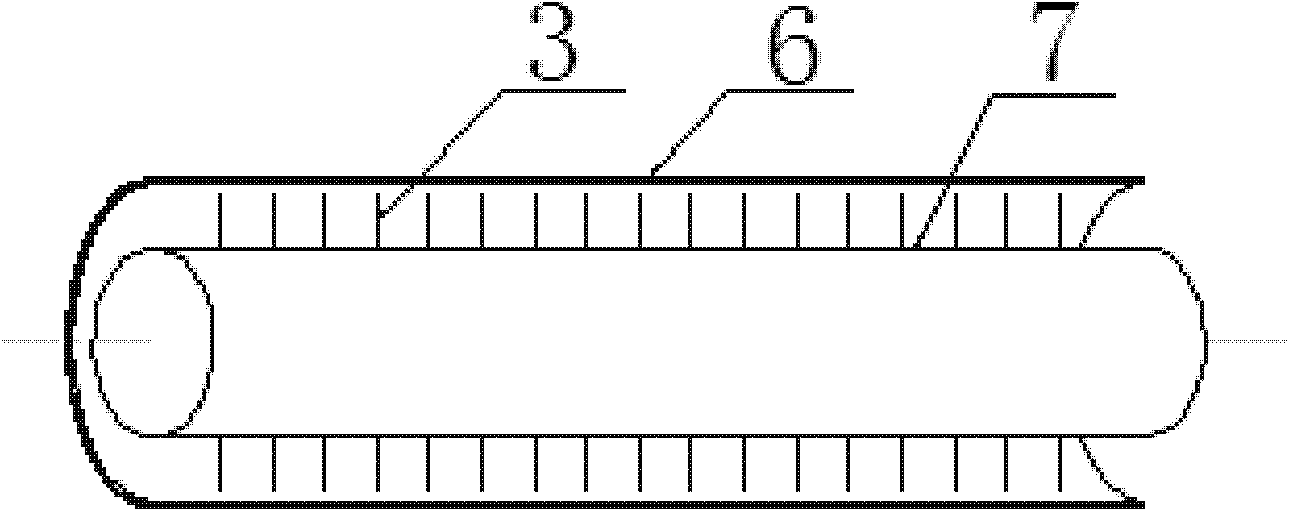

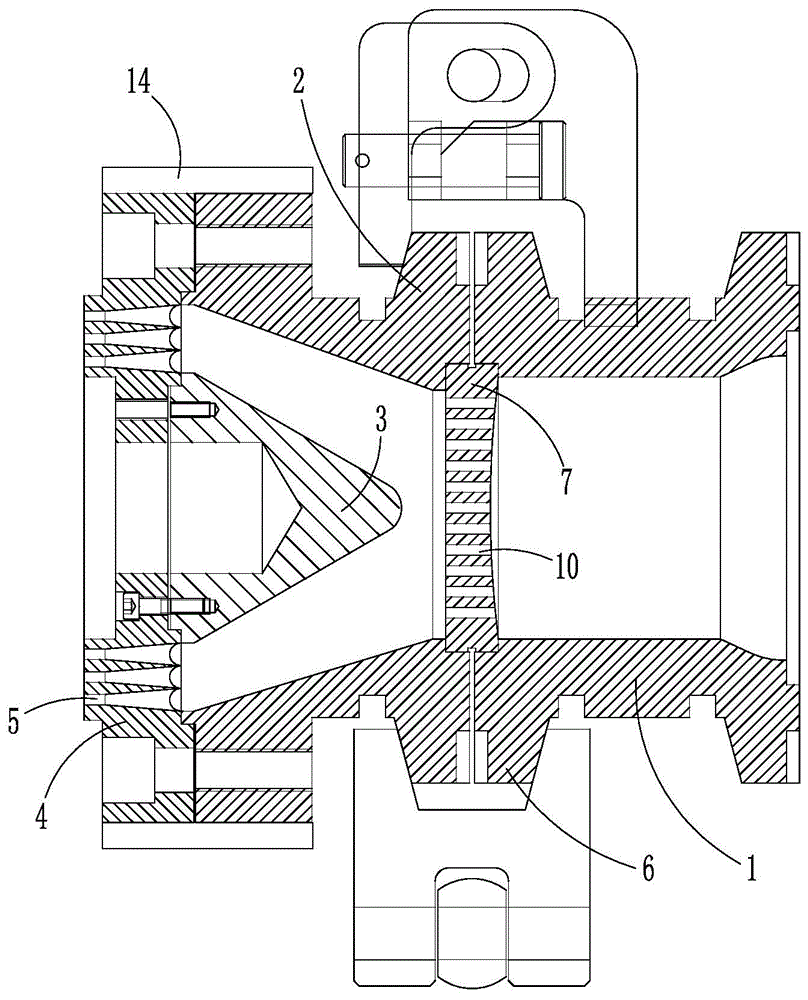

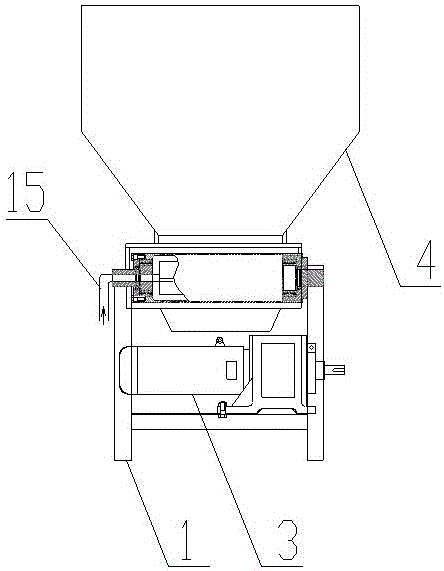

Telescopic compound fertilizer rotary drum granulator

ActiveCN102432404AReduce volumeSmall footprintFertiliser formsFertilizer mixturesStructural engineeringRaw material

The invention relates to a telescopic compound fertilizer rotary drum granulator comprising a support (1), a feeding port (2), a supporting wheel (4), a frame (8), and a discharging port (9). The frame (8) is provided with an inner cylinder (7) and an outer cylinder (6) sleeved on the inner cylinder (7), wherein the rotation directions of the inner cylinder (7) and the outer cylinder (6) are the same, but the rotation speeds of the inner cylinder (7) and the outer cylinder (6) are different. Granulating rods (3) are distributed in a threaded form on the outer wall of the inner cylinder (7). The inner cylinder (7) is arranged on the support (1) through a shaft, wherein the cylinder (7) can rotate. The outer cylinder (6) is arranged on the frame (8) through the supporting wheel (4). The feeding port (2) is arranged on one end of the outer cylinder (6), and the discharging port (9) is arranged on the other end of the outer cylinder (6). Compared to existing technologies, the granulator provided by the invention is advantaged in small volume, simple structure, high granulating rate, and no restriction on raw material performance. With the telescopic compound fertilizer rotary drum granulator provided by the invention, materials with any formula can be produced.

Owner:SHANGHAI RES INST OF CHEM IND

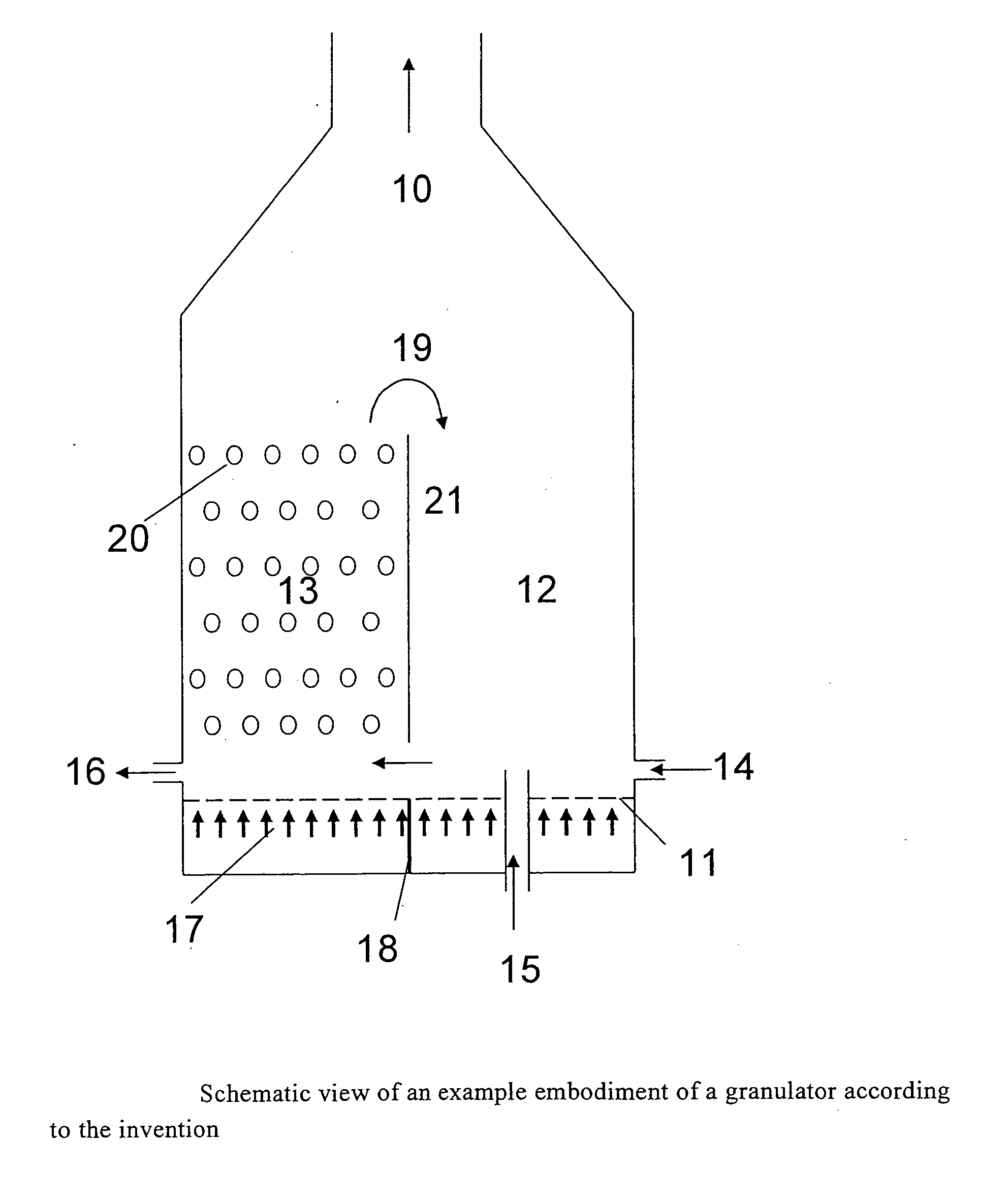

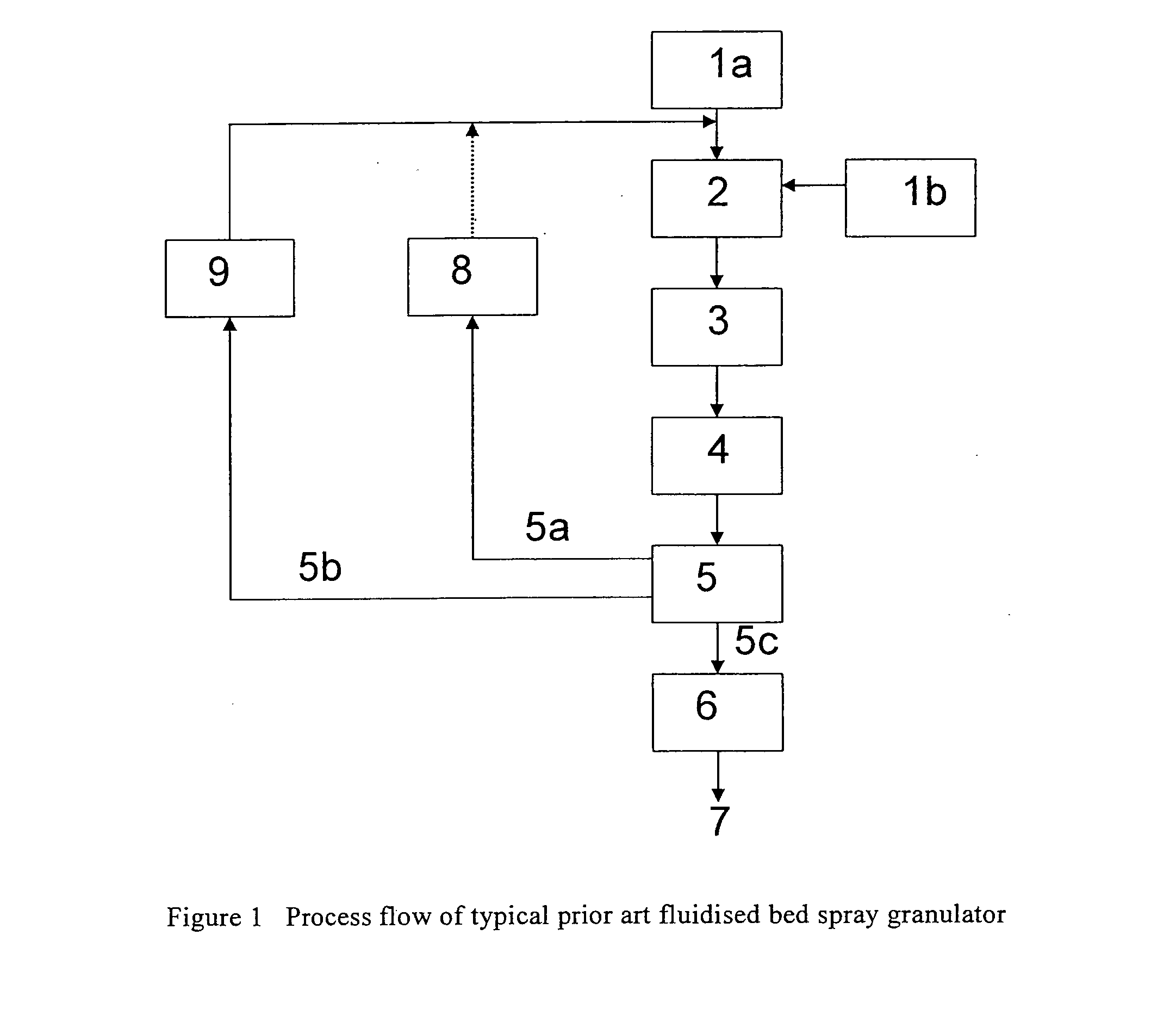

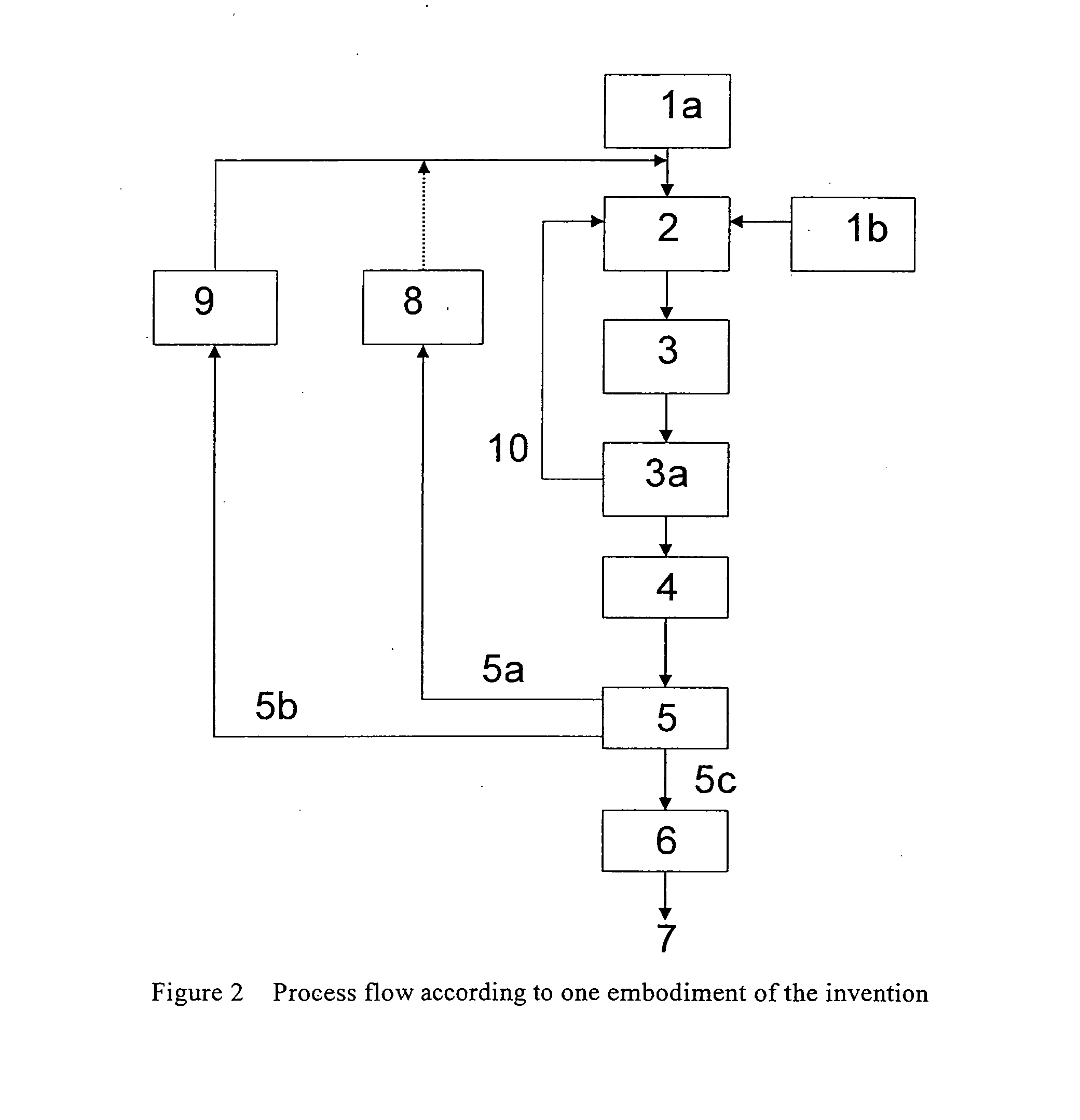

Method and device for processing of granules

ActiveUS20110159180A1Improve productivityIncrease ratingsLiquid surface applicatorsGranulation by powder suspensionLiquid productFluidized bed

Owner:YARA INT ASA

Methods and systems for manufacturing polycrystalline silicon and silicon-germanium solar cells

InactiveUS20100178435A1Low costOvercome limitationsMolten spray coatingChemical vapor deposition coatingGas phaseSolar cell

The present invention relates to a novel, unconventional methods and systems for the fabrication of silicon on silicon-germanium photovoltaic cell applications. In some embodiments high purity gaseous and / or liquid intermediate compounds of silicon (or silicon germanium) are converted directly to polycrystalline films by a thermal plasma chemical vapor deposition process or by a thermal plasma spraying technique. The intermediate compounds of silicon (or silicon germanium) are injected into the thermal plasma source where temperatures range from 2,000 K to 20,000 K. The compounds dissociate and silicon (or silicon germanium) is deposited onto substrates. Polycrystalline films having densities approaching the bulk value are obtained on cooling. PN junction photovoltaic cells can be directly prepared by spraying, or doped films after heat treatment are subsequently transformed to viable photovoltaic cells having high efficiency, low cost at a high throughput. In some embodiments a roll-to-roll or a cluster-tool type automated, continuous system is provided.

Owner:SENERGEN DEVICES

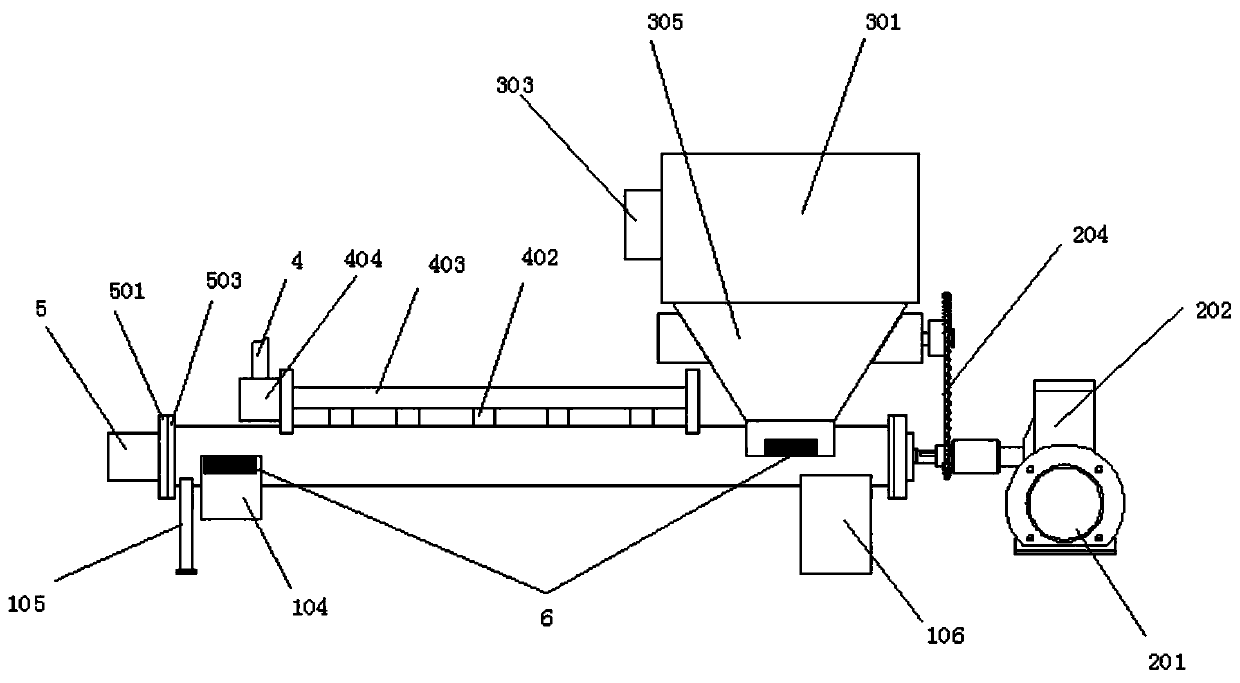

Granulating and screening machine for feed production

InactiveCN107581643AMalleableImprove granulation qualityFeeding-stuffAgricultural engineeringWater pipe

The invention discloses a granulating and screening machine for feed production. The granulating and screening machine comprises a charging device, a conditioning mechanism, a granulating box and a screening box, wherein a charging opening is formed in the upper end of the charging device, a first rotating shaft is arranged in the conditioning mechanism, stirring paddles distributed in arrays arearranged on the first rotating shaft, water filling pipes distributed in arrays are arranged on the conditioning mechanism on the left and right sides of the stirring paddles, a squeezing plate is arranged in the granulating box, a granulating plate is arranged in the granulating box on the right side of the squeezing plate, a cutting device is arranged on the granulating box on the right side ofthe granulating plate, a charging pipe is arranged on the upper end of the screening box, a screening plate is arranged in the screening box on the lower side of the charging pipe, and a discharging pipe is arranged on the screening box on the right side of the screening plate. According to the granulating and screening machine for feed production disclosed by the invention, the contact area between water and feed is large, the conditioning effect is good, the conditioning mechanism is provided with vertical conditioning for solving the problems of insufficient stirring and water addition anddifficulty in discharging of a transverse conditioning mechanism, the granulating efficiency is high, and the feed granulating quality is high.

Owner:遂昌县宏创技术开发有限公司

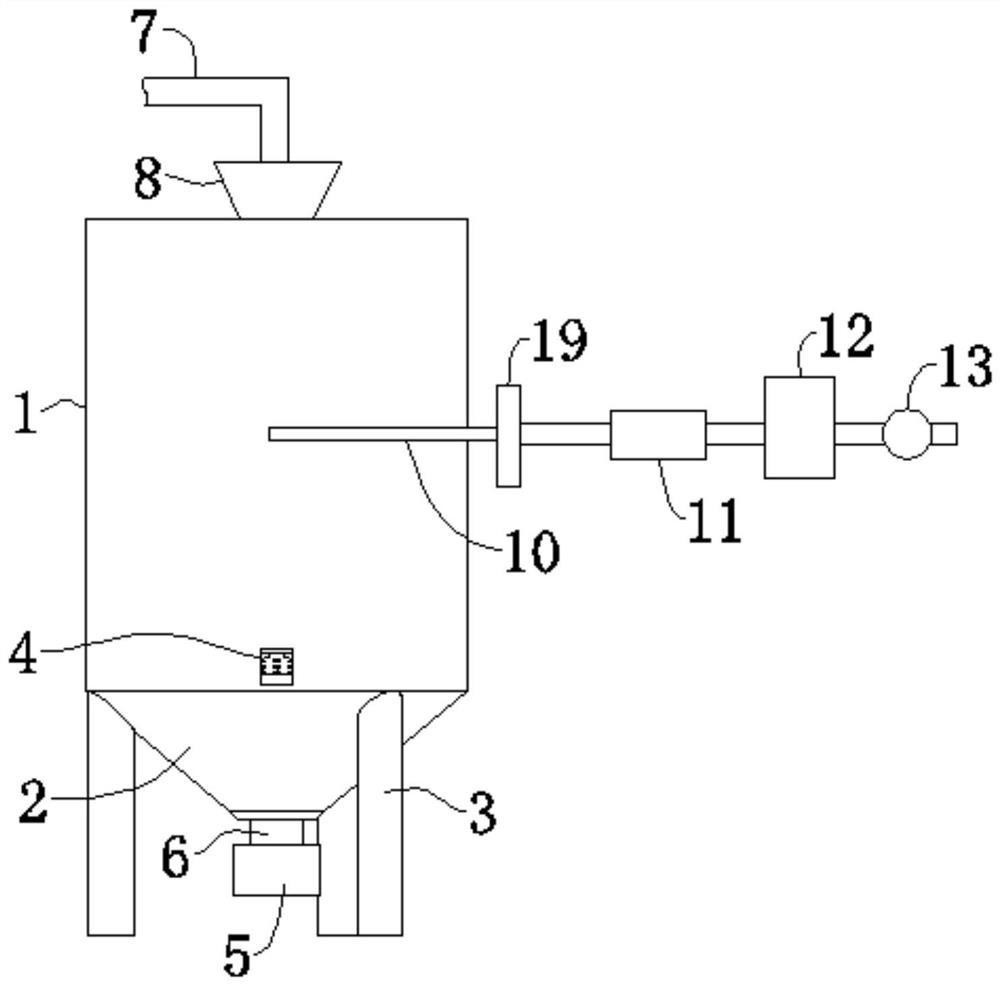

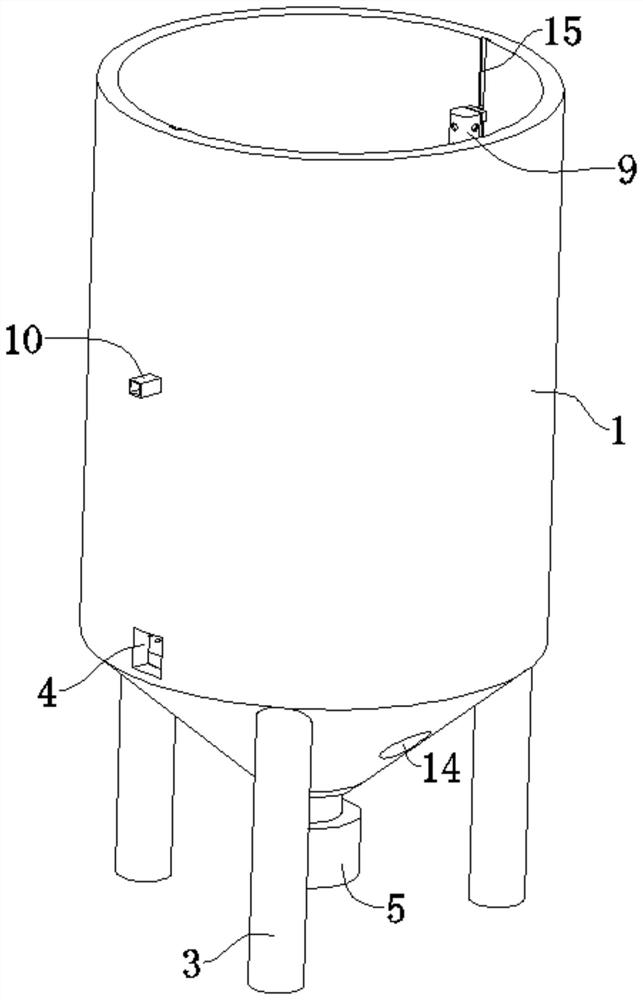

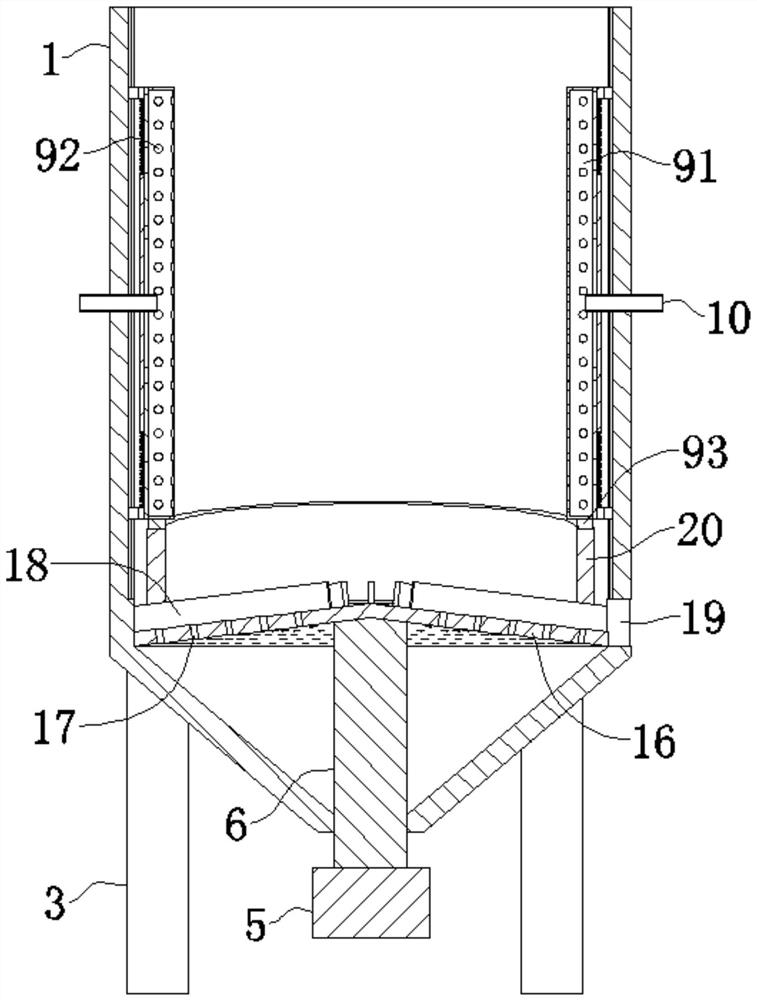

Disk granulator

InactiveCN102179203AImprove granulation qualityImprove quality and efficiencyGranulation in rotating dishes/pansFertiliser formsCircular discAdditive ingredient

Owner:CHINA AGRI UNIV

Wheat variety W020580E1

ActiveUS9137962B1Increased seed yieldImprove granulation qualityHorticulture methodsVector-based foreign material introductionTriticeaeMutagenic Process

A wheat variety designated W020580E1, the plants and seeds of wheat variety W020580E1, methods for producing a wheat plant produced by crossing the variety W020580E1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W020580E1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W020580E1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W020580E1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety W020189J1

ActiveUS8669448B1High seed yieldWell agronomic qualityBiocideDough treatmentMutagenic ProcessWheat plant

A wheat variety designated W020189J1, the plants and seeds of wheat variety W020189J1, methods for producing a wheat plant produced by crossing the variety W020189J1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W020189J1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W020189J1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W020189J1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety XW10V

ActiveUS9144207B1Increased seed yieldImprove granulation qualityPlant tissue cultureHorticulture methodsTriticeaeTriticum turgidum

A wheat variety designated XW10V, the plants and seeds of wheat variety XW10V, methods for producing a wheat plant produced by crossing the variety XW10V with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety XW10V with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety XW10V. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety XW10V and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety 25R32

ActiveUS8119889B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationTriticeaeMutagenic Process

A wheat variety designated 25R32, the plants and seeds of wheat variety 25R32, methods for producing a wheat plant produced by crossing the variety 25R32 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety 25R32 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety 25R32. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety 25R32 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety W010328W1

ActiveUS8604324B1Increased seed yieldImprove granulation qualityBiocideDough treatmentBiotechnologyGenetics

A wheat variety designated W010328W1, the plants and seeds of wheat variety W010328W1, methods for producing a wheat plant produced by crossing the variety W010328W1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W010328W1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W010328W1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W010328W1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety W990117E1

ActiveUS8115086B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationBiotechnologyGenetics

A wheat variety designated W990117E1, the plants and seeds of wheat variety W990117E1, methods for producing a wheat plant produced by crossing the variety W990117E1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W990117E1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W990117E1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W990117E1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

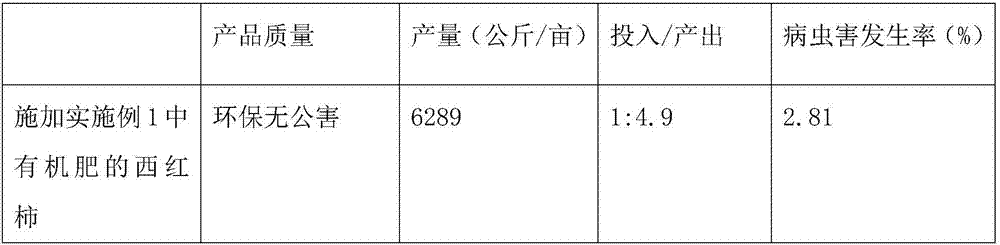

Fertilizer for tomatoes and preparation method thereof

InactiveCN107141159AProtective structureStrong water absorptionBio-organic fraction processingAlkali orthophosphate fertiliserSodium BentonitePeat

The invention provides a fertilizer for tomatoes and a preparation method thereof, and relates to the technical field of fertilizers. The fertilizer for tomatoes comprises the following raw materials in parts by weight: decayed fruits, poultry manure, corn cobs, peanut shells, peat, coal gangue, vinasse, vermiculite powder, flavescent sophora roots, peanut oil residues, cushaw stems, Chinese medical stones, rice bran, perlite, diammonium phosphate, potassium chloride, bacterial strain powder, bentonite, pea powder, zeolite powder, attapulgite, humus, corn straw, and rapeseed cakes; the preparation method comprises the following steps: (1) weighing of raw materials, (2) crushing, (3) fermentation, (4) mixing, (5) granulation and drying. The fertilizer for tomatoes solves the problems that tomatoes with fertilizer applied in the prior art have weak disease resistance, low yield and bad quality, and usage of fertilizers deteriorates soil and harm health of human bodies with high cost.

Owner:HEFEI BAILYVSHENG AGRI TECH CO LTD

Wheat variety W000850B1

ActiveUS8492626B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationTriticeaeHybrid species

A wheat variety designated W000850B1, the plants and seeds of wheat variety W000850B1, methods for producing a wheat plant produced by crossing the variety W000850B1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W000850B1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W000850B1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W000850B1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety 25R40

ActiveUS8492625B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationTriticeaeMutagenic Process

A wheat variety designated 25R40, the plants and seeds of wheat variety 25R40, methods for producing a wheat plant produced by crossing the variety 25R40 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety 25R40 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety 25R40. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety 25R40 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety 26R20

ActiveUS8158868B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationTriticum turgidumMutagenesis

A wheat variety designated 26R20, the plants and seeds of wheat variety 26R20, methods for producing a wheat plant produced by crossing the variety 26R20 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety 26R20 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety 26R20. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety 26R20 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety W000582Z2

ActiveUS8766063B1Increased seed yieldImprove granulation qualityBiocideDough treatmentTriticeaeMutagenic Process

A wheat variety designated W000582Z2, the plants and seeds of wheat variety W000582Z2, methods for producing a wheat plant produced by crossing the variety W000582Z2 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W000582Z2 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W000582Z2. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W000582Z2 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Wheat variety W030578B1

ActiveUS9144217B1Increased seed yieldImprove granulation qualityHorticulture methodsVector-based foreign material introductionBiotechnologyGenetics

A wheat variety designated W030578B1, the plants and seeds of wheat variety W030578B1, methods for producing a wheat plant produced by crossing the variety W030578B1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W030578B1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W030578B1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W030578B1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

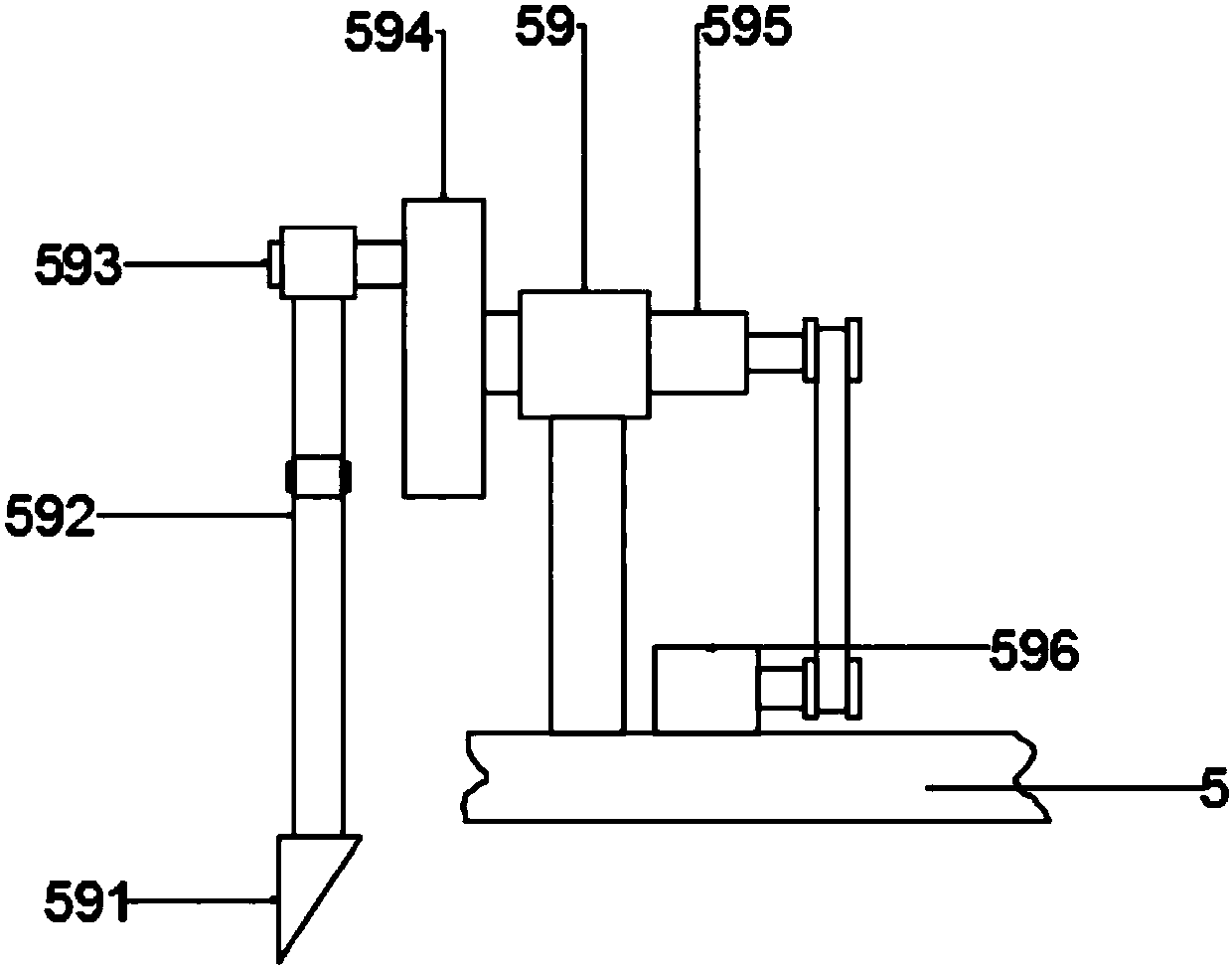

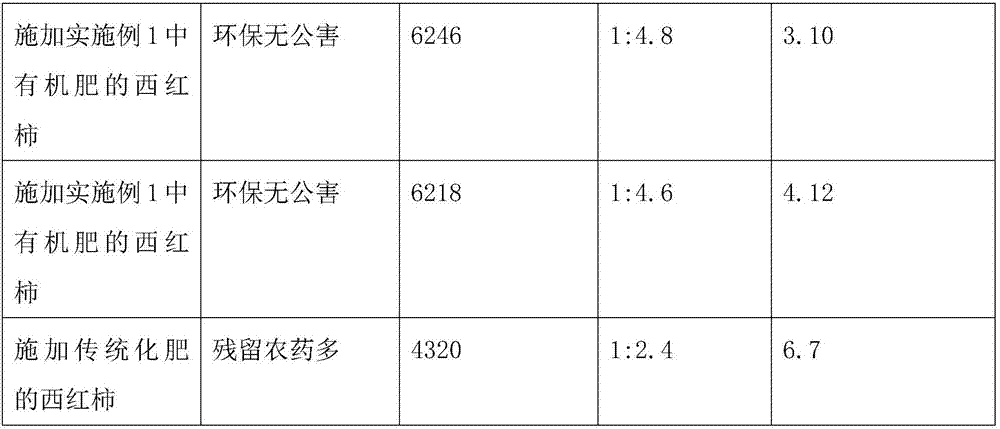

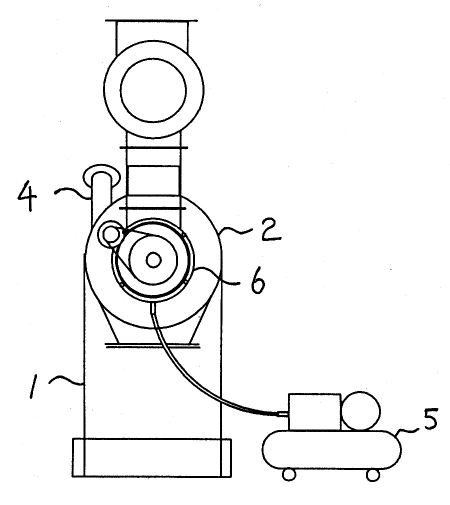

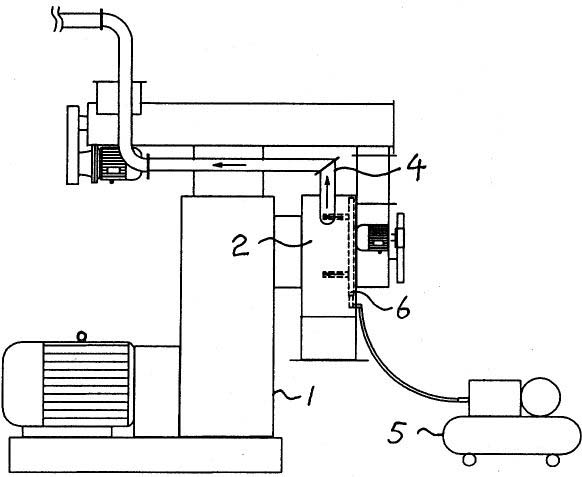

Pneumatic anti-clogging cooling device of biomass particle granulator ring mold

InactiveCN102068942AReduce indoor temperatureRealize cold press formingGranulation by pressingShaping pressCooling effectForced-air

The invention discloses a pneumatic anti-clogging cooling device of a biomass particle granulator ring mold. The device is characterized by comprising a forced air supply pipe (6) and air supply branch pipes (7), wherein the forced air supply pipe (6) is annular, a plurality of air supply branch pipes (7) communicated with the forced air supply pipe (6) are axially arranged on the forced air supply pipe (6), and the air supply branch pipes (7) are communicated with the interior of a ring mold (8) of a granulator (1). The air is directly and forcibly circulated from the interior of the ring mold to the outside by means of mold holes of the ring mold, and the air cooling effect is direct and thorough, so overheating of the ring mold is radically avoided; and meanwhile, the compressed air can impact the mold holes of the ring mold to play a role in dredging and blow away the powder deposited at the mold holes of the ring mold so as to effectively avoid clogging.

Owner:溧阳市华生机械制造有限公司

Centrifugal spray granulation process for preparing high-density ITO target material

The invention discloses a centrifugal spray granulation process for preparing a high-density ITO target material, and belongs to the technical field of ITO target material processing, the centrifugal spray granulation process comprises the following steps: S1, In2O3 nano powder and SnO2 nano powder are weighed, deionized water and a dispersant are added, and uniformly stirred to obtain slurry; s2, the slurry is subjected to ball milling through a sand mill, then a binder and a defoaming agent are added, and slurry to be granulated is obtained after uniform mixing; s3, external air is extracted through a draught fan, so that the air sequentially passes through a filter, a heater and an air collecting pipe and then is exhausted into the tank body through an air distributing pipe in the tank body for granulation till the tank body is full of hot air with the temperature of 130-240 DEG C; the slurry to be granulated is conveyed through the feeding pipe, so that the slurry to be granulated is atomized through the atomizer and then sprayed into the tank body, and the required granulated powder is obtained. The problem that in the ITO target material spray drying process, the drying rate of the vaporous raw materials is low is solved.

Owner:株洲火炬安泰新材料有限公司

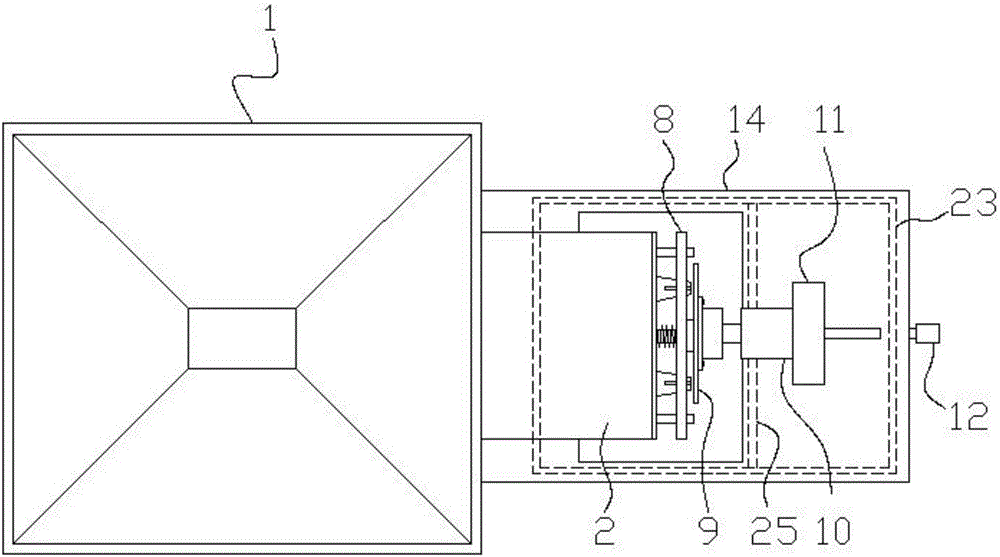

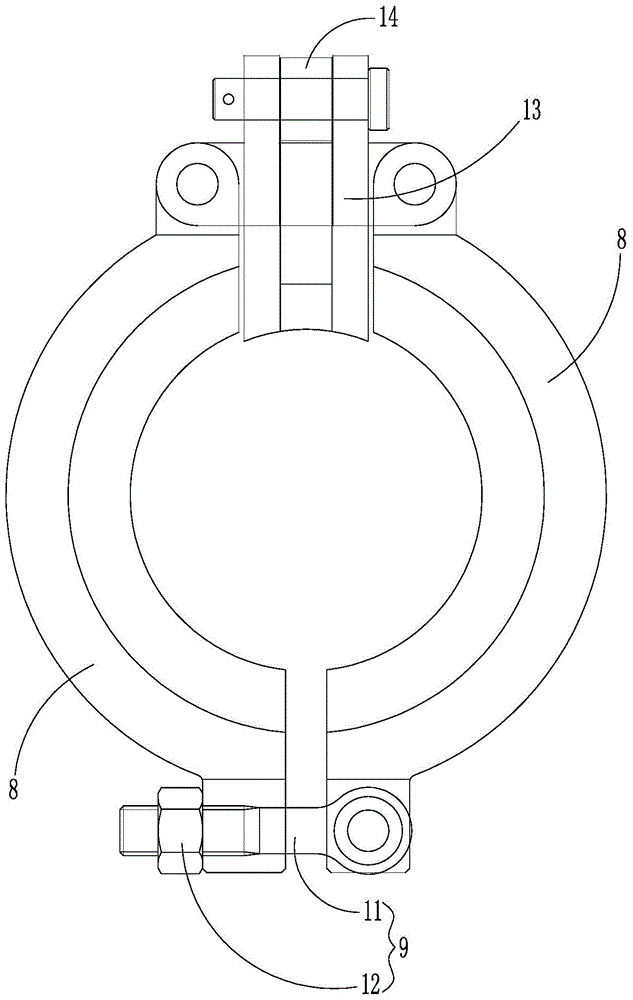

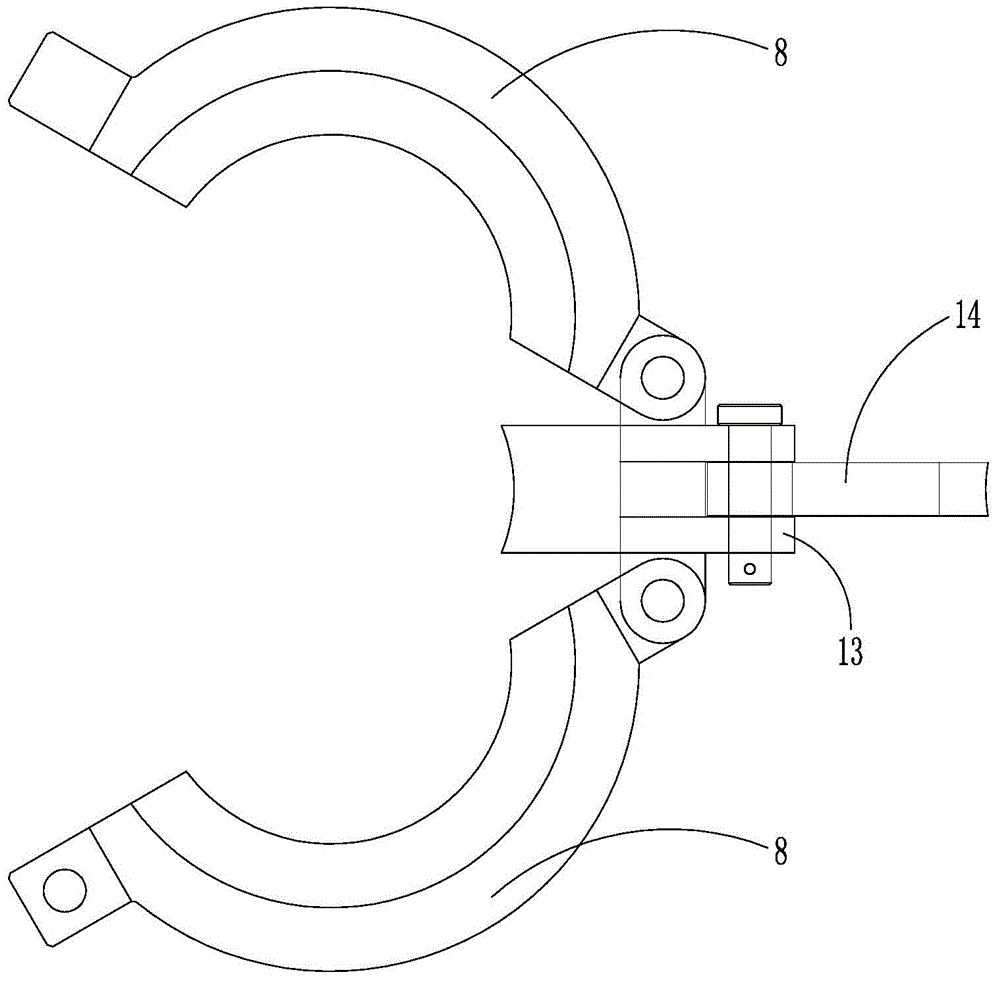

Rapid manual screen replacing device

InactiveCN104972635ARealize quick disassembly and quick assemblyNovel structureStructural engineeringMechanical engineering

The invention discloses a rapid manual screen replacing device. The rapid manual screen replacing device comprises a forming part and a rapid opening and closing part. The forming part comprises a transition base, a mold body, a distribution cone and a mouth die plate which are coaxially arranged in sequence. The ends, close to the mold body, of the transition base are provided with circumferential protruding ribs protruding outwards in the radial direction respectively. A transition plate is clamped between the end faces, close to the mold body, of the transition base. The rapid opening and closing part comprises a rapid Haff buckle. The rapid Haff buckle comprises two bodies which can be buckled together. Each body is in a semicircular arc shape, the two bodies are buckled to the outer circumferences of the two protruding ribs in the circumferential direction of the bodies, and the inner walls of the bodies are matched with the two protruding ribs, and one ends of the two bodies are hinged together. A rapid disassembly buckle is arranged between the other ends of the two bodies. According to the rapid manual screen replacing device, the transition plate is clamped and positioned through the rapid Haff buckle by means of the transition base and the mold body, in this way, rapid disassembly and assembly of a filter plate are achieved, and the filter plate can be cleaned to remove impurities or replaced; the structure is novel and reliable; operation is easy and convenient; the workload of workers is small, and the efficiency is high; the granulation quality is improved; energy consumption is low.

Owner:SUZHOU DYUN RECYCLING MACHINERY

Wheat variety W980052N1

ActiveUS8129603B2Increased seed yieldImprove granulation qualityVector-based foreign material introductionPlant genotype modificationTriticeaeTriticum turgidum

A wheat variety designated W980052N1, the plants and seeds of wheat variety W980052N1, methods for producing a wheat plant produced by crossing the variety W980052N1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W980052N1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W980052N1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W980052N1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

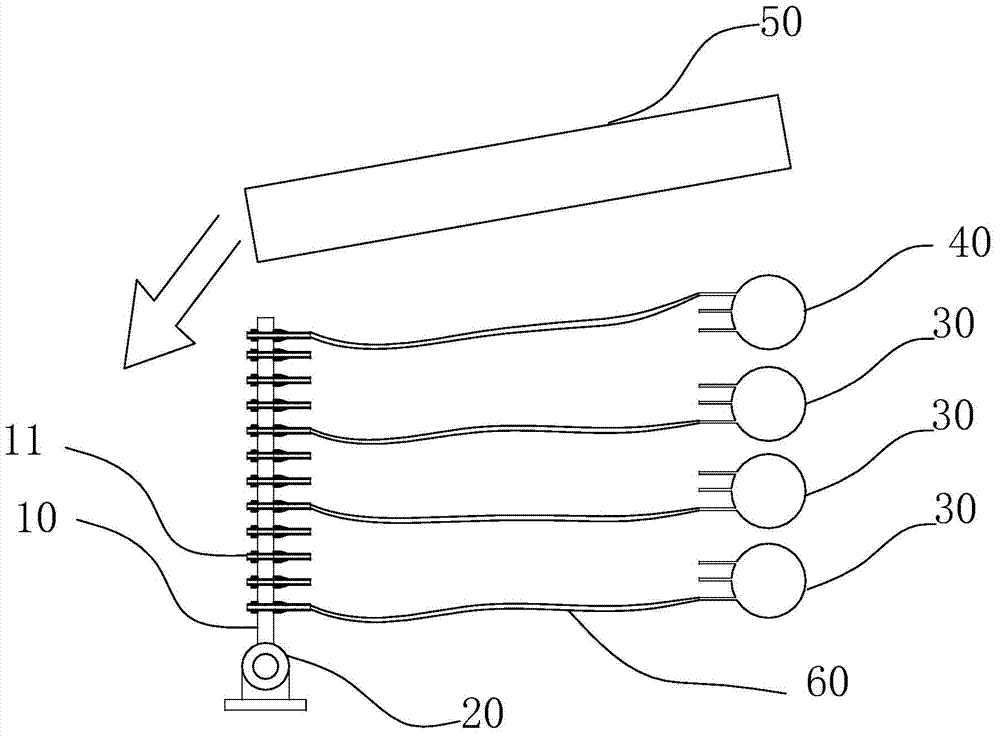

Screw conveyor used in wet material smashing process

InactiveCN111086892ASpiral transmission is smoothEasy to useLarge containersLoading/unloadingAugerAgricultural engineering

The invention discloses a screw conveyor used in the wet material smashing process. A first material conveying screw rod and a second material conveying screw rod are arranged in a material conveyingcylinder side by side, and a first auger and a second auger are arranged on the ring-shaped face of the first material conveying screw rod and the ring-shaped face of the second material conveying screw rod correspondingly. A feeding box is arranged on the top of the arc side face of the end, close to a motor installation seat, of the material conveying cylinder in an erected manner, and a storagebattery is connected to the end face of the end, away from the motor installation seat, of the material conveying cylinder. An external connection water conveying pipeline is fixedly arranged above the arc side face of the material conveying cylinder. The first material conveying screw rod is arranged to be of a hollow structure, and a heating pipe is arranged in the hollow structure of the firstmaterial conveying screw rod. Fertilizer wet materials in the material conveying cylinder are heated according to the temperature needed during fertilizer wet material pelletizing, the quality of fertilizer pelletizing is improved, the humidity of the fertilizer wet materials in the material conveying cylinder is controlled by controlling the external connection water conveying pipeline, the screw conveyor can be used for regulating the temperature and water in the material conveying process, and the practicability of the screw conveyor is improved.

Owner:李晓睿

Wheat variety W020457M1

ActiveUS9084406B1Increased seed yieldImprove granulation qualityHorticulture methodsVector-based foreign material introductionBiotechnologyGenetics

A wheat variety designated W020457M1, the plants and seeds of wheat variety W020457M1, methods for producing a wheat plant produced by crossing the variety W020457M1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W020457M1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W020457M1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W020457M1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Melt granulation apparatus

InactiveCN104759235AFull impact dispersionUniform grainGranulation by liquid drop formationQuenchingSpray nozzle

The invention provides a melt granulation apparatus, which can effectively avoid the blast condition generated due to water quenching granulation. For realizing the above purpose, the melt granulation apparatus comprises a nozzle, and is characterized in that several nozzles are arranged on the nozzle at intervals, in the nozzle, a part of the nozzle can be communicated to a water source pipeline, a part of the nozzle can be communicated to a steam pipeline, and the outlet of the nozzle points to a falling path of a melt flow. Through verification, the part of the nozzle is connected to the middle pressure steam pipeline with pressure being as 2.5Mpa, steam cab fully impact the melt for dispersing, so that uniform granulation can be realized. According to the invention, blast phenomenon generated in a water quenching granulation process and accordingly generated noise, granulation quality can be simultaneously increased.

Owner:TONGLING NON FERROUS METAL GROUP CORP

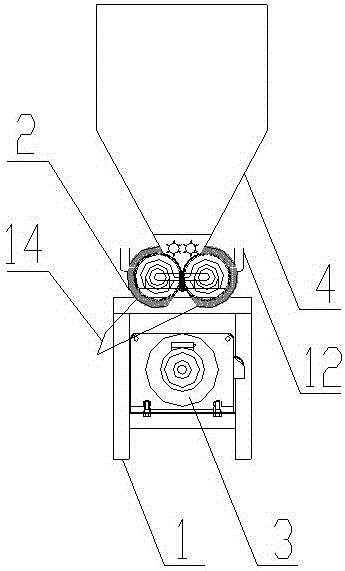

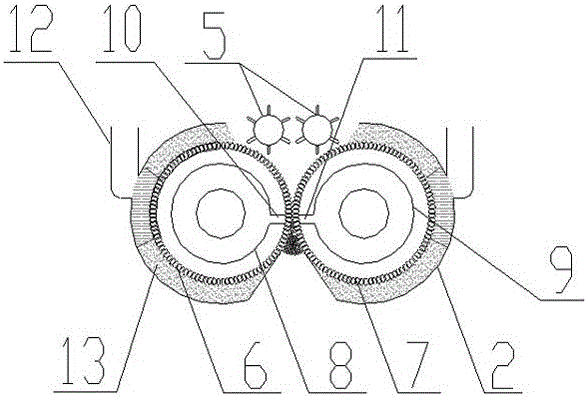

Gas-cap demolding pair-roller biofertilizer granulator

InactiveCN105688749AReduce adhesionReduce the impact of granulationGranulation by pressingEngineeringVentilation shaft

Disclosed is a gas-cap demolding pair-roller biofertilizer granulator which comprises a rack (1), a granulator shell (2), a motor (3), a material bin (4), a pair of material pressurizing wheels (5), a granulating roller A (6), a granulating roller B (7), a ventilation shaft A (8), a ventilation shaft B (9), a gas way A (10), a gas way B (11), a hydraulic oil inlet (12), felt (13) and a discharging hopper (14). The gas-cap demolding pair-roller biofertilizer granulator has the advantages that granules are enabled to go out of a groove in the surface of a drum through airflow, so that adhesion of the granules on the drum is reduced; the felt dipped with hydraulic lubricating oil smears the rotating drum to enable the surface of the drum to be smoother, so that adhesion of materials and the granules on the drum is further reduced, influence on granulating at the next time is lowered, and granulating efficiency and granulating quality are improved.

Owner:尚迪荆门生态科技有限公司

Wheat variety W010712A1

ActiveUS8796523B1Increased seed yieldImprove granulation qualityBiocideDough treatmentMutagenic ProcessWheat plant

A wheat variety designated W010712A1, the plants and seeds of wheat variety W010712A1, methods for producing a wheat plant produced by crossing the variety W010712A1 with another wheat plant, and hybrid wheat seeds and plants produced by crossing the variety W010712A1 with another wheat line or plant, and the creation of variants by mutagenesis or transformation of variety W010712A1. This invention also relates to methods for producing other wheat varieties or breeding lines derived from wheat variety W010712A1 and to wheat varieties or breeding lines produced by those methods.

Owner:PIONEER HI BRED INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com