Patents

Literature

183results about "Wax physical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

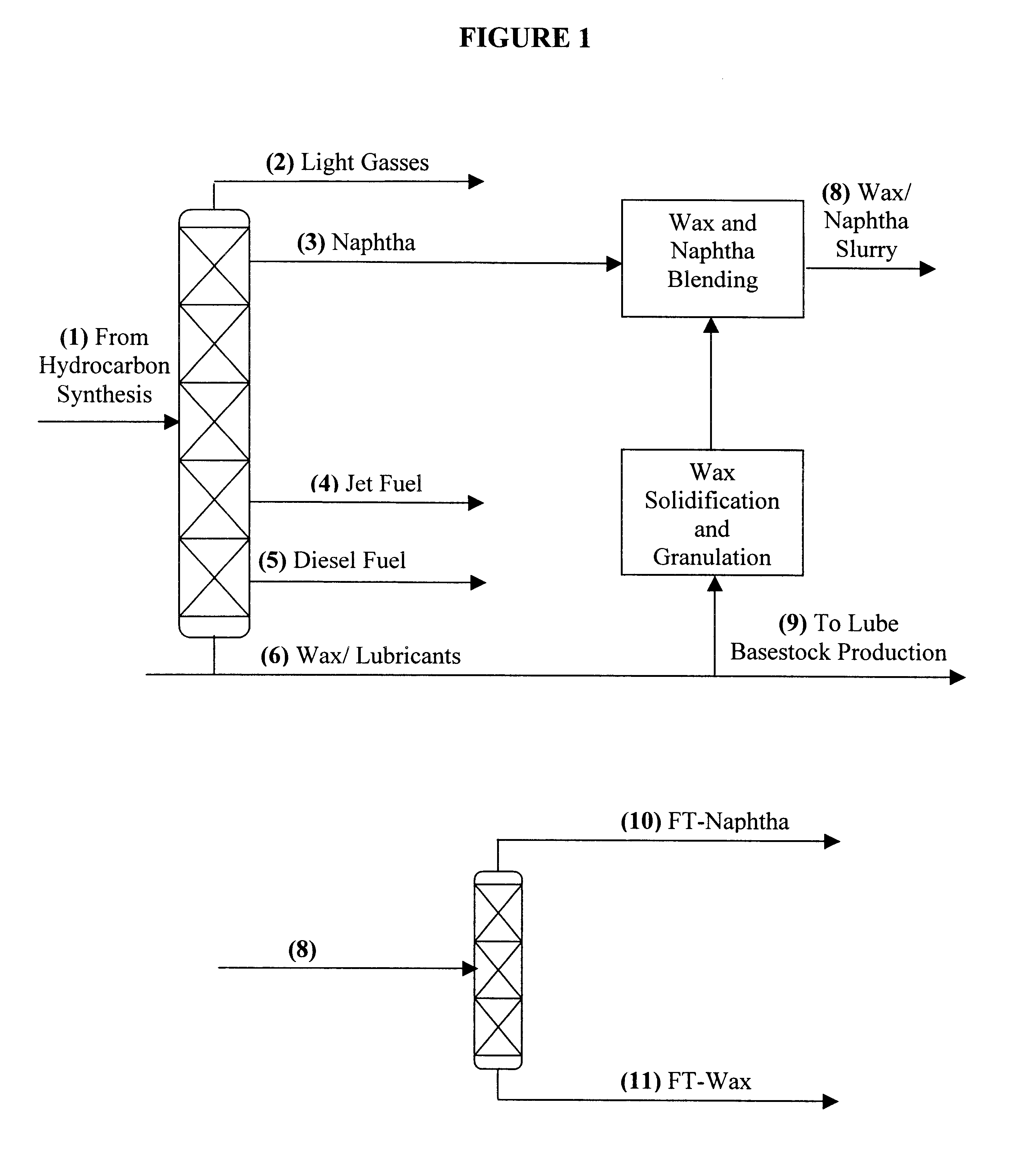

Fischer-Tropsch wax and hydrocarbon mixtures for transport (law938)

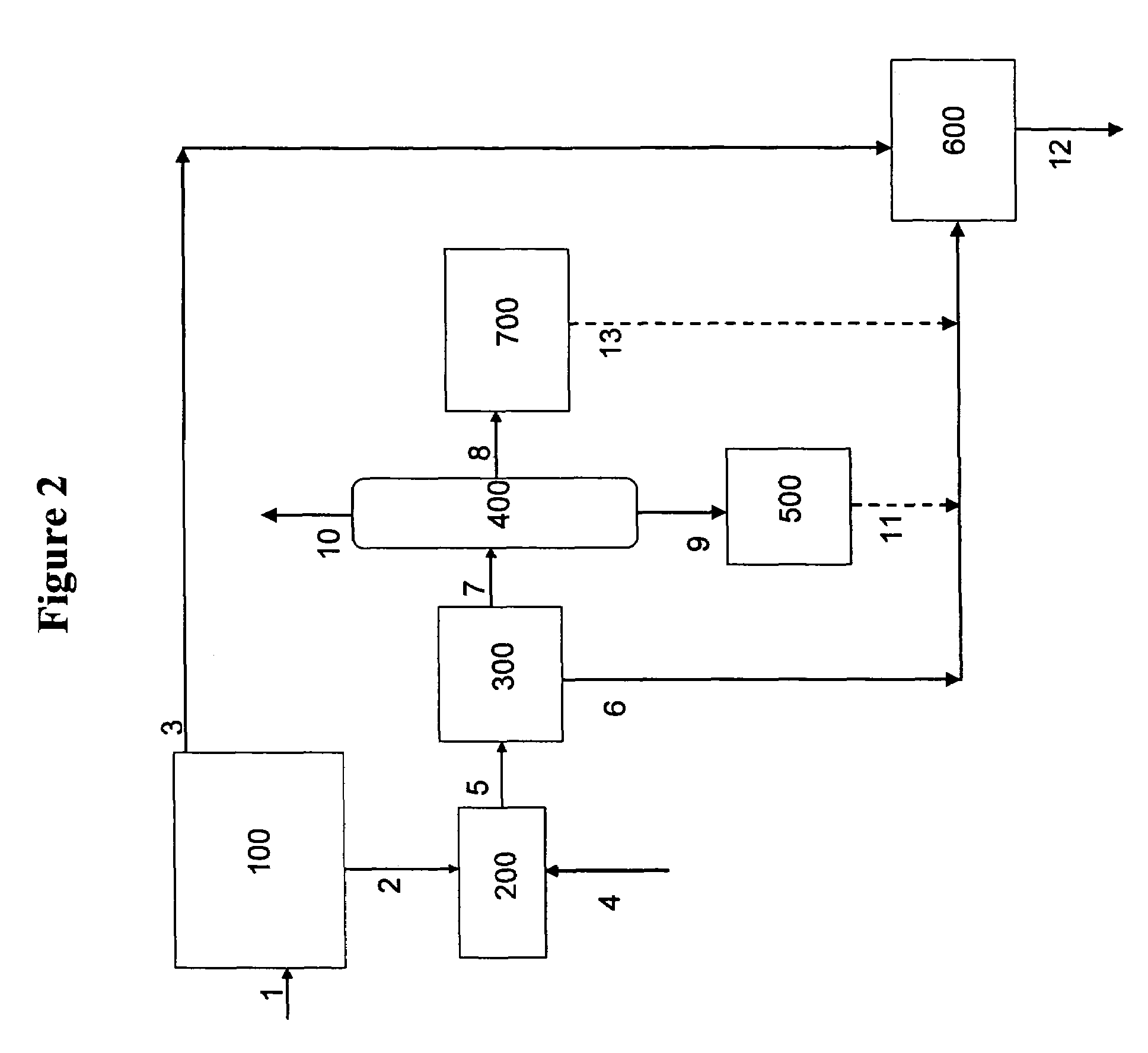

The invention is a process for producing a mixture of Fischer-Tropsch product that is solid at ambient conditions (between 32° F. and 95° F.), such as wax, and hydrocarbon liquid, such as naphtha, that can be pumped at ambient temperature (between 32° F. and 95° F.). The temperature of the mixture is controlled below the melting point of the Fischer-Tropsch product. The present invention provides for the transport of Fischer-Tropsch product from a remote location in a readily available medium, such as naphtha, via pipeline, tanker or railcar. At the completion of the transport, the hydrocarbon liquid and Fischer-Tropsch product are separated by conventional methods such as flashing, distillation, or filtration with minimal contamination from the hydrocarbon liquid.

Owner:EXXON RES & ENG CO

Fischer-tropsch wax composition and method of transport

InactiveUS20060065573A1Efficient transportMaintain stabilityOrganic compound preparationWax physical treatmentParaffin waxNaphtha

The present invention relates to transportable product for the transportation of paraffinic wax and methods of transporting using this transportable product. The transportable product comprises 90 to 20 weight % of a hydrocarbonaceous liquid, wherein the hydrocarbonaceous liquid comprises ≧75 weight % of a liquid selected from the group consisting of naphtha, heavy oil, distillate, lubricant base oil, and mixtures thereof, and 10 to 80 weight % of wax particles, wherein the wax particles comprise ≧90 weight % of wax particles larger than 2.4 mm. The transportable product and methods of transporting according to the present invention are able to accommodate a relatively high weight % of paraffinic wax particles in the transportable product while avoiding interparticle adhesion and clumping by ensuring that the wax particles are not too small and the amount of small wax particles is not excessive.

Owner:CHEVROU USA INC

Fischer-tropsch wax composition and method of transport

InactiveUS20060069296A1Efficient transportMaintain stabilityOrganic compound preparationWax physical treatmentParaffin waxPolymer chemistry

The present invention relates to transportable product for the transportation of paraffinic wax and methods of transporting using this transportable product. The transportable product comprises 90 to 20 weight % of a liquid comprising ≧50 weight % water and having a pH of >5 and a true vapor pressure of ≦14.7 psia when measured at 20° C., and 10 to 80 weight % of wax particles, wherein the wax particles comprise ≧75 weight % of wax particles larger than 0.1 mm. The transportable product and methods of transporting according to the present invention are able to accommodate a relatively high weight % of paraffinic wax particles in the transportable product while avoiding interparticle adhesion and clumping by ensuring that the wax particles are not too small and the amount of small wax particles is not excessive.

Owner:CHEVROU USA INC

Fischer-Tropsch wax composition and method of transport

InactiveUS20060069295A1Efficient transportMaintain stabilityWax physical treatmentHydrocarbon purification/separationAlkaneWax

The present invention relates to transportable product for the transportation of paraffinic wax and methods of transporting using this transportable product. The transportable product comprises 90 to 20 weight % of a liquid comprising >50 weight % alcohol and having a true vapor pressure of ≦14.7 psia when measured at 20° C., and 10 to 80 weight % of wax particles, wherein the wax particles comprise ≧75 weight % of wax particles larger than 0.1 mm. The transportable product and methods of transporting according to the present invention are able to accommodate a relatively high weight % of paraffinic wax particles in the transportable product while avoiding interparticle adhesion and clumping by ensuring that the wax particles are not too small and the amount of small wax particles is not excessive.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Paraffin emulsifier and its making method

InactiveCN1570038AGood water solubilityImprove stabilityWax physical treatmentTransportation and packagingParaffin waxEthylene oxide

Owner:杨建军

Method for preparing nano micro-emulsified wax

InactiveCN101250436ASmall particle sizeModerate viscosityWax physical treatmentPolymer scienceOil emulsion

The invention discloses a process for preparing nanometer micro emulsifying wax, wherein components of raw material which is formed according to percentage by weight are that paraffin 2-40%, viscosity additive 1-30%, emulsifying agent 3-12%, oxygenated polythene wax 1-50%, oxygenated polypropylene wax 0.001-40%, water 30-70% and alkali 0.001-5%, the process for preparation comprises the following steps: batching paraffin, additive and emulsifying agent according to the above percentage by weight, and then placing into a special-purpose reaction kettle to heat up, wherein the temperature is 80-150 DEG C, batching water and alkali again according to the above percentage by weight, and then placing into another reaction kettle, heating up, wherein the temperature is 80-150 DEG C, slowly adding water in the second reaction kettle into the oil phase of the first reaction kettle, and slowly stirring, emulsifying, cooling nanometer oil emulsion through water after emulsifying for 10-160 minutes, wherein the temperature is 20-60 DEF C, and taking out nanometer oil emulsion. The process for preparation of the invention has the advantages of adjustable product solid phase component fusing point, thin and fine grain diameter, correct viscosity and extended application.

Owner:上海五将化工科技有限公司

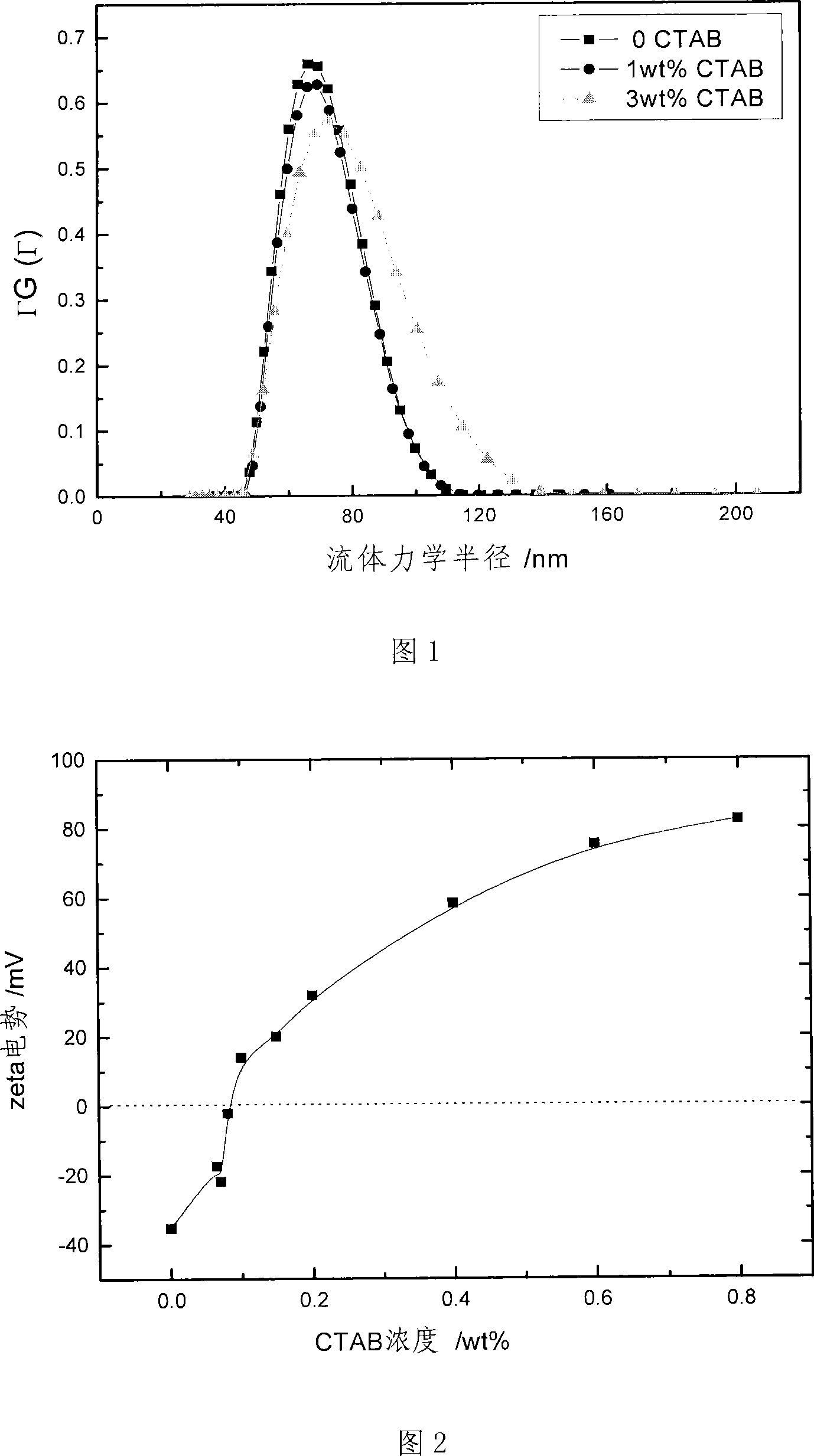

Paraffin nano emulsion with positive charge and preparation method thereof

InactiveCN101168686ANarrow particle size distributionImprove stabilityWax physical treatmentParaffin waxOil phase

The invention discloses a preparation method of paraffin wax nanometer emulsion with positive electricity. Oil phase liquid paraffin, nonionic surfactant and water are added into a reactor together, are heated and blended up to the emulsifying temperature, are blended for certain time and then cooled down quickly, thereby, the paraffin wax nanometer emulsion is obtained, and then cationic surfactant is added into the paraffin wax nanometer emulsion and blended, so as to obtain the paraffin wax nanometer emulsion with positive electricity. The invention also discloses the paraffin wax nanometer emulsion with positive electricity produced by using the method, and the emulsion has the advantages that the emulsion particle size is small, the particle size distribution is narrow, the stability is good, the preparation method of the invention is simple, and the charged amount of the emulsion droplet can be controlled conveniently.

Owner:SHANDONG UNIV

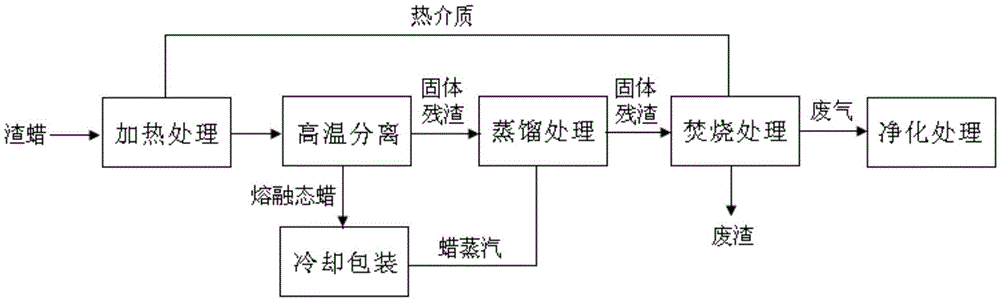

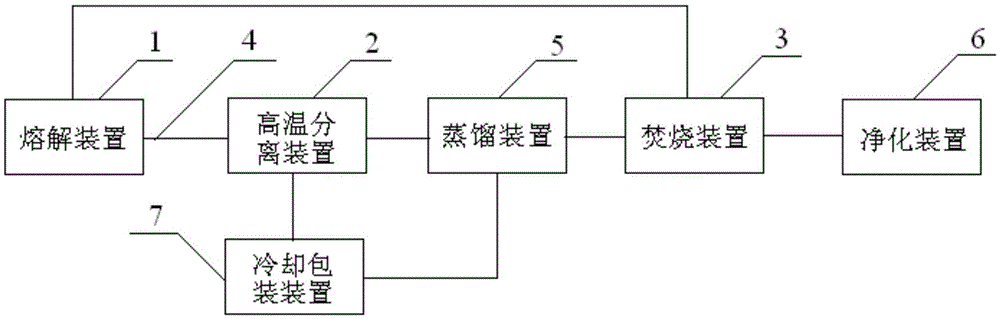

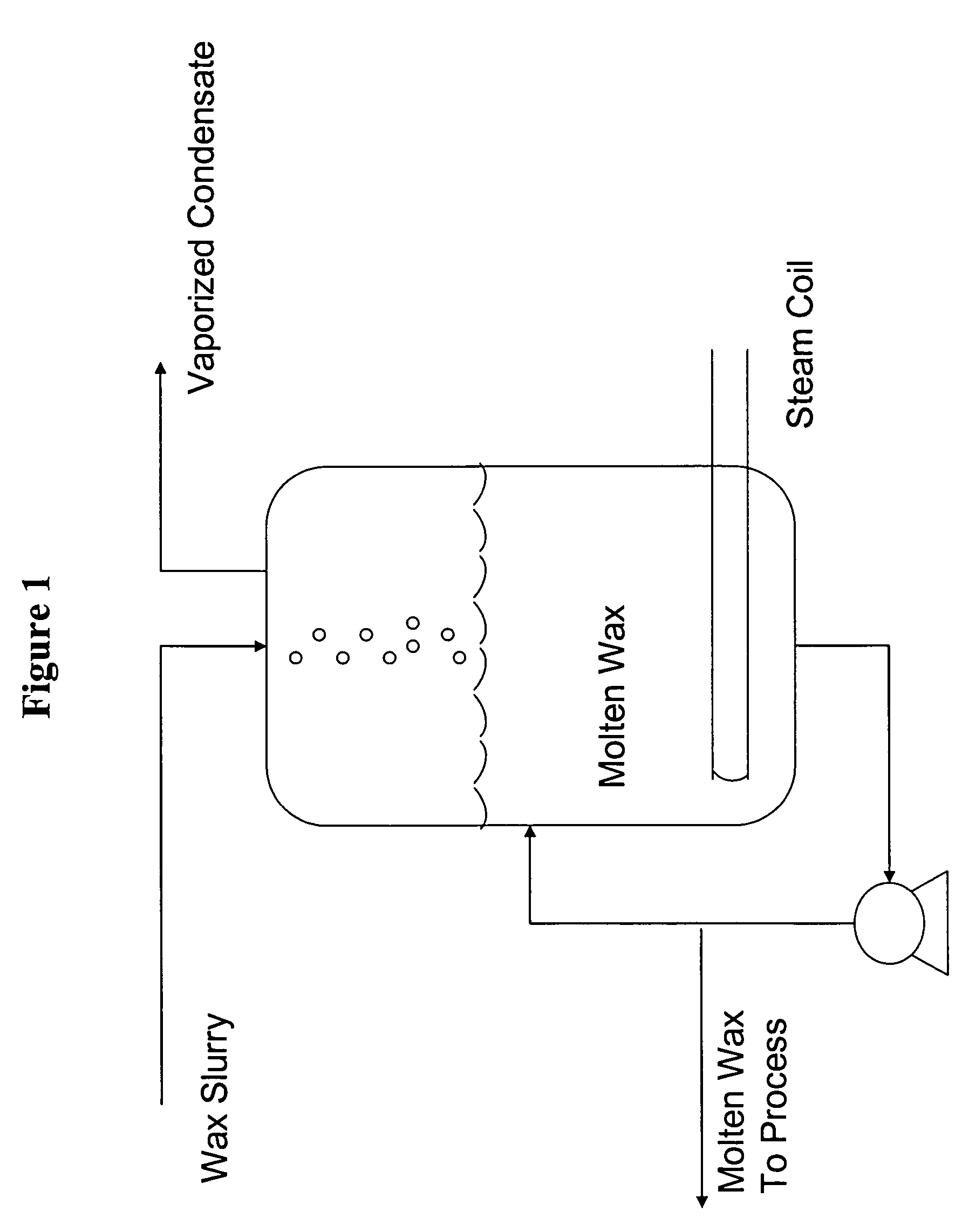

Wax residue treating method and system

InactiveCN105542855AFull recoveryAvoid wastingWax physical treatmentHydrocarbon oils treatmentWaxEconomic benefits

The invention provides a wax residue treating method and system. The method comprises the steps of 1, heating wax residues to enable wax in the wax residues to stay molten; 2, conducting high-temperature separation on the heated wax residues to obtain molten wax and solid residues; 3, conducting incineration disposal on the solid residues. Through melting and high-temperature separation of wax in the wax residues, recovery of wax in the wax residues is achieved, waste of the wax resource is avoided greatly based on environment-friendly discharge of the wax residues, and economic benefits are increased.

Owner:BEIJING KINGTECH SCI & TECH CO LTD

Method for preparing waterproofing agent of saponin-free cation paraffin emulsion artificial board

InactiveCN101649224AHigh molecular weightImprove hydrophobicityOther chemical processesWax physical treatmentParaffin waxFiber

The invention discloses a method for preparing a waterproofing agent of a saponin-free cation paraffin emulsion artificial board. The method comprises the following steps: under the function of a cosolvent which can be mutually soluble to water, taking vinyl monomers, such as styrene, an acrylate class monomer, a cation monomer, acrylamide and a derivative thereof and the like, as a copolymerization monomer and preparing a saponin-free benzene polymer with strong cation charges by a saponin-free emulsion polymerization method; taking the saponin-free benzene polymer as a high molecular emulsifying agent of solid paraffin, emulsifying and dispersing the paraffin and preparing the waterproofing agent of the saponin-free cation paraffin emulsion artificial board with favorable stability by homogenizing at high pressure. The invention overcomes the defects of poor waterproof effect, poor stability, easy bubbling of emulsion and the like due to the addition of a small molecular emulsifyingagent in the traditional paraffin emulsion; the product adopts the saponin-free benzene polymer with strong cation charges as the high molecular emulsifying agent of the solid paraffin, and the high molecular emulsifying agent which can generate a very strong hydrogen bond function with fibre in the artificial board not only enhances the water resistance of a board material but also can enhance the physical strength of the artificial board.

Owner:SHAANXI UNIV OF SCI & TECH

Paraffin wax emulsions modified with petroleum resin and method of manufacturing the same

The invention relates to the wax emulsion which uses the petroleum resin to modify and contains the paraffin wax, the petroleum resin, the oxidized wax, the paraffin emulsifier and water. The components are 2 per cent to 30 per cent paraffin wax, 2 per cent to 30 per cent the petroleum resin, 0.4 per cent to 12 per cent oxidized wax, 0.6 per cent to 12 per cent paraffin emulsifier and 16 per cent to 95 per cent water. The process steps of the preparation method are that (1) the raw materials are put in a high-pressure reactor and heated to about 100 DEG C. to melt; (2) the raw materials are stirred evenly at the speed of 400r / min; (3) half of the total water is heated to 95 DEG C. and poured with oil phase, and then is stirred at the speed of 800r / min to 1200r / min and emulsified for 10min to 30min; (4) the other half of the total water is added in the emulsified liquid at the normal temperature without heating and continuously stirred, and then reduces temperature to 40 DEG C. to discharge to produce the wax emulsion modified by the petroleum resin. The positive effect of the invention is that the wax emulsion modified by the petroleum resin can significantly improve the adhesion, the water resistance and the acid and alkaline resistance of the wax mask and greatly expand the properties and the purposes.

Owner:EAST CHINA UNIV OF SCI & TECH

Cationic emulsified wax and its prepn

InactiveCN1388222AImprove adsorption capacityUniform film formationWax physical treatmentParaffin waxAntistatic agent

The cationic emulsifier wax includes paraffin, cationic surfactant, coemulsifier and water. It is prepared through the process including smelting and mixing paraffin and coemulsifier in the container with stirrer and heating to emulsifying temperature; heating to dissolve cationic surfactant in water inside one other container and heating to emulsifying temperature to prepare water solution of surfactant; adding the water solution of surfactant slowly into reactor while stirring for some period; cooling while stirring to room temperature and packing the product. The product may be stored stably for at least 60 days. It may be used as antistatic agent and softening agent for fabric.

Owner:EAST CHINA UNIV OF SCI & TECH

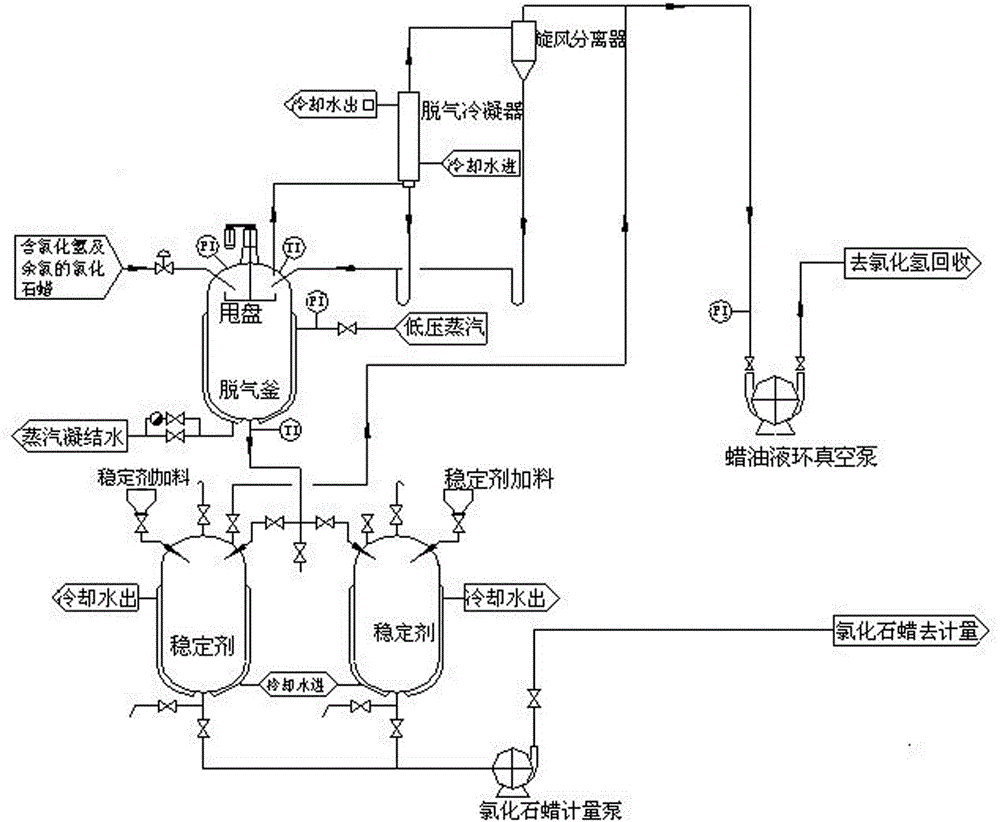

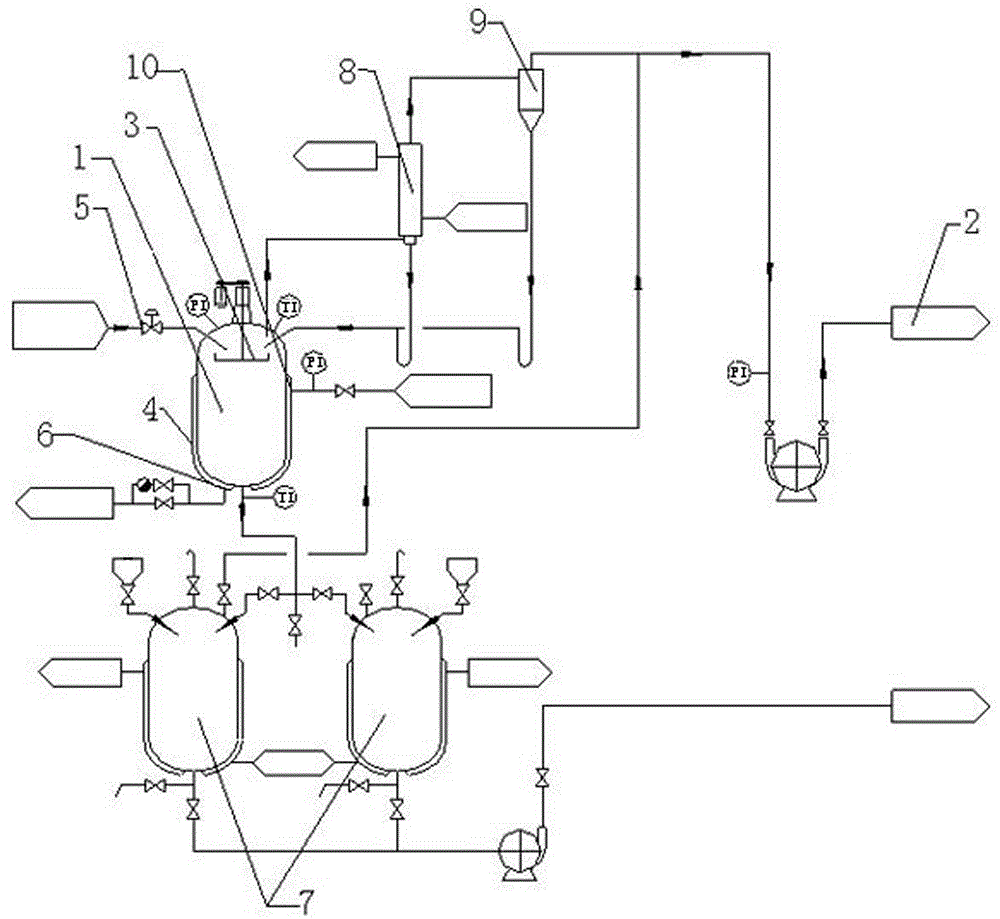

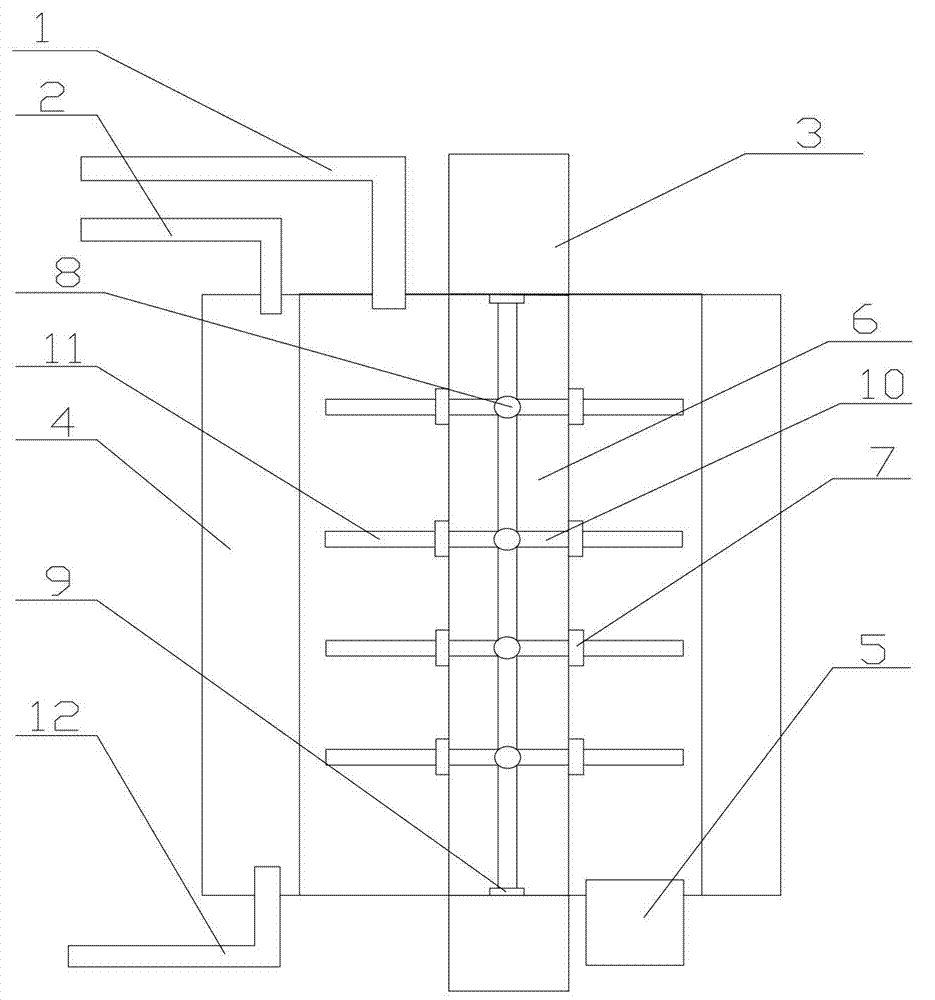

Method and device for removing hydrogen chloride and residual chlorine from liquid chlorinated paraffin

ActiveCN104415580AReduce partial pressureEvenly arrangedLiquid degasificationWax physical treatmentChlorinated paraffinsHydrogen chloride

The invention relates to a method for removing hydrogen chloride and residual chlorine from liquid chlorinated paraffin, which comprises the following steps: (1) turning on a vacuum device, vacuumizing a degassing kettle; (2) turning on a throwing disc of the degassing kettle; (3) injecting steam or heat transfer media into the jacket of the degassing kettle; (4) opening a liquid chlorinated paraffin feed valve on the degassing kettle, allowing the liquid chlorinated paraffin to flow into the rotating throwing disc; (5) heating the chlorinated paraffin liquid film during continuous falling through the degassing kettle jacket; (6) allowing the liquid chlorinated paraffin with hydrogen chloride and residual chlorine removed to flow out from the bottom of the degassing kettle, adding a stabilizing agent into the liquid chlorinated paraffin with hydrogen chloride and residual chlorine removed, stirring uniformly, and metering by a chlorinated paraffin metering pump. The method is simple in process, easy to control, continuous in production, large in productivity, simple in equipment investment, stable in quality of the prepared product, and easy for tail gas treatment, can continuously and automatically remove a large amount of hydrogen chloride and residual chlorine in liquid chlorinated paraffin, and guarantee the continuous production of liquid chlorinated paraffin.

Owner:DANYANG CITY AUX CHEM PLANT

High stability emulsified wax producing method

InactiveCN1306012CReduce energy consumptionReduce technical difficultyWax physical treatmentParaffin waxEmulsion

A process for preparing high-stability emulsified paraffin wax is characterized by that the paraffin wax is emulsified by cationic surfactant as emulsifier in weakly acidic condition. The resultant paraffin wax emulsion has features of high stability, flowability and content of paraffin wax, and fine granularity.

Owner:TAISHAN UNIV

Fischer-Tropsch wax composition and method of transport

InactiveUS7479216B2Efficient transportMaintain stabilityWax physical treatmentHydrocarbon purification/separationParaffin waxAlcohol

The present invention relates to transportable product for the transportation of paraffinic wax and methods of transporting using this transportable product. The transportable product comprises 90 to 20 weight % of a liquid comprising >50 weight % alcohol and having a true vapor pressure of ≦14.7 psia when measured at 20° C., and 10 to 80 weight % of wax particles, wherein the wax particles comprise ≧75 weight % of wax particles larger than 0.1 mm. The transportable product and methods of transporting according to the present invention are able to accommodate a relatively high weight % of paraffinic wax particles in the transportable product while avoiding interparticle adhesion and clumping by ensuring that the wax particles are not too small and the amount of small wax particles is not excessive.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Self-emulsifying paraffin wax and its preparing process

A self-emulsifying paraffin wax is prepared from modified paraffin wax (70-90 wt.%), emulsifier (5-20 wt.%) and surfactant (1.2-20 wt.%) through fusing said modified paraffin wax and emulsifier, mixing them together and cooling. It is characterized by that when it is dissolved in hot water, a stable emulsion is generated.

Owner:EAST CHINA UNIV OF SCI & TECH

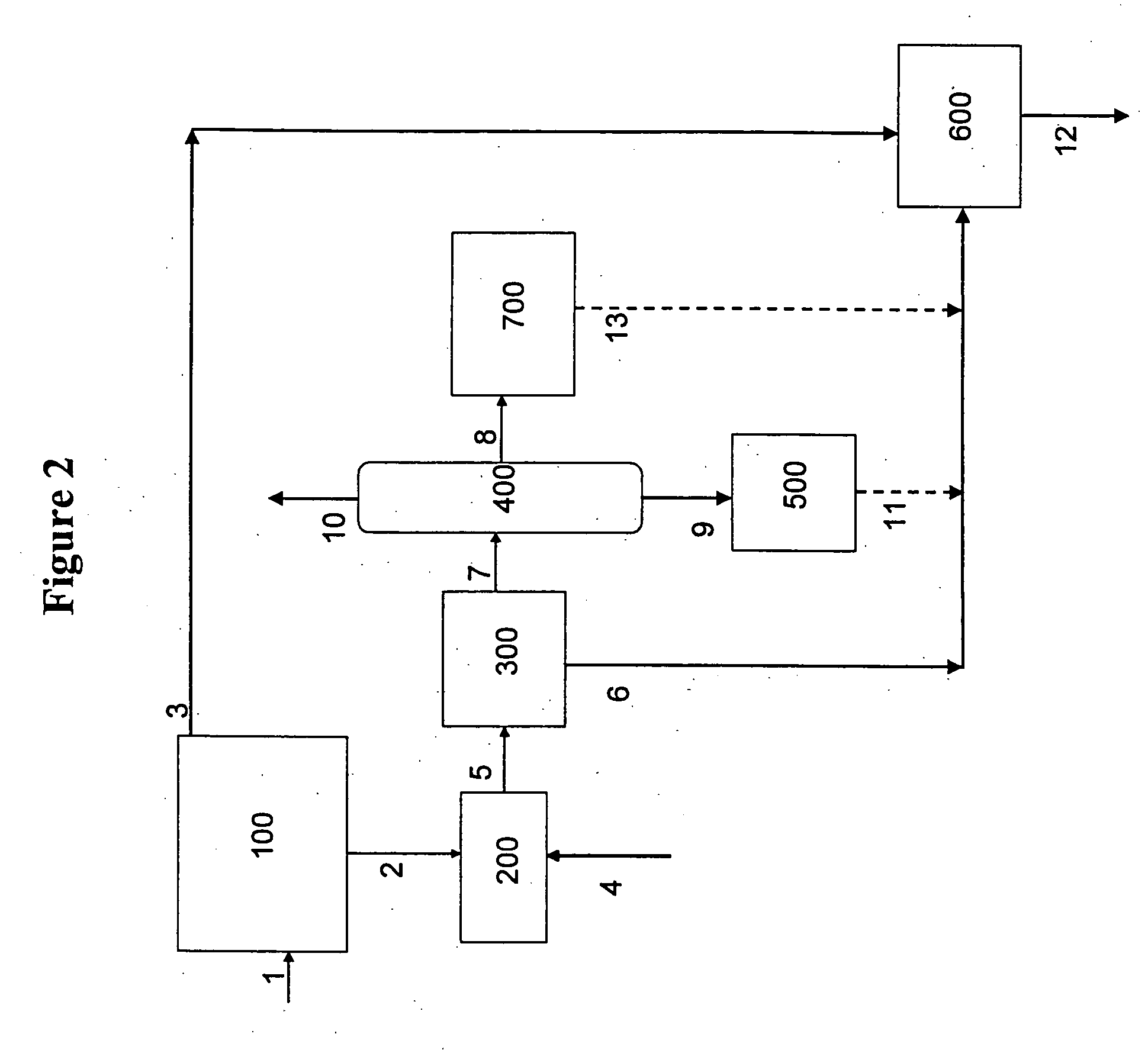

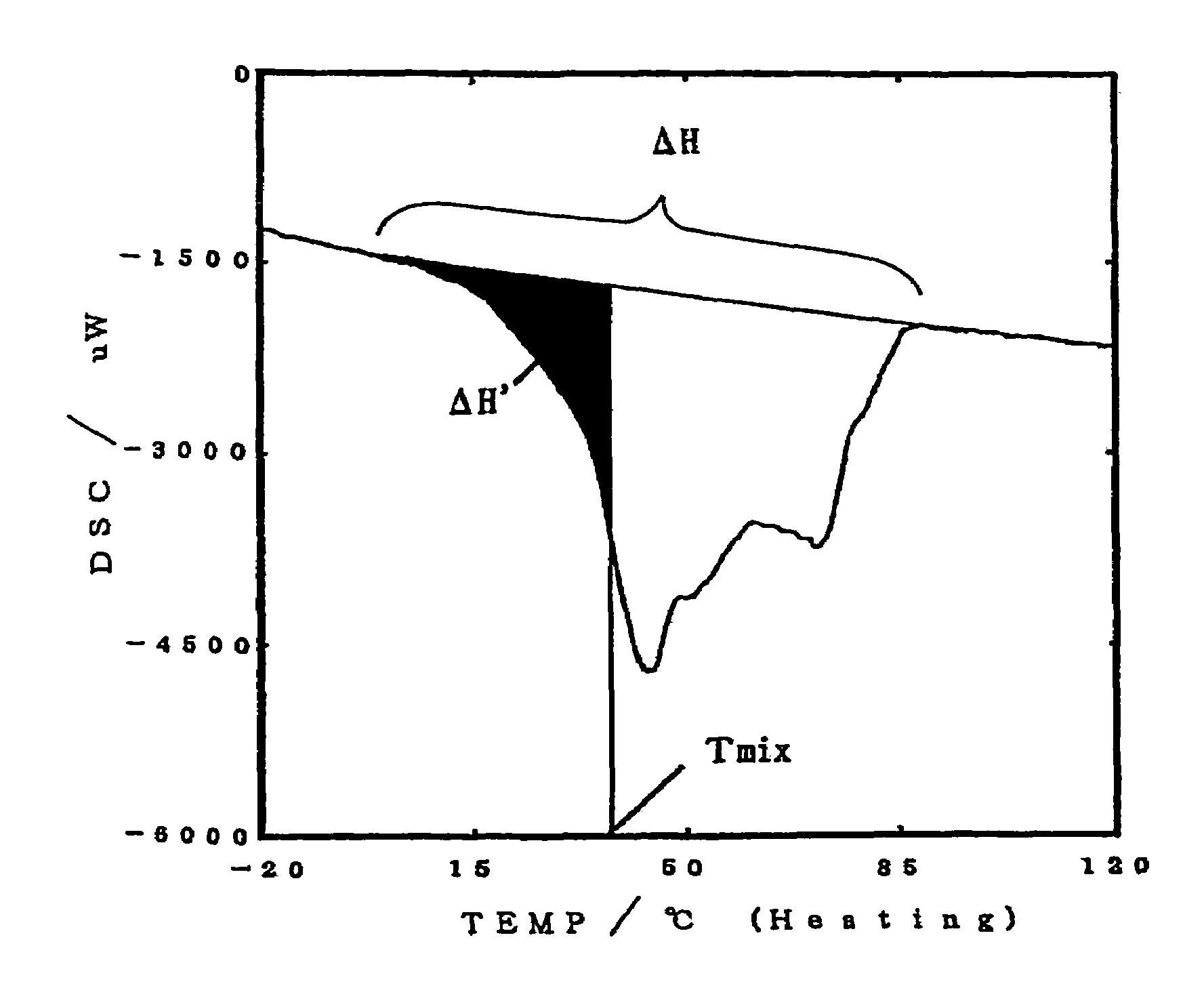

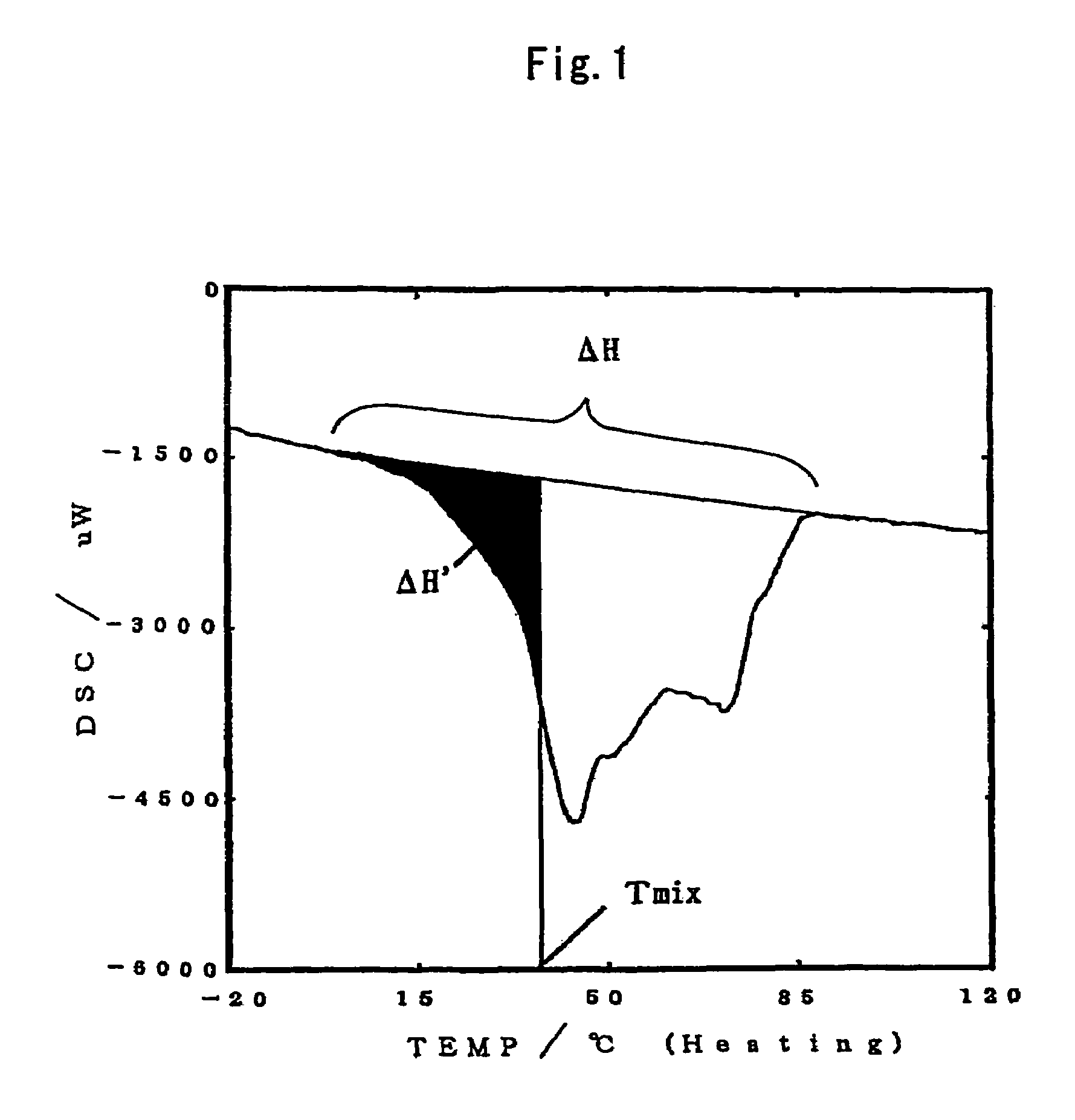

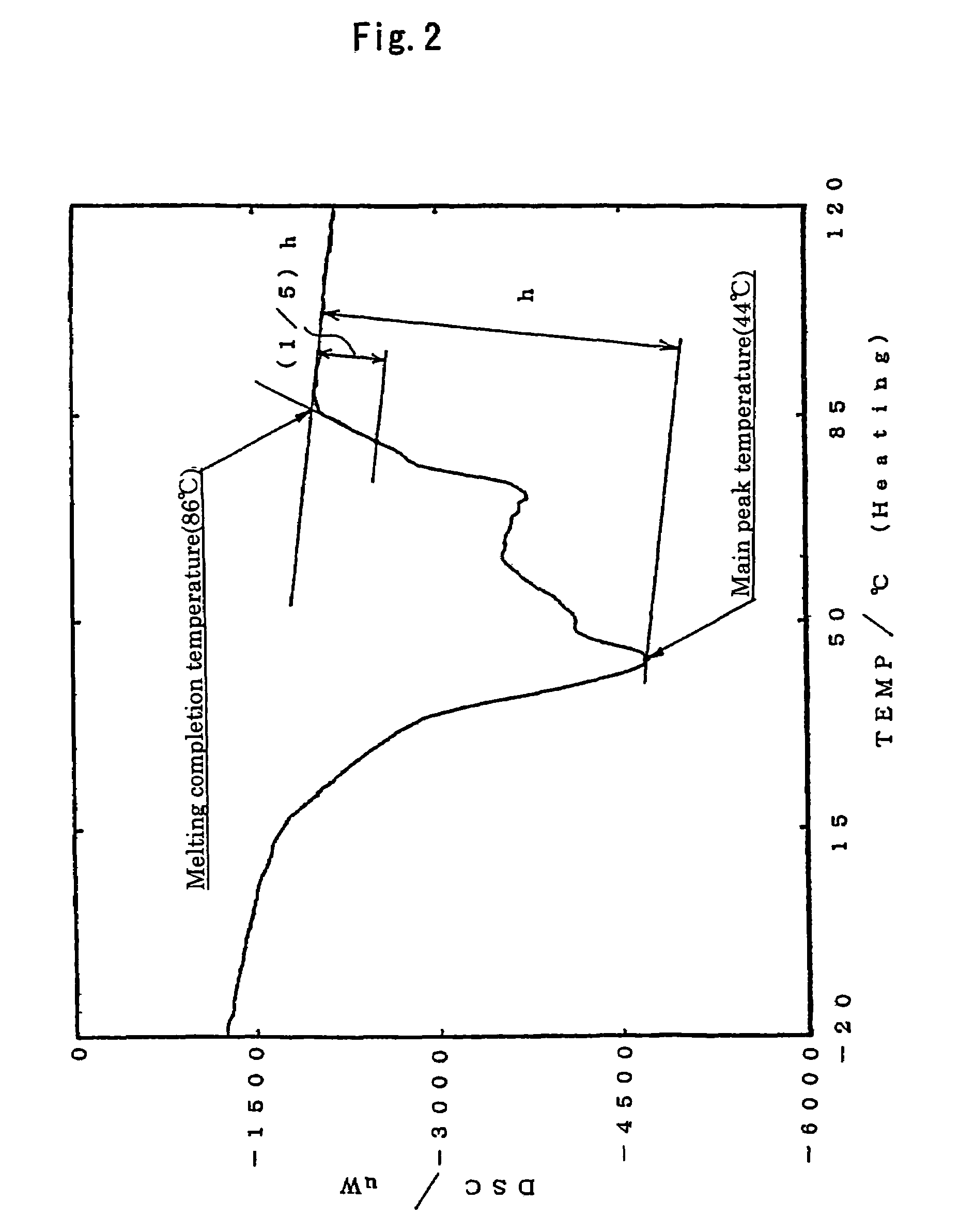

Preparation method of high latent heat phase change material

ActiveCN107513374AEasy dischargeEasy to separateWax physical treatmentPetroleum wax refiningSolid componentDistillation

The invention discloses a preparation method of a high latent heat phase change material. The preparation method comprises carrying out hydro-conversion on an F-T synthesis product as a raw material under action of a catalyst, carrying out distillation on the hydrogenation product to obtain a sweating raw material for a distillation range and carrying out emulsification and sweating to obtain a desired product. Based on the ordinary sweating method, a high temperature keeping stage at an appropriate temperature is used in the cooling process and airflows pass through a wax layer and carry away a liquid component in the sweating process so that the separation effects on a solid component and the liquid component is improved and a separation rate is accelerated, and preferably, the raw materials and a solution of a substance decomposable into gas are emulsified so that the liquid component can be fast discharged and the sweating method without solvent separation can produce the high latent heat phase change material. The method has the advantages of low equipment investment, simple production process, low operation cost, safety, energy saving and no solvent pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing a series of phase change wax products

ActiveCN110628391AChemically stableNot corrosiveWax physical treatmentPetroleum wax refiningPhase change enthalpyCarbon number

The invention discloses a method for producing a series of phase change wax products. The method comprises: refining a Fischer-Tropsch synthetic wax raw material through a hydrogenation reaction to obtain a Fischer-Tropsch refined wax; carrying out pressure reducing distillation on the Fischer-Tropsch refined wax; and separating continuous distillates with distillation range of 5-30 DEG C by continuously increasing the operation temperature to obtain a series of phase change wax products, wherein the pressure of the pressure reducing distillation is 0-1000 pa, the tower top operation temperature is 120-260 DEG C, and the phase change enthalpy value of the series of phase change wax products is larger than or equal to 170 J / g. According to the method of the invention, various trademark phase change wax products with the melting points of 5-80 DEG C can be separated from the Fischer-Tropsch refined wax, the carbon number of the products is concentrated, the enthalpy value is high, and the process is high in flexibility, can achieve customization according to needs, is low in production cost, and is suitable for industrial production.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Multifunctional emulsifying wax and preparation method thereof

The invention discloses multifunctional emulsifying wax and a preparation method thereof. The application field of the emulsifying wax can be expanded. The emulsifying wax comprises the following chemical components: carnauba wax, microcrystalline wax, a compound emulsifier, a compound thickener, a defoamer and deionized water. The preparation method of the emulsifying wax comprises the following steps: according to the chemical components of the emulsifying wax, firstly putting the carnauba wax and the microcrystalline wax in a reactor in a constant temperature water bath; starting a stirrer to stir the wax at a low speed till the wax is fully melted; slowly adding the compound emulsifier, the compound thickener and the defoamer; then adding the balance of boiled water; then stirring at a low speed and removing the water bath; continuously stirring the wax till the emulsion is cooled to room temperature. The multifunctional emulsifying wax disclosed by the invention has the characteristics of being multifunctional, low in production cost, convenient to use, free of environmental pollution and low in foam content, further has relatively excellent anti-rust performance, stability performance, temperature-resisting performance and surface smoothness compared with those of similar products in the using process, and has the advantages of being good in mobility, salt fog resistance, humidity resistance and the like.

Owner:UNIV OF SCI & TECH LIAONING

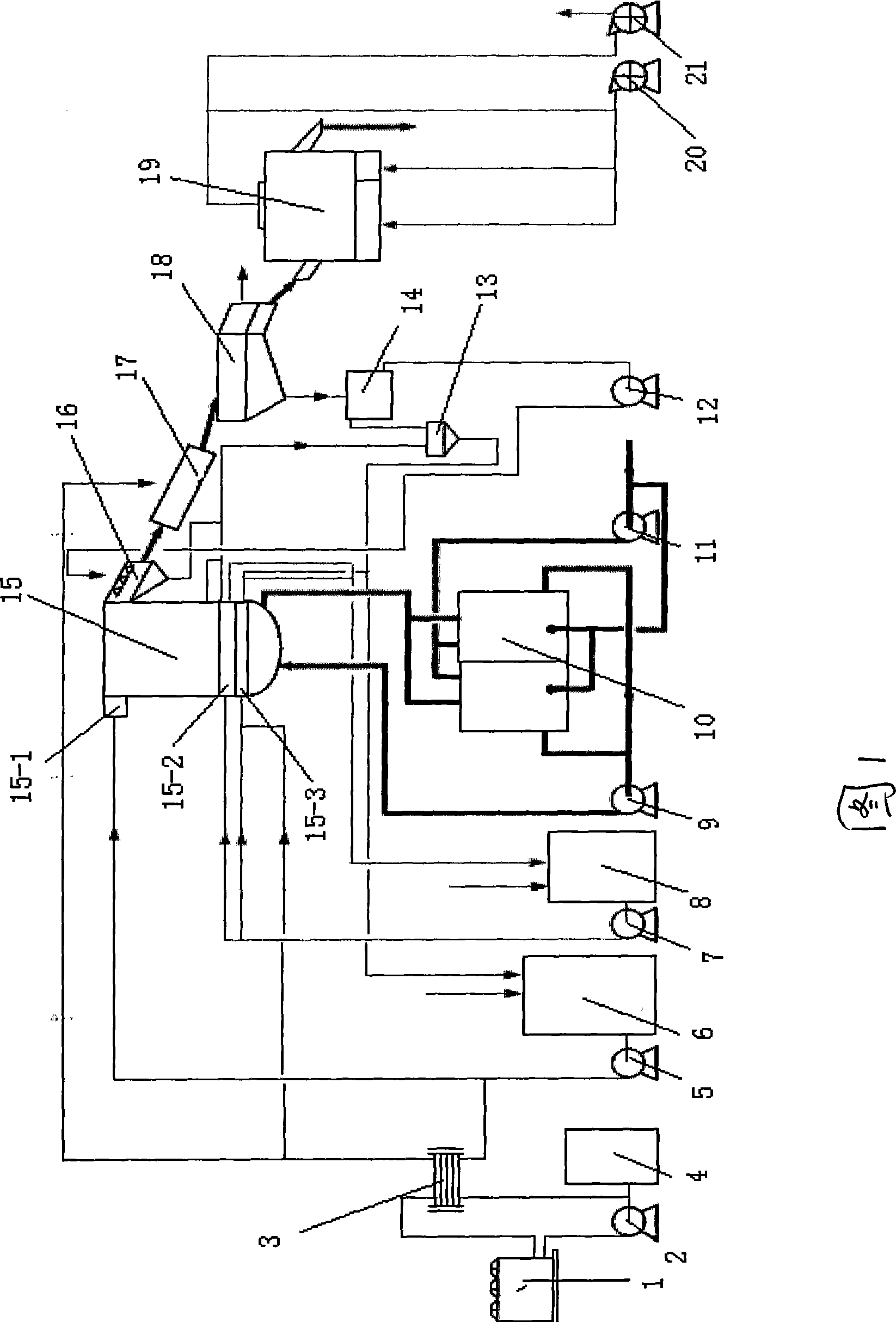

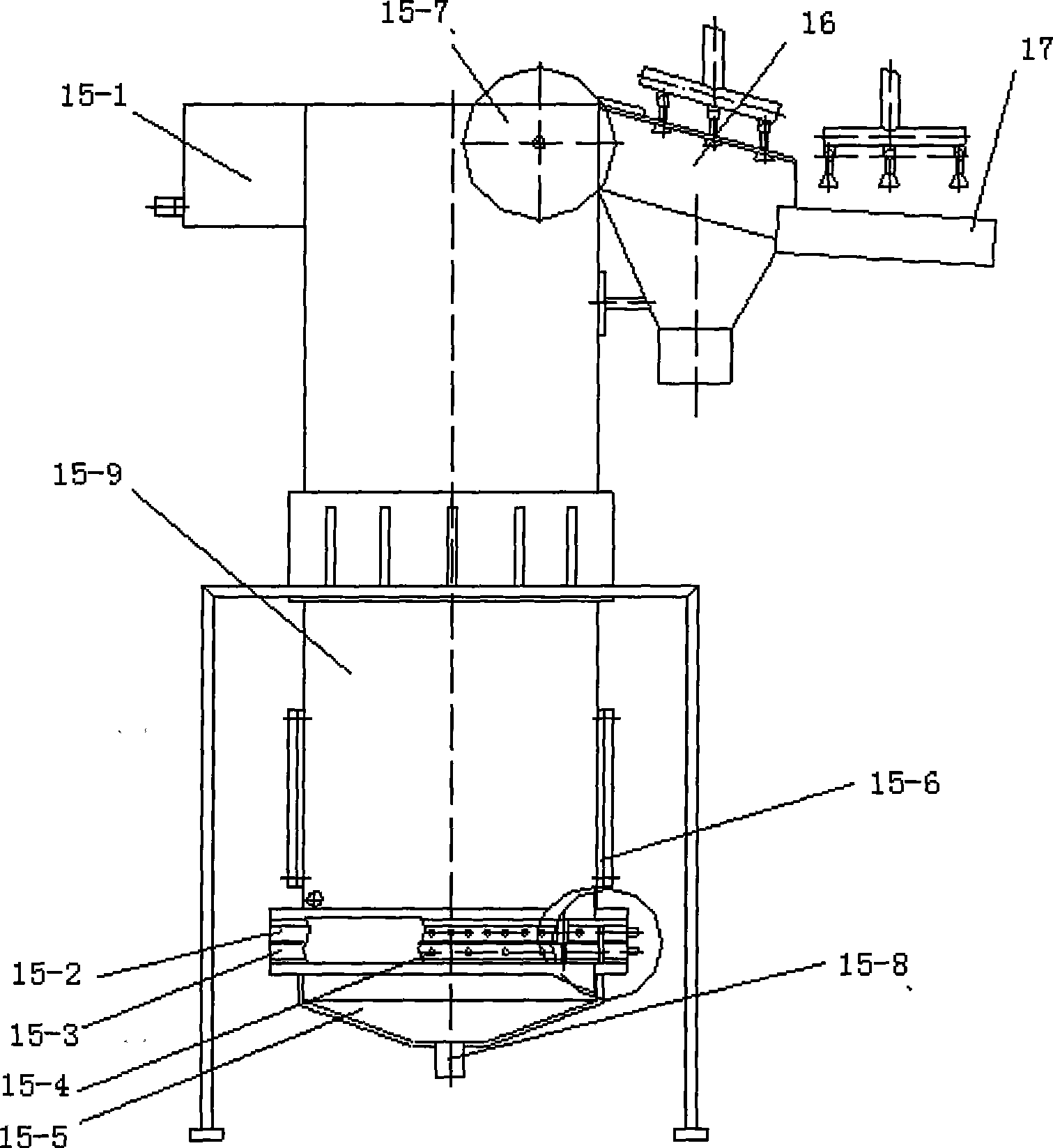

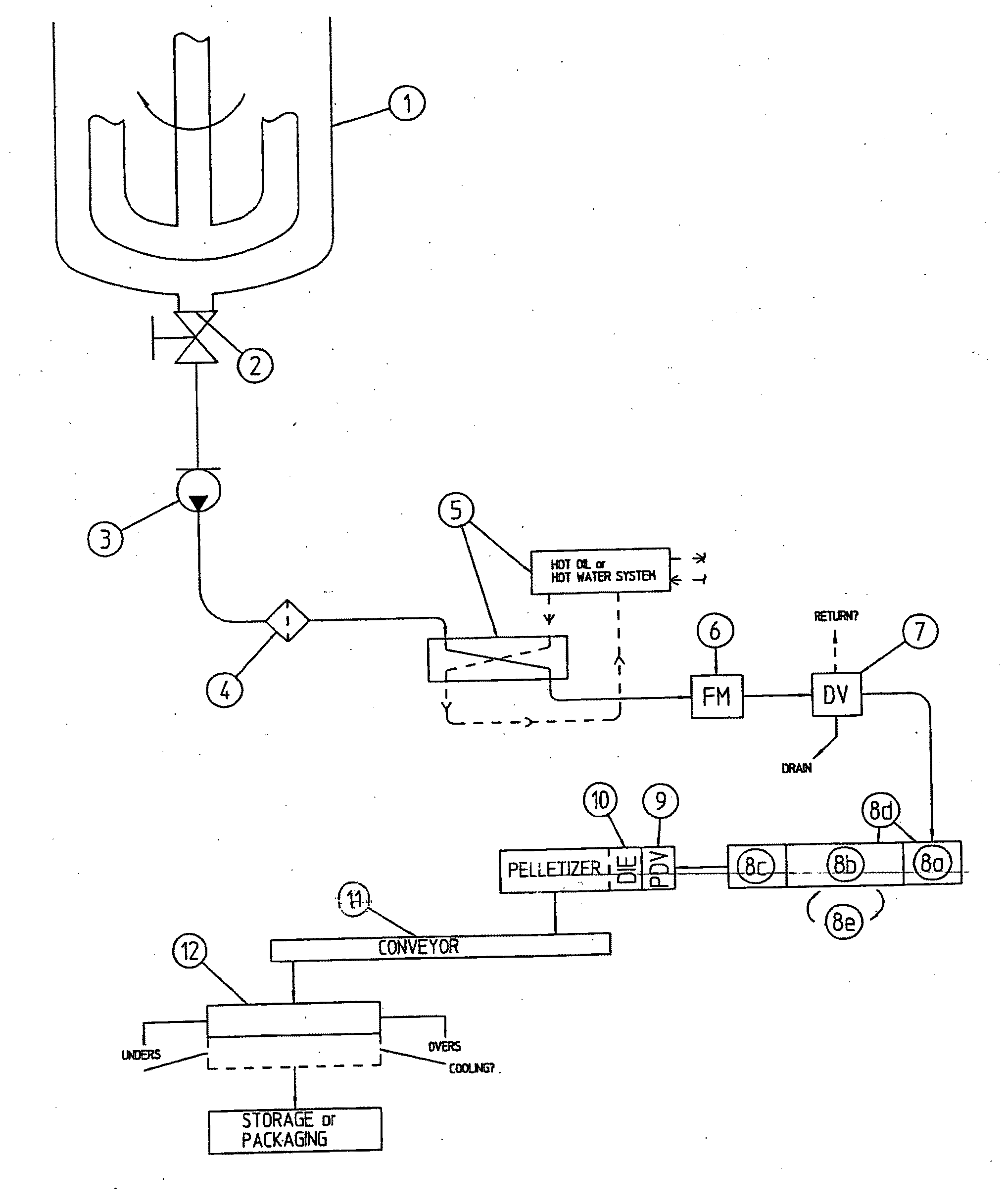

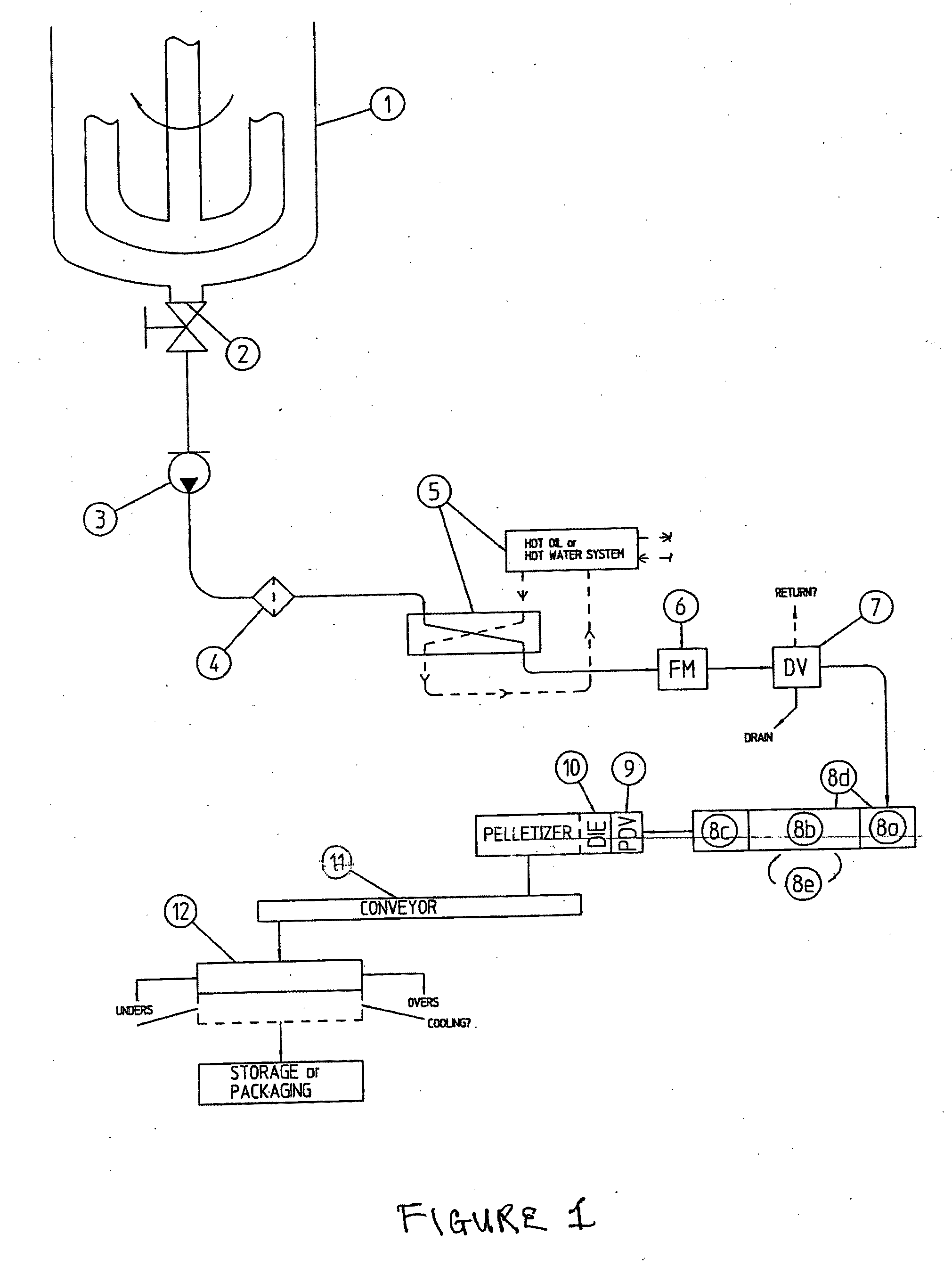

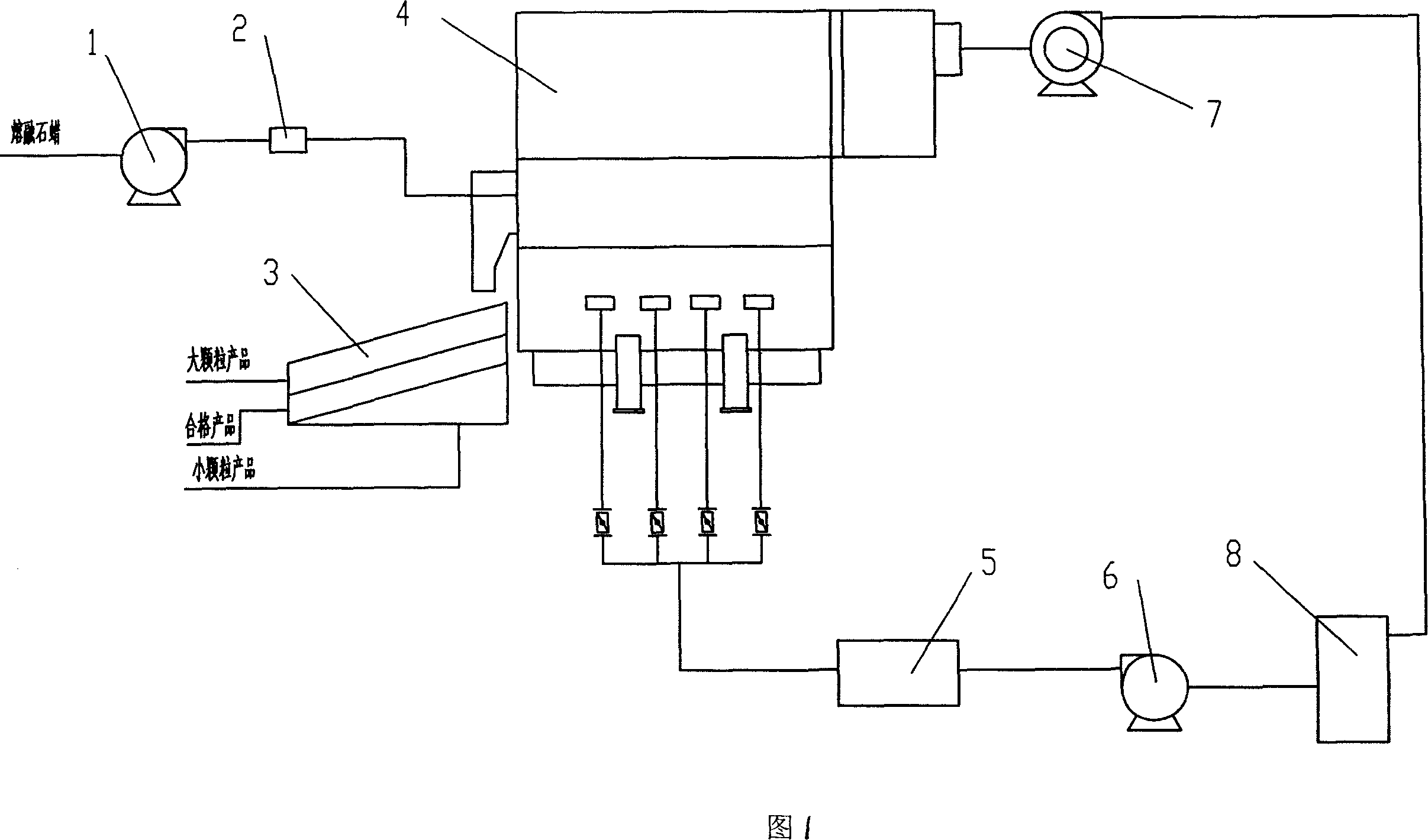

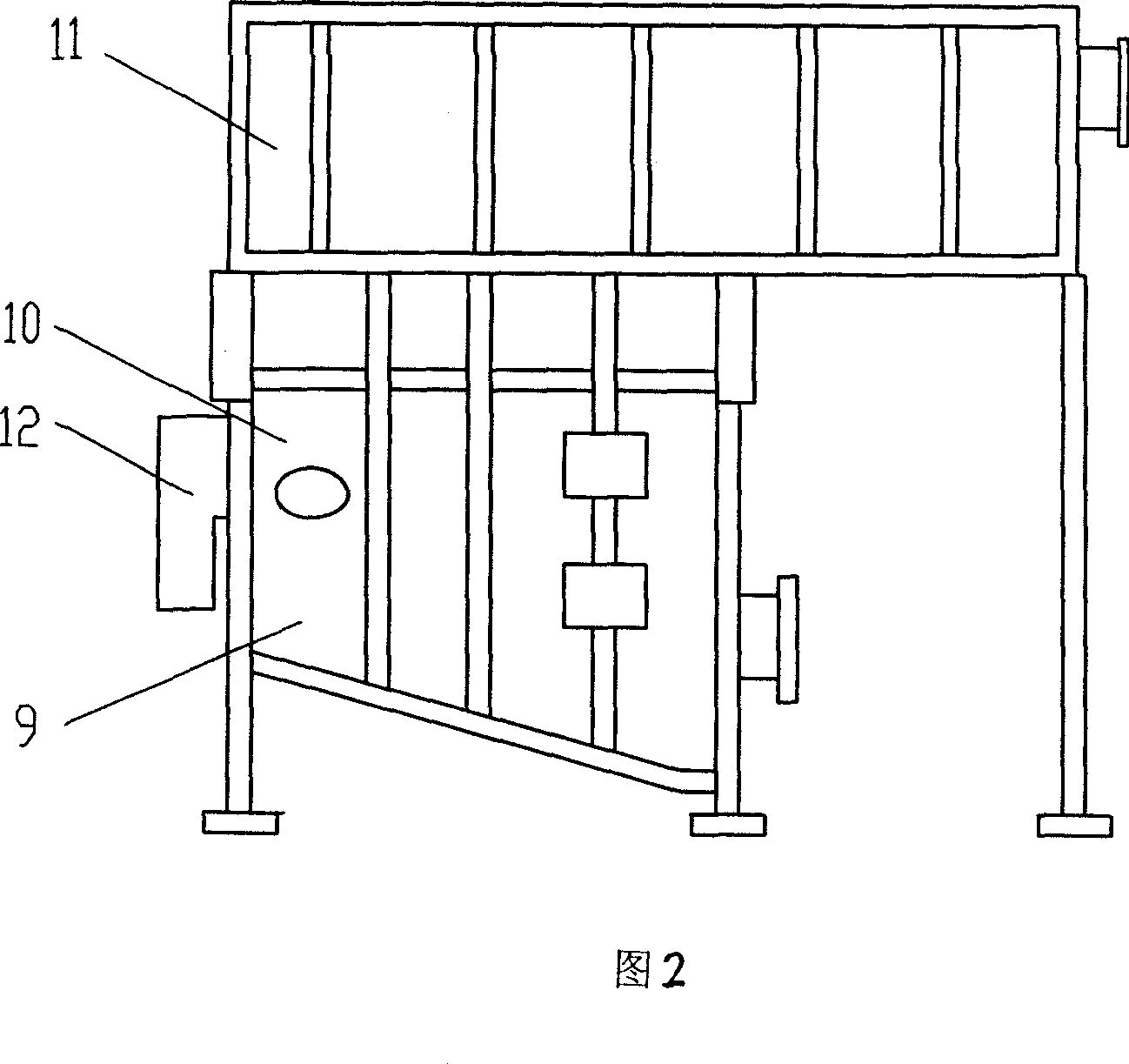

Paraffin granulation underwater production method

ActiveCN101397512AGuaranteed uptimeSatisfy the requirements of granular wax moldingWax physical treatmentParaffin waxAir blower

The invention relates to a production method for paraffin wax underwater granulation, which comprises the following steps: liquid wax is sprayed out of the lower part of a granulator through nozzles of a switch board and a heated board, solidified into solid wax in demineralized water, subjected to spraying, draining and air drying, and then solidified into finished products; hot demineralized water is respectively driven into the switch board and the heated board of the granulator, and the temperature is controlled; the demineralized water is returned to a circulating tank through the granulator and a filter tank, sprayed downwards above a cooling chute as second spray water through heat exchange, partially overflows into the filter tank through a draining sieve and a cold water buffer tank and returned to the circulating tank, and partially serves as first spray water through the cold water buffer tank; the water coming from a refrigerator is returned for circulation after heat exchange with circulating water through a heat exchanger; hot air supplied by an air blower respectively enters the front half part and the rear half part of air dryer, waste air is discharged outdoor from the top of the air dryer through an induced draft fan, granular wax is regular spherical particle with the grain size of 3-5mm, pelletization qualification rate is more than 95 percent, and energy consumption of the system operation is lower than that of the existing water cooling steel belt granulation technology.

Owner:PETROCHINA CO LTD

Fischer-tropsch wax composition and method of transport

InactiveUS7488411B2Efficient transportMaintain stabilityWax physical treatmentSolid fuelsParaffin waxPolymer chemistry

The present invention relates to transportable product for the transportation of paraffinic wax and methods of transporting using this transportable product. The transportable product comprises 90 to 20 weight % of a liquid comprising ≧50 weight % water and having a pH of >5 and a true vapor pressure of ≦14.7 psia when measured at 20° C., and 10 to 80 weight % of wax particles, wherein the wax particles comprise ≧75 weight % of wax particles larger than 0.1 mm. The transportable product and methods of transporting according to the present invention are able to accommodate a relatively high weight % of paraffinic wax particles in the transportable product while avoiding interparticle adhesion and clumping by ensuring that the wax particles are not too small and the amount of small wax particles is not excessive.

Owner:CHEVROU USA INC

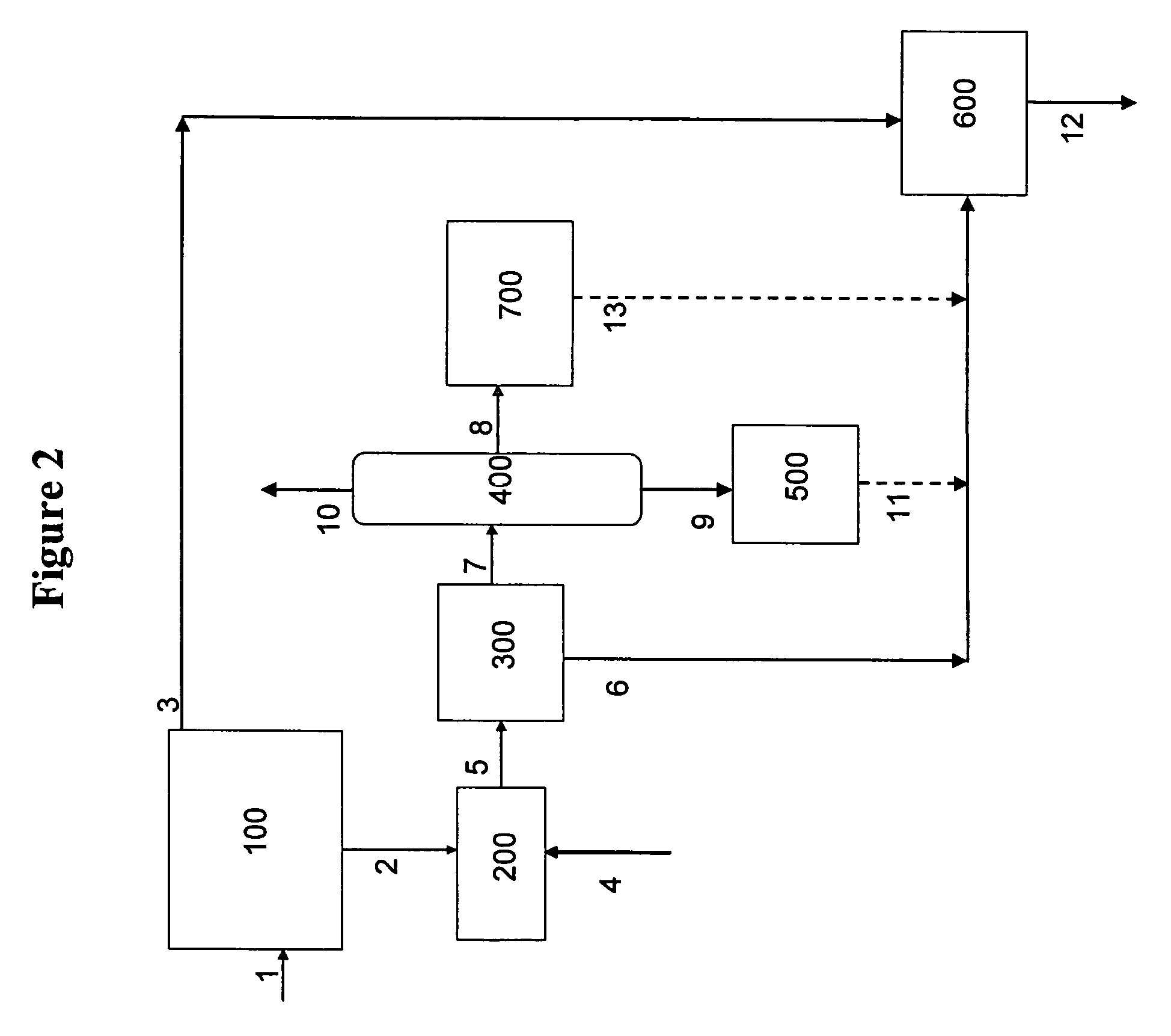

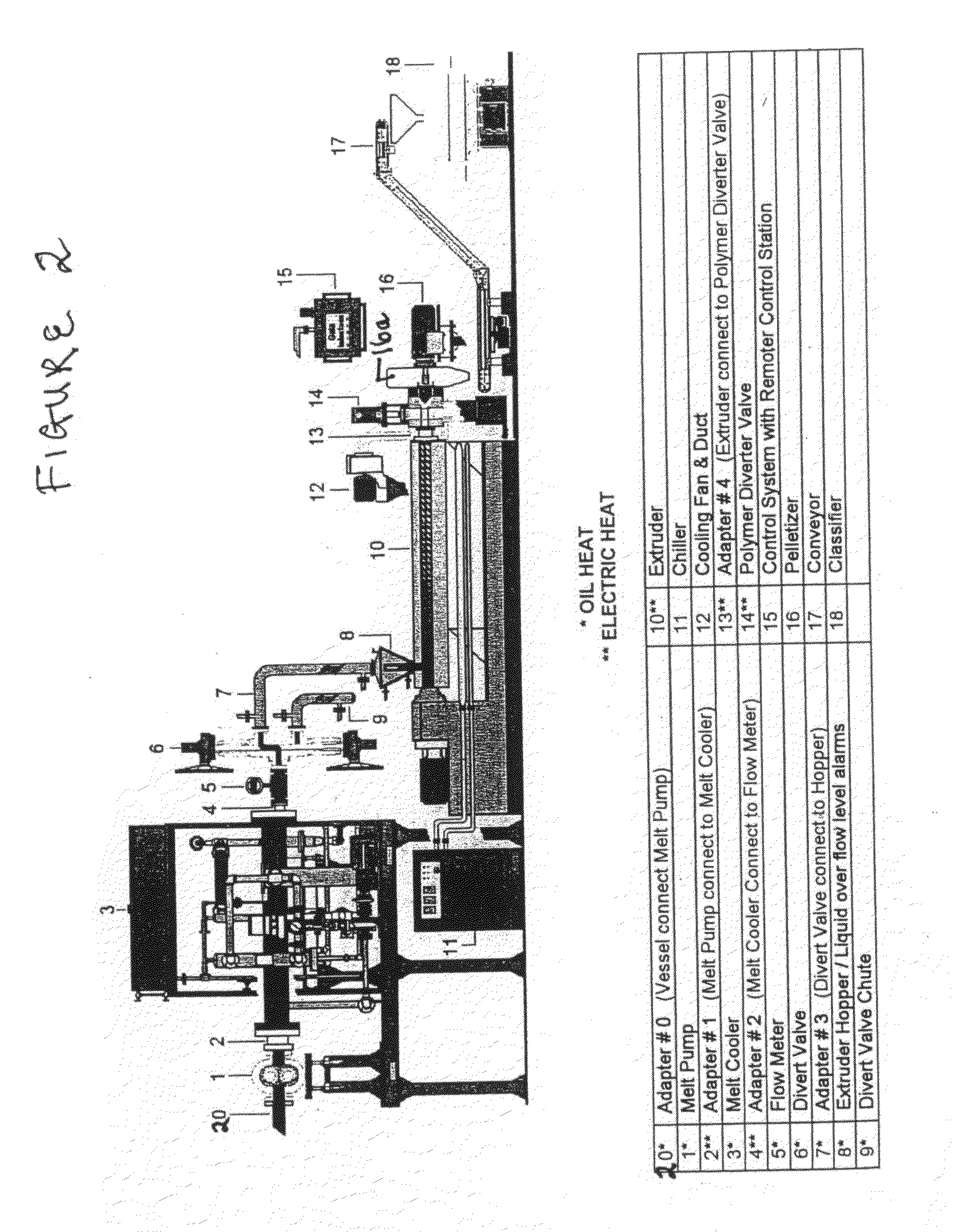

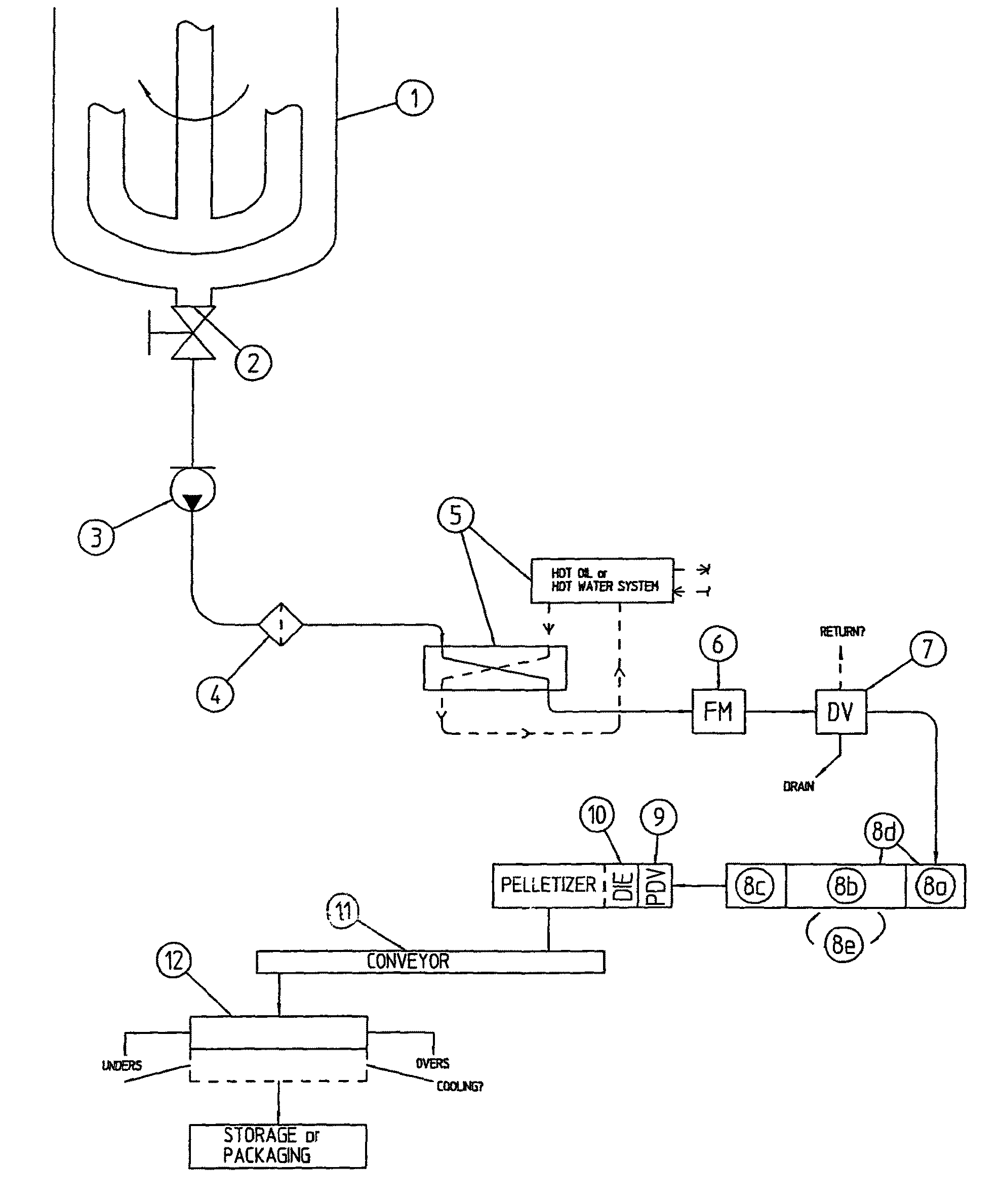

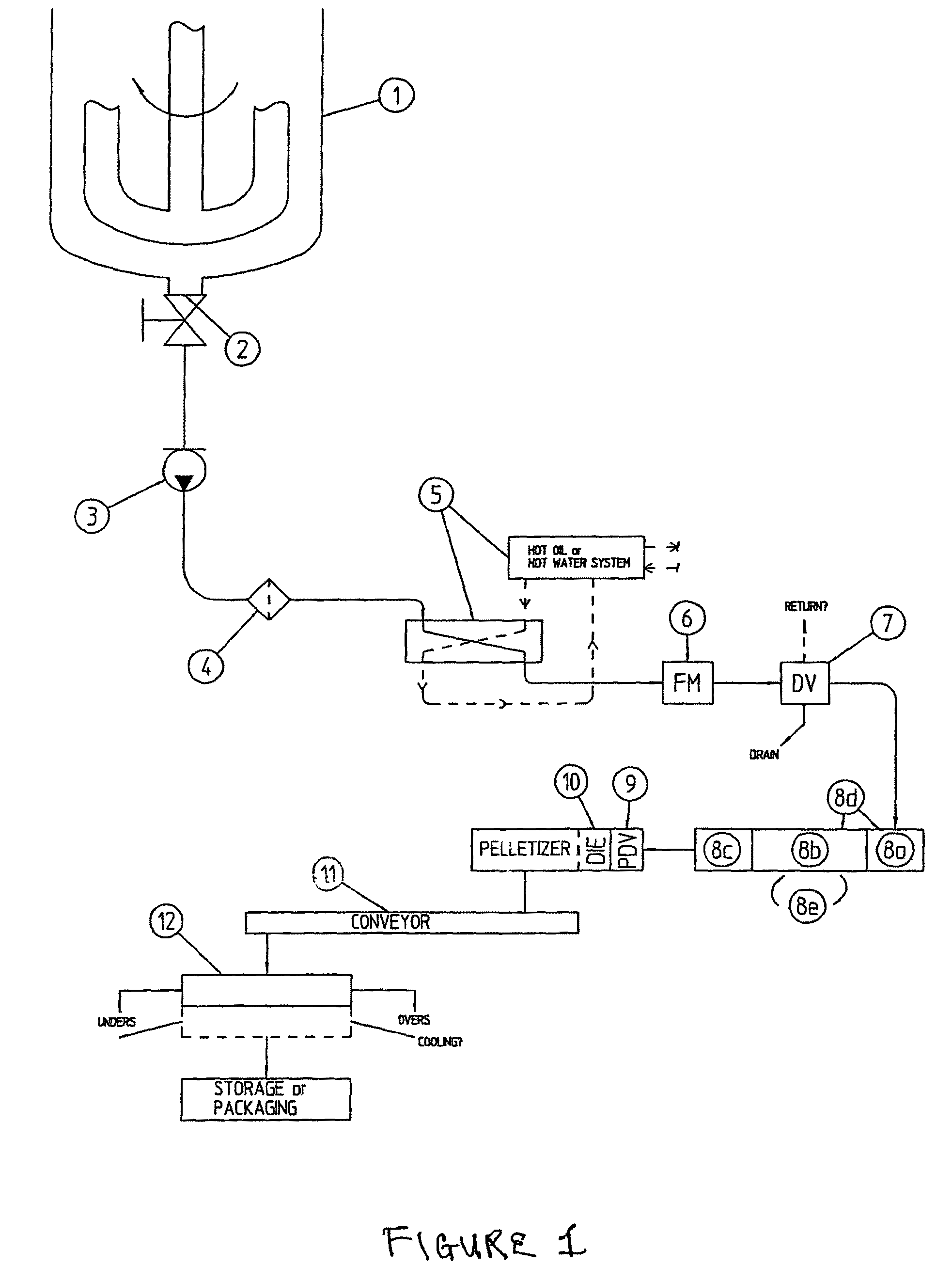

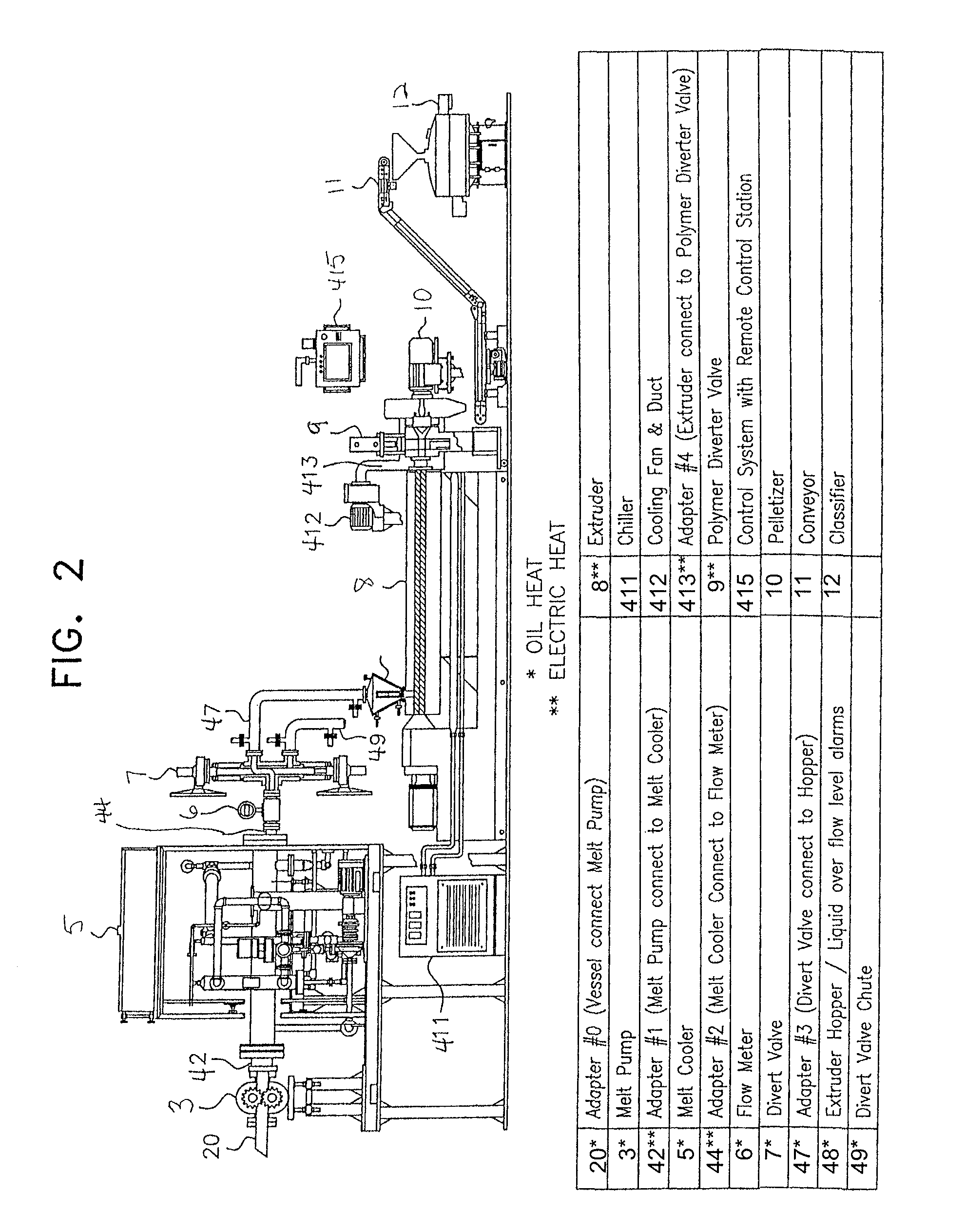

Apparatus and Method for Pelletizing Wax and Wax-Like Materials

InactiveUS20100289170A1Easy to produceReliably producedTailstocks/centresWax physical treatmentWaxHot melt

An apparatus and method for the pelletization of waxes, wax-like and other materials having a sharp melt point include a vessel for forming the wax into a hot molten material. A heat exchanger then cools the molten wax to a temperature just above its melt temperature. The cooled liquid wax is fed to an extruder which further reduces the temperature and mixes the liquid wax into a thoroughly mixed extrudable solid wax. The solid wax is then extruded through die orifices of a die plate into a cutting chamber, and a rotary cutter cooperating with the die face of the die plate cuts the extruded solid wax strands into pellets. The die plate, cutting chamber and rotary cutter can have the same structure as an underwater pelletizer, but operating without water or liquid as a dry face pelletizer. The thus formed wax pellets drop out of the cutting chamber by gravity through an opening in the bottom thereof.

Owner:GALA INDUSTRIES INC

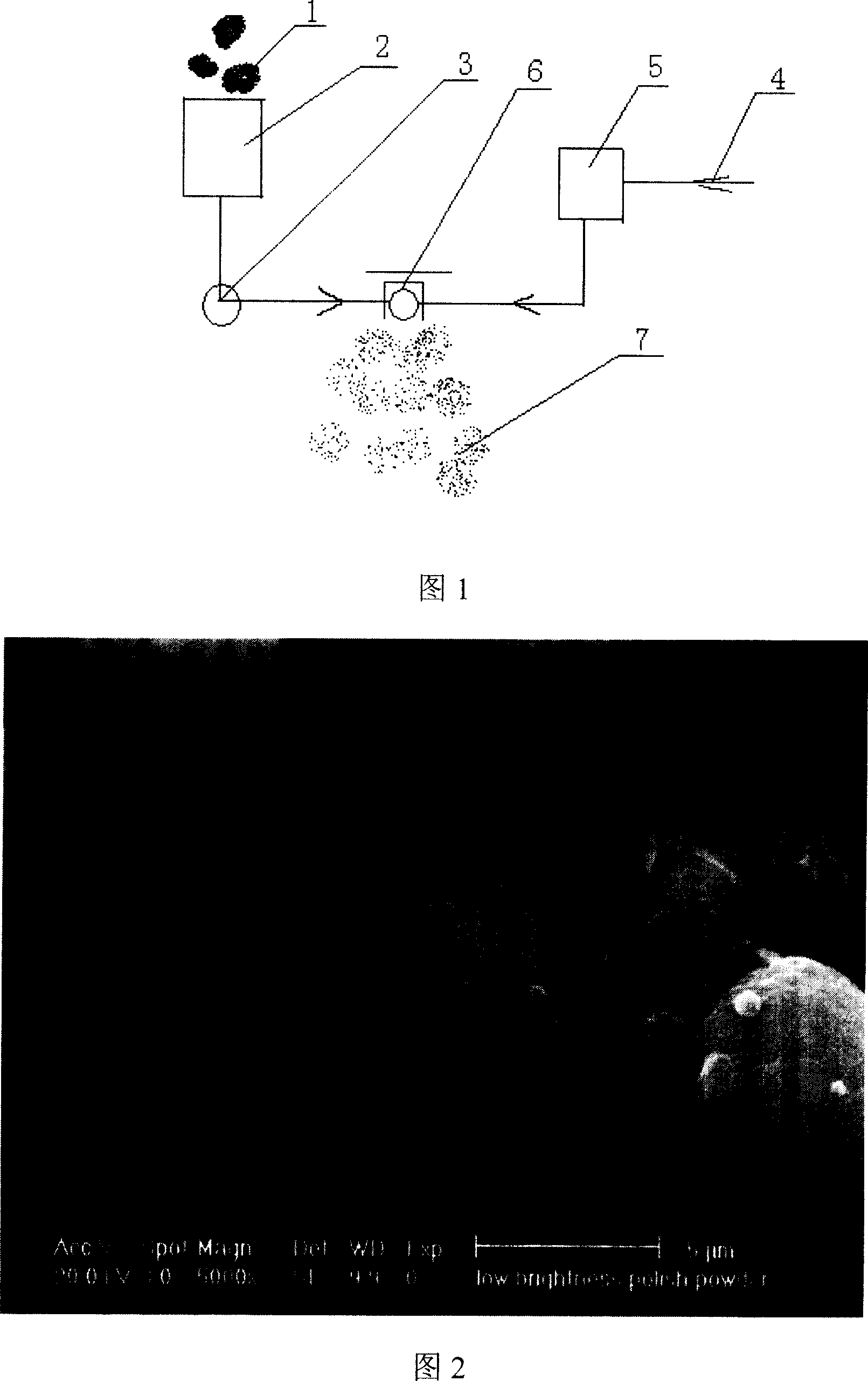

Method of manufacturing spherical micro mist wax

The invention discloses a preparation method of the spheric polymeric wax, which consists of the following steps: a. the granule materials are heated to the molten state in a reactor and continuously raise the temperature to 5 DEG C. to 200 DEG C.; b. the granule materials are extracted from the reactor and are pressed to 0.1MPa to 100MPa by a liquid loading device; c. the pressed air is purified and pressed to 0.1MPa to 20MPa by an air compressor; d. the pressed air meets the molten materials in the environment with temperature lower than the melt temperature and is sprayed to the microaggregate by a granulation plant. The method of the invention has convenient operation, stable material handling, high shaping rate and high finished product yield of the spheric or approximately spheric micro particles. Besides, the prepared polymeric wax is good in dispersion, resistant in scrap wounding and scratch and low in addition, which greatly reduces the cost manufacturer.

Owner:SHANGHAI TONGS SCI & TECH

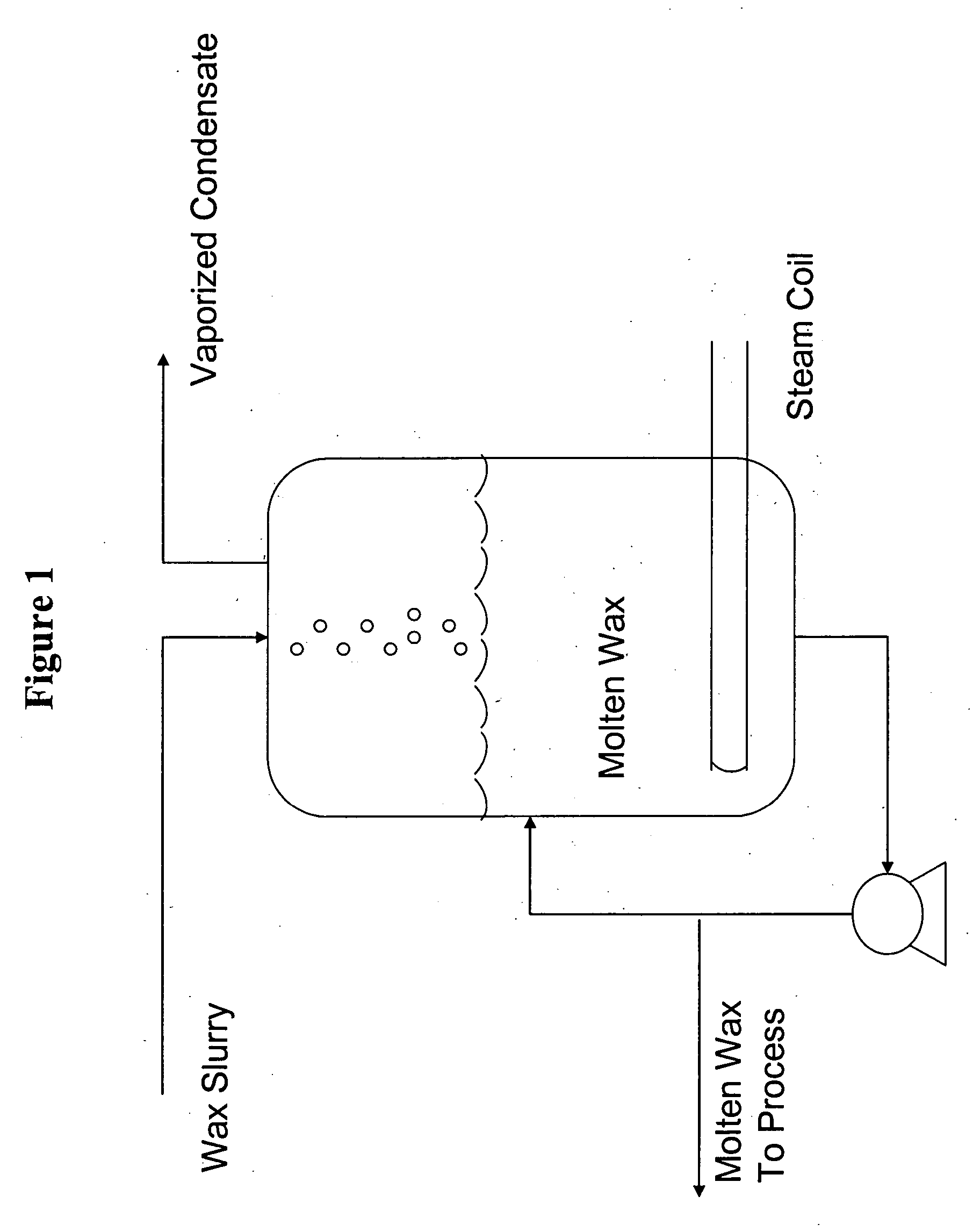

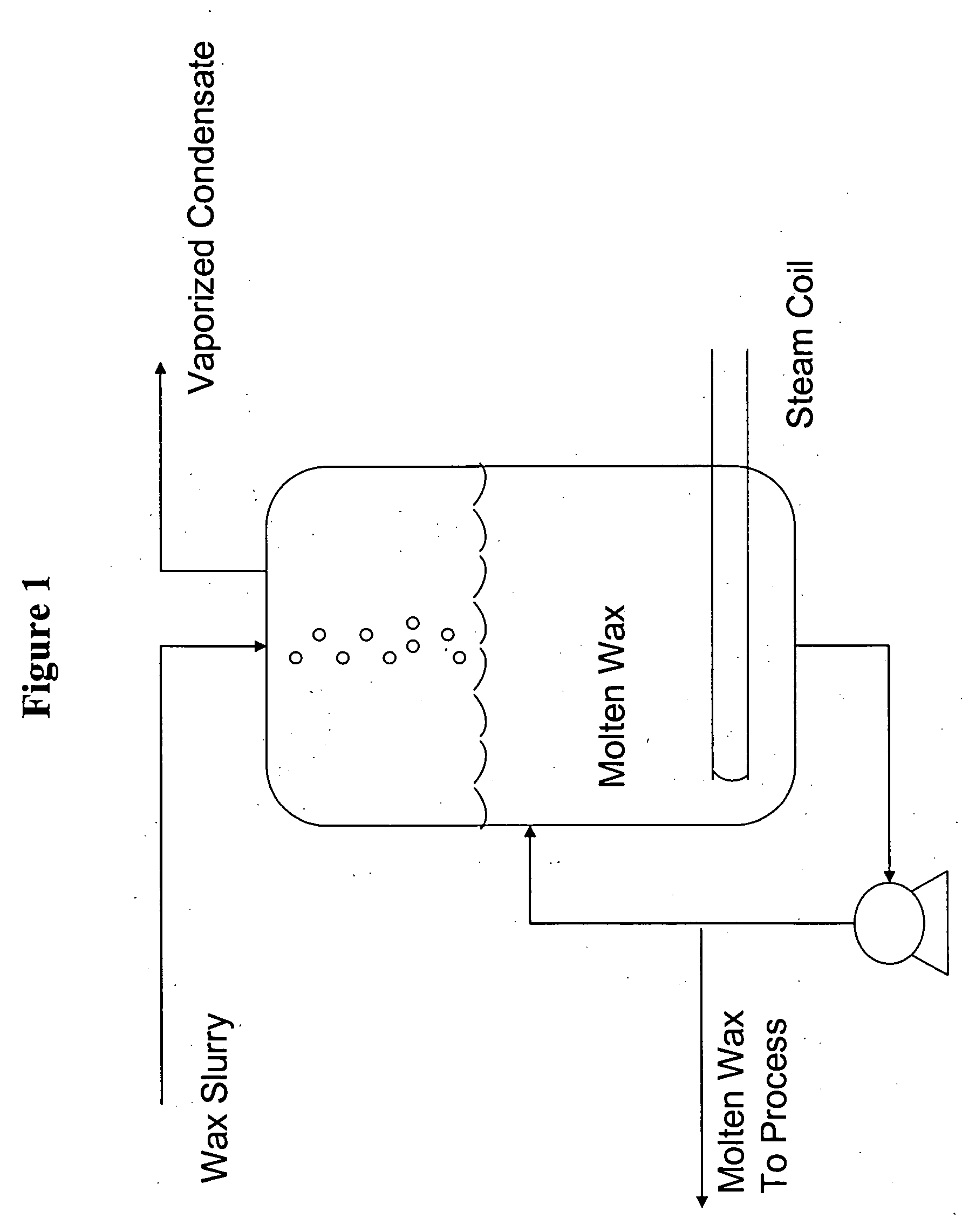

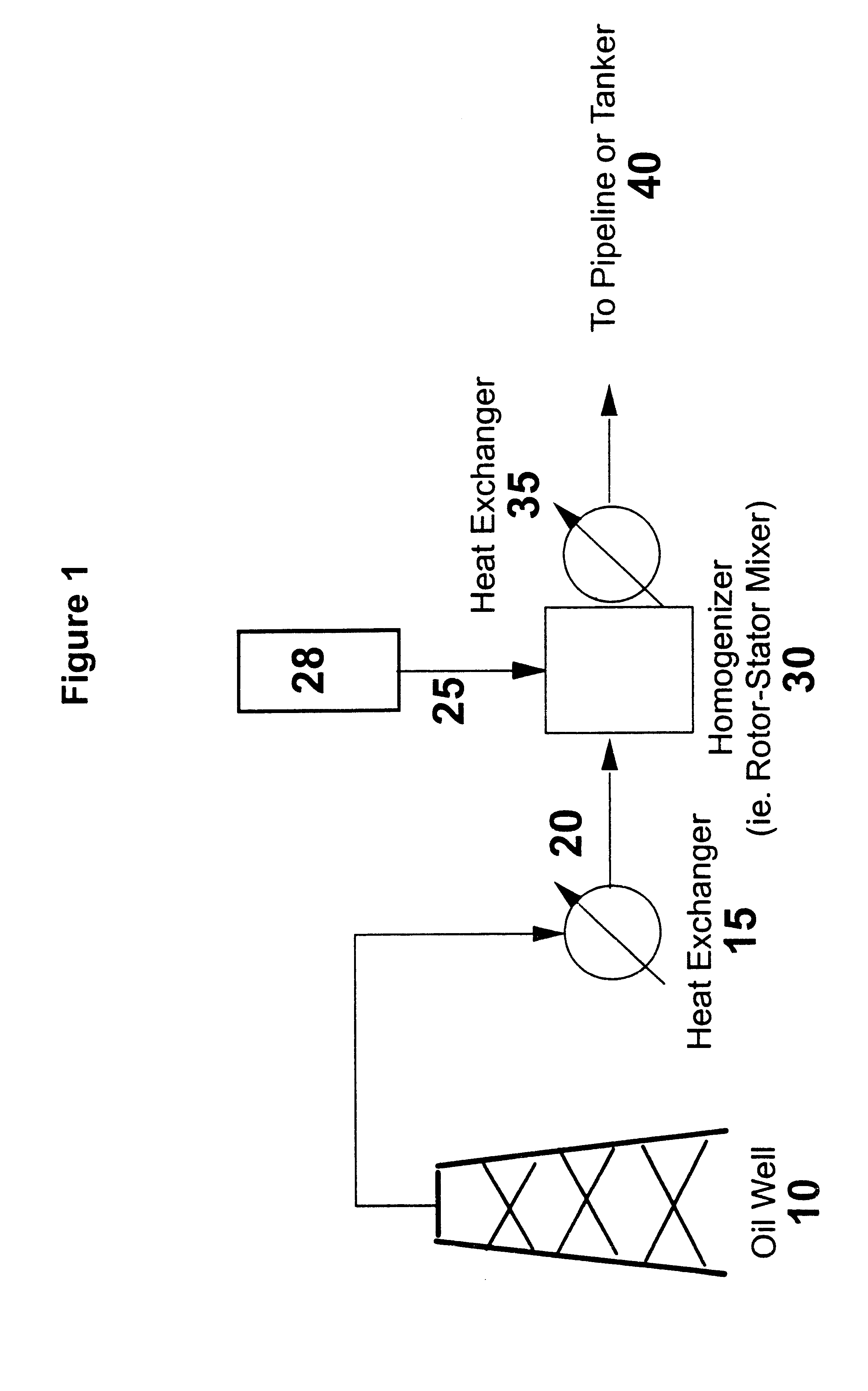

Fischer-tropsch wax and crude oil mixtures having a high wax content

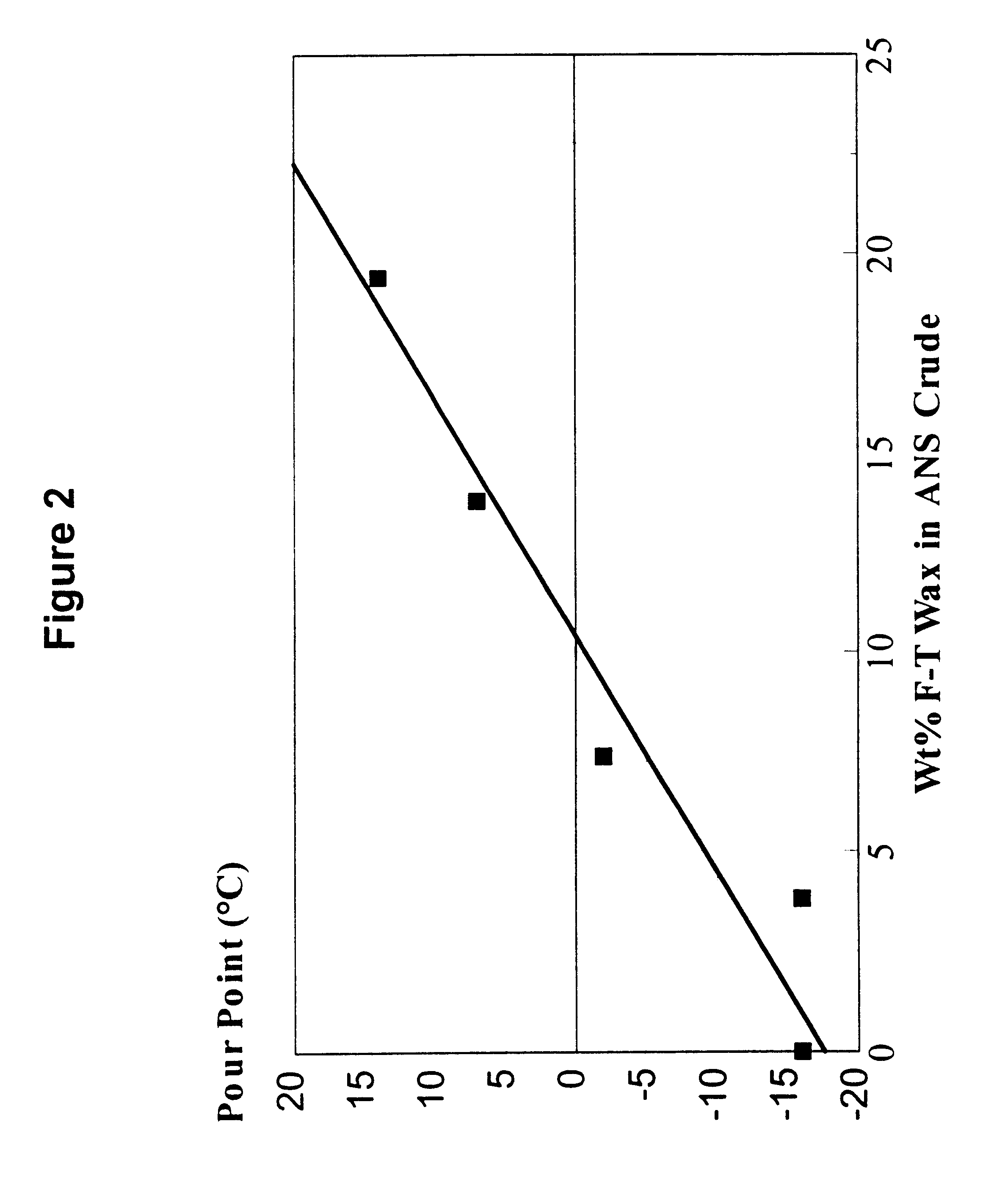

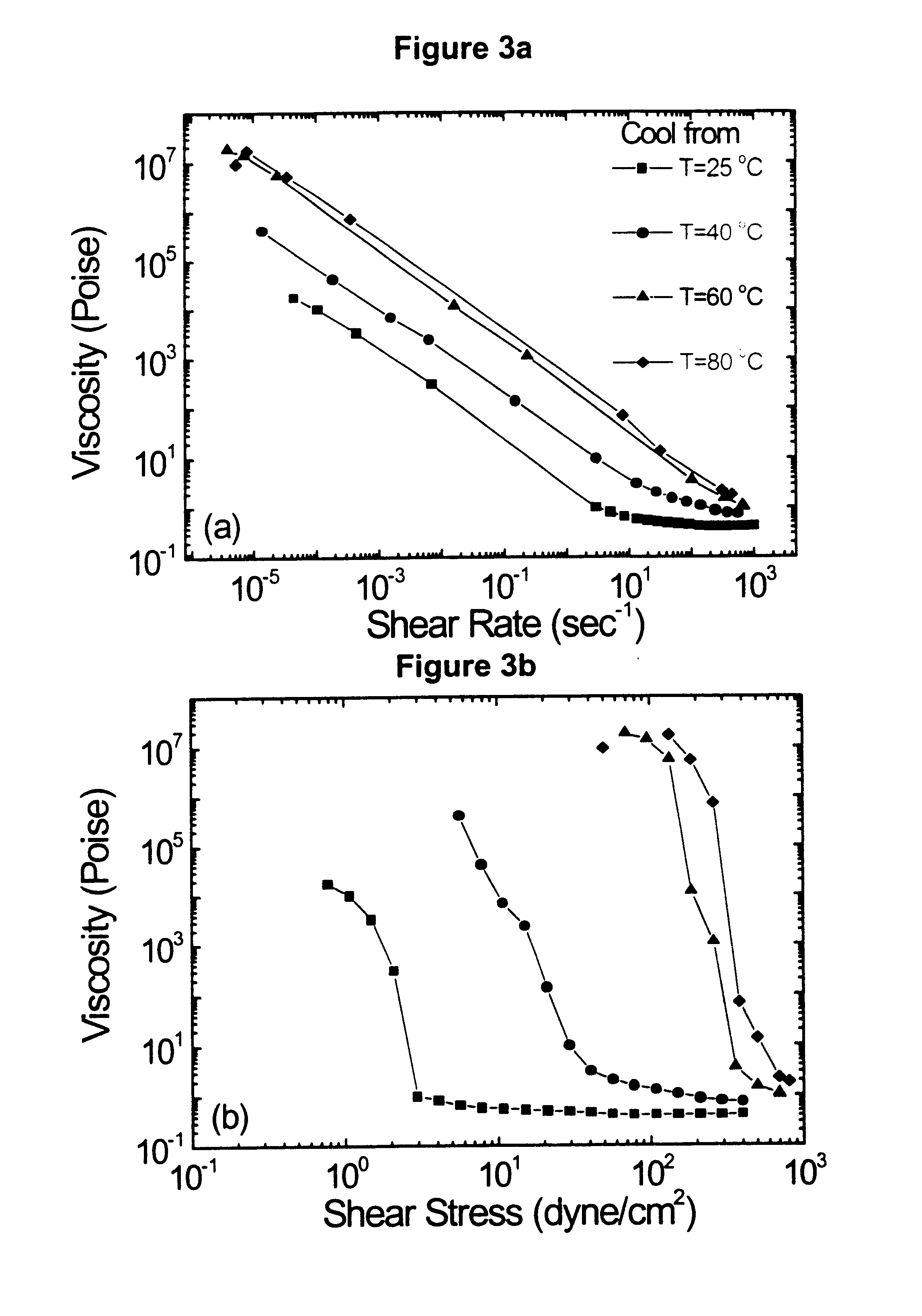

InactiveUS6268401B1Reduce the possibilityIncrease contentWax physical treatmentRotary stirring mixersTemperature controlWax

The invention is a process for producing a mixture of wax and crude oil which can be pumped at ambient temperature. The wax is preferably a Fisher-Tropsch wax. The temperature of the crude oil is controlled to a level below the dissolution temperature of the wax. The wax crystals are homogenized and dispersed into the crude oil to form a mixture. The present invention prevents the wax from dissolving in the crude oil and subsequently re-crystallizing at lower temperatures which can substantially increase the viscosity of the mixture thereby decreasing the effectiveness of transporting the mixture.

Owner:EXXON RES & ENG CO

Prepn of paraffin emulsion with waste water from medium density fiber plate defibrator system

InactiveCN1974731AEmulsification process is easyWax physical treatmentMixing methodsParaffin waxStearic acid

The process of preparing paraffin emulsion with waste water from medium density fiber plate defibrator system features that paraffin emulsion is prepared with solid paraffin and the waste water from medium density fiber plate defibrator system as main material, stearic acid and triethanolamine as emulsifier, ammonia water as catalyst, and sodium carboxymethylcellulose as colloid protectant. The process is simple, and the paraffin emulsion is used for the production of medium density fiber plate. Reusing partial waste water can reduce the quantity of waste water to be treated.

Owner:福人集团有限责任公司

Apparatus and method for pelletizing wax and wax-like materials

InactiveUS8562883B2Risk minimizationReduce probabilityTailstocks/centresWax physical treatmentWaxHot melt

An apparatus and method for the pelletization of waxes, wax-like and other materials having a sharp melt point include a vessel for forming the wax into a hot molten material. A heat exchanger then cools the molten wax to a temperature just above its melt temperature. The cooled liquid wax is fed to an extruder which further reduces the temperature and mixes the liquid wax into a thoroughly mixed extrudable solid wax. The solid wax is then extruded through die orifices of a die plate into a cutting chamber, and a rotary cutter cooperating with the die face of the die plate cuts the extruded solid wax strands into pellets. The die plate, cutting chamber and rotary cutter can have the same structure as an underwater pelletizer, but operating without water or liquid as a dry face pelletizer. The thus formed wax pellets drop out of the cutting chamber by gravity through an opening in the bottom thereof.

Owner:GALA INDUSTRIES INC

Method for preparing 3D printing wax

ActiveCN107513428AEasy dischargeEasy to separateWax physical treatmentPetroleum wax refiningParaffin waxSolid component

The invention discloses a method for preparing 3D printing wax. The method comprises emulsification, sweating and blending and utilizes appropriate paraffin as a raw material. Based on the ordinary sweating method, airflows pass through a wax layer and carry away a liquid component in the sweating process so that a solid component and the liquid component are forcibly separated and preferably, the sweating raw material and water or a salt solution are emulsified so that the liquid component can be fast discharged and thus the sweating method without solvent separation can produce a base material which has a melting point of about 70 DEG C and does not contain a low-melting point component. After blending of the base material, toughened resin, tackifying resin, animal wax and / or plant wax, an antioxidant and a pigment and extrusion filamentation, the 3D printing wax is obtained. The method has the advantages of low equipment investment, simple production process, low operation cost, safety, energy saving and no solvent pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient paraffin cooling device

InactiveCN102965145ARealize industrial productionInnovative designWax physical treatmentWater storageSalt water

The invention discloses an efficient paraffin cooling device. The efficient paraffin cooling device comprises a paraffin inlet pipe, a water inlet pipe, a high-pressure water pipe, a water storage part, a paraffin discharge port, a high-pressure water passage, a mechanical seal, a spindle, a rotating shaft, an inner blade, an outer blade and a water outlet pipe, wherein the high-pressure water passage is arranged in the device; the water storage part is arranged on the outer side of the device; a paraffin cooling part is arranged between the water storage part and the high-pressure water passage; the upper side of the high-pressure water passage is connected with the high-pressure water pipe; a shaft with an inner blade and an outer blade is arranged in the high-pressure water passage; the inner blade and the outer blade are connected with the shaft through the spindle; and the rotating shafts capable of rotating the shaft are arranged on the upper and lower parts of the shaft. According to the efficient paraffin cooling device, both the water storage part and the high-pressure water passage are provided with cold salt water for cooling paraffin flowing therebetween, so that the paraffin cooling speed is increased. The paraffin cooling device is applied to industrial production.

Owner:DALIAN LONSIN NEW MATERIALS

Granular solid wax particles

InactiveUS20070243381A1Easily transported in bulkWax physical treatmentHydrocarbon purification/separationParaffin waxNeedle penetration

A granular solid wax particle comprising a highly paraffinic wax having a low T10 boiling point less than 427° C. and an inorganic powder coating; optionally with a layer of higher boiling wax over the highly paraffinic wax having a low T10 boiling point, and an inorganic powder coating over the layer of higher boiling wax. In separate embodiments, a highly paraffinic wax having a T10 boiling point less than 427° C. or a highly paraffinic wax having a needle penetration greater than 3 mm / 10 at 25° C. is coated with a powder that adsorbs the wax without being encapsulated by the wax in a hot drop wax test. Also, a process for transporting highly paraffinic wax having a T10 boiling point less than 427° C. as granular solid wax particles. And, a method of making base oil from granular solid wax particles transported from a distant location.

Owner:CHEVROU USA INC

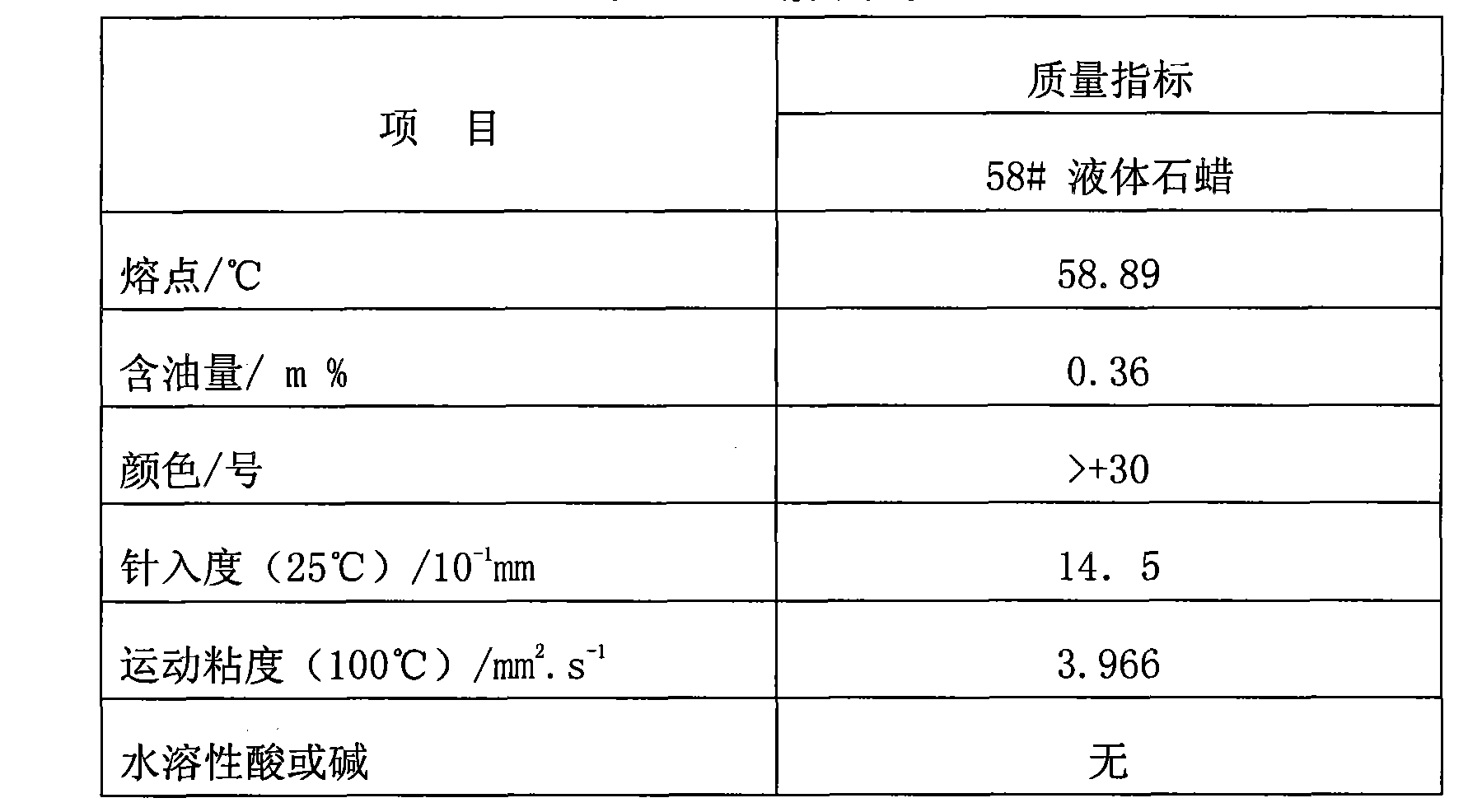

Paraffin fluidization cooling granulation process

The present invention provides one kind of paraffin fluidizing, cooling and pelletizing process. The process includes the following steps: melting paraffin at the temperature 15-20 deg.c higher than its smelting point and stirring, compression filtering and spraying out through nozzle to contact with cold air for cooling, fluidizing for further cooling to obtain paraffin grain, sieving, packing while returning the paraffin grains beyond the required size to smelting, cooling the tail gas and filtering to obtain fine powder material, returning the recovered fine powder material to smelting, purifying the filtered tail gas and reusing the purified tail gas in the temperature lower than the environment temperature. The process has high production efficiency, reliable product quality, reduced environmental pollution and saving in material and energy source.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com