Patents

Literature

99 results about "Ceresin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceresin (also cerin, cerasin, cerosin, ceresin wax or ceresine) is a wax derived from ozokerite by a purifying process. The purifying process of the ozokerite commonly comprises a treatment with heat and sulfuric acid, but other processes are also in use.

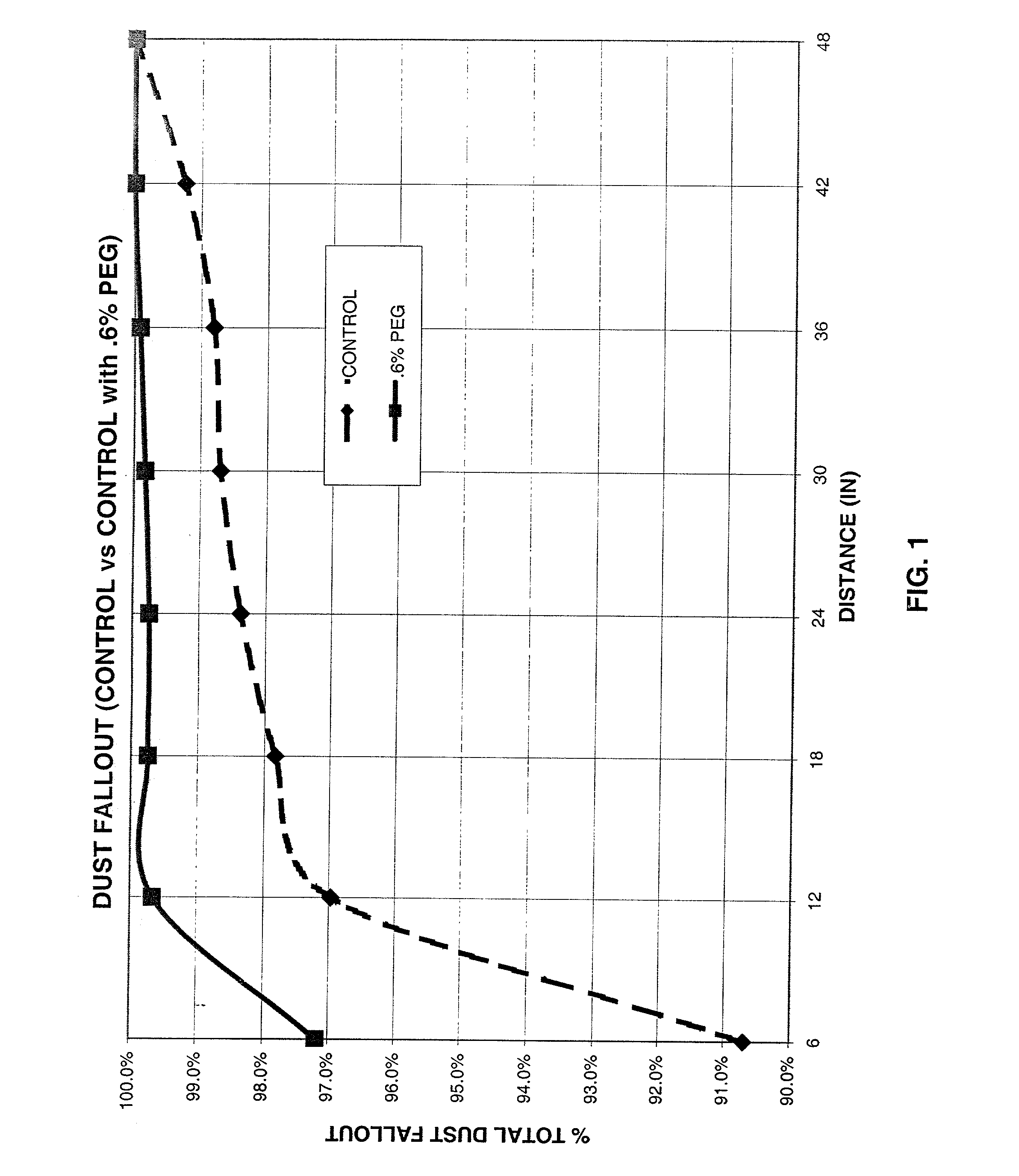

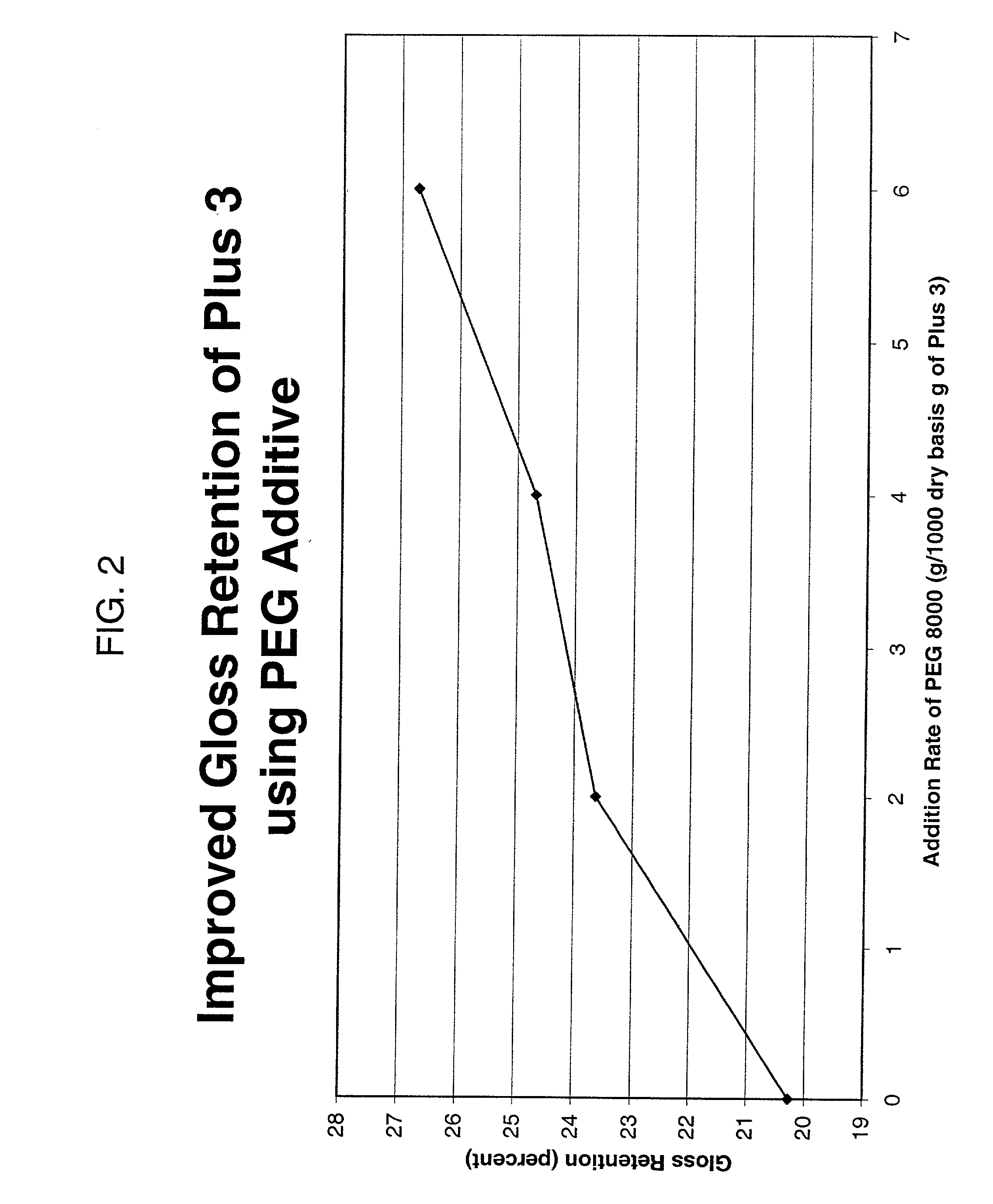

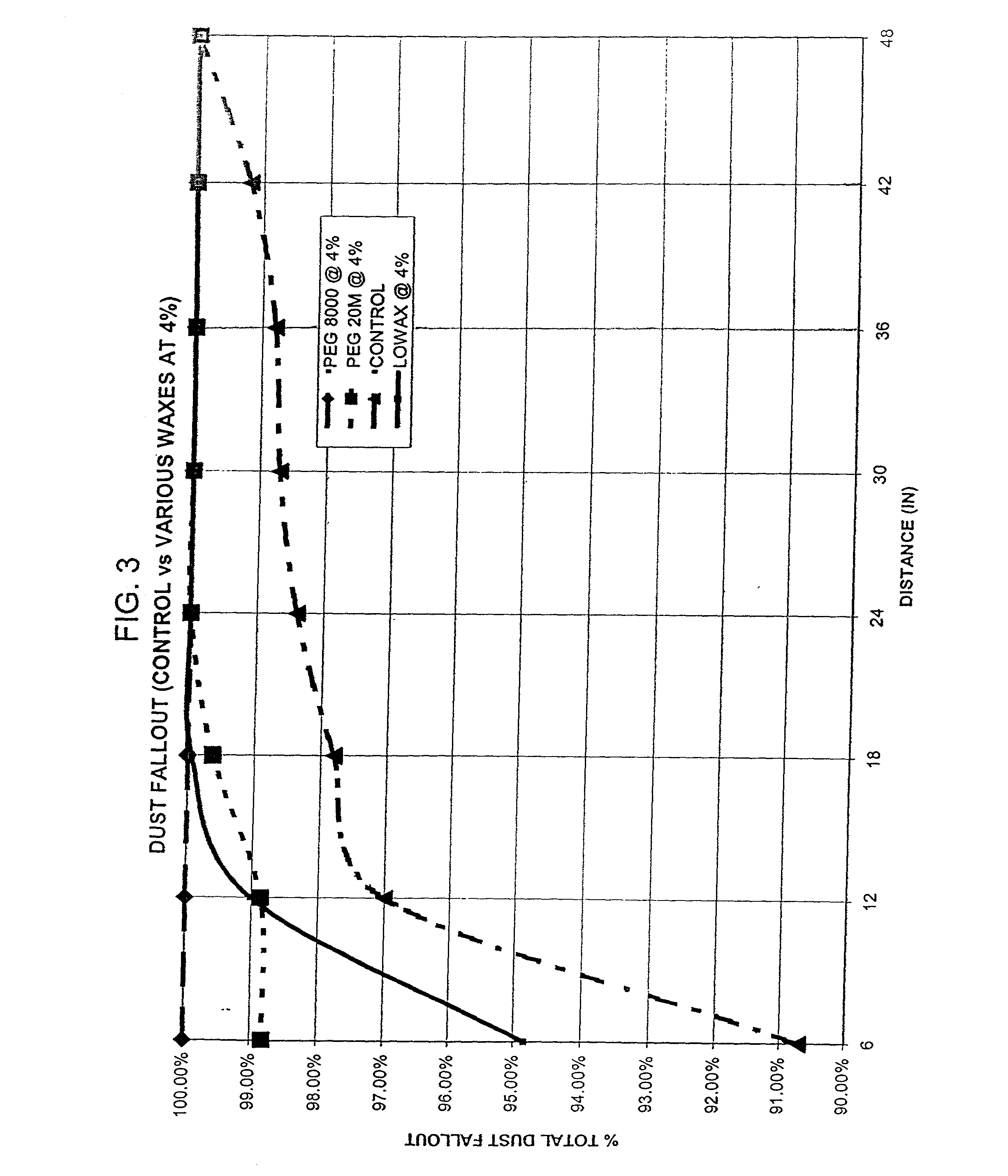

Joint compound providing low dusting and good gloss retention

InactiveUS20020129744A1Minimizes and localizes dustGood gloss retentionCoatingsPigment pastesWaxJoint compound

The present invention provides a low dusting joint compound comprising a filler, a binder, a thickener and one or more synthetic polymeric waxes that are at least slightly soluble in water and are solid at room temperature. Preferably the wax includes a high molecular weight polyethylene glycol or methoxy polyethylene glycol having an average melting point of from about 80.degree. F. (27.degree. F.) to about 150.degree. F. (80.degree. C.). These additives impart low dusting properties without a sticky or oily feel. High molecular weight synthetic waxes also act as an internal binder to hold the joint compound together and improves paint gloss retention. The invention results in a joint compound with improved properties for drywall finishing.

Owner:UNITED STATES GYPSUM CO

Highly effective viscosity-reducing agent for thermodynamic oil extraction process

ActiveCN101235279ASolve the problem of emulsification blockageImprove timelinessDrilling compositionSolubilityPetroleum product

High efficiency viscosity-reducing agent which is used on THE thermal oil extraction technology, which is formed by the following raw materials with percentage by weight, firstly phenyl benzene, fused ring aromatic hydrocarbon or fused ring aromatic hydrocarbon derivative which does not contain chlorine element and sulfur element, secondly liquid petroleum product whose aromatic hydrocarbons content is no more than 5%, petroleum resin which is liquid state under the constant temperature or hydrocarbons natural aggregation which is particle state under the constant temperature, thirdly water-soluble anionic surface active agent, water-soluble non-ionic surface active agent, oil solubility anionic surface active agent or oil solubility non-ionic surface active agent, fourthly fusel oil, fifthly alcohol ether, sixthly oil solubility or water-soluble polymer which respectively has nonpolar portion which has eutectic crystal with ceresin wax molecular and polar portion which can make wax crystal system twisty on main chain and or branch chain, seventhly hyperoxide, eighthly carbamide, ammonium carbonate, ammonium acid carbonate or ammonium nitrite and ninthly ketone. The high efficiency viscosity-reducing agent has strong suitability, strong viscosity-reducing ability, safety and reliability, can largely reduce extract cost and increase the yield of oil pump, and increases the final recovery efficiency of oil reservoir.

Owner:盘锦河升大地石油科技有限公司

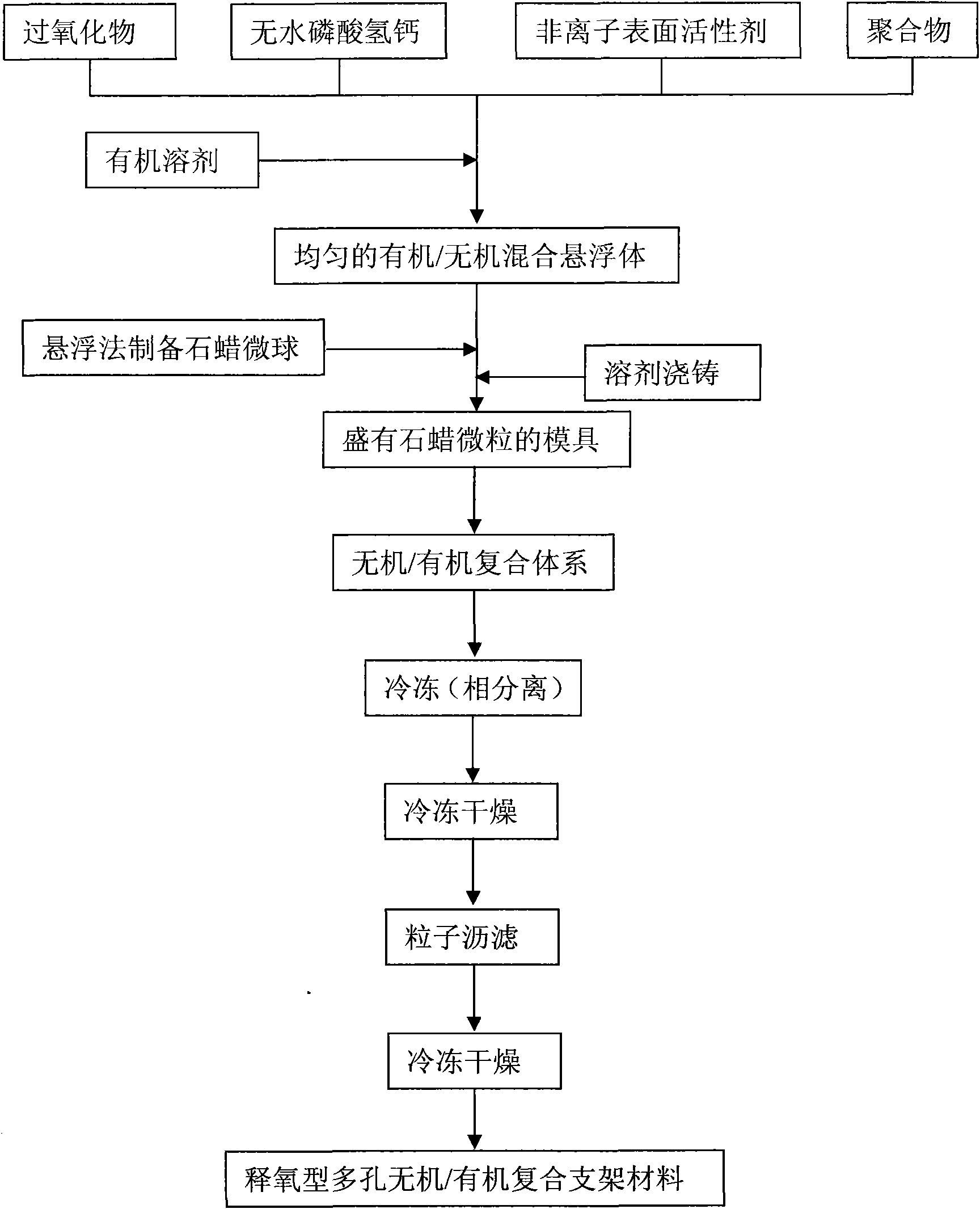

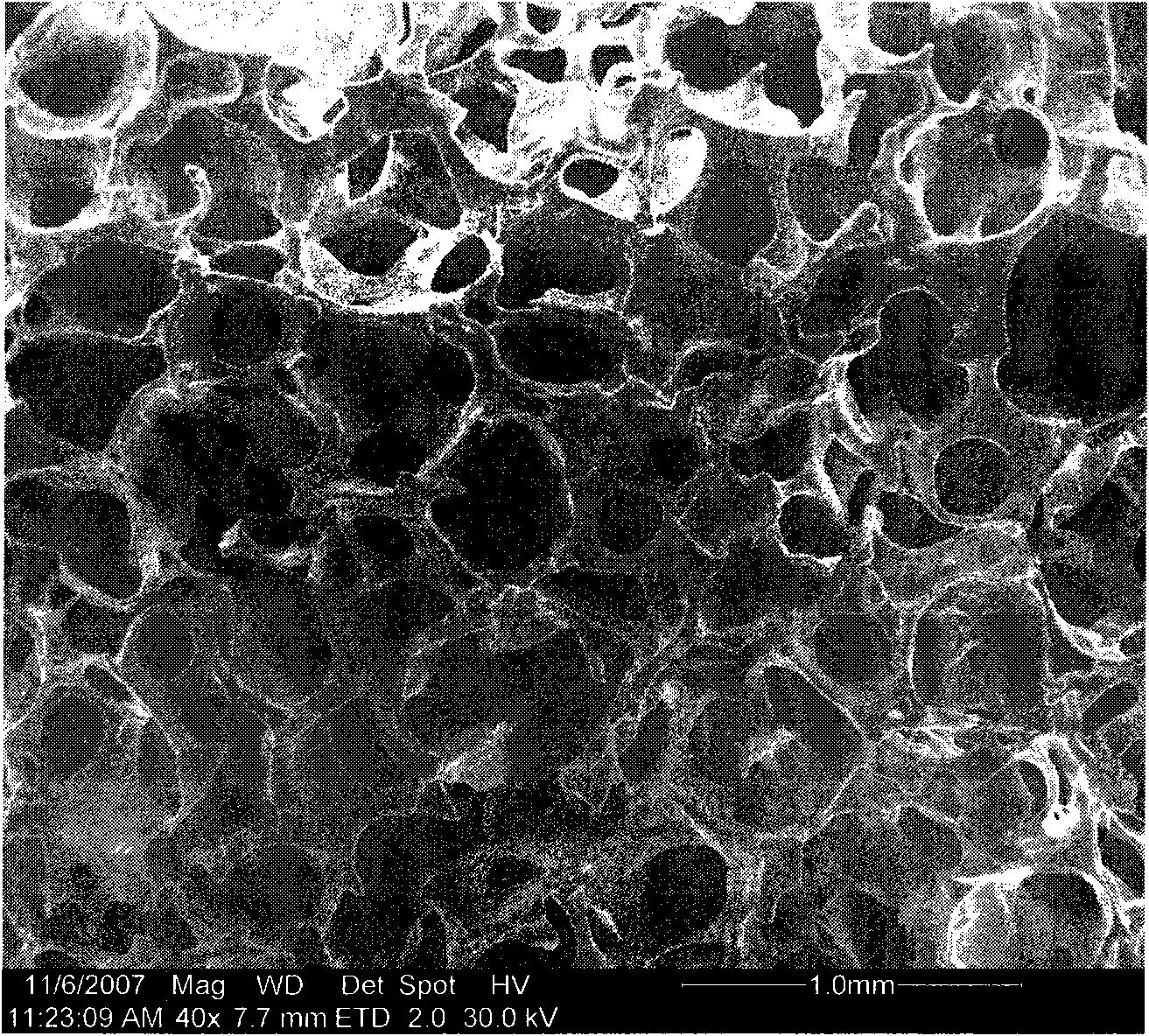

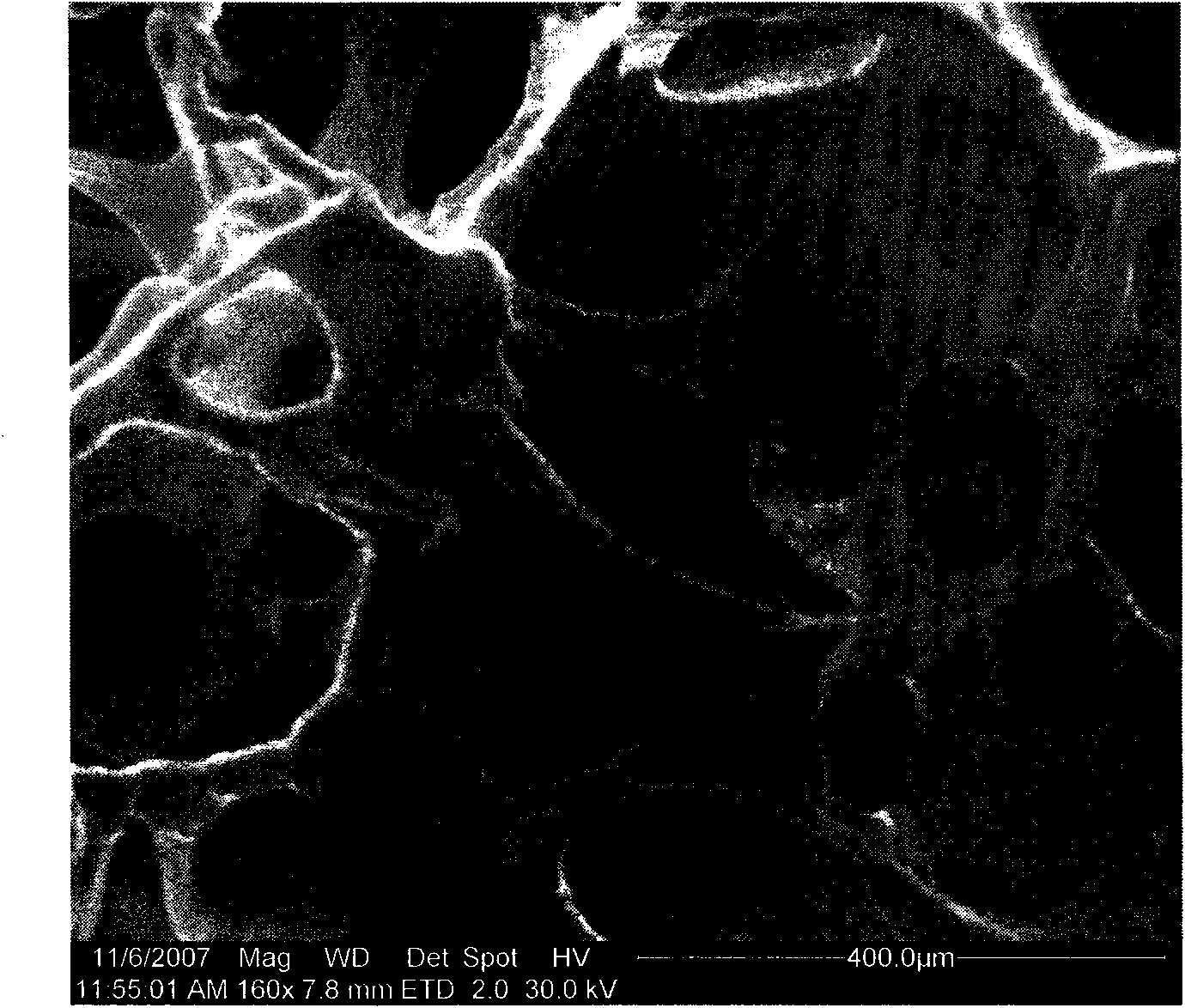

Release oxygen type stephanoporate abio/organic composite material stent

InactiveCN101549176AMeet the needs of metabolismAperture controllableMicroballoon preparationProsthesisPorosityParaffin wax

The present invention provides a release oxygen type stephanoporate abio / organic composite stent material which is composed of abio-hyperoxide, anhydrous hydrogen phosphate and degradable polymericcompound which contains non-ionic surface active agent, wherein, hyperoxide weight is 1%-10% of degradable polymericcompound weight, molar ratio of anhydrous hydrogen phosphate to hyperoxide is 1.0-2.0:1, non-ionic surface active agent weight is 10%-40% of degradable polymericcompound weight, the porosity of the stent material is larger than 90%. A preparing method includes steps as follows: preparing a ceresin wax micro-ball firstly, preparing a symmetric suspension body composed of non-ionic surface active agent, hyperoxide, anhydrous hydrogen phosphate and degradable polymericcompound, pouringin a die equipment filled with ceresin wax micro-ball, then freezing forming, freezing dehydration and removing organic solvent, finally, removing ceresin wax micro-ball by using organic solvent andobtaining the products. The stent material has advantages of continuous oxygen releasing, favorable biocompatibility, biodegradability, biological activity and hydrophilicity which is suitable for thebiological medicine field and the organizing engineering project field.

Owner:WUHAN UNIV OF TECH

Chromatic bituminous cement and preparation method and application thereof

The invention discloses a coloured asphalt cement, preparing method and application, which is characterized by the following: including 1-5% FT ceresin wax; introducing little FT ceresin wax to decrease the processing temperature; decreasing the odor of cementing agent; making the coloured asphalt cement with better high temperature stability.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

Paraffin emulsifier and its making method

InactiveCN1570038AGood water solubilityImprove stabilityWax physical treatmentTransportation and packagingParaffin waxEthylene oxide

Owner:杨建军

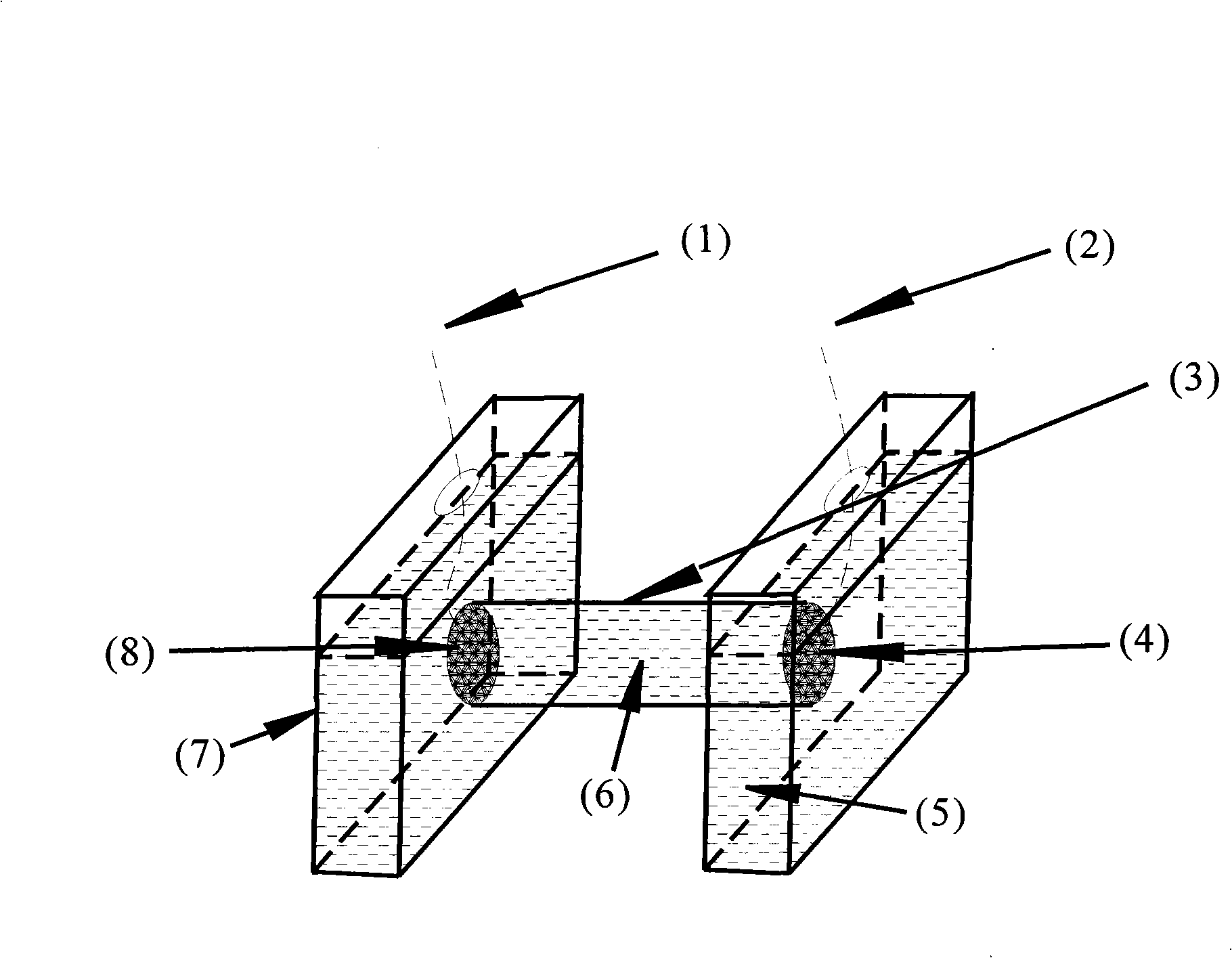

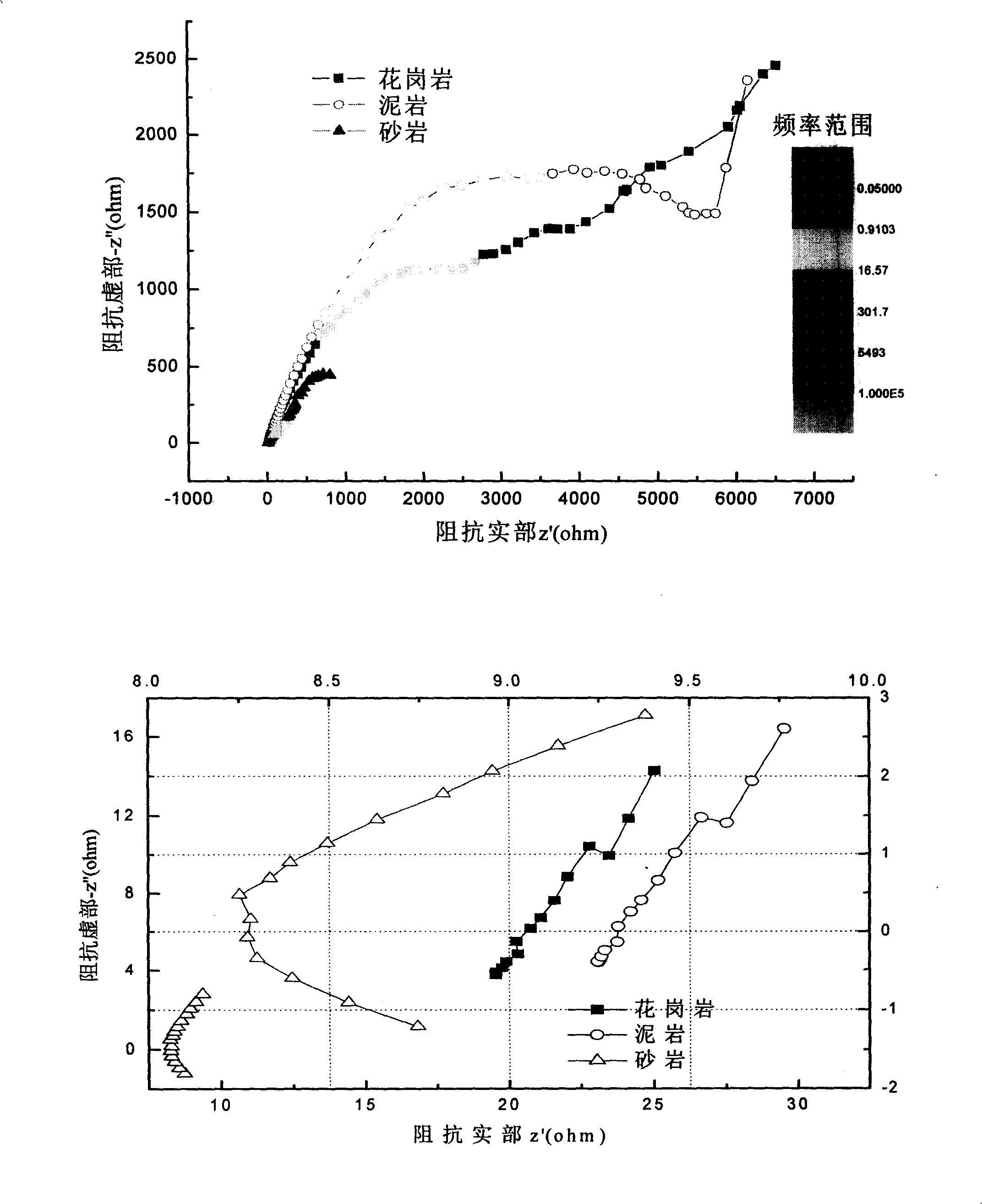

Method for testing rock microcracks

InactiveCN101303321AImprove detection accuracyEasy to detectMaterial impedanceDisturbance voltageRock microstructure

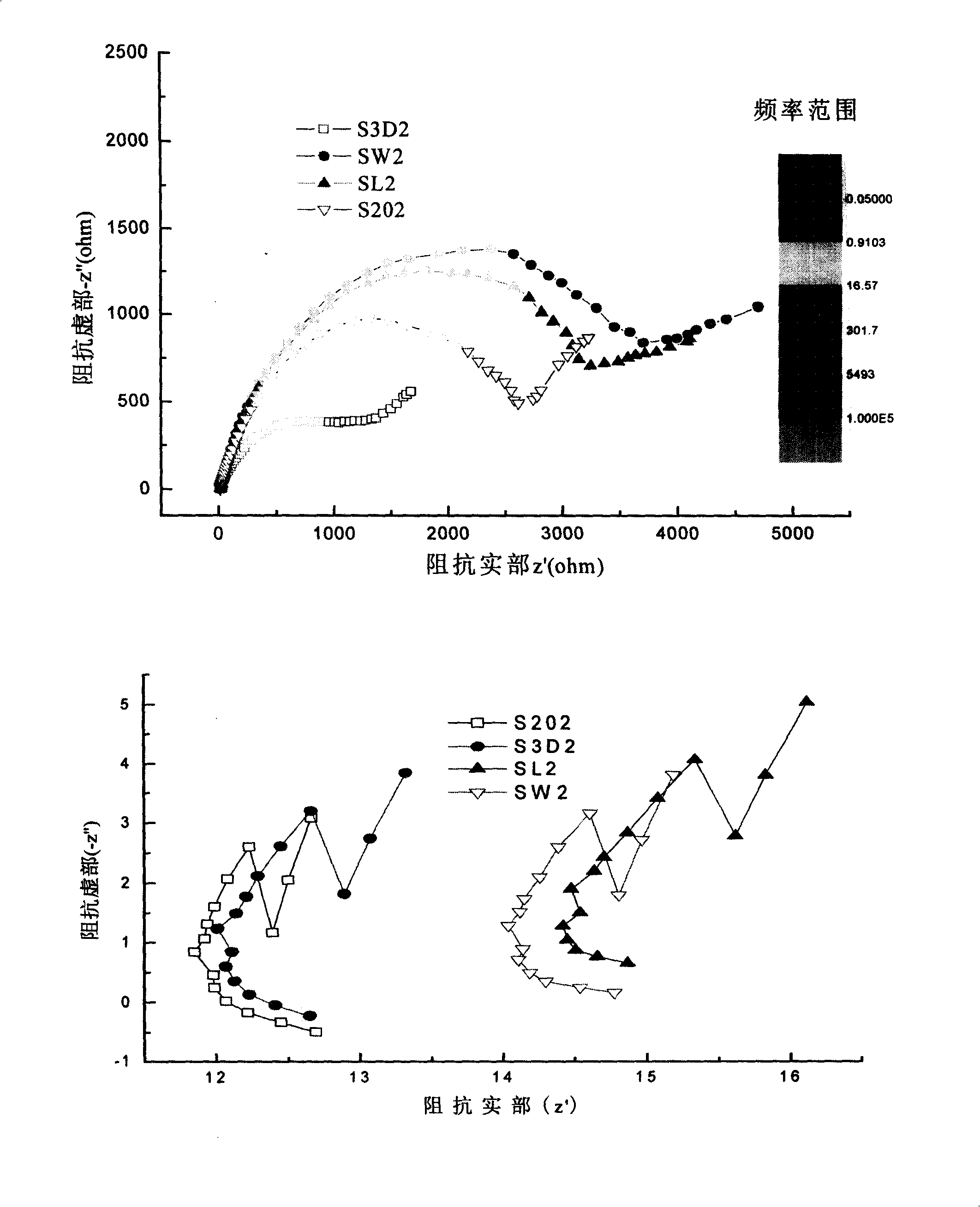

The invention relates to a rock microcrack testing method for testing the deep engineering rock microstructure, including electrolytic solution preparing, rock sample mounting, rock alternating current impedance spectrum data acquisition and data fitting analysis; coating conducting adhesive on the sample for connecting wires, horizontally mounting the sample between containers, and infusing the electrolytic solution in the containers; enveloping mineral butter or ceresin wax on the sample, connecting the wires to the electrochemistry workstation, testing the natural potential of the rock sample tester, zeroing using the electrochemistry workstation; adopting a 5mV disturbance voltage to test the electrochemistry impedance spectrum of the sample, whose frequency range is from 1*10<6>Hz to 0.1Hz; selecting a high-frequency arc frequency range, ciphering the test data points, using the 5mV disturbance voltage to test the sample high-frequency arc electric impedance spectrum, and using the full-frequency band electric impedance spectrum to qualitatively distinguish the size variation of the rock microcracks; according to the high-frequency arc measured data, using ZPLOT to simulate the electrology element numerical values on the high-frequency arc equivalent circuit, calculating the microcrack sizes inside the sample, thereby having the advantages of high accuracy, easy test and convenient operation.

Owner:ZHONGYUAN ENGINEERING COLLEGE

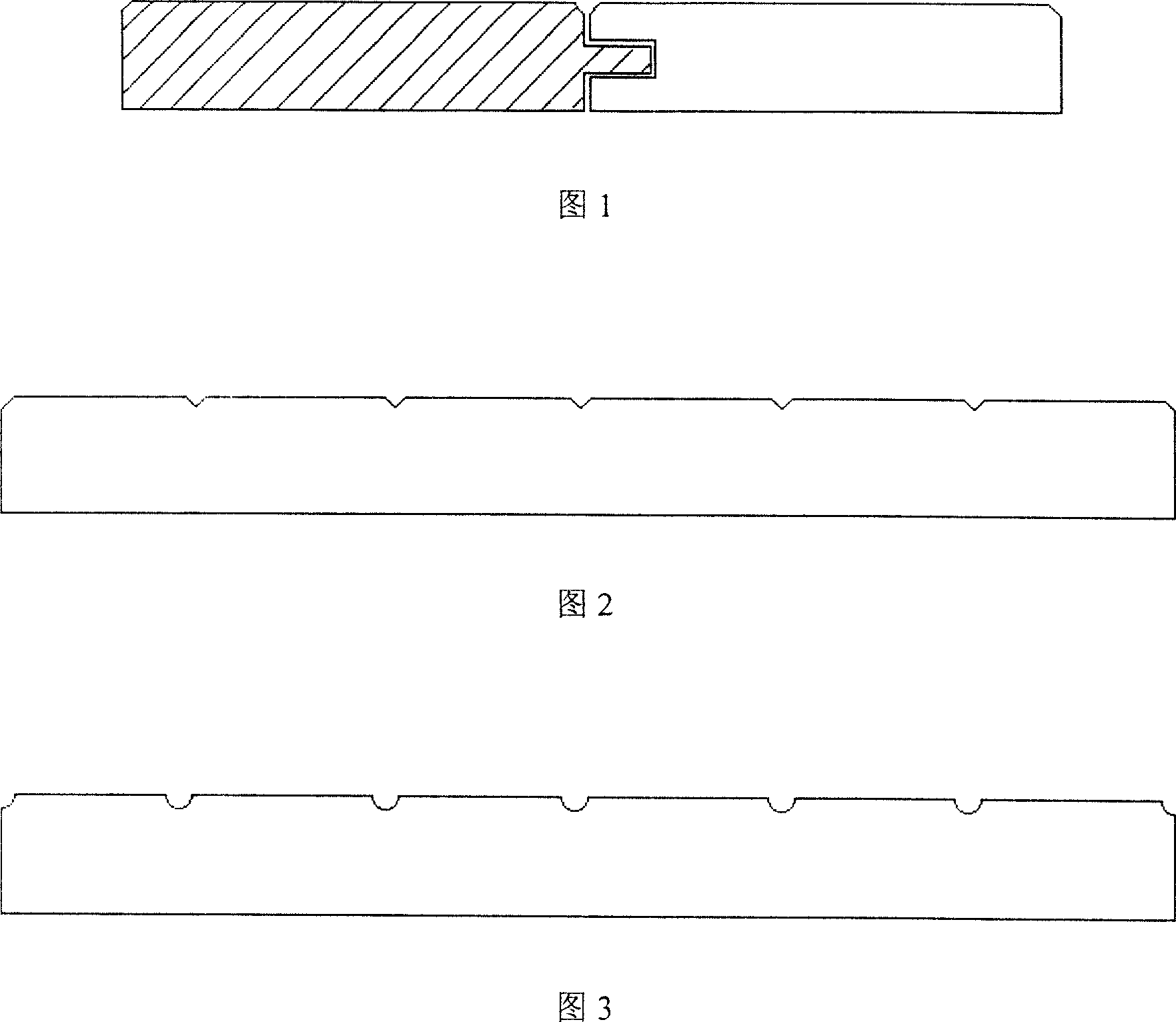

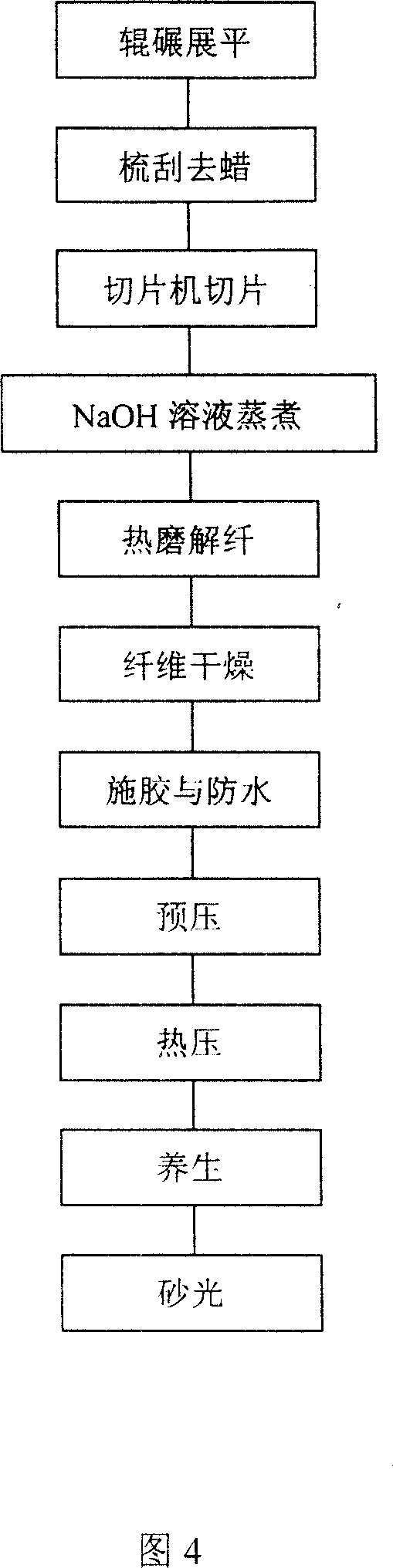

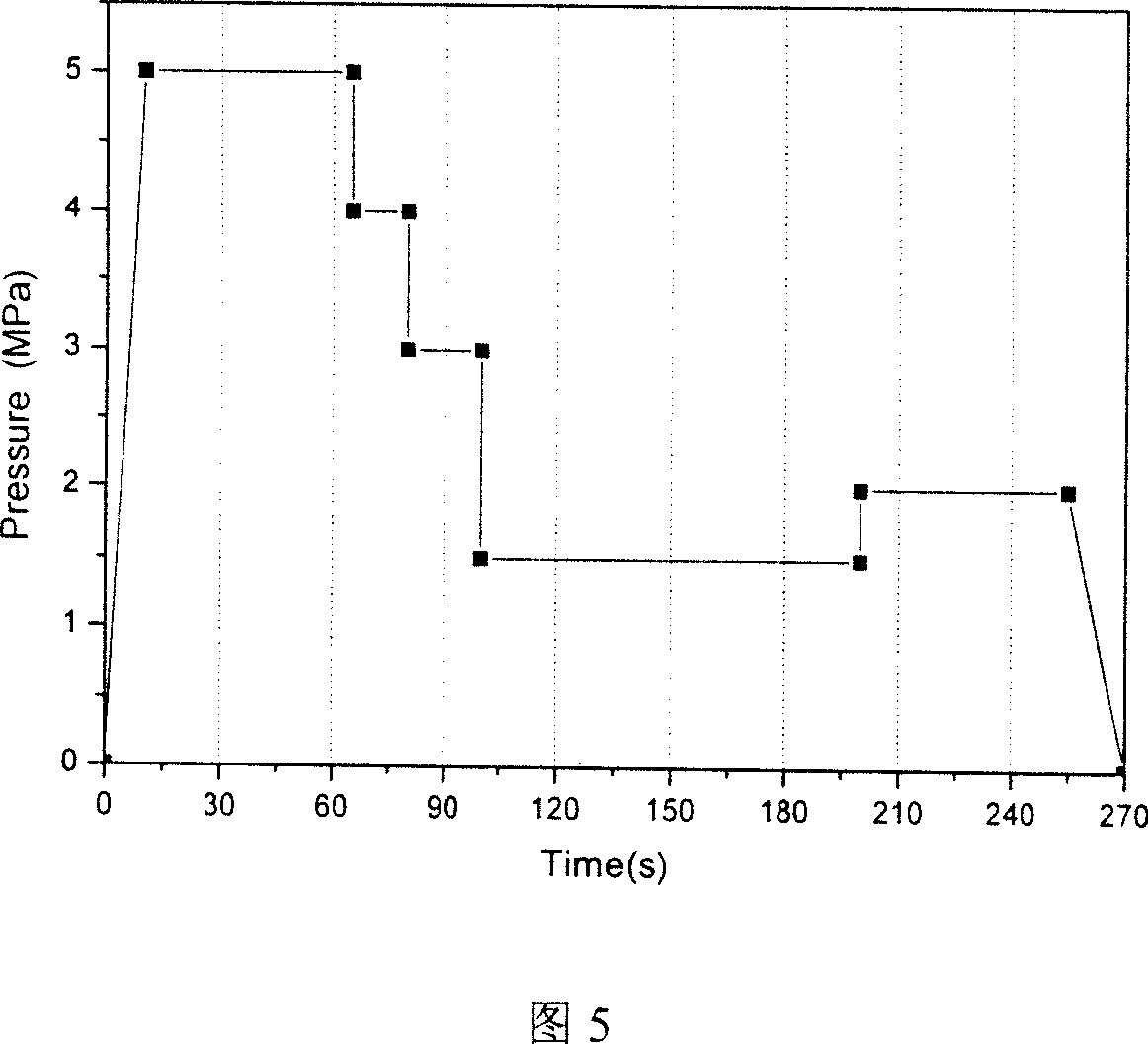

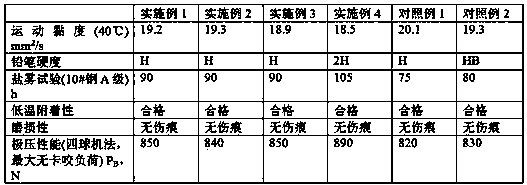

Medium density fiber board made from bamboo

InactiveCN1994702AIncrease profitImprove appearance qualityFibrous raw materialsDomestic articlesParaffin waxFiber

The invention relates to a bamboo middle-density fiber plate, made from bamboo and Japanese cedar, wherein it is formed by 50-95 Japanese cedar sheets, 1-100 bamboo sheets, 8-15 urea-formaldehyde glue, 0.5-5 anti-fungus agent, 0.2-3 solidifier, and 1-3 ceresin wax. And its preparation comprises that: putting bamboo sheets into solution while NaOH is 1-5% of bamboo weight; at 80-130Deg. C and 0.5MPa pressure, boiling it for 10-15min, to be mixed with Japanese cedar sheets, to be grinded and dried; plating urea-formaldehyde glue added with anti-fungus agent, solidifier and wax emulsion on the fiber to be thermally compressed.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

Injection moulding method for preparing zirconia tube of metallurgic oxygen sensor

InactiveCN1808109AIncrease injection pressureThe preparation process is stable and controllableMaterial electrochemical variablesVegetable oilMetallic materials

Disclosed is a method for making zirconium oxide pipe with injection modeling as metallurgy, which comprises: mixing MgO part stable zirconium oxide powder with binding agent, getting the base of the zirconium oxide tube after being injected, getting the metallurgy zirconium oxide with certain oxide after degreasing and sintering. The making method comprises: according to weight percentage, getting polyethylene or polypropylene 10~30%, vegetable oil 10~40%, oleic acid 1~5%, and the other is ceresin wax, mixing them under 130~160íµ; making materials of binding agent and zirconium oxide powder according to weight percentage (15~25)%: (85~75)%.

Owner:UNIV OF SCI & TECH BEIJING

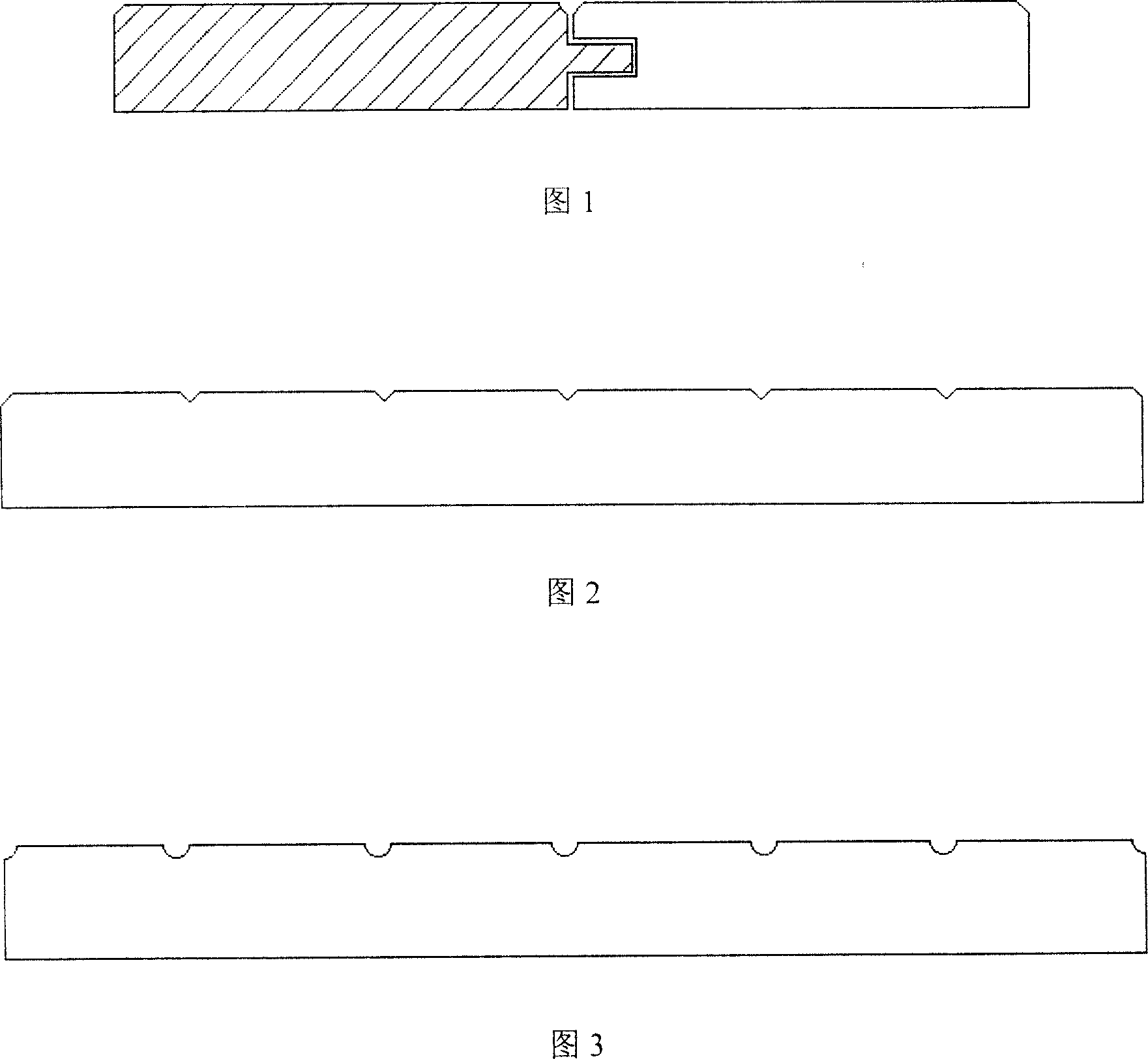

Medium density fiber board made from bamboo and wood

InactiveCN1994700AHigh yieldImprove mechanical propertiesFibrous raw materialsFlat articlesFiberParaffin wax

The invention relates to a bamboo middle-density fiber plate, made from bamboo and Japanese cedar, wherein it is formed by 50-95 Japanese cedar sheets, 5-50 bamboo sheets, 8-15 urea-formaldehyde glue, 0.5-5 anti-fungus agent, 0.2-3 solidifier, and 1-3 ceresin wax. And its preparation comprises that: putting bamboo sheets into solution while NaOH is 1-5% of bamboo weight; at 80-130Deg. C and 0.5MPa pressure, boiling it for 10-15min, to be mixed with Japanese cedar sheets, to be grinded and dried; plating urea-formaldehyde glue added with anti-fungus agent, solidifier and wax emulsion on the fiber to be thermally compressed.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

Military camouflage ointment and preparation thereof

The invention relates to a military camouflage ointment and a preparation method thereof, comprising 70 to 92 parts of matrix raw material; 1 to 8 parts of lake; 1 to 6 parts of titanium oxide; 1 to 6 parts of nano-zinc oxide; and 5 to 10 parts of DEET. Mineral oil and dimethyl silicone oil are firstly mixed and stirred, hydrogenated castor oil, ceresin and lanolin are added till the dissolution; talcum powder, the titanium oxide and the nano-zinc oxide are further added and stirred for even mixing; the lake and the DEET are added, and then the homogenization, the filling, the sealing and the preservation are carried out. The ointment of the invention can solve the technical problems that the existing military camouflage ointment can not simultaneously meet the purposes of meeting camouflage, preventing UV burns, infrared ray, visible light and mosquito bites, the ointment of the invention can prevent the UV burns, the mosquito bites and the infrared ray, thus having the advantages of safety, no allergy, no toxicity or side effects, mild aroma, good air permeability, insolubility in water, easy cleaning, high performance-price ratio, convenient carrying and good stability.

Owner:XIAN HANGJIE CHEM TECH

Drainage phase-change temperature-regulation heat-insulation coating and preparation method thereof

InactiveCN101693807ASolve problems that are prone to flash erosionCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsPolyethylene glycolFar infrared

The invention relates to drainage phase-change temperature-regulation heat-insulation coating and a preparation method thereof. The coating is characterized by comprising the following components in parts by weight: 30-80 parts of component A, 20-60 parts of component B, 15-40 parts of titanium dioxide rutile, 10-25 parts of flyash cenosphere, 1-10 parts of vacuum ceramic micro-sphere, 1-5 parts of far-infrared radiated substance, 0.1-1 part of flash rusting resistant agent, 0.1-0.8 part of silane coupling agent, and 0.2-2 parts of thickener, wherein the component A is a mixture of 3-10 parts of polyethylene glycol 800, 1-8 parts of polyethylene glycol 1000, 1-6 parts of ceresin wax, 15-35 parts of expanded perlite, 5-15 parts of kieselguhr, 0.1-0.5 part of JFC, 0.1-0.6 part of sodium dodecyl sulfate, 0.1-0.3 part of OP-10, and 40-60 parts of deionized water; and the component B is a mixture of 20-50 parts of silicone-acrylate emulsion, 10-30 parts of polyurethane emulsion, 5-20 parts of fluororesin emulsion, 0.1-0.3 part of film forming assistant, 0.1-0.8 part of flowing deformation assistant and 10-30 parts of deionized water. Based on the coating of the invention, the preparation method comprises three steps: component A preparation, component B preparation and coating preparation.

Owner:天津市耀新科技发展有限公司

Preparation method of hard film anti-rust oil with high hardness

The invention relates to a preparation method of hard film anti-rust oil with high hardness and belongs to the technical field of anti-rust oil. The method comprises the following steps: uniformly stirring light diesel oil, beeswax, turpentine, sunflower seeds, poly oxidation alkyl glycol, ricinus oil oxypropylene polymer, triethanolamine, ceresin wax, ethyl acetate and a non-ionic surfactant, heating, preserving heat and stirring uniformly to obtain a first mixture; adding petroleum barium sulfonate into ethylene glycol, adding diethylene glycol, kerosene and styrene-acrylic emulsion in sequence, heating, preserving heat and stirring uniformly to obtain a second mixture; mixing the first mixture and the second mixture, adding an antifoaming agent, an antioxygen, a thixotropic agent, an anti-rust agent and stirring uniformly. The anti-rust oil provided by the invention is better in hardness and anti-rust performance.

Owner:启东市鸿洋润滑产品有限公司

Method of producing novel wood plastic wall

The invention discloses a preparing method of new type wood plastic wall, which is characterized by the following: the factory formula and mass percent is: 30.9%-32.1% plastic, 10.4%-16.1% wood powder, 51.6%-40.2% heavy calcium carbonate, 0.5%-1.2% organotin stabler, 0.5%-0.8% calcium stearic acid, 0-0.4% ceresin wax, 0-0.4 % geoceric acid, 1.5%-2.4% CPE135A, 1.5%-2.4% ACR401, 2.1%-2.4% epoxide hydrocarbon ils, 1.0%-1.2% dioctyl and 0-0.4% colorant; the whole course does not produce waste gas and waste water without radiation.

Owner:青岛三合装配式房屋有限公司

Environment-friendly type power cable plastic protecting tube

ActiveCN1767291ANo pollution in the processComply with the environmental protection requirements of entering the groundCable installations in underground tubesEpoxyStearic acid

The invention discloses an environmental friendly type power cable plastic preserving pipe. It comprises: chlorinated polyvinyl chloride, polyvinyl chloride, methacrylic acid, butadiene, styrene ternary polymerization resin, heavy calcium carbonate and so on. It adds nontoxic compound calcium zinc stabilizer, stearic acid, chlorinated polyvinyl chloride, epoxy soya oil, ceresin and white oil and so on and the macromole compound.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

CuSn10 alloy injection forming method

The invention relates to an injection shaping method of CuSn 10 alloy, wherein said method comprises that: the diameter of CuSn 10 alloy is 6-50 mum; the adhesive is the polymer of ceresin wax PW, polyphenylacetylene PS, acetic acid ethyenyl ester polymer EVA, and geoceric acid SA. And the method comprises that: mixing and cubing the CuSn10 powder and adhesive at 55-66vol%, injecting and shaping; using solvent defatting method and thermal defatting method to remove adhesive to be sintered at 600-750Deg. C; at last, under reducing gas or inertia gas, sintering to obtain the final element. The invention can produce copper alloy element with complex shape and high quality with low cost.

Owner:UNIV OF SCI & TECH BEIJING

Paint remover formula

ActiveCN101875796ALow costGood paint removal performanceChemical paints/ink removersParaffin waxO-Phosphoric Acid

The invention relates to a paint remover, in particular to a paint remover formula, which comprises the following compositions in part by weight: 70 to 80 parts of methylene chloride, 3 to 4 parts of acetone, 1.8 to 2.2 parts of pyridine, 1.8 to 2.2 parts of formic acid, 1.8 to 2.2 parts of ceresin wax, 1.4 to 1.6 parts of cellulose acetate, 1.4 to 1.6 parts of alcohol, 1.4 to 1.6 parts of phosphoric acid and 2 to 3.5 parts of aqueous ammonia; meanwhile, the paint remover formula can also be prepared from the following compositions in part by weight: 80 to 85 parts of methylene chloride, 2 to 3 parts of acetone, 1 to 1.5 parts of pyridine, 2 to 3.5 parts of formic acid, 1.5 to 2 parts of ceresin wax, 1.5 to 2 parts of cellulose acetate, 0.8 to 1 parts of phosphoric acid and 3 to 3.5 parts of aqueous ammonia. The paint remover formula is suitable for removing amino paints, ethylene perchloride paints, epoxy paints on aluminum ware, steel ware and copper ware and the films of spurted plastic ware, and has the advantages of excellent paint removing performance, low material cost, and simple and convenient operation and application.

Owner:西安北方光电有限公司

Air bubble bag packing material

InactiveCN102070814AQuality improvementPrevent leakageContainers to prevent mechanical damageLow-density polyethyleneLinear low-density polyethylene

The invention discloses an air bubble bag packing material, which is prepared by blow molding of the following components in percentage by weight: 88 to 95 percent of waste low-density polyethylene plastic granule, 3 to 9.8 percent of linear plastic granule, 1 to 2 percent of functional aid and 0.01 to 0.5 percent of brightening agent, wherein the waste low-density polyethylene plastic granule is a high-pressure waste low-density polyethylene plastic granule; the linear plastic granule is a linear low-density polyethylene granule; the functional aid is one or combination of dioctyl phthalate, ceresin wax and stearic acid; and the whitening agent is 1,2-bis(5-methyl-2-benzoxazolyl)-ethylene. The air bubble bag packing material is prepared into air bubble bags with stable quality and airtightness by the traditional preparation method, wastes are recycled and the cost is low.

Owner:WUHU HONGFANG PACKAGING TECH

Attapulgite hot-melt adhesive and preparation method thereof

InactiveCN105219298ALow costHigh viscosityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAlpha-olefinButadiene-styrene rubber

The invention provides an attapulgite hot-melt adhesive and a preparation method thereof. The attapulgite hot-melt adhesive is characterized by comprising 20 to 50% of matrix resin, 20 to 50% of tackifying resin, 10 to 30% of a diluent, 2 to 40% of attapulgite and 0.1 to 1% of an anti-oxidant, wherein the matrix resin is any one or a composite of more selected from the group consisting of ethylene-vinyl acetate copolymer (EVA), ethylene-butyl acrylate copolymer (EBA), ethylene-acrylic acid copolymer (EAA), ethylene-ethyl-acrylic acid copolymer (EEA), styrene-isoprene copolymer (SIS), styrene-butadiene copolymer (SBS) and amorphous alpha-olefin polymer (APAO), the tackifying resin is selected from the group consisting of rosin, polymerized rosin, resin 145, resin 138, terpene resin, petroleum resin and hydrogenated petroleum resin, the diluent may be paraffin, ceresine, polyethylene wax or Fischer-Tropsch wax, the attapulgite may be raw attapulgite or modified attapulgite like viscous attapulgite, brightened attapulgite and acidified attapulgite, the anti-oxidant is 2,6-di-t-butyl-4-methylphenol, i.e., 264, or pentaerythritol tetrakis[beta-(3',5'-di-t-butyl-4'-hydroxyphenyl)propionate], i.e., 1010, and the matrix resin has VA% of 5 to 40 and a melt index of 15 to 400.

Owner:蒋寿悟

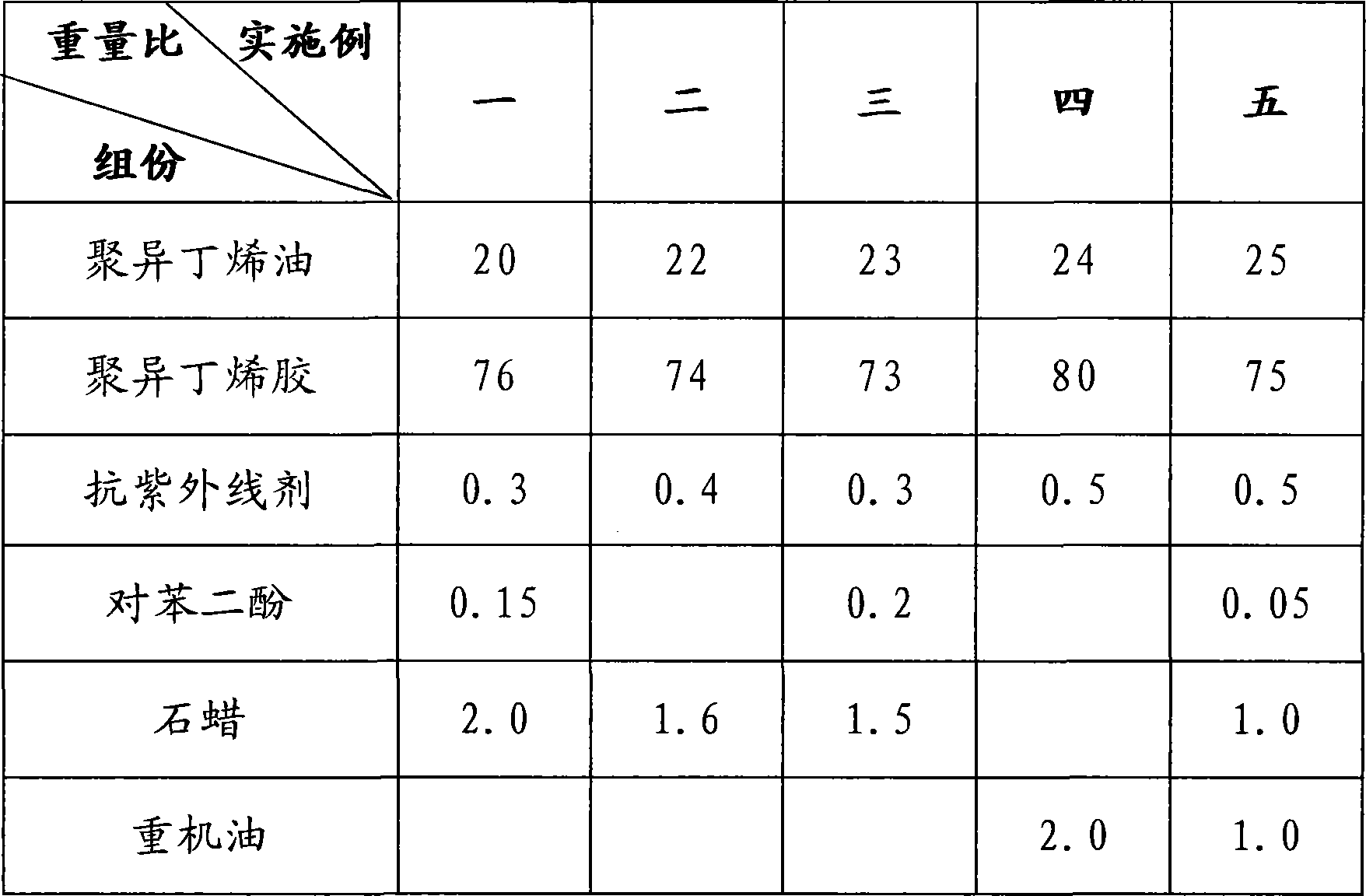

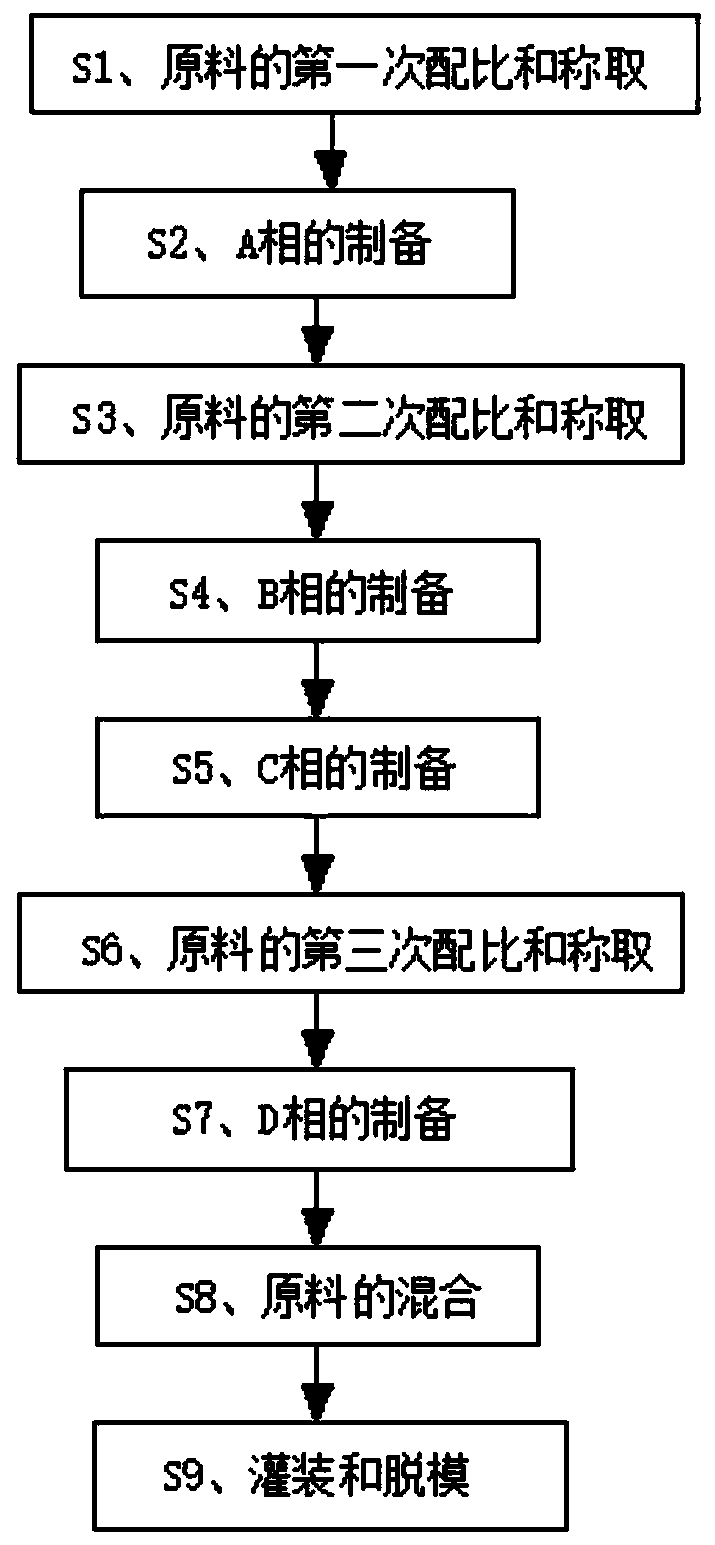

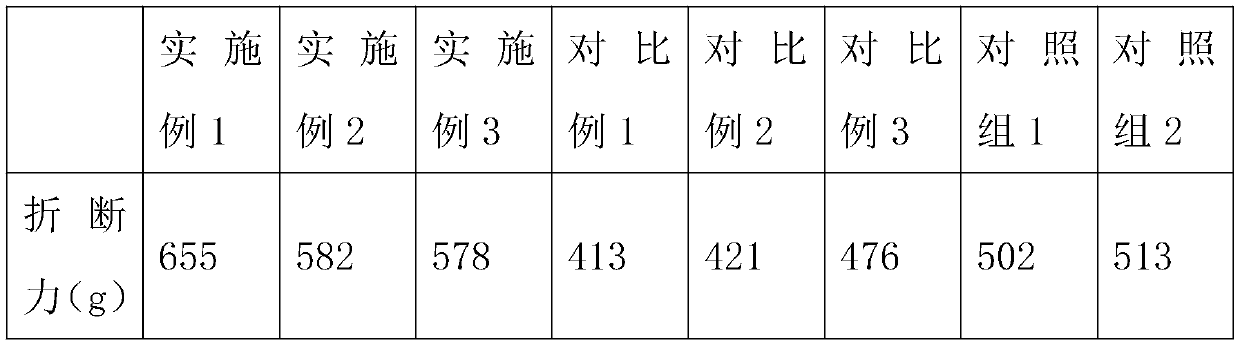

Adhesive tape for mosquito eradication lamp, hot-melt adhesive of the adhesive tap and preparation method of the hot-melt adhesive

ActiveCN101186794AImprove sag resistanceImprove touch tackFilm/foil adhesivesWax adhesivesMolten stateParaffin wax

The invention discloses a hot melt adhesive for adhesive tapes, which is composed of 73-80 polyisobutene glue, 20-25 polyisobutene oil, 0.3-0.5 ultravioresistant agent, 0-0.2 hydroquinone and 1-2 ceresin wax according to weight ratio, heavy engine oil can be added according to needs or heavy engine oil can be utilized to substitute for hydroquinone and ceresin wax with weight ratio of 1 to 2. The process for preparing the hot melt adhesive is that firstly various materials except polyisobutene glue are mixed and heated to 120-140 DEG C, the mixture is kept in the state of melting, and homogenously mixed after being blended, and then the polyisobutene glue is added, the constant temperature is kept between 120 DEG C and 140 DEG C, then the blending enables the system to be homogenously mixed, consequently the cooling is accomplished. Adhesive tape for a mosquitocide light is formed by evenly coating the prepared hot melt adhesive on a carrier. The hot melt adhesive of the invention is perfect in flow resistance and adhesive property, high in light resistance and oxidation resistance and environment-friendly in materials, which is capable of effectively sticking winged insects in -10 to 70 DEG C. In addition, the adhesive tape is durable, a relatively long adhesive tape placed in an adhesive tape box can be multiply used by sections, and the cost of consumable materials can be reduced.

Owner:惠来县战臣电器有限公司

Anatomical wax tray and production method thereof

The invention provides an anatomical wax tray. The anatomical wax tray contains the following components in parts by mass: 7-20 parts of microcrystalline wax, 14-31 parts of paraffin, 6-17 parts of ozocerite, 7-15 parts of polybutylene, 14-28 parts of beewax, 7-12 parts of polyethylene wax, 3-11 parts of calcified rosin, 2-8 parts of castor oil, 4-11 parts of liquid paraffin, 2-9 parts of butyl rubber, 2-5 parts of albolene and 2-6 parts of white oil. The wax tray produced according to the formula is smooth in surface, moderate in toughness and not liable to rupture due to brittlement; wax chippings are hardly generated and needle holes are easily restored after the anatomical wax tray is punctured by a dissecting needle or an insect needle for many times; the anatomical wax tray is odour-free and convenient to remodel and form; under an extreme environment temperature condition (0-50 DEG C), the anatomical wax tray has low-temperature toughness and impact resistance and is not liable to rupture due to brittlement; at a high temperature, the anatomical wax tray is hardly softened to be sticky and does not volatilize odour. The anatomical wax tray provided by the invention is simple in production method, stable in performance, and capable of meeting anatomy needs on biological and medical experiment specimens in different temperature environments.

Owner:SHANXI UNIV

Preparation method of hyaluronic acid small fragment plaster for promoting the wound healing

InactiveCN101283979AUniform colorImprove textureOrganic active ingredientsAerosol deliveryEthyl hydroxybenzoateSmall fragment

The invention relates to a method for preparing hyaluronan fragment ointment for promoting wound healing. The preparation method comprises the steps of: preparing oligosaccharides of hyaluronan, identifying, separating, and purifying to obtain 4-20mers of oligosaccharides of hyaluronan fragment (o-HA); mixing glycerin monostearate, ceresin and white vaseline, melting, adding liquid paraffin, and keeping at 80 DEG C to obtain oil phase; mixing 4-20mers of o-HA, ethyl p-hydroxybenzoate, OP emulsifying agent and Span-80, adding distilled water, and keeping at 70-80 DEG C to obtain water phase; adding water phase into oil phase while stirring until emulsification completes, and condensing to obtain o-HA ointment. The o-HA ointment can effectively delay the local release of o-HA at the wound site, promote local vascularization at the wound site, and promote wound healing.

Owner:SHANGHAI JIAO TONG UNIV

Fullerene color-changing lipstick and preparation method thereof

InactiveCN111388357AEasy to spreadEasy to develop colorCosmetic preparationsMake-upCaprylyl GlycolPolymer science

The invention discloses a fullerene color-changing lipstick and a preparation method thereof, and relates to the technical field of skin care products. The fullerene color-changing lipstick includes the following components in parts by weight: 10-15 parts of water, 3-6 parts of white beeswax, 1-3 parts of candelilla wax, 4-6 parts of polyethylene, 2-4 parts of polyisobutylene, 1-2 parts of bis-diglyceryl polyacyladipate-2, 2-7 parts of phytosteryl oleate, 7-10 parts of ethylhexyl palmitate, 12-15 parts of cetyl ethyl hexanoate, 18-25 parts of polyglyceryl-2 diisostearate, 8-12 parts of ozokerite, 0.1-1 part of caprylyl glycol, 15-18 parts of polyglyceryl-2 triisostearate, 0.1-0.2 part of fullerene, 0.1-0.15 part of polyvinylpyrrolidone, 5-7 parts of butanediol, 2-3 parts of orange 4, 0.5-0.8 part of red 28, and 0.1-0.2 part of iron black. The fullerene color-changing lipstick provided by the invention is easy to spread, easily develops color, has a good makeup holding effect without lip balm primer, has anti-inflammatory effects, effectively alleviates cleft lip, has no obvious lip lines, modifies lip contour, makes a lip appear a full and soft state, and is very translucent.

Owner:广州市拉凯尔干细胞研究所

Blacking and its preparation method

The invention discloses blacking and its preparation method. The blacking comprises the following components by weight: 5-10 parts of carnauba waxes, 2-5 parts of stearic acid, 10-20 parts of ceresin, 5-10 parts of crude montan waxes, 80-100 parts of turpentine, and 1-5 parts of oil-soluble aniline black. The raw materials are subjected to heating melting, mixing, stirring, cooling and other steps so as to obtain the blacking, which can endow leather shoes with a uniform color and good glossiness when used for shoe polishing, and is environment-friendly and free of stimulating smell.

Owner:罗朝雯

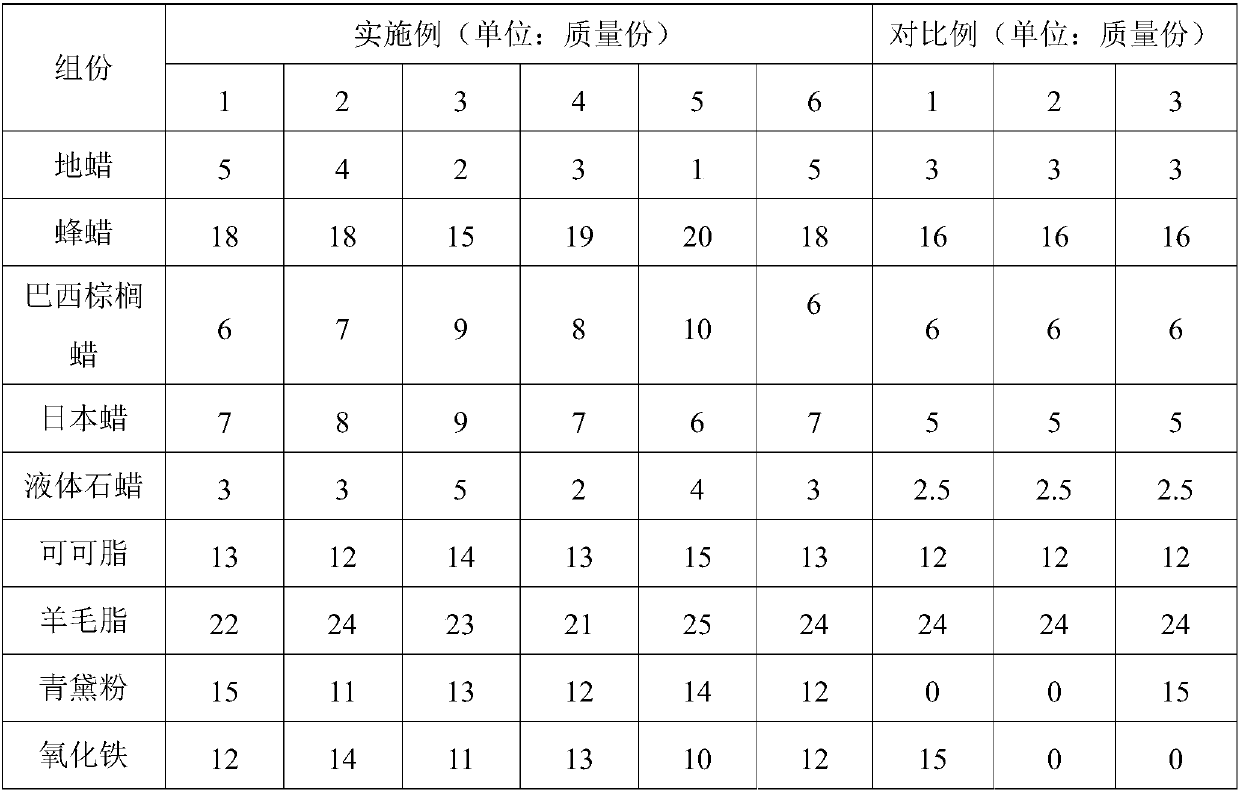

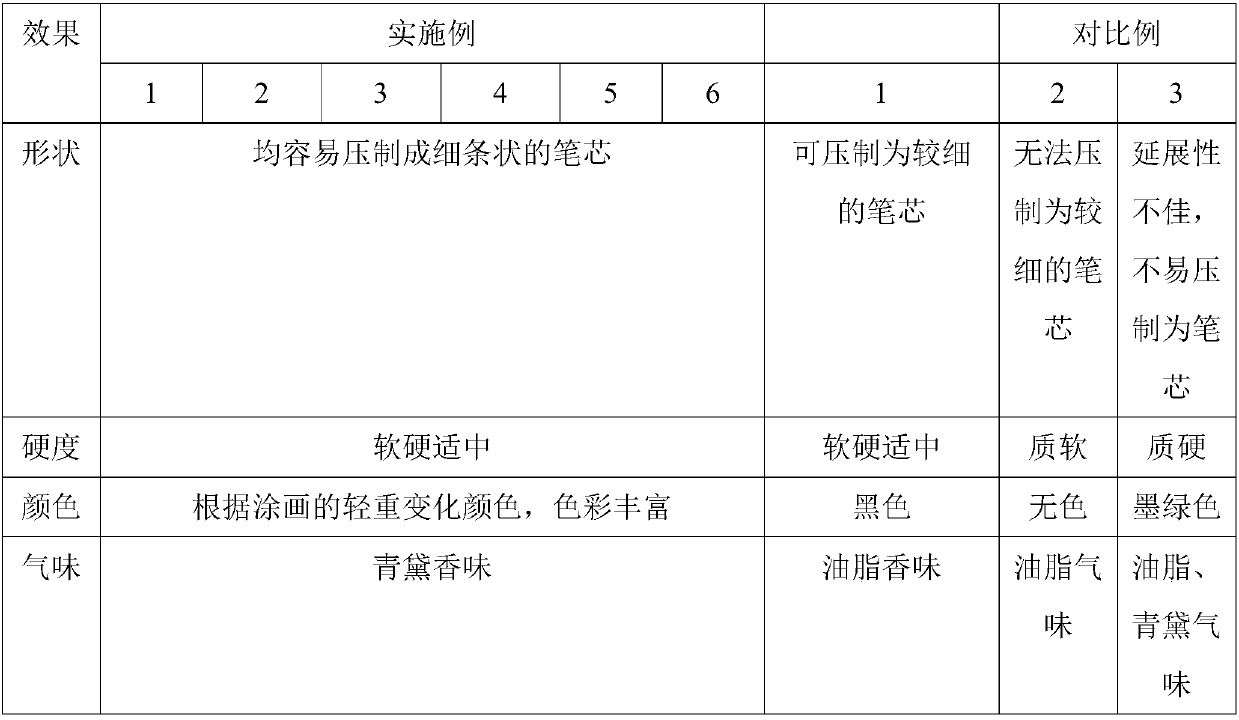

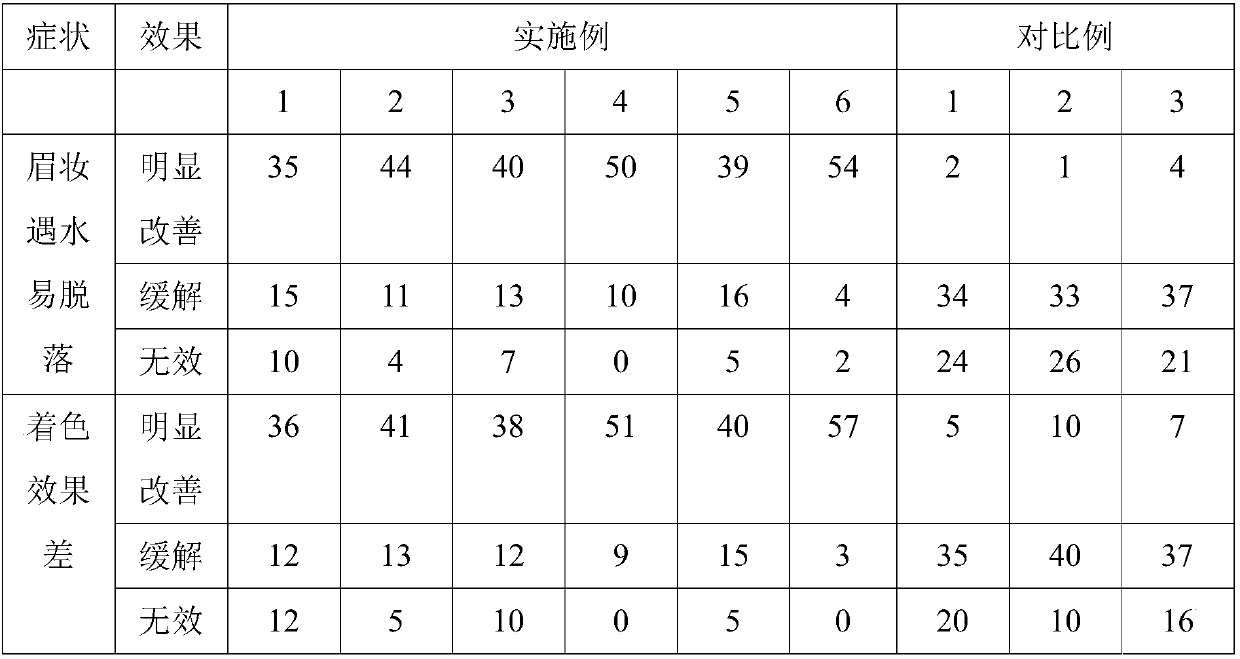

Natural indigo eyebrow pencil refill as well as preparation method and application thereof

The invention discloses a natural indigo eyebrow pencil refill as well as a preparation method and the application thereof. The eyebrow pencil refill comprises the following raw materials in parts bymass: 1-5 parts of ceresin, 16-20 parts of beeswax, 6-10 parts of carnauba wax, 5-9 parts of Japanese wax, 1-5 parts of liquid paraffin, 11-15 parts of cacao butter, 21-25 parts of lanolin, 11-15 parts of a natural indigo powder and 10-14 parts of iron oxide. An eyebrow pencil made of the refill after painting achieves uniform color and rich hue, has a special green black and scent, can clear heatand remove speckles, and is not easy to fall off when touching water. In addition, the eyebrow pencil refill is moderate in hardness, and is easy for compression molding.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Flame-retardant environmental-friendly PVC (polyvinyl chloride) floor and preparation method thereof

InactiveCN106905638AImprove wear resistanceExcellent flame retardantFlat articlesZinc boratePolyvinyl chloride

The invention provides a flame-retardant environmental-friendly PVC floor and a preparation method thereof. The floor is prepared from, by weight, 150-160 parts of PVC, 50-53 parts of calcium powder, 1-4 parts of nano zinc borate, 3-6 parts of ceresin wax, 15-18 parts of stabilizer, 13-15 parts of ACR, 7-9 parts of CPE, 6-12 parts of diatomaceous earth, 1-2 parts of magnesium borate whisker, 0.8-1.5 parts of polyoxyethylene alkylphenol ether and 0.5-2.5 parts of compatilizer. The PVC floor made by the steps of modification, blending, mixing, laminating, cutting and cold pressing molding has excellent flame-retardant, antibacterial, abrasion-resistant, weather-resistant, anti-corrosion and antistatic effects, the impact strength, tensile strength and elastic modulus are remarkably improved, and the processing performance is good, and the floor has the advantages of beautiful appearance, smooth formation, good performance, safety and environmental protection, and the service life is prolonged greatly.

Owner:ANHUI TIANRUN PLASTIC IND

Long-lasting moisturizing lipstick and preparation method thereof

PendingCN111743821AMoisturizingEasy to spreadCosmetic preparationsMake-upPolymer scienceEthylhexyl palmitate

The invention discloses a long-lasting moisturizing lipstick and a preparation method thereof. The long-lasting moisturizing lipstick is prepared from bis-diglycerol polyacyladipate-2, cetyl ethyl hexanoate, tridecyl trimellitate, diisostearyl malate, polymethyl methacrylate, ozocerite, polyethylene, ethylhexyl palmitate, microcrystalline wax, hydrogenated castor oil dipolylinoleate, stearyl polydimethylsiloxane, an antioxidant, phytosterol / octyldodecanol lauroyl glutamate, jojoba seed oil, meadowfoam seed oil, a preservative, a moisturizing conditioner, a dispersing agent, a coloring agent and the like. The long-lasting moisturizing lipstick provided by the invention not only can endow the lip skin with natural color, but also has the advantage of difficulty in makeup removal; through thesynergistic effect of the raw materials, the lipstick has the effects of moistening and moisturizing; the lipstick is easy to spread and make up, and the makeup effect is uniform; and in addition, the preparation process is simple, and industrial production is easy.

Owner:广州卡洛莱化妆品有限公司

Improved concealer pen

An improved concealer pen is composed of a component A, a component B, a component C, a component D and a component E. The component A is composed of water, butanediol, glycerin, sodium chloride, sodium dehydroacetate, shea butter, potassium sorbate, sodium hyaluronate, methyl methacrylate cross-linked polymer, and an aqueous solution of sodium hyaluronate. The component B is composed of a mixture of cyclohexasiloxane and cyclopentasiloxane, C12-15 alkyl benzoate, aluminum oxide, and a mixture of titanium dioxide and triethoxycaprylylsilane. The component C is composed of ozocerite, hydrogenated coco-glycerides, copernicia cerifera wax and cetyl PEG / PPG-10 / 1 polydimethylsiloxane. The component D is composed of a mixture of ethylhexylglycerin and phenoxyethanol, glycine betaine and butanediol. The component E is composed of a mixture of polymethylsiloxane and talcum powder, a mixture of hydrogenated macadamia seed oil and macadamia seed oil, and panthenol. The improved concealer pen is refreshing and breathable, has a moisturizing effect, and can better fit skin.

Owner:丽鑫生技化妆品(上海)有限公司

Special matt agent for rubber and preparation method thereof

The invention relates to a special matt agent for rubber applied in rubber products and a preparation method thereof. The matt agent comprises the following raw materials by weight: 6-12 portions of rubber softening oil, 14-20 of portions stearic acid, 2-8 portions of zinc stearate, 7-13 portions of ceresin, 21-27 of portions emulsifier, 2-8 portions of inorganic carrier, and 27-33 portions of coupling agent. The preparation method comprises the steps as follows: 1) controlling the temperature of a reaction kettle at 180-200 DEG C; 2) sequentially adding the rubber softening oil, the stearic acid, the zinc stearate, the ceresin, the emulsifier, the inorganic carrier and the coupling agent into the reaction kettle; 3) discharging materials after reaction for 60-minute and cooling; 4) crushing and sieving; and 5) checking and packing. The special matt agent for rubber makes the appearance of the rubber products reach ideal matt degree without blooming and white spraying, has no influence to the performance of original products, does not need to change of the formulation of original products, and is simple and convenient as being directly added to the original formulation. The invention is suitable for all the rubber products that need the matt degree, and meets the requirements of domestic and foreign markets.

Owner:JIHUA 3517 RUBBER PROD

Paraffin hydrogenation refining catalyst and its preparation method

ActiveCN1769394APore Distribution ImprovementGood dispersionPetroleum wax refiningParaffin waxCeresin

The invention provides a refining catalysis for ceresin wax hydrogenation and its method. First, make out new carrier Al203 which is characterized on being hydrogenation refining catalysis of high activity. At the same time, the bore diameter of said Al203 is larger, and the bore distribution is much assembled, average pore size is between 10 and 15 nm, the rate of the bores whose diameter is lager than 15 nm could be more than 20%, while the mechanical strength is larger than 160N / cm(ªŽú¢1.2mm strip form)íú Therefore, it is suitable to be hydrogenation refining catalysis carrier for making special raw ceresin wax. Comparing with present ceresin wax hydrogenation refining catalysis, said invention has projecting adaptability when dealing with raw ceresin wax and its decolouration effect, demetal rate, aromatic hydrocarbon saturation are both increased appreciablely.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-bright liquid shoe cream

The invention relates to a self-bright liquid shoe cream which is prepared from the following components: 500g of Brazilian wax, 300g of refined beeswax, 500g of ceresin wax, 600g of yellow wax, 600g of Montague wax, 200g of castor wax, 300g of calcined soda, 100g of soap flakes, 800g of rubberlith, 800g of essence, 500g of glycerin, 100g of multi-ethyl cetyl alcohol and 6000g of deionized water. The self-bright liquid shoe cream is prepared by adopting the following steps: firstly proportionally heating and melting all the waxes; dissolving an emulsifier in water in another container; heating to a melting temperature of the mixed wax; pouring the melted mixed wax in the deionized water; fully stirring into a wax emulsion; then, sequentially adding and evenly stirring the calcined soda, the soap flakes, the rubberlith, the essence, the glycerin, the multi-ethyl cetanol and bottling in a bottle with a brush.

Owner:刘光玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com