Structure parameter design method for suppressing nonlinear effect of micro-perforated plate

A non-linear effect, micro-perforated plate technology, applied in the field of sound absorption and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Example 1: Design and realize the structural parameters of the micro-perforated plate sound absorbing body with nonlinear suppression to 110dB.

[0118] First, in step 1, analyze the frequency spectrum and sound pressure level of the high sound intensity noise field, and determine that the maximum sound pressure level of the actual noise environment is P 0 =110dB and the maximum noise reduction frequency point is f 0 = 2000Hz;

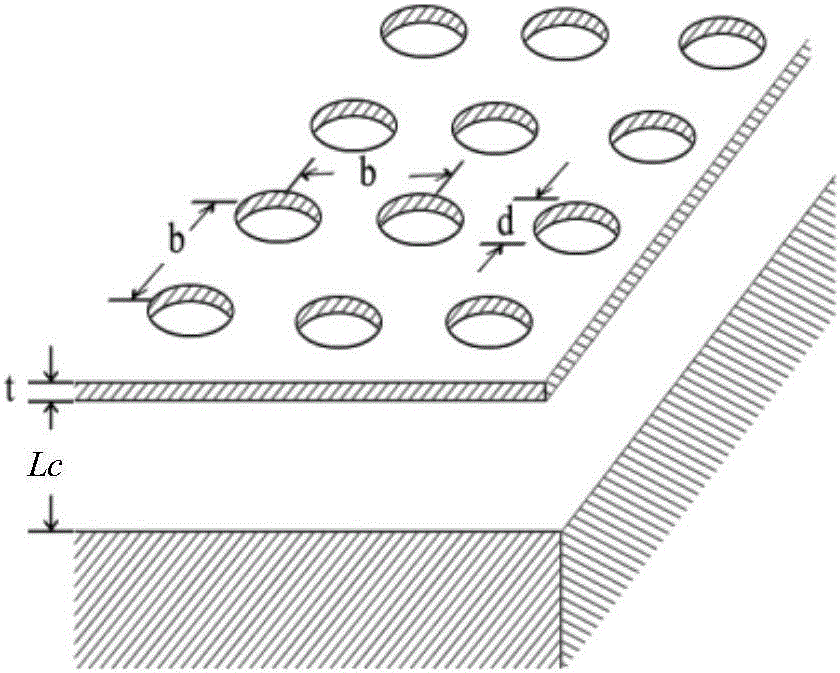

[0119] Later, since 110dB is moderate, considering the production cost, a larger aperture and a smaller perforation rate can be selected first. Therefore, first select d=0.5×10 -3 m, t / d=1, calculated according to the formula (1) to obtain the perforation rate σ=0.0084;

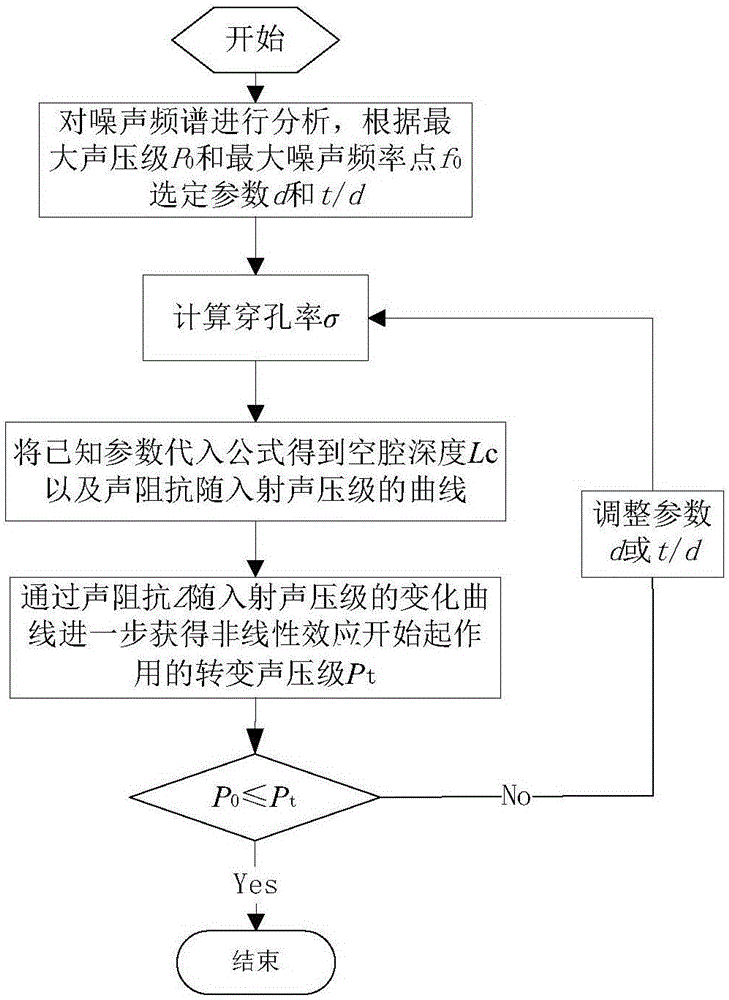

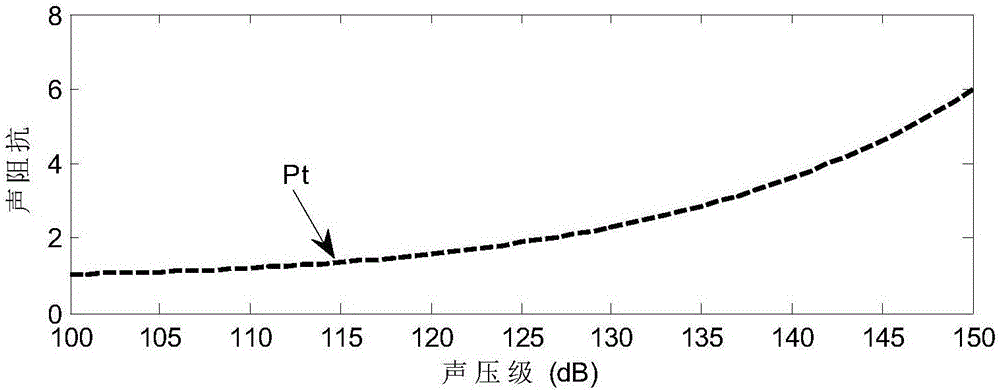

[0120] Then, the known parameters are substituted into formulas (2)-(28) to obtain the cavity depth L c =0.0032m and the curve of acoustic impedance versus incident sound pressure level, such as image 3 shown. observe image 3 , it can be seen that the transition sound ...

Embodiment 2

[0122] Embodiment 2: Design and realize the structural parameters of the micro-perforated plate sound absorbing body with nonlinear suppression to 140dB.

[0123] First, in step 1, analyze the frequency spectrum and sound pressure level of the high sound intensity noise field, and determine that the maximum sound pressure level of the actual noise environment is P 0 =140dB and the maximum noise reduction frequency point is f 0 = 3000Hz;

[0124] Then, since 140dB is larger, you can start with a smaller aperture and a smaller perforation rate. Therefore, first select d=0.1×10 -3 m, t / d=4, calculated according to the formula (1) to obtain the perforation rate σ=0.066;

[0125] Then, the known parameters are substituted into formulas (2)-(28) to obtain the cavity depth L c =0.0218m and the curve of acoustic impedance versus incident sound pressure level, such as Figure 4 shown. observe Figure 4 , it can be seen that the transition sound pressure level at which the nonlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com