Ethylene-tetrafluoroethylene copolymer and preparation method and application thereof

A technology of tetrafluoroethylene and copolymers, applied in the field of fluorine-containing polymer materials, can solve the problems of application limitations, poor adhesion to fluorine-free polymers, insufficient stress cracking resistance of copolymers, etc., and achieve good adhesion, The effect of saving polymerization reaction time and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

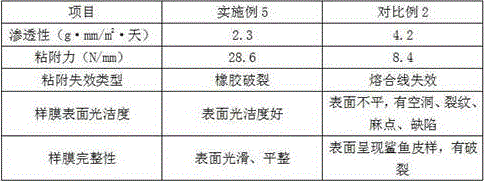

Examples

Embodiment 1

[0031] The 5L stainless steel autoclave equipped with stirring device, temperature control device, electric heating, and circulating cooling water was cleaned, fully dried, evacuated, and replaced with nitrogen three times until the oxygen content was below 10 ppm, evacuated to 0.0001 MPa, and added 2.5 L of deionized water containing 50 g of sodium dodecyl sulfonate, stirred and heated to 58 ° C, after the temperature of the system was constant, slowly add the initial monomer into the system, when the pressure reached 0.9 MPa, add 2 g of water using a metering pump. Oxidized di-tert-butylcyclohexyl dicarbonate initiates a polymerization reaction, wherein the molar percentage of each raw material in the initial monomer is 75% of tetrafluoroethylene, 20% of ethylene, CF 2 =CFOCF 2 CF (CF 3 )OCF 2 CF 2 CF 3 3%, Acryloyloxyethyl succinate 2%.

[0032] After the reaction started, the additional monomer was continuously added, the pressure was maintained at 1.5 MPa, and the te...

Embodiment 2

[0035] The 5L stainless steel autoclave equipped with stirring device, temperature control device, electric heating, and circulating cooling water was cleaned, fully dried, evacuated, and replaced with nitrogen three times until the oxygen content was below 10 ppm, evacuated to 0.0001 MPa, and added 3 L of deionized water containing 420 g of sodium lignosulfonate, stirred and heated to 62° C. After the temperature of the system was constant, slowly add the initial monomer into the system, and when the pressure reached 1.2 MPa, add 3 g of peroxydicarbonate with a metering pump Di-tert-butyl cyclohexyl ester initiates a polymerization reaction, wherein the molar percentage of each raw material in the initial monomer is 80% of tetrafluoroethylene, 15% of ethylene, CF 2 =CFOCF 2 CF (CF 3 )OCF 2 CF 2 CF 3 2%, acryloyloxyethyl succinate 3%.

[0036] After the reaction started, the supplementary monomer was continuously added, the temperature was maintained at 62 ° C and the pr...

Embodiment 3

[0039] Wash it in a 5L stainless steel autoclave equipped with a stirring device, temperature control device, electric heating, and circulating cooling water, fully dry it, and then vacuumize it and replace it with nitrogen three times until the oxygen content is below 10ppm, and then vacuumize to 0.0001MPa. Add 2.8L of deionized water containing 140g of sodium dodecyl sulfonate and sodium lignosulfonate, stir and heat up to 60°C, after the temperature of the system is constant, slowly add the initial monomer into the system, when the pressure reaches 1.0MPa , using a metering pump to add 2.52g of di-tert-butyl cyclohexyl peroxydicarbonate to initiate a polymerization reaction, wherein the molar percentage of each raw material in the initial monomer is 78% of tetrafluoroethylene, 18% of ethylene, CF 2 =CFOCF 2 CF (CF 3 )OCF 2 CF 2 CF 3 3%, acryloyloxyethyl succinate 1%.

[0040] After the reaction started, the additional monomer was added continuously, the temperature wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com