Patents

Literature

127results about How to "With bending resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

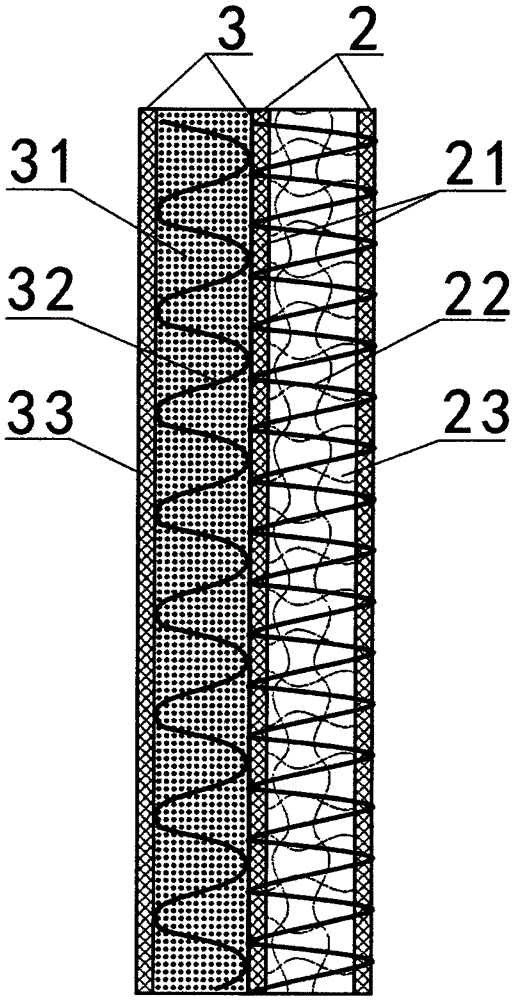

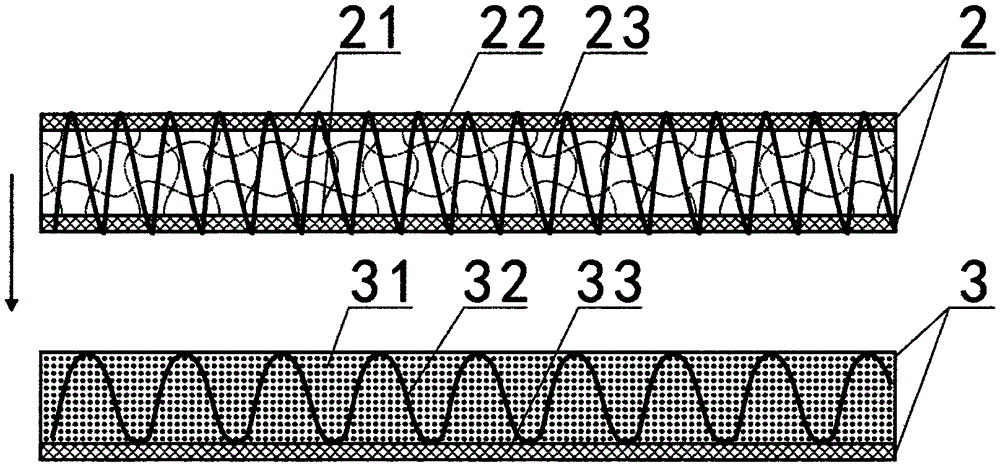

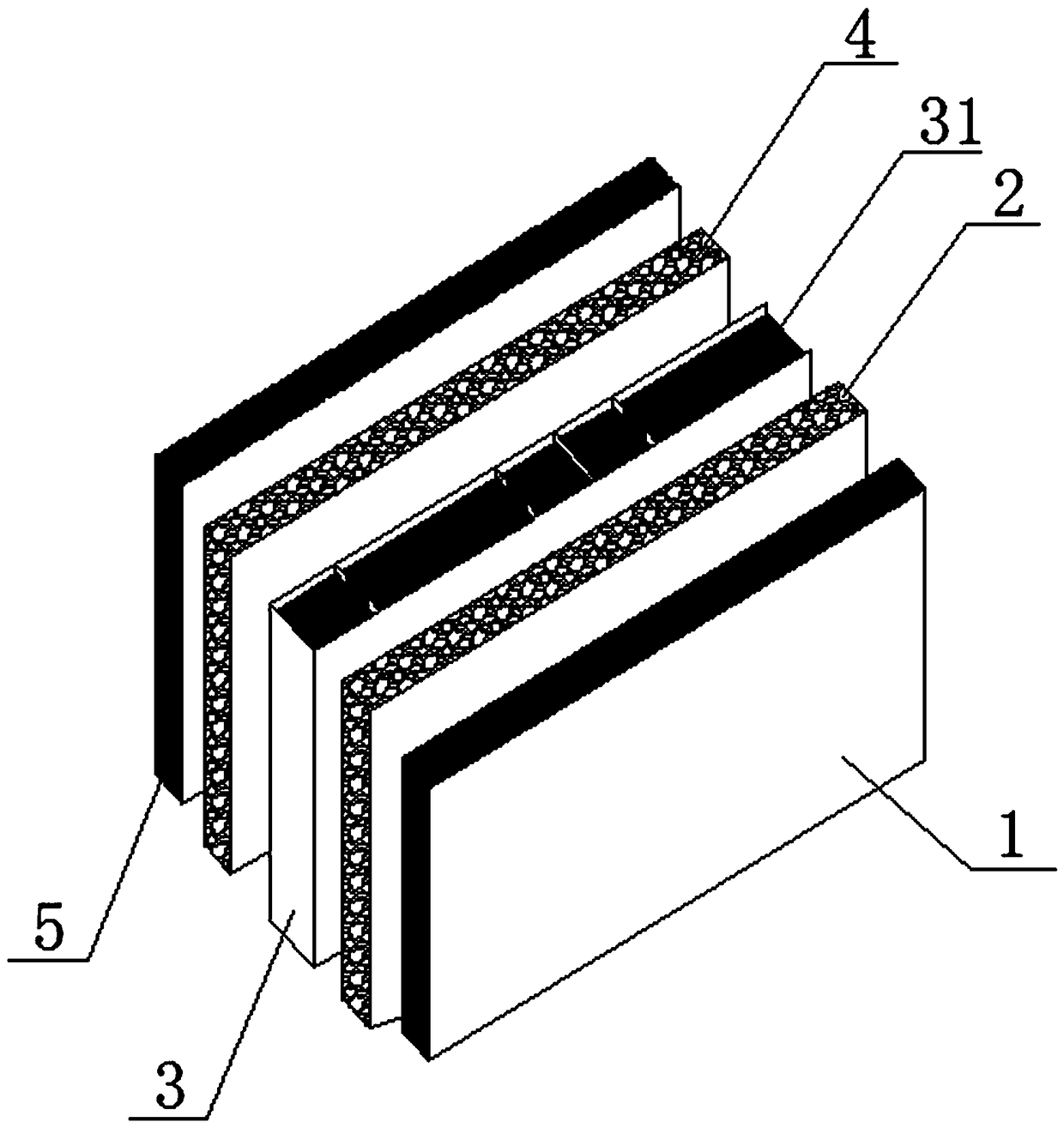

Foldable display device

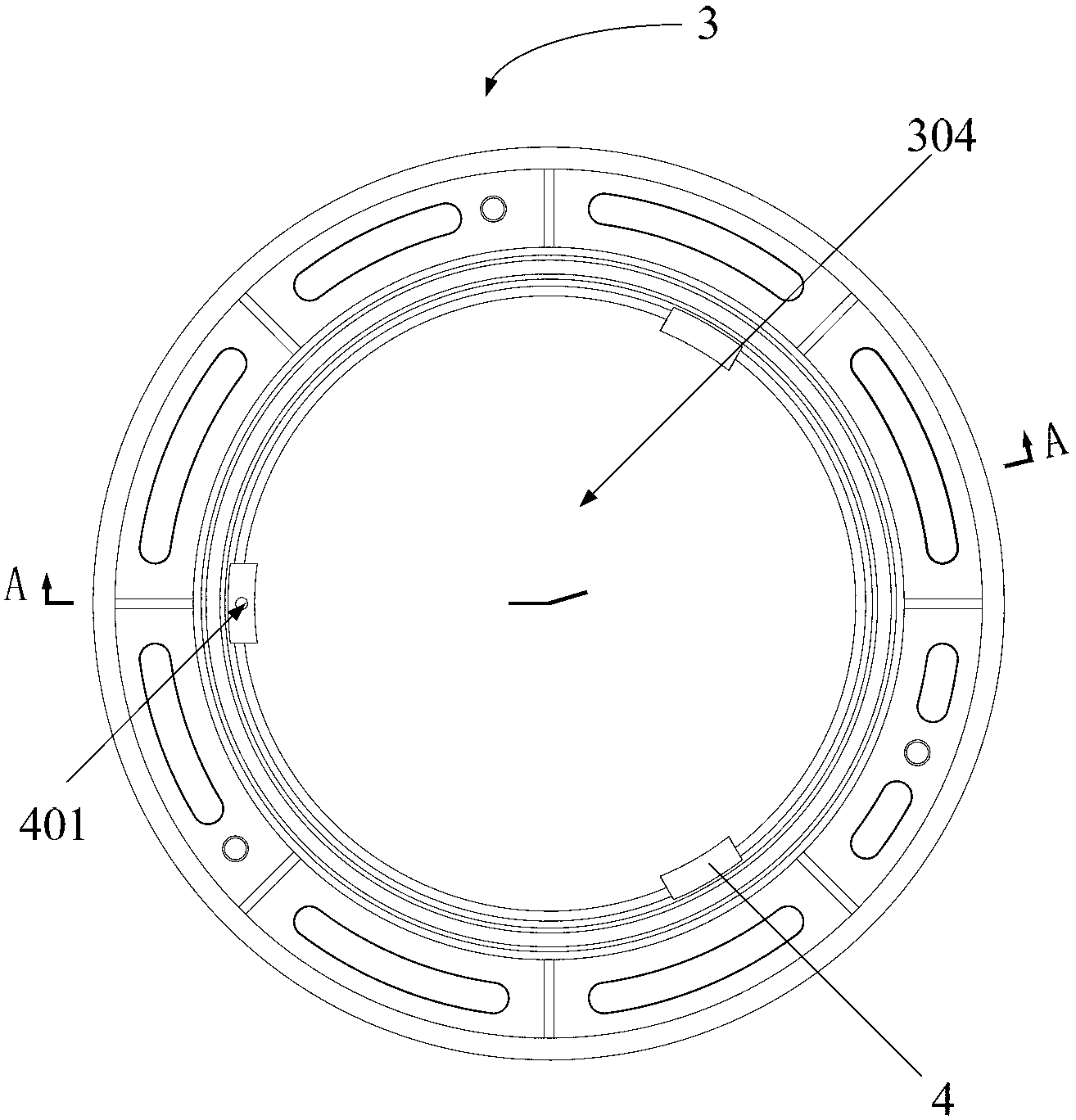

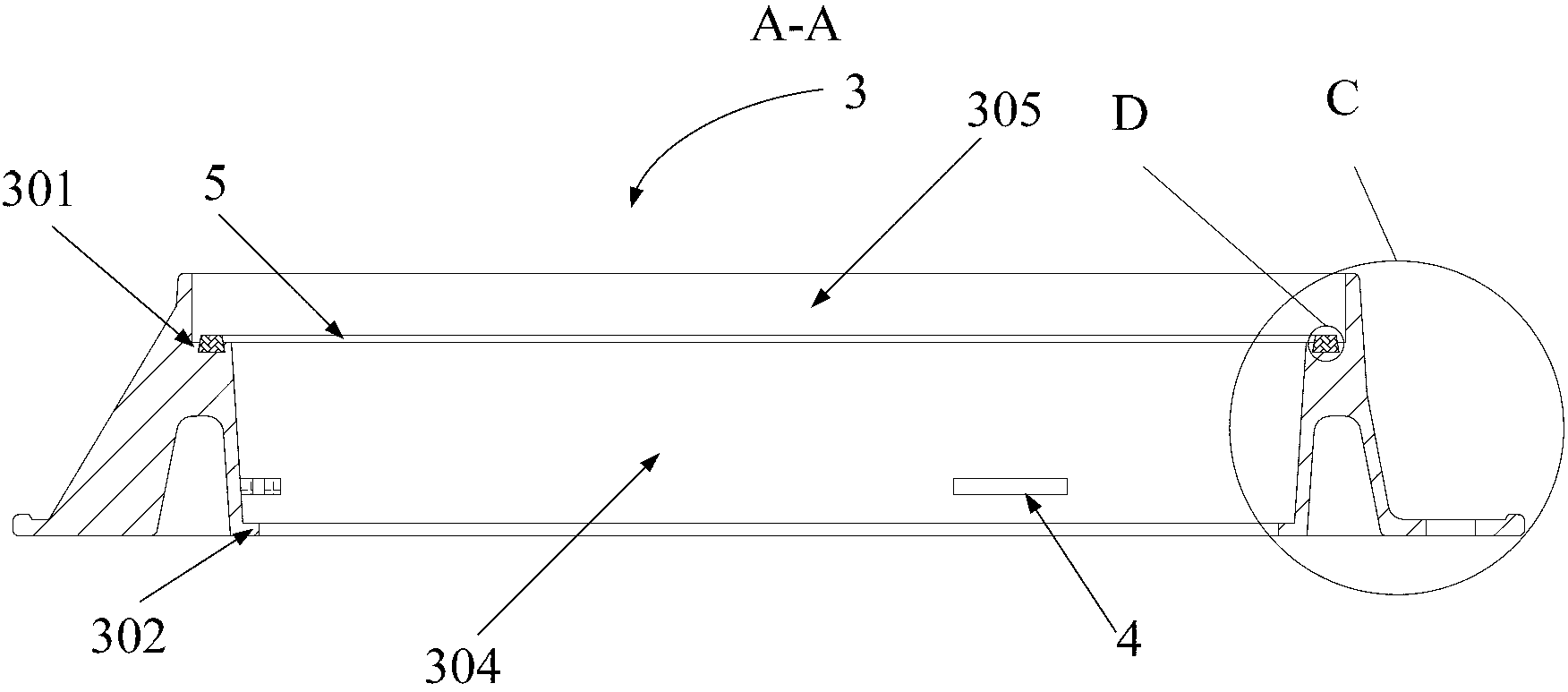

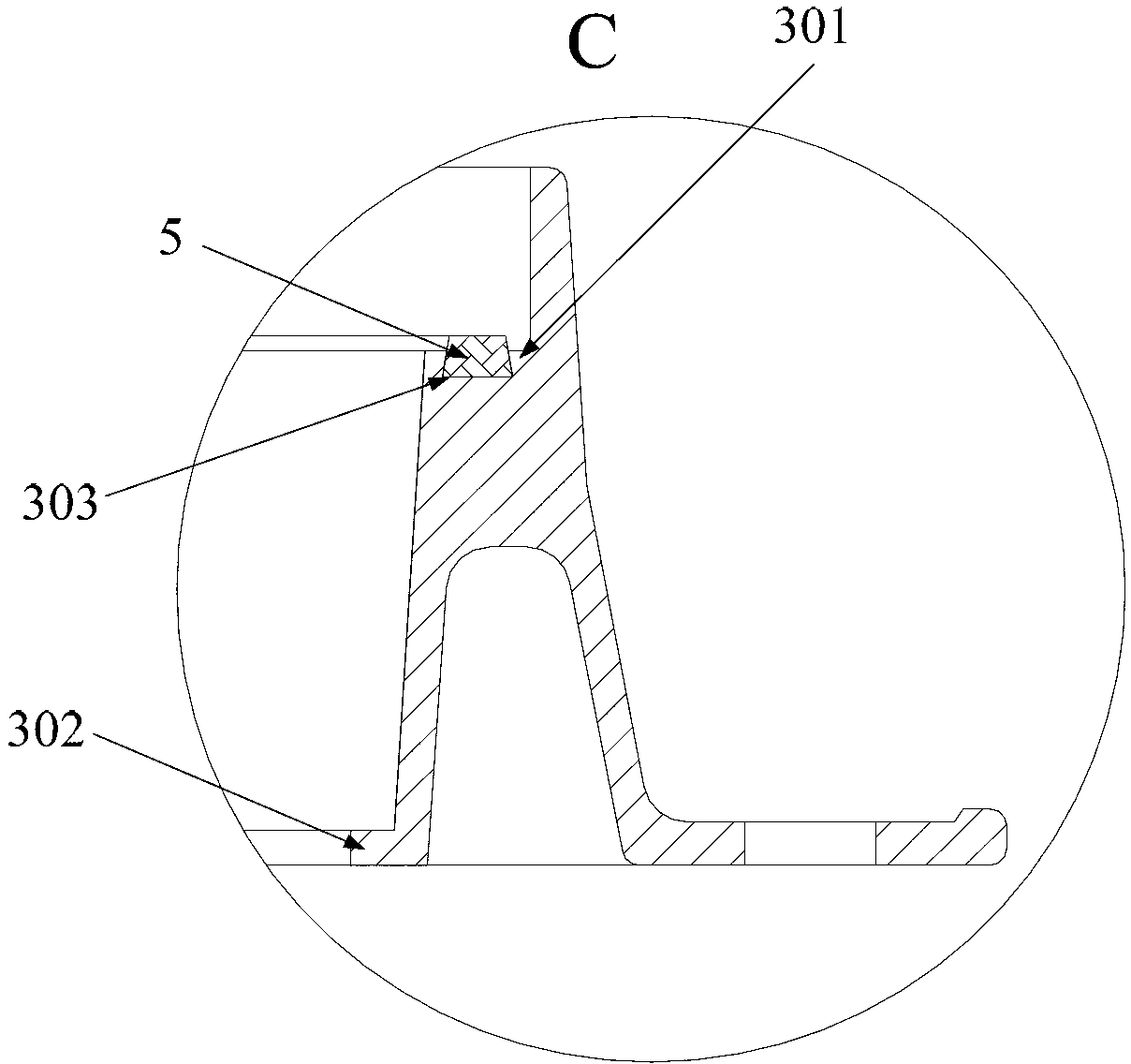

ActiveCN106652802AImprove rigidityWith bending resistanceIdentification meansDisplay deviceEngineering

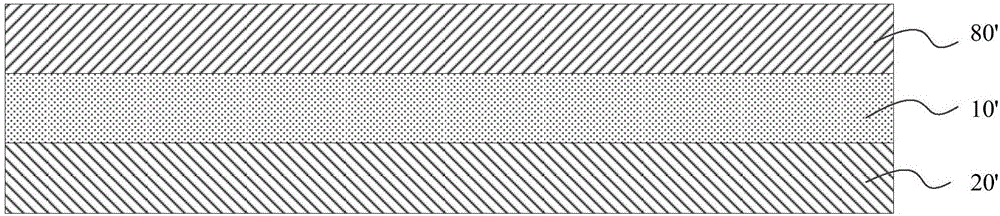

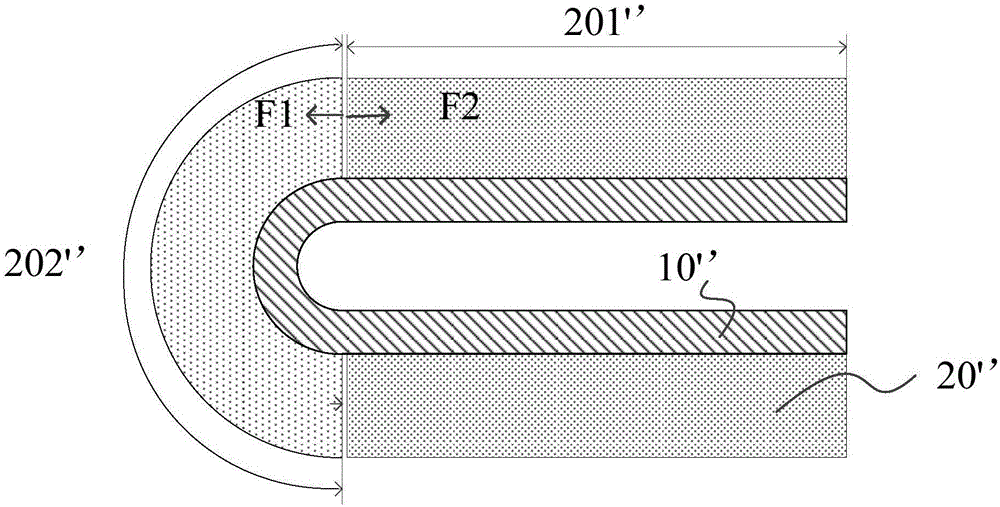

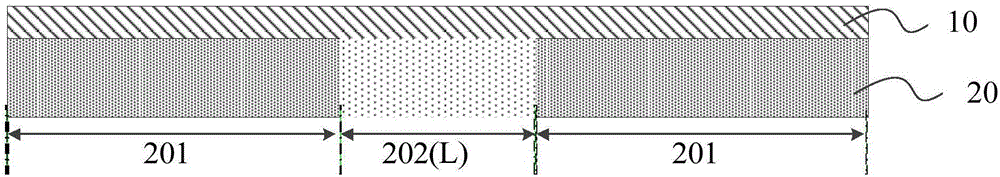

The invention provides a foldable display device, comprising a display panel and a support plate arranged on a backlight side of the display panel, wherein the support plate includes a folded area and an unfolded area, the folded area and the unfolded area are integrated without an interface, the folded area comprises a flexible portion, and the unfolded area comprises a rigid portion, the elastic modulus of which is greater than the elastic modulus of the flexible portion, therefore, the folded area has resistance to bending, and the unfolded area has relatively strong rigidity to achieve foldable display in a fixed area. The folded area and the unfolded area are integrated without the interface, so that cracking at the interface while bending is avoided.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

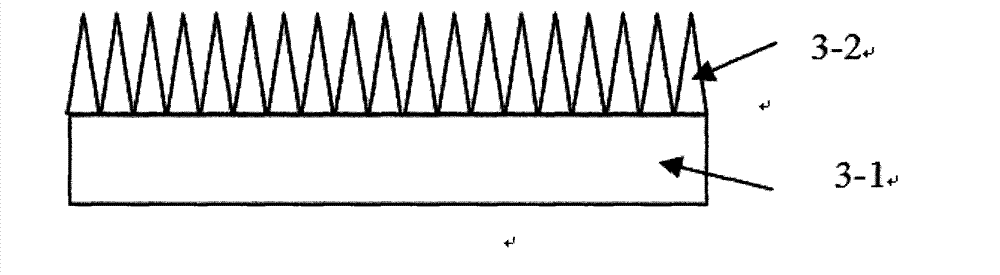

Preparation method of large-area surface enhancement raman scattering substrate

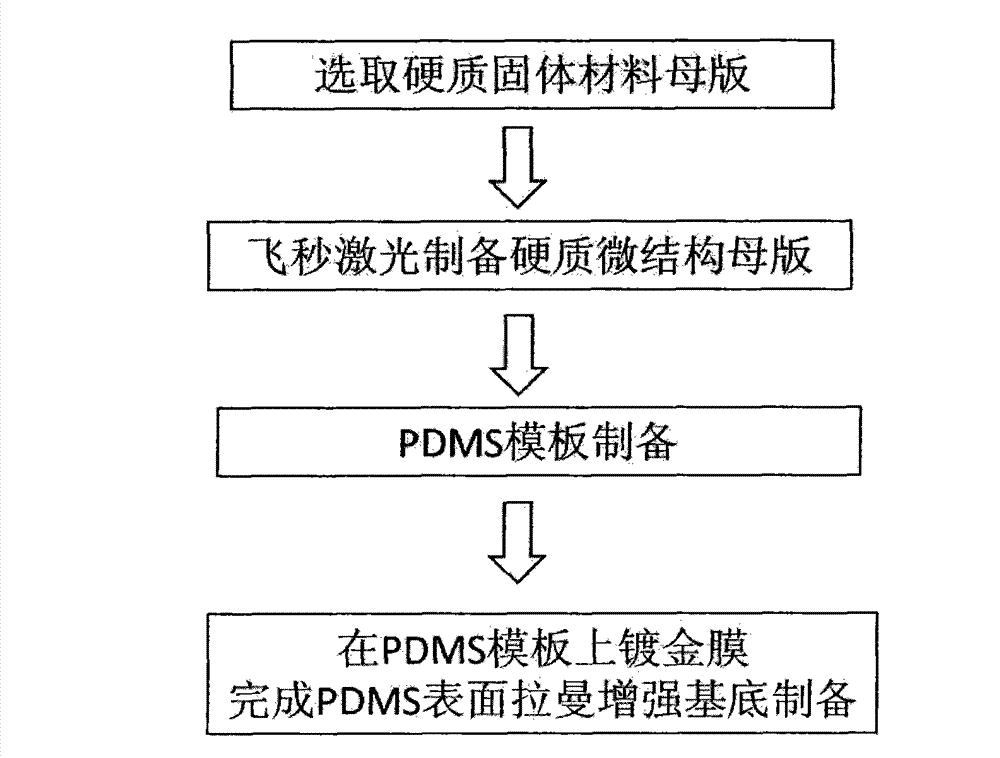

The invention discloses a preparation method of a large-area surface enhancement raman scattering substrate. The preparation method comprises the following steps: at first, the surface of a hard solid material is irradiated by femtosecond laser to prepare a large-scale hard microstructural mother set; then, polydimethylsiloxane (PDMS) is poured on the hard microstructural mother set by the nanoimprint lithography technology, and the structure on the hard microstructural mother set is copied to prepare a PDMS framework; and finally, a gold film is plated on the PDMS framework to prepare the PDMS surface enhancement raman scattering substrate. The experiment results show that the preparation method has the advantages that the enhancement factors are high, enhancement factors in different positions of the substrate have good uniformity, the large-area surface enhancement raman scattering substrate can be prepared, the mother set can be repeatedly imprinted, the production cost is reduced, and in addition, god is taken as raman enhancement metal, so that the defect that silver is oxidized very easily is avoided.

Owner:NANKAI UNIV

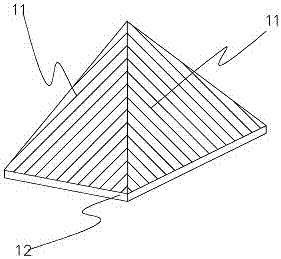

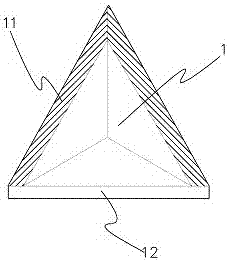

Micron order prism pyramid monomer and manufacturing method thereof

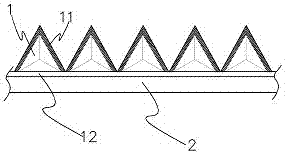

PendingCN107144903AAvoids the phenomenon of sedimentation at the bottom of the fluidImprove reflective effectOptical elementsMicron scalePolymer science

The invention relates to the light reflection material technology field and provides a micron order prism pyramid monomer and a manufacturing method thereof. The prism pyramid is capable of accommodating both the light flashing and light reflecting effects, and can exist independently without being attached to a carrier film. Only with adhesive glue, oil painting, hair glue and nail polishing oil and other colorless or colored transparent fluid or liquid media, it is possible to let the prism pyramid monomer to be attached on objects such as films, cloth, wires and plates requiring to be added with light or to realize light flash so that these materials can present the lighting effect. The monomer can be applied widely in great practical use, and the manufacturing method for the monomer is also simple and easy to implement. Therefore, with the method, batched monomer can be produced and used.

Owner:YEAGOOD INC

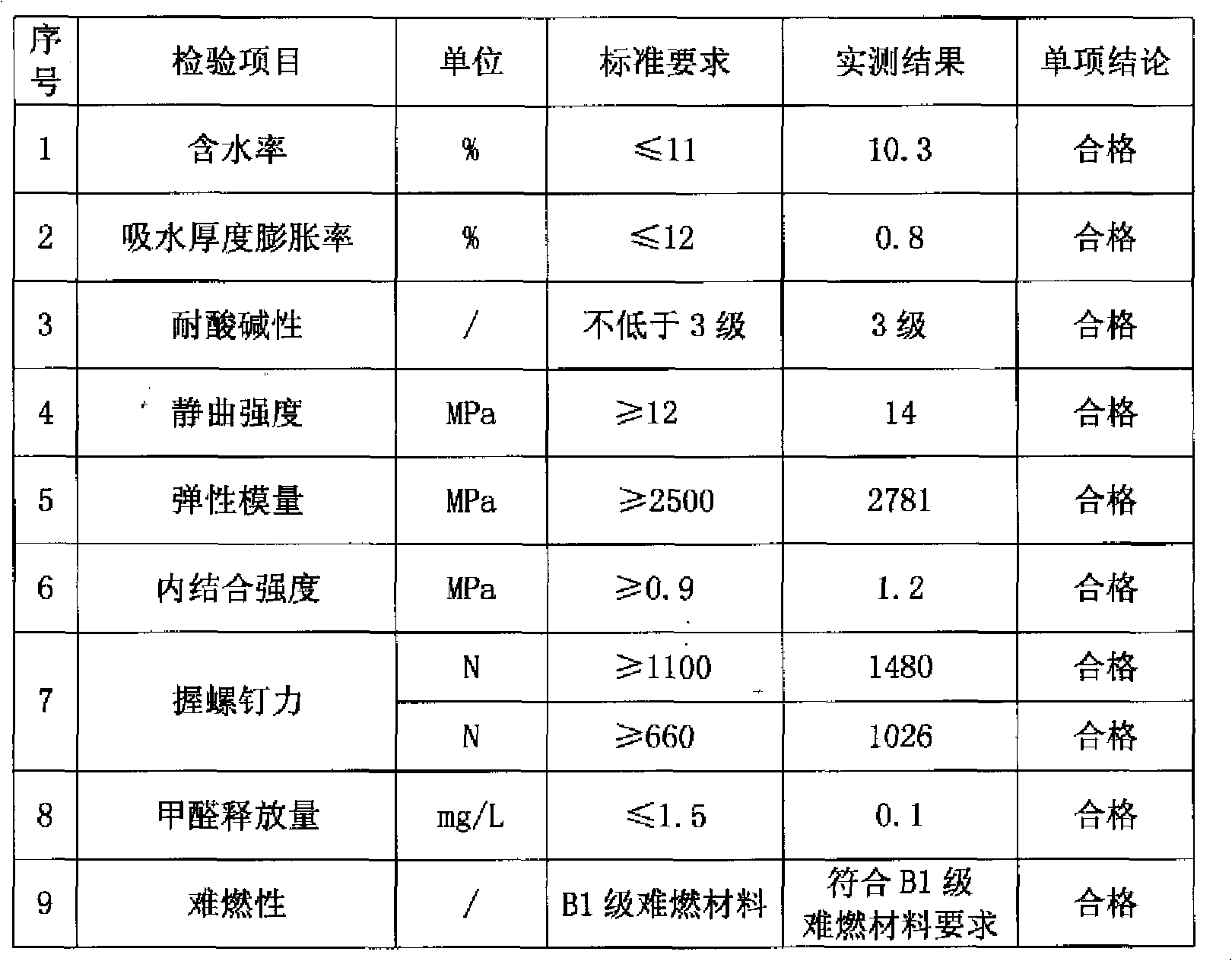

Flame-retardant fiber board and manufacturing method thereof

InactiveCN101602224ALow priceMaterials are readily availableDomestic articlesFlat articlesFiberPolymer science

The invention relates to a flame-retardant fiber board and a manufacturing method thereof. The flame-retardant fiber board is prepared from the following raw materials in portion by weight: 80 to 120 portions of fiber, 80 to 120 portions of magnesia, 80 to 200 portions of water solution of magnesium sulfate, 5 to 30 portions of active silica, 0.5 to 2 portions of organosilicon waterproof agent, and 0.5 to 1.5 portions of plasticizer. The manufacturing method comprises the steps: 1) preparing the fiber, namely cleaning and drying crop straws, wood branches or wood processing residual materials, and then obtaining the fiber through the crushing by a crushing machine; 2) preparing an inorganic adhesive, namely mixing the magnesia, the water solution of the magnesium sulfate, the active silica, the organosilicon waterproof agent and the plasticizer, and stirring the mixture to obtain the inorganic adhesive; 3) mixing the fiber and the inorganic adhesive prepared through the step 1 and the step 2, stirring the mixture, and paving the mixture after the screening by a screening machine; 4) paving a reinforcing network on the upper and lower surfaces of a paved slab; and 5) finally performing hot pressing on the board paved with the reinforcing network for 10 to 25 minutes at a temperature of between 100 and 110 DEG C at a pressure of between 12 and 30MPa to obtain the flame-retardant fiber board. The flame-retardant fiber board has broad application field.

Owner:湖南迪普环保建材有限公司

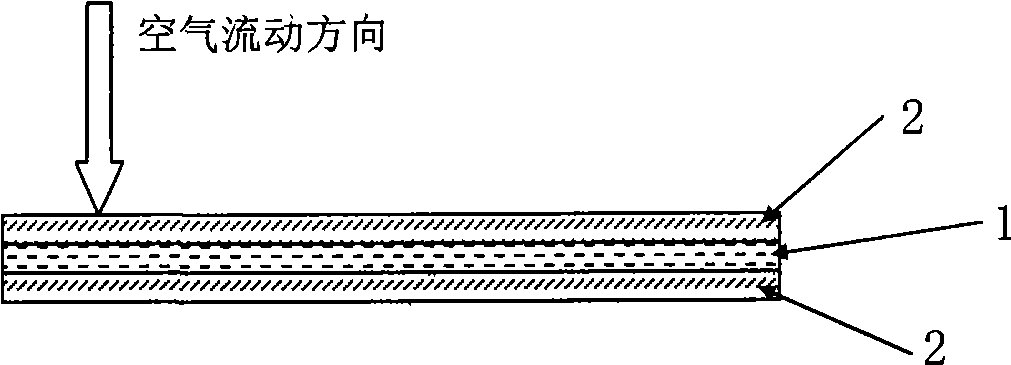

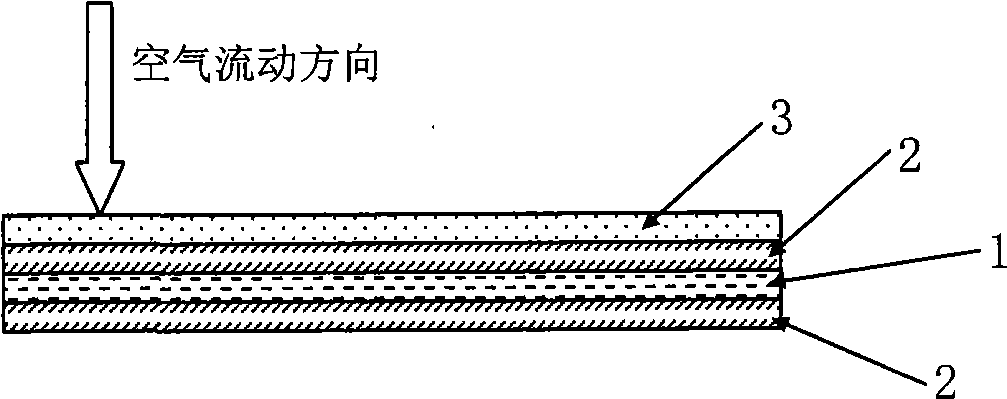

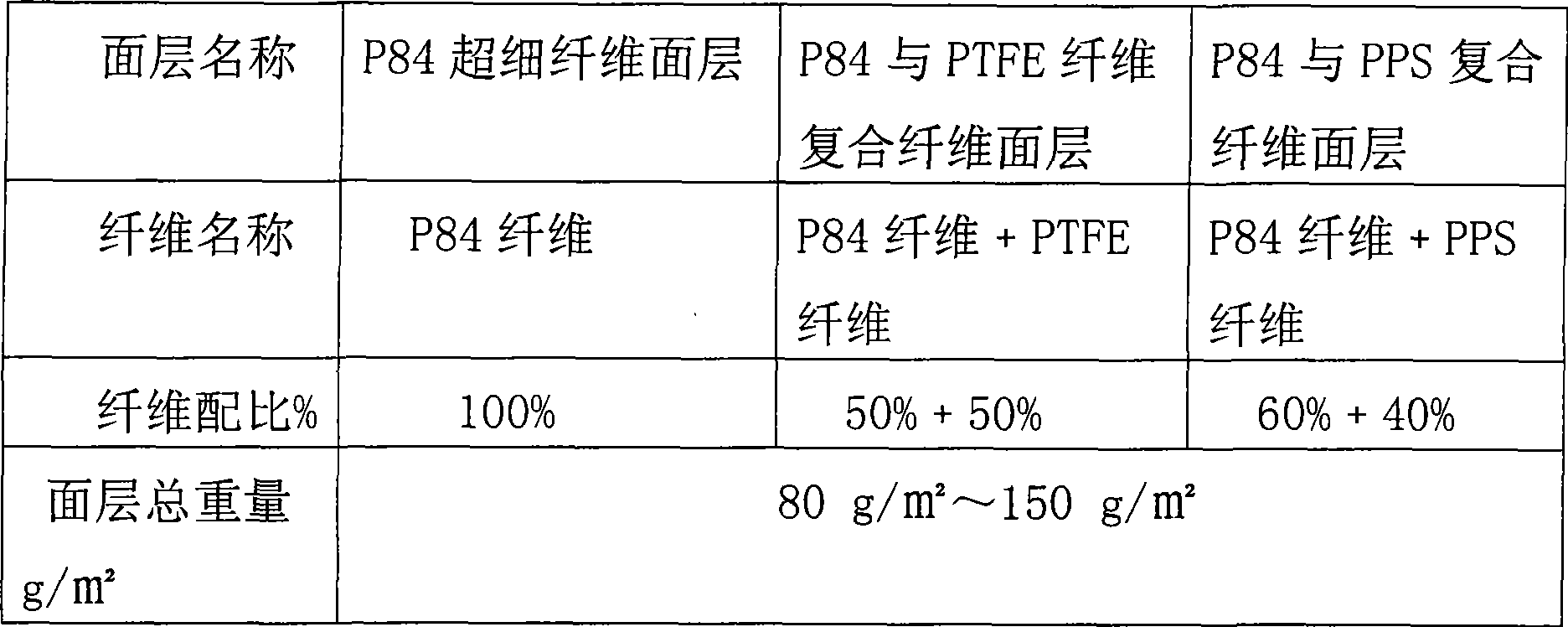

Non-woven filter felt combining air-laid web with pinprick reinforcement and production method

ActiveCN101530698AHigh temperature resistantAnti-acid and alkali corrosionLayered productsFiltration separationSurface layerPunching

The invention provides a non-woven filter felt combining air-laid web with pinprick reinforcement, wherein, the non-woven filter felt has a layered structure, the intermediate layer is high-tenacity and low-elongation type base cloth, and the upper surface and the lower surface of the high-tenacity and low-elongation type base cloth are symmetrically glued with a fiber surface layer or an extra fine fiber surface layer. The production method essentially comprises the technology of producing the surface layer air-laid web: producing the base cloth; producing the needled-punched felt; impregnating; calendering; coating; preliminary drying; solidifying in a way of curing; trimming; winding; and finishing a product. The invention has the advantage that the technology combining the air-laid web with the pinprick reinforcement is used for producing the non-woven filter felt, thereby combining the respective advantage of the two technologies, improving the service life of filter materials, and having high filtration efficiency, high physical and mechanical properties, as well as low cost. Compared with the normal method for filtrating materials with needle punching, the invention can obviously improve the wearing resistance, the fold-resistance capability and the tensile strength, and can bear hyperfiltration load, wherein, the filtering rate can reach more than 1.0 m / min, and the running resistance is low.

Owner:SHANGHAI BG INDAL FABRIC

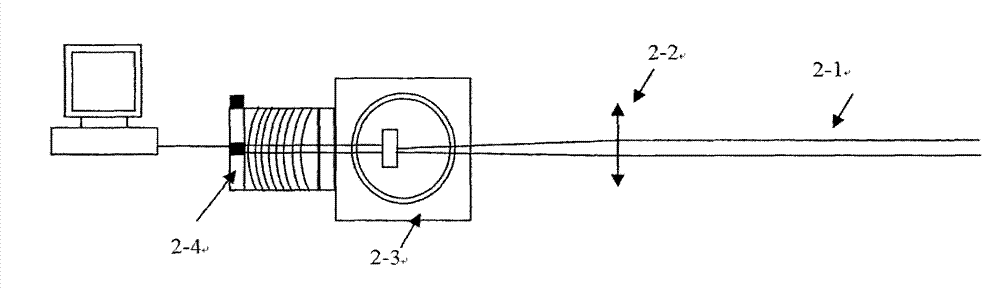

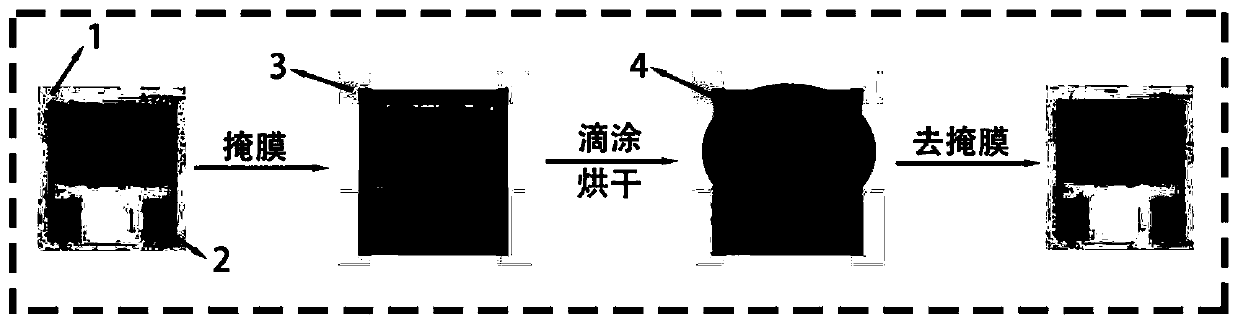

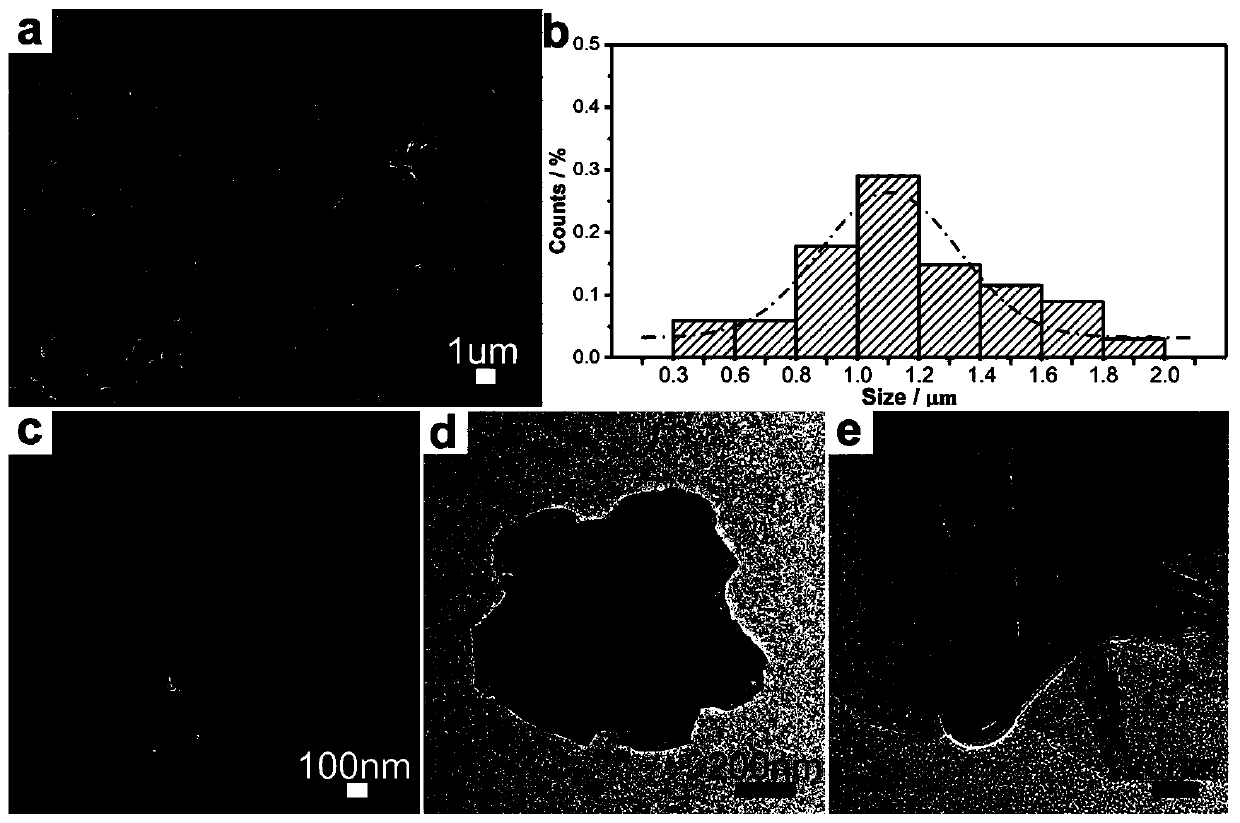

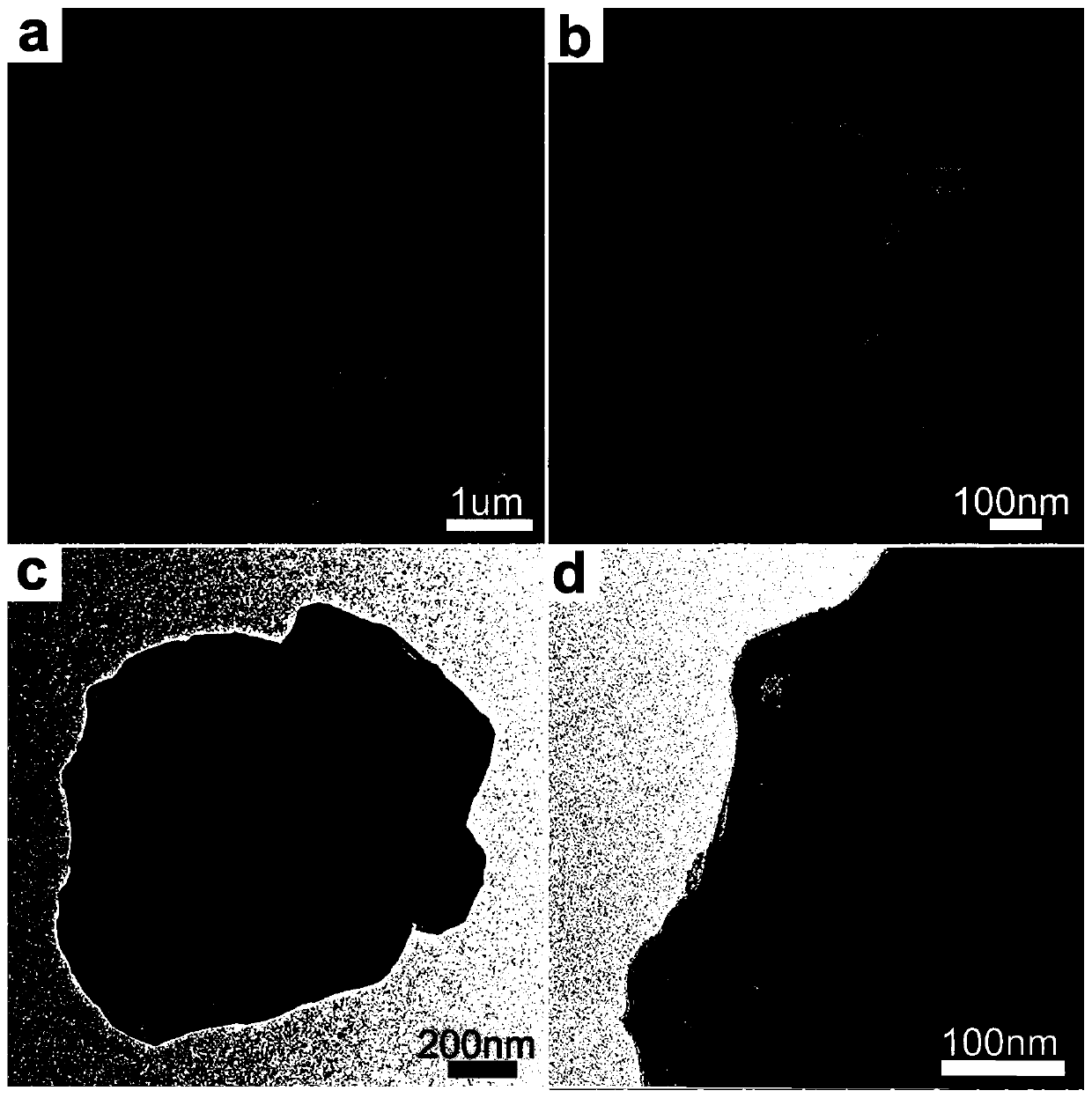

Planar flexible room-temperature NO<2> sensor based on three-dimensional MXene folded ball/ZnO composite material and preparation method thereof

ActiveCN110672670ALarge specific surface areaHigh NO2 sensing performanceMaterial resistanceZno nanoparticlePolyimide

The invention discloses a planar flexible room-temperature NO<2> sensor based on a three-dimensional MXene folded ball / ZnO composite material and a preparation method thereof, and belongs to the technical field of gas sensors. The sensor is composed of a polyimide flexible substrate having an Au interdigital electrode and three-dimensional MXene folded ball / ZnO composite material sensitive electrodes prepared on the interdigital electrode and the substrate. According to the planar flexible room-temperature NO<2> sensor based on the three-dimensional MXene folded ball / ZnO composite material andthe preparation method thereof provided by the invention, with the MXene material as a basis, the MXene is treated via an ultrasonic spraying method to prepare the anti-aggregating three-dimensionalMXene folded ball, thus achieving the advantages of being anti-aggregating, and maintaining a large specific surface area of the MXene; meanwhile, the oxidation is composited, and a ZnO nanoparticle is increased on a surface of the three-dimensional MXene folded ball, so that a sensing site is increased; and compared with a two-dimensional MXene and pure three-dimensional MXene folded ball, the sensor prepared based on the three-dimensional MXene folded ball / ZnO composite material obtains higher NO<2> sensing property, and has very good selectivity, resilience and bendability.

Owner:JILIN UNIV

Novel environment-friendly and fireproof composite biomass board

InactiveCN101786852ALow priceWide variety of sourcesSolid waste managementCeramic shaping apparatusSodium silicateScrap

The invention relates to the technical field of decorating and building materials, in particular to a novel environment-friendly and fireproof biomass board. The board is characterized by comprising the following components in percentage by weight: 65.0-75.0% of biomass packings, 15.0-25.0% of sodium silicate, 5.0-10.0% of sodium fluosilicate and 0.05-1.0% of fiberglass mesh, wherein the biomass packings are wood scraps, wood branches or crop straws. The environment-friendly and fireproof composite biomass board prepared by organically combining the wastes with good impact resistance and nail holding power, such as crop straw fibers or wood fibers, fiberglass with excellent tensile property and inorganic adhesives with unique fireproofness and waterproofness can be widely applied to the household products such as furniture, indoor and outdoor decoration of buildings, advertisement designing, building templates and other special-purpose boards.

Owner:王春莉

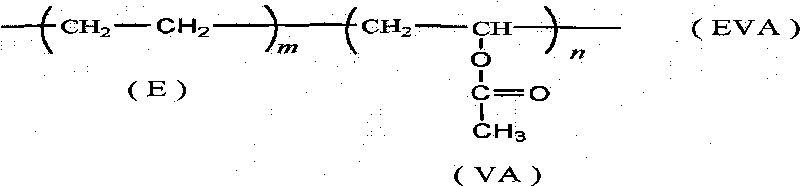

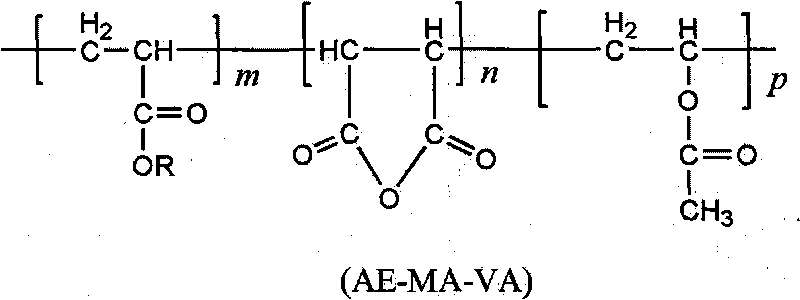

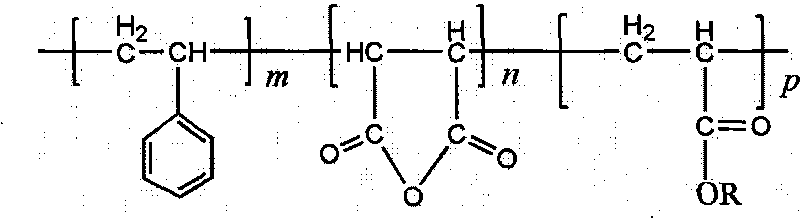

Andalusite fiber size and preparation method thereof

The invention provides a multifunctional size for andalusite fibers, which uses an organic compound containing flexible chains in molecules as a main body and compounds a plurality of auxiliary agents. The size comprises the following components in percentage by weight: 0.5-1.5 percent of film forming agent, 1-10 percent of softening agent (penetrating agent), 0.05-0.3 percent of antistatic agent(antiseptic), 0.01-0.2 percent of dispersant, 0.01-0.07 percent of coupling agent, 0.05-0.1 percent of catalyst and the balance of tap water. The size has good convergence, lubricating property, filmforming property, antistatic property and antiseptic characteristic. Not only fibers processed through the size have flexible, anti-bending and anti-stretching characteristics, but also the fibers sprayed with the size have good dispersive property in water and can be used for the surface soakage treatment of multiple silicate fibers.

Owner:甘肃紫鑫矿业煤化工有限公司

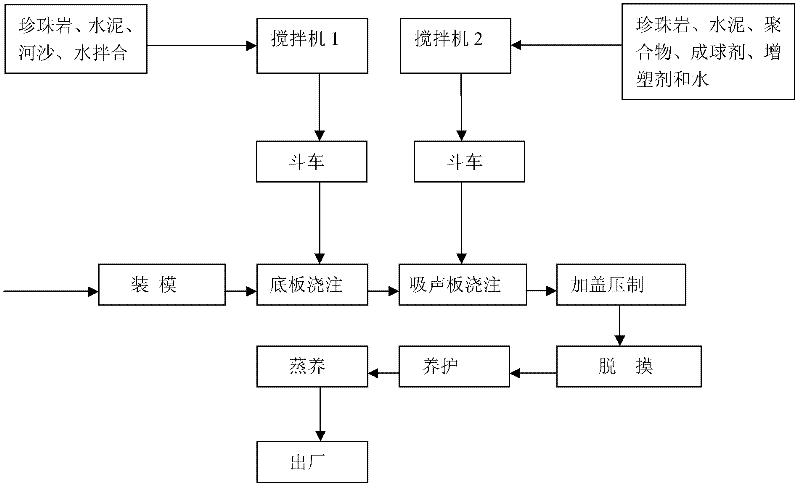

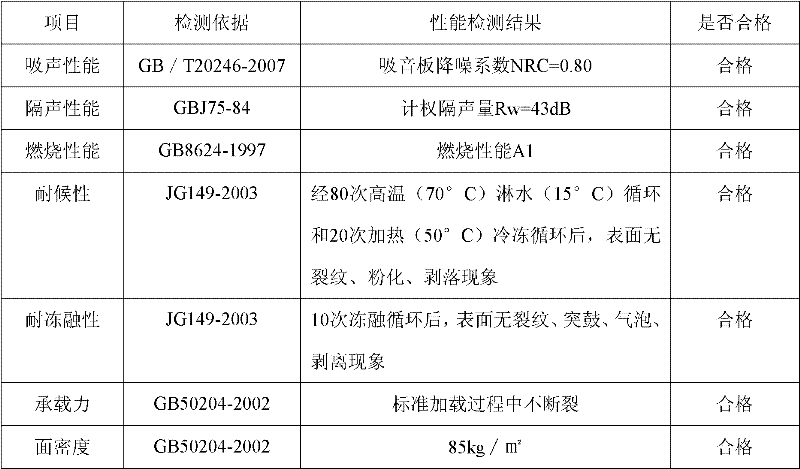

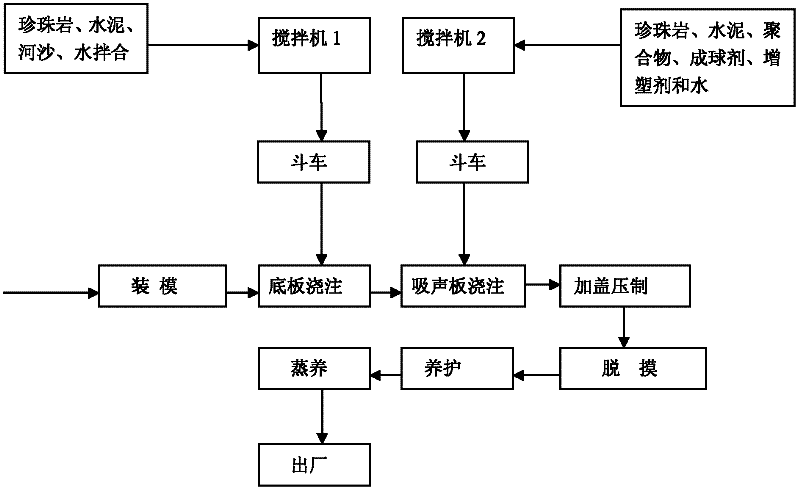

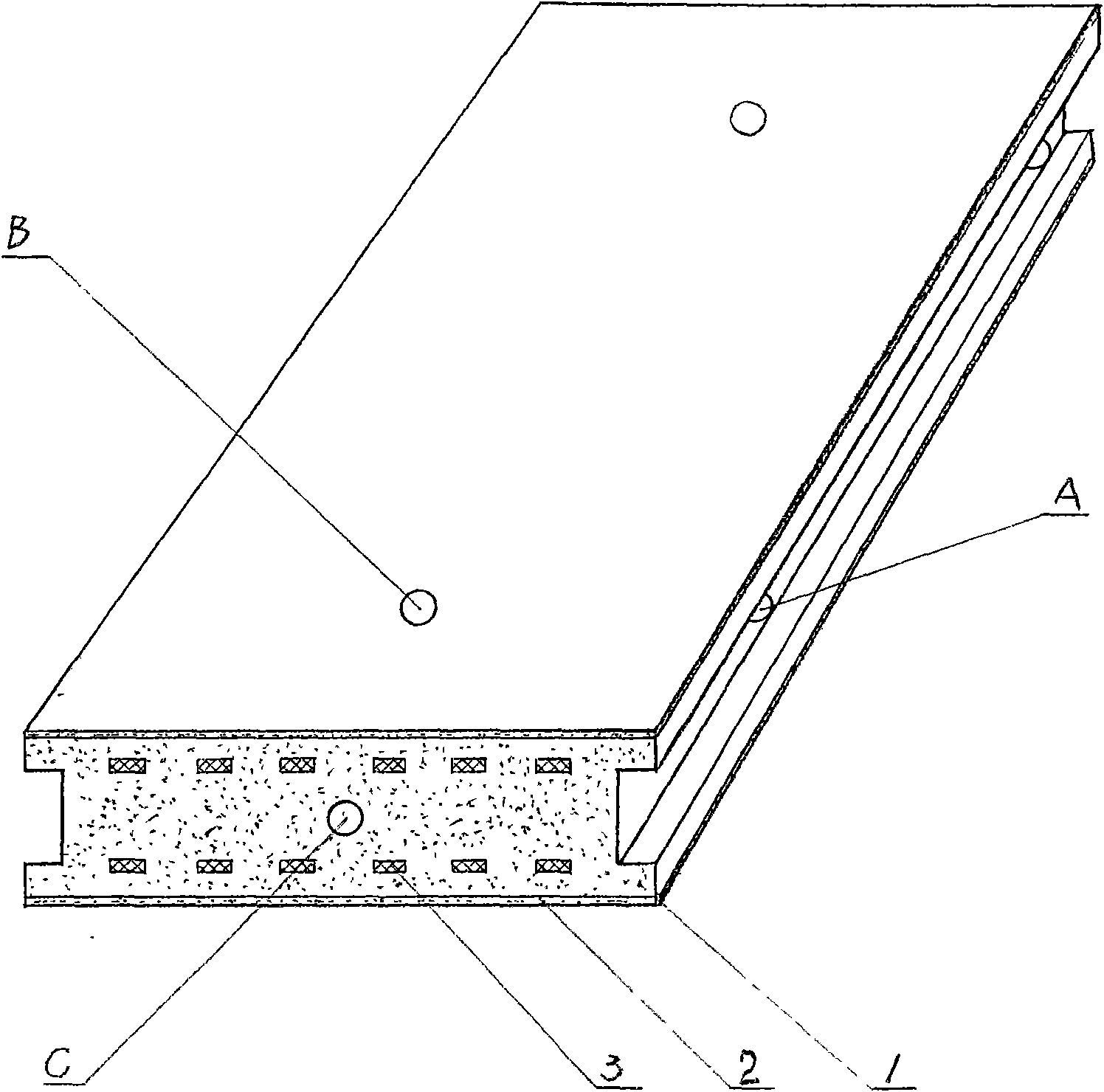

Porous perlite sound absorption material

The invention discloses a porous perlite sound absorption material used for building a sound absorption wall, characterized in that the porous perlite sound absorption material is prepared by the following procedures: blending and pelletizing the materials, pouring a soleplate, pouring a sound absorption plate, pressing, demolding, curing and vapor curing at 40 DEG C, and the like; the material is composed of the following ingredients in mass ratio: 1 part of perlite, 6 parts of 425 cement, 0.3 parts of high early strength cement, 0.1 part of polymer emulsion, 0.1 part of pelletizing agent, 0.01 part of plasticizer and 0.1 part of other accessory ingredients. The sound absorption material using perlite as aggregate disclosed by the invention has the advantages of excellent sound absorption effect, large anti-bending and anti-pressing strength, high sound absorption coefficient and wide sound absorption frequency band, and the sound absorption material has such excellent functions as fire resistance, moisture resistance, durability and innocuity, and the like, so that the sound absorption material has an extensive application prospect.

Owner:四川昊龙高科轨道交通新材料科技股份有限公司

Light aggregate concrete outer wall batten

InactiveCN101684678ACan absorb impact energyLight weightSolid waste managementBuilding componentsPolystyreneBatten

The invention discloses a light aggregate concrete outer wall batten which is a wall blank formed by hydrating polystyrene foam, rice husk, straw, starch building glue, anhydrous calcium chloride, alkyl sodium sulfonate and cement; two rows of parallel bamboo reinforcements are distributed at the upper part and the lower part of the internal part of the wall blank; a reinforcing layer which is combined by cement, water, polypropylene fiber, starch building glue, polystyrene foam and calcium chloride is coated on the periphery; three communicated holes A, B and C are drilled at both ends in a horizontal and vertical manner. The light aggregate concrete outer wall batten has the advantages of light quality, high strength, compression resistance, energy conservation, capability of absorbing impact energy of earthquake, convenient connection and installation.

Owner:上海四维科技研究所 +2

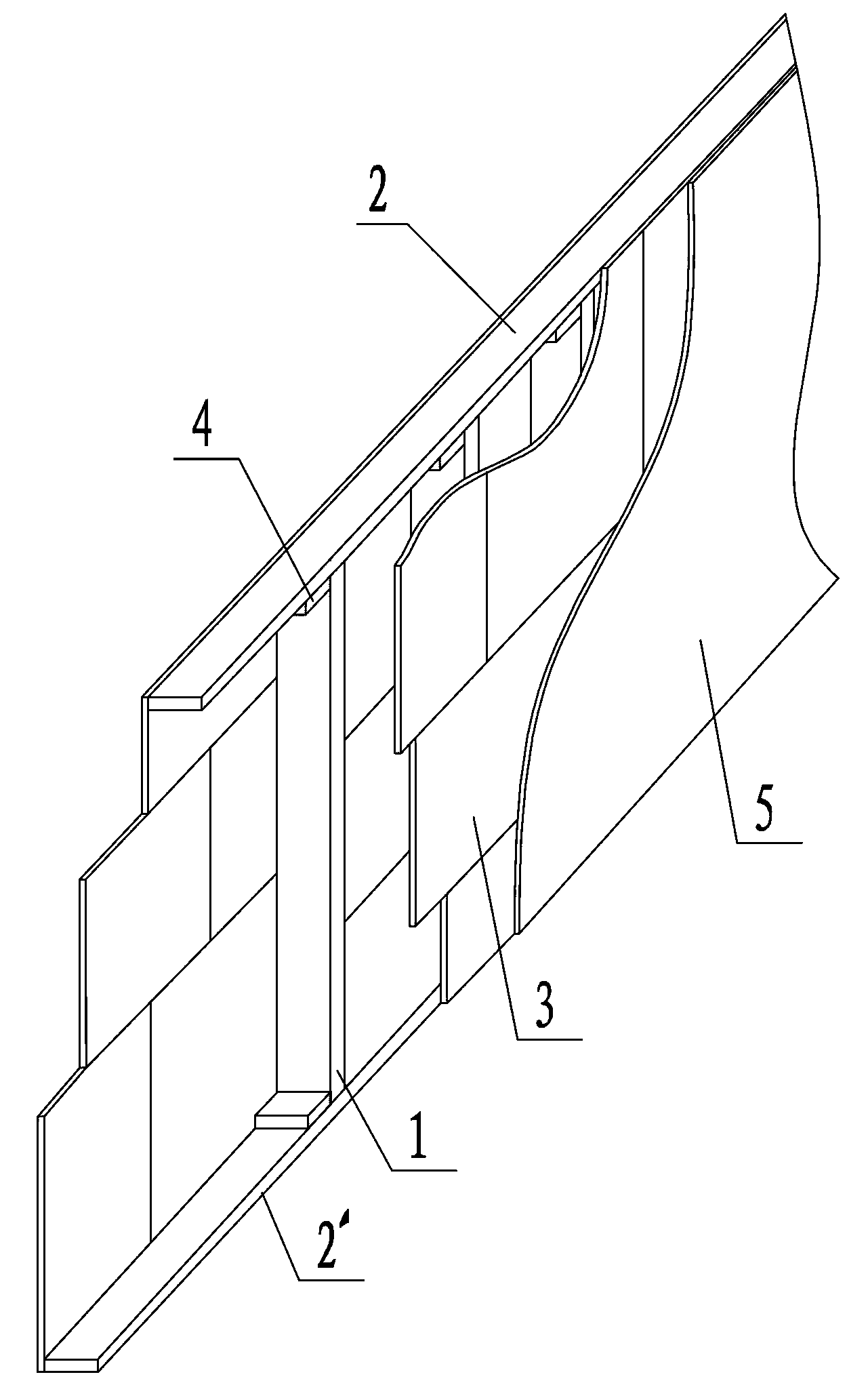

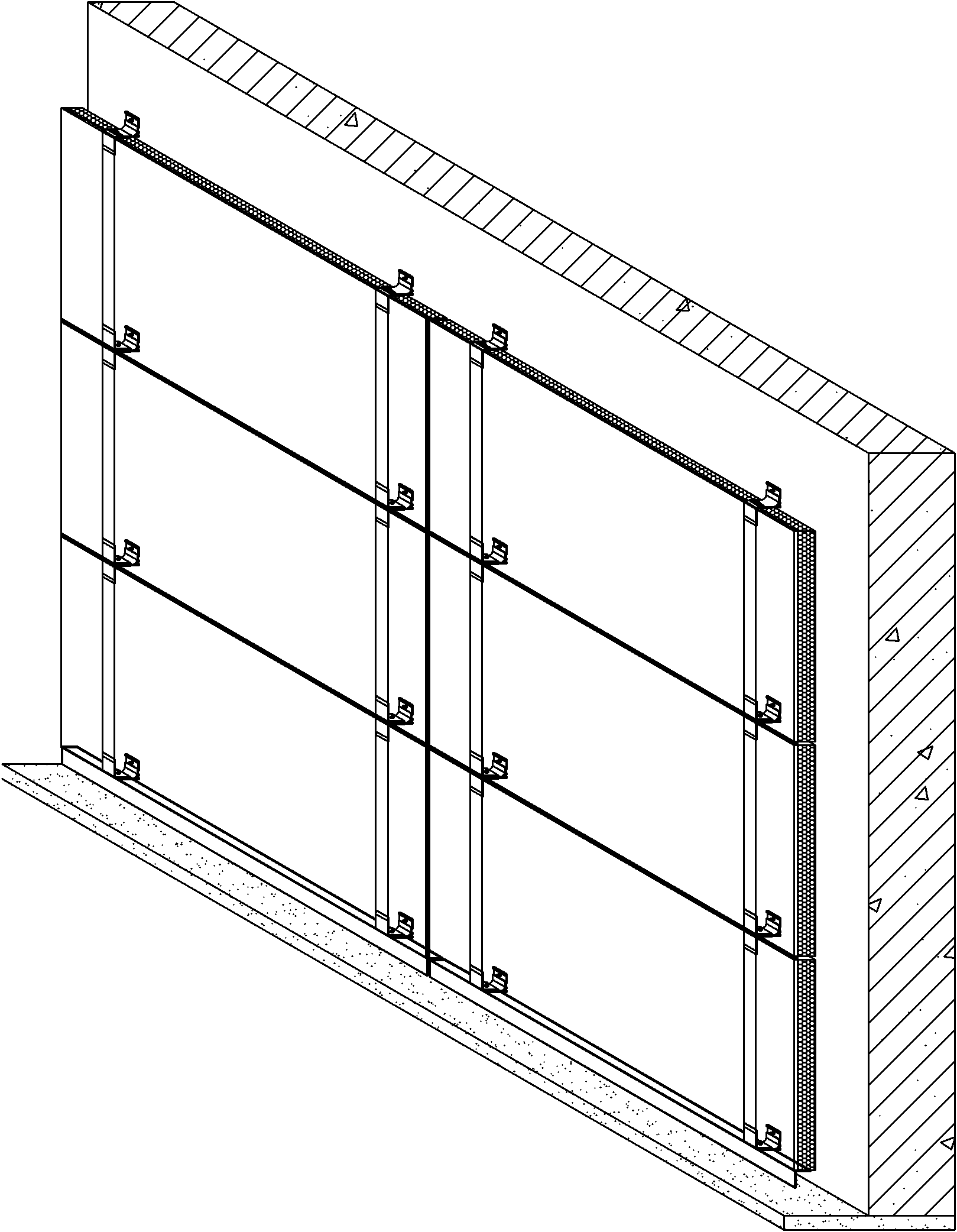

Assembly type wallboard and installation method thereof

The invention relates to an assembly type wallboard and an installation method of the assembly type wallboard. The assembly type wallboard comprises an edgewise locating plate, a plurality of keels, face plates and decorative surface layers, wherein the edgewise locating plate is arranged perpendicular to the horizontal installation datum of the wallboard; the keels are arranged in a vertical state according to a basic array pitch modulus with the edgewise locating plate as the datum relative to the horizontal installation datum of the wallboard, and the upper ends and the lower ends of all the keels are fixed; the face plates are installed on the two sides of the keels in a fastening mode through row nails, and gaps are reserved between the face plates on each side; the decorative surface layers are arranged outside the face plates arranged on the two sides, and the gaps are filled with expansible joint materials, and anti-cracking bands adhere to the gaps. As a result, the assembly type wallboard is easy and convenient to install and locate, high in strength and resistant to water.

Owner:BAOTOU JIANQIANG LIGHT-WEIGHT SLAB CO LTD

Formulation of microcrystal wear-resisting alumina ceramic

The invention belongs to the field of ceramic materials, and in particular relates to a formulation of a microcrystal wear-resisting alumina ceramic. The formulation of the microcrystal wear-resisting alumina ceramic consists of the following components: Al2O3 powder, kaolin, burnt talc, barium carbonate, magnesium oxide, dolomite, blank enhancing powder and complex additive, wherein the complex additive consist of polyvinyl alcohol, sodium tripolyphosphate and liquefacients, and the liquefacients are agents of code 9300 and code 5040 produced by Germany Schwarz Corporation. The formulation has the following advantages: the formulation is added with a proper amount of the complex additive which is advantageous for reducing the grain size of the Al2O3; simultaneously, with the addition of the complex additive, the formulation is advantageous for improving the bending strength and the hardness of the Al2O3 complex phase ceramic; and when the added amount of the complex additive is 10 percent, the bending strength of the Al2O3 microcrystal wear-resisting ceramic is more than 400 Pa, and the hardness Hv of the Al2O3 microcrystal wear-resisting ceramic is also up to 1,456 MPa.

Owner:JINGANG NEW MATERIALS

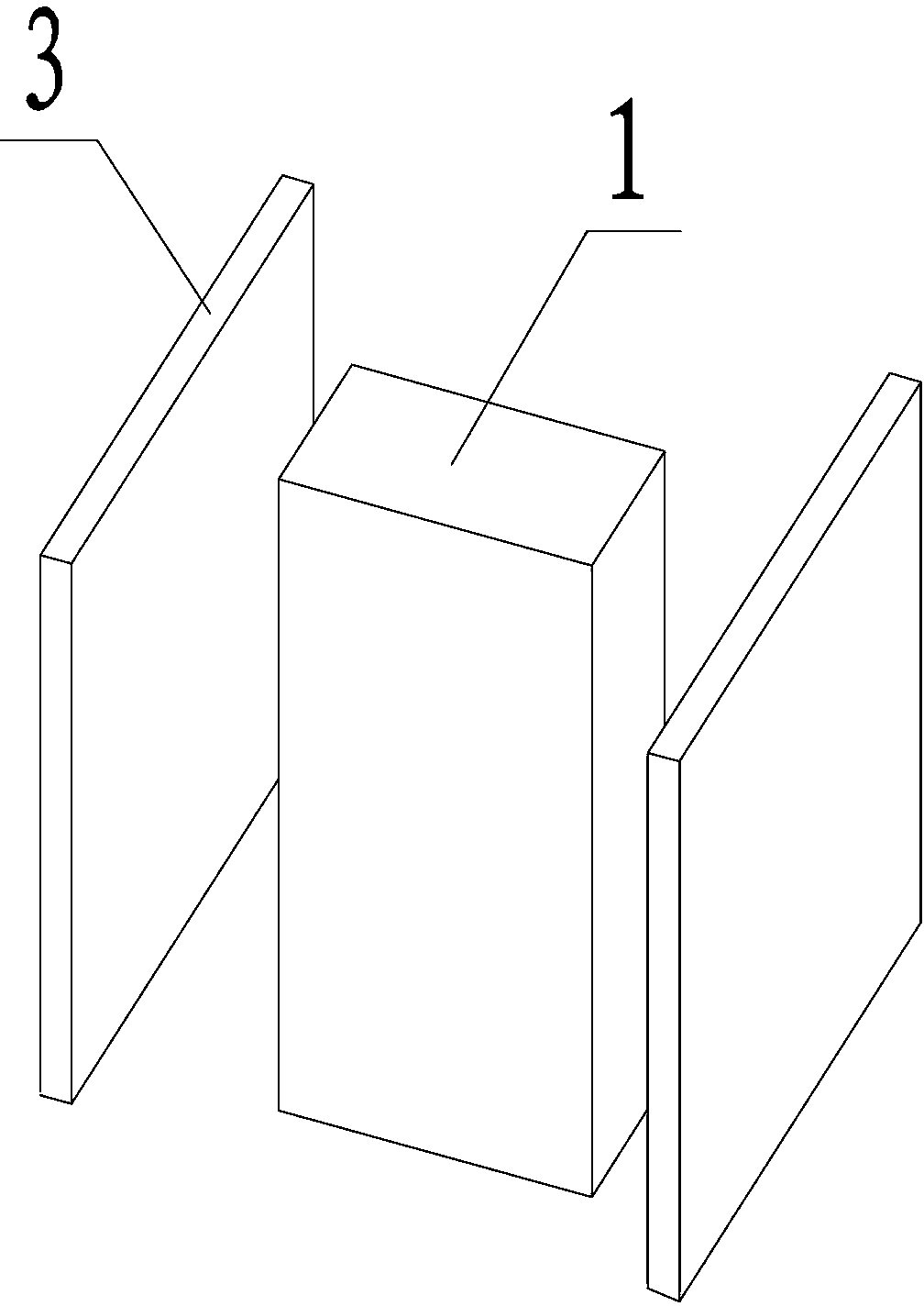

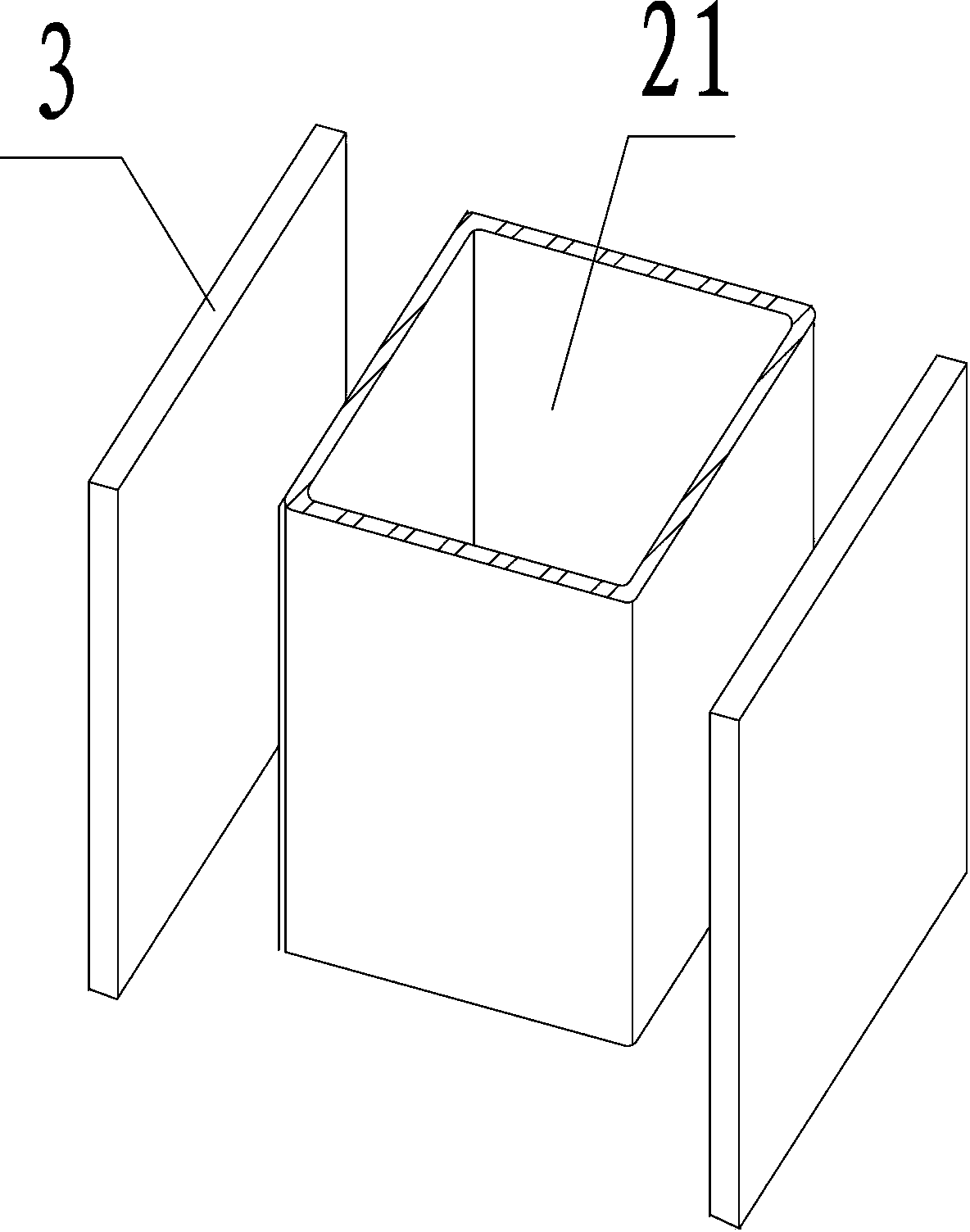

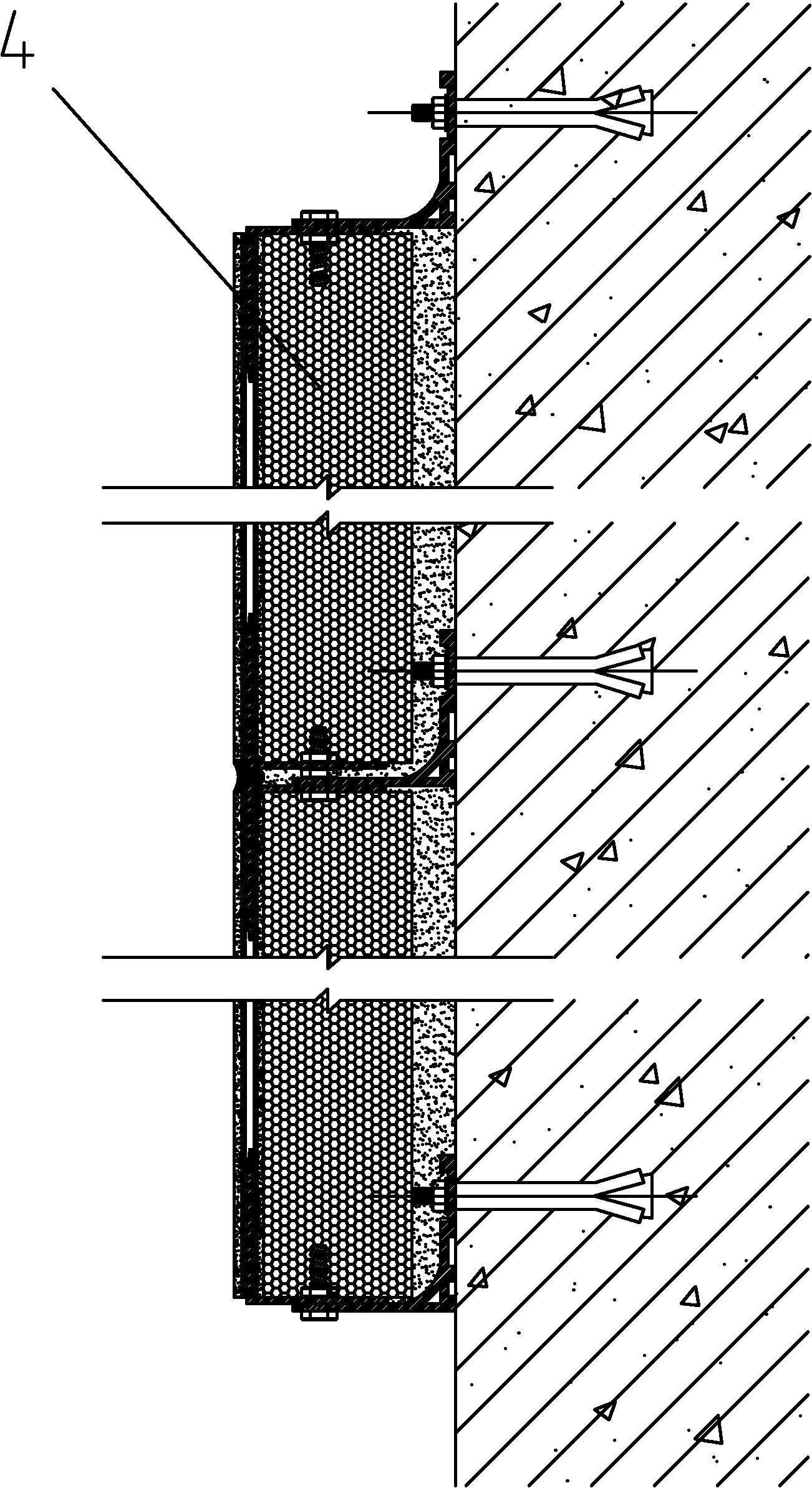

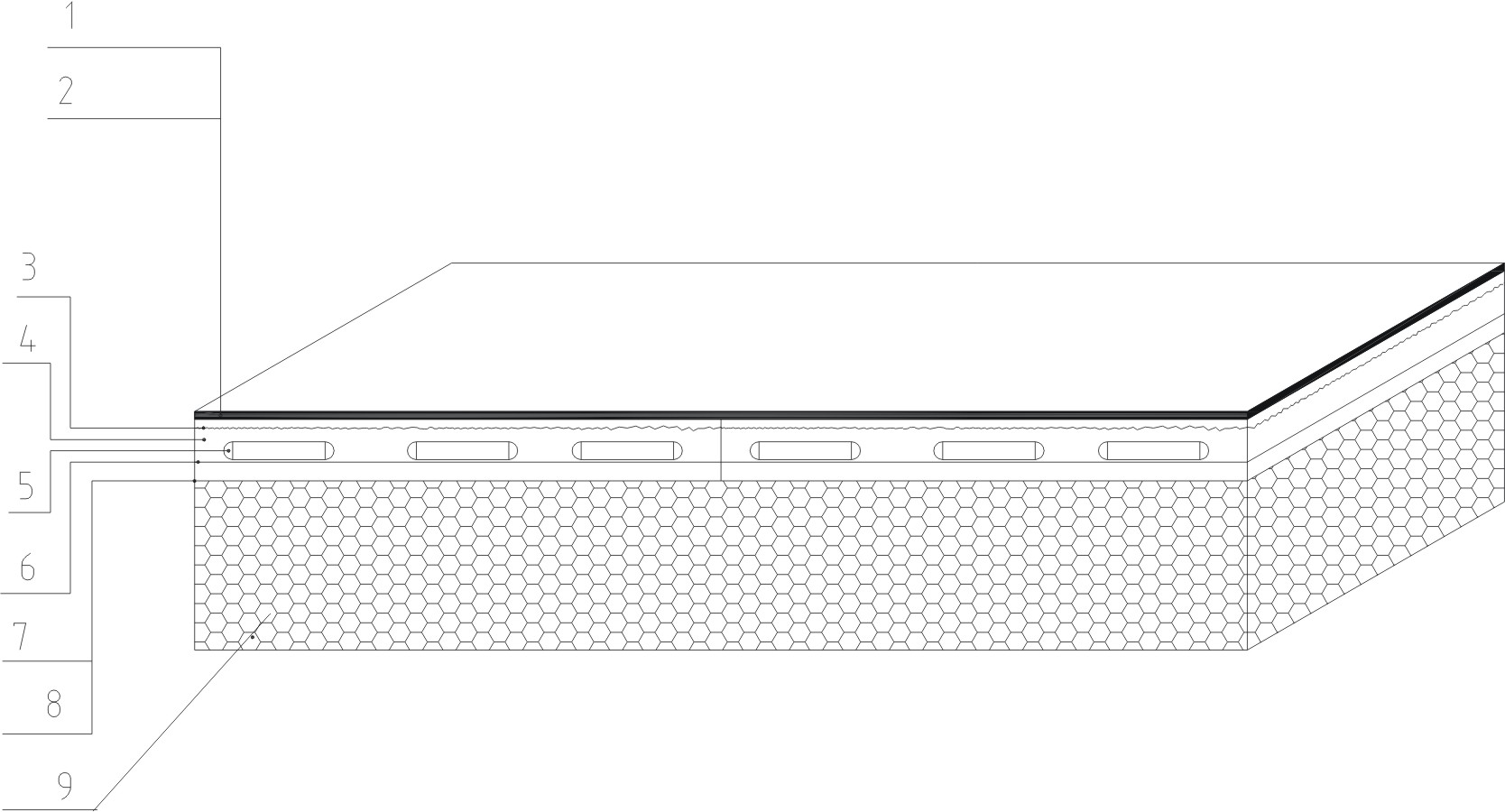

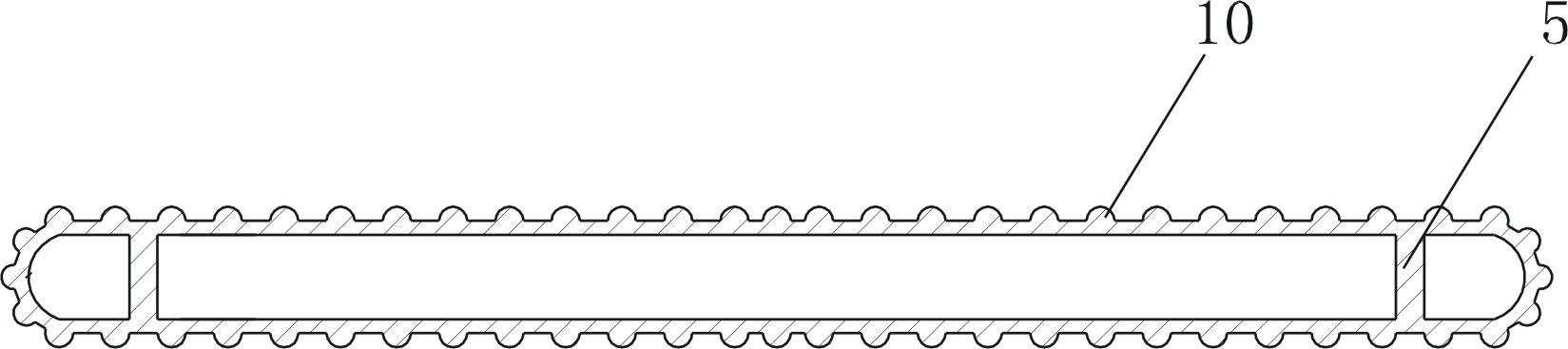

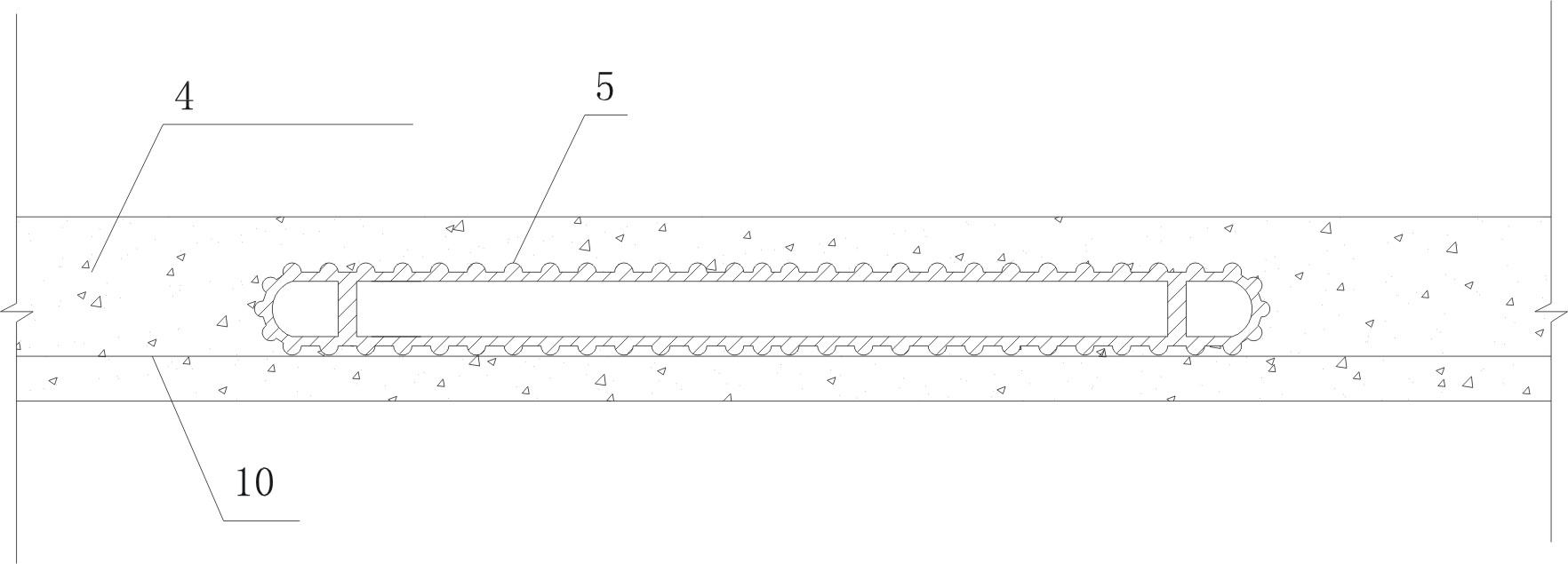

Process for mounting splicing type low-carbon heat insulating energy-saving plate

The invention relates to a process for mounting a splicing type low-carbon heat insulating energy-saving plate. The process is characterized by comprising the following specific steps of: processing a base layer; hanging a wire; anchoring a customized connecting hanging piece A; mounting a low-carbon heat insulating energy-saving plate of a bottom layer starting position; mounting a low-carbon heat insulating energy-saving plate; and cleaning the surface of the low-carbon heat insulating energy-saving plate, wherein a layer construction method from top to bottom is adopted during the installation. The invention has the advantages that the process for mounting the low-carbon heat insulating energy-saving plate is simple and quick; a special adjustable dry hanging connecting piece is matched; and a hollow splicing pipe is pre-embedded in a surface material decoration layer to ensure that the mounting process is firm and reliable and saves labor and time, thereby the construction period is shortened, and the mounting cost is greatly reduced.

Owner:易科美德(天津)环保建材有限公司

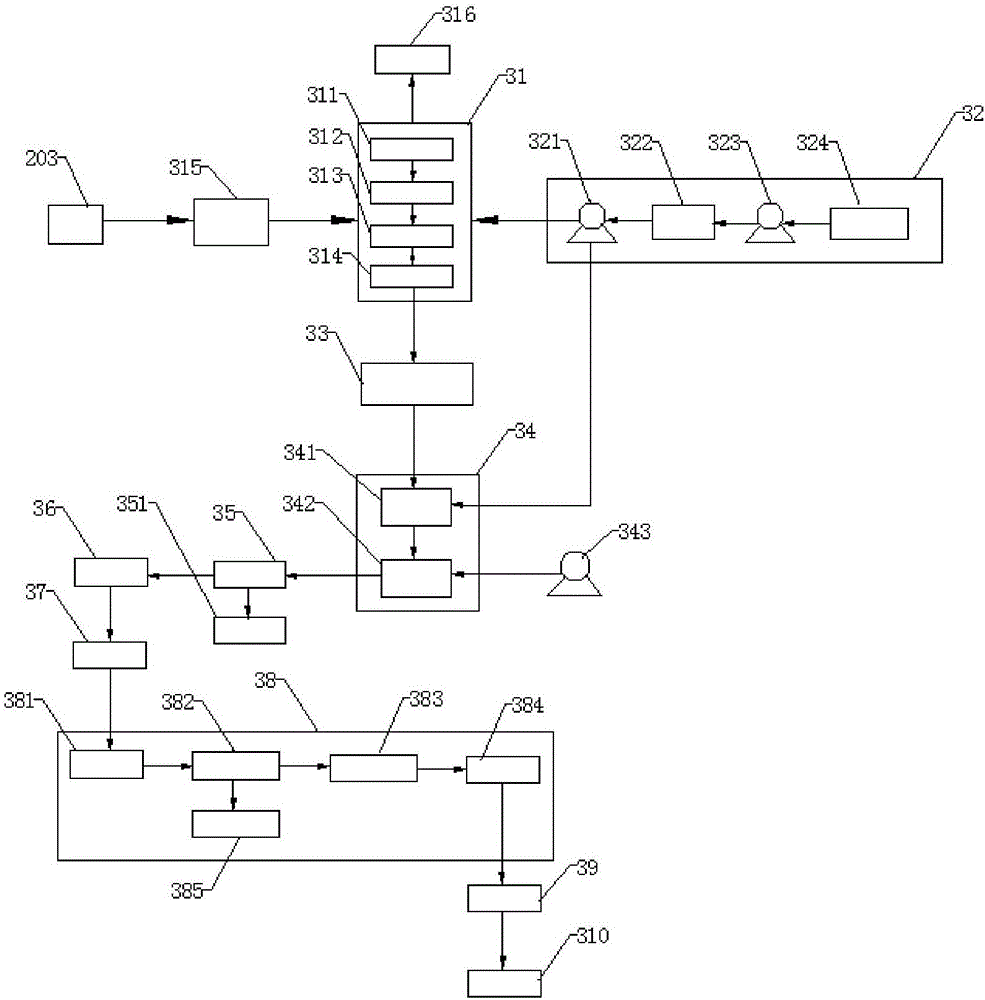

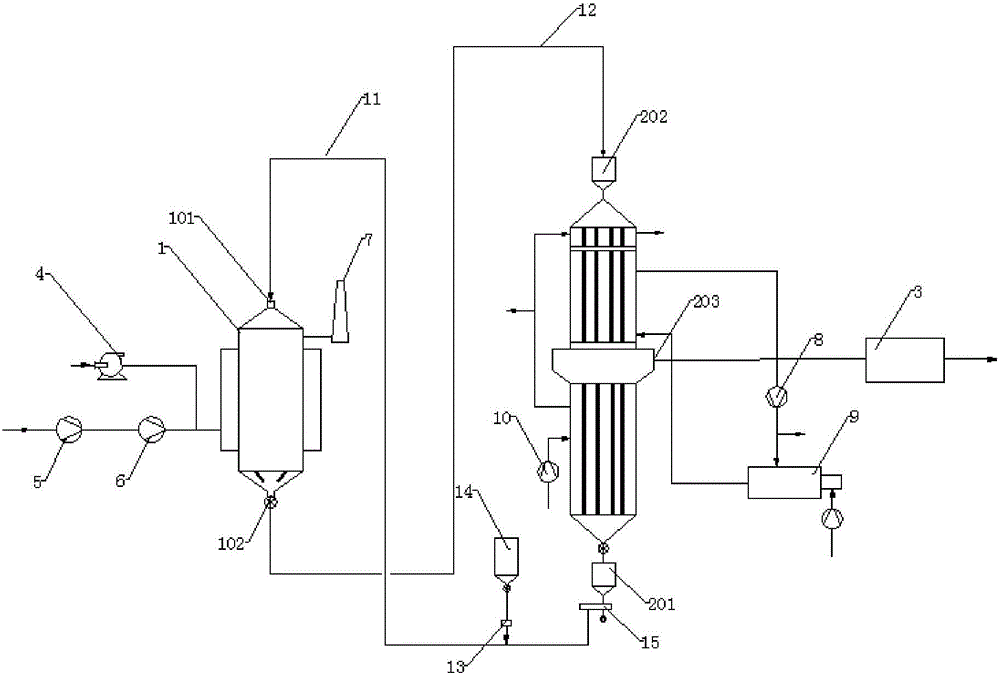

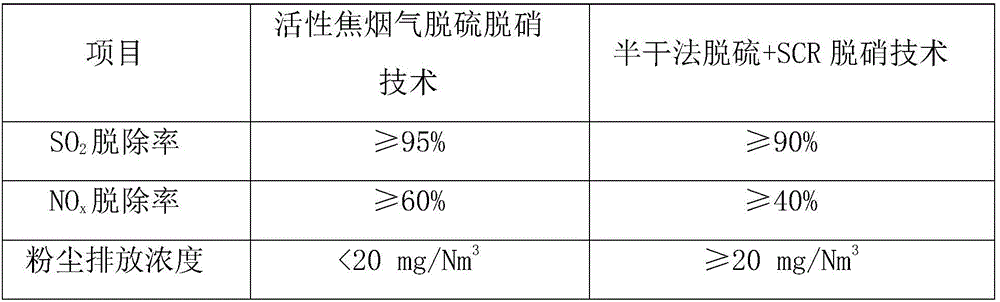

Conversion device of desulfurized and denitrified side products of active-coke flue gas, desulfurizing and denitrifying system and method

InactiveCN106178819AWide range of usesWaterproofGas treatmentDispersed particle separationEngineeringGas release

The invention belongs to the technical field of environmental protection, and relates to an integrated purification technology of flue (waste) gas, in particular to a conversion device of desulfurized and denitrified side products of active-coke flue gas, a desulfurizing and denitrifying system and a method. The conversion device comprises an absorbing tower, an alkali preparation unit, an intermediate-product storage tank, a neutralizing kettle, an evaporator, a concentrated-material tank, a centrifugal unit and a drying device, wherein the absorbing tower is provided with a gas inlet end which is connected with a output end of sulfur-dioxide gas released in the desulfurizing and denitrifying system of the active-coke flue gas; and the alkali preparation unit, the absorbing tower, the intermediate-product storage tank, the neutralizing kettle, the evaporator, the concentrated-material tank, the centrifugal unit and the drying device are connected in sequence. The conversion device, the desulfurizing and denitrifying system and the method have the advantages that the production additional value of the desulfurizing and denitrifying system of the active-coke flue gas can be increased, and the economic benefit can be improved, so that the economic and environment-friendly effects are achieved; the process is simple, the layout is compact, the energy consumption is low, and no waste water, solid waste and secondary pollution are caused, so that the resource recycling is realized.

Owner:朱双跃

A60-level lightweight refractory deck composition

InactiveCN103172329AImprove thermal insulationHigh-strength thermal insulationExpanded clay aggregateNeoprene

The invention provides an A60-level lightweight refractory deck composition, comprising at least one component A and component B, wherein the mass ratio of the component A to the component B is (1 to 6) to (1 to 8); the component A is neoprene latex; the component B is prepared from ordinary silicon 42.5 cement, large ceramsite, small ceramsite, large vermiculite and small vermiculite; the grain size of the large ceramsite is 2-5mm; the grain size of the small ceramsite is 0.5-2mm; the grain size of the large vermiculite is 2-4mm; the grain size of the small vermiculite is 0.2-2mm; and the component B contains the ingredients by weight ratio of 50-55% of ordinary silicon 42.5 cement, 20-25% of large ceramsite, 5-10% of small ceramsite, 14-20% of large vermiculite and 5-10% of small vermiculite. The A60-level lightweight refractory deck composition has good lightness, compressive property, fracture resistance and shock resistance, and can effectively prevent sound transmission and heat conduction; and the fire resistance can achieve A-60 level.

Owner:湖北海风新材料股份有限公司

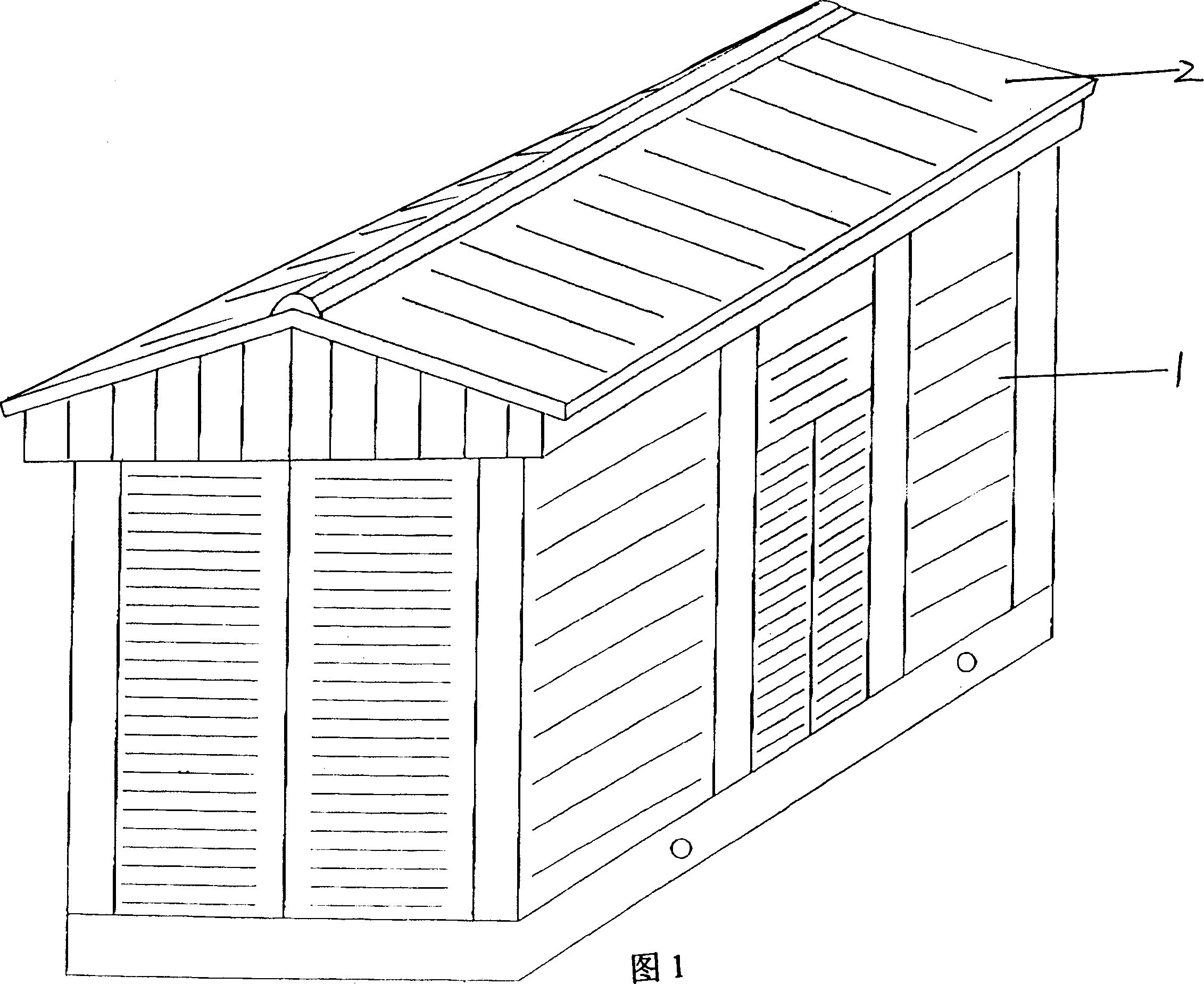

Processing method for assembling non-metal box transforming station case

InactiveCN1822460AVarietyHigh material strengthCeramic shaping apparatusSubstation/switching arrangement casingsFiberGlass fiber

Present invention relates to transformer station casing, in particular referring to transformer station stand casing working method, providing a low cost, simple processing, assembly type nonmetal tank type transformer station shell. Present invention working method as follows, selecting fiberglass reinforced plastics resemble type art mould, casting cement, spun glass, sand and intensifier surface layer pulp in mould, then casting main part pulp in mould, stripping, integrally welding roof shell and wall shell through pre-burying member. Said invented transformer station casing has shock resistant and indehiscent property, adopting artistic design mould production process capable of once moulding out tree stem, timber, bamboo, masonry, straw, lacework and pattern, reducing and cost.

Owner:王亦民

Heat conducting insulating film material and method for manufacturing same

InactiveCN101333314AHigh thermal conductivityEasy to shapePlastic/resin/waxes insulatorsCooling/ventilation/heating modificationsFilm materialBoron nitride

The invention relates to thermally conductive insulated film material and a fabrication method thereof. The material contains 8-20wt% of cubic boron nitride, 5-15wt% of nano zirconia, 2-10wt% of nano-molybdenum disulfide, and 60-85wt% of rubber material; wherein the rubber material is rubber material capable of withstanding rolling and biaxial tension, particularly polyisobutylene. The fabrication method is that: putting above materials based on mixture ratio into a reactor or a double screw extruder; mixing for 1-5h under 150-170 DEG C; molding through rolling at temperature of 100-250 DEG C and pressure of 100-300MPa; molding through stretching: firstly, fusing and extruding the sheet material or the thick film, then conducting biaxial stretching to the sheet material or the thick film; the film will be finished after certain cooling or heating treatment. The film is 0.01-3mm thick, with thermal conductivity of 5-20W / mK and volume resistivity of 0.1*10<5>m-1.7*10<5>m.

Owner:晟茂(青岛)先进材料有限公司

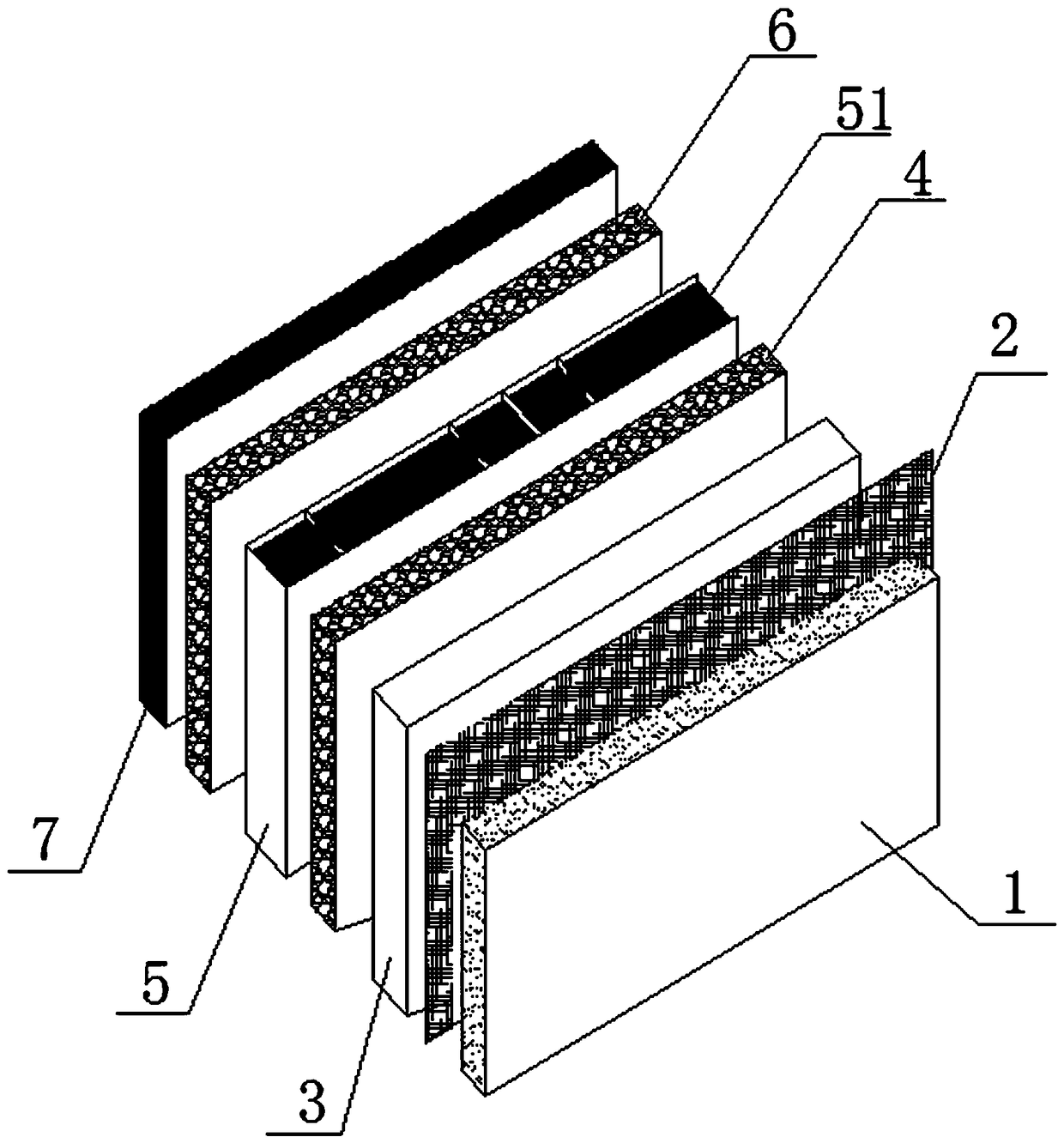

Plug-in type low-carbon heat preservation energy-saving board

The invention relates to a plug-in type low-carbon heat preservation energy-saving board, which is characterized in that the board is an integral board formed by sequentially connecting a decorative finishing layer, a finishing layer, a middle layer glass fiber mesh, a low-carbon board, a stainless steel welded mesh, a bottom layer glass fiber mesh, a soundness glue layer and an SPS extrusion molding heat preservation board. The invention has the advantages that the board not only is an excellent substitute for coatings, ceramic tiles, stones, timbers and metal boards, but also has a heat preservation function which simultaneously simplifies the complicated construction steps specified in three-step energy-saving requirements of national regulation, and ensures that the heat preservation and energy saving as well as decorative effects are achieved synchronously; and the installation process is simple and fast, special matched adjustable dry hanging connecting pieces are provided, and a hollow plug-in pipe is embedded in a plane material decorative layer in advance, which enables the installation process to be firm and reliable.

Owner:易科美德(天津)环保建材有限公司

Self-insulating composite wallboard and production method

PendingCN105672561AEasy to installStrong nail gripClimate change adaptationBuilding componentsTwo layerTextile

The invention discloses a self-insulating composite wallboard which comprises an outer board and an inner board.In the outer board, two layers of outer grid cloth clamp a middle board in the middle and are sewn and connected together through inorganic alkali-resisting sewing threads and arranged in cement-based mortar.In the inner board, inner grid cloth is arranged on the inner side of steel wire meshes, and the steel wire meshes and the inner grid cloth are evenly arranged in the cement-based mortar.One side of the outer board is fixedly connected with the outer side of the inner board together.The invention further discloses a production method of the self-insulating composite wallboard.The outer board is firstly produced, then the inner board is manufactured, the outer board is arranged on the inner board when inner board mortar is not dried, and the composite wallboard is obtained after drying.The self-insulating composite wallboard adopts the structure that the inner board and the outer board are compounded and meanwhile has the advantages of self insulation, heat insulation, water proofing, fire proofing, cracking prevention, seismic resistance, fracture resistance, light weight, convenient installation, any cutting, strong nail-holding power and convenient slotting and pipe laying.

Owner:罗寅

Super-smooth plastic colored pencil and production process thereof

InactiveCN107053898AWith mechanical propertiesWith cutting performancePencil leadsNon-propelling pencilsFiberModified carbon

The invention relates to a super-smooth plastic colored pencil which comprises a penholder, a skin and a refill, wherein the refill is produced from the following materials in parts by weight: 20-30 parts of polystyrene, 10-20 parts of SBS, 30-50 parts of talcum powder, 10-20 parts of pigment, 1-5 parts of pigment dispersant, 1-5 parts of lubricating assistant, 1-5 parts of seaweed extract, 2-5 parts of modified carbon fiber and 3-6 parts of modified polycarbonate. According to the invention, high polymer material is adopted, and the pencil produced according to a scientific and reliable formula has the physical and mechanical performances and cutting characteristic of wood pencils, can resist falling and fracture, is smooth in writing and moderate in concentration and abrasion, and can be subjected to various contour machining on common machining equipment.

Owner:ZHEJIANG PENGSHENG STATIONERY CO LTD

Crease-proof fire-proof heat-conductive and electrically insulating plastic composition and its prepn

The present invention relates to one kind one polypropylene-base plastic composition and its preparation process. The composition contains alumina 50-80 wt% and fireproof polypropylene composition 20-50 wt%. The fireproof polypropylene composition consists of pentaerythritol phosphate and melamine polyphosphate in the ratio of 1 to 2-4 in 28-40 wt%, propylene monopolymer in 0-30 wt% and propylene copolymer in 30-72 wt%. The insulating sheet made of the composition has excellent breaking performance, fireproof performance, heat conductance and electric insulating performance, is environment friendly and may be used in electric equipment and electronic equipment products.

Owner:SUN YAT SEN UNIV

Wall of light steel structural house

The invention discloses a wall of a light steel structural house. The wall is divided into an inner wall and an outer wall, wherein the inner wall is composed of gypsum boards, wall surface OSBs and alight steel keel, with the light steel keel as a bearing framework, the two sides of the light steel keel are each provided with one wall surface OSB, and the gypsum boards are located on the outermost layers; the outer wall is composed of a gypsum board, one wall surface OSB, a light steel keel, the other wall surface OSB, an insulating layer, a ventilation layer and an outer wall hanging platefrom inside to outside. The middle of each light steel keel is filled with a heat preserving and insulating material, a wood keel is arranged in the middle of the ventilation layer, breathing paper isattached to the surface, close to the insulating layer, of the ventilation layer, and all layers of the inner wall and the outer wall are connected together by cold-rolled steel nails from the two sides in a fastened mode. The wall is low in weight and good in wind and quake resistance, has good features of heat preserving and insulating, sound insulating, fire resistance, moisture prevention, corrosion prevention and the like, and can be widely applied to office buildings, villas, storehouses, stadiums, entertainment venues and tourism buildings.

Owner:黎金莲

Non-asbestos high-density temperature and wear resisting heat insulation plate and processing technology thereof

ActiveCN105084812AEliminate environmental risksHigh temperature resistantSolid waste managementFiberGlass fiber

The invention discloses a non-asbestos high-density temperature and wear resisting heat insulation plate. The heat insulation plate is characterized by comprising, by weight, 200-260 parts of kaolin, 15-40 parts of alumina powder, 200-260 parts of aluminum silicate refractory fiber, 10-20 parts of dry paper pulp, 5-15 parts of glass fiber, 10-20 parts of cationic starch, 1-1.5 parts of polyvinyl alcohol and 1-1.5 parts of high-elastic emulsion. The non-asbestos high-density temperature and wear resisting heat insulation plate completely has no asbestos, eliminates environment risks brought by asbestos fiber in the production, maintenance and cleaning processes, is environmentally friendly and has the advantages of resisting high temperature, high pressure, bending and wear, being high in density and good in tenacity and the like. The high temperature lower than or equal to 1200 DEG C can be resisted, and the density reaches up to 900-1100 kg / m<3>. The tenacity is good, and the compression ratio can reach 1:1.4. The shot content in the non-asbestos high-density temperature and wear resisting heat insulation plate is low, and it is ensured that products making contact with the heat insulation plate are not damaged in the using process.

Owner:JINGMEN KAIDI IND TECH CO LTD

Preparation method of low-resistance low-additive conductive thin film

InactiveCN104575870AAdd lessGood electrical conductivityCable/conductor manufactureChemistryN-butyl acrylate

The invention discloses a preparation method of a low-resistance low-additive conductive thin film. A reaction is conducted after stirring and dissolving are carried out on an ethylene glycol solution of AgNO3, PVP and FeCl3. A nanometer silver wire is obtained after cooling, acetone washing, deionized water washing and centrifuging are carried out. Even mixing is carried out on the nanometer silver wire, cellulose nanocrystalline, dimethylacrylic acid polyol / polyether and butyl acrylate. Dehydration and the deoxygenization are carried out by injecting nitrogen, and the mixture is sealed in a mould. The low-resistance low-additive conductive thin film is obtained after catalytic curing is conducted through azodiisobutyronitrile. According to the preparation method of the conductive thin film, a compound of the cellulose nanocrystalline, the dimethylacrylic acid polyol / polyether and a butyl acrylate copolymer is used as a base material, the base material has the percolation network of hydrogen bonds and the entropy elasticity of highly cross-linked high molecules, and therefore the thin film has the breaking resistance and the high elasticity. The prepared conductive thin film has the advantages that the additive amount of conductive materials is low, the electric conducting capability is good, and the volume resistivity is low.

Owner:XIAN UNIV OF TECH

Anti-seismic vegetable fiber cement composite strip plate and producing method thereof

InactiveCN104909655AImprove corrosion resistanceImprove water resistanceSolid waste managementAcoustic absorptionThermal insulation

The present invention discloses an anti-seismic vegetable fiber cement composite strip plate which is prepared from the following raw materials by weight: 30-35 parts of vegetable fiber, 20-25 parts of Portland cement, 40-46 parts of fly ash, 10-20 parts of silica fume, 10-13 parts of diatomite, 7-9 parts of nano calcium carbonate, 3-5 parts of algae carbon fiber, 0.2-0.4 part of potassium bisulfate, 0.3-0.5 part of aluminum nitride, 14-18 parts of water-soluble phenolic resin, 6-10 parts of glycol dimethacrylate, 4-6 parts of methylsilicone oil, 0.1-0.2 part of polyvinylpyrrolidone, and proper amount of water; the obtained anti-seismic vegetable fiber cement composite strip plate has the advantages of anti-seismic, acoustic absorption thermal insulation, compressive strength, fracture resistance, strong density, good permeability and the like, and is suitable for large-scale construction of the anti-seismic energy-saving houses.

Owner:HEFEI RUIHE DECORATION ENG

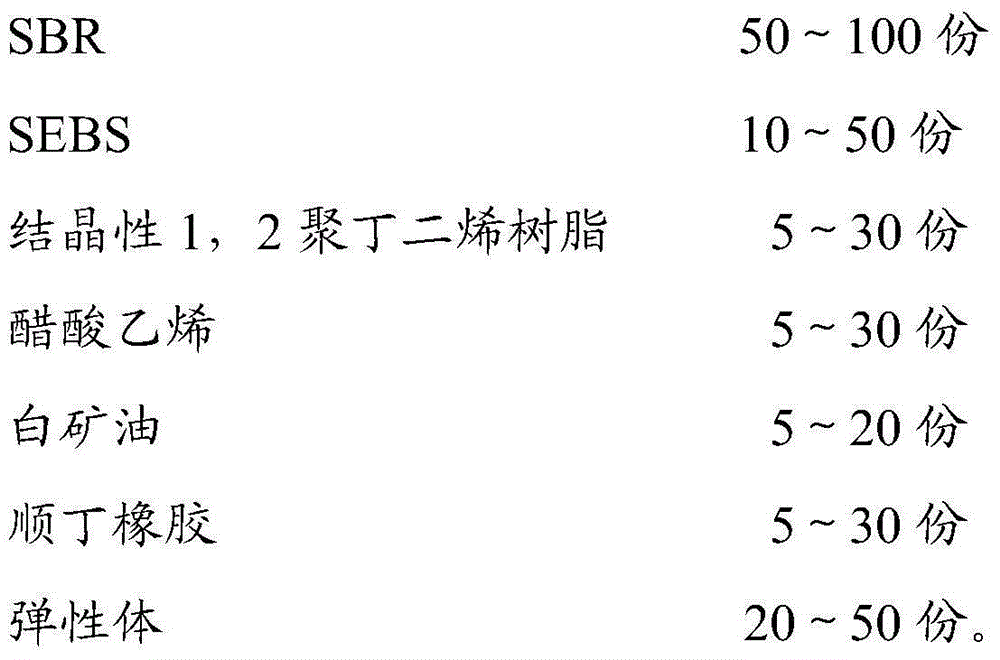

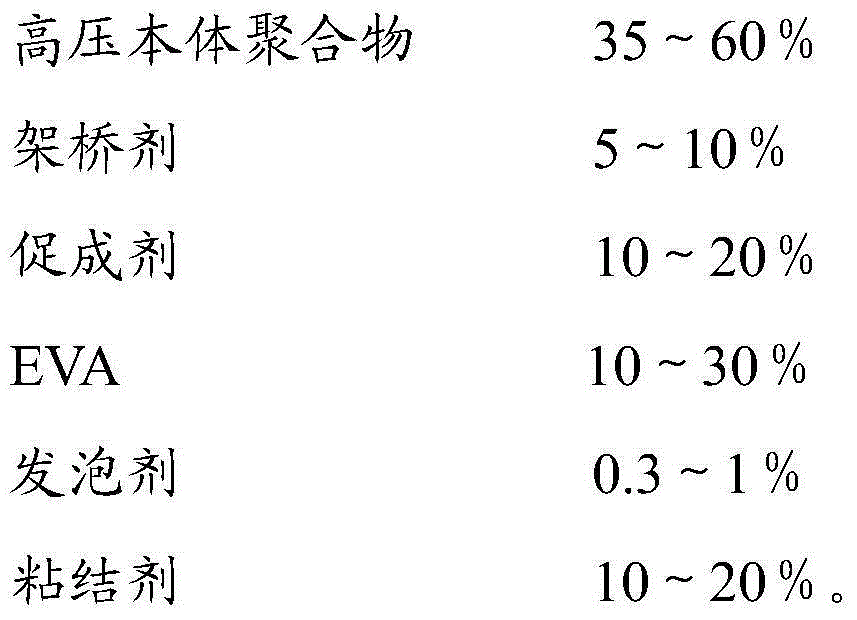

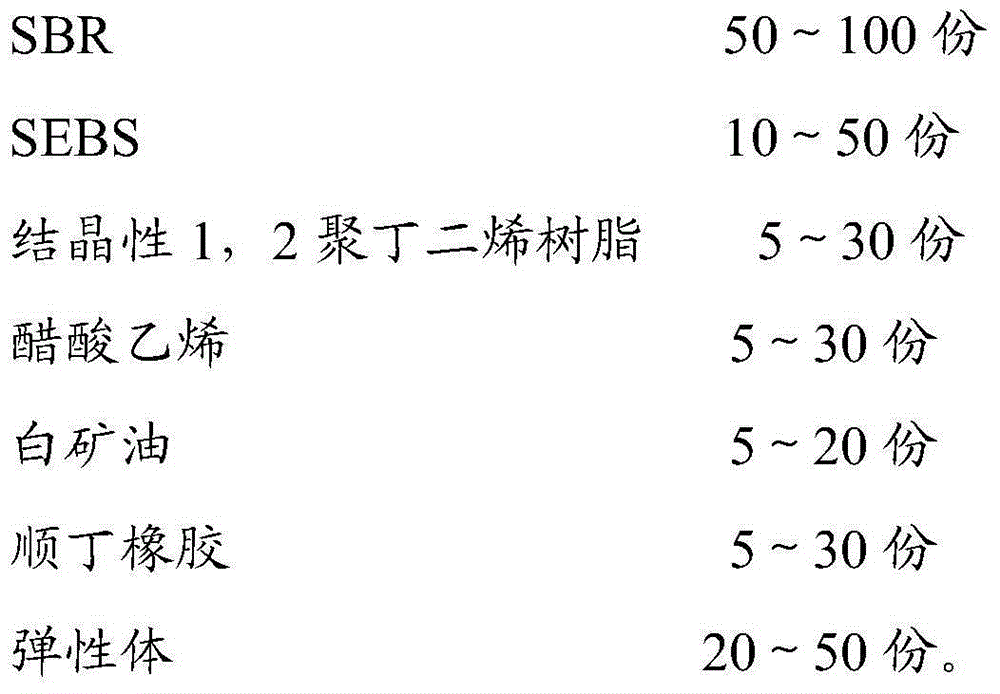

Polymer composite lightweight rubber and preparation method thereof

The invention belongs to the technical field of new materials and in particular relates to polymer composite lightweight rubber and a preparation method thereof. The rubber comprises the following components in parts by weight: 50-100 parts of SBR (styrene butadiene rubber), 10-50 parts of SEBS (styrene-ethylene / butylene-styrene elastomer), 5-30 parts of crystalline 1,2-polybutadiene resin B, 5-30 parts of vinyl acetate, 5-20 parts of white mineral oil, 5-30 parts of cis-polybutadiene and 20-50 parts of elastomer. The rubber and the preparation method have the beneficial effects that the rubber has excellent properties as traditional vulcanized rubber, such as high elasticity, aging resistance, high wear resistance and oil resistance, also has the independent characteristics of high property, light specific gravity, flex resistance, high pressure resistance and no vulcanization and can be produced by adopting the processing methods, such as injection molding, extrusion and blow molding; wastes (extruded waste rubber and raw edges) generated in the production process and finally emerging wastes can be directly returned and recycled, thus reducing the cost and environmental pollution and expanding the resource regeneration sources.

Owner:DONGGUAN JISU PLASTIC TECH

Method for remediating uranium-contaminated soil by virtue of woody plants

ActiveCN107309258AImprove survival rateEasy SurvivalContaminated soil reclamationWoody plantUranium mine

The invention relates to a method for remediating uranium-contaminated soil by virtue of woody plants. The method for remediating the uranium-contaminated soil by virtue of the woody plants specifically comprises the following steps: branches of American bamboo-willow No. 3 are directly cut in the uranium-contaminated soil, and survive and grow, the American bamboo-willow No. 3 absorbs uranium in the soil into the own bodies of the plants during a growth process and transfers uranium to overground parts, and the overground parts are harvested and subjected to centralized treatment, so that uranium in the uranium-contaminated soil is reduced; and meanwhile, lots of uranium can also be fixed in roots of the American bamboo-willow No. 3, so that migration and diffusion of uranium are reduced. The method is applicable to remediation for uranium-contaminated soil in the peripheries of places such as uranium mines, uranium hydrometallurgical plants, uranium waste-rock yards and uranium tailing reservoirs.

Owner:NANHUA UNIV

High polymer material for pipeline and preparation method of high polymer material

The invention relates to a high polymer material for a pipeline and a preparation method of the high polymer material. The high polymer material comprises 4-8 parts of urea resin, 3-10 parts of polyisocyanurate, 2-6 parts of polyisobutene, 3-8 parts of brominated butyl rubber, 3-6 parts of dicyclohexyl phthalate, 2-5 parts of glass fiber, 4-7 parts of polytetrafluoroethylene, and 3-8 parts of furan resin. The preparation method comprises the following steps: step 1, taking all of the components, feeding the components in an agitator tank, and heating the agitator tank till the components are smelted; step 2, conducting twin-screw extrusion on the uniformly stirred material in the step 1 with a twin-screw extrusion machine, extruding out the material and granulating the material to obtain the high polymer material for the pipeline. The prepared high polymer material for the pipeline has the advantages of being high in tensile strength and shock strength.

Owner:苏州凯欧曼新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com