Paraffin granulation equipment and method

A granulation equipment, paraffin wax technology, applied in the direction of physical wax processing, etc., can solve the problems of inconsistent cooling speed, high energy consumption, difficult cooling and molding of paraffin wax, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

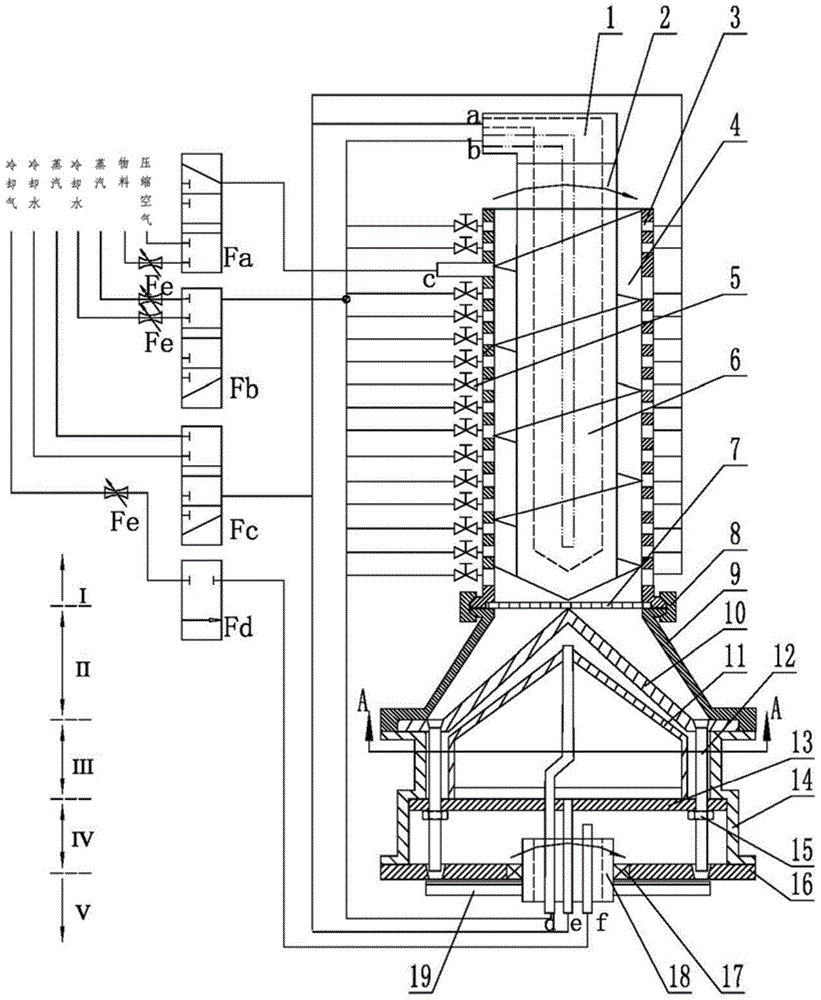

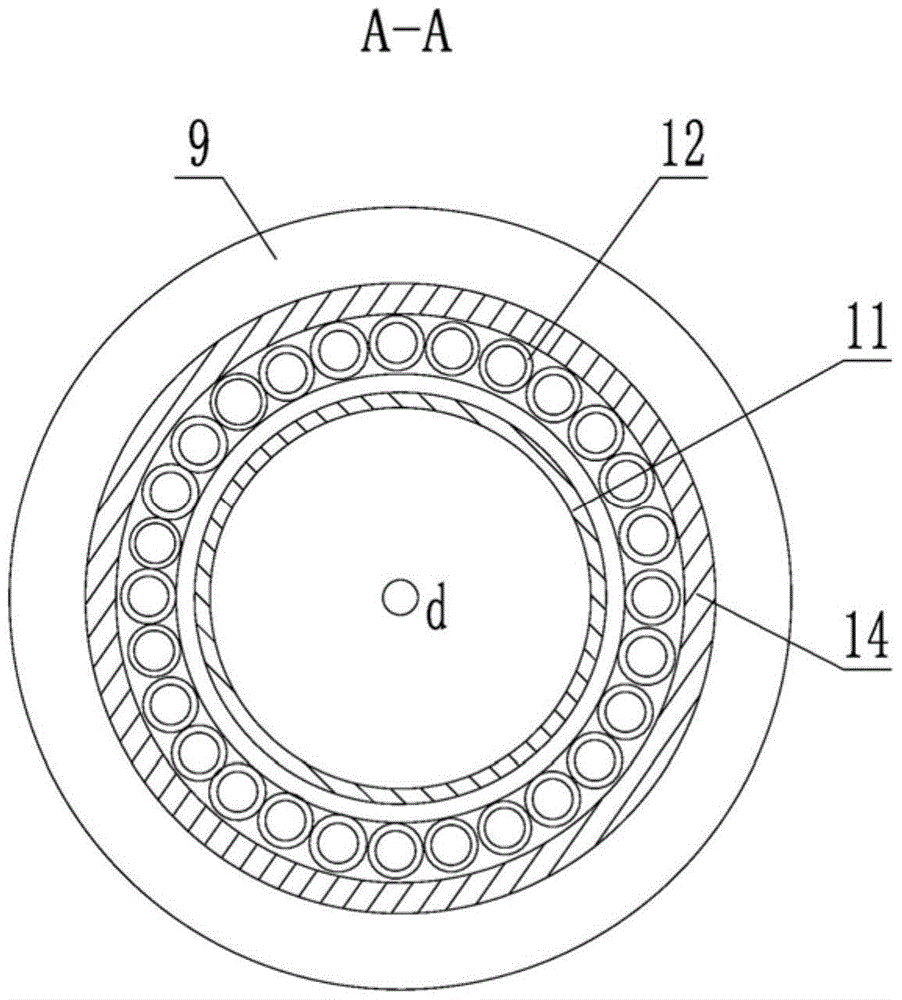

[0022] Combine the following Figure 1~2 The specific content of the present invention is described in detail. The paraffin granulation equipment adopts a vertical structure, which mainly includes a feeding mechanism, a forming mechanism (or an extrusion mechanism), and a cutting mechanism. Among them, the feeding mechanism includes a machine barrel 3 with a jacket structure, a conduit c arranged on the top of the machine barrel 3 and connected to the inner wall of the machine barrel 3, a filter plate 7 arranged at the bottom of the machine barrel 3, and coaxially arranged on the machine barrel 3 The internal cavity screw 2, the rotary joint 1 installed on the screw 2, the rotary joint 1 is provided with a conduit b communicating with the bottom of the screw cavity, the screw cavity 6 is provided with an opening a on the rotary joint 1, and the outer wall of the screw 2 There are auger blades on the top, the auger blades just match the inner wall of the barrel 3, and a number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com