Non-woven filter felt combining air-laid web with pinprick reinforcement and production method

An air-laid and non-woven technology, applied in the field of filter felt, can solve the problems of high fiber damage rate, unsatisfactory filtration performance and service life, etc., and achieve high physical and mechanical properties, high tensile strength and low running resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is made through the following steps as a nonwoven felt combined with air-laid and needle-punched reinforcement and its manufacturing method:

[0041] Step 1. Fabrication of the base fabric—weaving the glass fiber yarn into a high-strength and low-stretch base fabric;

[0042] Step 2. Fabrication of surface layer—mix glass fiber and P84 fiber at a ratio of 7:3, and then air-laid to make a fiber surface layer.

[0043] Among them, the air-laid process adopts the air flow to transport the fibers to form a uniform fiber web with disorderly arrangement of fibers. Under the joint action of the airflow, the fibers fall off from the sawtooth, and are evenly transported by the airflow to condense on the mesh curtain, forming a three-dimensional distribution, and a fiber web with small vertical and horizontal strength differences.

[0044] The specific air-laid process steps are as follows:

[0045] (1) Opening

[0046] (2) Removal of impurities

[0047] (3) M...

Embodiment 2

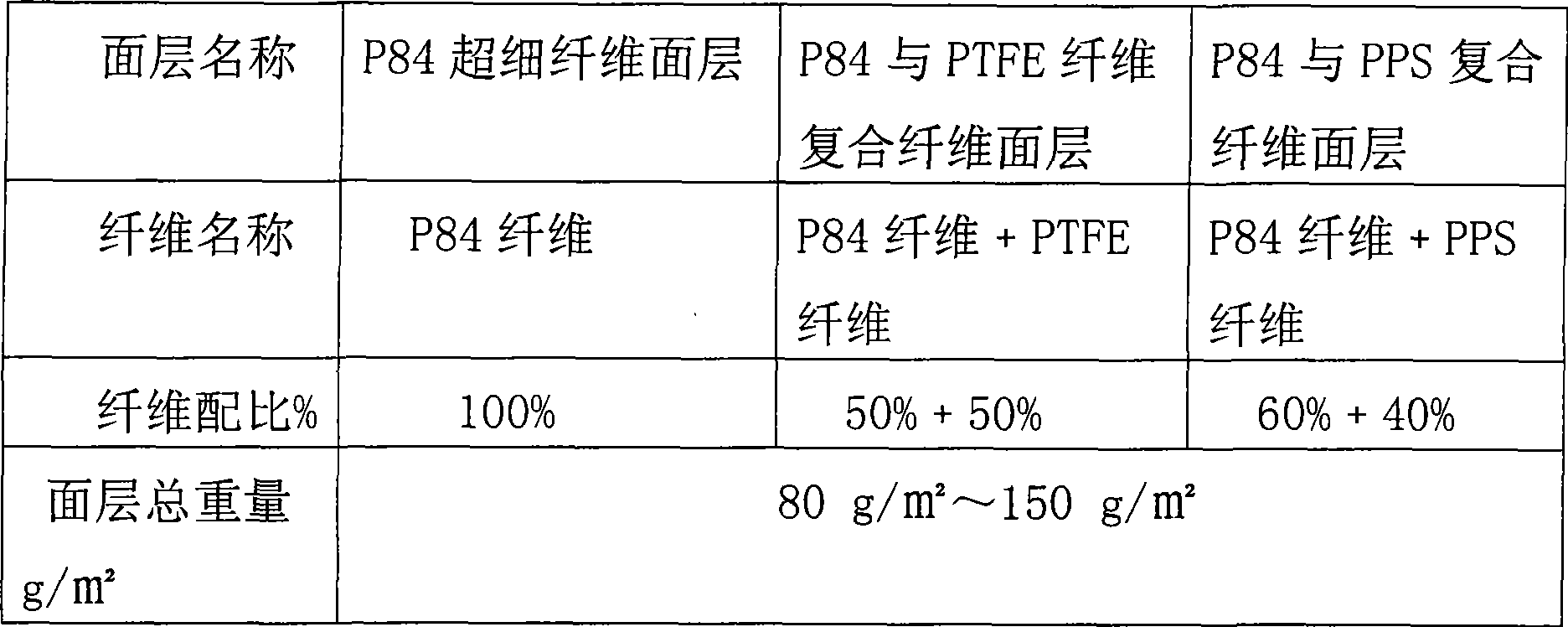

[0081] This embodiment is basically the same as Embodiment 1, except that the fiber surface layer adopts a P84 superfine fiber layer. For special industrial and mining conditions, the air-laid method has been developed to make ultra-fine fiber surface layers, such as: P84 ultra-fine fiber surface layer, P84 and PTFE fiber composite ultra-fine surface layer, P84 and PPS fiber composite ultra-fine surface layer, etc., to achieve surface Combined with deep filtering. The weight of the microfiber surface layer is 80g / m 2 ~150g / m 2 .

[0082] The ratio of ultra-fine surface layer fibers is shown in Table 7:

[0083]

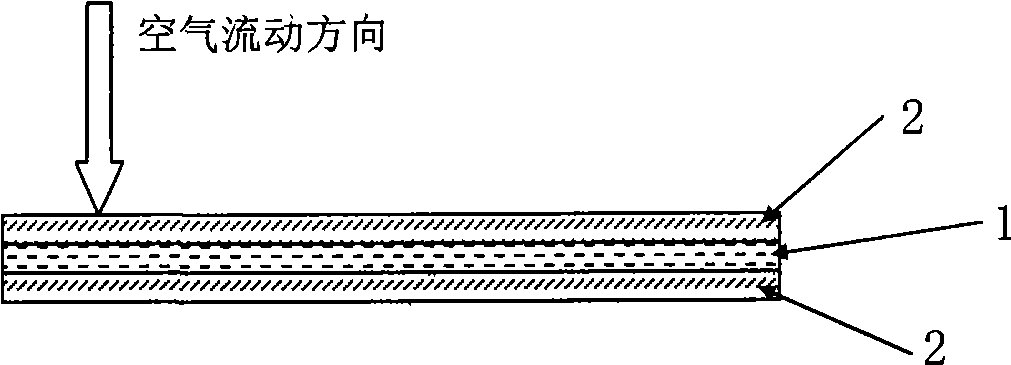

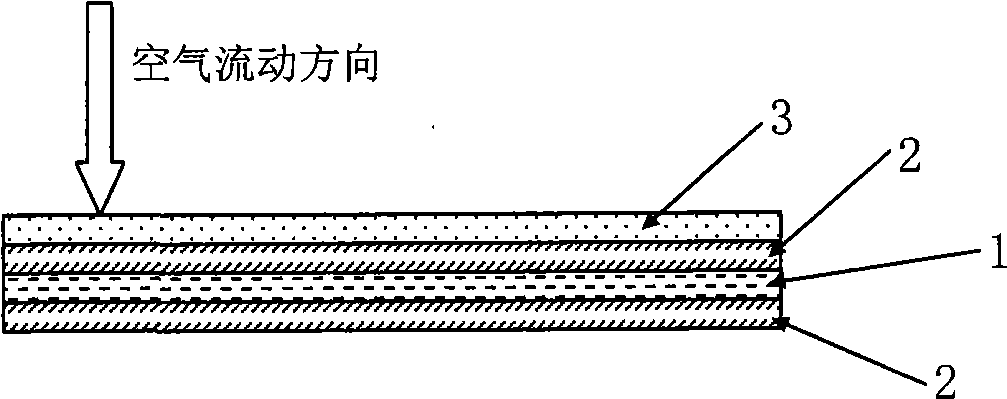

[0084] Needle-punched felt production--stack two layers of fiber surface layers and glass fiber base cloth, the glass fiber base cloth is located in the middle of the fiber layer, and then attach an ultra-fine surface layer on the upper surface of the fiber layer, and then form it by needle punching felt.

[0085] The acupuncture process parameters are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com