Gardening tool

A technology of garden tools and tool bars, which is applied in the direction of hand tools, etc., can solve the problems of large occupation and high manufacturing cost, and achieve the effect of reducing the storage space and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

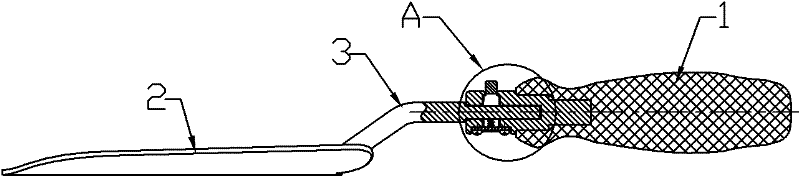

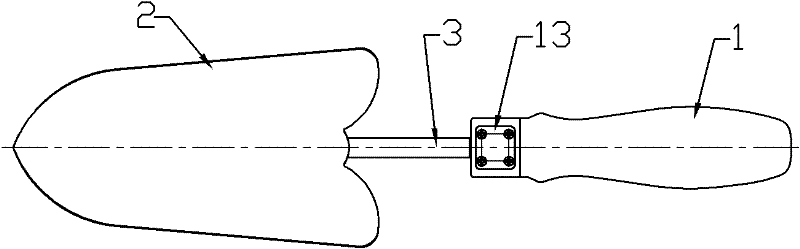

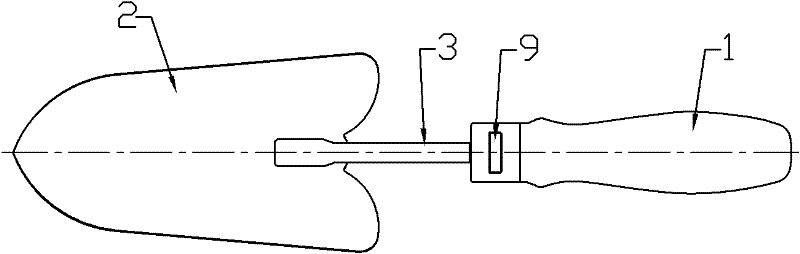

[0023] Such as Figure 1-3 As shown, the garden tool includes a handle 1 and a head 2, the head 2 has a tool bar 3 extending backward, the handle 1 is provided with a mounting hole 4, the tool bar 3 is inserted in the mounting hole 4 and the tool bar 3 is installed The hole 4 cooperates to prohibit the rotation of the tool bar 3 and affects the use. In this embodiment, a plane 6 is provided on the tool bar 3, and the mounting hole 4 is provided with a hole wall that matches the plane 6 of the tool bar. The plane 6 and the hole wall (generally, when the section of the tool bar 3 and the mounting hole 4 are circular, the tool bar is easy to rotate in the mounting hole, so when the section of the tool bar 3 and the mounting hole 4 is limited to a non-circular When round, such as ellipse, triangle, square, etc., you can also set keys and keyways on the tool bar and the mounting hole respectively, so that the tool bar can be prohibited from rotating); in addition, the handle 1 is p...

Embodiment 2

[0026] The example is Figure 7-9 As shown, the locking and unlocking of the locking part by the locking assembly is realized according to the following structure (other structures are the same as in Embodiment 1, and will not be described in detail): the locking part is the surface of the tool bar, and the locking assembly includes a The push button 15 on the handle 1, the lock sleeve 16 pushed by the push knob 15 and the elastic element 17 (spring) supporting the lock sleeve 16, the tool bar 3 is inserted in the lock sleeve 16 and locked by the elastic element 17 Cover 16 is inclined to support so that locking sleeve 16 is stuck on the surface of tool bar so as to Figure 8 Lock the tool bar in the mounting hole as shown. Generally, the surface of the tool bar 3 is a plane or a wave-like undulating surface.

[0027] This example, when replacement is required, such as Figure 9 As shown, push the push button 15 to the right by hand, and the locking sleeve 16 will be straig...

Embodiment 3

[0029] The example is Figure 10-12 As shown, the locking and unlocking of the locking part is realized by the locking assembly according to the following structure (other structures are the same as in Embodiment 1, and will not be described in detail): the locking part is a recess 18 provided on the tool bar 3 (such as Ring groove, pit, etc.), the locking assembly includes a locking sleeve 19 that is threaded on the handle 1 and a locking pin 20 that is placed in the corresponding recess on the handle 1. The locking sleeve 19 has the function of pressing the locking pin 20 in the concave portion Bevel 21 in 18. The locking pin 20 is supported by the elastic element and disengages from the recess 18 on the tool bar so that the working bar is pulled out from the installation hole when unlocking (the assembly relationship between the lock pin and the elastic element can be like the assembly relationship between the button and the elastic element in Embodiment 1).

[0030] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com