Adhesive tape for mosquito eradication lamp, hot-melt adhesive of the adhesive tap and preparation method of the hot-melt adhesive

A technology of hot-melt adhesives and tapes, which is applied in the direction of film/sheet adhesives, adhesives, wax adhesives, etc., which can solve the problems of poor touch adhesion, non-environmental protection of materials, and increased cost of consumables, etc., to achieve anti-sagging Improved performance and tackiness, strong light and oxidation resistance, and reduced cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

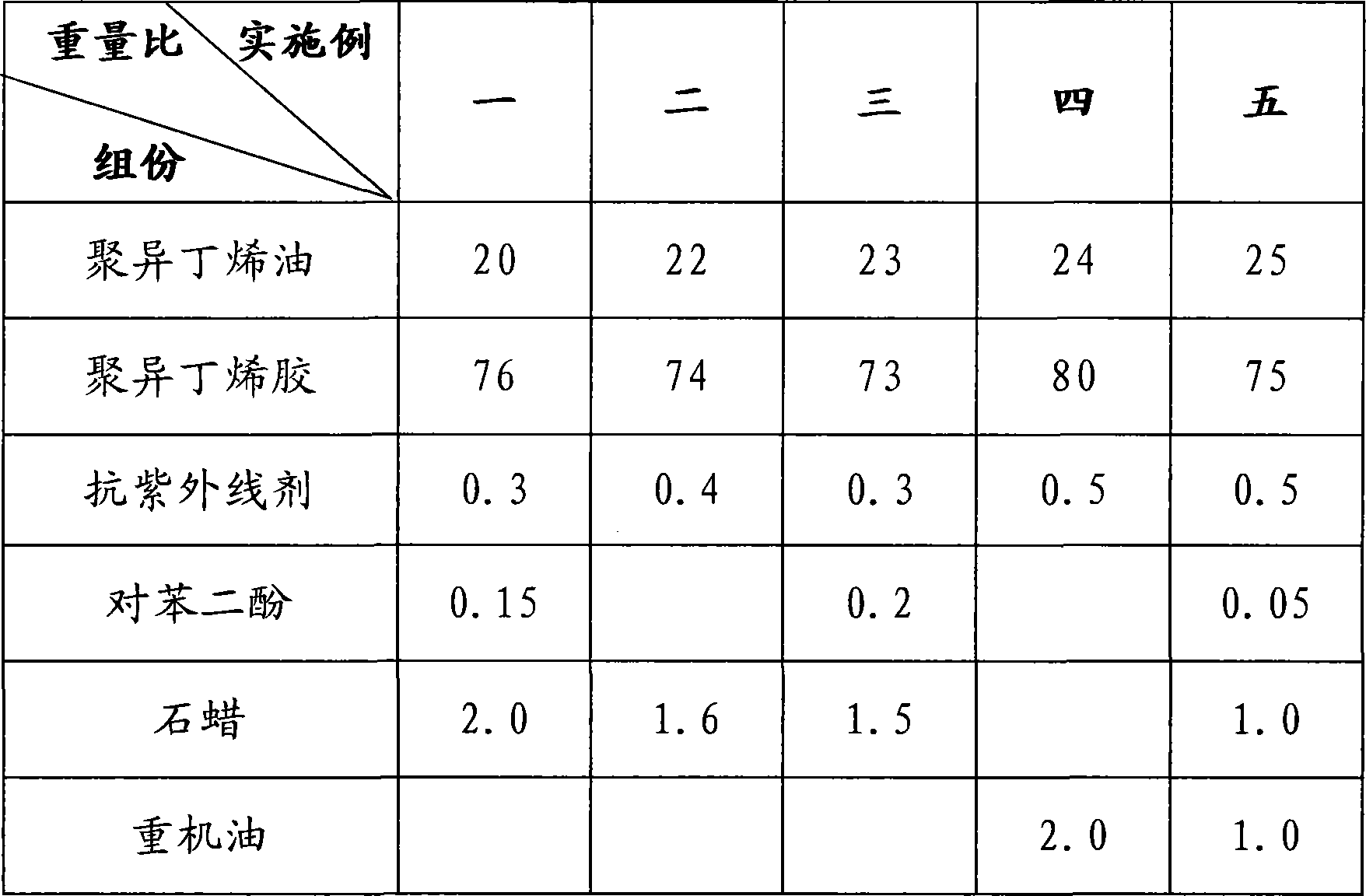

[0043] Please refer to the following table 1. Table 1 discloses five specific embodiments of the hot melt adhesive for the adhesive tape of the present invention. The present invention will be described in more detail below in conjunction with table 1:

[0044] Table 1: The concrete kilogram weight ratio of each embodiment:

[0045]

[0046] In the first embodiment shown in Table 1, 20kg of polyisobutylene oil, 76kg of polyisobutylene glue, 0.3kg of anti-ultraviolet agent, 0.15kg of hydroquinone, and 2.0kg of paraffin wax can be prepared, prepared according to the following method:

[0047] First, mix and heat the various materials mentioned above except polyisobutylene glue, namely polyisobutylene oil, anti-ultraviolet agent, hydroquinone, paraffin, etc., to 120-140°C to make the system in a molten state. After stirring, use It is mixed evenly; then, polyisobutylene glue is added, the temperature is raised to 120-140° C. and kept at a constant temperature, stirred to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com