Patents

Literature

40results about How to "Raise the polymerization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supported metallocene catalyst and preparation method and application thereof

The invention provides a supported metallocene catalyst which comprises a carrier, and an alkylaluminoxane / magnesium chloride complex and a metallocene compound which are supported on the carrier; the carrier is spherical mesoporous silica, wherein the carrier has an average particle diameter of 20-80 microns, a specific surface area of 550-650 square meter / g, a pore volume of 0.4-1.2 ml / g, and a most probable pore size of 1-7 nanometers; the metallocene compound has a structure as shown in formula 1. When the supported metallocene catalyst of the invention is used for catalyzing olefin polymerization, the catalytic efficiency for homopolymerization at 70 DEG C is up to 2.3*10<8> gPE / (mol Zr.h), and the catalytic efficiency for copolymerization at 70 DEG C is up to 2.2*10<8> gPE / (mol Zr.h); the supported metallocene catalyst overcomes the defect of kettle adhesion, has a low polymerization temperature, and thus reduces the energy consumption to some extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

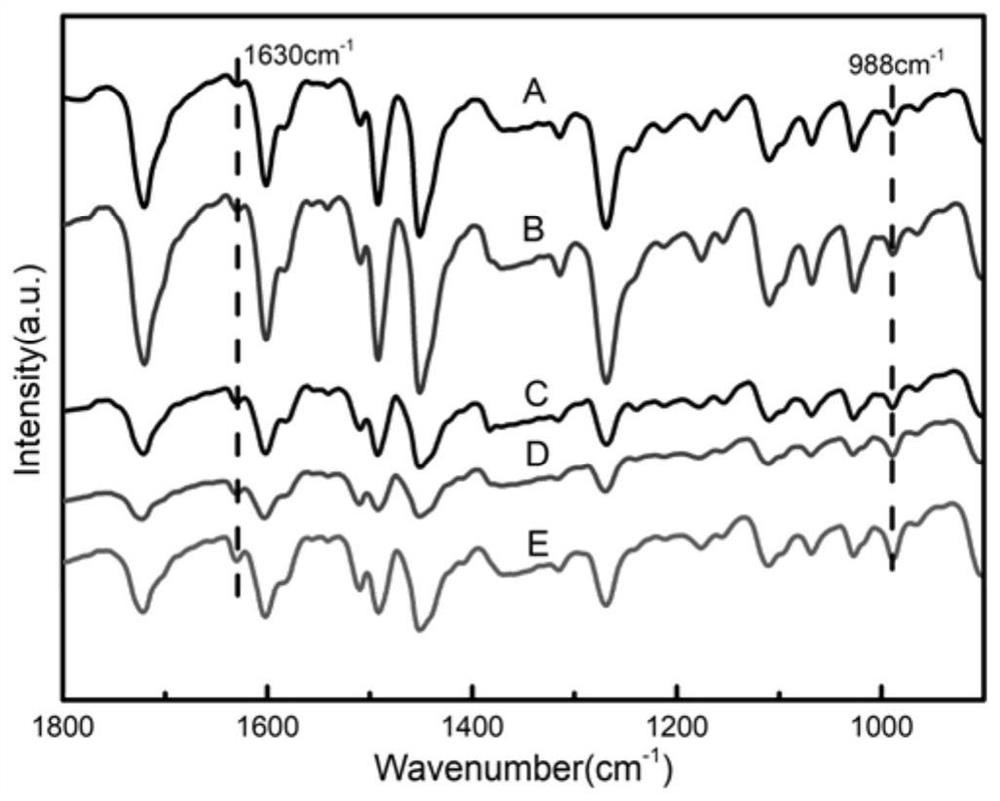

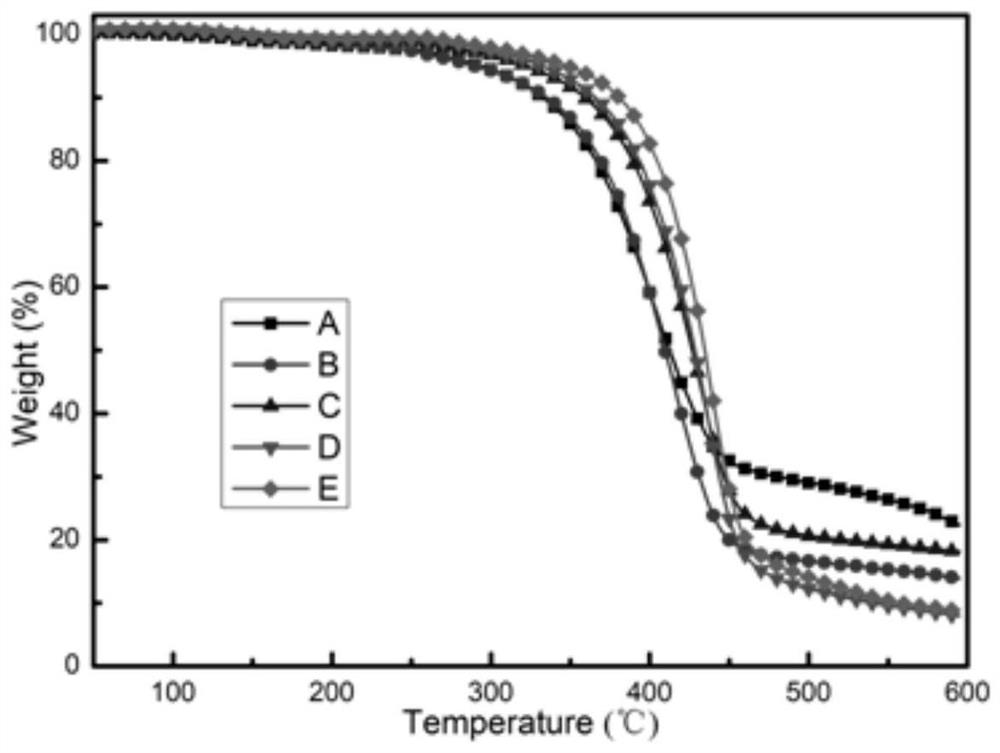

Flame-retardant interfacial modifier and preparation method and flame retardant polycarbonate composition

InactiveCN101456936AImprove flame retardant performanceHigh impact strengthMethacrylatePolymer science

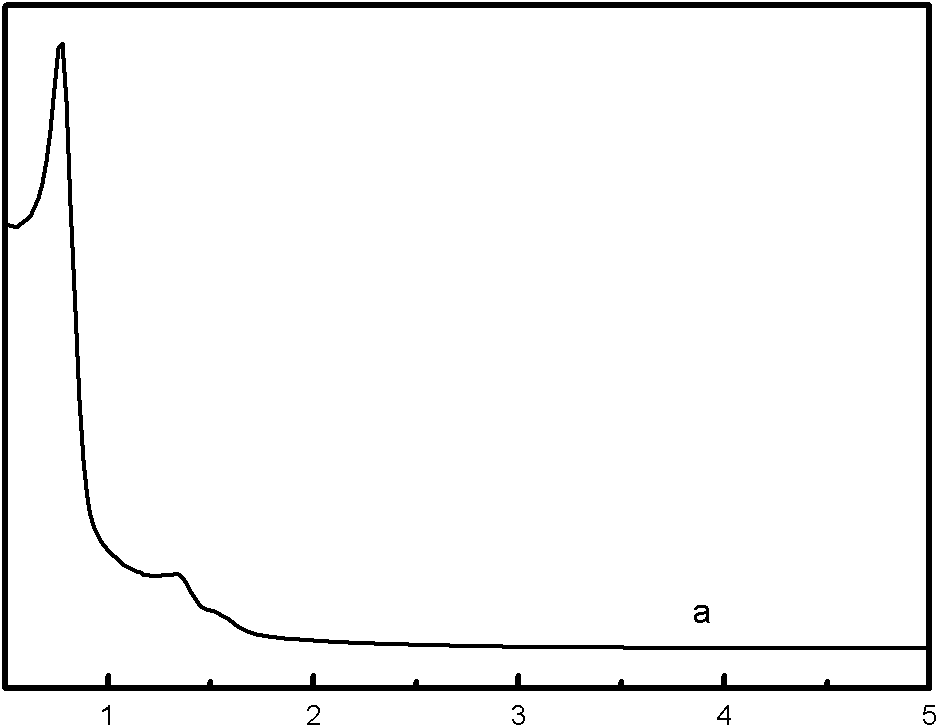

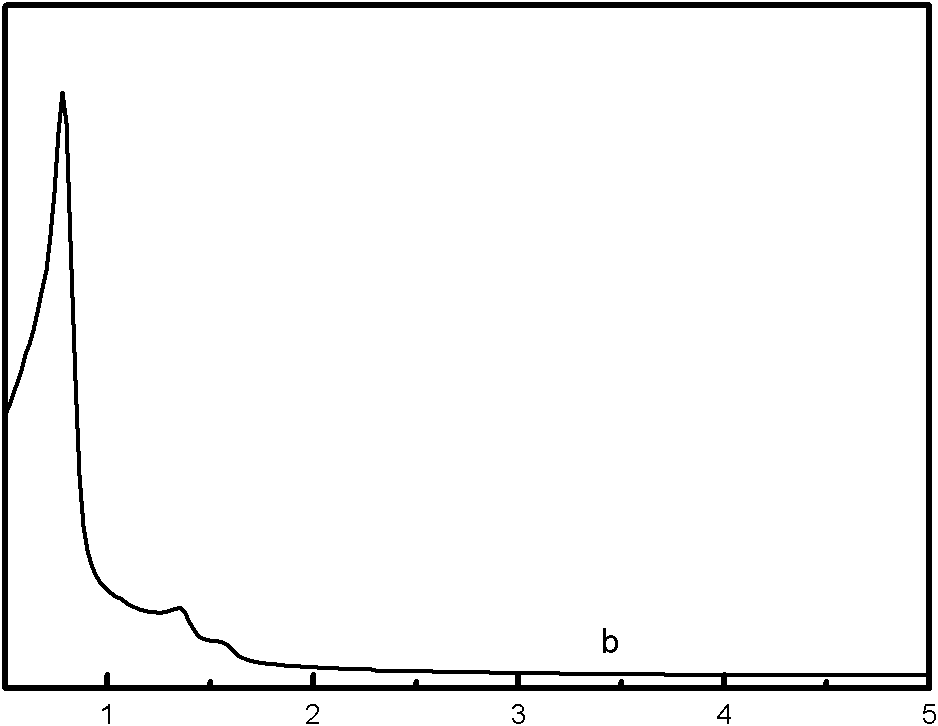

The invention discloses an inflaming retarding interface modifier and a preparation method thereof, and an inflaming retarding polycarbonate composite. The inflaming retarding interface modifier comprises two parts, namely high phenyl polysilsesquioxane and polyacrylate which are combined through a vinyl free radical polymerization reaction. The preparation method comprises: the emulsion copolymerization of high phenyl polysilsesquioxane, acrylic esters, and methacrylate in turn, and the emulsion breaking and drying. The inflaming retarding polycarbonate composite comprises: 97.8 to 99.3 mass portions of polycarbonate, 0.1 to 1.0 mass portion of the inflaming retarding interface modifier, 0.05 to 1.0 mass portion of fluoro-resin, and 0.05 to 1.0 mass portion of organic sulphonate. The total dosage of the three flame retardants is 0.5 portion; and the polycarbonate composite spline with the thickness of 1.6mm can be enabled to reach the UL94V-0 grade. The composite can be used for preparing all kinds of office automation equipment, electronic and electric equipment and so on.

Owner:SOUTH CHINA UNIV OF TECH

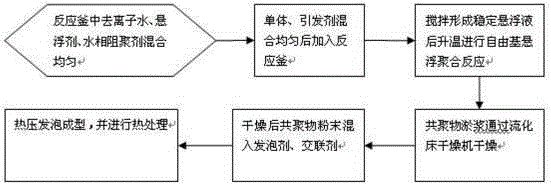

Preparation method for acrylonitrile/methacrylic acid copolymer foamed plastic

The invention discloses a preparation method for acrylonitrile / methacrylic acid copolymer foamed plastic. The preparation method comprises the following steps: adding deionized water, a suspending agent and an aqueous phase inhibitor into a reactor, and uniformly agitating; uniformly mixing monosomic acrylonitrile, methacrylic acid and an initiator, adding the mixture into the reactor, agitating the mixture at the room temperature so as to obtain a stable suspension, rising the temperature to a reaction temperature, and performing free radical suspension polymerization under the condition of agitation; drying a slurry-shaped mixture obtained after the reaction; uniformly mixing copolymer powder, a carbamide foaming agent and a bismaleimide (BMI) crosslinking agent which are obtained after drying; performing hot-pressing foaming formation of the mixture, and otaining polymethacrylimide foamed plastic via heat treatment. The technical scheme provided by the invention is high in production efficiency and yield, can obtain a product with stable performance, is simple and convenient to operate and environmental-friendly, and realizes a beneficial implement effect.

Owner:HAOBO FUJIAN NEW MATERIAL TECH

Load-type metallocene catalyst, preparation method thereof and application thereof

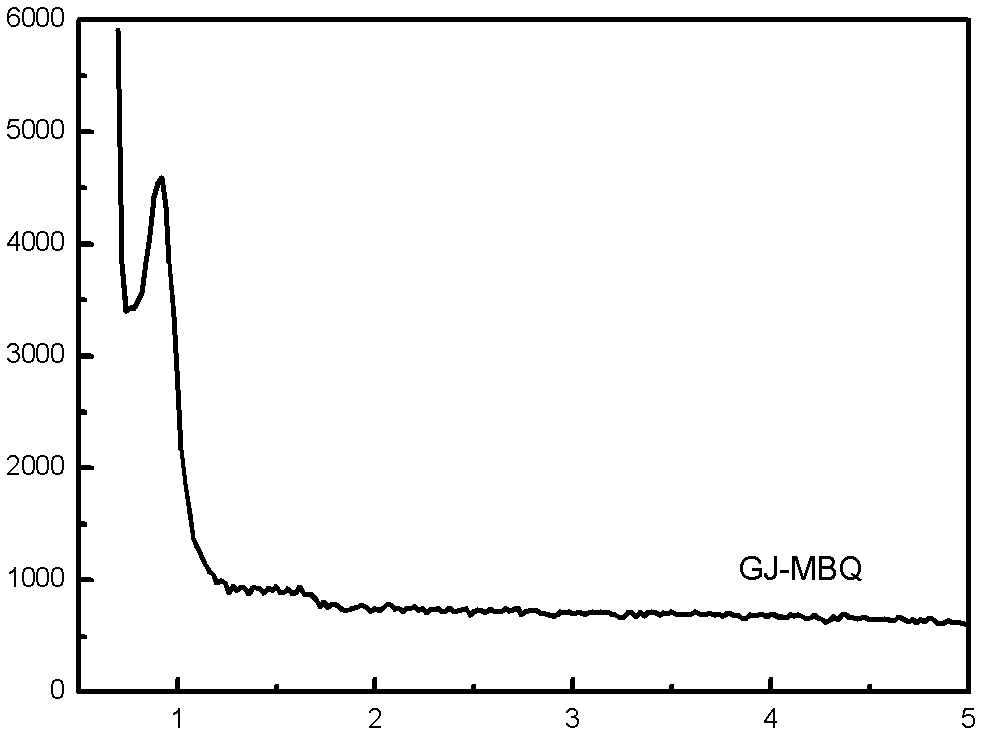

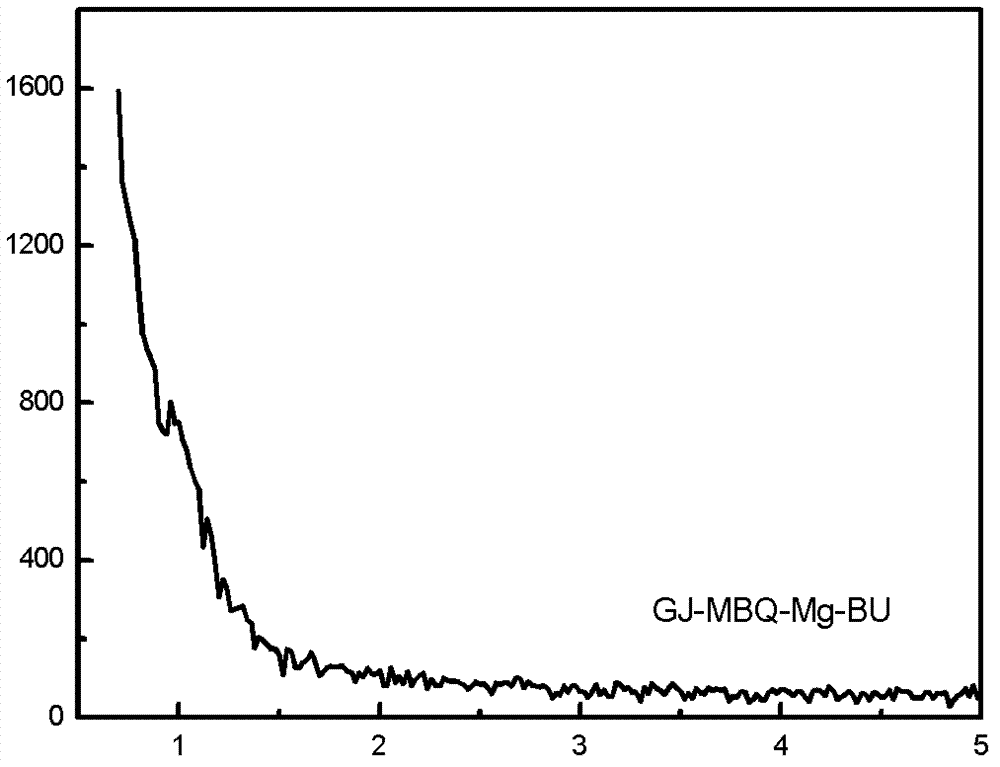

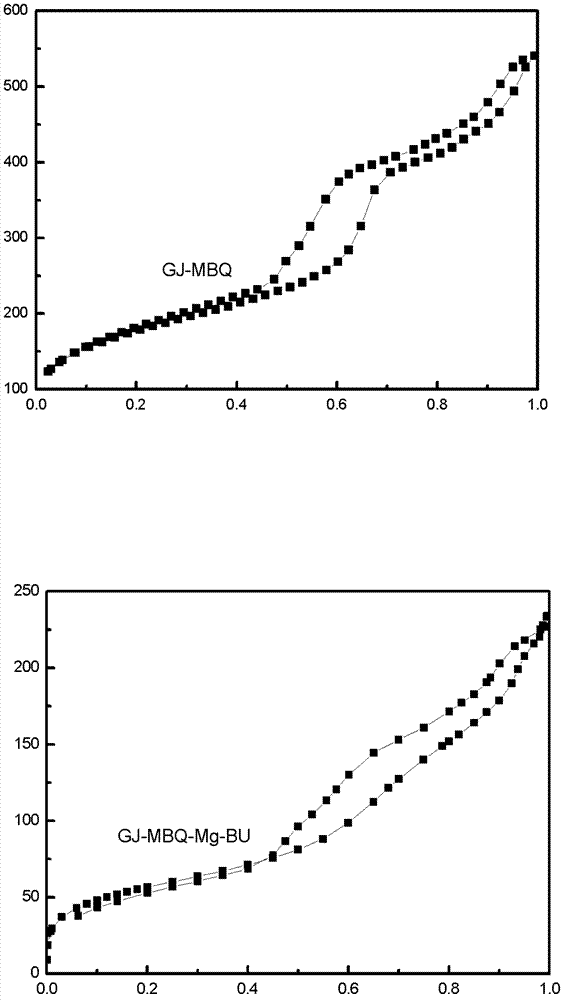

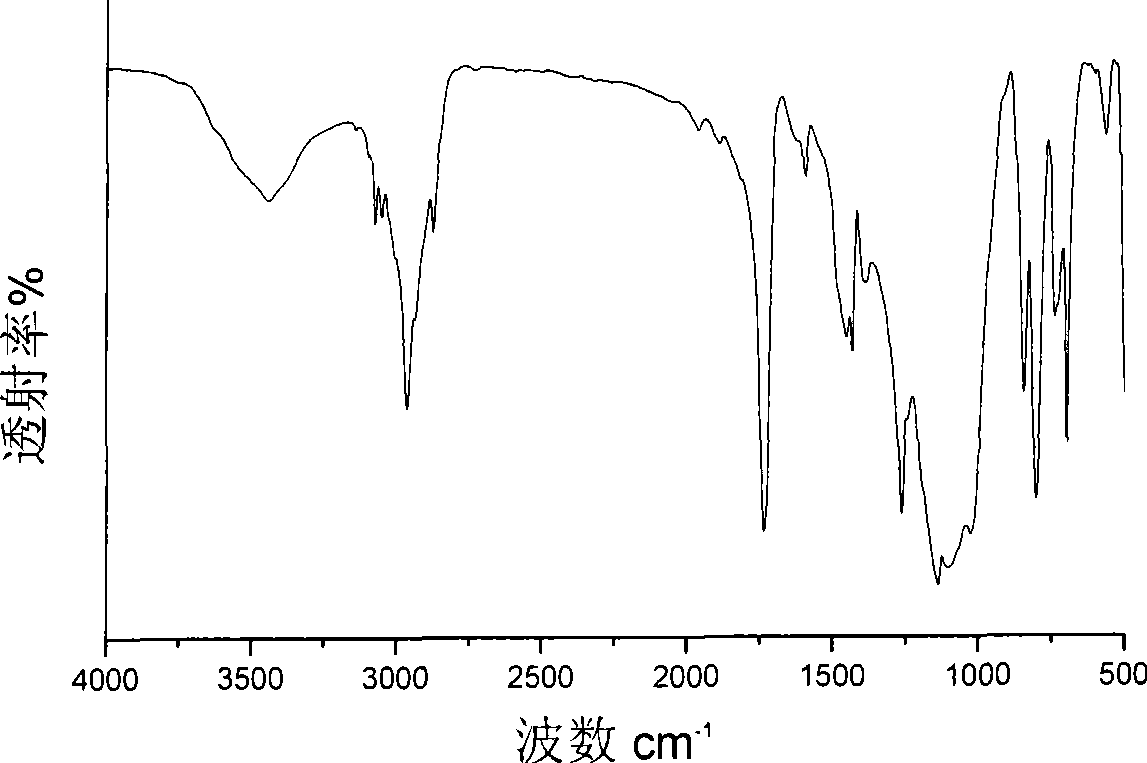

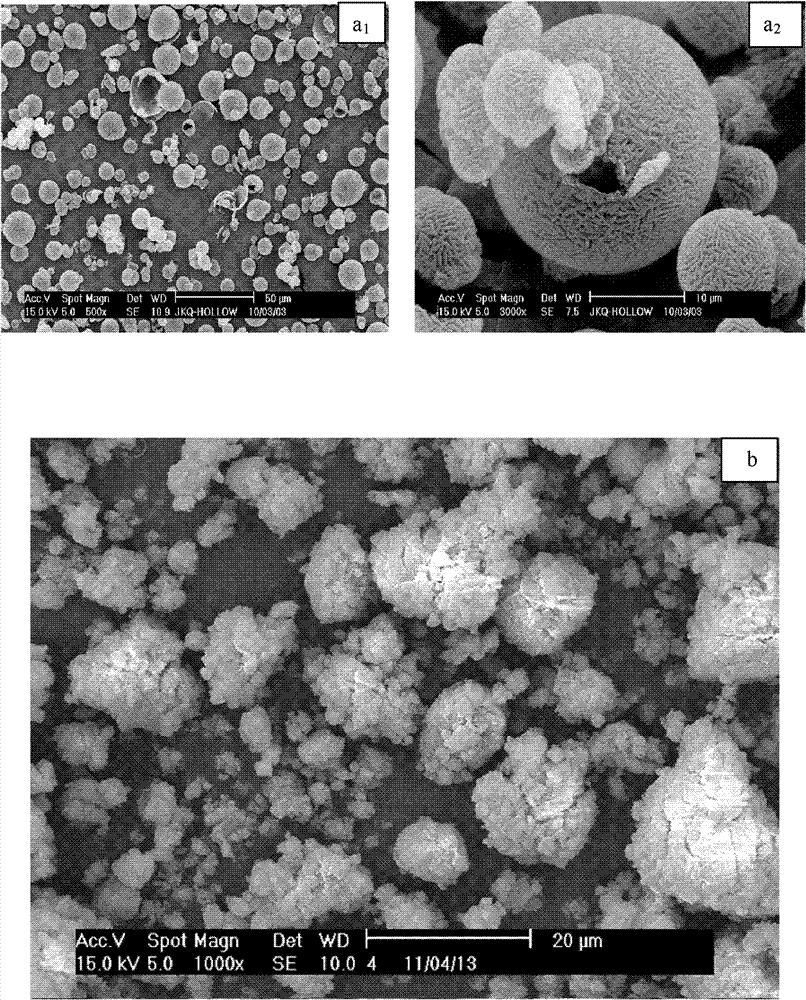

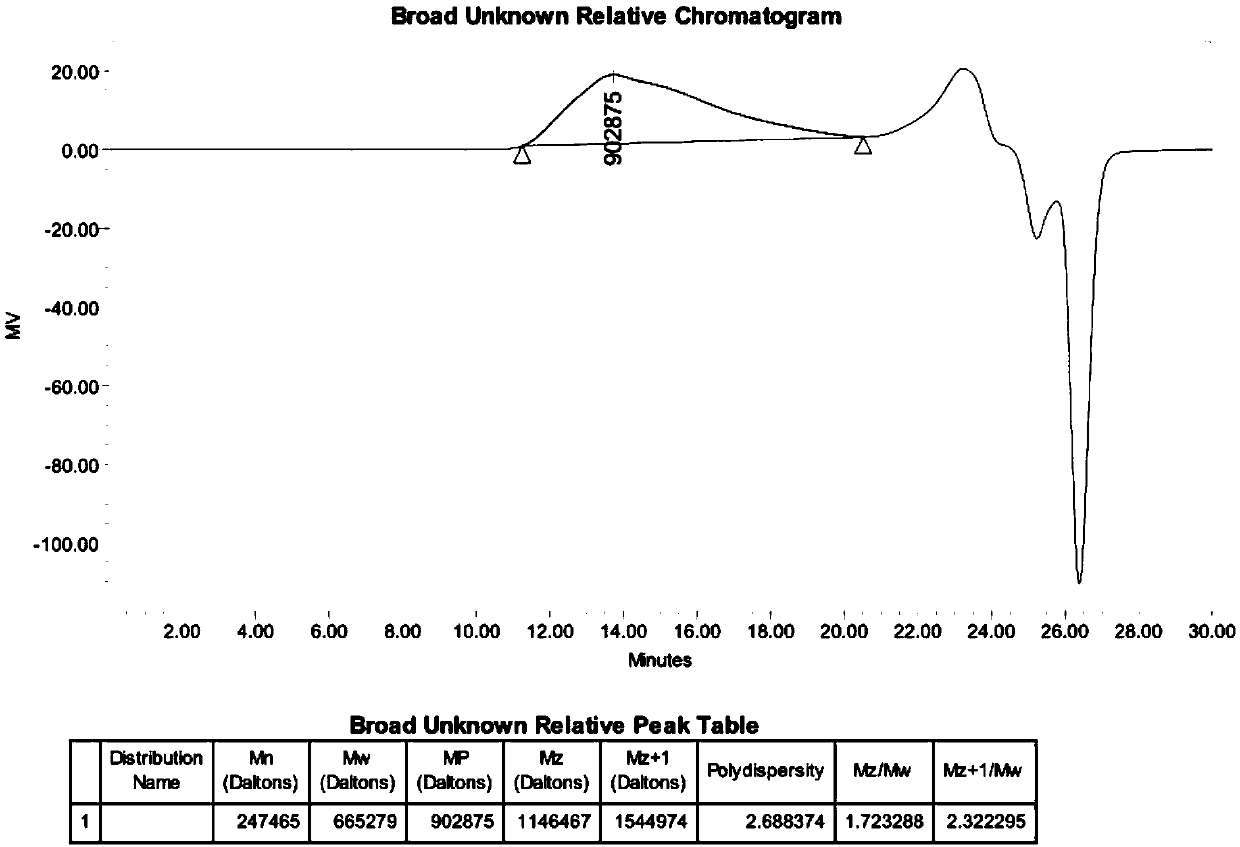

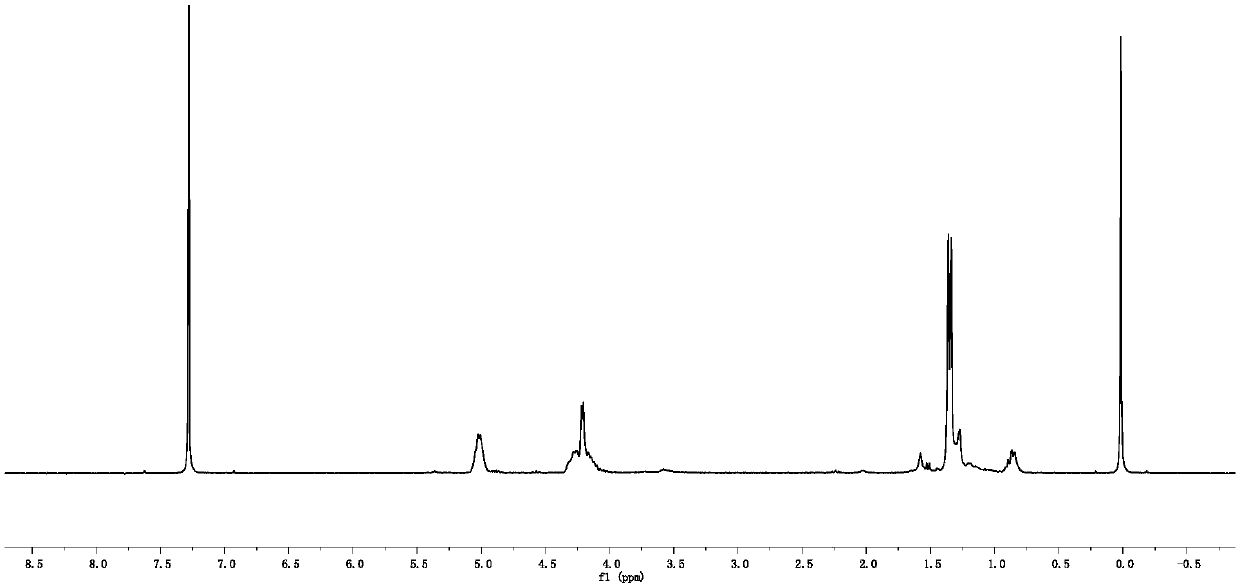

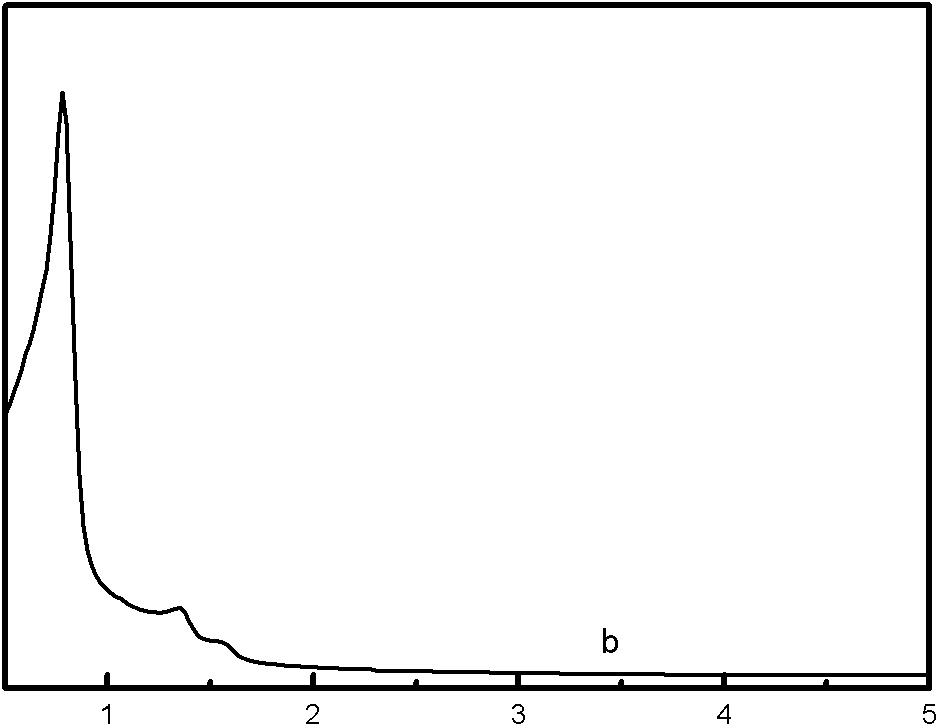

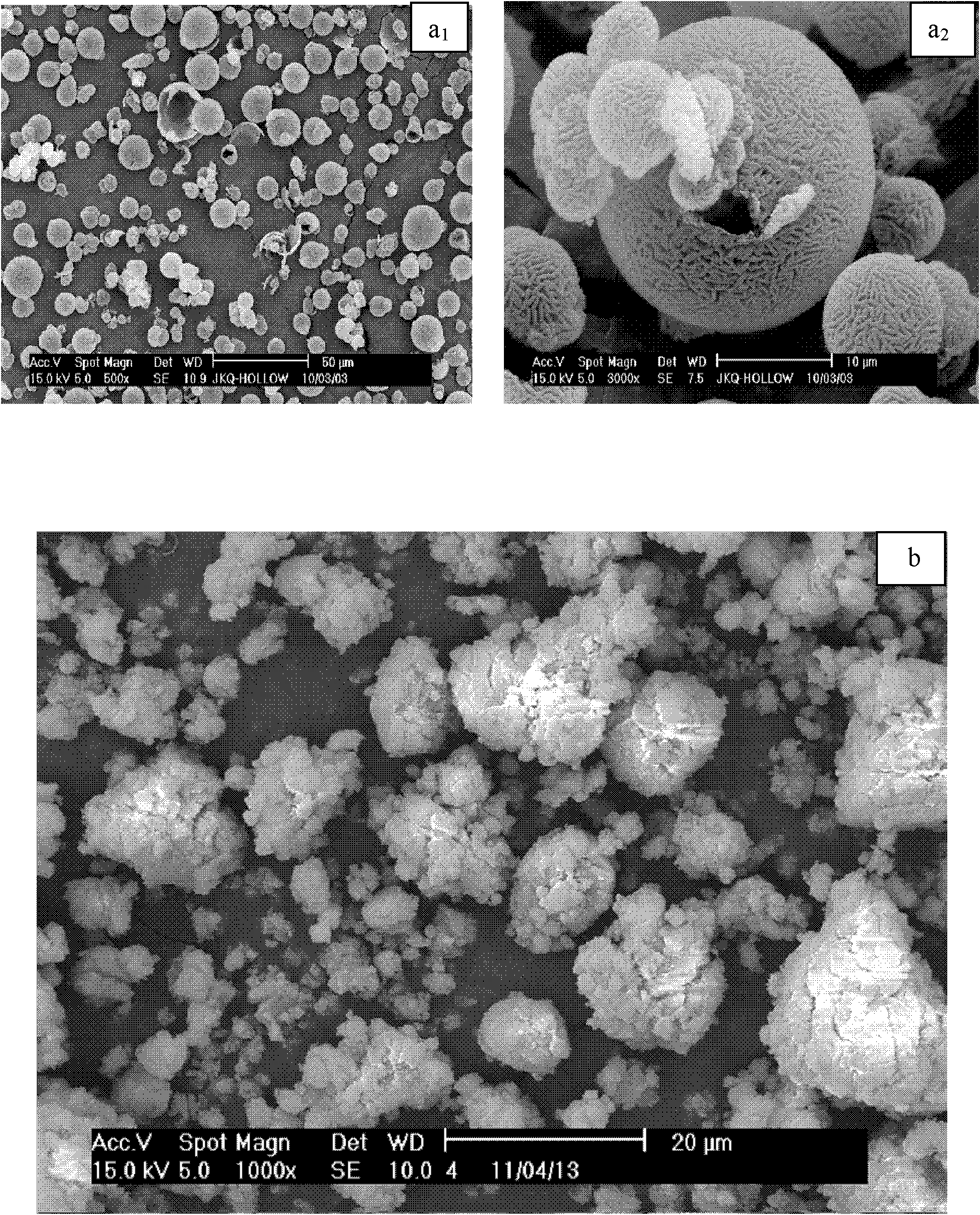

The invention provides a load-type metallocene catalyst which comprises a carrier and an alkyl aluminoxane / magnesium chloride complex and a metallocene compound loaded on the carrier. The hollow ball mesoporous silica carrier has an average particle diameter of 3 to 20 micrometers, a specific surface area of 200 to 300 square meter per gram, a pore volume of 0.5 to 1.5 milliliter per gram, a most probable pore size of 3 to 20 nanometers and an average pore wall thickness of 1 to 2.9 micrometers. The metallocene compound has a structure as shown in formula 1. The load-type metallocene catalyst provided by the invention has a catalytic efficiency up to 3.8 * 10<8> gPE / (mol Zr * h) while homopolymerization and a catalytic efficiency up to 3.7 * 10<8> gPE / (mol Zr * h) while copolymerization under 70 DEG C, overcomes defects of sticking to kettles, is low in a polymerization temperature, and reduces energy consumption to some extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

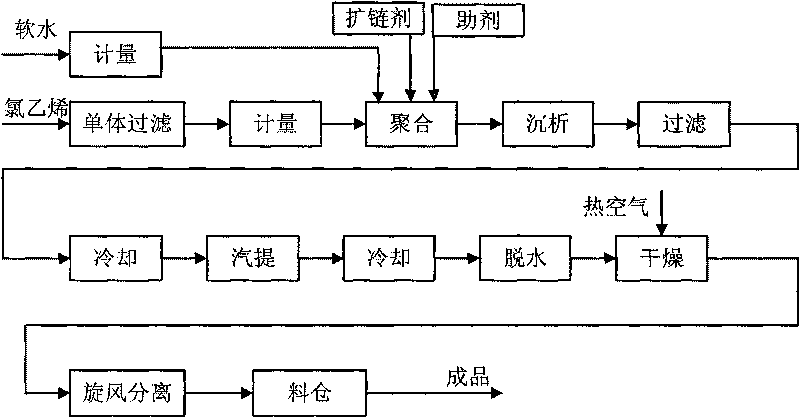

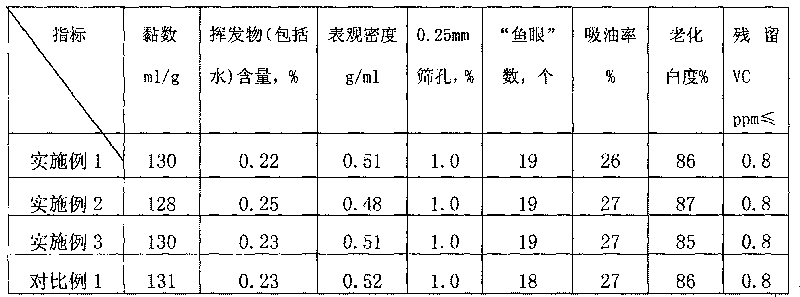

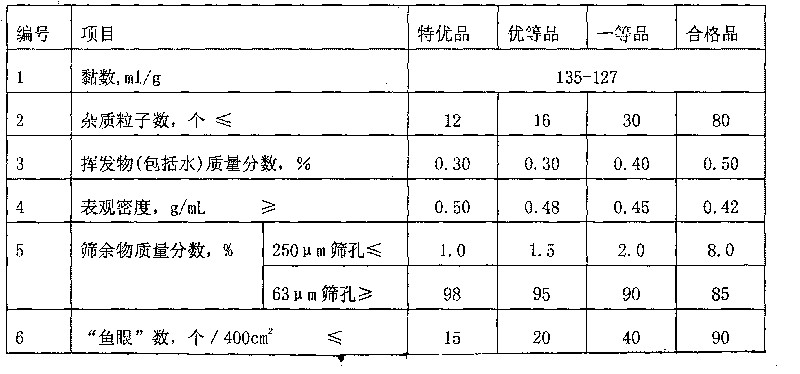

New process for SG3 type PVC (polyvinyl chloride) resin production

ActiveCN101735373ARaise the polymerization temperatureShorten the polymerization reaction timePolymer sciencePolyvinyl chloride

The invention relates to a new process for SG3 type PVC (polyvinyl chloride) resin production, which comprises the following steps of: adding a vinyl chloride monomer, pure water, a dispersant, an initiator and a conventional amount of thermal stabilizer and terminator into a reaction kettle, and meanwhile adding a chain extender of maleic acid di-allyl ester into the reaction kettle; wherein the reaction kettle is in a middle size, the mass proportion of the monomer, the pure water, the dispersant, the initiator and the chain extender is 20,000-25,000:30,000-33,000:490-530:120-140:4.5-5.5, and the temperature of polymerization reaction is 54-58 DEG C. Under the condition of no changing of traditional main production equipment, the invention adjusts the proportioning of relevant auxiliary agents, improves the temperature of the polymerization reaction, optimizes the control conditions of the production, and shortens the time of the polymerization reaction for about 60 minutes while adding a proper amount of the chain extender in a production formula, thereby saving power and energy consumption, improving production capacity of the equipment, and having safe and stable production system operation and better economic benefit.

Owner:昊华宇航化工有限责任公司

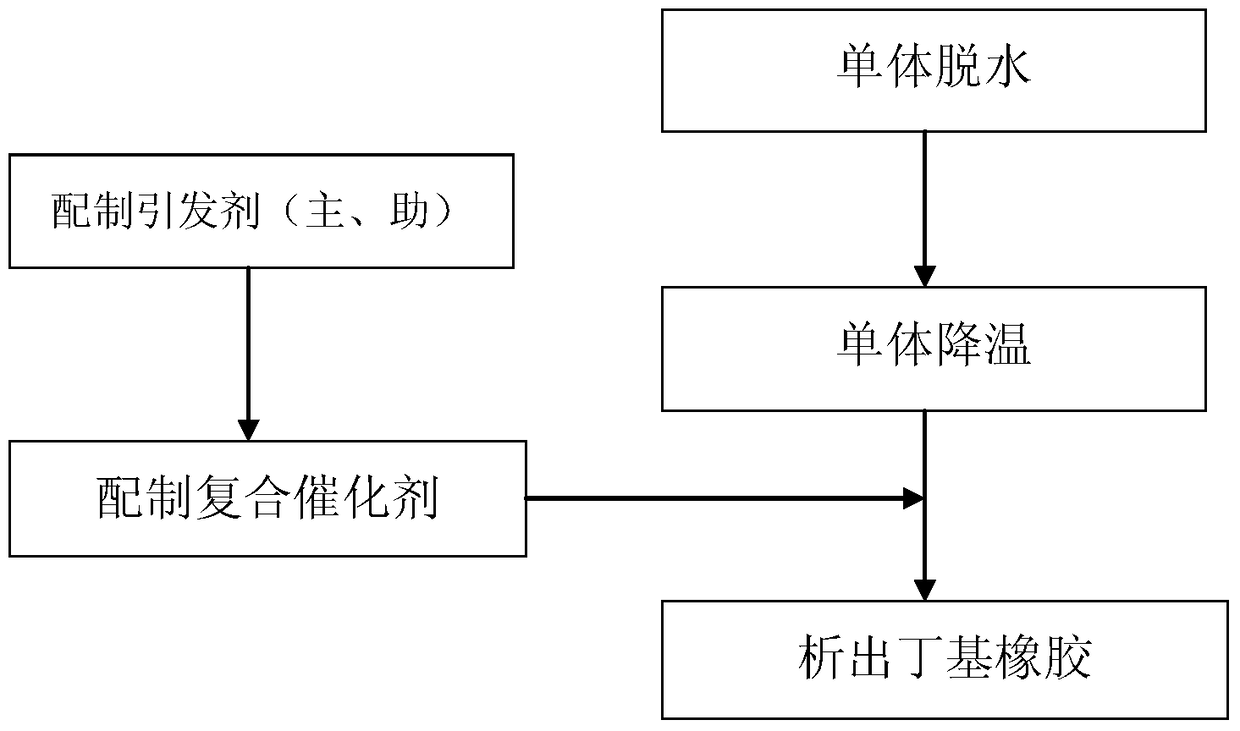

Solution method for synthesizing butyl rubber

The invention relates to a solution method for synthesizing butyl rubber. A mixture of C4-C8 monoolefine monomers and C4-C14 polyene hydrocarbon monomers is taken as a raw material, and in a system that hexane and chloromethane are solvents, polymerization reaction is initiated by an initiating system to prepare butyl rubber polymer, wherein the reaction pressure is normal pressure, the reaction temperature ranges from 0 to -90DEG C, and the initiating system has the concentration of 0.01-0.001mol / L, and is prepared by dissolving a main initiator, namely deionized water and a coinitiator, namely aluminum alkyl dihalide by using a polar solvent CH2Cl2 for mixing, and adding alkylol amines; the molar ratio of the coinitiator to the main initiator is 1:1-10:1, and the molar ratio of a third component to the main initiator is 1:10-1:25; and the adding amount of the mixed solvent is 1 to 50 times volume of the polymerization monomers. According to the method, reaction is mild, polymerization temperature is improved, the stability and initiation efficiency of the initiators are high, and the molecular weight distribution of the product is narrow.

Owner:PETROCHINA CO LTD

Supported metallocene catalyst and preparation method and application thereof

The invention provides a supported metallocene catalyst which comprises a carrier, and an alkylaluminoxane / magnesium chloride complex and a metallocene compound which are supported on the carrier; the carrier is rodlike macroporous mesoporous silica which has a length of 2-20 microns, an aspect ratio of 2-8:1, a specific surface area of 320-380 square meter / g, and a pore volume of 0.5-1.5 ml / g. The metallocene compound has a structure as shown in formula 1. When the supported metallocene catalyst of the invention is used for catalyzing olefin polymerization, the catalytic efficiency for homopolymerization at 70 DEG C is up to 2.7*10<8> gPE / (mol Zr.h), and the catalytic efficiency for copolymerization at 70 DEG C is up to 4.2*10<8> gPE / (mol Zr.h); the supported metallocene catalyst overcomes the defect of kettle adhesion, has a low polymerization temperature, and thus reduces the energy consumption to some extent. Formula 1 is as follows.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aliphatic polycarbonate preparation method

The invention provides an aliphatic polycarbonate preparation method, which includes adopting a heterogeneous catalyst to polymerize carbon dioxide, propylene oxide and a comonomer to obtain aliphaticpolycarbonate, wherein the comonomer comprises a copolymer of one or more of styrene, acrylonitrile or vinyl acetate and glycidyl methacrylate or a glycidyl methacrylate homopolymer. According to themethod, the comonomer is introduced in the copolymerization process of carbon dioxide and propylene oxide to preform copolymerization, and thus the polymerization temperature is increased, and the generation amount of byproducts is reduced, so that the reaction time is reduced, and the utilization rate of equipment is improved. An experimental result shows that the method can improve the reactionrate by 2-4 times, improve the utilization rate of equipment and reduce the investment and production cost on the premise of ensuring low byproducts and high molecular weight.

Owner:联泓格润(山东)新材料有限公司

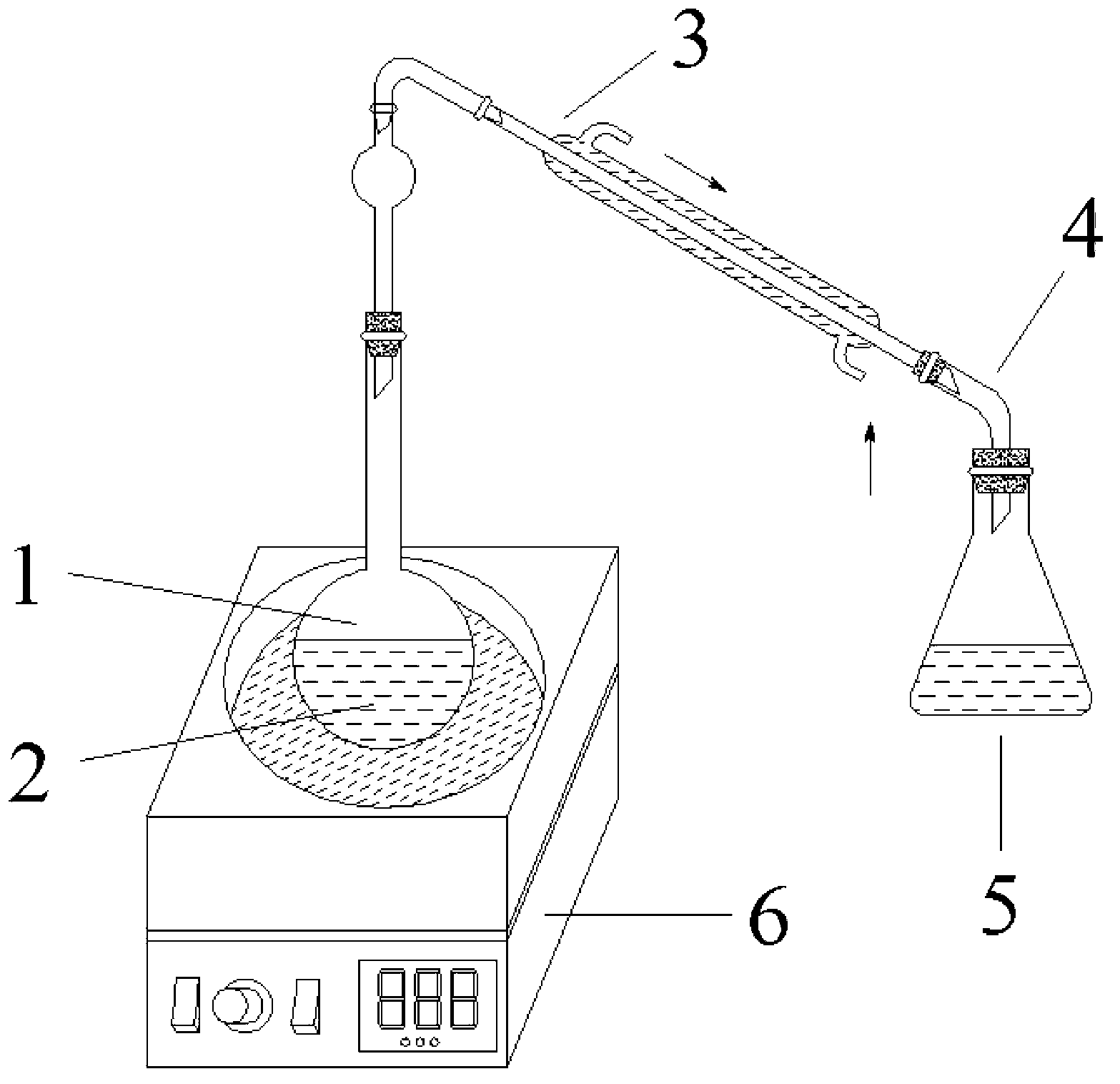

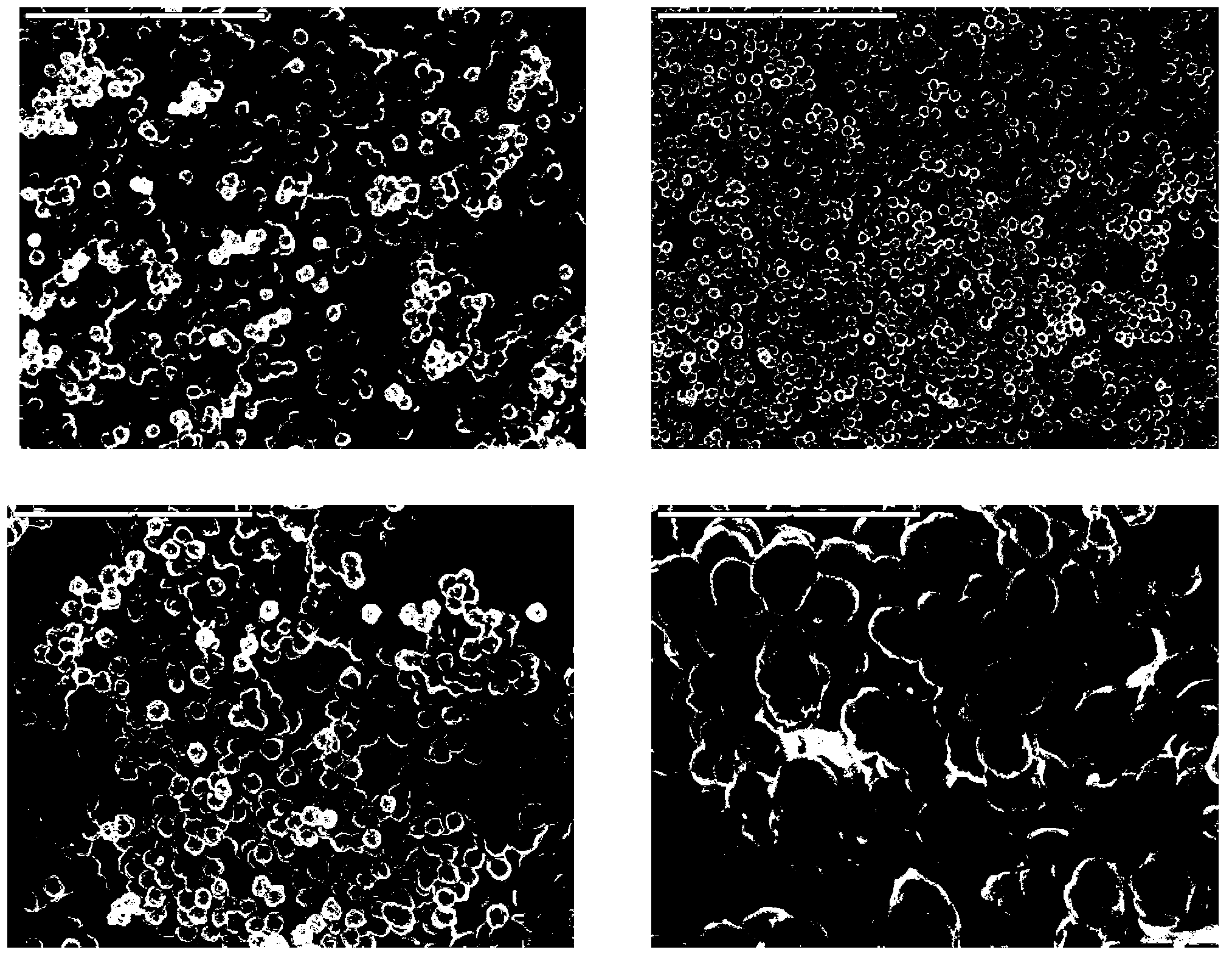

Preparation method of composite microspheres

InactiveCN102796219AIncreased rate of induced decompositionIncrease growth rateMicrospherePerylene derivatives

The invention relates to a preparation method of composite microspheres, in particular to the preparation method of the composite microspheres which are obtained by using acrylamide as well as acrylic acids and derivatives thereof as monomers and carrying on multivariate copolymerization on the monomers by a distillation precipitation method. The preparation method of the composite microspheres, provided by the invention, can be widely used for the biological medical, medical immunology and cosmetic manufacturing fields, in particular the tertiary oil recovery field, and can be used for profile control and oil flooding of low-permeability reservoirs. Polymer microspheres are prepared by using the distillation precipitation method, an improvement is made on the basis of the precipitation method and stirring is replaced with distillation; and the preparation method comprises the following steps of: in a distilled state, copolymerizing a mixture of one or more of the acrylamide as well as the acrylic acids and the derivatives thereof in a reaction container in the presence of an oil-soluble initiator; after all solvents are distilled, dispersing and washing obtained solid polymer microspheres by ethanol; and centrifuging, drying and grinding the solid polymer microspheres so as to obtain dry microspheres. The preparation method of the composite microspheres, provided by the invention, has the advantages of simple process and convenience in implementation.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of size-controllable spherical SDB hydrophobic carrier and Pt/SDB hydrophobic catalyst

ActiveCN113019464AReduce surface tensionIncreased Hydrophobic Carrier YieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationBenzoyl peroxideEtching

The invention provides a preparation method of a size-controllable spherical SDB hydrophobic carrier and Pt / SDB hydrophobic catalyst. The preparation method comprises the following steps: mixing a styrene and divinyl benzene polymerized monomer in a determined ratio, a polymerization initiator benzoyl peroxide, a mixed pore-foaming agent of toluene and n-heptane in a determined ratio and a density regulator to obtain an organic phase; and performing low-temperature prepolymerization on the mixed organic phase in a low-surface-tension aqueous solution to generate liquid drop coalescence, heating to initiate polymerization reaction to obtain a spherical SDB hydrophobic carrier crude product, performing acetone extraction, performing physical etching of mechanical grinding and chemical etching of oxidizing acid oxidation to realize surface roughening, and performing water washing and drying to obtain the spherical SDB hydrophobic carrier. The density of the polymer liquid beads formed by the organic phase is approximately the same as the density of the water phase with low surface tension, so that the polymer liquid beads can perfectly suspend in the water phase to form a nearly spherical polymer precursor, and the SDB hydrophobic carrier with uniform surface and regular shape is prepared.

Owner:HARBIN ENG UNIV

Method for preparing butyl rubber polymer

InactiveCN102020740AHigh number average molecular weightImprove conversion ratePolymer scienceChloride

The invention relates to a method for preparing a butyl rubber polymer. In the method, a mixture of C4-C8 monoolefine monomer and C4-C14 polyene monomer serving as a main material is subjected to polymerization at the temperature of between -90 and -70 DEG C and in absence of water and oxygen by taking the mixture of ionized water, hexane and monoalkyl aluminum dihalide as a catalyst and the mixture of methyl chloride and hexane as a solvent to form the butyl rubber polymer. The method has the advantages of simplicity, high polymerization temperature, low cost, high stability and initiation efficiency of the catalyst, high number average molecular weight of a product, high conversion rate and narrow molecular weigh distribution.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

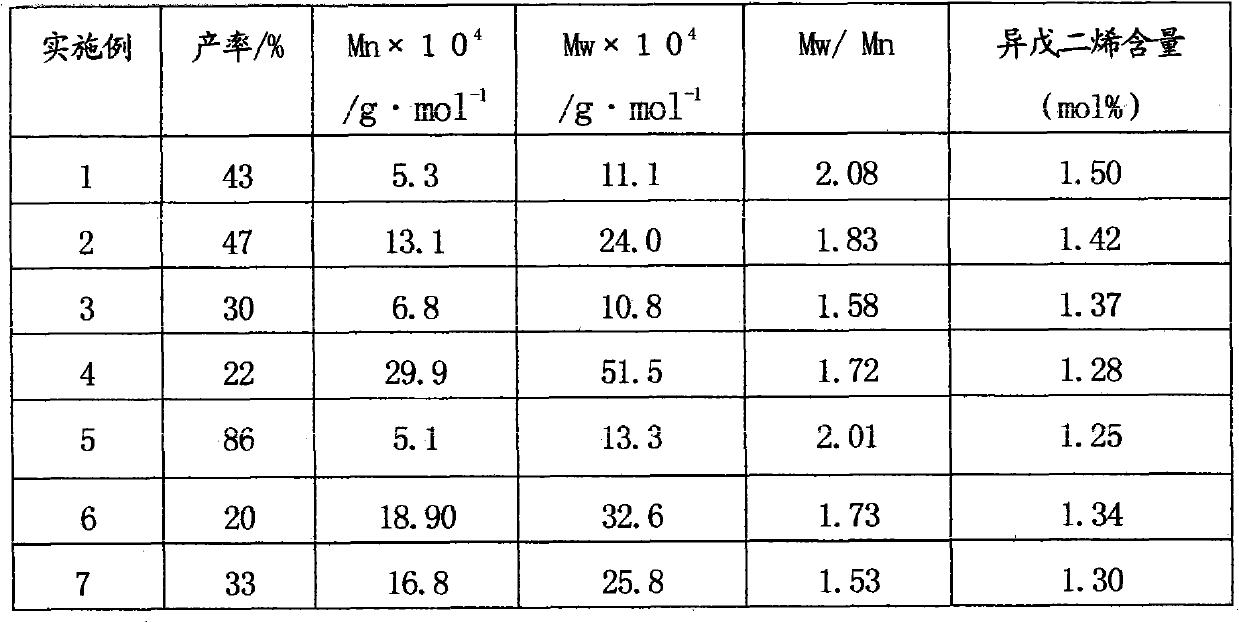

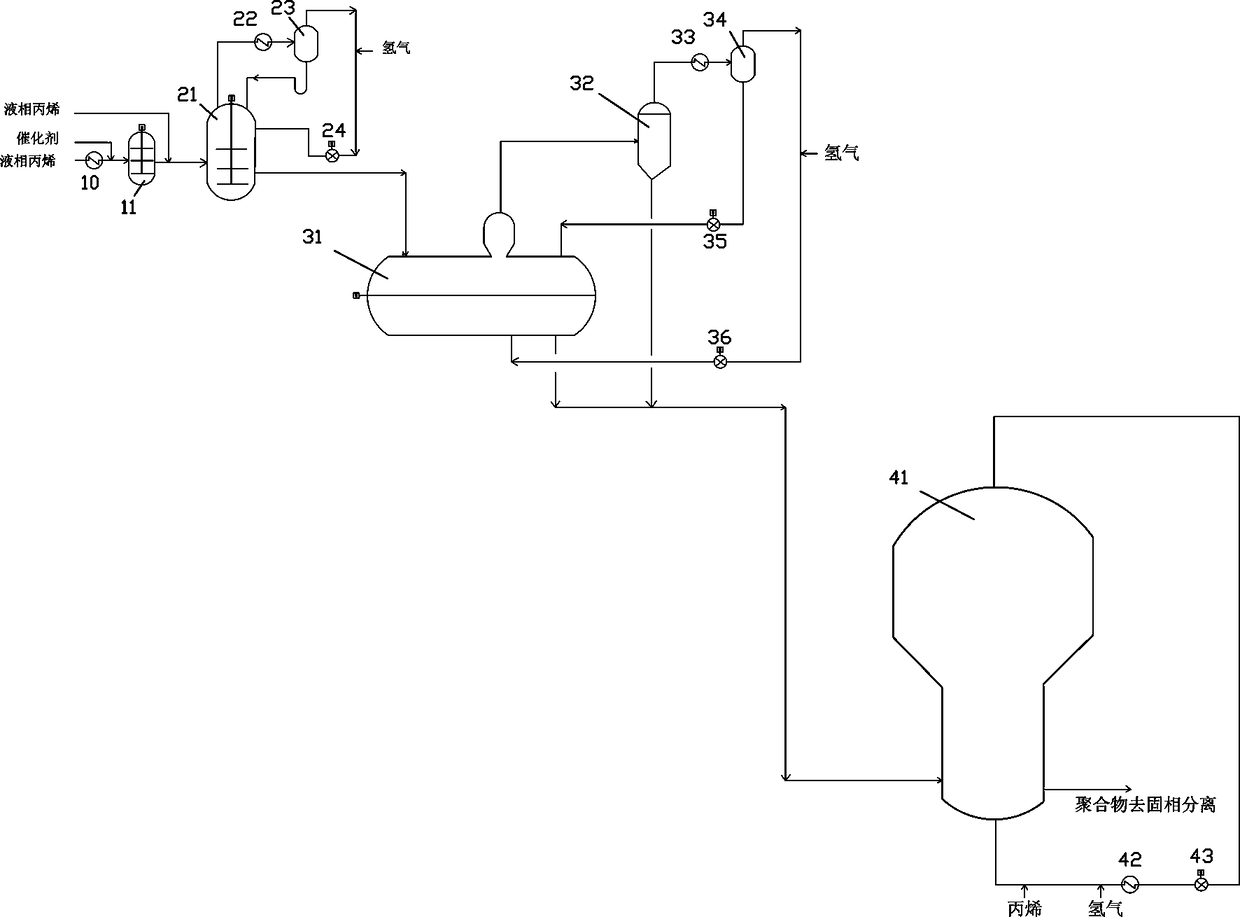

Multistage polymerization method and device of propylene

PendingCN108794669AControl the content of volatile organic compoundsImprove liquidityProcess control/regulationSequential/parallel process reactionsPolymer scienceGas phase

The invention relates to a multistage polymerization method and device of propylene. After prepolymerization reaction, liquid phase polymerization reaction is conducted and then gas phase polymerization reaction is conducted; and two-step reaction is adopted in the gas phase polymerization reaction, and material composition and reaction systems in two reaction regions are the same or different, sothat molecular weight distribution can be widened. By the method and the device, homo-polypropylene, binary random co-polypropylene, ternary co-polypropylene or impact-resistant co-polypropylene withhigh rubber content can be produced; and the prepared polymer is uniform in particle size distribution, has low volatile organic matter content, wide molecular weight distribution and excellent mechanical property and processing property.

Owner:ZHEJIANG SATELLITE ENERGY CO LTD

Preparation method of paclitaxel nano micelle

InactiveCN102423301AAvoid cyclizationRaise the polymerization temperaturePowder deliveryOrganic active ingredientsPolyesterEvaporation

The invention relates to a preparation method of paclitaxel nano micelle, which comprises the following steps of: taking a block copolymer of polyether and polyester as a medicine supplementary material and paclitaxel as a medicine; and preparing the paclitaxel nano micelle by rotating an evaporation solvent, wherein the medicine supplementary material is prepared through body ring-opening polymerization, and the terminal hydroxyl group of the copolymer is modified into carboxylate so as to increase the stability of the micelle. According to the micelle disclosed by the invention, during the preparation process, no stabilizing agent is added, and the obtained medicine-carrying micelle can stably exist for over 48h under the body fluid environment, is a paclitaxel nano sustained-release carrier with a good application prospect, and has the characteristics of stability and tumour targeted effect.

Owner:上海微丸医药开发有限公司

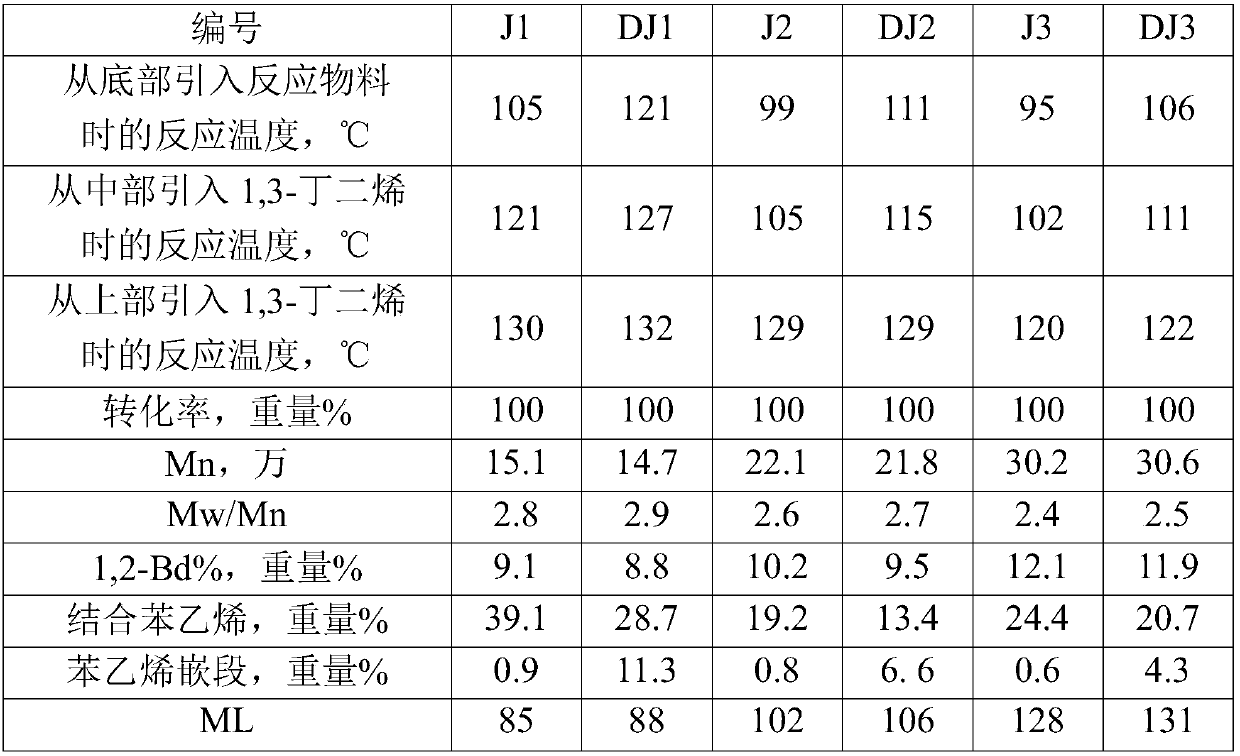

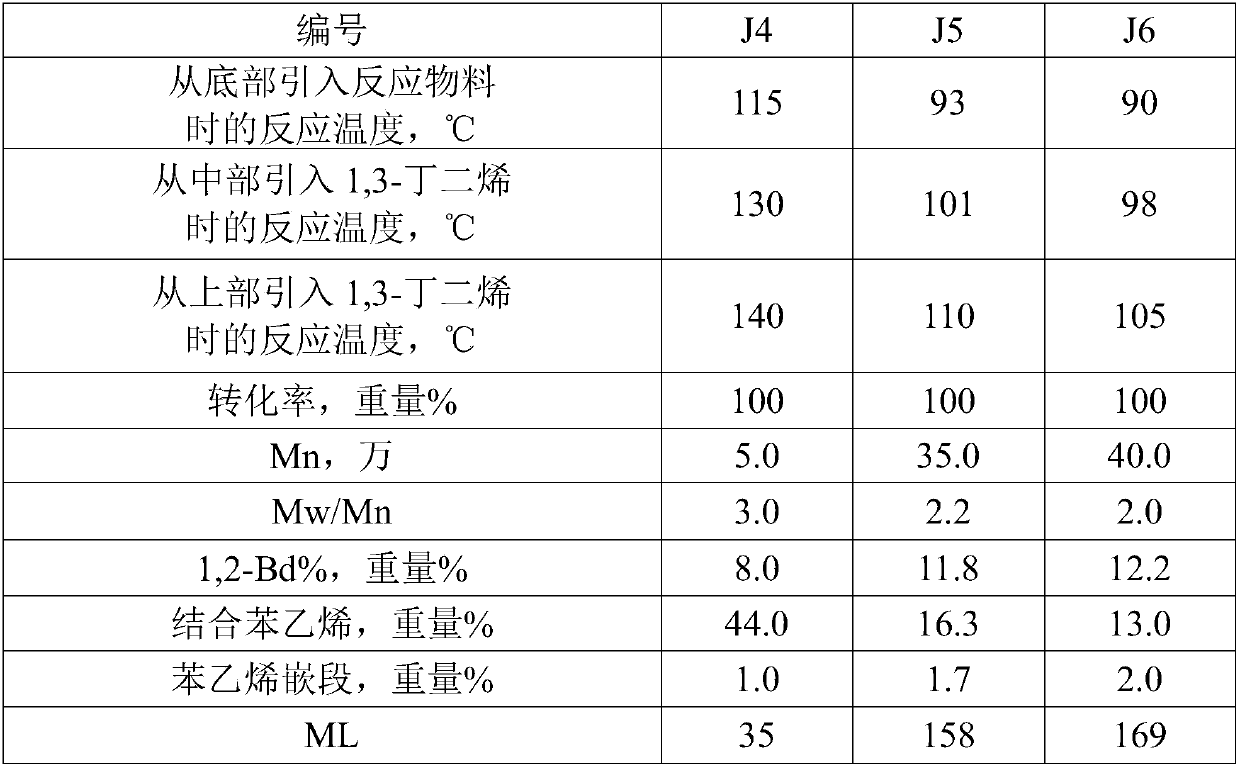

Conjugated diene and monovinylarene random copolymer, and preparation method thereof

The invention relates to the field of conjugated diene and monovinylarene random copolymers, and discloses a conjugated diene and monovinylarene random copolymer, and a preparation method thereof. Thepreparation method includes the following steps that under the condition of anionic polymerization, reaction materials containing the first part of conjugated diene, monovinylarene, solvents, gel inhibitors and single organic lithium initiators are continuously introduced from the first reactor of a continuous polymerization reaction device, the sequential copolymerization reaction is carried outin each reactor of the continuous polymerization reaction device, the second part of conjugated diene is introduced into each reactor, and the polymerization temperature is controlled to be 90-140 DEG C. According to the preparation method, under the conditions that any structural regulators or random agents are not added, the reaction temperature is high, and residence time is reasonable, the conjugated diene and monovinylarene random copolymer can be prepared with controllable basic molecular weight and low vinyl content.

Owner:CHINA PETROLEUM & CHEM CORP +1

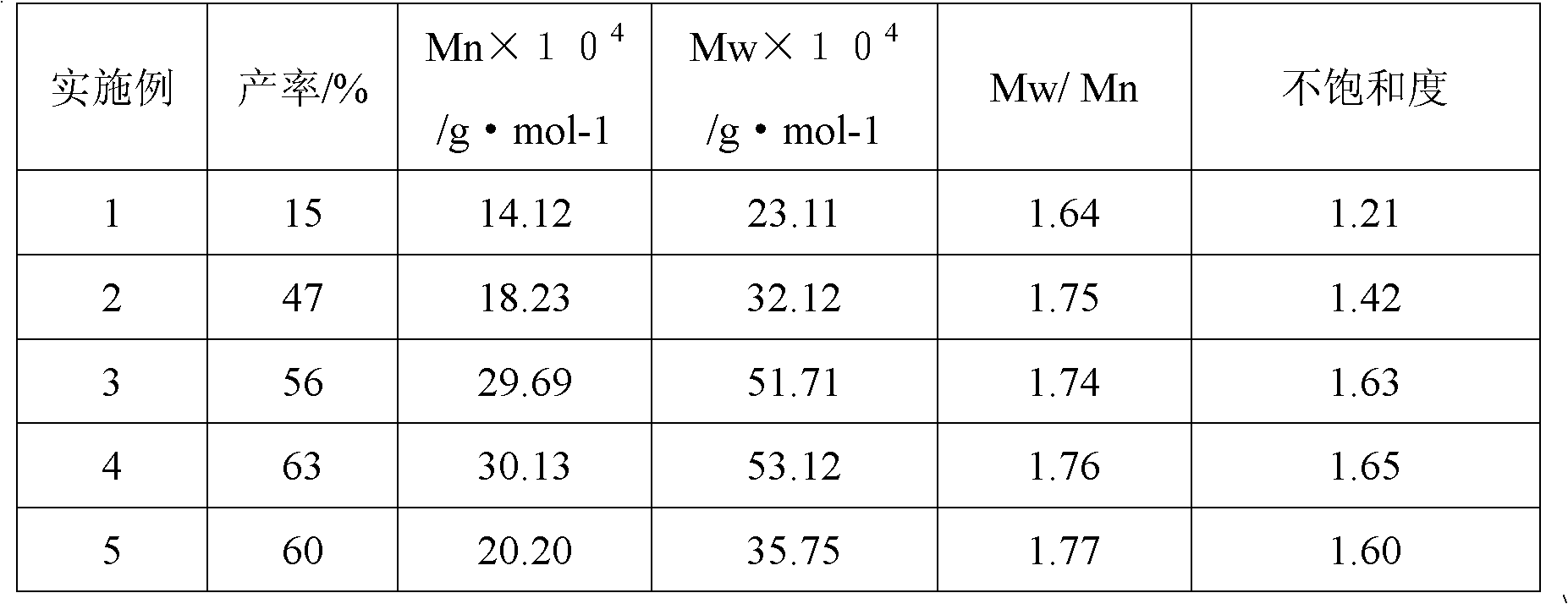

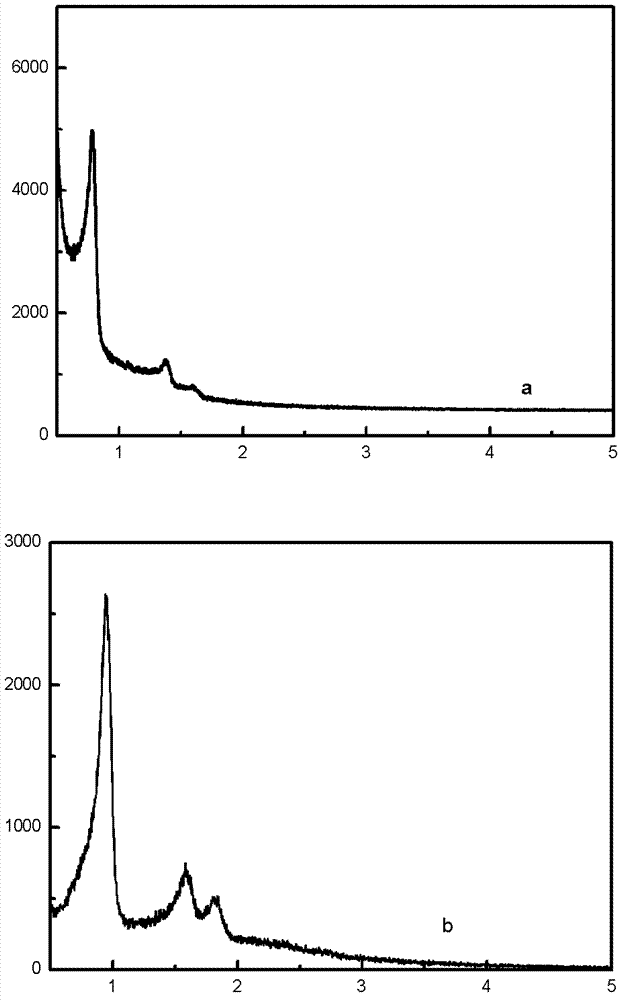

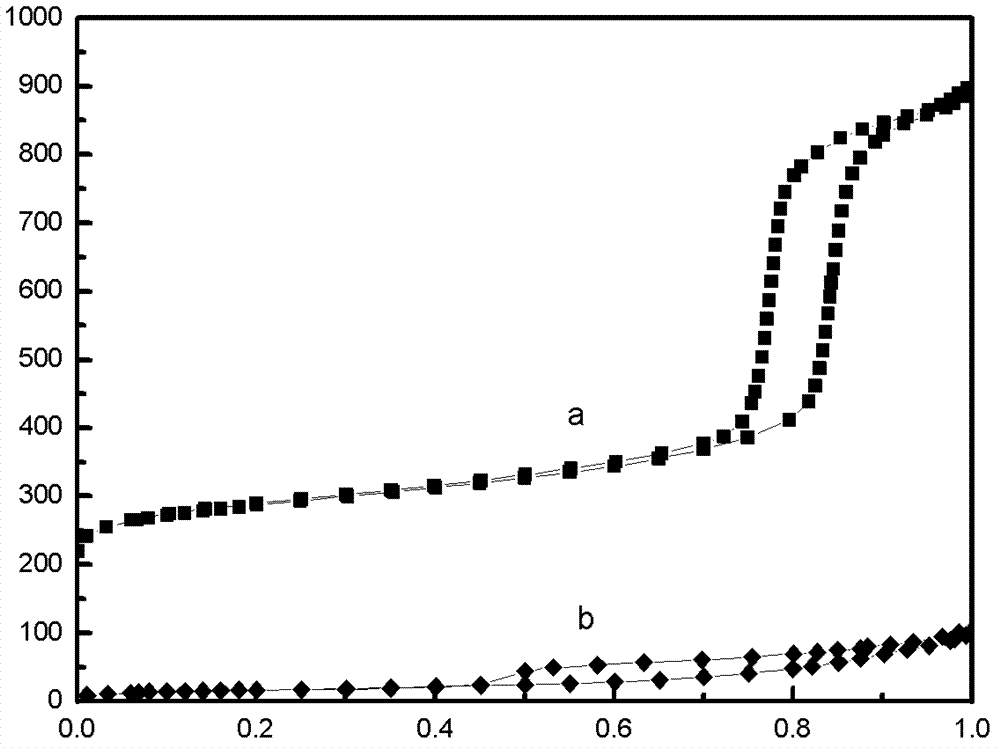

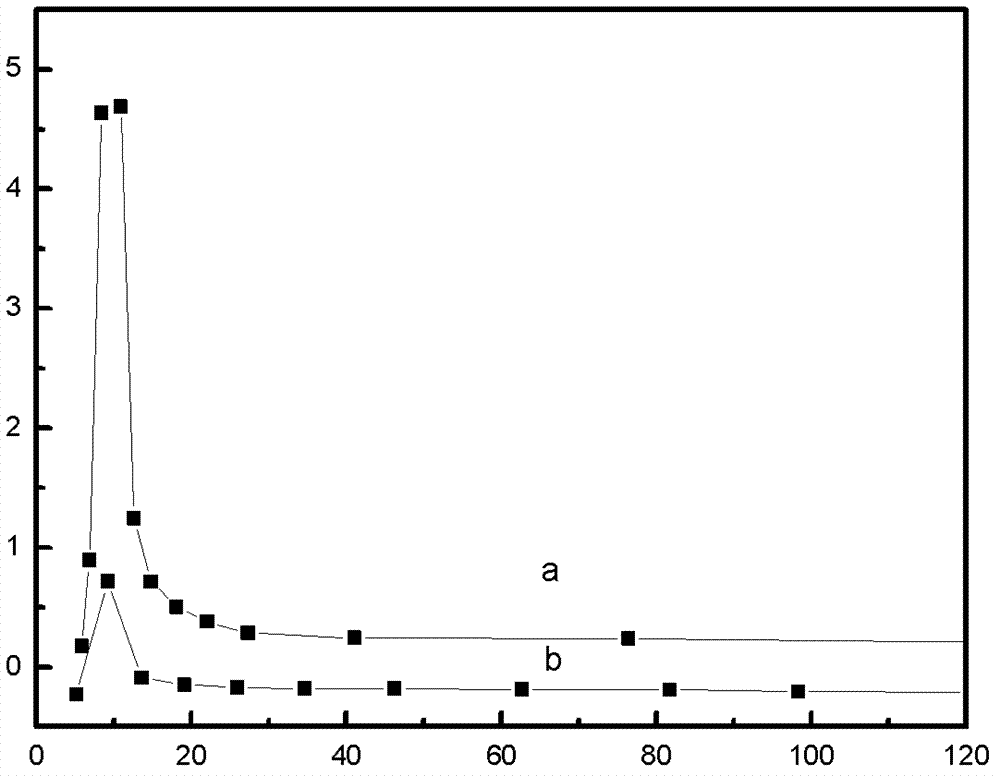

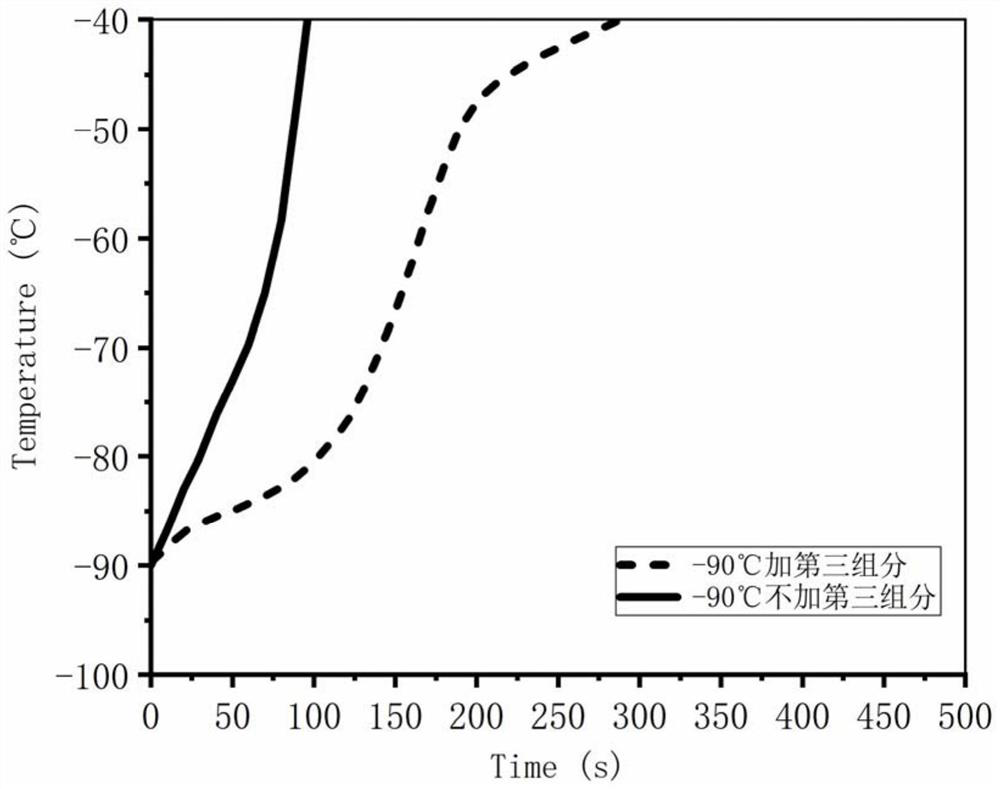

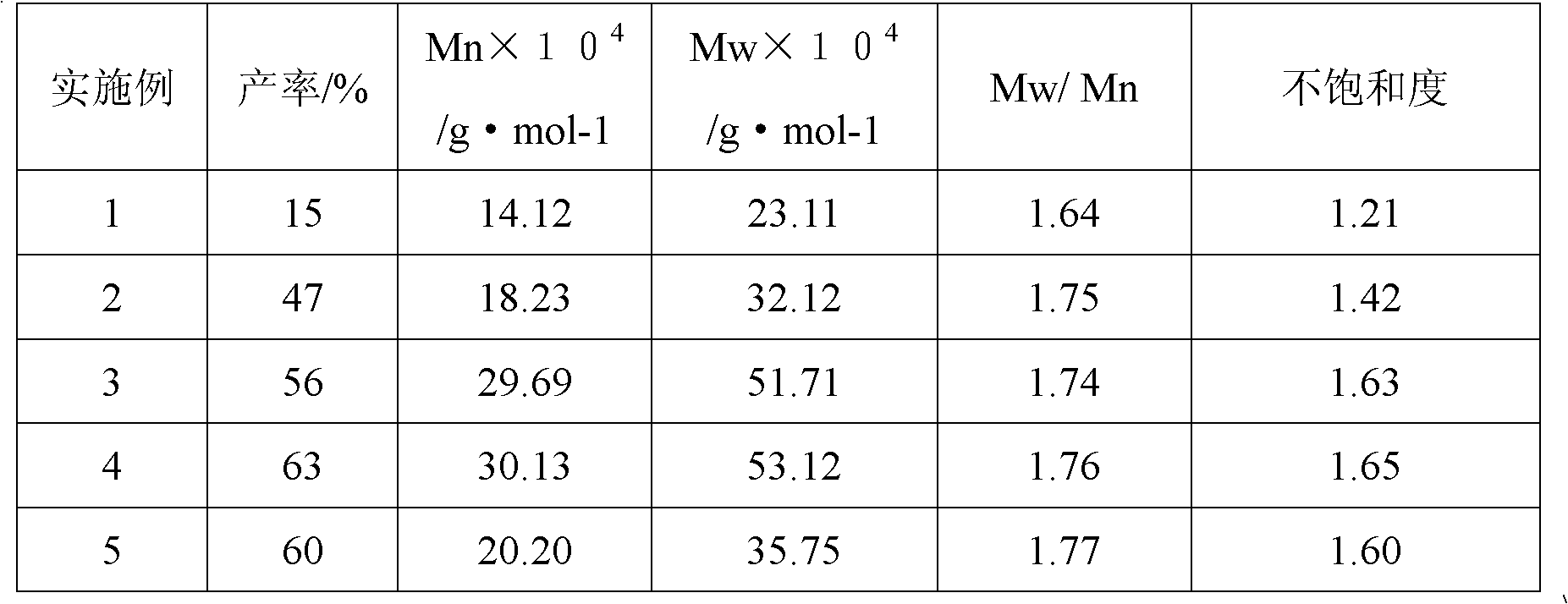

Preparation method for improving polymerization temperature of polyisomonoolefin-based elastomer or molecular weight of elastomer

The invention discloses a series of synthesis methods for increasing the polymerization reaction temperature or molecular weight of a polyisobutylene-based elastomer by adding a third component in a cationic polymerization process. In the traditional production process technology for synthesizing the polyisobutylene-based elastomer, in order to reduce many uncontrollable factors brought to polymerization reaction due to the fact that reaction heat is not discharged in time, extremely low reaction temperature is usually needed. Aromatic ketone, aromatic ether or aromatic ester or a mixture of the aromatic ketone, the aromatic ether or the aromatic ester is added as a third component, so that the active center of carbon cations is stabilized, and the polymerization rate is slowed down. Through exploration, when products with the same molecular weight are prepared, the polymerization temperature can be increased by 5-40 DEG C, the volatilization consumption of a coolant is reduced, the energy consumption is reduced, and the continuous operation period of the polymerization kettle is prolonged. And under the conditions of the same heat transfer area and reaction temperature, the prepared product can obtain higher molecular weight.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

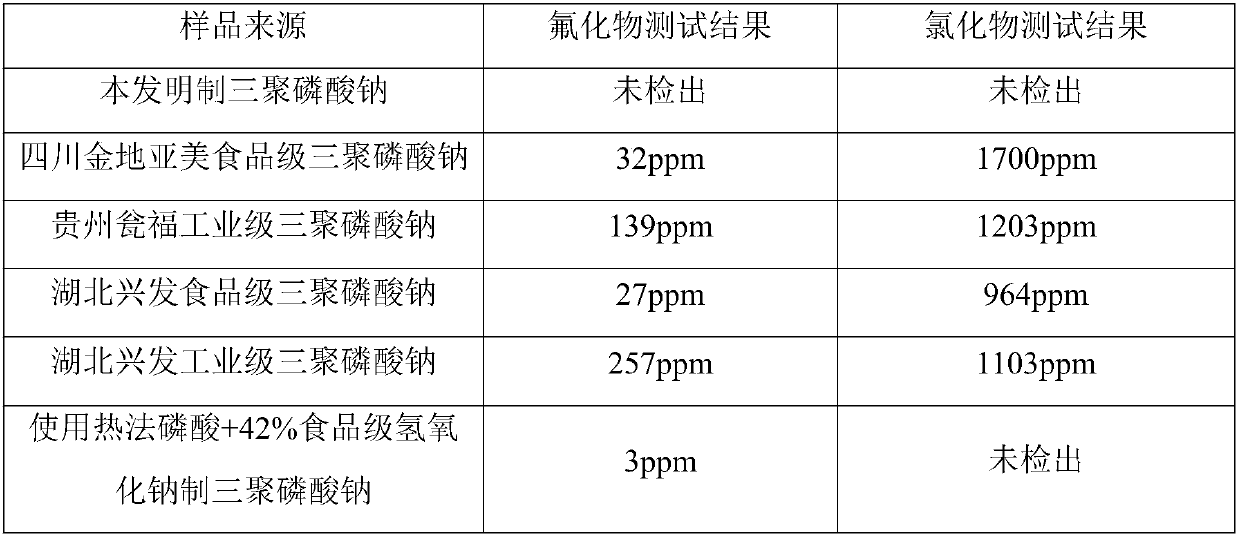

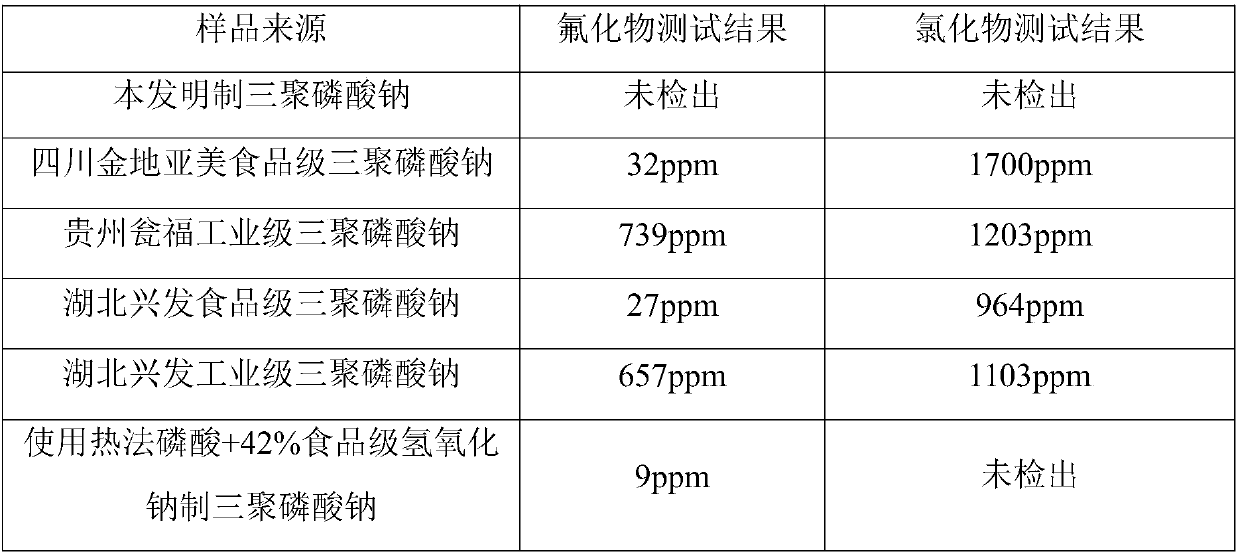

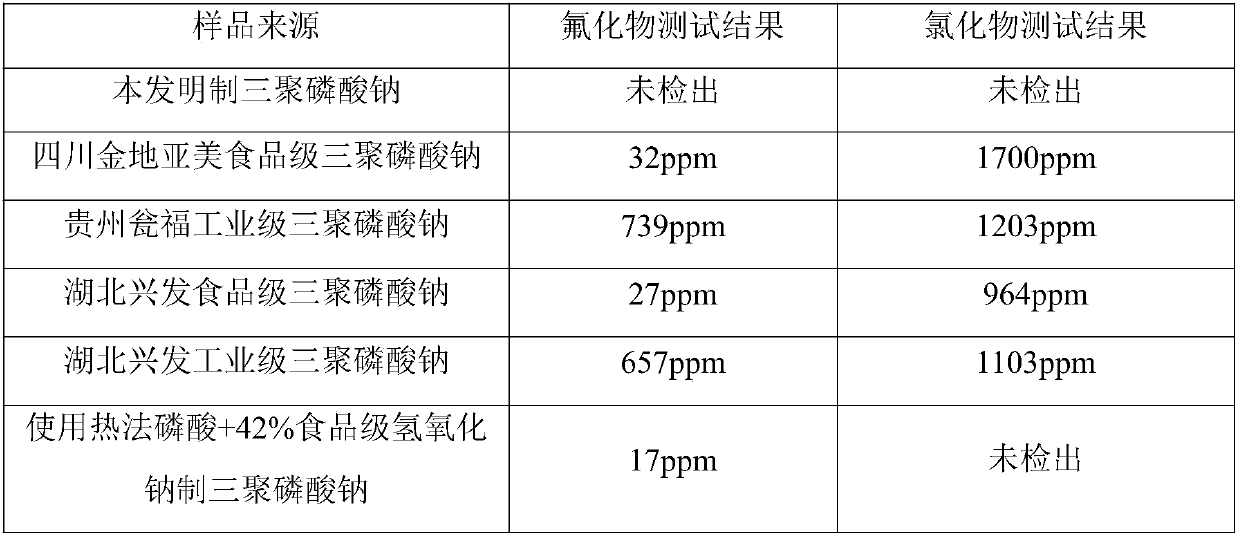

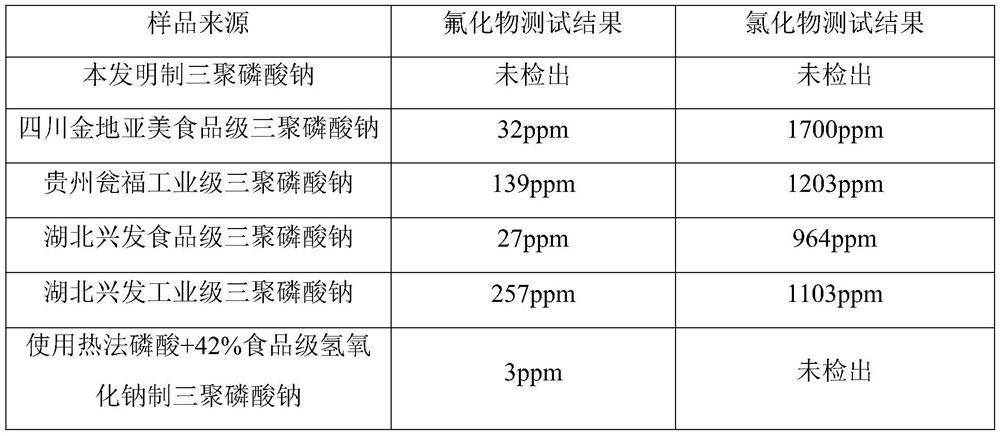

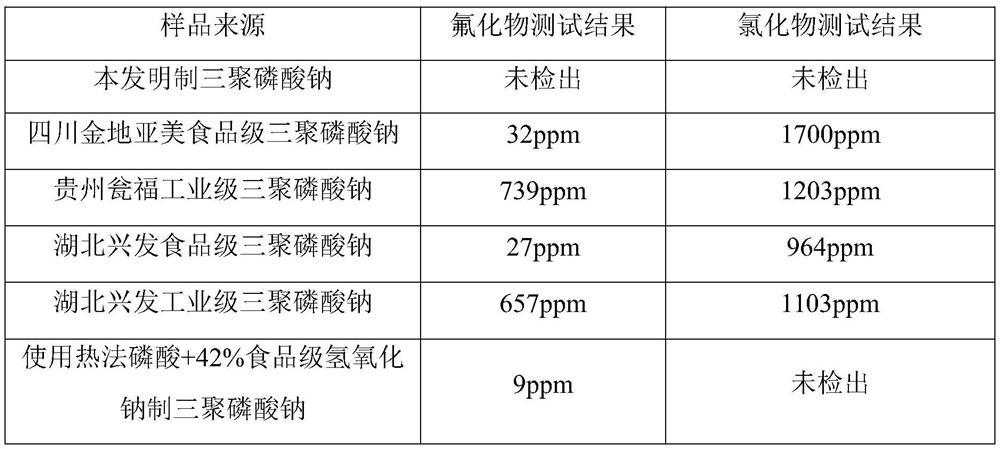

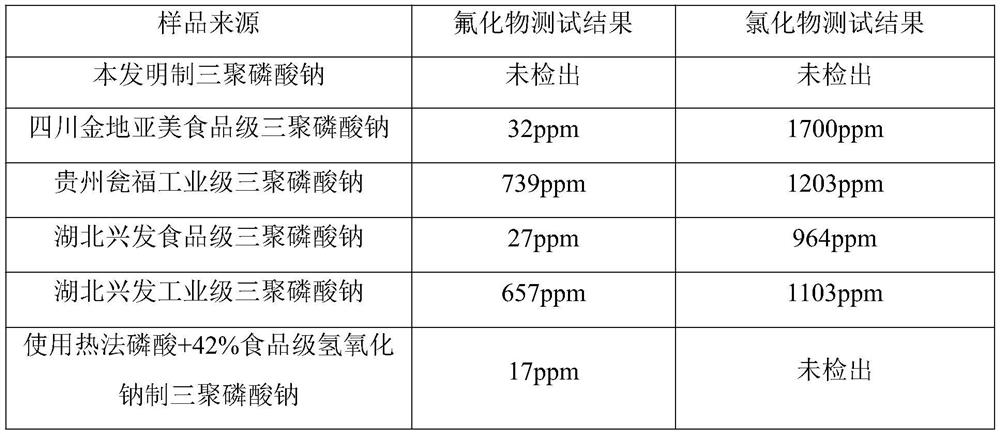

Method for producing sodium tripolyphosphate without chloride or fluoride

ActiveCN107792841APromote escapeIncrease partial pressurePhosphorus compoundsSilicon tetrafluorideSlurry

The invention discloses a method for producing sodium tripolyphosphate without chloride or fluoride. The method comprises the following steps: firstly, neutralization reaction: adding water into a neutralization pot for heating, and adding sodium carbonate for stirring until the sodium carbonate is completely dissolved; when the temperature of a solution is raised to 90 to 120 DEG C, slowly addingphosphoric acid while stirring and adjusting the K value of neutralizing slurry to 2.8+ / -0.2; then adding silicon dioxide, continuously reacting for 3.5+ / -0.5 hours until a mixed solution is viscous,and filtering to obtain a viscous slurry for later use; secondly, drying and dehydrating: feeding the viscous slurry obtained by neutralization into a drying tower for atomization and dehydration; thirdly, polymerization and generation: carrying out polymerization reaction on dried and dehydrated raw materials to obtain the sodium tripolyphosphate; fourthly, carrying out alkali wash on tail gas contained hydrogen chloride, hydrogen fluoride and silicon tetrafluoride and emptying after the substances are determined to be qualified by detecting. The production method of the sodium tripolyphosphate, provided by the invention, has the advantages that the cost of the raw materials is low, the process is simple, the industrialization is easy to realize and the raw materials are easy to obtain;the obtained sodium tripolyphosphate does not contain the chloride or the fluoride.

Owner:HUBEI XINGFA CHEM GRP CO LTD

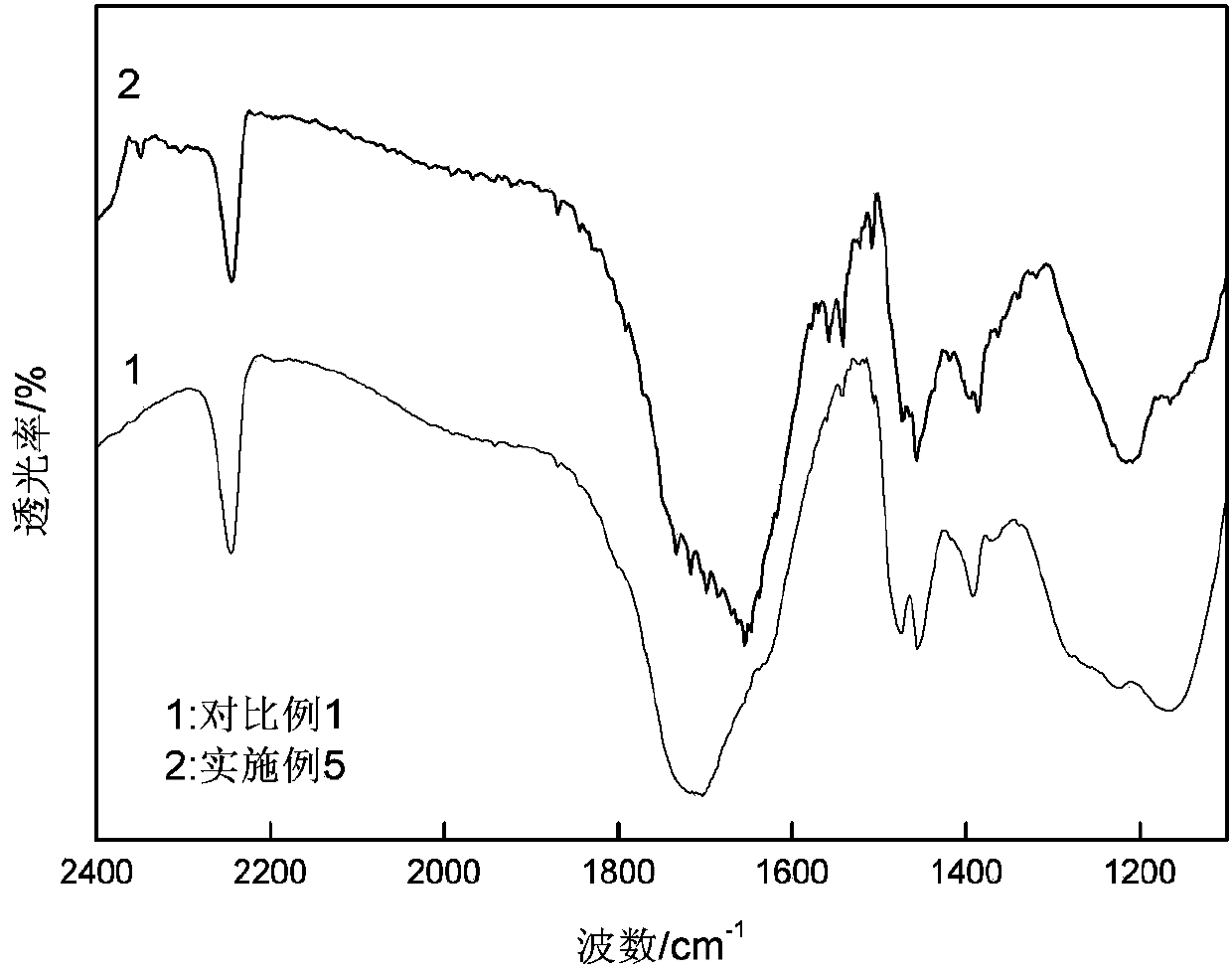

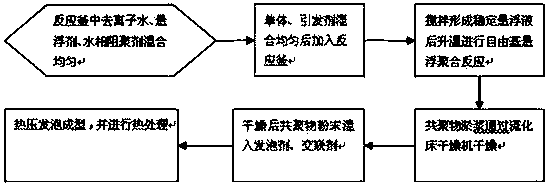

A kind of preparation method of acrylonitrile/methacrylic acid copolymer foamed plastics

ActiveCN103421206BRaise the polymerization temperatureShorten the polymerization reaction timeImidePolymer science

The invention discloses a method for preparing an acrylonitrile / methacrylic acid copolymer foam plastic, which comprises the following steps: adding deionized water, a suspending agent and a water-phase polymerization inhibitor into a reaction vessel, and stirring evenly; After the nitrile, methacrylic acid and initiator are mixed evenly, add to the reaction vessel, and stir at room temperature to obtain a stable suspension, heat up to the reaction temperature, and carry out free radical suspension polymerization reaction under the condition of stirring again; the slurry obtained after the reaction The mixture is dried; after drying, the obtained copolymer powder, carbonamide foaming agent, and bismaleimide (BMI) crosslinking agent are mixed evenly; the obtained mixture is hot-pressed and foamed, and heat-treated to obtain polymethacrylic Amine foam. The technical scheme of the invention has high production efficiency, high yield, stable product performance, simple and convenient operation, and environmental friendliness, thereby obtaining beneficial implementation effects.

Owner:HAOBO FUJIAN NEW MATERIAL TECH

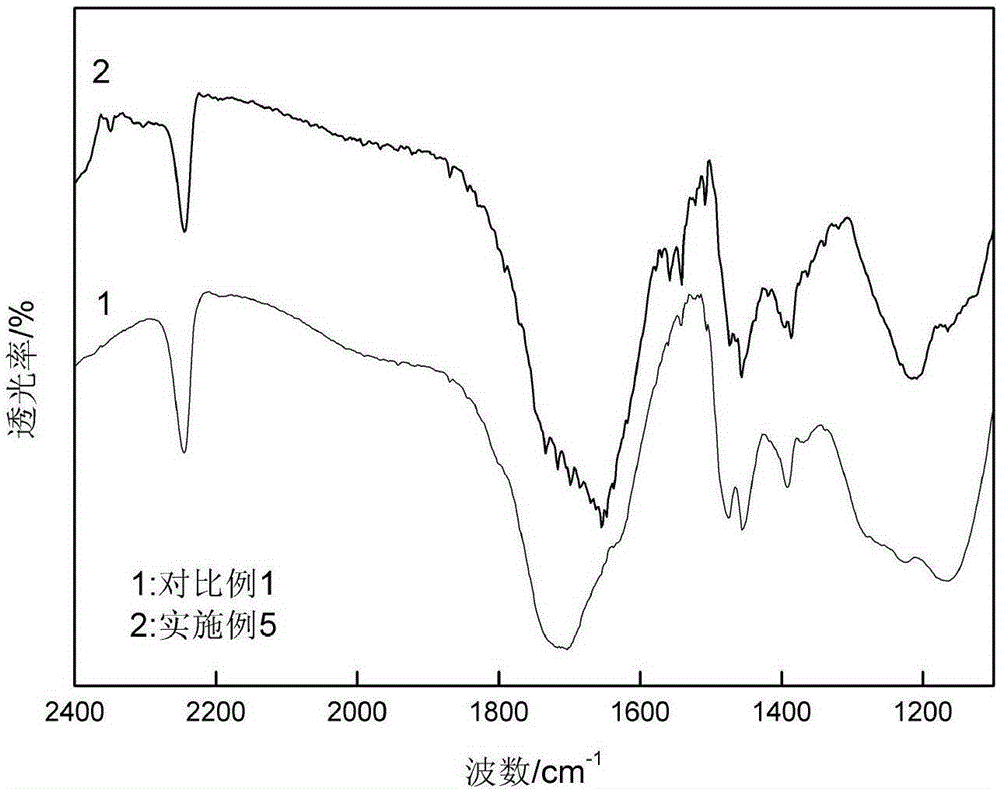

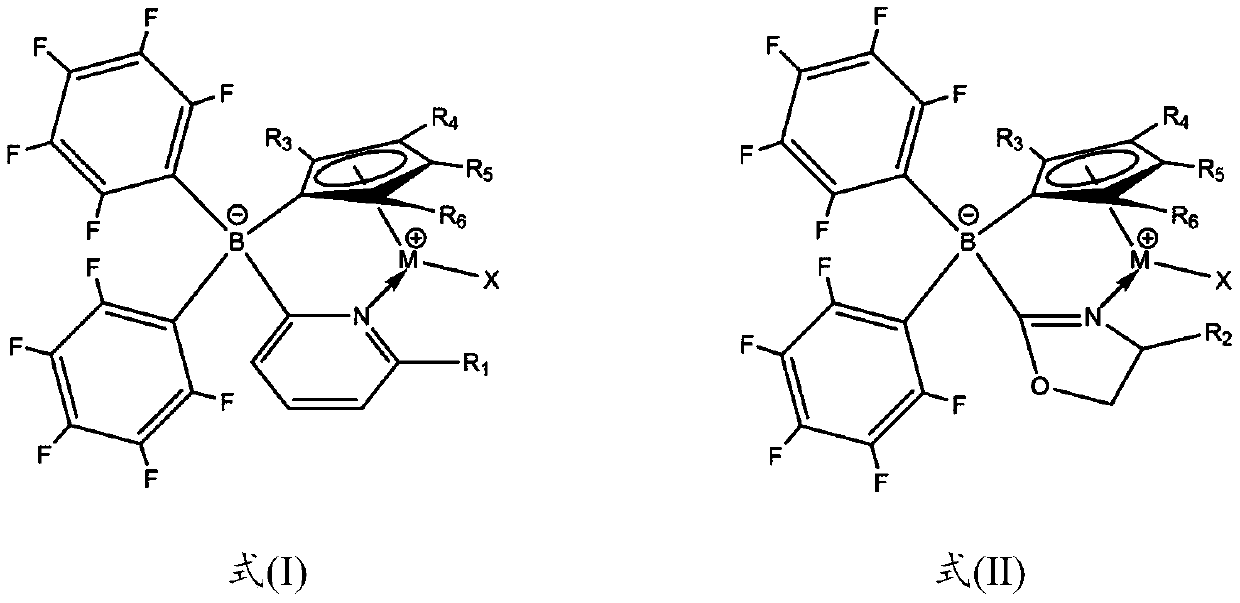

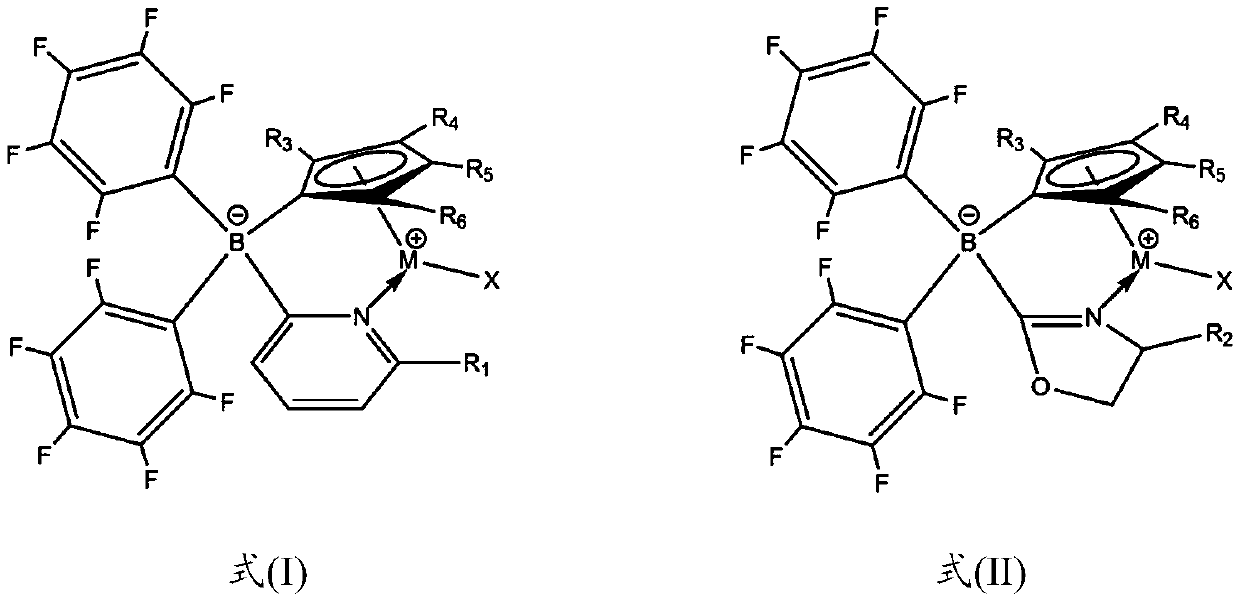

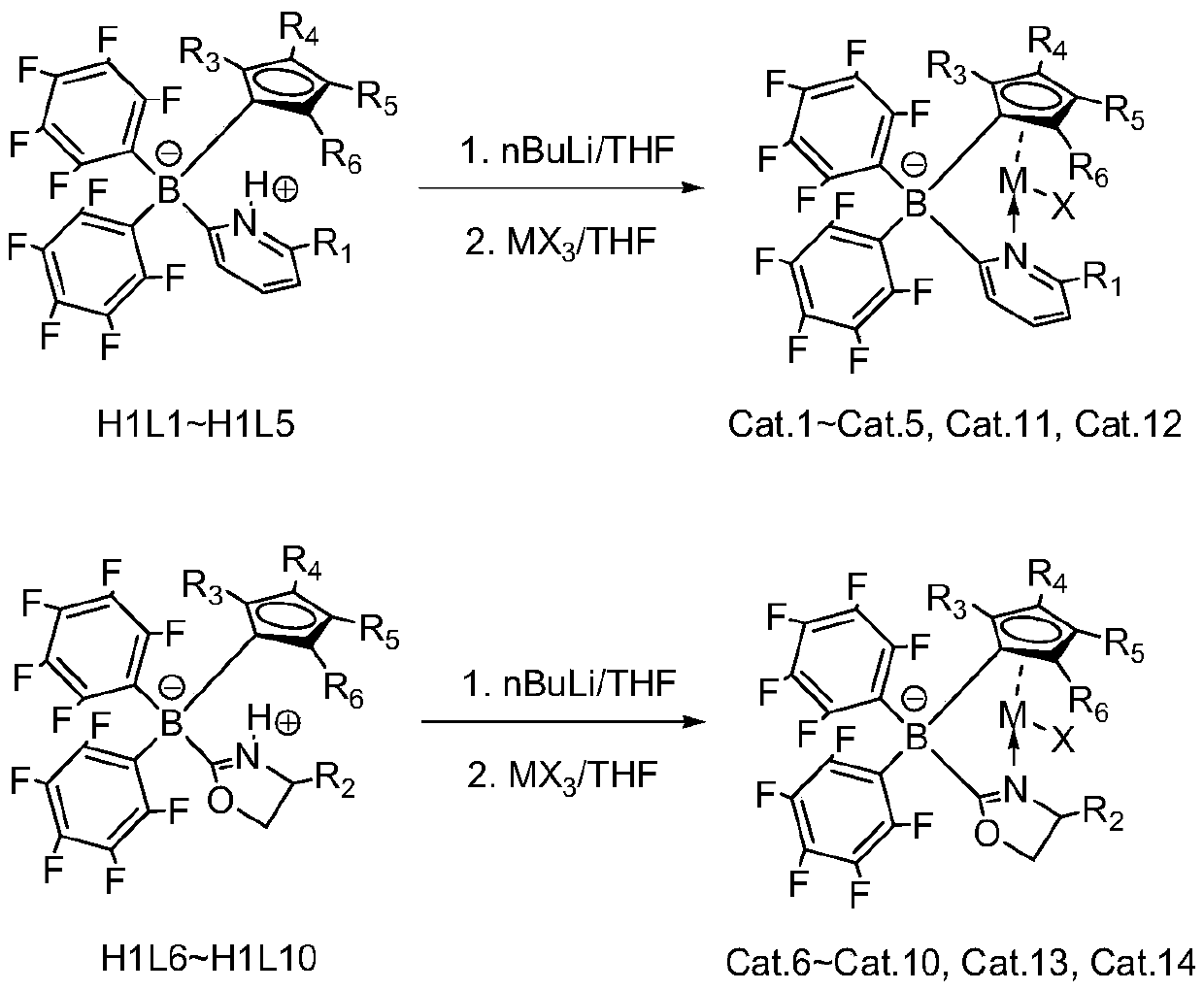

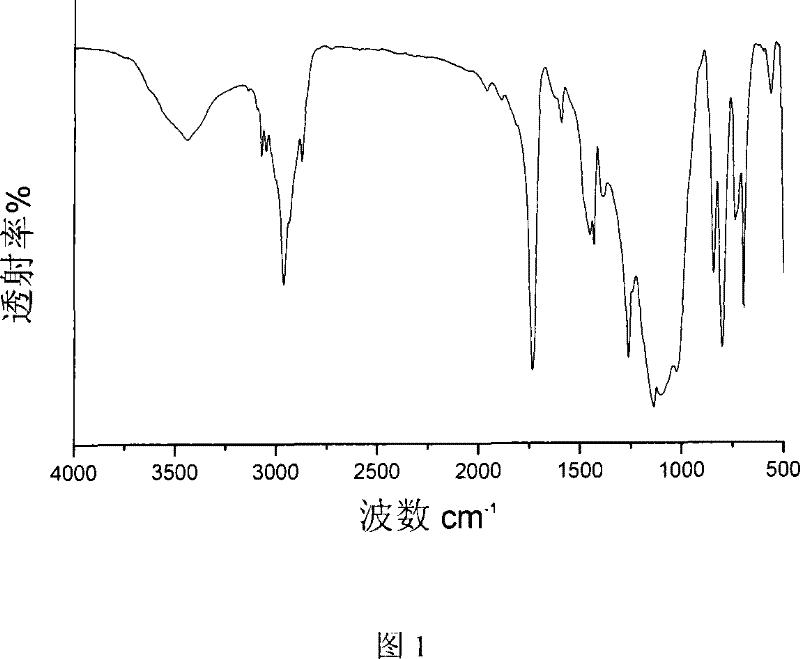

Mono-metallocene complex and application thereof, and ethylene polymerization method

ActiveCN111454300AImprove protectionImprove thermal stabilityMetallocenesPolymer scienceEthylene Polymers

The invention provides a mono-metallocene complex with a structure shown as a formula (I) or a formula (II), and also provides application of the mono-metallocene complex as an ethylene polymerizationcatalyst, and an ethylene polymerization method. The mono-metallocene complex and the ethylene polymerization method provided by the invention can significantly improve the catalytic activity and theservice life of the catalyst, are suitable for a variety of polymerization processes, can improve the production efficiency and product quality of ethylene polymers, and have large-scale industrial application prospects.

Owner:WANHUA CHEM GRP CO LTD

Preparation method and application of macroporous penicillin acylase immobilized magnetic bead polymer carrier

The invention relates to a preparation method of a polymer carrier, particularly a preparation method of a macroporous penicillin acylase immobilized magnetic bead polymer carrier, which comprises the following steps: dissolving Fe<2+> and Fe<3+> salts used as magnetic source precursors in a polar organic solvent formamide while introducing nitrogen, regulating the pH value of the solution to 8-11 with concentrated ammonia water, curing at 60-90 DEG C for 30-60 minutes, and forming a magnetic fluid under alkaline conditions; by using a surfactant as a dispersant, a vinyl compound as a monomer and a nonpolar organic substance as a dispersion medium, carrying out cross-linking polymerization under the action of an initiator by an reversed phase suspension technique; and washing with acetone to separate the product in a magnetic field, washing with an organic solvent, and carrying out vacuum drying at room temperature to obtain the carrier. The invention has the advantages of unique method, low synthesis cost and simple process, omits the processes of Fe3O4 preparation and surface modification, is beneficial to industrialized application, and can obtain the magnetic macroporous bead penicillin acylase immobilized carrier. The carrier is used for preparing high-activity segregative immobilized enzymes by penicillin acylase immobilization.

Owner:NINGXIA UNIVERSITY

Flame-retardant interfacial modifier and preparation method and flame retardant polycarbonate composition

InactiveCN101456936BImprove flame retardant performanceHigh impact strengthMethacrylatePolymer science

Owner:SOUTH CHINA UNIV OF TECH

A kind of method of producing chloride-free, fluoride-free sodium tripolyphosphate

ActiveCN107792841BPromote escapeIncrease partial pressurePhosphorus compoundsPhosphoric acidSilicon tetrafluoride

The invention discloses a method for producing sodium tripolyphosphate without chloride or fluoride. The method comprises the following steps: firstly, neutralization reaction: adding water into a neutralization pot for heating, and adding sodium carbonate for stirring until the sodium carbonate is completely dissolved; when the temperature of a solution is raised to 90 to 120 DEG C, slowly addingphosphoric acid while stirring and adjusting the K value of neutralizing slurry to 2.8+ / -0.2; then adding silicon dioxide, continuously reacting for 3.5+ / -0.5 hours until a mixed solution is viscous,and filtering to obtain a viscous slurry for later use; secondly, drying and dehydrating: feeding the viscous slurry obtained by neutralization into a drying tower for atomization and dehydration; thirdly, polymerization and generation: carrying out polymerization reaction on dried and dehydrated raw materials to obtain the sodium tripolyphosphate; fourthly, carrying out alkali wash on tail gas contained hydrogen chloride, hydrogen fluoride and silicon tetrafluoride and emptying after the substances are determined to be qualified by detecting. The production method of the sodium tripolyphosphate, provided by the invention, has the advantages that the cost of the raw materials is low, the process is simple, the industrialization is easy to realize and the raw materials are easy to obtain;the obtained sodium tripolyphosphate does not contain the chloride or the fluoride.

Owner:HUBEI XINGFA CHEM GRP CO LTD

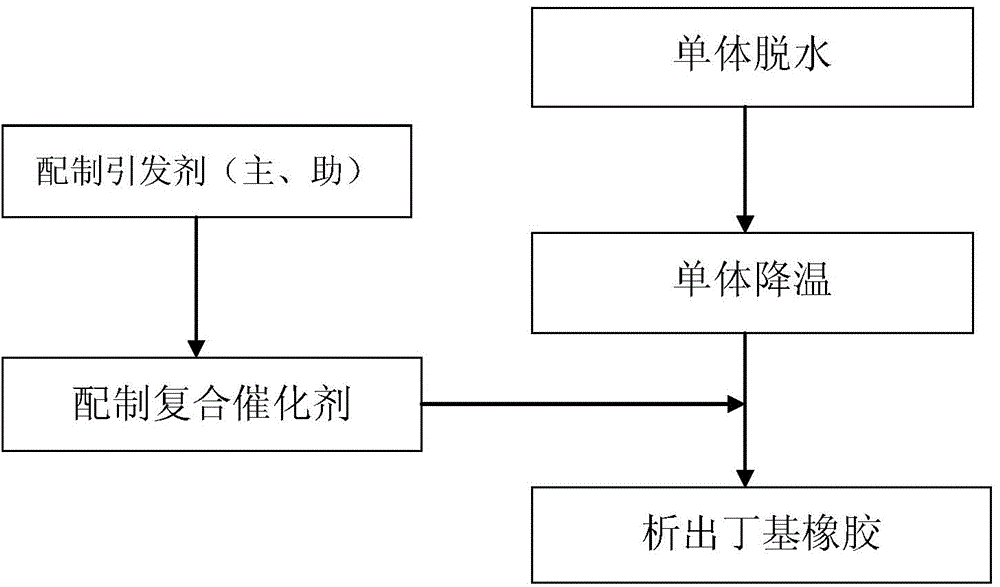

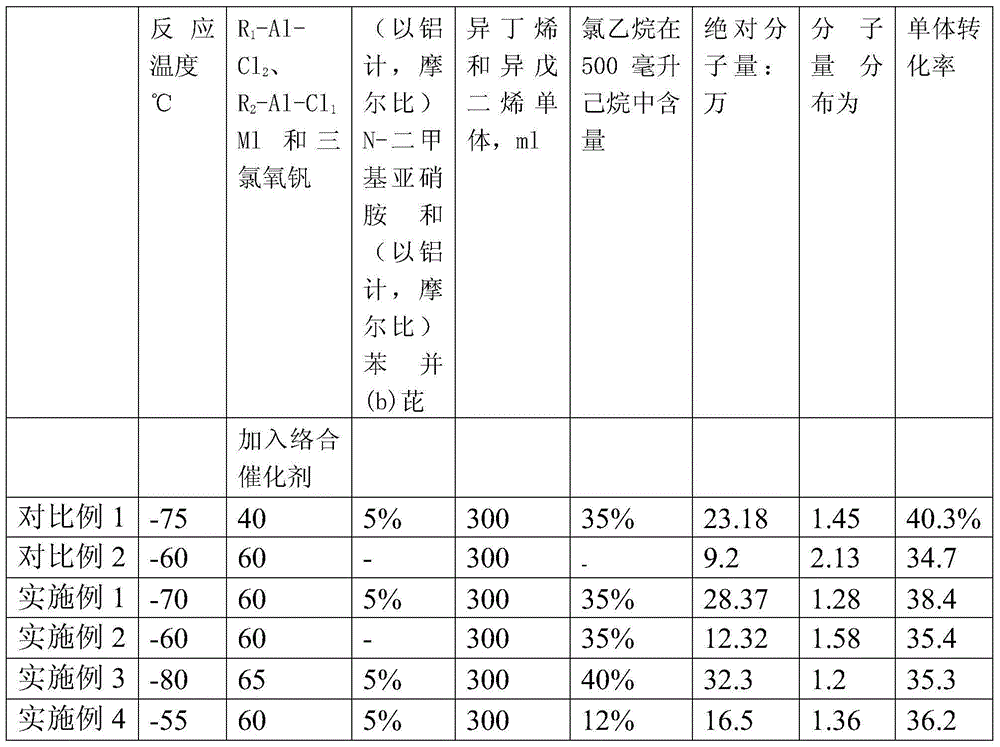

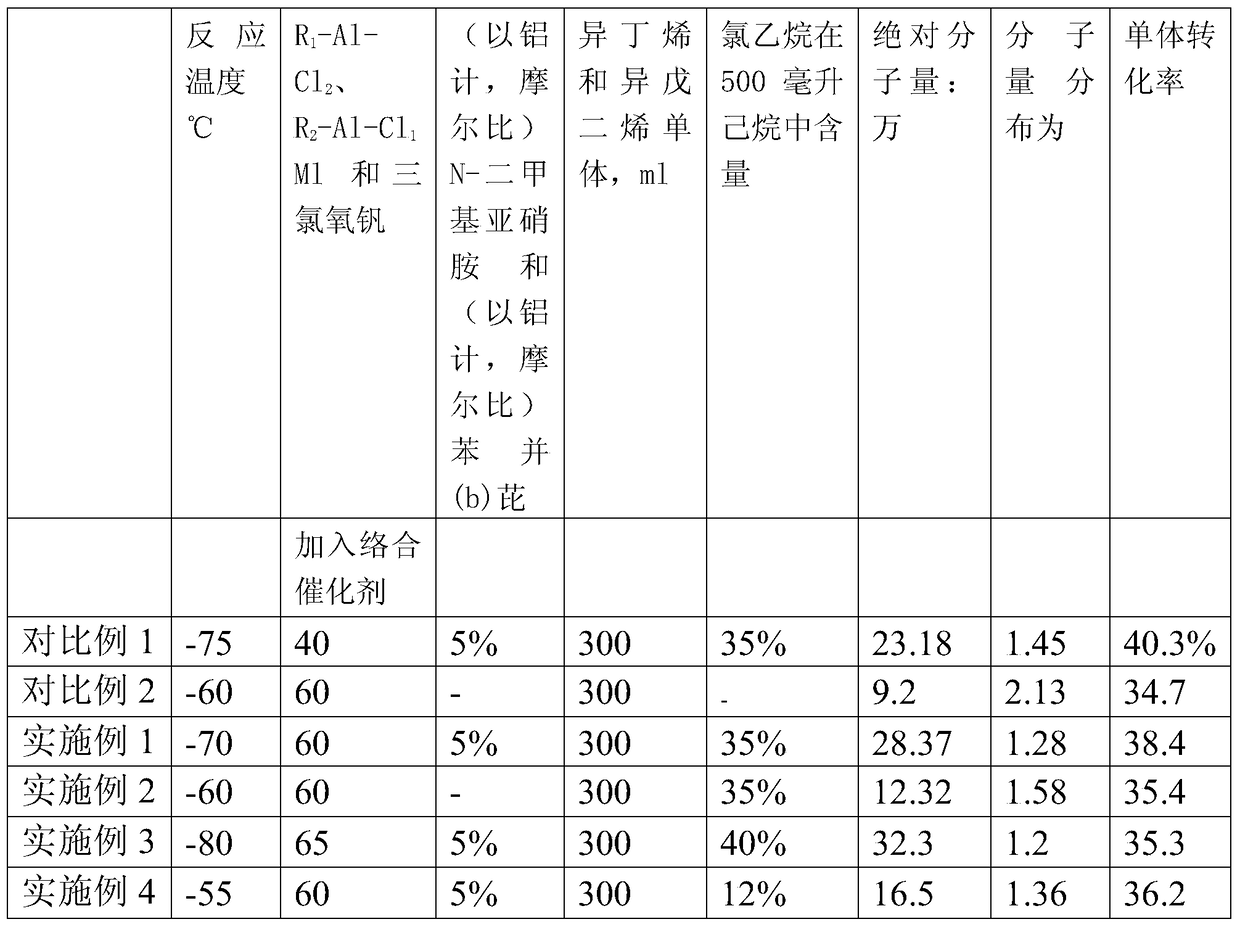

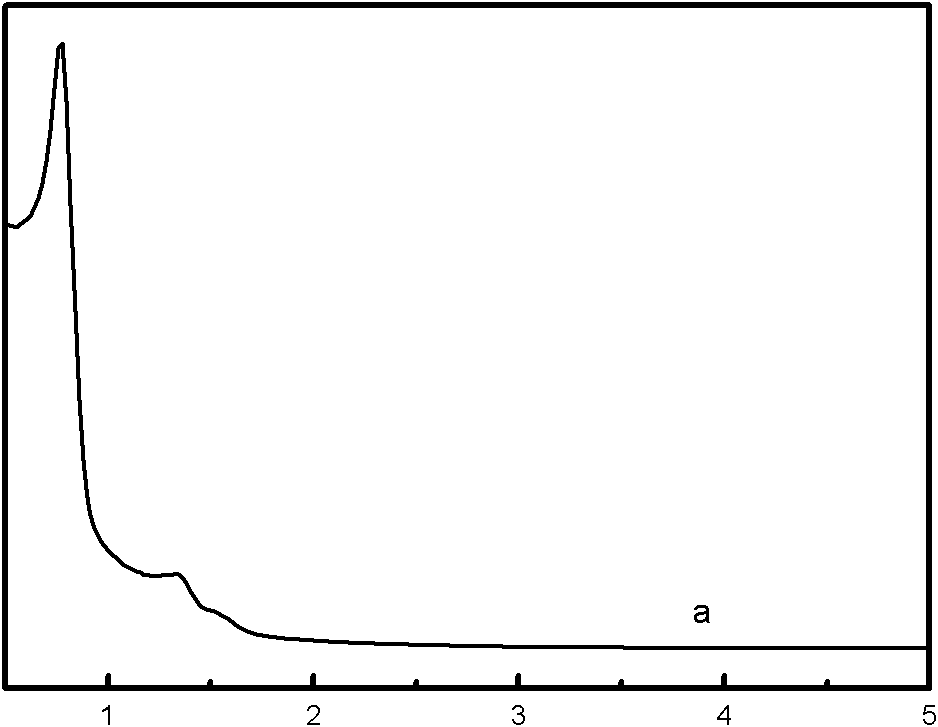

Narrow molecular weight distribution butyl rubber synthesis method

The invention belongs to the technical field of rubber synthesis, and is a method for synthesizing butyl rubber with a narrow molecular weight distribution. The solvent used in the method is a solvent formed by mixing halogenated alkanes and saturated alkanes with carbon four to ten carbons, wherein the volume ratio of the content of halogenated alkanes is 1 %~55%; the composition of the main catalyst used is R-Al-Cl 2 :R 2 -Al-Cl 1 : vanadyl trihalide, add a certain proportion of water in the catalyzer; Add benzopyrene and / or nitrosamine compound again in the prepared main catalyst, form co-initiator; Main initiator is R-Al-Cl 2 and R 2 -Al-Cl 1 . The advantages of the present invention: the catalytic system is a homogeneous system, which is convenient for feeding; by adding a small amount of water, a stable complex initiation system is formed; the method can solve the problem that the molecular weight of butyl rubber decreases with the increase of temperature, and the obtained butyl The number average absolute molecular weight of the rubber is 2,000 to 550,000, and the molecular weight distribution is between 1.1 and 2.0.

Owner:PETROCHINA CO LTD

A kind of butyl rubber synthetic method of narrow molecular weight distribution

The invention belongs to the technical field of rubber synthesis and provides a narrow molecular weight distribution butyl rubber synthesis method. The method utilizes a haloalkane-C4-10 saturated alkane mixed solvent, the content of haloalkane is in a range of 1-55% by volume, a used main catalyst comprises R-Al-Cl2, R2-Al-Cl1 and vanadium trihalide oxide, water is added into the catalyst according to a certain ratio, benzopyrene and / or nitrosamine compound is added into the main catalyst so that an initiator aid is formed and a main initiator comprises R-Al-Cl2 and R2-Al-Cl1. The catalysis system is a homogeneous system and is convenient for charging. Through use of a trace amount of water, a stable complex initiation system is formed. The method solves the problem that butyl rubber molecular weight is reduced along with temperature increasing. The butyl rubber has number-average absolute molecular weight of 2000-550000 and molecular weight distribution of 1.1-2.0.

Owner:PETROCHINA CO LTD

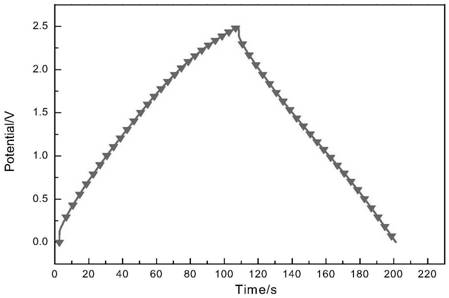

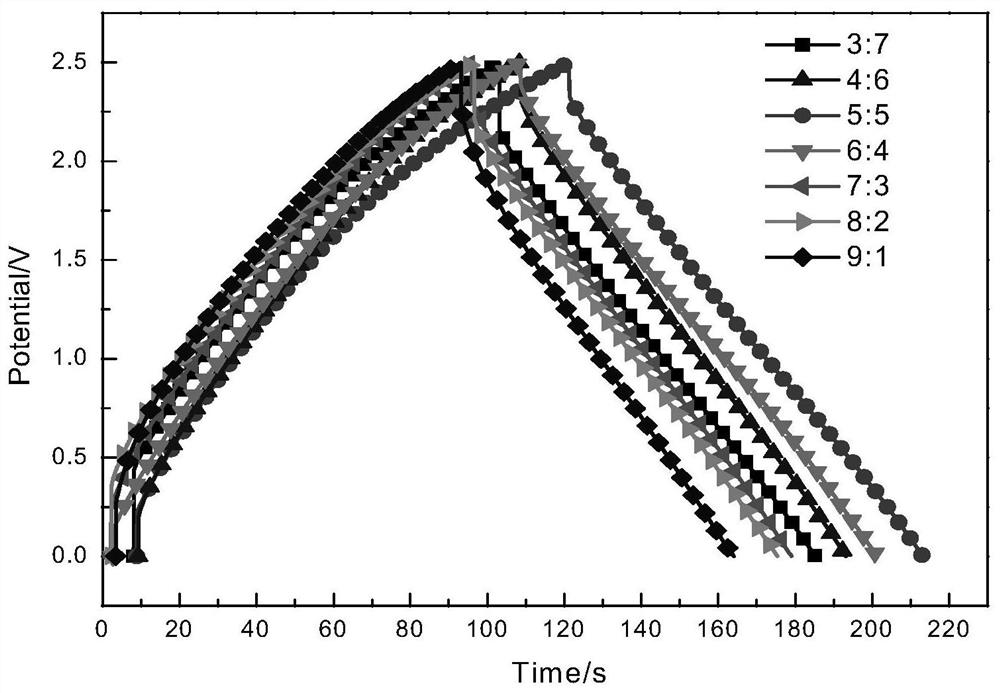

A kind of capacitor composite electrolyte and its preparation method and application

ActiveCN110112009BSteps to reduce injectionImprove electrochemical performanceHybrid capacitor electrolytesElectrolytic agentN dimethylformamide

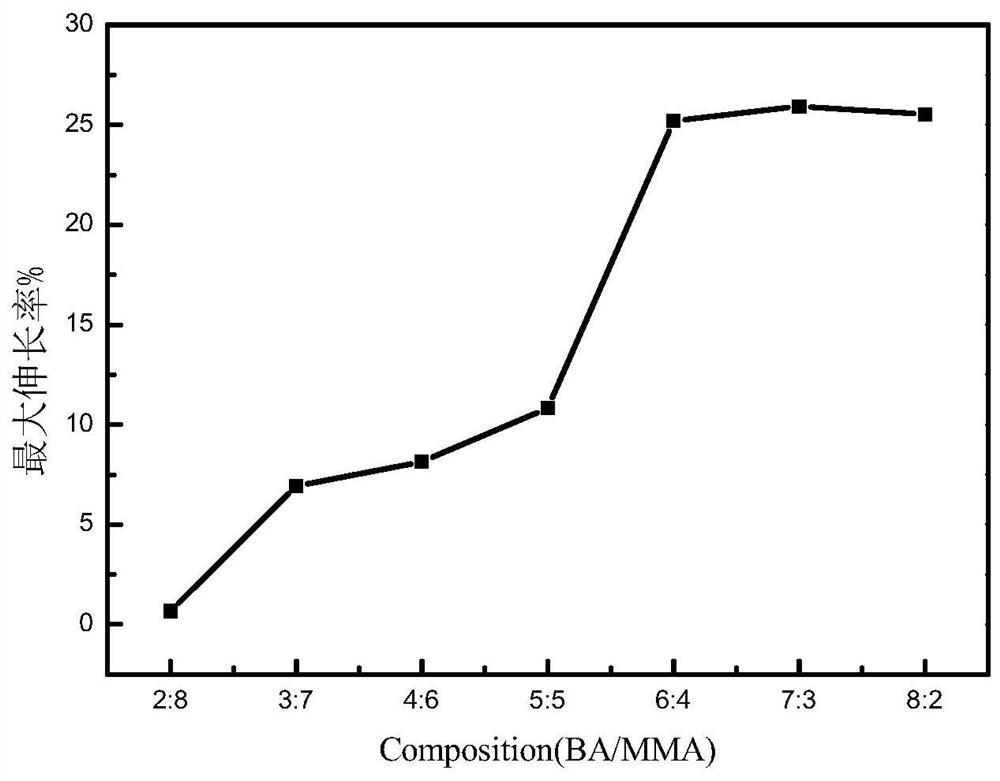

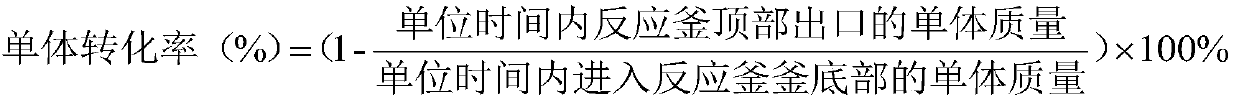

The invention provides a method for preparing a capacitor composite electrolyte. In the method, butyl acrylate and methyl methacrylate are copolymerized with dipropylene phthalate as a crosslinking agent to obtain a white copolymer, and then the white copolymer is The material, electrolyte matrix and nano-oxides are dispersed in N-N dimethylformamide solvent, heated and stirred to form a gel; the gel is coated into a film, soaked in water for phase exchange, and then dried to obtain a composite polymer Membrane: immersing the composite polymer membrane in tetraethylammonium tetrafluoroborate electrolyte and activating to obtain the capacitor composite electrolyte. The composite electrolyte obtained by the method of the invention has good mechanical properties and good electrochemical properties at the same time, and does not need an additional support to improve the mechanical properties.

Owner:GUANGZHOU UNIVERSITY

Method for polymerization of alpha, beta-unsaturated carbonyl and nitrile monomer

This invention puts forward a polymerization method of alpha,beta-unsaturation carbonyl and nitrile grouping monomer. Initiator system is consisted by organic lithium and monovalence cupric salt and monovalence organic copper compound or monovalence cupric salt and monovalence copper organic complex, then polymerization reaction is initiated proceeded byalpha,beta-unsaturation carbonyl and nitrile grouping monomer. Polymerization side reaction is few when initiator is reacted with alpha,beta-unsaturation carbonyl and nitrile grouping monomer, so the polymerization can proceed under room temperature and can be used conveniently to synthesis of polarity- nonpolarity block copolymer. Quick polymerization reaction and high efficiency of initiation and yield are features.

Owner:CHINA PETROLEUM & CHEM CORP +1

Conjugated diene and monovinylarene random copolymer, and preparation method thereof

The invention relates to the field of conjugated diene and monovinylarene random copolymers, and discloses a conjugated diene and monovinylarene random copolymer, and a preparation method thereof. Themethod is the continuous polymerization reaction conducted in each reactor, and includes the following steps that under the condition of anionic polymerization, reaction materials containing the first part of conjugated diene, monovinylarene, solvents, gel inhibitors and single organic lithium initiators are continuously introduced from the bottoms of reactors, the second part of conjugated dieneis introduced in the middles of the reactors, the third part of conjugated diene is continuously introduced on the upper parts of the reactors, and the polymerization temperature is controlled to be90-140 DEG C. According to the preparation method, under the conditions that any structural regulators or random agents are not added, the reaction temperature is high, and residence time is reasonable, the conjugated diene and monovinylarene random copolymer can be prepared with controllable basic molecular weight and low vinyl content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solution method for synthesizing butyl rubber

The invention relates to a solution method for synthesizing butyl rubber. A mixture of C4-C8 monoolefine monomers and C4-C14 polyene hydrocarbon monomers is taken as a raw material, and in a system that hexane and chloromethane are solvents, polymerization reaction is initiated by an initiating system to prepare butyl rubber polymer, wherein the reaction pressure is normal pressure, the reaction temperature ranges from 0 to -90DEG C, and the initiating system has the concentration of 0.01-0.001mol / L, and is prepared by dissolving a main initiator, namely deionized water and a coinitiator, namely aluminum alkyl dihalide by using a polar solvent CH2Cl2 for mixing, and adding alkylol amines; the molar ratio of the coinitiator to the main initiator is 1:1-10:1, and the molar ratio of a third component to the main initiator is 1:10-1:25; and the adding amount of the mixed solvent is 1 to 50 times volume of the polymerization monomers. According to the method, reaction is mild, polymerization temperature is improved, the stability and initiation efficiency of the initiators are high, and the molecular weight distribution of the product is narrow.

Owner:PETROCHINA CO LTD

Load-type metallocene catalyst, preparation method thereof and application thereof

The invention provides a load-type metallocene catalyst which comprises a carrier and an alkyl aluminoxane / magnesium chloride complex and a metallocene compound loaded on the carrier. The hollow ball mesoporous silica carrier has an average particle diameter of 3 to 20 micrometers, a specific surface area of 200 to 300 square meter per gram, a pore volume of 0.5 to 1.5 milliliter per gram, a most probable pore size of 3 to 20 nanometers and an average pore wall thickness of 1 to 2.9 micrometers. The metallocene compound has a structure as shown in formula 1. The load-type metallocene catalyst provided by the invention has a catalytic efficiency up to 3.8*10<8> gPE / (mol Zr*h) while homopolymerization and a catalytic efficiency up to 3.7*10<8>gPE / (mol Zr*h) while copolymerization under 70 DEG C, overcomes defects of sticking to kettles, is low in a polymerization temperature, and reduces energy consumption to some extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of heat-resistant, corrosion-resistant high molecular weight polyarylene sulfide sulfone

The invention discloses a preparation method of novel heat-resisting and corrosion-resisting polyarylene sulfide sulfone with high molecular weight and relates to the field of high molecular materials. The preparation method takes sodium sulfide and 4,4'-dichlorodiphenylsulfone as raw materials, lithium chloride and sodium acetate as catalysts, N-methyl pyrrolidone as a solvent and sodium hydroxide as an auxiliary agent; a specific process flow for producing the novel heat-resisting and corrosion-resisting polyarylene sulfide sulfone successively comprises the following steps: pre-polymerizing, preparing a 4,4'-dichlorodiphenylsulfone solution, re-polymerizing and separating out, washing, filtering, drying and packaging and the like to prepare a polyarylene sulfide sulfone product. According to the preparation method, a relatively high polymerization temperature can be obtained under low pressure through adopting a manner of pre-polymerizing and re-polymerizing; a low-pressure polymerization method is adopted and the dangerousness of operation is reduced; meanwhile, the production cost is greatly reduced; the lithium chloride and the sodium acetate are used as the catalysts, so that the synthesis period of polyarylene sulfide sulfone resin is shortened and the energy consumption is reduced; furthermore, the polyarylene sulfide sulfone resin is subjected to separation treatment by adopting water; the separation cost is low, the effect is good and particles of a product are more uniform.

Owner:四川中科兴业高新材料有限公司

Supported metallocene catalyst and preparation method and application thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com