Wall of light steel structural house

A light steel structure and wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of no wind resistance and earthquake resistance, the strength does not meet the requirements, and the high requirements are not met, and achieve excellent thermal insulation. The effect of heat insulation, good wind and shock resistance, and high screw holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

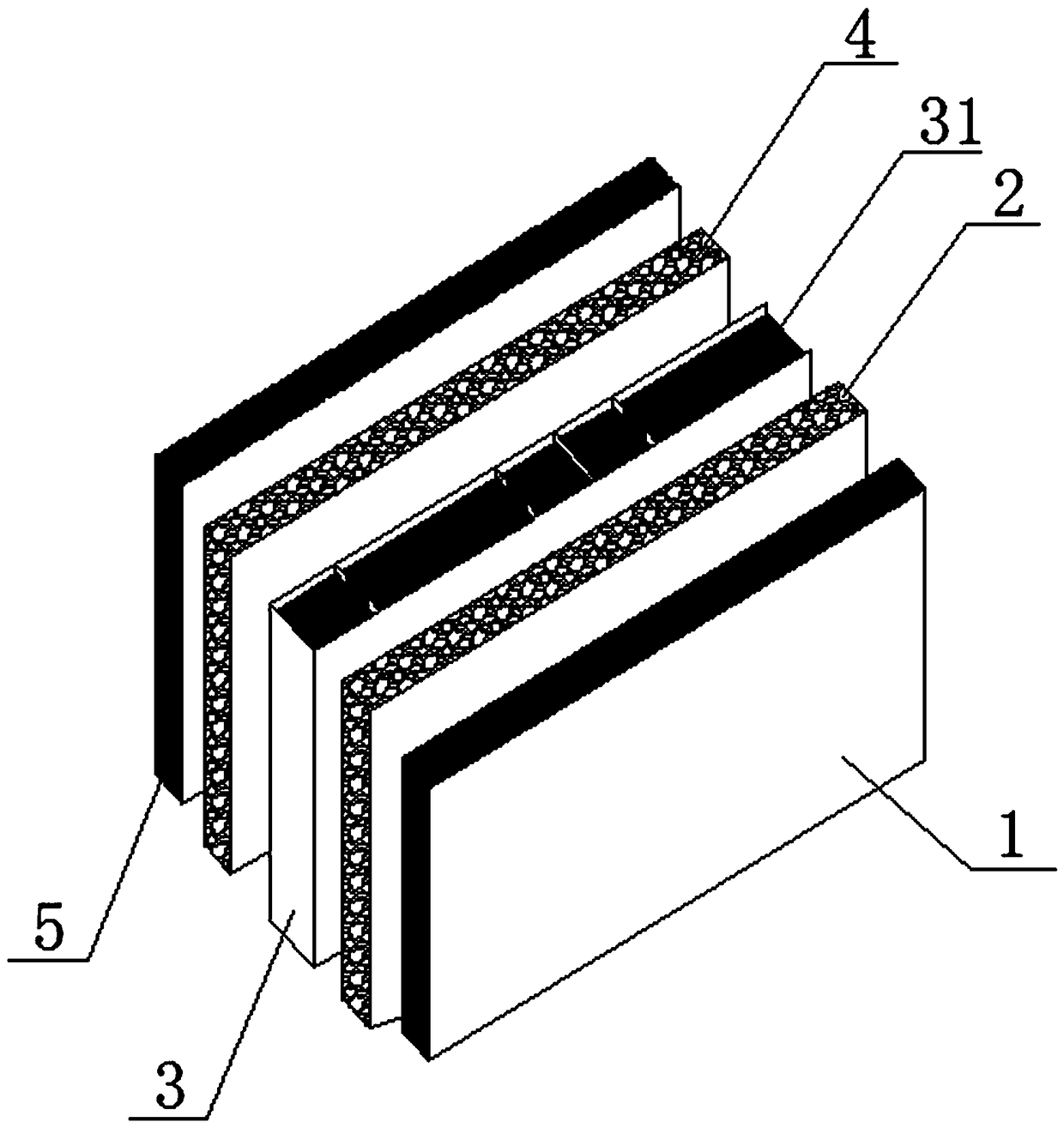

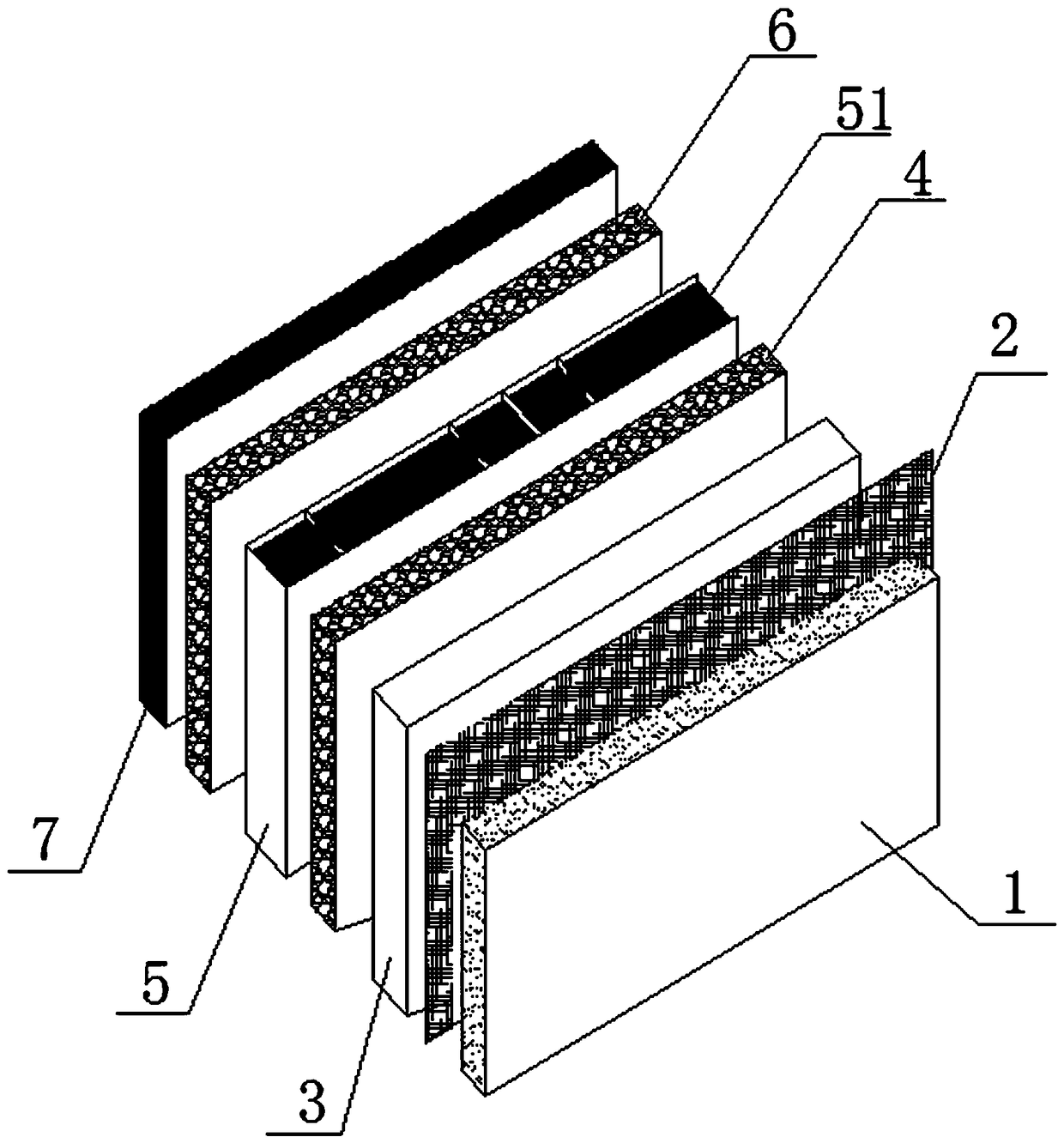

[0024] The wall of a light steel structure house is divided into an inner wall and an outer wall. The inner wall is composed of gypsum board, wall OSB board, and light steel keel. The light steel keel is used as the load-bearing framework, and there is a wall OSB board on each side. The outer layer is gypsum board; see the structure diagram figure 1 In the figure, 1 is gypsum board, 2 is wall OSB board, 3 is light steel keel, 31 is thermal insulation material, 4 is wall OSB board, and 5 is gypsum board. From the inside to the outside, the external walls are gypsum board, wall OSB board, light steel keel, wall OSB board, insulation layer, ventilation layer, external wall hanging board, see the structure diagram figure 2 In the figure, 1 is the external wall hanging board, 2 is the breathing paper, 3 is the insulation layer, 4 is the wall OSB board, 5 is the light steel keel, 51 is the thermal insulation material, 6 is the wall OSB board, 7 is the gypsum board. The light steel ...

Embodiment 2

[0034] The wall of a light steel structure house is divided into an inner wall and an outer wall. The inner wall is composed of gypsum board, wall OSB board, and light steel keel. The light steel keel is used as the load-bearing framework, and there is a wall OSB board on each side. The outer layer is gypsum board; see the structure diagram figure 1 In the figure, 1 is gypsum board, 2 is wall OSB board, 3 is light steel keel, 31 is thermal insulation material, 4 is wall OSB board, and 5 is gypsum board. From the inside to the outside, the external walls are gypsum board, wall OSB board, light steel keel, wall OSB board, insulation layer, ventilation layer, external wall hanging board, see the structure diagram figure 2 In the figure, 1 is the external wall hanging board, 2 is the breathing paper, 3 is the insulation layer, 4 is the wall OSB board, 5 is the light steel keel, 51 is the thermal insulation material, 6 is the wall OSB board, 7 is the gypsum board. The light steel ...

Embodiment 3

[0044] The wall of a light steel structure house is divided into an inner wall and an outer wall. The inner wall is composed of gypsum board, wall OSB board, and light steel keel. The light steel keel is used as the load-bearing framework, and there is a wall OSB board on each side. The outer layer is gypsum board; see the structure diagram figure 1 In the figure, 1 is gypsum board, 2 is wall OSB board, 3 is light steel keel, 31 is thermal insulation material, 4 is wall OSB board, and 5 is gypsum board. From the inside to the outside, the external walls are gypsum board, wall OSB board, light steel keel, wall OSB board, insulation layer, ventilation layer, external wall hanging board, see the structure diagram figure 2 In the figure, 1 is the external wall hanging board, 2 is the breathing paper, 3 is the insulation layer, 4 is the wall OSB board, 5 is the light steel keel, 51 is the thermal insulation material, 6 is the wall OSB board, 7 is the gypsum board. The light steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com