Patents

Literature

88 results about "Uranyl nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uranyl nitrate (UO₂(NO₃)₂) is a water soluble yellow uranium salt. The yellow-green crystals of dioxouranium nitrate hexahydrate are triboluminescent. Uranyl nitrate can be prepared by reaction of uranium salts with nitric acid. It is soluble in water, ethanol, acetone, and ether, but not in benzene, toluene, or chloroform.

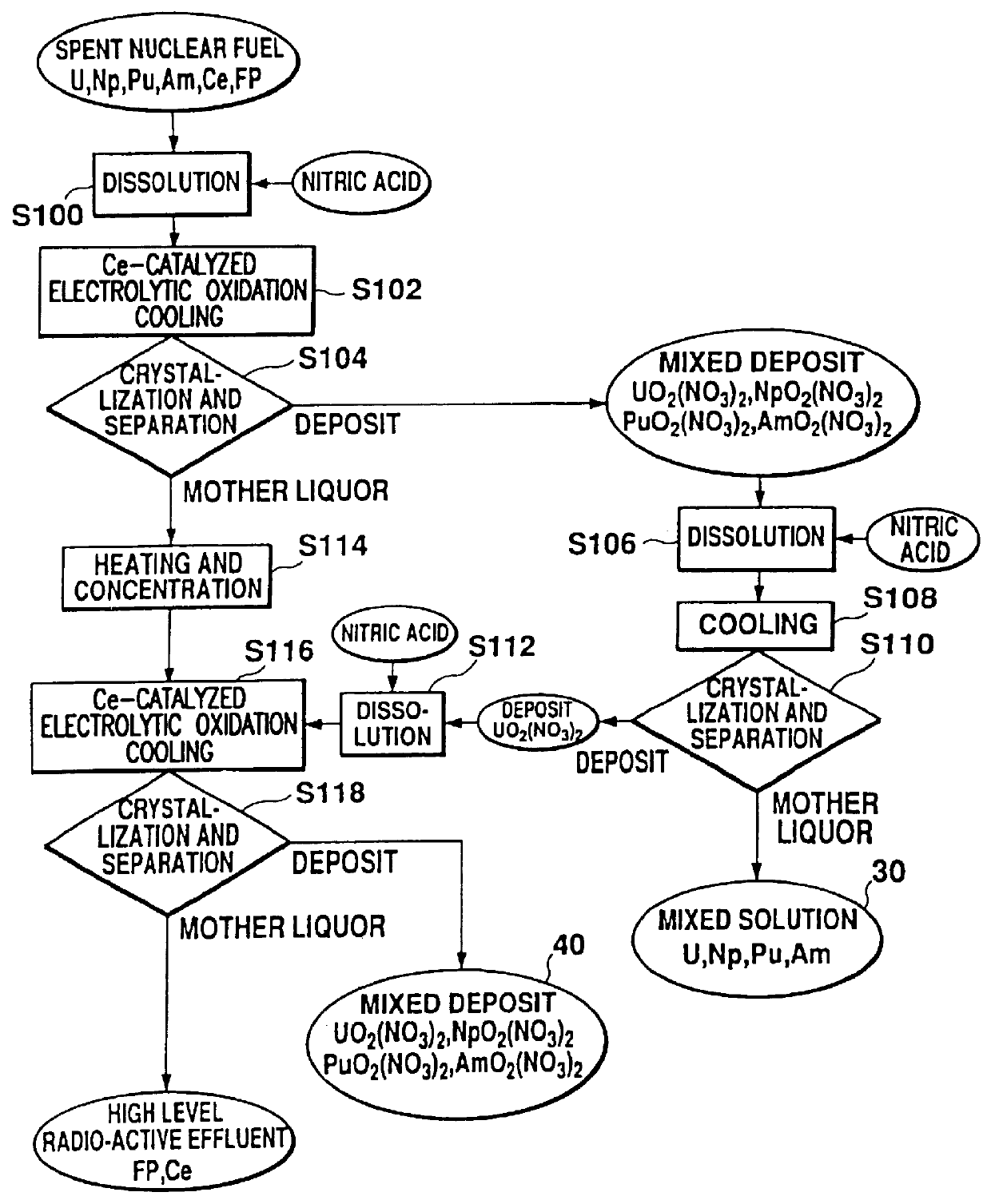

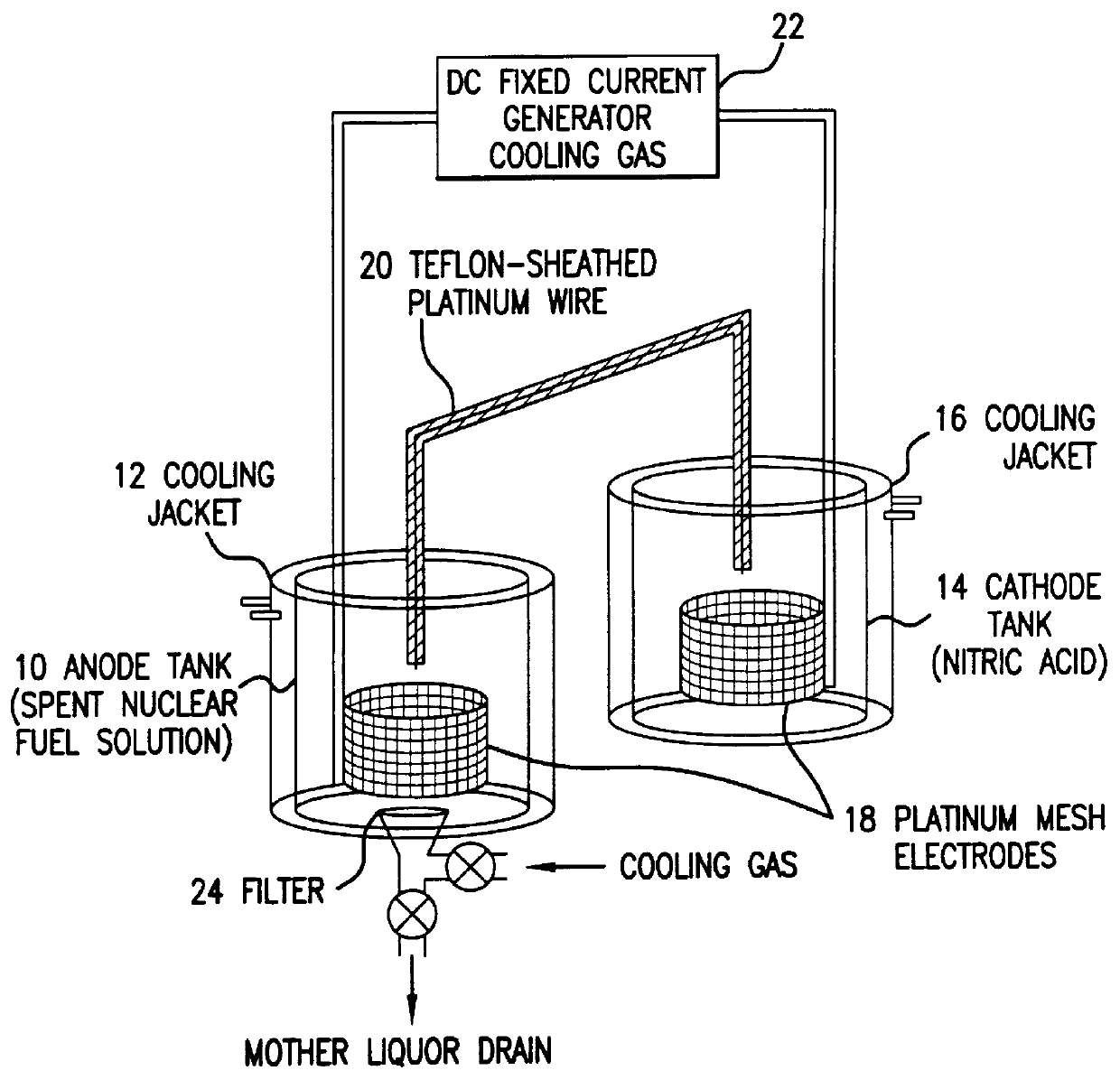

Method of recovering uranium and transuranic elements from spent nuclear fuel

InactiveUS6033636AReduce solubilityPromote recoveryElectrolysis componentsSolvent extractionSolventWaste material

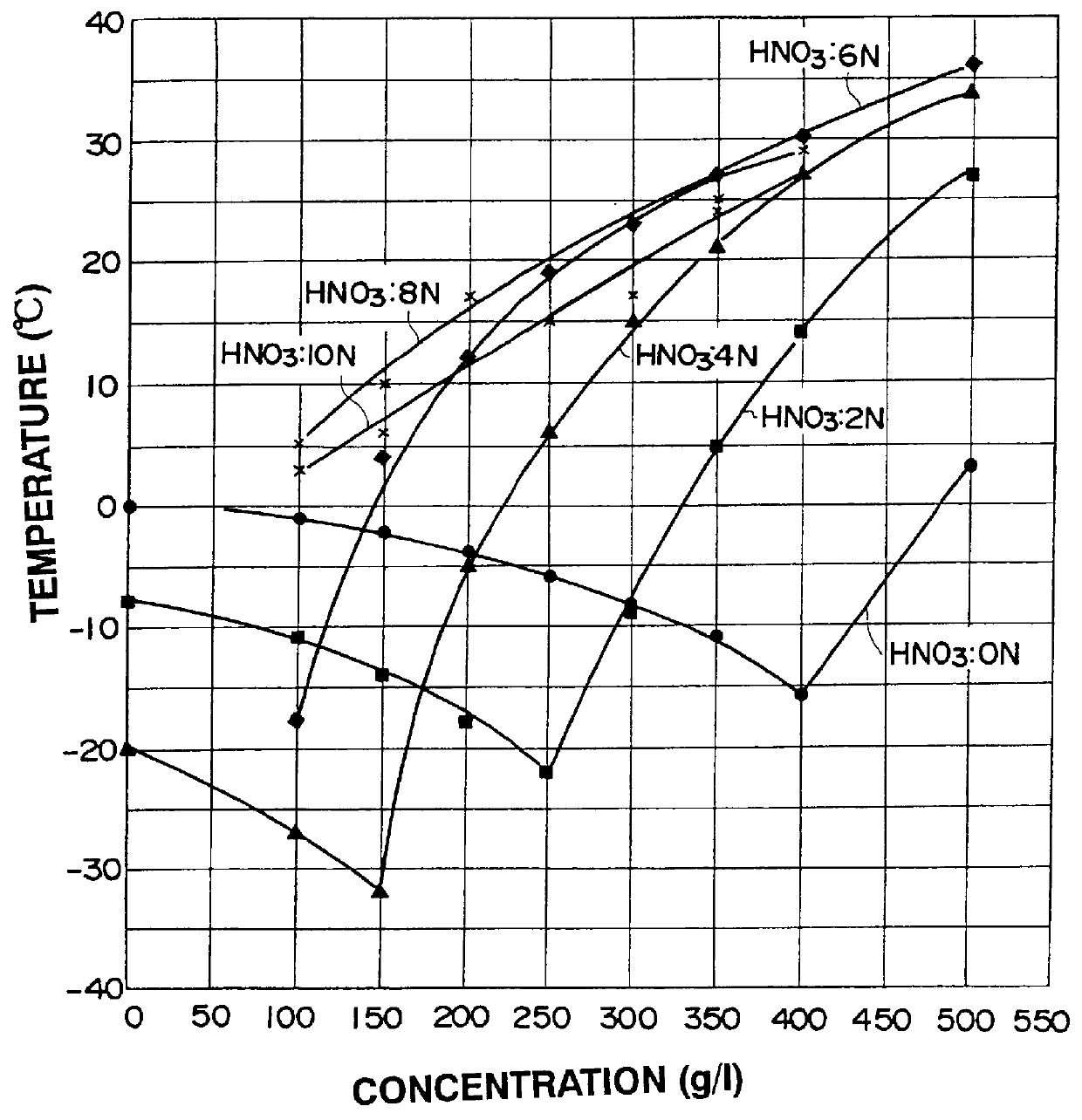

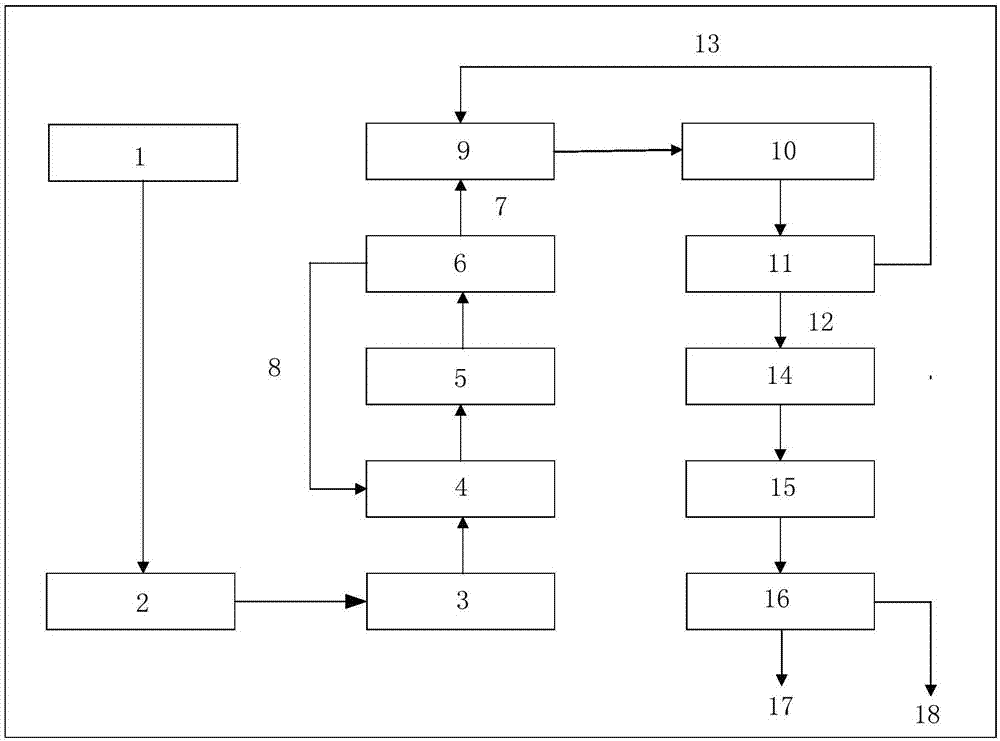

The steps for recovering uranium and transuranic elements are simplified, and the generation of waste solvent and waste materials is suppressed. Spent nuclear fuel is dissolved in nitric acid (S100) and the resulting solution is subjected to electrolytic oxidation so that U, Np, Pu, Am is oxidized to VI using Ce as oxidation catalyst. The solution is cooled, and nitrates of valence VI thereby deposit as crystals and are separated from the mother liquor (S104). The mother liquor is heated and concentrated (S114). The mixed crystalline deposit is dissolved in nitric acid (S106), uranyl nitrate is deposited alone by cooling (S108), and the crystals are separated from the U, Np, Pu, Am mixed solution (S110). The uranyl nitrate is dissolved in nitric acid (S112), and the heated and concentrated mother liquor is added to it to prepare another mixed solution. This mixed solution is then subjected to electrolytic oxidation to oxidize the remaining U, Np, Pu, Am to valence VI, and the solution is cooled so that U, Np, Pu, Am are coprecipitated with uranyl nitrate as crystals, and can be separated from high level radioactive effluent (S118).

Owner:DORYOKURO KAKUNENRYO KAIHATSU JIGYODAN

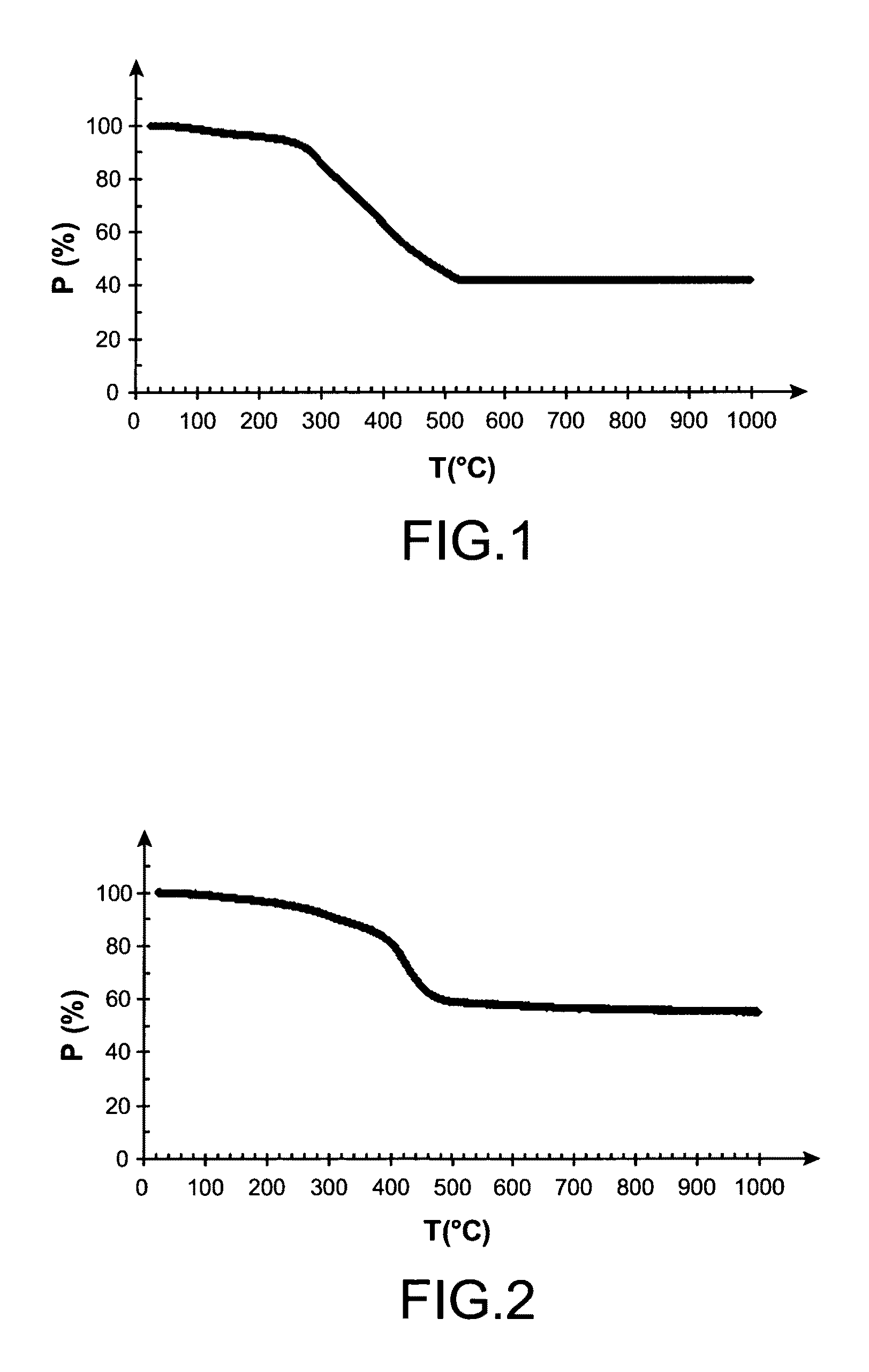

Preparation method of thorium-uranium mixed oxide ceramic microspheres

ActiveCN103165206ANo stringent requirementsFlat surfaceNuclear energy generationReactors manufactureOxide ceramicMixed oxide

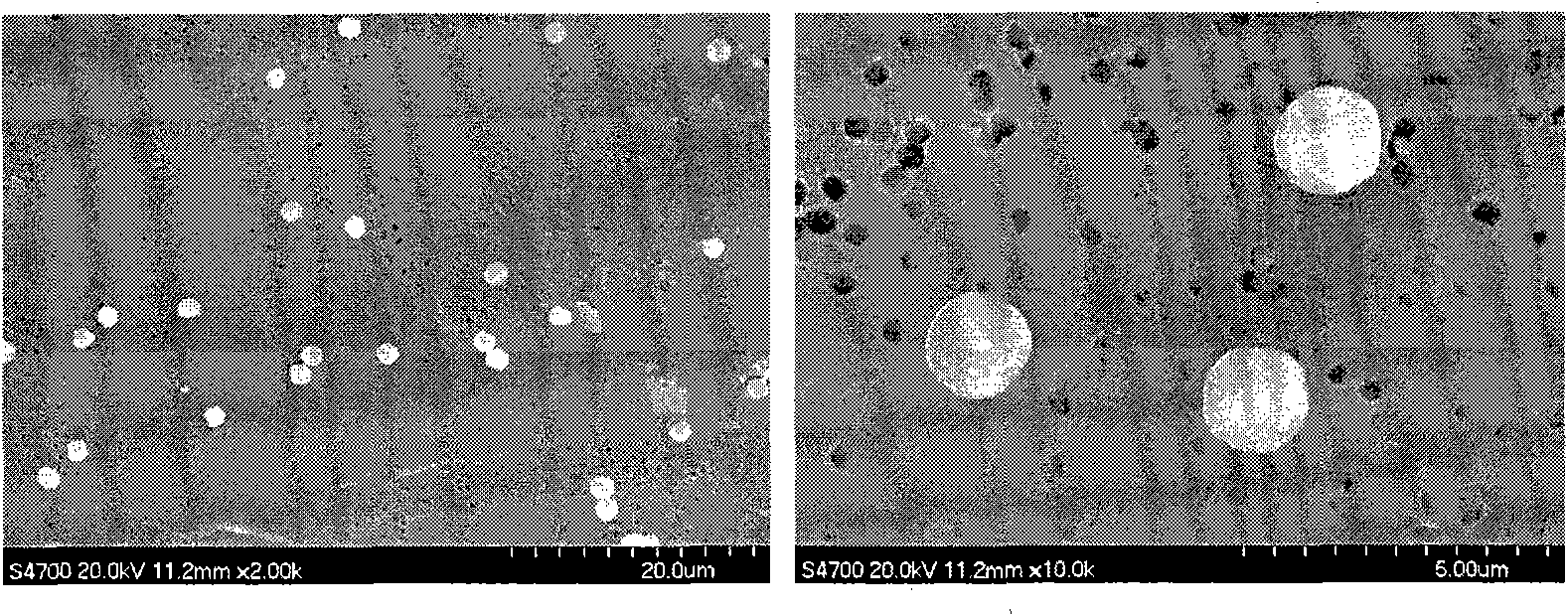

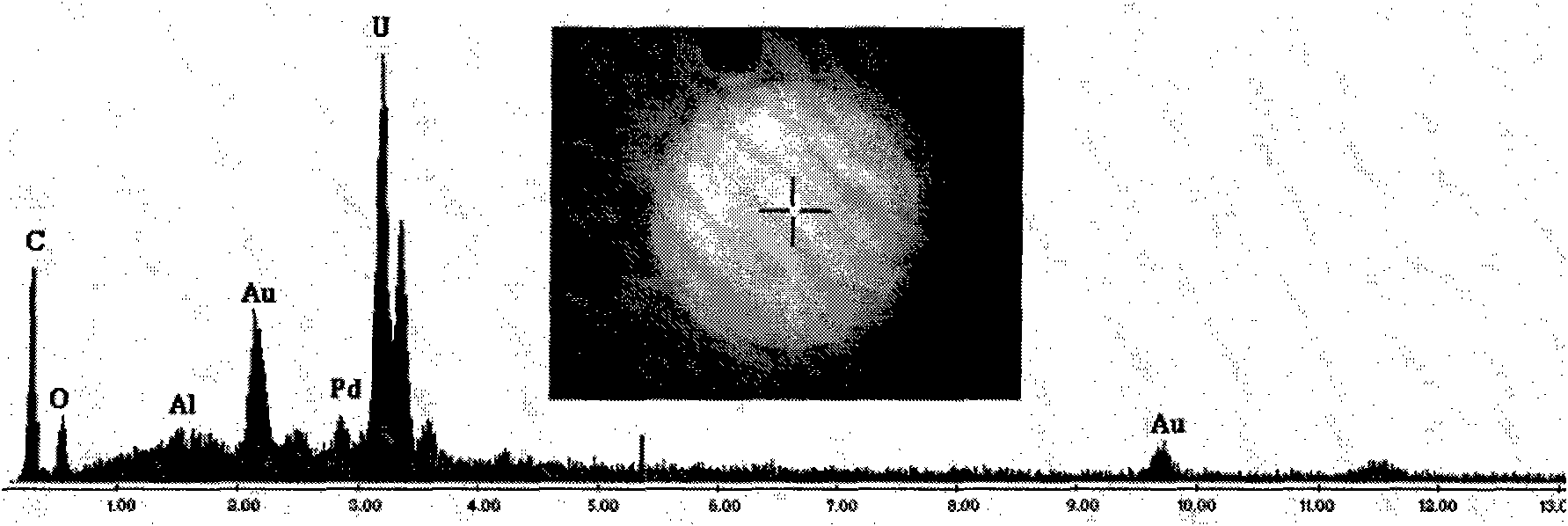

The invention belongs to a preparation method of nuclear fuel, and concretely relates to a preparation method of thorium-uranium mixed oxide ceramic microspheres. The method uses an internal gelation method, and comprises using an acid-lacking uranyl nitrate solution and thorium nitrate as raw materials, preparing sol, dispersing gelling, washing, drying, calcining and reduction sintering to prepare ThO2-UO2 microspheres with a diameter of 0.05-0.20 mm. The ThO2-UO2 microspheres has outstanding advantages of smooth surface, good sphericity, compact inside, uniformly distributed thorium, and a density being greater than 96.8% TD; and the method is simple, and can prepare the thorium-uranium mixed oxide ceramic microspheres with different thorium contents.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Preparation technology of UO2-graphene composite fuel

ActiveCN107342110AEvenly dispersedEvenly distributedNuclear energy generationReactors manufactureNuclear reactor coreNuclear reactor

The invention belongs to the field of preparation of nuclear reactor fuels, and provides a preparation technology of a UO2-graphene composite fuel pellet in order to solve the problems of uneven physical mixing, low production efficiency and high production cost existing in existing preparation technologies of a UO2-graphene composite fuel and low density of fuels prepared through other sintering technologies. The technology mainly comprises the following steps: 1, synthesizing UH3 powder; 2, synthesizing a uranyl nitrate solution; 3, synthesizing (NH4)2U2O7-graphene composite powder; 4, synthesizing UO2-graphene composite powder; 5, mixing the UO2-graphene composite powder with the UH3 powder; 6, carrying out cold press molding to form a green body of the fuel pellet; and 7, carrying out pressureless sintering to form the fuel pellet. The technology adopting a chemical method has the advantages of high production efficiency and low cost, and solves the problems of uneven elements and low density of the composite fuel, the relative density of the prepared composite fuel is about 95%, and the composite fuel has excellent thermophysical performances.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

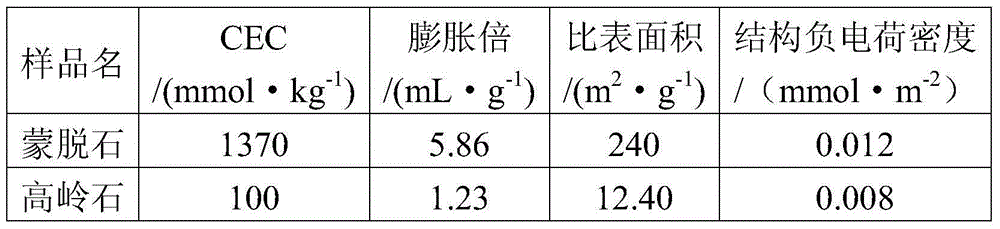

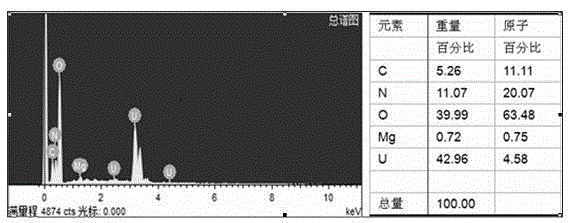

Method for calculating mineralization relation of clay mineral object and uranium in sandstone type uranium deposit

ActiveCN103954739AAvoid mixingThe purification method is reasonable and feasibleEarth material testingClay mineralsOxidation zone

The invention belongs to geology technical field, and more specifically relates to a method for calculating mineralization relation of a clay mineral object and uranium in a sandstone type uranium deposit. A purpose of the method is a quantitative analysis of mineralization relation between the clay mineral object and uranium in the sandstone type uranium deposit. The method comprises the following steps: taking an interlayer oxidation zone, a transition zone and a reducing zone for selecting the samples for different subzones, calculating mass of three samples, uranium-containing mass and proportion; separating and purifying the clay mineral object, and calculating the mass; analyzing types, composition and property of the clay mineral object in three samples; calculating the uranium-containing mass and the uranium-containing proportion; performing an adsorption reaction experiment of the clay mineral object and uranyl nitrate to obtain the most favorable adsorption condition; researching the secondary adsorptivity of the clay mineral object in the sample to uranium under the most favorable adsorption condition; analyzing the adsorptivity difference of a typical mineral standard sample mixture and the clay mineral object in the sample, comparing the area geology background and the most favorable adsorption condition, and determining the enrichment effect of the clay mineral object to uranium.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

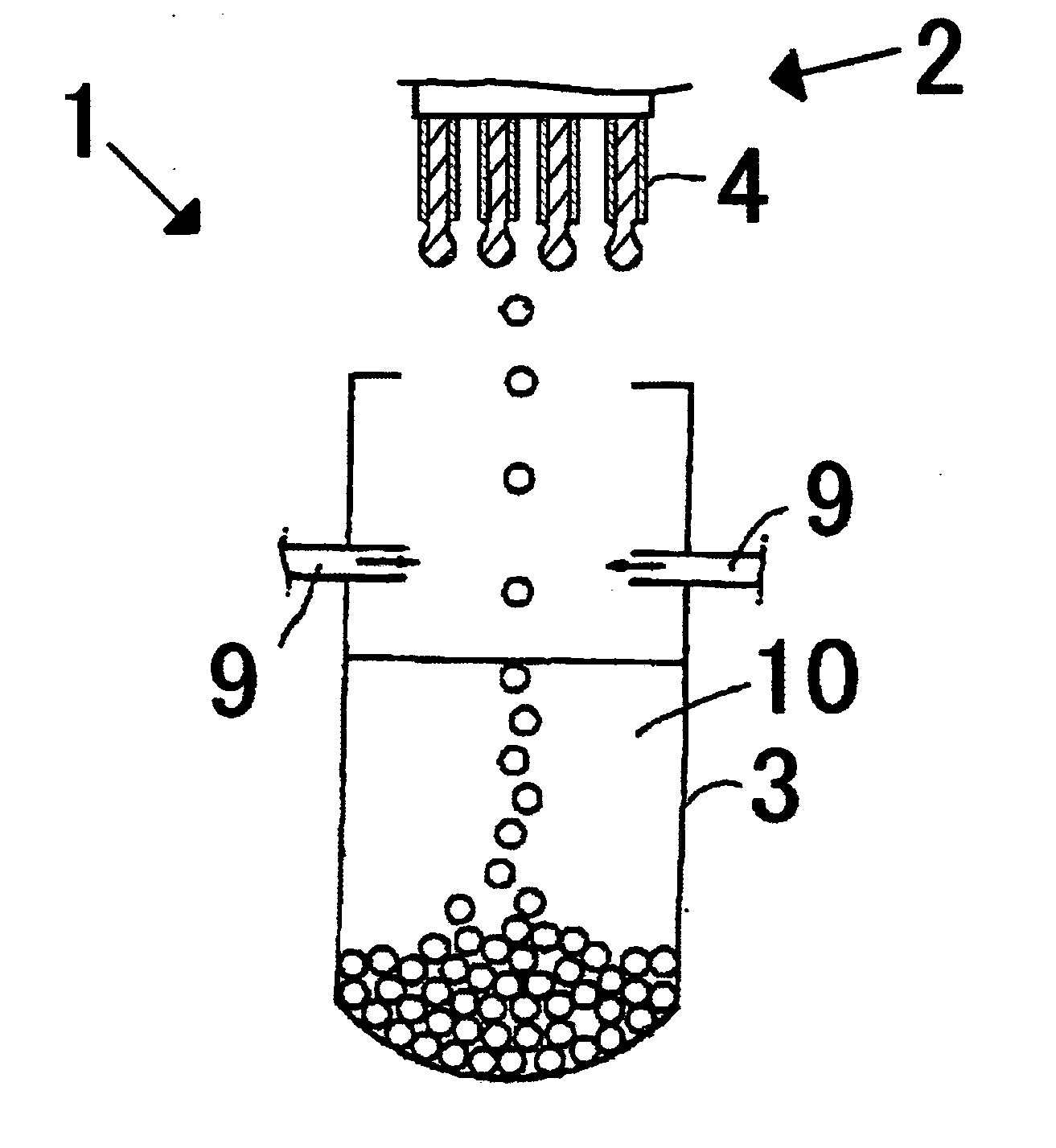

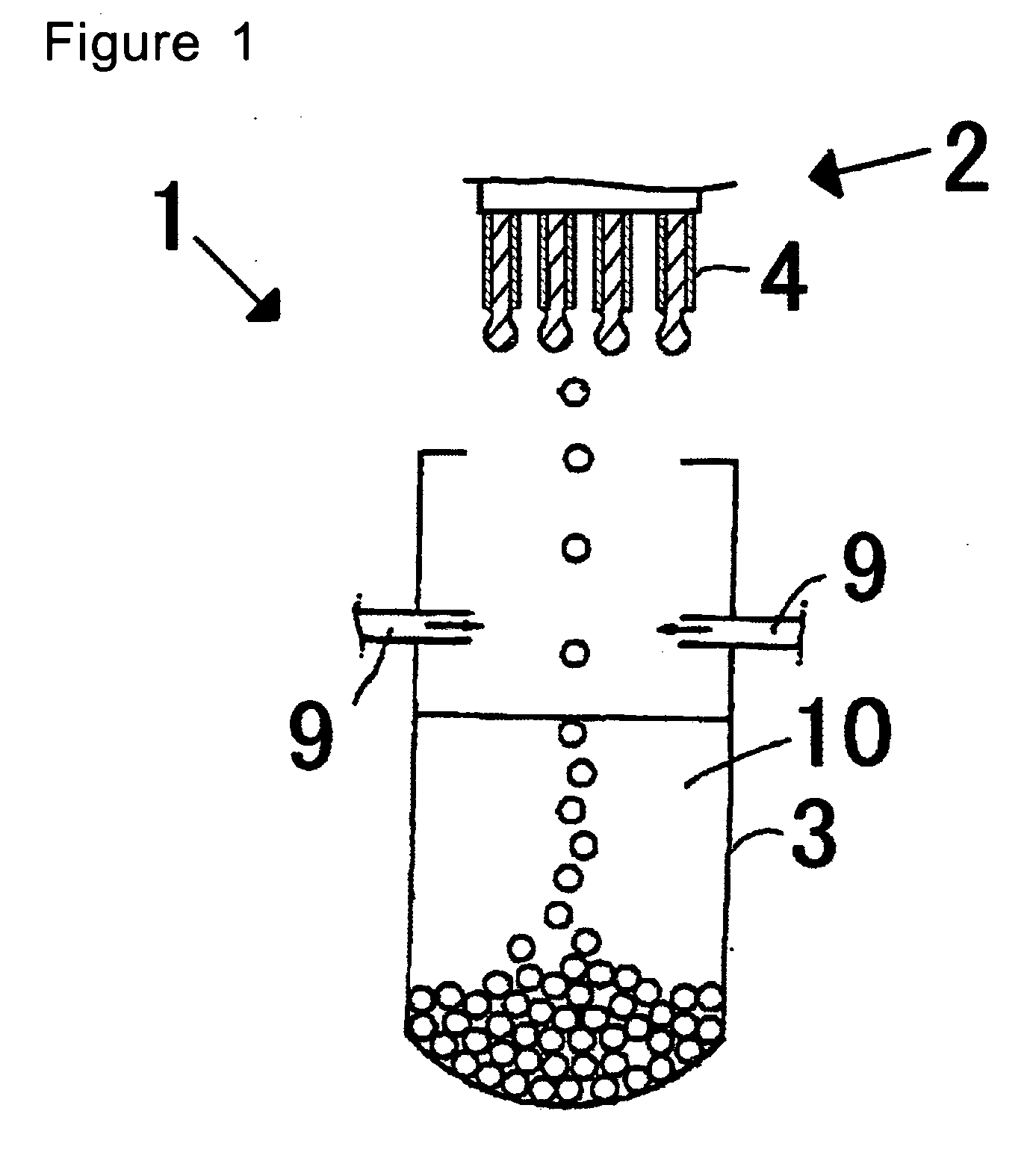

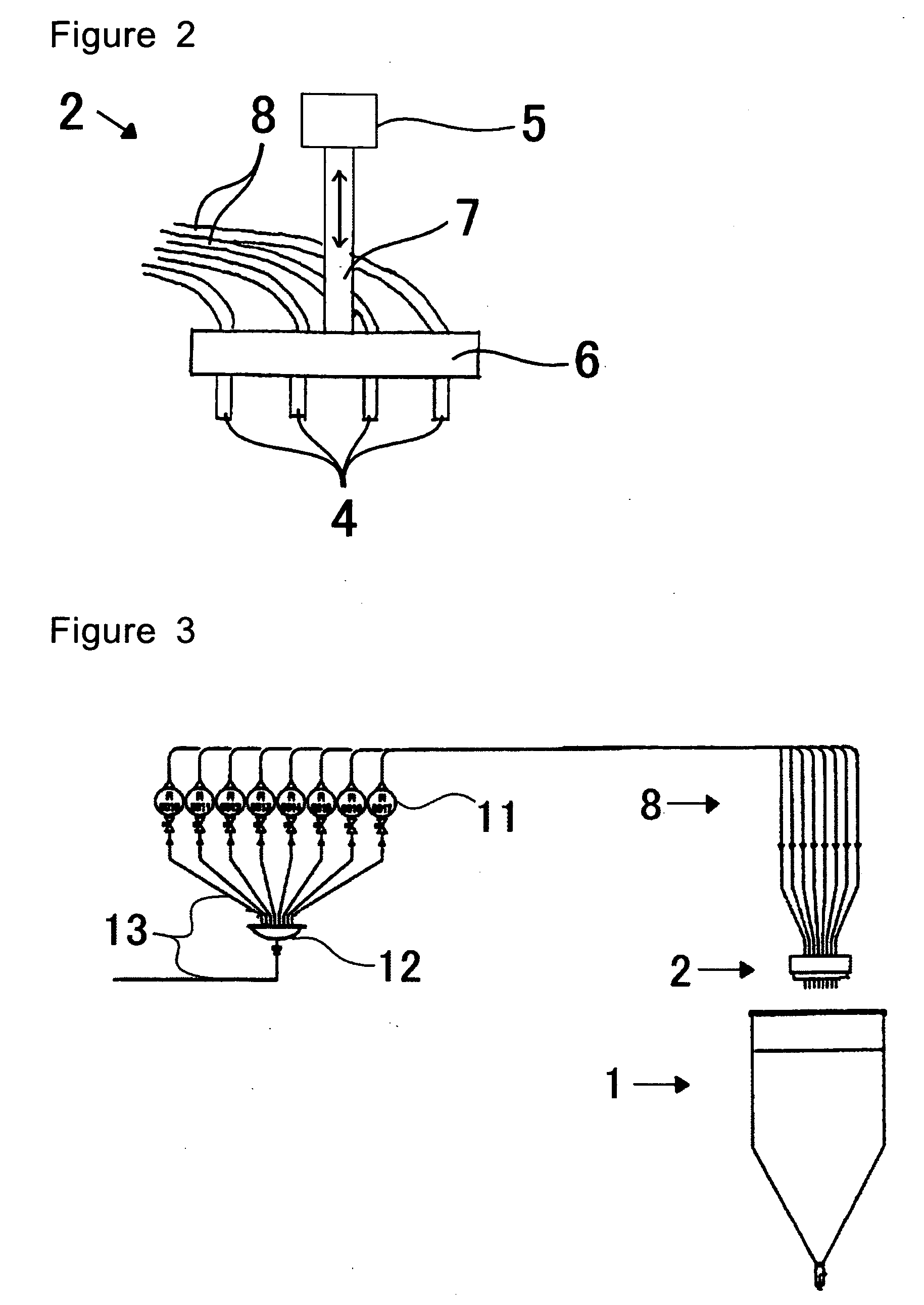

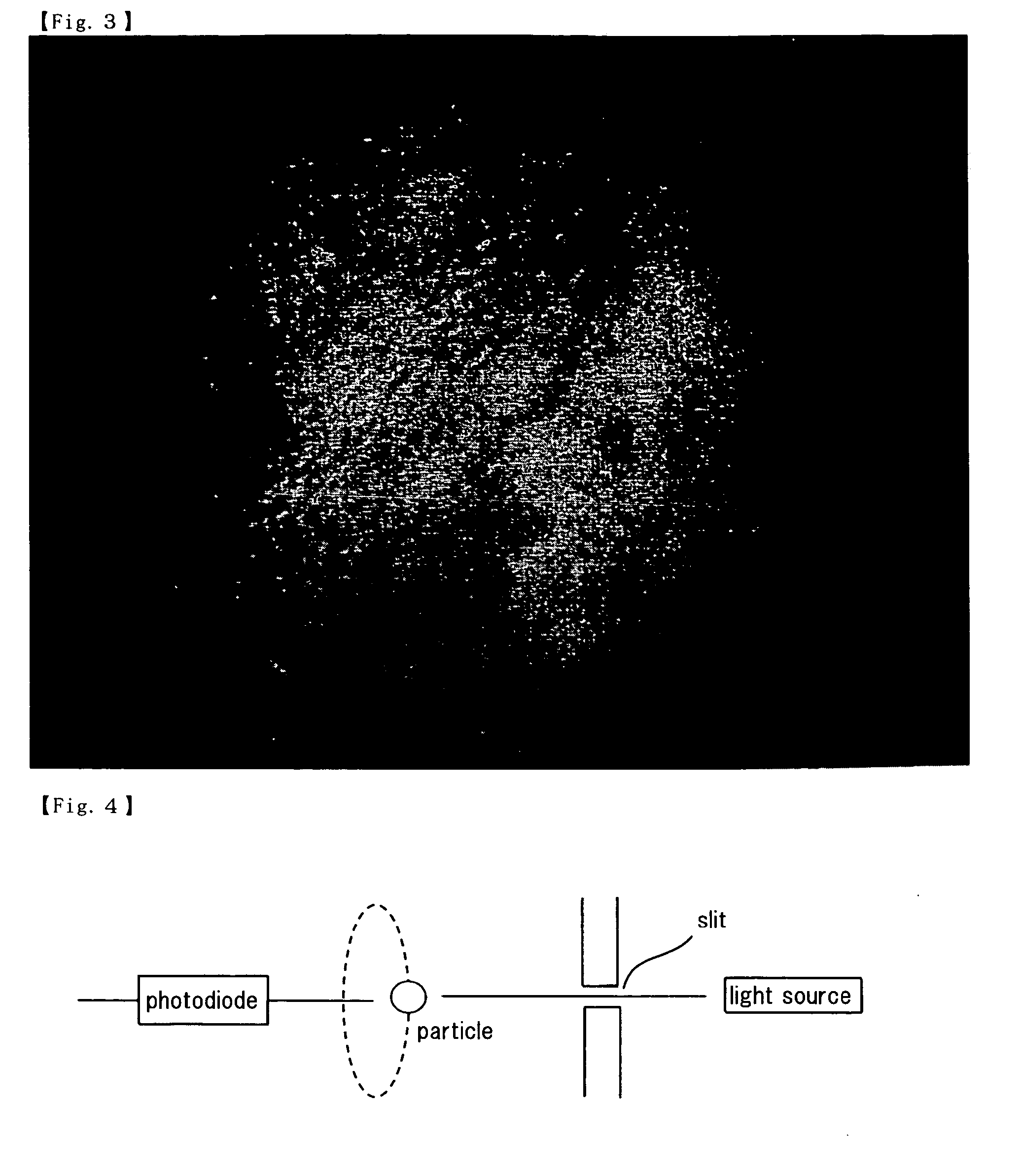

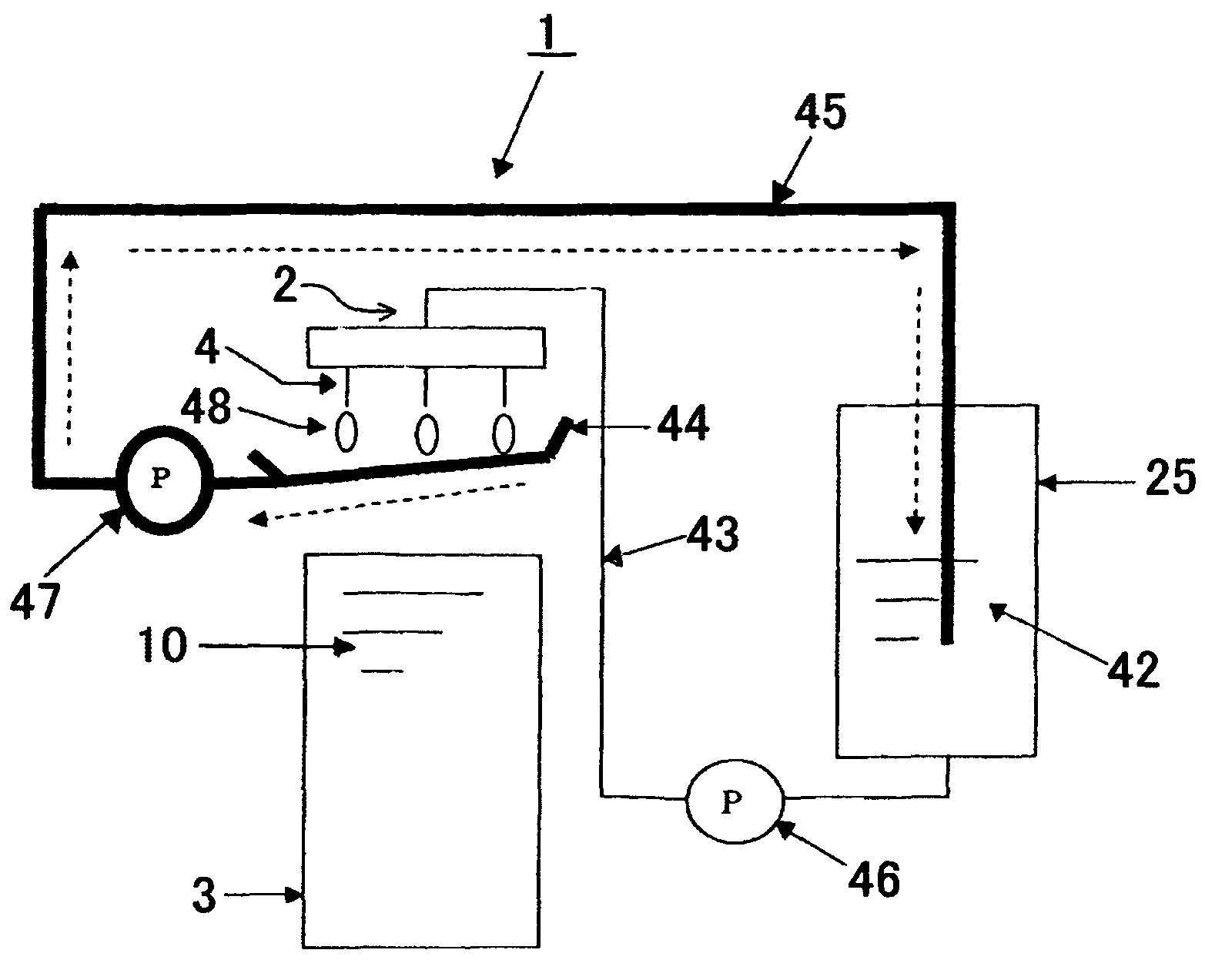

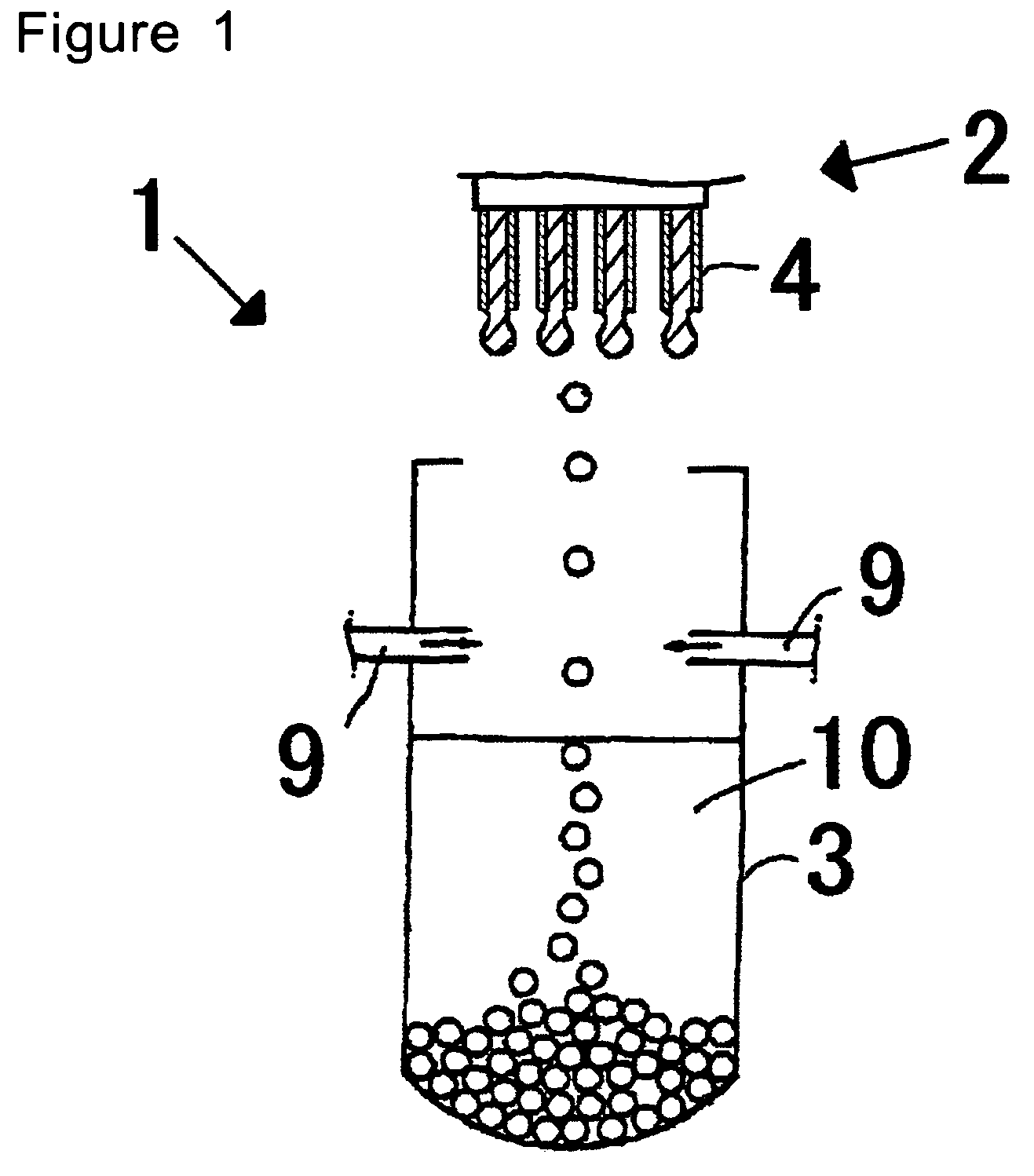

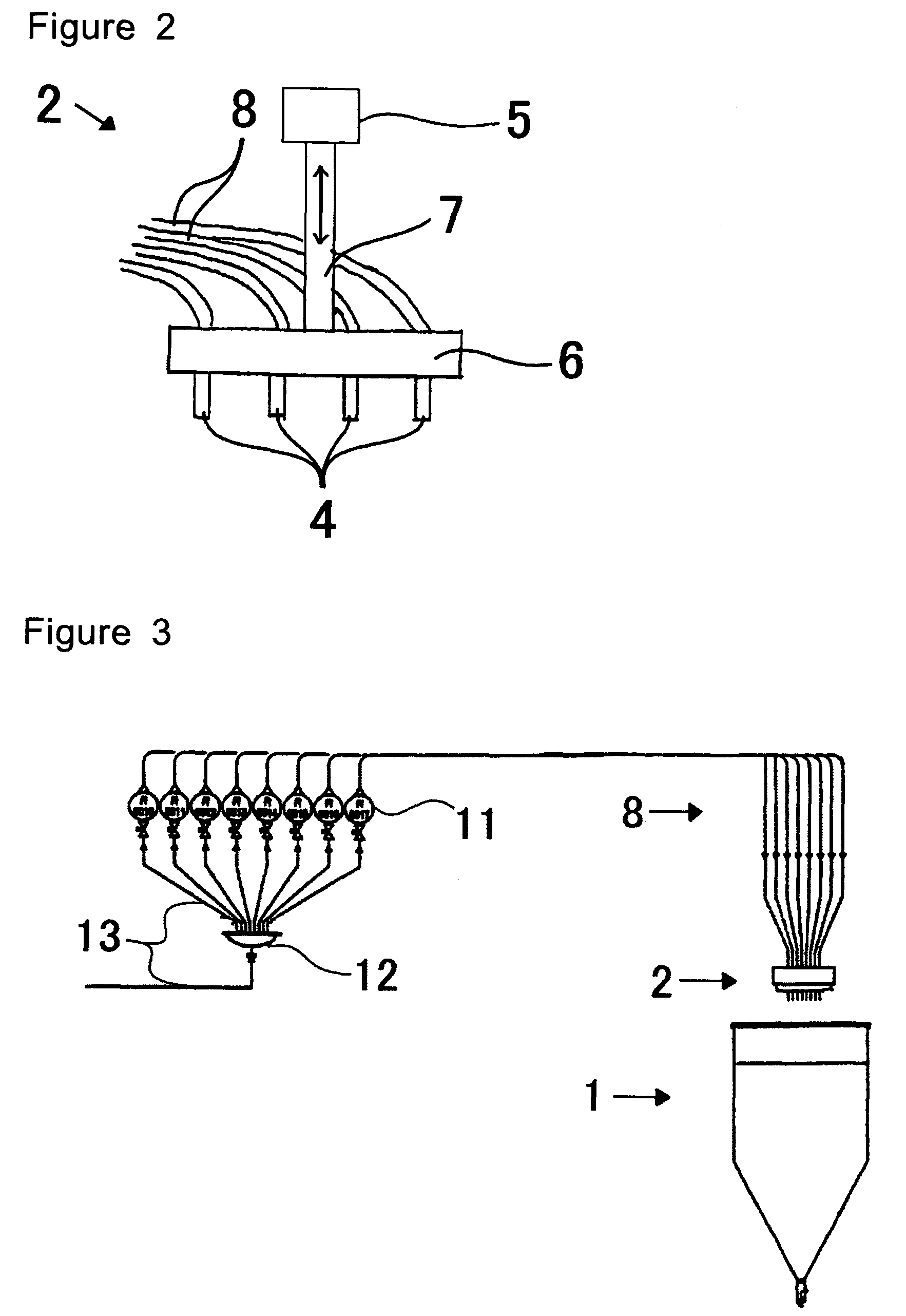

Dripping nozzle device, device for recovering feedstock liquid, device for supplying a feedstock liquid, device for solidifying the surfaces of drops, device for circulation aqueous ammonia solution, and apparatus for droducing ammonium diuranate particles

InactiveUS20070056637A1Particle diameters of the drops can be controlled easilyEliminate resonanceShaking/oscillating/vibrating mixersGranulation by liquid drop formationAmmonium hydroxideAmmonium diuranate

This invention provides a dripping nozzle device to produce ADU particles with good sphericity, a device for recovering a feedstock liquid to prepare a uniform feedstock liquid, a device for supplying a feedstock liquid to form drops with a uniform volume, a device for solidifying the surfaces of drops so that the drops will not deform easily when they fall onto and hit the surface of an aqueous ammonia solution, a device for circulating an aqueous ammonia solution so that the uranyl nitrate in the drops can be changed to ammonium diuranate completely, to such an extent that uranyl nitrate in the center of each drop is changed to ammonium diuranate, and an apparatus for producing ammonium diuranate particles with good sphericity. The dripping nozzle device is provided with a single vibrator to vibrate nozzles simultaneously. The device for recovering a feedstock liquid recovers the feedstock liquid remaining in the nozzles and mixes it with a fresh feedstock liquid. The device for supplying a feedstock liquid is provided with a light irradiator for irradiating falling drops with light. The device for solidifying the surfaces of drops sprays ammonia gas over each of the paths along which the drops dripping from the nozzles fall. The device for circulating an aqueous ammonia solution enables drops to flow upward in the aqueous ammonia solution in the aqueous ammonia solution reservoir. The apparatus for producing ammonium diuranate utilizes these devices.

Owner:NUCLEAR FUEL INDS

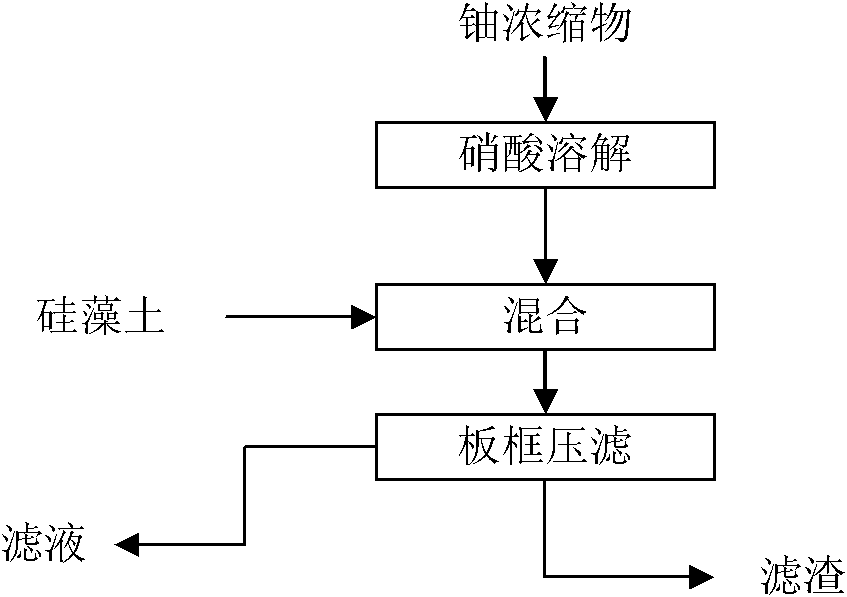

Preparation method of high-clarity uranium solution

InactiveCN102127639AMeet quality requirementsSolve the problem of energy consumptionCLARITYFiltration

The invention provides a preparation method of a high-clarity uranium solution, comprising the following steps of: (1) dissolving diuranate solid in a nitric acid solution until the diuranate solid is completely dissolved to finish acid dissolution; (2) within 0-24 hours after acid dissolution, under the condition of stirring, adding 1-50kg of kieselguhr per cubic meter of the uranium dissolving solution obtained in the step (1), reacting for 0.5-1 hour; and (3) within 0-5 hours after the step (2), filtering the uranium dissolving solution by a plate and frame filter press to obtain a uranyl nitrate solution with the solid concentration of less than 50mg / L, wherein a layer of kieselguhr is pre-coated on the filter cloth of the plate and frame filter press, the coating thickness of the kieselguhr is 1-2mm, and the filtration pressure is 0.2-0.6MPa. The preparation method provided by the invention acquires a high-clarity extraction stock solution by an economical means, and meets the requirements of the subsequent extraction process on the quality of the extraction stock solution.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

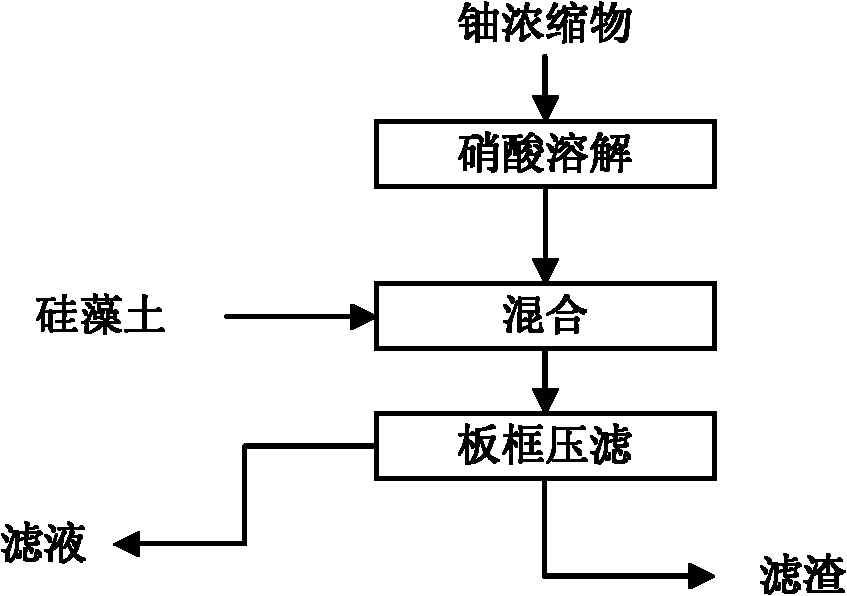

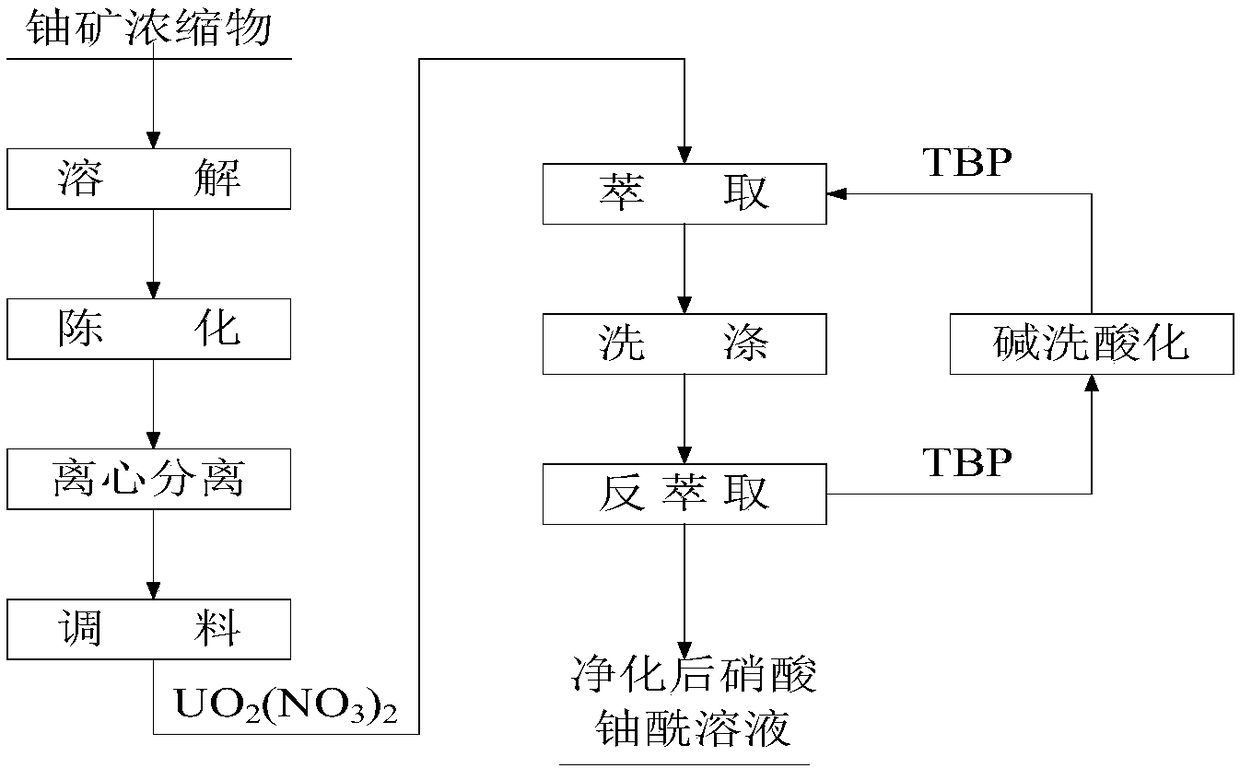

Uranium purification method for ammonium biuranate

The invention belongs to the technical field of dissolution and purification treatment technologies for ammonium biuranate in the uranium purification and conversion process, in particular to the technologies of dissolution of the ammonium biuranate, extraction and purification treatment of a uranyl nitrate solution and the like and provides a uranium purification method for the ammonium biuranate. The uranium purification method for the ammonium biuranate comprises the following steps that (1) dissolution is conducted so as to prepare a qualified uranyl nitrate solution for extraction and purification; (2) extraction is conducted, the solution to be extracted and an extraction agent are mixed and conduct matter transfer in a pulse extraction column, uranium in the material is carried into the extraction agent, and an organic phase containing the uranium is obtained; (3) washing is conducted, the organic phase containing the uranium and a washing agent are fully mixed and conduct matter transfer in a pulse washing column, impurity elements in the organic phase containing the uranium are rewashed and enter a water phase, the purity of the uranium is further improved, and the purified organic phase containing the uranium is obtained; and (4) reverse extraction is conducted, the purified organic phase containing the uranium and the washing agent are fully mixed and conduct matter transfer in the pulse washing column, the uranium enters the water phase again through reverse extraction, the purified uranyl nitrate solution is obtained, and an uranium oxide is prepared from the purified uranyl nitrate solution through concentration and denitration manners.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

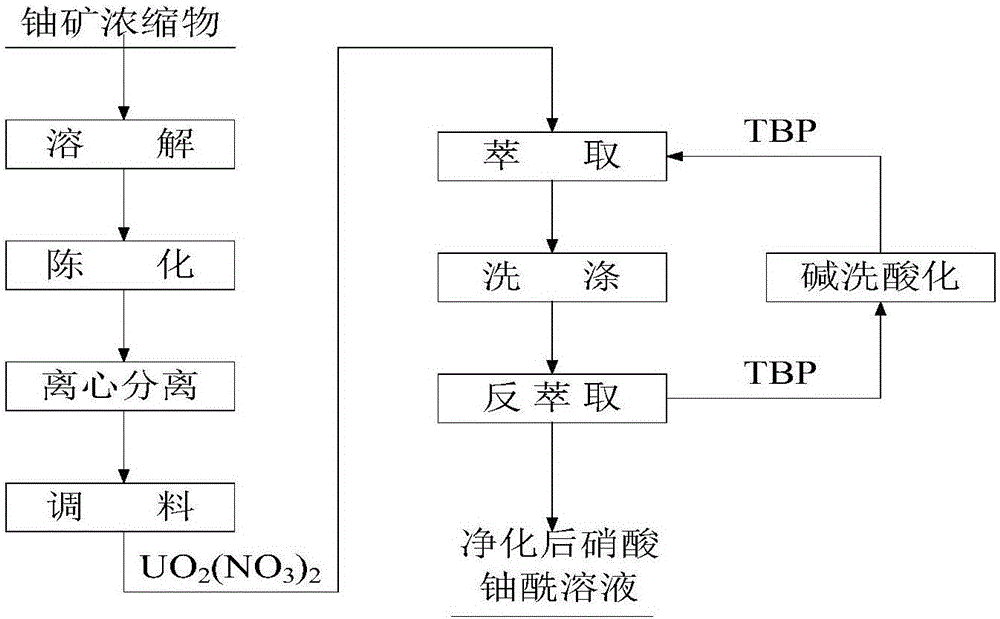

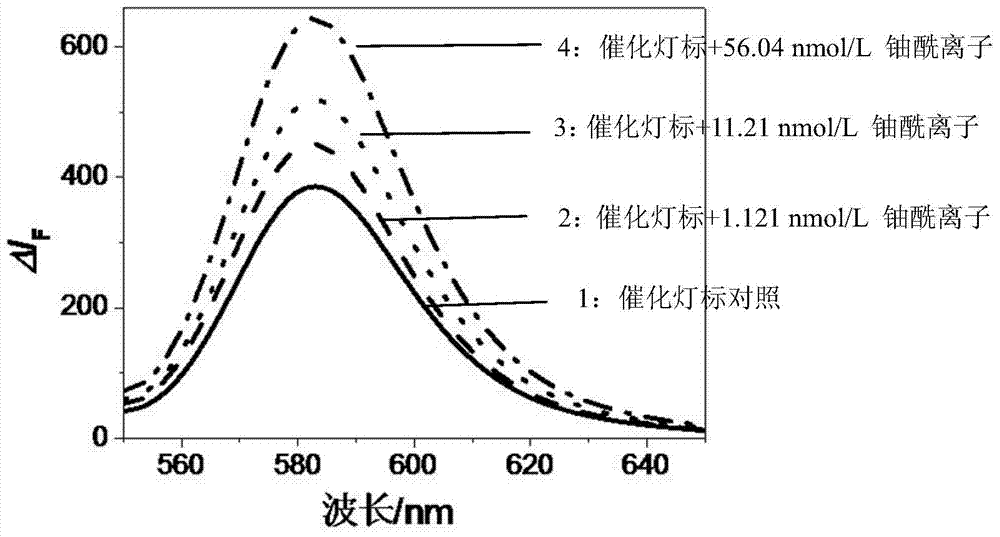

Catalytic light mark and preparation method thereof, and method for determination of trace uranium by catalytic light mark

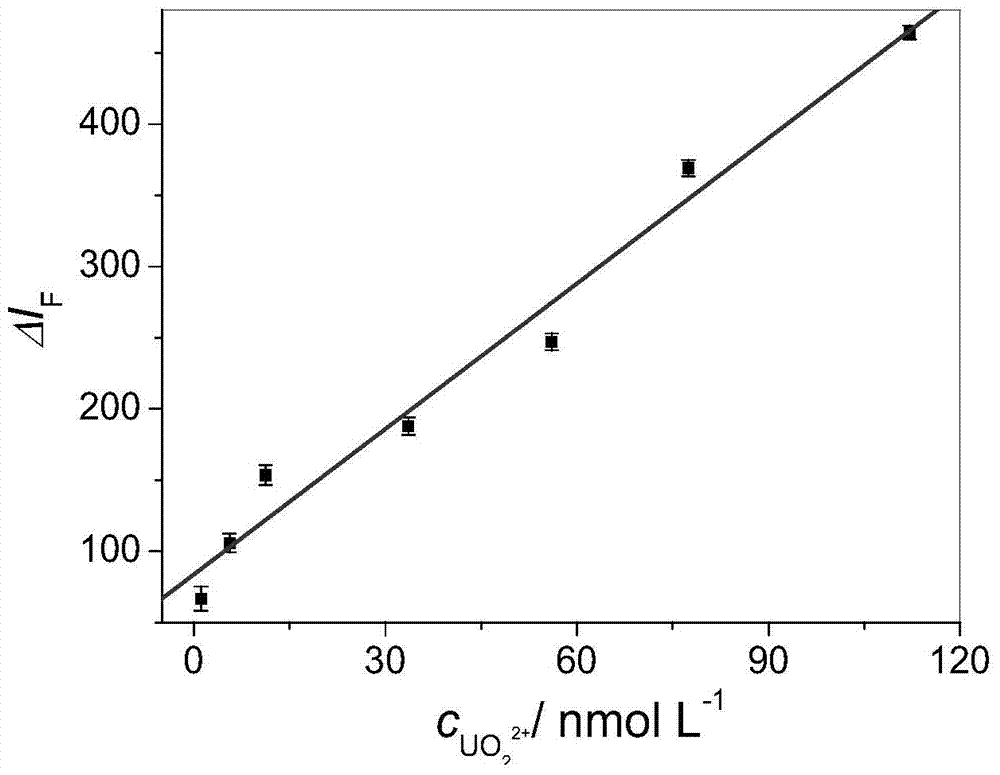

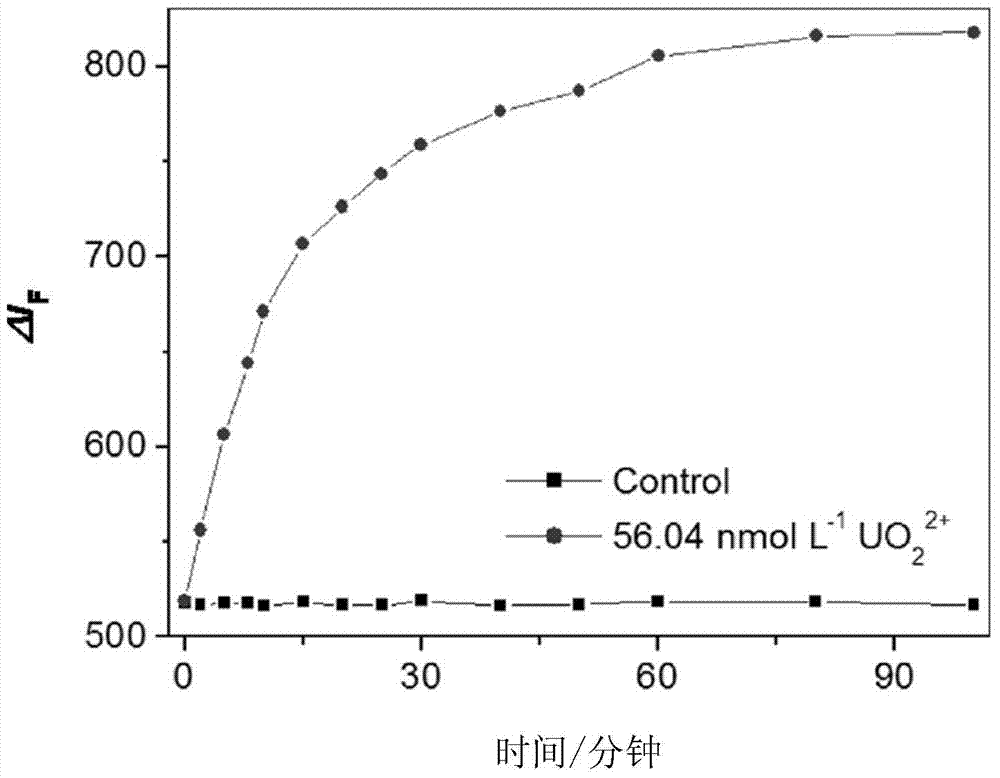

InactiveCN104774915AThe detection process is fastImprove accuracyMicrobiological testing/measurementFluorescence/phosphorescenceMethyl groupUranyl nitrate

The invention discloses a catalytic light mark and a preparation method thereof, and a method for determination of trace uranium by the catalytic light mark. The catalytic light mark is composed of two parts of a DNA enzyme and a substrate DNA, a 3' end of a DNA enzyme sequence comprises four continuous guanine deoxynucleotides (G), the middle of a substrate DNA sequence has an adenine nucleotide (rA), and a 5' end of the substrate DNA is modified by a 4-methyl-6-carboxyl rhodamine (TAMRA) fluorescent dye. The DNA enzyme and the substrate DNA are in mixing hybridization to form the catalytic light mark, the catalytic light mark is added to a reaction system of a to-be-measured sample to undergo a reaction, the fluorescence intensity of uranyl nitrate ions with known concentration and the fluorescence intensity of the sample are determined, and the uranium content in the sample can be obtained through calculation. The method is a fast, accurate, high-sensitivity and high-selectivity method for determination of trace uranium.

Owner:EAST CHINA UNIV OF TECH

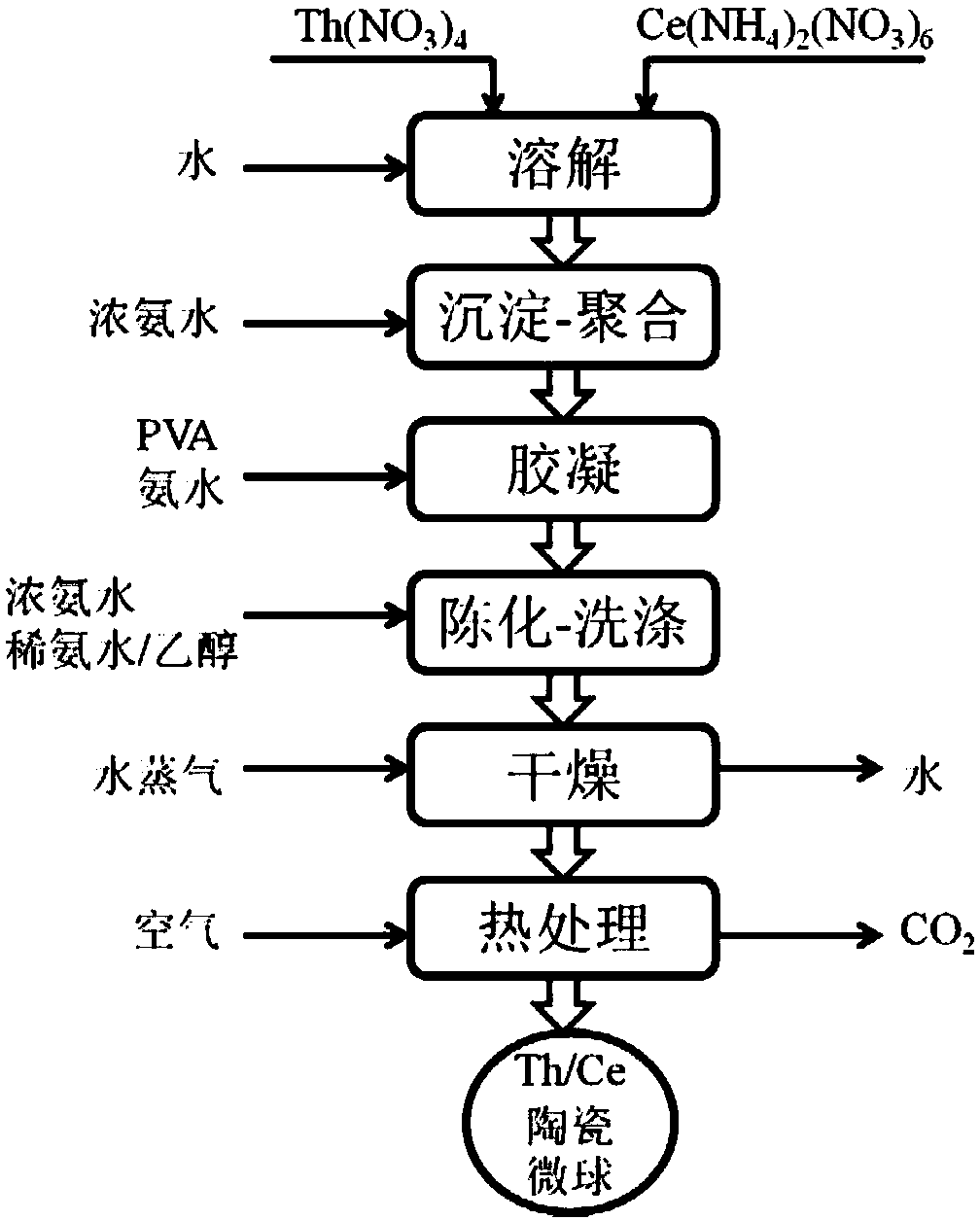

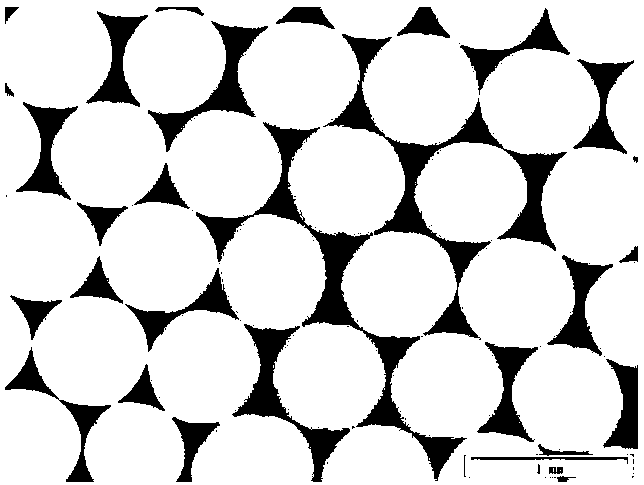

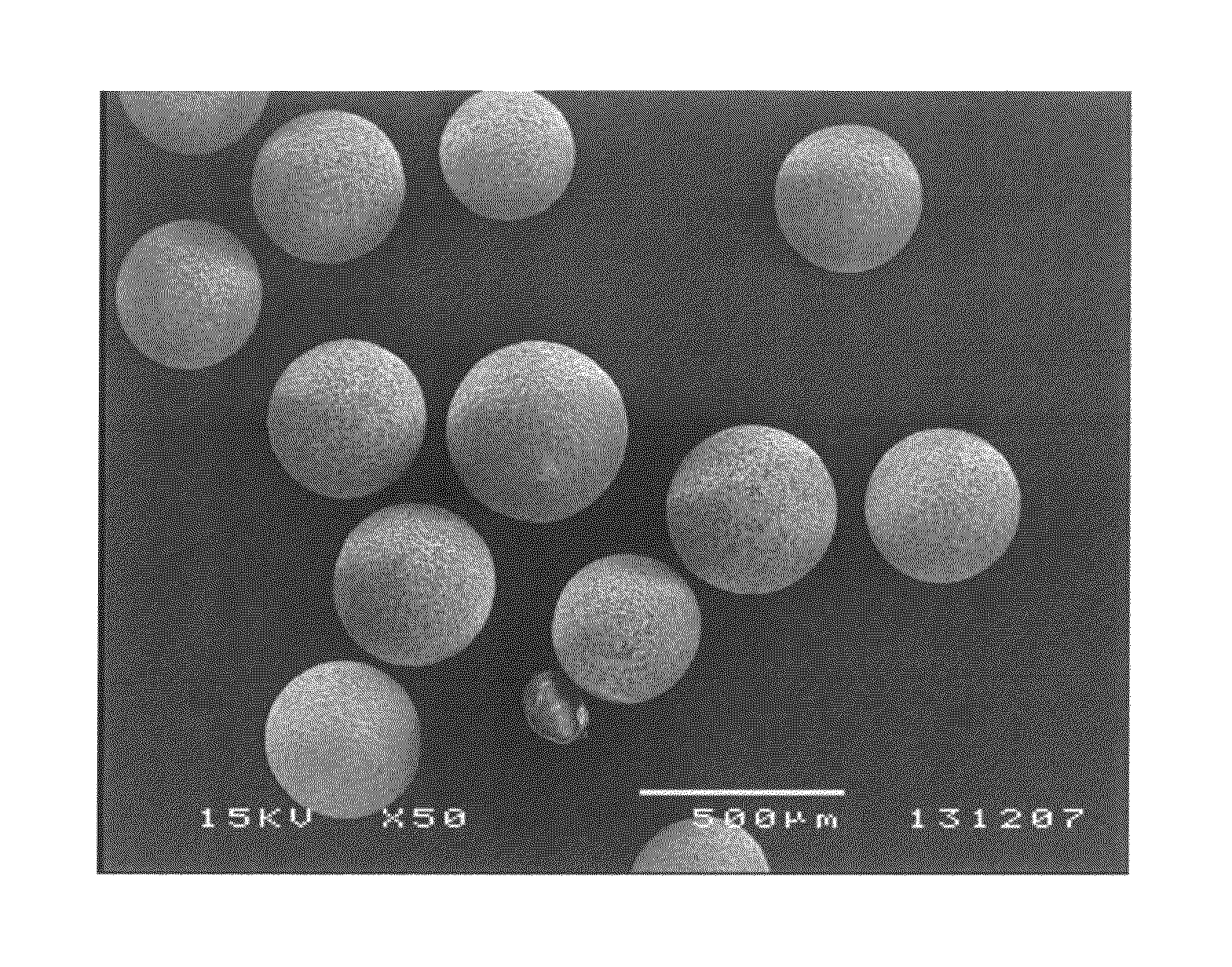

Preparation method of thorium-based mixed oxide ceramic microsphere

ActiveCN107833645AGuaranteed mechanical strengthAvoid deformationNuclear energy generationReactors manufactureAir atmospherePolyvinyl alcohol

The invention relates to a preparation method of a thorium-based mixed oxide ceramic microsphere. The preparation method comprises the following steps of under the conditions of heating and stirring,adding cerous ammonium nitrate or uranyl nitrate and plutonium nitrate solid into a thorium nitrate solution to form a mixed solution, using ammonium hydroxide to adjust the pH (potential of hydrogen)value to form a hydrolysis solution, adding a thickener (polyvinyl alcohol solution) into the hydrolysis solution, and stirring, so as to form a thorium-based mixed sol solution; enabling an exciterto disperse the thorium-based mixed sol solution into liquid droplets, sequentially sending into an air section and an ammonia gas section, and finally sending into the ammonium hydroxide to form a gel microsphere; heating and aging the gel microsphere in concentrated ammonium hydroxide, alternatively washing by ethyl alcohol and thin ammonium hydroxide, washing by deionized water, flatly paving the single layer of washed gel microspheres in a drying furnace, and leading water vapor to heat and dry, so as to obtain the dried gel microsphere; placing the gel microsphere into a sintering furnace, and heating and sintering in an air atmosphere, so as to obtain the mixed oxide ceramic microsphere. The preparation method has the advantage that the fuel with uniform distribution of elements canbe prepared.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

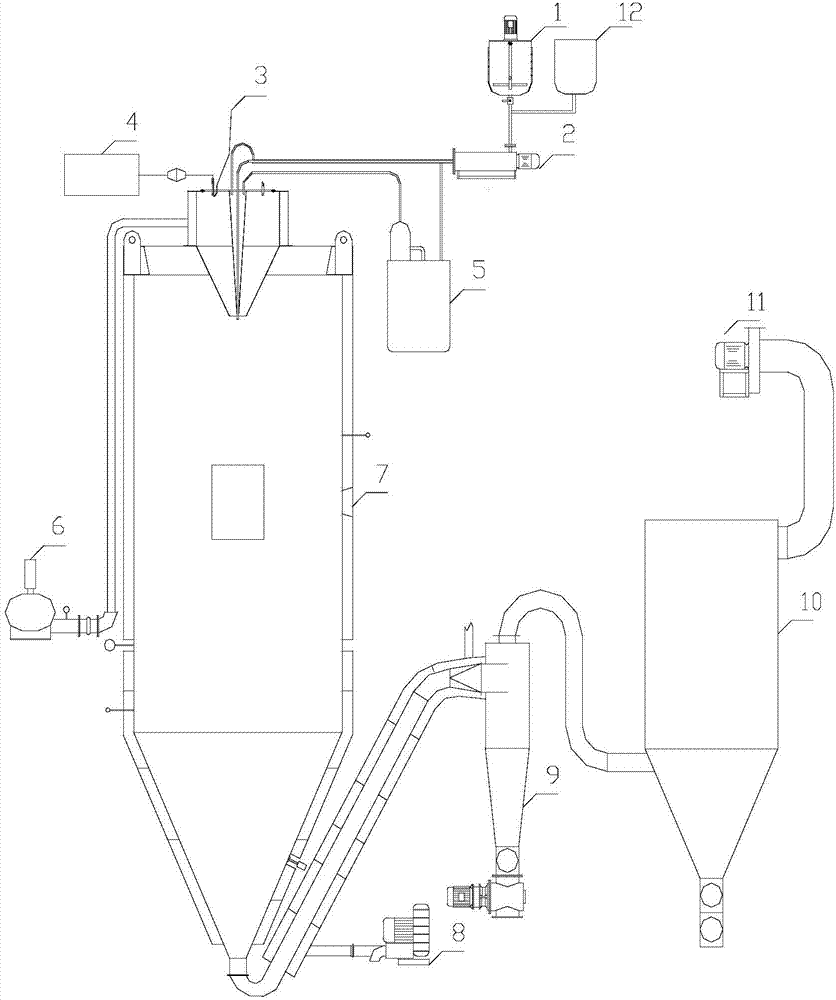

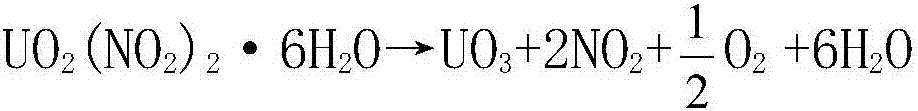

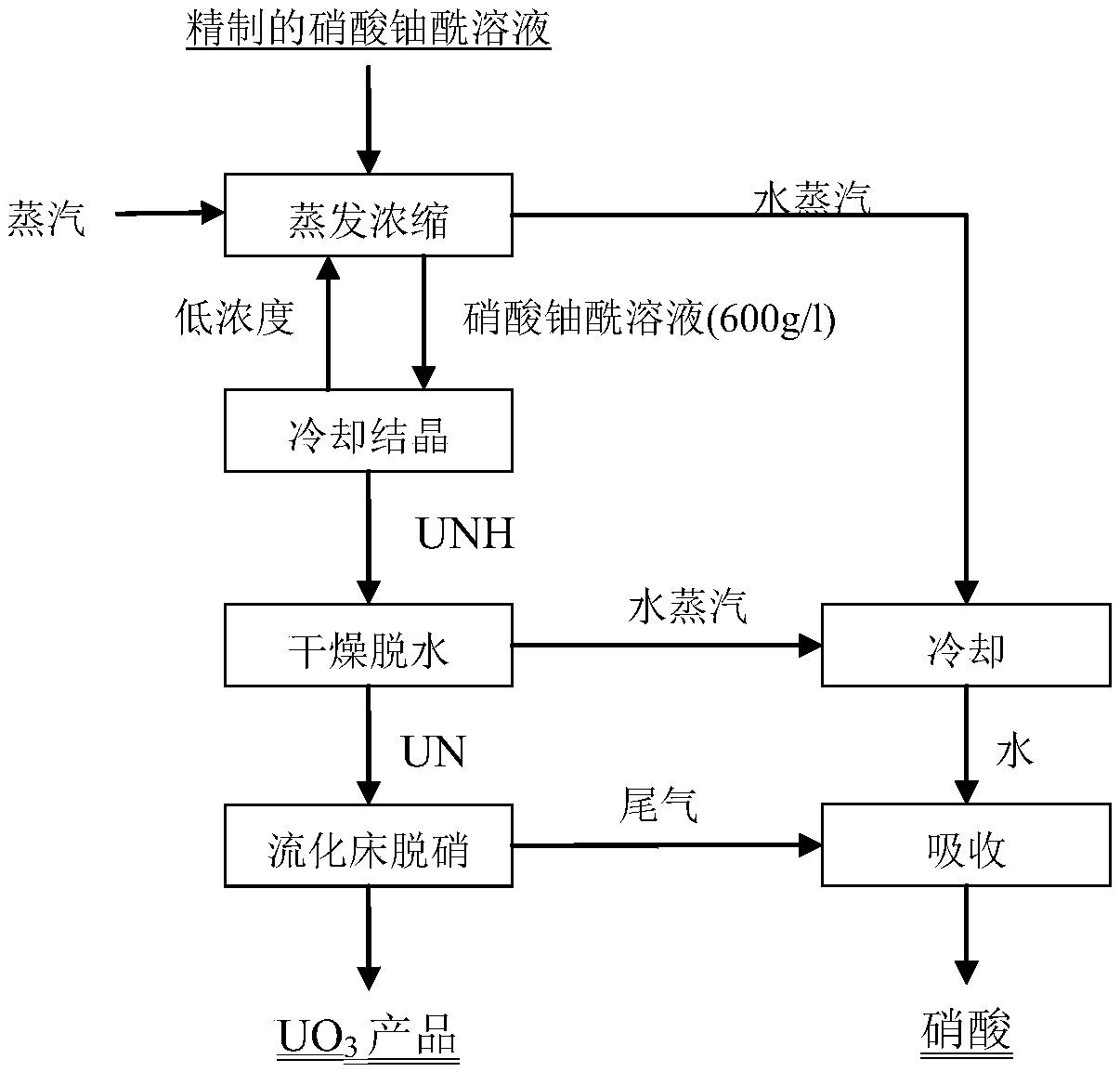

Process for preparing UO3 through uranyl nitrate air-blast atomization dry pyrolysis denitration

InactiveCN107162060AImprove conversion rateShort processUranium oxides/hydroxidesChemical reactionCombustion chamber

The invention discloses a process for preparing UO3 through uranyl nitrate air-blast atomization dry pyrolysis denitration. According to the process, a designed and processed combustion chamber and a denitration reactor are adopted as main body equipment of uranyl nitrate pyrolysis denitration, a high-temperature high-speed gas generated from combustion of propane and excessive air is adopted as a heat source and an atomization gas source, and a uranyl nitrate liquid is subjected to drying dehydration and pyrolysis denitration. The process has the advantages of being short in process procedure, simple in equipment structure, stable in operation and high in UNH (Uranyl-Nitrate Hexahydrate) conversion rate, the prepared UO3 is uniform in granularity distribution and good in chemical reaction activity, and the like.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

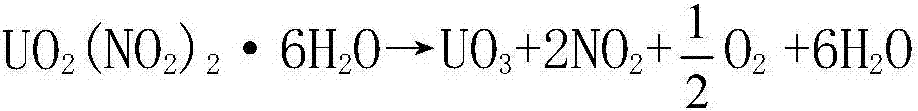

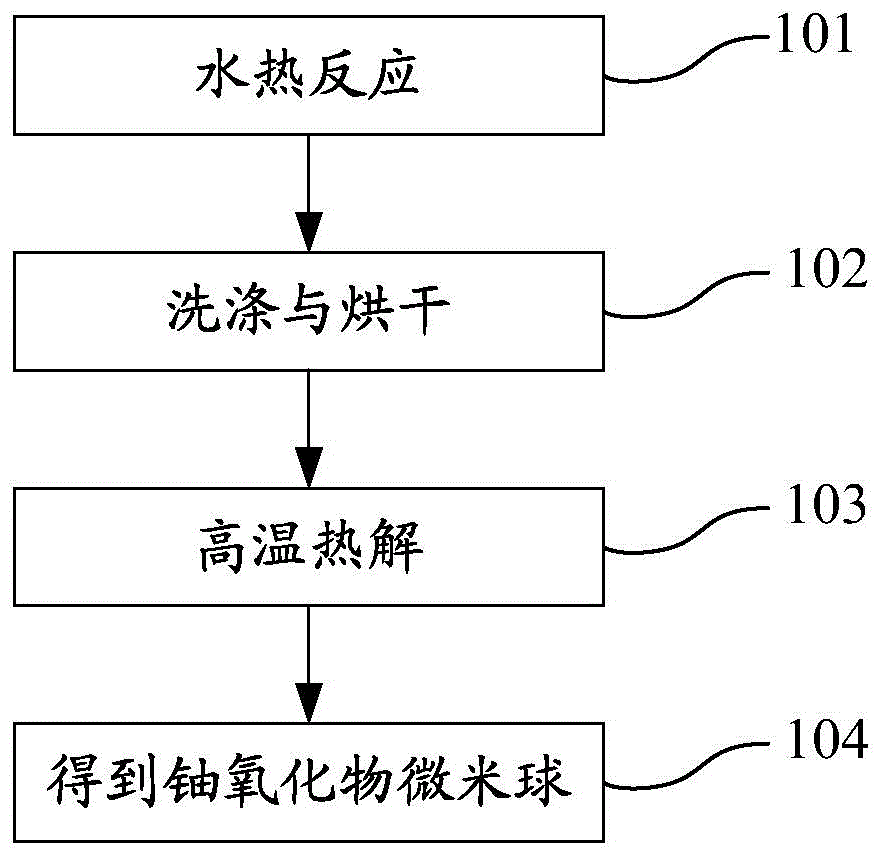

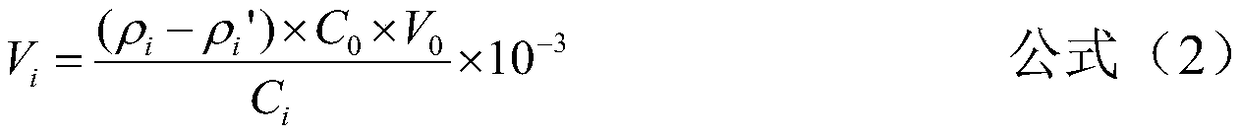

Preparation method of monodisperse micron-sized uranium oxide particle

ActiveCN101891253AShould be operatedEnsure safetyUranium oxides/hydroxidesUranium oxideThermal decomposition method

The invention discloses a method for preparing a monodisperse micron-sized uranium oxide particle by using a sol-spray thermal decomposition method. The method comprises the following steps of: forming a monodisperse aerosol by a uranyl nitrate solution by using a vibrating orifice aerosol generator; drying and carrying out static removal to form a uranyl nitrate solid particle; carrying out high-temperature thermal decomposition to form a monodisperse uranium oxide particle; and collecting after cooling, wherein carrier gas is preheated at the back end of a neutralizer to a temperature of 70-80 DEG C or so, the flow of the carrier gas is 35-45 L / min, and the high-temperature thermal decomposition is carried out by the direct heating of a muffle furnace. The technical scheme of the invention is simpler and more convenient and ensures the safety in the operation process.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

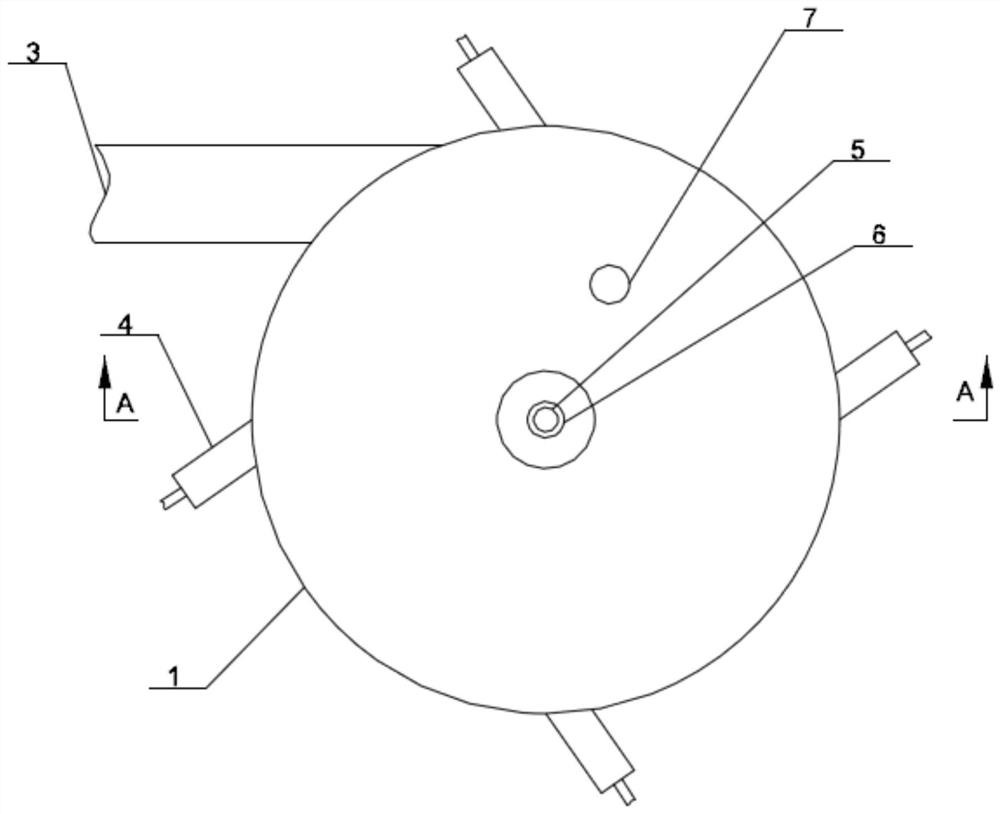

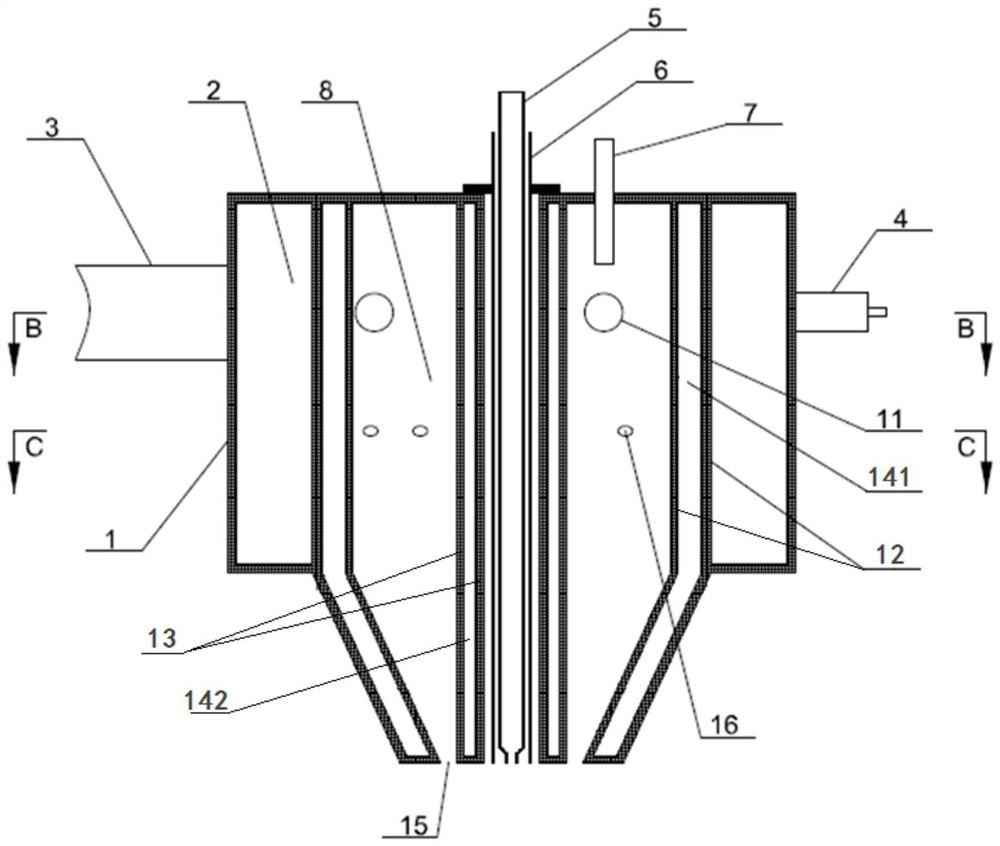

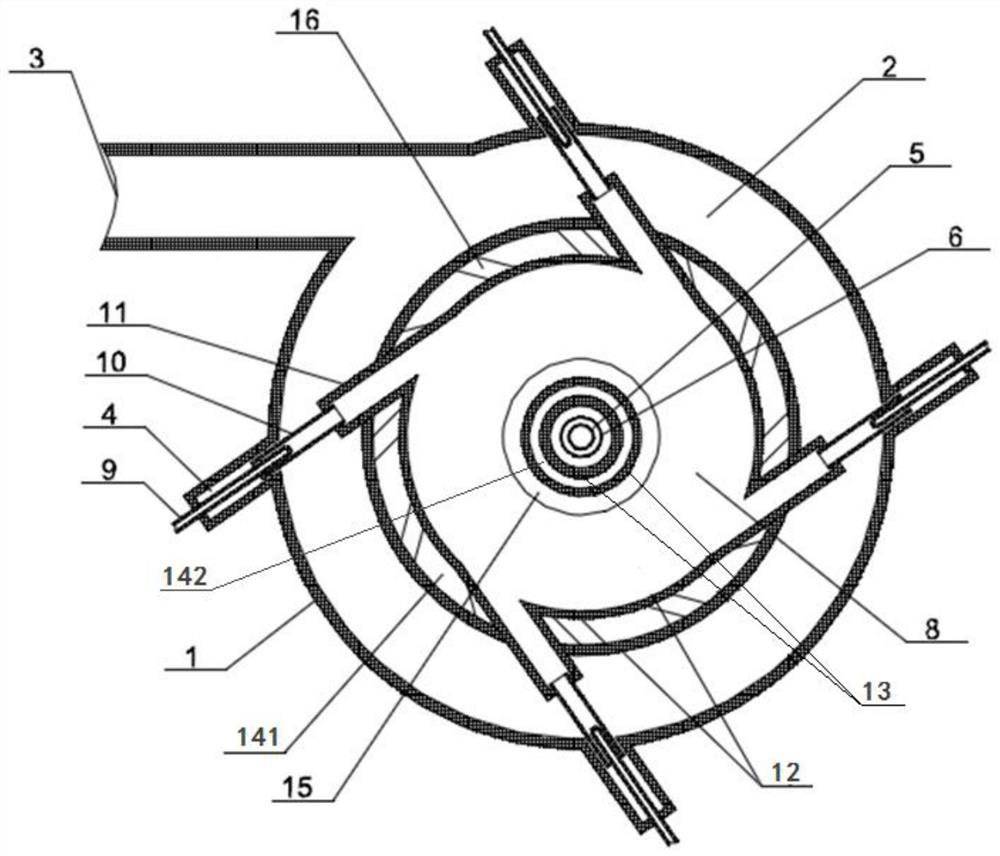

Dissolving device

InactiveCN102513001ASimple structureEasy to operateRotary stirring mixersMixer accessoriesHigh volume manufacturingEngineering

The invention relates to the technical field of a device for dissolving reactants, in particular to a dissolving device, which comprises a sealing reaction tank, a stirring device and a feeder, wherein the stirring device is inserted into the reaction tank, the feeder is connected with the reaction tank, the reaction tank is used for storing the reactants and providing reaction places, a heating sleeve used for providing temperature conditions required by reaction is arranged on the outer wall of the reaction tank, the bottom of the reaction tank is provided with a discharging tube for discharging, the stirring device is used for accelerating the dissolving speed of the reactants in the reaction tank, and the feeder is used for feeding the reactants. The dissolving device provided by the invention has the advantages that the structure is simple, the operation is convenient, the operation is stable, the yield is high, the mass production requirements can be met, U3O8 powder can be effectively, fast and fully dissolved, in addition, the acid-free dissolving can be reached, and the acid-free uranyl nitrate solution is obtained.

Owner:TSINGHUA UNIV

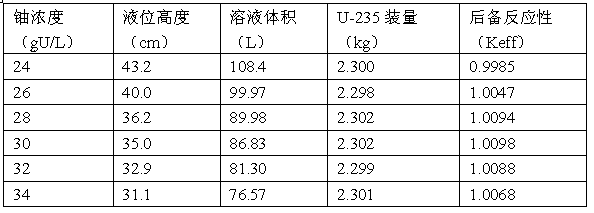

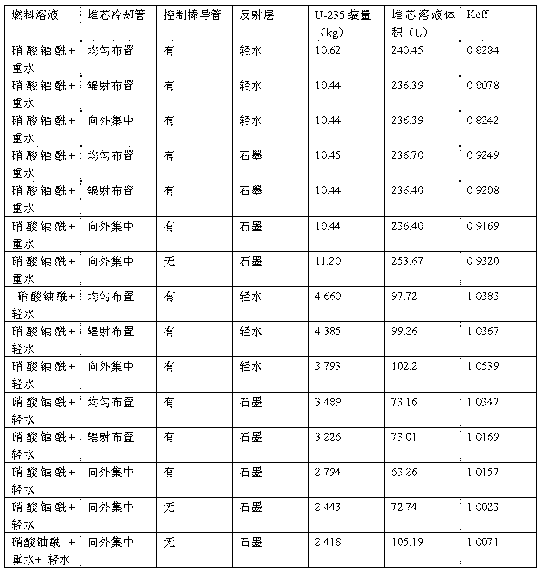

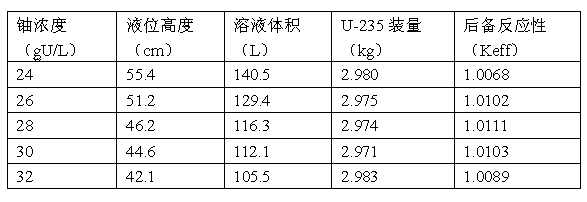

Medical isotope production reactor capable of reducing reactor core uranium inventory

ActiveCN102831946ASlow down abilityIncrease in sizeConversion in nuclear reactorIsotopeProcess engineering

The invention discloses a medical isotope production reactor capable of reducing reactor core uranium inventory. A fuel solution of the medical isotope production reactor is a water solution formed by mixing 24 to 34gU / L of uranium nitrate in concentration with 50 to 70% of heavy water and 30 to 50% of light water in volume. A reactor core reflecting layer is made of graphite. A reactor core is not provided with a control rod guide tube. A reactor core cooling tube in a reactor container is centralized outwards and annularly arranged between 0cm and 15cm of the inner wall of the reactor container approximately. The medical isotope production reactor reduces the uranium inventory and solves the problem of negative reactivity caused by water-adding dilution or evaporation-caused dehydration concentration of the reactor core.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

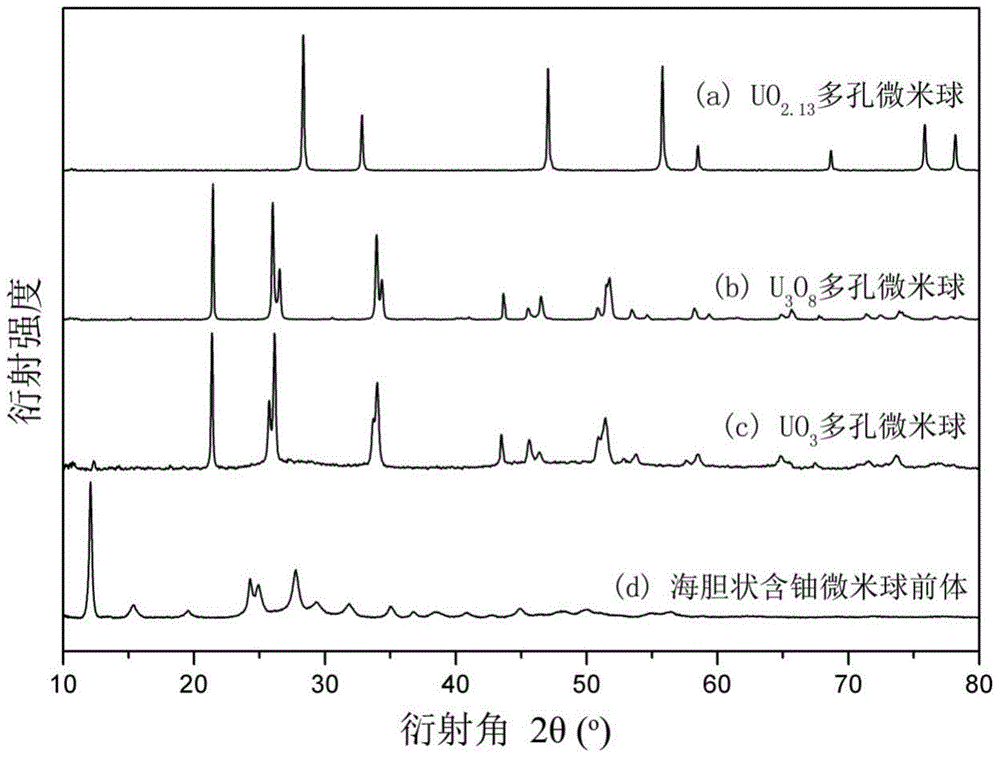

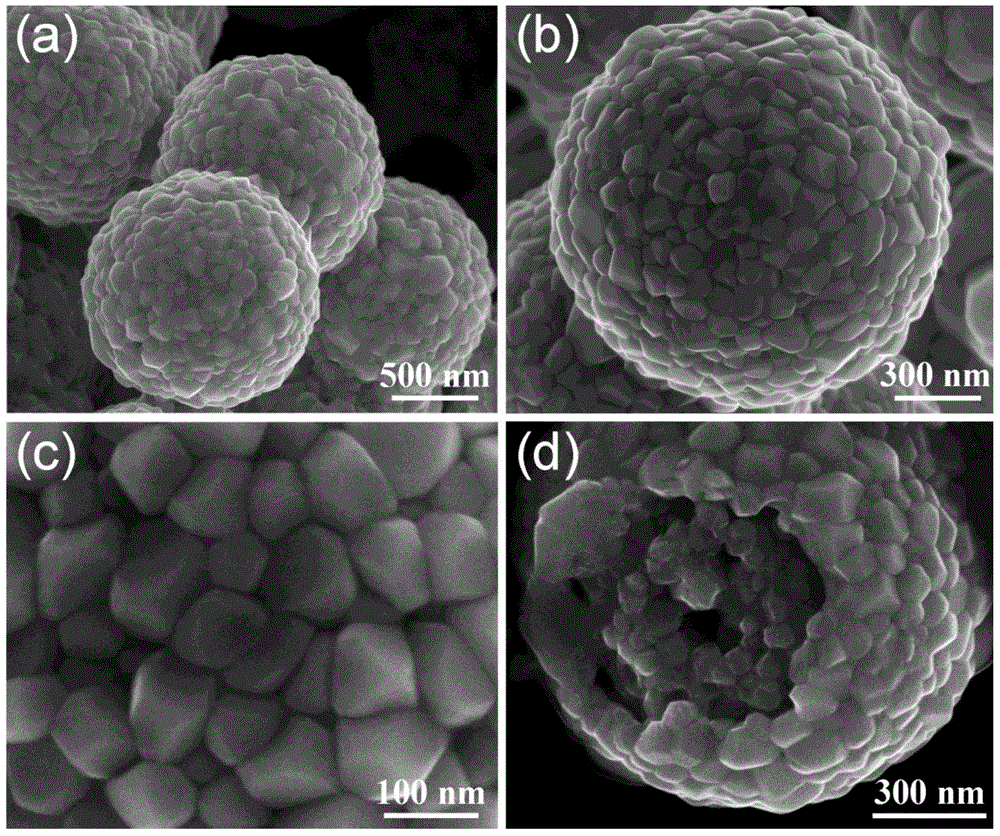

Uranium oxide micro-sphere and preparation method thereof

ActiveCN103936076AHigh capacity for storing fission gasStrong radiation resistanceUranium oxides/hydroxidesUranium oxideNanoparticle

The invention discloses an uranium oxide micro-sphere and a preparation method, a porous structure is provided in the uranium oxide micro-sphere, and the porous structure is composed of nano particles. The invention also comprises a preparation method of the uranium oxide micro-sphere, which comprises the following steps: 1)performing a hydro-thermal reaction on a mixing aqueous solution to obtain a sea urchin-state uranium-containing micro-sphere precursor, wherein the mixing aqueous solution comprises a uranyl nitrate aqueous solution, glycerol and urea; 3)washing and drying the uranium-containing micro-sphere precursor; and 3)placing the dried uranium-containing micro-sphere precursor in a tubular furnace for pyrolysis to obtain the uranium oxide micro-sphere. The preparation method has the advantages of simple process and easy control, and the prepared uranium oxide micro-sphere has the characteristics of small size and has porous structure, and has latent application value in the relative fields of catalysis and nuclear energy.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Method of preparing high-activity uranium trioxide by thermal denitration of uranyl nitrate

The invention belongs to the technical field of preparation of uranium trioxide, and particularly relates to a method of preparing high-activity uranium trioxide by thermal denitration of uranyl nitrate. The method comprises the following steps: step (1) evaporating and concentrating an uranyl nitrate solution to obtain a concentrated uranyl nitrate solution; step (2) conveying the concentrated uranyl nitrate solution to a cooling crystallizer, cooling the concentrated uranyl nitrate solution to a temperature below 40 DEG C, carrying out cooling crystallization to form UO2(NO3)2.6H2O crystals,and returning a saturated solution to an evaporation and concentration device in step (1); step (3) dehydrating the UO2(NO3)2.6H2O crystals obtained in step (2) by microwave drying, and converting the UO2(NO3)2.6H2O crystals obtained in step (3) into UO2(NO3)2 powder; and step (4) generating the UO3 product in a fixed bed by using the UO2(NO3)2 powder obtained in step (3) in a vacuum environmentthrough microwave heating. The method has the advantages of short technological process, no generation of radioactive ammonia-nitrogen wastewater, good product activity and the like, increases the integral level of a uranium purification and conversion technology in the nuclear fuel cycle, and has obvious social and economic benefits.

Owner:中核二七二铀业有限责任公司

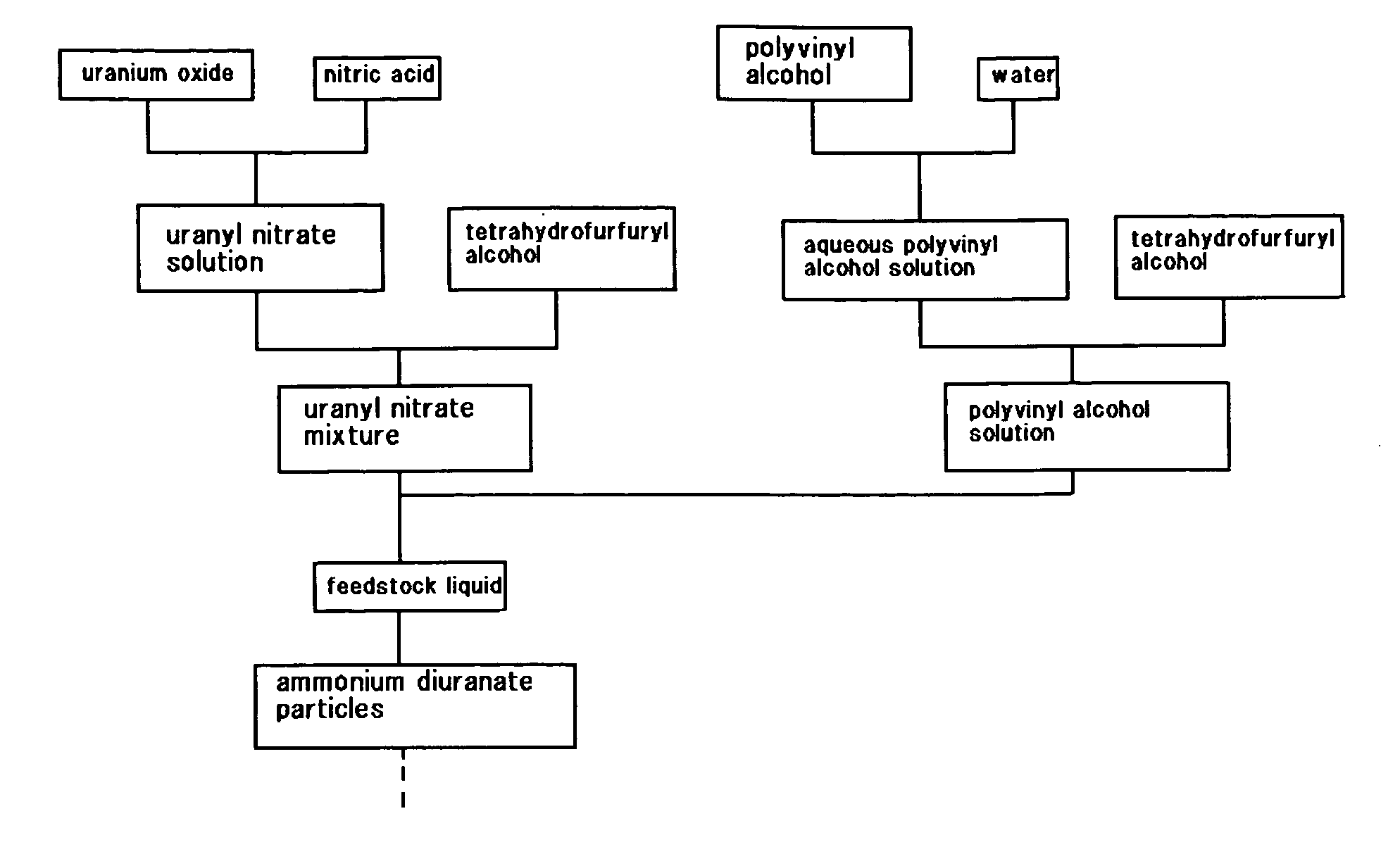

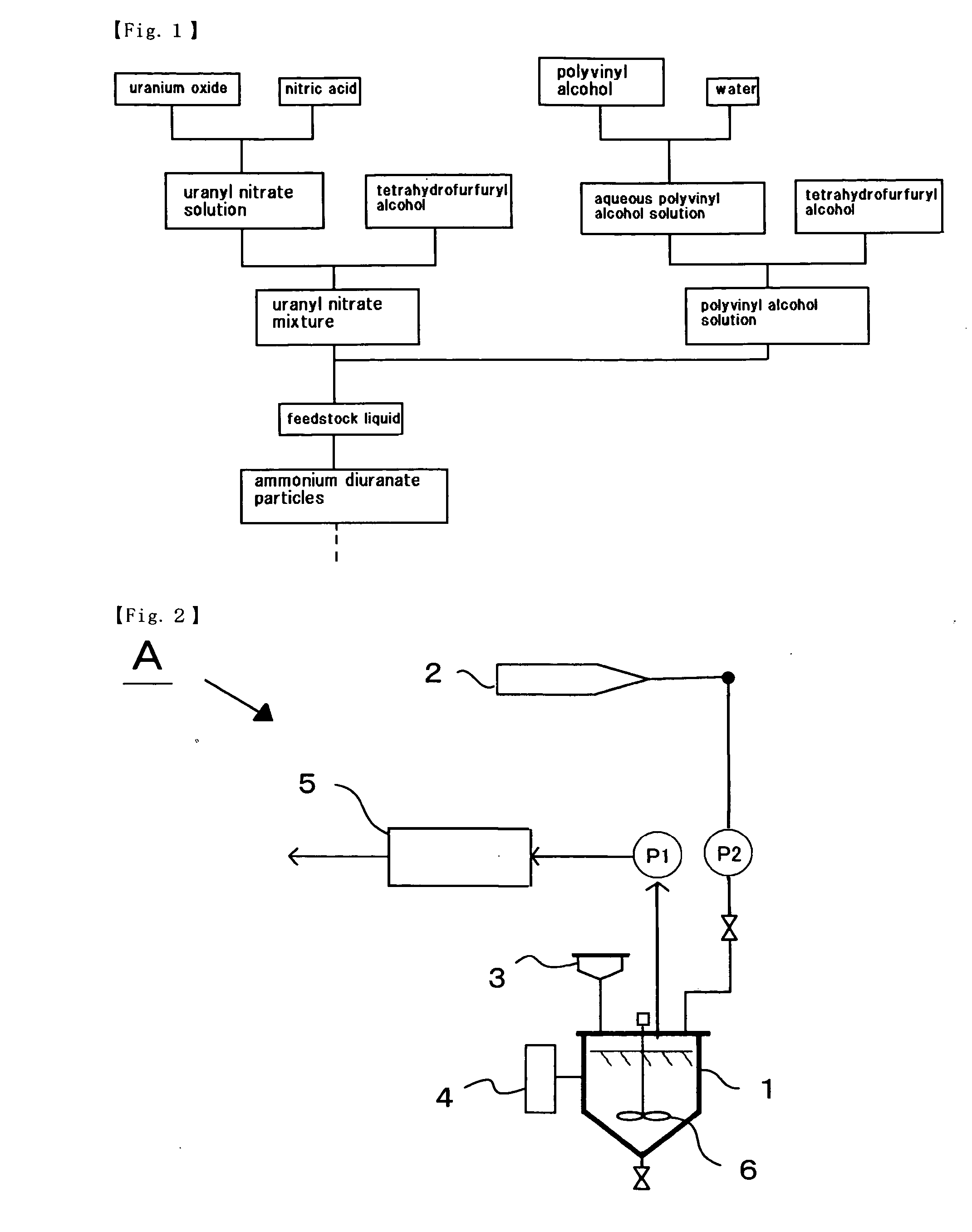

Method of preparing feedstock liquid, method of preparing uranyl nitrate solution, and method of preparing polyvinyl alcohol solution

InactiveUS20070178036A1Good spherical shapeSimple internal structureNuclear energy generationReactors manufacturePolyvinyl alcoholAmmonium diuranate

The object of the present invention is to provide a feedstock liquid, from which fuel kernels with good quality can be produced, and a method of preparing the feedstock liquid. The present invention provides a feedstock liquid with a viscosity from 4.0×10−2 to 6.5×10−2 Pa·s at 15° C., for the production of ammonium diuranate particles. The present invention also provides a method of preparing a feedstock liquid used for the production of ammonium diuranate particles, which includes mixing a uranyl nitrate solution and tetrahydrofurfuryl alcohol to produce a uranyl nitrate mixture, dissolving polyvinyl alcohol in water to produce an aqueous polyvinyl alcohol solution, mixing the aqueous polyvinyl alcohol solution with tetrahydrofurfuryl alcohol to produce a polyvinyl alcohol solution, and mixing the uranyl nitrate mixture with the polyvinyl alcohol solution.

Owner:NUCLEAR FUEL INDS

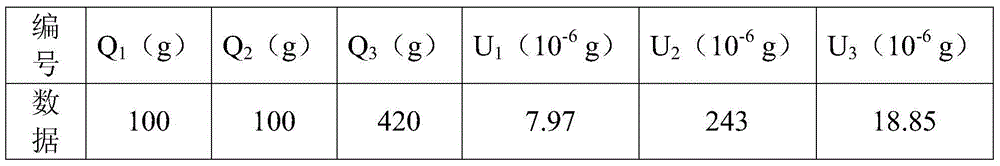

Preparation method of uranium and impurity element standard substances in triuranium octaoxide

ActiveCN109443874AEasy to manufactureSolve the quantitative additionPreparing sample for investigationAmmonium diuranateControllability

The invention relates to a preparation method of uranium and impurity element standard substances in triuranium octaoxide. The preparation method comprises the following steps: step one, sufficientlydissolving the raw material of triuranium octaoxide with MOS-level nitric acid; step two, preparing a constant-value element solution; step three, filtering a uranyl nitrate solution obtained in the step one; step four, converting the uranyl nitrate solution added with constant-value elements into a precipitation reaction tank; step five, filtering an ammonium diuranate sediment obtained in the step four; step six, carrying out drying, pyrolysis and calcinations on the ammonium diuranate sediment added with the constant-value elements in sequence to obtain the triuranium octaoxide product; andstep seven, carrying out grinding, electrostatic elimination, sieving and blending on the triuranium octaoxide product prepared and obtained in the step six by using a ball grinding mill. The preparation method solves the technical problems of quantitative addition and uniform distribution of trace constant-value elements in the triuranium octaoxide product, and is high in technological controllability.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

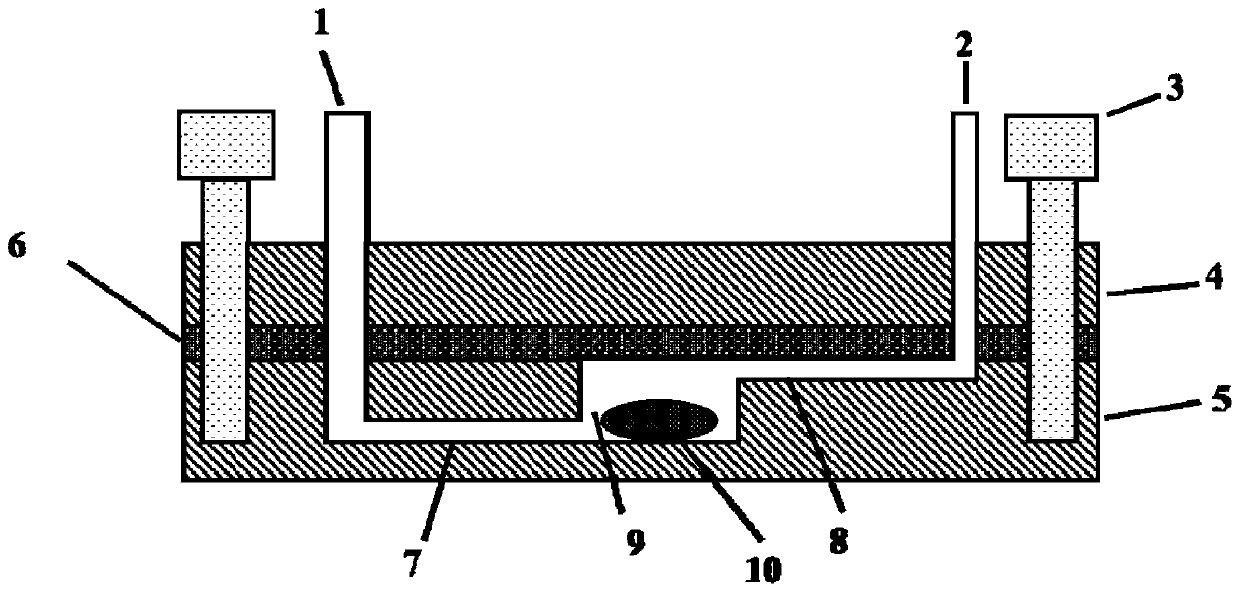

Nuclear-purity grade uranyl nitrate solution concentration device

InactiveCN107308819AEasy to operateEasy maintenanceSemi-permeable membranesSpecific water treatment objectivesProduction lineEconomic benefits

The invention belongs to the field of uranium purification, in particular relates to concentration techniques for uranyl nitrate solutions, and discloses a nuclear-purity grade uranyl nitrate solution concentration device which comprises a supply unit, a first-stage nanofiltration unit, a second-stage nanofiltration unit and a reverse osmosis unit, wherein the supply unit comprises a stoste tank, a stoste pump and a feeding tank firstly; secondly, the first-stage nanofiltration unit comprises a first-stage nanofiltration pump, a first-stage nanofiltration membrane and a first-stage nanofiltration tank; thirdly, the second-stage nanofiltration unit comprises a second-stage nanofiltration pump, a second-stage nanofiltration membrane and a second-stage nanofiltration tank; fourthly, the reverse osmosis unit comprises a pressurizing pump, a high-pressure pump, a reverse osmosis membrane and a reverse osmosis tank. In a uranium purification production line, the device with the combination of the nanofiltration membrane and the high-pressure reverse osmosis membrane for concentrating the uranyl nitrate solution is practical and feasible. Compared with conventional evaporation concentration, the device is relatively simple to operate and maintain and relatively low in energy consumption in the concentration process. Therefore, the device has certain economic benefits in relieving working intensity, improving working efficiency and the like.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

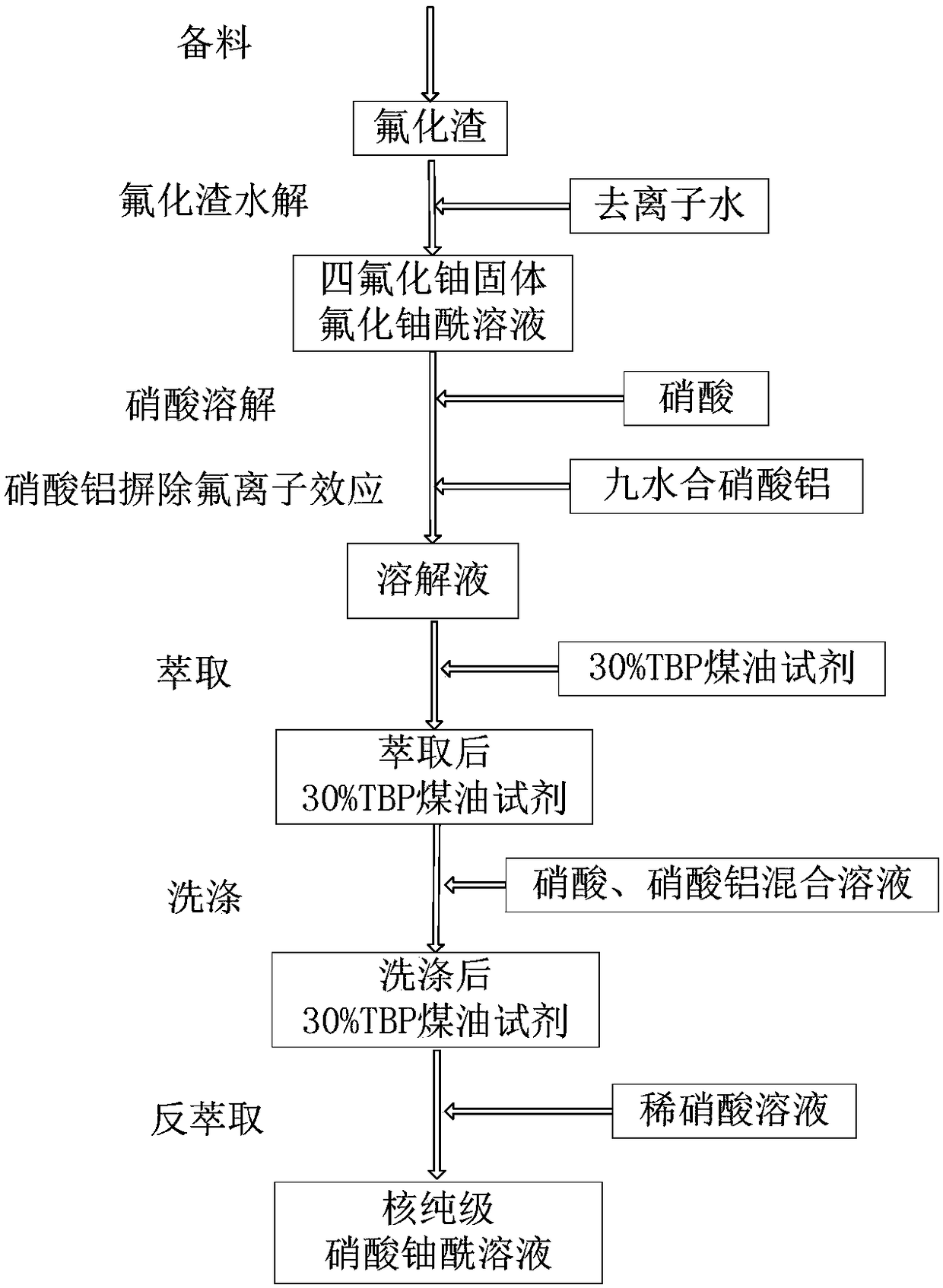

Extraction purification method for recycling uranium from fluoridation ash residues

InactiveCN108165747ASimple structureEasy to operateProcess efficiency improvementMetal impuritiesDissolution

The invention relates to the technical field of uranium conversion and particularly discloses an extraction purification method for recycling uranium from fluoridation ash residues. The extraction purification method comprises the following steps of 1, preparing materials; 2, conducting hydrolysis on the fluoridation residues; 3, conducting dissolution through nitric acid, and eliminating the fluorinion effect through aluminum nitrate; and 4, conducting extraction, washing and reextraction, so that a nuclear-purity-grade uranyl nitrate solution is obtained. According to the extraction purification method, special properties of a fluorination residue material are combined, and a process route which can be used for recycling the uranium from the fluoridation residues is developed; the process route is novel in concept, simple in procedure and feasible; by means of the method, metal impurity elements in the fluoridation residues can be effectively removed, and the nuclear-purity-grade uranyl nitrate solution is obtained; and the nuclear-purity-grade uranyl nitrate solution can be directly used as a uranium purification conversion process raw material.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Method for preparing a mixed fuel comprising uranium and at least one actinide and/or lanthanide applying a cation exchange resin

The invention relates to a method for preparing a fuel based on oxide, carbide, and / or oxycarbide comprising uranium and at least one actinide and / or lanthanide component, comprising the following steps:a step for preparing a load solution consisting in a nitric solution comprising said actinide and / or lanthanide in the form of actinide and / or lanthanide nitrates and uranium as a hydroxylated uranyl nitrate complex;a step for passing said solution over a cation exchange resin comprising carboxylic groups, with which the actinide and / or the lanthanide in cationic form and the uranium as uranyl remain bound to the resin;a heat treatment step of said resin so as to obtain said fuel.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Device for recovering feedstock liquid, device for supplying a feedstock liquid, device for solidifying the surfaces of drops, and apparatus for producing ammonium diuranate particles

InactiveUS7811526B2Particle diameters of the drops can be controlled easilyEliminate resonanceShaking/oscillating/vibrating mixersGranulation by liquid drop formationAmmonium hydroxideAmmonium diuranate

This invention provides a dripping nozzle device to produce ADU particles with good sphericity, a device for recovering a feedstock liquid to prepare a uniform feedstock liquid, a device for supplying a feedstock liquid to form drops with a uniform volume, a device for solidifying the surfaces of drops so that the drops will not deform easily when they fall onto and hit the surface of an aqueous ammonia solution, a device for circulating an aqueous ammonia solution so that the uranyl nitrate in the drops can be changed to ammonium diuranate completely, to such an extent that uranyl nitrate in the center of each drop is changed to ammonium diuranate, and an apparatus for producing ammonium diuranate particles with good sphericity. The dripping nozzle device is provided with a single vibrator to vibrate nozzles simultaneously. The device for recovering a feedstock liquid recovers the feedstock liquid remaining in the nozzles and mixes it with a fresh feedstock liquid. The device for supplying a feedstock liquid is provided with a light irradiator for irradiating falling drops with light. The device for solidifying the surfaces of drops sprays ammonia gas over each of the paths along which the drops dripping from the nozzles fall. The device for circulating an aqueous ammonia solution enables drops to flow upward in the aqueous ammonia solution in the aqueous ammonia solution reservoir. The apparatus for producing ammonium diuranate utilizes these devices.

Owner:NUCLEAR FUEL INDS

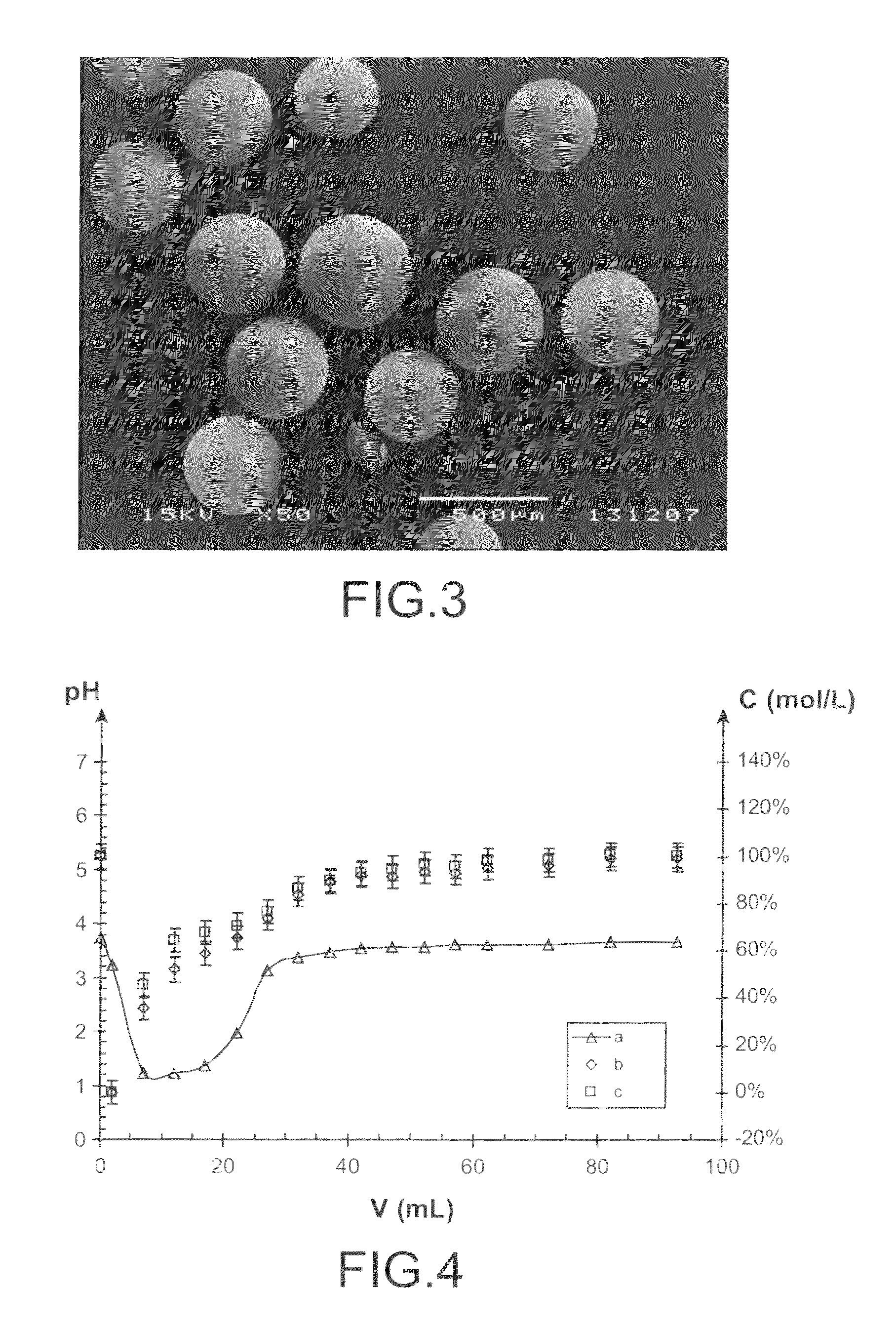

Method for preparing uranium dioxide microspheres at normal temperature

ActiveCN111039326AOvercomes the disadvantage of needing to freezeLow thermal conductivityUranium dioxideUranium oxideHexamethylenetetramine

The invention relates to a method for preparing uranium dioxide microspheres at normal temperature, and belongs to the technical field of ceramic forming. According to the method, components in an internal gel solution are divided into a uranyl nitrate solution (ADUN) stable at normal temperature and a mixed solution (HMUR) of urea and hexamethylenetetramine; the two solutions are rapidly mixed inan automatic mixing device to form an unstable uranium glue solution; the mixed uranium glue solution rapidly enters silicone oil, and is shear into liquid drops with uniform sizes by the silicone oil; the liquid drops and the silicone oil are cured into gel microspheres by a microwave heating device; and the gel microspheres are washed, dried and sintered to obtain monodisperse UO2 sintered microspheres with uniform sizes and good sphericity. According to the invention, microfluidic control is adopted in the whole process of the method, so that the UO2 microspheres are prepared at normal temperature through an internal gel method without human interference, and the automation degree is high.

Owner:TSINGHUA UNIV

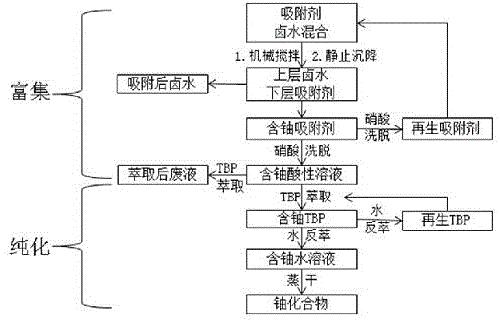

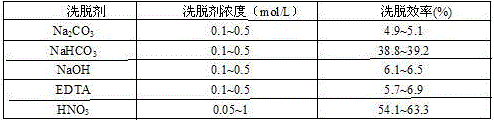

Extraction method of uranium in salt lake brine

The invention relates to an extraction method of uranium in salt lake brine. The extraction method comprises the following steps that (1) a self-made silicon dioxide adsorbent is added to the salt lake brine, and a filter cake is obtained after solid-liquid separation is carried out; (2) the filter cake is eluted by 0.1-1mol / L nitric acid acting as an eluting agent; (3) eluting liquid is condensed, and extraction is carried out with an extraction agent under the circumstance that the concentration of nitric acid is adjusted to be 4-6mol / L; and (4) extraction liquid is subjected to reverse extraction with water, drying by distillation is carried out, and uranyl nitrate is obtained. The extraction method is applicable to the acquisition of uranium from intercrystalline brine, salt lake brine and old brine.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Concentration method for nuclear-pure uranyl nitrate solution

InactiveCN107349788AReduce energy consumptionSimple normal temperature operationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisChemical reactionReverse osmosis

The invention belongs to the field of uranium purification, and concretely relates to a concentration method for a uranyl nitrate solution. The method comprises the following steps: 1, determining a system used by the method; 2, carrying out water test; 3, verifying the performances of membranes; 4, carrying out nanofiltration membrane concentration; and 5, carrying out reverse osmosis membrane concentration. The method has the advantages of simplicity in membrane separation concentration technology and device, normal temperature operation, no chemical reaction, low energy consumption, cleanness and no pollution.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

A kind of uranium purification method of ammonium diuranate

The invention belongs to the technical field of dissolving and purifying ammonium diuranate in the process of purifying and converting uranium, and specifically includes technologies such as dissolving ammonium diuranate, extracting and purifying uranyl nitrate solution, and the like. It includes the following steps: (1) dissolving, preparing a qualified uranyl nitrate solution for extraction and purification; (2) extracting, mixing and mass-transferring the extraction stock solution and the extraction agent in the pulse extraction column, and carrying the uranium in the material into the extraction (3) washing, the organic phase containing uranium and the detergent are fully mixed and mass-transferred in the pulse washing column, and the impurity elements in the organic phase containing uranium are re-washed into the water phase to further improve the Purified uranium-containing organic phase is obtained; (4) back extraction, the purified uranium-containing organic phase and detergent are fully mixed and mass-transferred in the pulse washing column, and the uranium is back-extracted into the water phase again, The purified uranyl nitrate solution is obtained; the purified uranyl nitrate solution is then concentrated and denitrated to prepare uranium oxide.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

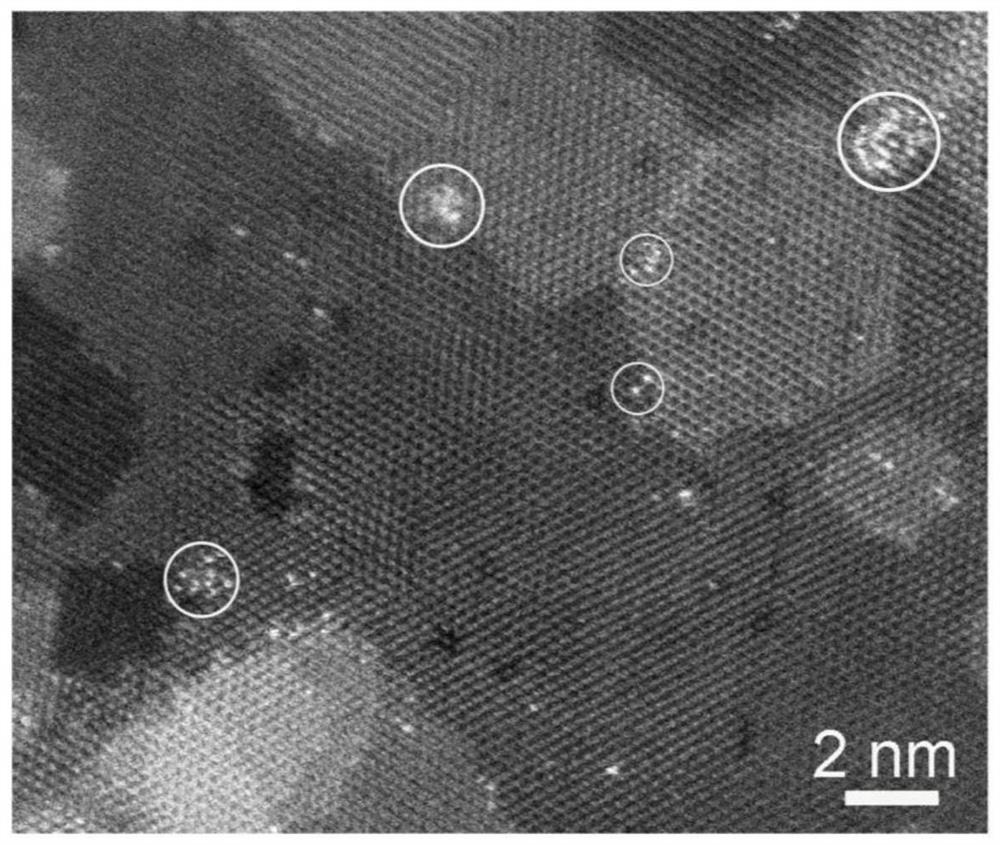

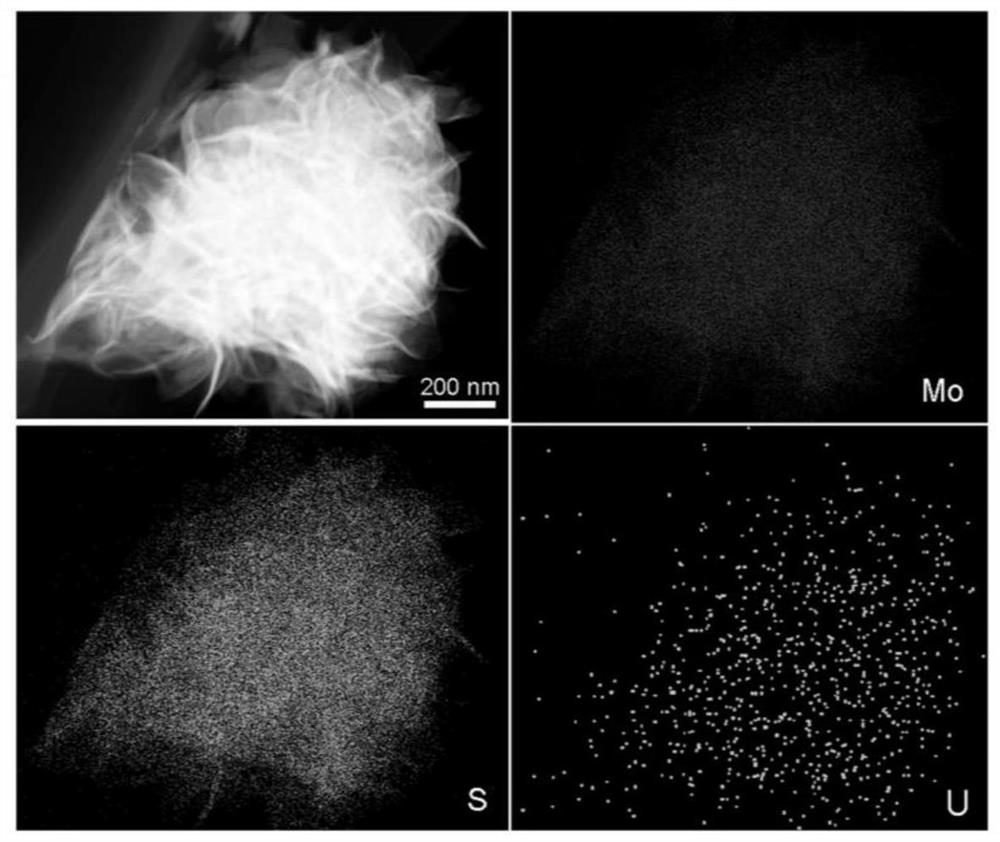

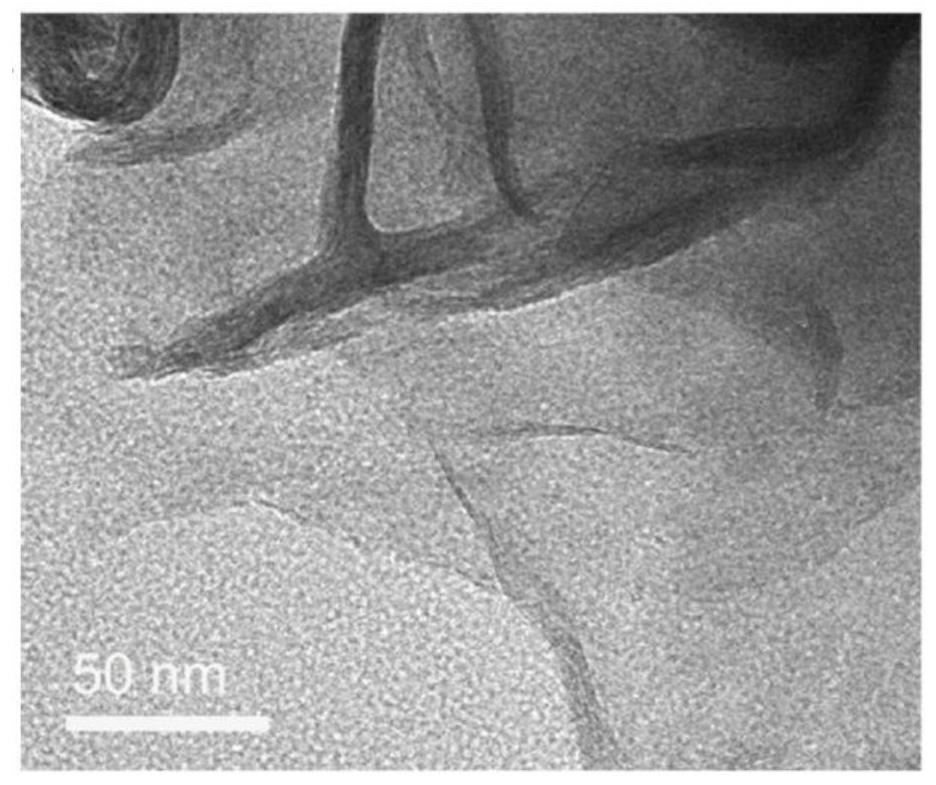

Application of sulfur boundary defect molybdenum disulfide in electrochemical seawater uranium extraction

ActiveCN114395764AImprove the extraction effectEasy extractionProcess efficiency improvementElectrodesCarbon graphiteUranyl nitrate

The invention discloses an application of sulfur boundary defect molybdenum disulfide in electrochemical seawater uranium extraction, which comprises the following steps: adding sulfur boundary defect molybdenum disulfide, activated carbon and a Nafion solution into ethanol, and carrying out ultrasonic treatment to obtain uniform ink; carbon graphite felt is uniformly coated with the ink, and the ink is used as a working electrode in a dual-electrode system after being dried; a counter electrode in the dual-electrode system is a graphite rod; the method comprises the following steps: filtering seawater through a 0.2 [mu] m filter to remove particles and microorganisms, then adding uranyl nitrate into the seawater to obtain simulated uranium seawater, adding the simulated uranium seawater into an electrolytic tank, placing a dual-electrode system into the simulated uranium seawater of the electrolytic tank, stirring the simulated seawater for electrolysis to extract uranium from the seawater, setting the voltage of the electrolytic tank to be-3 to-3.5 V, and electrolyzing for 1-10 hours. The molybdenum disulfide nanosheet with the sulfur boundary defect is prepared and is applied to uranium extraction of uranium seawater by simulating uranium; the sulfur boundary defect molybdenum disulfide nanosheet shows considerable extraction capacity, which indicates that the molybdenum disulfide nanosheet can realize high uranium extraction amount in the ocean.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Flame denitration combustor device and flame denitration system

PendingCN113339793AGuaranteed atomization effectStable combustionDispersed particle separationGaseous fuel burnerCombustorUranyl

The invention discloses a flame denitration combustor device. The device comprises a flame cavity, a combustion head and a material nozzle, wherein the combustion head communicates with the flame cavity and used for introducing mixed gas of fuel gas and air into the flame cavity, the mixed gas is ignited and combusted in the flame cavity and generates high-temperature gas, the flame cavity is provided with a combustion gas outlet, the combustion gas outlet is formed in the end, away from the combustion head, of the flame cavity, a penetrating inner hole is formed in the center of the flame cavity, the material nozzle is arranged in the penetrating inner hole of the flame cavity, penetrates through the flame cavity and is used for circulating uranyl nitrate, and a position of an outlet of the material nozzle and a position of the combustion gas outlet are at the same end of the flame cavity, so that the uranyl nitrate sprayed by the material nozzle can make contact with the high-temperature gas discharged from the combustion gas outlet to perform a denitration reaction. The invention further discloses a flame denitration system comprising the flame denitration combustor device. According to the device, stable operation of the uranyl nitrate denitration reaction can be ensured.

Owner:CHINA NUCLEAR POWER ENG CO LTD

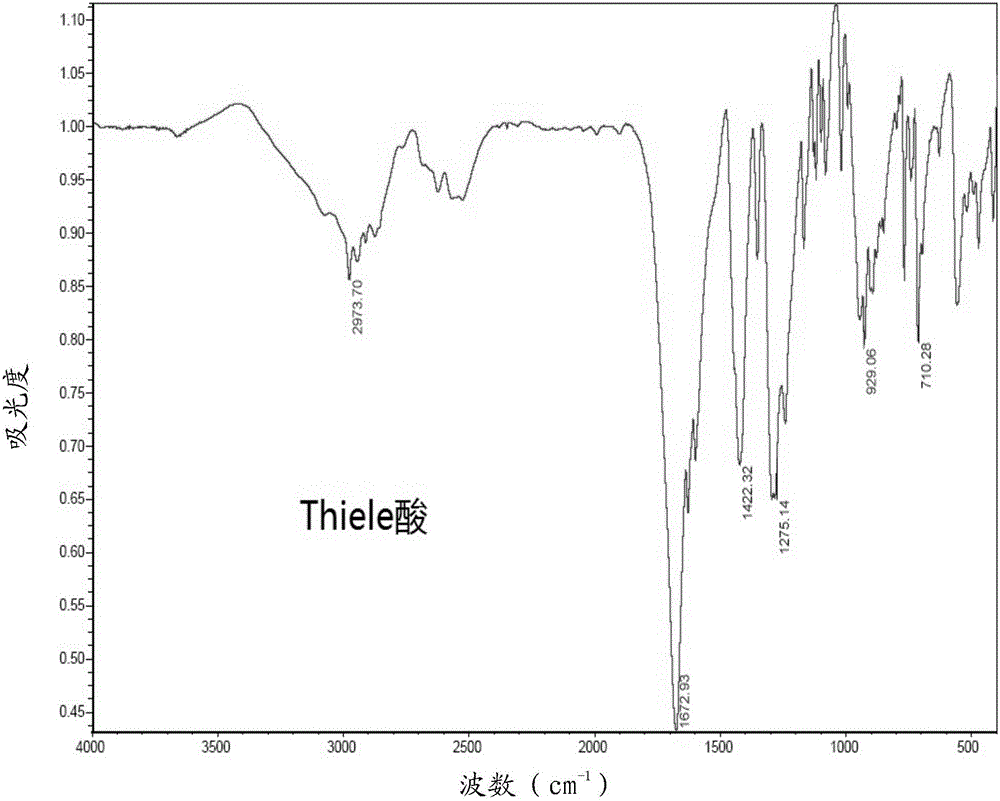

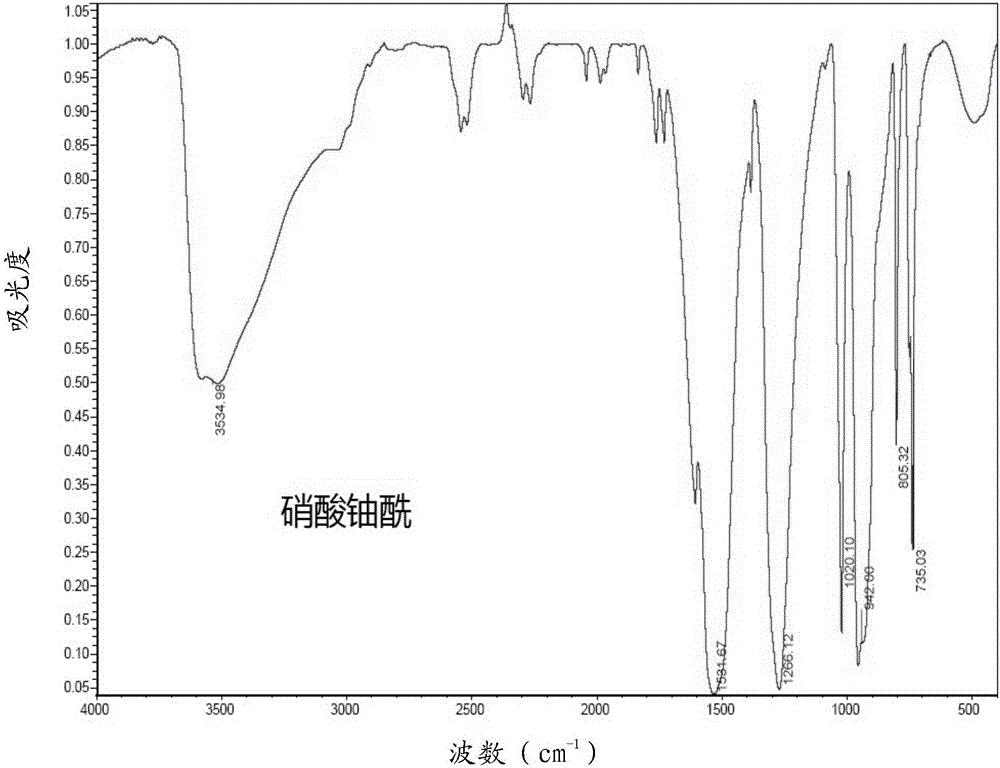

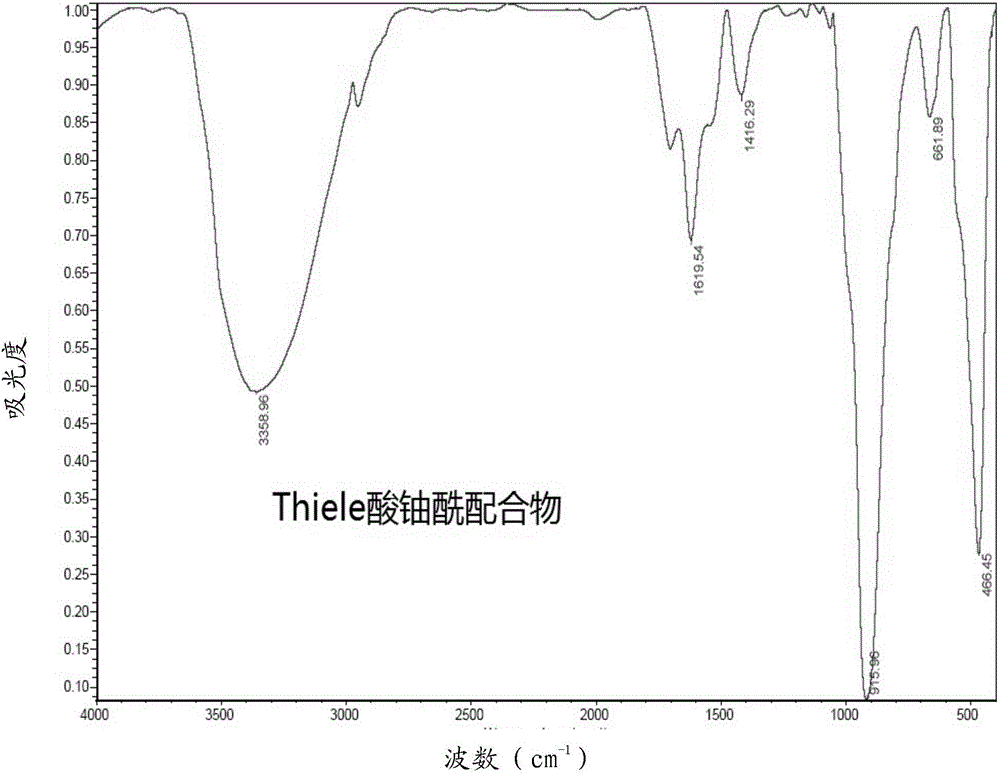

Thiele acid uranyl complex, preparation method thereof and Thiele acid application

ActiveCN105777789AImprove the coordination effectSimple manufacturing methodGroup 3/13 organic compounds without C-metal linkagesUranylCoordination complex

The invention discloses a Thiele acid uranyl complex, a preparation method thereof and Thiele acid application.The preparation method comprises the following steps that Thiele, Thiele acid and uranyl nitrate are used as raw materials, and the Thiele acid uranyl complex is synthesized through a hydrothermal method.The invention further provides a uranyl complex.The uranyl complex is prepared according to the preparation method.The Thiele acid uranyl complex is successfully synthesized through the hydrothermal method.In the preparation process of the complex, the preparation method is easy, convenient and practical, and the reaction efficiency is high.The product structure is determined through infrared and mass spectrograms, which further illustrates that Thiele acid has the strong complexing ability for uranyl and has the potential of becoming a uranium extraction agent.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

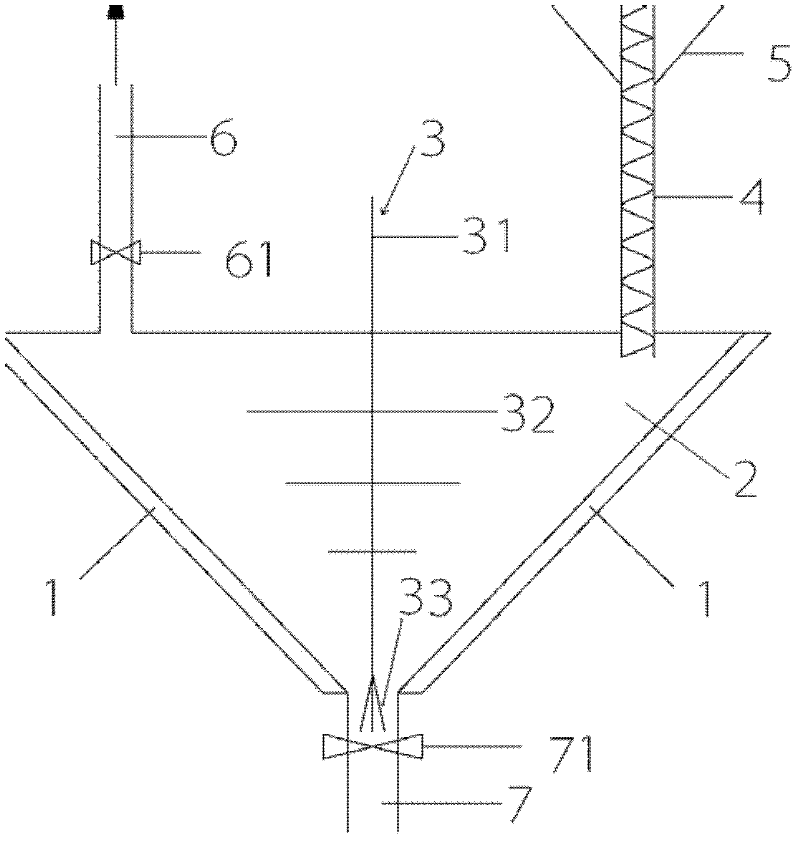

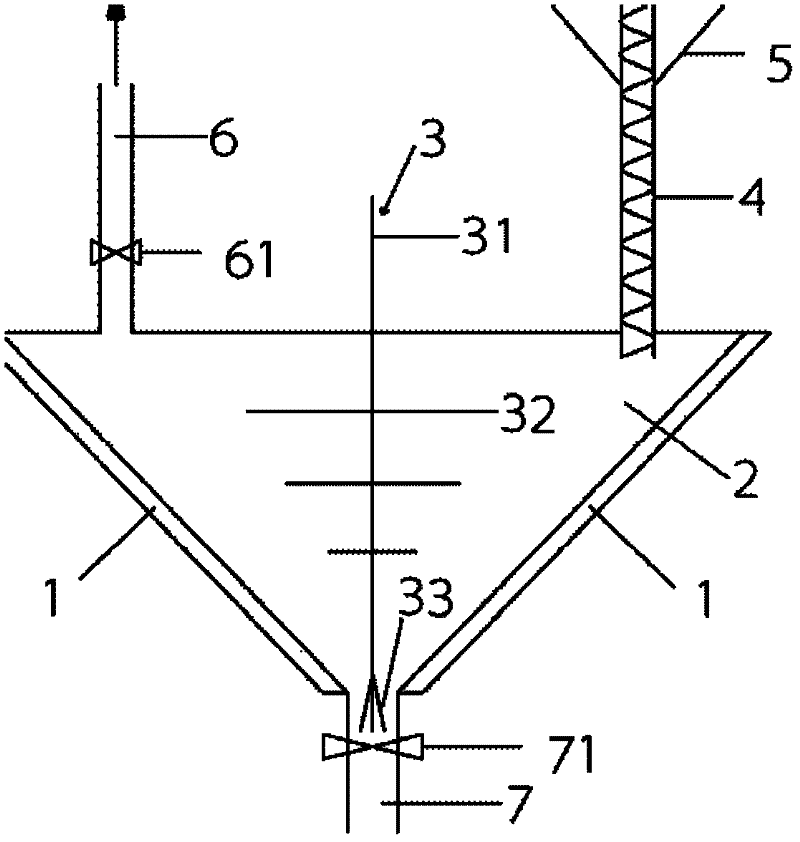

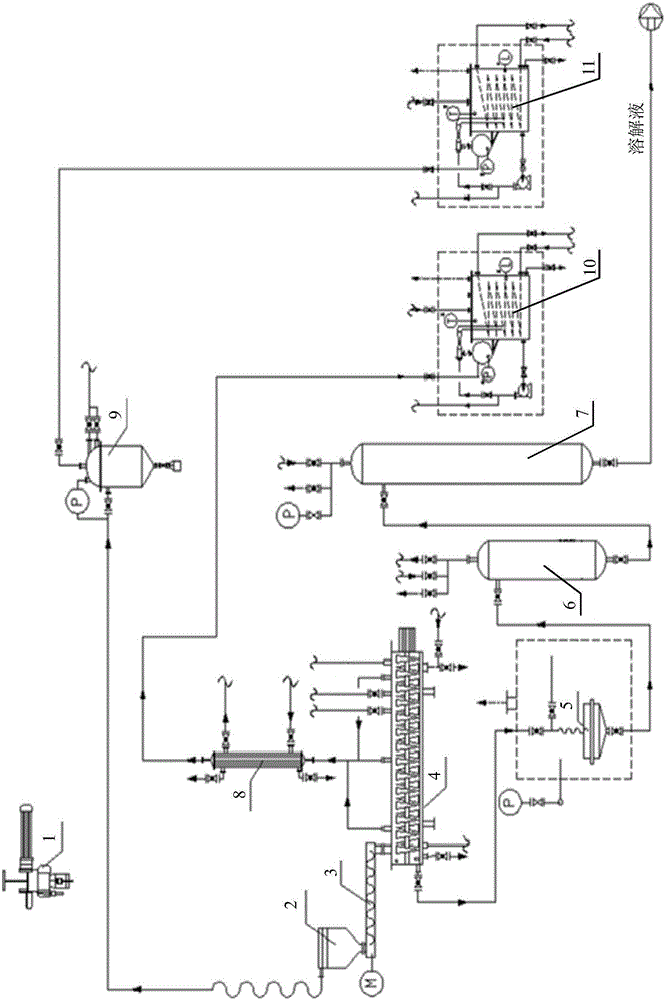

Horizontal dissolving technology and system for preparing uranyl nitrate

PendingCN106564956AImprove stabilityThe dissolution reaction is completeUranium compoundsTask completionWork task

The invention relates to a horizontal dissolving technology and system for preparing uranyl nitrate. The technology comprises the following steps: adding deionized water and nitric acid to a dissolving tank in a metering manner, horizontally forward pushing a uranium-containing material through a spiral feeder to continuously add the uranium-containing material to the dissolving tank, carrying out a dissolving reaction on the uranium-containing material in the dissolving tank, filtering the obtained dissolved solution after the uranium-containing material is completely dissolved, and sending the filtered solution to a solution storage tank for later use. The technology has the advantages of complete dissolving reaction, uniform concentration of the dissolved solution, no feeding obstruction phenomenon, design purpose reaching, working task completion, effective improvement of the stability of the dissolving reaction, smoothness in production operation, and improvement of the production efficiency and the economy safety of the process.

Owner:CHINA NUCLEAR POWER ENG CO LTD +1

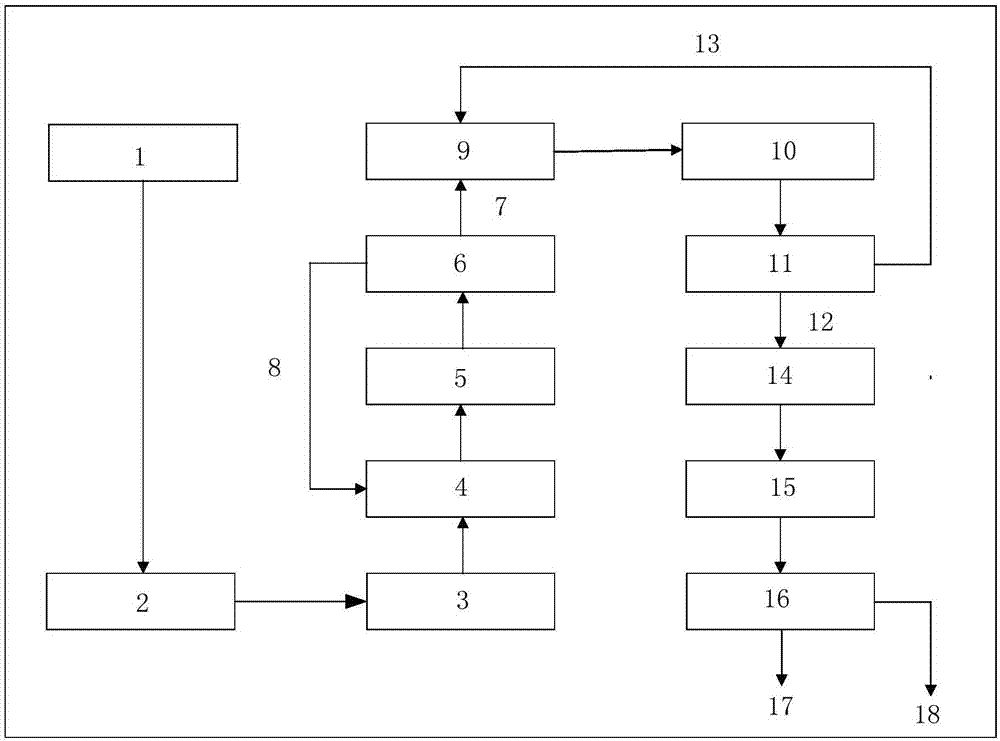

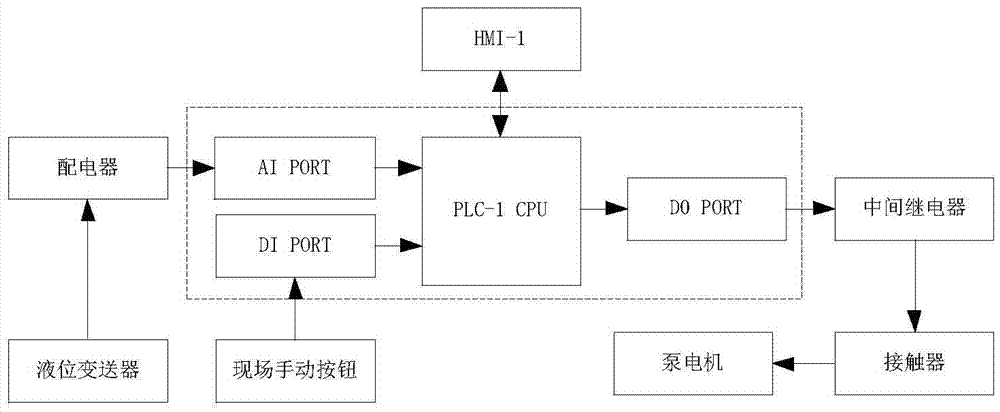

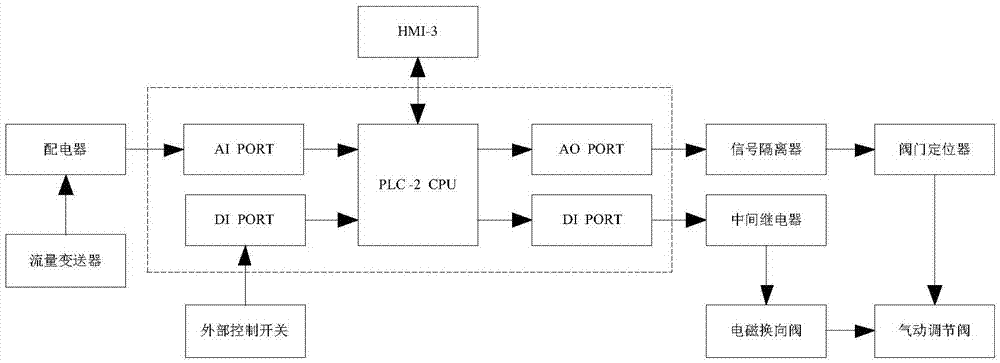

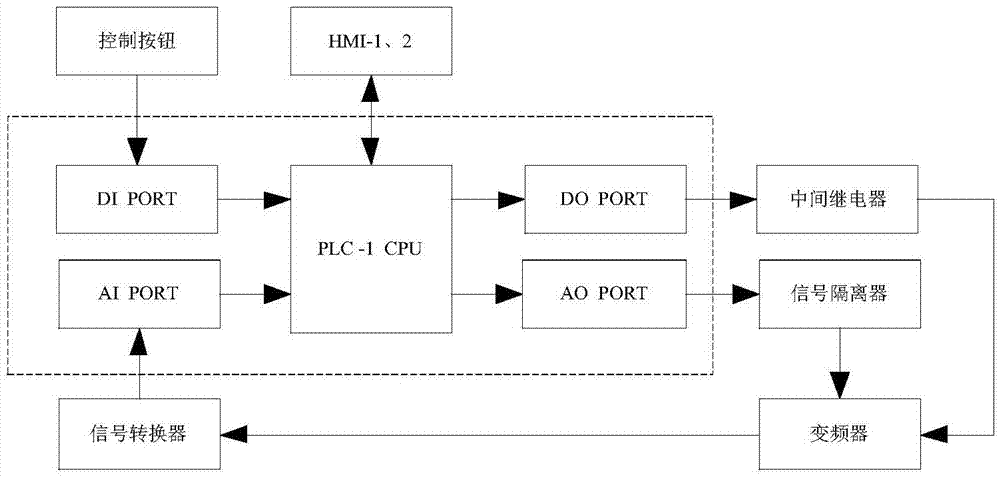

Uranium-containing material extraction process control method

InactiveCN106929674ARealize automatic chain controlRealize automatic adjustmentProgramme control in sequence/logic controllersCapacitanceMixer-settler

The invention relates to the technical field of treatment of uranium-containing waste materials during production of uranium dioxide powder and fuel pellets, in particular to a uranium-containing material extraction process control method. The method includes the steps of liquid level interlocking controlling over a liquid distribution tank and all liquid storing tanks, controlling over flows of all reaction media in the extraction process and the reextraction process, and controlling over the stirring speed of a mixer-settler. An electrical capacitance level meter is adopted for liquid level measurement; a putting-into-type liquid level meter is adopted for tributyl phosphate (TBP) liquid level measurement; a magnetic liquid level meter is adopted for nitric acid liquid level measurement; an electromagnetic flow meter is adopted for flow measurement of a uranyl nitrate solution; a mass flow meter is adopted for measurement of flow and density of a TBP extraction agent; and a metallic rotor flow meter is adopted for flow measurement of non-ionic water. The uranium-containing material extraction process control method is applied to production, the continuity, stability and the like of extraction production are greatly improved, the quality indexes including the uranium concentration, acidity, purity and other indexes of back water output to a precipitation station are stable and controllable, and the uranium content of waste water output to an adsorption station is greatly reduced.

Owner:CNNC JIANZHONG NUCLEAR FUEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com