Patents

Literature

420results about How to "Improve slump retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of preparation method of high performance water reducer

InactiveCN102286134AHigh priming activityIncrease the rate of polymerizationHigh strength concreteChemistry

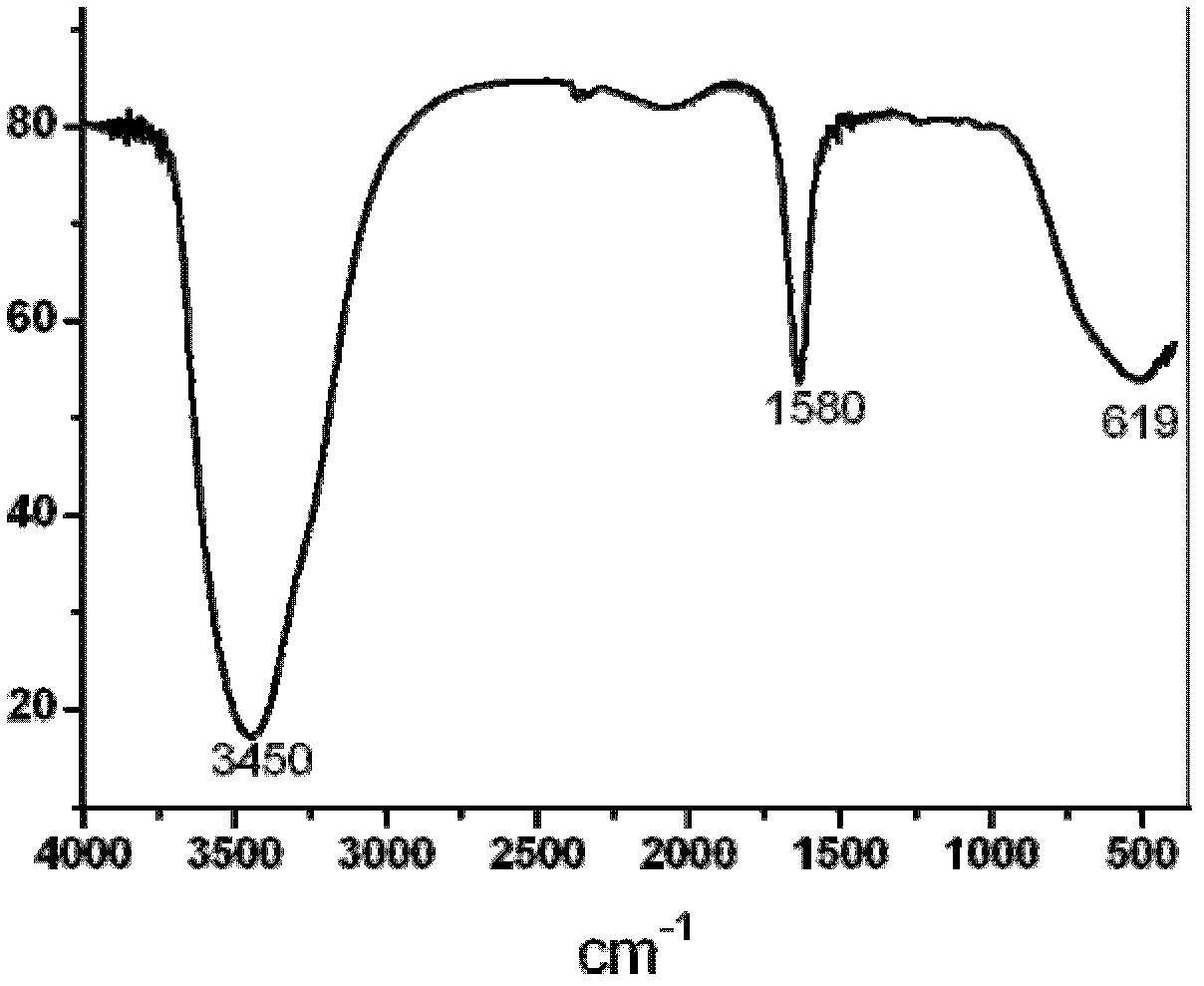

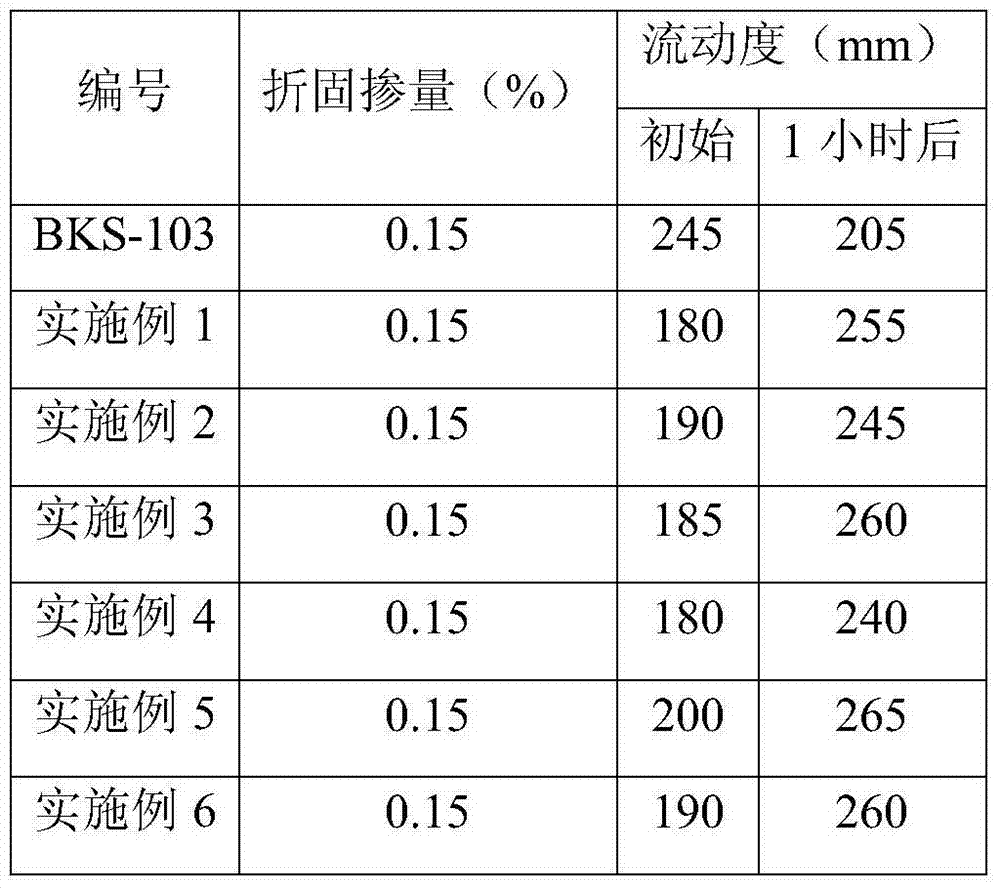

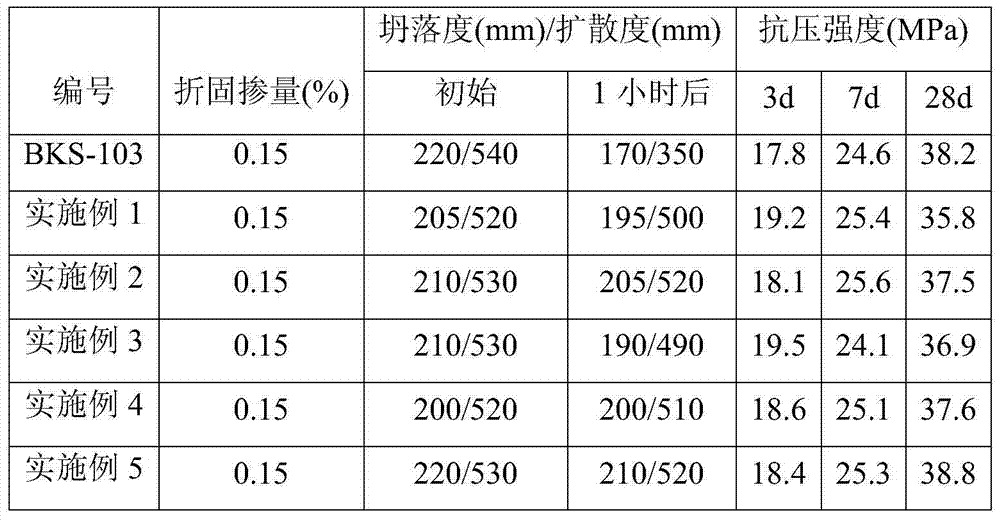

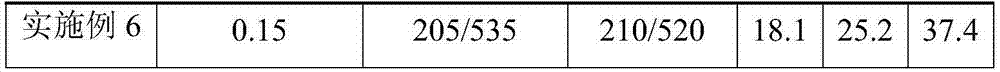

A preparation method of a polycarboxylate high-performance water reducer, under the protection of an inert gas and under the action of an oxidation-reduction initiation system and a chain transfer agent, the active macromonomer A (methallyl poly Oxyethylene ether), small molecule monomer B (methacrylic acid or acrylic acid) and small molecule monomer C (sodium methacrylate, sodium propylene sulfonate or sodium styrene sulfonate) are prepared by copolymerization in water. The invention adopts a highly active oxidation-reduction initiation system, which can increase the polymerization reaction rate, lower the polymerization temperature and shorten the reaction time, and the polymer has an ideal molecular structure. The water reducing agent prepared by the invention has excellent properties such as high water reducing rate, good dispersibility, no loss of slump over time, and high concrete strength; at the same time, the method of the invention adopts copolymerization reaction in water, the preparation process is simple, and it also has green Environmental protection, low energy consumption, low cost and other characteristics.

Owner:江苏天音化工有限公司 +1

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer is prepared from the following components: vinyl polyoxyethylene ether, sodium p-styrenesulfonate, an acrylic acid and acrylamide compounds as monomers as well as an alkaline neutralizer, an initiator and a molecule modulator as auxiliary materials through copolymerization. The mud-resistant polycarboxylic acid water reducer disclosed by the invention is high in water-reducing rate, small in slump loss, good in mud-resistant effect, free of formaldehyde pollution in a production process, and especially adapts to sand concrete with relatively high mud content.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

The amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent is prepared through the following steps: 1) free radical copolymerizing reaction of four kinds of monomers in certain proportion in water soluble medium; 2) crosslinking reaction through introducing crosslinking agent after the polymerization. The present invention proposes that the amphoteric ionic polymer can raise the saturated added amount of concrete super-plasticizing agent, and introduces amphoteric ion concept into the molecular design of concrete admixture. The concrete super-plasticizing agent of the present invention has high water reducing rate, can eliminate the environmental pollution caused by concrete water reducing agent and reduce the added amount while ensuring the outstanding dispersivity and slump maintaining capacity.

Owner:JIANGSU SOBUTE NEW MATERIALS

Polycarboxylic superplasticizer, synthesis method thereof and application method thereof

The invention discloses a synthesis method of a polycarboxylic superplasticizer. The raw materials for synthesis of the polycarboxylic superplasticizer are APEG of two types of molecular weight (respectively 500-1000 and 1600-2200), MPEGMA of two types of molecular weight (respectively 800-1400 and 2000-2500), maleic anhydride, acrylic acid, alkylphenol ethoxylate, hydrogen peroxide, ascorbic acid, ferrous sulfate, sodium persulfate, sodium hydroxide and deionized water. Since the APEG and MPEGMA of different types of molecular weight are simultaneously adopted as crossing branch chains, the invention not only has a high water-reducing rate, but also maintains good water-reducing rate, has good adaptability to sands and stones with high clay contents, and improves the strength of concrete, Compared with the prior art, the invention has the advantages that the raw materials of the product are easily available, the synthesis process can be easily controlled, the performance of the reaction product is stable, and the cost is reduced by 5-10 percent.

Owner:GUANGDONG REDWALL NEW MATERIALS

Method for preparing slump-retaining type polycarboxylic acid series high-performance water reducing agent in one step

The invention relates to a method for preparing a slump-retaining type polycarboxylic acid series high-performance water reducing agent in one step. The method comprises the following steps of: dissolving unsaturated polyoxyethylene ether into water, heating to 50 to 80 DEG C, adding oxidant solution and stirring uniformly; adding reducing agent solution and comonomer solution dropwise respectively to perform polymerization; preserving the heat and curing for 1 to 3 hours; and cooling to room temperature, adding an alkaline compound and adjusting the pH value to be 6.5 to 7 to obtain the slump-retaining type polycarboxylic acid series high-performance water reducing agent. In the method, unsaturated bond-containing allyl for hydrogen on terminated hydroxyl of the original unsaturated polyoxyethylene ether is substituted, so that the terminal group of alkoxy polyethylene glycol is changed from the original active hydroxyl into the conventional inert alkyl, byproducts of copolymerized products are greatly reduced, molecular weight distribution is narrowed, and the synthetized water reducing agent has a high water-reducing ratio and a high slump-retaining property.

Owner:NANJING RUIDI HIGH TECH

Method for preparing high-efficiency water-reducing agent of poly-carboxylic acid

The invention discloses a preparation method for a polycarboxylate high-performance water reducer, comprising the following steps: based on weight proportion, mixing 5-50% of unsaturated carboxylic acid, a derivative a of the unsaturated carboxylic acid, 45-95% of polyoxyethylene vinyl propionate ester, a derivative b of the polyoxyethylene vinyl propionate ester, as well as 0-30% of propyl sulfonate c to prepare a mixed monomer solution; then adding the initiator which takes up 0.5-15% of the total weight of the mixed monomer solution, and the chain transfer agent which takes up 0-15% of thetotal weight of the mixed monomer solution into the mixed monomer solution so as to prepare the polycarboxylate high-performance water reducer through binary or ternary copolymerization. The polycarboxylate high-performance water reducer disclosed in the invention can be widely applied to grout, mortar, concrete, gypsum and coal-water slurry, so that the mixed material can have higher mobility tosignificantly reduce the actual water consumption in the mixing process and effectively improve the concrete strength and durability, thereby showing the advantages of low mixing amount, high dispersion and high slump retaining performance.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Sustained-release polycarboxylic high-performance water reducing agent and preparation method thereof

The invention relates to a sustained-release polycarboxylic high-performance water reducing agent and a preparation method thereof. The water reducing agent comprises: 0.13mol of monomer methyl alkenyl polyoxyethelene or allyl polyoxyethylene ether or polyoxypropylene ether, 0.32mol of monomer acrylic acid or methacrylic acid, 0.01mol of monomer sodium methallyl sulfonate, 0.12mol of monomer acrylamide or 2-acrylamide-methylpropanesulfonic acid, and 0.05mol of monomer ethyl acetate or styrene. Deionized water is adopted as a reaction medium, and the materials are subjected to a reaction with an initiating agent and a chain transfer agent for 4-6h with a maintained temperature of 58-62 DEG C. Copolymerization is carried out, such that a polymer with a molecular weight of 50000-120000 is obtained; the temperature is reduced to below 40 DEG C, and an alkali solution is added for regulating the pH of the system to 6-8, such that the water reducing agent is obtained. The sustained-release polycarboxylic high-performance water reducing agent provided by the invention has high water reduction rate. When an equivalent solid dosage is 0.2%, a water reduction rate can reach 35%. A slump performance is good. Concrete slump and extension degree have no loss in 3h. The water reducing agent is widely adaptable with concrete raw materials.

Owner:广西云鹰新材料科技有限公司

Preparation method of phosphono-group-containing water reducing agent

The invention discloses a phosphono-group-containing water reducing agent and a preparation method thereof. The phosphono-group-containing water reducing agent is in a comb-like structure, wherein the main chain has an acid anhydride group, carboxylate group or amido group; the main chain does not provide the initial water reducing capacity, but releases adsorption groups after being hydrolyzed under alkaline conditions in the later period, thereby enhancing the slump retaining capacity; side chains comprise pure polyether side chains and polyether side chains with an adsorption group at the terminal; the pure polyether side chains provide steric hindrance; and the adsorption groups comprise phosphono groups and phosphorous acid groups, and have multiple and centralized adsorption sites, thereby providing the initial adsorption capacity and dispersion capacity of the water reducing agent. The main adsorption groups in the phosphono-group-containing water reducing agent are phosphono groups; and carboxylates or acid anhydrides in the water reducing agent structure can continuously release new carboxyl adsorption groups through the reaction of water under alkaline conditions in the later adsorption period, thereby achieving better slump retaining properties.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

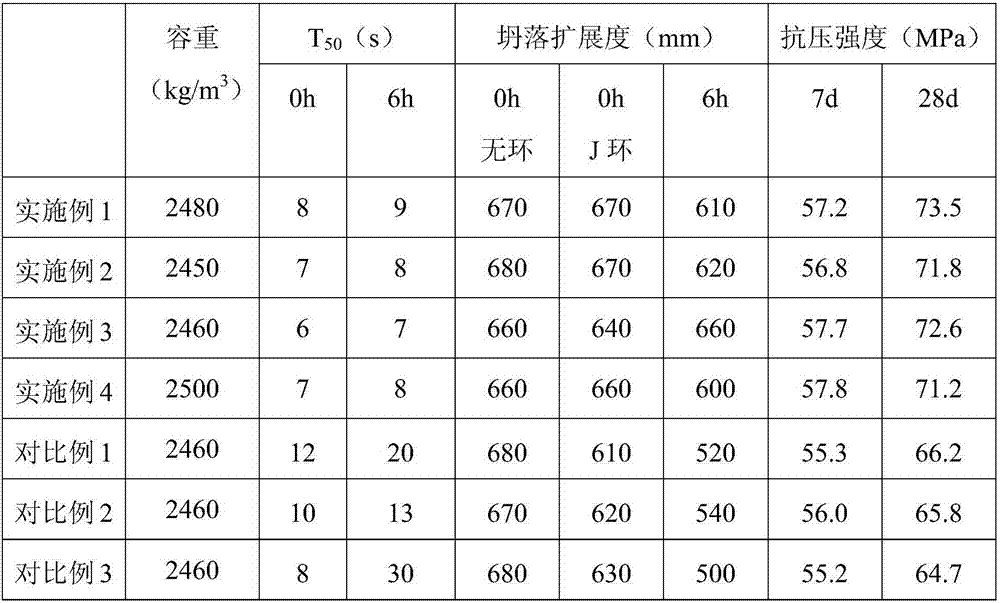

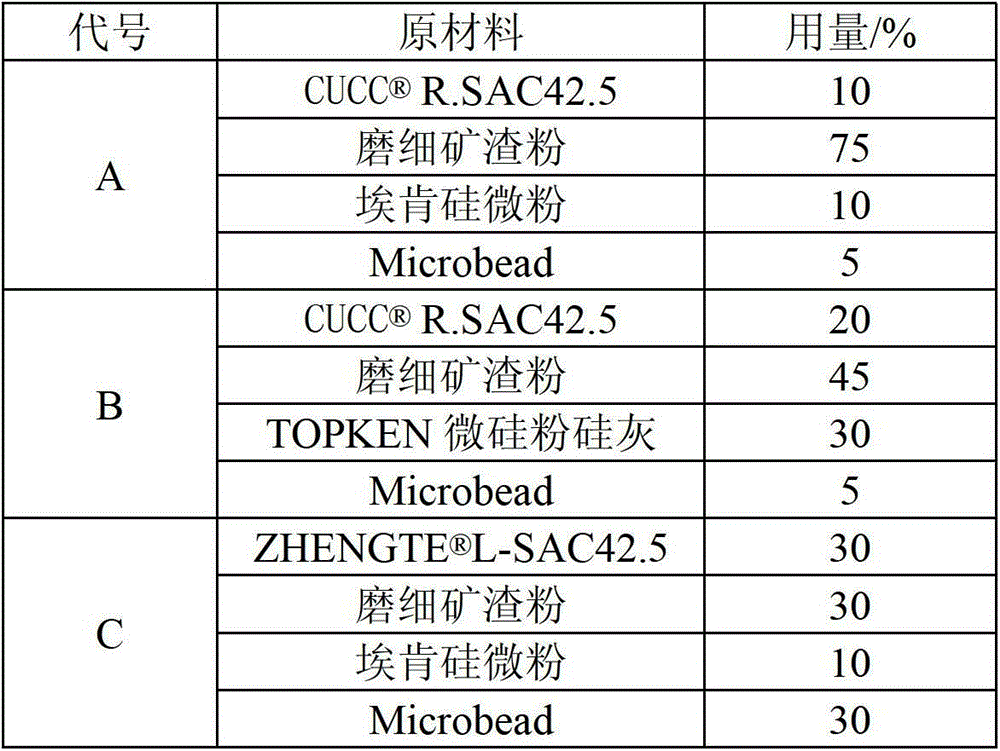

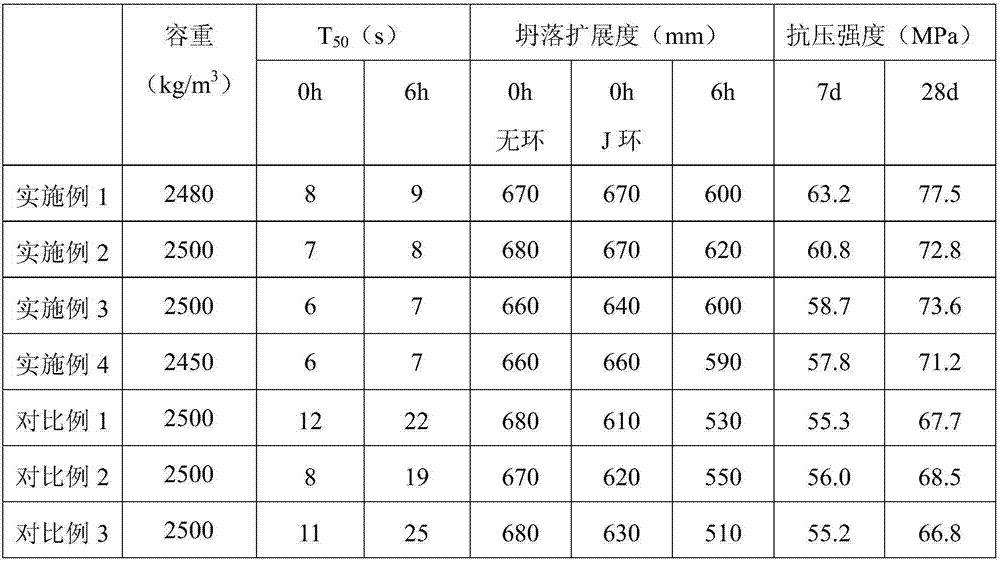

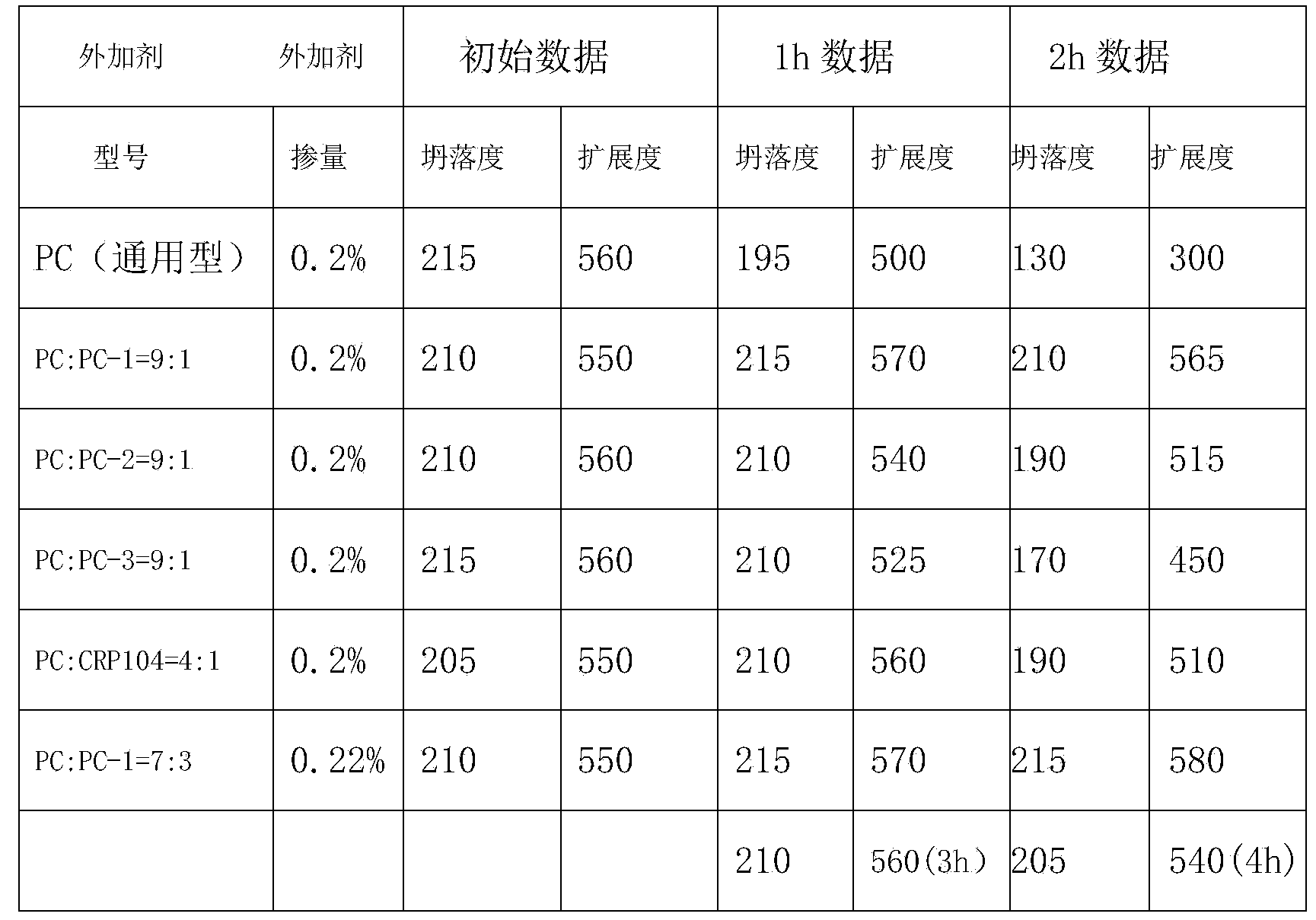

Self-compacting concrete

The invention discloses a self-compacting concrete and belongs to the technical field of concrete. The self-compacting concrete comprises the following components in parts by weight: 350-400 parts of cement, 54-80 parts of coal ash, 52-60 parts of slag powder, 50-62 parts of expanding agent, 9-13 parts of silica powder, 748-800 parts of mixed sand, 948-1020 parts of macadam, 140-165 parts of drinking water, 0-10 parts of compound additive and high-performance additive being 1-2% of the binding material in mass fraction. The concrete acquired according to the invention has excellent self-compacting property, fluidity, collapse prevention, cohesiveness and separation resistance, and meanwhile, a test proves that the compressive strength after 7 days is about 57MPa and the compressive strength after 28 days is about 70MPa, so that the concrete provided by the invention has higher compressive strength.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Green preparation method of slow-release polycarboxylic-acid high-performance water reducing agent

The invention relates to a green preparation method of a slow-release polycarboxylic-acid high-performance water reducing agent, which comprises the following steps: firstly, dissolving unsaturated polyethenoxy ether in water, adding an oxidant solution, and evenly stirring; then, respectively and dropwisely adding a reducer / chain-transfer agent mixed solution and a comonomer solution, and polymerizing; and finally, adding an alkaline regulator to neutralize and age the solution, thereby obtaining the slow-release polycarboxylic-acid high-performance water reducing agent. In the invention, hydrogen on the terminal hydroxyl group of the original unsaturated polyethenoxy ether is substituted by an allyl group containing unsaturated bond, so that the terminal group of methoxypolyethylene glycol is converted from the original active hydroxyl group into the inert methoxy group at present; and thus, the byproducts of the copolymerization product are greatly reduced, and the molecular weight distribution is narrow, so that the synthesized water reducing agent has the advantages of high water reduction rate and slump resistance. The redox system with low activation energy is used for initiating the monomer copolymerization, so that the polymerization can be implemented at normal temperature, thereby implementing the production of the product by a no heat source method, simplifying the production equipment and lowering the energy consumption and cost.

Owner:NANJING RUIDI HIGH TECH

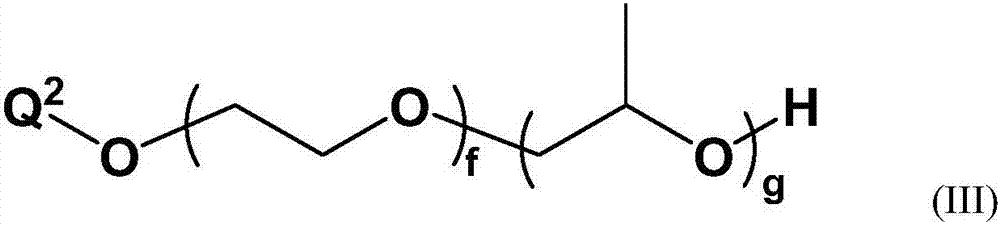

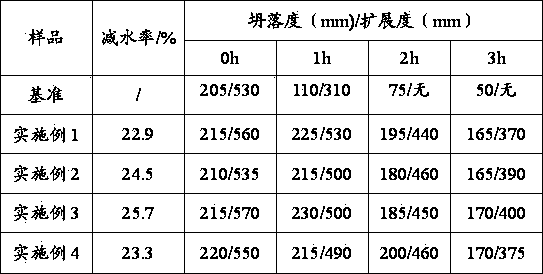

Polycarboxylic water reducer with viscosity reducing and slump retaining functions, and preparation method thereof

InactiveCN109021181AReduce the hydrophilic-lipophilic balanceReduce generationHigh strength concreteWork performance

The invention discloses a polycarboxylic water reducer with viscosity reducing and slump retaining functions, and a preparation method thereof, and belongs to the technical field of building materials. The polycarboxylic water reducer is prepared through the following steps: free radical polymerization of an unsaturated polyether monomer I, an unsaturated block modified polyether monomer II, an unsaturated carboxylic acid monomer, an unsaturated carboxylic acid alkyl ester, an unsaturated phosphate ester monomer, a chain transfer agent, an oxidant, a reducing agent and deionized water in an aqueous solution at 15-30 DEG C, addition of an alkali solution to adjust the pH value, and water supplementation. The water reducer can meet the requirements of the water-reducing and slump-retaining performances of high-strength concrete, and also can greatly reduce the viscosity of the concrete and significantly improve the working performances of the high-strength concrete, so the problems of fast slump loss and excessive viscosity of existing polycarboxylic water reducers are solved. The preparation method can be carried out at normal temperature without a heat source, so the preparation method has the advantages of simple production device, reasonable process, simplicity in operation, high production efficiency, and suitableness for industrial production and promotion.

Owner:SICHUAN TONGZHOU CHEM TECH

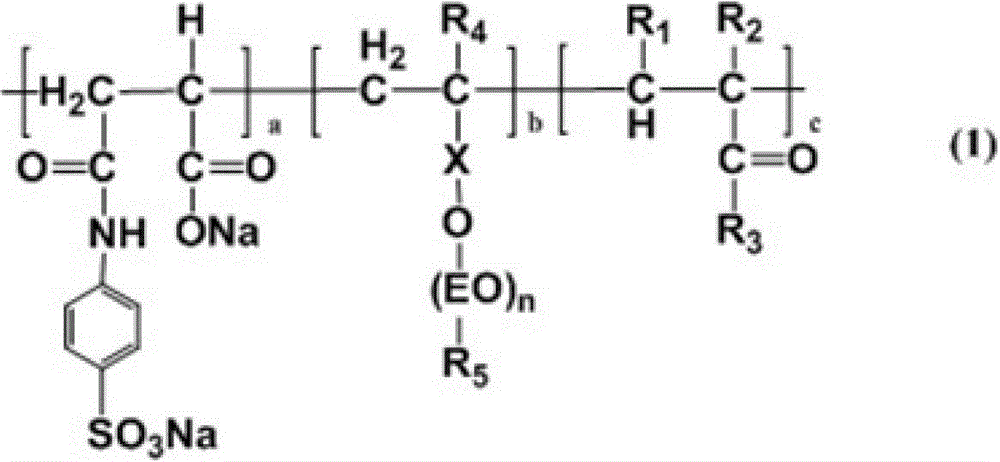

Hyperbranched polymer, hyperbranched polycarboxylic acid-series super plasticizer and preparation method thereof

ActiveCN102504247AEasy to getSimple processSulfonic acids salts preparationEthylene diaminePolymer science

The invention provides a hyperbranched polymer, a hyperbranched polycarboxylic acid-series super plasticizer and a preparation method thereof. The preparation method comprises the following steps of: undergoing an addition reaction and an ammonolysis reaction on alkenyl amine, polymethylmethacrylate, ethylene diamine and 2-acrylamide-2-sodium methylacrylsulfonate serving as raw materials to obtain a hyperbranched polymer with a structure shown as a formula (I), (II), (III) or (IV); undergoing a polymerization reaction on the hyperbranched polymer, an esterification monomer and a crosslinking agent; and preparing a hyperbranched polycarboxylic acid-series super plasticizer with a two-step process. The preparation method provided by the invention has the advantages of simple process, easiness for controlling a preparing process and operating, readily-available raw materials, low production cost and suitability for industrial production. Due to the adoption of the hyperbranched polycarboxylic acid-series super plasticizer, the comprehensive performance of concrete is improved. As proved by an experiment result, the hyperbranched polycarboxylic acid super plasticizer provided by the invention has high slump loss resistance, high water-reducing rate and high compressive strength.

Owner:安徽海螺材料科技股份有限公司

Concrete mixture for PHC (Prestressed High-strength Concrete) pipe pile and PHC pipe pile prepared therefrom

ActiveCN103145390ALow maintenance energy consumptionImprove automationHigh strength concreteCombustion

The invention discloses a concrete mixture for a PHC (Prestressed High-strength Concrete) pipe pile. The concrete mixture comprises the following raw materials: 400-520kg / m<3> of cementing material, 120-145kg / m<3> of water, 675-870kg / m<3> of sand, 1050-1110kg / m<3> of gravel and a polycarboxylate water reducing agent, wherein the usage amount of the polycarboxylate water reducing agent by mass is 1.0-1.5% the mass of the cementing material, and the cementing material is prepared from the following ingredients in percentage by mass: 80-95% of cement and 5-20% of mineral admixture. According to the concrete mixture, after centrifugal molding, the concrete mixture can be over 80MPa only through normal-pressure steam curing and short-time natural curing and can be over 85 MPa through 28-day natural curing, a high-pressure steam curing process is not needed, the production cycle is shortened, and approximately 70% of the consumption of standard combustion coal for the production of every one meter of the pipe pile can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

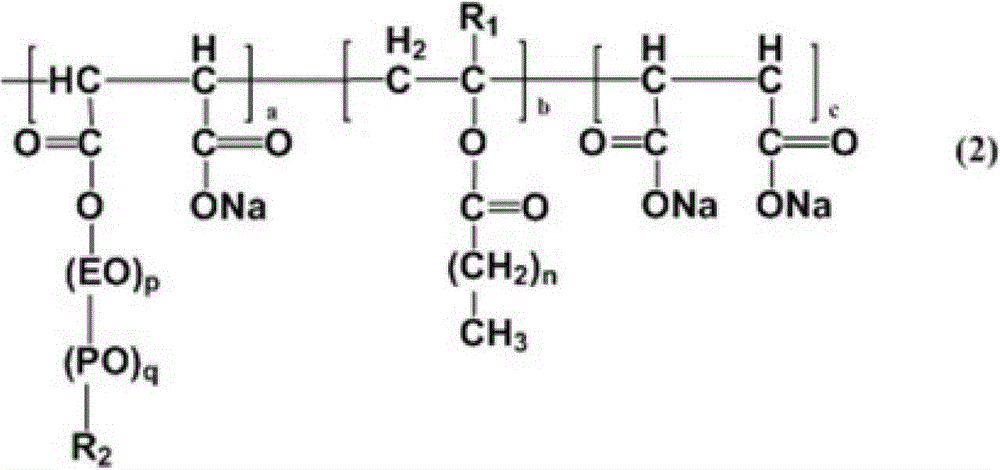

A polycarboxylate water reducer with high water reducing rate and high slump retention, its synthesis method and its use

The invention belongs to the technical field of building materials, and specifically relates to a polycarboxylic acid water reducer with a high water-reducing rate and high slump constant holding capacity, and its synthetic method and use method. The polycarboxylic acid water reducer comprises 2-methallyl polyoxyethylene ether (TPEG), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), methacrylic acid (MAA), ammonium persulfate (APS), sodium hydroxide and water. The synthetic method comprises the following steps that 1, TPEG, AMPS and MAA are prepared respectively into mixed solutions with concentrations in a range of 20 to 50%; 2, simultaneously, APS is added with a proper amount of water and is dissolved in the water; 3, the TPEG and AMPS monomer mixed solutions prepared by the step 1 are added into a reactor; nitrogen is fed into the mixture in the reactor; a condenser tube is mounted; the mixture is heated to a temperature of 60 to 100 DEG C with stirring; the MAA monomer solution prepared by the step 1 and the APS solution prepared by the step 2 are respectively added dropwisely into the heated mixture, wherein dropwise addition time of the MAA monomer solution is in a range of 1 to 5 hours and dropwise addition time of the APS solution is in a range of 1.5 to 5.5 hours; and after the dropwise addition is finished, the mixture with the MAA monomer solution and the APS solution undergoes a reaction at a constant temperature for 1 to 2 hours; 4, reaction products obtained by the step 3 are cooled and are neutralized by a NaOH solution to form desired products. The synthetic method of the polycarboxylic acid water reducer is a one-step synthetic method and has simple processes. Products prepared through the synthetic method have the advantages of stable performances, low doping quantity, high water-reducing rate, high slump constant holding capacity and good market prospects.

Owner:KZJ NEW MATERIALS GROUP CO LTD

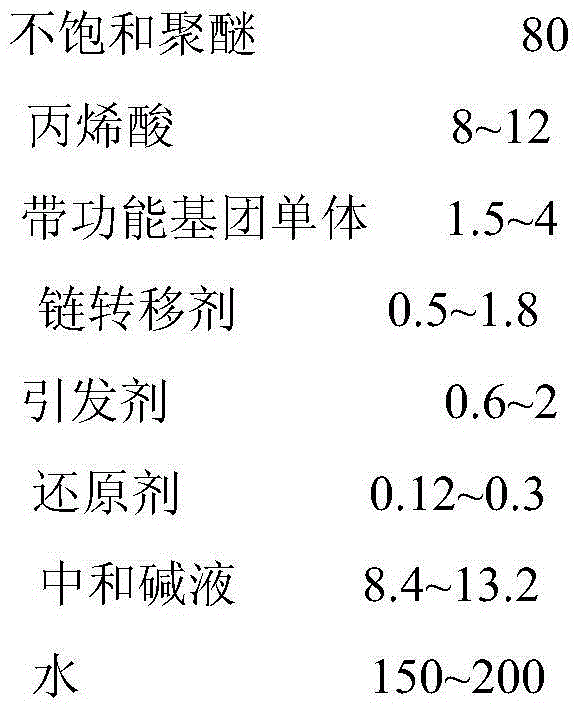

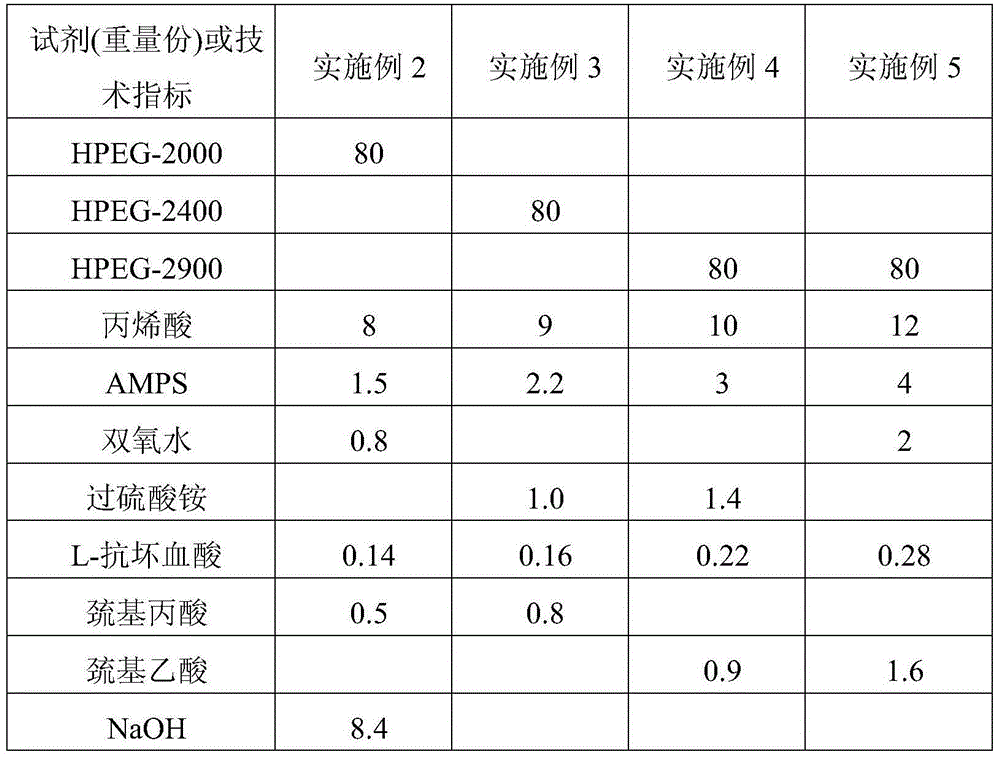

Multifunctional enhancement-type concrete admixture and preparation method thereof

The invention relates to a multifunctional enhancement-type concrete admixture and a preparation method thereof. The concrete admixture is composed of an early-strength polycarboxylic acid water reducing agent (PCs) and nano graphene oxide (GO). The mass ratio of the solid to the GO in the early-strength water reducing agent (PCs) is (10-30):1. The early-strength polycarboxylic acid water reducing agent (PCs) is composed of the following components in parts by weight: 80 parts of unsaturated polyether, 8-12 parts of acrylic acid, 1.5-4 parts of monomer with functional groups, 0.5-1.8 parts of chain-transfer agent, 0.6-2 parts of initiator, 0.12-0.3 part of reducer, 8.4-13.2 parts of neutralizing alkali liquor and 150-200 parts of water. The admixture has an obvious enhancement action on concrete, implements high-strength long-service-life green concrete, and has important meanings in the field of application of high-strength high-performance concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

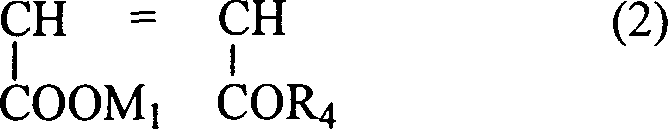

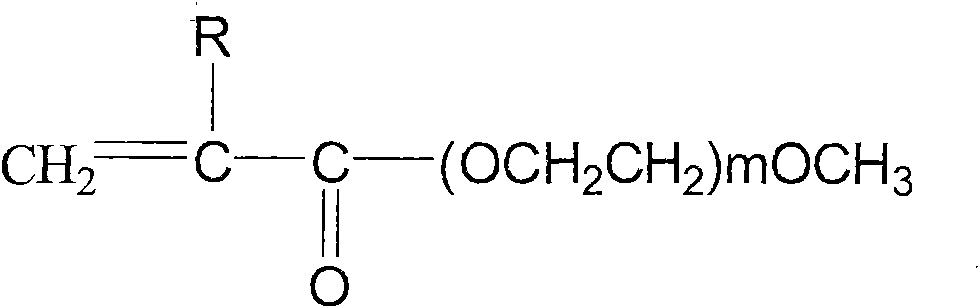

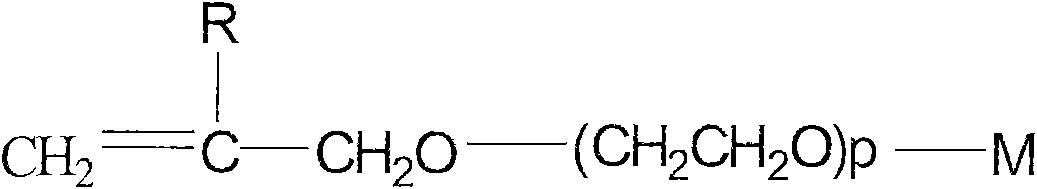

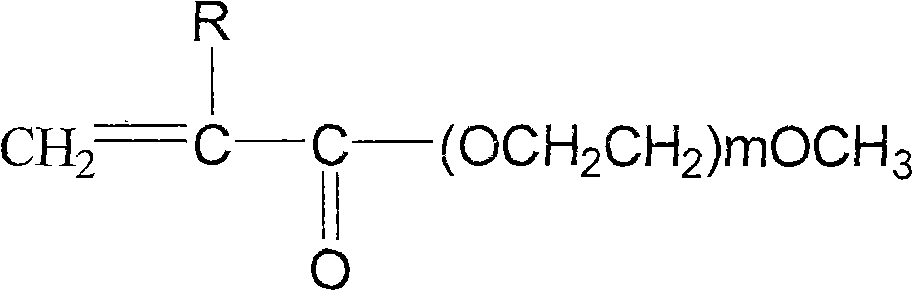

Design and preparation of coagulation time controllable high performance polycarboxylic acid water reducing agent

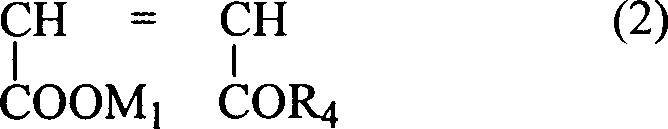

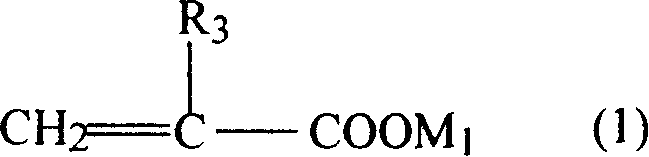

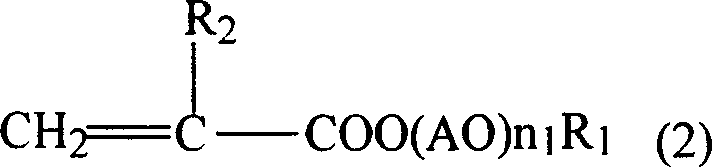

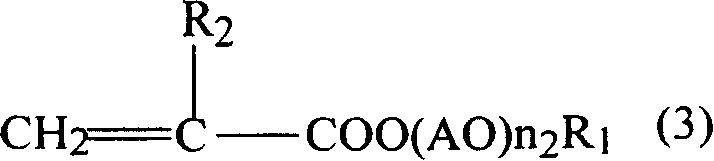

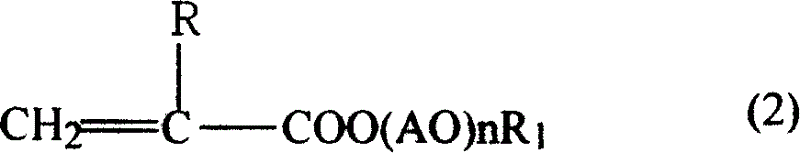

The invention relates to the design and synthesis of a poly carboxylic acid water reducing agent, the coagulating time of which can be controlled. The poly carboxylic acid water reducing agent is prepared by co-polymerize the following three monomers in water: the monomer a occupying 30 to 70 percent and indicated by a general expression 1, the monomer b occupying 10 to 50 percent and indicated by the general expression 2, and the monomer c occupying 10 to 40 percent and indicated by the general expression 3. The coagulating time is controlled by the monomer a which is made by condensing maleic anhydride and polyoxyethylene monoalkyl ether. The length of a polyoxyethylene monoalkyl ether chain controls the change of the coagulating time: the longer the chain, the shorter the coagulating time is; and the shorter the chain is, the longer the coagulating time is. The monomer a does not contain inhibitive substances in the process of synthesis, therefore, the water reducing agent is easy to be controlled in the coagulating process. The poly carboxylic acid water reducing agent is suitable for the construction of concrete under different temperature conditions: under higher temperature, the water reducing agent with longer coagulating time can be adopted, and under lower temperature, the water reducing agent with shorter coagulating time can be adopted. The poly carboxylic acid water reducing agent has good adaptability to cement and admixtures and has the advantages of low mixing quantity, good slump constant hold facility and water segregation resistance, and the like.

Owner:武汉格瑞林建材科技股份有限公司

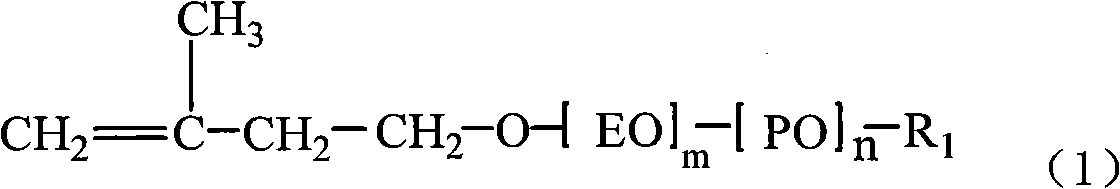

Prenyl polyether polycarboxylate water reducing agent and synthesis method thereof

The invention provides a prenyl polyether polycarboxylate water reducing agent which is a polymer of prenyl polyoxyethylene ether or prenyl polyoxyethylene propylene ether (big monomer A) and unsaturated carboxylic acid and derivatives thereof (small monomer B), belonging to the field of concrete additives. A synthesis method of the water reducing agent comprises the following steps of: with water as a solvent, initiating the big monomer A and the small monomer B by adopting a redox initiation system under the lower temperature, and carrying out copolymerization under the action of a chain transfer agent to obtain the finished product. The water reducing agent overcomes the defects of low water reducing rate, poor slump loss resistance, long condensation time, and the like of a water reducing agent synthesized by allyl polyoxyethylene ether and has the advantages of high slump loss resistance, plenty water reducing and small influence on the condensation time of concrete.

Owner:SHANXI UNIV +1

Polycarboxylic acid cement dispersant and its prepn process

InactiveCN1847187AHigh water reduction rateGood slump retentionPolycarboxylate CementDicarboxylic acid

The present invention discloses polycarboxylicacid cement dispersant and its preparation process. The cement dispersant is prepared with unsaturated polyoxyethylene ether monomer, unsaturated binary carboxylic acid monomer and other monomer capable of copolymerizing with the said monomers, and through copolymerization in redox system. The cement dispersant of the present invention has high water reducing rate, low slump loss and other advantages, and the preparation process has low power consumption, high efficiency, high repeatability and other advantages and is suitable for producing polycarboxylicacid cement dispersant.

Owner:SHANGHAI SUNRISE CHEMISTRY CO LTD

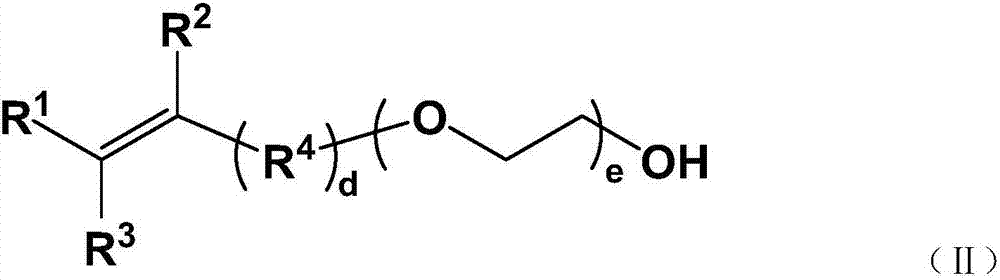

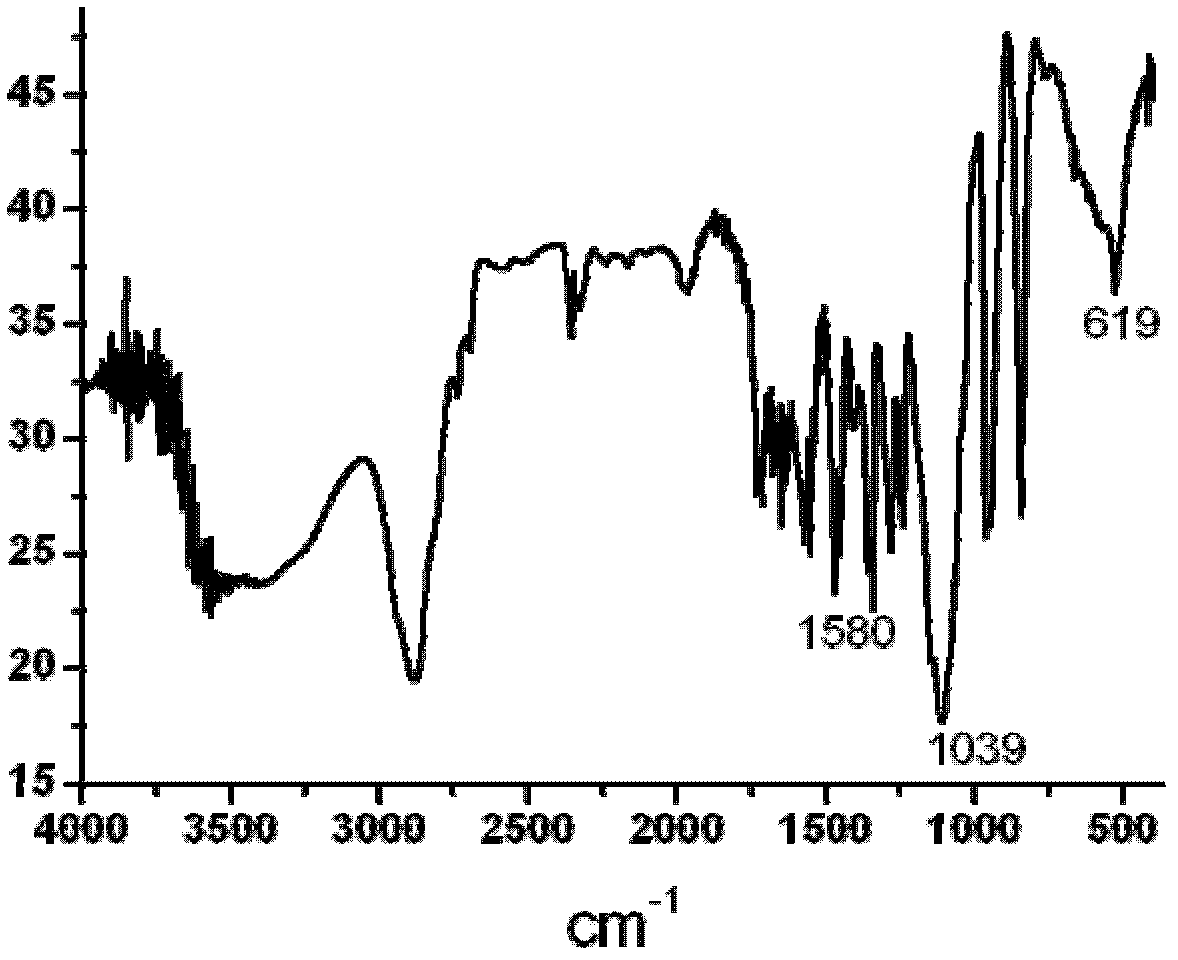

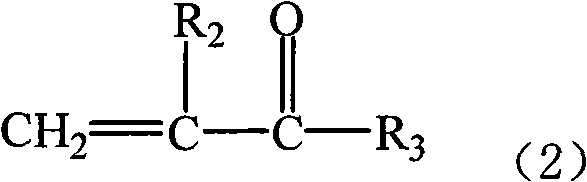

Multifunctional carboxylic-acid comb-shape graft copolymer concrete superplasticizer

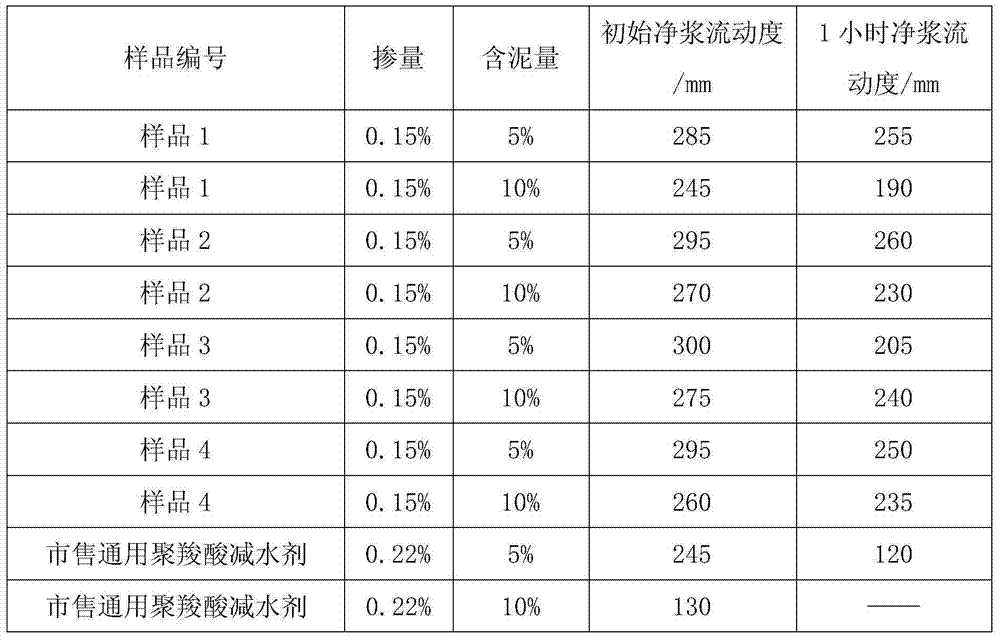

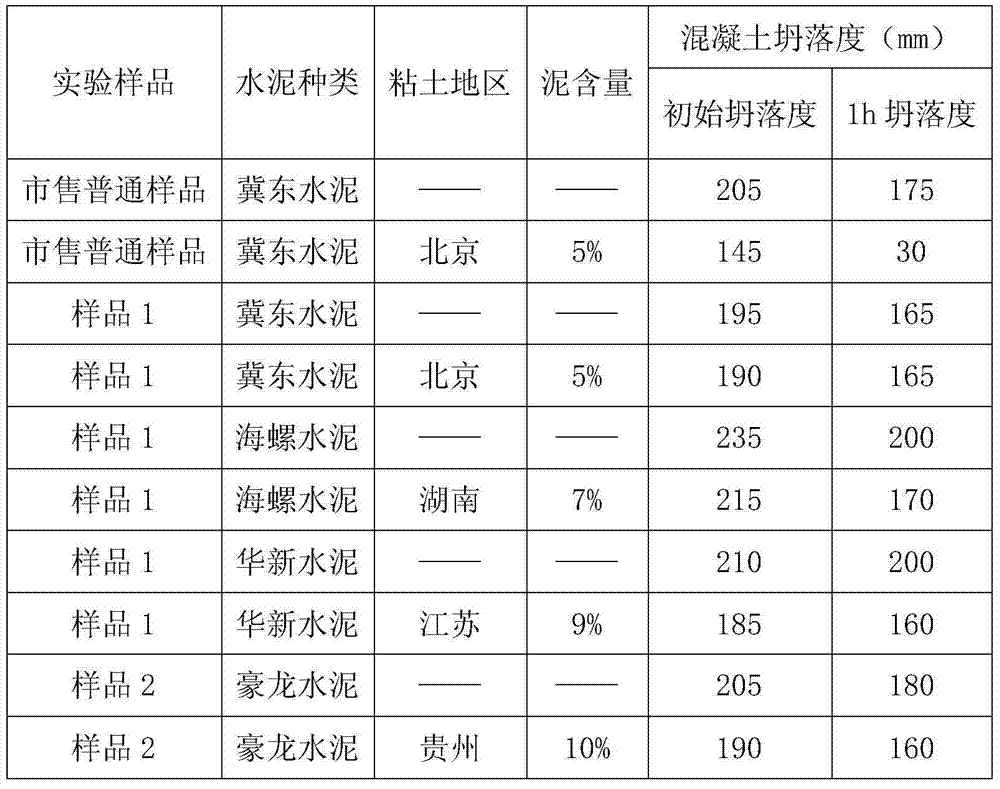

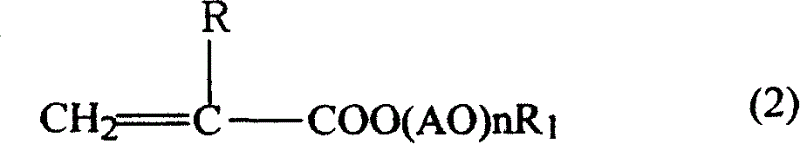

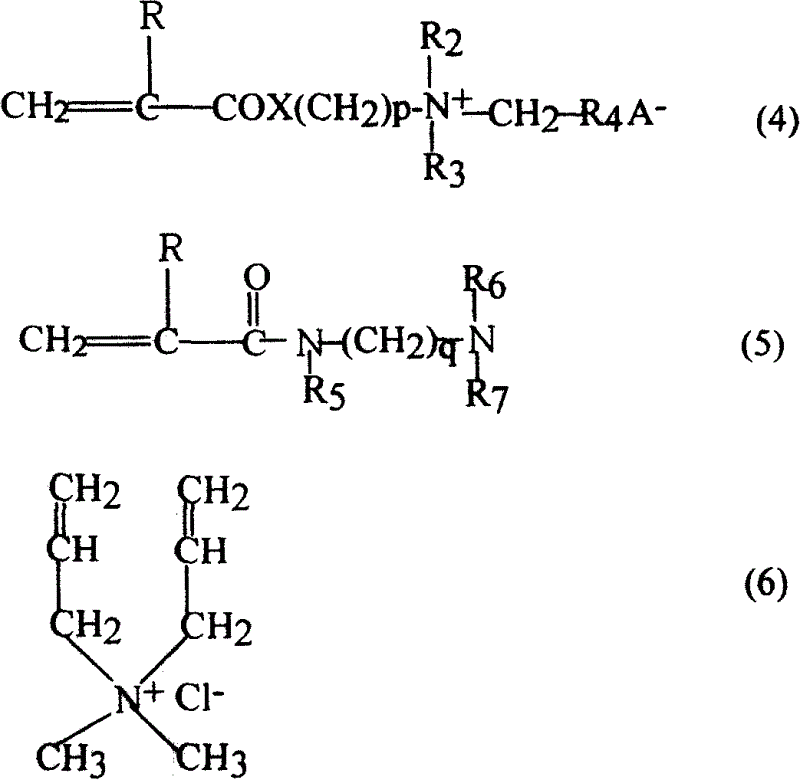

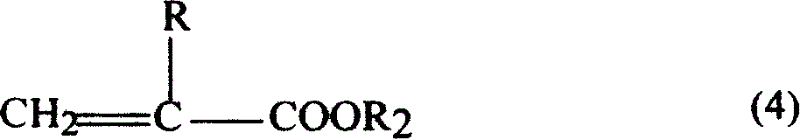

The multifunctional super concrete plasticizing agent of carboxylic acid comb grafting copolymer is prepared through the water free radical copolymerization of the following monomers: monomer A with the general expression I in 10-40 wt%, monomer B with the general expression II in 30-70 wt%, monomer C with the general expression III in 10-50 wt%, monomer D with the general expression IV in 3-15 wt%, monomer F with the general expression VI in 0-15 wt%, and reactive defoaming agent E in 0.2-2 wt% of the sum of foregoing five kinds of monomer. The present invention can reduce the shrinkage of concrete, and has good adaptability on cement and admixture material, good dispersivity and slump maintaining performance, high weeping resistance and resolution resistance, small pumping drag, product yield near 100 % and no waste produced in the production process.

Owner:JIANGSU SOBUTE NEW MATERIALS

Self-compacting non-shrinkage concrete-filled steel tube

The invention discloses a self-compacting non-shrinkage concrete-filled steel tube, belonging to the technical field of concrete. The self-compacting non-shrinkage concrete-filled steel tube is prepared from the following components in parts by weight: 360-400 parts of cement, 53-100 parts of coal ash, 15-35 parts of ground slag, 50-80 parts of a compound expansion agent, 700-770 parts of mixed sand, 1040-1070 parts of gravel, 150-160 parts of drinking water and a high performance admixture, wherein the amount of the high performance admixture accounts for 1.7-1.8% of the total mass of a cementing material by mass percent. The self-compacting non-shrinkage concrete-filled steel tube provided by the invention has good self-compacting property, expansibility, fluidity, slump loss resistance,cohesiveness, segregation resistance and higher compression strength; furthermore, the expansion process and strength of concrete-filled steel tube are synergistically developed.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

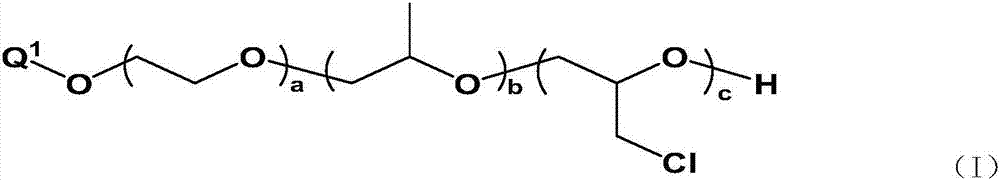

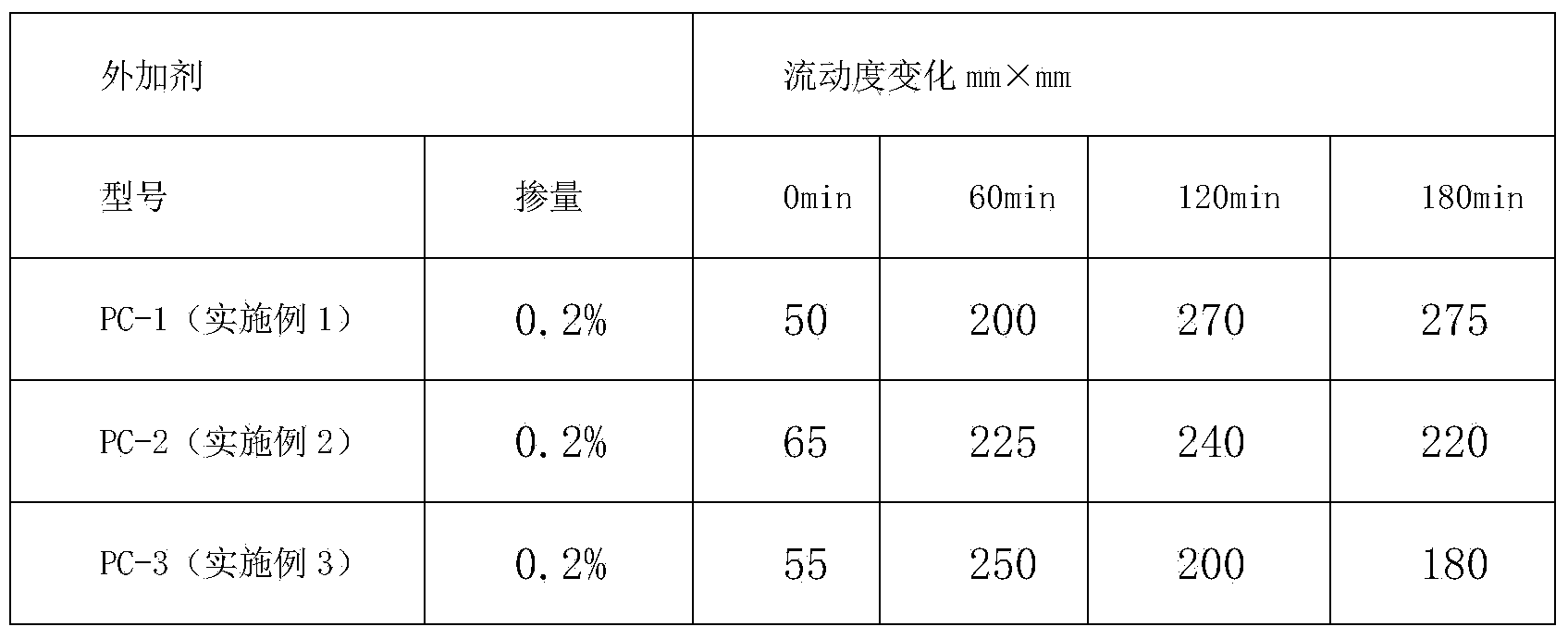

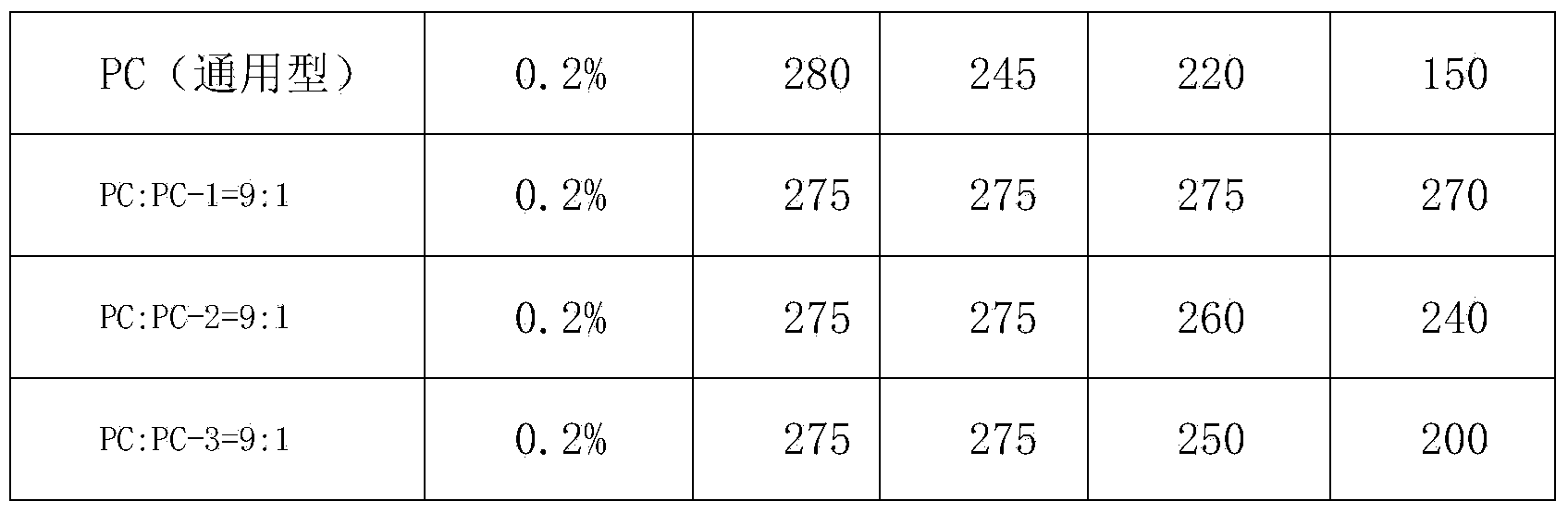

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

Solid flaky polycarboxylate water-reducer and polymerization preparation method thereof

The invention discloses a solid flaky polycarboxylate water-reducer and a polymerization preparation method thereof. The polymerization preparation method comprises the following specific steps: placing 850 to 890 parts of polyether macro-monomer in a reaction kettle without adding water or any organic solvent, and heating to 65 to 75 DEG C; stirring until the polyether macro-monomer is dissolved completely, keeping the temperature at 65 to 75 DEG C, putting 5 to 10 parts of weak chain transferring agent, 2.5 to 5.0 parts of organic peroxide initiator, 7.5 to 12.5 parts of unsaturated dicarboxylic acid and 25 to 40 parts of acrylic acid at a time; after the materials are added at a time, starting to dropwise add a mixed solution of 50 to 80 parts of acrylic acid and 1.2 to 3.5 parts of strong chain transferring agent, and adding an azoic initiator at two times in the dropwise adding process; after finishing the dropwise adding, curing for 1 to 2 hours, adding 7.5 to 16.0 parts of neutralizing agent, stirring uniformly, and slicing after cooling to obtain a finished product. The solid flaky polycarboxylate water-reducer is convenient to store, is low in long-distance transportation cost, is completely water-soluble, and is suitable for cement-based binding materials in civil engineering.

Owner:HUBEI UNIV OF TECH

Multi-branched polycarboxylic water reducer with excellent function of slump protection and preparation method thereof

The invention relates to a plastic retaining agent for newly mixed cement paste, mortar, concrete and the like, in particular to a multi-branched polycarboxylic water reducer with an excellent function of slump protection and a preparation method thereof. The water reducer is prepared with the following monomers through aqueous solution polymerization under the effect of a polymerization initiator: a monomer a of 30-60 percent of the total weight of reactants, a monomer b of 20-50 percent of the total weight of the reactants, a monomer c of 10-30 percent of the total weight of the reactants, and a monomer d of 5-15 percent of the total weight of the reactants. The multi-branched polycarboxylic water reducer still has an excellent performance of maintaining the plasticity of the concrete under the low dosage, and even in construction at the high temperature in summer, the slump loss of the fresh concrete is small, the scope of application in the cement is wide, and no obvious delayed coagulation occurs to the concrete. Therefore, the invention greatly improves the early and late strength of the concrete.

Owner:浙江五龙新材股份有限公司

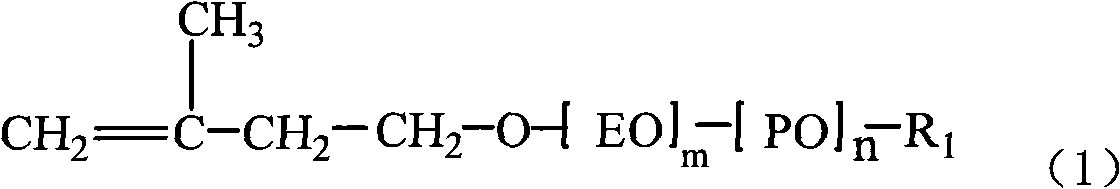

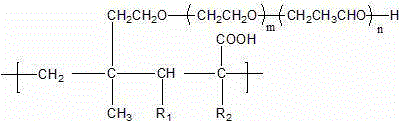

Concrete polycarboxylate water reducing agent and preparing method thereof

The invention provides a concrete polycarboxylate water reducing agent and a preparing method thereof. The concrete polycarboxylate water reducing agent is a polymer copolymerized by a monomer A and a monomer B, wherein the weight-average molecular weight of the polymer ranges from 5,000 to 30,000. The chemical structural formula is shown in the specification, wherein m is an integer ranging from 14 to 66, n is an integer ranging from 0 to 40, R1 is H or COOH, and R2 is H or CH3. The performance is stable, the water-reducing rate is high, and cement adaptation is high; the concrete polycarboxylate water reducing agent has the excellent water reducing performance and the excellent slump retaining performance, and has the advantages that the preparing process is simple in technology, time is short, reaction energy consumption is low, operability is high, and pollution to the environment is avoided.

Owner:国能辽宁环保产业集团有限公司材料分公司

Preparation method of strengthening and toughening polycarboxylate water reducing agent

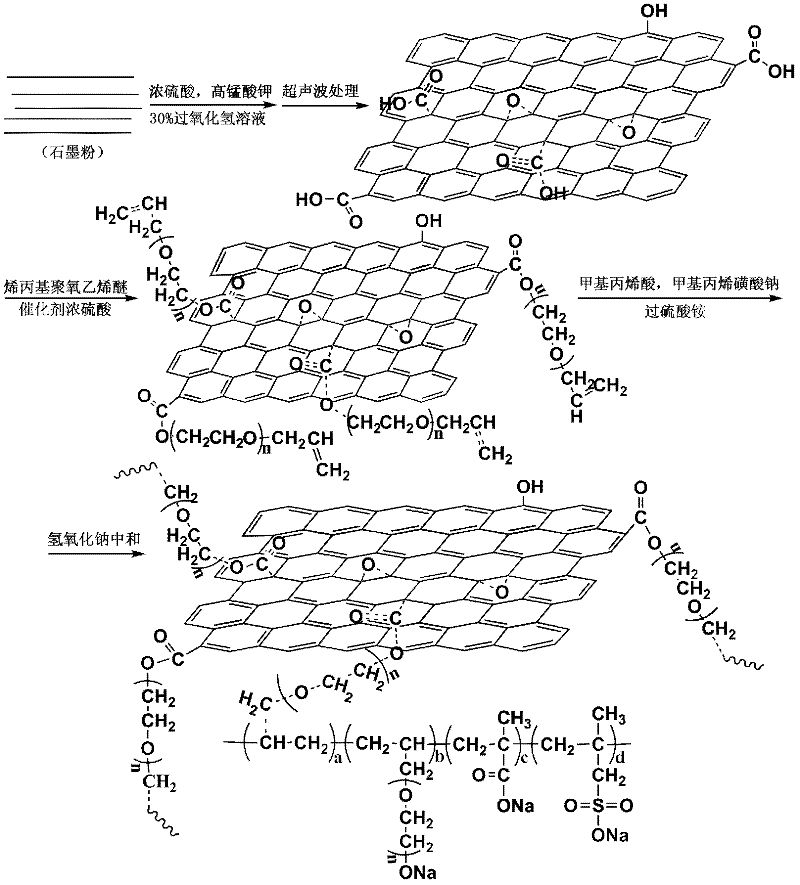

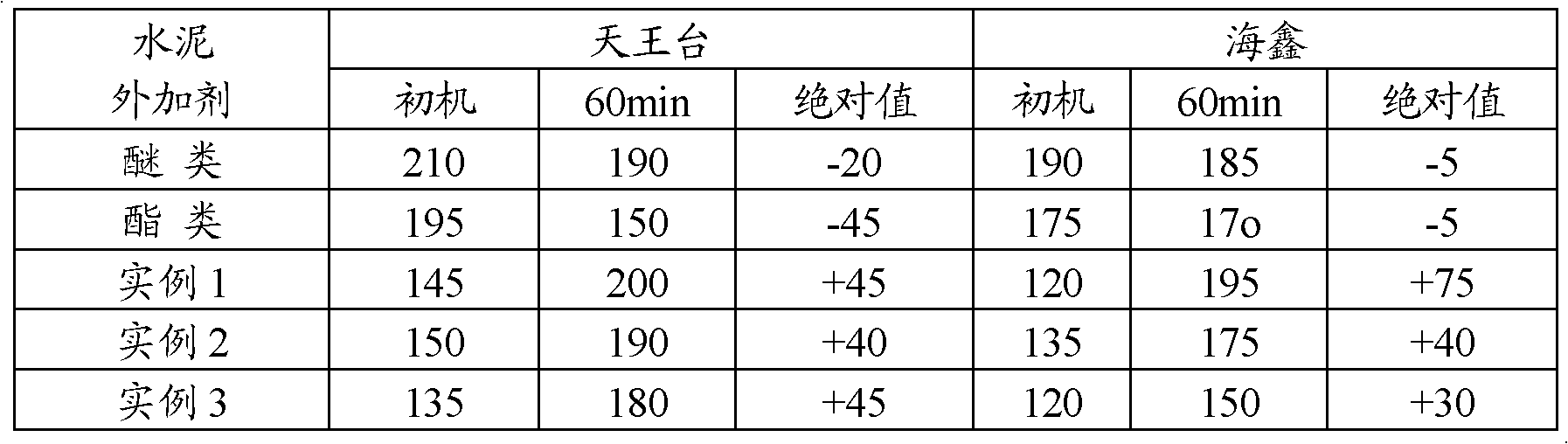

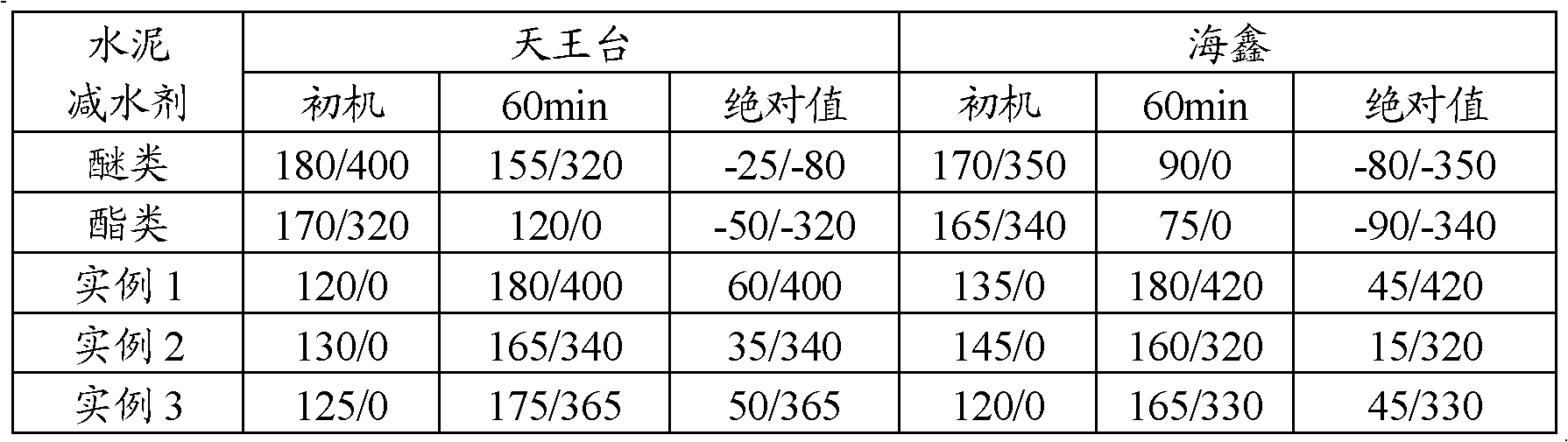

The invention relates to a preparation method of a strengthening and toughening polycarboxylate water reducing agent. The method comprises the following steps of: oxidizing graphite powder by using concentrated sulfuric acid and potassium permanganate, then carrying out ultrasonic separation to obtain graphene oxide structurally containing carboxyl, hydroxyl, epoxy group and the like, and then, subjecting graphene oxide and allyl polyoxylethylene ether to esterification reaction under the action of ultrasonic; then carrying out free radical copolymerization reaction with methacrylic acid and sodium methylacrylsulfonate under the initiation of ammonium persulfate to obtain the strengthening and toughening polycarboxylate water reducing agent. The method provided by the invention has the innovation points as follows: a graphene oxide structure is introduced to the molecule of the polycarboxylate water reducing agent through oxidation, separation, esterification and free radical copolymerization reaction, so that the strength of concrete is increased by the high water-reducing rate of the water reducing agent, and in addition, the graphene also has strengthening and toughening effects for the concrete.

Owner:河北圣通建材科技有限公司

Preparation method for polycarboxylic acid type concrete slump-retaining agent

The invention provides a preparation method for a polycarboxylic acid type concrete slump-retaining agent, wherein the slump-retaining agent is a polycarboxylic acid copolymer obtained by dissolving modified polyether and unsaturated polycarboxylic acid in aqueous solution, adopting a redox system, and synthesising under the action of a chain transfer agent; the molar ratio of the modified polyether to the unsaturated polycarboxylic acid is 1: (1.0 to 7.0); the dosage of an oxidant is 0.2-5.0% in ratio by weight of the total of the modified polyether and the unsaturated polycarboxylic acid; the dosage of a reductant is 0.02-4.0% in ratio by weight of the total of the modified polyether and the unsaturated polycarboxylic acid; and the dosage of the chain transfer agent is 0.03-6.0% in ratio by weight of the total of the modified polyether and the unsaturated polycarboxylic acid. The method provided by the invention has no need of independently preparing a polymerized macromonomer, as well as is low in reaction temperature, simple in process, and convenient to operate. The slump-retaining agent prepared by the method provided by the invention is excellent in slump-retaining capacity.

Owner:SHANXI HUANGTENG CHEM

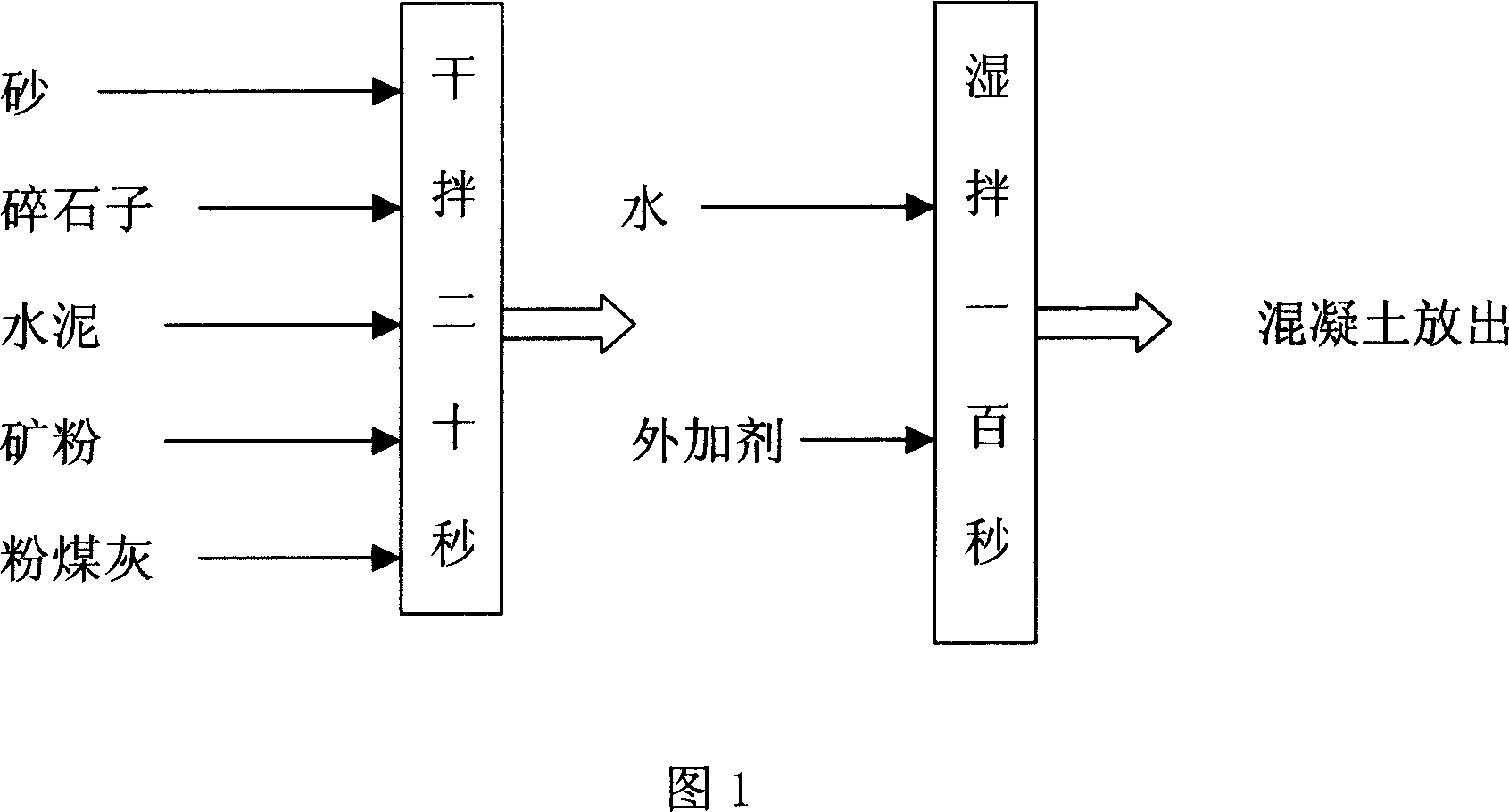

Autodensing concrete using polycarboxylic acid series additive and its technology

ActiveCN100999399AGood slump retentionWide adaptability of cementSolid waste managementSlagSilicate Cement

This invention relates to a self-compacting concrete that using polycarboxylate additive agent, mixed by aggregate, cementitious materials, additive agent and water. According to weight, sand rate of 45%, the total amount of slag and fly ash mixture is more than 30% of the total cementitious Materials, the water-cement ratio is not more than 0.4; select ordinary silicate cement of no less than 42.5; slag and fly ash ratio of 1:1; the Polycarboxylate, polyethylene oxide chain length of 10 ~ 300 Moore, the molar ratio of allyl part of 1 / 9 to 6 / 9, molecular weight of polymer is 30,000 to 80,000. It's Process: aggregate and cementitious materials by dry mixing 20 seconds later, add water and additive agent, wet mixing 00seconds then release concrete.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Heat source-free short-time preparation method of controlled-release type polycarboxylic acid high-performance slump retaining agent

The invention relates to a polycarboxylate superplasticizer, and particularly relates to a heat source-free short-time preparation method of a controlled-release type polycarboxylic acid high-performance slump retaining agent. The heat source-free short-time preparation method comprises the following steps: adding methyl allyl polyethenoxy ether and water in a container, after stirring for 0.5 hour at normal temperature, adding an initiator and an initiation additive, stirring for 2min at normal temperature; titrating a mixed water solution of acrylic acid, hydroxyethyl acrylate and 2-acrylamide-2-methylacrylsulfonate, and a chain transfer agent water solution simultaneously within 1 hour, then insulating heat for 0.5 hour, regulating a pH value to 6-7 by adopting an alkaline liquor, and finally diluting by adding water until the solid content is 40 percent. The heat source-free short-time preparation method is simple in preparation process, simple in equipment, and free from heating in the whole reaction process so that energy resources are saved; the production period is only 2 hours, and thus the production efficiency is greatly increased, and the application range is wide; and the synthesized controlled-release type polycarboxylic acid high-performance slump retaining agent has the characteristics of less doping amount, good slump retaining property, environment friendliness and the like.

Owner:山东卓星化工有限公司

Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

The amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent is prepared through the following steps: 1) copolymerizing three kinds of monomers in certain proportion in water soluble medium to obtain intermediate product PCE; 2) preparing cationic copolymer CNP through Hofmann degradation or Mannich reaction of polyacrylamide or the copolymerization of acrylamide monomer and two other kinds of monomer in water soluble medium; 3) mixing the copolymer PCE and polymer CNP through stirring to obtain amphoteric carboxylic acid grafted copolymer; and 4 ) heating the comb grafted copolymer produced in the last step to 60-100 deg.c and adding crosslinking agent to produce crosslinking reaction producing the amphoteric carboxylic acid comb grafted copolymer. The concrete super-plasticizing agent of the present invention can reduce the water consumption of concrete greatly, and has excellent construction performance.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com