Porous perlite sound absorption material

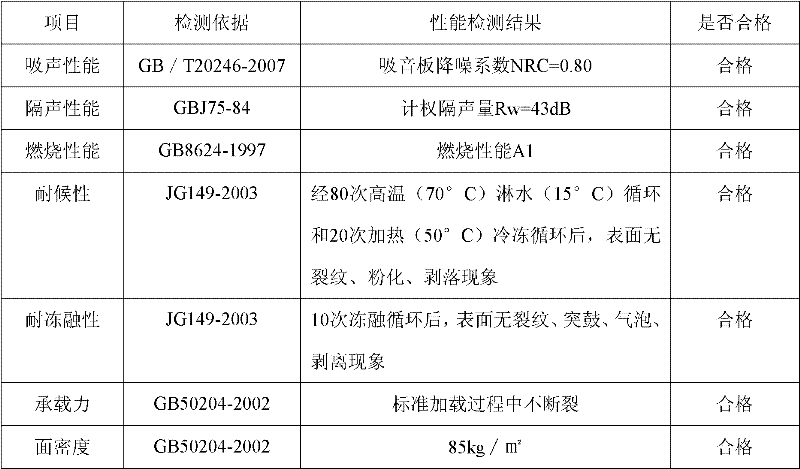

A sound-absorbing material, perlite technology, applied in the field of expanded perlite sound-absorbing material formula and production technology, can solve the problems of being unable to replace fibrous sound-absorbing materials, narrow sound-absorbing frequency band, poor performance such as fire resistance and aging resistance, etc. Achieve excellent sound absorption effect, high compressive strength, and sound absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Acoustic panels:

[0016] The material of the sound-absorbing board adopts the following ratio (mass ratio): 1 part by weight of perlite; 6 parts by weight of ordinary Portland cement; 0.3 part by weight of rapid-hardening sulfoaluminate cement; and 0.1 part by weight of phenylacrylic acid emulsion as the polymer emulsion; The granulating agent is 0.1 part by weight of vinyl acetate emulsion; the plasticizer is 0.01 part by weight of polyacrylamide emulsion; the early strengthening agent is 0.1 part by weight of sodium aluminate.

[0017] Bottom plate:

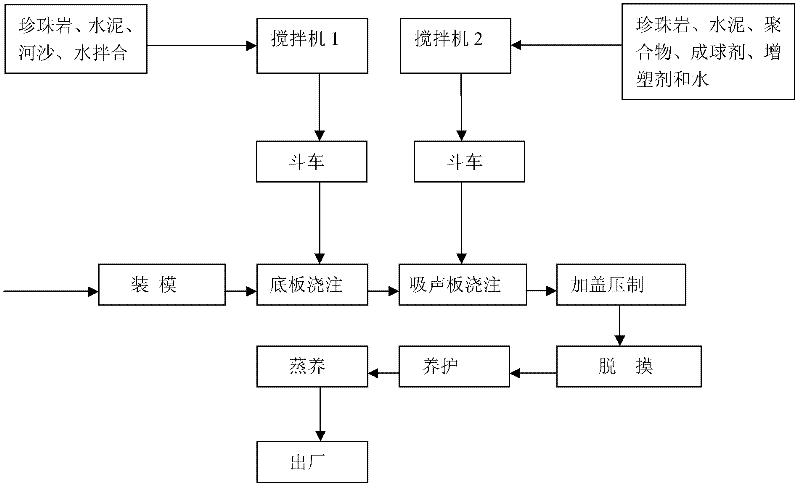

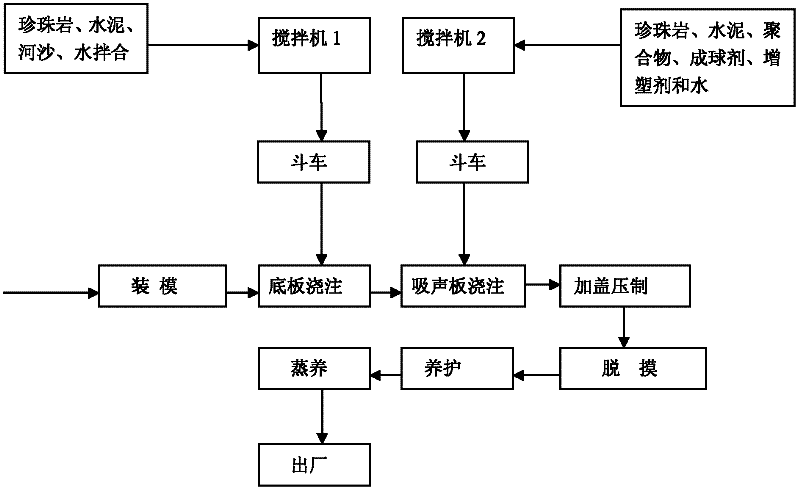

[0018] The bottom plate material adopts the following ratio (mass ratio): 1 weight part of perlite; 8 weight parts of ordinary Portland cement; 1 weight part of rapid hardening sulfoaluminate cement; and 5 weight parts of river sand. And make according to the technological process of Fig. 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com