Conjugated diene polymers and preparation method thereof, and polybutadiene and polyisoprene

A conjugated diene and polybutadiene technology, which is applied to conjugated diene polymers and their preparation, as well as the fields of polybutadiene and polyisoprene, can solve the problem of narrow molecular weight distribution of conjugated diene polymers, etc. problem, to achieve the effect of controllable basic molecular weight and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

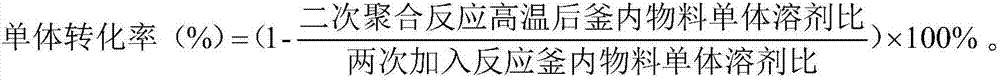

[0019] The present invention provides a method for preparing a conjugated diene polymer. The method is to perform batchwise polymerization of conjugated diene in a single reactor. The polymerization of conjugated diene includes primary polymerization and secondary polymerization. The polymerization reaction includes the following steps: (1) Under anionic polymerization conditions, the reaction material containing the first part of the conjugated diene monomer, the polarity regulator, the solvent and the monoorganolithium initiator is added to the reactor to perform a polymerization reaction. The maximum temperature of the polymerization reaction is 80-110°C; (2) When the maximum temperature of the primary polymerization reaction is reached, the second part of the conjugated diene monomer is added to the reactor for secondary polymerization reaction, and the maximum temperature of the secondary polymerization reaction is It is 110~160℃.

[0020] The inventor of the present inventi...

Embodiment 1

[0052] This example illustrates the preparation method of the polybutadiene of the present invention.

[0053] (1) Under the protection of high-purity nitrogen, add a cyclohexane / n-hexane mixed solvent (the weight ratio of cyclohexane to n-hexane is 82:18, the same below) 4000g, 1. 889 g of 3-butadiene, 21.37 mmol of tetrahydrofurfuryl ethyl ether. Add 26.66mmol of n-butyl lithium to initiate a polymerization reaction, control the initial initiation temperature of the polymerization reaction to 50°C, and the pressure of the polymerization reaction to 0.2MPa;

[0054] (2) When the primary polymerization reaction reaches the maximum temperature of the primary polymerization reaction, 444 g of 1,3-butadiene is added for the second time for the secondary polymerization reaction, and the pressure of the secondary polymerization reaction is 0.2 MPa;

[0055] (3) After the secondary polymerization reaction was heated to the highest temperature of the secondary polymerization reaction, the ...

Embodiment 2

[0065] This example illustrates the preparation method of the polybutadiene of the present invention.

[0066] (1) Under the protection of high-purity nitrogen, sequentially add 4000 g of cyclohexane, 750 g of 1,3-butadiene, and 15.27 mmol of tetrahydrofurfuryl ethyl ether into a 10-liter polymerizer. Adding 8.33 mmol of n-butyl lithium to initiate a polymerization reaction, control the initial initiation temperature of the polymerization reaction to 55° C., and the pressure of the polymerization reaction to be 0.25 MPa.

[0067] (2) When the primary polymerization reaction reaches the highest temperature of the primary polymerization reaction, 250g of 1,3-butadiene is added for the second time for the secondary polymerization reaction, and the pressure of the secondary polymerization reaction is 0.25 MPa;

[0068] (3) After the secondary polymerization reaction was heated to the highest temperature of the secondary polymerization reaction, the reaction was continued for 10 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com