Method for improving molecular weight of thermotropic liquid crystal polymer

A technology of liquid crystal polymers and thermotropic liquid crystals, applied in liquid crystal materials, chemical instruments and methods, etc., to achieve the effects of chemical corrosion resistance, high dimensional precision, and low linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 1.344mol of p-hydroxybenzoic acid, 0.336mol of 6-hydroxy-2-naphthoic acid, 0.36mol of hydroquinone and 0.36mol of terephthalic acid into a 1L stainless steel reactor, add 2.88mol of acetic anhydride and 0.01mol of potassium acetate . After passing nitrogen for 30 min, set the nitrogen flow rate to 20 mL / min. Heat to reflux for 1h, then increase the temperature, at 200 o C kettle temperature reaction 1h, emit by-product acetic acid and excess acetic anhydride. with 1 o C / min increase the reaction temperature to 300 o C, react at this temperature until no acetic acid is distilled off, with 10 o C / min increase the reaction temperature to 340 o C, evacuate to a vacuum degree of 50 Pa, continue to evacuate for 30 minutes, record the motor torque, release the vacuum with nitrogen, stop heating, and end the reaction.

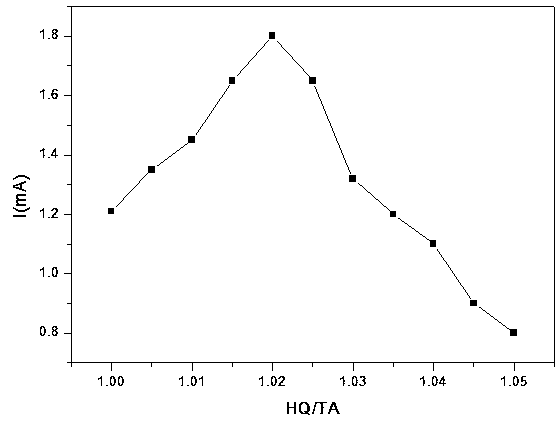

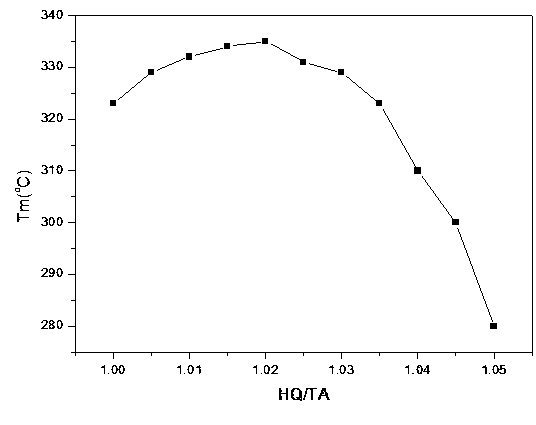

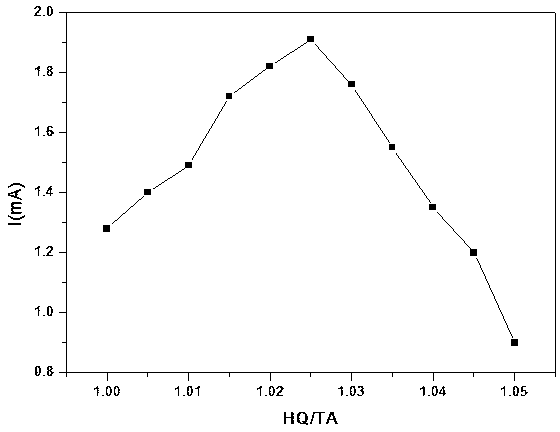

Embodiment 2-11

[0022] Embodiment 2-11 synthetic method with reference to embodiment 1, the amount of p-hydroxybenzoic acid, 6-hydroxyl-2-naphthoic acid and terephthalic acid is constant, and the amount of hydroquinone is respectively 1.005, 1.010, 1.015, 1.020, 1.025, 1.030, 1.035, 1.040, 1.045, 1.050 times.

Embodiment 12

[0024] Add 1.344mol p-acetoxybenzoic acid, 0.336mol 6-acetoxy-2-naphthoic acid, 0.36mol hydroquinone diacetate, 0.36mol terephthalic acid and 0.01mol potassium acetate to 1L stainless steel for reaction in the cauldron. After passing nitrogen for 30 min, set the nitrogen flow rate to 20 mL / min. Heat up to 200 o C kettle temperature reaction 1h, release the by-product acetic acid. with 1 o C / min increase the reaction temperature to 300 o C, react at this temperature until no acetic acid is distilled off, with 10 o C / min increase the reaction temperature to 340 o C, evacuate to a vacuum degree of 50 Pa, continue to evacuate for 30 minutes, record the motor torque, release the vacuum with nitrogen, stop heating, and end the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com