Concrete polycarboxylate water reducing agent and preparing method thereof

A polycarboxylic acid and water reducing agent technology, applied in the field of concrete admixtures, can solve the problems of weak environmental adaptability, poor cement compatibility, fast slump loss, etc., and achieves concentrated molecular weight distribution, high water reduction rate, and reduced The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

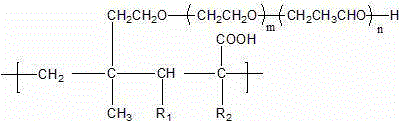

[0032] Example 1: Prepare a polycarboxylate water reducer for concrete. The raw materials are monomer A and acrylic acid. The chemical structural formula (I) of monomer A is:

[0033] (I)

[0034] Where m=50, n=2, the selected components and mass ratio are: methallyl polyoxyethylene ether: acrylic acid: ammonium persulfate: sodium hypophosphite: thioglycolic acid=7.27:1:0.036:0.023 : 0.064; In a reaction vessel equipped with a stirrer, add 160g monomer A (molecular weight 2400) and 130g water, stir until monomer A dissolves, add 0.8g ammonium persulfate, after stirring evenly, add the aqueous solution of acrylic acid dropwise at the same time (including 22g of acrylic acid, 50g of water) and aqueous solution of thioglycolic acid and sodium hypophosphite (of which 1.4g of thioglycolic acid, 0.5g of sodium hypophosphite, and 45g of water), add two-thirds of it dropwise in the first 45 minutes, and the remaining one-third The dropwise addition is completed in the last 45 minut...

Embodiment 2

[0037]Example 2: Prepare a polycarboxylate water reducer for concrete. The raw materials are monomer A and methacrylic acid. In the chemical structural formula (I) of monomer A, m=39, n=10, and the selected components and mass ratio For monomer A: methacrylic acid: hydrogen peroxide: ascorbic acid: 3-mercaptopropionic acid = 7: 1: 0.0532: 0.016: 0.056; in a reaction vessel equipped with a stirrer, add 350g monomer A (molecular weight 2400) and 180g Water, stir until monomer A dissolves, add 2.66g of hydrogen peroxide, stir evenly, add dropwise the aqueous solution of acrylic acid (50g of acrylic acid, 80g of water) and the aqueous solution of 3-mercaptopropionic acid and ascorbic acid (2.8g of 3-mercaptoacetic acid , ascorbic acid 0.8g, water 96g), the dropping time is 3.5h, after the reaction is completed, the temperature is lowered to room temperature, and the pH value is adjusted to neutral with NaOH aqueous solution, and the polycarboxylate water reducer is obtained, and it...

Embodiment 3

[0040] Embodiment 3, prepare a kind of concrete polycarboxylate superplasticizer, raw material adopts monomer A and monomer B (acrylic acid and maleic anhydride), m=17, n=31 in monomer A chemical structural formula (I), choose The components and mass ratios are monomer A: acrylic acid: maleic anhydride: ammonium persulfate: sodium bisulfite: 2-mercaptoacetic acid=11.25:1:1.3:0.12:0.1:0.054; In the reaction vessel, add 225g of monomer A (molecular weight: 2600) and 260g of water, stir until the monomer A is dissolved, add 2.4g of ammonium persulfate, stir evenly, and add the aqueous solution of acrylic acid and maleic anhydride (20g of acrylic acid, Maleic anhydride 26g, water 56g) and 2-mercaptoacetic acid, sodium bisulfite aqueous solution (including 2-mercaptoacetic acid 2.0g, sodium bisulfite 1.08g, water 45g), dropwise time is 2h, cool down after the reaction To normal temperature, adjust the pH value to neutral with NaOH aqueous solution to obtain polycarboxylate water re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com