Horizontal dissolving technology and system for preparing uranyl nitrate

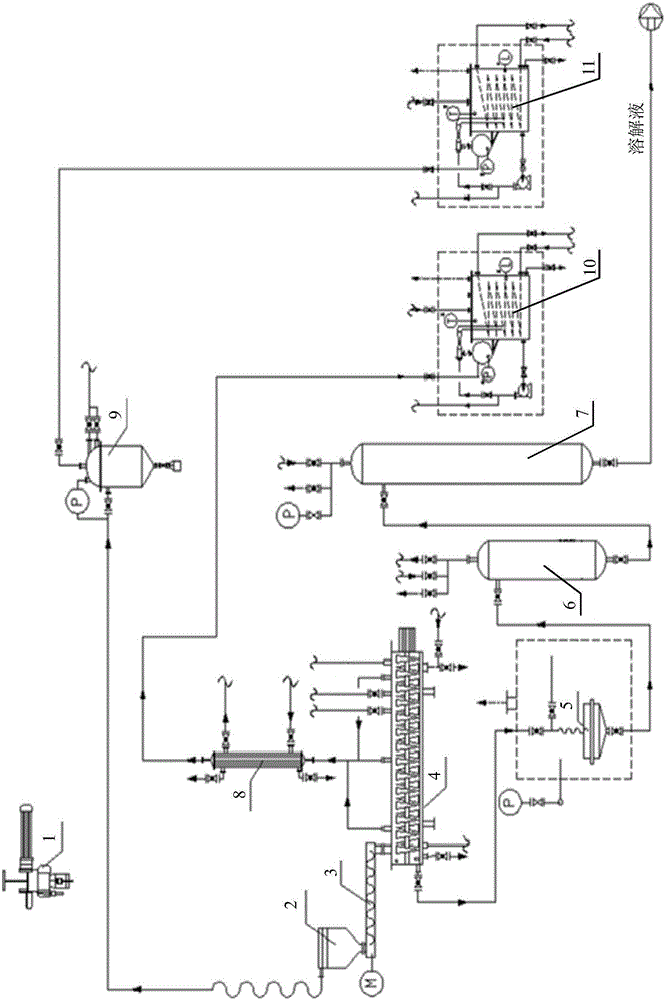

A uranyl nitrate and solution technology is applied in the field of dissolving uranium-containing materials, and can solve the problems of clogging of a liquid outlet, incomplete dissolution reaction, accumulation, etc., and achieve the effects of improving stability, uniform concentration of dissolved solution, and complete dissolution reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] U 3 o 8 The barrel is hoisted to the screw feeder and the docking is completed. First measure a certain amount of deionized water and add it into the dissolving tank, then measure a certain amount of 65% nitric acid and slowly add it into the dissolving tank. After the addition of nitric acid is completed, circulate hot water into the jacket of the dissolution tank, and when the temperature in the dissolution tank reaches 60-65 °C, start the switch of the screw feeder, U 3 o 8 The powder is fed into the dissolving tank at a certain speed through the screw feeder for dissolution, and the feeding is completed in 1 hour. After stirring for 30 minutes, raise the temperature to 75-80°C, and continue stirring for 3-4 hours; during the dissolution process, adjust the flow rate of circulating cooling water or hot water to control the temperature of the dissolution tank within the range of 65°C-90°C. Personnel observe the reaction situation through the sight glass at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com