Conjugated diene and monovinylarene random copolymer, and preparation method thereof

A technology of monovinyl aromatic hydrocarbons and conjugated dienes, which is applied in the field of preparation of random copolymers of conjugated dienes and monovinyl aromatic hydrocarbons. The conversion of ethylene monomer is not very complete, etc., to achieve the effect of increasing the polymerization temperature of the system, increasing Mw/Mn, and fast monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

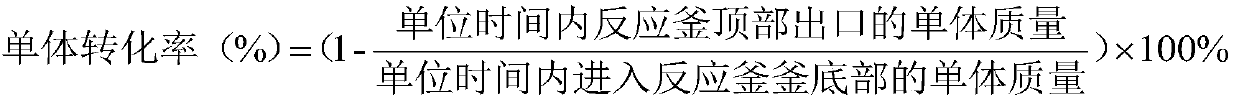

[0018] The preparation method of the random copolymer of conjugated diene and monovinylarene provided by the present invention is to carry out continuous copolymerization reaction in a single reactor, the method comprises: under the condition of anionic polymerization, will contain the first part of conjugated The reaction materials of olefin, monovinylarene, solvent, gel inhibitor and monoorganolithium initiator are continuously introduced from the bottom of the reactor, and a second part of conjugated diene is continuously introduced in the middle of the reactor, The third part of conjugated diene is continuously introduced into the upper part of the reactor, and the polymerization temperature is controlled at 90-140°C.

[0019] In the present invention, when the vertical distance between the upper and lower vertices of the reactor is used as a reference, the vertical distance between the upper feed port of the reactor and the upper apex is the vertical distance between the u...

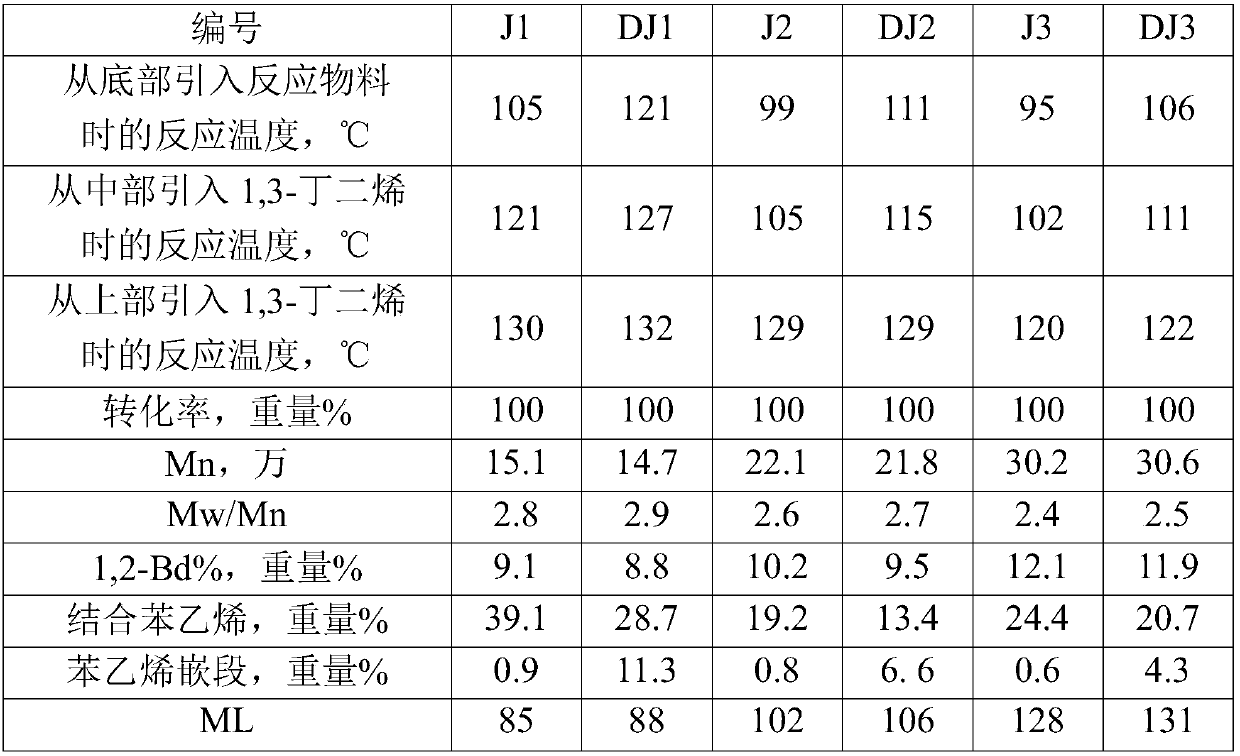

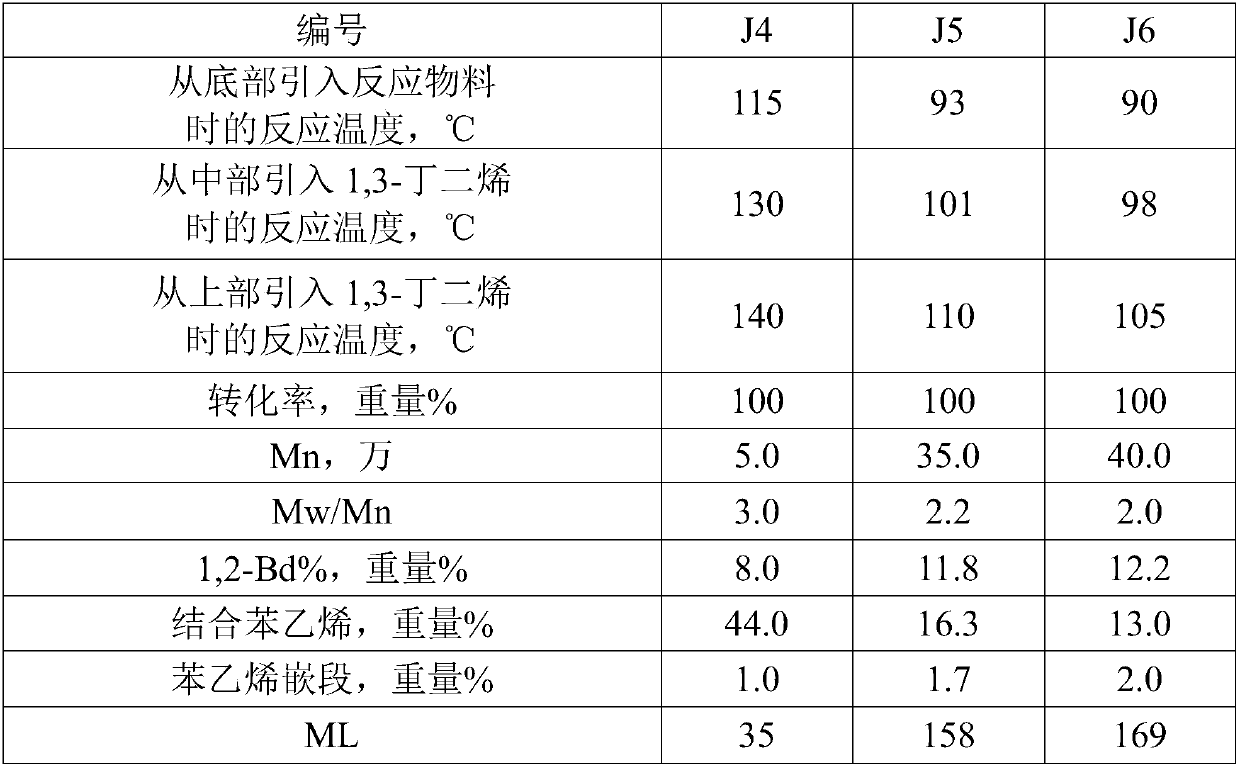

Embodiment 1

[0056] This example illustrates the preparation of the random copolymer of conjugated diene and monovinylarene of the present invention.

[0057] A 16-liter tower-type polymerization reactor is used as a continuous polymerization reaction device.

[0058] In the continuous polymerization reaction device, under the protective atmosphere of high-purity nitrogen, the total residence time of the reaction materials in the kettle is 50 minutes, and the polymerization reaction pressure is controlled at 0.7±0.05MPa:

[0059] (1) Add reaction materials from the bottom of the reactor: hexane fraction 9792g / h, styrene 1305.6g / h, 1,3-butadiene 1175g / h, n-butyllithium 21.76mmol / h and 1,2 -Butadiene 6.36g / h, carry out polymerization reaction;

[0060] (2) Add 1,3-butadiene 392g / h in the middle of the reactor;

[0061] (3) Add 1,3-butadiene 392g / h at the top of the reactor;

[0062] (4) Add terminator water at 0.39g / h to terminate the reaction at the top outlet of the reactor (the tempera...

Embodiment 2

[0072] This example illustrates the preparation of the random copolymer of conjugated diene and monovinylarene of the present invention.

[0073] A 16-liter tower-type polymerization reactor is used as a continuous polymerization reaction device.

[0074] In the continuous polymerization reaction device, under the protective atmosphere of high-purity nitrogen, the total residence time of the reaction materials in the kettle is 60 minutes, and the polymerization reaction pressure is controlled at 0.8±0.05MPa:

[0075] (1) Add reaction materials from the bottom of the reactor: cyclohexane 8486g / h, styrene 479g / h, 1,3-butadiene 575g / h, n-butyllithium 10.88mmol / h and 1,2- Butadiene 4.67g / h, carry out first kettle continuous polymerization reaction;

[0076] (2) Add 1,3-butadiene 766g / h in the middle of the reactor;

[0077] (3) Add 1,3-butadiene 574g / h at the top of the reactor;

[0078] (4) Add terminator water at 0.16 mg / h to terminate the reaction at the top outlet of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com