Rapid manual screen replacing device

A fast, phantom technology, applied in the field of fast manual screen changing devices, can solve the problems of low mechanization work, large manual workload, long operation time, etc., and achieve the effect of small manual workload, easy operation and improved granulation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

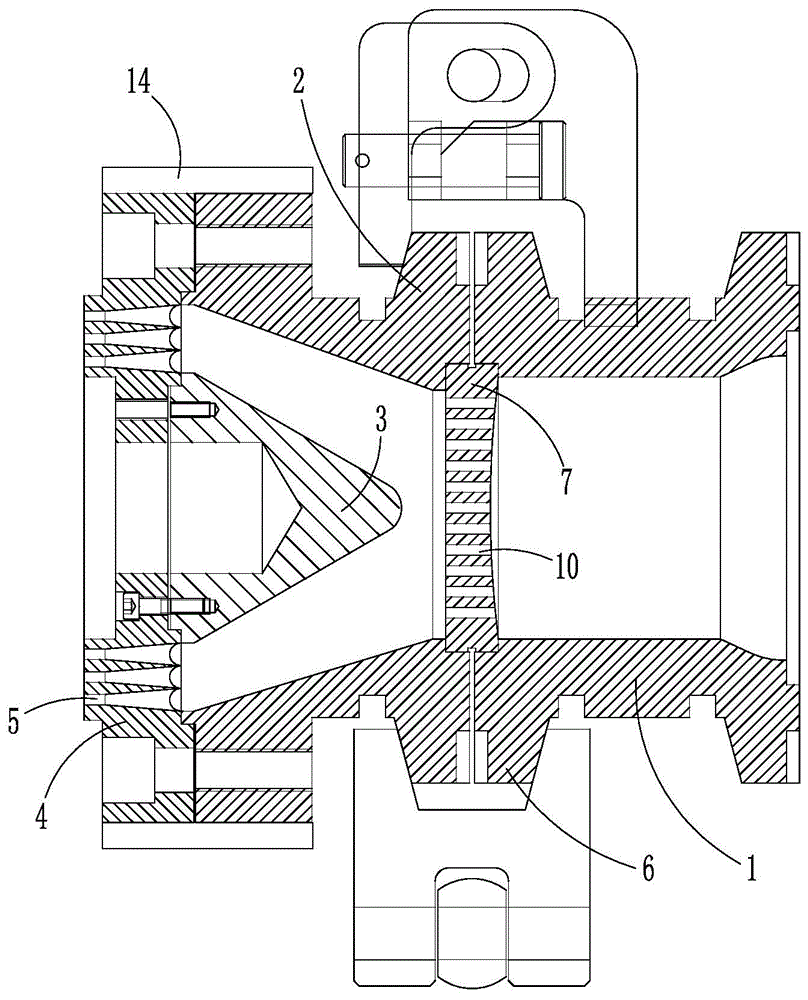

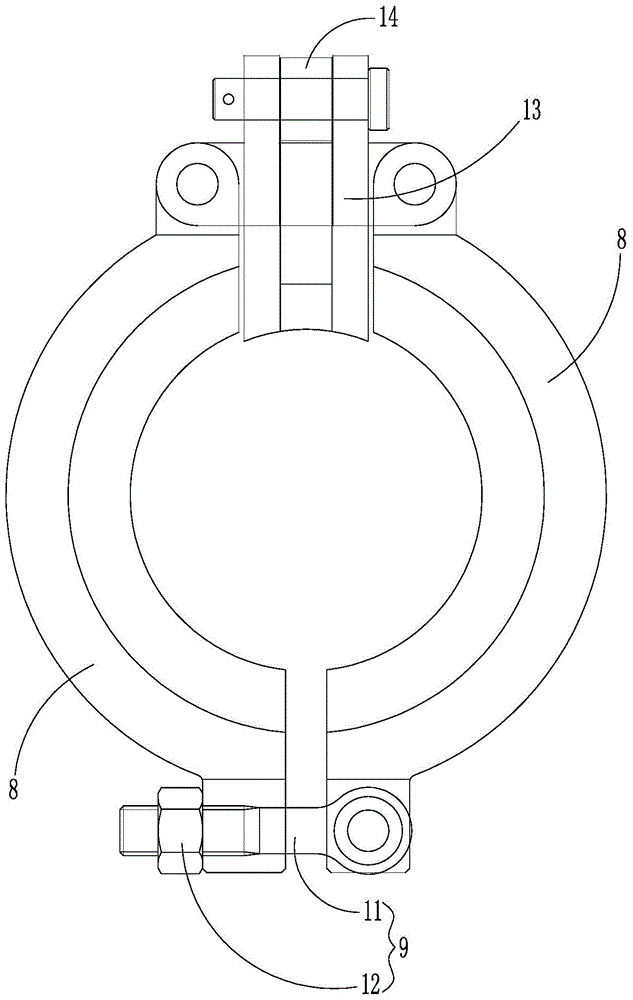

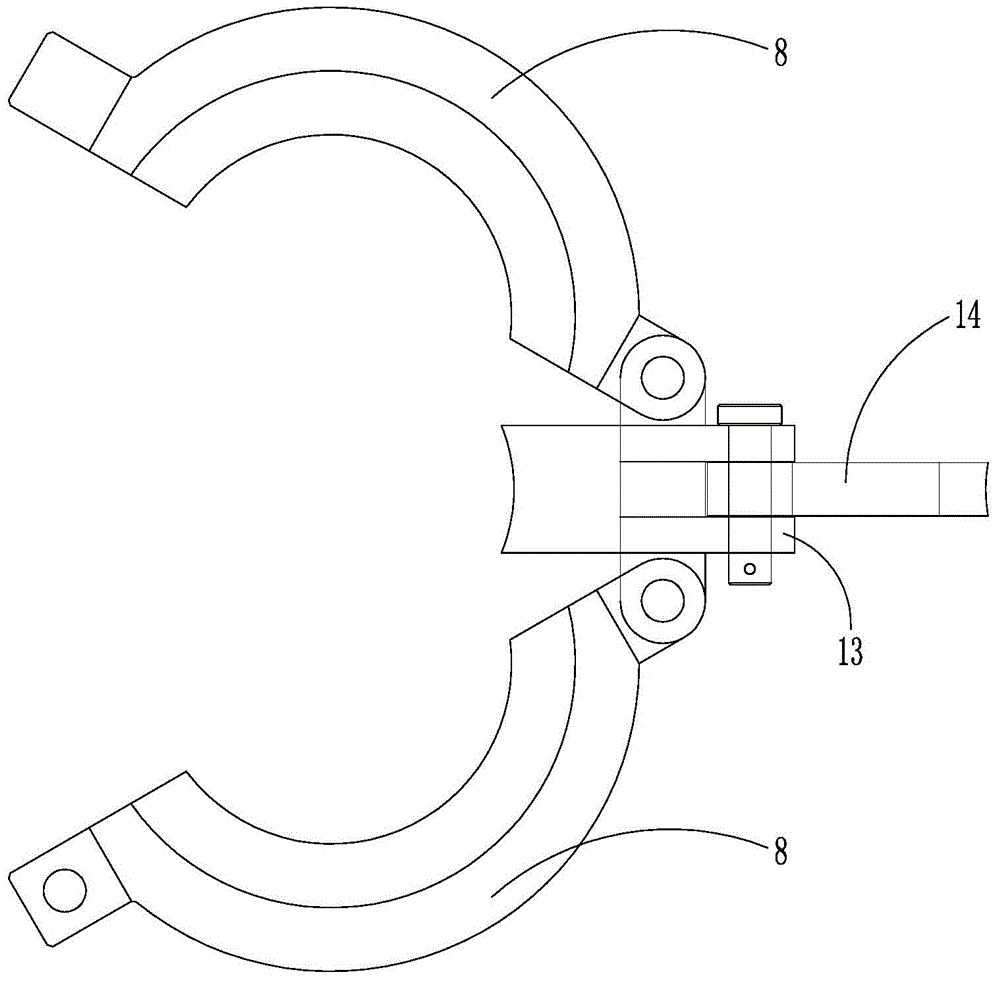

[0020] as attached figure 1 and attached Figure 4 As shown, a fast manual screen changing device includes a forming part and a quick opening and closing part. The forming part includes a coaxial transition seat 1, a mold body 2, a splitter cone 3, and a mouth plate 4. The mouth plate 4 has an inner ring , the outer ring, the connecting part between the inner ring and the outer ring, as attached Figure 5 As shown, several forming holes 5 are opened in the axial direction on the connecting part, the outer ring is fixedly connected with the mold body 2 in the axial direction through fasteners, the inner ring is fixedly connected with the splitter cone 3 in the axial direction through fasteners, and the transition The ends of the seat 1 and the mold body 2 that are close to each have radially outwardly protruding circumferential ribs 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com