Self-compacting non-shrinkage concrete-filled steel tube

A technology for shrinking steel pipes and concrete, applied in the field of concrete, can solve the problems of slow strength growth, low elastic modulus, fast slump loss, etc., and achieve long-term stable expansion performance, high expansion performance, and increased segregation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

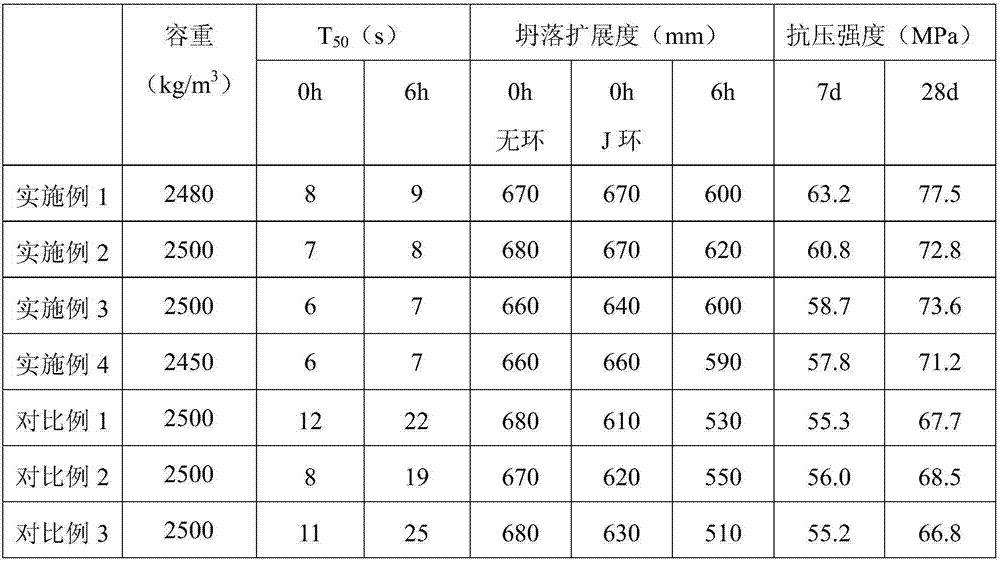

Examples

Embodiment 1

[0026] A self-compacting non-shrinkage steel pipe concrete, comprising the following components by weight: 400 parts of cement, 65 parts of fly ash, 25 parts of slag powder, 80 parts of composite expansion agent, 700 parts of mixed sand, 1050 parts of gravel, drinking water 160 parts and 1.7% of the high-performance admixture accounting for the total mass fraction of the above-mentioned gelling material, that is, 9.7 parts of the high-performance admixture in this embodiment.

[0027] The composite expansion agent includes 30 parts of light-burned calcium oxide clinker, 20 parts of light-burned magnesium oxide clinker, 10 parts of gypsum and 10 parts of fly ash. The CaO content in the light-burned calcium oxide clinker oxide composition in the composite expansion agent is 90wt%; the MgO content in the light-burned magnesium oxide clinker oxide composition in the composite expansion agent is 95wt%, and the activity index is 100s. The preparation method of the composite expansio...

Embodiment 2

[0032] A self-compacting non-shrinkage steel pipe concrete, comprising the following components by weight: 392 parts of cement, 53 parts of fly ash, 35 parts of slag powder, 50 parts of composite expansion agent, 770 parts of mixed sand, 1045 parts of gravel, drinking water 155 parts and high-performance admixtures accounting for 1.8% of the total mass fraction of the above-mentioned cementitious materials.

[0033] The above-mentioned composite expansion agent includes 40 parts of light-burned calcium oxide clinker, 40 parts of light-burned magnesium oxide clinker, and 20 parts of gypsum. The CaO content in the light-burned calcium oxide clinker oxide composition in the composite expansion agent is 90wt%; the MgO content in the light-burned magnesium oxide clinker oxide composition in the composite expansion agent is 95wt%, and the activity index is 150s. The preparation method of the composite expansion agent is to sinter the light-burned calcium oxide clinker and the light-...

Embodiment 3

[0038] A self-compacting non-shrinkage steel pipe concrete, including 365 parts of cement, 100 parts of fly ash, 15 parts of slag powder, 60 parts of composite expansion agent, 740 parts of mixed sand, 1070 parts of crushed stone, 150 parts of drinking water and the above-mentioned gelling The high-performance admixture with a total mass fraction of 1.8% of the material.

[0039] The above-mentioned composite expansion agent includes 60 parts of light-burned calcium oxide clinker, 40 parts of light-burned magnesium oxide clinker, and 20 parts of fly ash. The CaO content in the light-burned calcium oxide clinker oxide composition in the composite expansion agent is 90wt%; the MgO content in the light-burned magnesium oxide clinker oxide composition in the composite expansion agent is 95wt%, and the activity index is 200s. The preparation method of the composite expansion agent is to sinter the light-burned calcium oxide clinker and the light-burned magnesium oxide clinker at 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com