Patents

Literature

237results about How to "Reduce margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

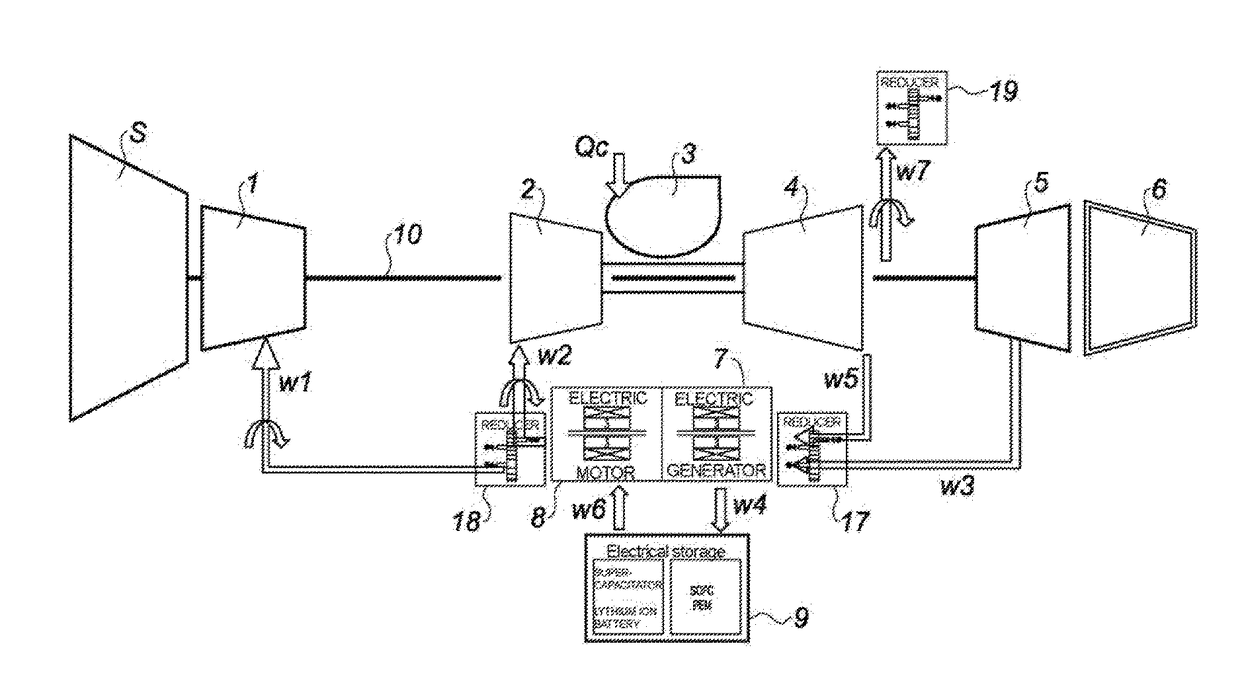

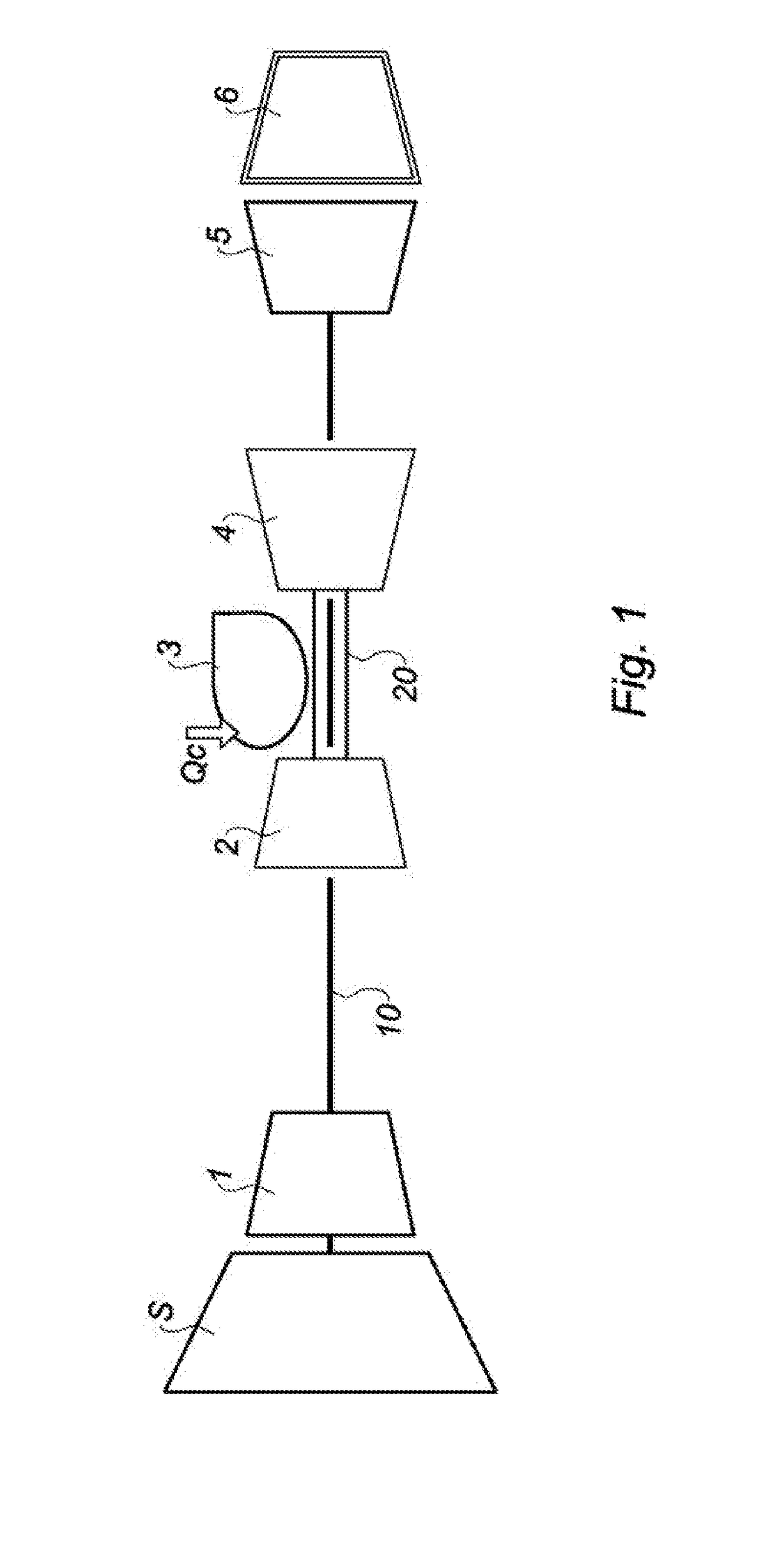

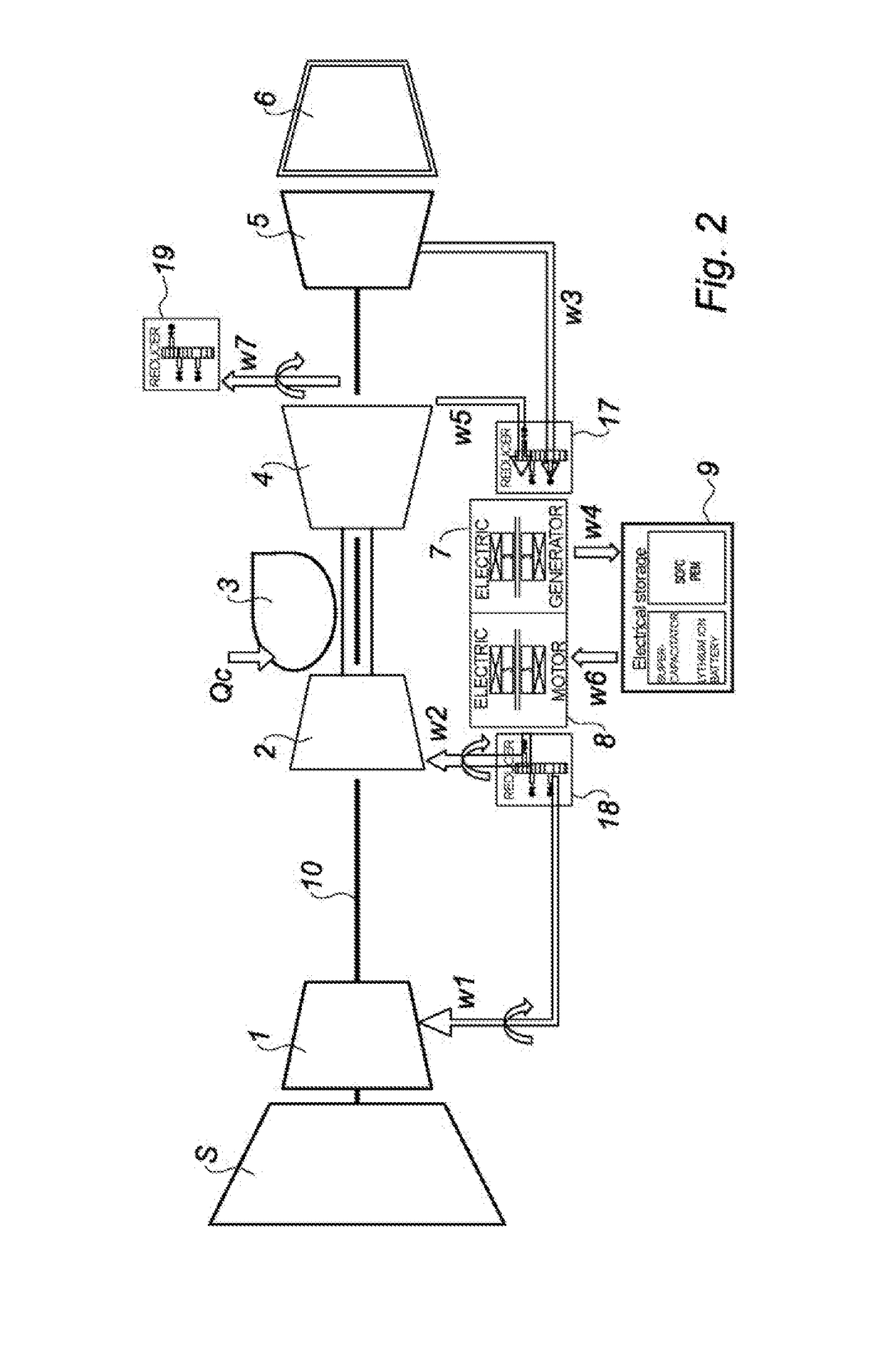

Hybridisation of the compressors of a turbojet

PendingUS20170226934A1Optimising surge marginReduce constraintsEfficient propulsion technologiesGas turbine plantsCombustion chamberJet engine

twin-flow, double body turbojet includes a fan that is positioned upstream from a gas generator and delimits primary and secondary flows. The gas generator is traversed by the primary flow and includes a low-pressure compressor, a high-pressure compressor, a combustion chamber, a high-pressure turbine and a low-pressure turbine. The low-pressure turbine is linked to the low-pressure compressor by a low-pressure rotating shaft, and the high-pressure turbine is linked to the high-pressure compressor by a high-pressure rotating shaft. The turbojet has an electric motor for injecting mechanical power into at least one of the rotating shafts. The turbojet also has a device for removing power from at least one of the rotating shafts and transforming the excess power into electrical energy. An electric storage means is positioned between the device for removing power and the electric motor.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

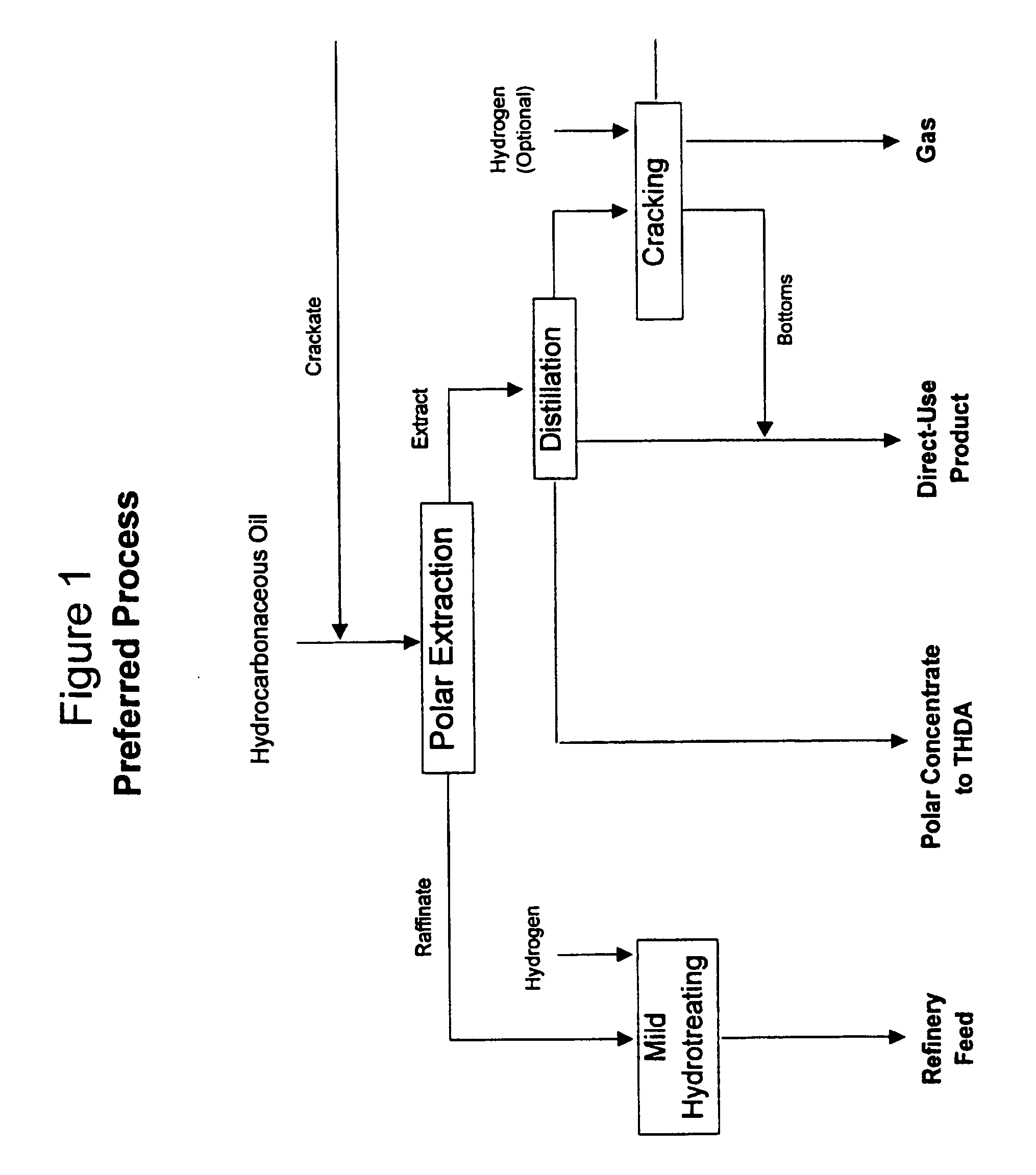

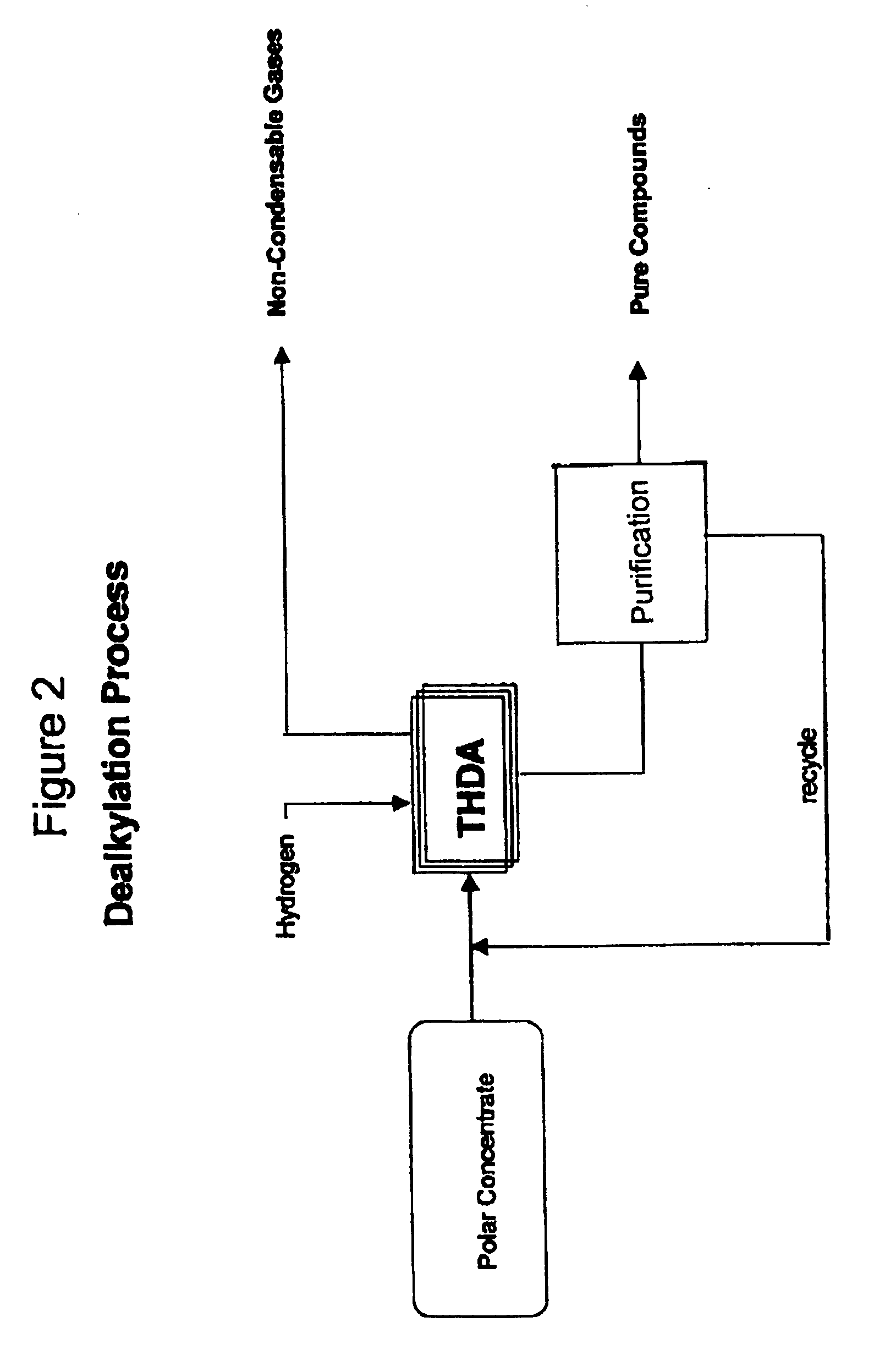

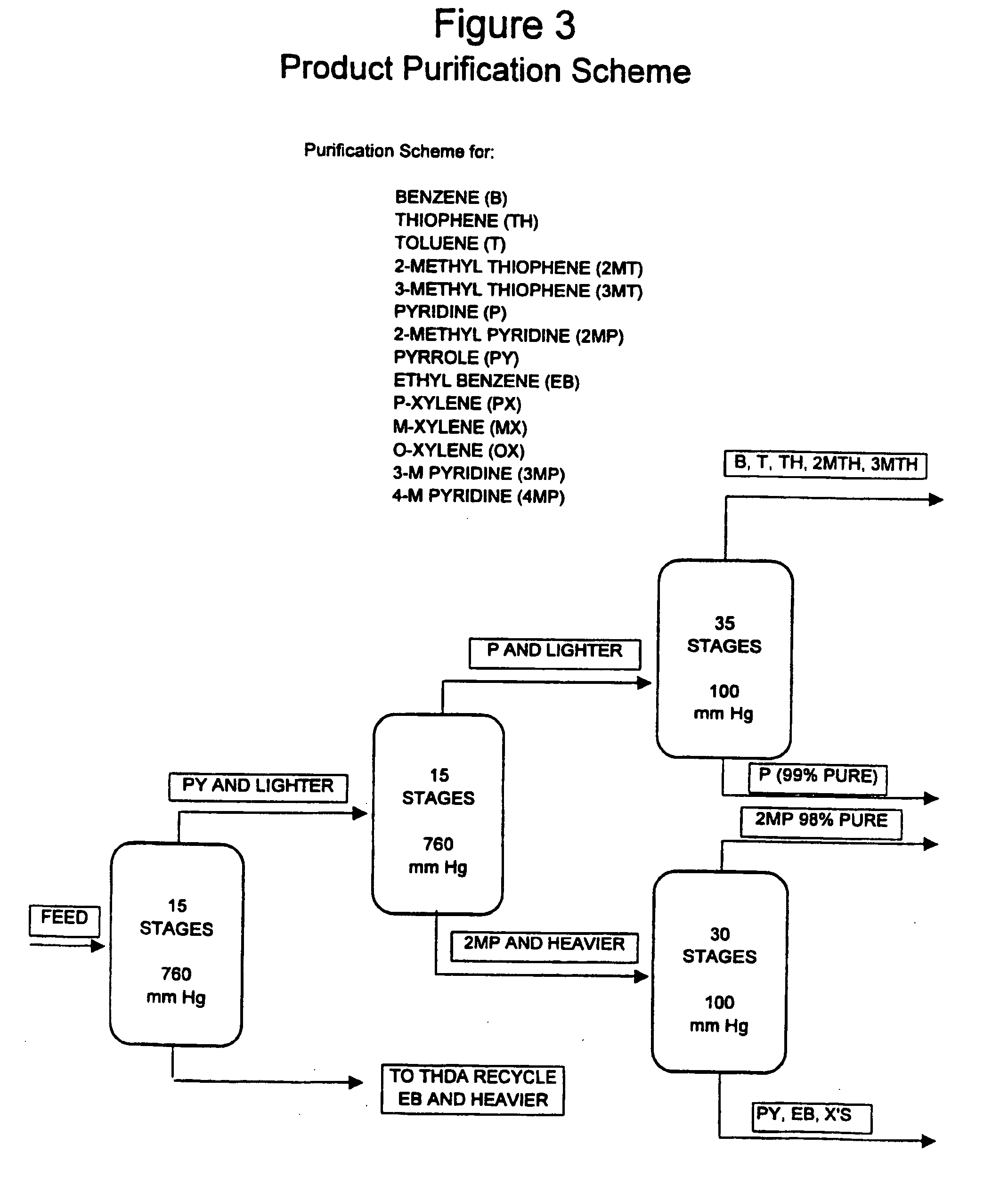

Process for enhancing the value of hydrocarbonaceous natural resources

InactiveUS20050167337A1Little and wasteLittle and valueHydrocarbon distillationTreatment with hydrotreatment processesSolubilityNatural resource

A process for upgrading hydrocarbonaceous oil containing heteroatom-containing compounds where the hydrocarbonaceous oil is contacted with a solvent system that is a mixture of a major portion of a polar solvent having a dipole moment greater than about 1 debye and a minor portion of water to selectively separate the constituents of the carbonaceous oil into a heteroatom-depleted raffinate fraction and heteroatom-enriched extract fraction. The polar solvent and the water-in-solvent system are formulated at a ratio where the water is an antisolvent in an amount to inhibit solubility of heteroatom-containing compounds and the polar solvent in the raffinate, and to inhibit solubility of non-heteroatom-containing compounds in the extract. The ratio of the hydrocarbonaceous oil to the solvent system is such that a coefficient of separation is at least 50%. The coefficient of separation is the mole percent of heteroatom-containing compounds from the carbonaceous oil that are recovered in the extract fraction minus the mole percent of non-heteroatom-containing compounds from the carbonaceous oil that are recovered in the extract fraction. The solvent-free extract and the raffinate concentrates may be used directly or processed to make valuable petroleum, chemical or industrial products.

Owner:JAMES W BUNGER & ASSOC

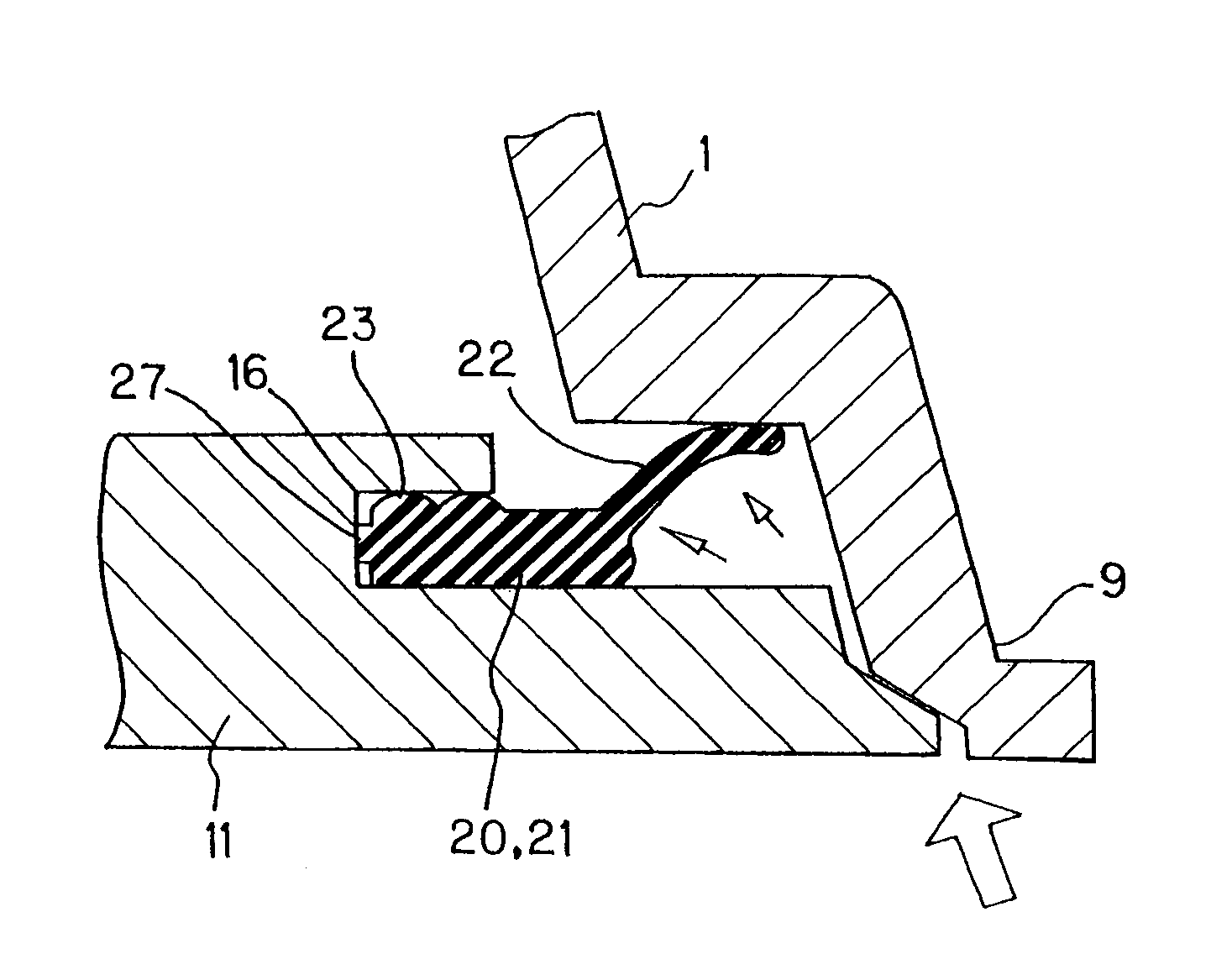

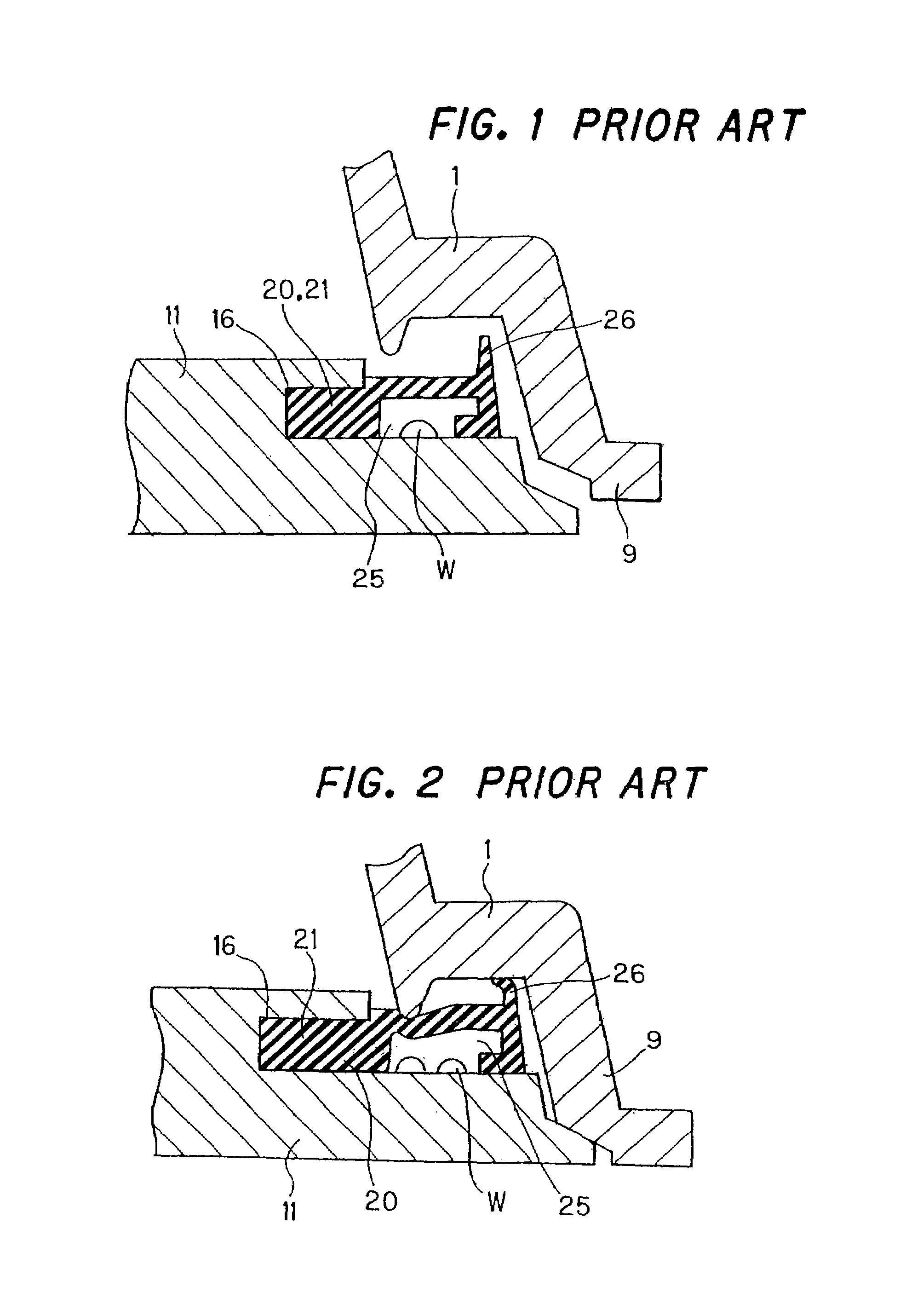

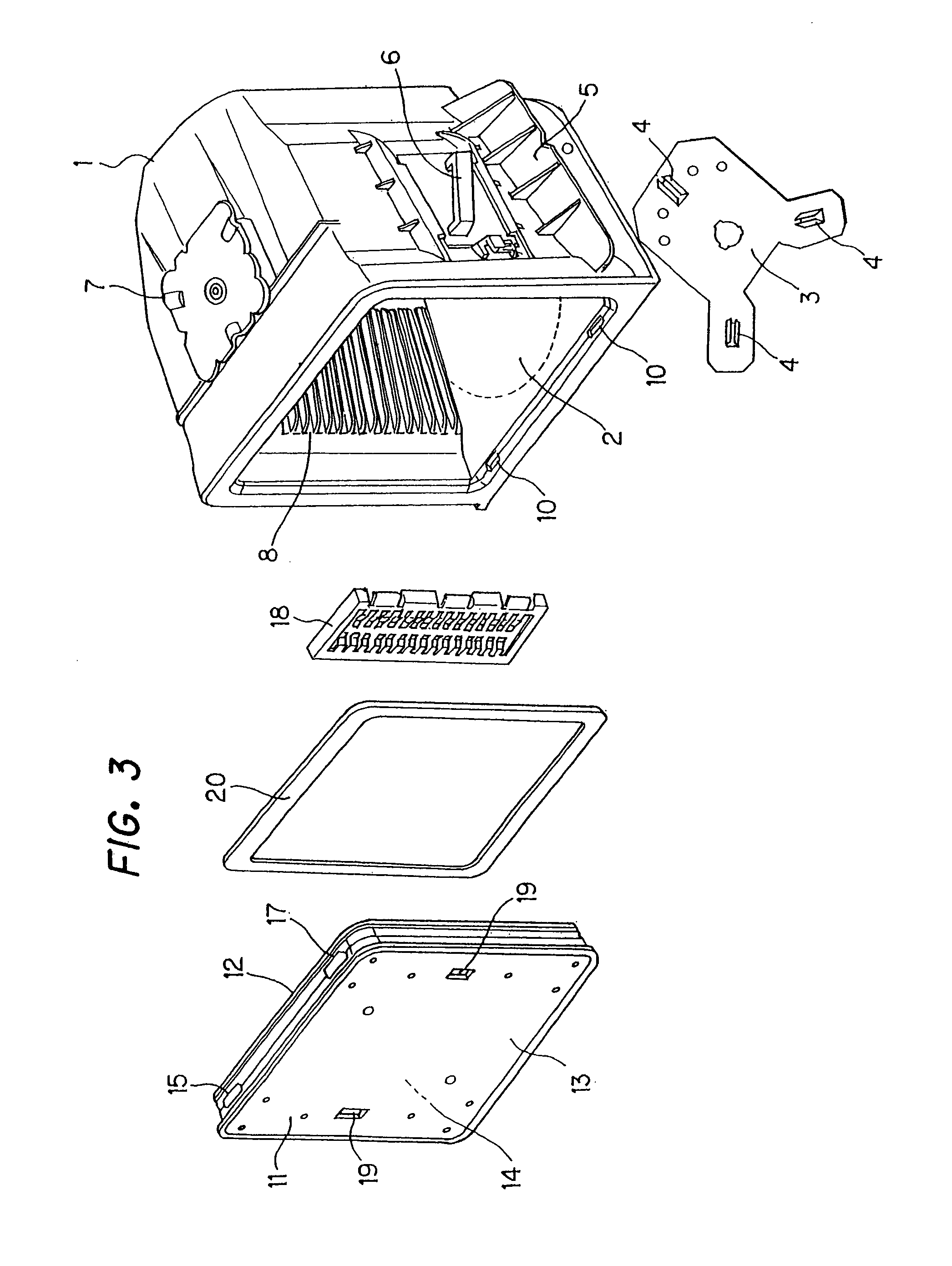

Sealing element with a protruding part approximately obliquely outward and a hermetic container using the same

InactiveUS7413099B2Clean thoroughlyEvenly sealedEngine sealsSemiconductor/solid-state device manufacturingAcute angleEngineering

A fit-holding groove is formed by notching the outer periphery of a door element to be fitted to close a container body. A sealing element interposed between the container body and door element is composed of an endless portion to be fitted into the fit-holding groove, a protruding part projected from the peripheral corner of the endless portion, obliquely and outwardly with respect to the open front of the container body, forming a substantially acute angle between itself and the contact surface of the open front of the container body and a pair of fitting ribs projectively formed on the obverse surface of the endless portion so as to be fitted in contact with the compartmentalized inner wall of the fit-holding portion.

Owner:SHIN-ETSU POLYMER CO LTD +1

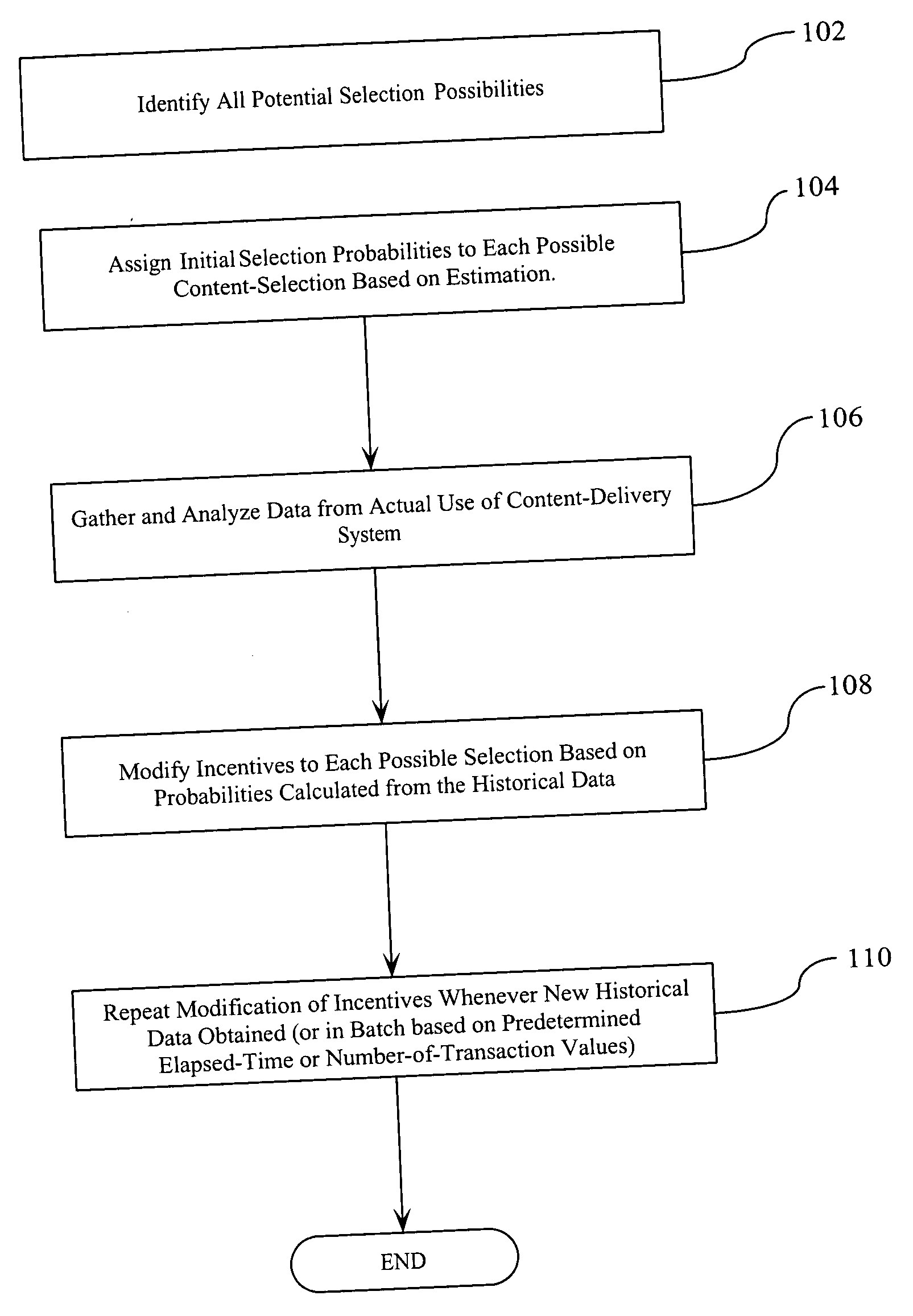

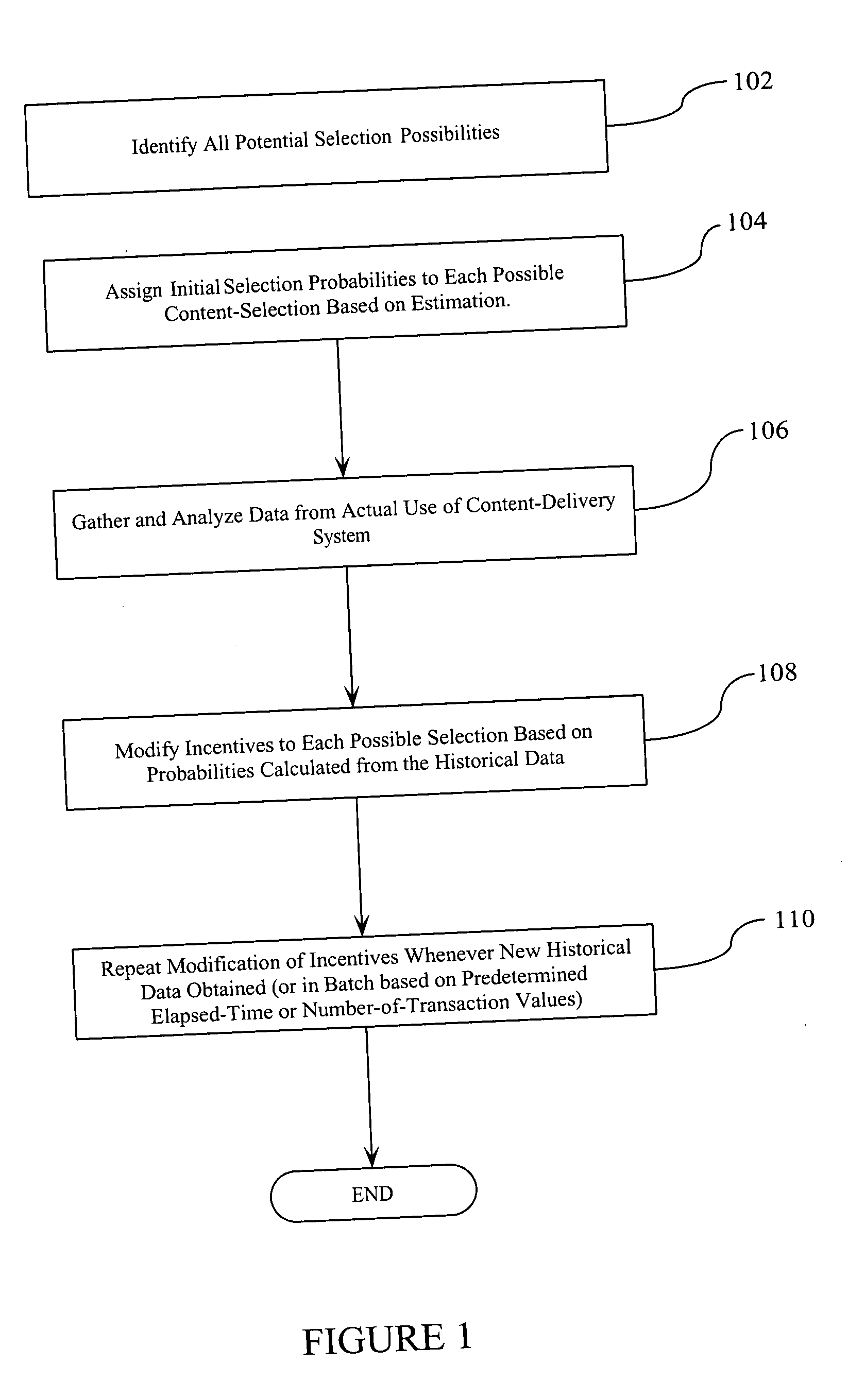

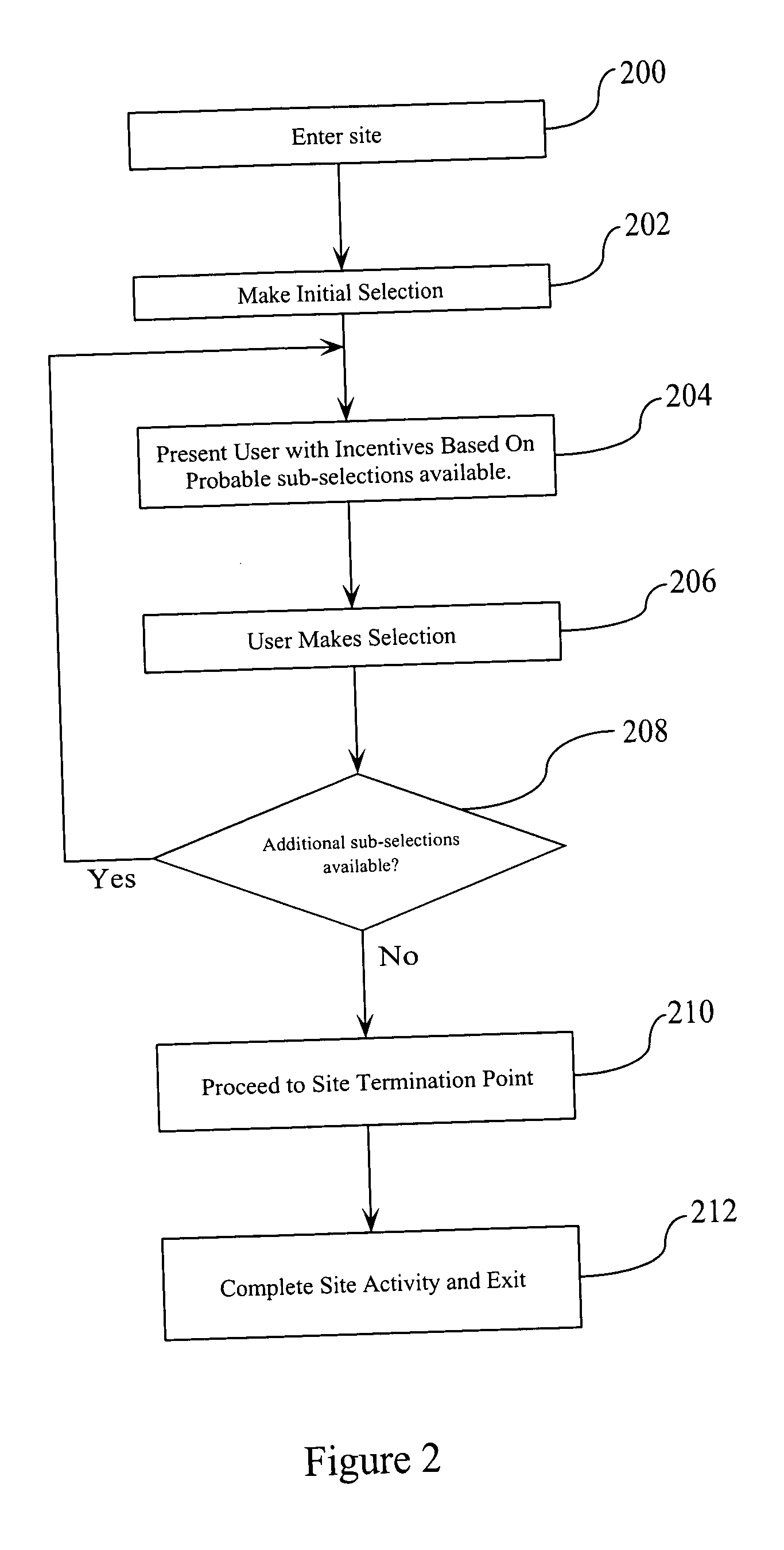

Incentive-based website architecture

ActiveUS20050071221A1Raise the possibilityMargin is maximizedSpecial data processing applicationsMarketing

The present invention applies gaming theory and well-understood sales processes and techniques to allow the operator of an interactive sales medium to control what is displayed to a user of the medium in a manner that signals their intentions (e.g., looking for a lower price, looking for a particular incentive, etc.) so that the “strategies” being used by the consumer can be identified and exploited to lead the consumer to a desired end choice. In particular, upon identification of the strategies being used by the consumer, incentives (e.g., gradually increasing rewards and / or decreasing “punishments”) are presented to the consumer in such a way that the margins achieved by an eventual sale are slowly decreased with each presentation of the incentives to the consumer. Since the presentation of each incentive increases the likelihood the consumer will make a purchase, margins are maximized for the seller.

Owner:TERRACE LICENSING LLC

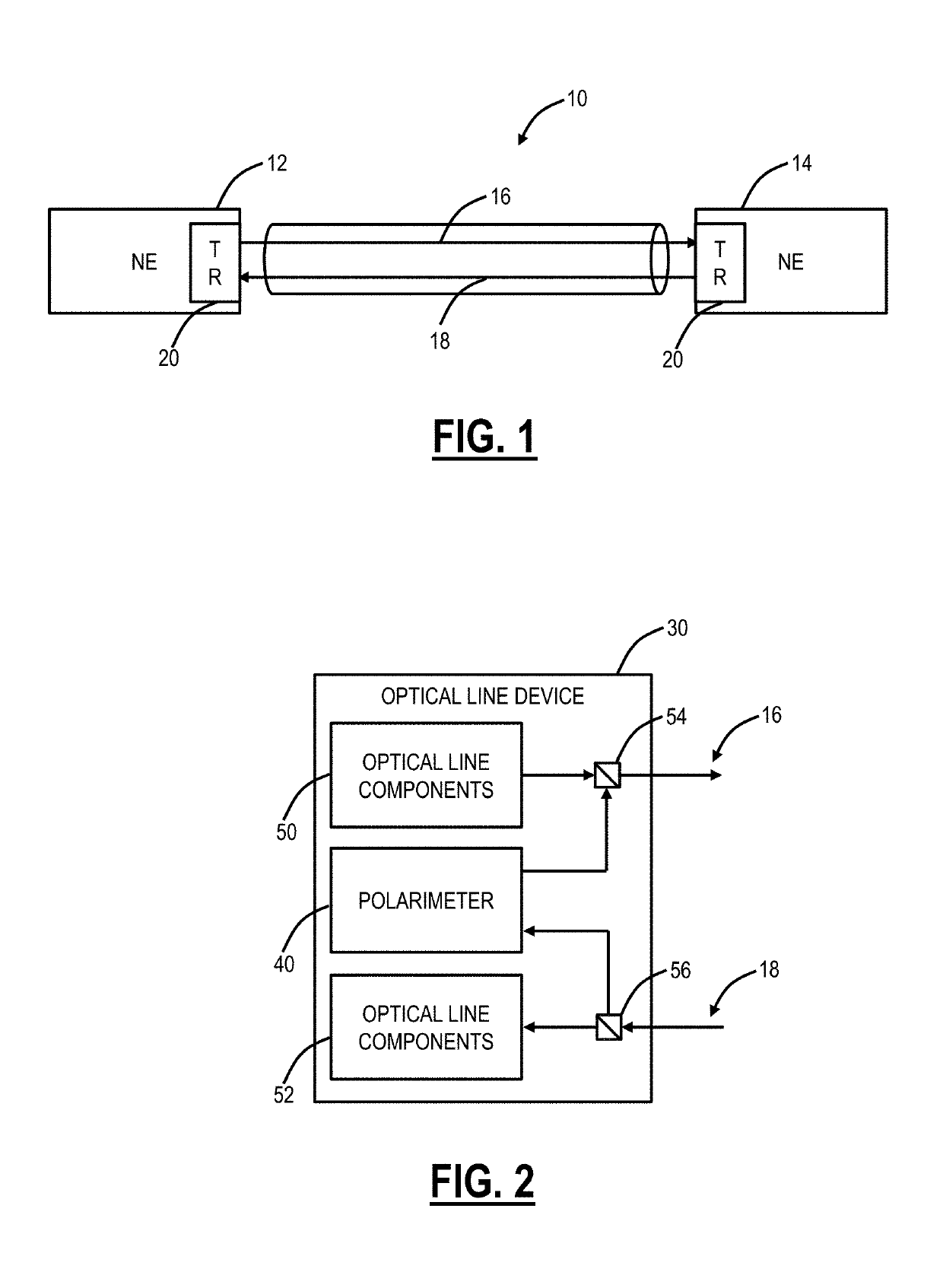

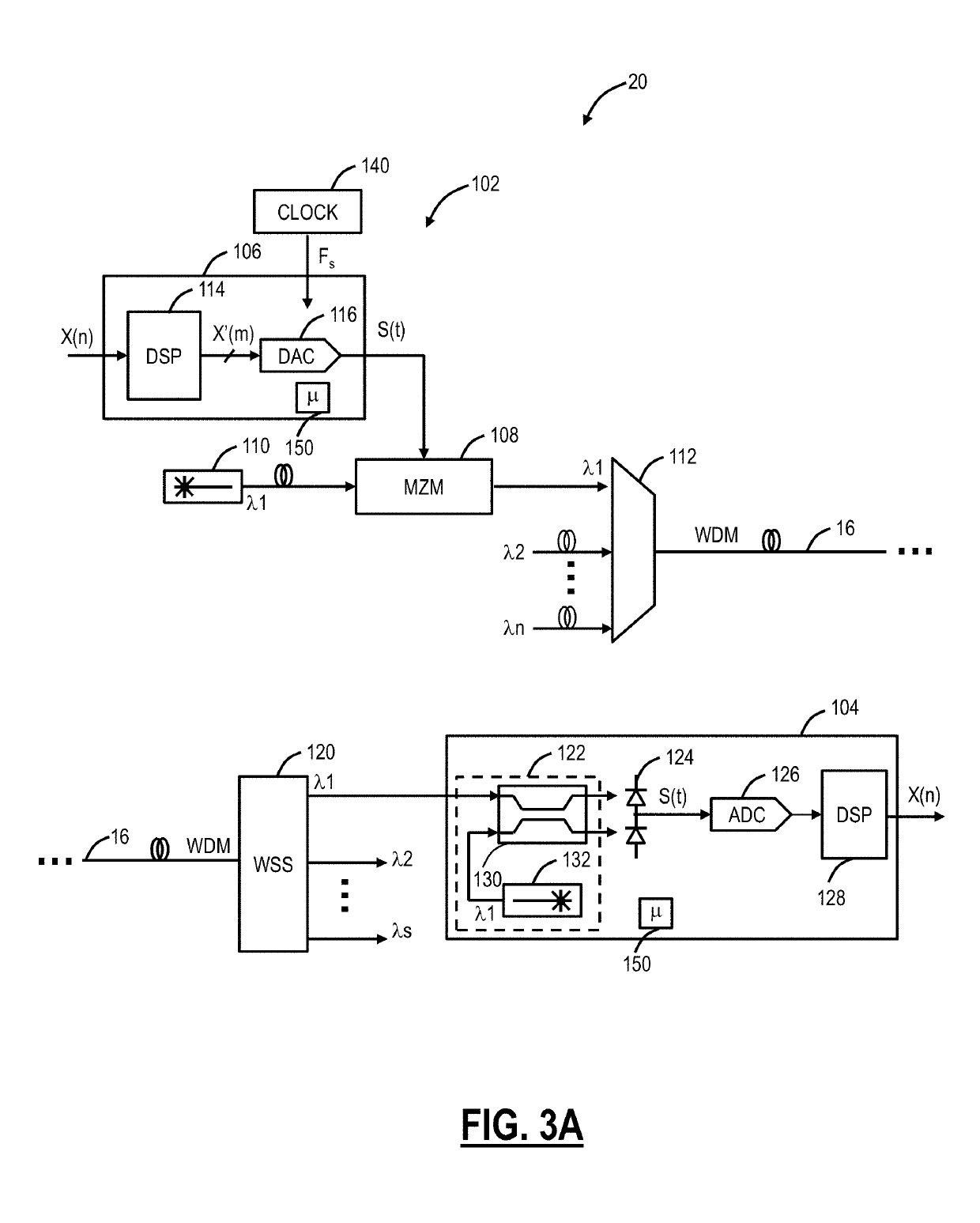

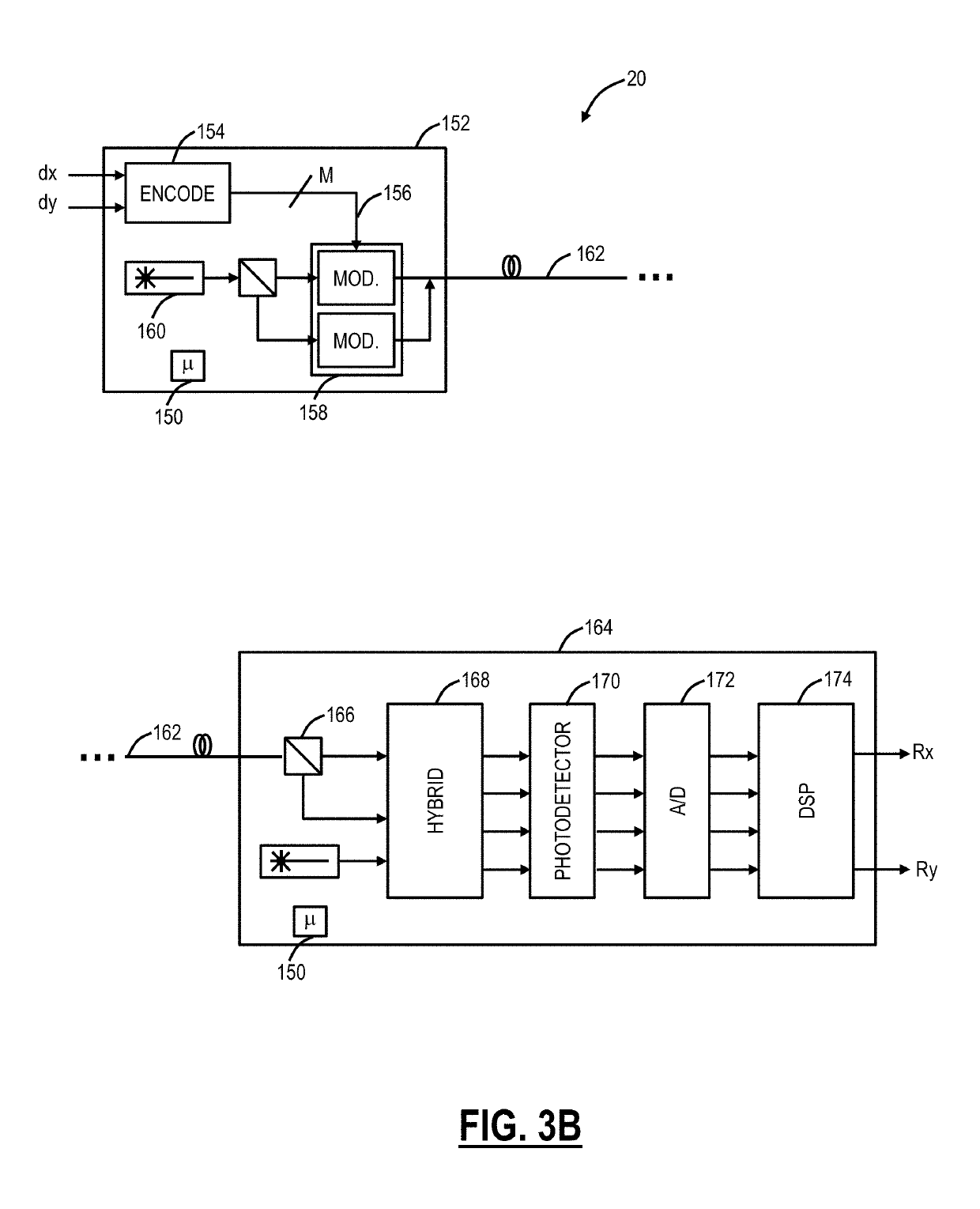

Adaptive optical modem configuration based on operating conditions

Systems and methods for operating an optical modem include operating with first operating settings; and, responsive to detection or expectation of a disturbance in an operating condition associated with the optical modem, operating with second operating settings for a time period based on statistical properties of the disturbance. The systems and methods can further include reverting to the first operating settings after the time period. The disturbance can be a polarization transient or a transient affecting a laser or a clock. The second operating settings can cause a reduced margin relative to the first operating settings for the time period.

Owner:CIENA

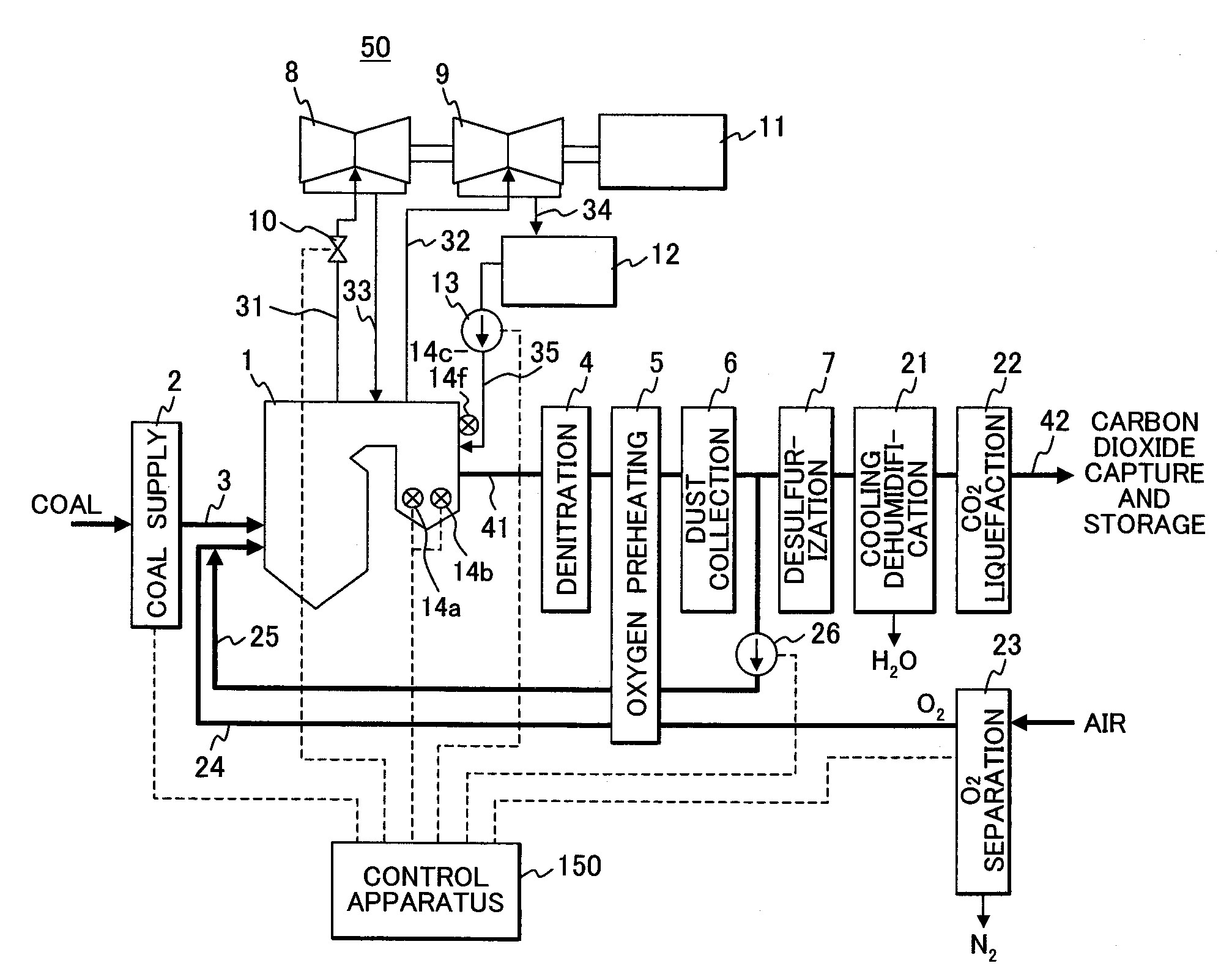

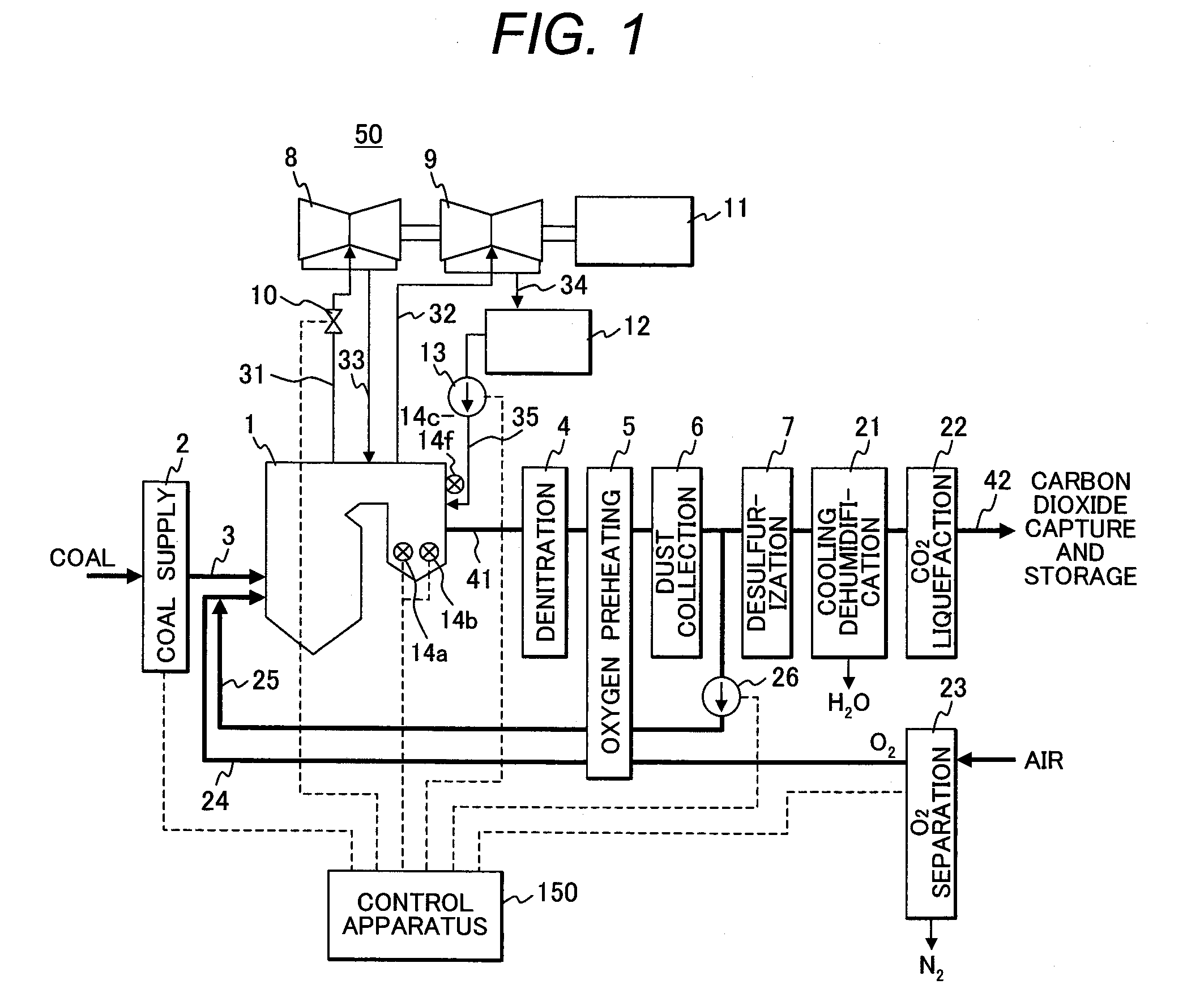

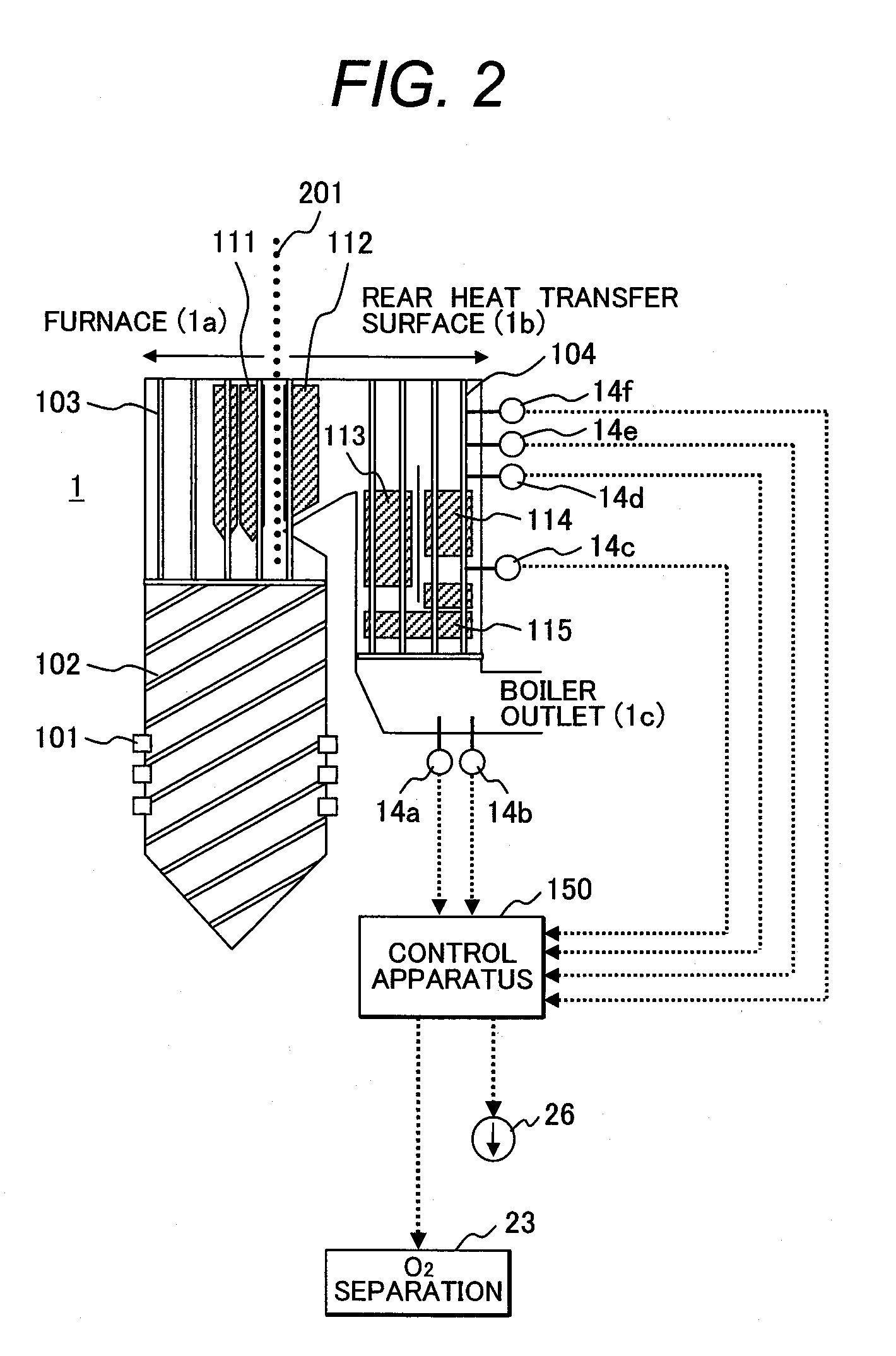

Oxyfuel Boiler and a Method of Controlling the Same

ActiveUS20100101462A1Cost reductionHigh reliabilityFluegas recirculationDirect carbon-dioxide mitigationBoiler furnaceProcess engineering

An oxyfuel boiler 1 is equipped with an oxygen separation apparatus 23 to produce oxygen by separating oxygen from the air, a recirculation fan 26 to supply a portion of combustion flue gas branched from the combustion flue gas discharged from the boiler to the oxyfuel boiler 1, a temperature sensor 14a to detect gas temperature at a boiler outlet 1d in the oxyfuel boiler 1, and a control apparatus 150 to calculate gas temperature at a furnace outlet 1c in the boiler from the gas temperature at the boiler outlet 1d detected by the temperature sensor 14a and control the operating condition of the recirculation fan 26 so that the calculated gas temperature at the furnace outlet 1c becomes a desired preset gas temperature.

Owner:MITSUBISHI POWER LTD

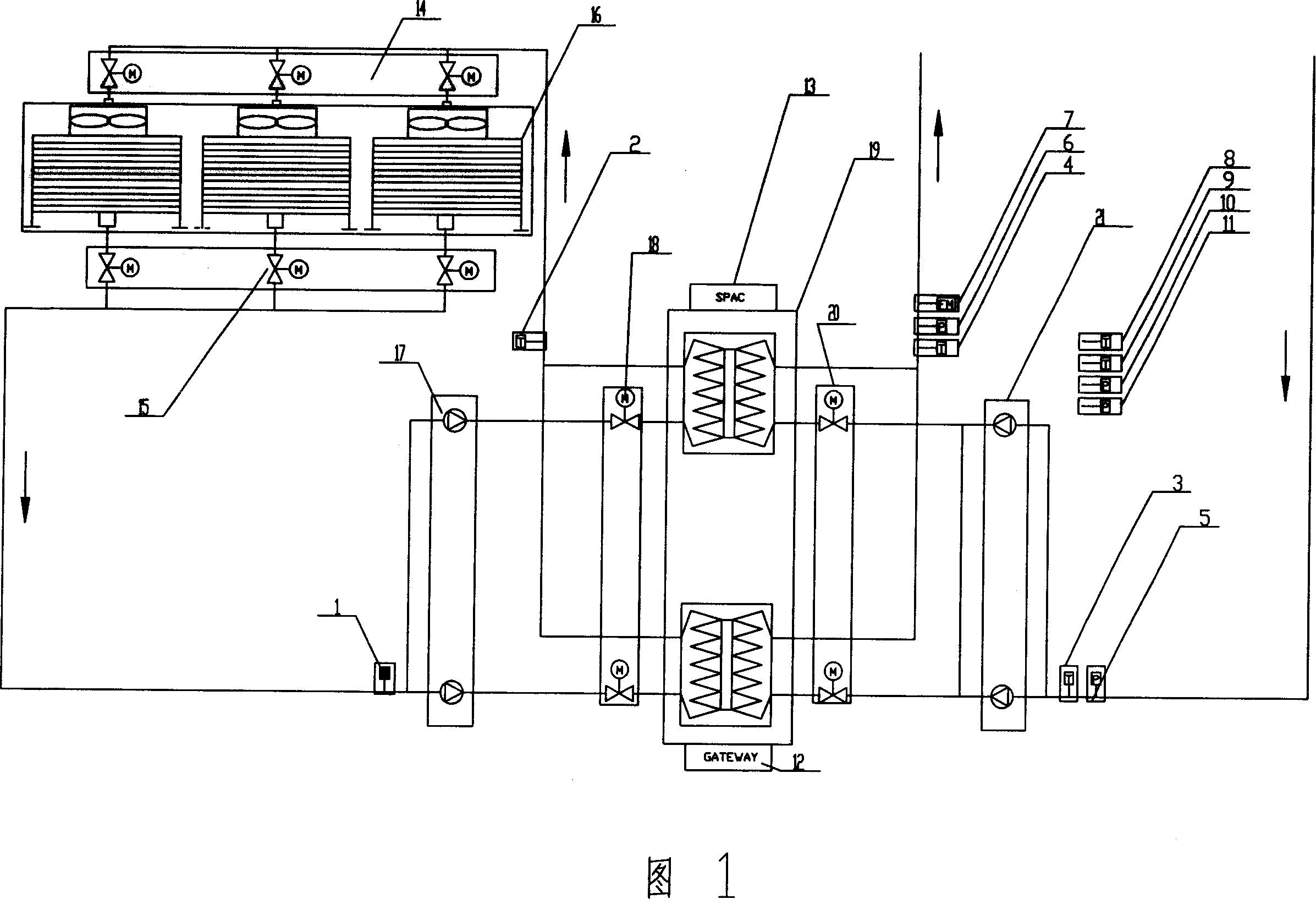

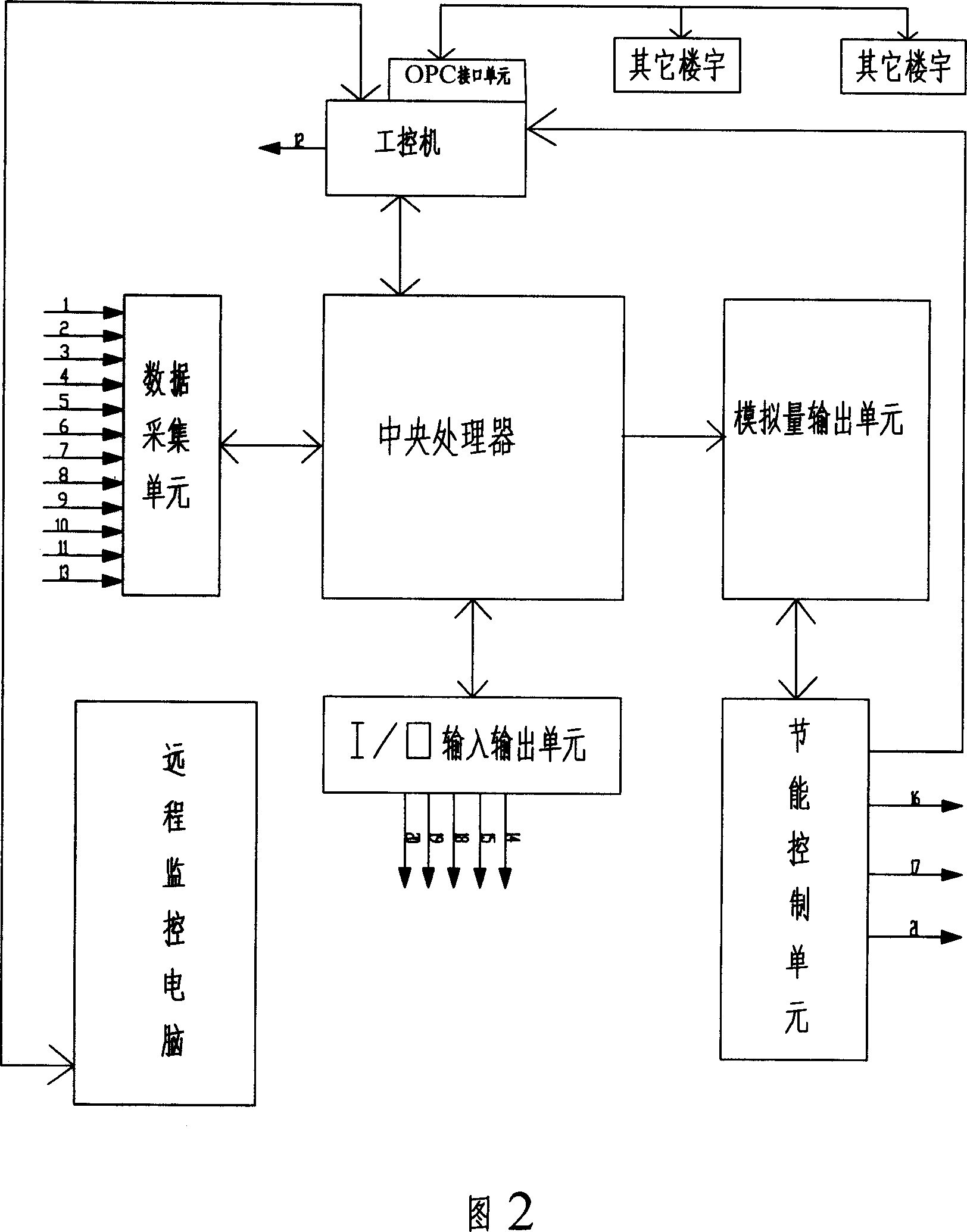

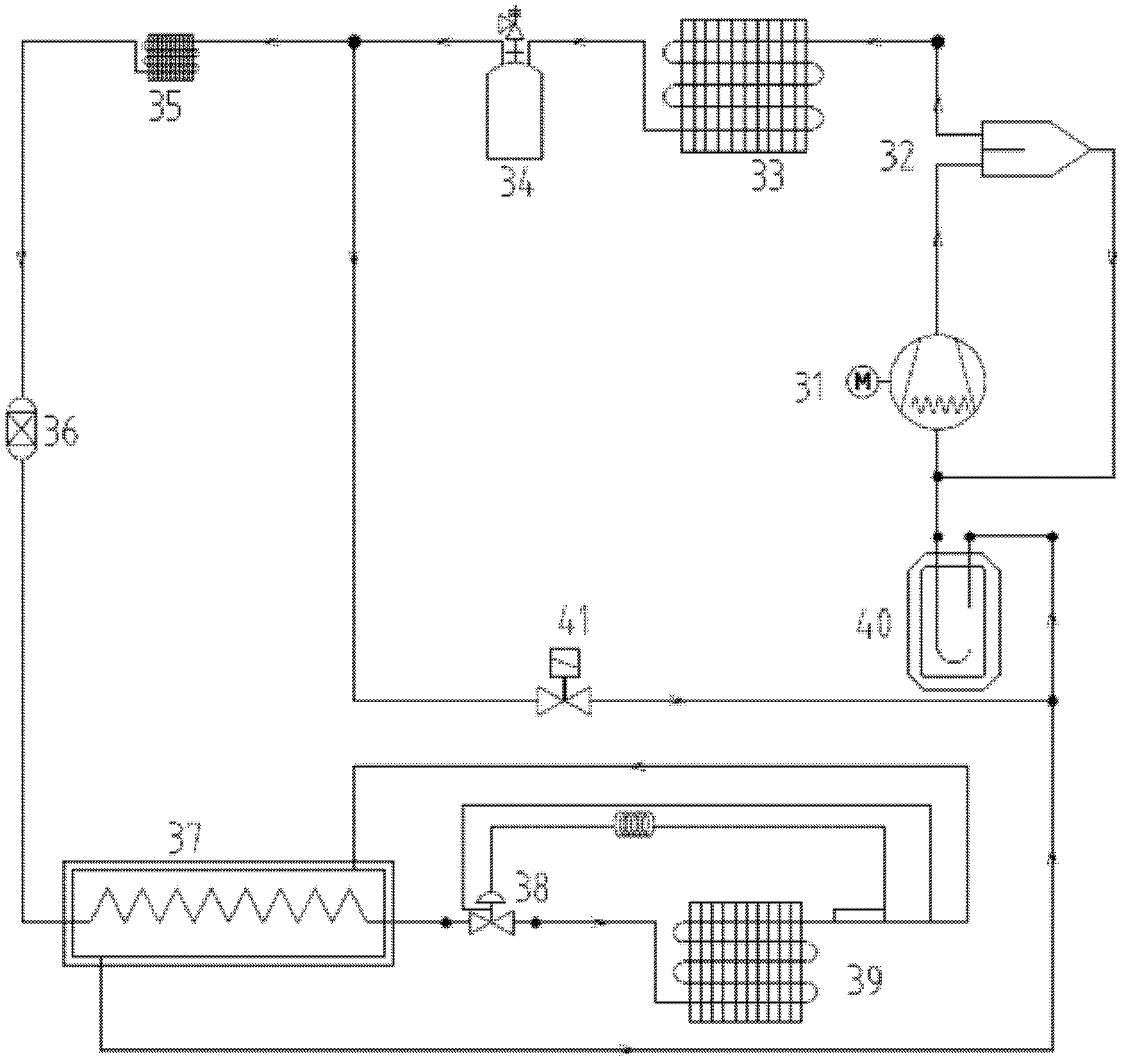

Intelligent cluster control system of central air-conditioning

InactiveCN101017021AReasonable calculationReduce marginSpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerCooling tower

The invention discloses a central air-conditioning intelligent group control system, comprising a host, a cooling tower, a cooling pump, a central processor, and a data collector, a cooling reflux output temperature sensor, a freezing reflux output temperature sensor, a freezing reflux output pressure sensor, a controller connected with the central processor for reading the parameters of a frequency changer via on-site bus, and a network gate between the host and the controller. The sensor is connected with the data collector which can transmit the signal of sensor to the central processor. The invention uses several parameters to group control to fully utilize frequency change technique to reduce the abundant refrigeration most. And the invention uses the controller to on-time memory the data of air conditioner, to show variable power curvatures, watched and modified by user.

Owner:广州金关节能科技发展有限公司

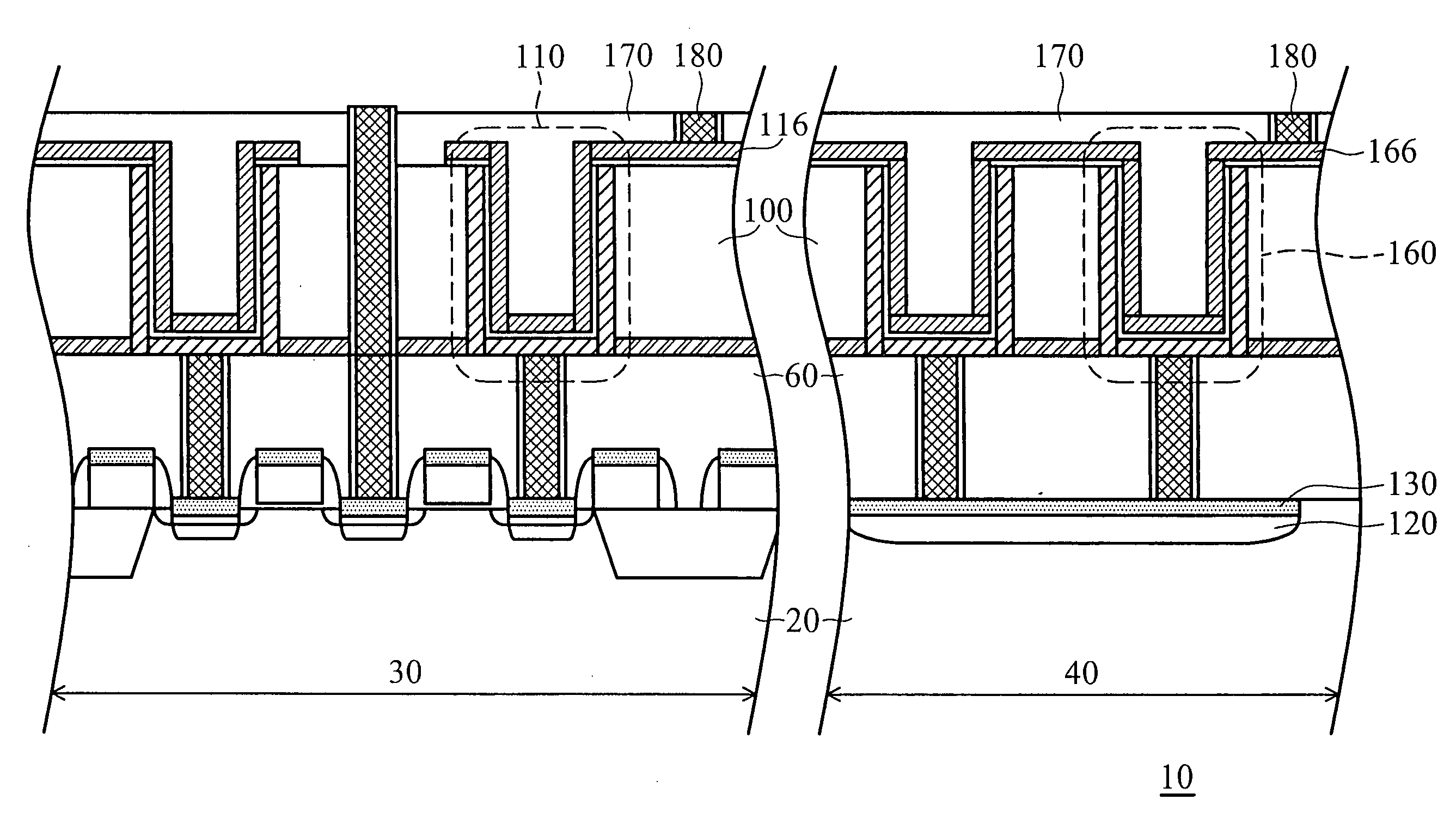

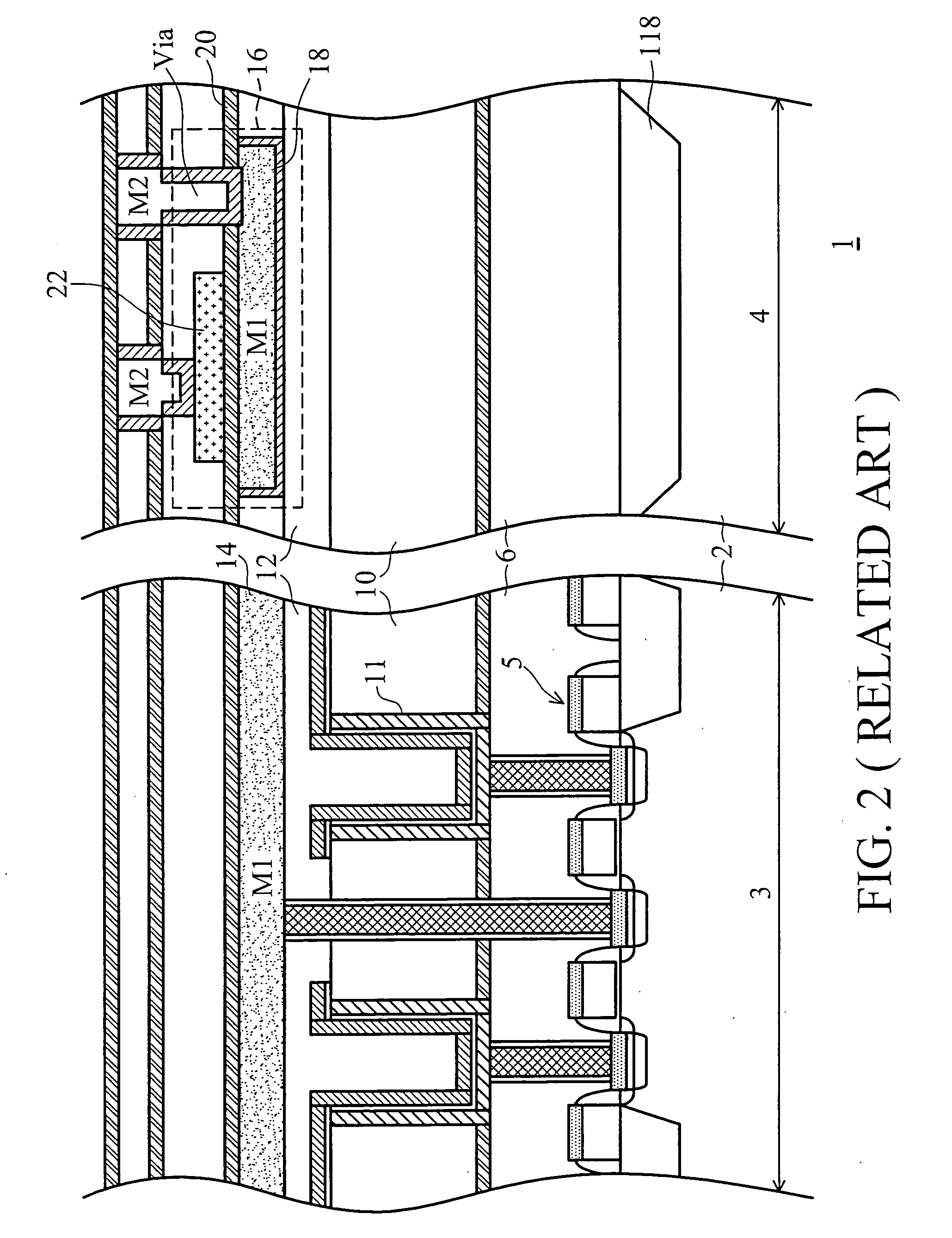

Semiconductor devices with MIM-type decoupling capacitors and fabrication method thereof

InactiveUS20080122032A1Reduce capacitanceIncrease the areaSemiconductor/solid-state device manufacturingCapacitorsActive componentDielectric layer

A semiconductor device. The semiconductor device includes a substrate having an array region and a decoupling region, a first dielectric layer overlying the substrate, a second dielectric layer overlying the first dielectric layer, a plurality of active components formed in the first dielectric layer within the array region, a first capacitor formed in the second dielectric layer within the array region, a second capacitor formed in the second dielectric layer within the decoupling region, and a first plug formed in the first dielectric layer within the array region electrically connecting the active component and the first capacitor. The invention also provides a method of fabricating the semiconductor device.

Owner:TAIWAN SEMICON MFG CO LTD

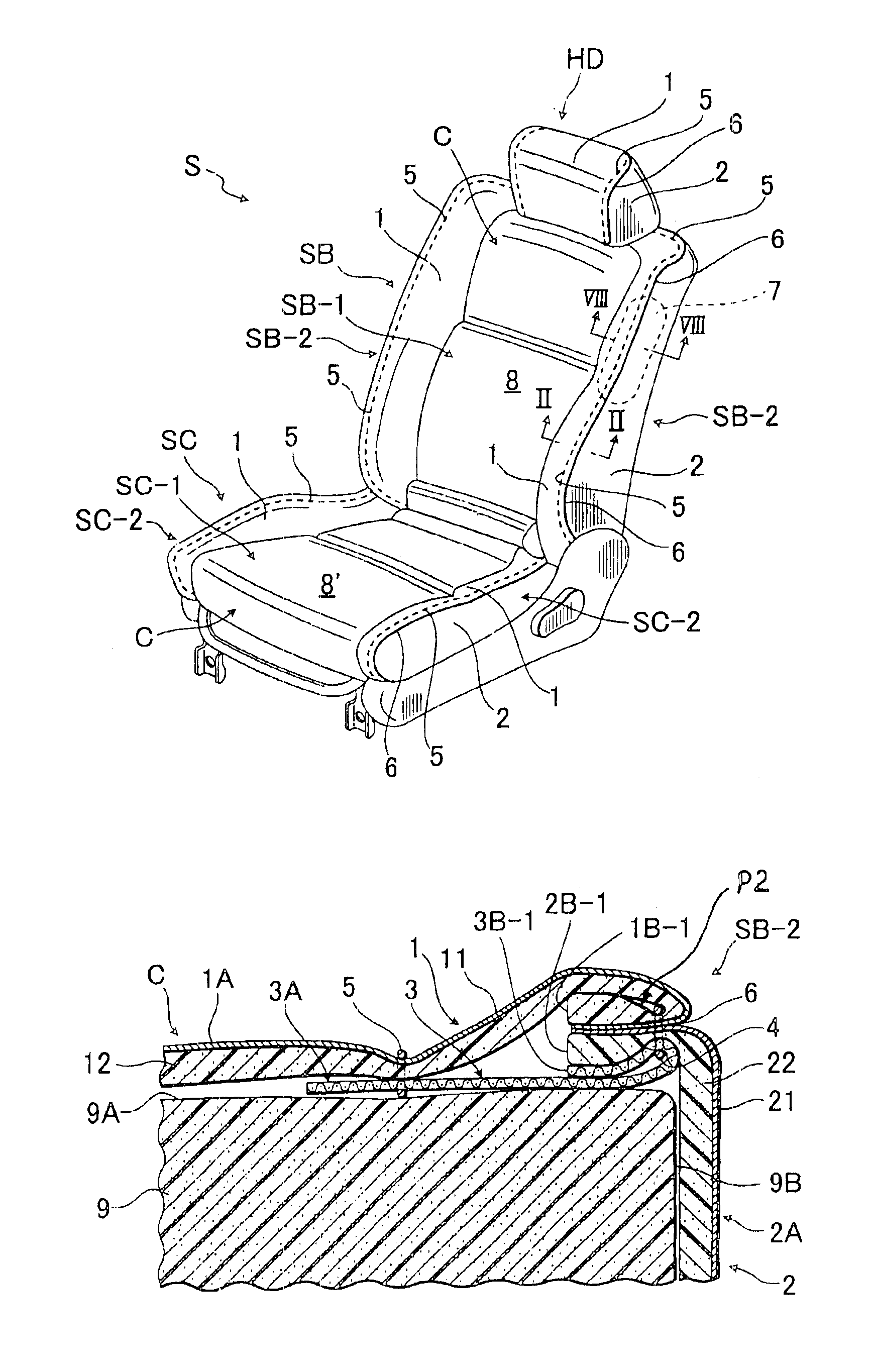

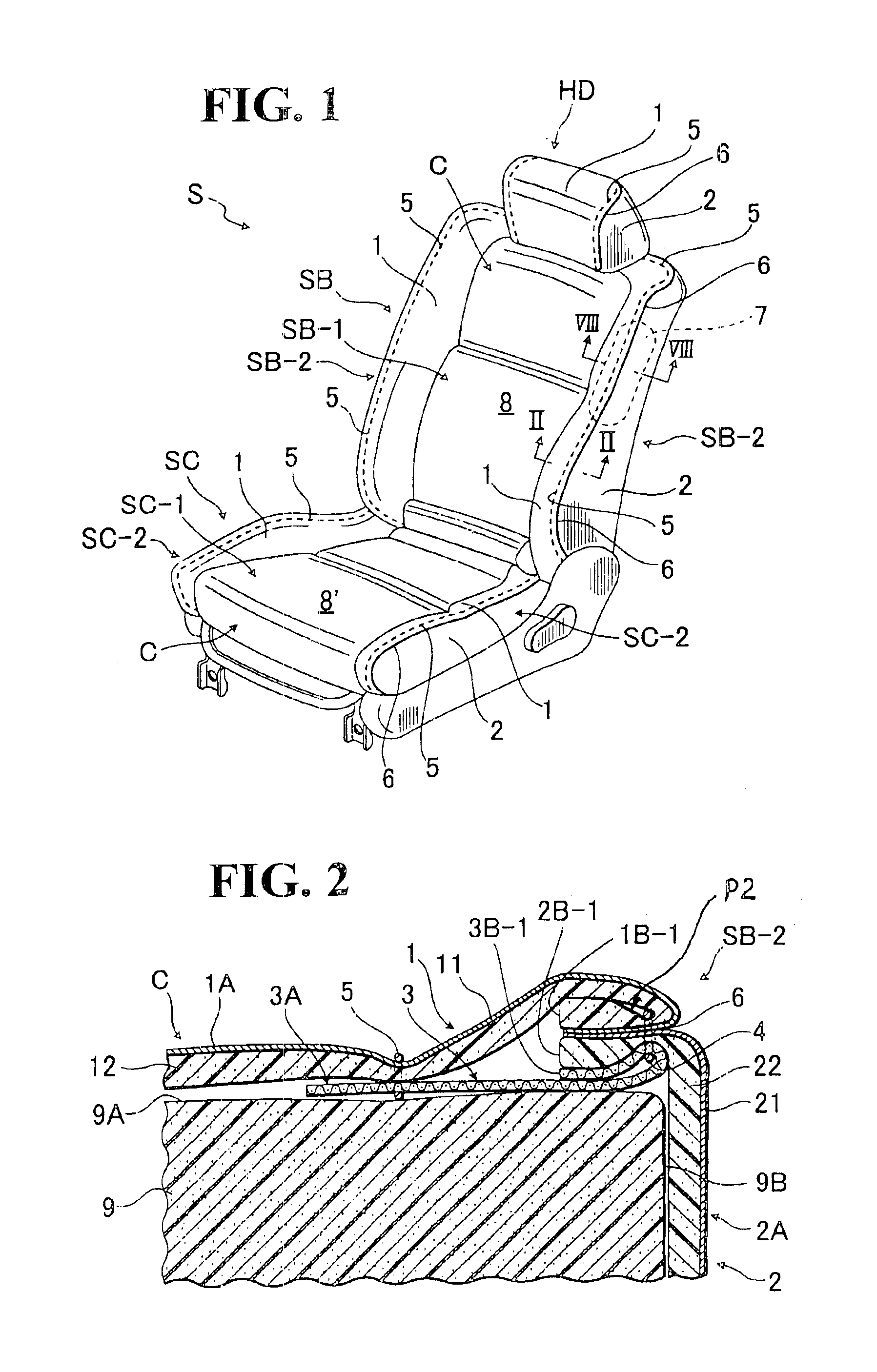

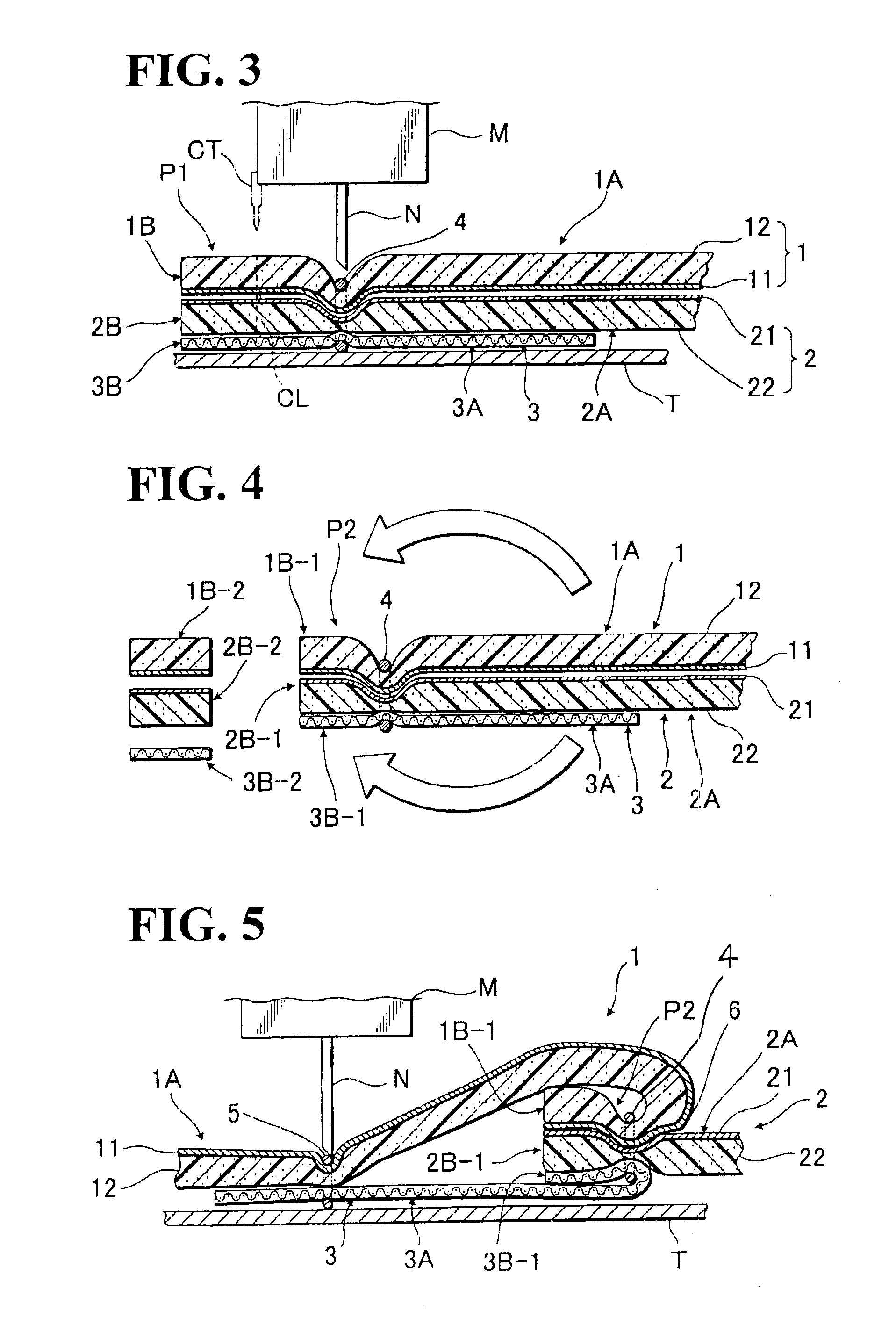

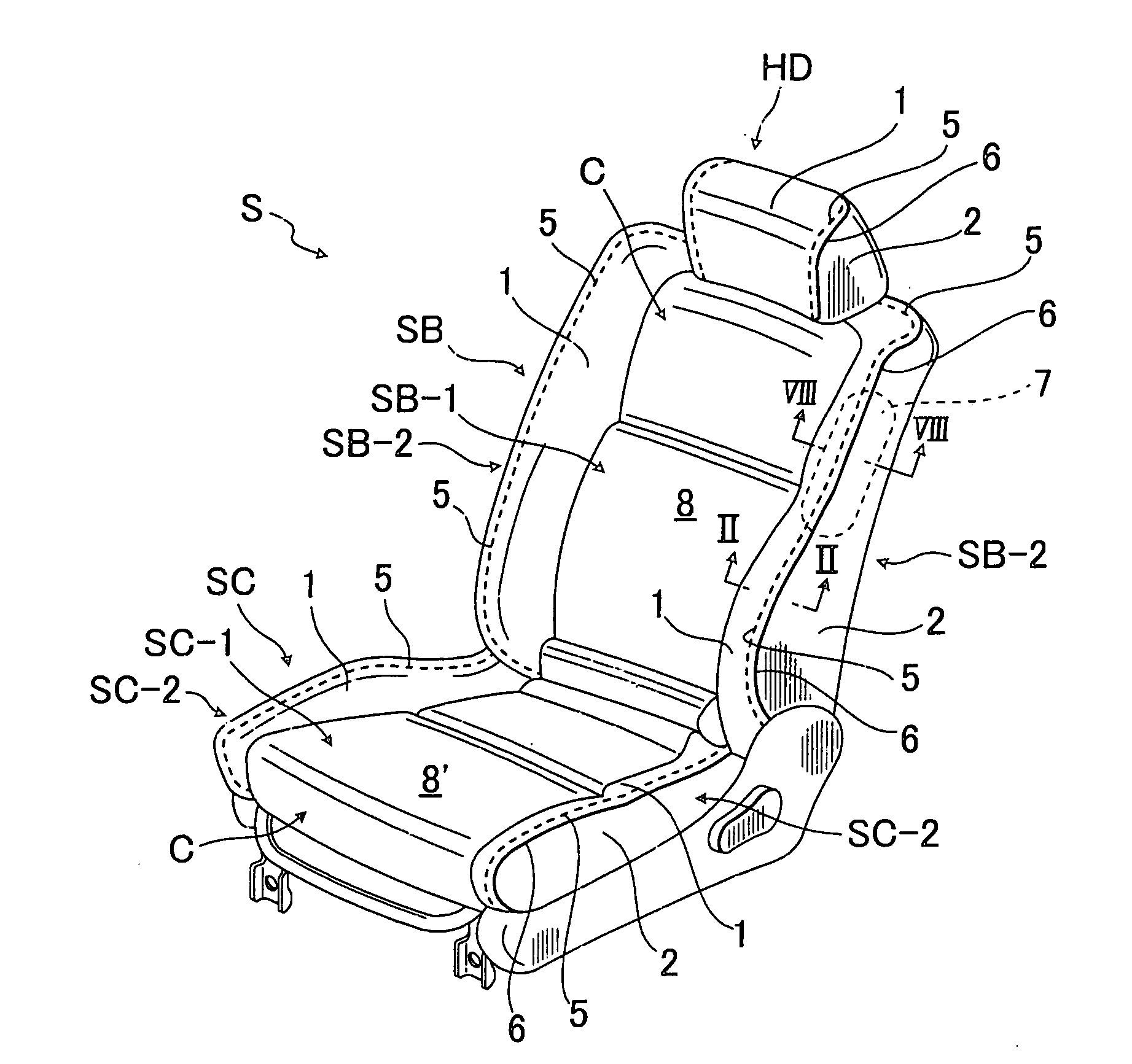

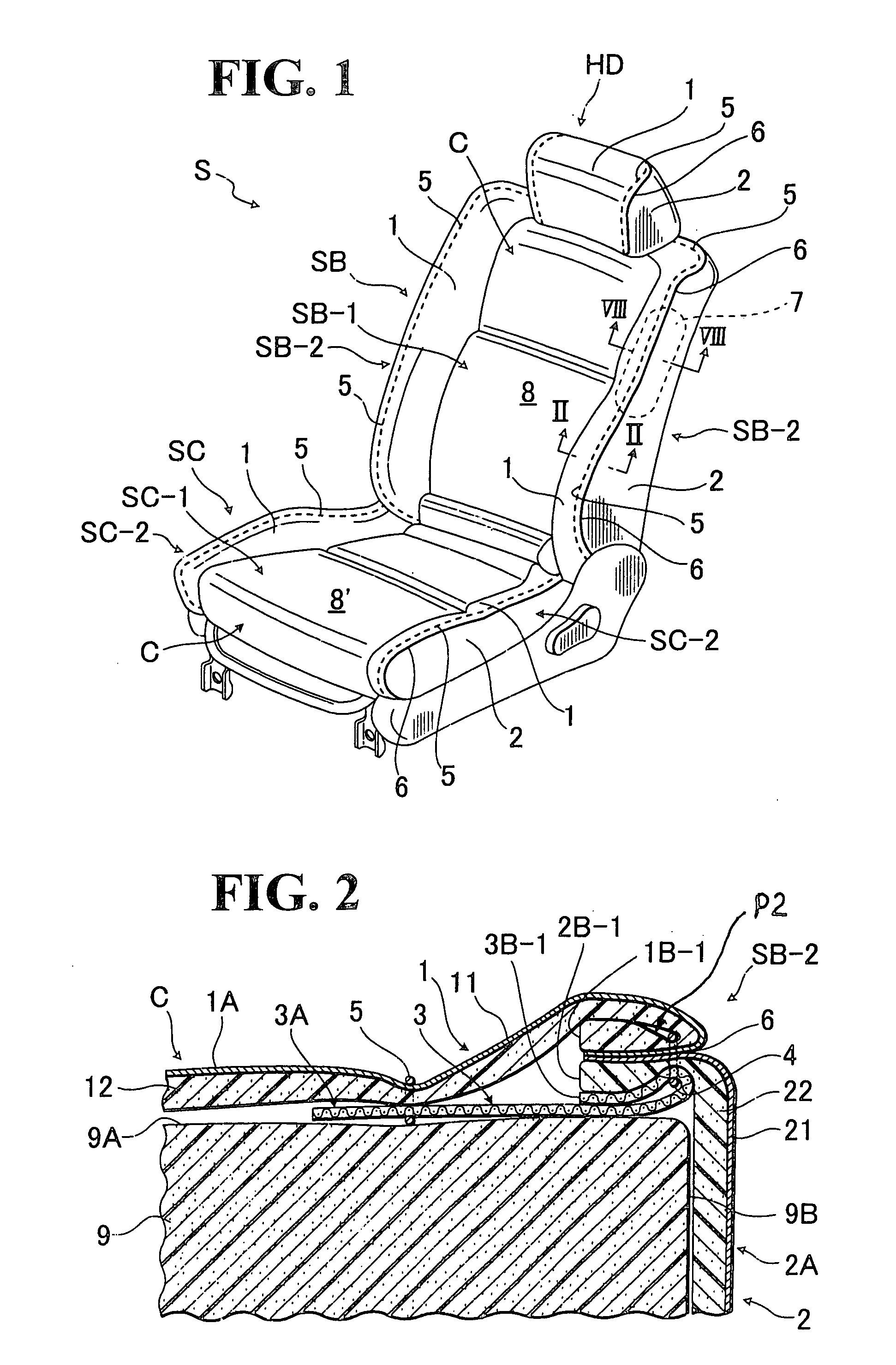

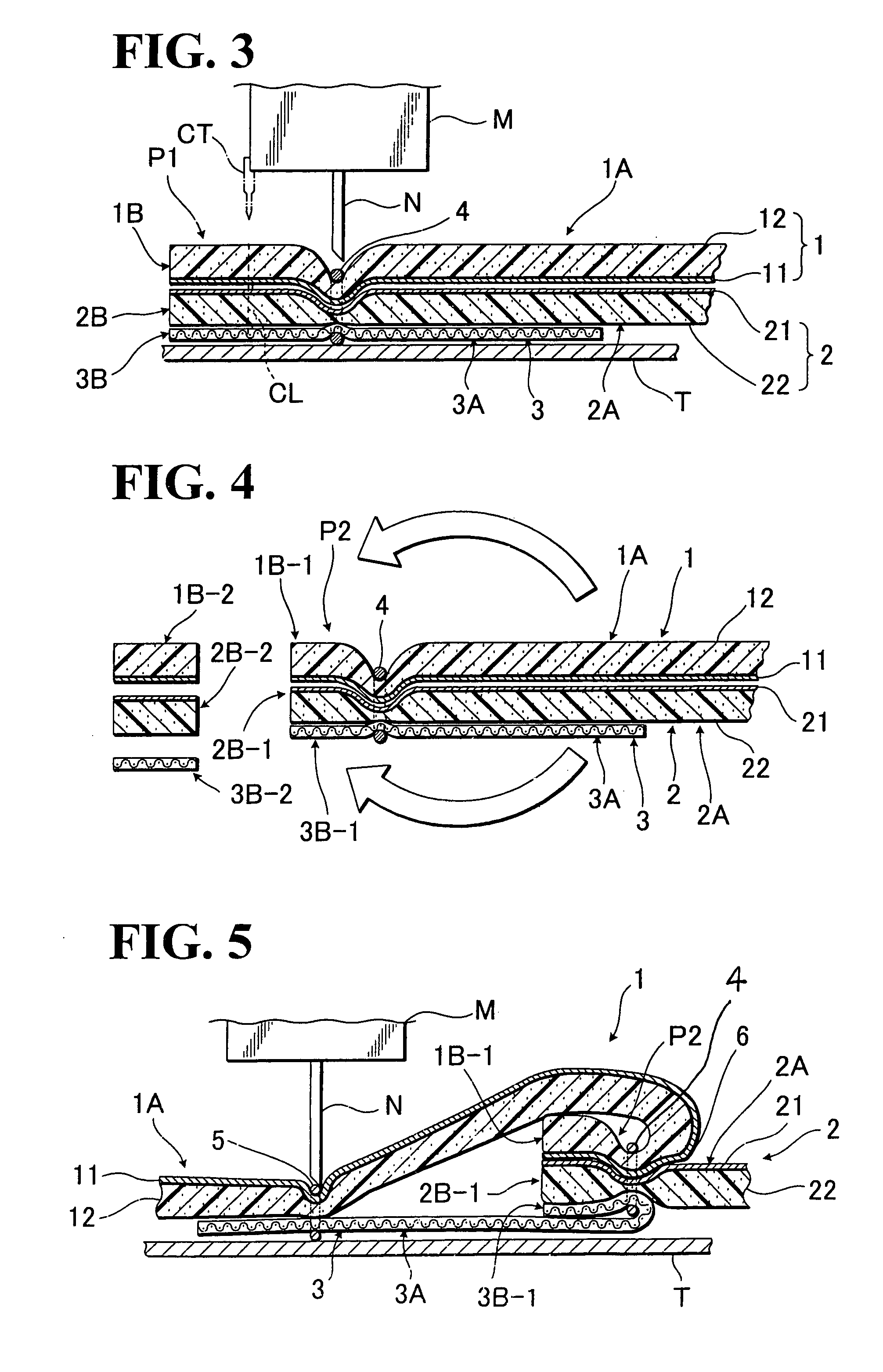

Sewing method to form a trim cover assembly and automotive seat using the trim cover assembly

InactiveUS6886479B1Good lookingReduce marginSeat coveringsLeather sewingEngineeringMechanical engineering

A sewing method to form a trim cover assembly for automotive seat, and an automotive seat using the trim cover assembly. Firstly, a first cover material, a second cover material and a backing tape are used and juxtaposed on one another, with their ends aligned with one another, and then sewn together to create a first seam and a sewn connection portion. Such sewn connection portion is cut off into a shortened sewn connection portion. Thereafter, the first cover material and backing tape are turned over relative to the shortened connection portion and sewn together, thereby forming one portion of the trim cover assembly. Another portion of the trim cover assembly may be formed by avoiding use of the backing tape and simply turning over the first cover material relative to the sewn connection portion, and sewing together the thus-turned portions of the first cover material.

Owner:TACHI S CO LTD

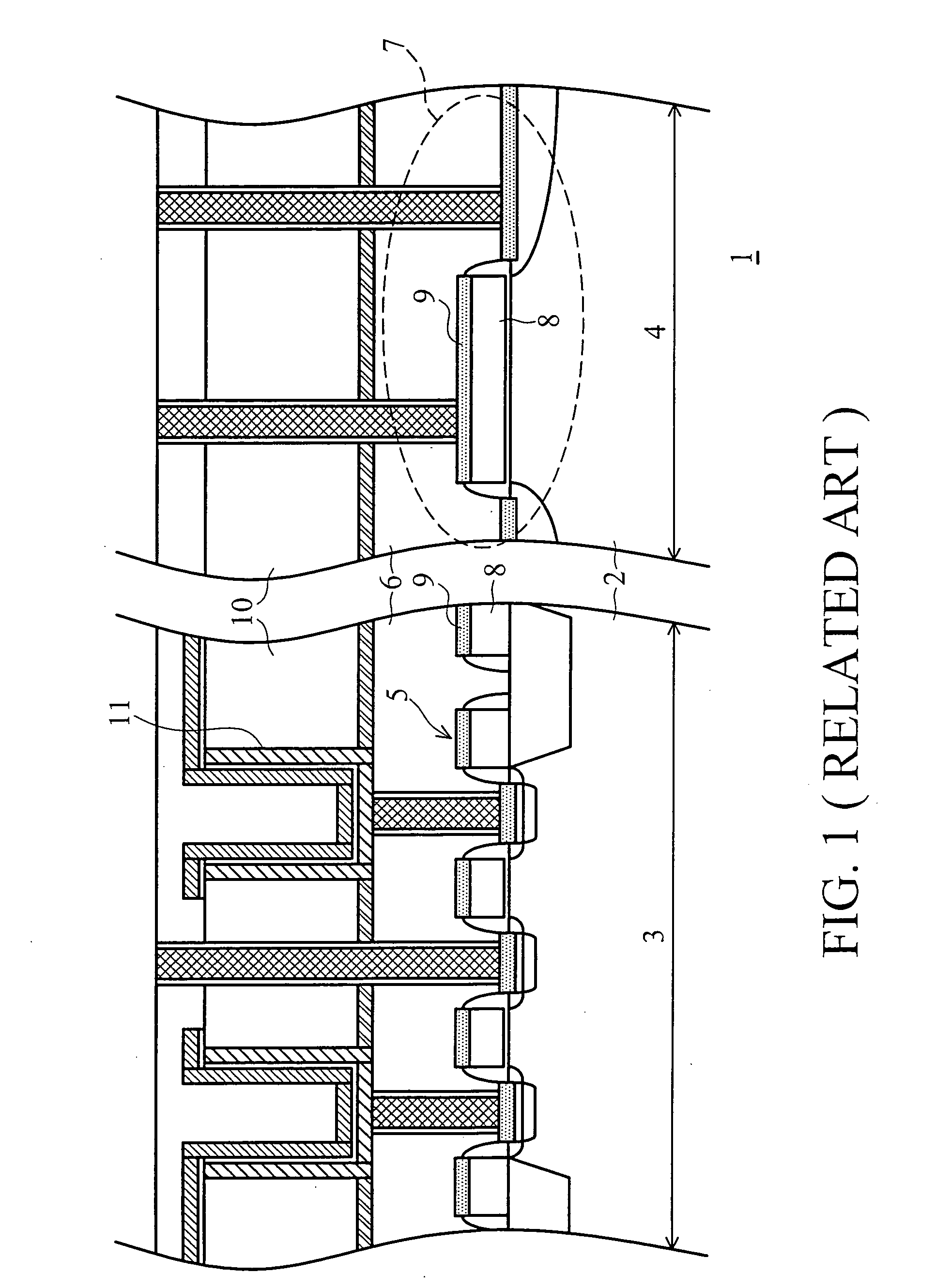

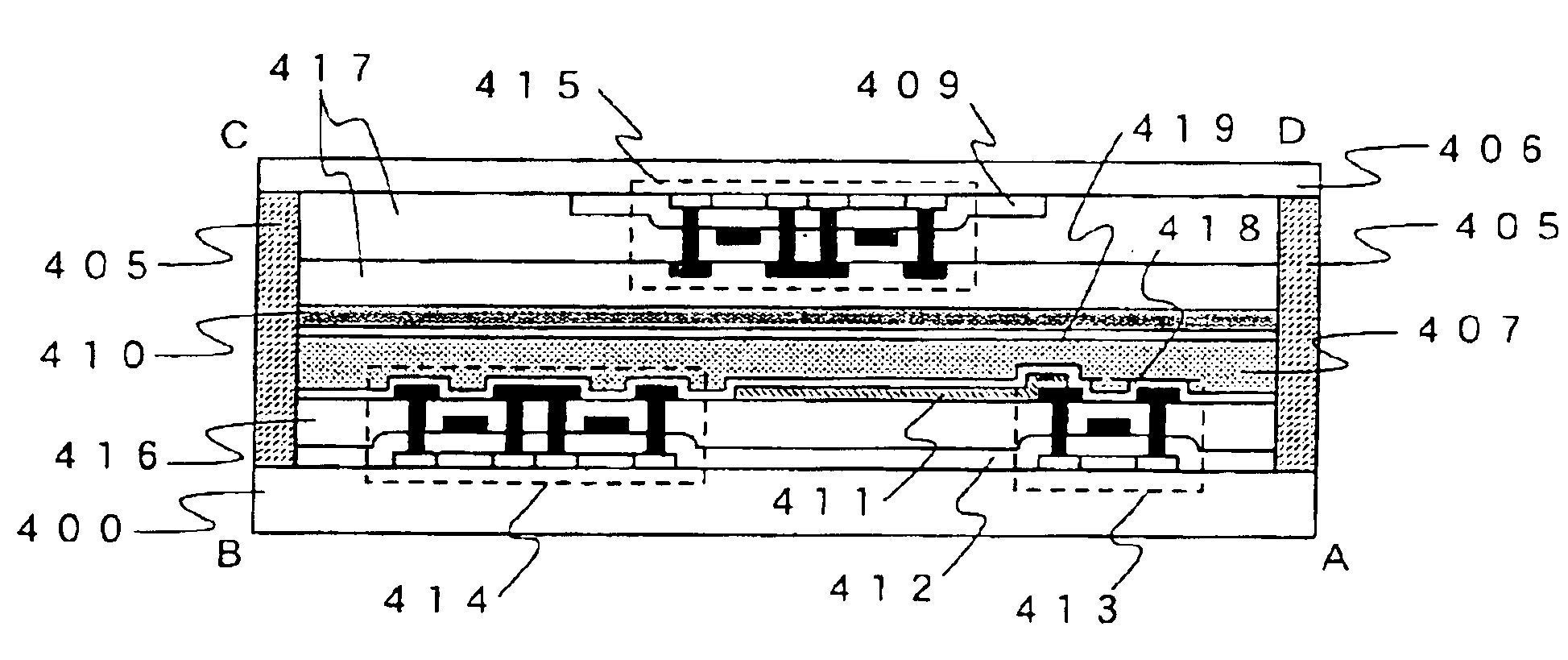

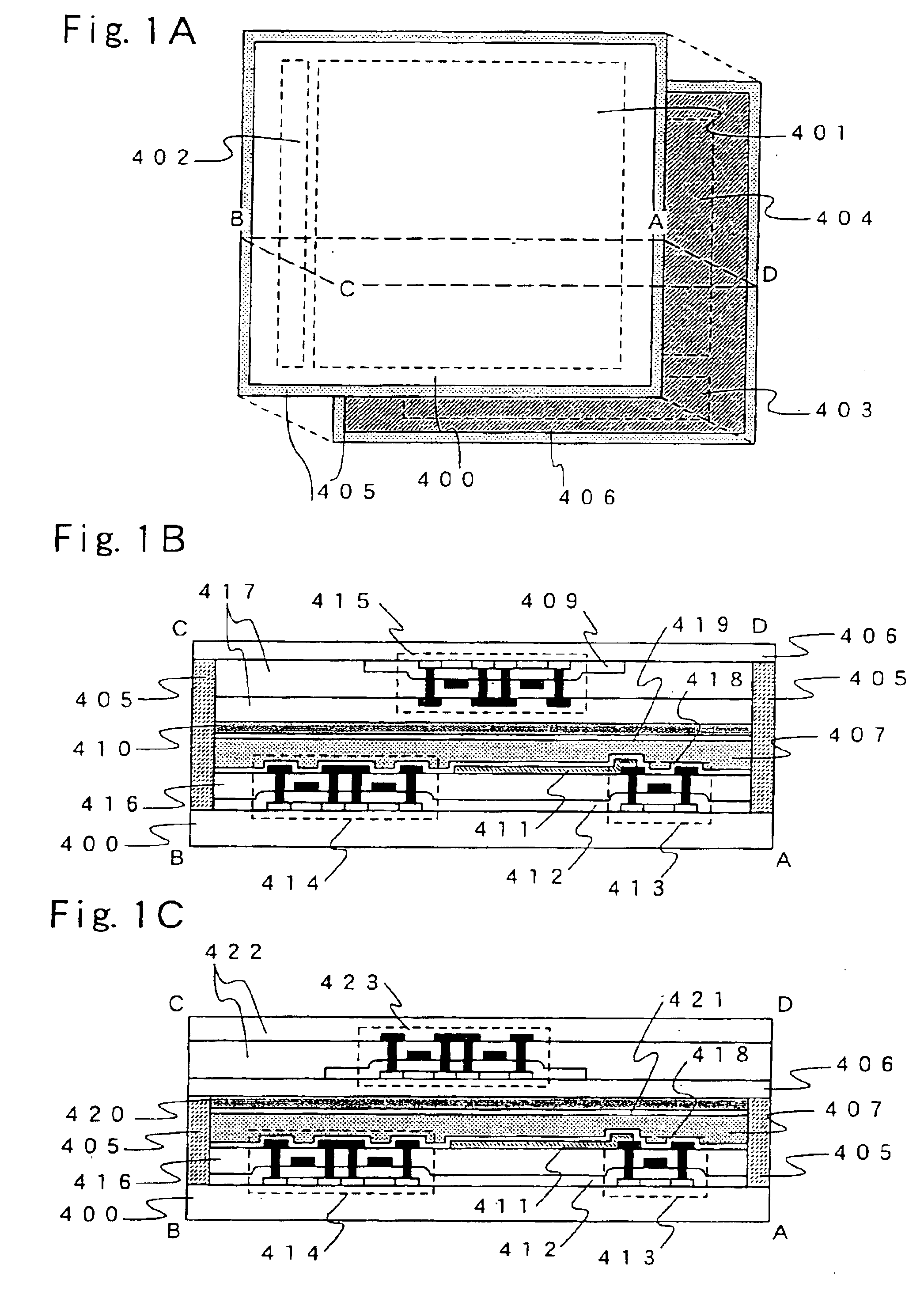

Active matrix display device and manufacturing method thereof

InactiveUS6911675B2Small sizeReduce marginSolid-state devicesSemiconductor/solid-state device manufacturingDriver circuitActive matrix

A semiconductor device reduced in size is provided in which the surface area outside of a display portion required for IC chips to mounted is reduced in a semiconductor device having an active matrix display portion. Further, signal wiring connection defects that accompany IC chip mounting are reduced. By manufacturing TFTs on an opposing substrate in a reflecting active matrix semiconductor device, thus manufacturing a desired logic circuit, the logic circuit, conventionally mounted externally, is formed on the opposing substrate. Further, the semiconductor device is made high speed and high performance by using suitable TFT structures and electric power source voltages for pixels and driver circuits on a pixel substrate and for the logic circuit on the opposing substrate.

Owner:SEMICON ENERGY LAB CO LTD

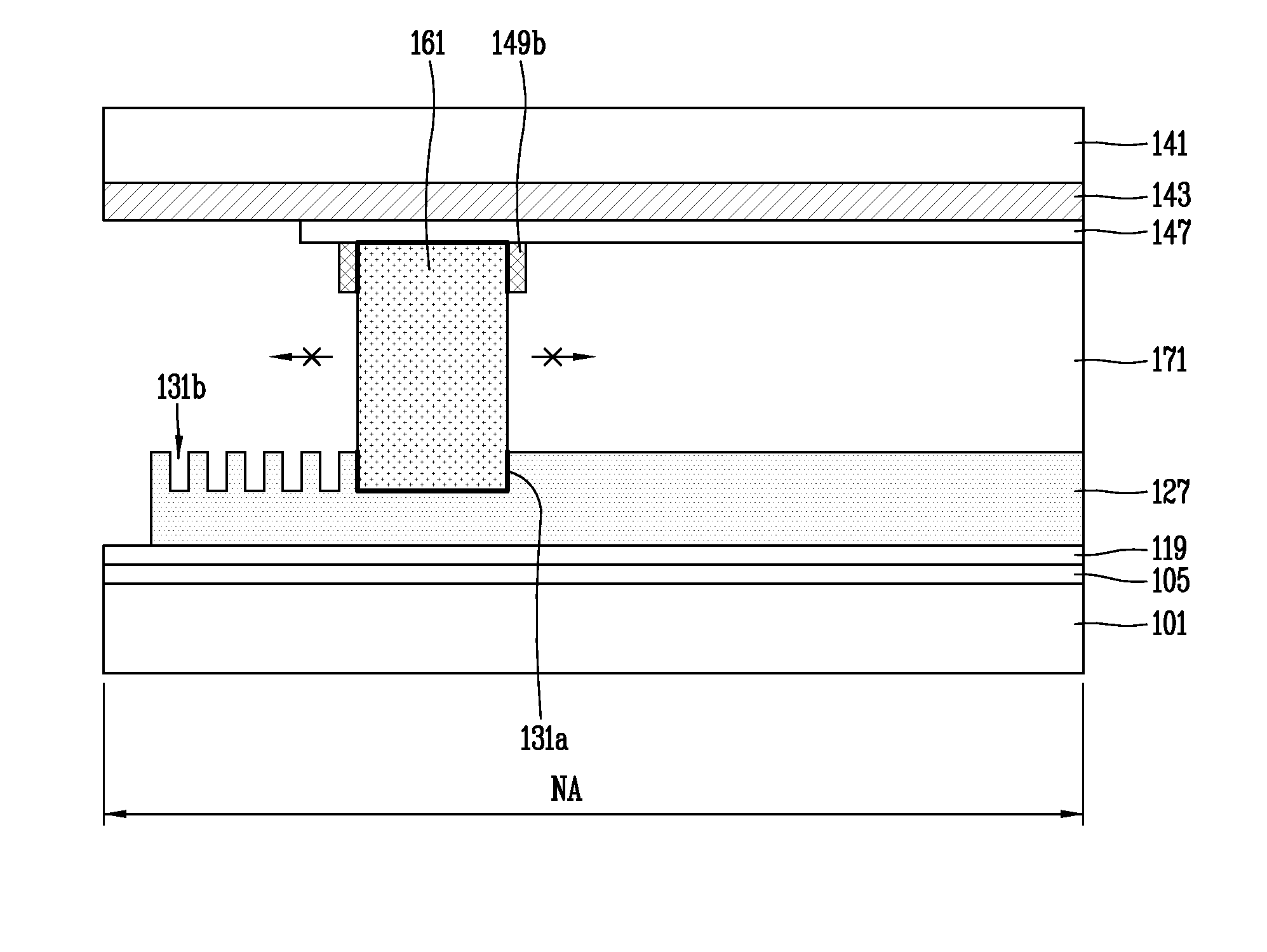

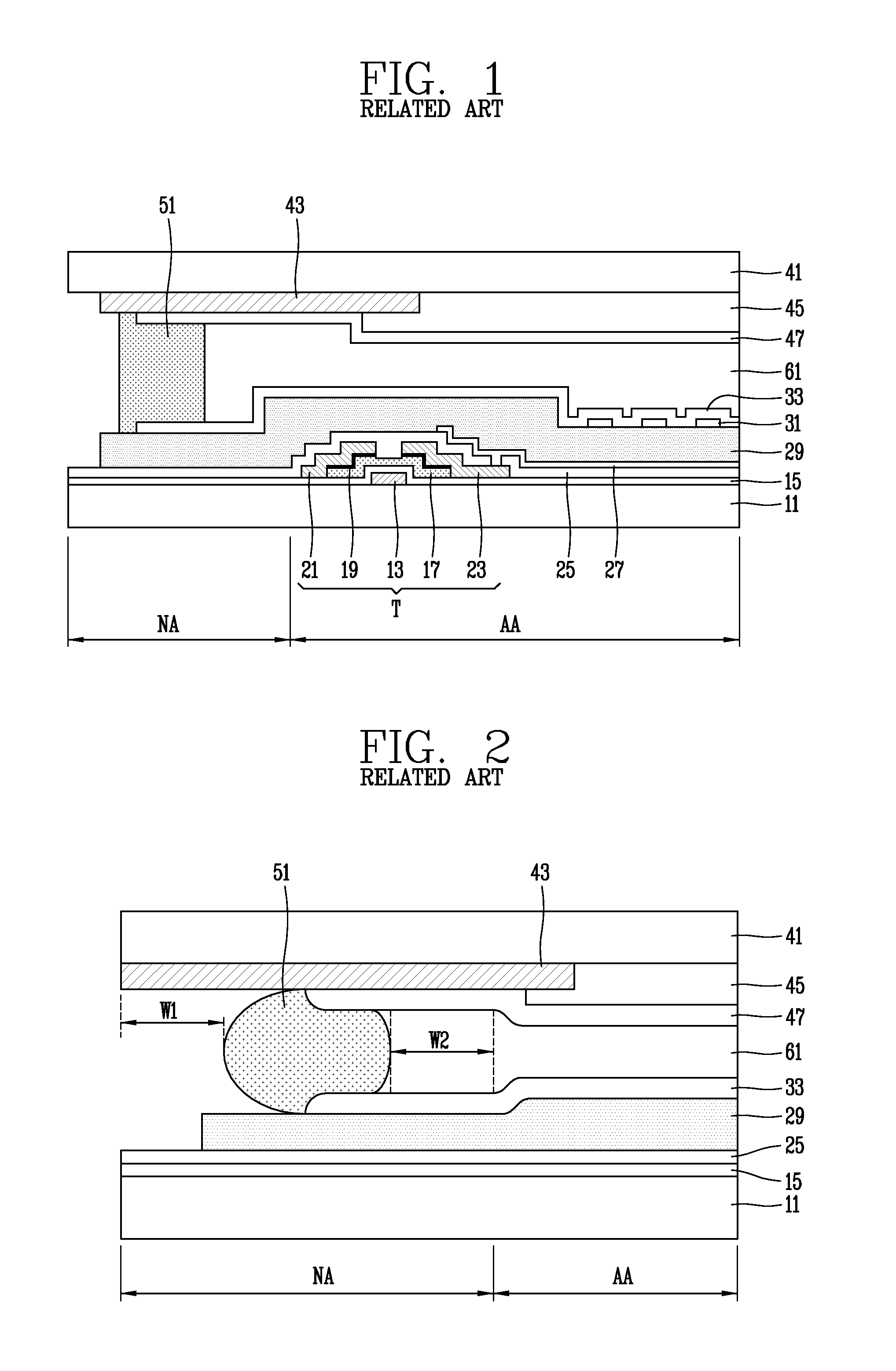

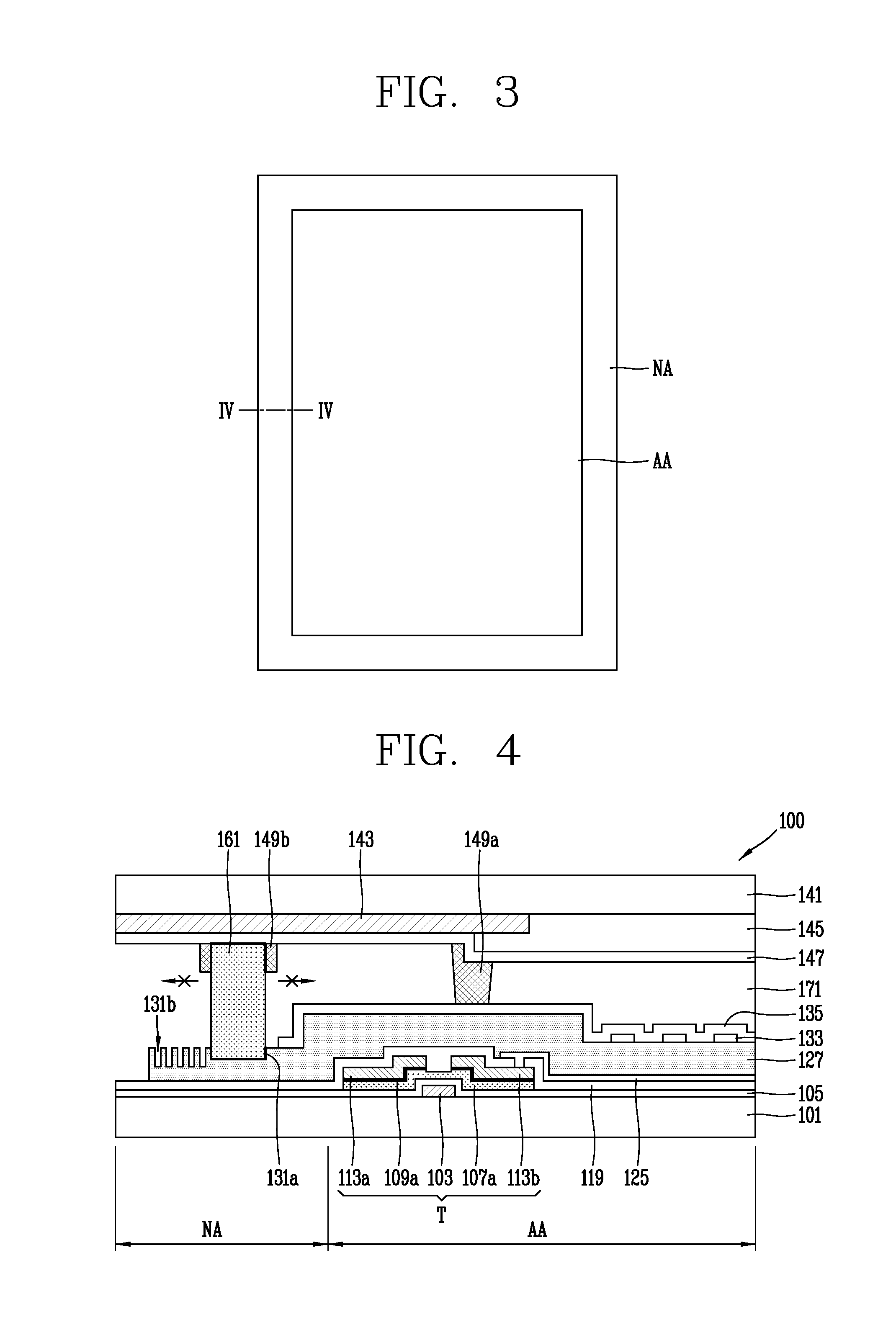

Liquid crystal display device and method for fabricating the same

ActiveUS20140176895A1Fine seal patternAvoid spreadingSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

The present disclosure relates to a liquid crystal display device and a fabricating method thereof. The device includes a thin film transistor formed on a lower substrate, a pixel electrode formed on the lower substrate, a planarization layer formed on an entire surface of the lower substrate, a black matrix formed on the upper substrate, a color filter layer formed on a upper substrate, partition walls formed on the upper substrate and forming a space corresponding to a seal pattern insertion groove, a liquid crystal layer interposed between the lower substrate and the upper substrate, and a seal pattern inserted between the seal pattern insertion groove located on the non-display region of the lower substrate and the upper substrate and the partition walls.

Owner:LG DISPLAY CO LTD

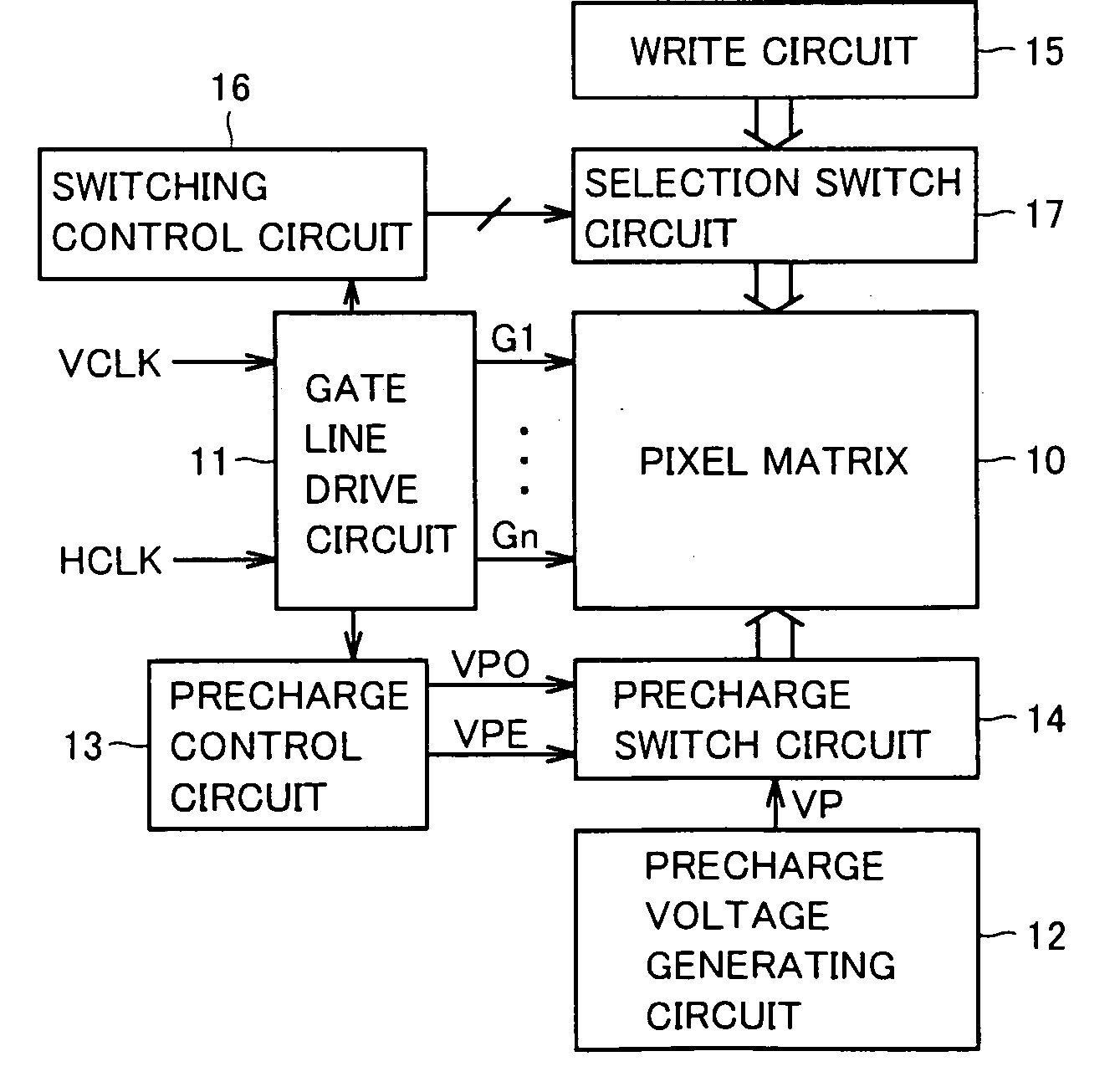

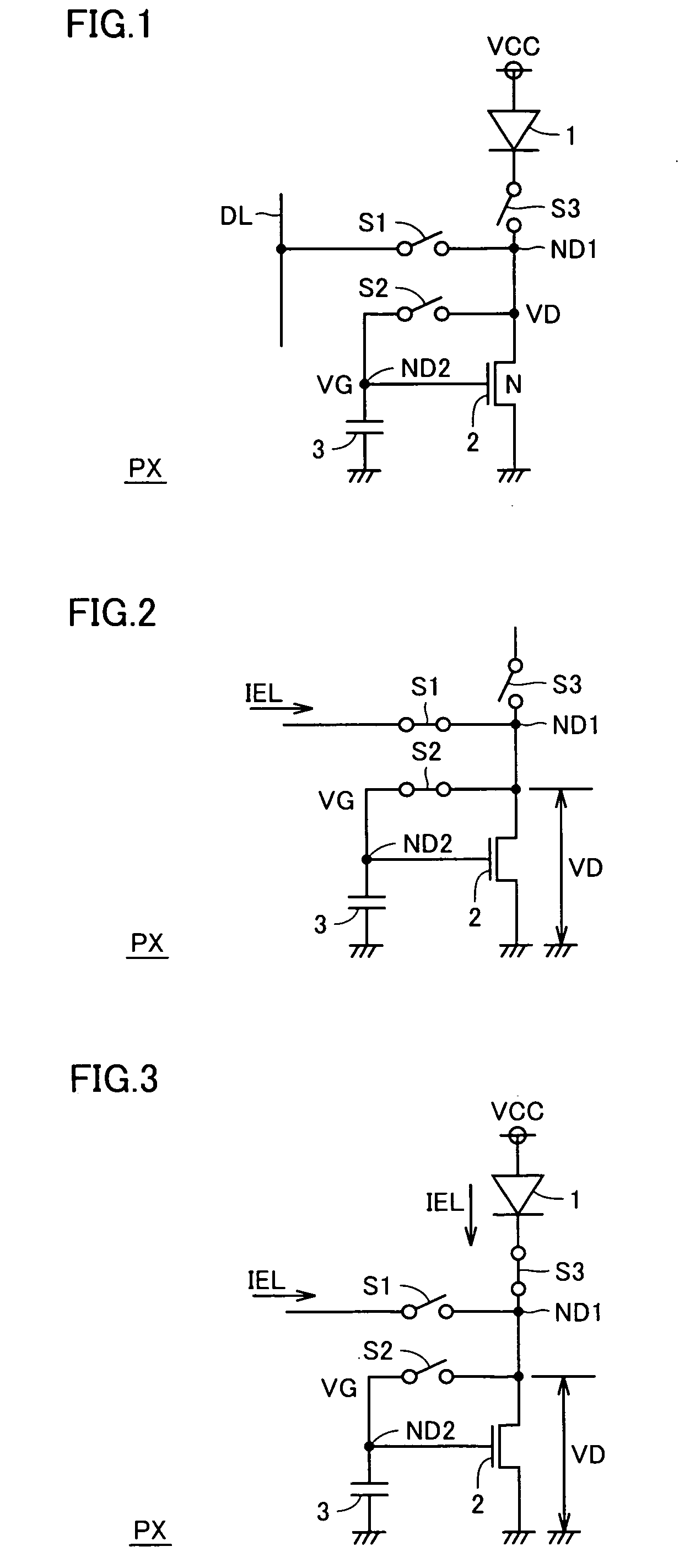

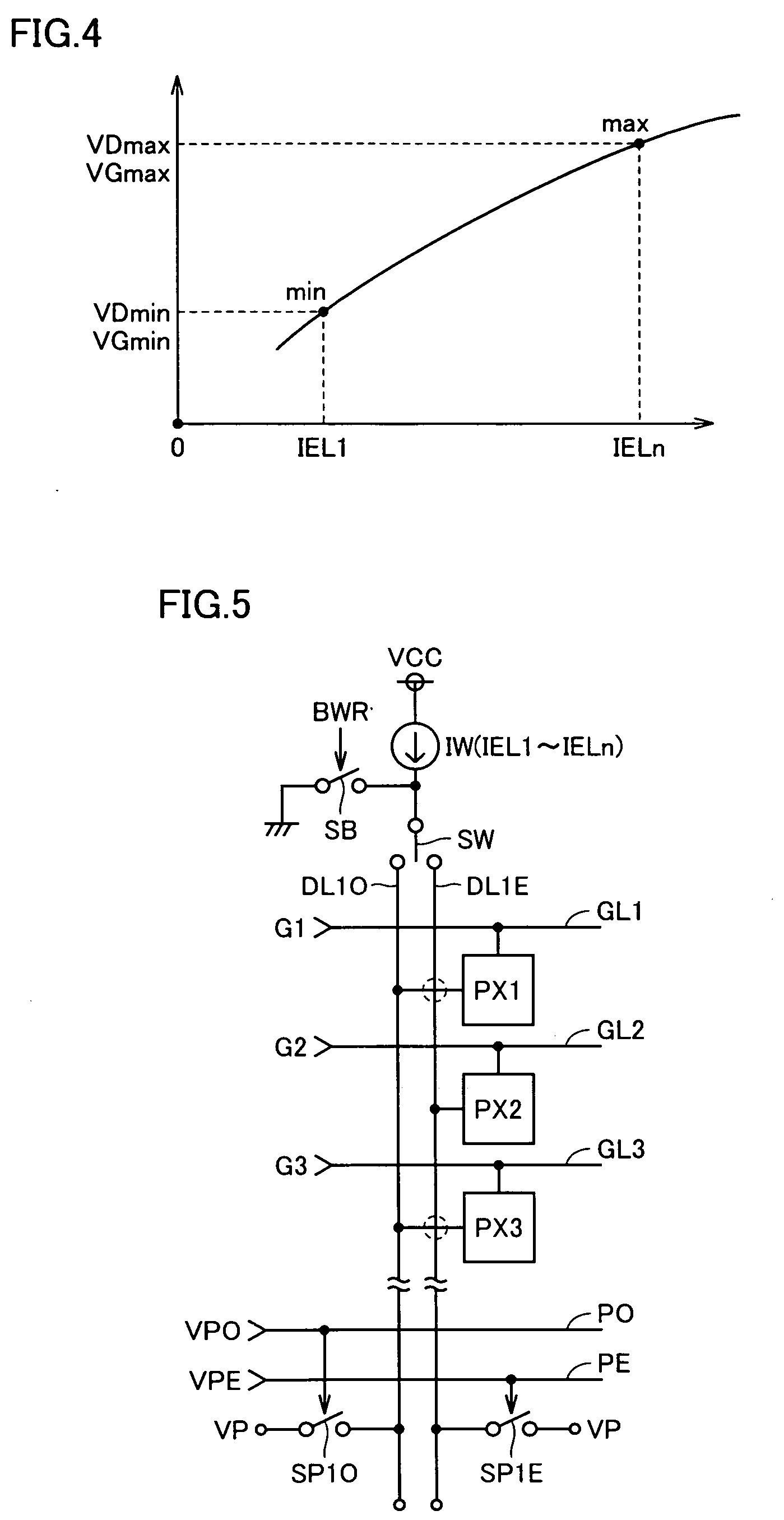

Display device

InactiveUS20060007215A1Reduce marginIncrease marginElectrical apparatusElectroluminescent light sourcesDisplay deviceComputer science

A plurality of data lines are provided for pixels arranged in one column. One of the data lines is precharged to a predetermined voltage, and a write current of a voltage corresponding to black data is supplied to a selected pixel via another data line. These data lines are connected to the pixels in different rows in a predetermined sequence. A display device capable of writing a complete black signal without impairing a margin for a write time can be provided.

Owner:MITSUBISHI ELECTRIC CORP

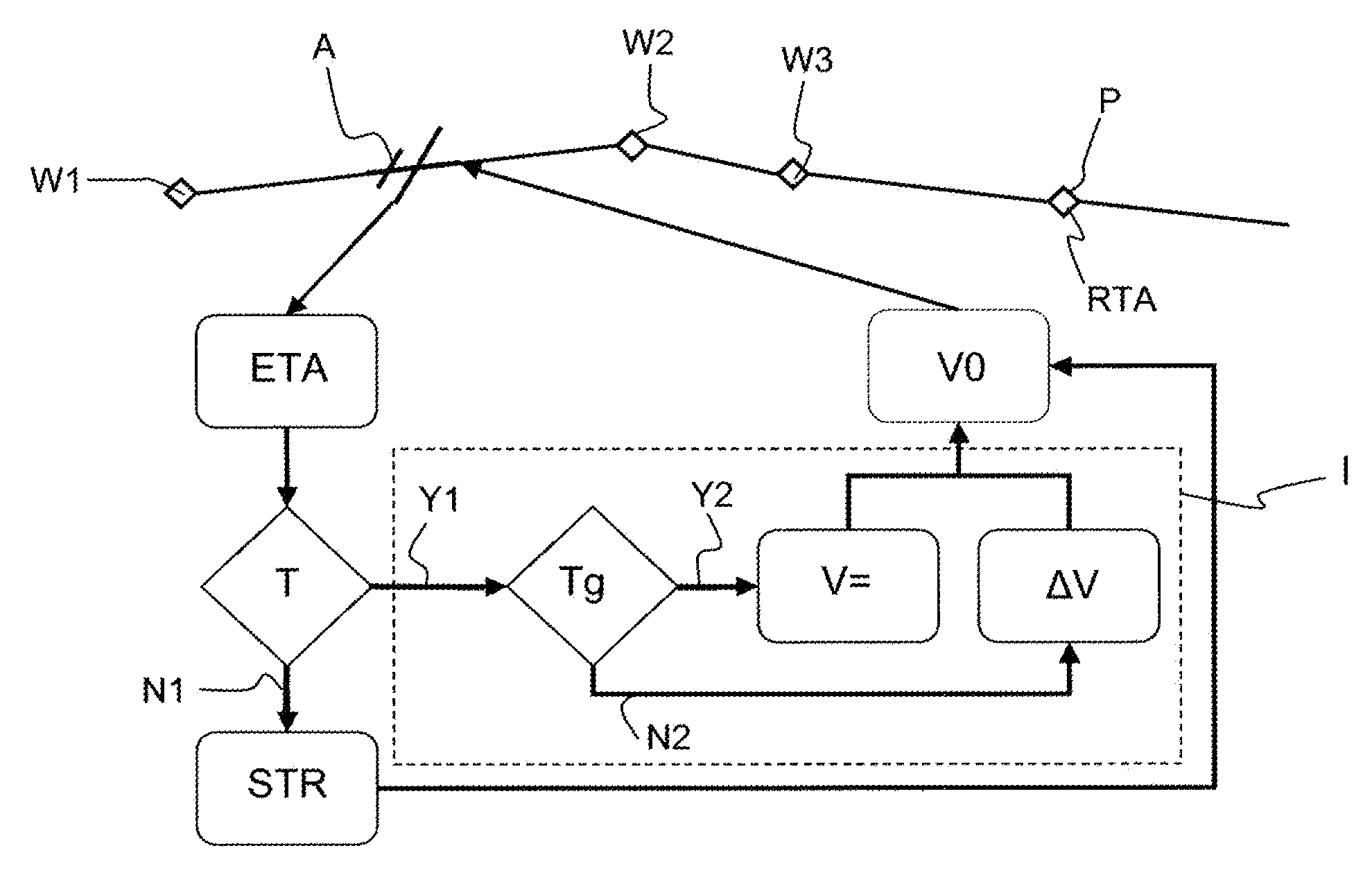

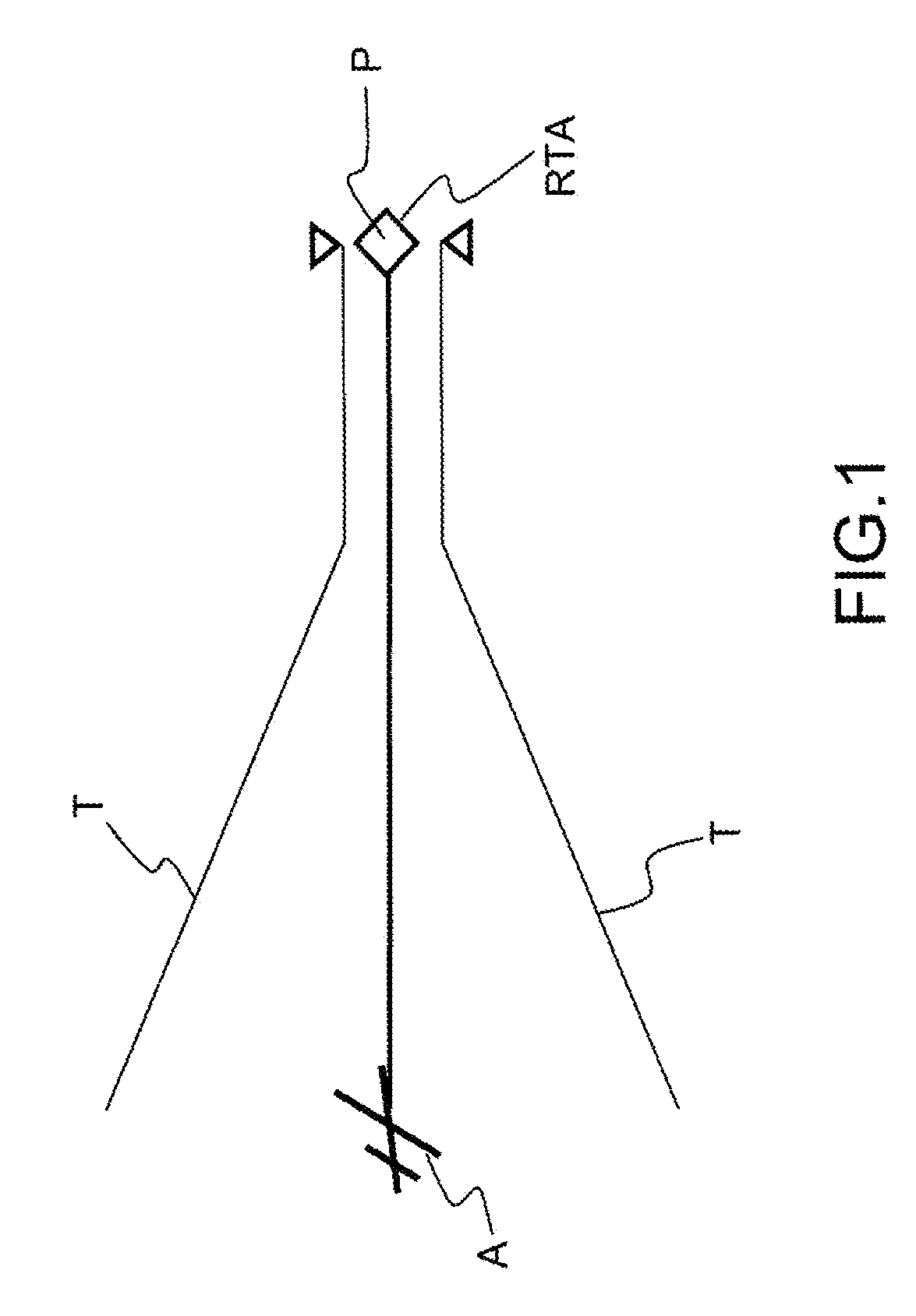

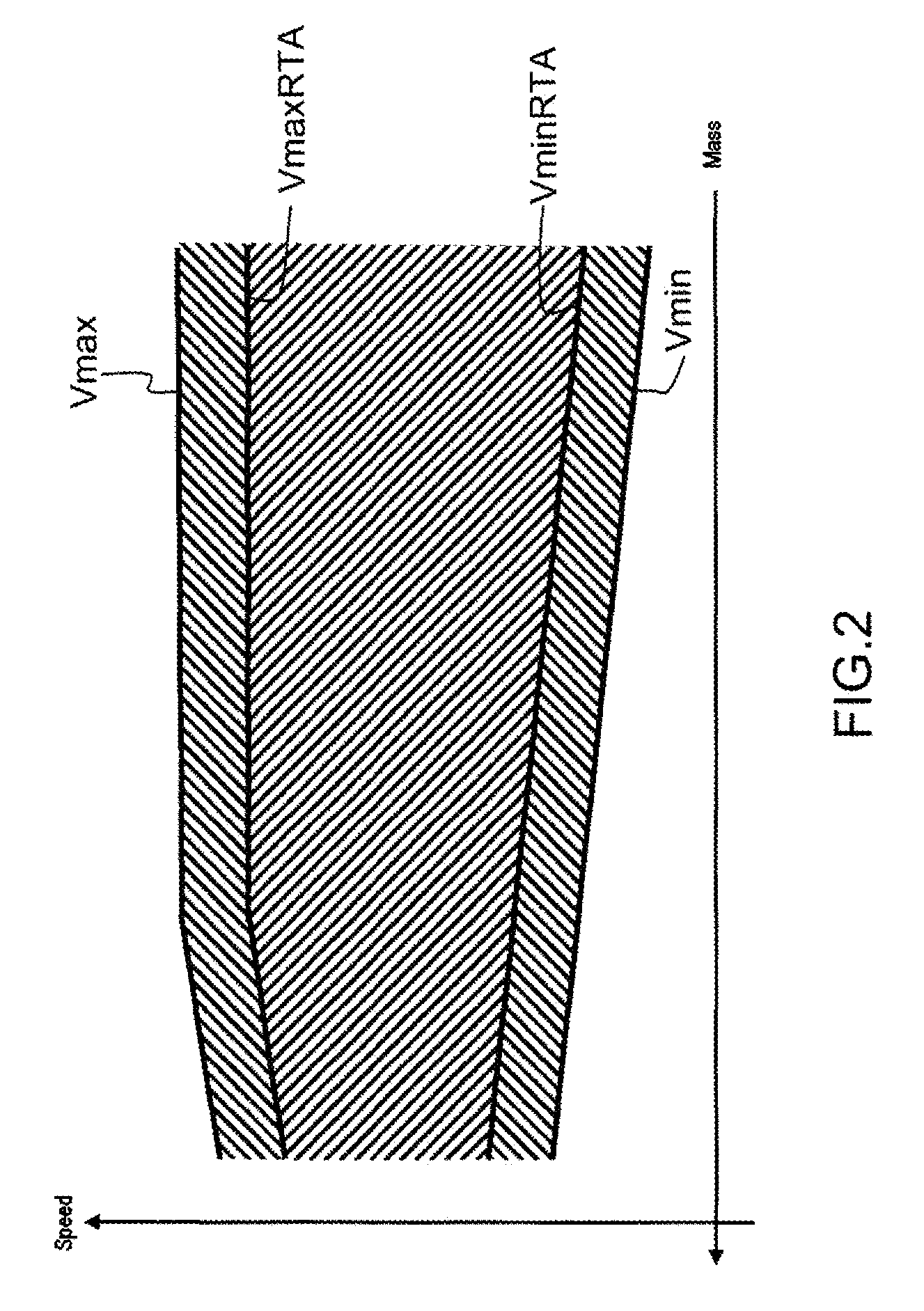

Method for assisting in the management of the flight of an aircraft in order to keep to a time constraint

ActiveUS20100131125A1Shorten speedReduce distanceEnergy saving arrangementsDigital data processing detailsFlight vehicleCivil aviation

The invention relates to the field of civil aviation and, more specifically, relates to the flight management systems, more commonly known by the English acronym FMS. The method for assisting in the management of the flight of an aircraft in order to keep to a time constraint according to the present invention allows for a control of the keeping to the time constraint that presents a rapid dynamic, by avoiding as far as possible having the estimated time of arrival (ETA) at a particular point (P) able to drift relative to a required time of arrival (RTA) at said particular point (P), thanks to the use of a manoeuvring margin (M) granted to the guidance module of the aircraft.

Owner:THALES SA

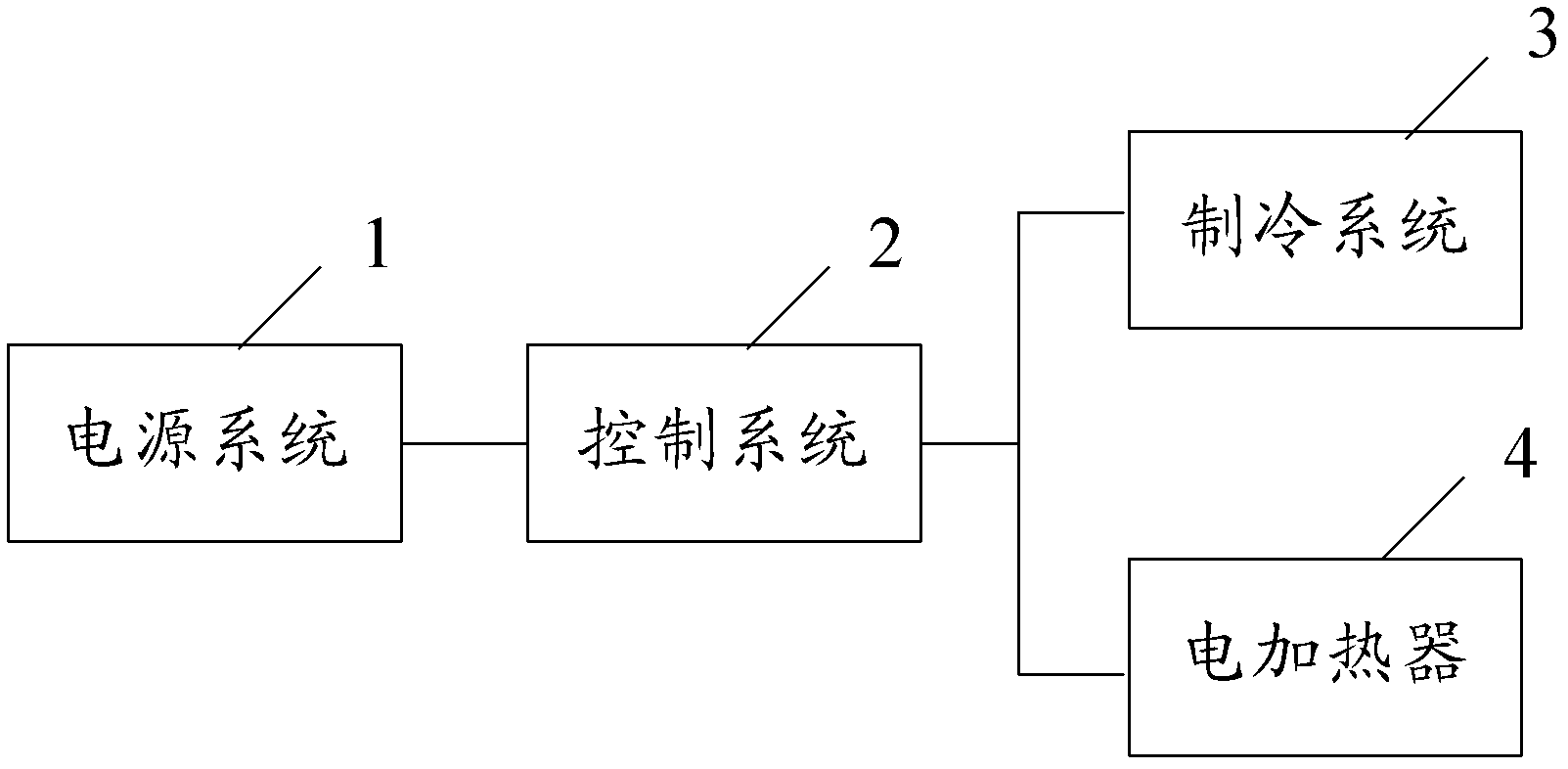

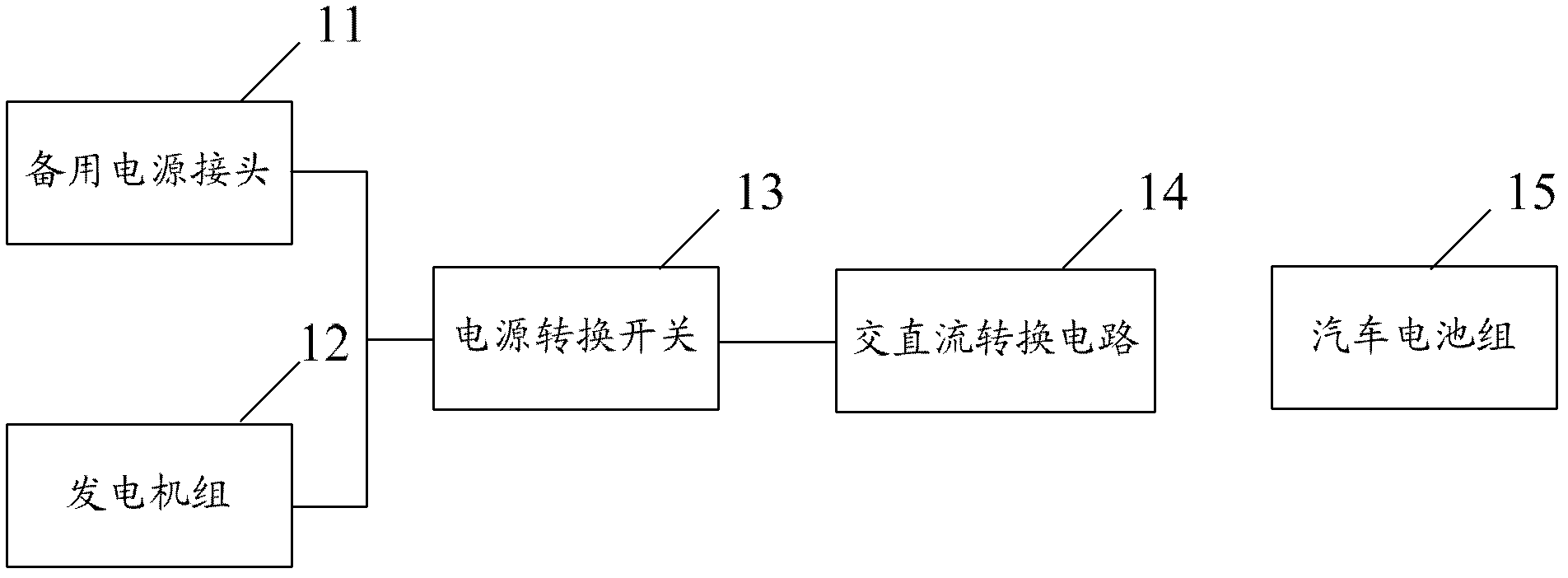

Vehicle self-contained refrigeration machine set

InactiveCN102627064AReduce work performanceAvoid failure to startAir-treating devicesVehicle heating/cooling devicesLow speedControl signal

The invention discloses a vehicle self-contained refrigeration machine set, which comprises: a power system, a control system, a refrigeration system and an electrical heater set, wherein the power system is connected with the control system, the power system is used for supplying the control system with electric power and is controlled by the control system; the control system is connected with the refrigeration system and the electrical heater set, the control system collects working parameters of the refrigeration system and the states of a refrigeration box, generates a control signal after data processing and adopts the control signal to control the operations of the refrigeration system and the electrical heater set. Driven by an alternating current variable frequency motor or a direct current variable frequency motor, the machine set adopts a low-speed starting compressor, therefore the current is small when the machine set is started, and no impact on an engine system is caused, thus the allowance in selecting style of diesel engine is reduced, a generator set with smaller model is selected, and fuel consumption is reduced. In addition, by adopting an electrical heating manner to produce heat and to deforest, design of the refrigeration system is greatly simplified, and the heat producing and the deforesting are realized directly and simply.

Owner:王军 +2

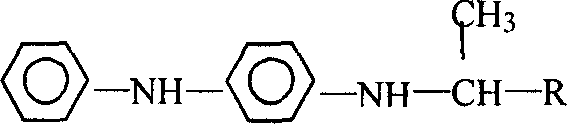

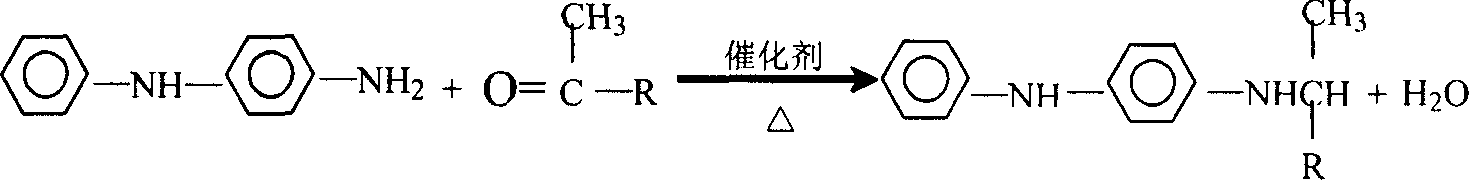

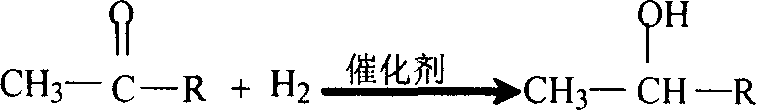

Condensating reductive alkylation catalyst, preparation method and uses thereof

ActiveCN101204658AAppropriate areaAvoid wastingPreparation by reductive alkylationMetal/metal-oxides/metal-hydroxide catalystsWater useOrganic acid

The invention provides a condensation reductive alkylation catalyst and preparation method and use thereof. The catalyst pertains to copper-based catalyst, and is prepared by coprecipitation method with acid or salt thereof as precipitator. The preparation method is energy saving and environment friendly for including no impurity natrium, which avoids environmental protection problem existing in catalysis preparation technology with traditional precipitation method and reduces washing water use. The specific surface area of the catalyst is 30.0 to 75.0m<2> / g and pore volume 0.08 to 0.15ml / g. The catalyst can be used in condensation technology of RT Base and aliphatic ketone to inhibit an unnecessary side reaction in production of anti-aging agent 4010NA and 4020, especially to a reaction of aliphatic ketone alkylation regent hydrogenated to corresponding mellow.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Method for processing thin wall welder cases of revolving body structures

InactiveCN102794610ASolve the structural sizeSolve the coaxial problem of front and rear installation side weldingArc welding apparatusPre deformationEngineering

The invention discloses a method for processing thin wall welder cases of revolving body structures, belonging to the technical field of aero-engine metal plate forming and welding. According to the invention, a whole pre-deformation welding / forming method is used for solving the problems that sizes of mounting edges are out of tolerance, coaxiality of front and rear mounting edges with main bodies after welding is out of tolerance and residual stress distribution of welding components is unbalanced. The method provided by the invention comprises the following steps of: carrying out technological structure welding deformation allowance compensation design on a mounting edge and a main body of a thin wall welder case before the welding according to the plastic deformation characteristics of materials; plastically forming an expansion block according to an expander work part, size and final structural size requirement of parts; carrying out automatic argon arc welding on the mounting edge and the main body; assembling the welded welder case and expansion block on the expander work part to carry out expansion plastic forming and controlling the expansion forming size through adjusting pressure of the expander; and unloading the pressure of the expander, recovering the expander work part and unloading the parts to complete the welding / forming process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

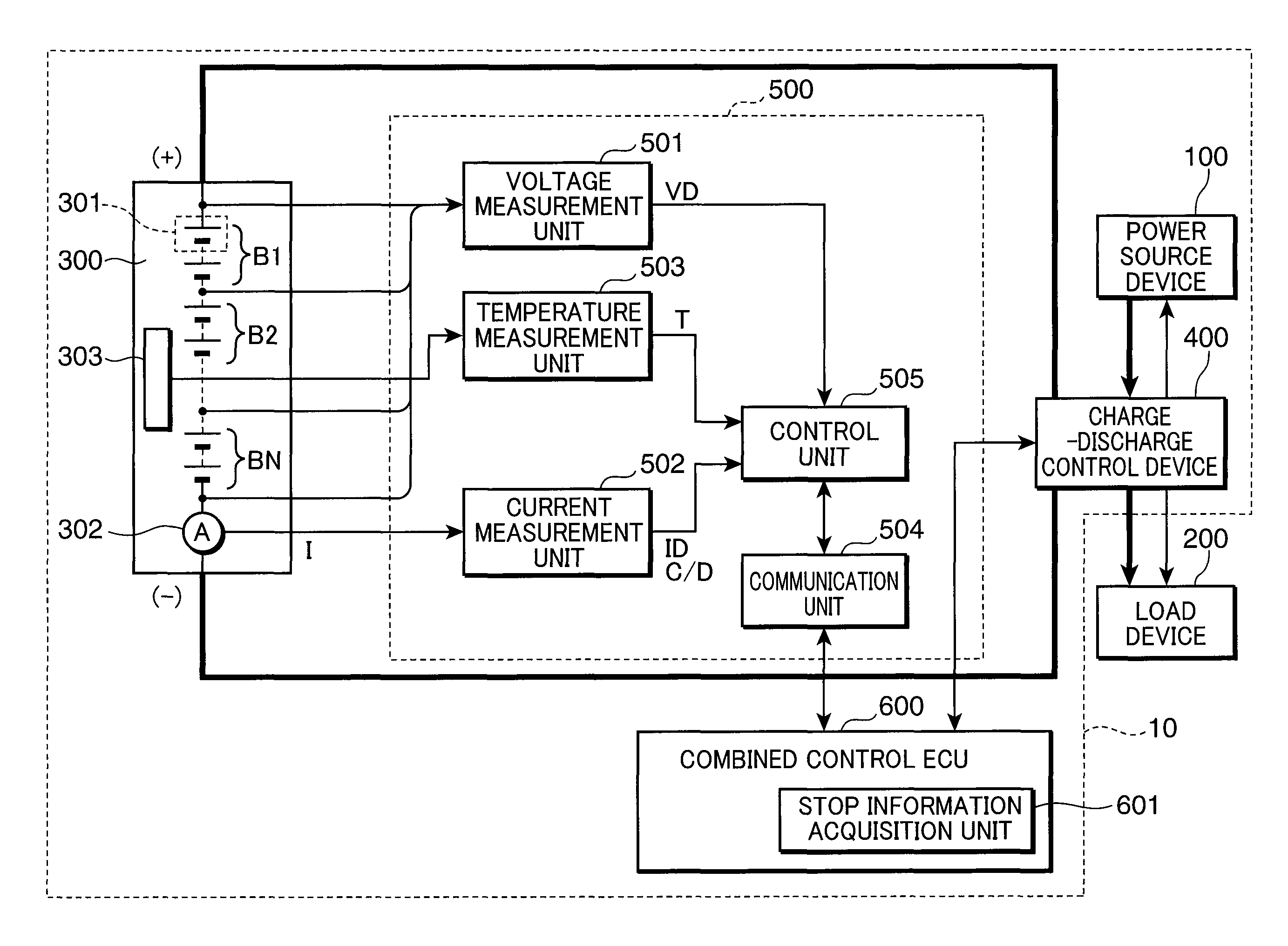

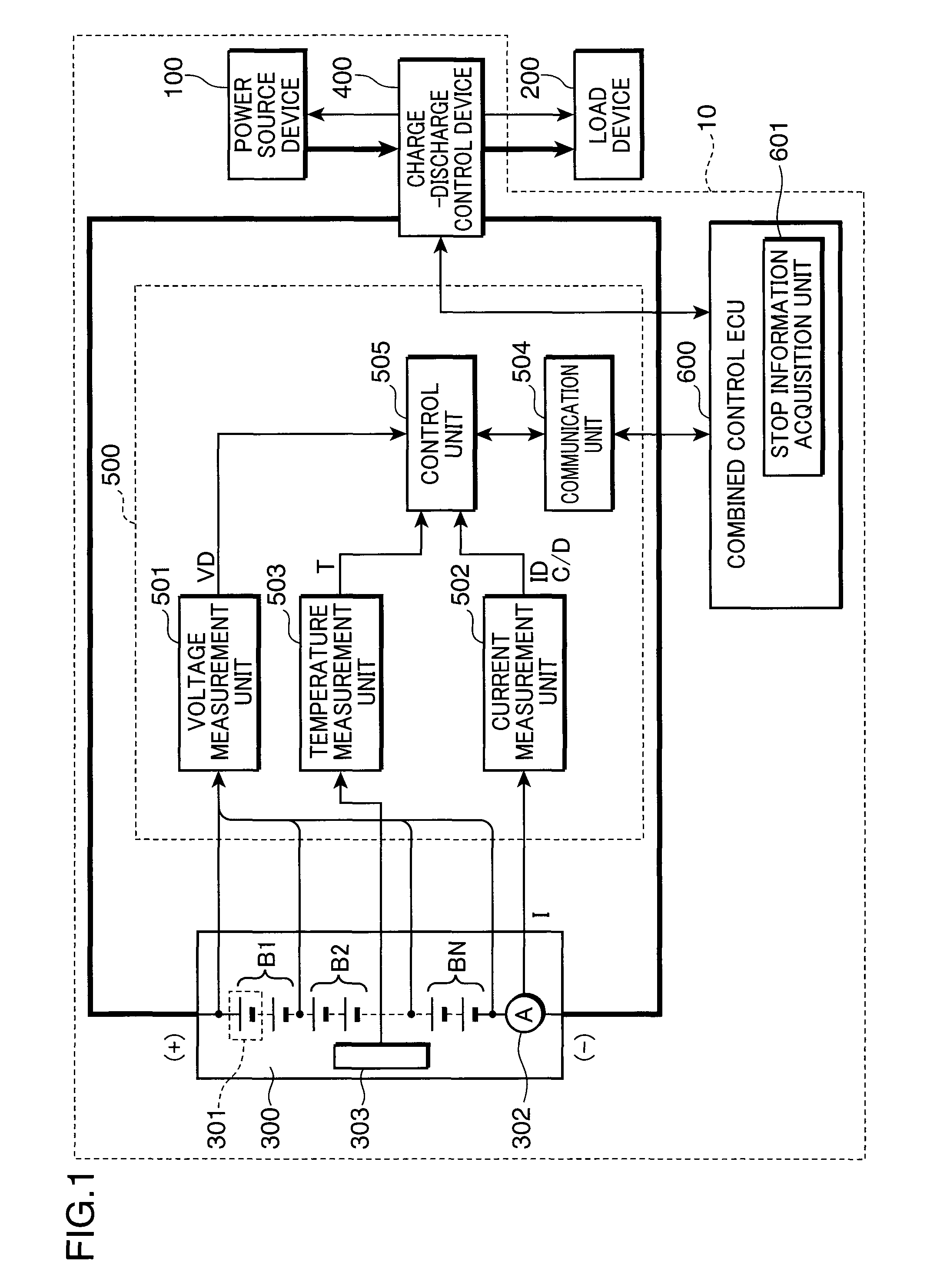

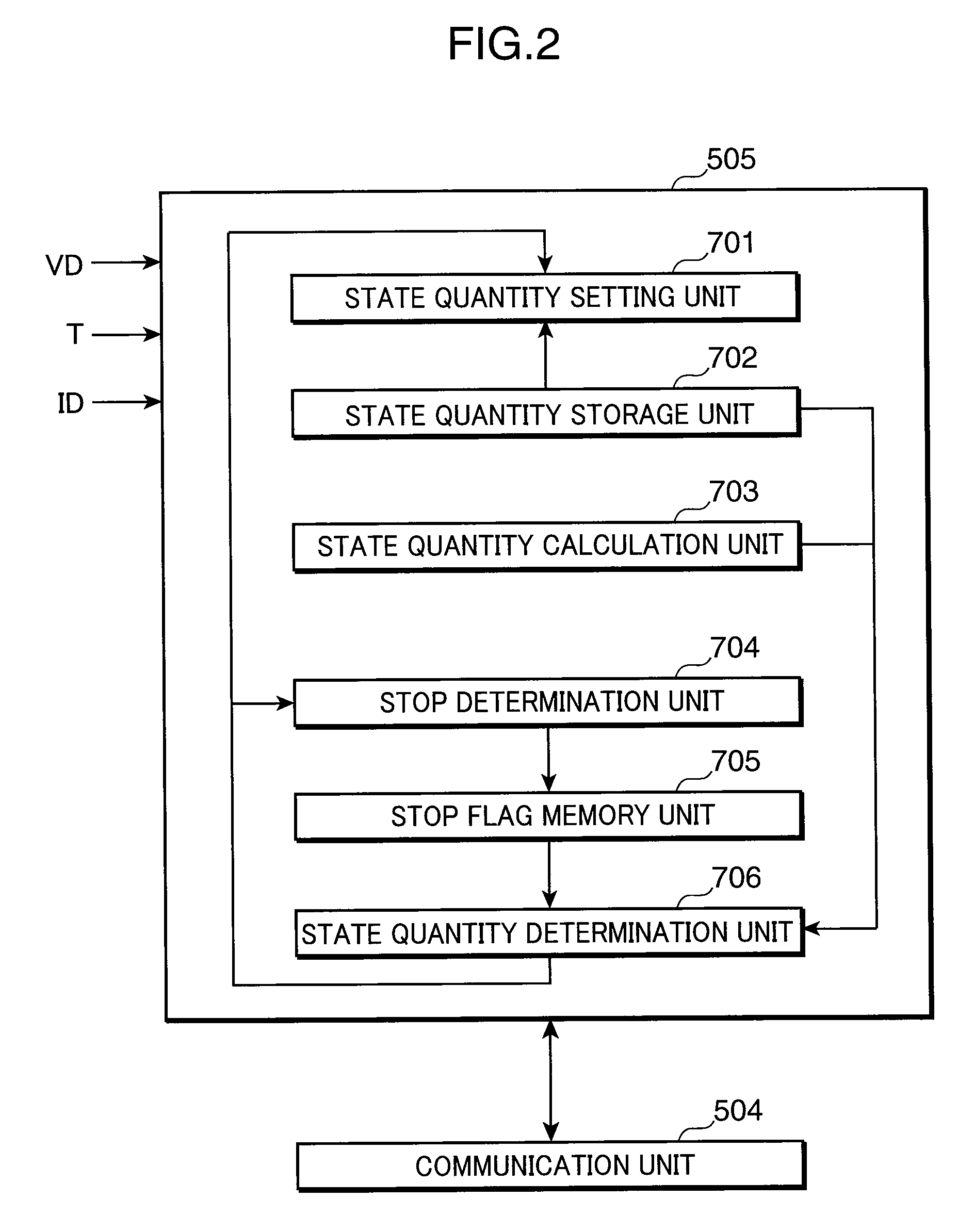

Power source system, power supply control method for the power source system, power supply control program for the power source system, and computer-readable recording medium with the power supply control program recorded thereon

InactiveUS8159186B2Increasing the power supply capacity of a power storage deviceImprove stateCircuit monitoring/indicationDifferent batteries chargingState of chargeSource system

The present invention provides a power source system that increases the power supply capacity of a power source device and continuously supplies the power necessary for a load device when a power source device stops. A control unit has a state quantity setting unit that sets a first target state quantity indicating a state of charge of the power storage device that is to be a target value when charge and discharge of the power storage device are controlled. When the power source device stops, the state quantity setting unit can change the first target state quantity to a second target state quantity that is to be a target value exceeding the first target state quantity and can increase the target state quantity of the power storage device. As a result, when the power source device stops, charge and discharge of the power storage device are controlled on the basis of the target state quantity exceeding that during the operation of the power source device. Therefore, the state of charge of the power storage device can be improved over that during the operation of the power source device. As a result, the power supply capacity of the power source device can be increased and the power necessary for the load device can be continuously supplied, in place of the power source device.

Owner:PANASONIC CORP

Sewing method to form a trim cover assembly and automotive seat using the trim cover assembly

InactiveUS20050103247A1Good lookingReduce marginSeat coveringsLeather sewingEngineeringMechanical engineering

A sewing method to form a trim cover assembly for automotive seat, and an automotive seat using the trim cover assembly. Firstly, a first cover material, a second cover material and a backing tape are used and juxtaposed on one another, with their ends aligned with one another, and then sewn together to create a first seam and a sewn connection portion. Such sewn connection portion is cut off into a shortened sewn connection portion. Thereafter, the first cover material and backing tape are turned over relative to the shortened connection portion and sewn together, thereby forming one portion of the trim cover assembly. Another portion of the trim cover assembly may be formed by avoiding use of the backing tape and simply turning over the first cover material relative to the sewn connection portion, and sewing together the thus-turned portions of the first cover material.

Owner:TACHI S CO LTD

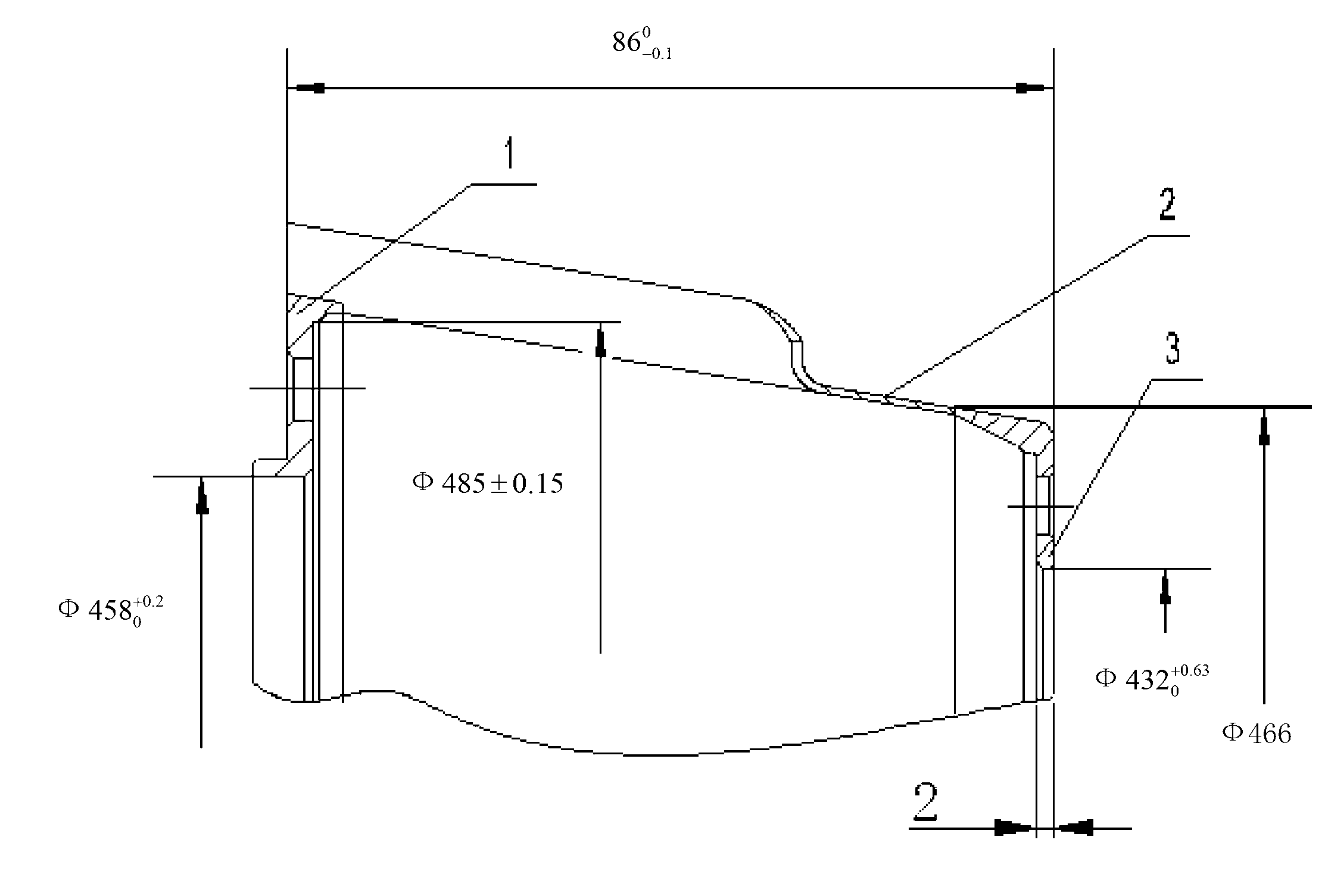

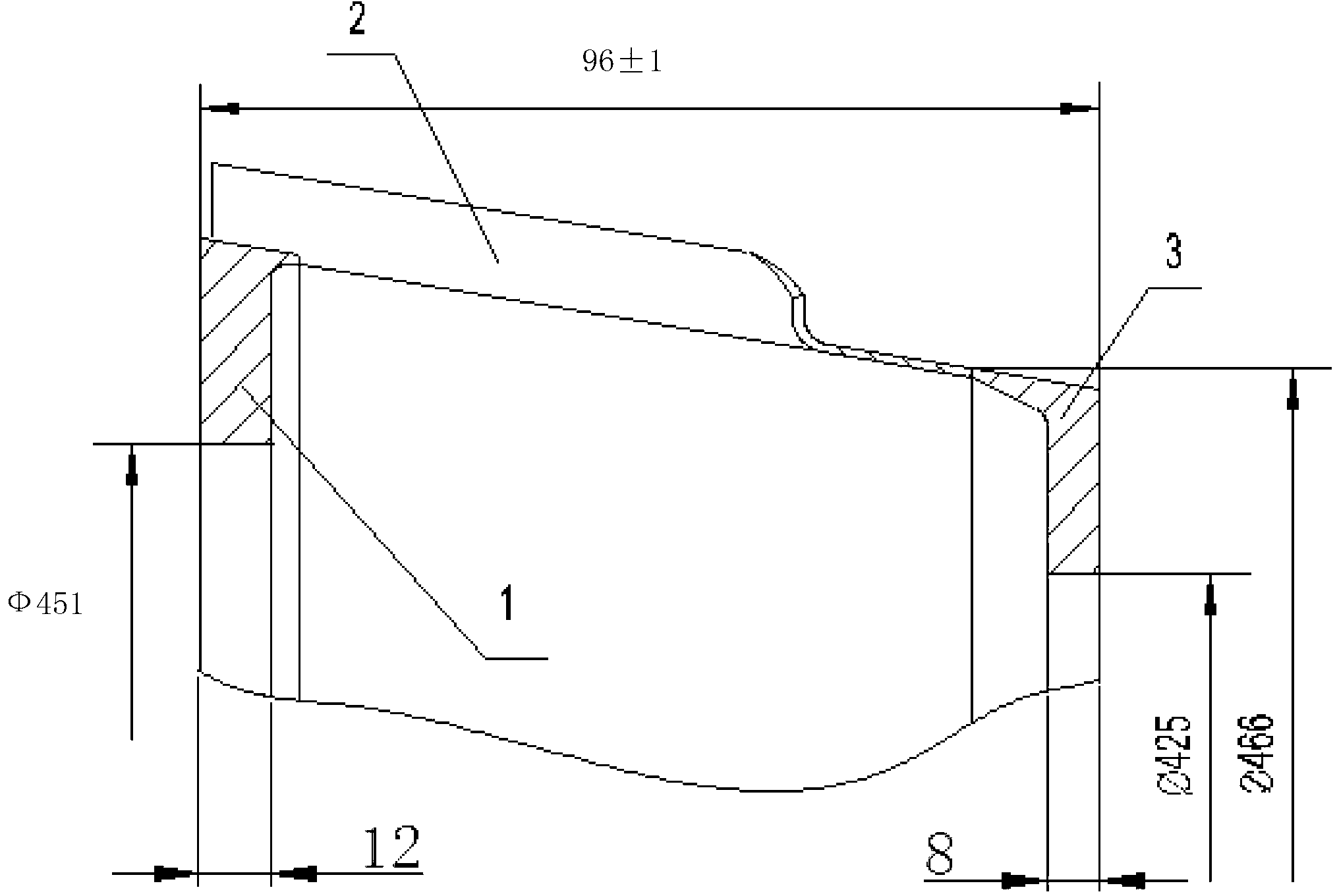

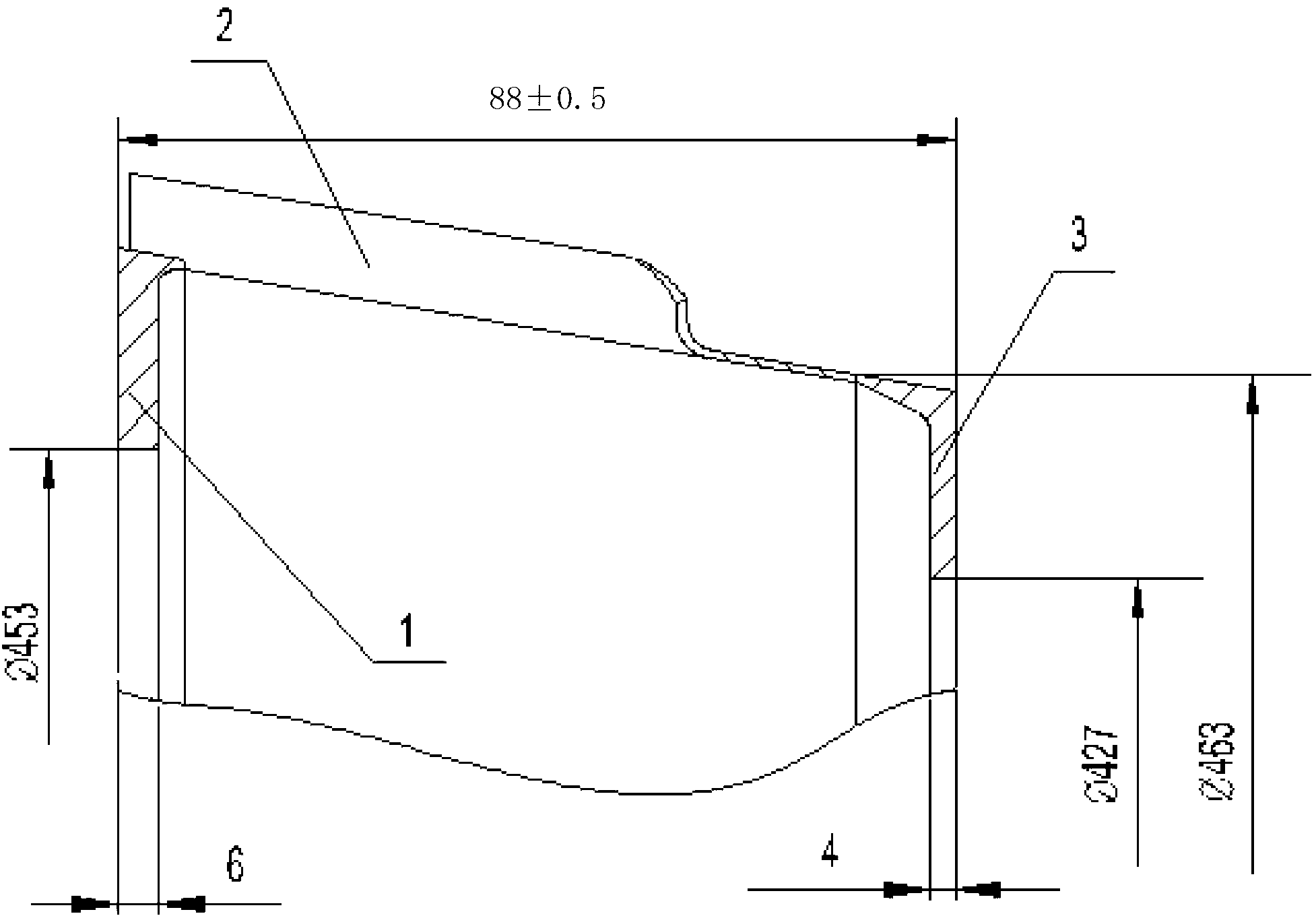

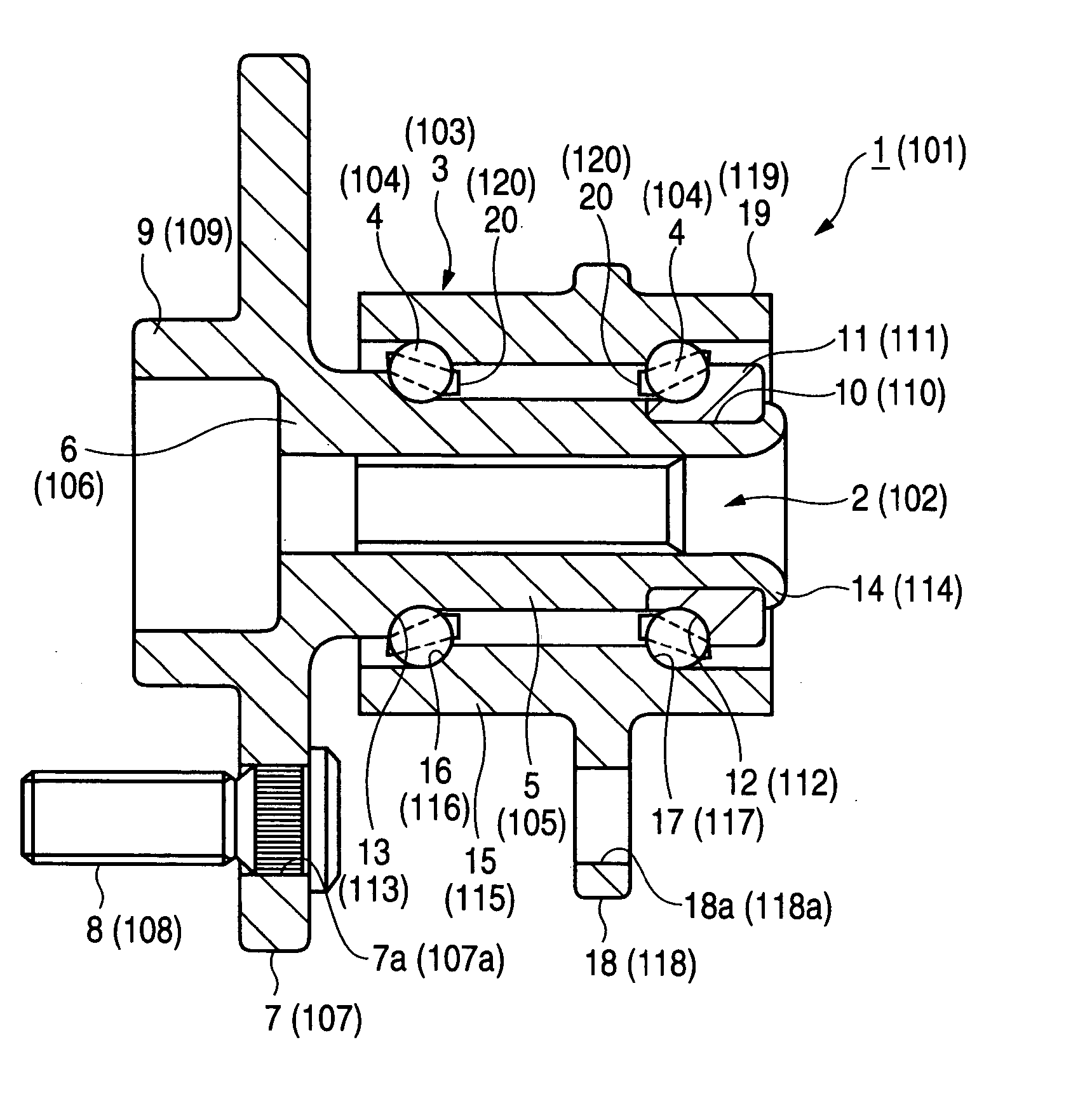

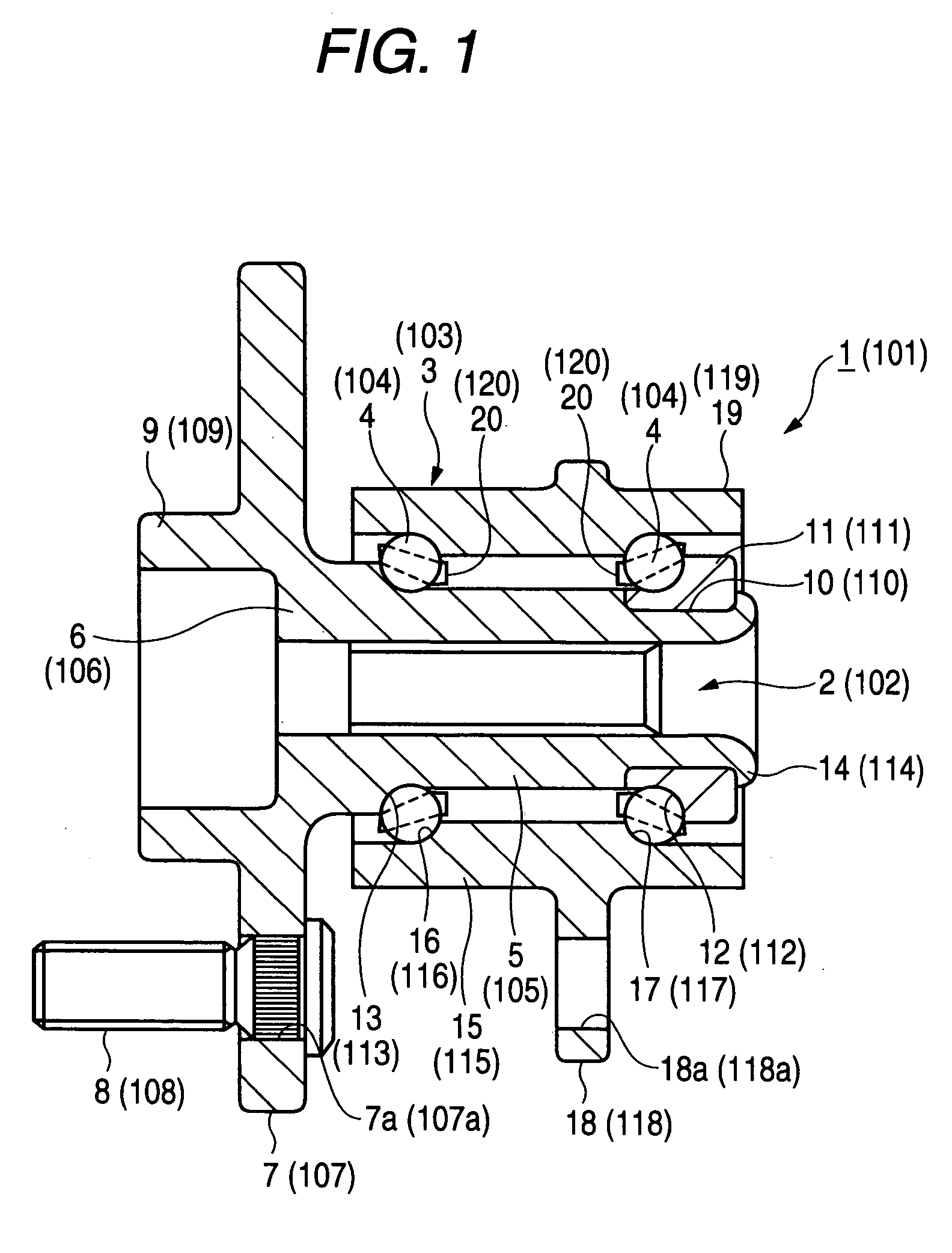

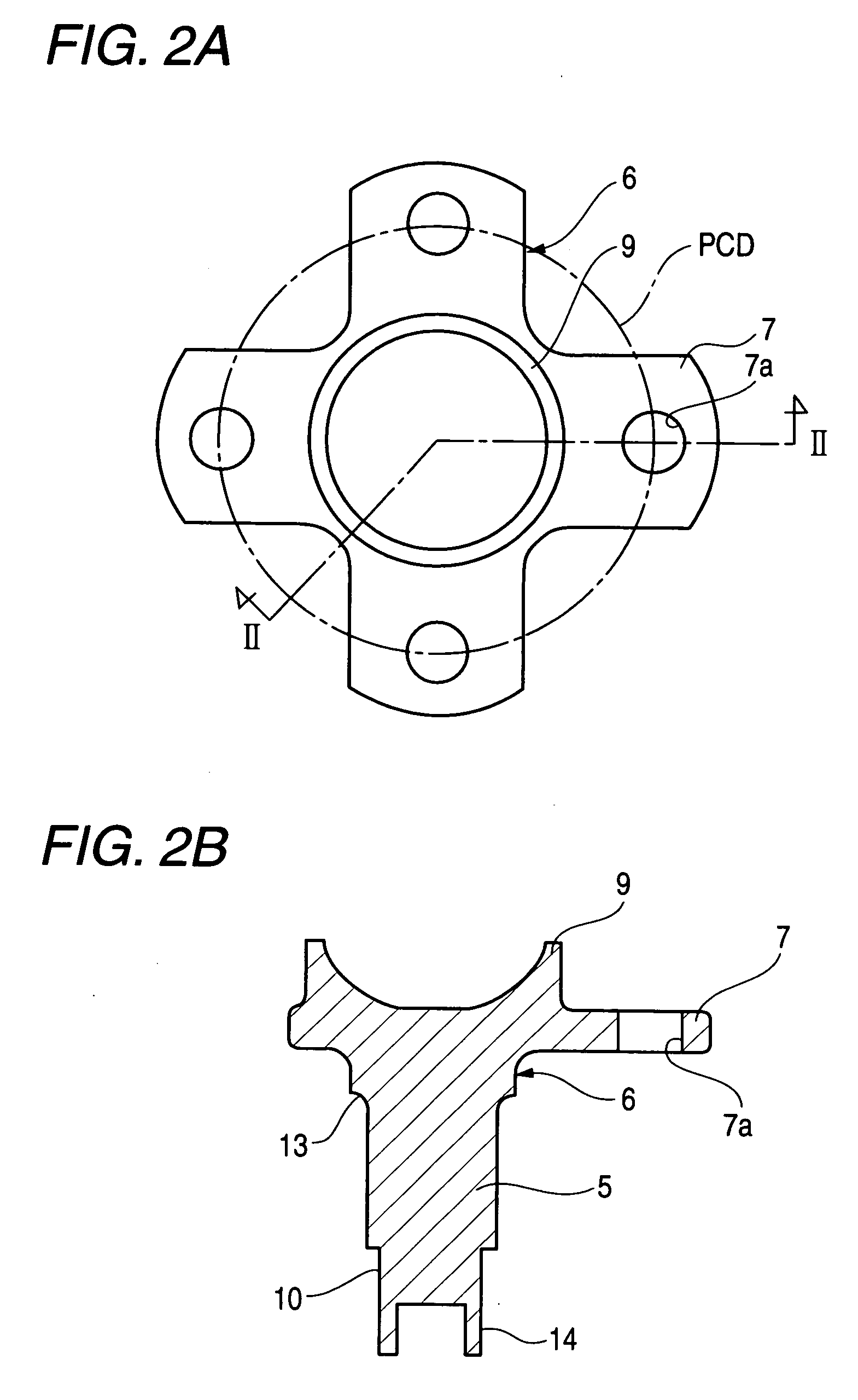

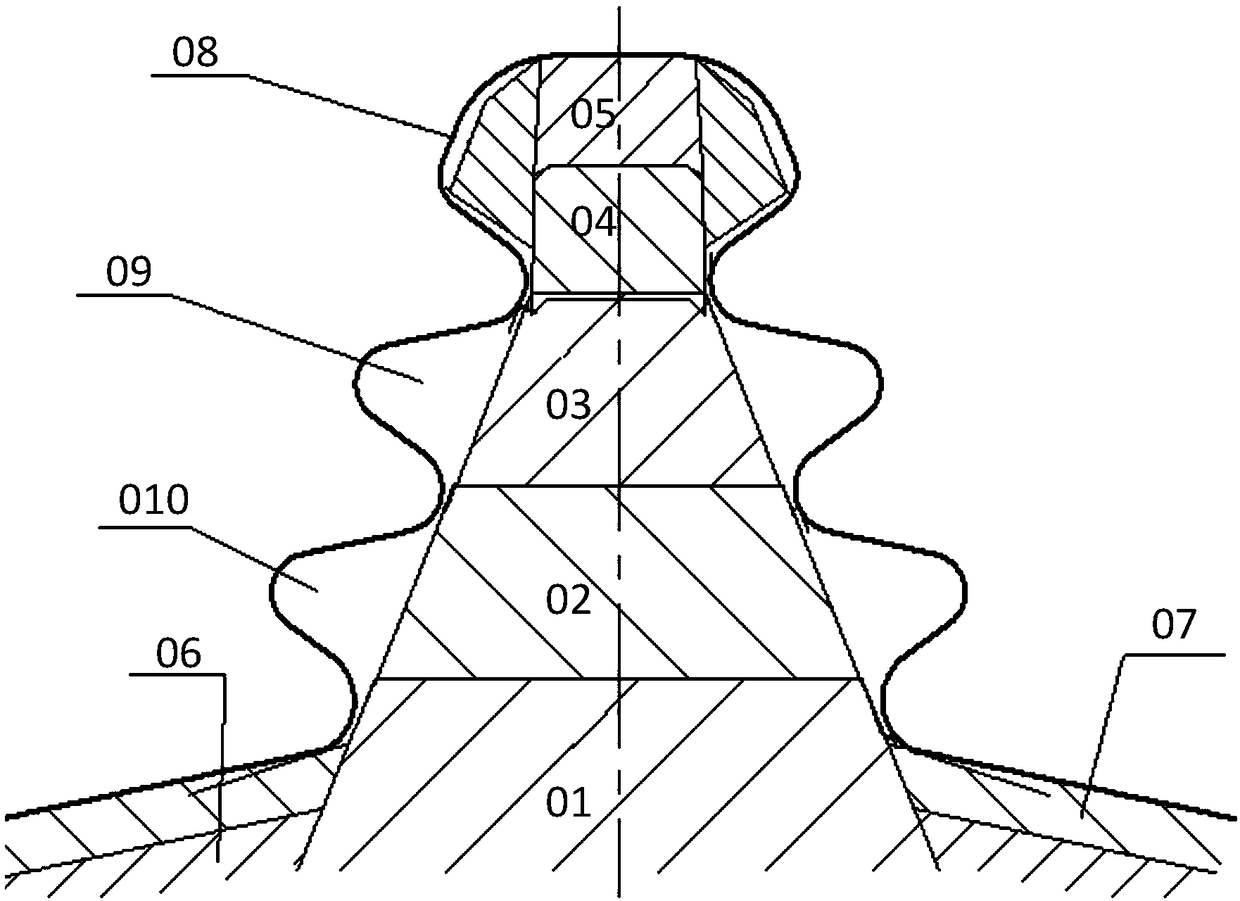

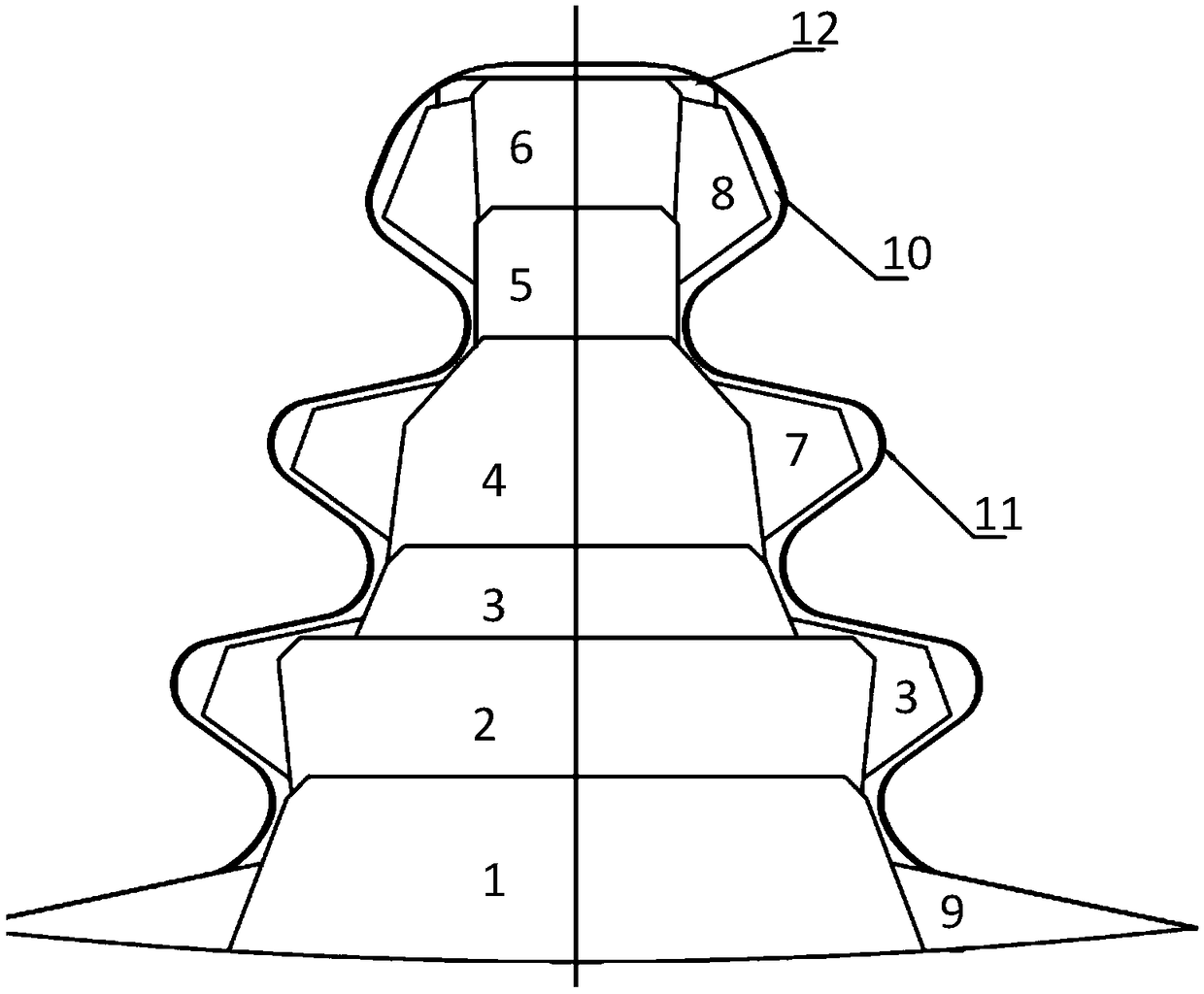

Wheel support hub unit, bearing ring member for wheel support hub unit, and method of manufacturing the same

ActiveUS20060117903A1Small loadReduce marginRolling contact bearingsHubsEngineeringMechanical engineering

A raceway member 6 of a wheel support hub unit, having wheel or vehicle body fixing portions 7 extending radially outward from a solid or hollow shaft portion, and a wheel or vehicle body positioning cylindrical portion 9 extending concentrically with the shaft portion, the fixing portion 7 being formed by the cold side extrusion so that the fixing portion is integral with the shaft portion 5.

Owner:NSK LTD

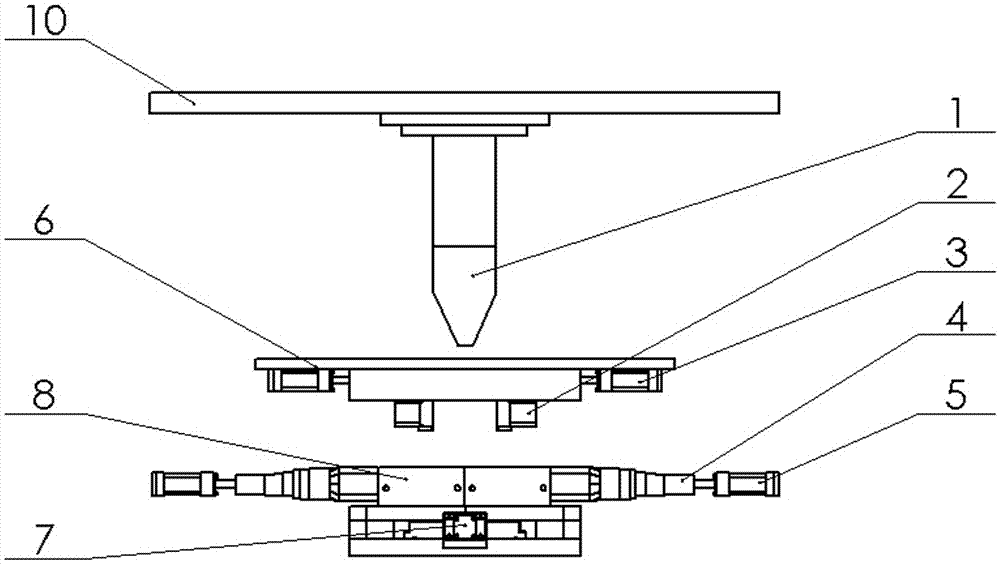

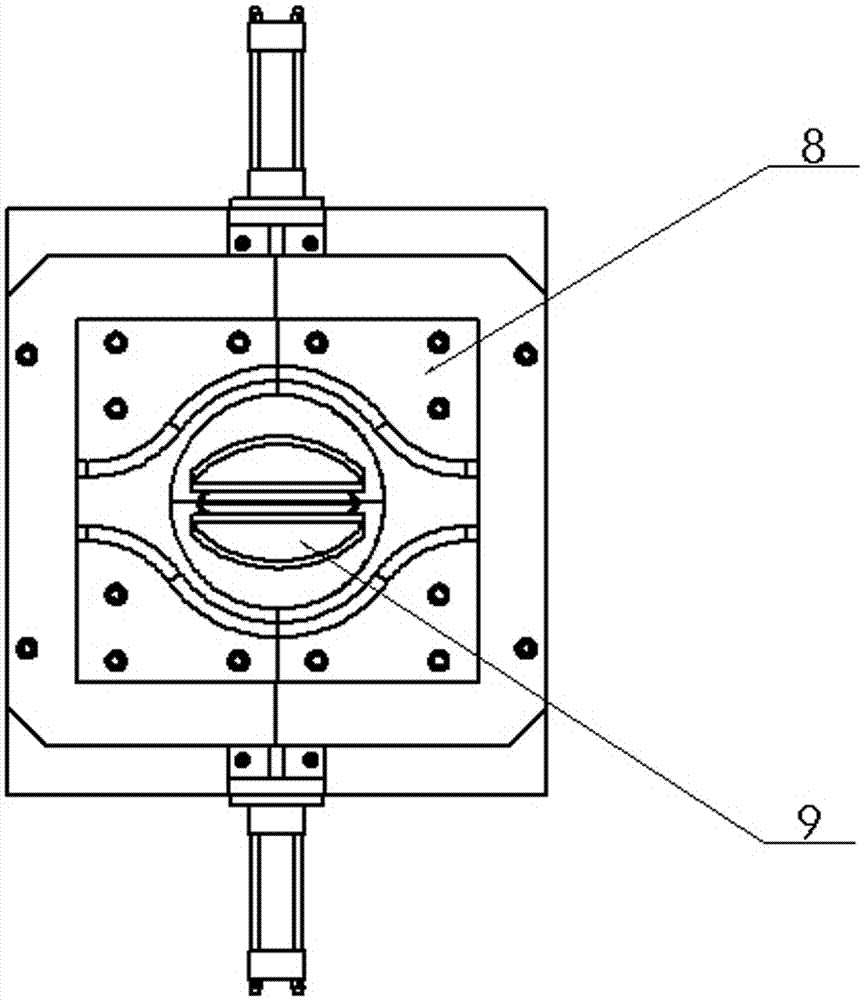

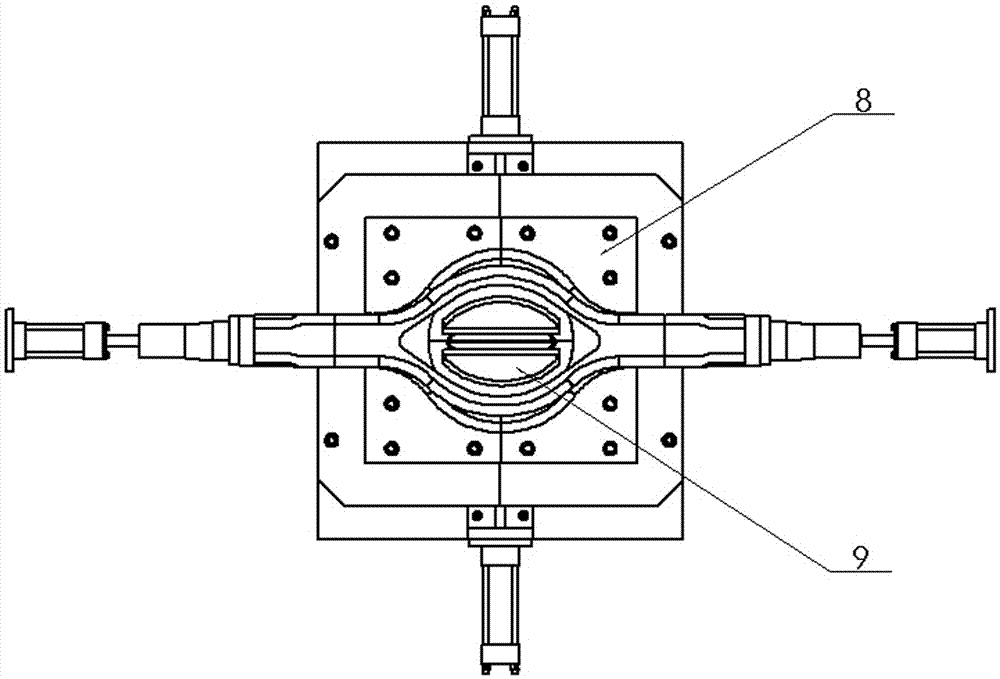

Forming method for banjo axle housing

ActiveCN105436350AEliminate product defectsImprove product qualityShaping toolsEngine componentsHydraulic cylinderEngineering

The invention discloses a forming method for a banjo axle housing. The forming method includes the following steps of (S1) blanking, (S2) extrusion of a shaft head, (S3) square pushing, (S4) manufacturing of a process groove, (S5) heating of a workpiece, (S6) radial expansion, (S7) shaping and (S8) upward resetting of a lower press sliding block and taking-out of the workpiece. According to the (S6), a wedge punch penetrates through a central hole of the lower press sliding block, pushes two radial expansion core molds to expand the radial direction of a workpiece central hole and axially squeezes the workpiece synchronously. According to the (S7), two axial shaping core molds are attached, the lower press sliding block moves downwards to enable the axial shaping core molds to be inserted into the position between two radial shaping core molds, an upper press sliding block moves downwards, and the wedge punch is inserted into the position between the two axial shaping core molds to shape the workpiece central hole and axially squeeze a hydraulic cylinder for axial limitation. The forming method integrates heat expansion and shaping, work procedures are reduced, a process chain is shortened, and the outline size accuracy is obviously improved.

Owner:吴志强 +1

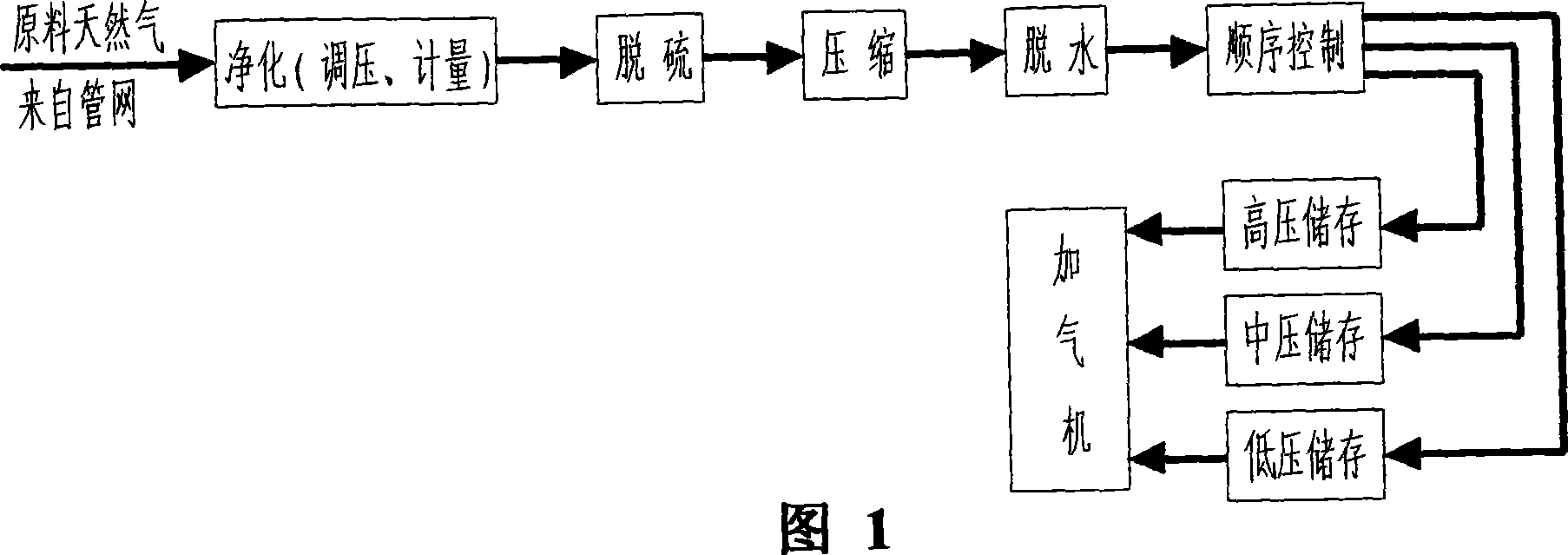

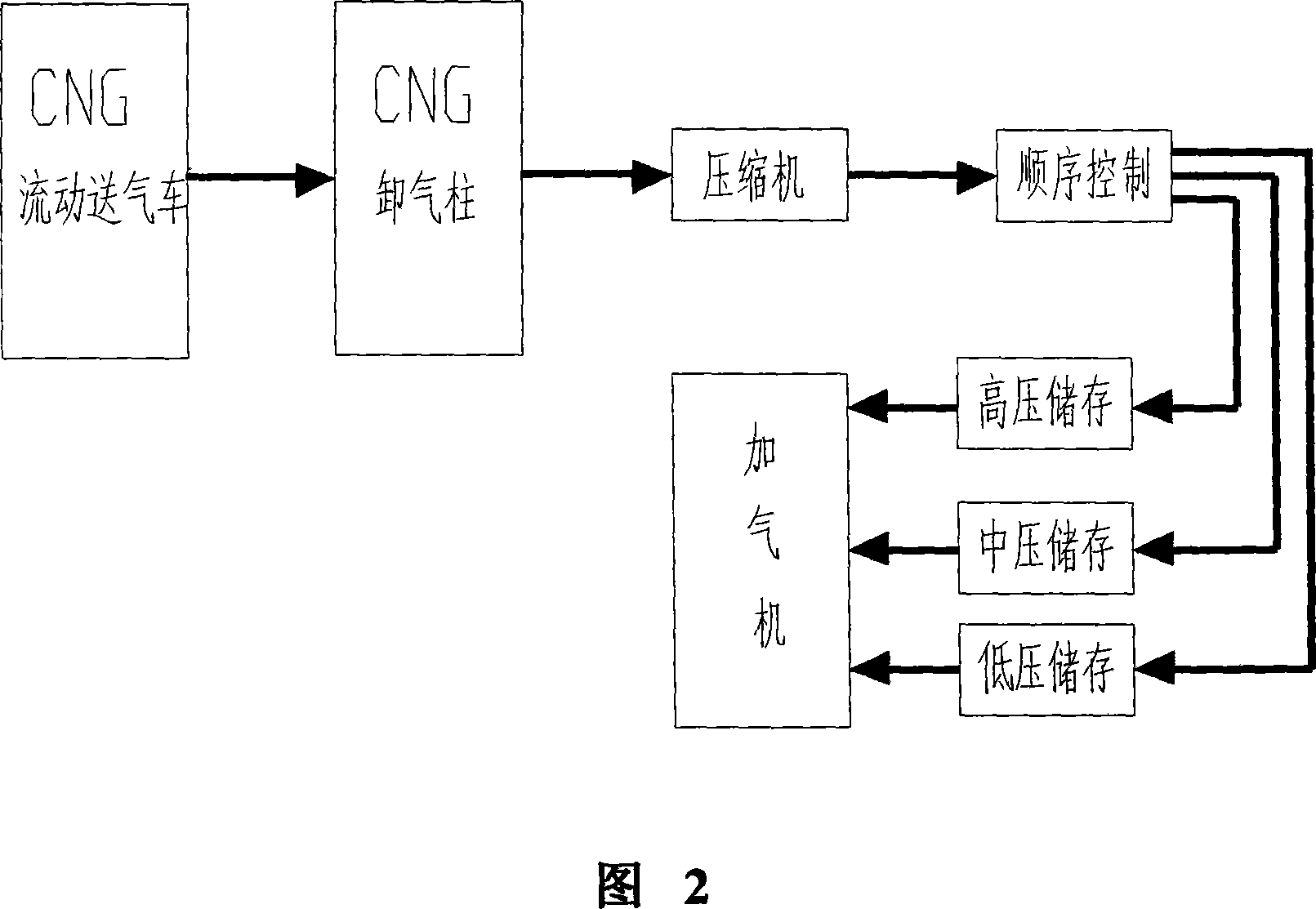

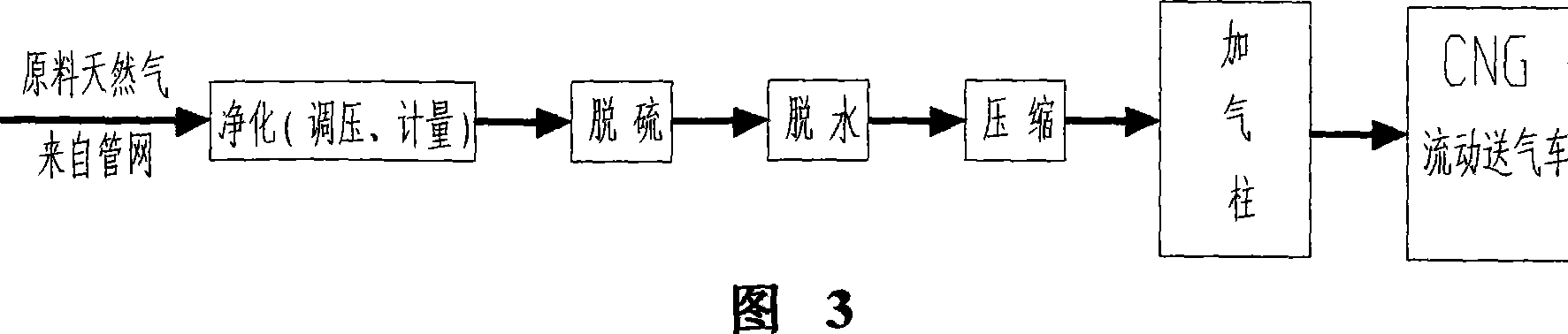

Gas-supply method of CNG gas-charging station for automobile

InactiveCN101059203AGuaranteed refueling serviceFull degassingPipeline systemsContainer filling under pressureProcess engineeringHigh pressure

The present invention discloses a gas supply method for vehicle CNG gas station (including ordinary, standard, sub-station gas stations) which is supplied gas by the natural gas pipe network or CNG mobile gas supply vehicles one by one. Said CNG mobile gas supply vehicles supply gas for the CNG gas station through gas releasing device; the high pressure gas releasing mouth of said gas releasing device is equipped with two gas releasing channels which supply gas to the high pressure gas storing device and the gas station separately; the medium (low )pressure gas releasing mouth of said gas releasing device is equipped with two gas releasing channels which supply gas for the medium or low pressure gas storing device and the gas station; said gas releasing device is equipped with residual gas releasing channel which is connected with the inlet of CNG gas station compressor technology system and supplies gas for the compressor. The advantages are: the CNG gas station has the function of CNG sub-station gas station at the same time, the CNG mobile gas supply vehicles can supply gas when the pipe network can not supply gas, the gas releasing speed is fast and the gas releasing is exhaustive. The operation is controlled intelligently and the operation is safe and reliable. So the disposition number of the CNG mobile gas supply vehicles is reduce, the CNG gas station technology and equipment resources are used fully and the CNG sub-station costs are reduced.

Owner:李富国

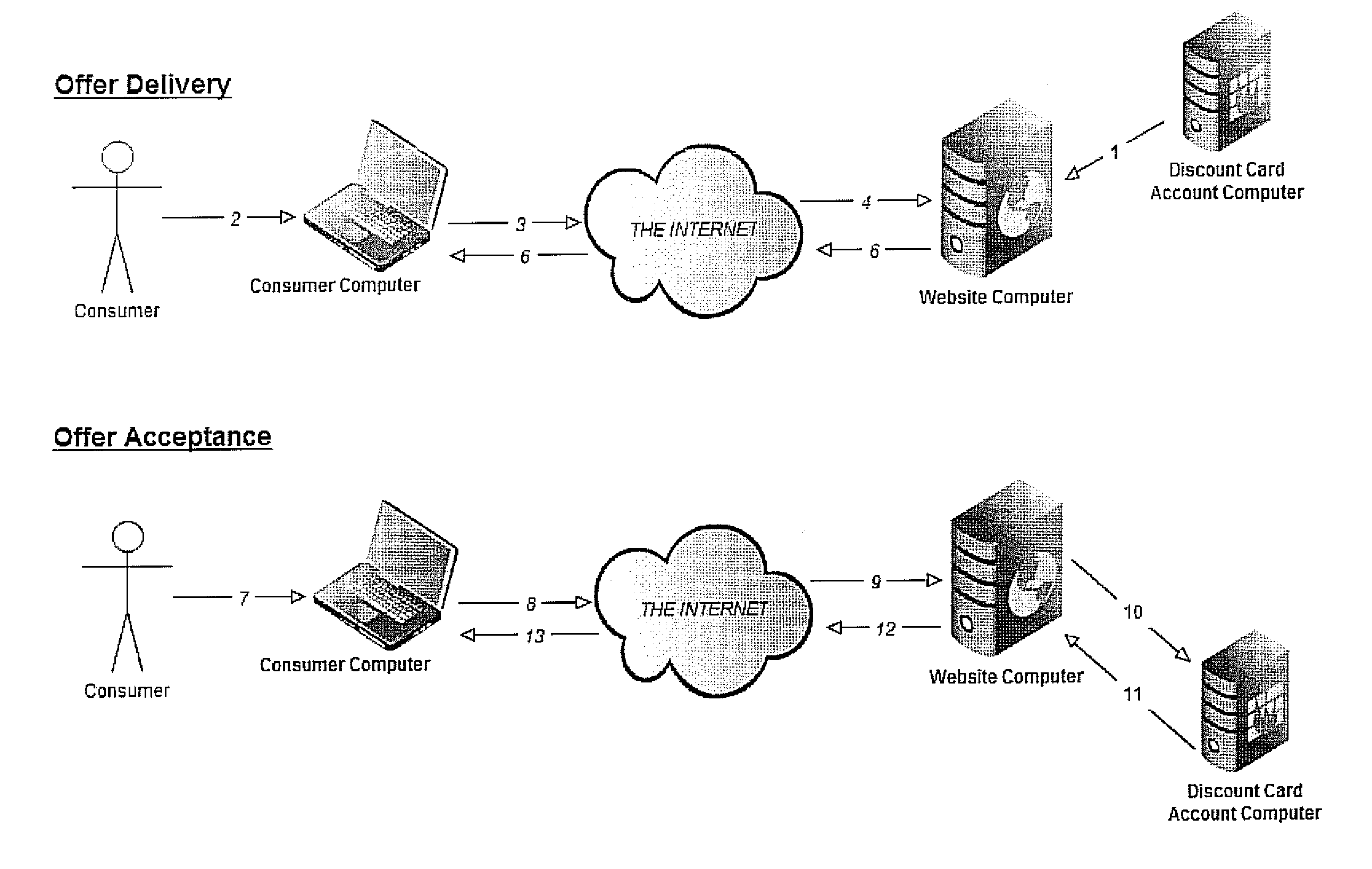

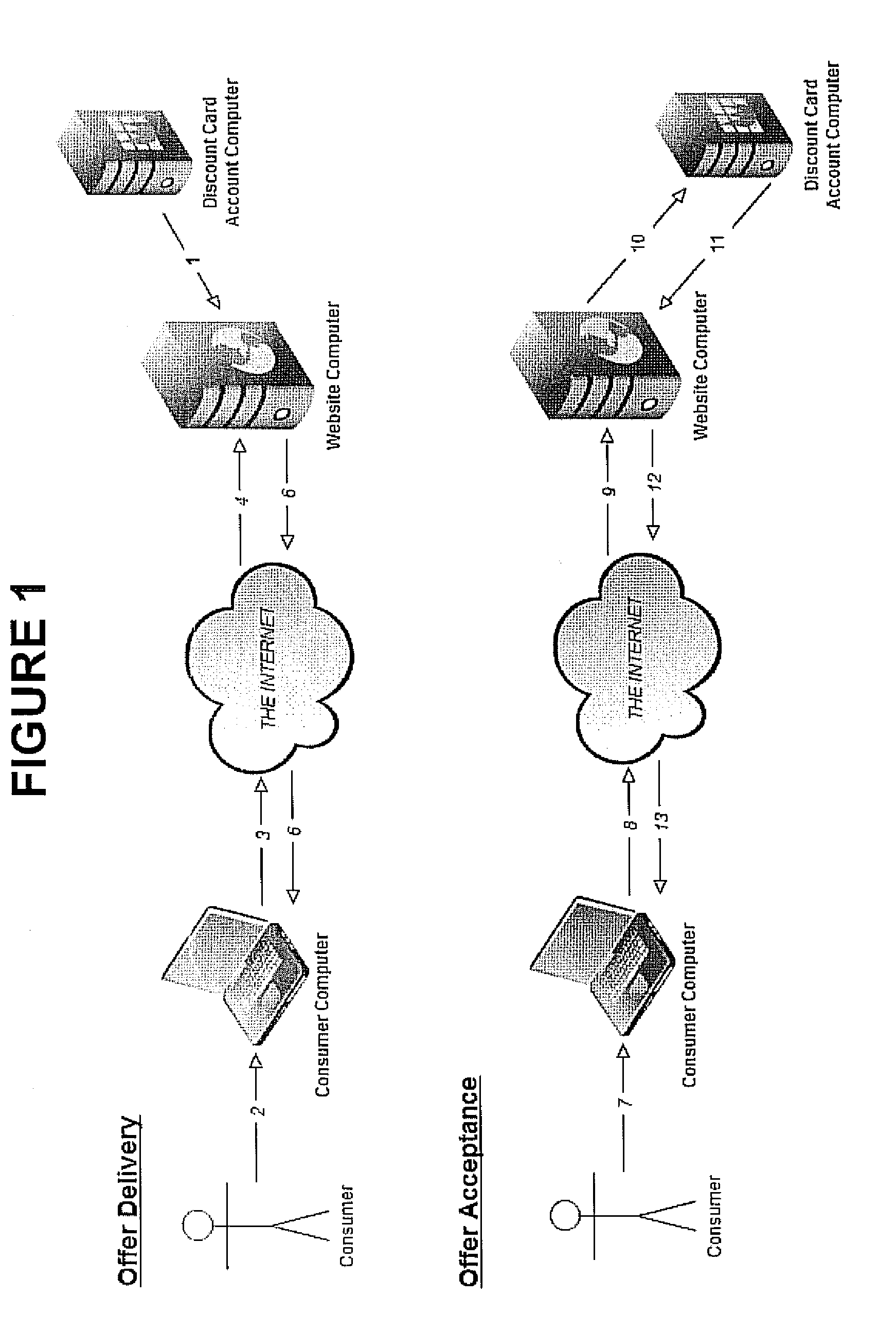

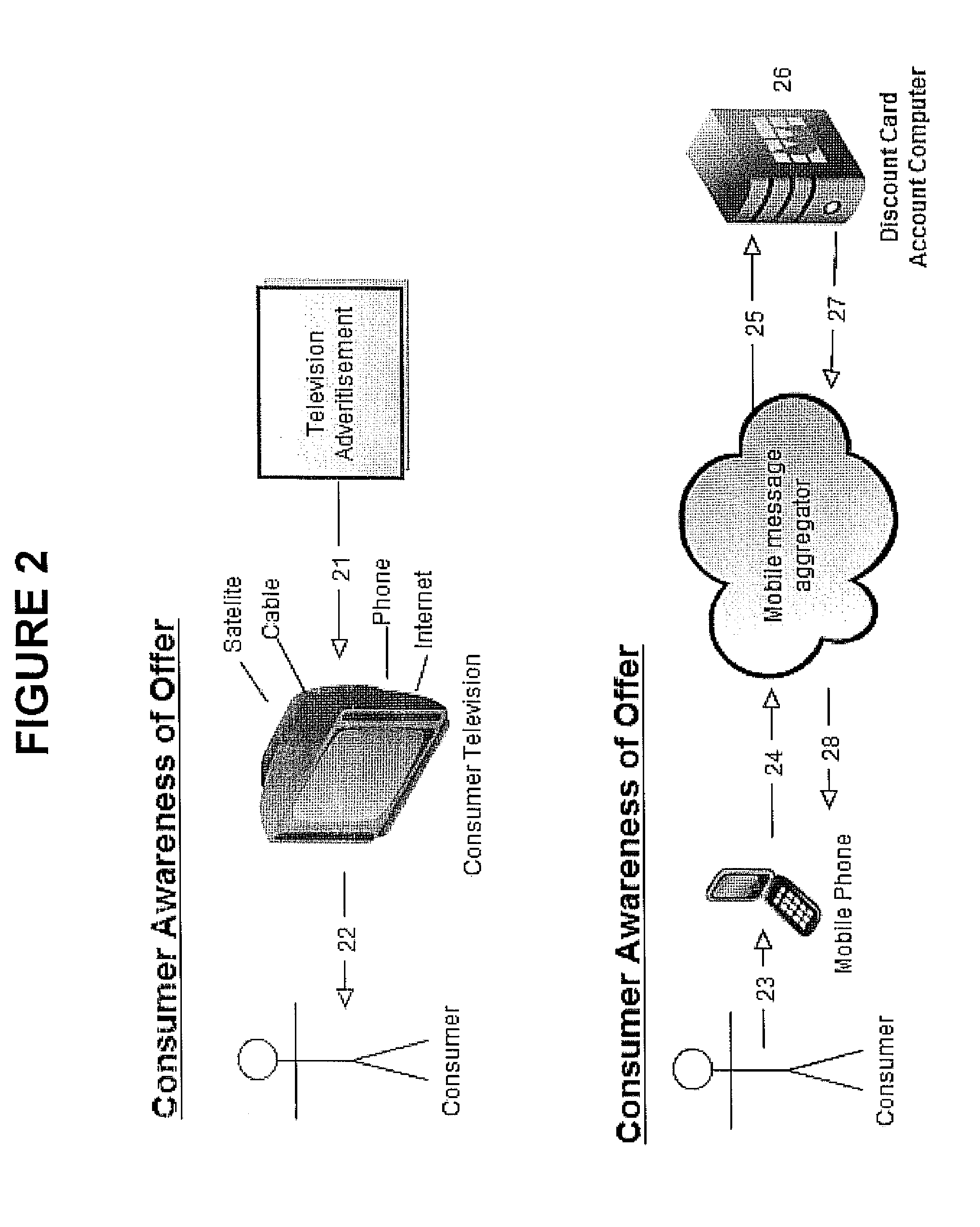

Intelligent discount card system

InactiveUS20120278151A1Reduce marginEfficient measurementPayment architectureMarketingPaymentReal-time computing

The present invention provides an intelligent discount card system for integrating with an existing bank payment network to provide for ubiquitous acceptance offered by a bank payment network while offering a real-time point of sale transaction experience, real-time discounting and financial settlement benefits typically only available through proprietary connections to retailers.

Owner:GALIT SCOTT

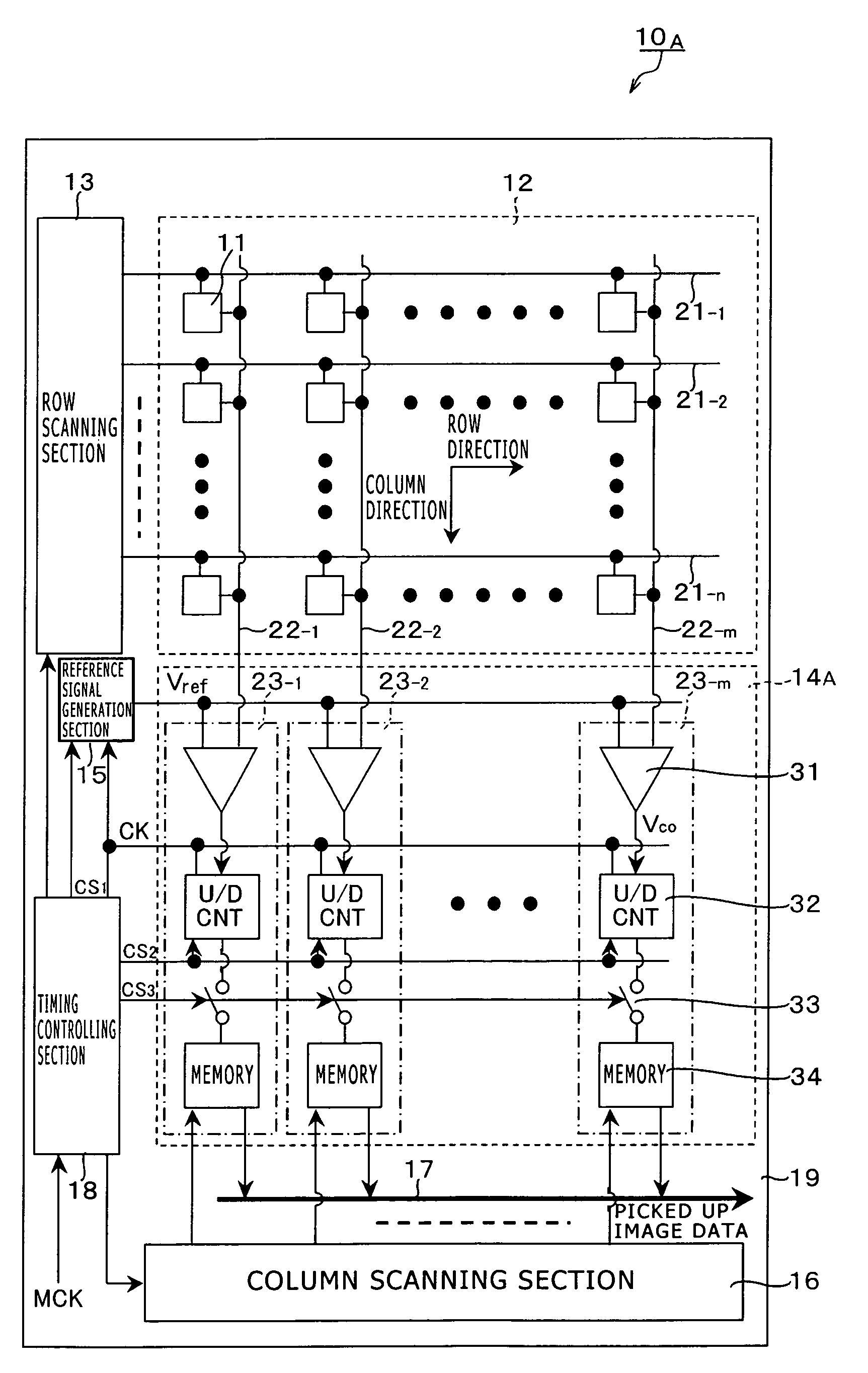

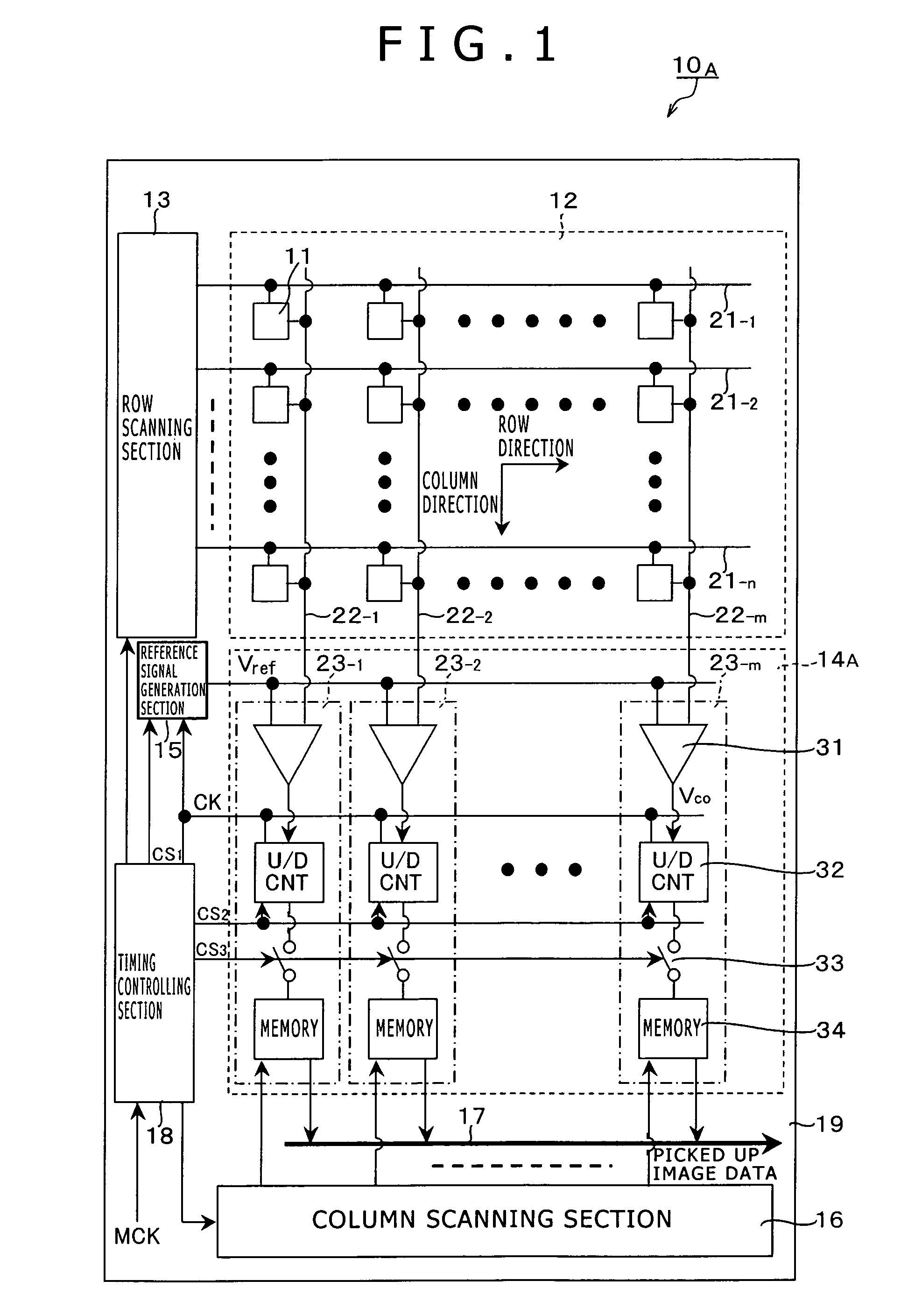

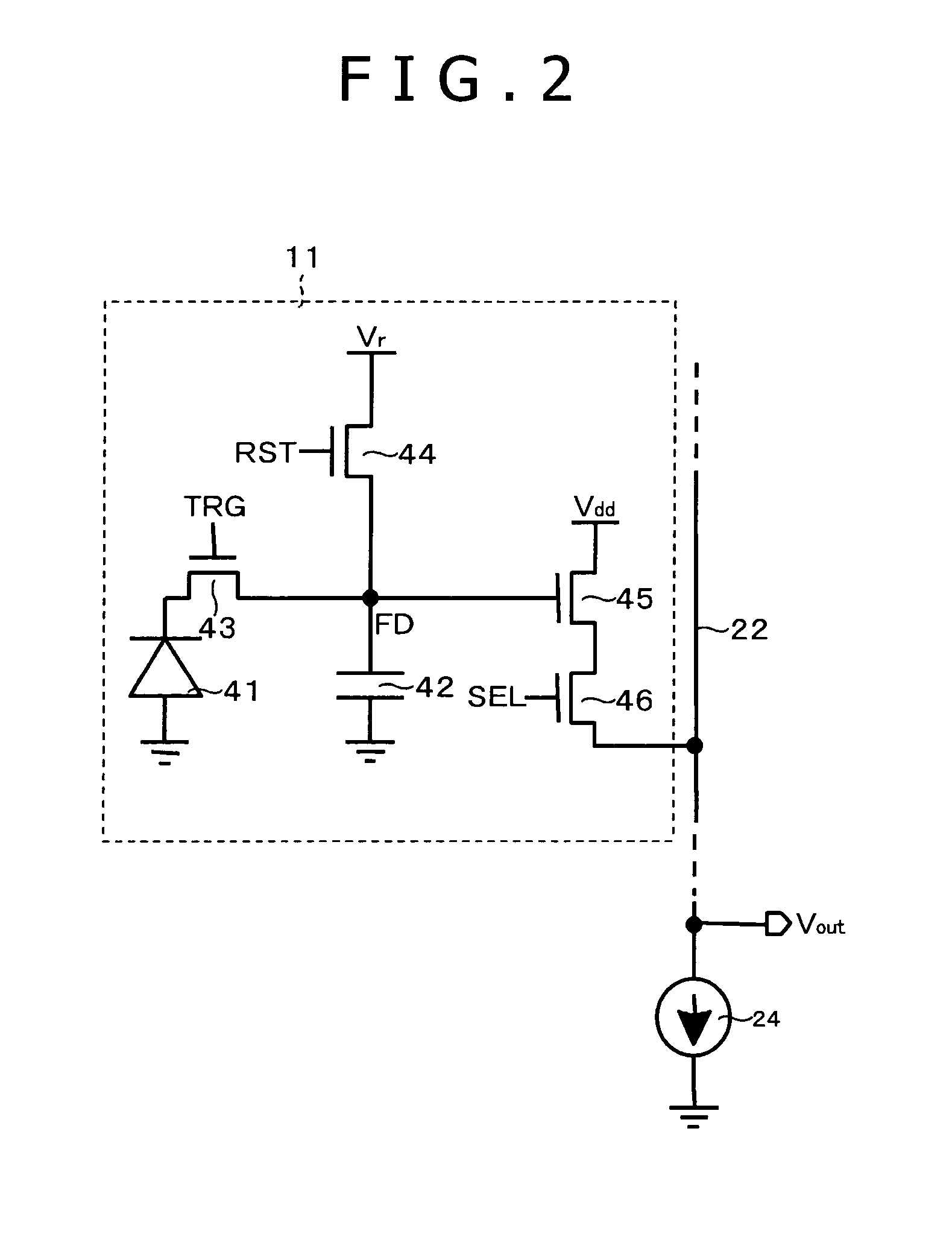

Solid-state image pickup apparatus signal processing method for a solid-state image pickup apparatus, and electronic apparatus

InactiveUS8576317B2Eliminate differencesReduce outputTelevision system detailsTelevision system scanning detailsCharge detectionEngineering

Disclosed herein is a solid-state image pickup apparatus, including a pixel array section in which a unit pixel including a photoelectric conversion section and a charge detection section for detecting charge generated by photoelectric conversion by the photoelectric conversion section is disposed; a driving section adapted to carry out driving of reading out a signal of the unit pixel divisionally by twice as a first signal and a second signal; and a signal processing section adapted to set the first signal read out first from the unit pixel as a reference voltage for a processable input voltage range of the signal processing section, adjust the reference voltage so that the first and second signals may be included in the input voltage range and carry out signal processing for the first and second signals using the adjusted reference voltage.

Owner:SONY CORP

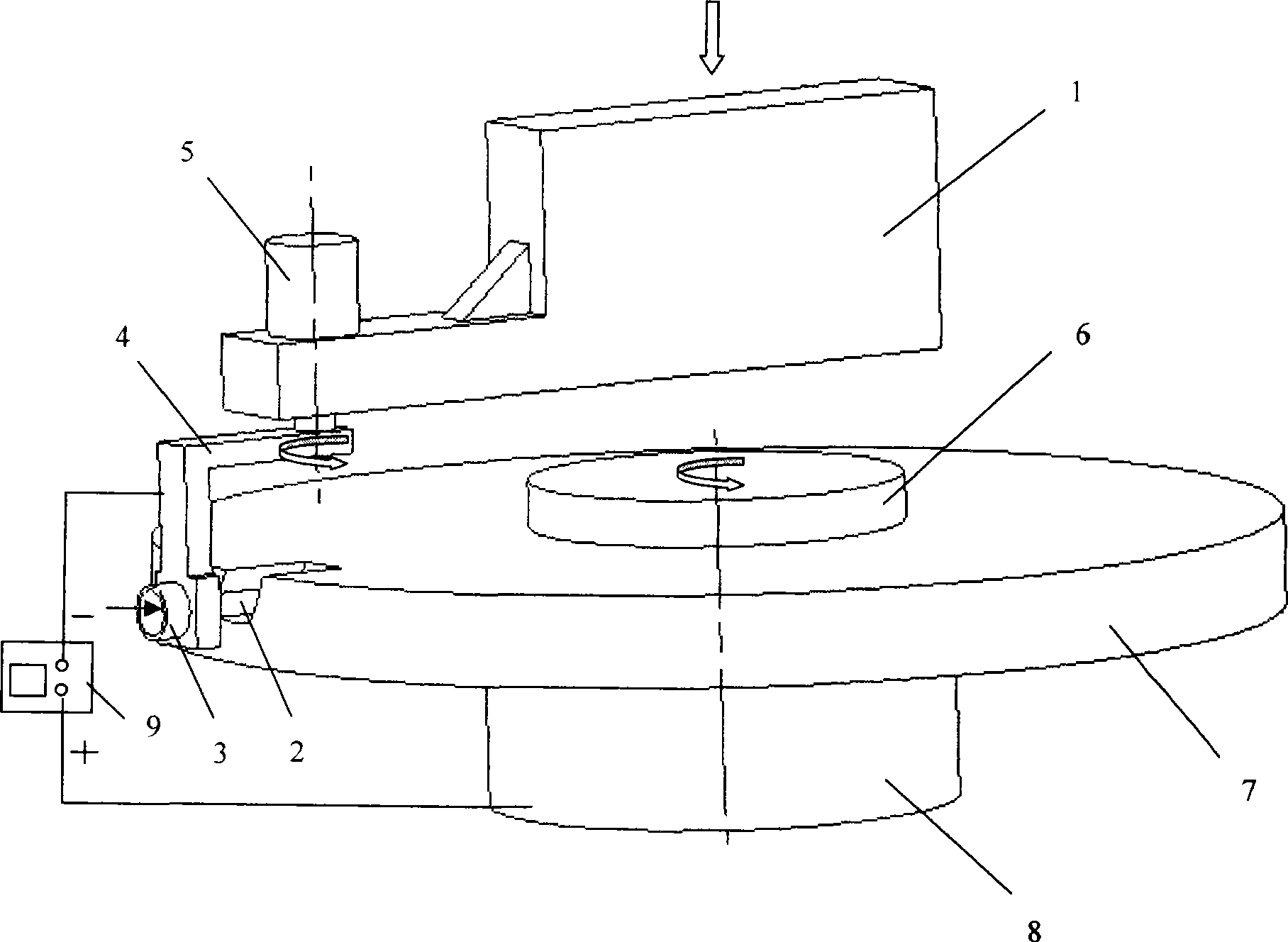

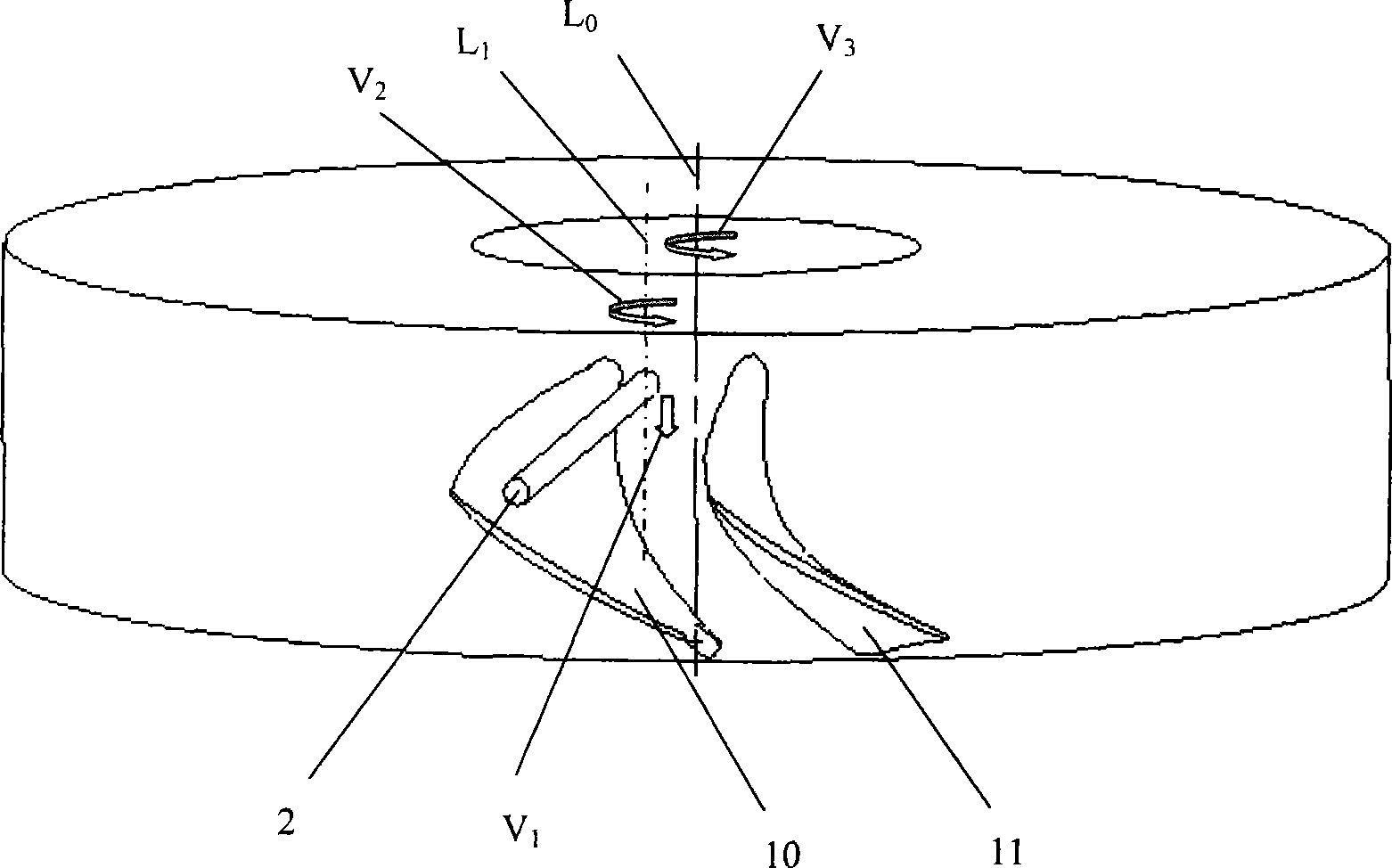

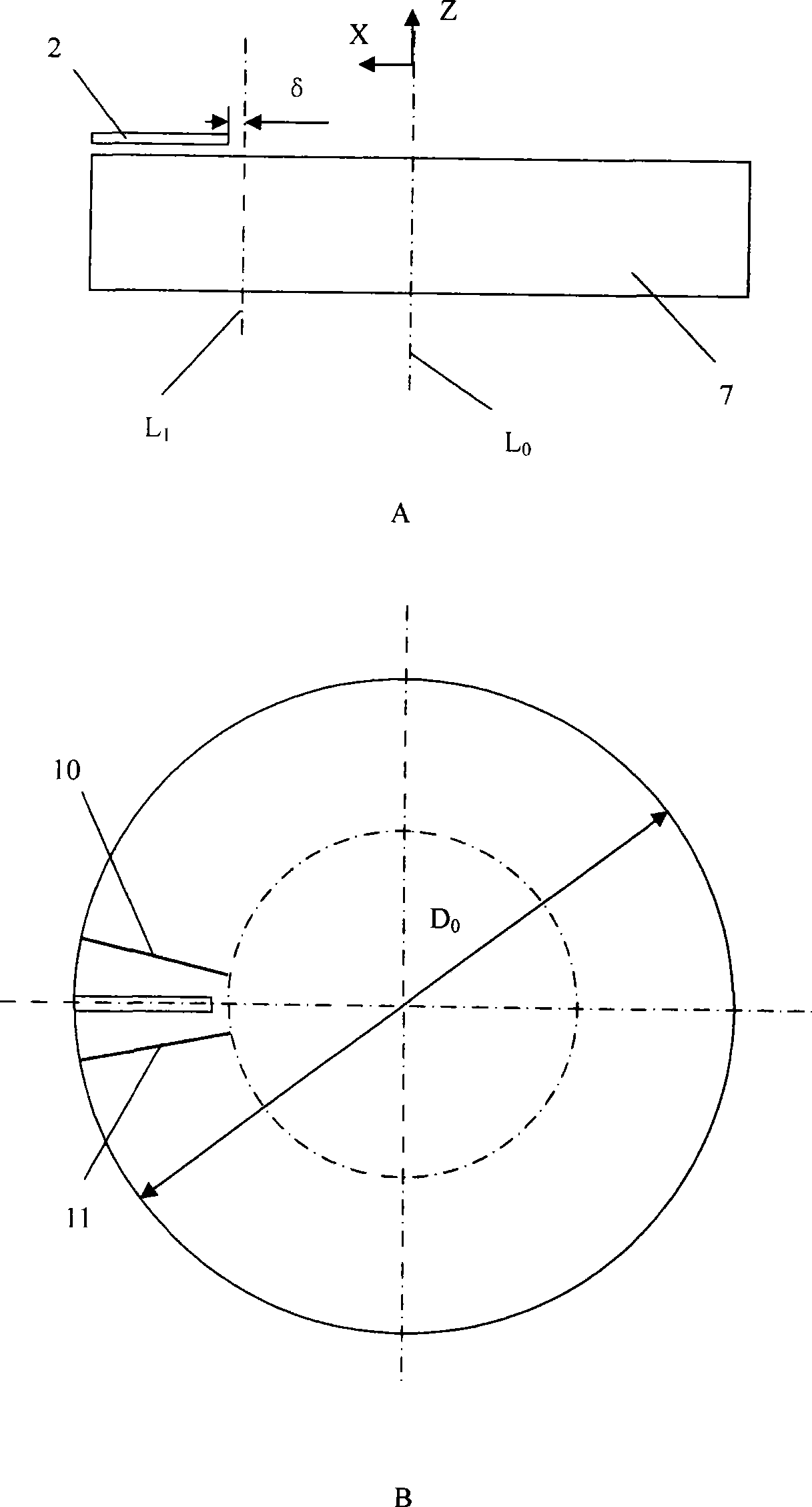

Spacing track optimizing method of tool electrode for electrolytic machining of integral wheel

InactiveCN101502900AOptimize the trajectory of space movementReduce marginElectrochemical machining apparatusImpellerElectricity

The invention relates to a space trajectory optimization method of an integral impeller electrolytic processing tool electrode and pertains to the field of electrolytic processing technology. In the processing, a tool electrode is linearly fed along the axis of an integral impeller rough cast at a certain speed V1 and rotates around a straight line in parallel with the axis of the impeller rough cast at a certain speed V2; meanwhile, the self axis of the impeller rough cast rotates at a certain angle speed V3. In the processing, the tool electrode is connected with the cathode of a power supply and the impeller rough cast is connected with the anode of the power supply; the electrolyte flows in from one end of the tool electrode and flows out from the clearance of the electrode; the impeller rough cast is continuously eroded and finally a nearly molded inter-impeller channel is obtained. According to the specific situation, different combinations of V1, V2 and V3 can be selected; according to the speed arbitration guideline of the invention, the space trajectory of the tool electrode is optimized and the inter-impeller channel has small margin and fine uniformity. The method is also applicable to the simultaneous processing of a plurality of electrodes, thus greatly increasing the processing efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

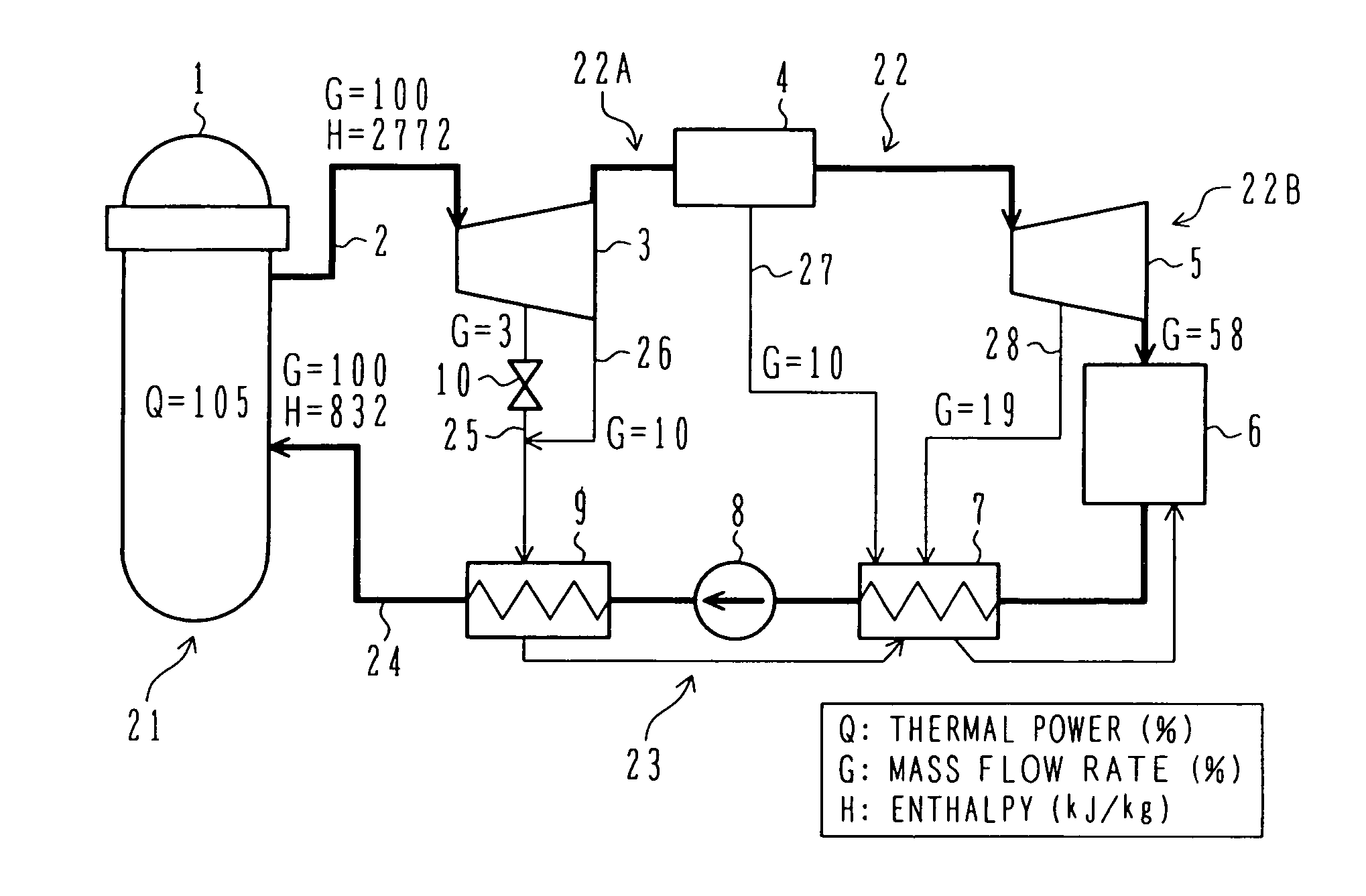

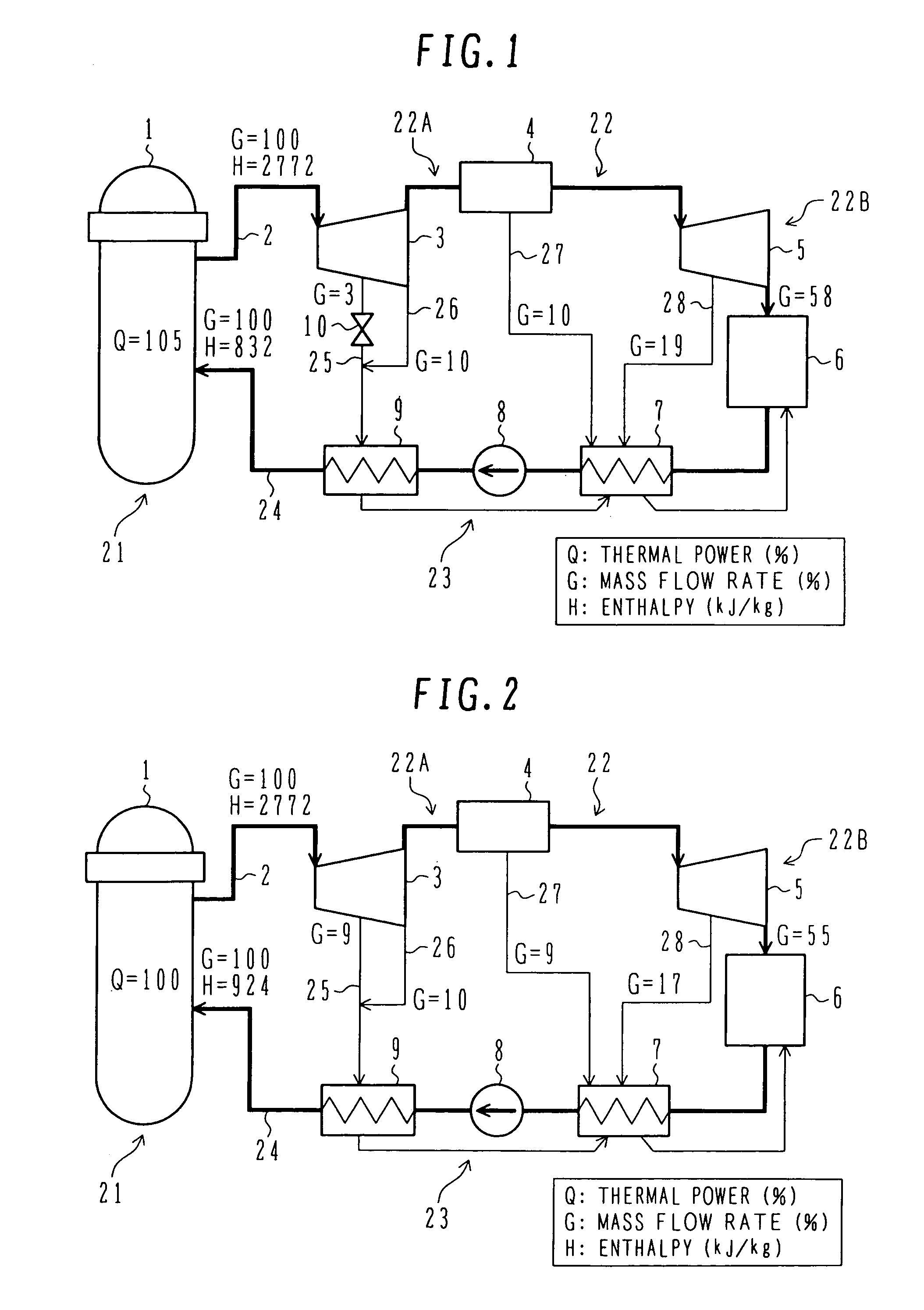

Operation method of nuclear power plant

ActiveUS7614233B2Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

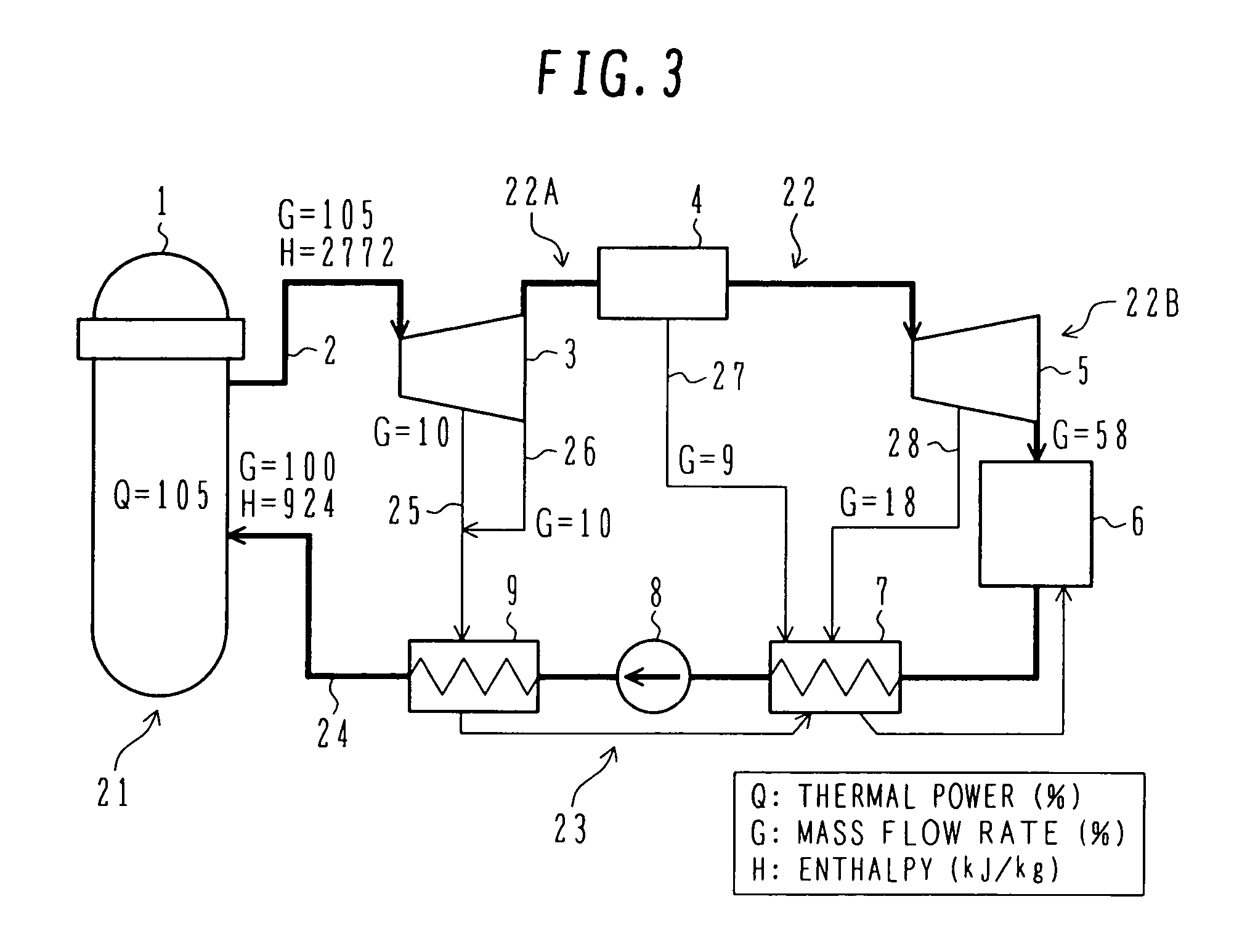

Method for machining tongues and grooves of turbine discs

InactiveCN108723481AReduce marginImprove processing qualityBroaching machinesTongue and grooveEngineering

The invention discloses a method for machining tongues and grooves of turbine discs. The method includes steps of 1), forming section grooves in turbine disc blanks along reference lines of tooth crests of tongue teeth in rough broaching stroke; 2), cutting preset tongue tooth groove locations on the side walls of the section grooves to form tongue tooth rough grooves in semi-finish broaching stroke; 3), continuing to carry out cutting on the basis of the tongue tooth rough grooves to obtain tongue tooth grooves. The method for machining the tongues and grooves of the turbine discs has the advantages that the semi-finish broaching stroke is added between the rough broaching stroke and the finish broaching stroke, the partial tongue tooth rough grooves in allowance stroke can be removed bythe aid of the semi-finish broaching stroke, then the remaining tongue tooth grooves in the allowance stroke can be removed by the aid of the finish broaching stroke, finish broaching tools and semi-finish broaching tools are jointly responsible for tongue tooth groove allowance cutting, accordingly, allowance required to be cut by the various broaching tools can be reduced, broaching force in broaching procedures can be reduced, tool damage phenomena can be prevented, and the purposes of protecting the broaching tools, prolonging the service lives of the broaching tools and improving the component machining quality can be achieved.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

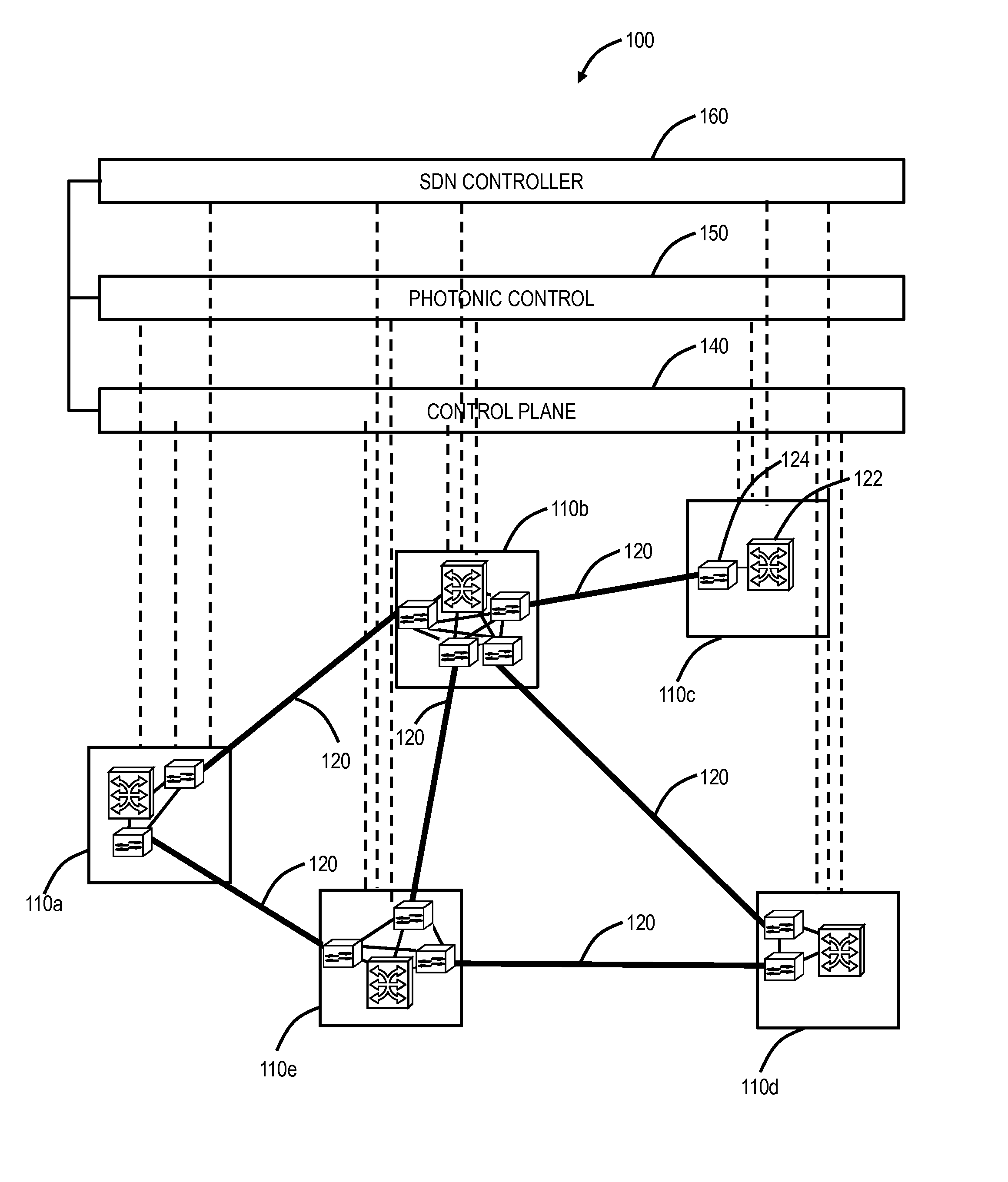

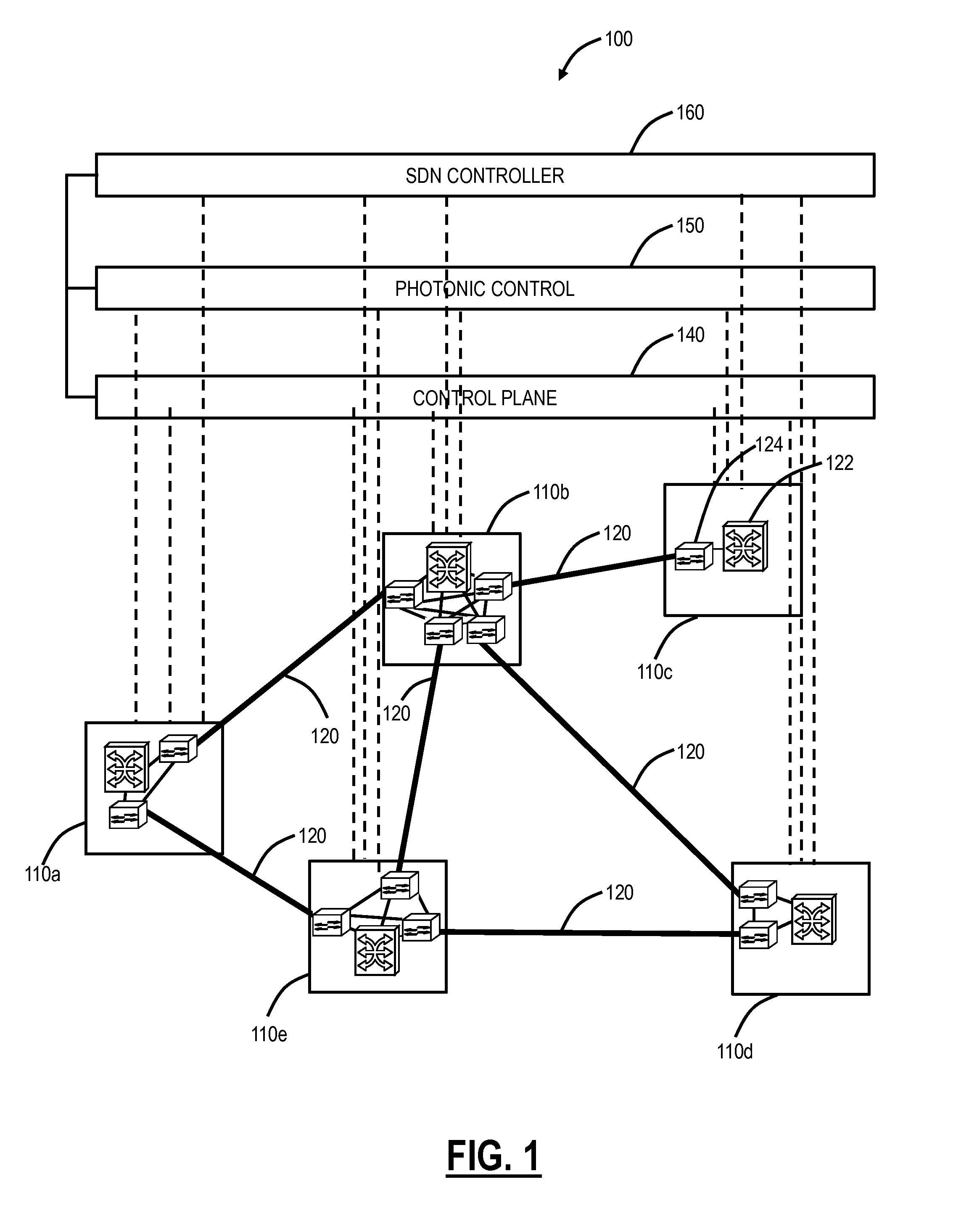

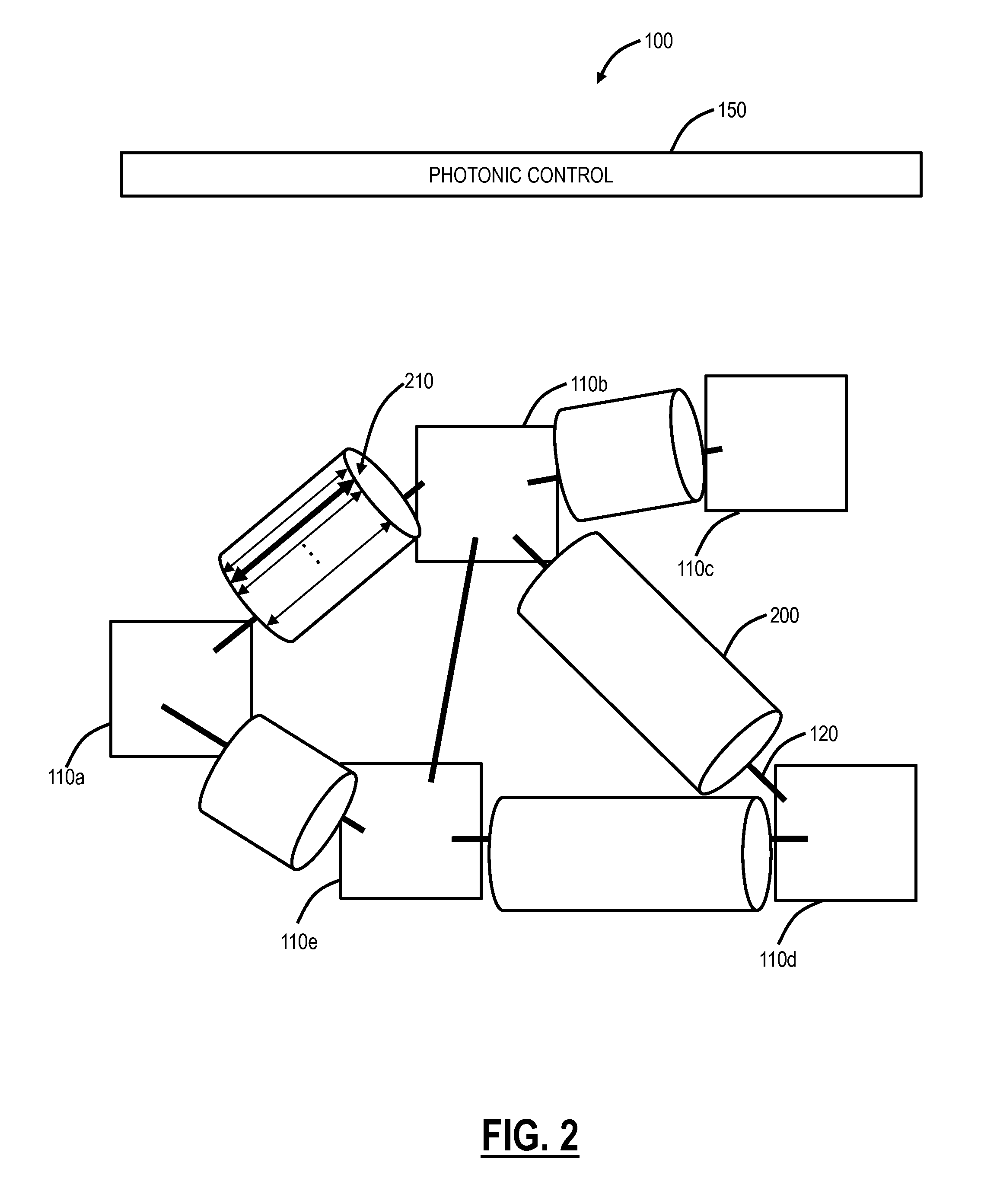

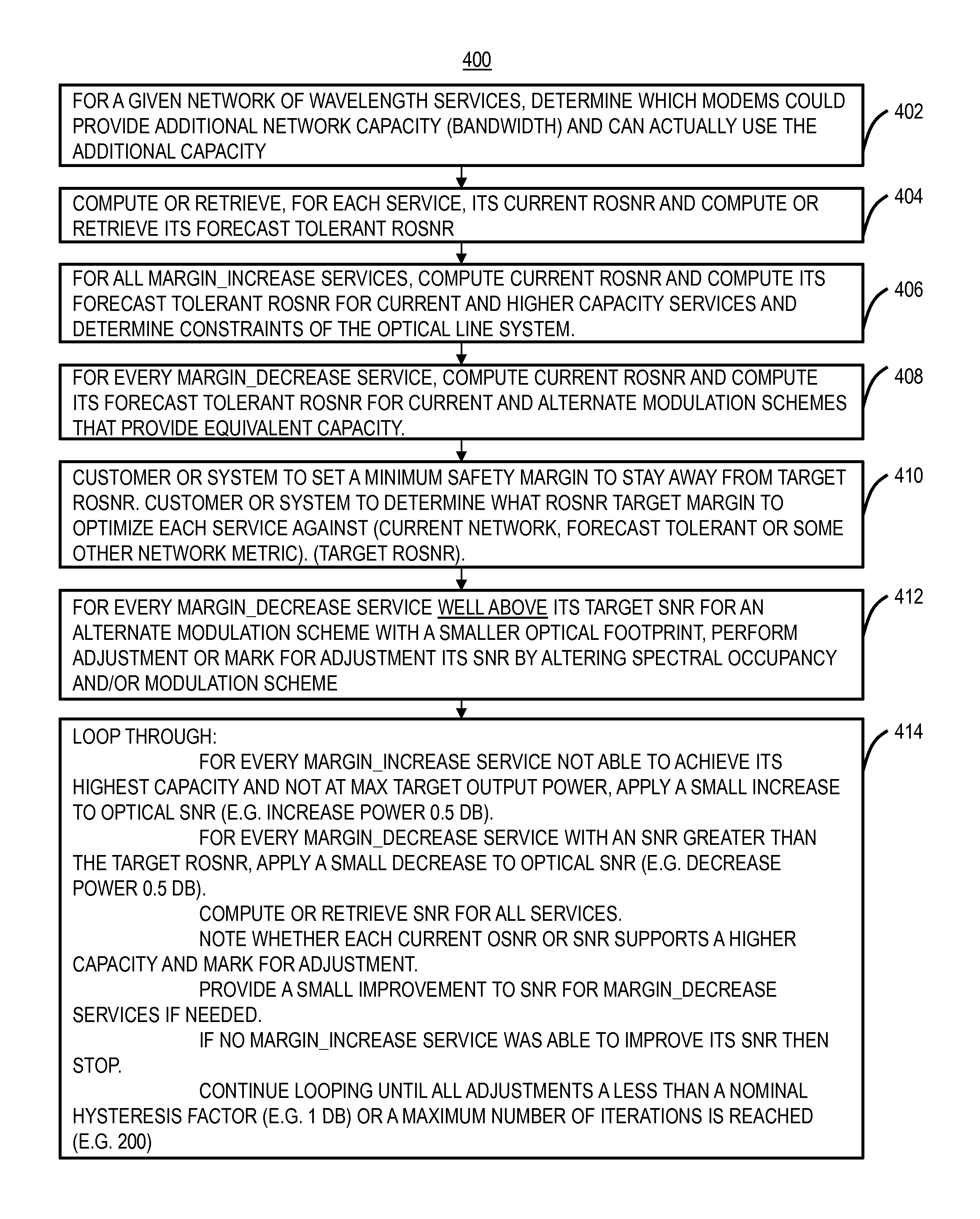

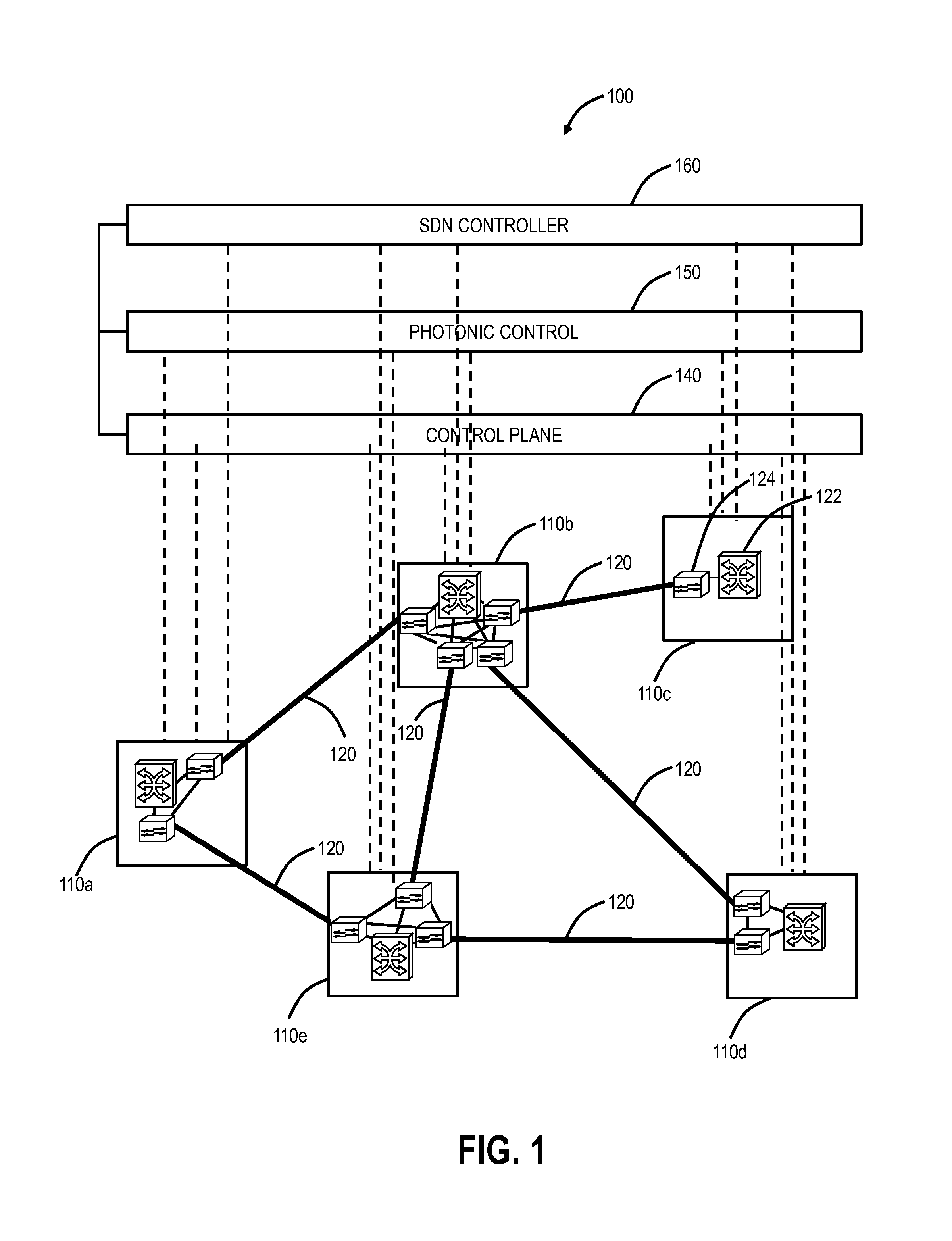

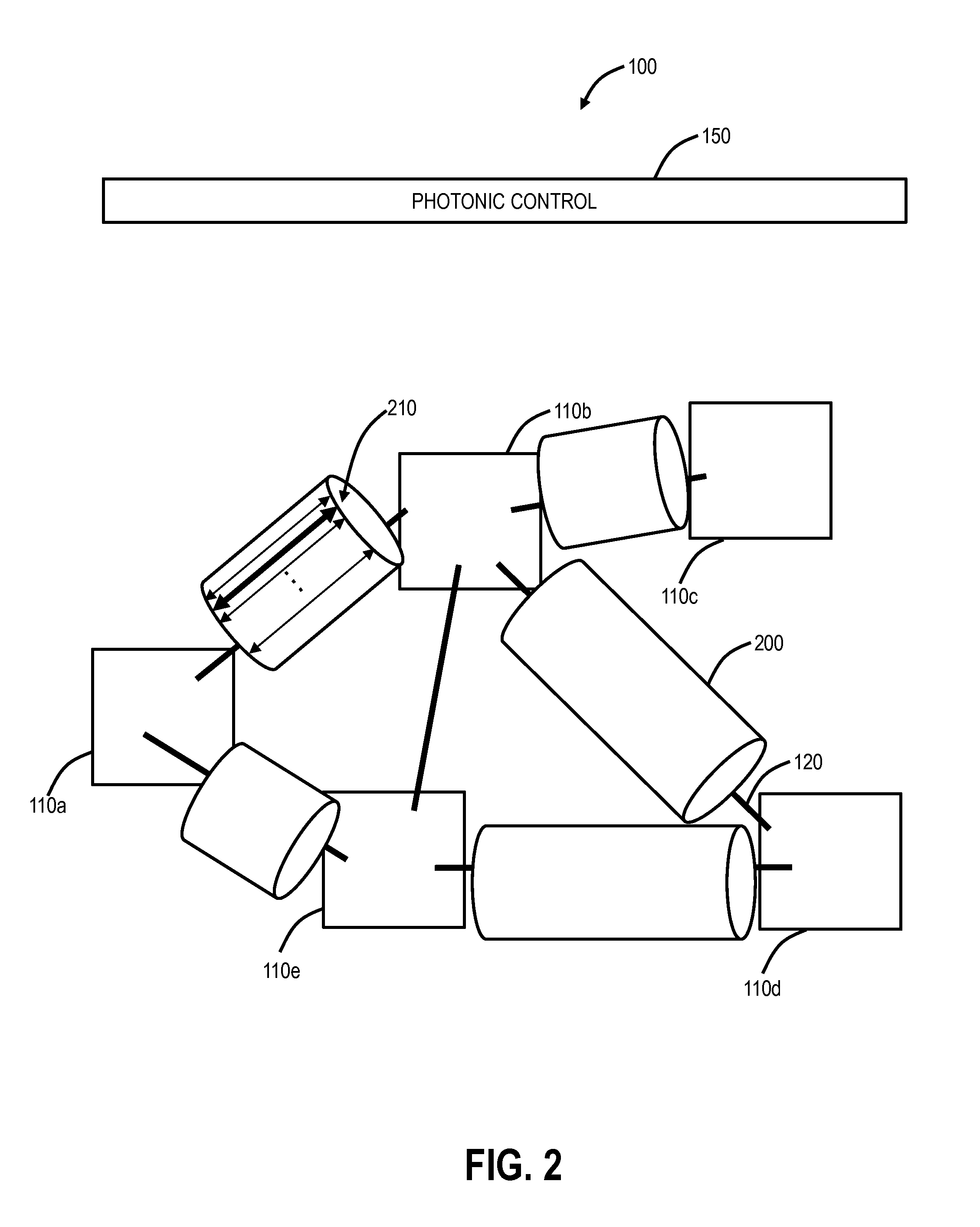

Margin-based optimization systems and methods in optical networks to unblock superchannels

ActiveUS20150333864A1Reduce marginOptimize capacityWavelength-division multiplex systemsSignalling characterisationOptimization systemEdge based

Systems and methods of increasing the supportable capacity from a first point to a second point in an optical network, include identifying a first optical signal that occupies a first portion of optical spectrum from the first point to the second point; identifying a second optical signal that occupies a second portion of the optical spectrum from the first point to the second point, wherein the second portion is adjacent to the first portion; adjusting the second optical signal to minimize part of or remove all of the second portion that is adjacent to the first optical signal to provide a freed up portion of the second portion; and adjusting the first optical signal to occupy some or all of the freed up portion.

Owner:CIENA

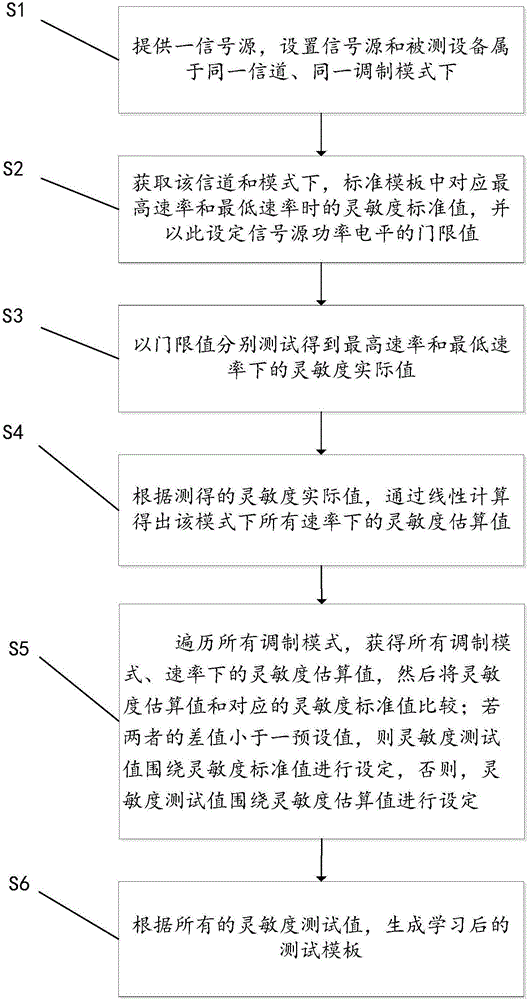

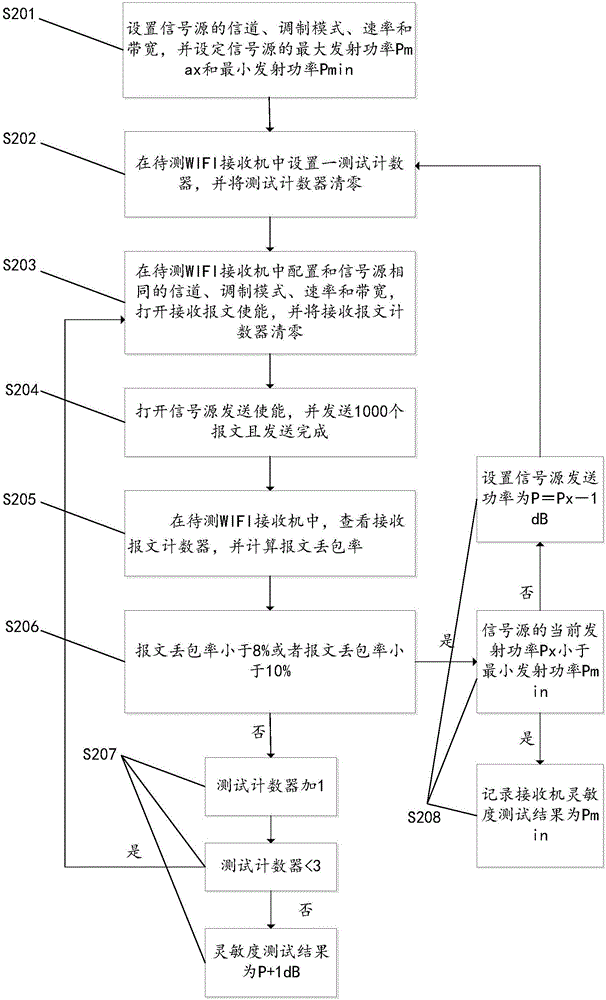

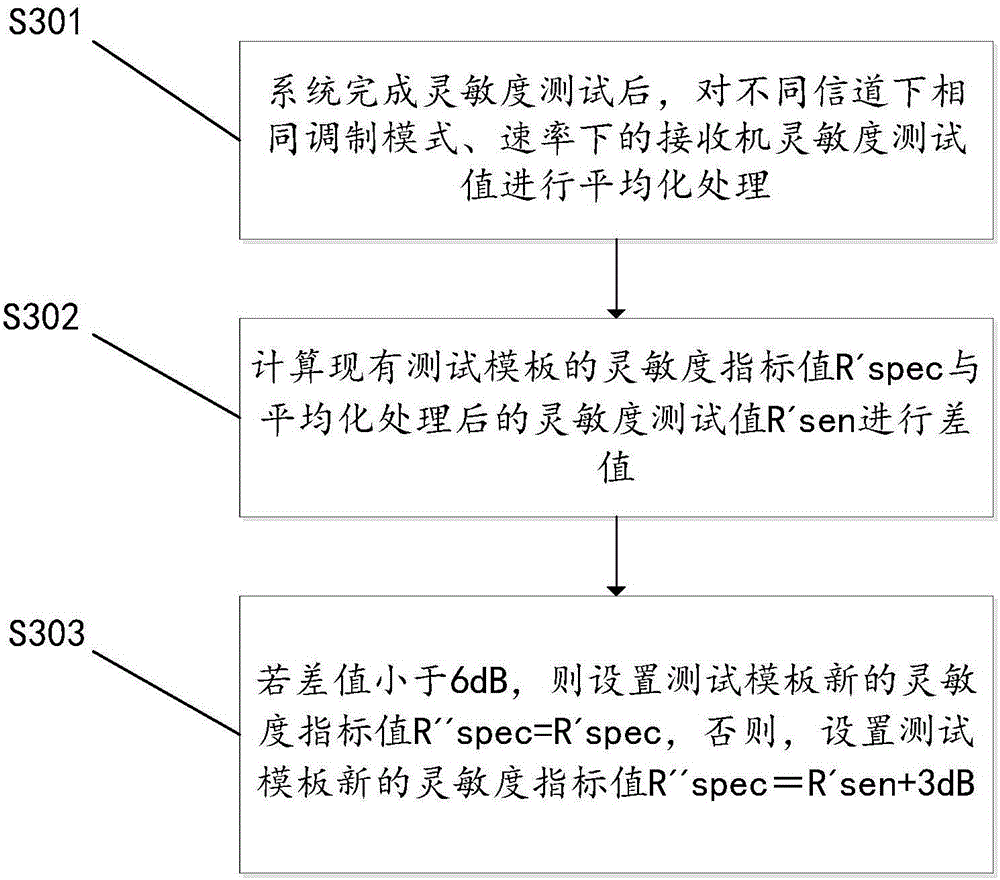

Sensitivity testing method and system

The invention discloses a sensitivity testing method and system. The method comprises the following steps of: setting that a signal source and tested equipment belong to the same channel and are in a modulation mode; obtaining sensitivity standard values corresponding to the highest rate and the lowest rate in a standard template under the mode, and thereby setting a threshold value of the power level of the signal source; according to the threshold value, respectively testing to obtain sensitivity practical values under the highest rate and the lowest rate; according to the tested sensitivity practical values, linearly calculating to obtain sensitivity estimation values under all rates in the mode; then, comparing the sensitivity estimation values with the corresponding sensitivity standard values; if the difference value of the two is less than a pre-set value, setting sensitivity testing values according to the sensitivity standard values, and otherwise, setting the sensitivity testing values according to the sensitivity estimation values; and generating a testing template after being learned according to all the sensitivity testing values. The testing time is reduced; and the testing efficiency is increased.

Owner:湖州帷幄知识产权运营有限公司

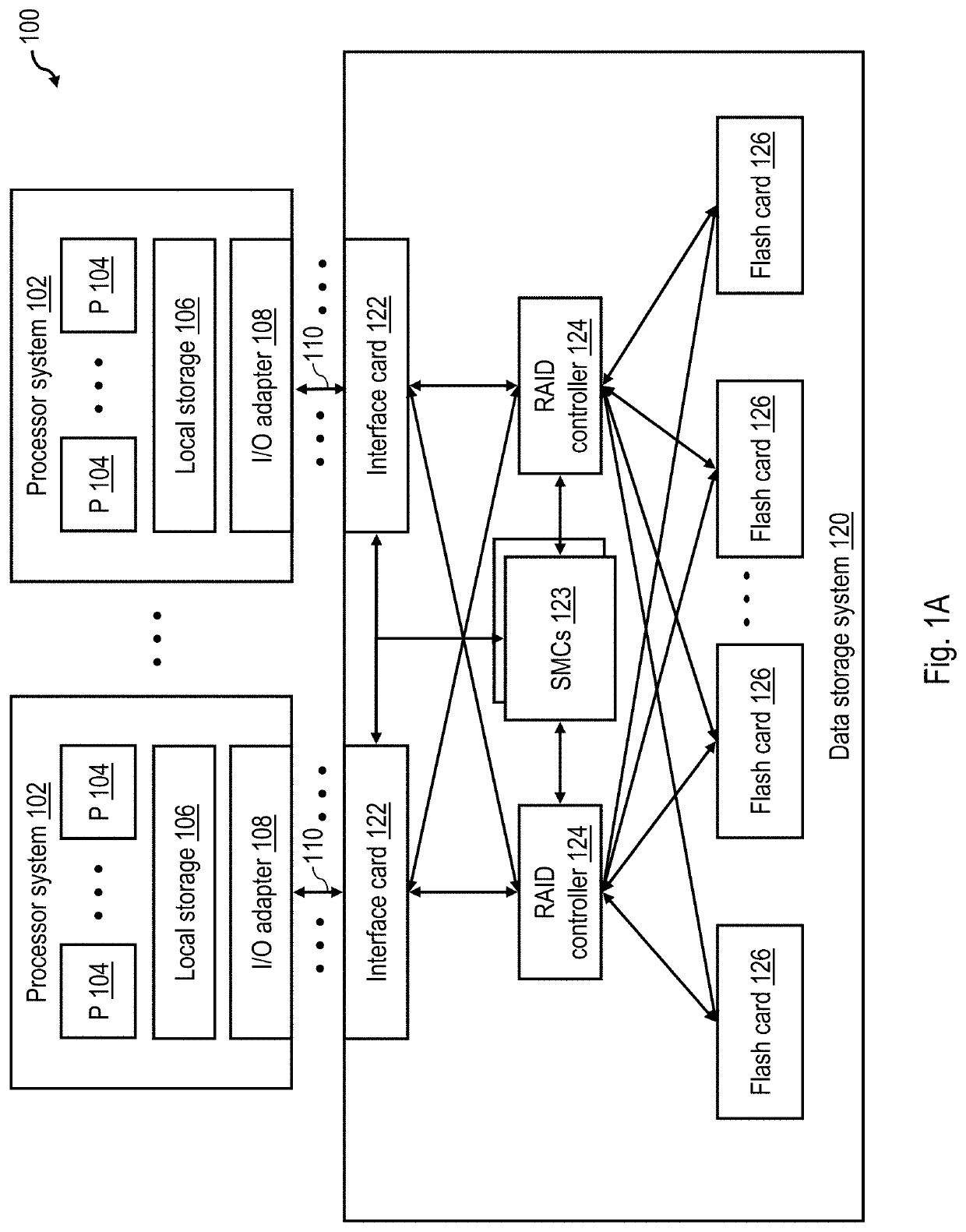

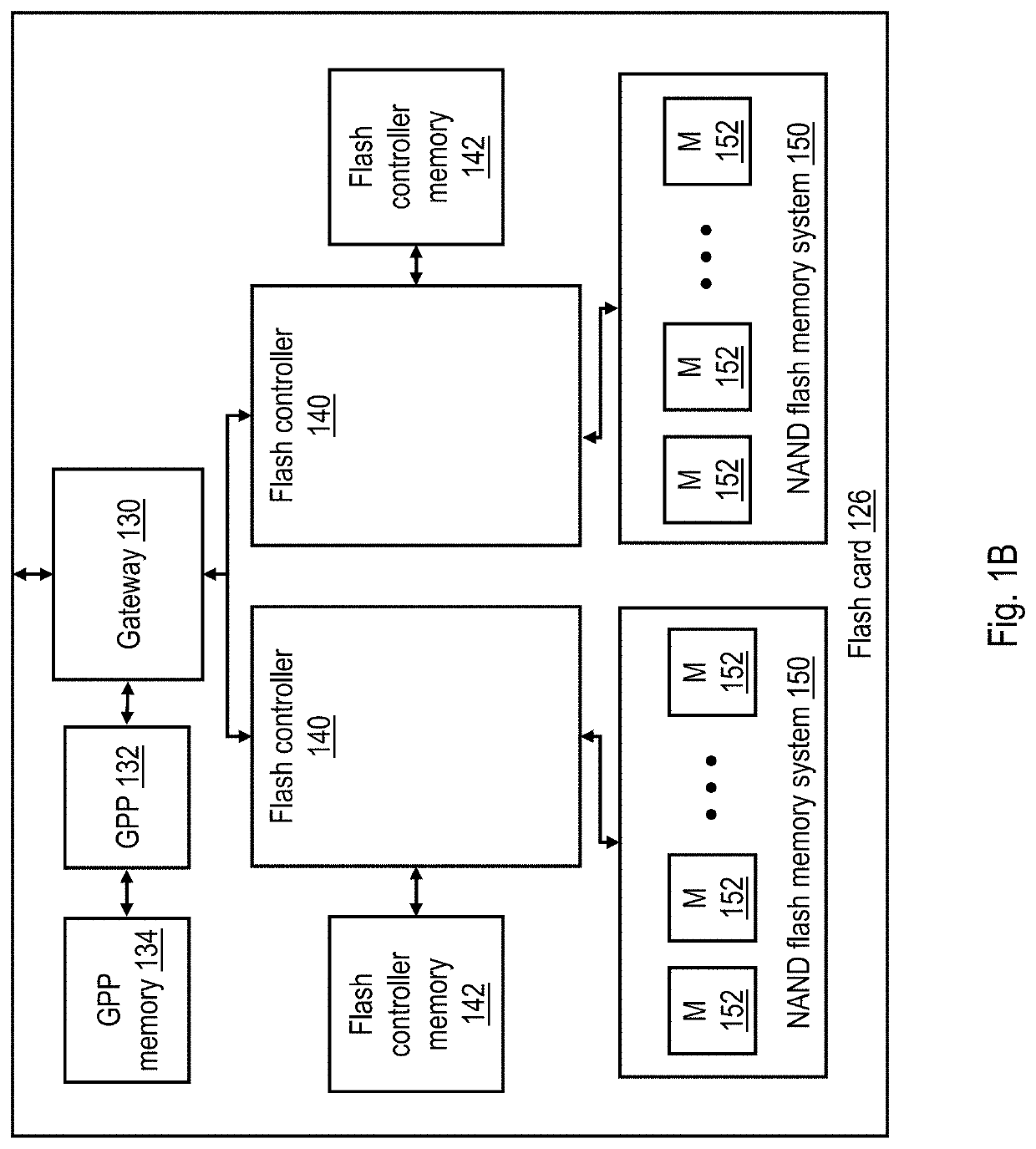

Garbage collection in non-volatile memory that fully programs dependent layers in a target block

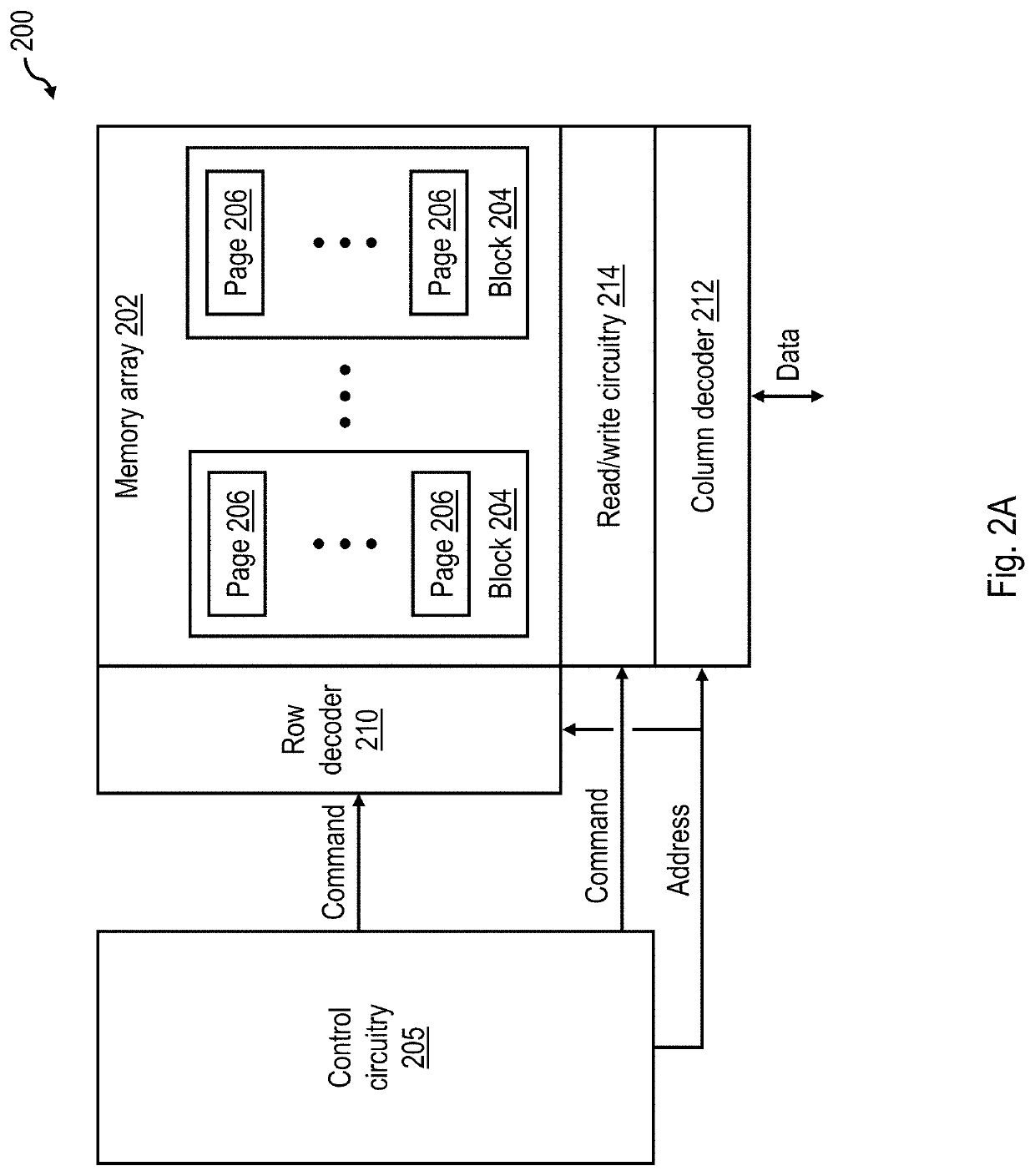

ActiveUS20200257621A1Improve bit error rateDecrease over-provisioningMemory architecture accessing/allocationInput/output to record carriersComputer architectureInvalid Data

A non-volatile memory includes a plurality of blocks of physical memory, including a target block and at least one source block containing at least some valid data and some invalid data. Responsive to determining to perform garbage collection for the non-volatile memory, the controller transfers valid data from the at least one source block to the target block. The controller ends garbage collection on the at least one source block with at least some valid data present in the at least one source block and all interfaces of the target block closed at the boundary of independent layers. In at least some embodiments, the target block may be configured to store more bits per cell than the at least one source block.

Owner:IBM CORP

Margin-based optimization systems and methods in optical networks for capacity boosting

ActiveUS9438369B2Increase capacityReduce marginWavelength-division multiplex systemsSignalling characterisationLength waveOptimization system

Systems and methods of optimizing capacity of an optical network include identifying a first wavelength with an associated target capacity; determining that the first wavelength has insufficient capability to operate at the associated target capacity; and adjusting one or more wavelengths to increase capability of the first wavelength such that the first wavelength can operate at the associated target capacity.

Owner:CIENA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com