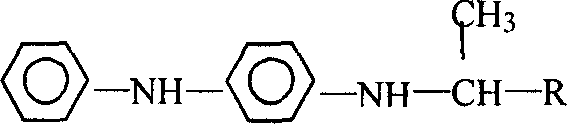

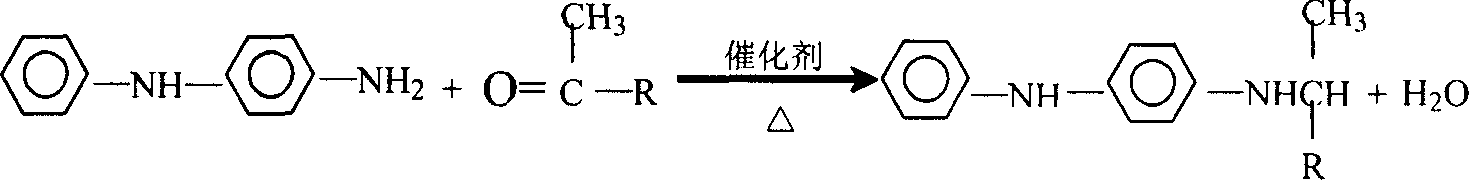

Condensating reductive alkylation catalyst, preparation method and uses thereof

A catalyst and alkylation technology, applied in the direction of reductive alkylation preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of consumption of raw material ketone and hydrogen, product quality decline, raw material waste, etc. The effect of suitable surface area and pore volume, reducing operating intensity, and reducing environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

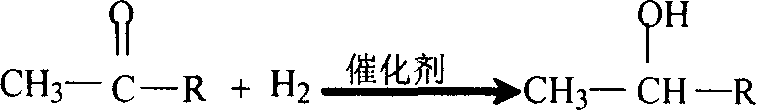

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 206gCu(NO 3 ) 2 , 250gZn (NO 3 ) 2 and 24gAl 2 (NO 3 ) 3 Make a 2L mixed solution, make 225g oxalic acid into a 2L solution, place the two solutions in a high-level tank, and heat to 50°C at the same time. Under the condition of heat preservation and stirring, add the two into the low tank at the same time, then age under stirring for 0.3h, filter, dry the filter cake at 110°C for 8h, roast at 400°C for 4h, then add appropriate amount of graphite and mix well Tablet molding, that is, the catalyst. The molar ratio of copper to zinc in the prepared catalyst is 0.8:1, and the molar ratio of aluminum to copper is 0.10, and the specific surface area is 51.32m 2 / g, the pore volume is 0.11ml / g.

Embodiment 2

[0031] The catalyst described in Example 1 was ground to 100 mesh particles. Under the condition that the molecular ratio of acetone or methyl isobutyl ketone (MIBK) to RT base is 4, react at a reaction pressure of 5 MPa and a reaction temperature of 150°C for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com