Patents

Literature

314 results about "P-Hydroquinone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin care composition comprising hydroquinone and a substantially anhydrous base

InactiveUS20060120979A1High molecular weightCosmetic preparationsHair cosmeticsHydroquinone CompoundSolvent

The present invention is directed to an anhydrous topical skin care composition, comprising: hydroquinone and an anhydrous base comprising an anhydrous solvent and a high molecular weight silicone carrier. The composition is substantially free of water which imparts advantageous properties, including smooth feel and long shelf life, to the composition.

Owner:DERMATOLOGIC COSMETIC LAB

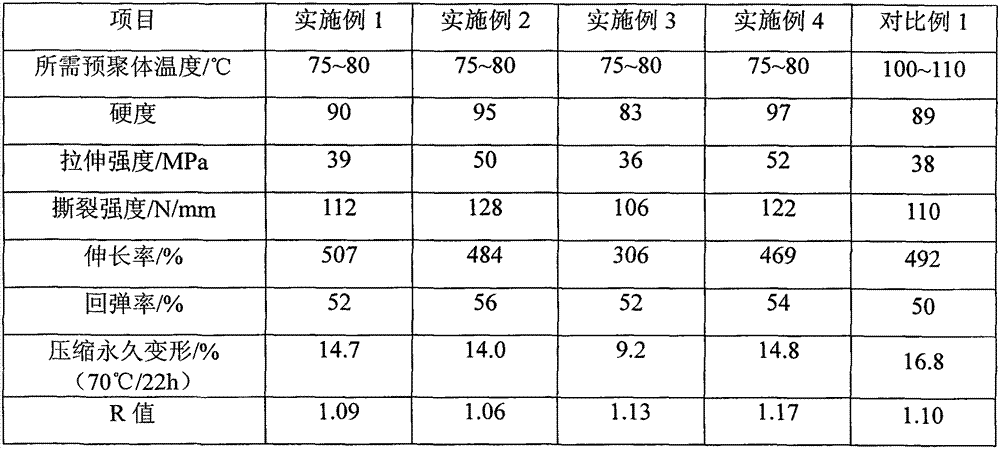

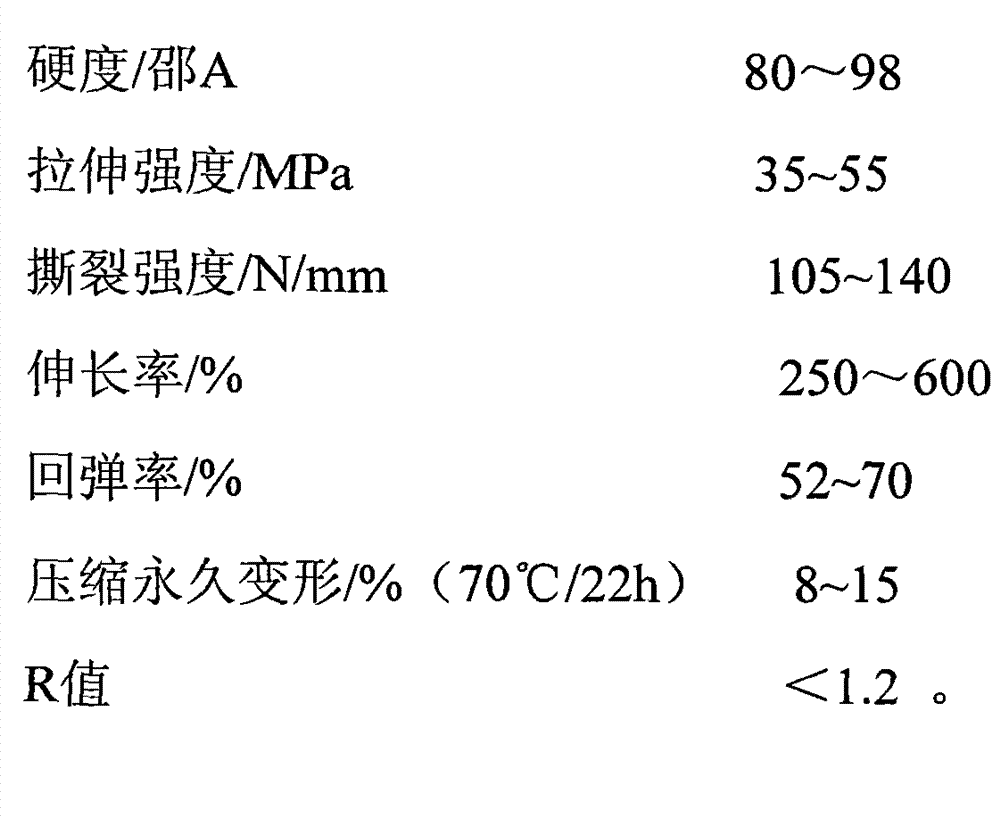

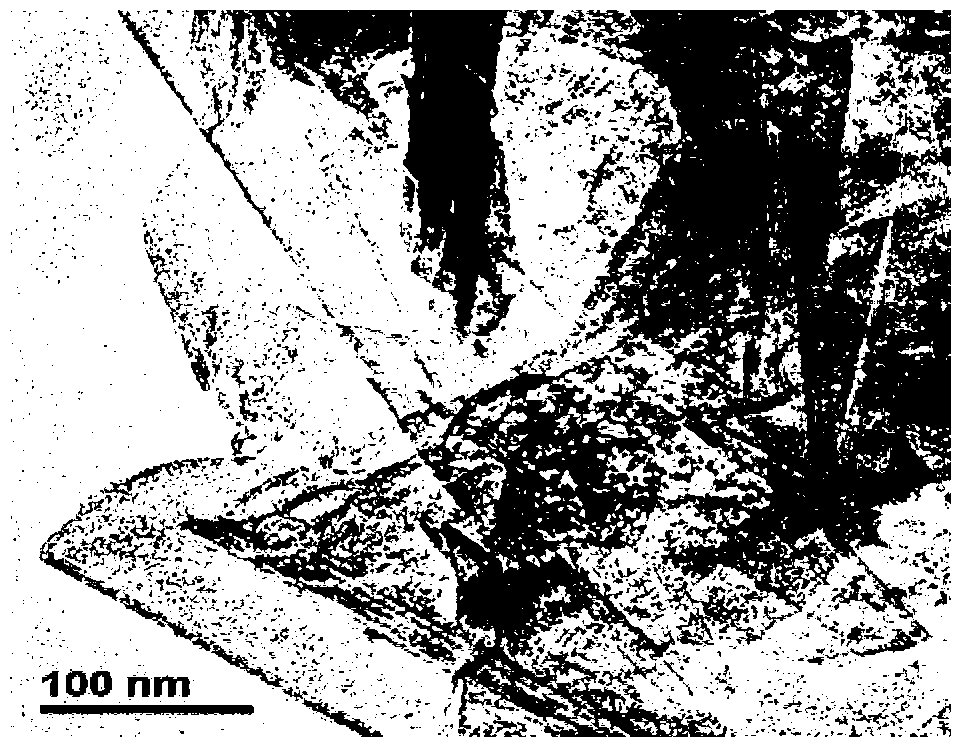

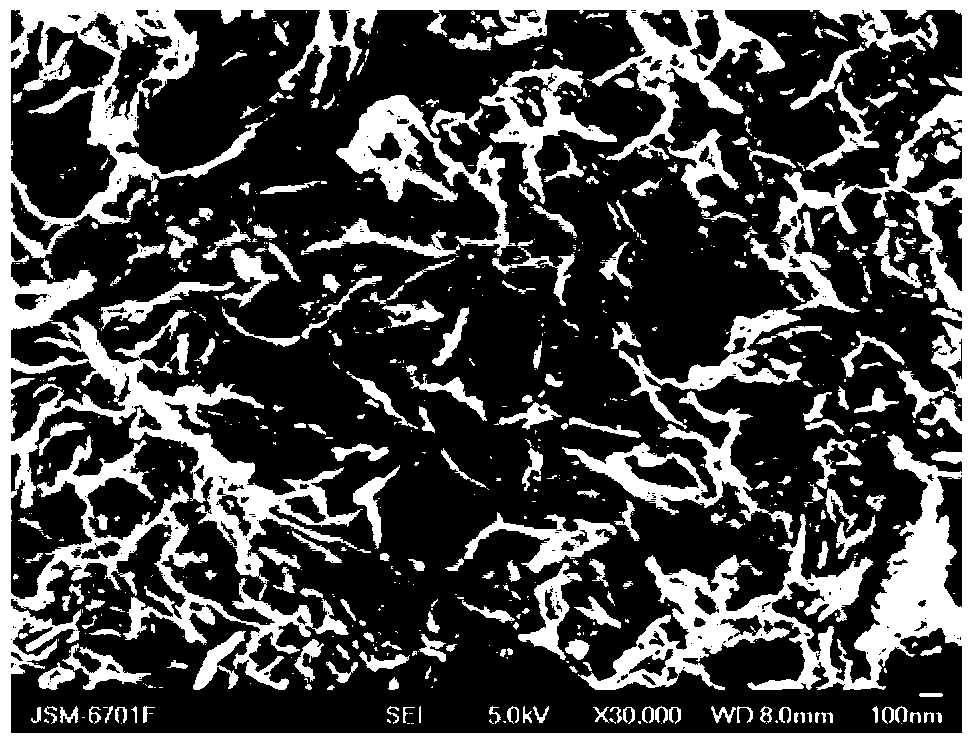

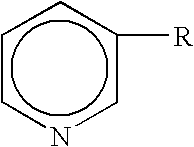

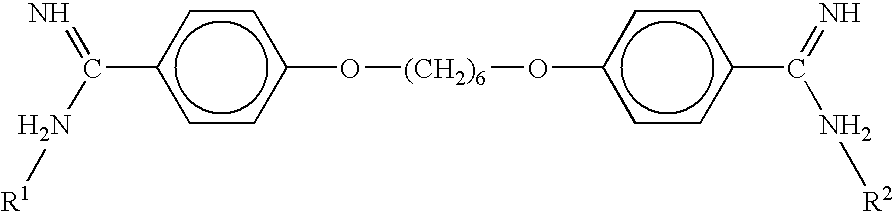

High-performance polyurethane elastomer and preparation method thereof

The invention discloses a high-performance polyurethane elastomer and a preparation method thereof. The high-performance polyurethane elastomer comprises two parts, i.e., a prepolymer component (component A) and a chain extender (component B), wherein the component A comprises the following materials in parts by weight: 100 parts of macromolecular dihydric alcohol and 14-35 parts of PPDI; the component B comprises the following materials in parts by weight: 100 parts of chain extender and 0.1-0.5 part of catalyst; the weight ratio of the component A to the component B is 100: 6-15; the chain extender is micromolecular dihydric alcohol, three-functionality-degree alcohol amine, three-functionality-degree alcohol or combination thereof; the micromolecular dihydric alcohol is selected from resorcinol-bi(beta-ethoxyl) ether (HER) or composition of the resorcinol-bi (beta-ethoxyl) ether (HER) and p-hydroquinone-bi(beta-ethoxyl) ether (HQEE) in the weight ratio of 1:0-2. The obtained elastomer material has the advantages that the permanent deformation is small, the resilience is excellent, the heat resistance and the mechanical performance are good and the temperature for the use and the operation of the prepolymer is low.

Owner:LIMING RES INST OF CHEM IND

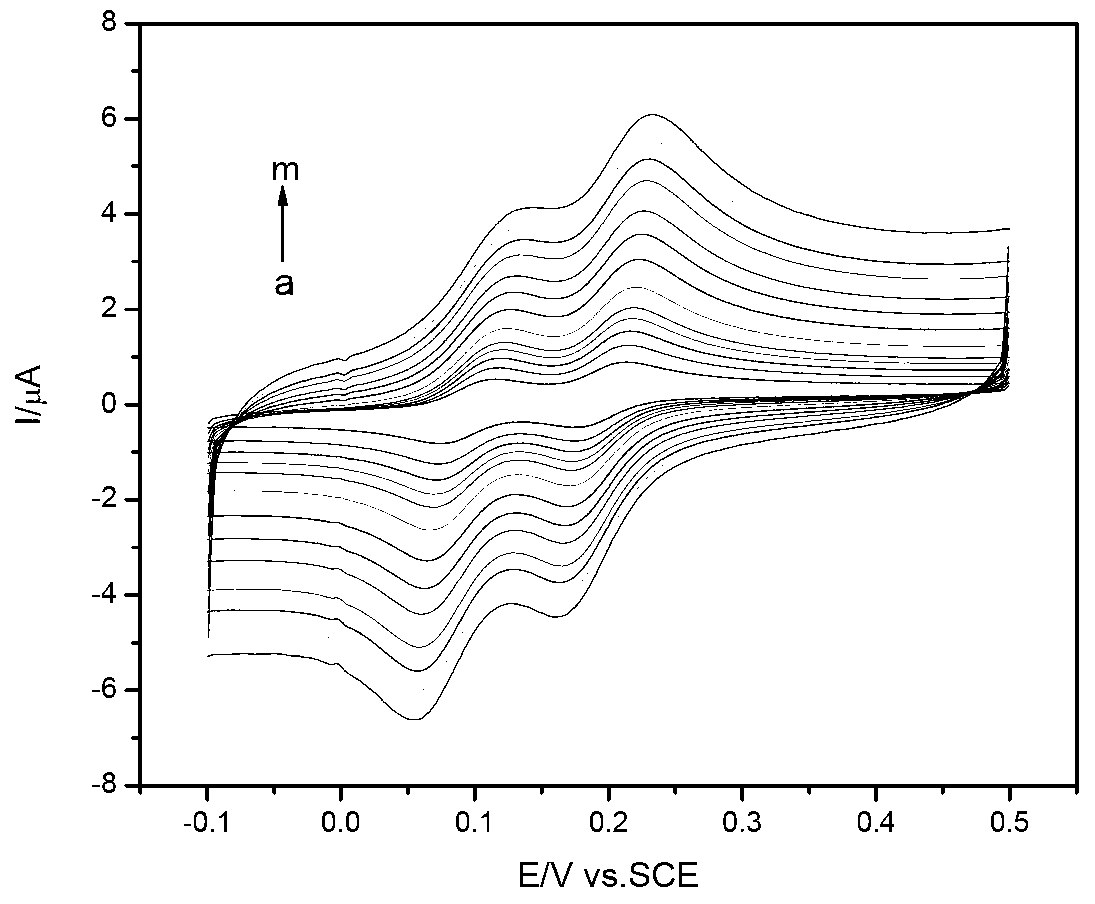

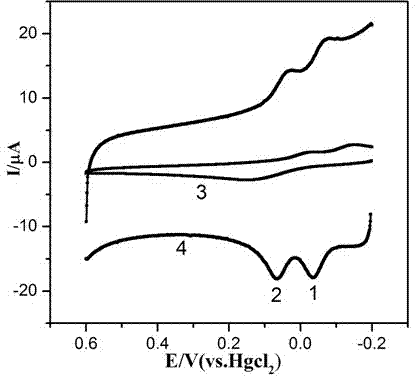

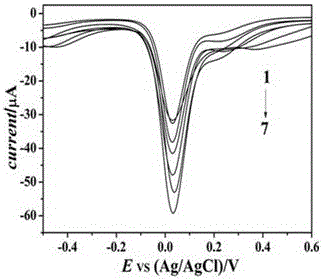

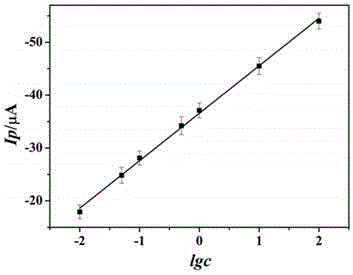

Method for simultaneous detection of hydroquinone and pyrocatechol, and preparation method for applied nitrogen-doped graphene-modified glassy carbon electrode

InactiveCN103267787AEasy to separateLarge specific surface areaMaterial electrochemical variablesPlatinumDoped graphene

The invention discloses a novel method for simultaneous detection of hydroquinone and pyrocatechol by using a nitrogen-doped graphene-modified electrode. The method comprises the following steps: 1) placing the nitrogen-doped graphene-modified electrode in a sodium phosphate buffer solution which has a concentration of 0.1 mol / L and a pH value of 7 and contains hydroquinone and pyrocatechol with a total concentration of 1* 10<-4> mol / L and carrying out cyclic voltammetric scanning of different scanning speeds with a platinum wire electrode used as a counter electrode and a saturated calomel electrode used as a reference electrode; 2) placing the nitrogen-doped graphene-modified electrode in a sodium phosphate buffer solution which has a concentration of 0.1 mol / L and a pH value of 7 and contains pyrocatechol with a concentration of 1* 10<-5> mol / L and hydroquinone with different concentrations and carrying out differential pulse voltammetric scanning with the platinum wire electrode used as the counter electrode and the saturated calomel electrode used as the reference electrode; and 3) placing the nitrogen-doped graphene-modified electrode in a sodium phosphate buffer solution which has a concentration of 0.1 mol / L and a pH value of 7 and contains hydroquinone with a concentration of 1* 10<-5> mol / L and pyrocatechol with different concentrations and carrying out differential pulse voltammetric scanning with the platinum wire electrode used as the counter electrode and the saturated calomel electrode used as the reference electrode.

Owner:NORTHWEST NORMAL UNIVERSITY

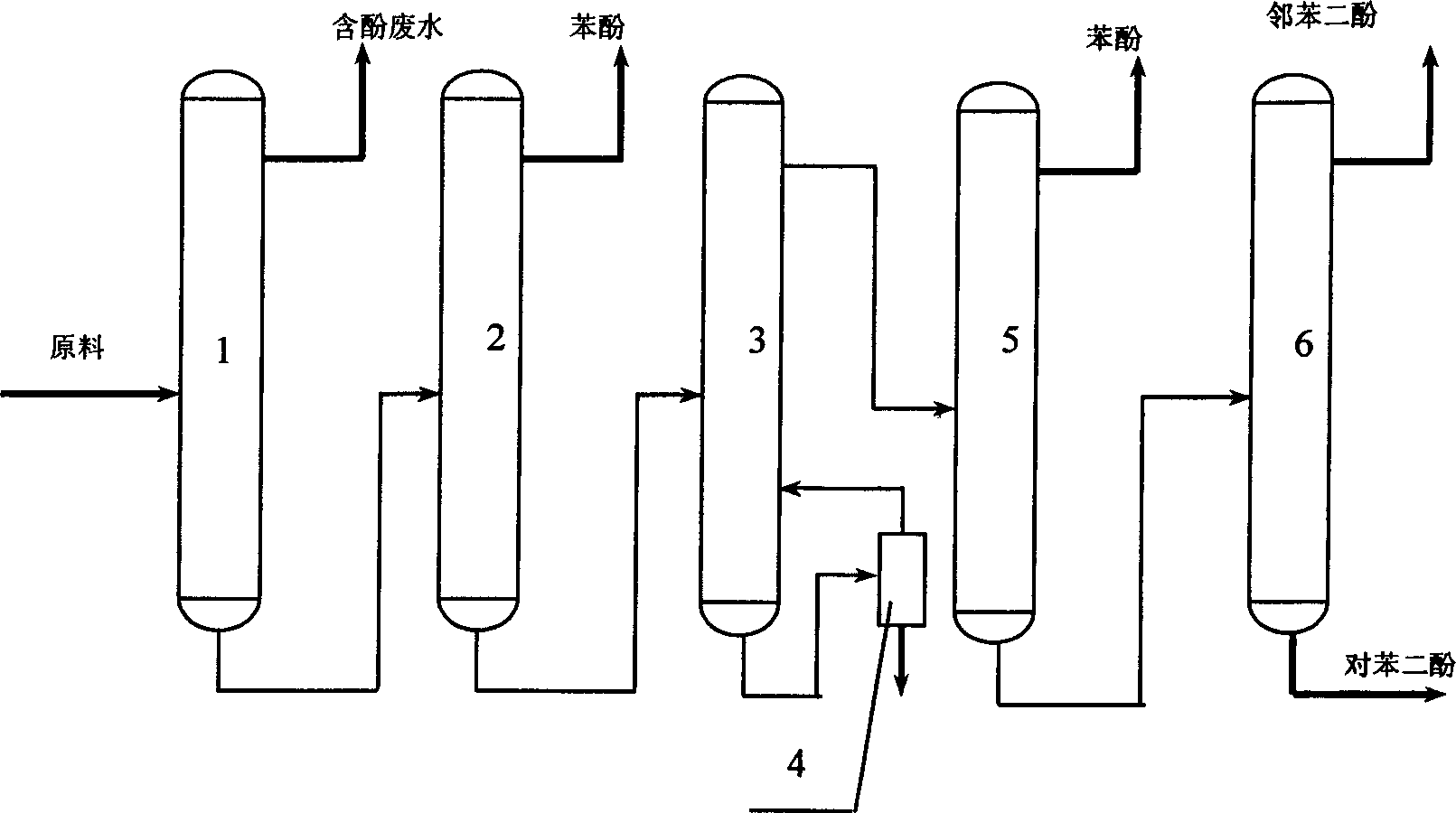

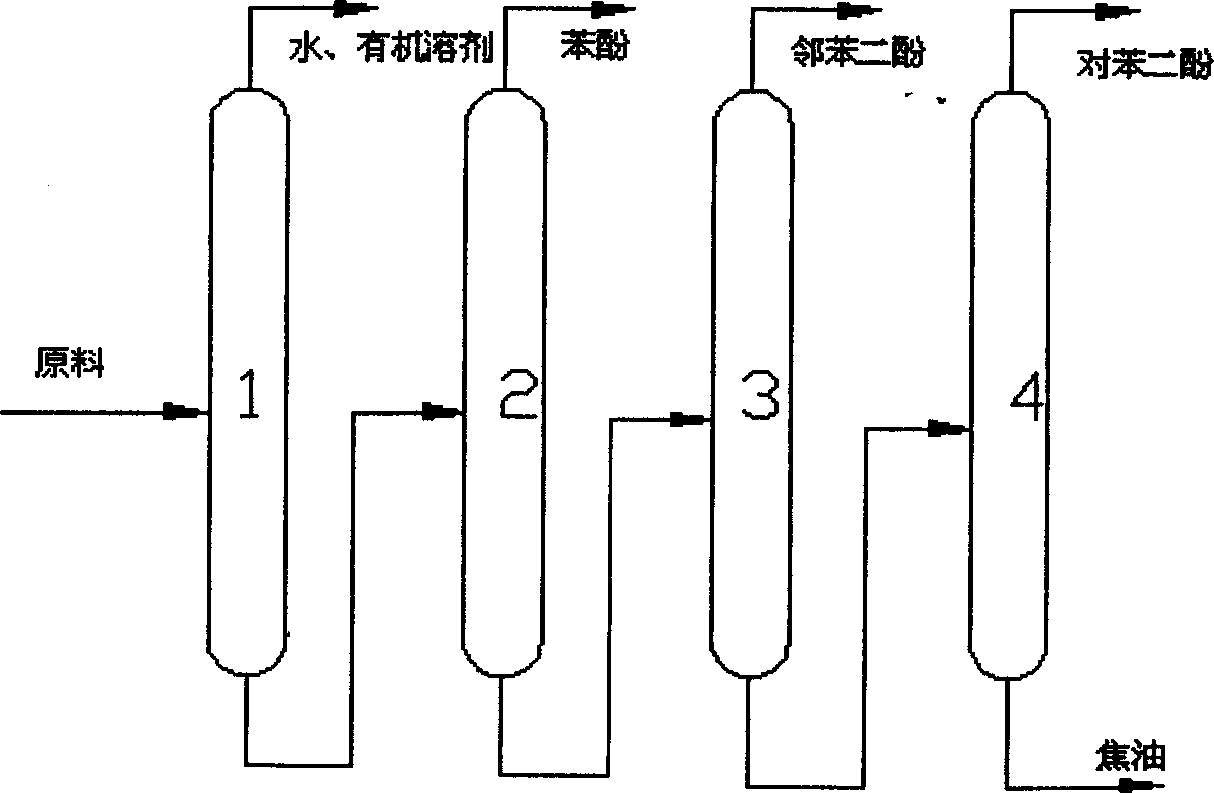

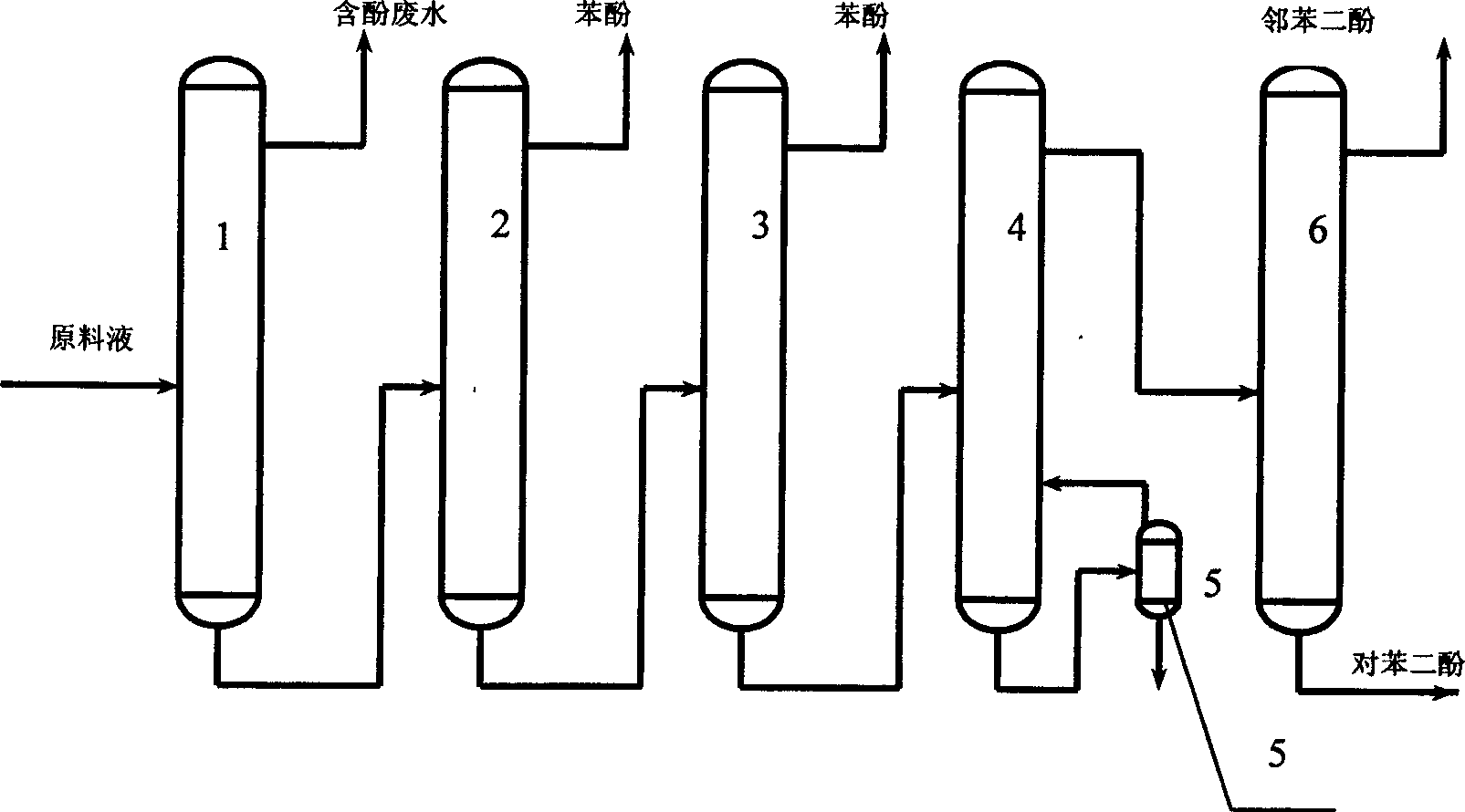

Apparatus and method of separating and purifying water solution of phenol, catechol, hydroquinone and tar

InactiveCN1847209ALittle risk of heat sensitivityHigh purityOrganic chemistryOrganic compound preparationP-BenzenediolTar

The present invention discloses the apparatus and method of separating and purifying phenol, catechol, hydroquinone and tar in water solution. The apparatus includes a dewatering distillation tower with entry end, a first phenol eliminating distillation tower, a second phenol eliminating distillation tower, a tar eliminating distillation tower, a deep distilling caldron, and a product distillation tower. The separating process includes the following steps: feeding the materials successively into the apparatus for rectification separating, and exhausting catechol and p-benzenediol separately in the top and the bottom of the product distillation tower. Owing to the continuous five tower vacuum distillation and high efficiency packing tower technology, the present invention has the features of low phenol content, low operation temperature, etc.

Owner:TIANJIN UNIV

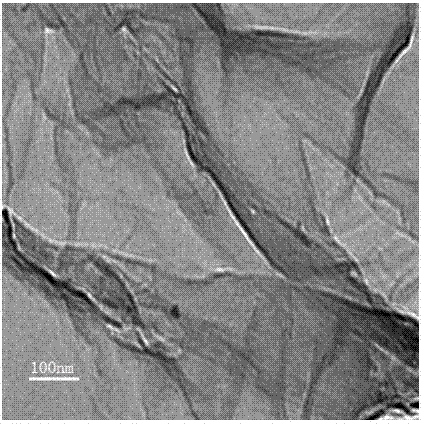

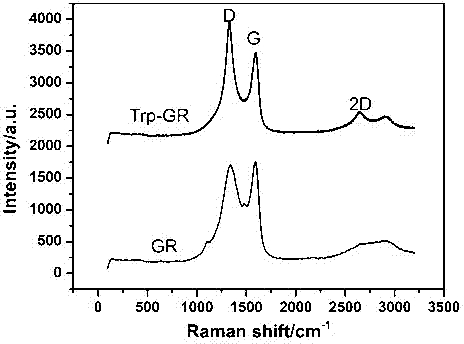

Modified electrode for detecting hydroquinone and catechol

InactiveCN103543189ASolve the problem that it is difficult to distinguish between the twoMaterial electrochemical variablesInterference problemHydroquinone Compound

The invention belongs to the field of electrochemical detection and discloses a modified electrode for detecting hydroquinone and catechol. The modified electrode comprises a substrate electrode as well as graphene treated by L-tryptophan and attached on the substrate electrode. The modified electrode disclosed by the invention can be used for respectively detecting the hydroquinone and the catechol in a quantitative manner without a mutual interference problem, wherein a detecting linear range of the catechol is 5*10<-6>mol / L-3*10<-4>mol / L, and detecting limit is 1.45*10<-7>mol / L; and the detecting linear range of the hydroquinone is 5*10<-6>mol / L-5*10<-4>mol / L, and the detecting limit is 1.69*10<-7>mol / L.

Owner:NORTHWEST NORMAL UNIVERSITY

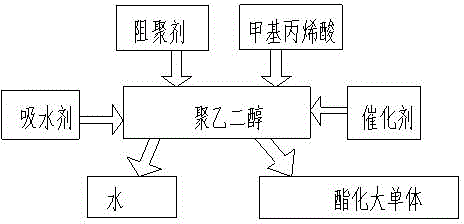

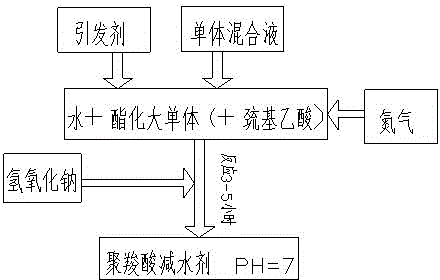

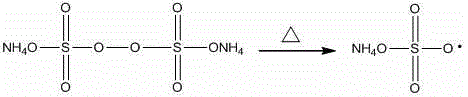

Low-cost polyester polycarboxylic acid water reducer

The invention discloses a low-cost polyester polycarboxylic acid water reducer, and relates to a building material. The low-cost polyester polycarboxylic acid water reducer is prepared from the following steps: an esterification reaction: conducting an esterification reaction on polyethylene glycol and methacrylic acid under effects of an inhibitor hydroquinone and a catalyst p-toluene sulphonic acid to generate esterification macromonomer polyethylene glycol methacrylate and water, wherein silica gel is used as an absorbent in the reaction to absorb water generated in the esterification reaction to proceed the reaction, and stopping the reaction when esterification rate reaches 40-60%; and a polymerization graft reaction: conducting isothermal reaction on the esterification macromonomer polyethylene glycol methacrylate with mixed monomer MAA, AM and SMAS in the presence of a chain transfer agent thioglycolic acid, an initiator ammonium persulfate and an initiating assistant hydrogen peroxide, cooling to room temperature after the reaction, and adding NaOH to adjust a pH value to 7. Compared with the prior art, the low-cost polyester polycarboxylic acid water reducer protected by the invention has advantages of low cost and good water reducing performance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

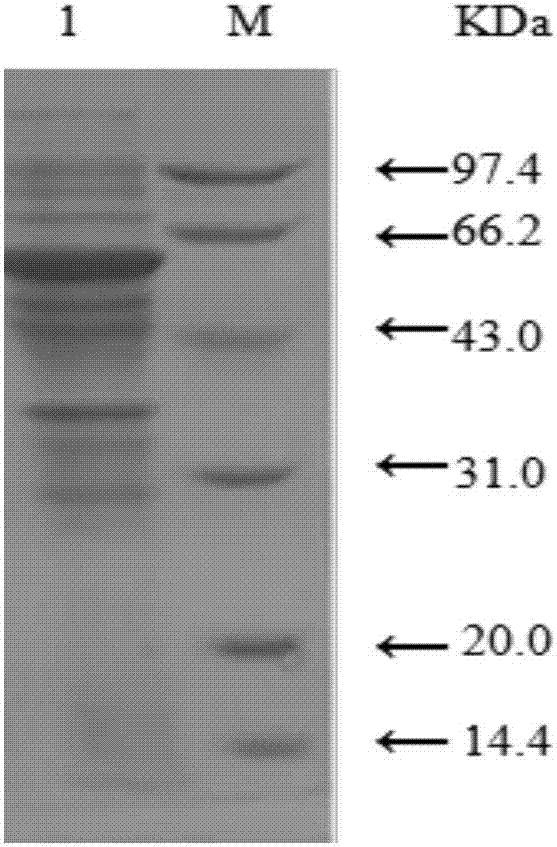

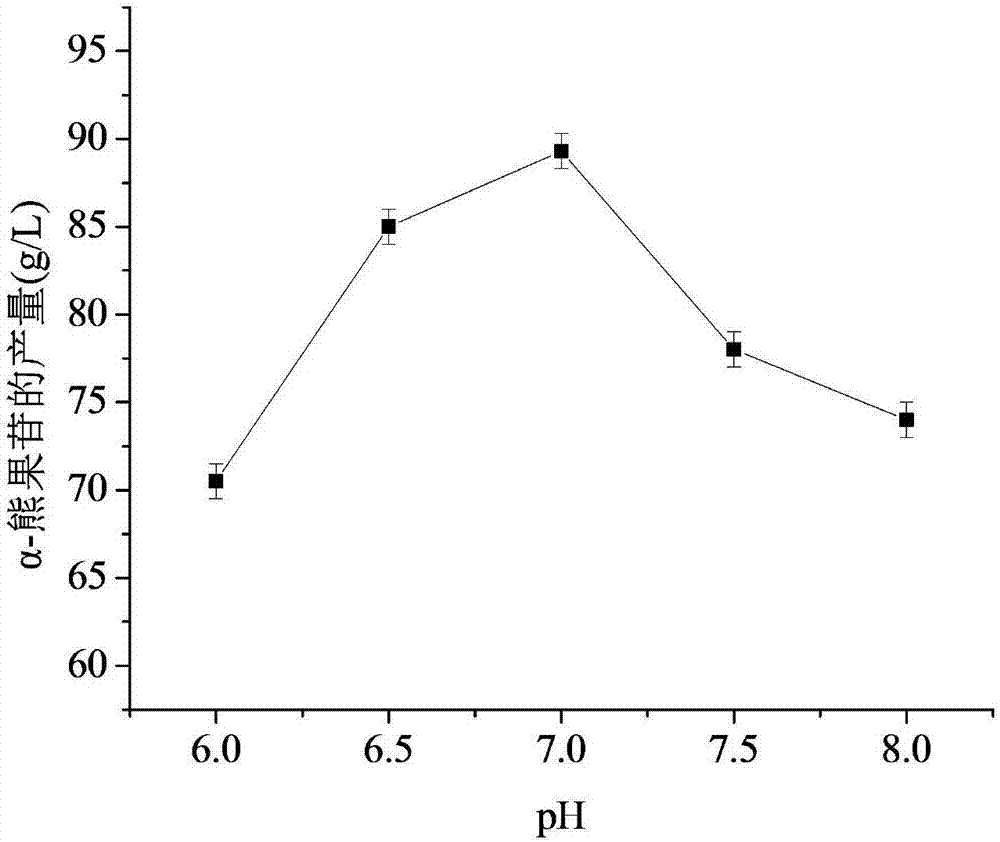

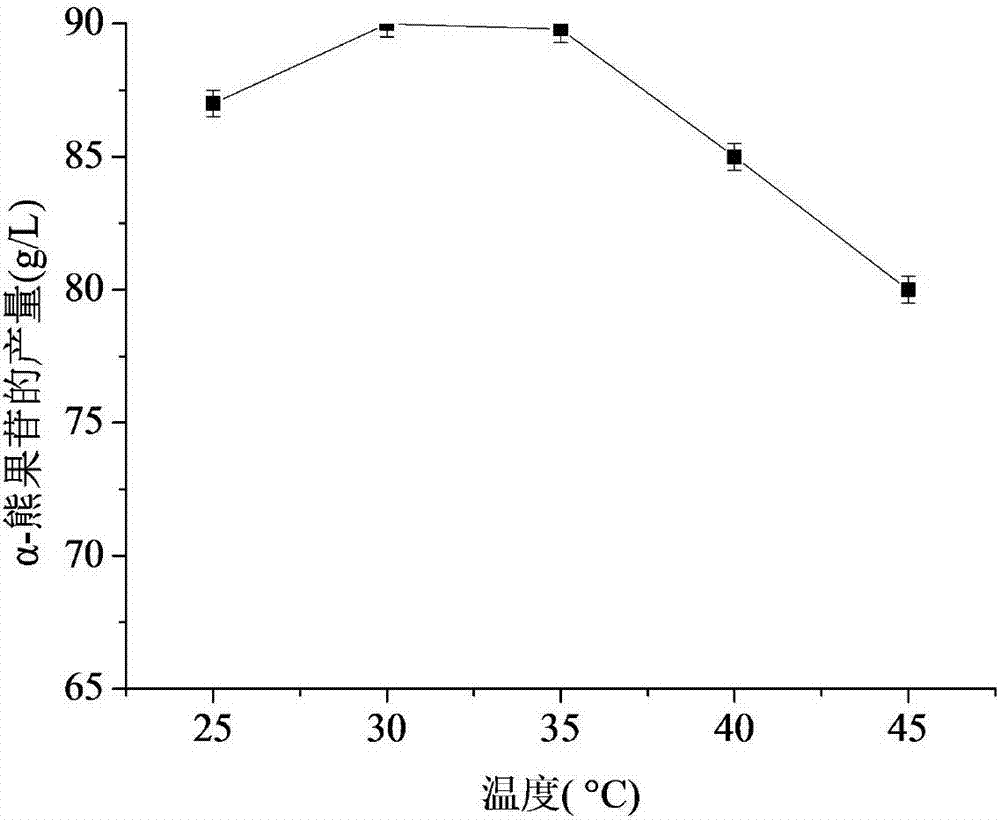

Genetically engineered bacterium for expressing sucrose phosphorylase and application of genetically engineered bacterium

The invention discloses a genetically engineered bacterium for expressing sucrose phosphorylase and application thereof, and belongs to the fields of gene engineering and enzyme engineering. The genetically engineered bacterium has the advantages that a gene shown in SEQ ID NO.1 is subjected to heterologous expression in escherichia coli, recombinant escherichia coli is constructed, and is fermented to produce recombinant sucrose phosphorylase, and enzyme activity in fermented supernatant reaches 40U.mL<-1>; when the recombinant sucrose phosphorylase is used for catalyzing saccharose and hydroquinone to generate alpha-arbutin, a conversion rate can reach 91%; the industrial application potential is higher.

Owner:金韵

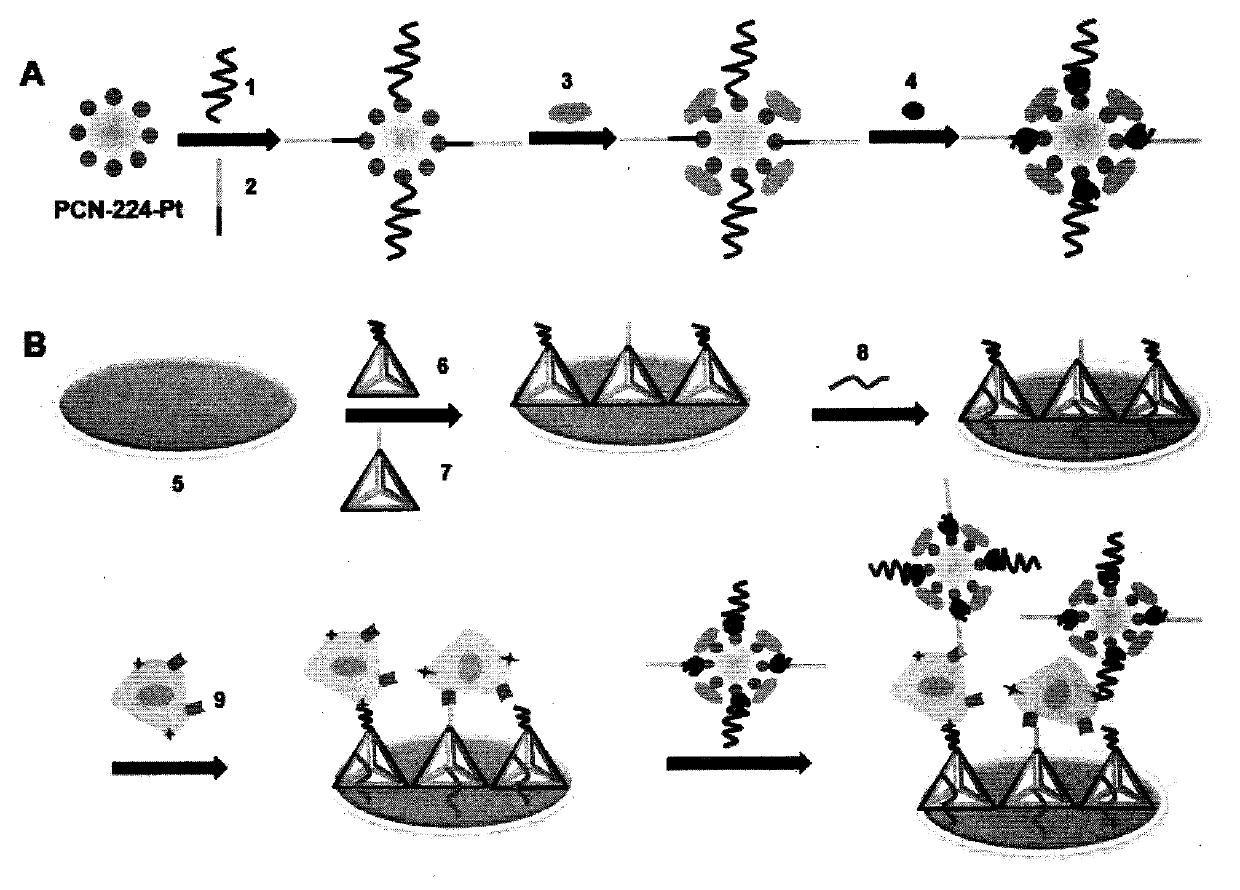

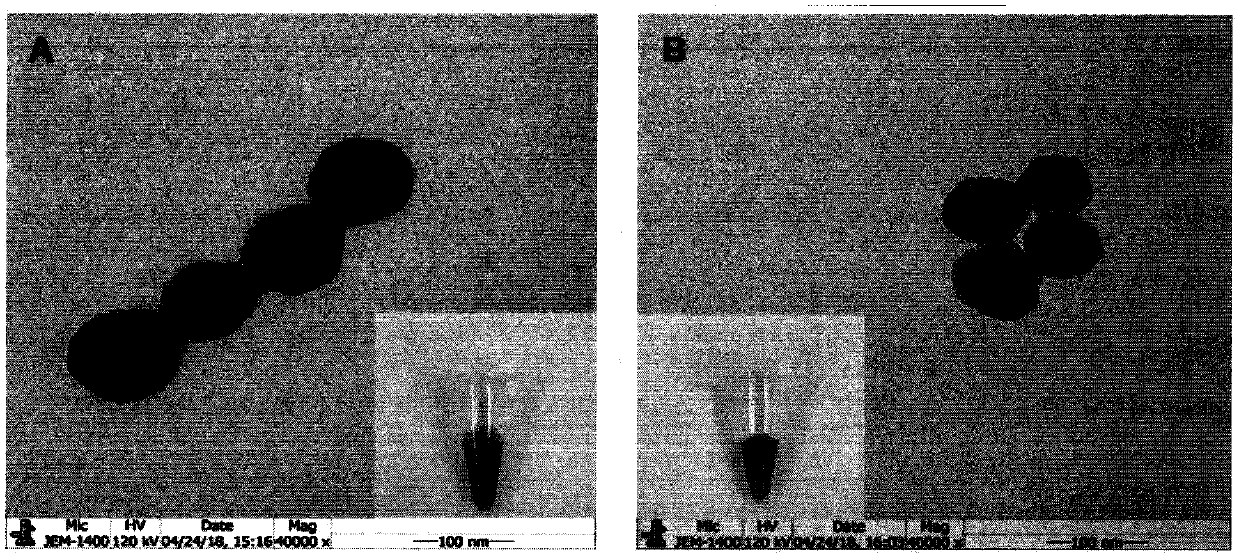

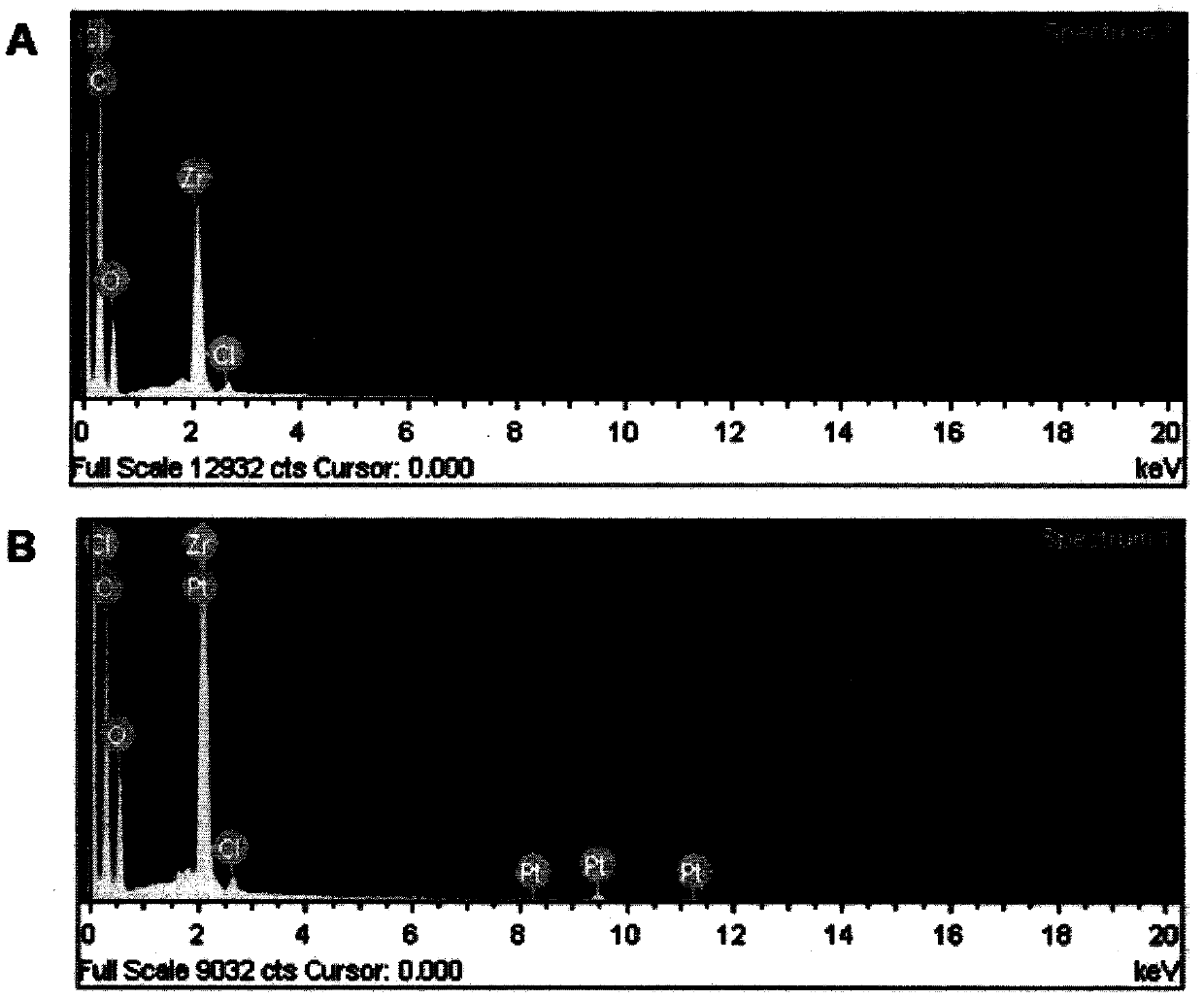

Biosensor capable of being modified repeatedly and used for detecting tumor cells and preparation method of biosensor

InactiveCN110057877AEfficient captureSpecific captureMaterial electrochemical variablesHydroquinone CompoundTetrahedron

The invention provides a biosensor capable of being modified repeatedly and used for detecting tumor cells and a preparation method of the biosensor. Tetrahedrons and aptamers are autonomously mountedon and fixed to a gold electrode through Au-S keys, and thus the human breast cancer cells are efficiently and specifically captured; and then a synthesized PCN-224-Pt / horse radish peroxidase / doubleaptamer / protoheme / G-quadruplet novel metal-organic framework nanoprobe is introduced into a cell sensing interface through combination of the aptamers and the cells, and hydroquinone (HQ)-hydrogen peroxide (H2O2) is catalyzed through three types of enzymes of horse radish peroxidase, a nano-enzyme (Pt nano-particles) and a DNA enzyme (protoheme / G-quadruplet). The biosensor can be used for detecting the tumor cells and has the advantages that selectivity is high, sensitivity is high, the simple, convenient and quick effects are achieved, and the electrode can be modified repeatedly.

Owner:SUN YAT SEN UNIV

Modified electrode for detecting pyrocatechol and hydroquinone and preparation method thereof

ActiveCN103901087AImprove stabilityAchieving Simultaneous DetectionMaterial electrochemical variablesMultiwalled carbonHydroquinone Compound

The invention discloses a modified electrode for detecting pyrocatechol and hydroquinone. The modified electrode comprises a substrate electrode and phthalic acid ethylene glycol diacrylate-carboxylate multiwalled carbon nanotube-graphene which is attached to the substrate electrode. The invention also discloses a method for preparing the modified electrode. The modified electrode can be used for detecting the pyrocatechol and hydroquinone. The linear range of pyrocatechol detection is 5.0*10<-7>-4.0*10 mol / L, and the detection limit is 1.8*10<-8>mol L-1; the linear range of hydroquinone detection is 5.0*10<-7>-4.0*10<-4> mol / L, and the detection limit is 2.0*10<-8> mol L-1. The modified electrode is simple in preparation method, the preparation conditions are easily controlled and realized, the linear detection range is wide, the detection limit is low, and the detection method is high in stability and high in sensitivity.

Owner:QINGDAO UNIV

Blackening agent used for steel and iron surface at room temperature and preparation method for blackening agent at room temperature

The invention discloses a blackening agent at room temperature and a preparation method for the blackening liquid at the room temperature, which are widely applied to the blackening processing for finished products or parts of various alloy steels, cast irons and the like. The blackening agent at the room temperature is prepared from the following components: 2-4g / L of copper sulfate, 5-8g / L of seleninic acid, 2-4g / L of monopotassium phosphate, 1.5-3g / L of hydroquinone, 3-5g / L of phosphoric acid and 0.08-0.3g / L of OP-10. The preparation method comprises the following steps: respectively dissolving the components except the phosphoric acid and the OP-10 with deionized water through heating and then mixing the components evenly, and finally adding the phosphoric acid and the OP-10 for evenly mixing. The blackening agent has the advantages of quick blackening, good film quality and low production cost.

Owner:JIANGSU DEMEI TECH

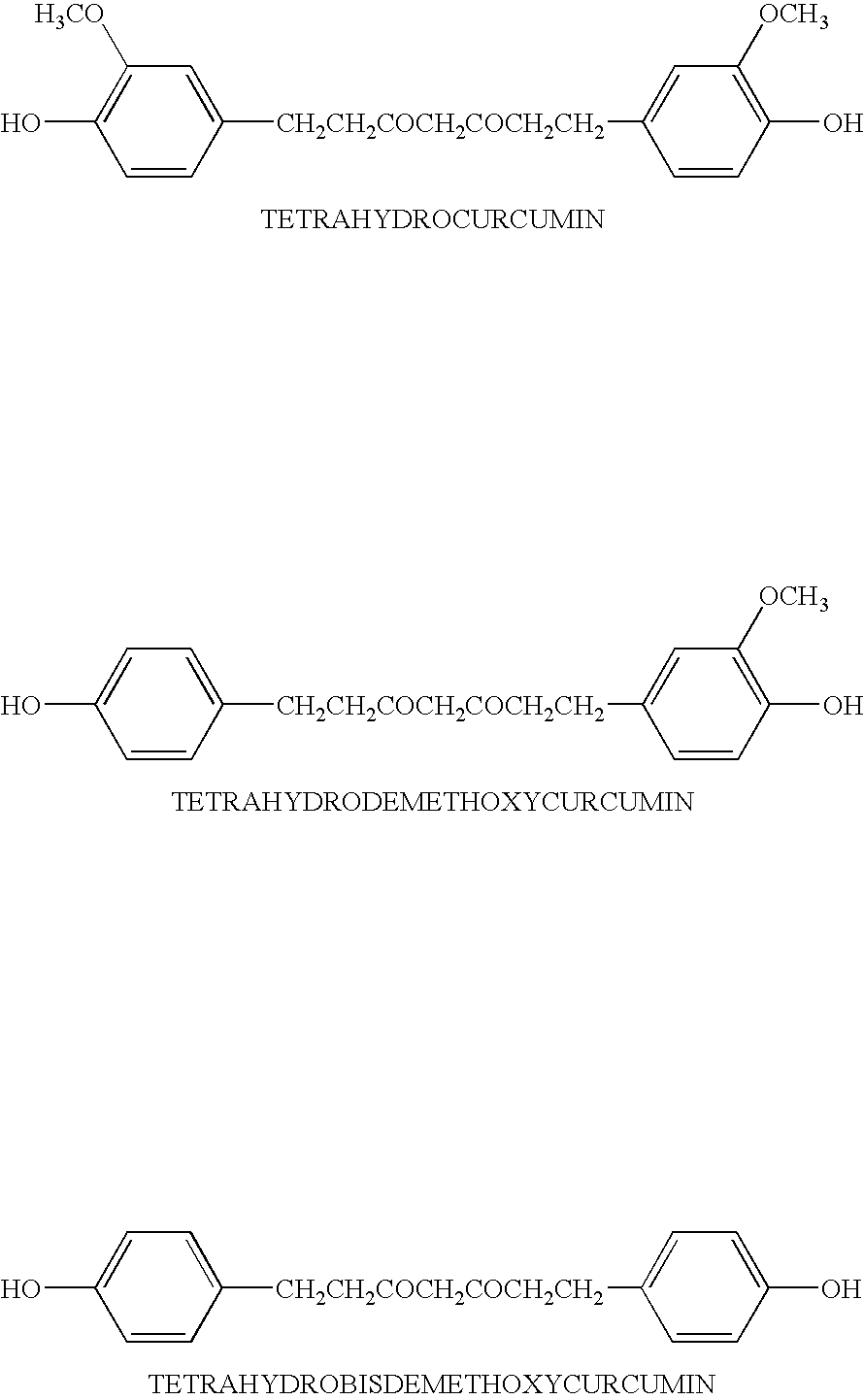

Regulation of mammalian keratinous tissue using personal care compositions comprising cetyl pyridinium chloride

InactiveUS20070020221A1Tactile feel is improvedImprove efficiencyCosmetic preparationsCationic surface-active compoundsDehydroacetic acidRetinoid

Personal care composition including a first skin and / or hair care active cetyl pyridinium chloride; and at least one additional skin and / or hair care active selected from the group consisting of tetrahydrocurcumin, sugar amine, vitamin B3, retinoids, hydroquinone, peptides, phytosterol, dialkanoyl hydroxyproline, hexamidine, salicylic acid, n-acyl amino acid compounds, sunscreen actives, water soluble vitamins, oil soluble vitamins, hesperedin, mustard seed extract, glycyrrhizic acid, glycyrrhetinic acid, carnosine, Butylated Hydroxytoluene (BHT) and Butylated Hydroxyanisole (BHA), ergothioneine, vanillin or its derivatives, diethylhexyl syrinylidene malonate, melanostatine, sterol esters, idebenone, dehydroacetic acid, Licohalcone A, creatine, creatinine, feverfew extract, yeast extract, beta glucans, alpha glucans, their salts, their derivatives, their precursors, and / or combinations thereof; and a dermatologically acceptable carrier. The invention further relates to methods for regulating the condition of mammalian keratinous tissue wherein the methods each comprise the step of topically applying to the keratinous tissue of a mammal needing such treatment, a safe and effective amount of the personal care composition of the invention.

Owner:THE PROCTER & GAMBLE COMPANY

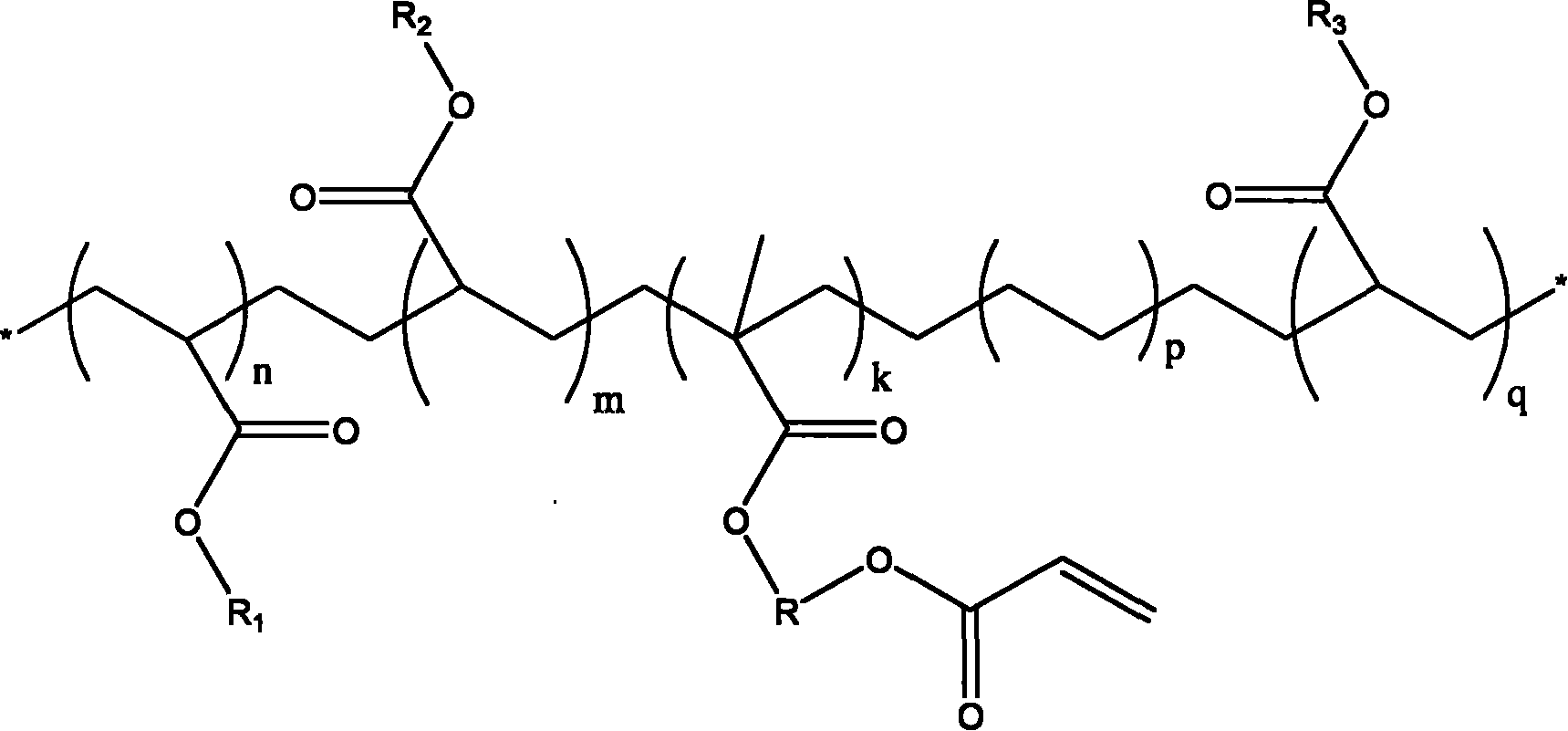

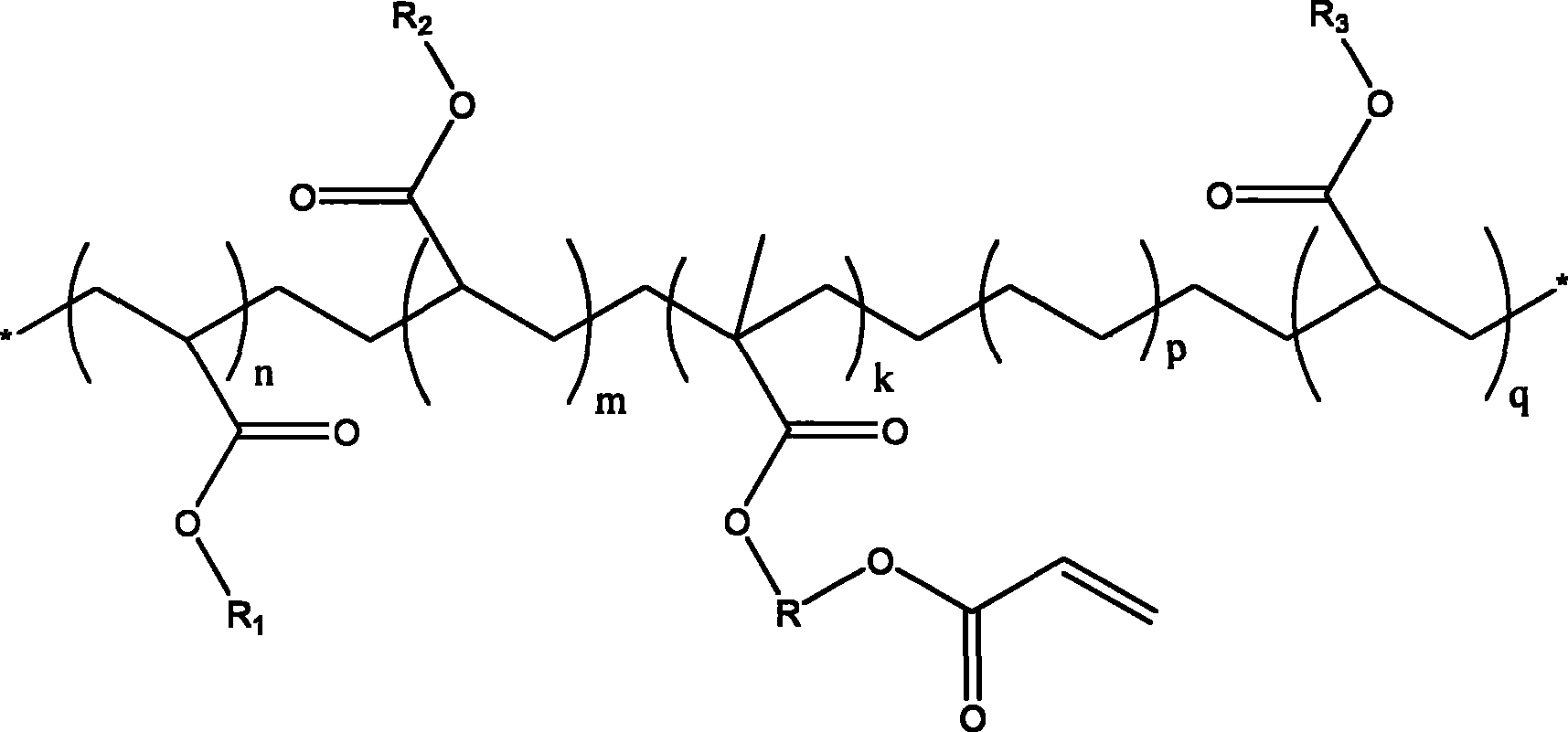

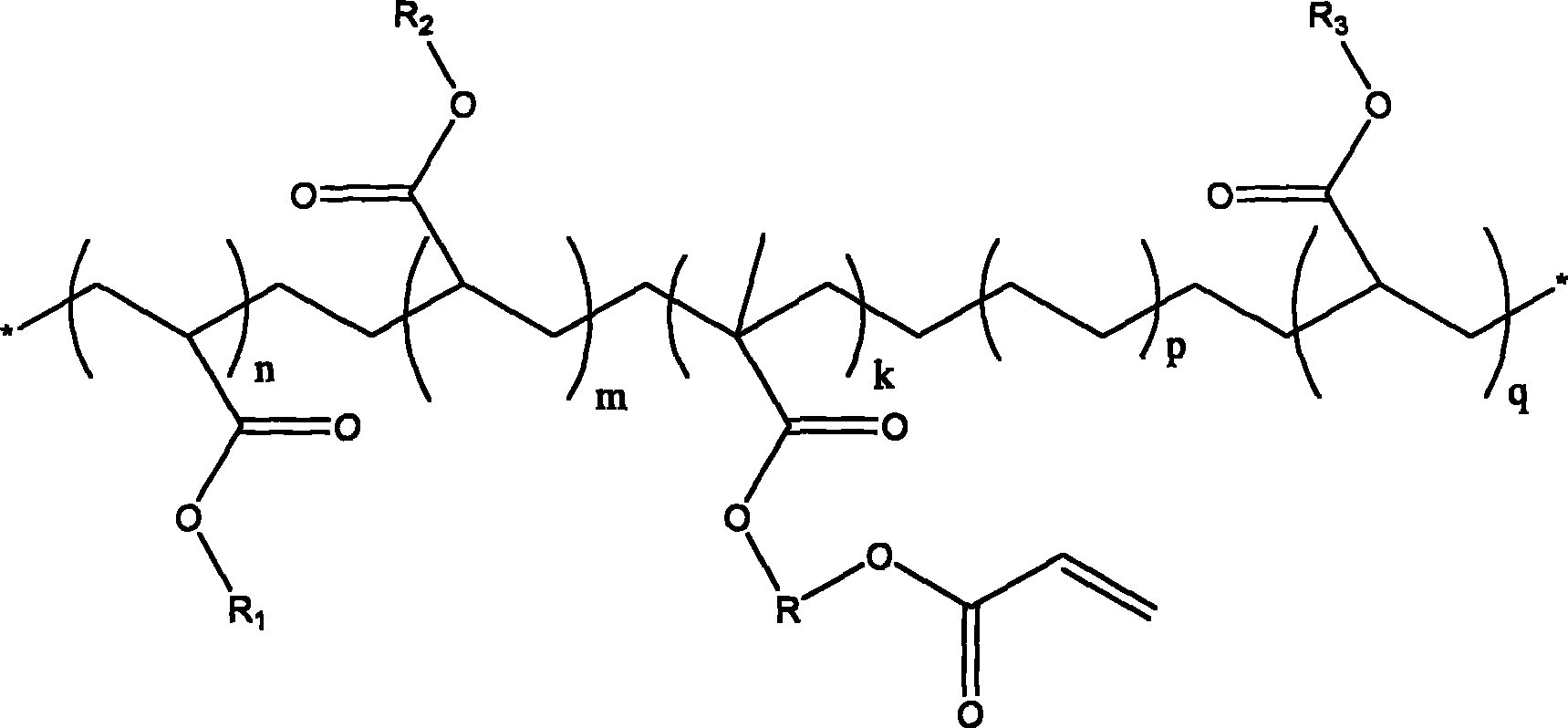

Esterified acrylie-ester high-polymer, its synthesis and use

An acrylic ester polymer and its synthesis are disclosed. The process is carried out by heat polymerizing for mixture of thermal initiator benzoyl peroxide and acrylic ester under agitation and nitrogen protection to obtain acrylic ester polymer, adding into acrylic acid, taking tosylate as catalyst and hydroquinone as inhibitor, reacting at 100-110 degree, removing water, decompressing, and removing solvent and inactive raw material to obtain final product. It can be used to machine building material cyanamide paper, and improve coating and substrate performances and adhesion.

Owner:扬州雅致达板饰有限公司

Medical adhesive

The invention discloses a medical adhesive, comprising the following substances in parts by weight: 65-80 parts of alpha-N-butylcyanoacrylate, 5-8 parts of hydroxypropyl methacrylate, 3-5 parts of sulfur dioxide, 1-2 parts of hydroquinone, 0.5-2 parts of polyurethane, 0.5-1.5 parts of agar, 0.8-1.2 parts of fibrin glue, 2-3 parts of water soluble phenol-formaldehyde resin, and 20-25 parts of deionized water. The medical adhesive has the beneficial effects that the medical adhesive provided by the invention is low in thrill, and excellent in bonding persistence; compared with the traditional common adhesive, the persistence of the medical adhesive can be up to 1.5-3 times; and animal experiments show that the toxic and side effects are small.

Owner:台山市弘毅医疗用品有限公司

High-efficiency ceramic water reducing agent and preparation method thereof

The invention provides a high-efficiency ceramic water reducing agent and a preparation method thereof. The high-efficiency ceramic water reducing agent comprises the following components by weight percent: 35 to 60 polyoxyalkylene, 0 to 10 methacrylic acid or maleic anhydride, 0 to 20 methacrylic acid, 0 to 10 sodium allyl sulfonate, 0 to 20 2-hydroxyethyl acrylate, 1.0 to 3.0 potassium persulfate, 0.5 to 1.0 hydroquinone and 1.0 to 2.0 p-toluenesulfonic acid, and the weight percent of the components is not zero. The high-efficiency ceramic water reducing agent can greatly reduce the water content of slurry after being added into ceramic pulp and satisfies fluidity needed by ceramic production. The high-efficiency ceramic water reducing agent is added into a glaze material, the glaze material has good fluidity and proper viscocity under a lower water-content condition, greatly reduces a glaze cutting phenomenon, and the like and increases product quality. The high-efficiency ceramic water reducing agent has good universality and can be suitable for various clay mineral materials.

Owner:HANSHAN NORMAL UNIV

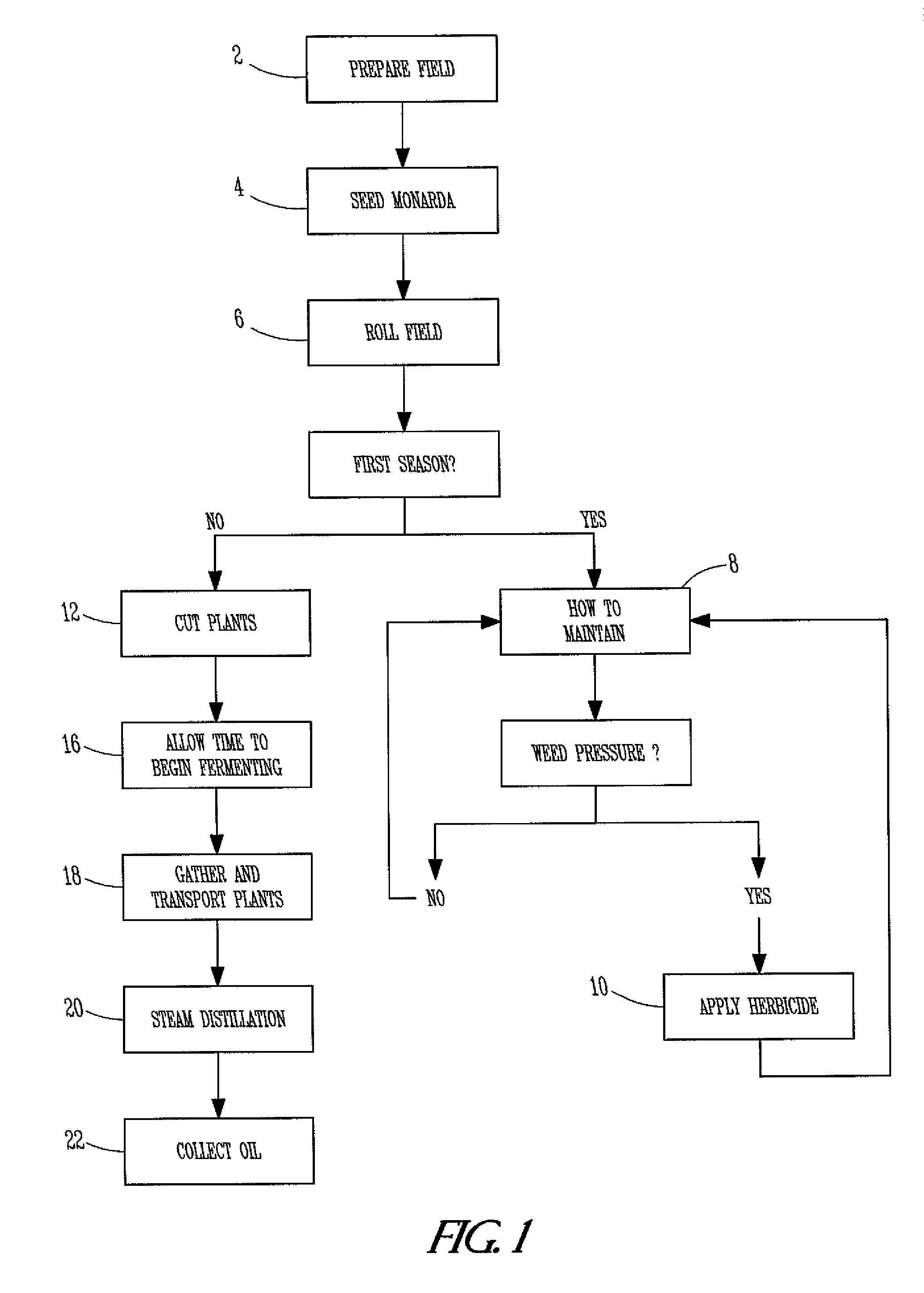

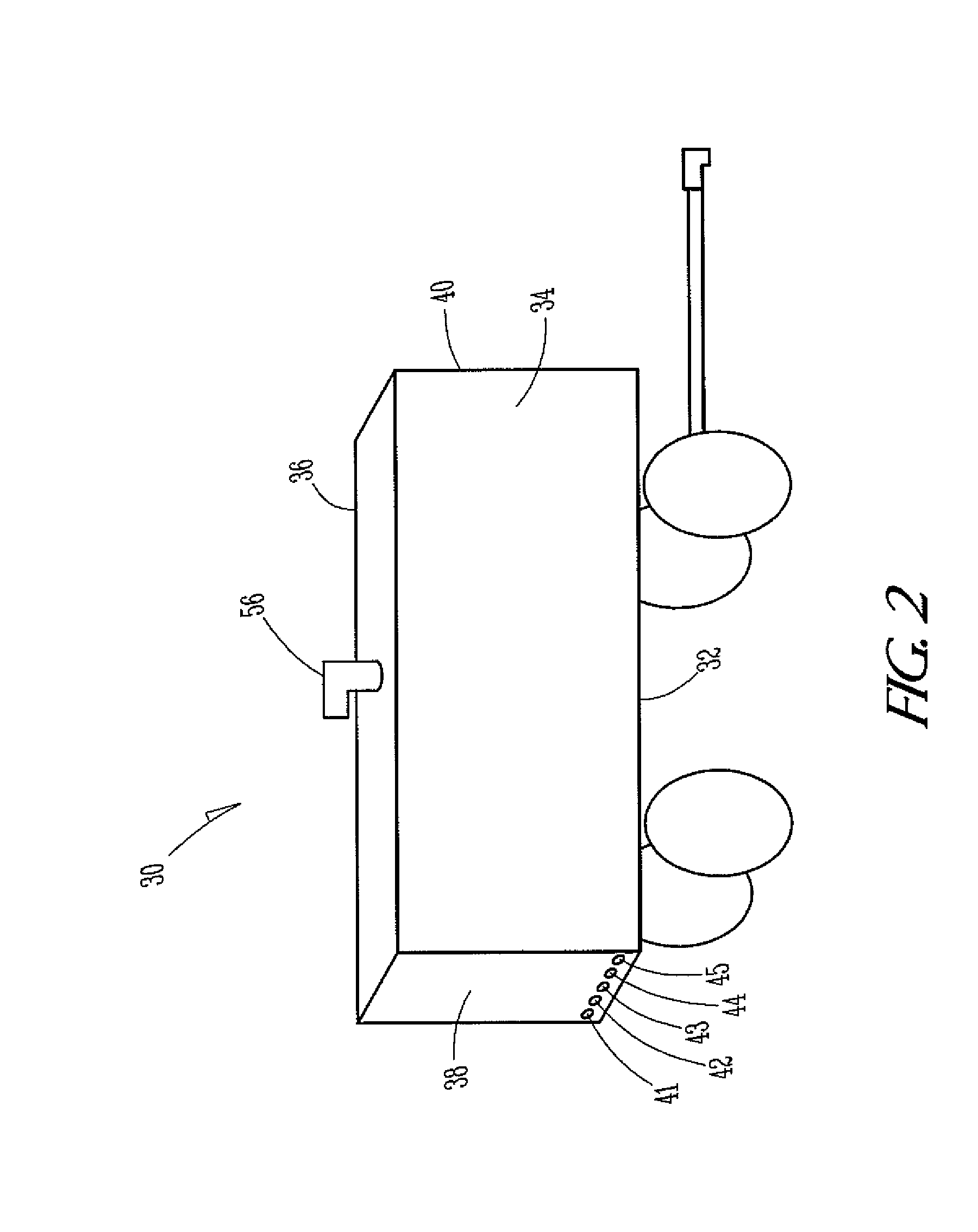

Method for Cultivation of Monarda Fistulosa for Production of Thymoquinone

ActiveUS20140275585A1Improve germination rateReduce fuel usageSeed and root treatmentOrganic compound preparationMoghania macrophyllaPlanting seed

A method for cultivating Monarda fistulosa for production of thymoquinone includes planting seeds at rates between about 2.5 and about 5 pounds per acre, preferably about 4 pounds per acre. The heavy rate of planting produces plants bearing oil without weed contamination and reduces herbicide use due to production of natural herbicides by the monarda plants. Seeding and mowing the first season, and harvesting in seasons thereafter reduce costs. The method results in increased production of essential oils including thymoquinone and thymohydroquinone at levels up to about 40% or more of recovered oils, and which may be distilled from the plant.

Owner:PRAIRIE PHARMA

Composition capable of whitening and brightening, preparation method thereof and application thereof in cosmetics

InactiveCN106619167AProlong the action timeReduce stimulationCosmetic preparationsToilet preparationsSunscreen agentsVitamin C

The invention relates to a composition capable of whitening and brightening, a preparation method thereof and an application thereof in cosmetics and belongs to the technical field of the cosmetics. The composition capable of whitening and brightening comprises the following ingredients in percentage by weight: 25% to 30% of arbutin, 10% to 15% of vitamin C or derivative thereof, 15% to 20% of nicotinamide, 3% to 6% of serpin, 1% to 2% of ginsenoside and 30% to 35% of sunscreen agent. According to the composition provided by the invention, the arbutin, the vitamin C derivative and the nicotinamide generate a whitening effect, and meanwhile, the serpin is used for protecting protein components of skin cells, promoting the activation and regeneration of the cells and eliminating cytotoxicity resulting from hydroquinone generated after the arbutin is reduced, so that the actions of long-acting whitening and cell activating are achieved; the composition has the advantages of little skin irritation and long acting time when the composition is applied to the cosmetics such as facial masks, emulsions and cream.

Owner:FENCHEM BIOTEK

Black phosphating liquid and use method thereof

ActiveCN102953055AStrong corrosion resistanceFast film formationMetallic material coating processesO-Phosphoric AcidHydroxylamine sulfate

The invention belongs to the technical field of metal surface treatment, and particularly relates to black phosphating liquid for phosphating the surface of alloy steel which does not need to be acid cleaned in preliminary treatment. The black phosphating liquid comprises components with the following weight percentage: 2 percent to 5 percent of acidic manganese phosphate, 2 percent to 4 percent of diammonium hydrogen phosphate, 1 percent to 3 percent of cobalt nitrate, 1 percent to 2 percent of guanidine nitrate, 0.5 percent to 1.5 percent of hydroquinone, 0.2 percent to 1 percent of hydroxylamine sulfate, 0.5 percent to 2 percent of phosphoric acid with the mass concentration being 80 percent to 90 percent, and the rest is pure water. Due to the use of the black phosphating liquid, the operation is simple, the stability is good, the film forming speed is high, a formed film is fine and uniform, the color is black, the film forming strength is high, the corrosion resistance is strong and the like, and the black phosphating liquid is applicable to the surface treatment of alloy steel parts of various models.

Owner:CHANGSHA WOER METAL SURFACE TECH

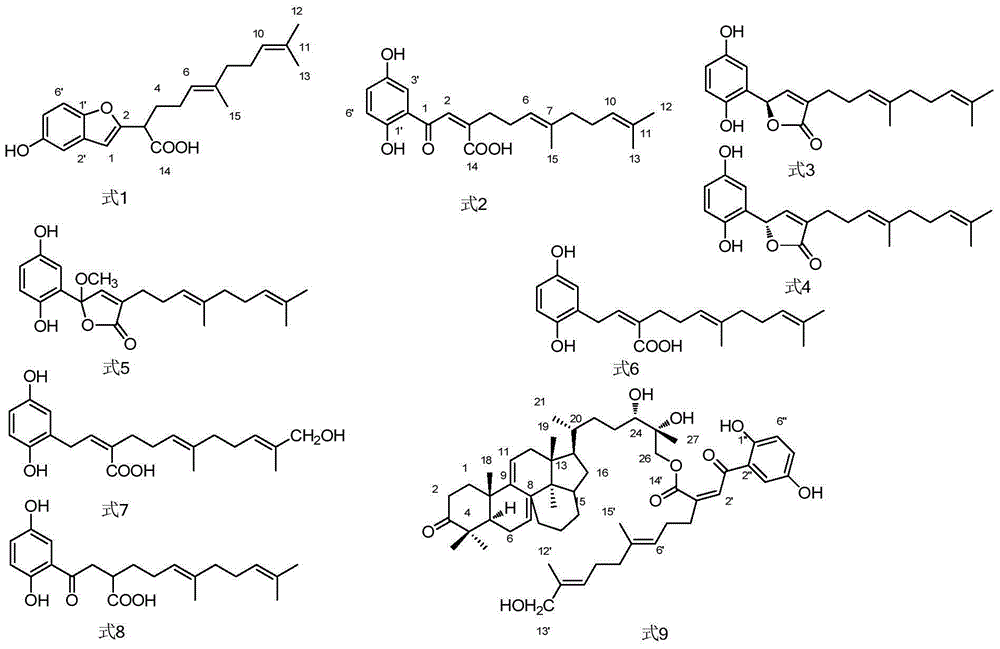

Application of hydroquinone farnesyl group compound

ActiveCN105213363APrevent proliferationMetabolism disorderDigestive systemTyrosineTherapeutic effect

The invention provides a hydroquinone farnesyl group compound and application of a pharmaceutical salt thereof in serving as an alpha-glucosidase, protein-tyrosine-phosphatase 1B or HMG-CoA reductase inhibitor, or in preparing drug for treating and / or preventing type-II diabetes or hyperlipidemia, or in preparing drug or functional healthcare products having hypoglycemic and hypolipidemic functions, or in preparing drug or functional healthcare products having a function of treating or preventing non-alcoholic fatty liver disease, or in preparing drug or functional healthcare products having liver protection effect, or in preparing drug or functional healthcare products for preventing and / or treating cancer or inhibiting tumor cell proliferation, or in serving as an RXRalpha receptor binding inhibitor, or in preparing drug serving as the RXRalpha receptor binding inhibitor. The inhibitors, the drug, food or the healthcare products prepared through the hydroquinone farnesyl group compound and the pharmaceutical salt are free of toxic and side effect and remarkable in treatment effect.

Owner:HANGZHOU BIO SINCERITY PHARMA TECH CO LTD

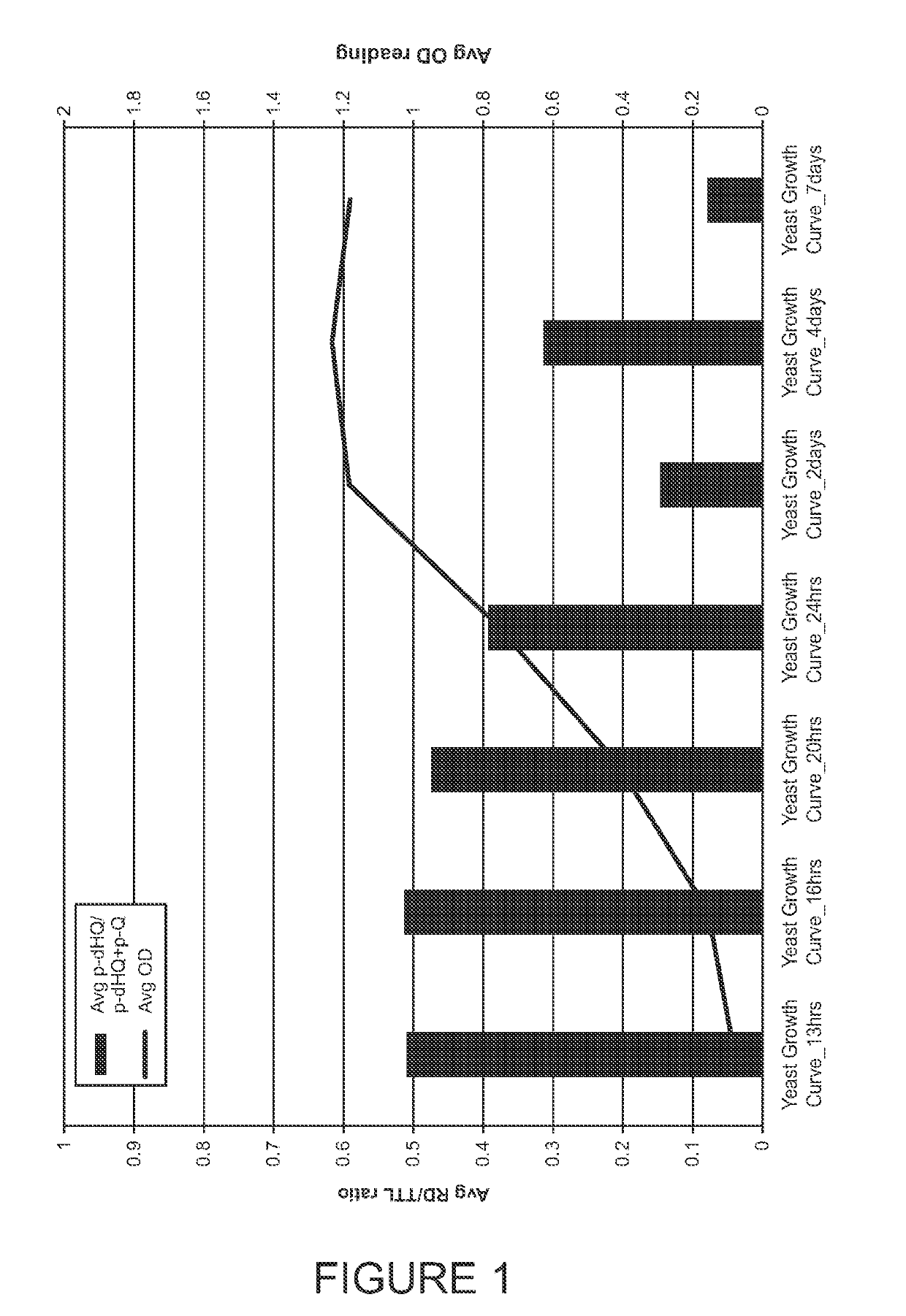

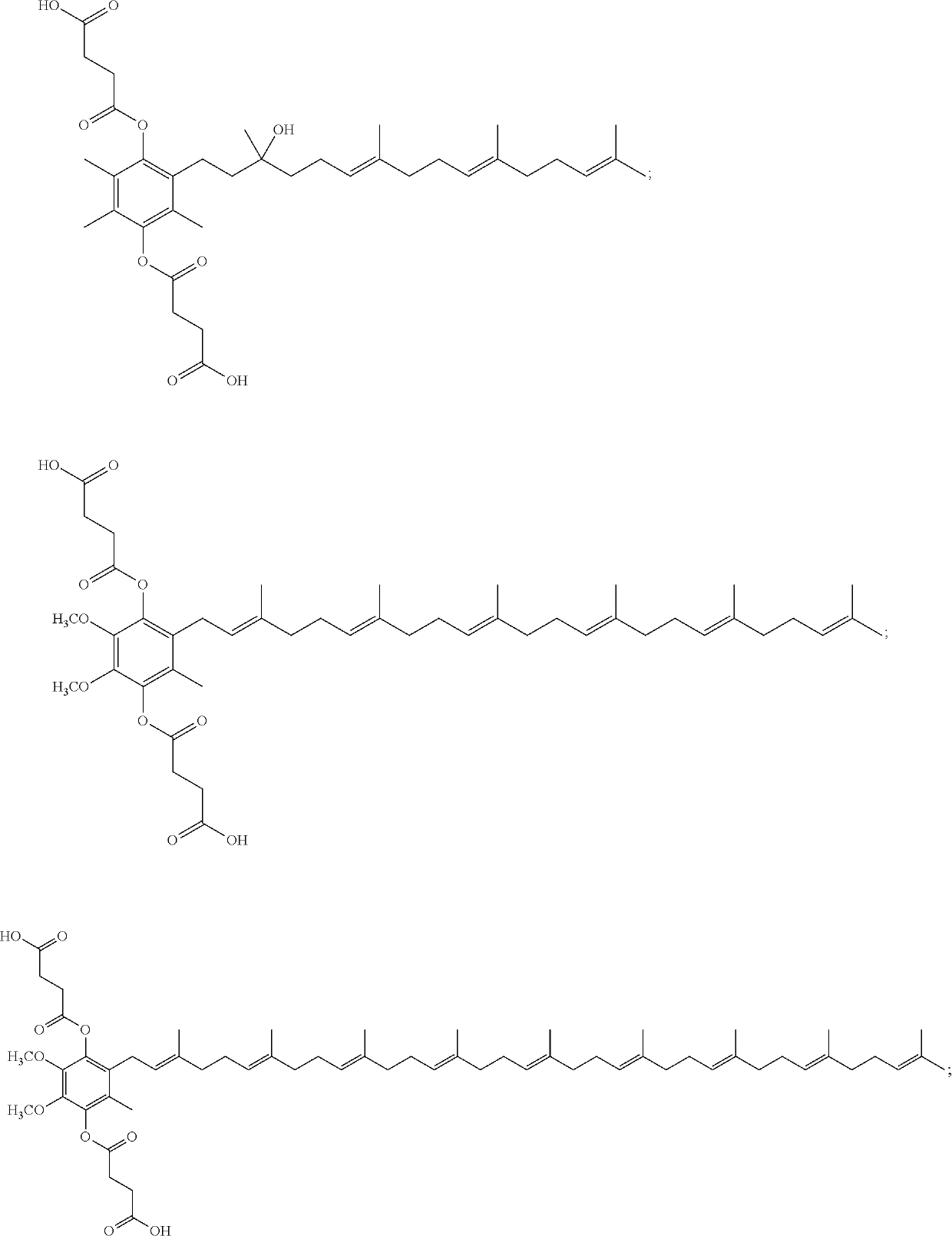

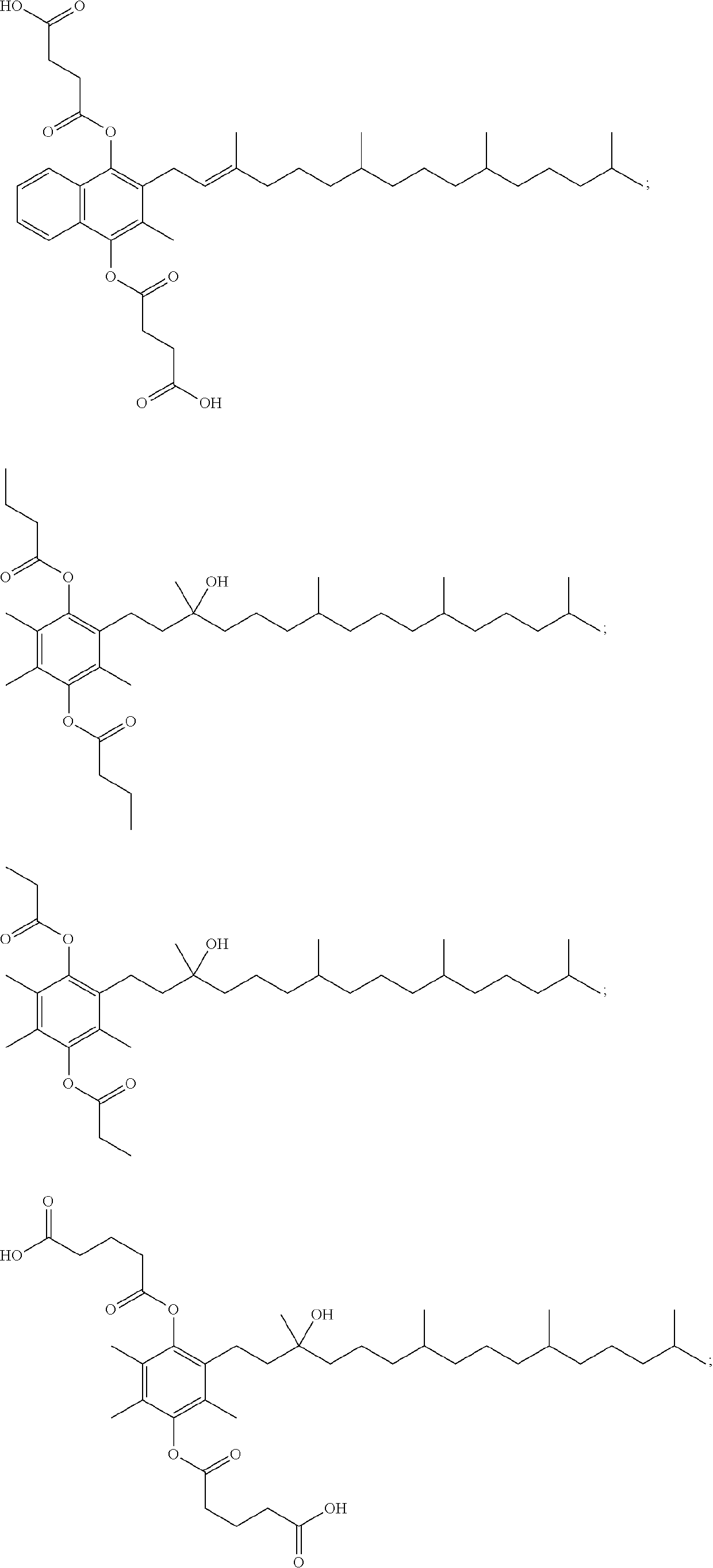

Methods for analyzing p-hydroquinone levels and ratios

Owner:BIOELECTRON TECH CORP

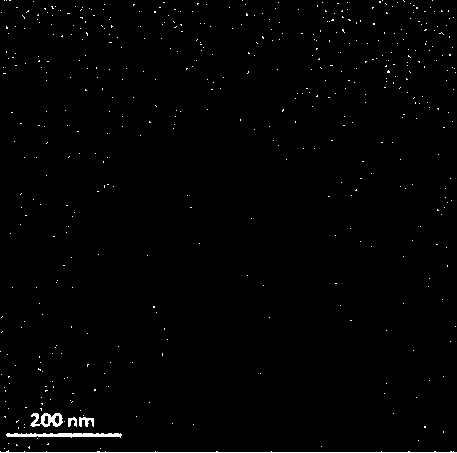

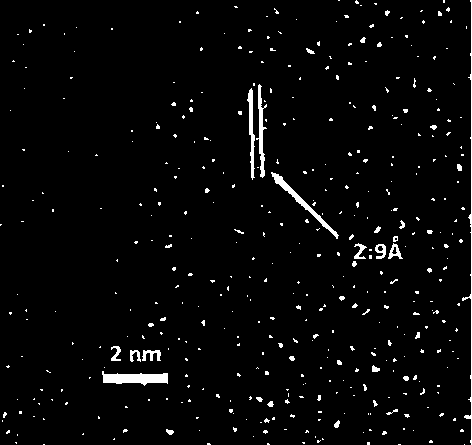

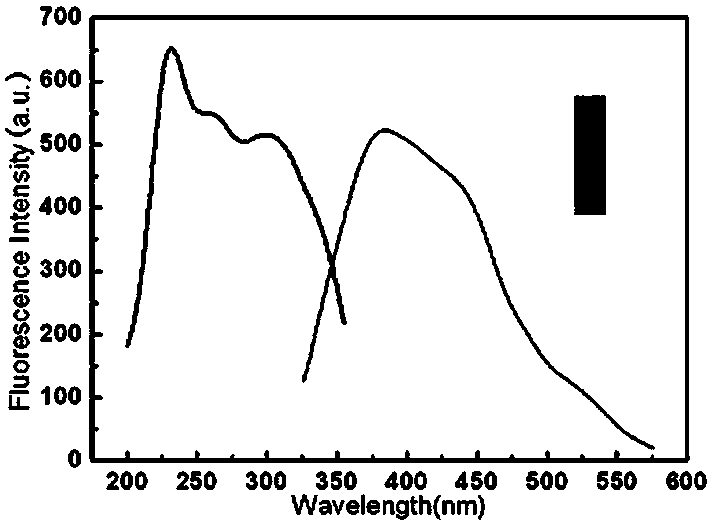

Preparation method of silicon doping carbon quantum dots by adoption of solvothermal method and applications thereof

InactiveCN103834396AHigh fluorescence quantum yieldLow toxicityMicrobiological testing/measurementNano-carbonProcess equipmentHydroquinone Compound

The invention relates to the field of carbon quantum dot preparation, and particularly relates to a preparation method of silicon doping carbon quantum dots by adoption of a solvothermal method and applications thereof. The preparation method includes: adding hydroquinone into a stainless steel high-pressure reactor the liner of which is polytetrafluoroethylene; adding acetone according to a ratio that 5 mL of the acetone is added for per 0.97 g of the hydroquinone; adding dropwise silicon tetrachloride into the reactor, putting the sealed reactor in an air dry oven, heating at 150-220 DEG C for 1-5 h, cooling to room temperature, and concentrating and evaporating the liquid mixture in the reactor to dryness by adoption of a rotary evaporation manner to obtain the silicon doping carbon quantum dots. The preparation method is simple, efficient and mild, and is low in operation cost and simple in preparation process equipment. The prepared silicon doping carbon quantum dots can be applied in cell biological imaging.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for synthesizing R-(+)-2-(4-hydroxyphenoxy)propionic acid through gas phase catalysis

ActiveCN111187155AHigh catalytic activityStrong acidOrganic compound preparationOrganic chemistry methodsPropanoic acidPtru catalyst

The invention discloses a method for synthesizing R-(+)-2-(4-hydroxyphenoxy)propionic acid through gas phase catalysis, and belongs to the field of organic synthesis. Hydroquinone and D-lactic acid are used as raw materials, and nitrogen is used as a carrier gas. The hydroquinone and the D-lactic acid are completely gasified and then enter a fixed bed reactor, and the R-(+)-2-(4-hydroxyphenoxy)propionic acid is continuously synthesized in a gas phase under the catalysis of a supported heteropolyacid catalyst. The method has the advantages of mild reaction conditions, simple reaction process, high effective conversion rate of hydroquinone and high selectivity of the R-(+)-2-(4-hydroxyphenoxy) propionic acid, and is completely suitable for industrial production, and the self-made supported heteropolyacid solid catalyst has excellent catalytic activity, strong acidity, good stability and no pollution to the environment, and is a green catalyst.

Owner:JIANGSU SANJILI CHEM

Anaerobic adhesive as well as preparation method and application thereof

ActiveCN104356992ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention relates to the field of adhesives, in particular to an anaerobic adhesive and a preparation method of the anaerobic adhesive. The anaerobic adhesive comprises 40-100 parts of modified methacrylic acid, 0.8-5 parts of an initiator, 1-4 parts of an accelerant and 0.5-2 parts of an accelerant aid. According to the anaerobic adhesive, polyurethane modified epoxy resin is adopted to modify methacrylic acid, and the preparation method specifically comprises the following steps: adding the polyurethane modified epoxy resin into a reaction kettle, heating to be 60-65 DEG C, adding hydroquinone, adding methacrylic acid when hydroquinone is completely dissolved, continuously heating to be 70-80 DEG C, adding triethylamine, uniformly mixing, heating to be 80-85 DEG C, reacting for 1-3 hours, further heating to be 98-100 DEG C, and reacting for 2-4 hours, so as to obtain the modified methacrylic acid. The anaerobic adhesive provided by the invention is good in toughness and low-temperature resistance, and is also relatively high in tension strength, shearing resistance and impact resistance.

Owner:SUZHOU JINQIANG NEW MATERIALS

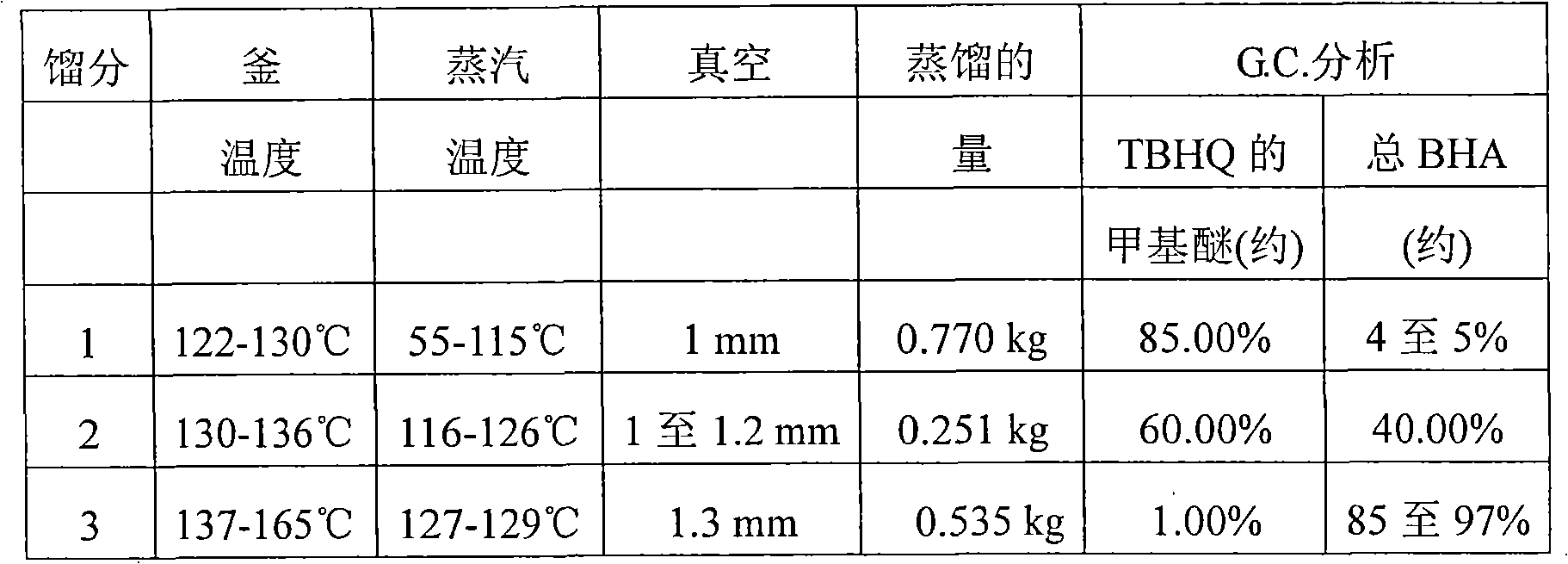

Improvement in synthesis of butylated hydroxyanisole from tertiary butyl hydroquinone

InactiveCN101583586AReduce the temperatureEther preparation by ester reactionsEther preparation by compound dehydrationHigh densityBHA - Butylated hydroxyanisole

An improved process for production and novel physical forms of butylated hydroxyanisole (BHA) is described wherein tertiary butyl hydroquinone (TBHQ) reacts within a range of about 30 to 50 DEG C with stoichiometrically slight excess of dimethyl sulphate and sodium hydroxide, the sodium hydroxide being added stoichiometrially in slight excess of dimethyl sulphate. Major portion of BHA formed in this reaction was recovered in a crystalline form in which 3-t-butyl-4-hydroxyanisole (3 isomer) is at least at about 99% level, usually at about 99.5% or more, and TBHQ at 100 ppm or less. BHA remaining in mother liquor after crystallization was recovered by distillation and had same purity as the crystalline BHA. The crystalline form was prepared as low density as well as high density form and further could be converted into compressed forms including flakes, tablets and the like.

Owner:凯姆琳精细化学有限公司

Normal temperature three-in-one phosphorizing agent capable of cleaning and derusting synchronously and preparing process thereof

The invention discloses a normal temperature three-in-one phosphorizing agent capable of cleaning and derusting synchronously and preparing process thereof, wherein the bonderite comprises phosphorus acid, methyl ketone, ethanol, hydroquinone, non-ionic active agent and water as raw material, which is prepared through the steps of agitating, emulsifying and restirring.

Owner:赵惠霖

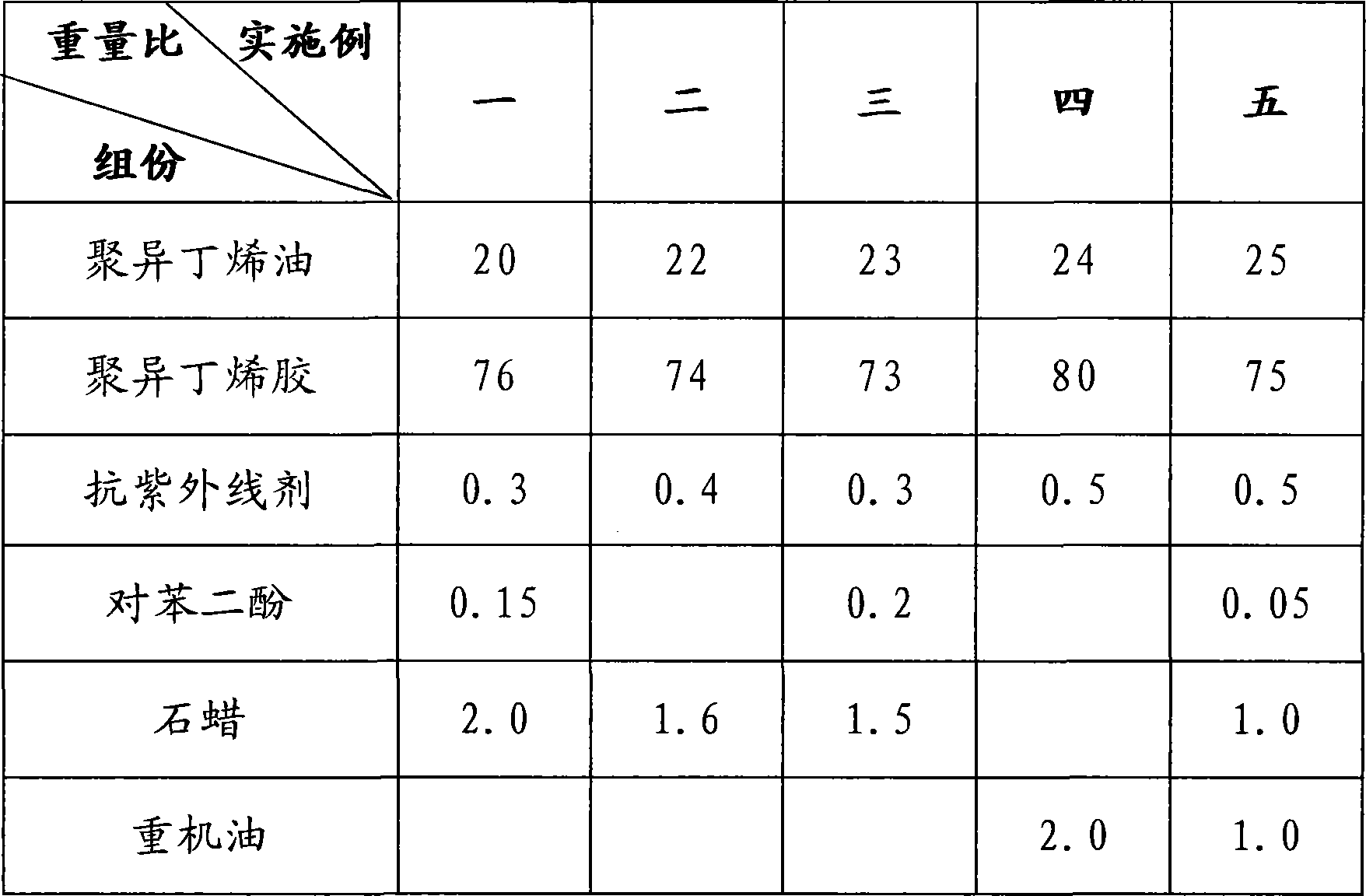

Adhesive tape for mosquito eradication lamp, hot-melt adhesive of the adhesive tap and preparation method of the hot-melt adhesive

ActiveCN101186794AImprove sag resistanceImprove touch tackFilm/foil adhesivesWax adhesivesMolten stateParaffin wax

The invention discloses a hot melt adhesive for adhesive tapes, which is composed of 73-80 polyisobutene glue, 20-25 polyisobutene oil, 0.3-0.5 ultravioresistant agent, 0-0.2 hydroquinone and 1-2 ceresin wax according to weight ratio, heavy engine oil can be added according to needs or heavy engine oil can be utilized to substitute for hydroquinone and ceresin wax with weight ratio of 1 to 2. The process for preparing the hot melt adhesive is that firstly various materials except polyisobutene glue are mixed and heated to 120-140 DEG C, the mixture is kept in the state of melting, and homogenously mixed after being blended, and then the polyisobutene glue is added, the constant temperature is kept between 120 DEG C and 140 DEG C, then the blending enables the system to be homogenously mixed, consequently the cooling is accomplished. Adhesive tape for a mosquitocide light is formed by evenly coating the prepared hot melt adhesive on a carrier. The hot melt adhesive of the invention is perfect in flow resistance and adhesive property, high in light resistance and oxidation resistance and environment-friendly in materials, which is capable of effectively sticking winged insects in -10 to 70 DEG C. In addition, the adhesive tape is durable, a relatively long adhesive tape placed in an adhesive tape box can be multiply used by sections, and the cost of consumable materials can be reduced.

Owner:惠来县战臣电器有限公司

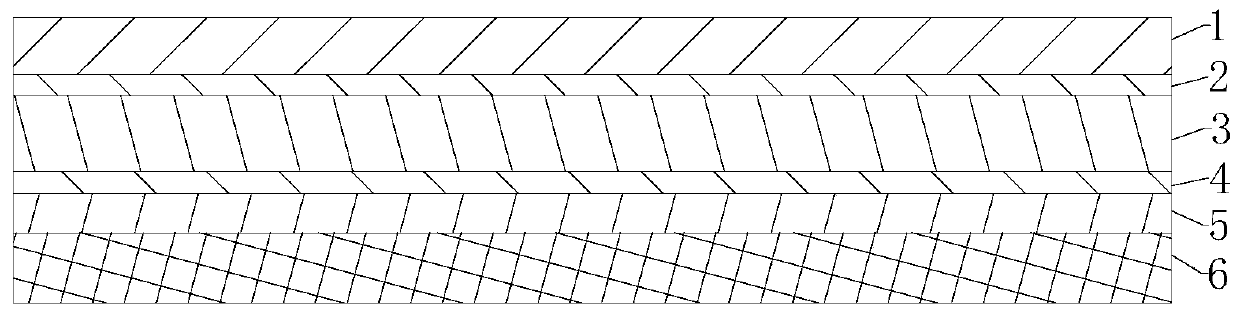

High-barrier corrosion-resistant lithium battery packaging film and preparation method thereof

ActiveCN110893705AImprove corrosion resistanceImprove electrochemical performanceFlexible coversWrappersPolypropylenePowder talc

The invention discloses a high-barrier corrosion-resistant lithium battery packaging film, which comprises a nylon layer, an aluminum foil layer and a heat-seal layer, and further comprises an outer graphene layer, an inner graphene layer and a silicone rubber layer, wherein the nylon layer, the outer graphene layer, the aluminum foil layer, the inner graphene layer, the silicone rubber layer andthe heat-seal layer are sequentially distributed from outside to inside, the nylon layer is prepared from MXD6, glass fibers, LLDPE-g-MAH, nanometer silicon dioxide, a silane coupling agent and hydroquinone, and the heat-seal layer comprises polypropylene, glass fibers, nanometer calcium carbonate, talcum powder and barium sulfate. The high-barrier corrosion-resistant lithium battery packaging film has good corrosion resistance.

Owner:NINGBO RUICHENG PACKING MATERIAL

Preparation and application of carcino-embryonic antigen electrochemical immunosensor based on Au@Ag@Au marker

InactiveCN106442675AHeavy loadFacilitates electron transferMaterial analysis by electric/magnetic meansCarcinoembryonic antigenHydroquinone Compound

The invention relates to the technical field of electrochemical immunosense, in particular to preparation and application of a carcino-embryonic antigen electrochemical immunosensor based on an Au@Ag@Au core-shell nano-composite (Au@Ag@Au NPs) marker. Specifically, the surface of a glassy carbon electrode is modified by nitrogen-doped graphene (NG) to prepare an antibody capture substrate, Au@Ag@Au NPs tracks and marks a carcino-embryonic antigen second antibody, the second antibody marked by Au@Ag@Au NPs is captured on the surface of the sensor through sandwich immune response, and detection of a carcino-embryonic antigen is achieved by detecting electrochemical signals of hydrogen peroxide and hydroquinone in a PBS solution.

Owner:UNIV OF JINAN

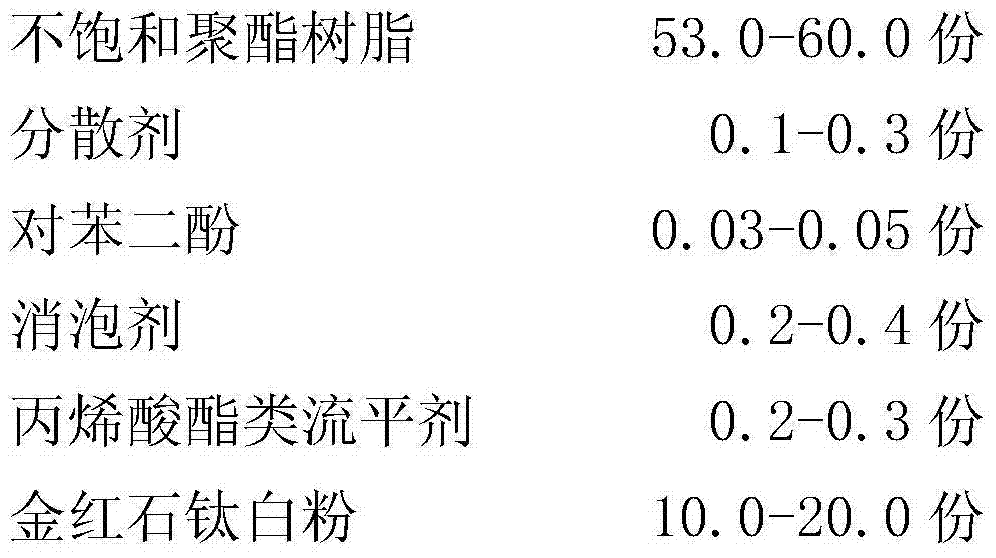

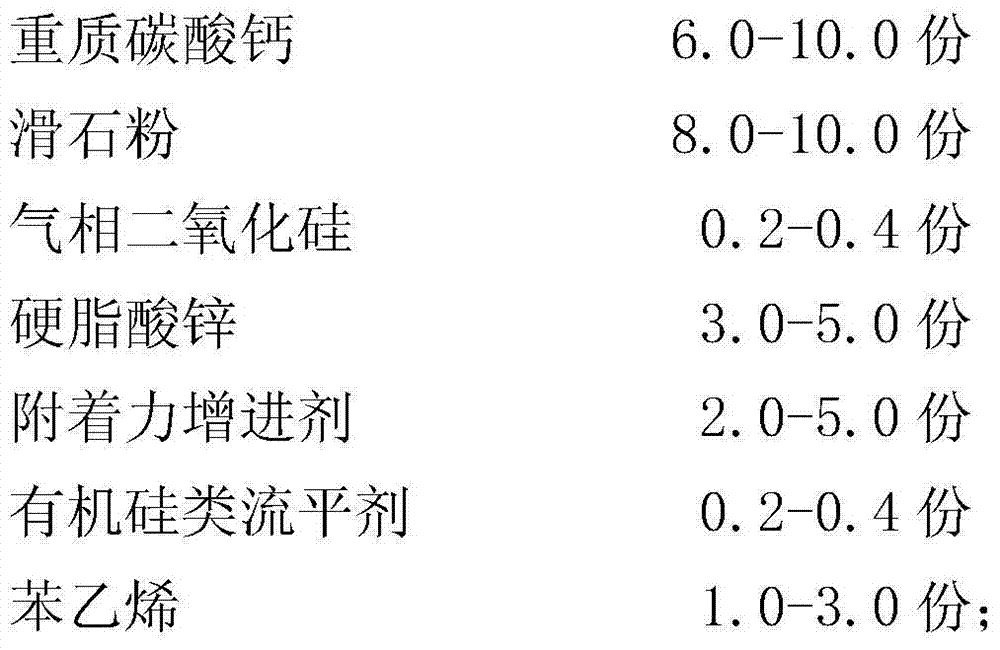

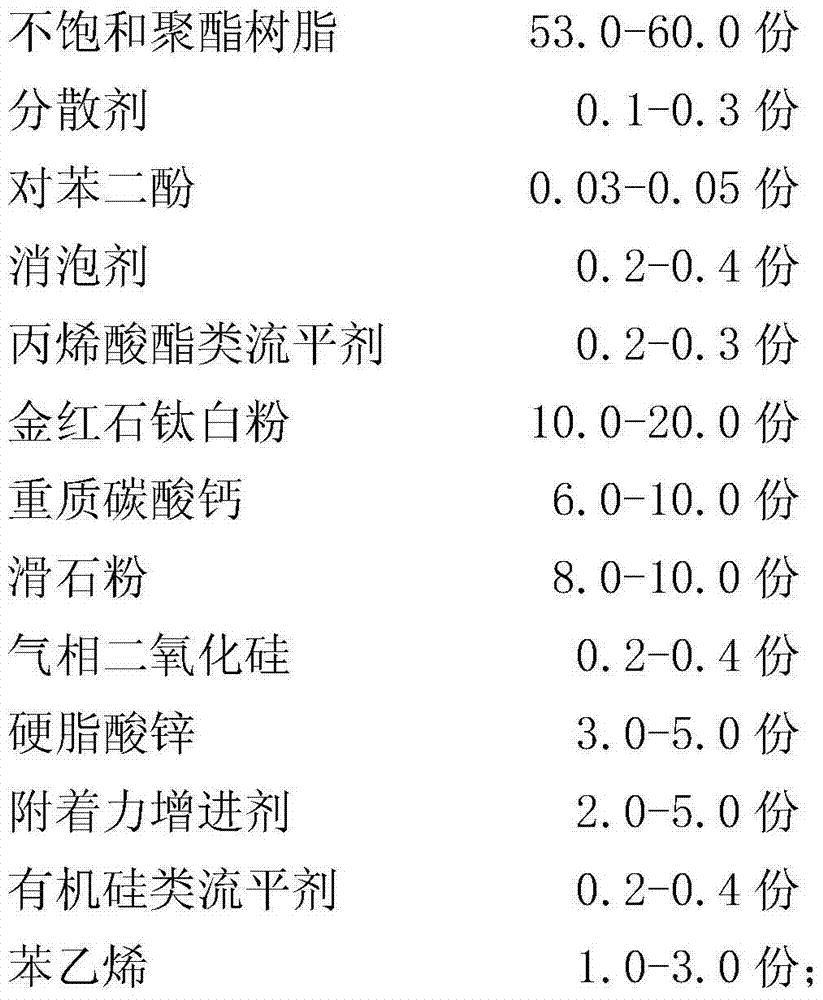

Sanding-free unsaturated polyester primer applicable to melamine substrates and preparation method thereof

InactiveCN104497812AStrong adhesionImprove mechanical propertiesLiquid surface applicatorsPolyester coatingsGas phaseSilicon dioxide

The invention relates to a sanding-free unsaturated polyester primer applicable to melamine substrates and a preparation method thereof. The sanding-free unsaturated polyester primer applicable to melamine substrates is prepared by mixing the following components in parts by weight: 100 parts of main paint, 1.0-1.2 parts of initiator and 1.2-1.4 parts of accelerator. The main paint is prepared from an unsaturated polyester resin, a dispersing agent, hydroquinone, a defoaming agent, a leveling agent, rutile titanium white, ground calcium carbonate, talcum powder, gas-phase silicon dioxide, zinc stearate, an adhesion enhancer and styrene; the accelerator is cobalt naphthenate; and the initiator is methylethyl ketone peroxide. The sanding-free unsaturated polyester primer applicable to melamine substrates can be directly sprayed without sanding the substrate when being applied to the melamine substrate, and has excellent adhesive force and fullness after being sprayed.

Owner:SKSHU PAINT

Preparation process of tert-butylhydroquinone

ActiveCN105294403AReduce usageLow DTBHQ contentOrganic chemistryOrganic compound preparationWarm waterEthylic acid

The invention relates to the technical field of antioxidant preparation methods, and particularly relates to a preparation process of tert-butylhydroquinone (TBHQ). The preparation process comprises the following steps of (1) simultaneously adding excessive dilute sulphuric acid, equimolar hydroquinone and tertiary butyl acetate to a reaction still, wherein the weight ratio of the dilute sulphuric acid to the tertiary butyl acetate is 1:(3 to 6); (2) stirring and heating to 85 to 95 DEG C, and reacting for 1 to 8 hours; (3) stopping stirring, cooling to 65 to 75 DEG C, and then performing centrifugal filtration, wherein filtrate of sulphuric acid is recycled, and obtained filter residues are washed with 1 to 3 times warm water, so as to obtain a crude product of the TBHQ. Compared with the prior art, the preparation process has the advantages that the hydroquinone and the tertiary butyl acetate are used as raw materials, and the dilute sulphuric acid is used as a catalyst and a reaction solvent, so as to promote a reaction; tertiary butyl is supplied by the tertiary butyl acetate, so that side reactions are reduced; the crude product contains 70% to 75% of TBHQ, the content of DTBHQ (Di-Tert-Butylhydroquinone) as a by-product is low, the yield can reach 65 to 70% after purification, the yield is greatly increased, and great economic benefits are obtained.

Owner:东莞市感恩食品科技有限公司

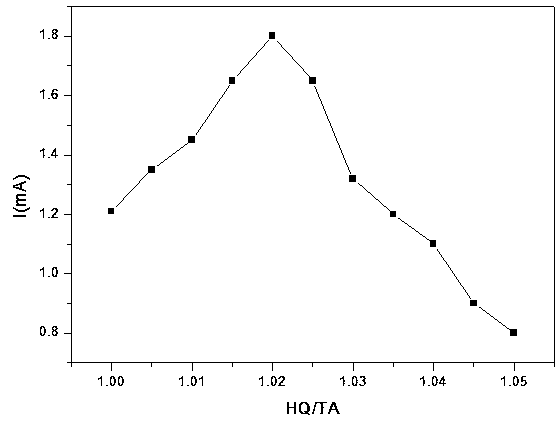

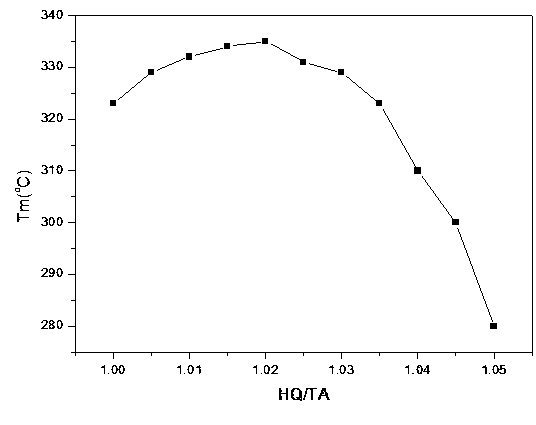

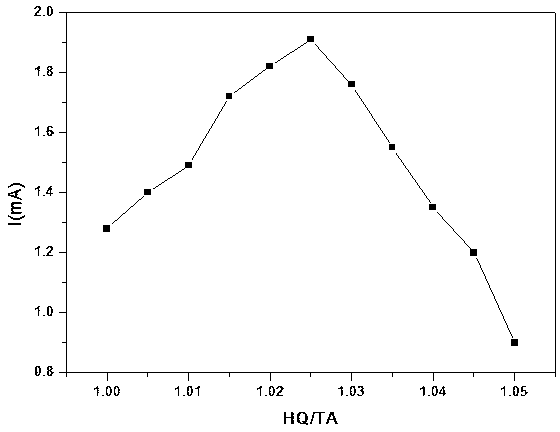

Method for improving molecular weight of thermotropic liquid crystal polymer

InactiveCN103804667AShorten the polymerization reaction timeIncrease productivityLiquid crystal compositionsBenzoic acidPolymer science

The invention provides a method for improving the molecular weight of a thermotropic liquid crystal polymer. According to the method, in the process of preparing the thermotropic liquid crystal polymer by using p-hydroxybenzoic acid / p-acetoxybenzoic acid, 6-hydroxy-2-naphthoic acid / 6-acetoxy-2-naphthoic acid, hydroquinone / hydroquinone diacetate and terephthalic acid, the molar ratio of the hydroquinone / hydroquinone diacetate to the terephthalic acid is controlled to be (1.005-1.025): 1. The molecular weight of the polymer product is controlled by controlling the addition amount of certain monomers, so that the polymerization time can be greatly shortened and the production efficiency is improved.

Owner:NANTONG HAIDI CHEM +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com