Patents

Literature

59results about How to "Good self-compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

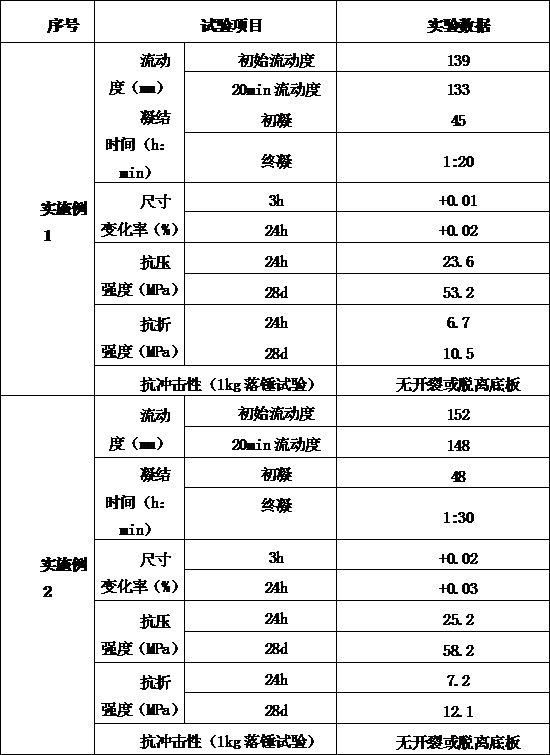

Quick setting and rapid hardening non-shrinkage anti-disturbance self-compacting concrete and preparation method thereof

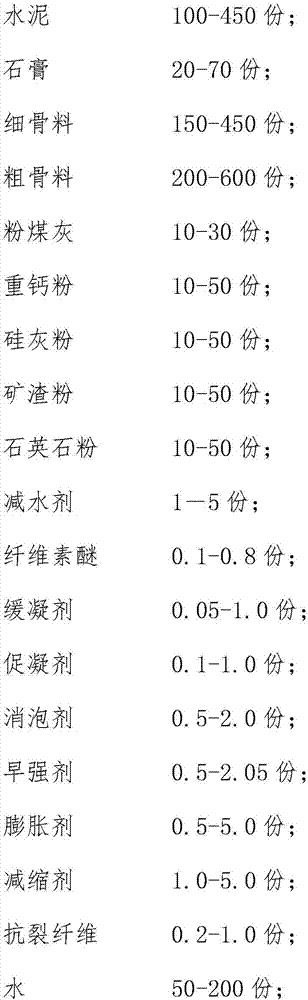

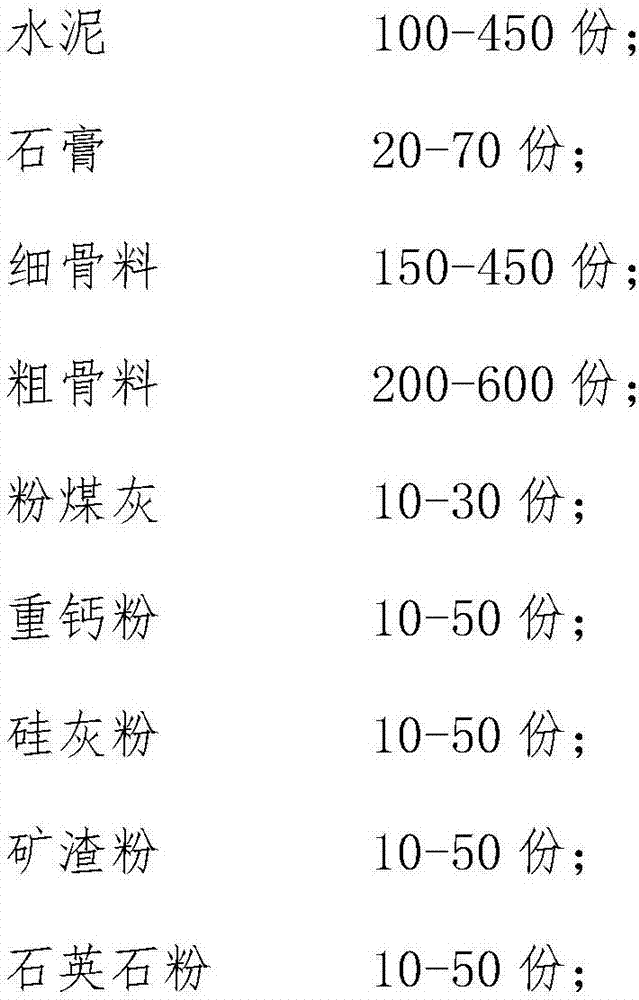

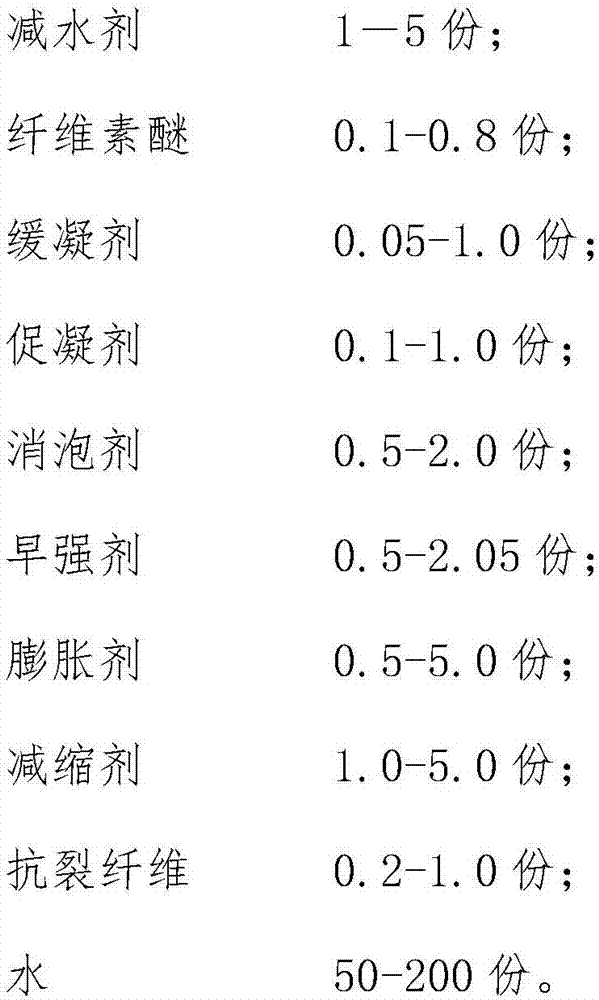

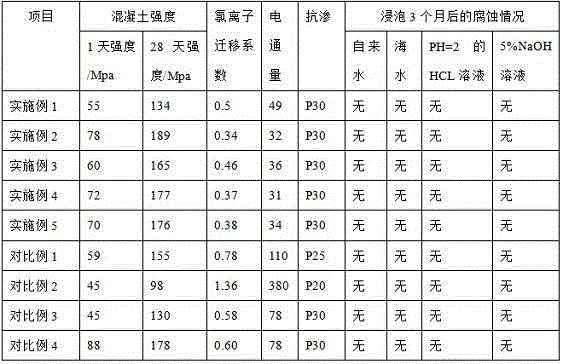

The invention relates to quick setting and rapid hardening non-shrinkage anti-disturbance self-compacting concrete and a preparation method thereof. Raw materials contain the following ingredient (by weight): 100-450 parts of cement, 20-70 parts of gypsum, 150-450 parts of fine aggregate, 200-600 parts of crude aggregate, 10-30 parts of fly ash, 10-50 parts of heavy calcium powder, 10-50 parts of silica fume, 10-50 parts of slag powder, 10-50 parts of quartz powder, 1-5 parts of a water reducer, 0.1-0.8 part of cellulose ether, 0.05-1.0 part of a retarder, 0.1-1.0 part of a coagulation accelerator, 0.5-2.0 parts of an antifoaming agent, 0.5-2.05 parts of an early strength agent, 0.5-5.0 parts of an expanding agent, 1.0-5.0 parts of a shrinkage reducing agent, 0.2-1.0 part of anti-crack fiber, and 50-200 parts of water. Through an optimum mixture ratio and by the use of a polycarboxylate superplasticizer, the early strength agent and other additives, properties such as early strength, disturbance rejection, crack resistance, durability, self-compaction and the like of concrete are greatly enhanced, and disadvantages of low early strength, long time interval of initial set and final set and the like of common concrete are solved.

Owner:张彬

Sea sand powder concrete

ActiveCN105084837AEasy to fillImprove mechanical propertiesSolid waste managementFiberCopper plating

The invention relates to sea sand powder concrete. The sea sand powder concrete comprises, by weight, 450-750 parts of cement, 250-450 parts of active mineral admixture, 50-150 parts of inert admixture, 850-1400 parts of sea sand, 24-32 parts of high efficiency slushing agents, 145-220 parts of seawater, 2-4 parts of organic fiber and 78-250 parts of copper-bearing steel fiber with the thickness ranging from 0.08 mm to 0.35 mm. According to the sea sand powder concrete, a compact stacking structure principle is adopted, the interior of the concrete is almost seamless in communication channel through optimization of particle size gradation, and a channel of internal ion medium migration is further eliminated through secondary hydration of the active mineral additive, so that the powder concrete obtained by stirring the raw materials through the seawater and the sea sand is ultra-high performance concrete with high durability, corrosion resistance and high mechanic property.

Owner:黄贺明

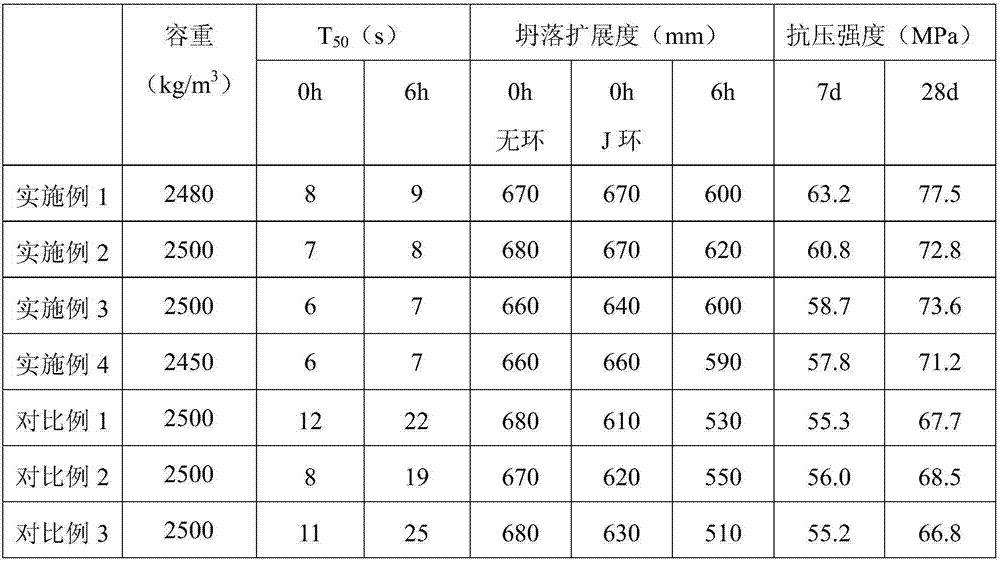

Self-compacting concrete

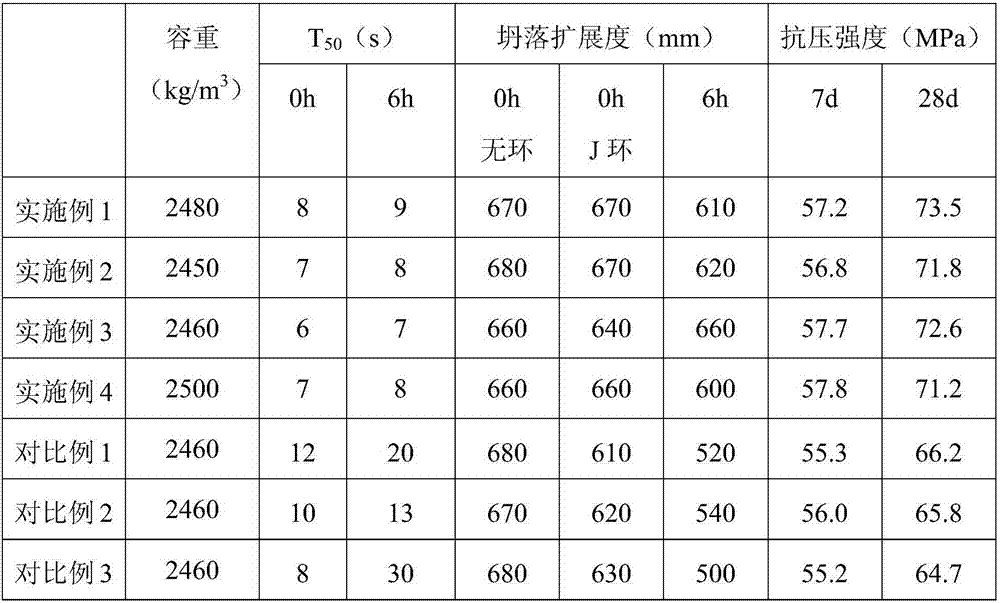

The invention discloses a self-compacting concrete and belongs to the technical field of concrete. The self-compacting concrete comprises the following components in parts by weight: 350-400 parts of cement, 54-80 parts of coal ash, 52-60 parts of slag powder, 50-62 parts of expanding agent, 9-13 parts of silica powder, 748-800 parts of mixed sand, 948-1020 parts of macadam, 140-165 parts of drinking water, 0-10 parts of compound additive and high-performance additive being 1-2% of the binding material in mass fraction. The concrete acquired according to the invention has excellent self-compacting property, fluidity, collapse prevention, cohesiveness and separation resistance, and meanwhile, a test proves that the compressive strength after 7 days is about 57MPa and the compressive strength after 28 days is about 70MPa, so that the concrete provided by the invention has higher compressive strength.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

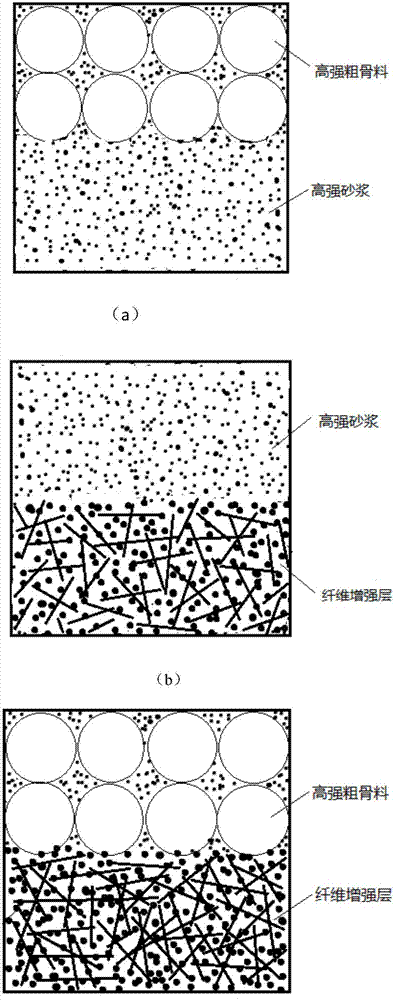

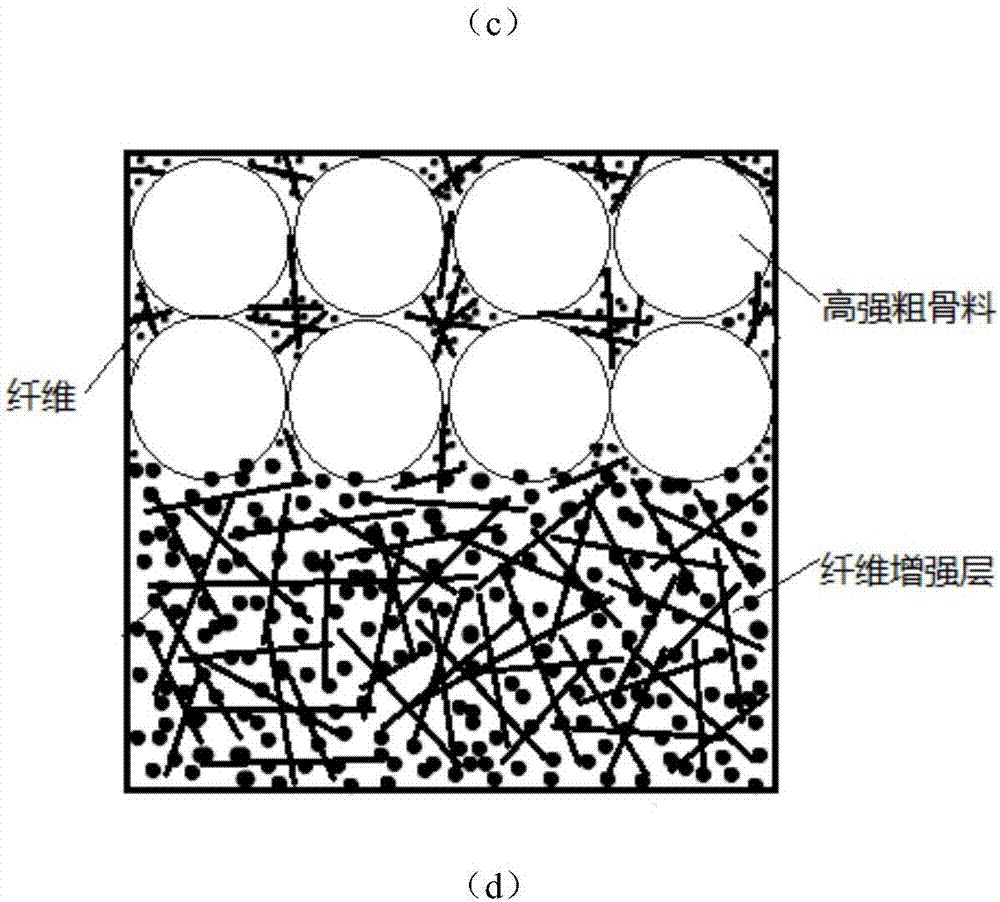

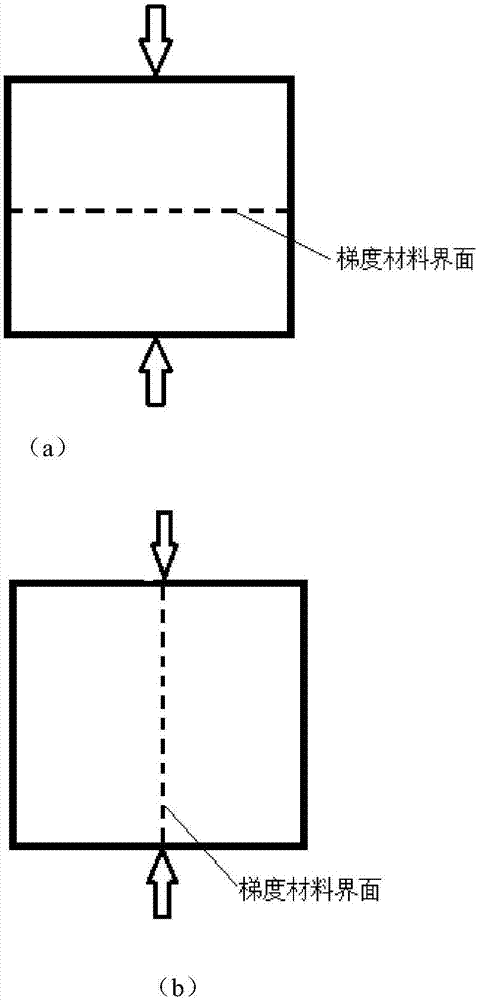

Functional gradient cement-based composite material enhanced by nano material and preparation method thereof

ActiveCN107098657AWide variety of sourcesConducive to ecological sustainable developmentCement pasteUltimate tensile strength

The invention discloses a functional gradient cement-based composite material enhanced by a nano material and a preparation method thereof. The composite material is composed of two or more of high-strength mortar, high-strength crude aggregate concrete, the fiber-enhanced super-high performance concrete, and the fiber-enhanced crude aggregate concrete according to isopyknic ratio. The nano material is doped into the composite material, an aperture and a gap of a gelling system can be filled with the material taken as a micro aggregate, the hydration rate at an early stage of cement paste is increased; at the same time, the gradient design is employed, by aiming at out-phase in the composite material and an interface in a functional zone, the performance of the cement-based composite material is effectively improved, and the functional gradient cement-based composite material is prepared, and the performances of intensity, toughness, impact resistance, penetration resistance, and blast resistance are greatly increased.

Owner:NANJING UNIV OF SCI & TECH

Self-compacting non-shrinkage concrete-filled steel tube

The invention discloses a self-compacting non-shrinkage concrete-filled steel tube, belonging to the technical field of concrete. The self-compacting non-shrinkage concrete-filled steel tube is prepared from the following components in parts by weight: 360-400 parts of cement, 53-100 parts of coal ash, 15-35 parts of ground slag, 50-80 parts of a compound expansion agent, 700-770 parts of mixed sand, 1040-1070 parts of gravel, 150-160 parts of drinking water and a high performance admixture, wherein the amount of the high performance admixture accounts for 1.7-1.8% of the total mass of a cementing material by mass percent. The self-compacting non-shrinkage concrete-filled steel tube provided by the invention has good self-compacting property, expansibility, fluidity, slump loss resistance,cohesiveness, segregation resistance and higher compression strength; furthermore, the expansion process and strength of concrete-filled steel tube are synergistically developed.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Self-compacting concrete and preparation method thereof

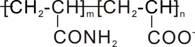

The invention discloses self-compacting concrete, which is prepared by taking low air entraining polycarboxylic acid and polyacrylamide as additives, taking continuous graded mineral waste rock of 5-20 millimeters as crude aggregate, taking mine waste rock of 0-5 millimeters as fine aggregate and using high-volume fly ash and mineral powder with a secondary feeding method. In the invention, the air entraining polycarboxylic acid and a polyacrylamide flocculent are taken as the additives, so that the defects of poor segregation resistance and poor stone coating property of self-compacting concrete in the conventional technology are overcome, the internal pore volume of freshly-mixed concrete paste matrix can be reduced remarkably, the paste matrix is more compact, and the compressive strength of the concrete is increased remarkably. In the invention, mine waste rock is adopted for completely replacing concrete aggregate, so that the utilization ratio of the mine waste rock is greatly increased, the cement using amount is reduced due to the application of the polyacrylamide, and the cost of the concrete is lowered. The flowing property, self-compacting property, pumping property anddemolded concrete representation of a self-compacting concrete mixture are superior to the prior art.

Owner:北京中联新航建材有限公司 +1

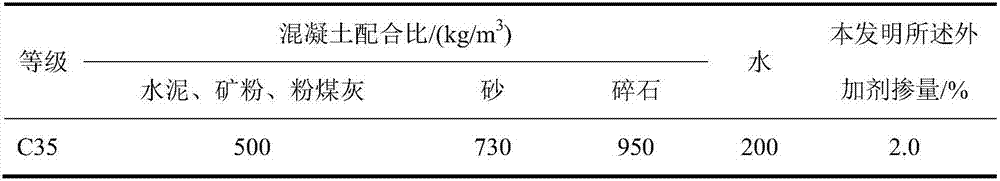

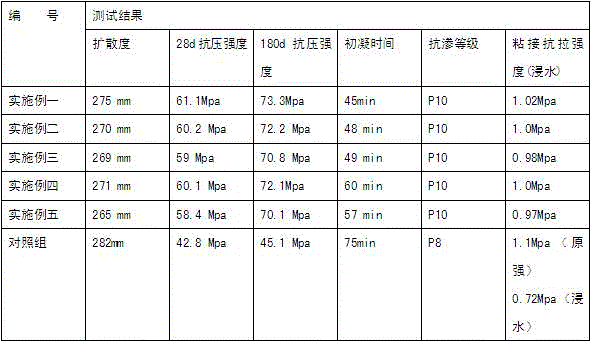

Retarding type high-fluidity high-strength underwater concrete additive and preparation method thereof

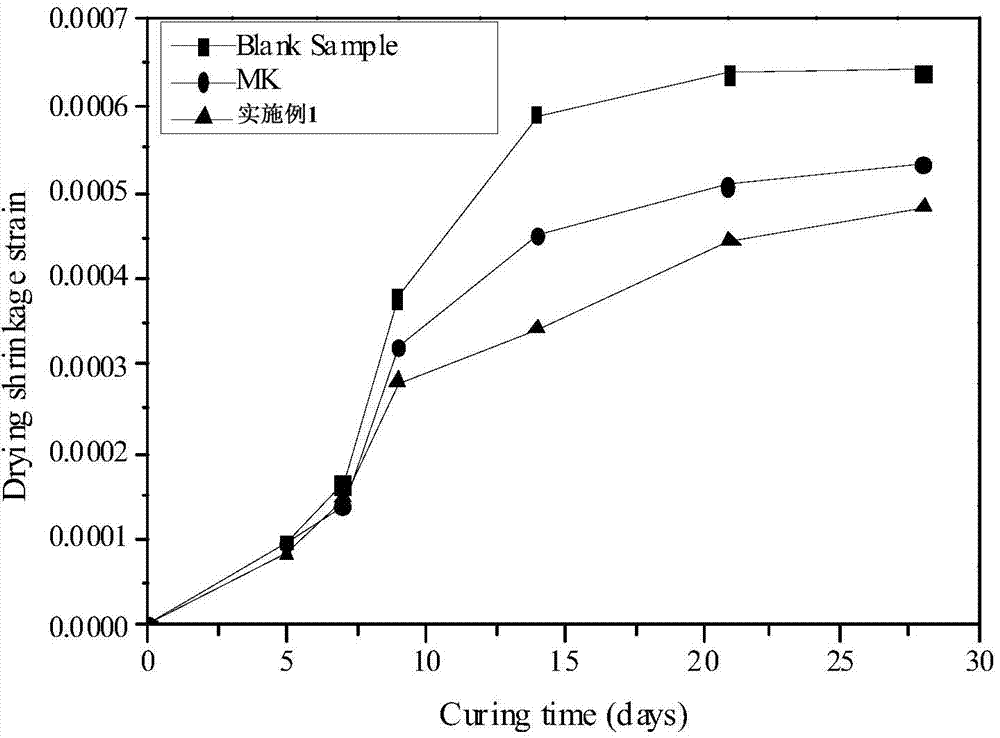

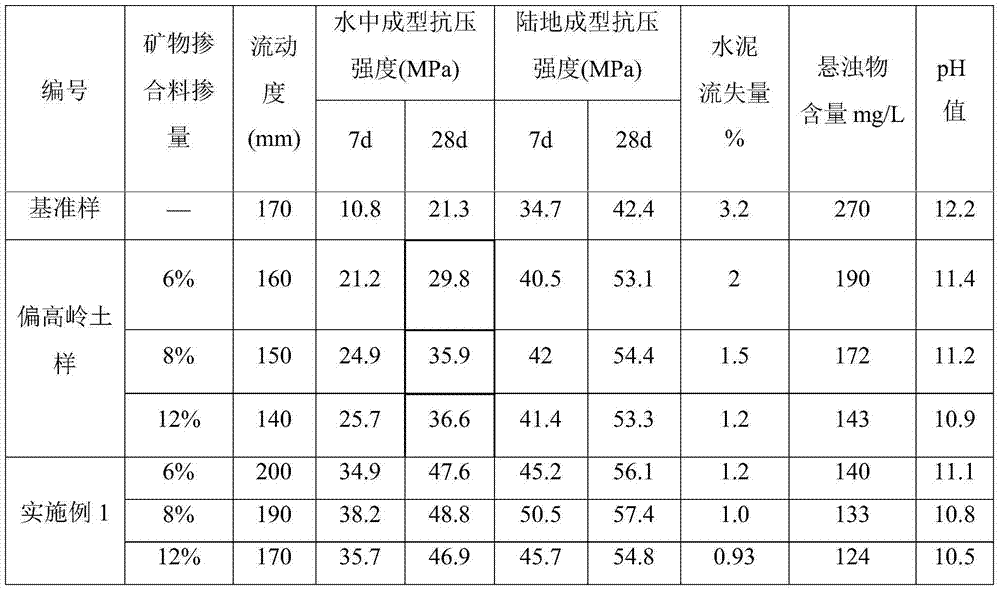

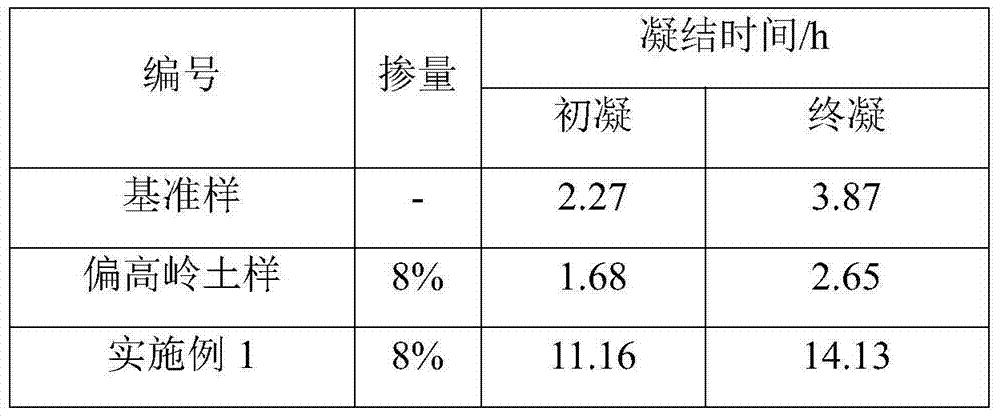

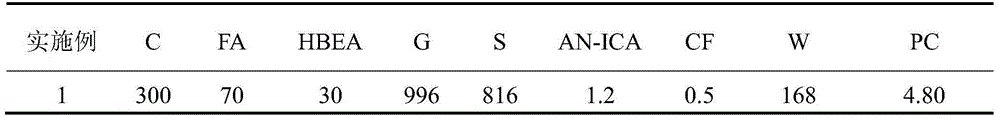

The invention belongs to the technical field of building materials, and particularly relates to a retarding type high-fluidity high-strength underwater concrete additive. The additive can effectively improve the strength and dispersion resistance of concrete and has the advantages of simple preparation process, low production cost and the like. The additive is characterized by comprising metakaolin and a composite modifier. The mass ratio of the metakaolin to the composite modifier is (50:1)-(15:1); the composite modifier is prepared by mixing 70-85% of polyacrylamide, 10-20% of superplasticizer and 5-15% of organic water-soluble polysaccharide substances all by mass based on a total of 100%. As an additive for underwater concrete, the additive can improve the working performance and dispersion resistance of underwater concrete and delay the setting time; and the strength at each age, particularly the early age strength of underwater concrete is remarkably improved. Meanwhile, the volume stability of underwater concrete can be effectively improved.

Owner:WUHAN UNIV OF TECH +1

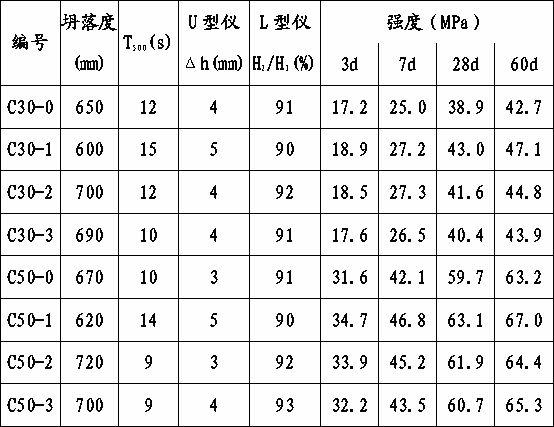

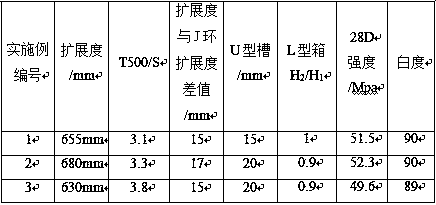

C30 self-compaction microexpanded concrete-filled steel tube and preparation method thereof

ActiveCN105084836ASolve the "out of the air" problemImprove cementing performanceSolid waste managementCelluloseCoal

The invention discloses a C30 self-compaction microexpanded concrete-filled steel tube and belongs to the field of building materials. The C30 self-compaction microexpanded concrete-filled steel tube is prepared by taking cement, coal ash, composite expansion agents, gravel, river sand, tackifying plasticity-maintaining ultra-dispersed additive, internal maintaining materials, micro-grade modified degreasing cotton cellulose and water as raw materials. The number of binding materials adopted in the C30 self-compaction microexpanded concrete-filled steel tube is small, and the C30 self-compaction microexpanded concrete-filled steel tube has the advantages of being good in self-compaction performance, low in gas content and high in durability, being slightly expanded and the like, is suitable for compact pouring of intensely reinforced large-pipe-diameter thin-wall steel tube concrete-filled steel tube underwater piles with complex shapes and a small section size, string tube pumping pouring of upper and lower concrete-filled steel tubes of concrete-filled steel tube truss bridges and high-throwing vibration-free pouring of concrete-filled steel tube pier studs. The problem of disengaging of the concrete-filled steel tube can be effectively solved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

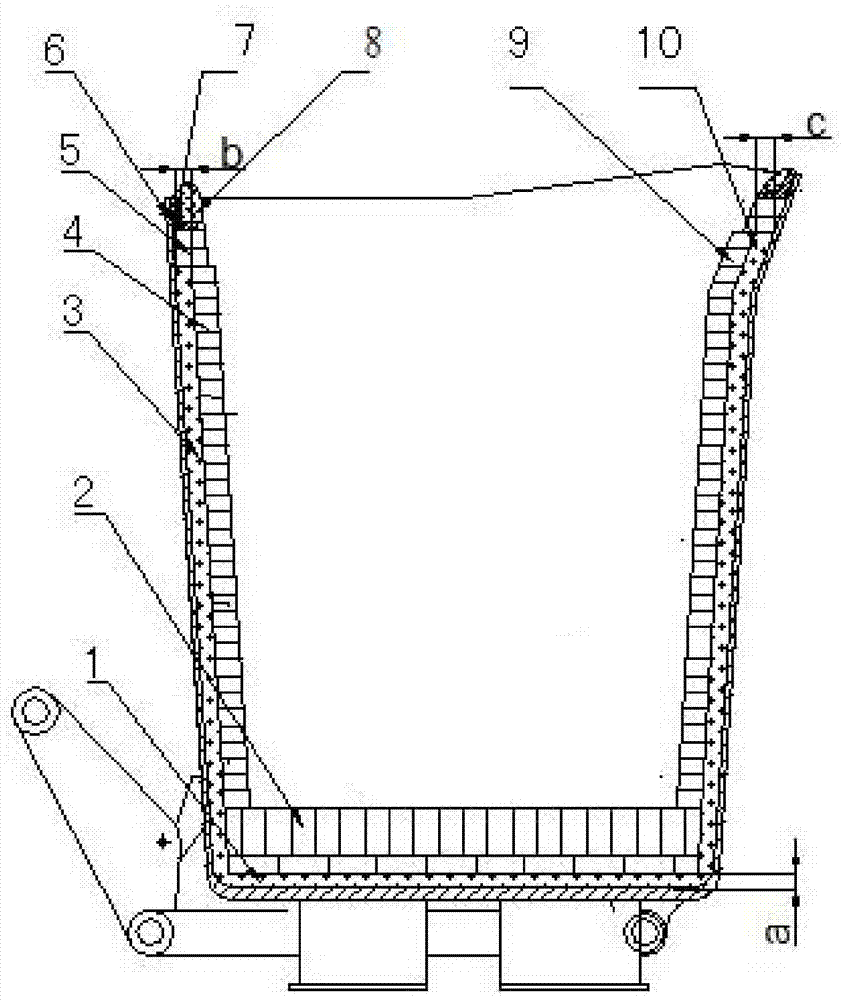

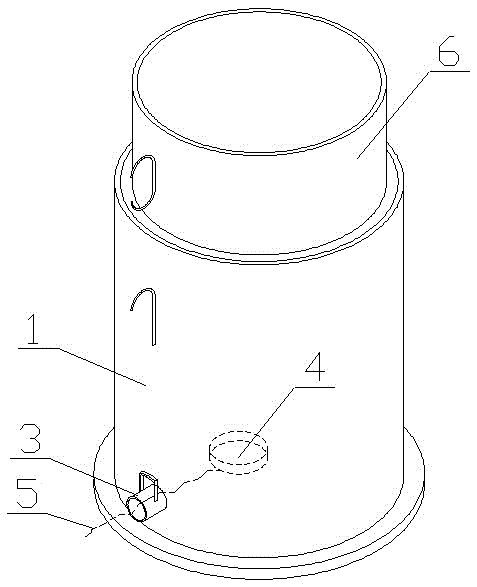

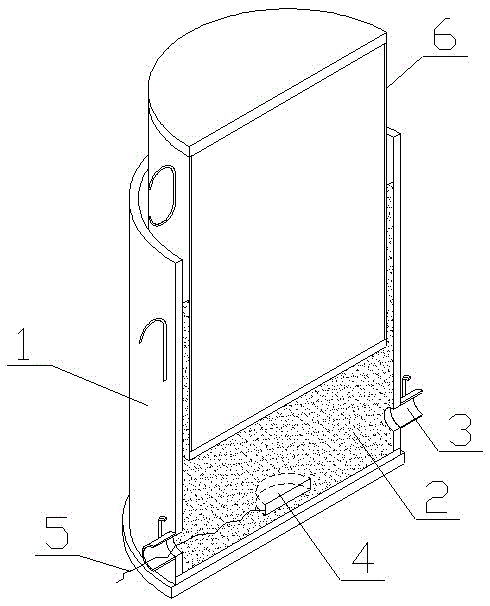

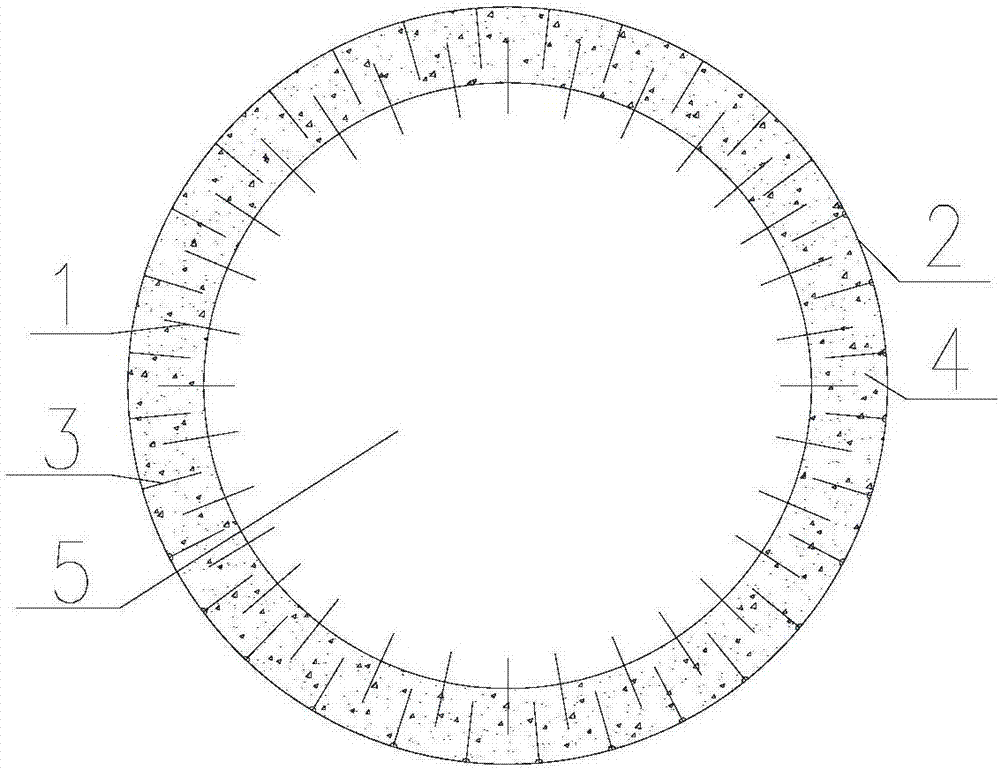

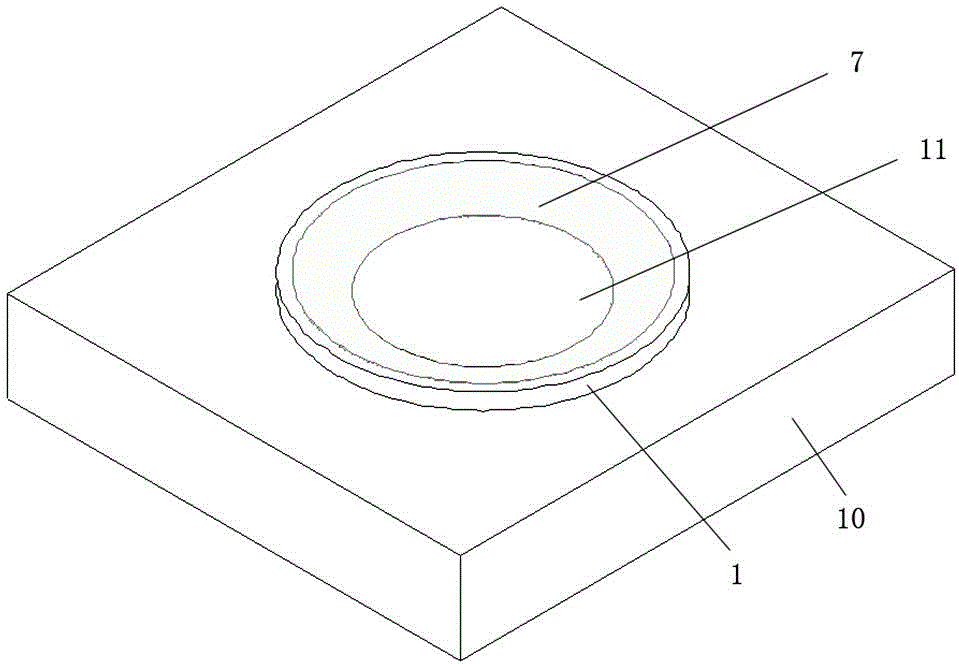

Ladle permanent lining and manufacturing method thereof

ActiveCN103785820AExtended service lifeSolve the problem of seeping steelMelt-holding vesselsBrickRefractory

The invention relates to a ladle permanent lining and a manufacturing method of the ladle permanent lining, and belongs to the technical field of ferrous metallurgy ladle lining fireproof material. The ladle permanent lining is laid on the inner wall of a shell (6) of a ladle and sequentially comprises a ladle bottom permanent lining (1), a ladle wall permanent lining (3) and a ladle nozzle permanent lining (10) from bottom to top. The ladle permanent lining is characterized in that the ladle permanent lining is manufactured by minimum-inflation artesian flow castable in a segmented casting mode, an overall casting forming die is not used, and the ladle permanent lining and a bricked working lining are constructed synchronously. The technological process of repairing and laying the ladle lining is simplified, the problem that in the prior art, the bricked working lining leaks steel because the high-aluminum artesian flow castable shrinks in the hardening process is solved, compared with the prior art, the service life of the ladle working lining is prolonged by 150 furnace round-200 furnace round, and the cost of ladle fireproof material is reduced by over 15%.

Owner:LAIWU IRON & STEEL GRP

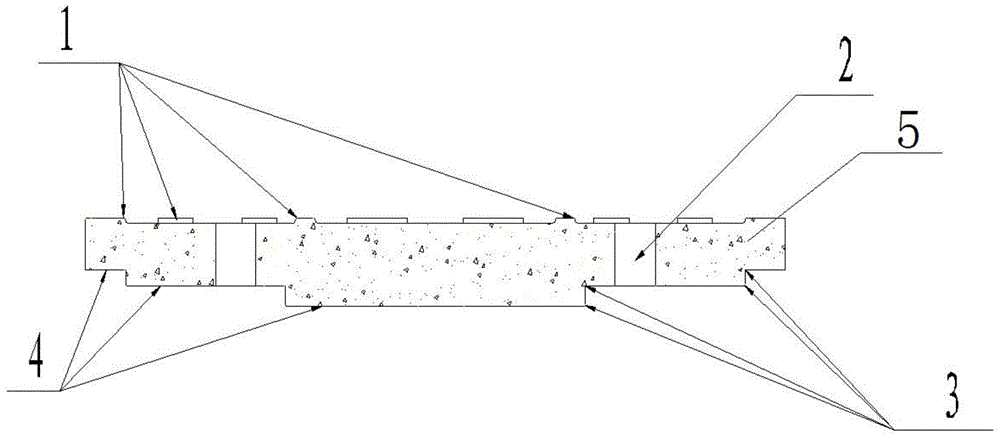

Unbalanced weight monitoring device and construction method for overall process of construction of hanging basket at upper part of horizontal rotation T structure

ActiveCN105484167AGood self-compactnessReduce settlementStatic/dynamic balance measurementBridge erection/assemblyWeight monitoringArchitectural engineering

Aiming at the defects of the existing bridge rotation construction monitoring method, the invention provides an unbalanced weight stress monitoring device and method for the overall process of construction of a hanging basket at the upper part of a horizontal rotation T structure. The monitoring device provided by the invention comprises outer sleeves of sand boxes, inner sleeves of the sand boxes, middle dry sand of the sand boxes and pressure boxes. The monitoring device is simple in structure, low in sand box cost and simple in manufacturing process. The monitoring device is simple in construction method, firm and stable in structure and easy to disassemble and clear after being used, and the cost of manpower and material resources can be saved. According to the invention, data can be read conveniently and reliably, thereby effectively ensuring the structure process safety.

Owner:HEFEI UNIV OF TECH +1

Underwater undispersed concrete flocculant

The invention belongs to the technical field of building materials, and particularly relates to an underwater undispersed concrete flocculant mainly composed of polyacrylamide, sodium dodecyl sulfate, cellulose ether, a polycarboxylate water reducer, silica fume and a fine-ground ore powder. The flocculant has quite strong dispersion resistance and relatively good fluidity, realizes self-leveling and self-compacting of the underwater concrete, inhibits dispersion of cement and aggregates during the underwater construction, besides, does not pollute construction water areas, and completely solves the influence of the old type flocculant unique 'flocculence' on construction machinery.

Owner:江西省建筑材料工业科学研究设计院

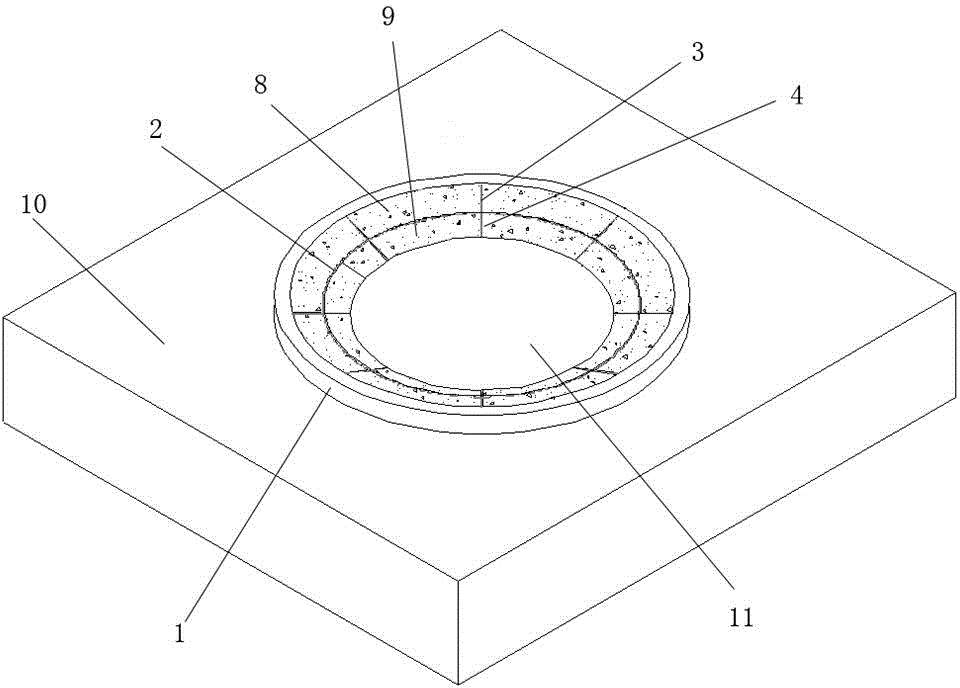

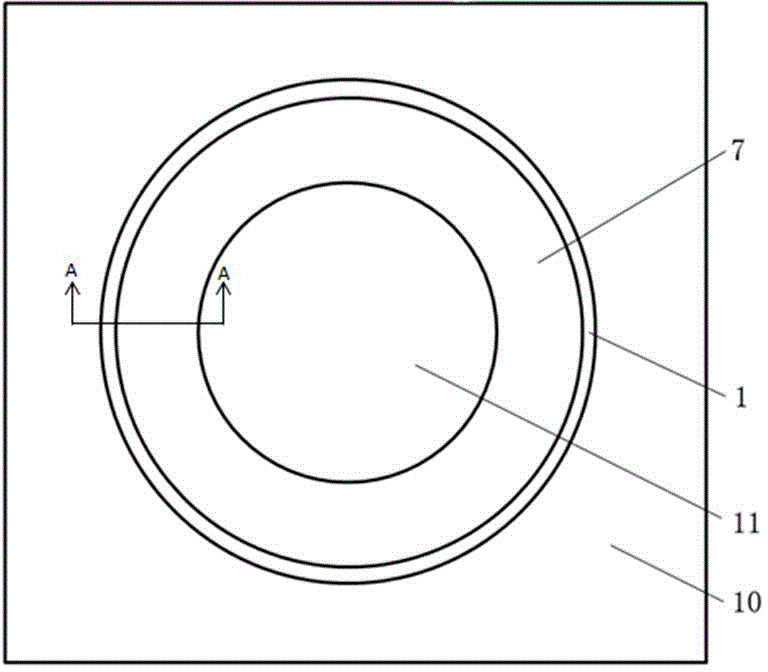

Method for reinforcing round-section pier by using polyurethane concrete materials and thin-wall steel sleeves

InactiveCN106869039AGood self-compactnessHealth time is shortBridge structural detailsBridge erection/assemblyQuincunxRebar

The invention relates to a method for reinforcing a round-section pier, in particular to the method for reinforcing the round-section pier by using polyurethane concrete materials and thin-wall steel sleeves. The method needs to solve the problem that in an existing frequently-used bridge reinforcing technique, the interface strength is insufficient, internal damage gaps can not be densely packed, the construction is tedious, the construction period is long, and the tensile strength and compressive strength of a component can not be improved at the same time. The method includes the following steps that a mortar layer on the surface of concrete on a concrete pier reinforcing part is chiseled away, and cleaning and drying are then conducted; connecting rebars are implanted in the concrete pier reinforcing part, and then welding shear nails are arranged according to the quincunx in semicircular thin-wall steel sleeves; every two of the semicircular thin-wall steel sleeves with the welding shear nails are oppositely welded to form the thin-wall steel sleeves on the surface of the concrete pier reinforcing part, the polyurethane concrete materials are prepared and poured in the thin-wall steel sleeves, and curing is conducted under natural conditions. The method is used for reinforcing the round-section pier by using the polyurethane concrete materials and the thin-wall steel sleeves.

Owner:NORTHEAST FORESTRY UNIVERSITY

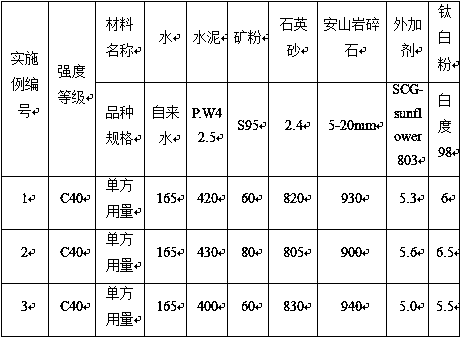

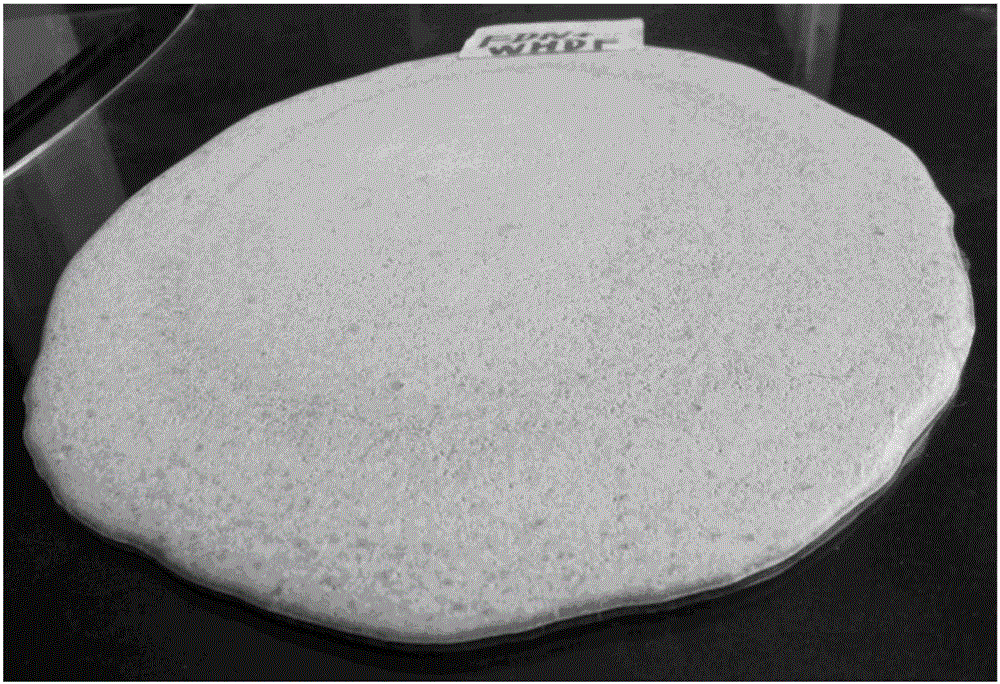

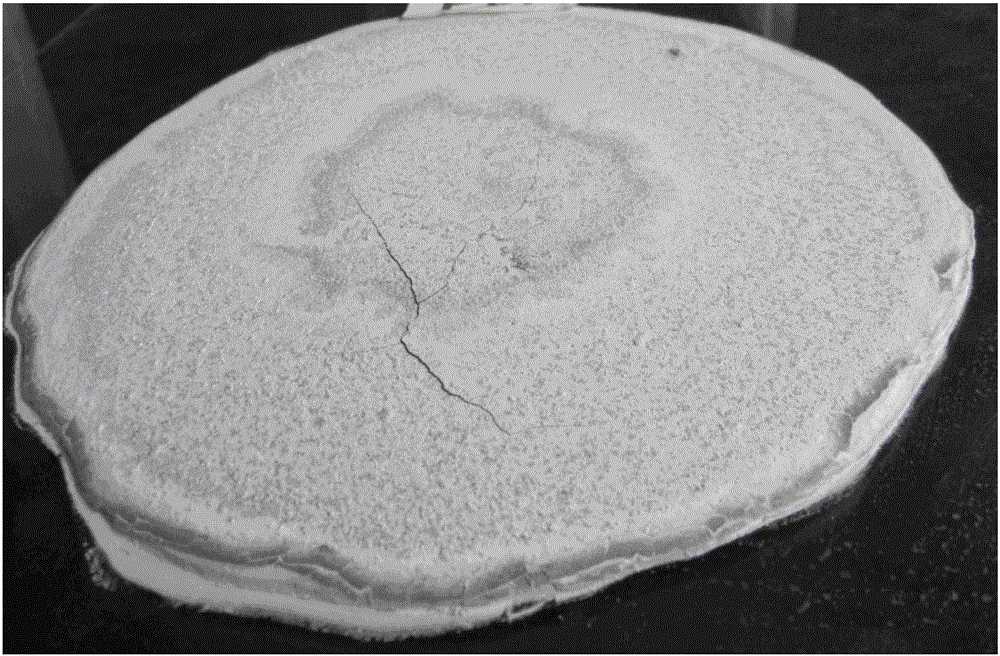

White self-compacting C40-pumping fair-faced concrete

The invention discloses white self-compacting C40-pumping fair-faced concrete including the components of: 350-430 kg / m<3> of cement, 50-80 kg / m<3> of slag micropowder, 790-830 kg / m<3> of quartz sand,5-6 kg / m<3> of additives, 155-165 kg / m<3> of blending water, 5-8 kg / m<3> of TiO2 pigment and 900-940 kg / m<3> of crushed andesite rock. The concrete has the performances of high flowability and self-compacting effect of regular self-compacting concrete and has a pure-white appearance that does not change along with time. The product also has the surface performances of fair-faced concrete, is lessin bubbles and has homogeneous color, so that the product has great application value in the field of decorative concrete. The concrete can serve as a structural concrete base material in an integrated shaping manner, is free of decoration on concrete surface, can save coatings and reduce manpower cost, and satisfies the green-construction idea in our country.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

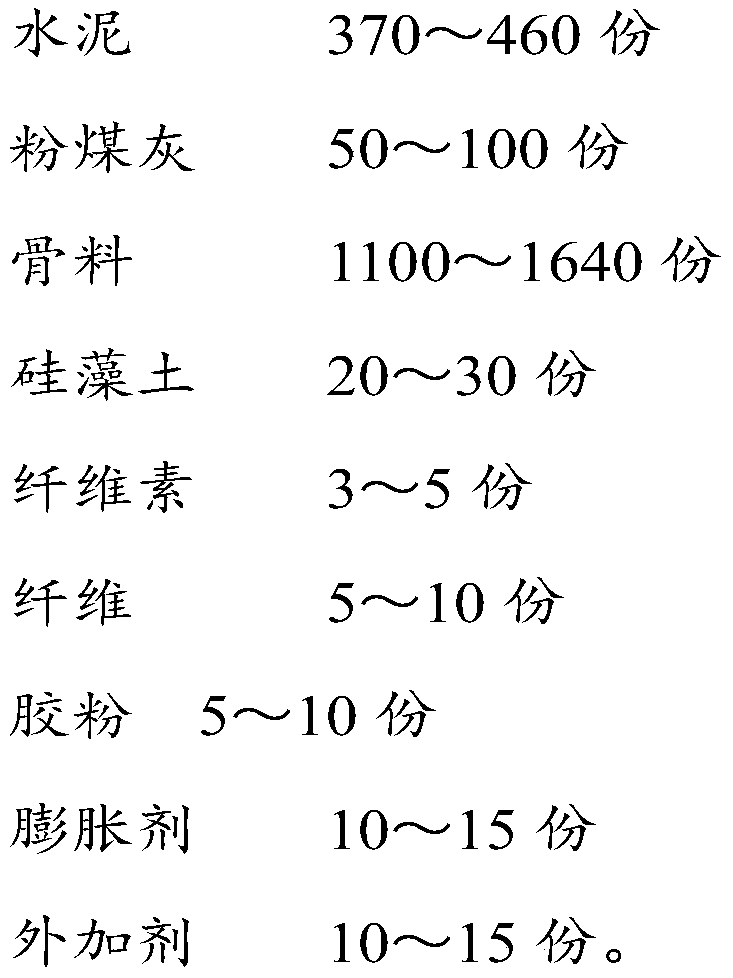

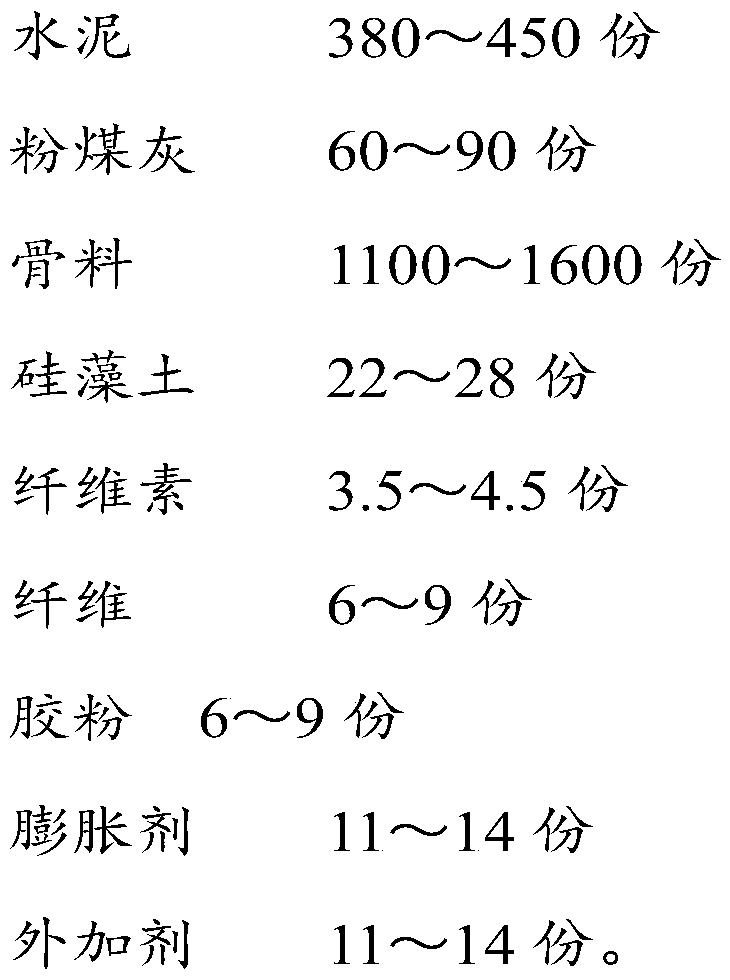

Fair-faced concrete and preparation method thereof

The invention provides fair-faced concrete and a preparation method thereof and relates to the field of building materials. The fair-faced concrete comprises the following raw materials in parts by weight: 370-460 parts of cement, 50-100 parts of fly ash, 1250-1640 parts of aggregate, 20-30 parts of diatomite, 3-5 parts of cellulose, 5-10 parts of fiber, 5-10 parts of rubber powder, 10-15 parts ofan expanding agent and 10-15 parts of an additive. According to the invention, the technical problem of lack of fair-faced concrete with good fluidity and high appearance quality after pouring in thedomestic market can be solved, and the purpose of improving the effect of the fair-faced concrete after pouring is achieved.

Owner:江西蓝宝新材料有限公司

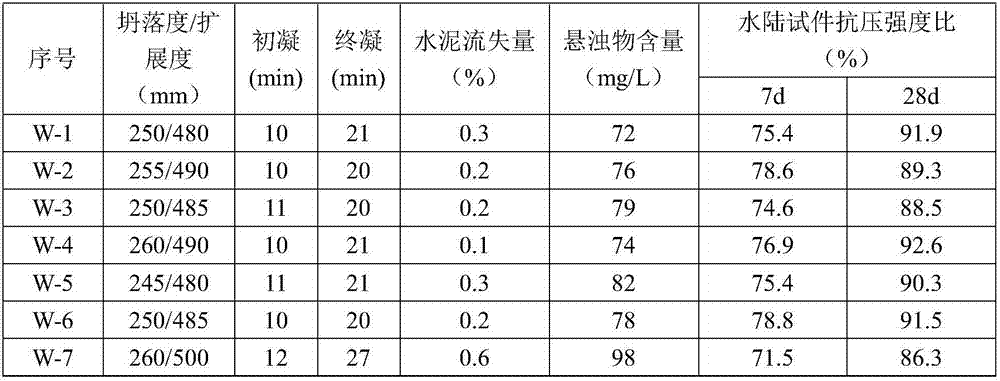

Multi-component concrete composite repair mortar

InactiveCN111875322AImprove liquidityGood self-compactnessStructural engineeringUltimate tensile strength

The invention belongs to the technical field of prefabricated building application, and particularly discloses multi-component concrete composite repair mortar, which is prepared from the following multiple mixtures according to a certain proportion: a cementing material, a mineral admixture, a plastic expanding agent and a functional additive; when multi-component concrete composite repair mortaris prepared from dry powder composed of the cementing material, the mineral admixture, the plastic expanding agent and the functional additive, the multi-component concrete composite repair mortar isprepared by stirring the dry powder and water according to the ratio of 0.11-0.16. The multi-component concrete composite repair mortar disclosed by the invention has the beneficial effects of good fluidity, strong self-compaction, high early strength, micro-expansion in volume, no collapse in later strength and good durability, and has the advantages of quick setting, quick hardening and strongconstruction adaptability.

Owner:江苏智信达建筑科技有限公司

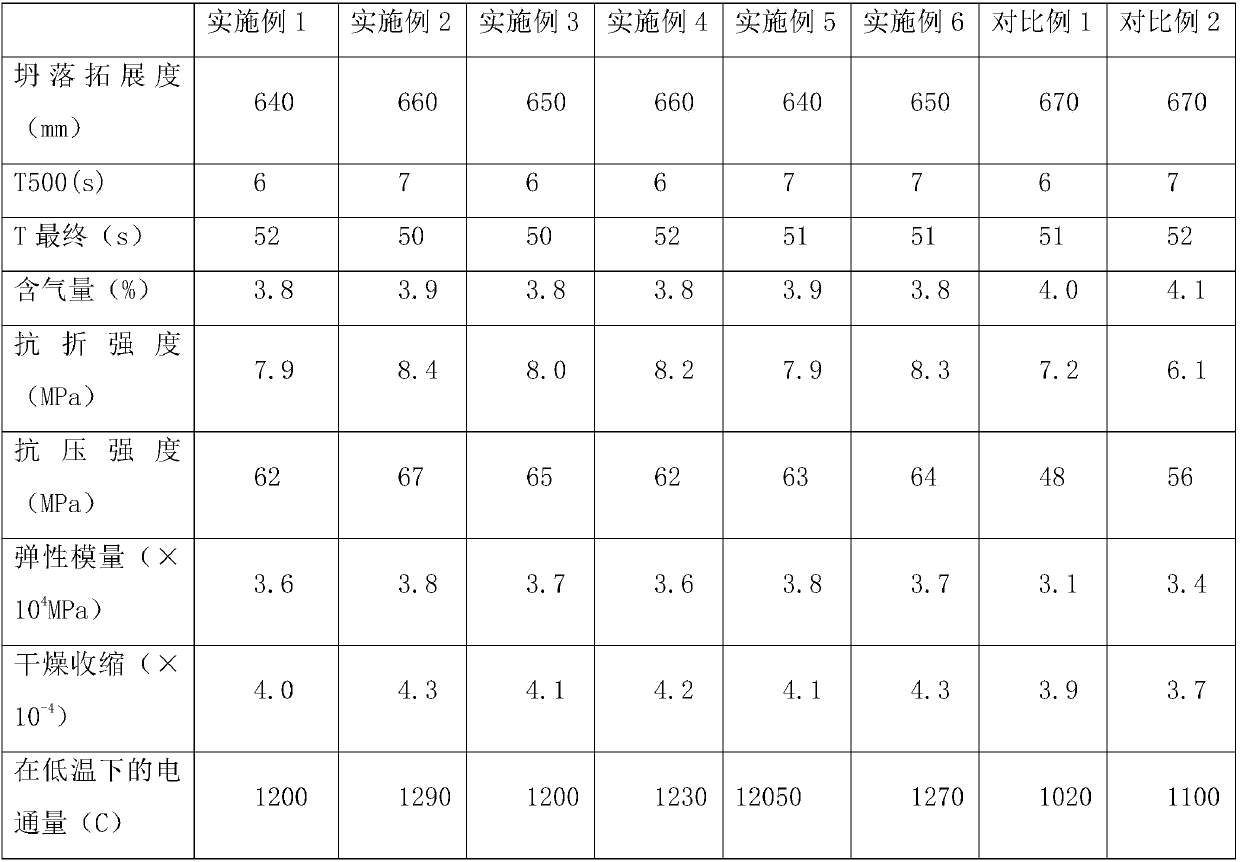

Non-dispersible underwater concrete additive, preparation method, and application thereof

ActiveCN106946492AImprove work performanceExcellent dispersion resistanceReducing agentMaterials science

The invention discloses a non-dispersible underwater concrete additive, which mainly includes a modified flocculating agent solution, a polycarboxylate water reducing agent A, a polycarboxylate water reducing agent B, a defoamer and an air entraining agent according to the following ratio, by mass, 75-93% of the modified flocculating agent solution, 5-12% of the polycarboxylate water reducing agent A, 2-10% of the polycarboxylate water reducing agent B, 0.02-0.6% of the defoamer, and 0.01-0.5% of the air entraining agent. The additive can effectively improve cohesiveness of the underwater concrete, guarantees strength of the concrete in an underwater environment, and effectively improve workability of the concrete.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Special high-performance additive for underwater masonry mortar

The invention discloses a special high-performance additive for underwater masonry mortar. The special high-performance additive is composed of, by weight, 2-5 parts of a thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of a thixotropic agent, 5-8 parts of special cement, 12-15 parts of a set controlling agent and 5-8 parts of an early strength agent. In the special high-performance additive for the underwater masonry mortar, the thickening agent can improve the adhesiveness of a mixed product, and therefore the underwater non-disperse mortar is endowed with the properties of dispersing and separating resistance. The super plasticizer can improve the fluidity and workability of the mixed product, and therefore the material is endowed with good self-leveling and self-compacting properties. The frequently-used super plasticizer mainly includes sulfonated resin or sulfonate, and therefore the material has the properties of underwater dispersing and separating resistance. Through the combined action of the doped special cement and the set controlling agent, the material is endowed with early strength and rapid hardening.

Owner:北京建工新型建材有限责任公司

Fair-faced concrete and preparation method thereof

InactiveCN112341076ASimple manufacturing methodEasy to operate and controlAggregate (composite)Metal-organic framework

The invention discloses fair-faced concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 30-40 parts of cement, 15-25 parts of volcanicash, 3-6 parts of nano hybrid hyperbranched polymer HB-SiO2, 75-85 parts of silica sand, 85-95 parts of coarse aggregate, 3-5 parts of basalt fibers, 1-3 parts of graphene oxide fibers, 7.5-8.5 partsof a composite additive, 15-20 parts of water, 1-3 parts of a carboxyl metal organic framework, 1-3 parts of zirconium citrate and 2-5 parts of zinc oxide nanofibers. The invention also provides a preparation method of the fair-faced concrete. The fair-faced concrete provided by the invention is better in comprehensive performance, higher in compressive strength and flowability, lower in bleedingrate, better in durability, environmental protection property and decorative effect, very good in appearance, smooth in surface and less in pores.

Owner:韩昌龙

Masonry mortar used in underwater alkaline environment

The invention discloses masonry mortar used in an underwater alkaline environment. The masonry mortar comprises the following components, according to a weight ratio, 180-220 parts by weight of Portland cement, 30-50 parts by weight of special cement, 705-715 parts by weight of natural medium sand, 13-18 parts by weight of resin glue powder, and 30-40 parts by weight of a special additive. The special additive is mixed from 2-5 parts by weight of a thickening agent, 0.5-1 part by weight of a super-plasticizer, 5-8 parts by weight of a thixotropic agent, 12-15 parts by weight of an adjusting admixture, and 5-8 parts by weight of an early strength agent. The masonry mortar is adjusted by high-performance additives special for underwater masonry mortar, and resin materials good in alkaline resistance are added, so that the masonry mortar is prevented from undergoing a reaction in the alkaline condition, and hardening and mortar performance aren't affected. At last, the masonry mortar is not prone to disperse, good in construction, resistant to alkaline, normal in underwater hardening, and high in strength in a working condition with water.

Owner:北京建工新型建材有限责任公司

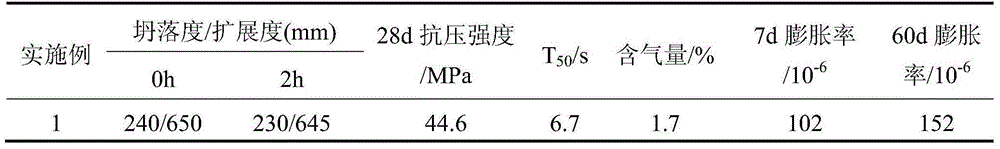

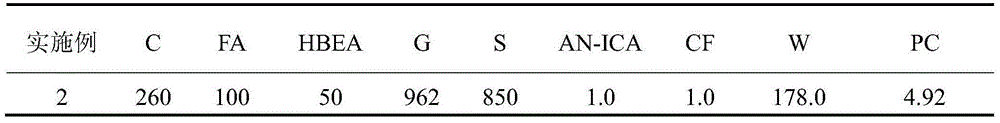

Preparation and application of dry-mixed mortar for asphalt carbon fiber cement-based self-compaction concrete of slab ballastless track

The invention provides preparation and application of dry-mixed mortar for asphalt carbon fiber cement-based self-compaction concrete of a slab ballastless track. A specific preparation method comprises the following steps: oxidizing asphalt carbon fibers in the air and carrying out immersion treatment in a toluene solution containing epoxy resin to obtain pre-treated asphalt carbon fibers; crushing rubber powder; activating by low-temprature plasma and treating by utilizing a silane coupling agent water solution to obtain activated rubber powder; stirring the asphalt carbon fibers and the activated rubber powder to form a mixed modifier; after slowly stirring cement, a mineral admixture and fine aggregate, adding the mixed modifier, a water-reducing and slump-loss-reducing component, a foaming component and an adhesive aggregation regulator in sequence; rapidly stirring to obtain the dry-mixed mortar for the asphalt carbon fiber cement-based self-compaction concrete of the slab ballastless track. The dry-mixed mortar for the self-compaction concrete, prepared by the preparation method, has excellent elasticity and modulus and low temperature lasting quality and can be used for thefields of slab ballastless tracks, transportation track engineering, building engineering and the like.

Owner:浙江省通用砂浆研究院 +1

High-perturbance underwater masonry mortar

High-perturbance underwater masonry mortar is prepared from, by mass, 50 parts of special rapid hardening cement, 220 parts of Portland cement, 15 parts of resin rubber powder, 675-685 parts of natural medium sand, 30-40 parts of an anti-perturbance additive and 40-50 parts of waterborne epoxy resin. The anti-perturbance additive is prepared from, by mass, 1-5 parts of silica powder, 2-5 parts of hydroxypropyl methylcellulose, 0.5-1 part of a super plasticizer, 5-8 parts of a thixotropic agent, 5-8 parts of special rapid hardening cement, 12-15 parts of a flocculating agent and 5-8 parts of an early strength agent. By adding the special rapid hardening cement, the underwear initial setting time of the mortar is short; by adding the waterborne epoxy resin and the silica powder, the surface of the mortar has high affinity, and the mortar is suitable for underwater repair. The high-perturbance underwater masonry mortar is reasonable in formula and convenient to prepare and use, and has the advantages of being not likely to disperse, easy to construct, capable of normally hardening underwater, high in strength and the like in work with water.

Owner:北京建工新型建材有限责任公司

Masonry mortar for underwater acid environment

The invention discloses masonry mortar for an underwater acid environment. The masonry mortar comprises, by weight, 180-220 parts of common cement, 30-50 parts of special cement, 695-705 parts of natural medium sand, 20-30 parts of resin adhesive powder and 30-40 parts of special additives, wherein the special additives are mixed by, by weight, 2-5 parts of thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of thixotropic agent, 12-15 parts of thickening time control agent and 5-8 parts of early strength agent. The masonry mortar has the advantages that by regulating the additives special for high-performance underwater masonry mortar and adding resin materials good in acid resistance, masonry mortar components are prevented from have reaction under acid conditions, the hardening and performance of the mortar cannot be affected, and the masonry mortar is less prone to dispersing, good in constructability, resistant to acid, capable of being normally hardened under water and high in strength under water operation conditions.

Owner:北京建工新型建材有限责任公司

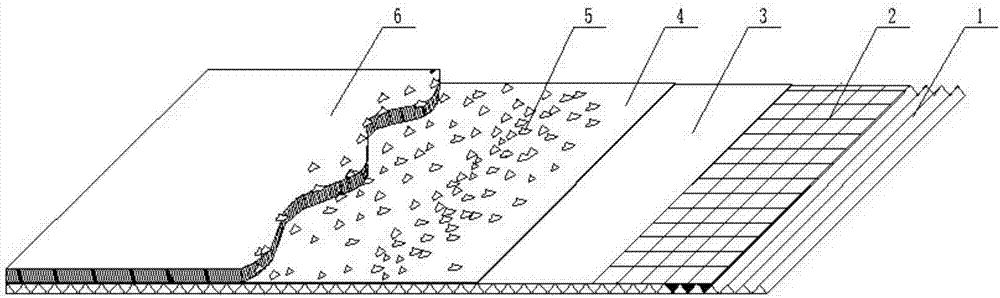

Combined bridge deck structure and construction method thereof

InactiveCN107059614APlay a waterproof roleGood self-compactnessClimate change adaptationBridge structural detailsBridge deckEngineering

The invention discloses a combined bridge deck structure and a construction method thereof. The combined bridge deck structure comprises a steel plate, an equal leg angle with the corrugated surface, a mesh layer, a first adhesive layer, a gravel layer, a second adhesive layer and an ECC material layer, wherein the equal leg angle is welded to the steel plate, the mesh layer is arranged on the upper side of the equal leg angle, the first adhesive layer is arranged inside meshes of the mesh layer, the gravel layer is arranged above the first adhesive layer, the second adhesive layer is arranged above the gravel layer, and the ECC material layer is located above the second adhesive layer. ECC is used for replacing existing concrete, the structural safety, durability and continuity can be improved.

Owner:INNER MONGOLIA UNIV OF TECH

WHDF-N type viscosity modifier applicable to self-compacting concrete

InactiveCN106517856AIncreased hydrationInhibit early rapid hydrationCrack resistanceTricalcium aluminate

The invention provides a WHDF-N type viscosity modifier applicable to self-compacting concrete. The WHDF-N type viscosity modifier comprises components in percentage by weight as follows: 15%-25% of a crystallization excitation component, 7%-13% of an activity excitation component, 10%-15% of a tricalcium aluminate inhibition component, 6%-14% of a workability regulation component, 2%-6% of an anti-microbe component and 30%-40% of water. Under actions of promoting cement hydration degree, optimizing a hydration product, inhibiting early rapid hydration of tricalcium aluminate, reducing early hydration heat and the like, the WHDF-N type viscosity modifier has the advantages that gel of a system is increased, pores are reduced, an aggregate interface structure and early hydration heat are improved, and the workability and self-compacting performance of a concrete mixture are improved effectively while the crack resistance, impermeability and durability of the concrete are improved remarkably.

Owner:武汉天衣新材料有限公司

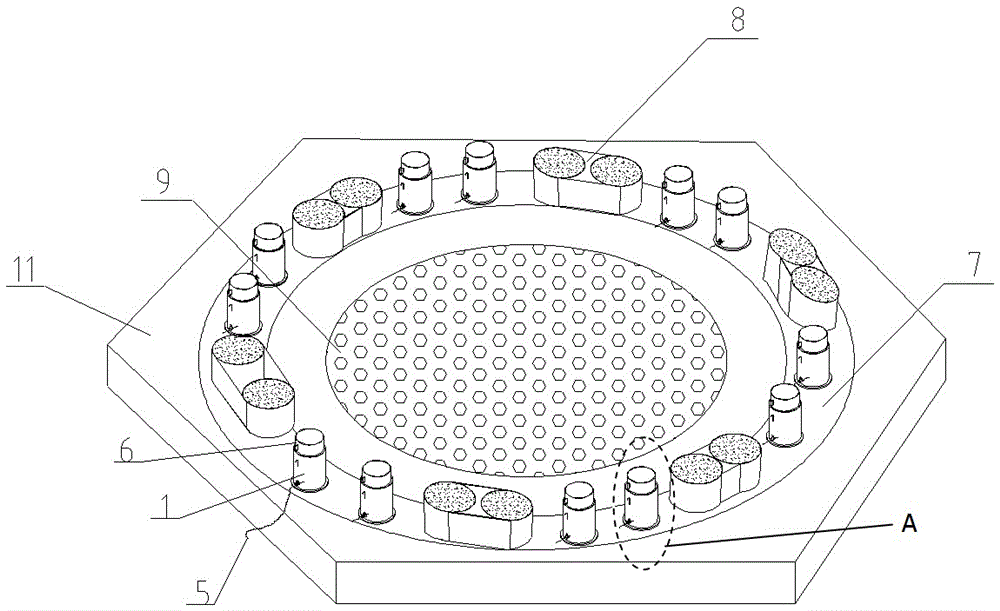

Membrane frame for constructing lower spherical segment of swivel bridge rotary table and construction method

ActiveCN104562939AReduce construction costsEasy to makeBridge erection/assemblyArchitectural engineeringSuper structure

The invention provides a membrane frame for constructing a lower spherical segment of a swivel bridge rotary table and a construction method, which is used for solving the difficulty in the swivel body construction that a template is poor in strength, likely to deform and difficult to disassemble. The membrane frame consists of a main ring body, a quasi ring body, a first supporting body, a second supporting body, a bottom cushion layer, a top first cover layer, a top second cover layer, a first filling member and a second filling member. The construction method comprises six steps of building the main ring body, laying a plastic film, embedding an annular foam plate and a radial foam plate, filling medium coarse sand, forming the top first cover layer in a folding way, and smearing sand pulp on the surface. The memberane frame and the construction method have the beneficial effects that the construction cost is low, the production is simple, the deformation is unlikely to occur, the stability is high, the construction precision of the upper building at a later period can be guaranteed, and the later maintenance work is simple.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

High durable underwater non-dispersible concrete flocculant

The invention discloses a durable underwater non-dispersible concrete flocculant. A preparation method of the durable underwater non-dispersible concrete flocculant comprises mixing and grinding a polyacrylamide solution, a polydimethyldiallyl ammonium chloride solution, sodium lauryl sulfate and a concrete super plasticizer according to a certain ratio and carrying out detection through the DLT 5117-2000 Underwater Dispersion Concrete Test Regulations. The durable underwater non-dispersible concrete has high curing efficiency, good hardening strength, a high water reduction rate of 20% and good concrete cohesiveness, is easy to stir, has good anti-freezing durability, is conducive to the construction of large-volume concrete, significantly reduces concrete shrinkage, has good product stability, prevents layering in long-term storage and prevents precipitation phenomenon.

Owner:DALIAN UNIV OF TECH

A special admixture for high-performance underwater masonry mortar

The invention discloses a special high-performance additive for underwater masonry mortar. The special high-performance additive is composed of, by weight, 2-5 parts of a thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of a thixotropic agent, 5-8 parts of special cement, 12-15 parts of a set controlling agent and 5-8 parts of an early strength agent. In the special high-performance additive for the underwater masonry mortar, the thickening agent can improve the adhesiveness of a mixed product, and therefore the underwater non-disperse mortar is endowed with the properties of dispersing and separating resistance. The super plasticizer can improve the fluidity and workability of the mixed product, and therefore the material is endowed with good self-leveling and self-compacting properties. The frequently-used super plasticizer mainly includes sulfonated resin or sulfonate, and therefore the material has the properties of underwater dispersing and separating resistance. Through the combined action of the doped special cement and the set controlling agent, the material is endowed with early strength and rapid hardening.

Owner:北京建工新型建材有限责任公司

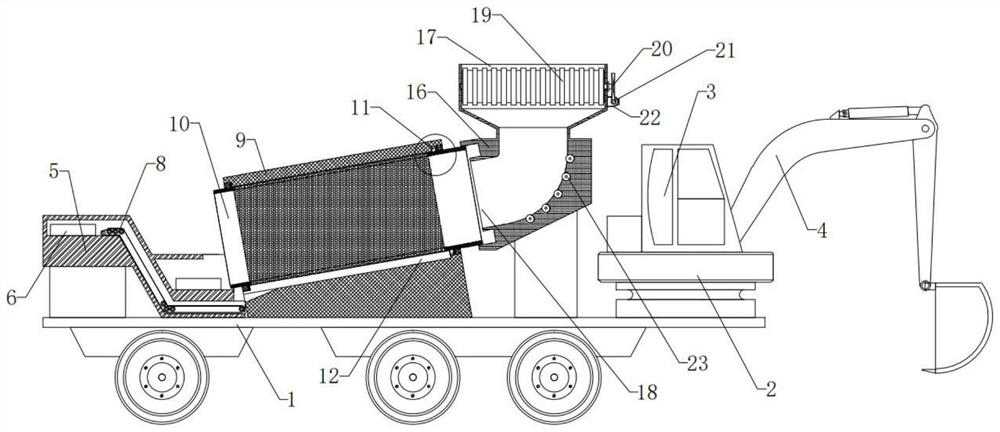

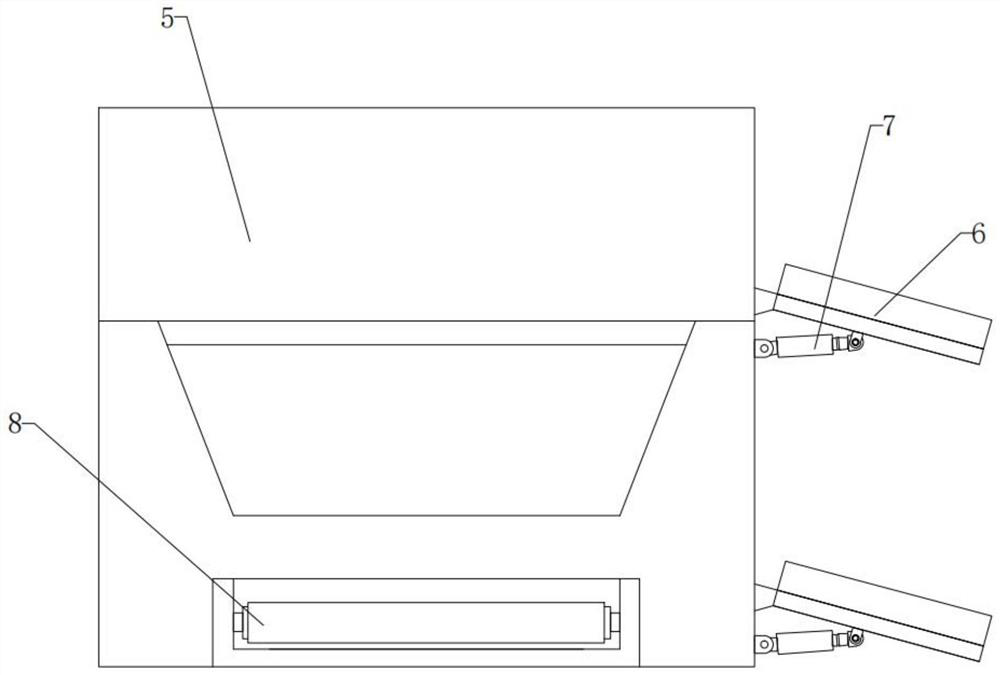

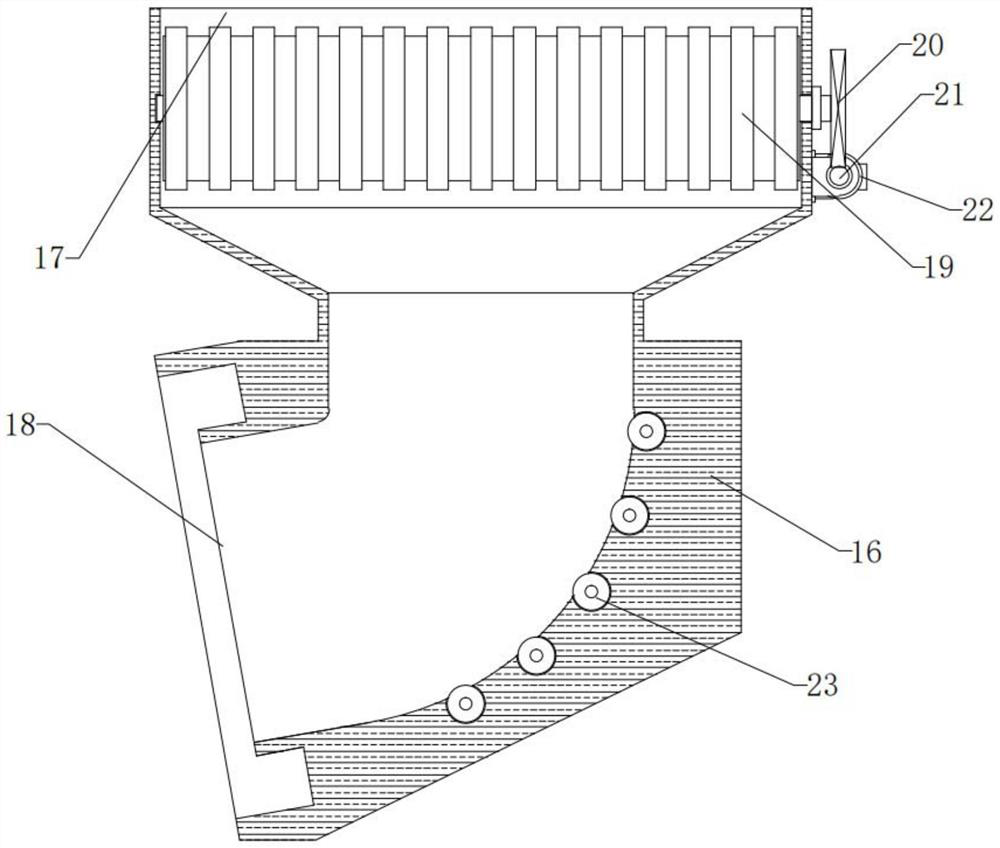

Production process for producing flow-state self-compacting backfill solidified soil by using solidifying material, application and equipment thereof

PendingCN114716205AReduce shippingReduce the storage areaSolid waste managementEmbankmentsPtru catalystSoil science

The invention discloses a production process, application and equipment for producing flow-state self-compacting backfill solidified soil by using a solidifying material, which comprises the following steps: taking soil, sludge and building residue soil as main solidifying materials, taking a catalyst and a solidifying agent as catalytic materials, taking tailings such as Portland cement, fly ash, phosphogypsum and lithium slag as auxiliary cementing materials, and adding a certain proportion of water, the mixture which has flowability and self-compaction performance and has certain strength and impermeability after being cured is formed, and the mixture can be widely applied to fertilizer groove backfilling, foundation reinforcement, road subgrade backfilling, mine goaf backfilling, municipal pipe gallery backfilling and wall decoration; according to different requirements of component properties of soil and strength of a finished product, the mass percent of each component material is as follows: 70-80% of soil; 5%-10% of a catalyst; 0.05% to 0.10% of a curing agent; 10%-20% of an auxiliary cementing material; the flowability and the water required by the reaction process are met. The material not only has high strength, but also has good flowability and water stability, is convenient to construct, is green and environment-friendly, and has a good application prospect.

Owner:中建三局四川建筑装备有限公司 +1

High-strength self-compacting concrete and preparation method thereof

The invention relates to the technical field of concrete, and particularly discloses high-strength self-compacting concrete and a preparation method thereof. The concrete is prepared from the following raw materials, by weight: cement, coal ash, mineral powder, fine aggregate, coarse aggregate, a water reducing agent, an expanding agent, water, diatomite and modified sepiolite powder. The invention also discloses a preparation method of the concrete. The method comprises the following steps: mixing the coarse aggregate and fine aggregate, adding the diatomite and modified sepiolite powder, anduniformly performing mixing to obtain a first mixture; mixing cement, fly ash and mineral powder to obtain a second mixture; mixing the water reducing agent, the water and the expanding agent to obtain an admixture solution, and stirring and mixing the admixture solution, the first mixture and the second mixture. Therefore, the obtained self-compacting concrete has excellent strength and self-compacting performance, the self-shrinking performance is improved, and the cracking possibility caused by self-shrinking is reduced.

Owner:北京天地建设砼制品有限公司

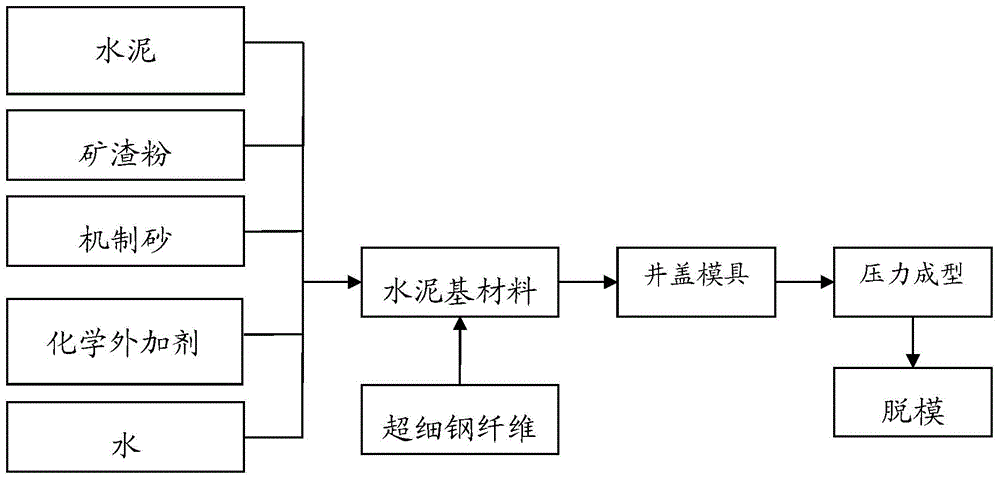

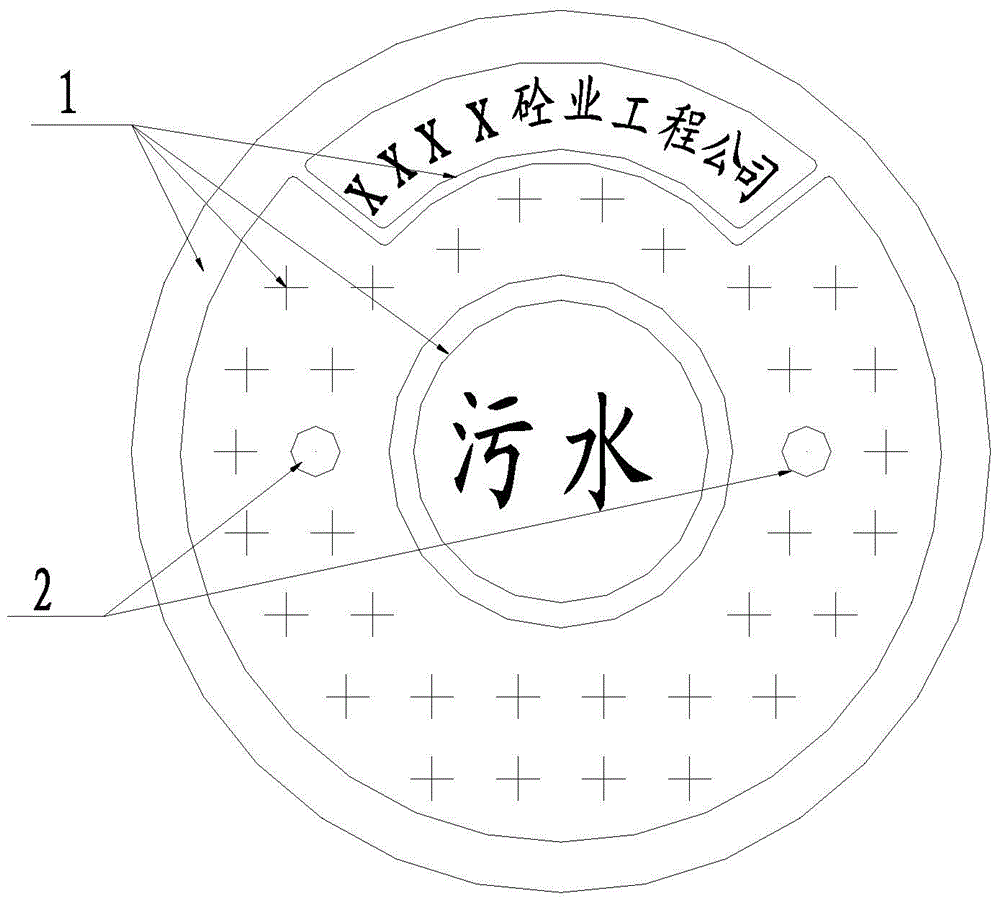

Super-strength steel-fiber cement-based material inspection well lid and making method thereof

InactiveCN104831753AGood self-compactnessHigh strengthArtificial islandsUnderwater structuresChemical admixtureSlag

The invention belongs to the technical field of inspection well lid making, and relates to a super-strength steel-fiber cement-based material inspection well lid and a making method thereof. Anti-skid strips are arranged on the surface of a lid body. Installation holes are formed in the two sides of the middle of the surface of the lid body. Steps of a three-layer structure are formed on the bottom face of the lid body from inside to outside. Arc chamfers are formed at the corners between the adjacent steps. The making method includes the steps that cement, slag powder and machine-made sand are dryly mixed to obtain dryly-mixed materials, then chemical additives and water are mixed to be added into the dryly-mixed materials to be stirred to form cement-based materials, ultra-fine steel fibers are added into the cement-based materials to be stirred, ultra-fine steel fiber cement-based materials are made to be poured into an inspection well lid mold, the inspection well lid mold with the ultra-fine steel fiber cement-based materials is pressed to be maintained, and the super-strength steel-fiber cement-based material inspection well lid is made. By means of the super-strength steel-fiber cement-based material inspection well lid and the making method, the structure is simple and practical, operation is convenient, the labor resources are saved, and the made inspection well lid is high in pressing resisting strength, low in making cost and good in anti-theft performance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com