Super-strength steel-fiber cement-based material inspection well lid and making method thereof

A technology of cement-based materials and fiber cement, which is applied in water conservancy projects, underwater structures, infrastructure engineering, etc., can solve problems such as easy theft and high noise, and achieve convenient operation, good wear resistance, and good anti-theft performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

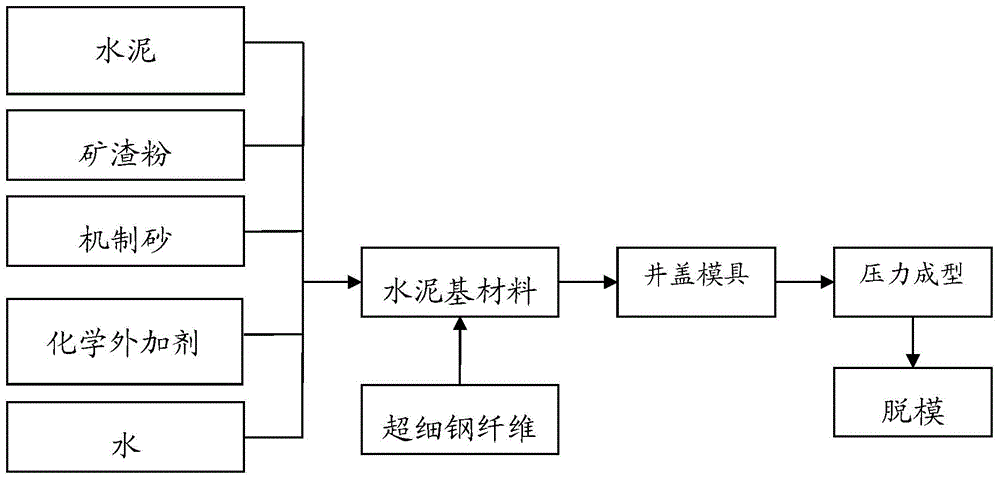

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the ultra-high-strength steel fiber cement-based material is composed of P.I.52.5 cement, S95 grade slag powder, machine-made sand, chemical admixture, ultra-fine steel fiber and water, and the ultra-high-strength steel fiber cement-based material per cubic meter of the cementitious material The mass occupied is one quality unit, among which P.I.52.5 cement accounts for 0.7 of the unit cementing material, S95 grade slag powder accounts for 0.3 of the unit cementing material, water accounts for 0.2 of the unit cementing material, and machine-made sand accounts for 1.0 of the unit cementing material , the chemical admixture accounts for 0.02 of the unit cementitious material, and the superfine steel accounts for 0% of the unit cementitious material. First, dry mix cement, slag powder and machine-made sand for 1 to 2 minutes to obtain the dry mixture, and then add the chemical admixture Add the dry mix into the mixing water, stir for 1-5 minutes to form ...

Embodiment 2

[0034]The ultra-high-strength steel fiber cement-based material used in this embodiment is a molding material made of P.I.52.5 cement, S95 grade slag powder, machine-made sand, chemical admixtures, ultra-fine steel fibers and water. The mass of steel fiber cement-based materials is a mass unit, of which cement accounts for 0.8 per unit of cementitious material, S95 grade slag powder accounts for 0.2 per unit of cementitious material, machine-made sand accounts for 1.2 per unit of cementitious material, and water accounts for 0.8 per unit of cementitious material. 0.22 of the material, chemical admixtures account for 0.018 of the unit cementing material, and ultra-fine steel fiber cement accounts for 5% of the unit cementing material. First dry mix the cement, slag powder and machine-made sand for 0-2 minutes to obtain the dry mixture. Then add the chemical admixture into the dry mixture, stir for 1-5 minutes to form a cement-based material, then add the weighed ultra-fine steel...

Embodiment 3

[0036] The ultra-high-strength steel fiber cement-based material used in this embodiment is a molding material made of P.I.52.5 cement, S95 grade slag powder, machine-made sand, chemical admixtures, ultra-fine steel fibers and water. The mass of steel fiber cement-based materials is one mass unit, and its cement accounts for 0.6 of the unit cementing material, S95 grade slag powder accounts for 0.4 of the unit cementing material, machine-made sand accounts for 1.2 of the unit cementing material, and water accounts for 0.6 of the unit cementing material. 0.18 of the material, 0.022 of the chemical admixture of the unit cementing material, and 15% of the ultra-fine steel fiber of the unit cementing material. Add the chemical admixture into the dry mixture, stir for 1-5 minutes to form a cement-based material, then add the weighed ultra-fine steel fiber into the cement-based material and stir for 1-5 minutes to prepare the ultra-fine steel fiber cement-based material, The obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com