Tensile wiring terminal and components thereof

A terminal and tensile type technology, which is applied in the field of tensile terminal and its components, can solve problems such as poor tensile performance, achieve the effect of improving tensile performance and solving poor tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

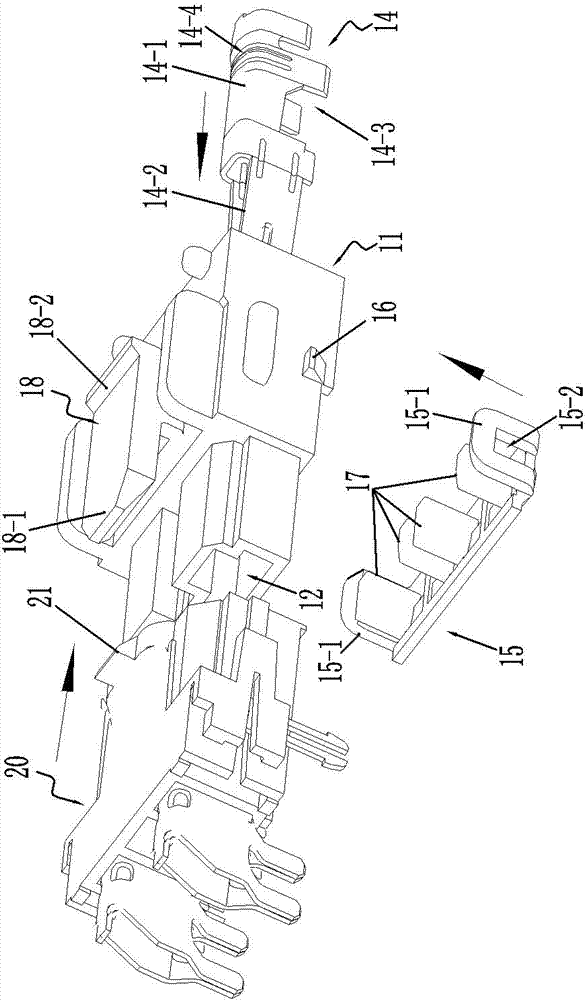

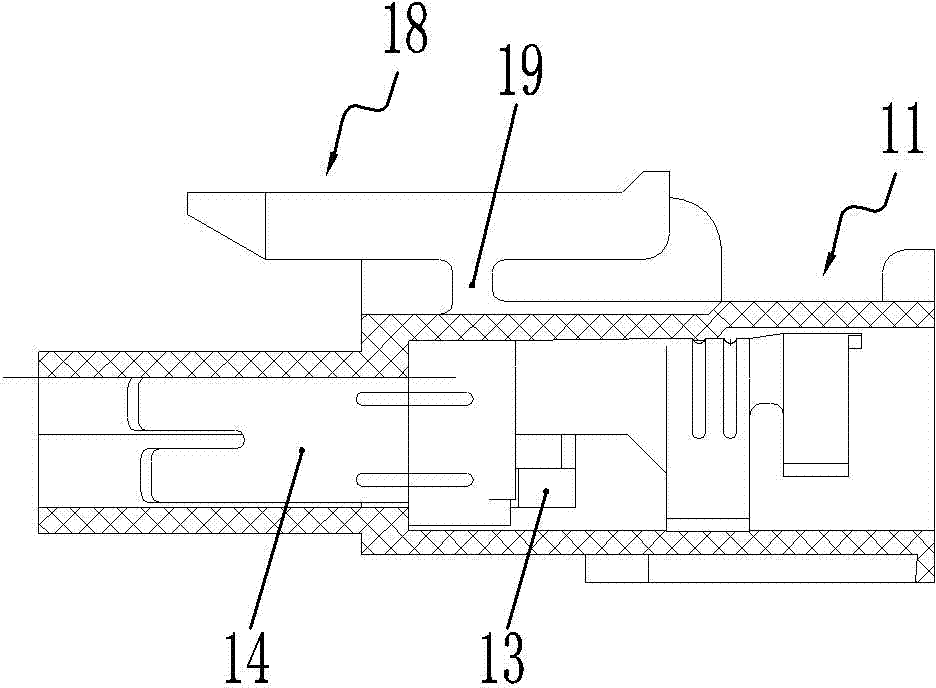

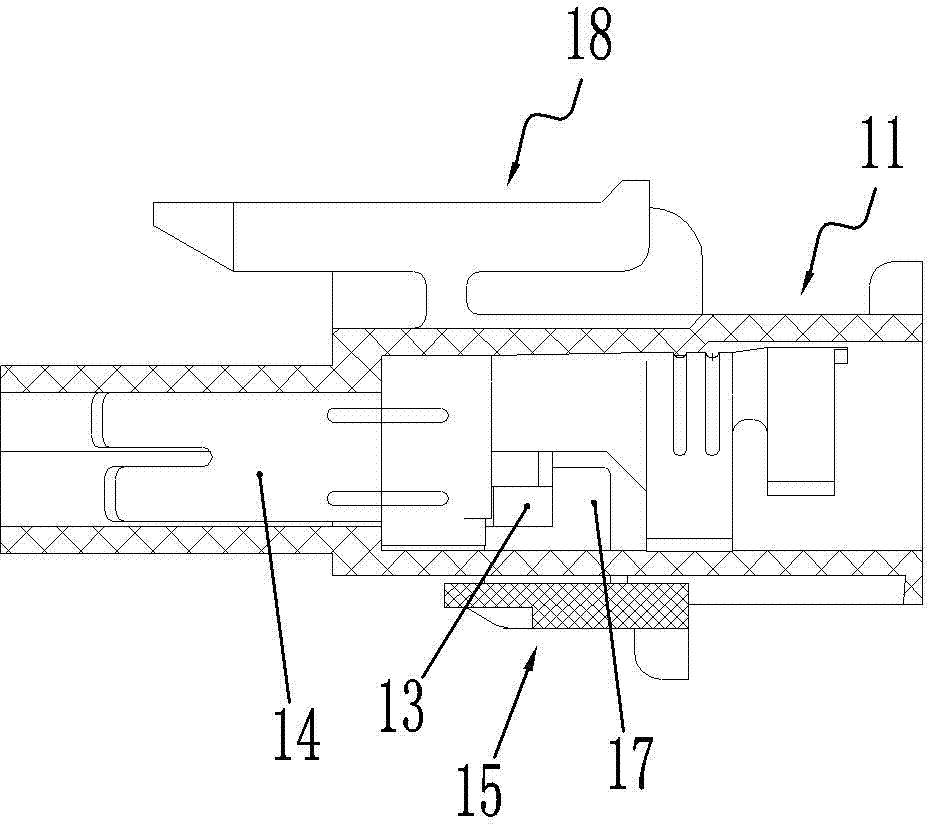

[0022] Embodiment 1 of the terminal block of the present invention, such as Figure 1-5 As shown, the connection terminal is a male terminal, including an insulating mounting base 11, and the mounting base 11 is provided with transparent mounting holes 12. In this embodiment, there are two mounting holes 12, and the two mounting holes are arranged side by side. Set on the installation base 11, each installation hole 12 is a stepped hole with a small front and a large rear, and the critical part of the small diameter section and the large diameter section of the installation hole 12 forms a step surface facing the rear. In addition, each installation hole 12 Elastic claws 13 are provided on the hole wall of the large diameter section; the mounting holes 12 are equipped with contact pieces 14 respectively. The volume requirements of the installation base 11, the contact piece 14 includes a fixed section 14-1 at the rear end and a contact section 14-2 integrally connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com