Patents

Literature

232results about "Uranium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromechanical actuators

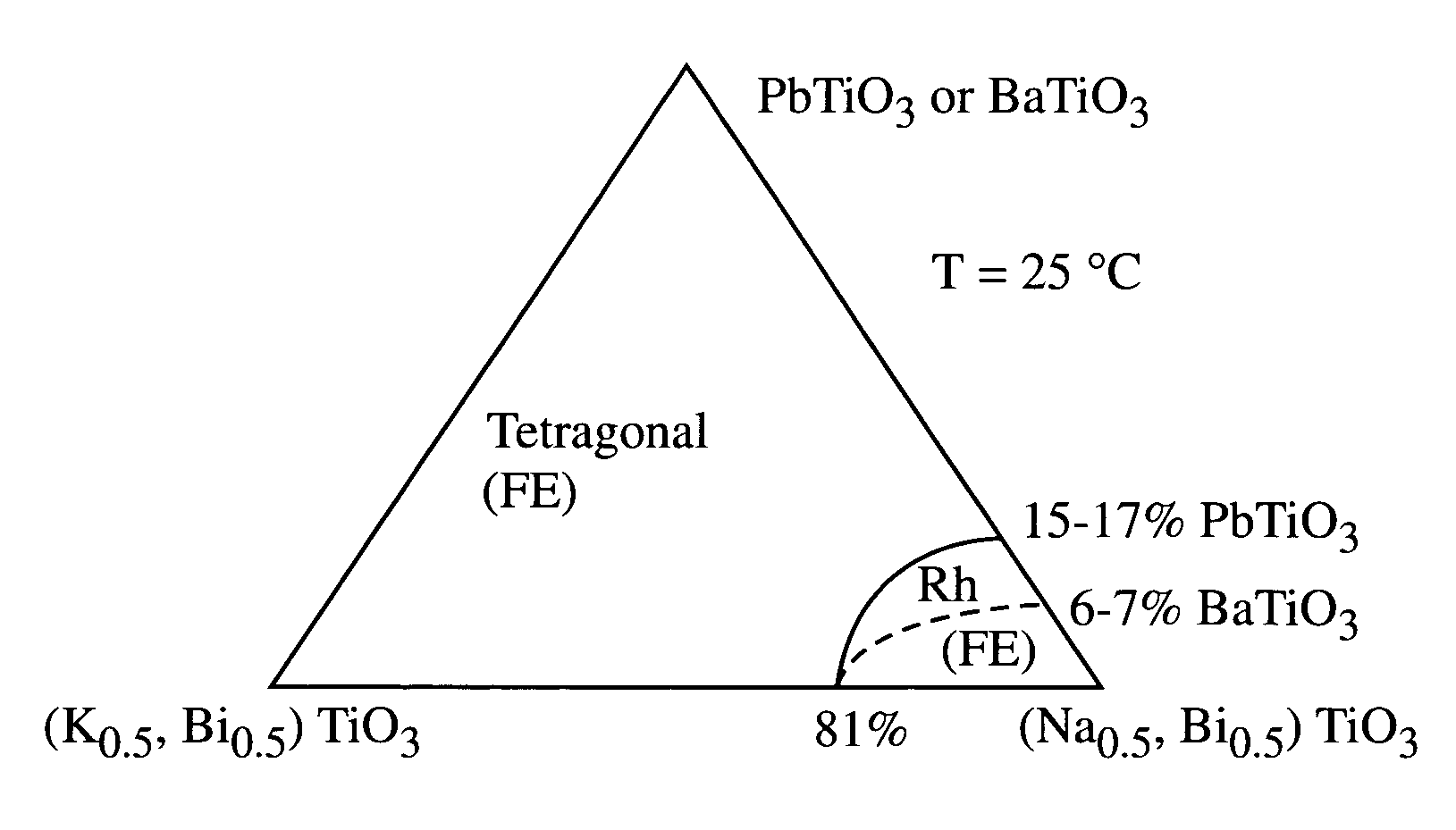

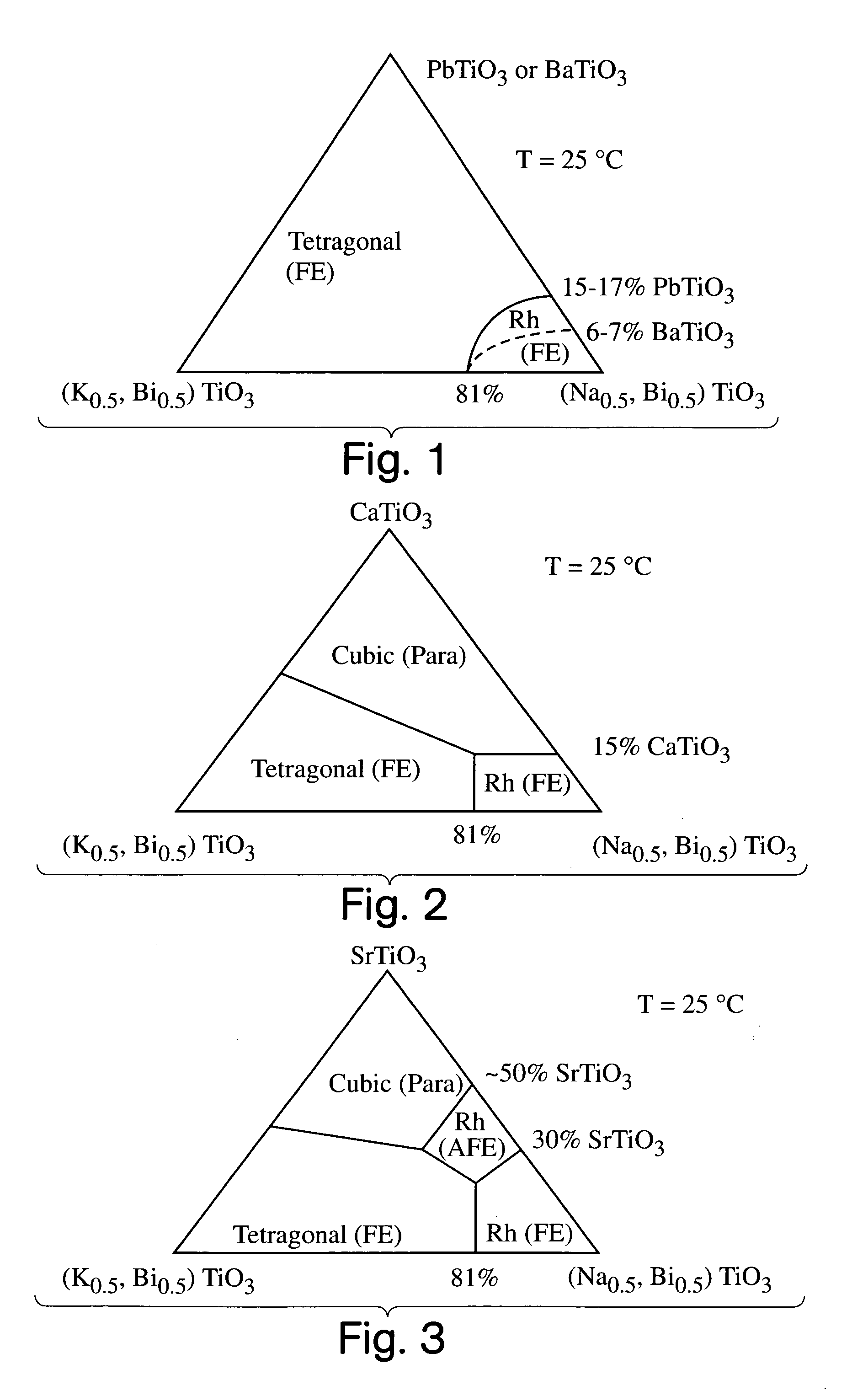

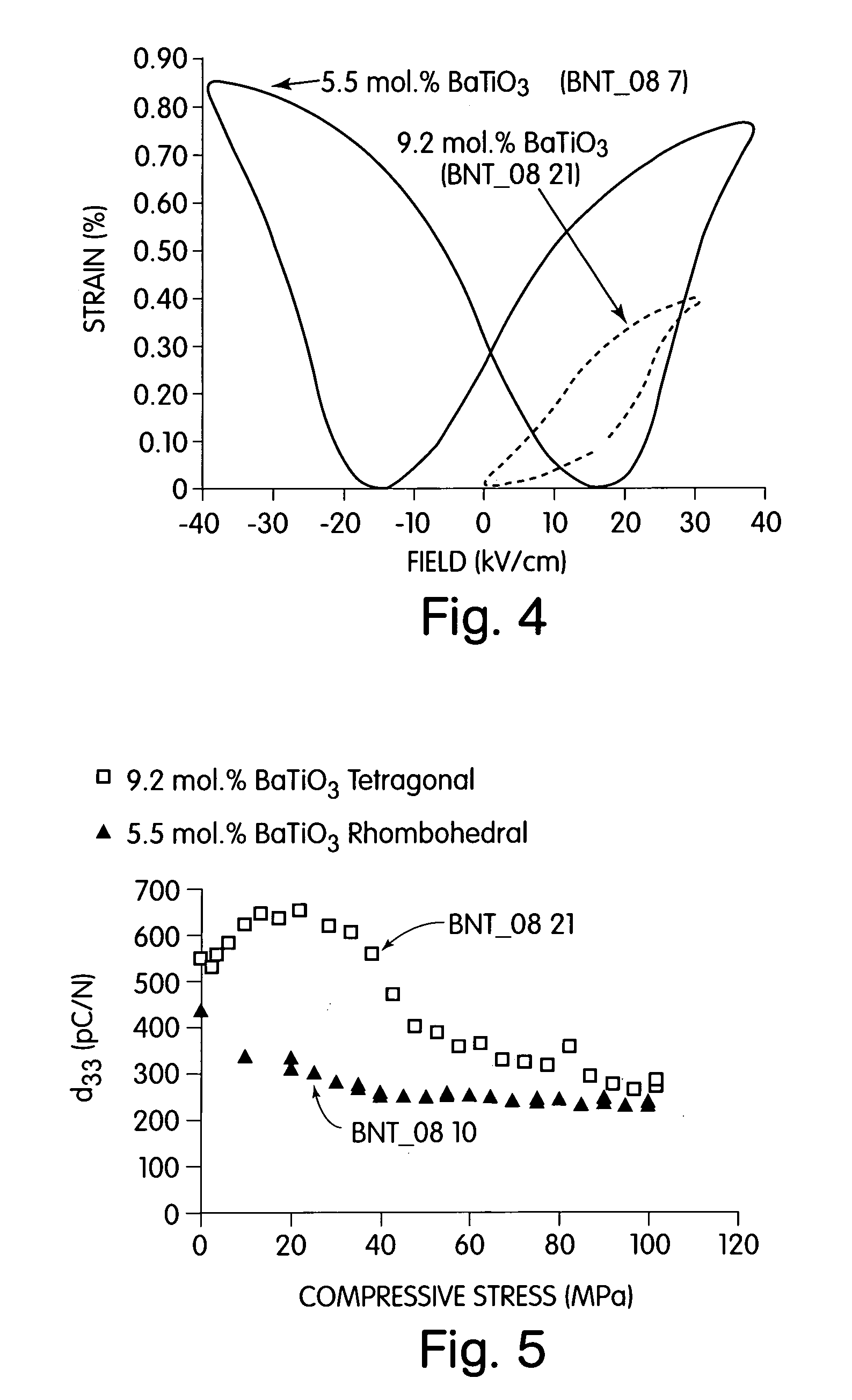

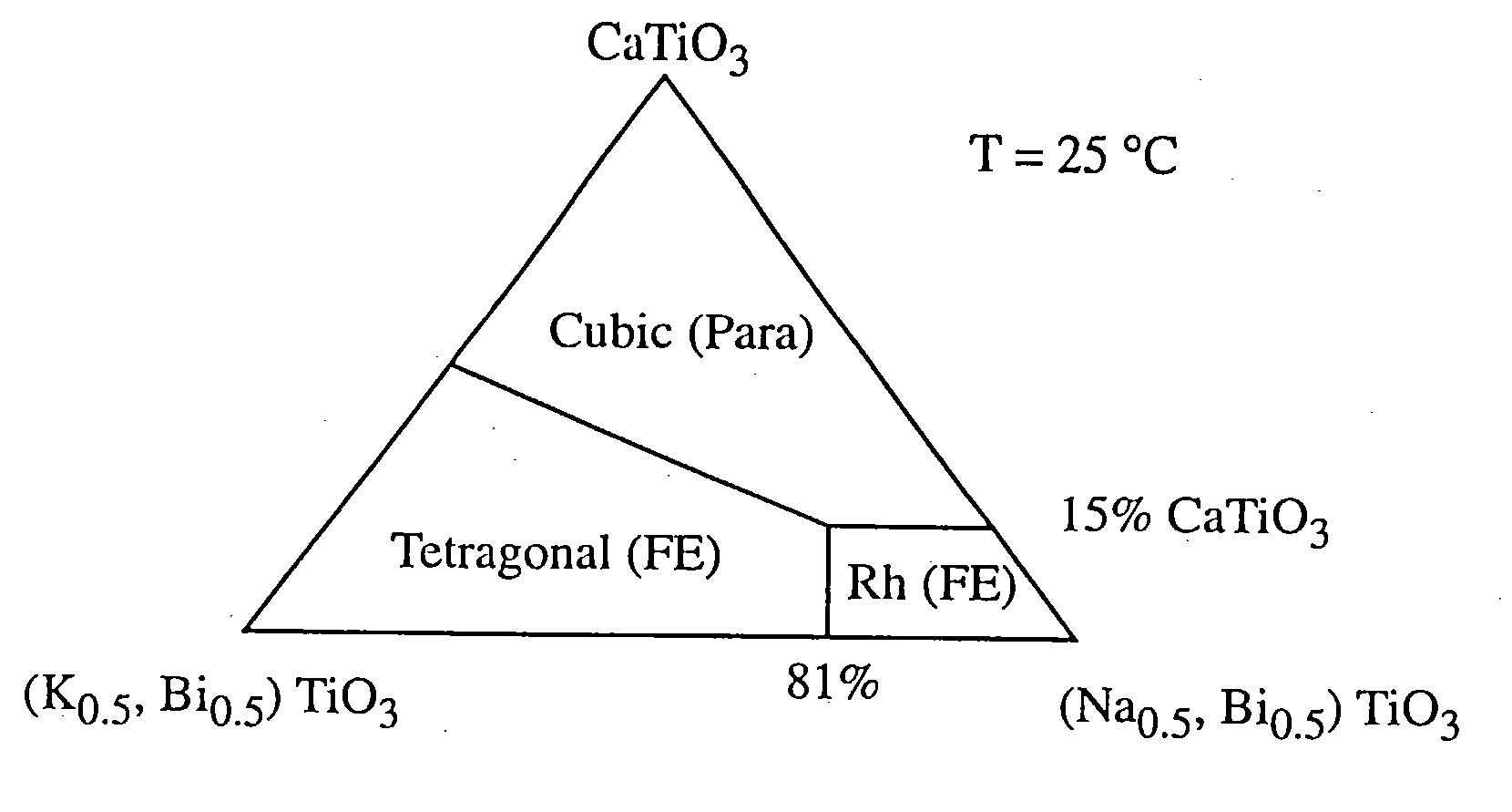

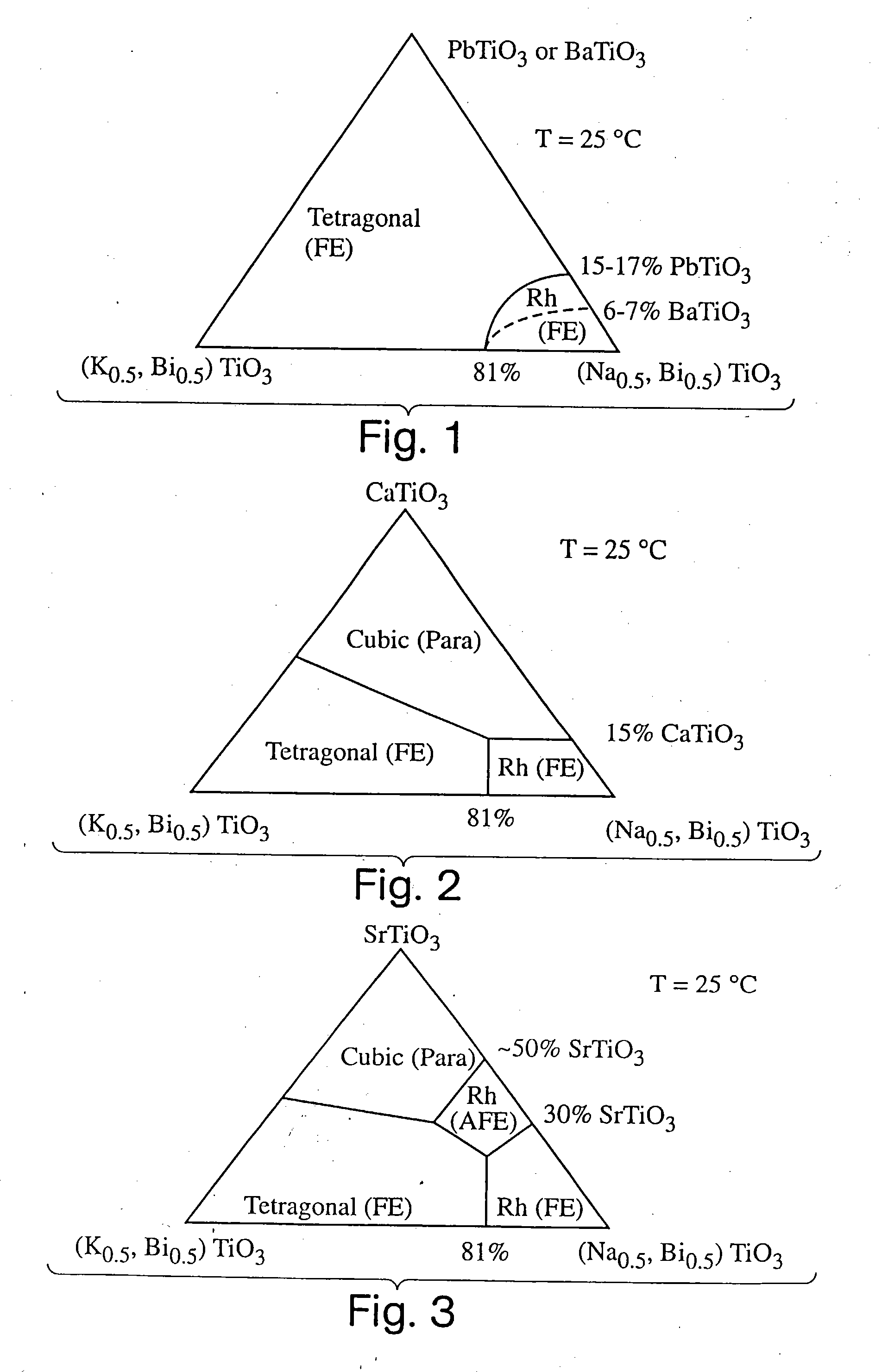

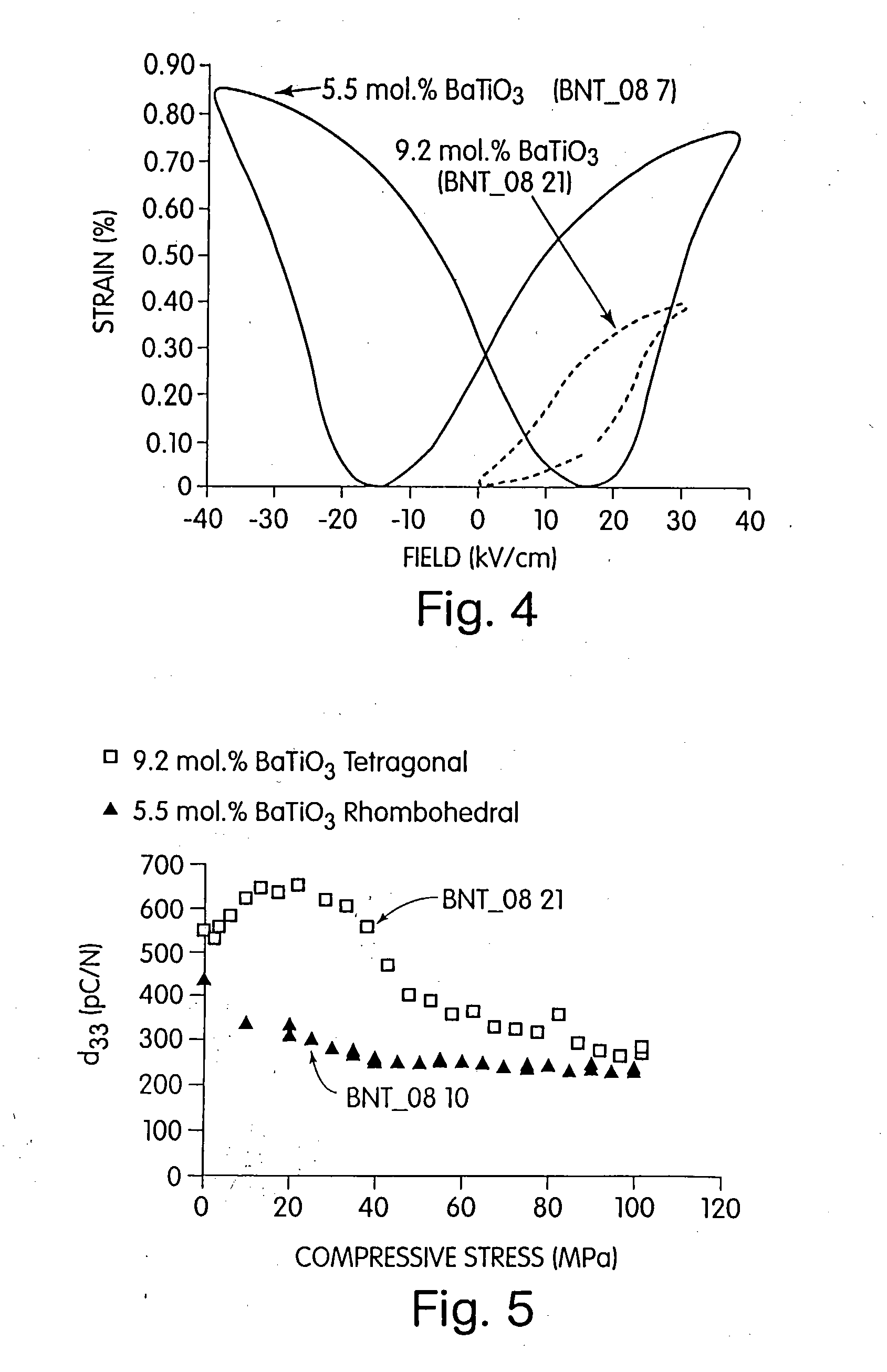

InactiveUS7090785B2Increased doping of BaTiOImprove propertiesAlkaline earth titanatesLighting support devicesElectroactive materialsMaterials science

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

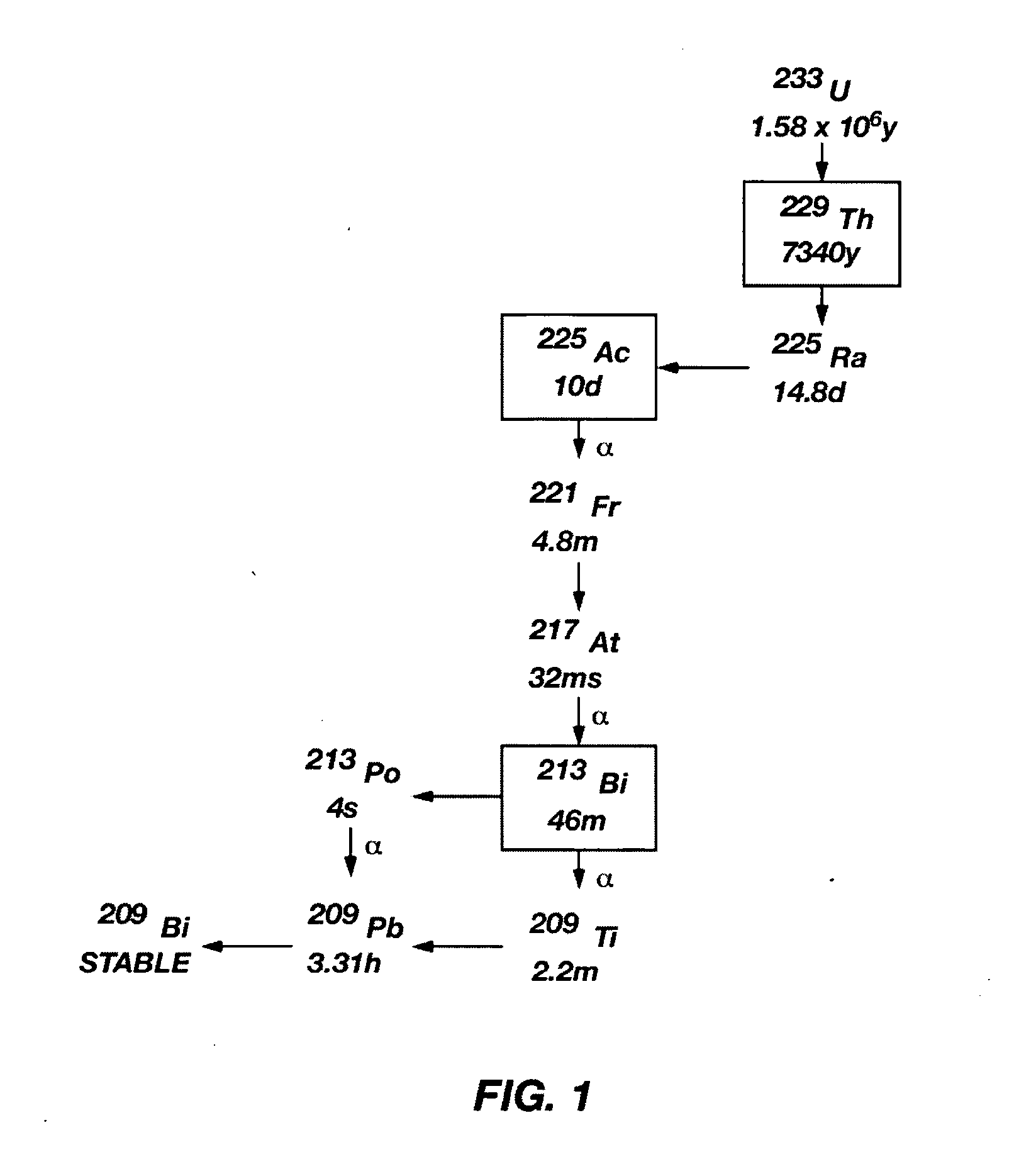

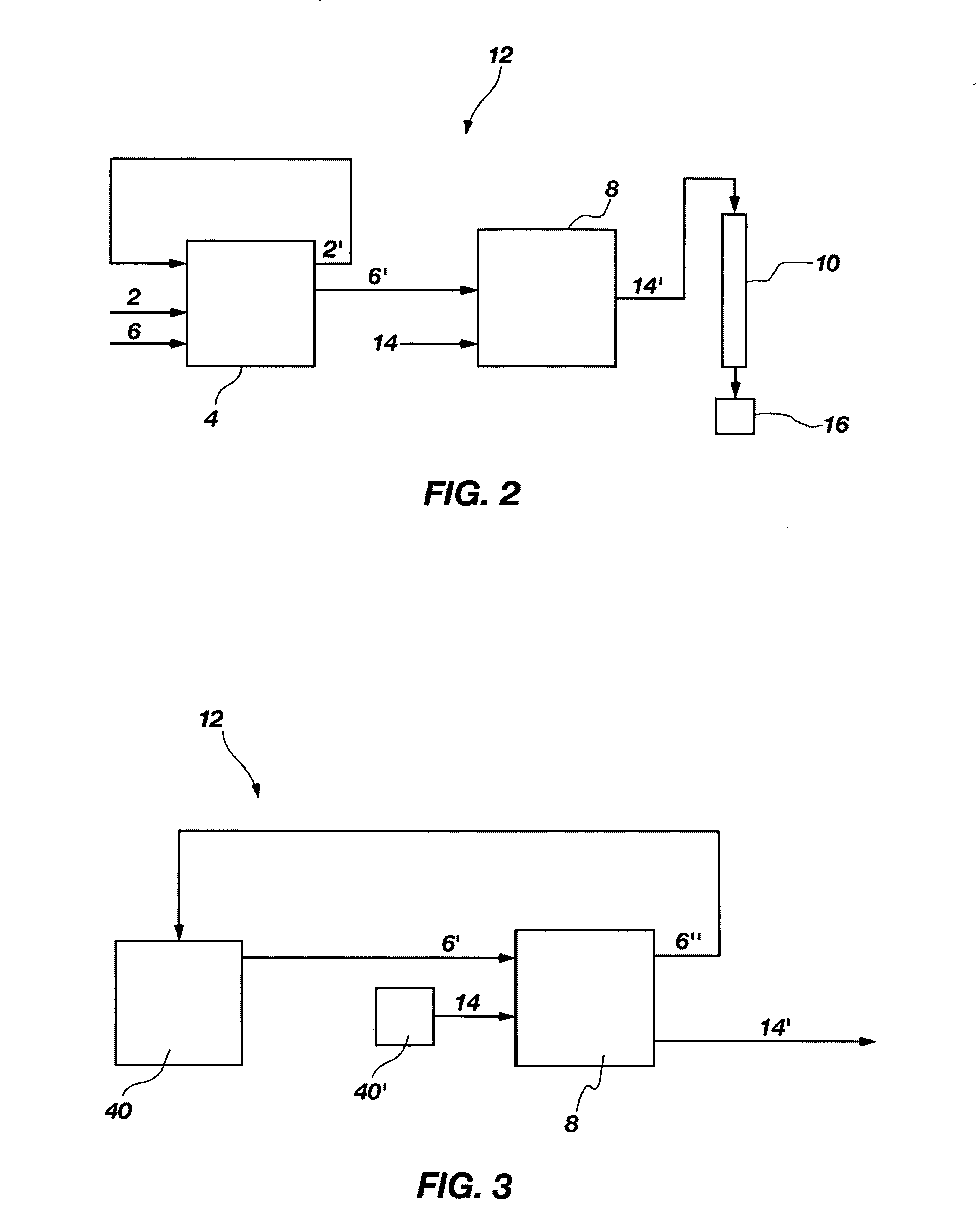

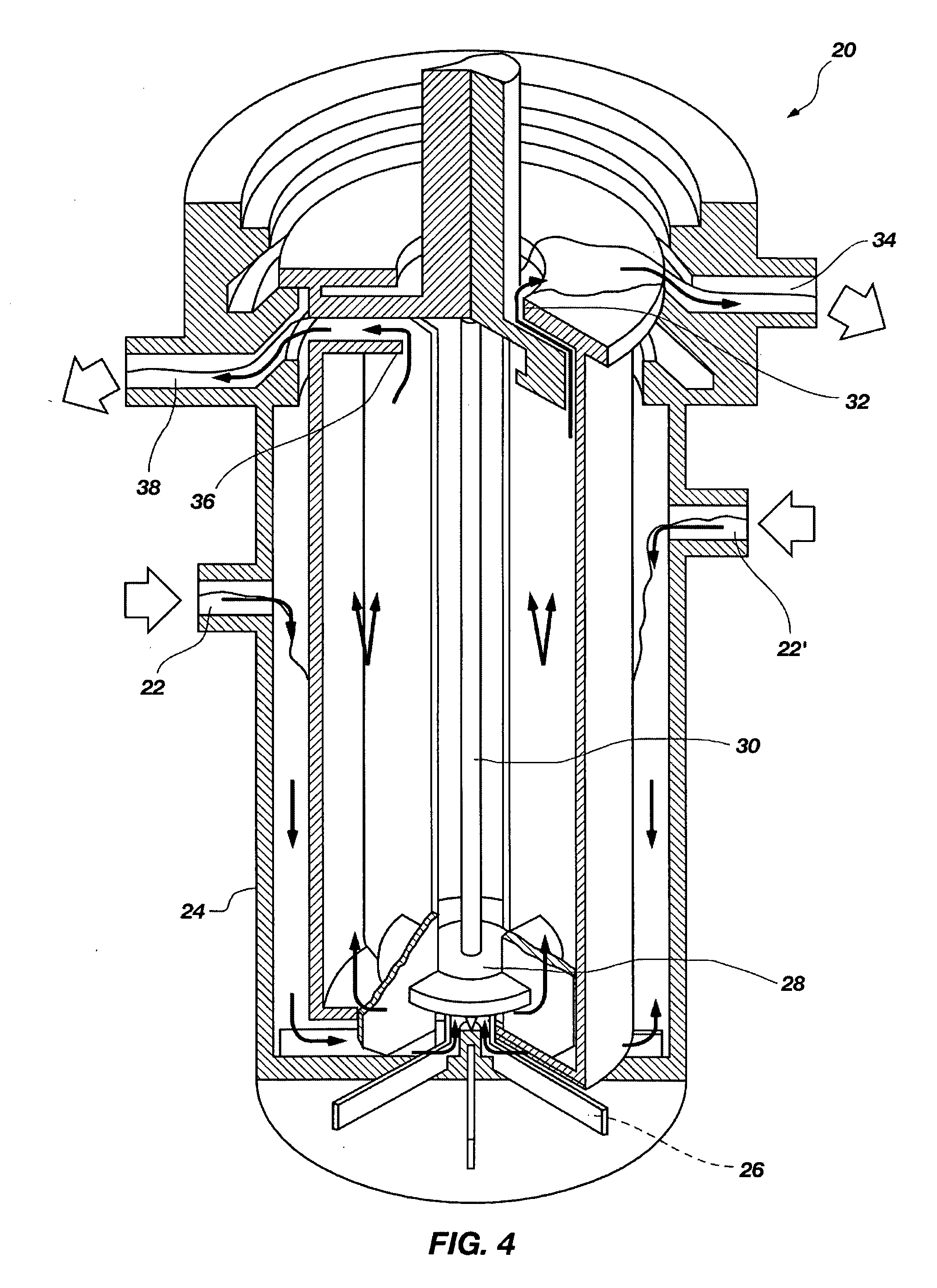

Process for radioisotope recovery and system for implementing same

A method of recovering daughter isotopes from a radioisotope mixture. The method comprises providing a radioisotope mixture solution comprising at least one parent isotope. The at least one parent isotope is extracted into an organic phase, which comprises an extractant and a solvent. The organic phase is substantially continuously contacted with an aqueous phase to extract at least one daughter isotope into the aqueous phase. The aqueous phase is separated from the organic phase, such as by using an annular centrifugal contactor. The at least one daughter isotope is purified from the aqueous phase, such as by ion exchange chromatography or extraction chromatography. The at least one daughter isotope may include actinium-225, radium-225, bismuth-213, or mixtures thereof. A liquid-liquid extraction system for recovering at least one daughter isotope from a source material is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

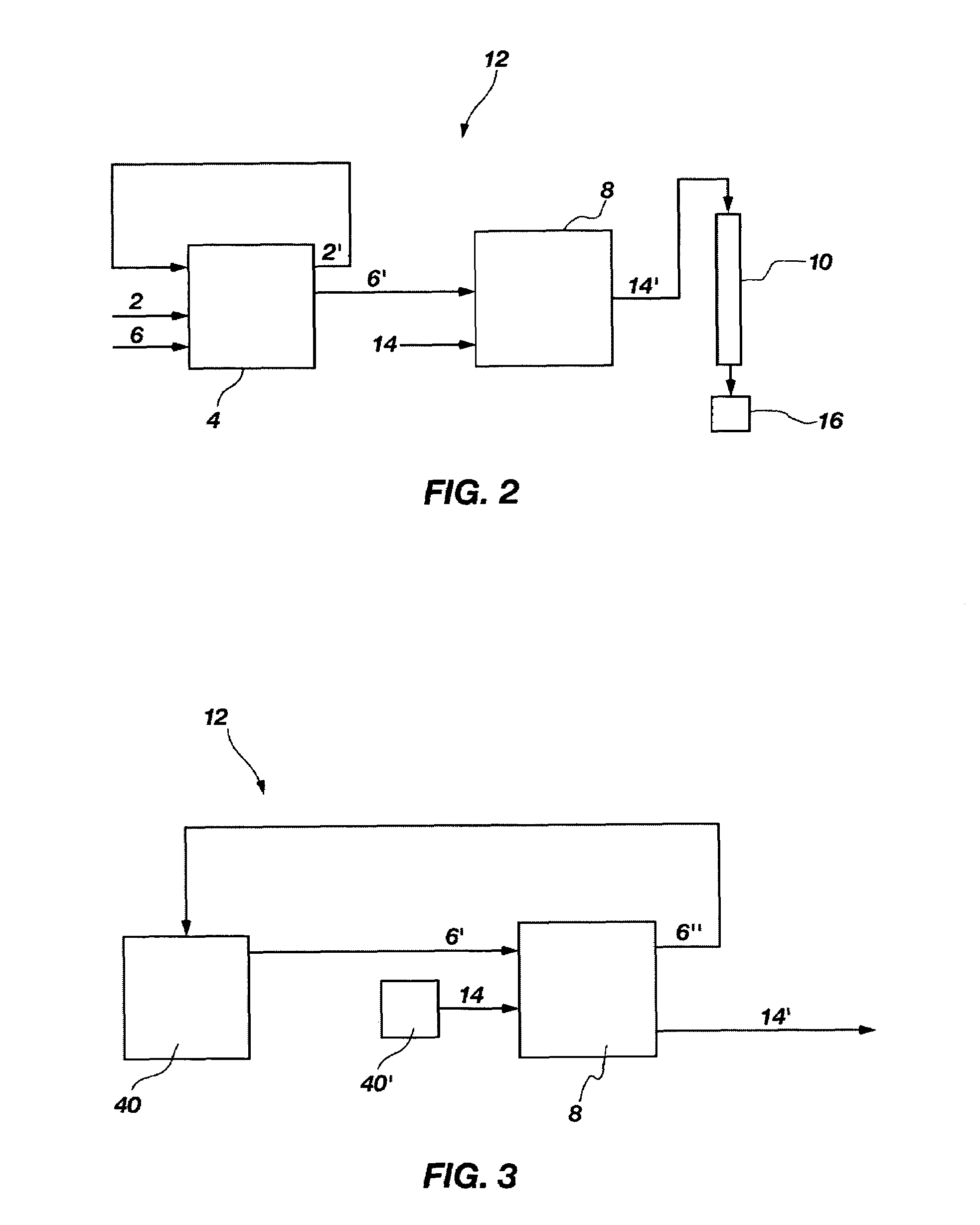

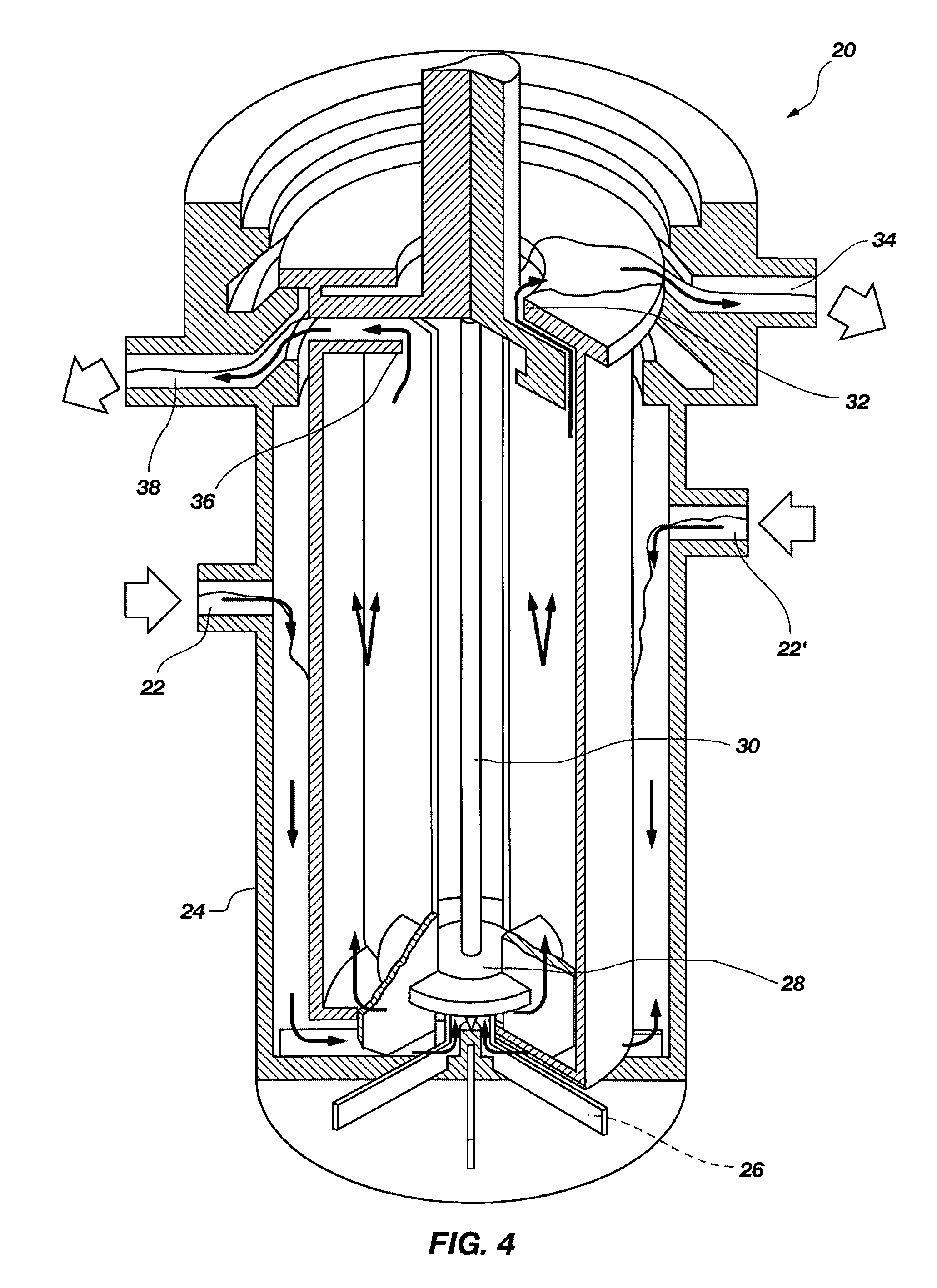

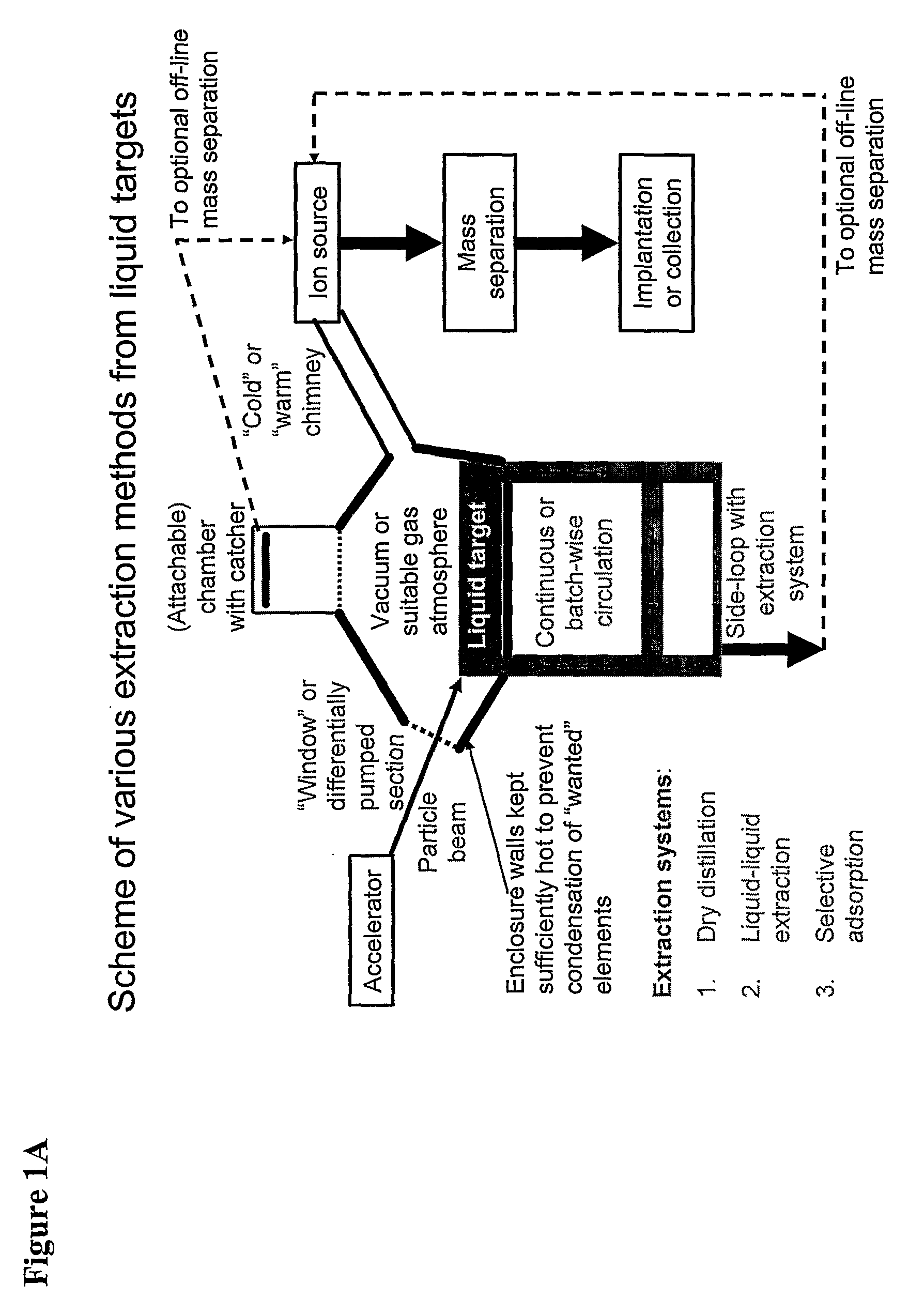

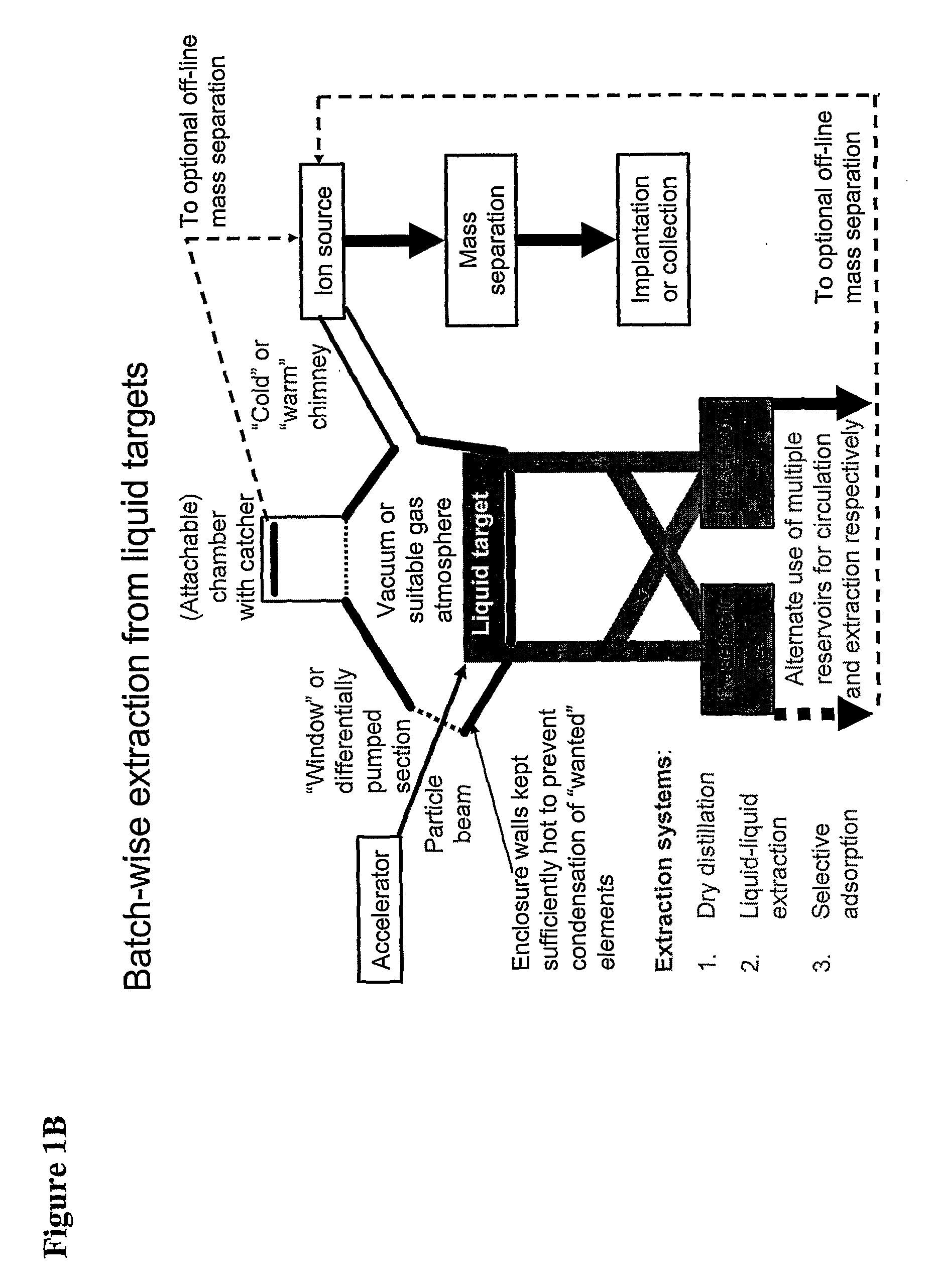

Method for Production of Radioisotope Preparations and Their Use in Life Science, Research, Medical Application and Industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimised individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

Process for the preparation of metal carbides having a large specific surface from activated carbon foams

InactiveUS6217841B1Easy accessPhysical/chemical process catalystsTransuranic element compoundsActivated carbonCarbide

The invention relates to a silicon carbide or metal carbide foam to be used as a catalyst or catalyst support for the chemical or petrochemical industry or for silencers, as well as the process for producing the same.The foam is in the form of a three-dimensional network of interconnected cages, whose edge length is between 50 and 500 micrometres, whose density is between 0.03 and 0.1 g / cm3 and whose BET surface is between 20 and 100 m2 / g. The carbide foam contains no more than 0.1% by weight residual metal and the size of the carbide crystallites is between 40 and 400 Angstroms.The production process consists of starting with a carbon foam, increasing its specific surface by an activation treatment using carbon dioxide and then contacting the thus activated foam with a volatile compound of the metal, whose carbide it is wished to obtain.

Owner:CENT NAT DE LA RECHERCHE SCI

Electromechanical actuators

InactiveUS20050109263A9Improve the overall coefficientImprove electromechanical performanceAlkaline earth titanatesLighting support devicesMaterials science

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

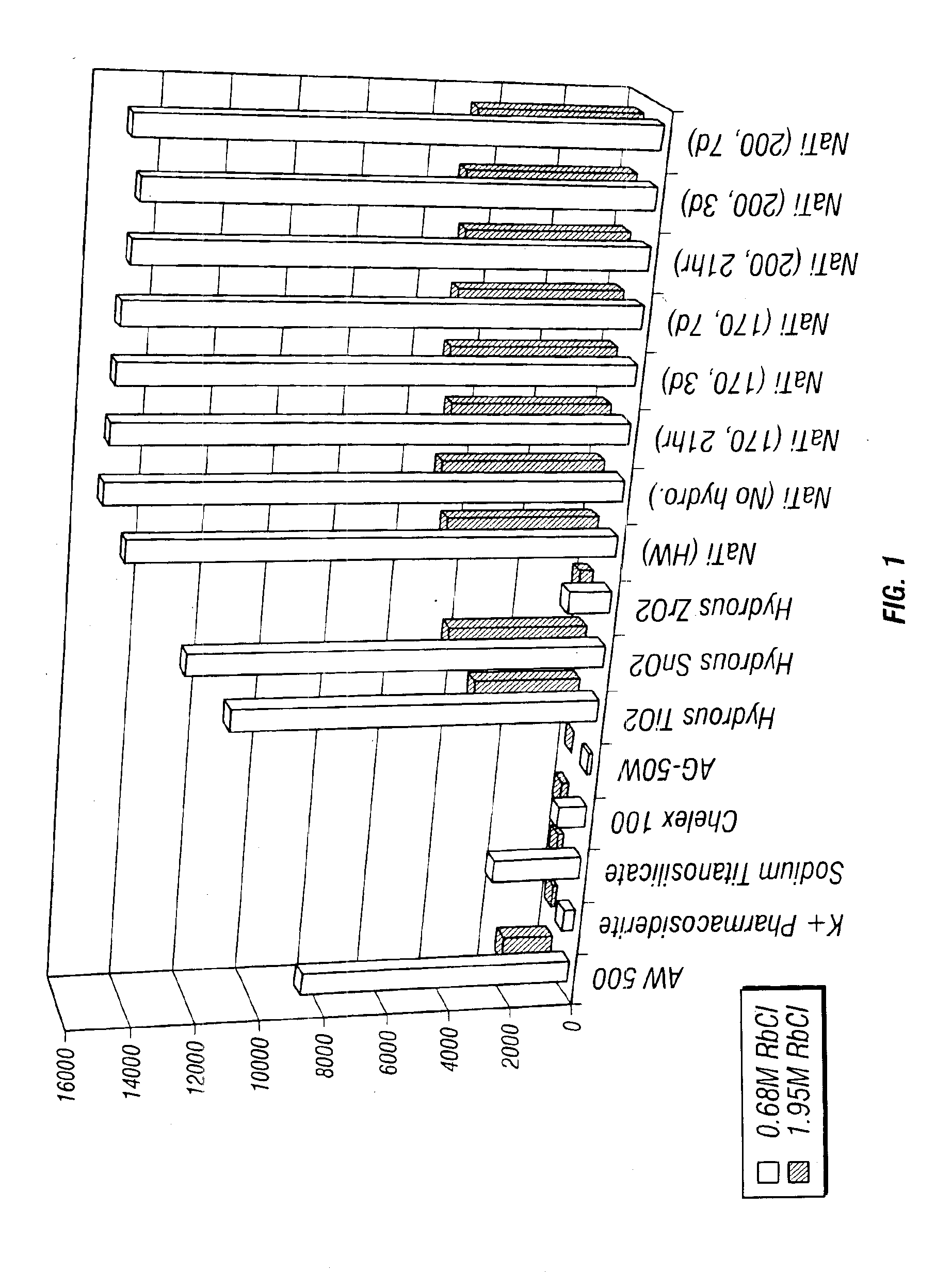

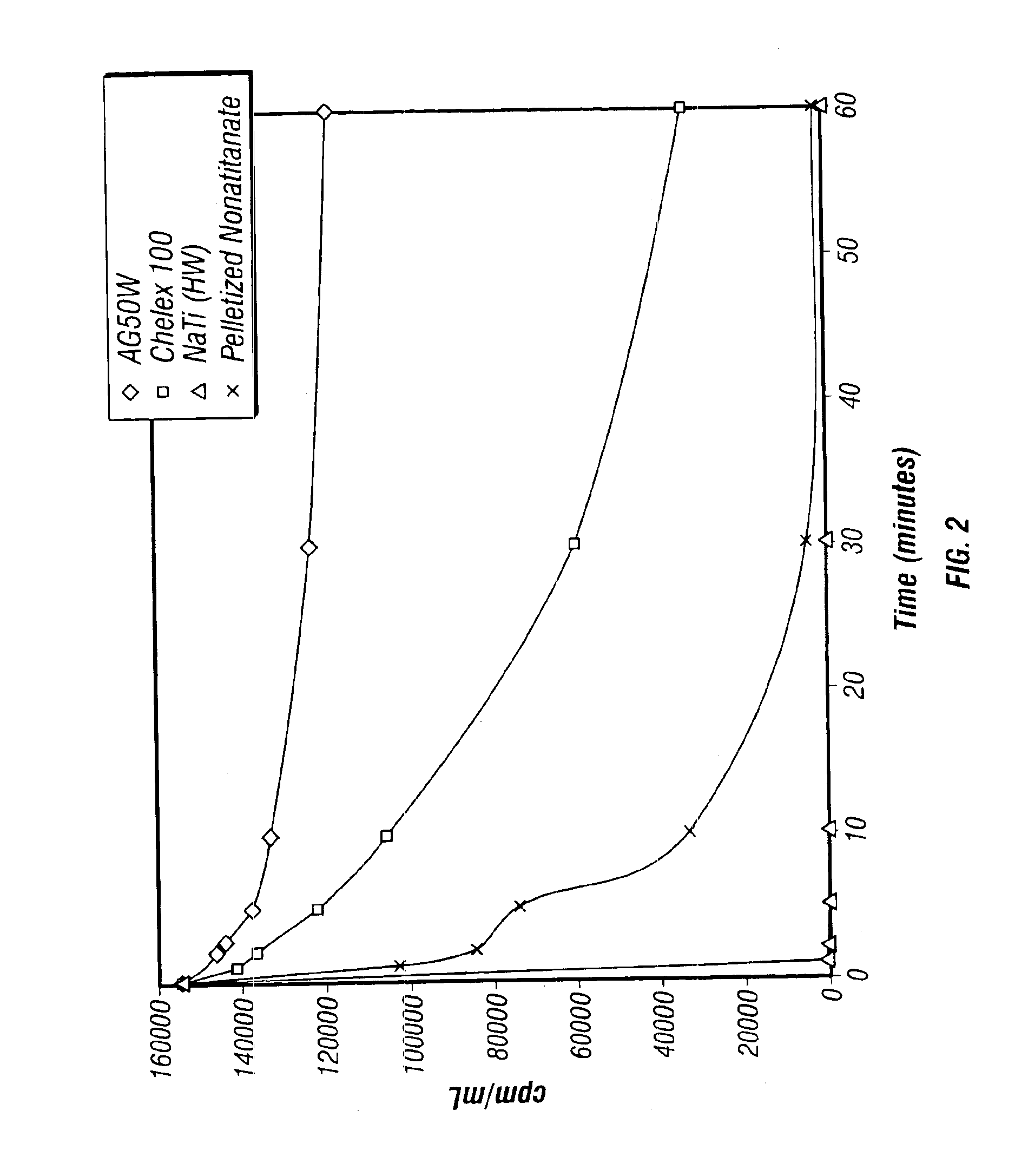

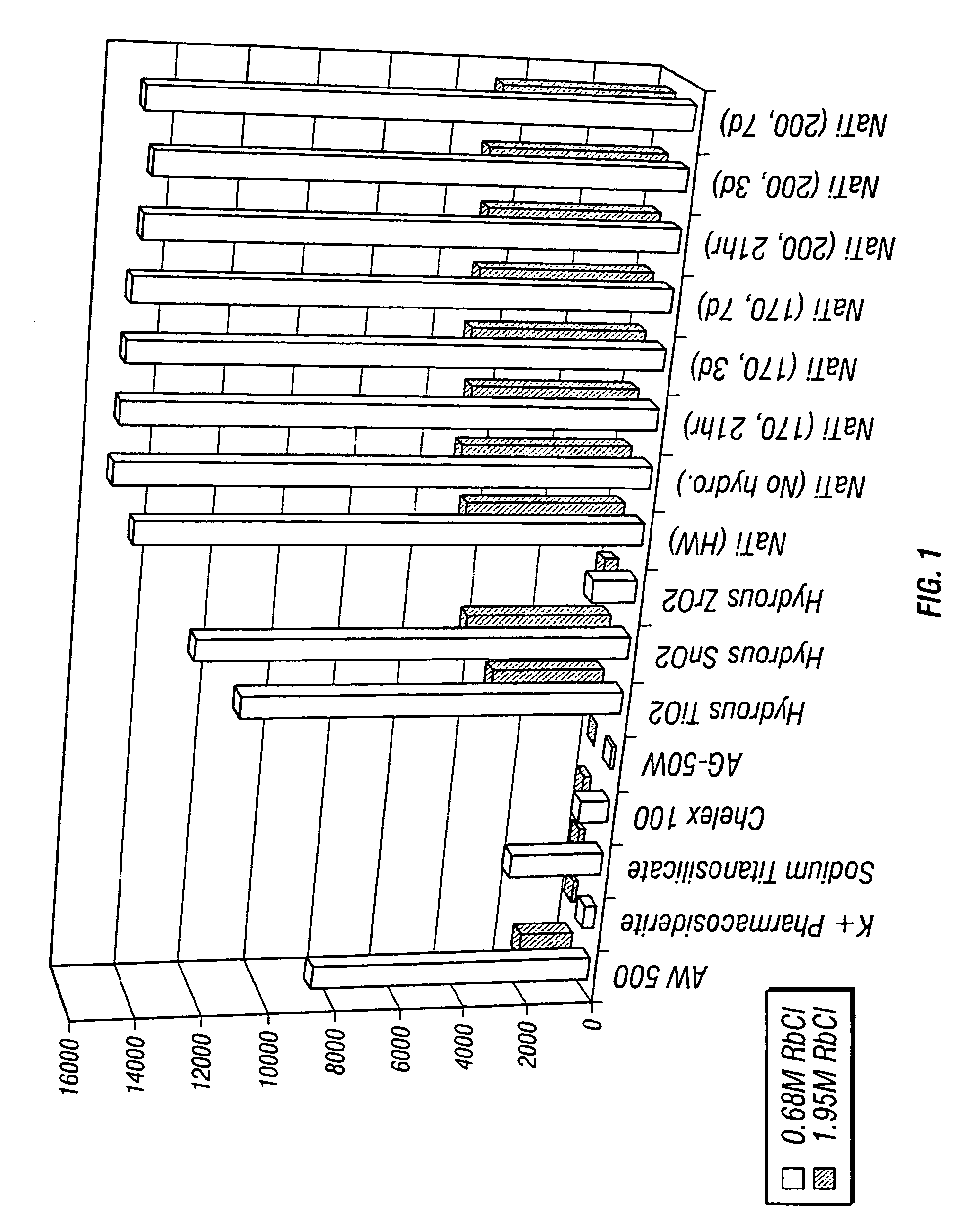

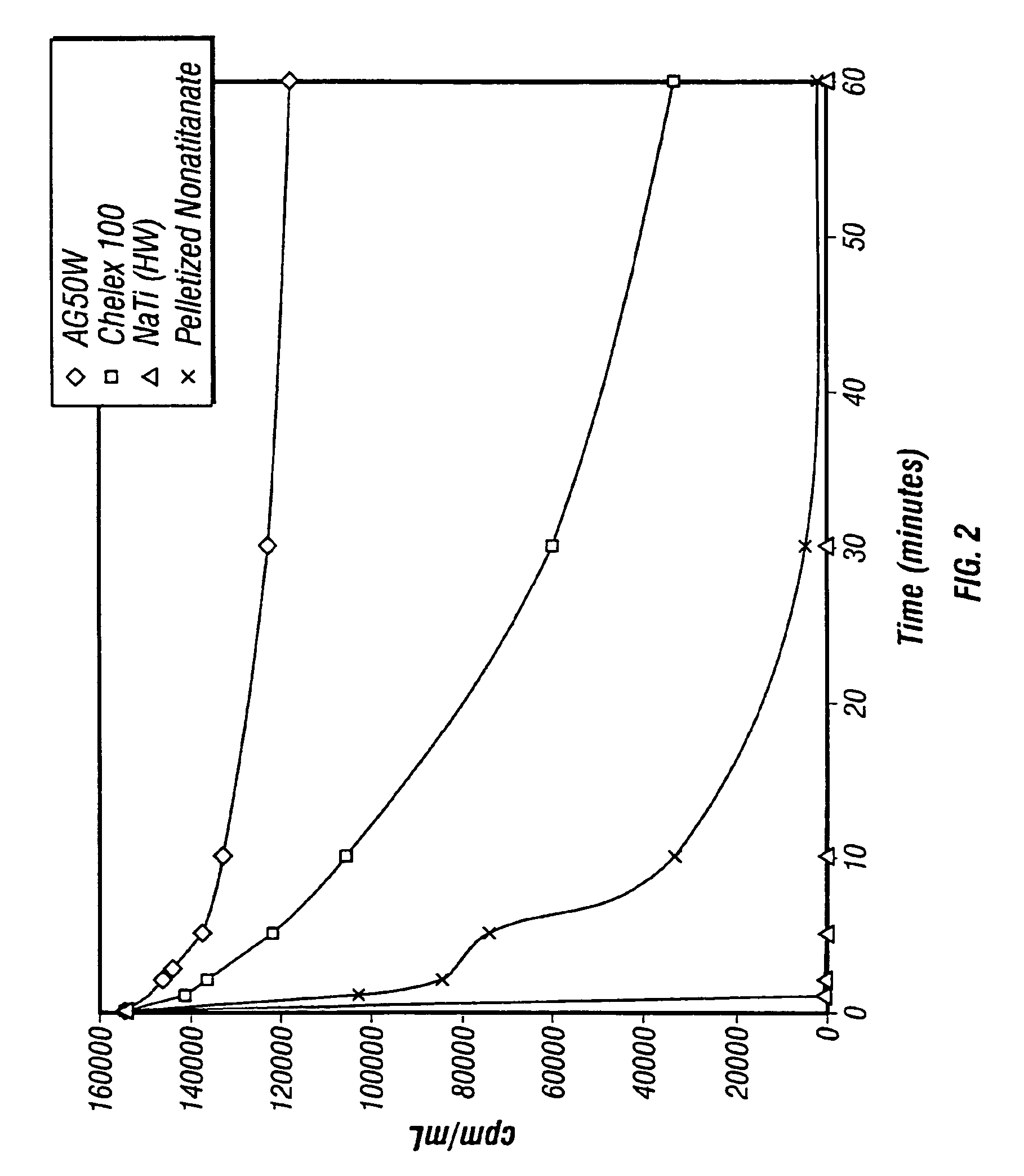

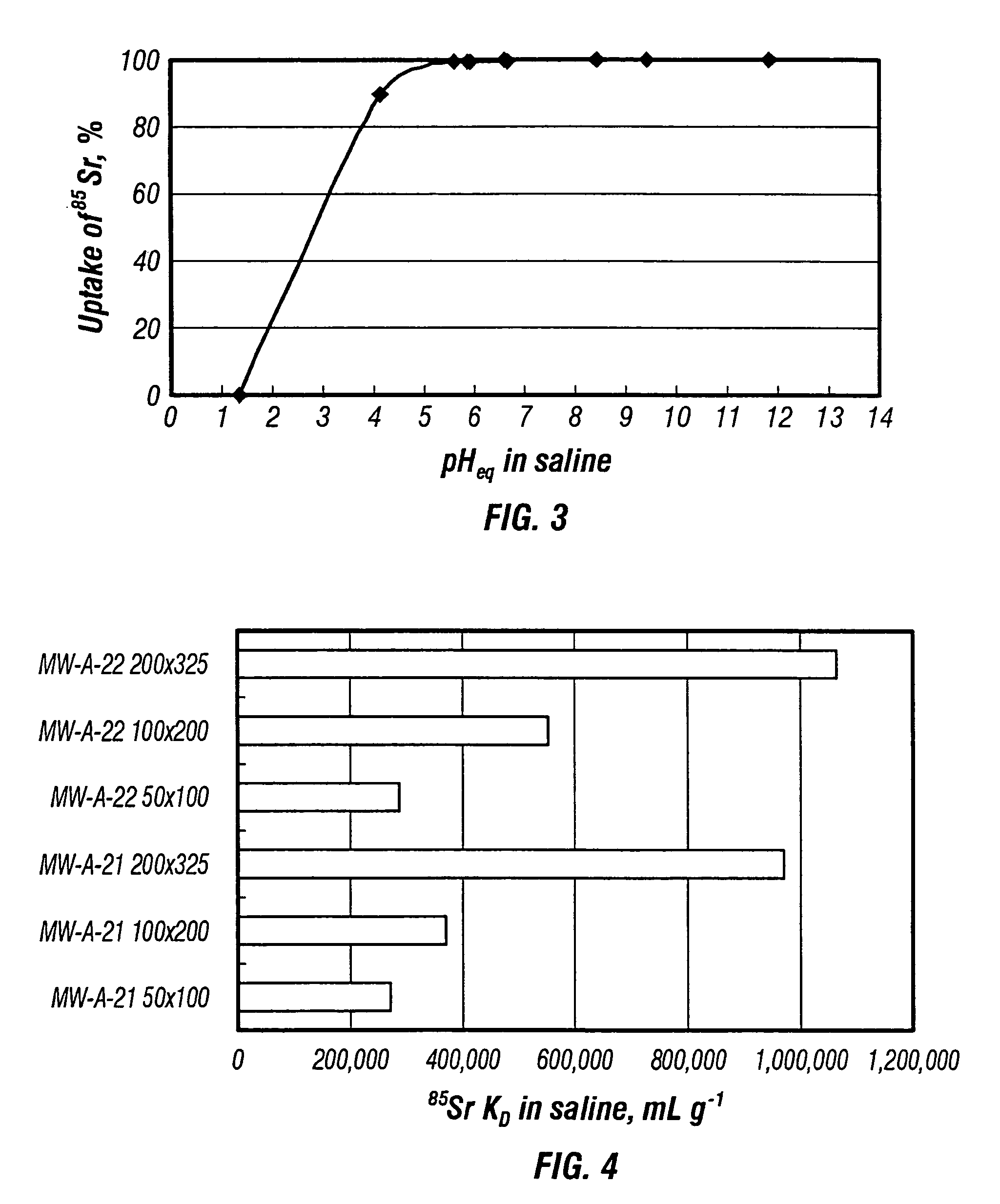

Rubidlum-82 generator based on sodium nonatitanate support, and improved separation methods for the recovery of strontium-82 from irradiated targets

InactiveUS6908598B2Effective recoveryOther chemical processesTransuranic element compoundsLow affinityRubidium

Sodium nonatitanate compositions, a method using the composition for recovery of 82Sr from irradiated targets, and a method using the composition for generating 82Rb. The sodium nonatitanate materials of the invention are highly selective at separating strontium from solutions derived from the dissolution of irradiated target materials, thus reducing target processing times. The compositions also have a very low affinity for rubidium, making it an ideal material for use as a 82Rb generator. Sodium nonatitanate materials of this type both improve the recovery of 82Sr and provide a safer, more effective 82Rb generator system.

Owner:LYNNTECH

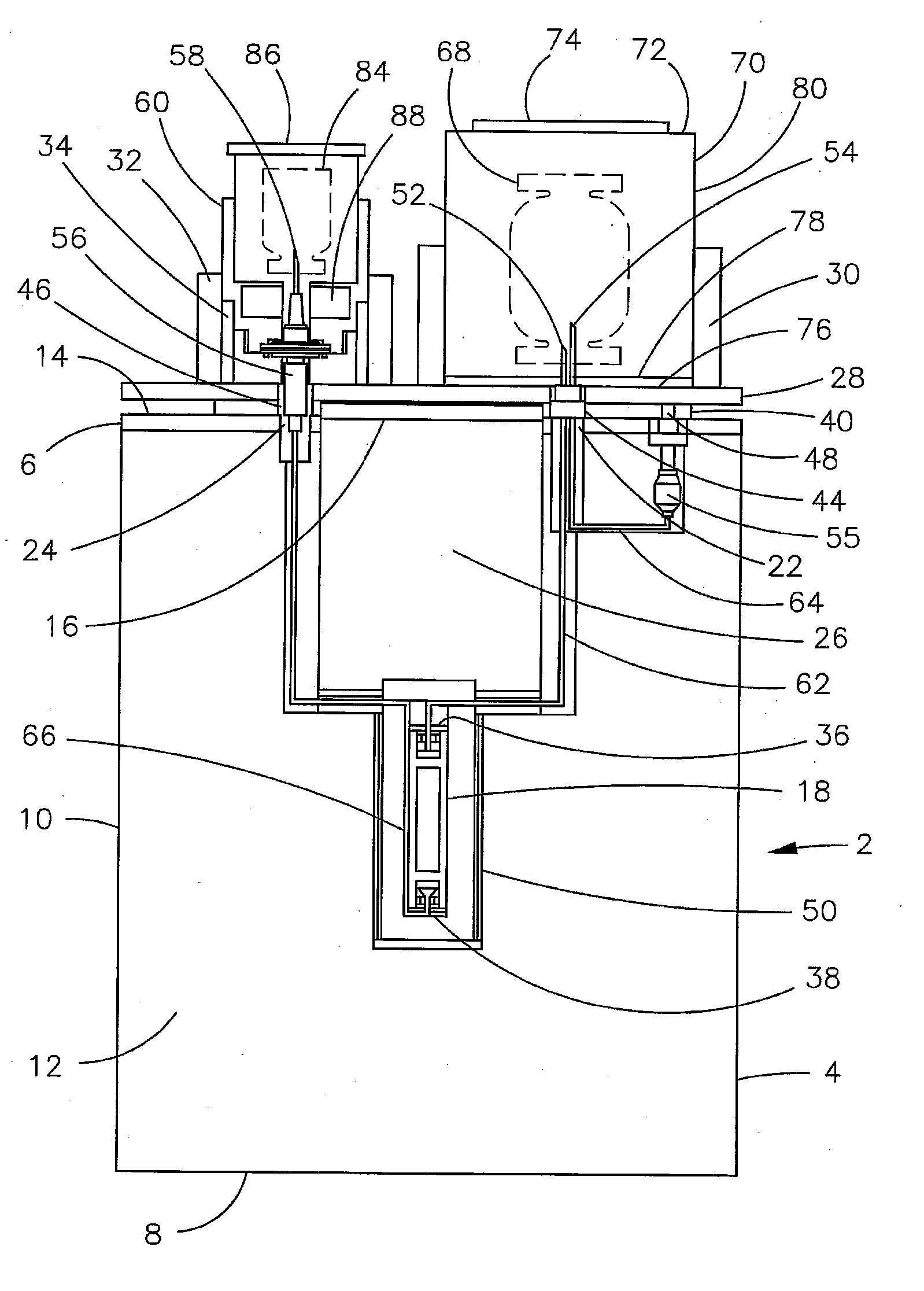

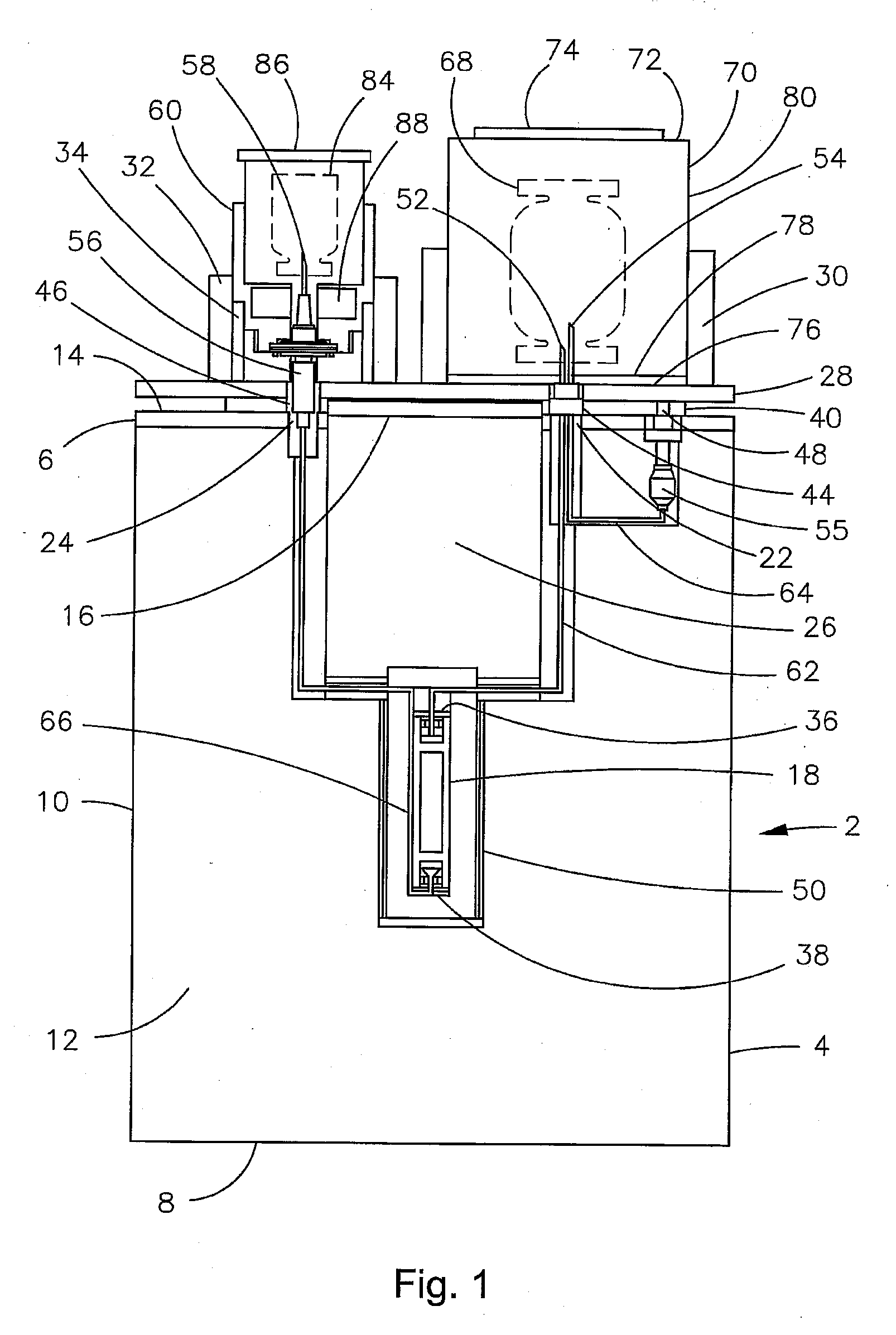

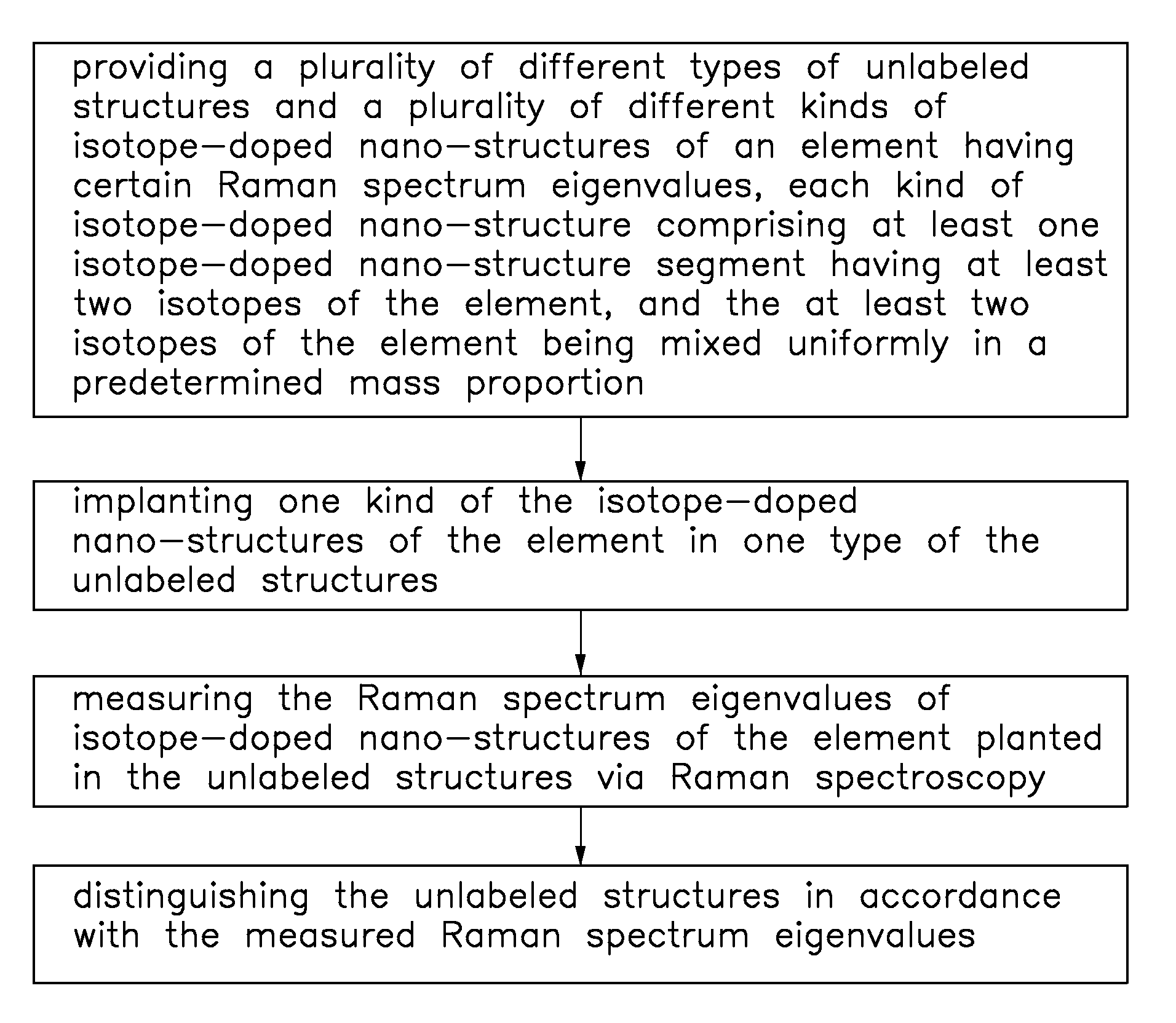

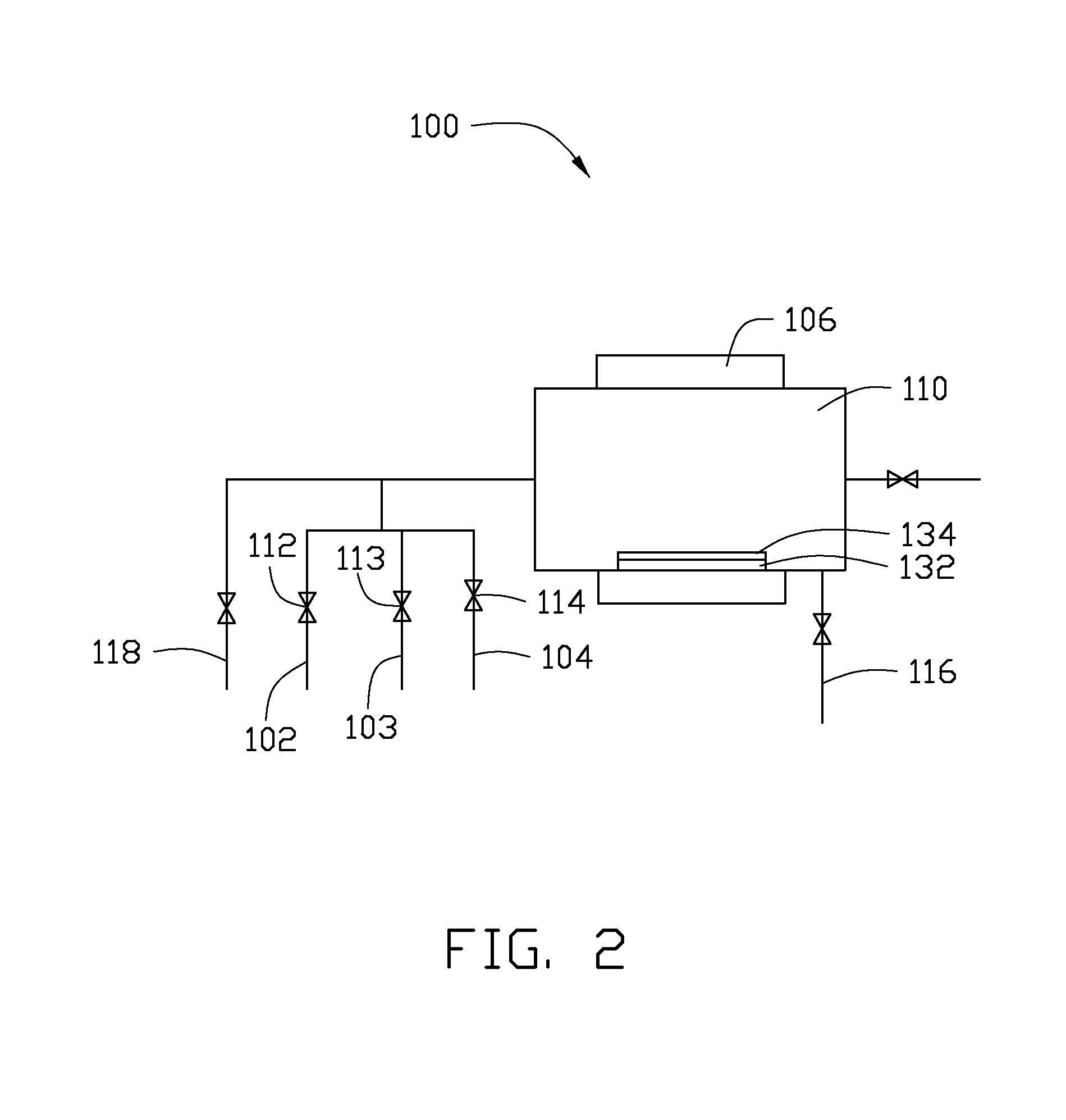

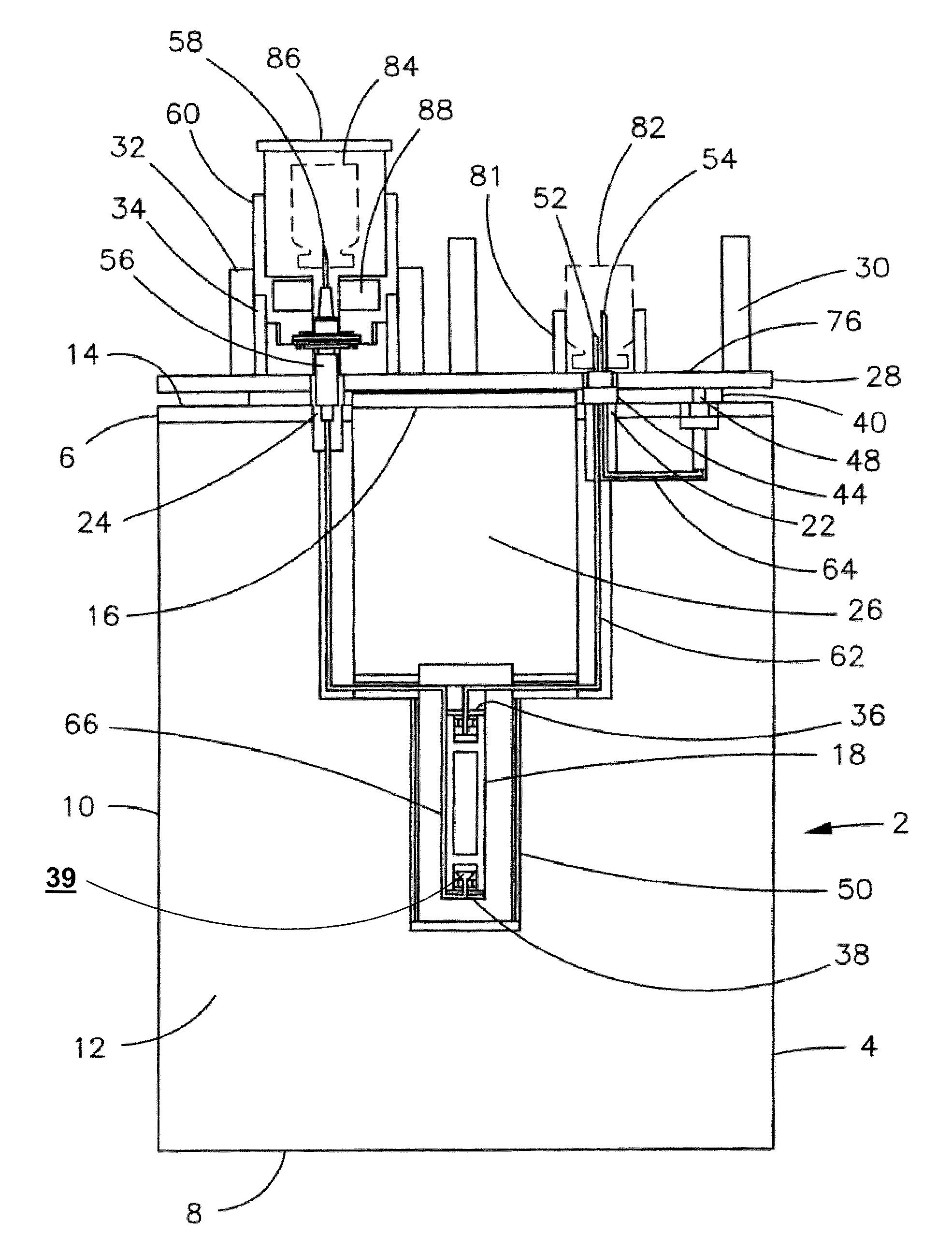

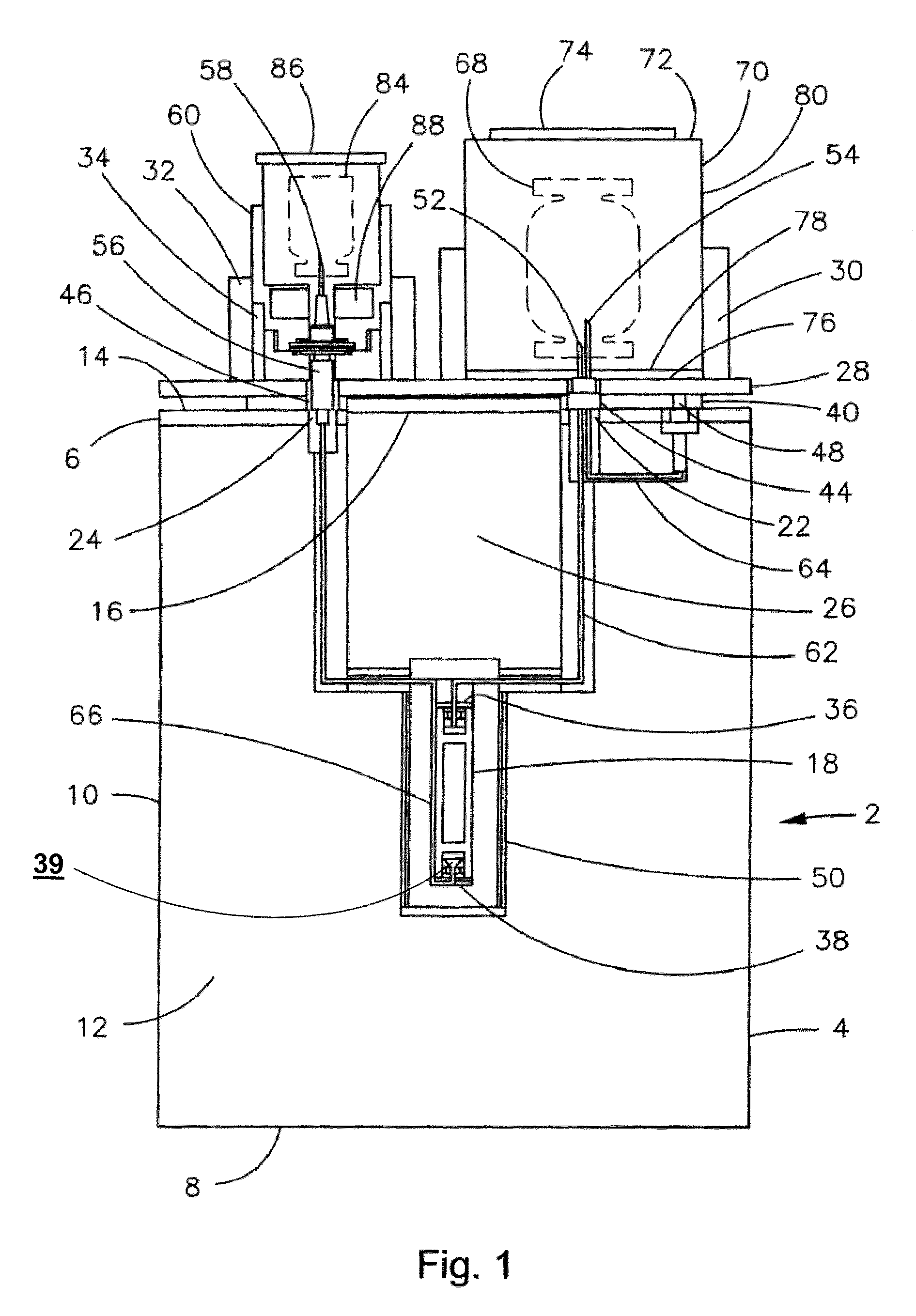

Systems and Methods for Radioisotope Generation

ActiveUS20080093564A1Isotope delivery systemsTransuranic element compoundsEngineeringChromatographic column

Systems and methods are disclosed for producing customized, predictable and reproducible supplies of radioisotopes using, for example, a reactor housing that is fabricated from a radioactive shielding material and has both an internal volume and a surface that comprises an entry port and an exit port, a chromatographic column that is positioned within said internal volume such that a first end of said column is in fluid communication with said entry port and a second end of said column is in fluid communication with said exit port, and a changeable filter module that is disposed external to said reactor housing and in fluid communication with said exit port.

Owner:JUBILANT DRAXIMAGE

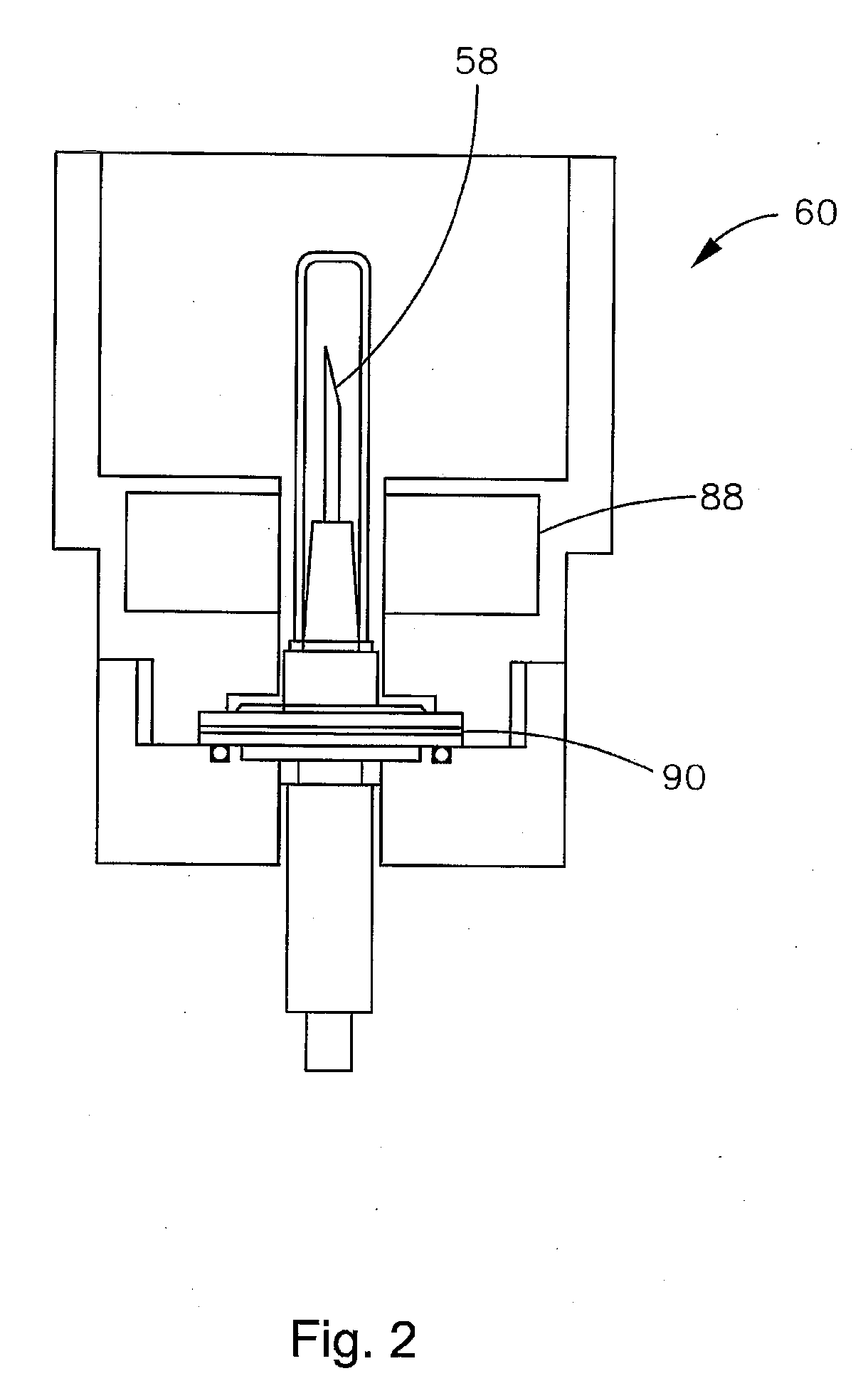

Isotope-doped nano-material, method for making the same, and labeling method using the same

An isotope-doped nano-structure of an element is provided. The isotope-doped nano-structure includes at least one isotope-doped nano-structure segment having at least two isotopes of the element, and the at least two isotopes of the element are mixed uniformly in a certain proportion. The present disclosure also provides a method for making the isotope-doped nano-structures, and a labeling method using the isotope-doped nano-structures.

Owner:TSINGHUA UNIV +1

Rubidium-82 generator based on sodium nonatitanate support, and improved separation methods for the recovery of strontium-82 from irradiated targets

InactiveUS7476377B2Effective recoveryTransuranic element compoundsOther chemical processesLow affinityRubidium

Sodium nonatitanate compositions, a method using the composition for recovery of 82Sr from irradiated targets, and a method using the composition for generating 82Rb. The sodium nonatitanate materials of the invention are highly selective at separating strontium from solutions derived from the dissolution of irradiated target materials, thus reducing target processing times. The compositions also have a very low affinity for rubidium, making it an ideal material for use as a 82Rb generator. Sodium nonatitanate materials of this type both improve the recovery of 82Sr and provide a safer, more effective 82Rb generator system.

Owner:LYNNTECH

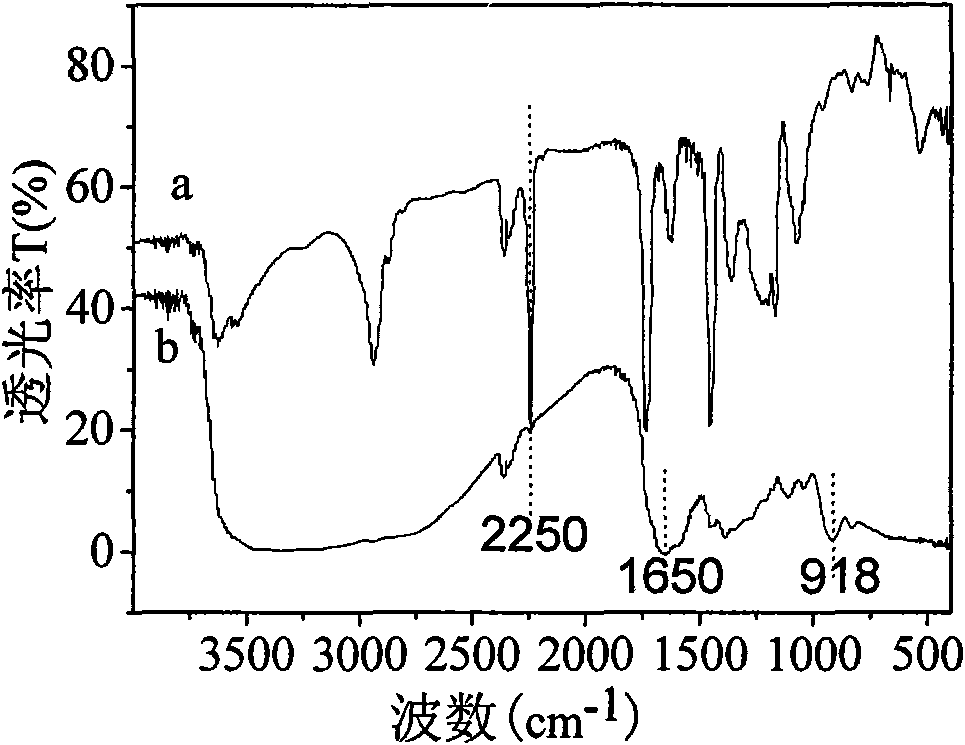

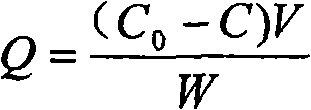

Preparation method of amidoxime group uranium extraction sorbent

InactiveCN101596449AHigh mechanical strengthImprove adsorption capacityOther chemical processesUranium compoundsAlcoholSorbent

The invention discloses a preparation method of amidoxime group uranium extraction sorbent, comprising the following steps: firstly, adopting polyacrylonitrile powder as a raw material, producing uranium extraction sorbent containing amidoxime group by amidoximation; adding titanium dioxide sol which is prepared by the sol-gel method for blending to ensure that the weight percent of titanium dioxide and polyacrylonitrile is 0.4-2.0%; producing hybridized amidoxime group uranium extraction sorbent by water washing, alcohol washing and drying. The invention has the advantages that the amidoxime group uranium extraction sorbent material which is hybridized with titanium dioxide has higher mechanical strength, higher adsorption quantity of uranium, and higher adsorption selectivity to uranium in the presence of calcium and magnesium ions.

Owner:OCEAN UNIV OF CHINA

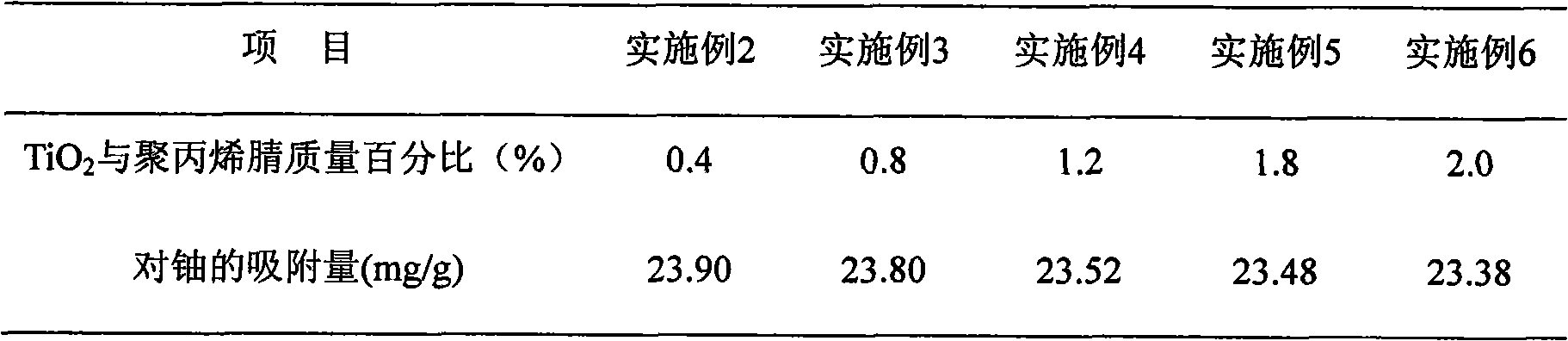

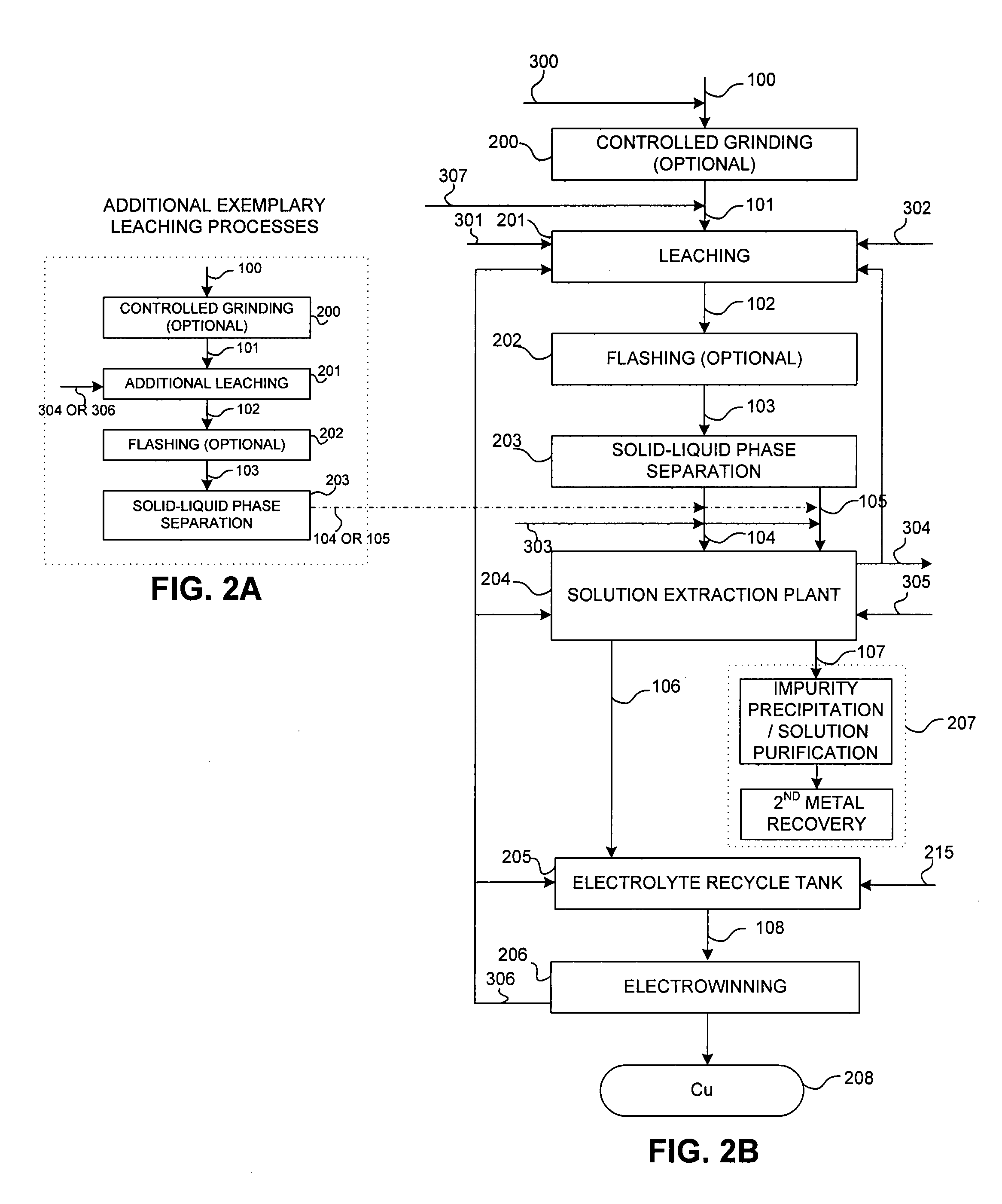

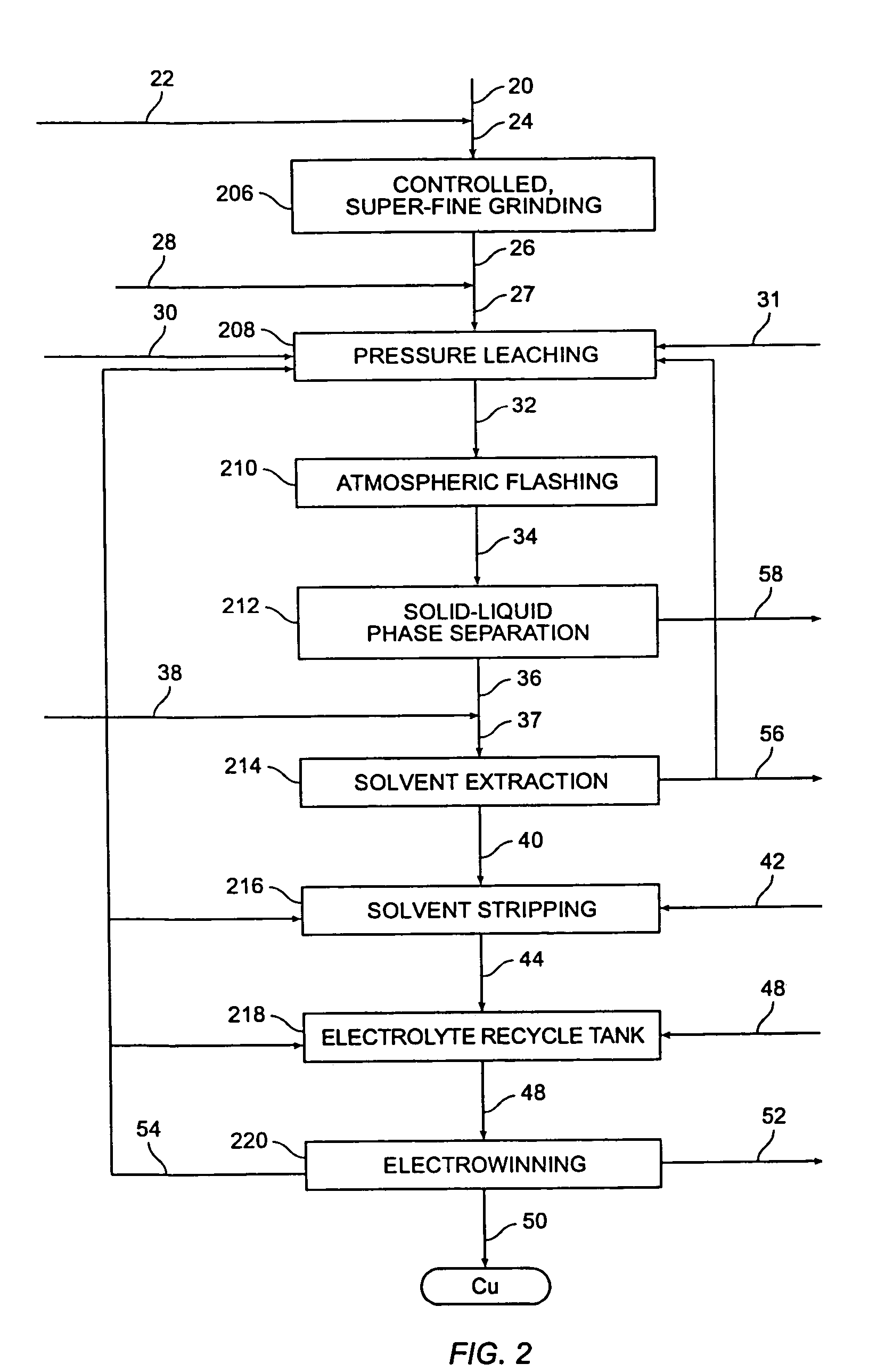

Controlled copper leach recovery circuit

ActiveUS20090074639A1Effective recoveryLow constantPhotography auxillary processesTransuranic element compoundsPregnant leach solutionLower grade

The present invention relates generally to a process for controlled leaching and sequential recovery of two or more metals from metal-bearing materials. In one exemplary embodiment, recovery of metals from a leached metal-bearing material is controlled and improved by providing a high grade pregnant leach solution (“HGPLS”) and a low grade pregnant leach solution (“LGPLS”) to a single solution extraction plant comprising at least two solution extractor units, at least two stripping units, and, optionally, at least one wash stage.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

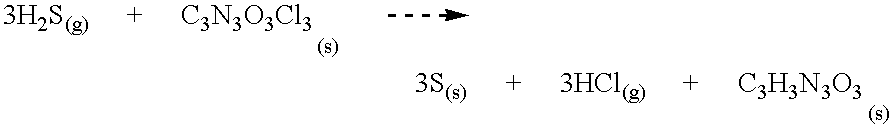

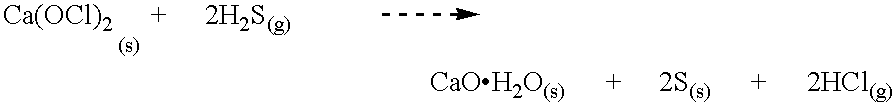

Hydrogen sulfide abatement with scale control and/or well acidizing

InactiveUS6375907B1Avoid disadvantagesLow costHydrogen bromideLiquid degasificationHydrogen halidePower station

The emissions of hydrogen sulfide during the production of natural gas, oil or geothermal fluids from subterranean formations and the subsequent processing of these fluids is reduced by converting the hydrogen sulfide into a hydrogen halide or a halogen acid and then using the hydrogen halide or halogen acid for scale control and / or well acidizing. In a preferred embodiment, hydrogen sulfide produced with geothermal fluids is converted into hydrochloric acid, which is then used to reduce pH and control scale formation during the extraction of energy from geothermal fluids in a geothermal power plant.

Owner:UNION OIL OF CALIFORNIA

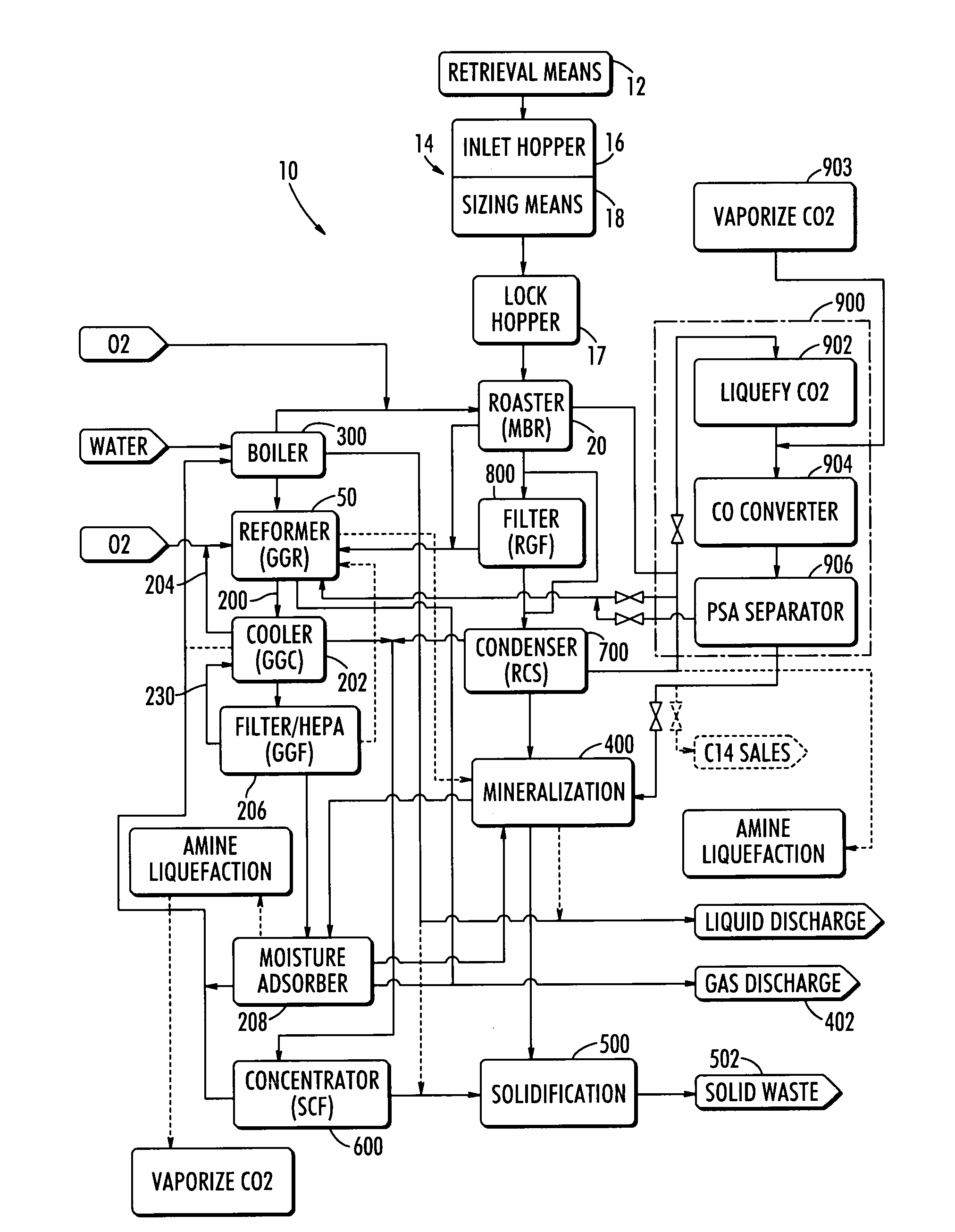

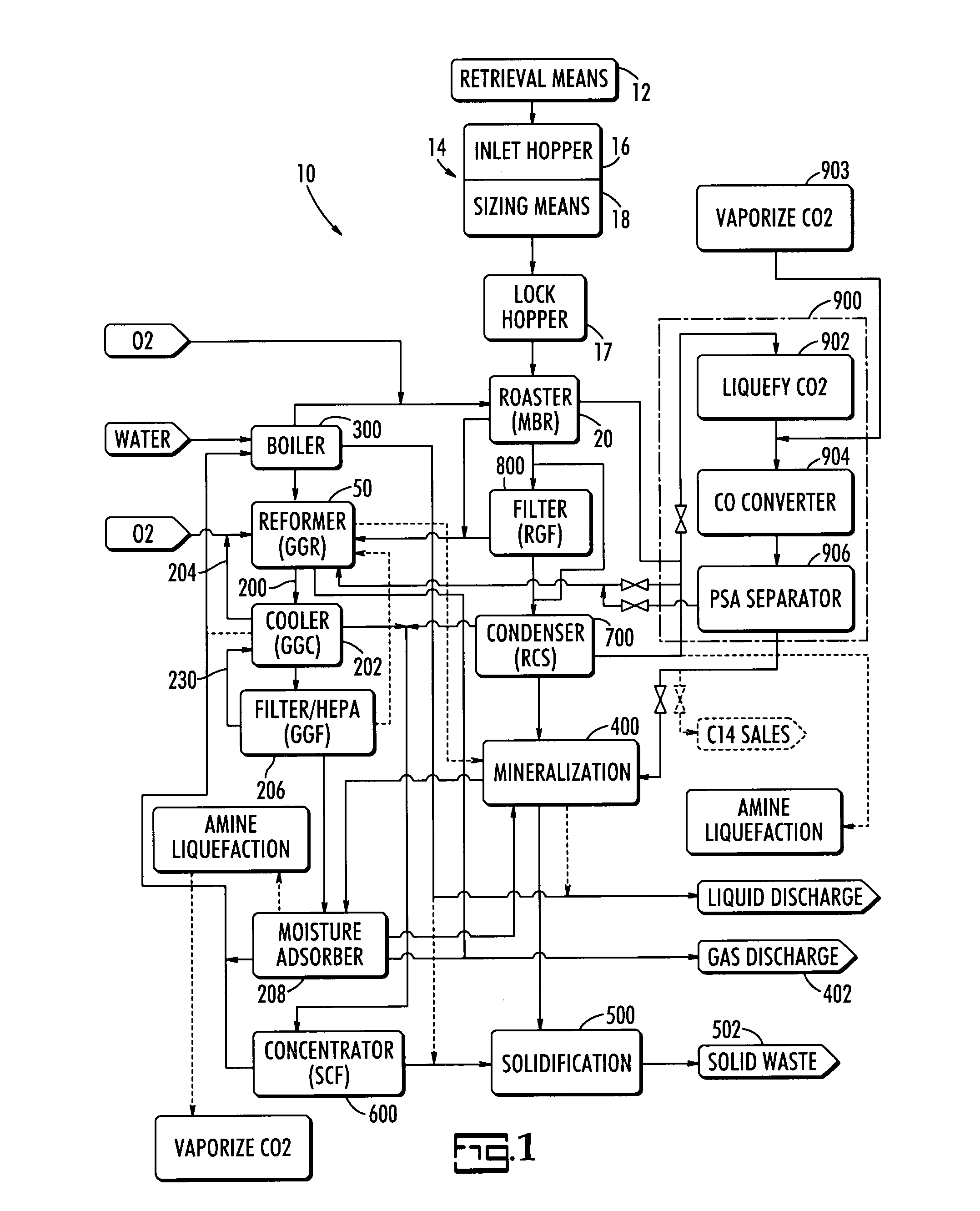

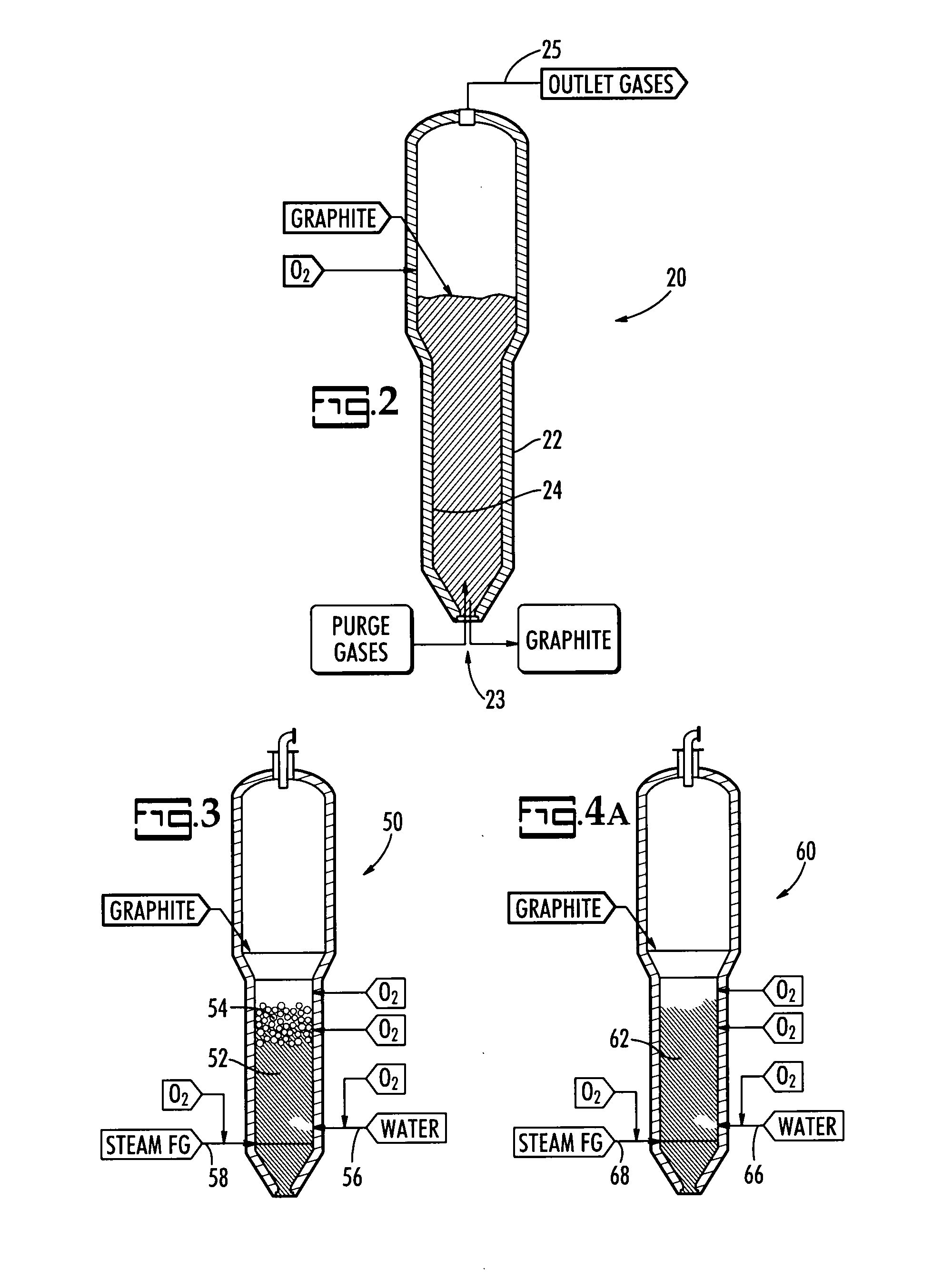

Steam reforming process system for graphite destruction and capture of radionuclides

InactiveUS20080181835A1Step is made and efficientAvoid excessive dischargeTransuranic element compoundsRadium compoundsProcess systemsSteam reforming

A system for the treatment and recycling of graphite containing radionuclides including a two stage method that employes a thermal roaster that is operatively connected to a steam reformer. In the first stage, radioactive graphite is roasted or heated to volatize a first amount of radionuclides contained in the graphite. In the second stage, the roasted graphite is reacted with steam or gases containing water vapor so that a second amount of radionuclides is removed. Optionally, the present system also processes the radionuclides to enable their disposal.

Owner:STUDSVIK INC

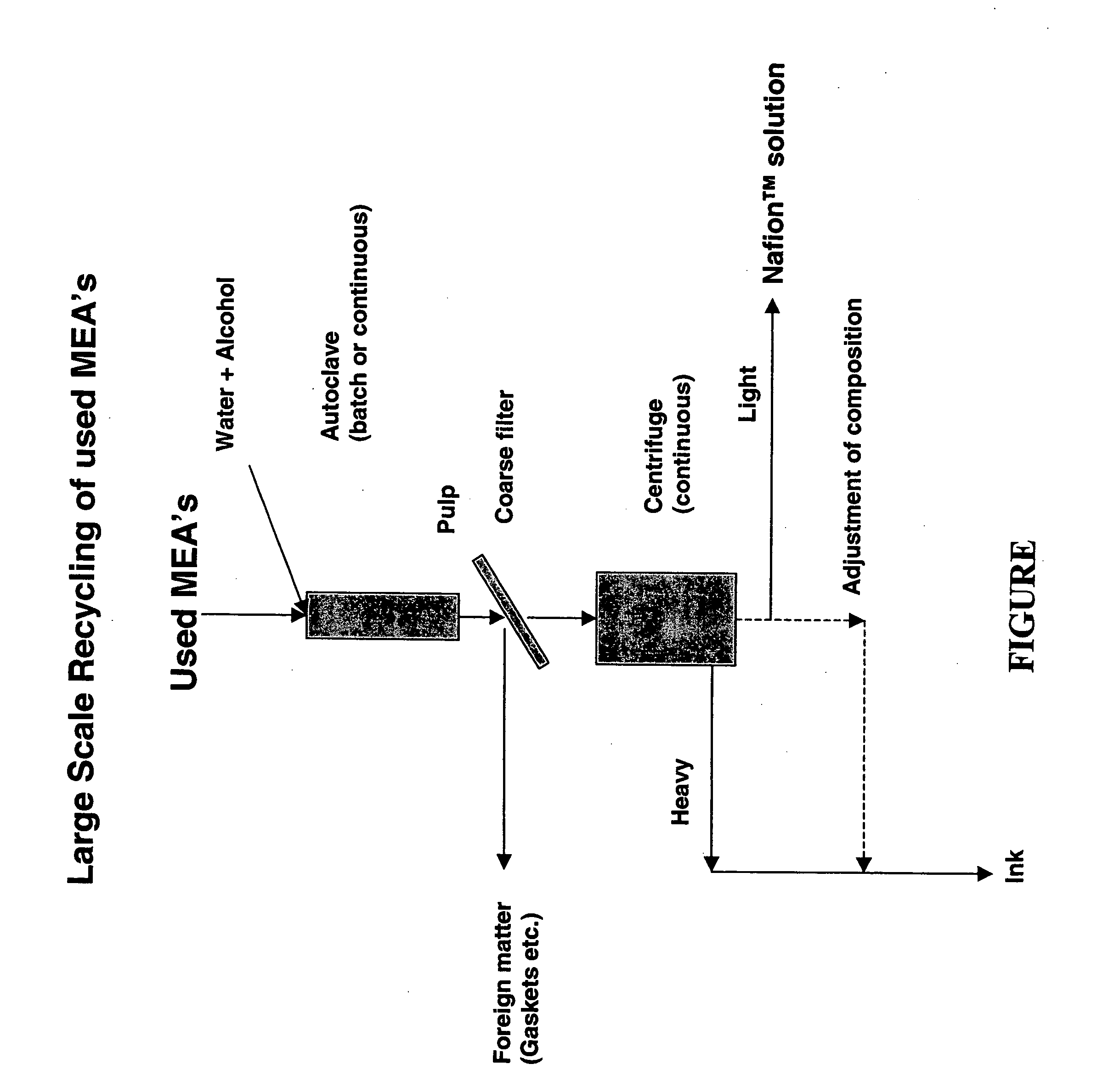

Recycling of used perfluorosulfonic acid membranes

InactiveUS20050211630A1Guaranteed long-term availabilityIncrease consumptionTransuranic element compoundsActive material electrodesSolventMembrane configuration

Owner:ION POWER

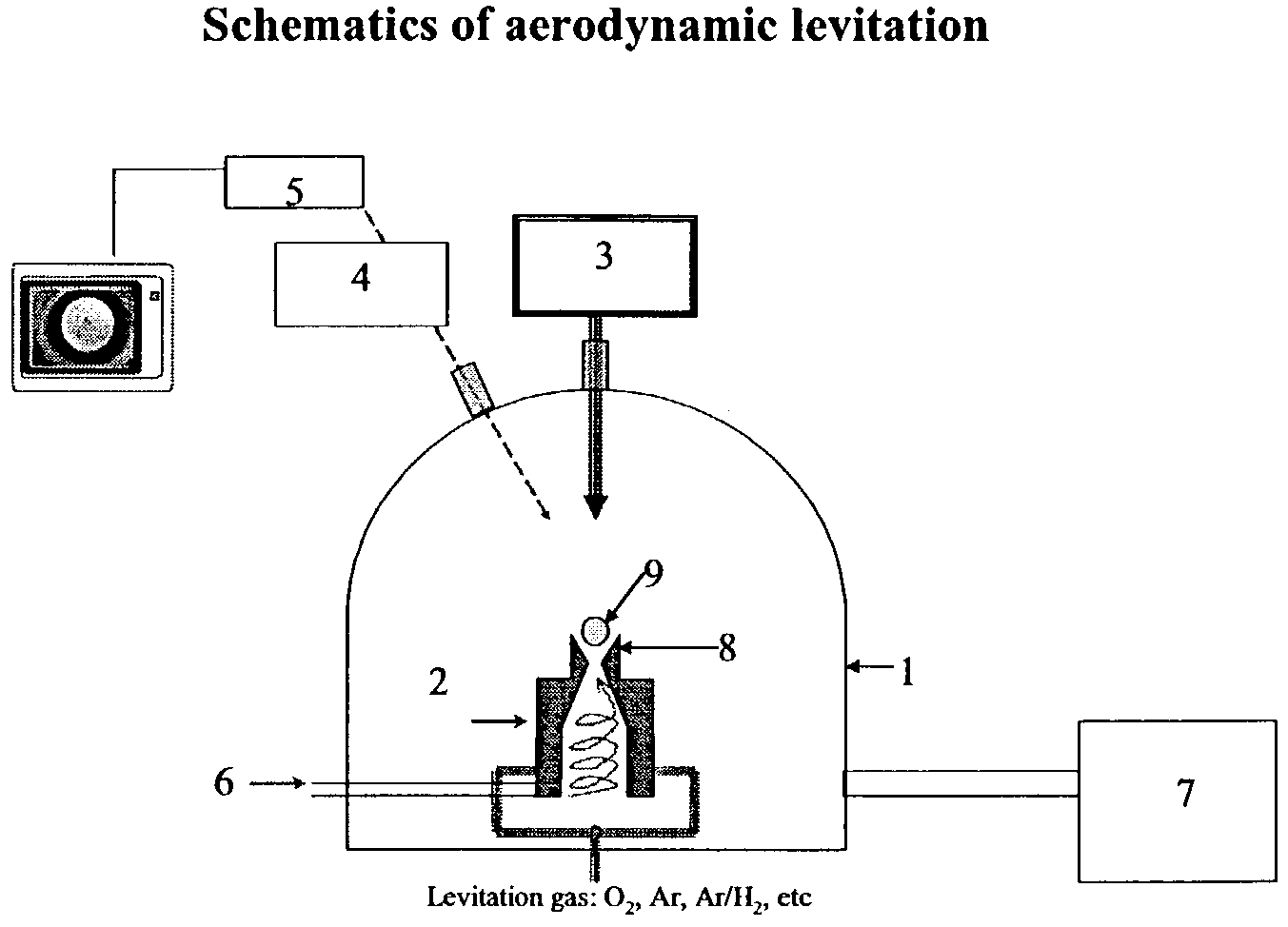

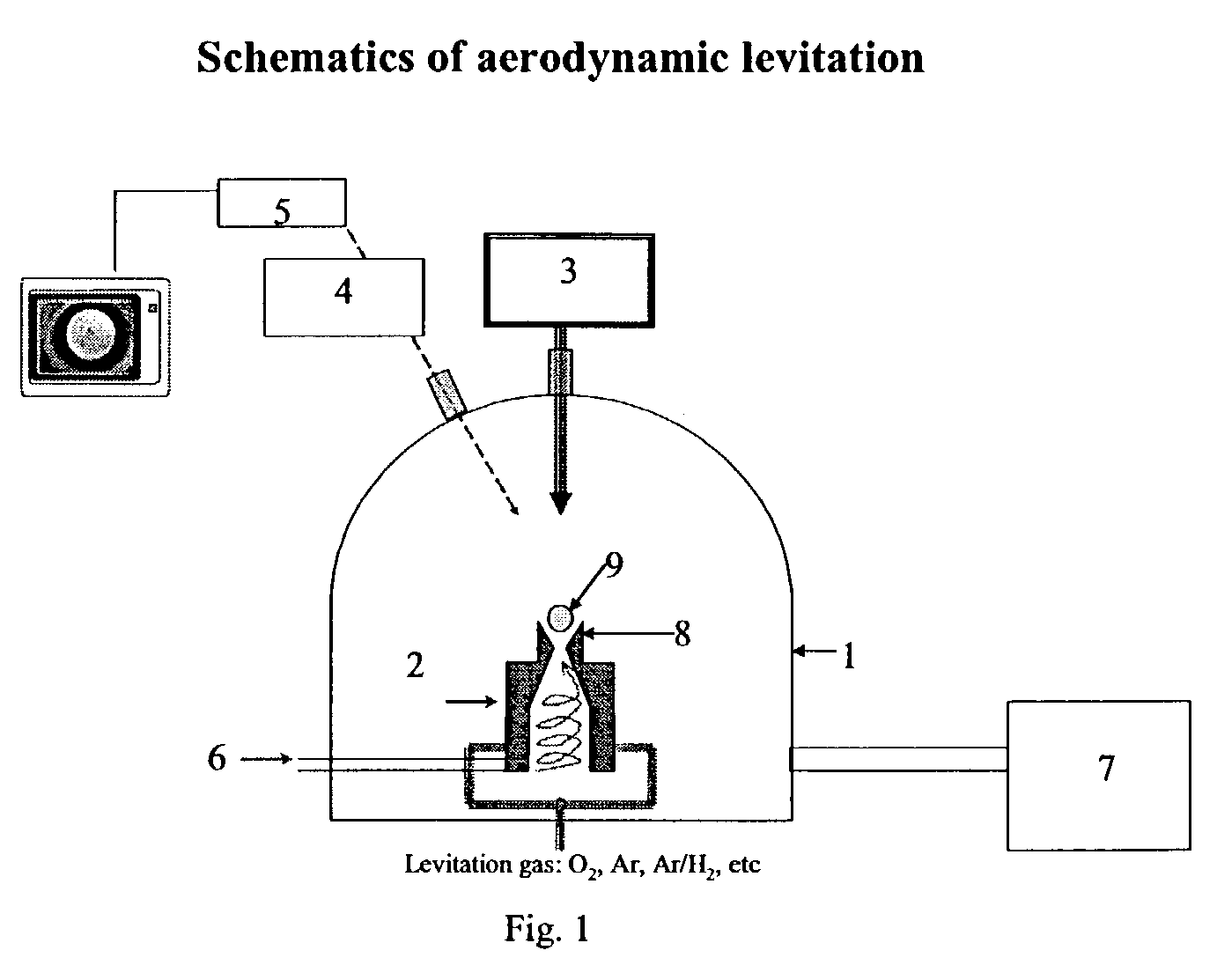

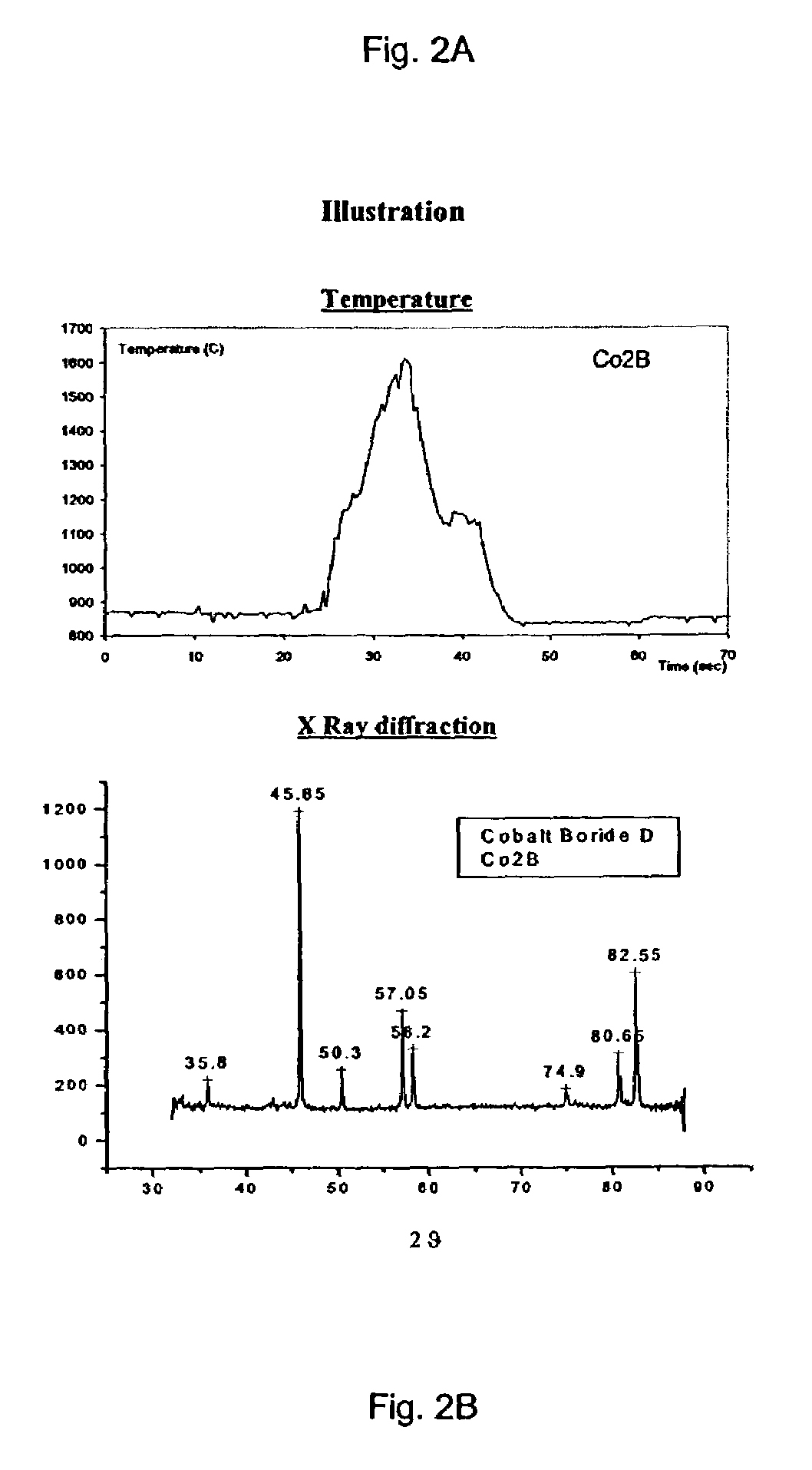

Method for synthesizing extremely high-temperature melting materials

The invention relates to a method of synthesizing high-temperature melting materials. More specifically the invention relates to a containerless method of synthesizing very high temperature melting materials such as borides, carbides and transition-metal, lanthanide and actinide oxides, using an Aerodynamic Levitator and a laser. The object of the invention is to provide a method for synthesizing extremely high-temperature melting materials that are otherwise difficult to produce, without the use of containers, allowing the manipulation of the phase (amorphous / crystalline / metastable) and permitting changes of the environment such as different gaseous compositions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Methods for making and processing metal targets for producing Cu-67 radioisotope for medical applications

ActiveUS20100028234A1Improve productivitySimple methodBacterial antigen ingredientsTransuranic element compoundsHigh energyCompound (substance)

The present invention provides a method for producing Cu67 radioisotope suitable for use in medical applications. The method comprises irradiating a metallic zinc-68 (Zn68) target with a high energy gamma ray beam. After irradiation, the Cu67 is isolated from the Zn68 by any suitable method (e.g., chemical and / or physical separation). In a preferred embodiment, the Cu67 is isolated by sublimation of the zinc (e.g., at about 500-700° C. under reduced pressure) to afford a copper residue containing Cu67. The Cu67 can be further purified by chemical means (i.e., dissolution in acid, followed by ion exchange).

Owner:UCHICAGO ARGONNE LLC

Systems and methods for radioisotope generation

Owner:JUBILANT DRAXIMAGE

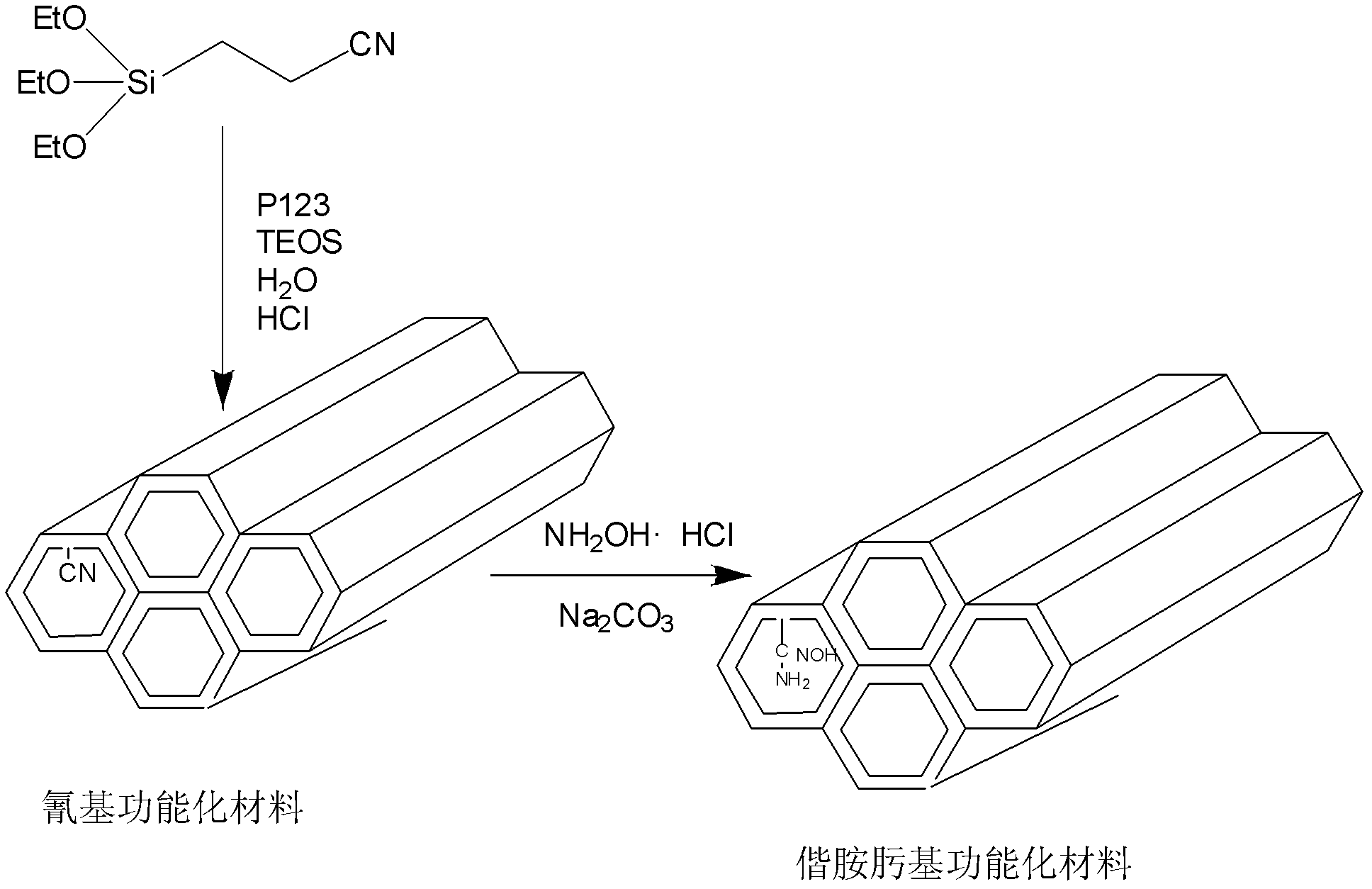

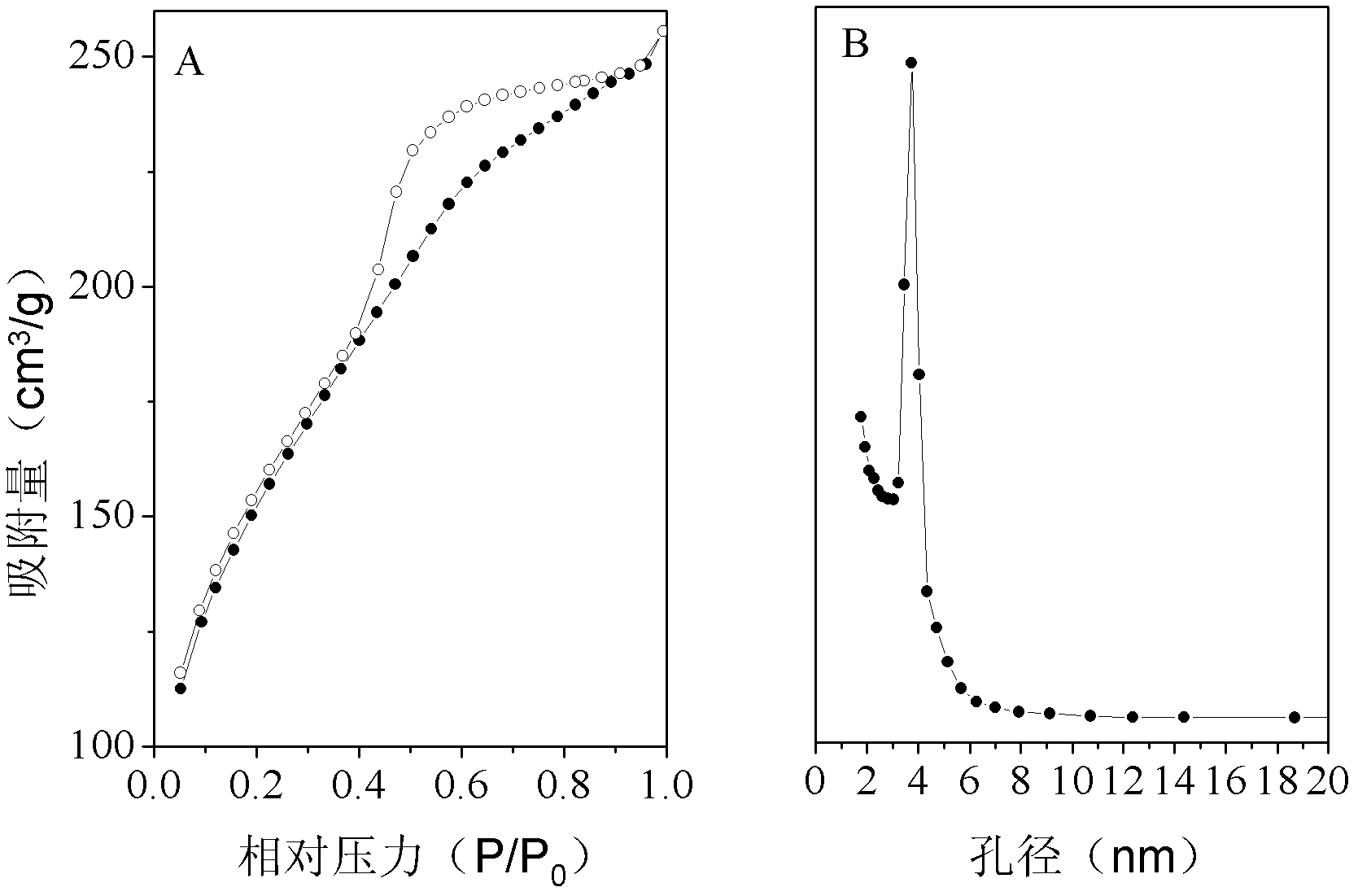

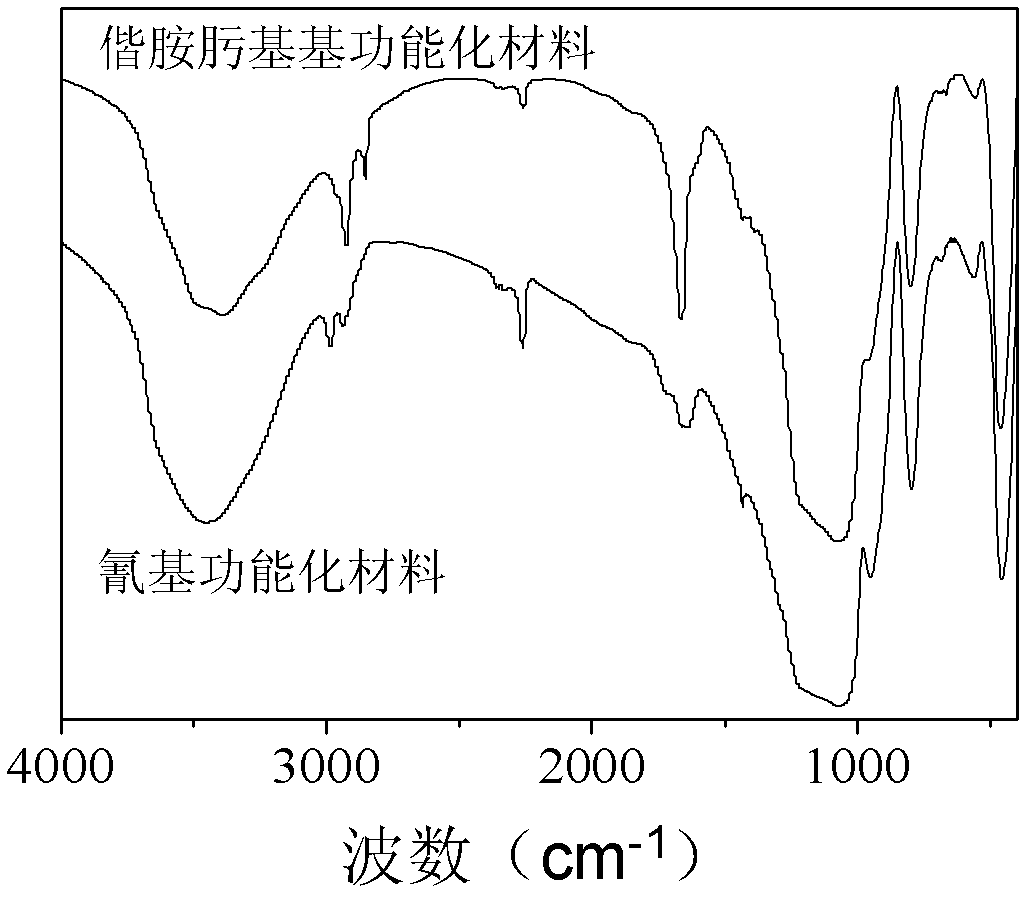

Amidoxime group uranium extraction sorbent and preparation method thereof

InactiveCN102211017AHigh mechanical strengthImprove hydrophilicityOther chemical processesUranium compoundsHydroxylamineSorbent

The invention relates to an amidoxime group uranium extraction sorbent and a preparation method thereof. The preparation method comprises the following steps: on the basis of utilizing an organic estersil containing nitrile groups and Si(OR)4 as a mixed silicone source and a nonionic type surface active agent as a structural guide agent, performing hydrolyzation and polymerization under an acidic condition to obtain a nitrile group functional organic-inorganic hybridized porous material; and reacting the nitrile group functional organic-inorganic hybridized porous material with hydroxylamine to obtain the amidoxime group uranium extraction sorbent. In the invention, cyanogroup is introduced into an inorganic material by virtue of hydrolytic condensation reaction, and the amidoxime group functional organic-inorganic hybridized porous material is prepared by virtue of amidoximation. Compared with the polymer material, the sorbent related by the invention has the advantages of obviously increased mechanical strength, strengthened hydrophilism and high uranium adsorption quantity; the amidoxime group functional organic-inorganic hybridized porous material has quite high selection to uranium almost without the interference of other coexisting ions in the solution containing Na<+>, K<+>, Ca<2+> and Mg<2+>.

Owner:OCEAN UNIV OF CHINA

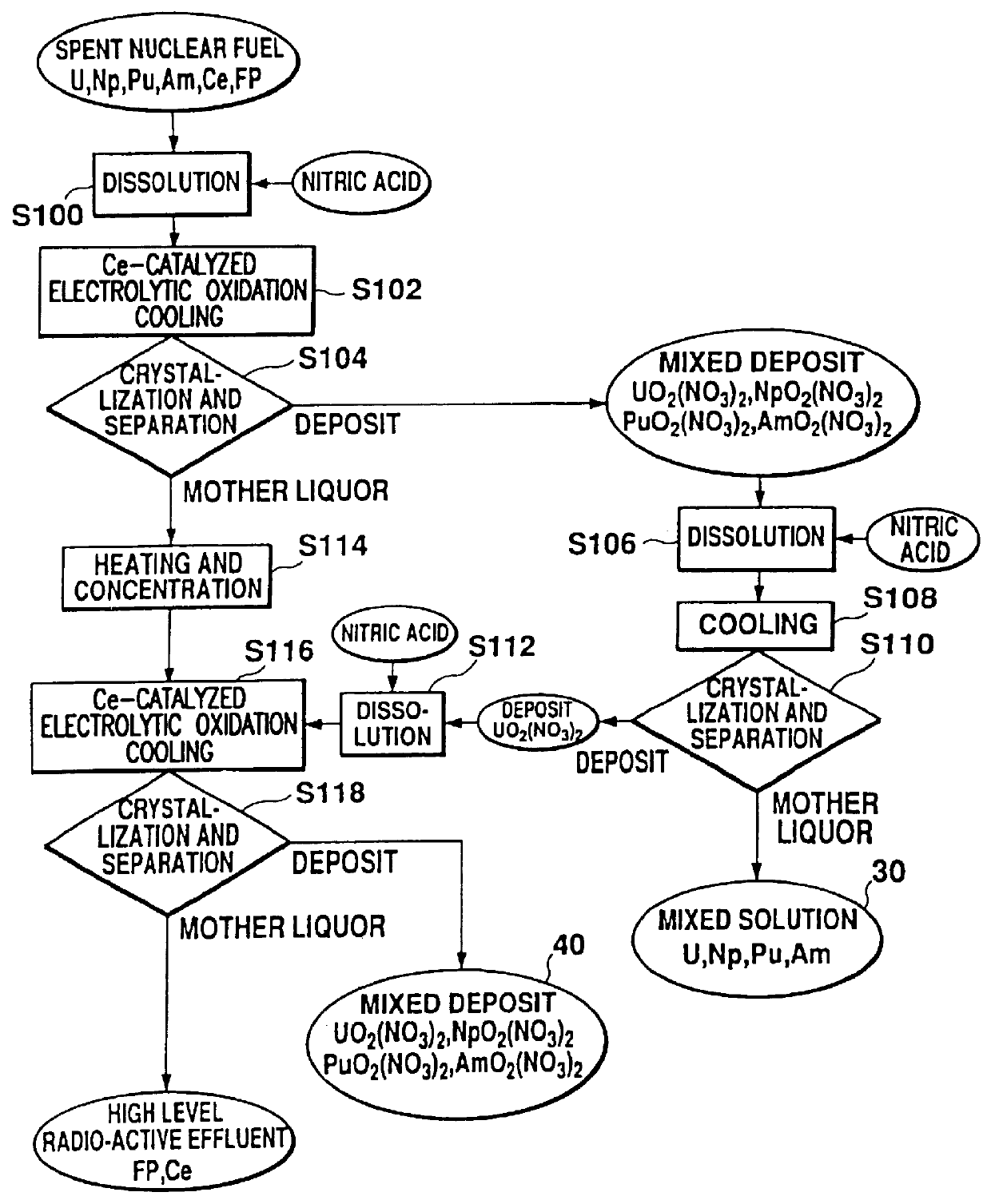

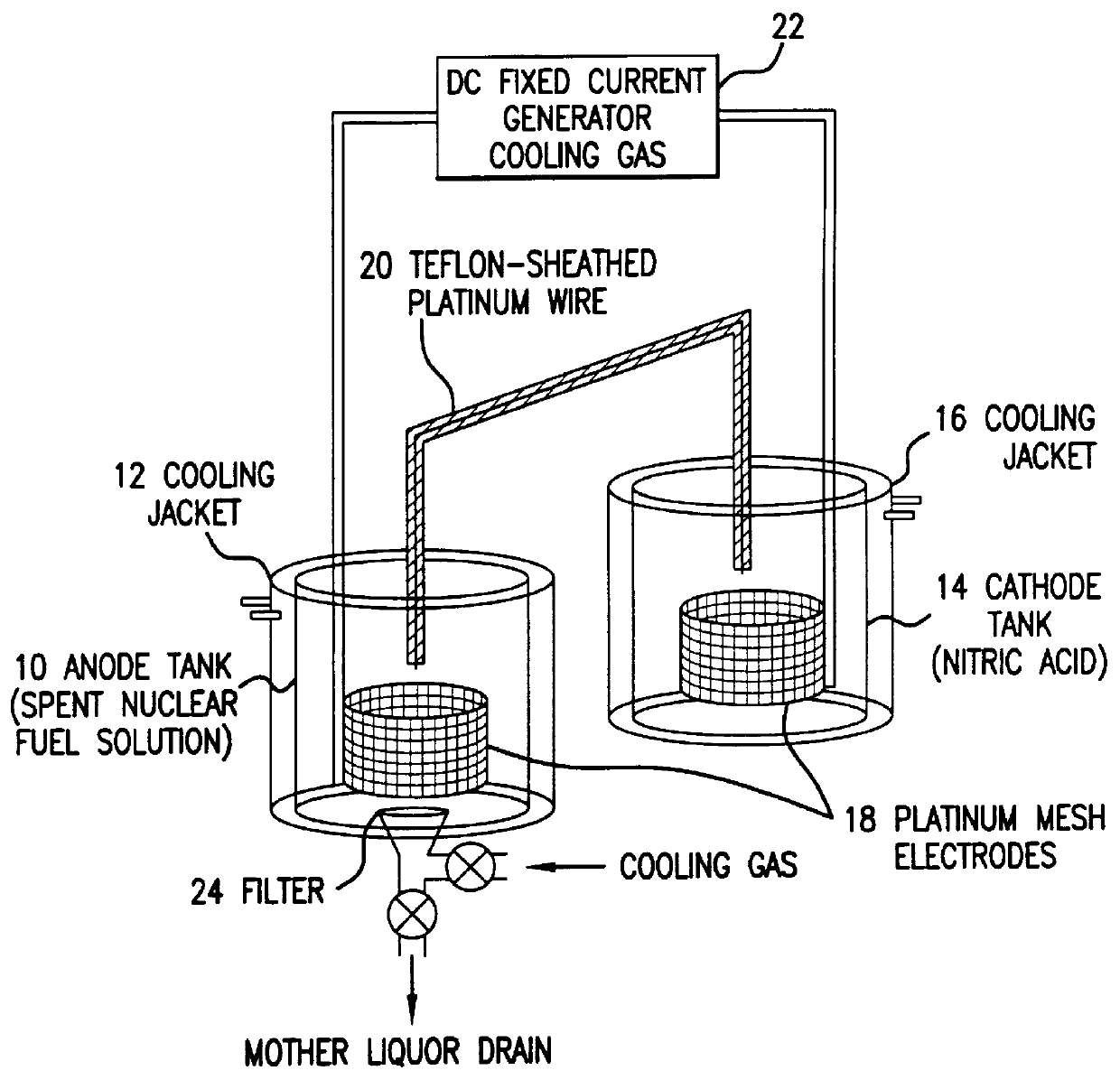

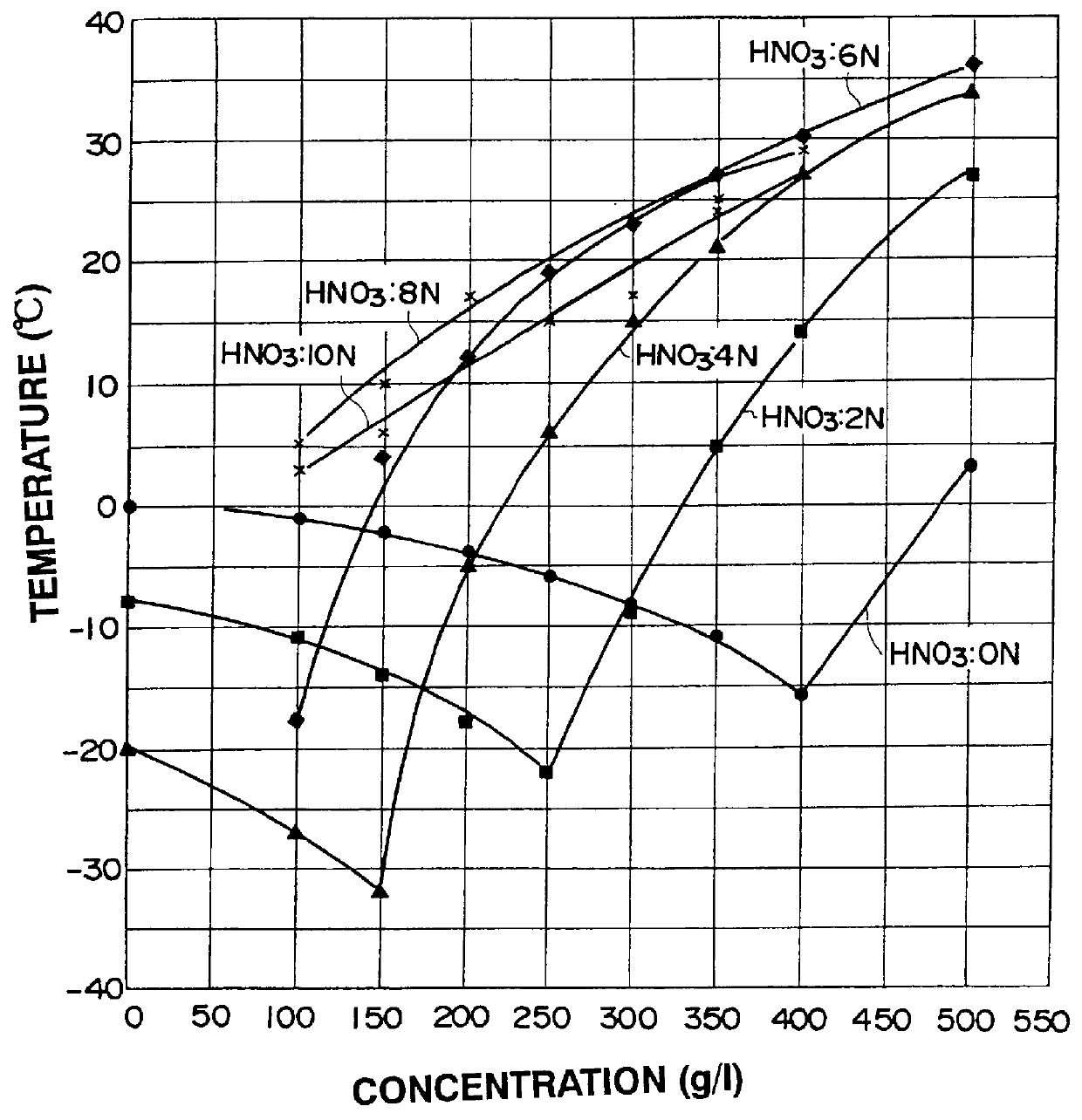

Method of recovering uranium and transuranic elements from spent nuclear fuel

InactiveUS6033636AReduce solubilityPromote recoveryElectrolysis componentsSolvent extractionSolventWaste material

The steps for recovering uranium and transuranic elements are simplified, and the generation of waste solvent and waste materials is suppressed. Spent nuclear fuel is dissolved in nitric acid (S100) and the resulting solution is subjected to electrolytic oxidation so that U, Np, Pu, Am is oxidized to VI using Ce as oxidation catalyst. The solution is cooled, and nitrates of valence VI thereby deposit as crystals and are separated from the mother liquor (S104). The mother liquor is heated and concentrated (S114). The mixed crystalline deposit is dissolved in nitric acid (S106), uranyl nitrate is deposited alone by cooling (S108), and the crystals are separated from the U, Np, Pu, Am mixed solution (S110). The uranyl nitrate is dissolved in nitric acid (S112), and the heated and concentrated mother liquor is added to it to prepare another mixed solution. This mixed solution is then subjected to electrolytic oxidation to oxidize the remaining U, Np, Pu, Am to valence VI, and the solution is cooled so that U, Np, Pu, Am are coprecipitated with uranyl nitrate as crystals, and can be separated from high level radioactive effluent (S118).

Owner:DORYOKURO KAKUNENRYO KAIHATSU JIGYODAN

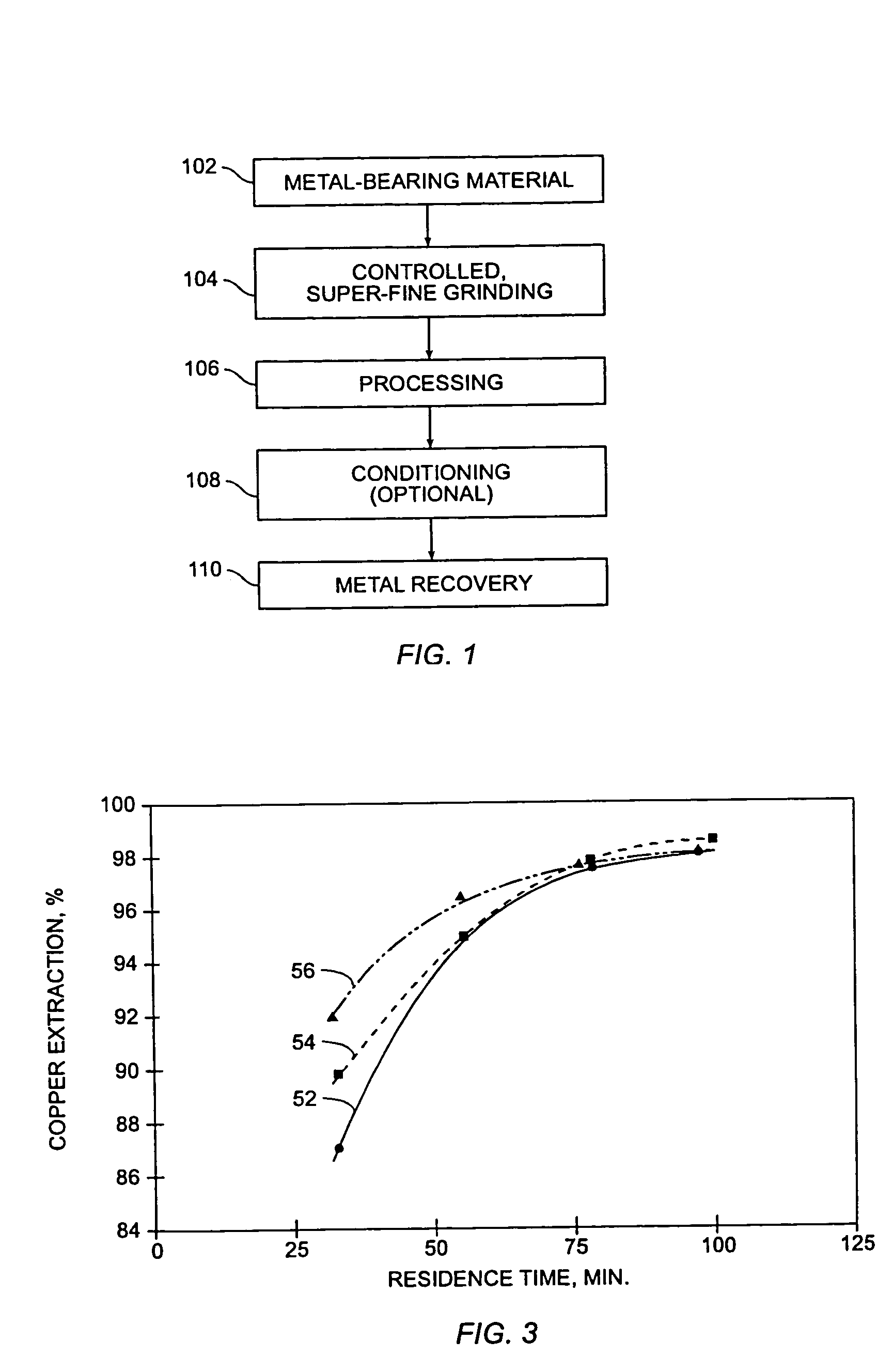

Method for recovery of metals from metal-containing materials using medium temperature pressure leaching

InactiveUS7341700B2Promote recoveryEnhanced metal value recoveryBiocideChromium compoundsRheniumMetallic materials

The present invention relates generally to a process for recovering copper and other metal values from metal-containing materials using controlled, super-fine grinding and medium temperature pressure leaching. Processes embodying aspects of the present invention may be beneficial for recovering a variety of metals such as copper, gold, silver, nickel, cobalt, molybdenum, rhenium, zinc, uranium, and platinum group metals, from metal-bearing materials, and find particular utility in connection with the extraction of copper from copper sulfide ores and concentrates.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

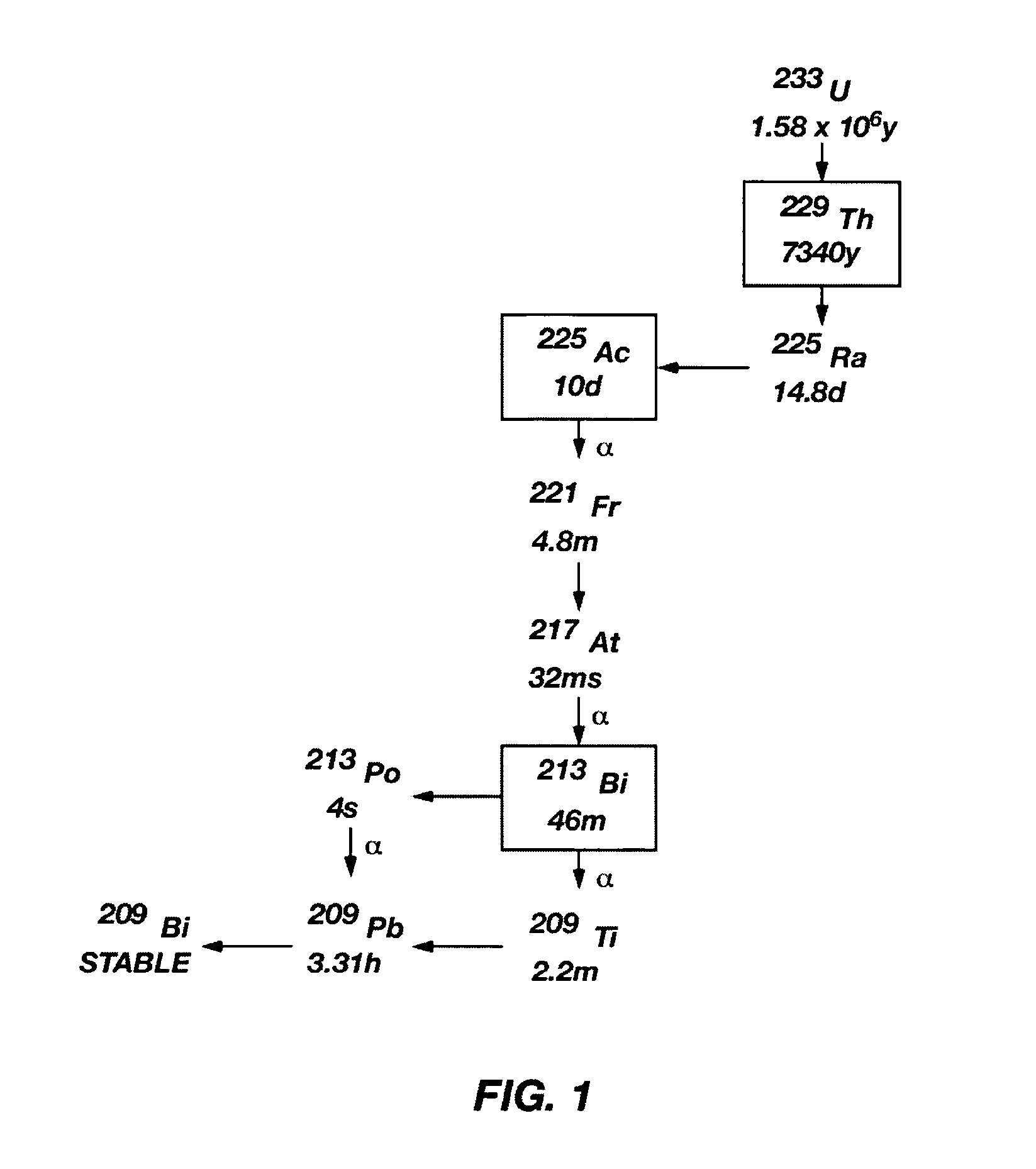

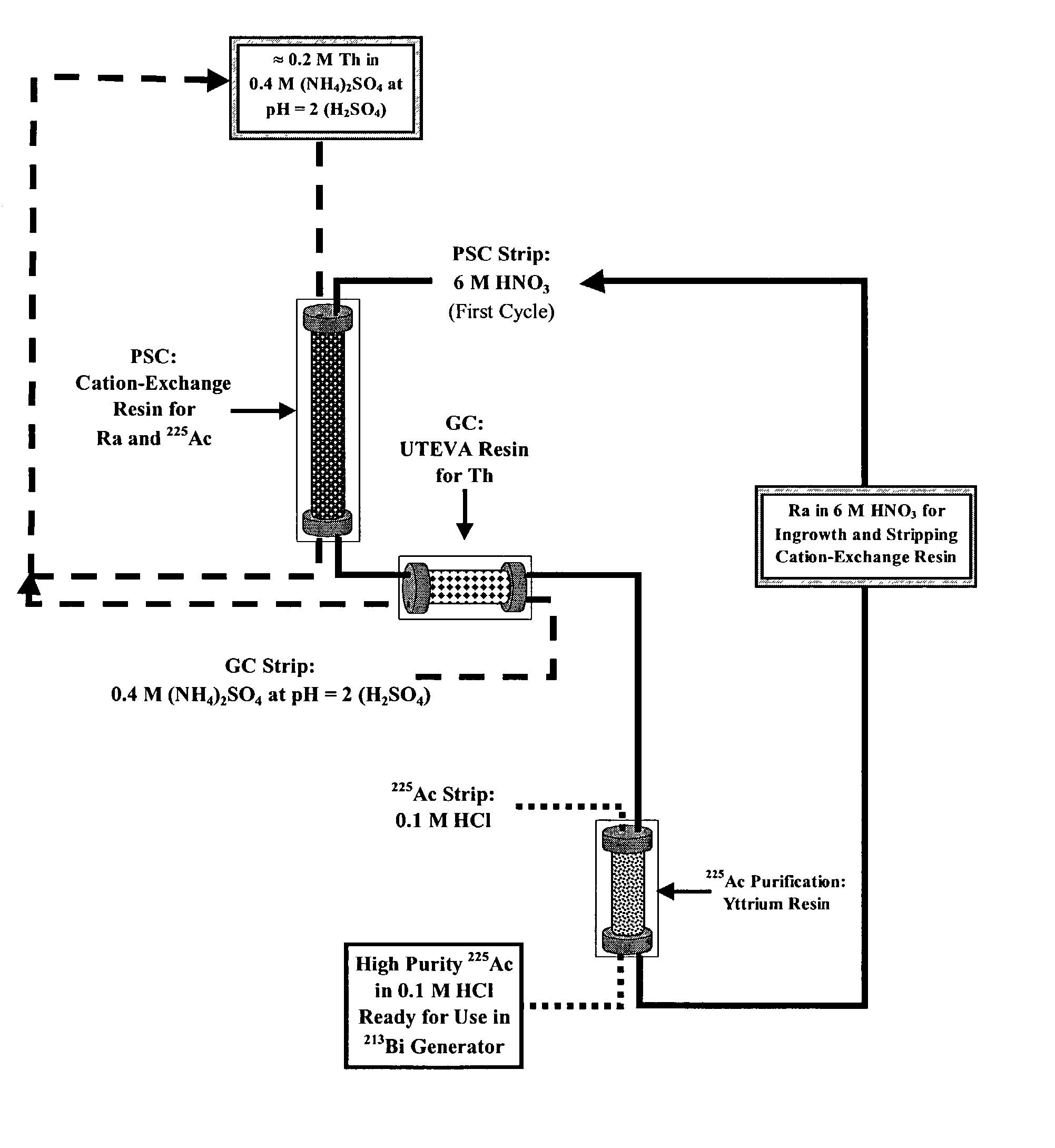

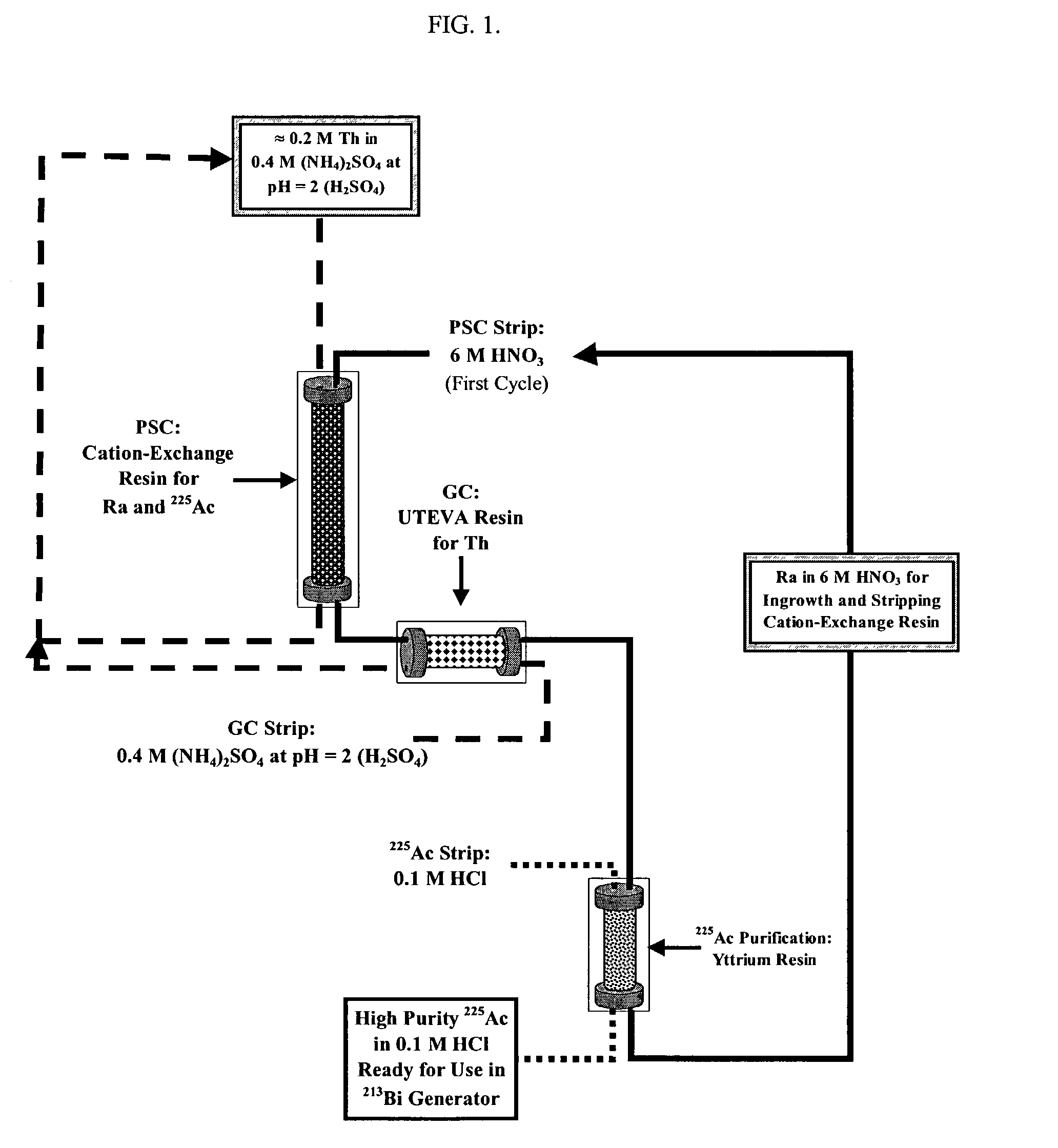

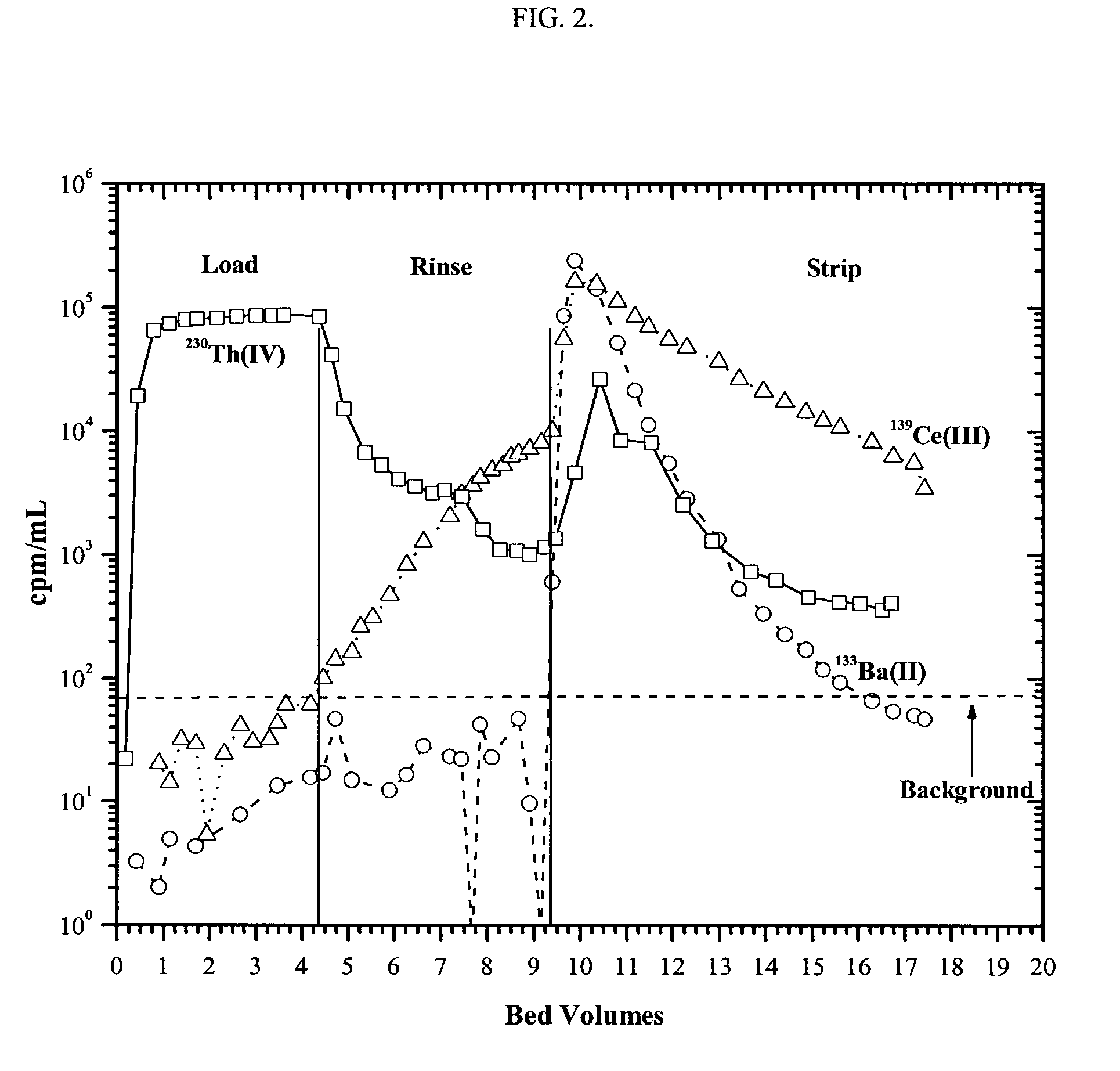

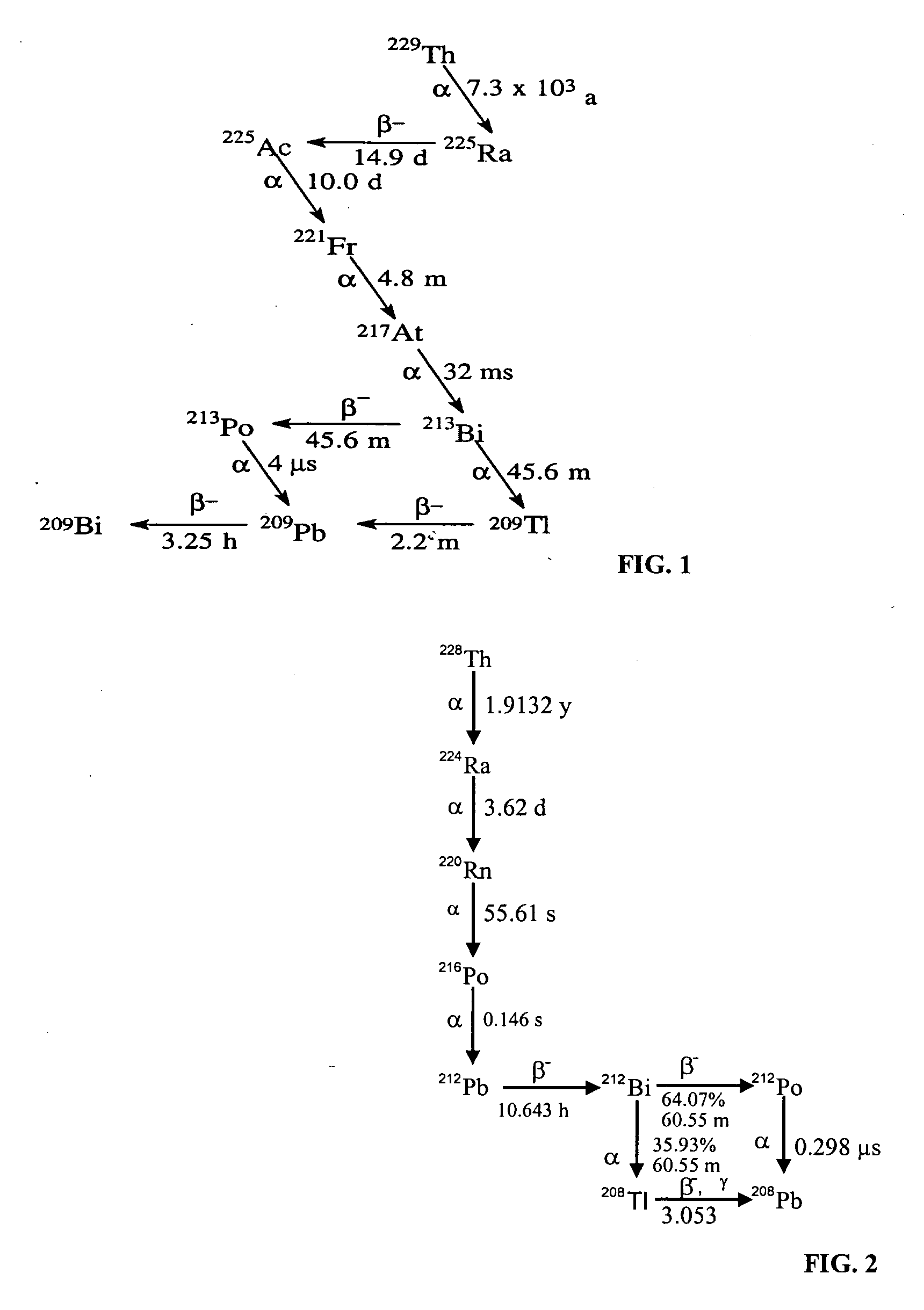

Multicolumn selectivity inversion generator for production of high purity actinium for use in therapeutic nuclear medicine

InactiveUS7087206B2Separation efficiency is highSmall volumeIsotope delivery systemsTransuranic element compoundsActiniumRadiation damage

A multicolumn selectivity inversion generator separation method has been developed in which actinium ions, a desired daughter radionuclide, are selectively extracted from a solution of the thorium parent and daughter radionuclides by a primary separation column, stripped, and passed through a second guard column that retains any parent or other daughter interferents, while the desired daughter actinium ions and radium ions elute. This separation method minimizes the effects of radiation damage to the separation material and permits the reliable production of radionuclides of high chemical and radionuclidic purity for use in diagnostic or therapeutic nuclear medicine.

Owner:PG RES FOUND

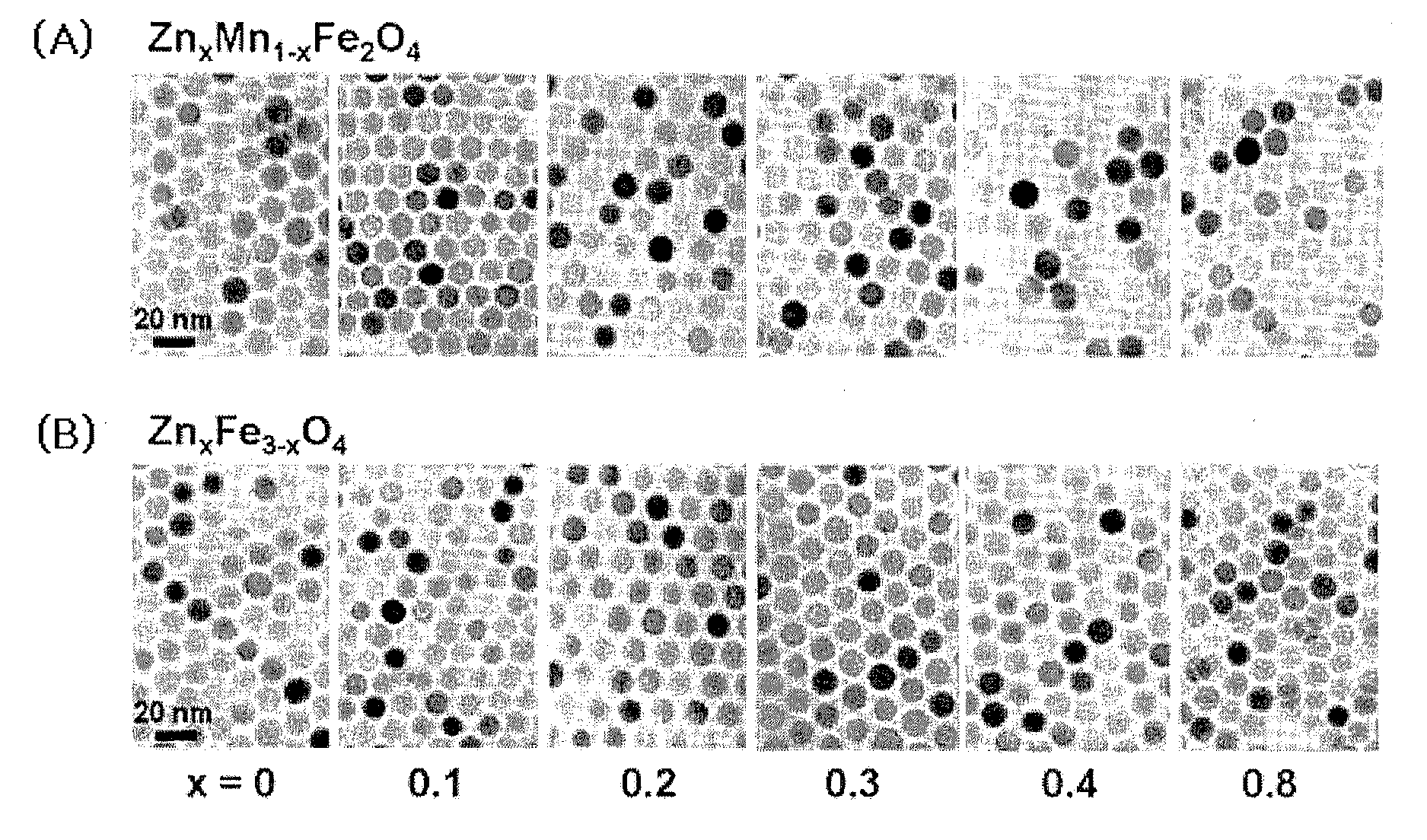

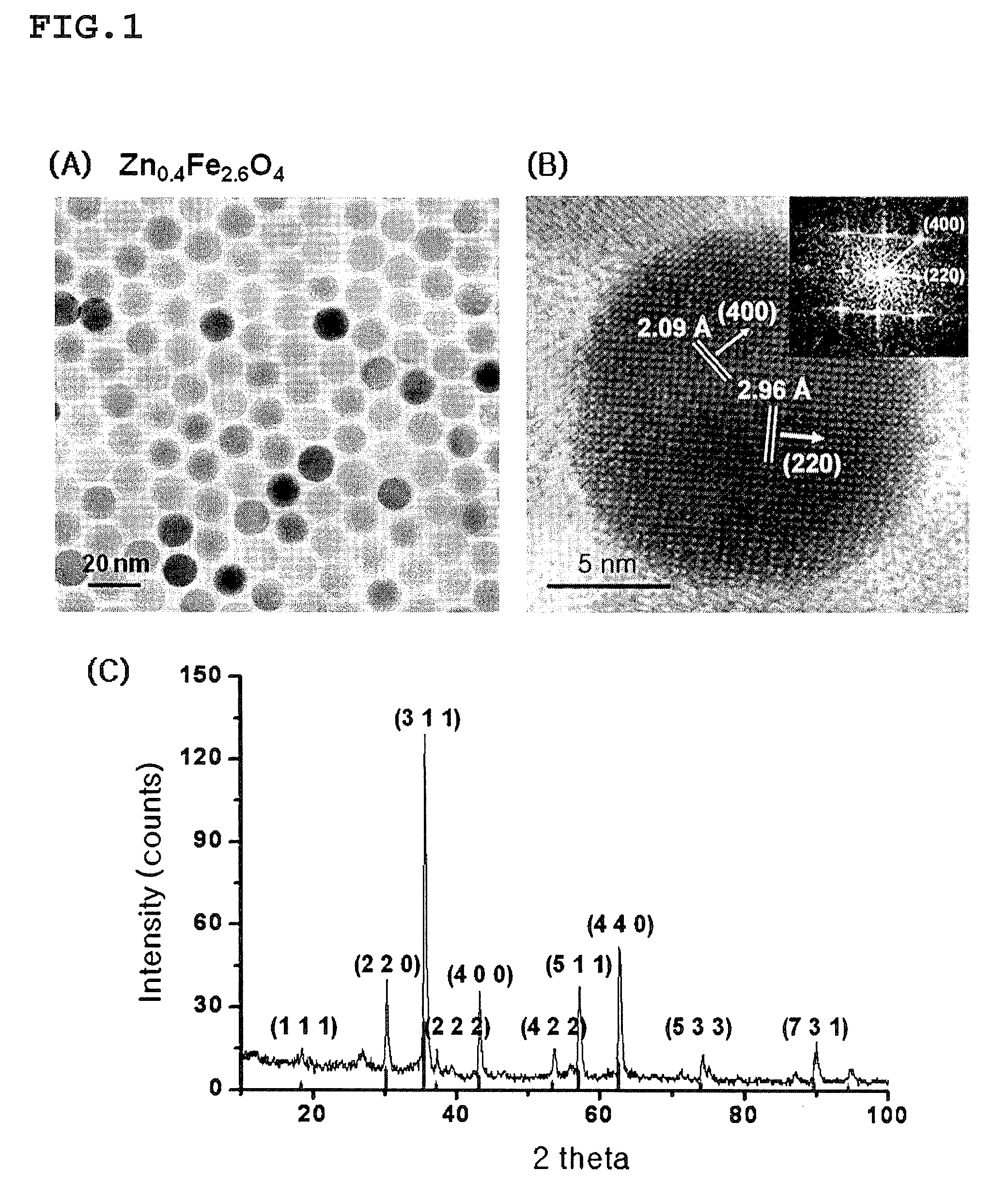

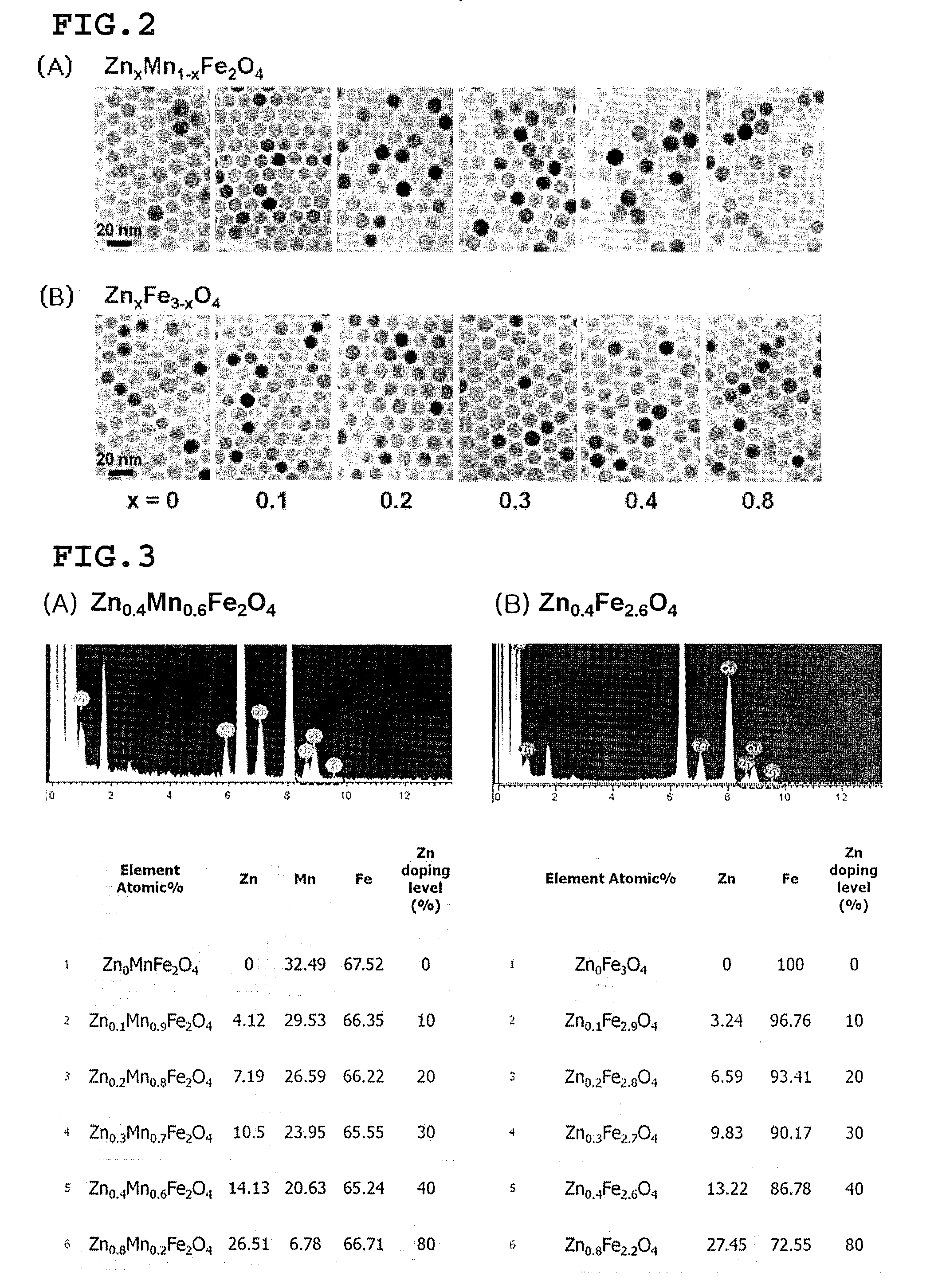

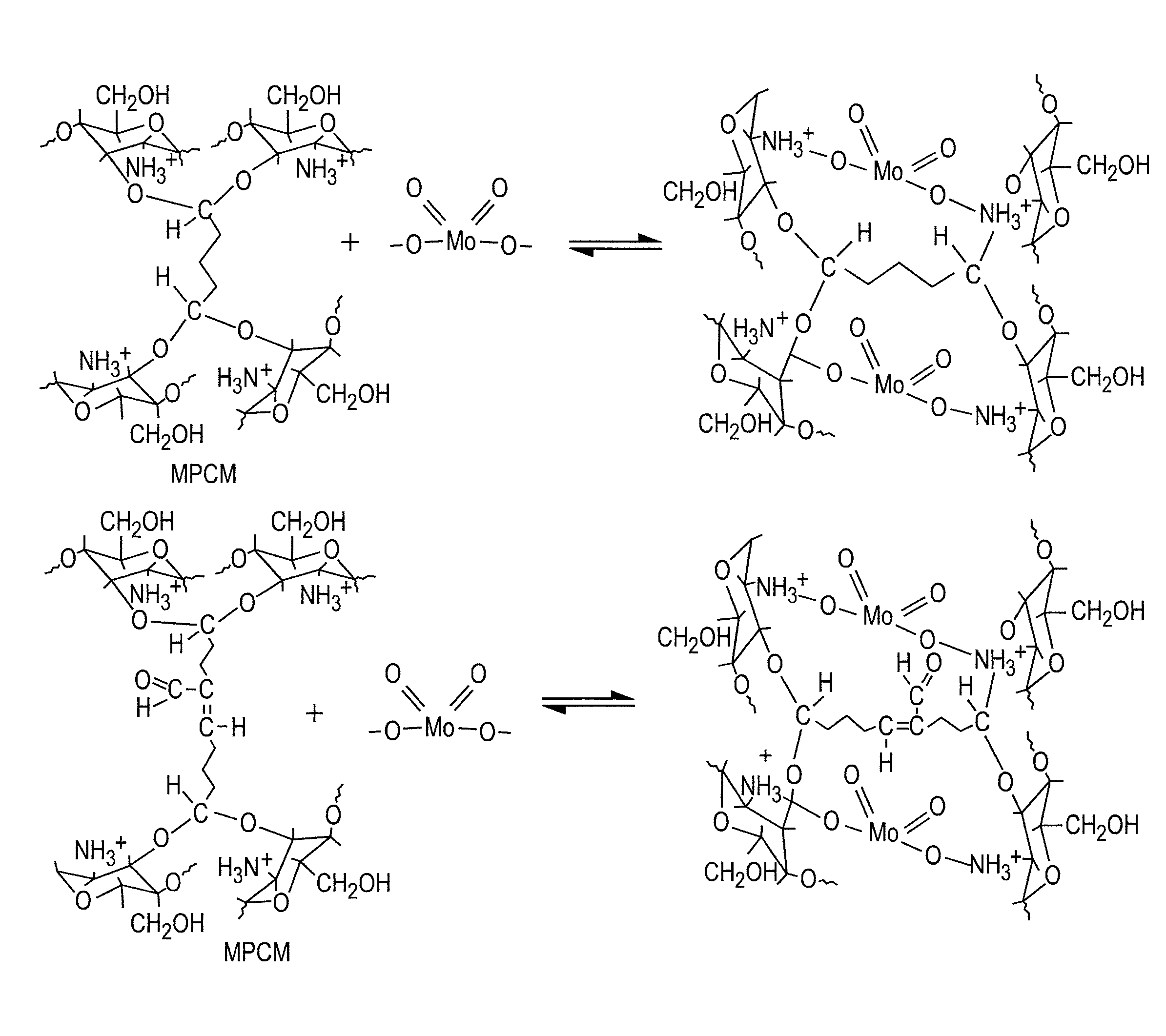

Magnetic resonance imaging contrast agents comprising zinc-containing magnetic metal oxide nanoparticles

ActiveUS20100143263A1Improve magnetic propertiesLow cytotoxicityBiocideNanomagnetismMRI contrast agentMetal oxide nanoparticles

The present invention relates to an MRI contrast agent that includes zinc-containing water-soluble metal oxide nanoparticles and has an improved contrast effect. The zinc-containing water-soluble metal oxide nanoparticles are characterized by addition of zinc to a matrix comprising the metal oxide nanoparticles or by substitution of metal in the matrix, resulting in the improved contrast effect of MRI. In addition, the zinc-containing metal oxide nanoparticles of the present invention include the MRI contrast agent t having hybrid structures of “zinc-containing metal oxide nanoparticle—biologically / chemically active material” in which the nanoparticle is conjugated with a bioactive material such as proteins, antibodies, and chemical materials.

Owner:INVENTERA PHARM INC

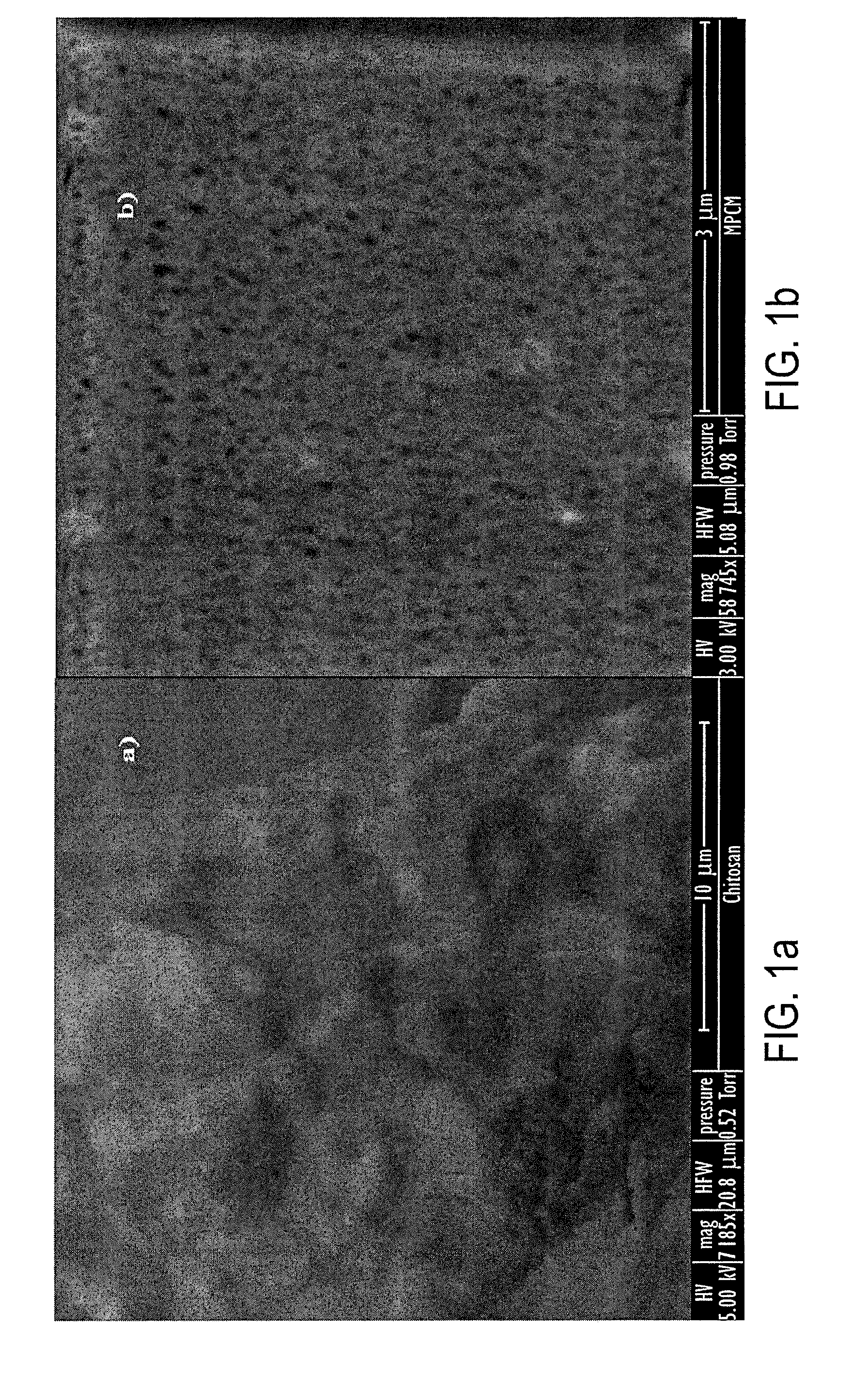

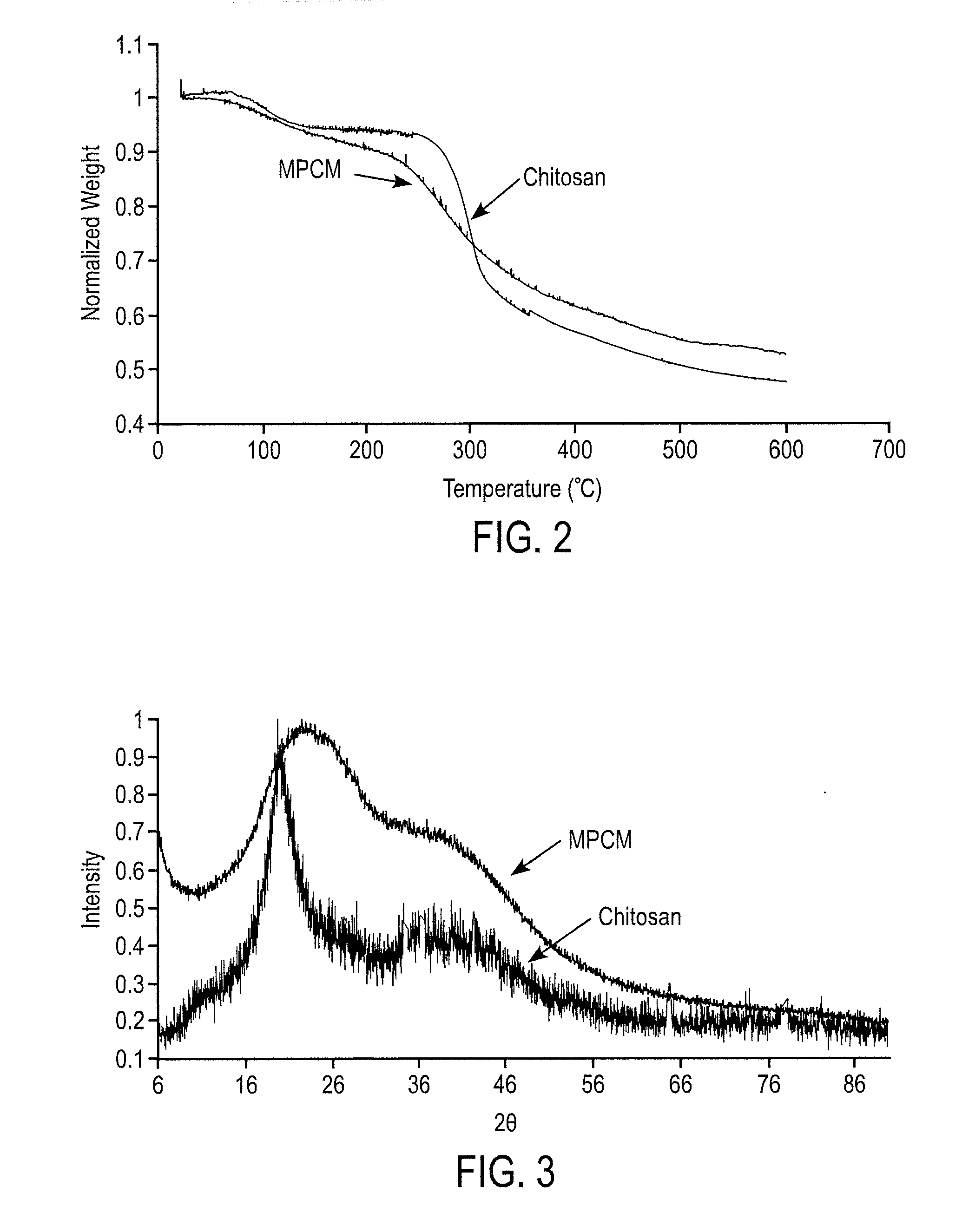

Preparation of chitosan-based microporous composite material and its applications

ActiveUS20130039822A1The material is lowCostTransuranic element compoundsRadium compoundsCrosslinked chitosanSorbent

Microporous glutaraldehyde-crosslinked chitosan sorbents, methods of making and using them, and a generator for the radioisotope 99Mo containing the sorbents.

Owner:PERMA FIX ENVIRONMENTAL SERVICES

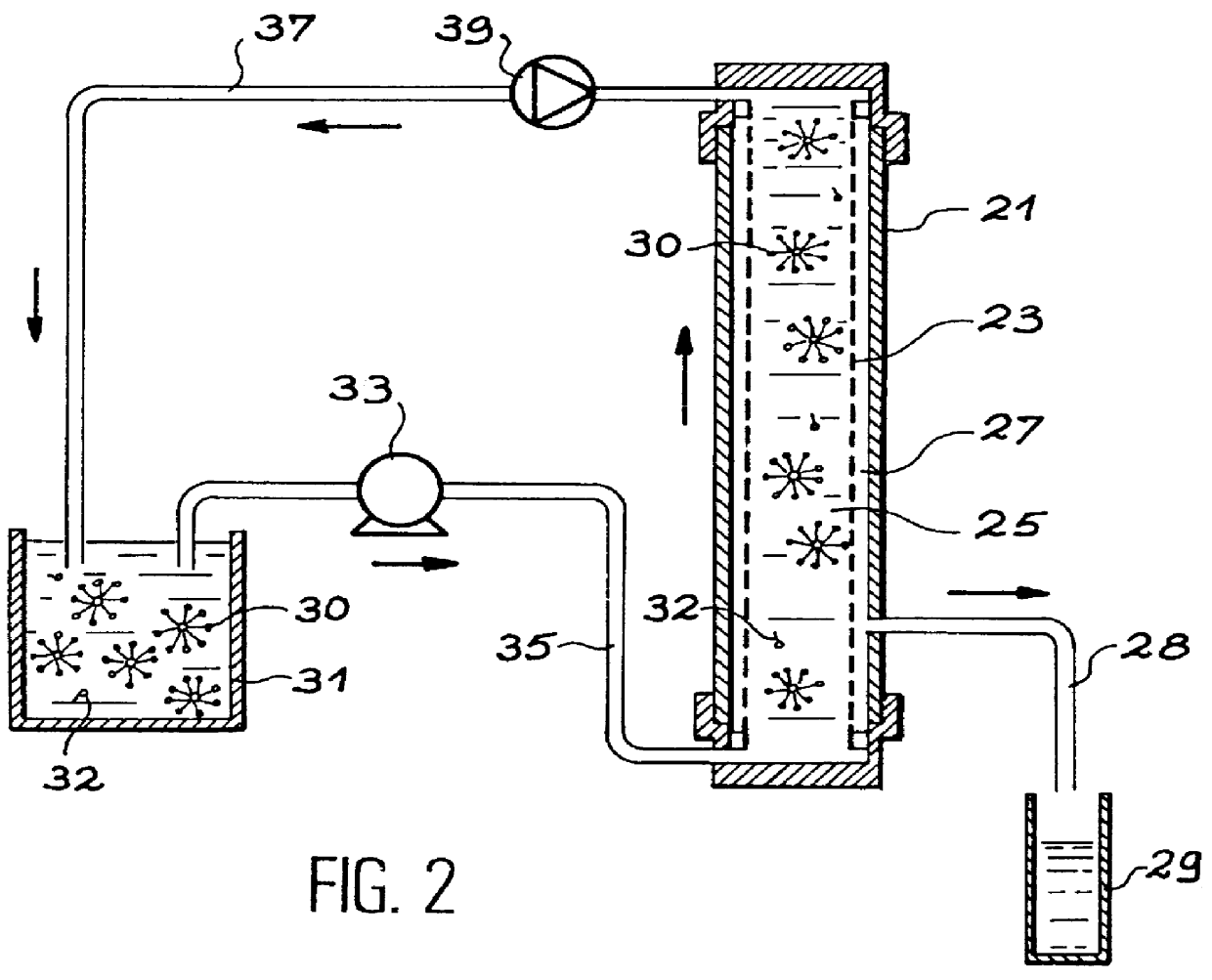

Process for radioisotope recovery and system for implementing same

InactiveUS20060153760A1Sure easySolvent extractionTransuranic element compoundsSource materialIon exchange

A method of recovering daughter isotopes from a radioisotope mixture. The method comprises providing a radioisotope mixture solution comprising at least one parent isotope. The at least one parent isotope is extracted into an organic phase, which comprises an extractant and a solvent. The organic phase is substantially continuously contacted with an aqueous phase to extract at least one daughter isotope into the aqueous phase. The aqueous phase is separated from the organic phase, such as by using an annular centrifugal contactor. The at least one daughter isotope is purified from the aqueous phase, such as by ion exchange chromatography or extraction chromatography. The at least one daughter isotope may include actinium-225, radium-225, bismuth-213, or mixtures thereof. A liquid-liquid extraction system for recovering at least one daughter isotope from a source material is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

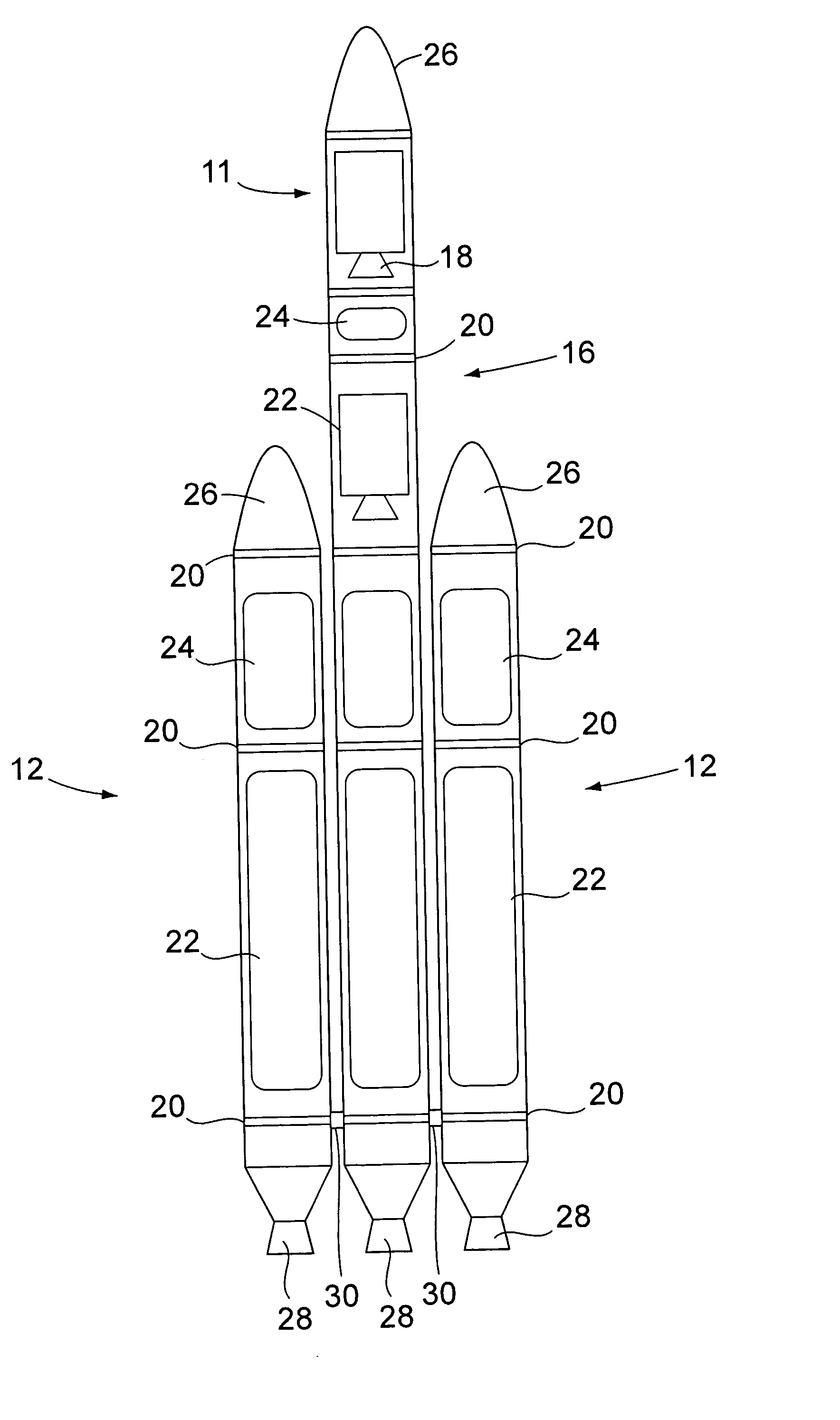

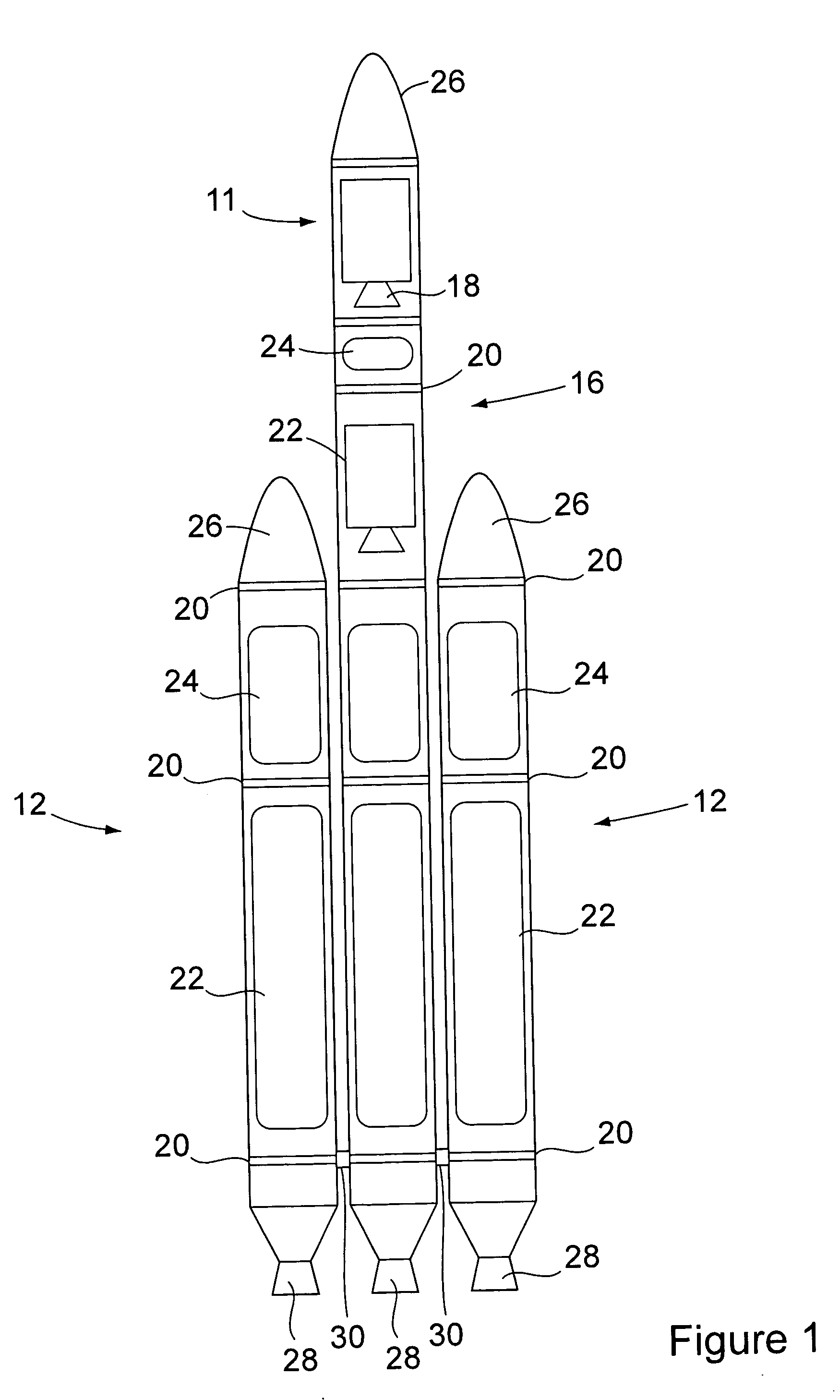

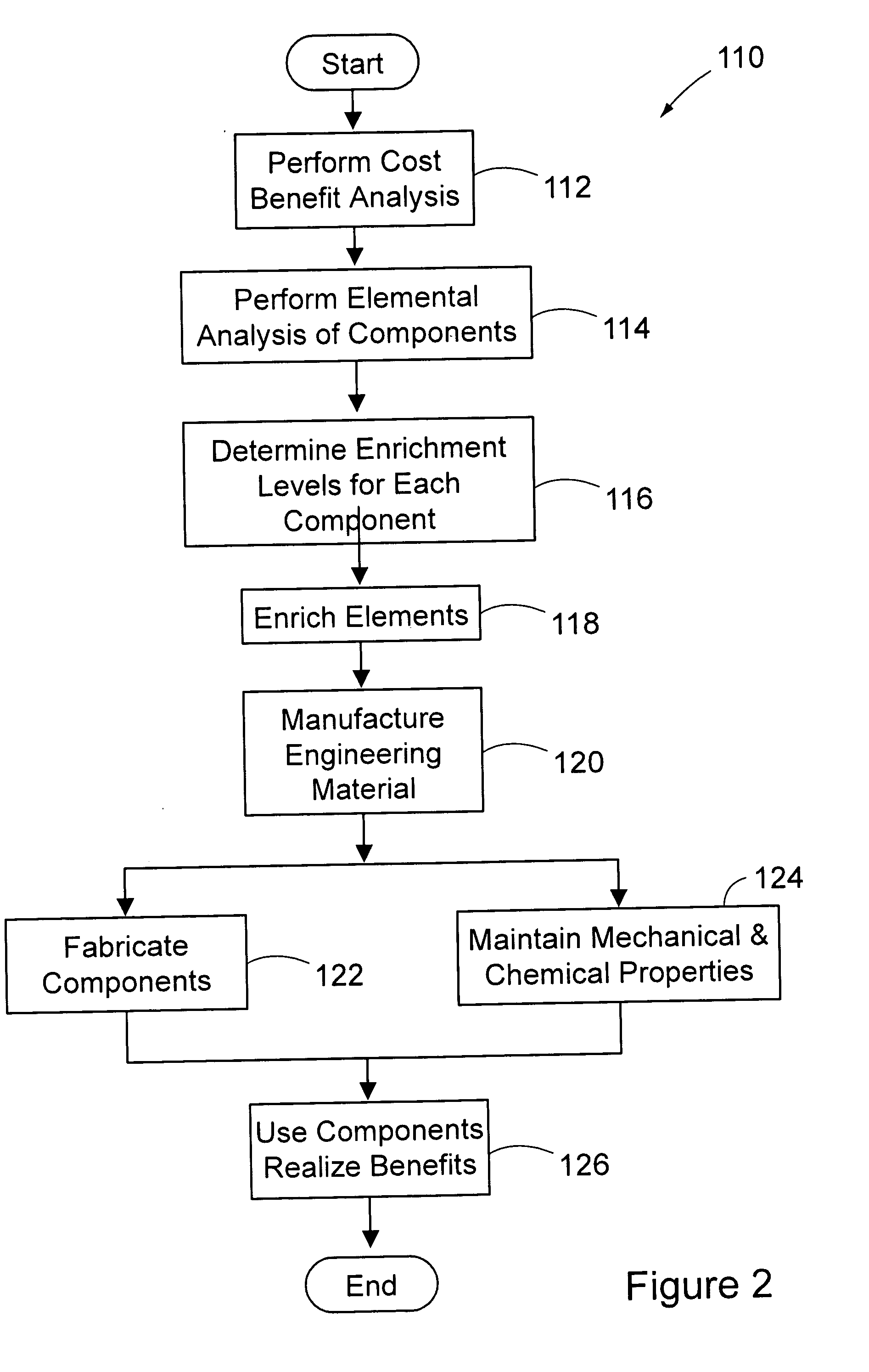

Isotopic lightening

ActiveUS20060102464A1Low densityLight weightTransuranic element compoundsLaunch systemsLithiumHydrogen

A method of manufacturing a component. In a preferred embodiment, the method includes enriching an element with an isotope and using the enriched element as a material of the component. A property of the first isotope being the same as a property of a second isotope and is preferably a mechanical, chemical, or electrical property. A second element can also be used as a material of the component, for instance, where the material is an alloy or a composite material. Further, the first isotope can be a lighter isotope of the element. Lightweight components may be manufactured using the method such that mobile platforms (e.g. spacecraft) can be assembled from the component(s). In other exemplary embodiments, the element can be hydrogen, lithium, boron, magnesium, titanium, or iron. Additionally, the component may carry a load. Components including isotopically enriched elements are also provided.

Owner:THE BOEING CO

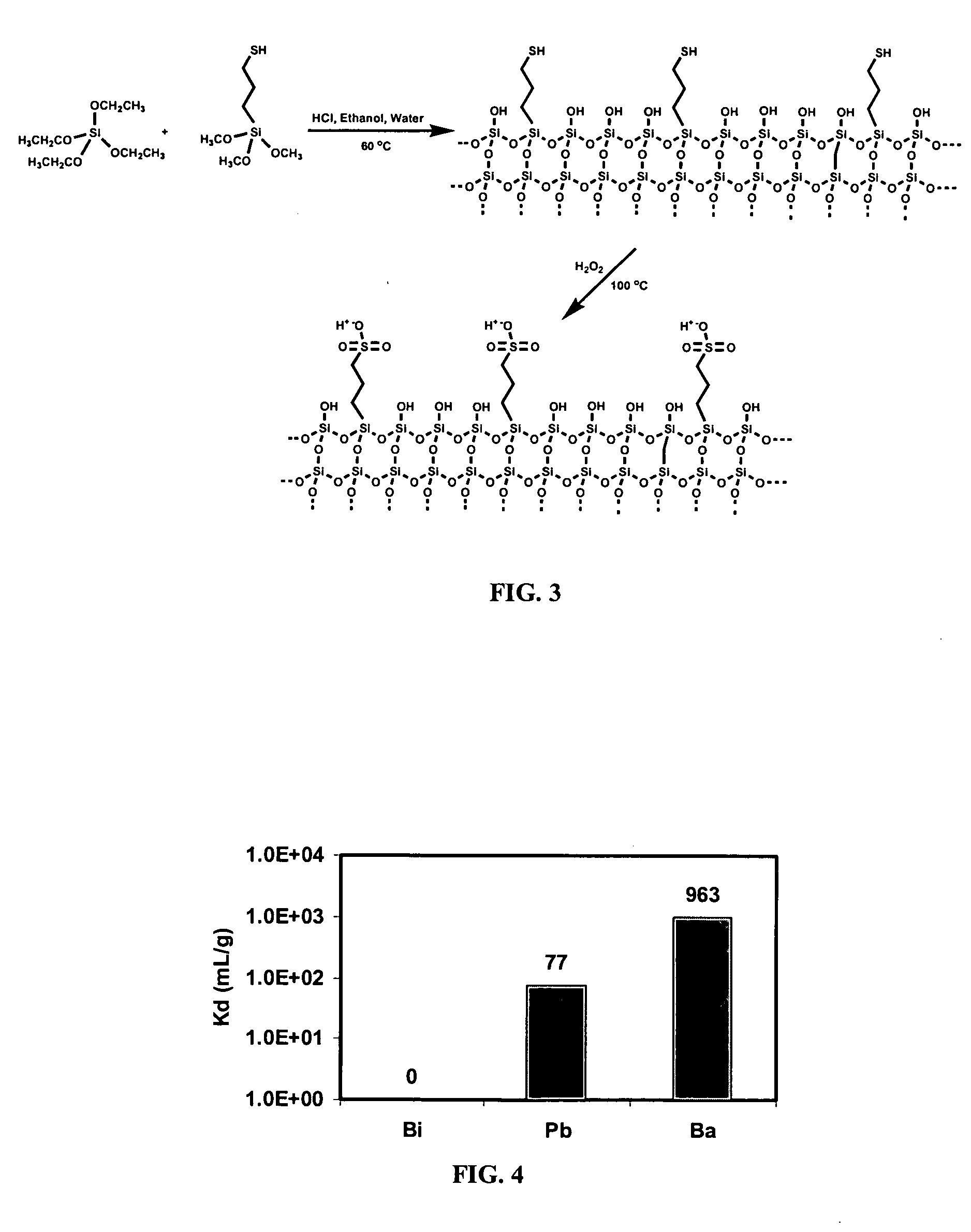

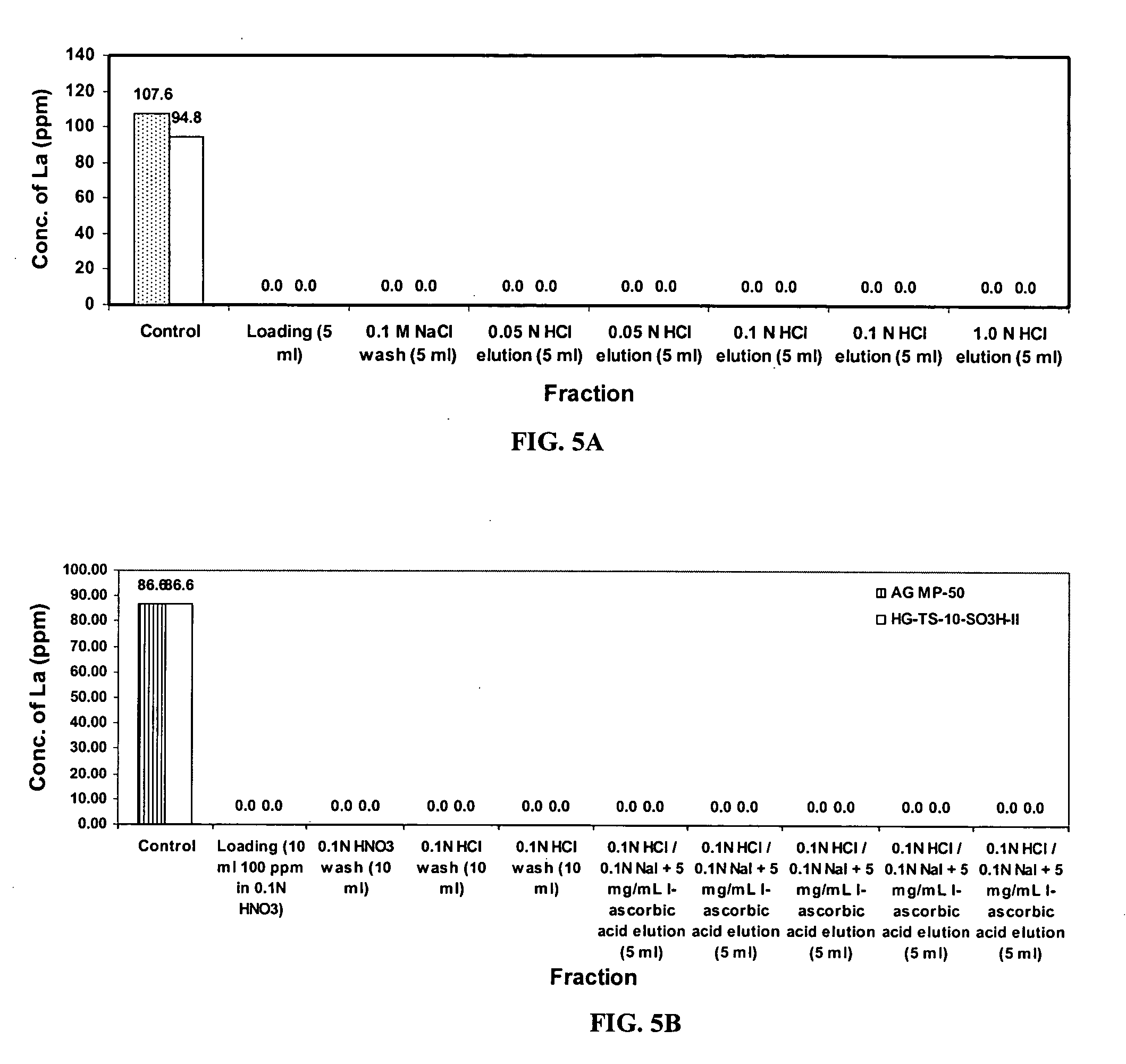

212Bi or 213Bi Generator from supported parent isotope

The invention includes a radionuclide generator having an ion exchange sorbent that comprises oxygen-containing functional groups grafted by organic linking groups to an inorganic oxygen-linked network and a parent isotope. For 212Bi or 213Bi generators, the parent isotope may be 224Ra, 225Ra or 225Ac. The surface area of the sorbent is preferably less than about 10 m2 / g and more preferably less than about 1 m2 / g. The exchange sorbent may be formed of any covalently bonded inorganic oxide that is capable of forming oxygen-linked networks. The oxidized functional groups may include sulfonato groups, may include moieties selected from —SO3H, —SO3Na, —SO3K, —SO3Li, —SO3NH4 or may include moieties selected from —PO(OX)2 or —COOX, wherein X is selected from H, Na, K or NH4 or combinations thereof. A 213Bi or 212Bi generator process includes eluting 213Bi or 212Bi with an aqueous solvent that includes 225Ac or 225Ra or 224Ra on the above support medium.

Owner:GALI HARIPRASAD +1

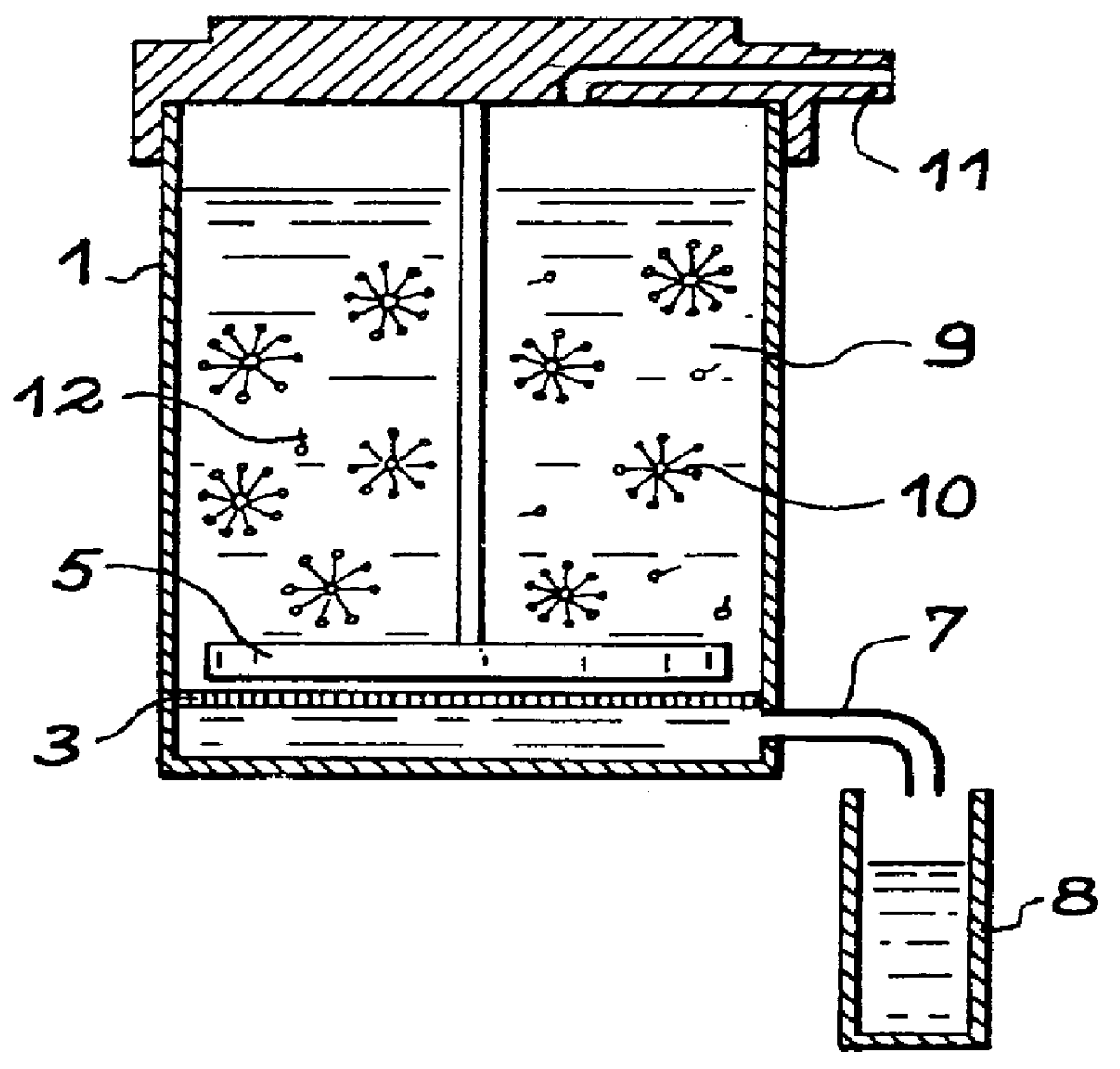

Method for separating metals by micellar ultrafiltration that can be used to process radioactive waste

The present invention relates to a method for separating metals by micellar ultrafiltration, that can be used to process radioactive waste. This process consists of adding to the aqueous solution a complexing anionic surfactant having the formula: M+=cation, for example NA+m=1 or 2 R=aliphatic group of at least eight carbon atoms, and optionally a nonionic surfactant such as Triton X-100 or Brij 35 to produce micelles (10) in the solution, and subsequently of filtering the solution through an ultrafiltration membrane (3) to retain the previously formed micelles.

Owner:COGEMA SA

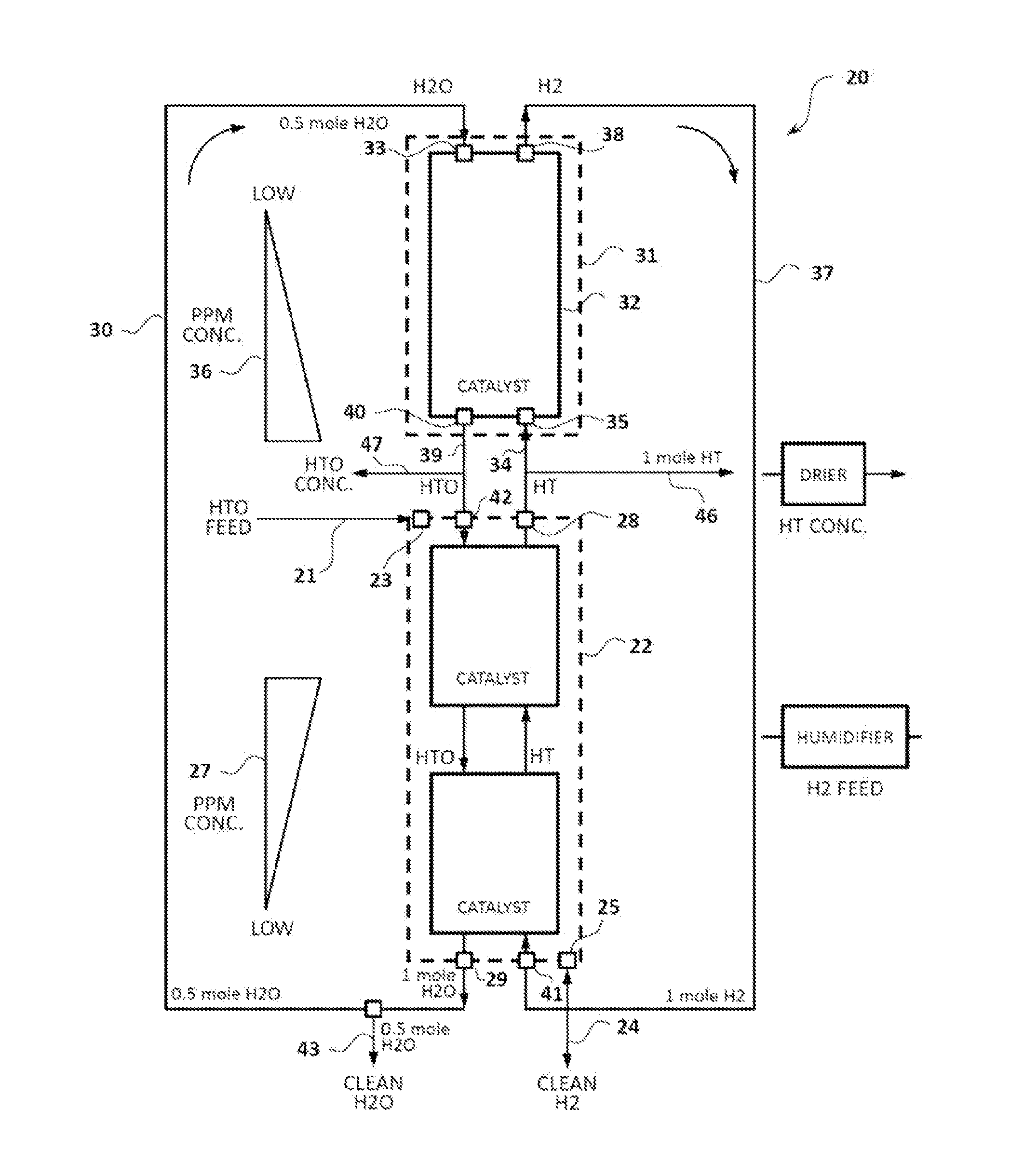

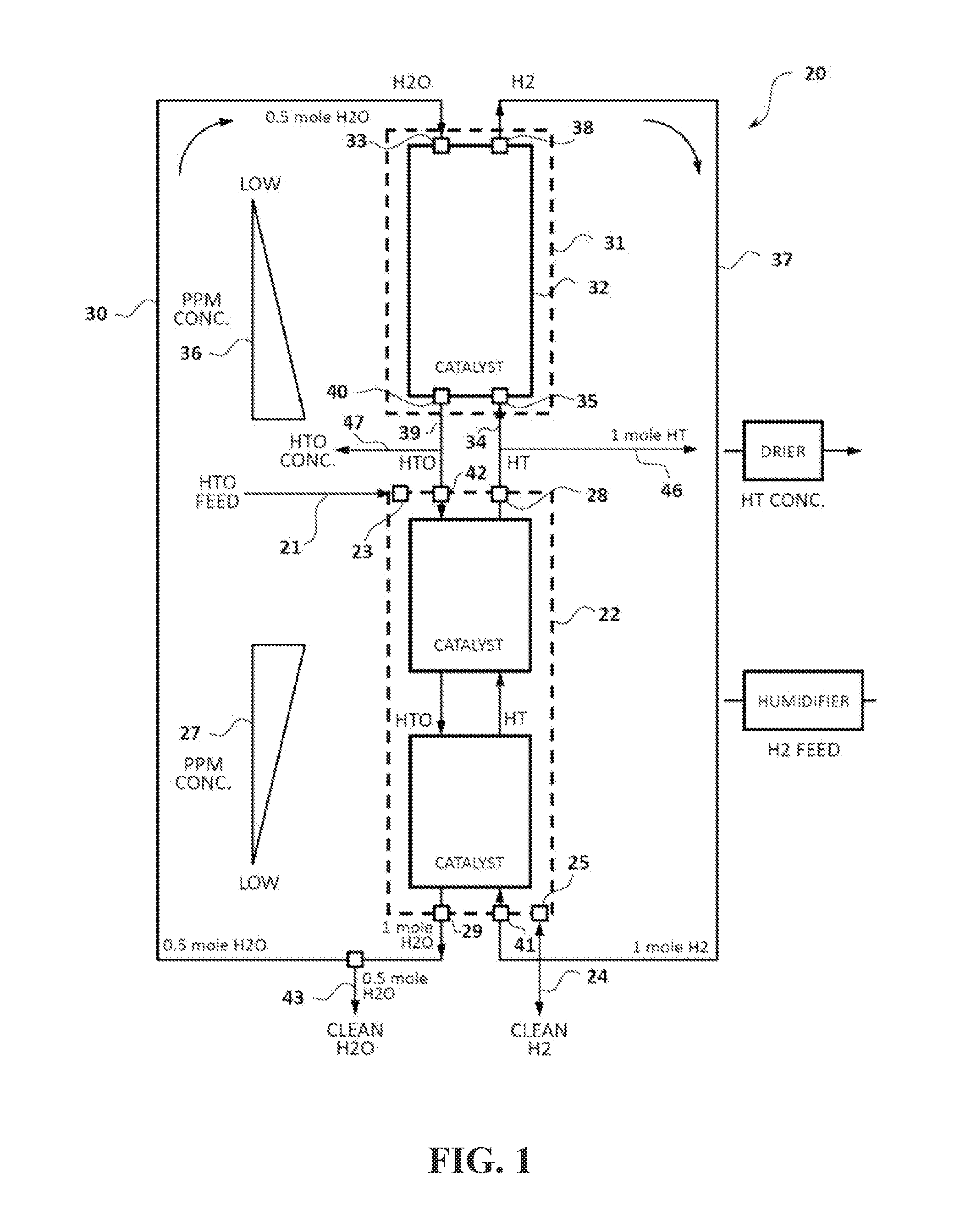

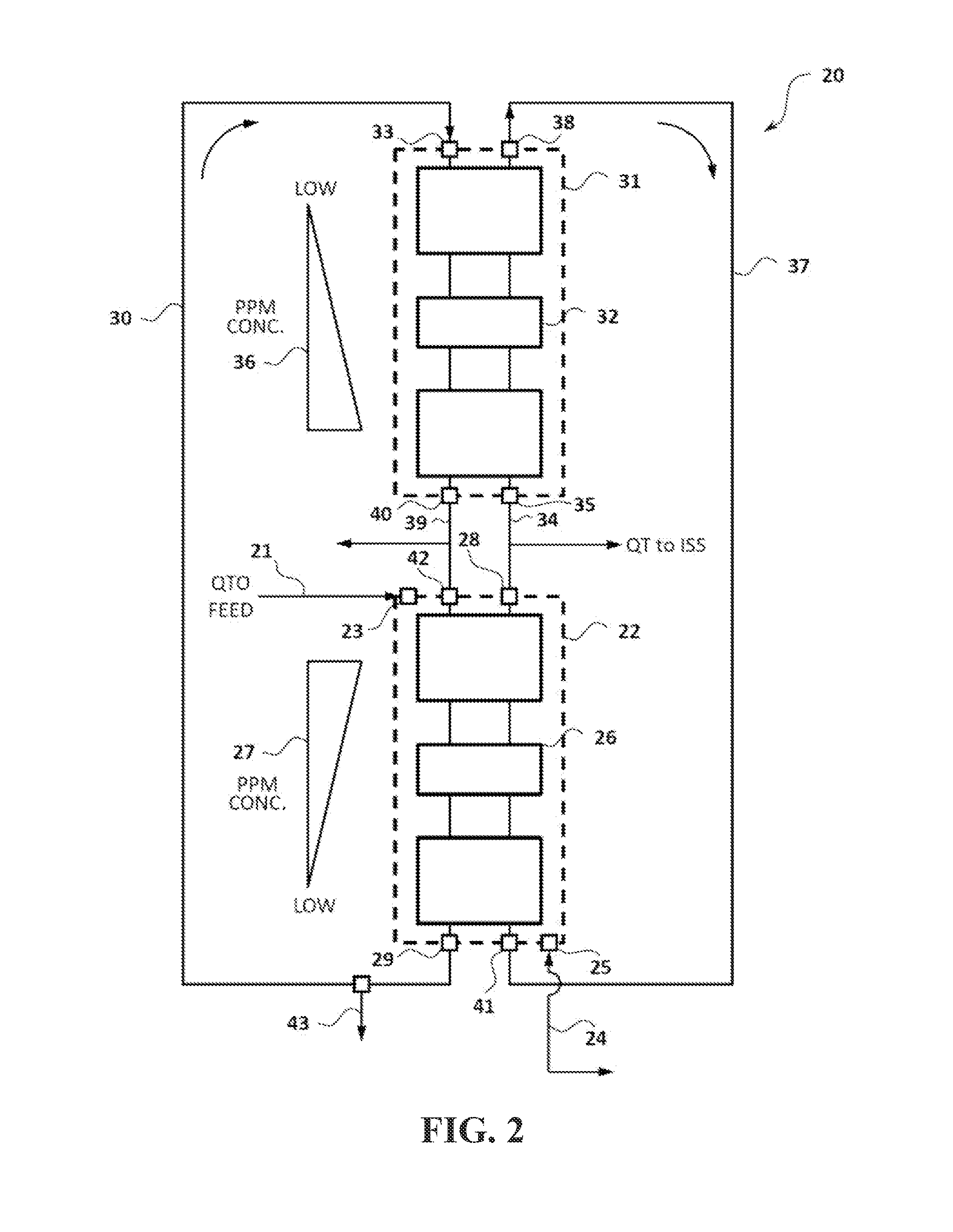

Balanced closed loop continuous extraction process for hydrogen isotopes

ActiveUS20140356270A1Valid conversionRapidly and economically extractTransuranic element compoundsNuclear energy generationWaste streamClosed loop

A system and method for tritium separation systems using a mixed bed catalytic exchange process in a Liquid Phase Catalytic Exchange / Closed Loop Continuous Process (LPCE / CLCP) system, that operates as a low temperature and low pressure continuous balanced process, designed to rapidly, economically and safely extract and isolate isotope specific products without generating unwanted products in the form of new waste streams.

Owner:KURION

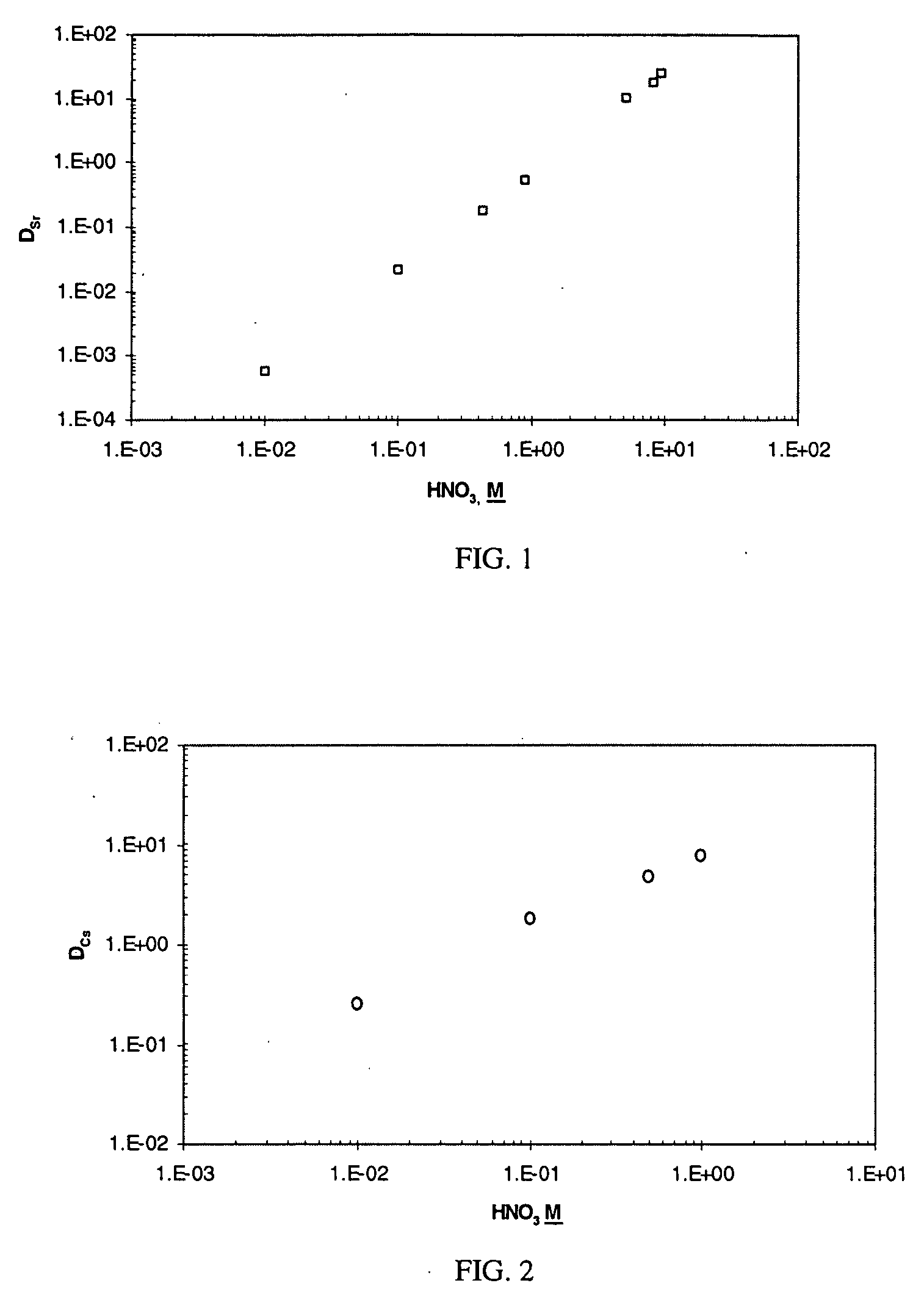

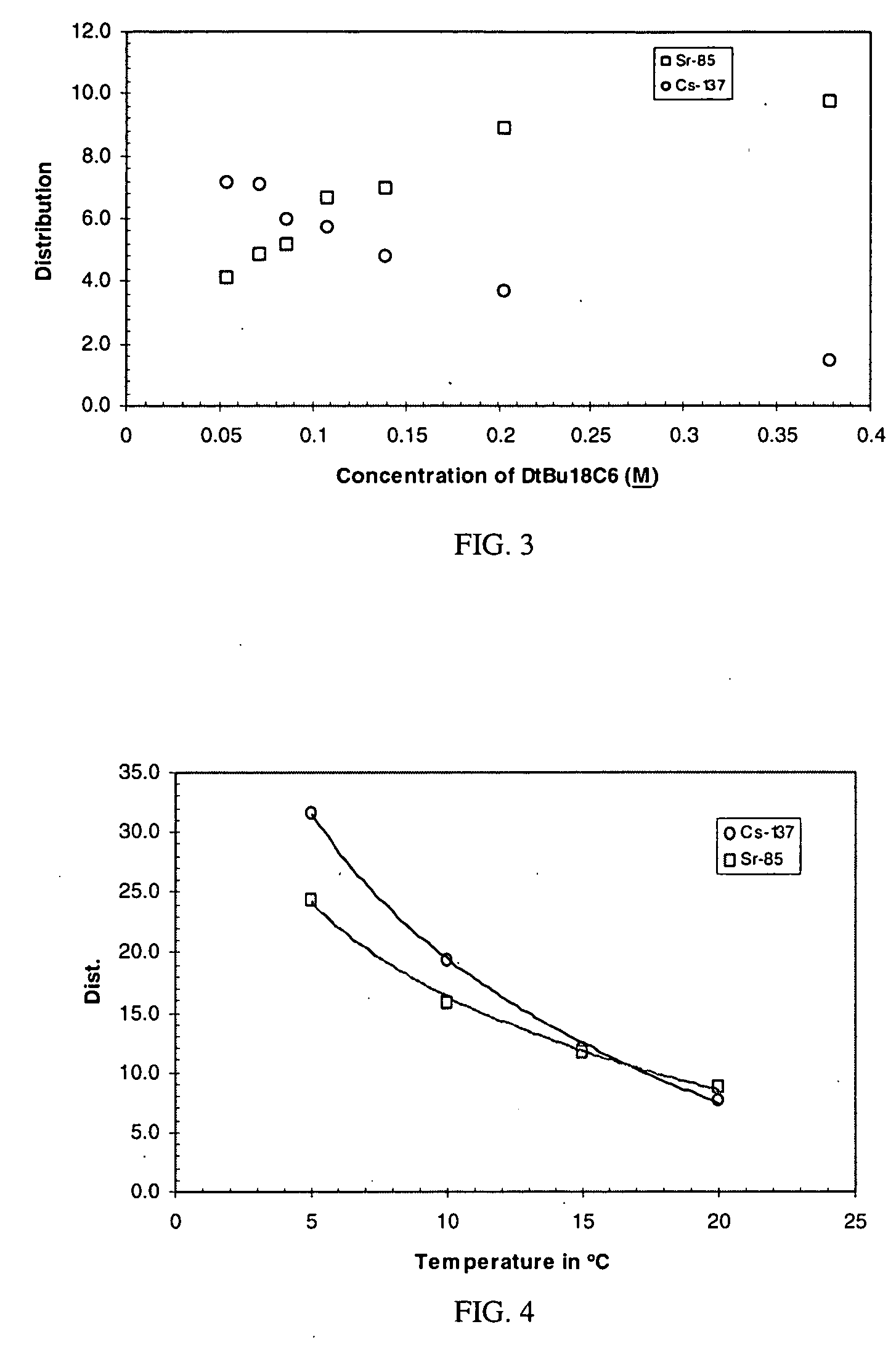

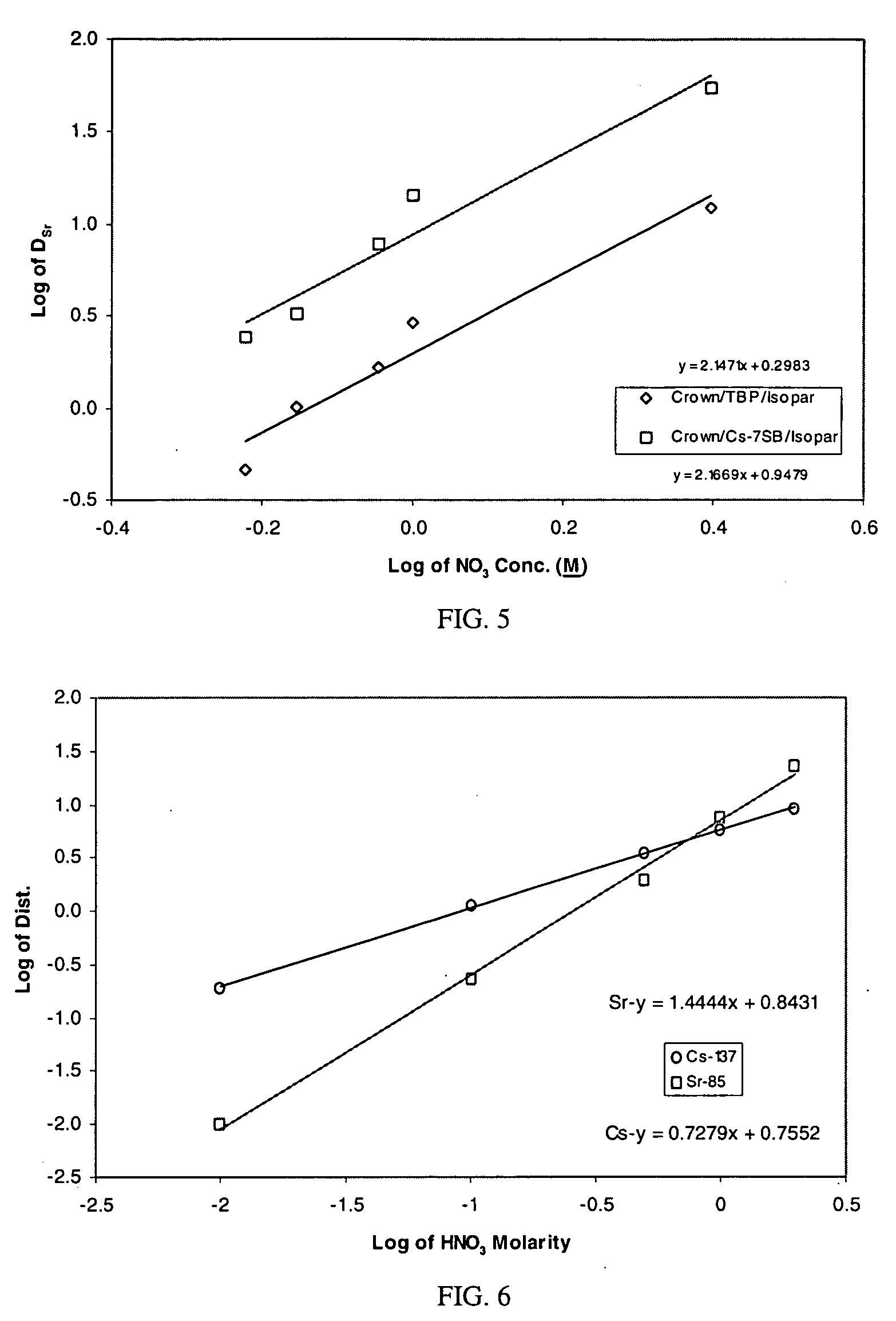

Cesium and strontium extraction using a mixed extractant solvent including crown ether and calixarene extractants

A mixed extractant solvent including calix[4]arene-bis-(tert-octylbenzo)-crown-6 (“BOBCalixC6”), 4′,4′,(5′)-di-(t-butyldicyclo-hexano)-18-crown-6 (“DtBu18C6”), and at least one modifier dissolved in a diluent. The mixed extractant solvent may be used to remove cesium and strontium from an acidic solution. The DtBu18C6 may be present from approximately 0.01 M to approximately 0.4M, such as from approximately 0.086 M to approximately 0.108 M. The modifier may be 1-(2,2,3,3-tetrafluoropropoxy)-3-(4-sec-butylphenoxy)-2-propanol (“Cs-7SB”) and may be present from approximately 0.01M to approximately 0.8M. In one embodiment, the mixed extractant solvent includes approximately 0.15M DtBu18C6, approximately 0.007M BOBCalixC6, and approximately 0.75M Cs-7SB modifier dissolved in an isoparaffinic hydrocarbon diluent. The mixed extractant solvent may form an organic phase in an extraction system that also includes an aqueous phase. Methods of extracting cesium and strontium as well as strontium alone are also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

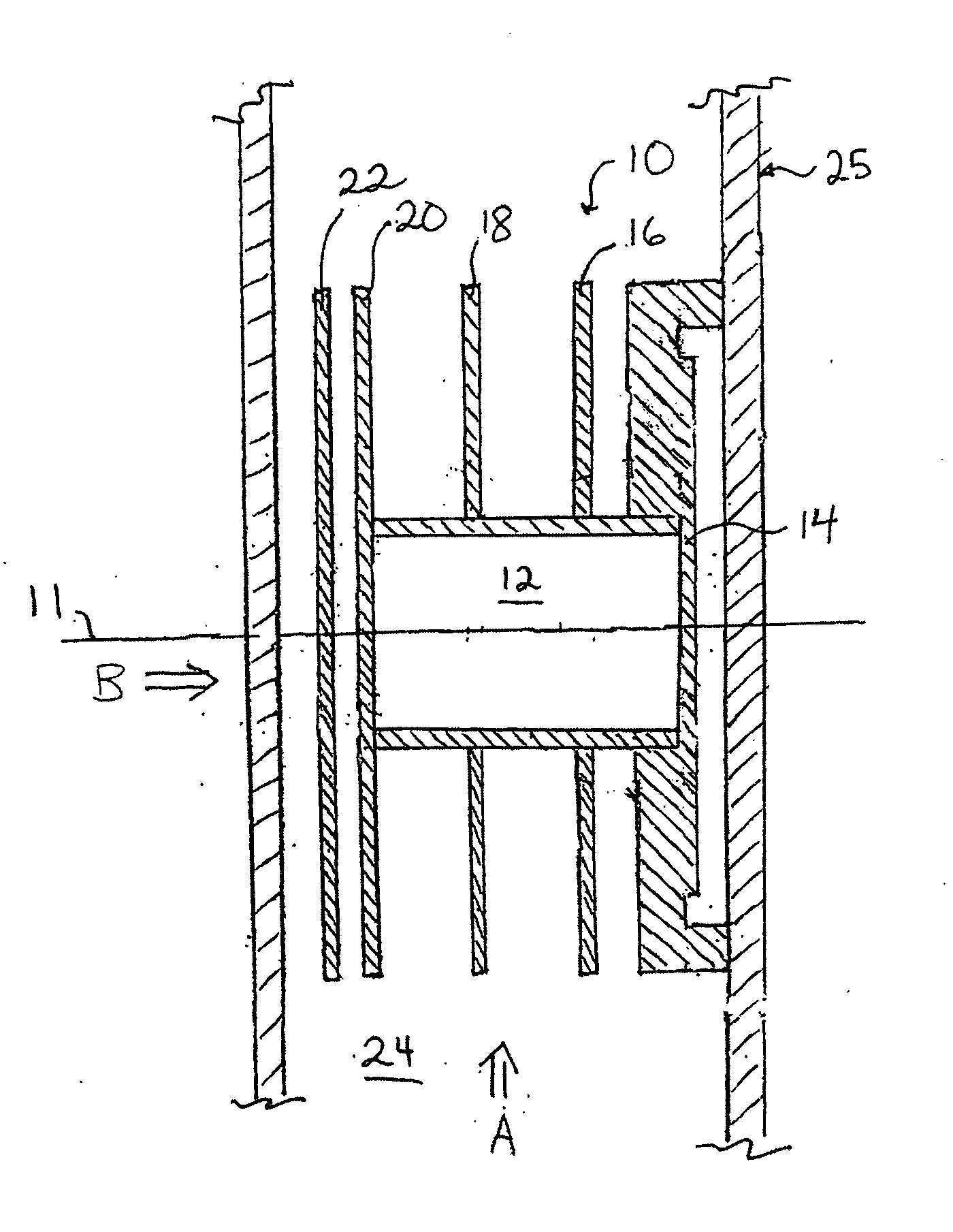

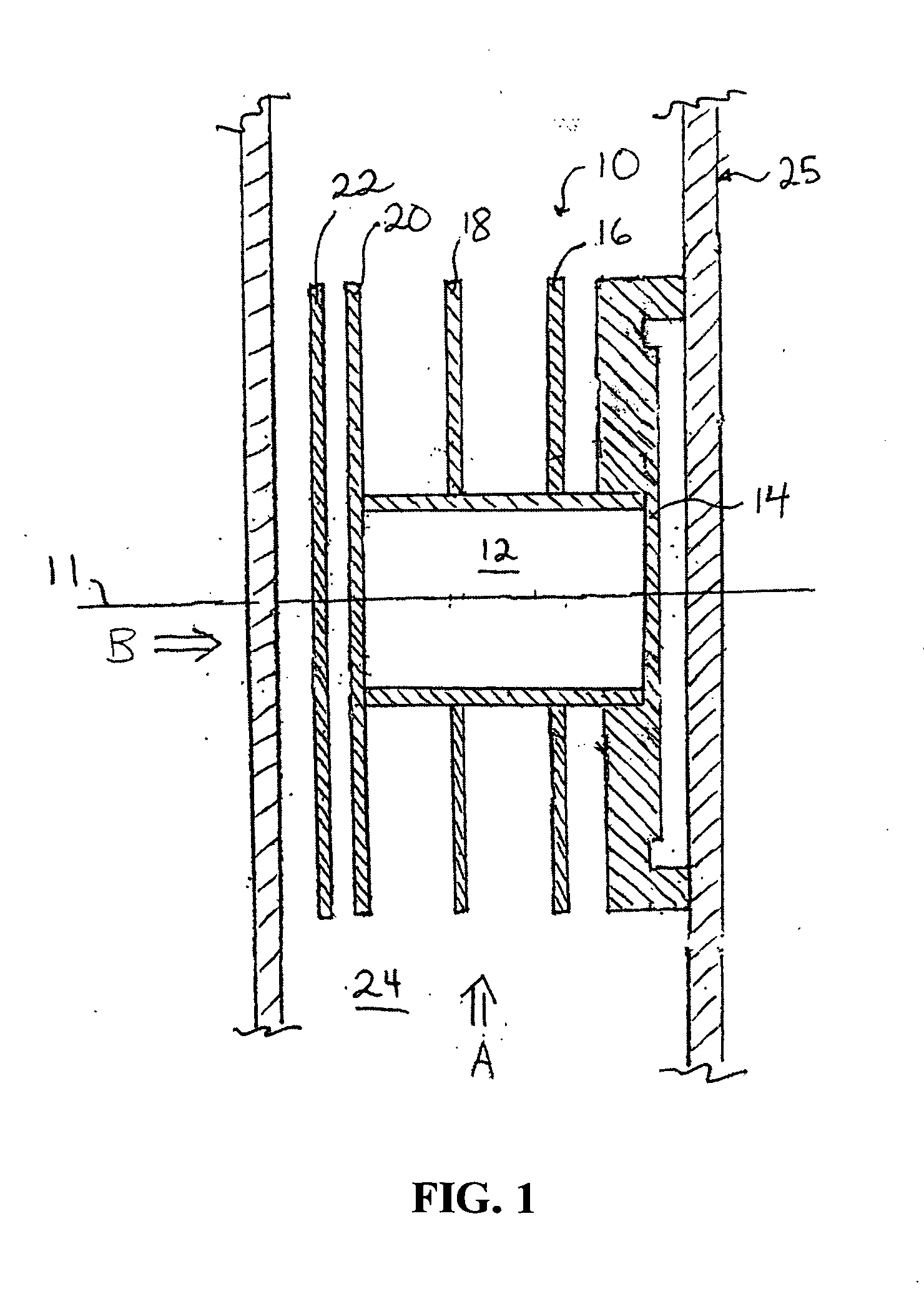

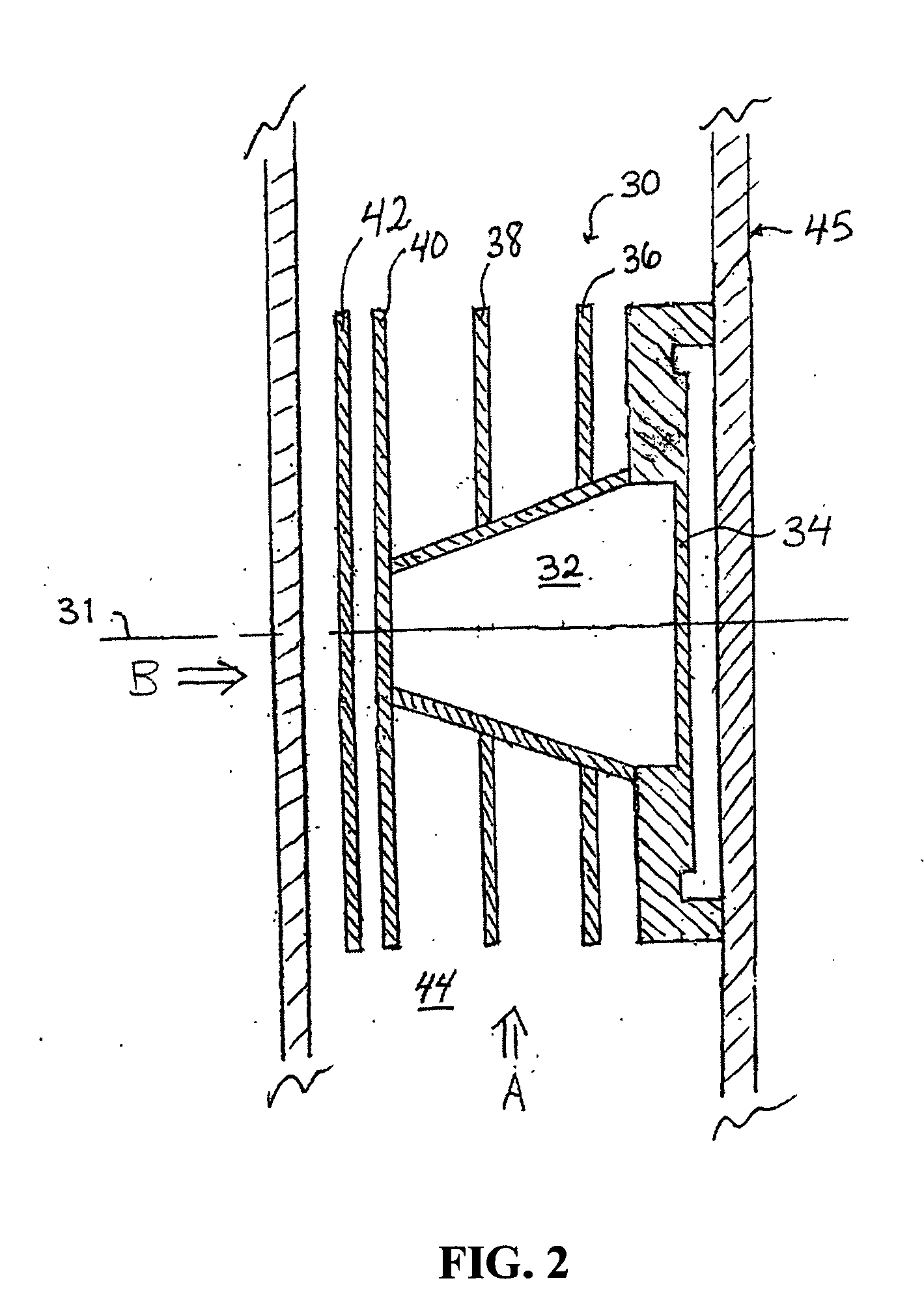

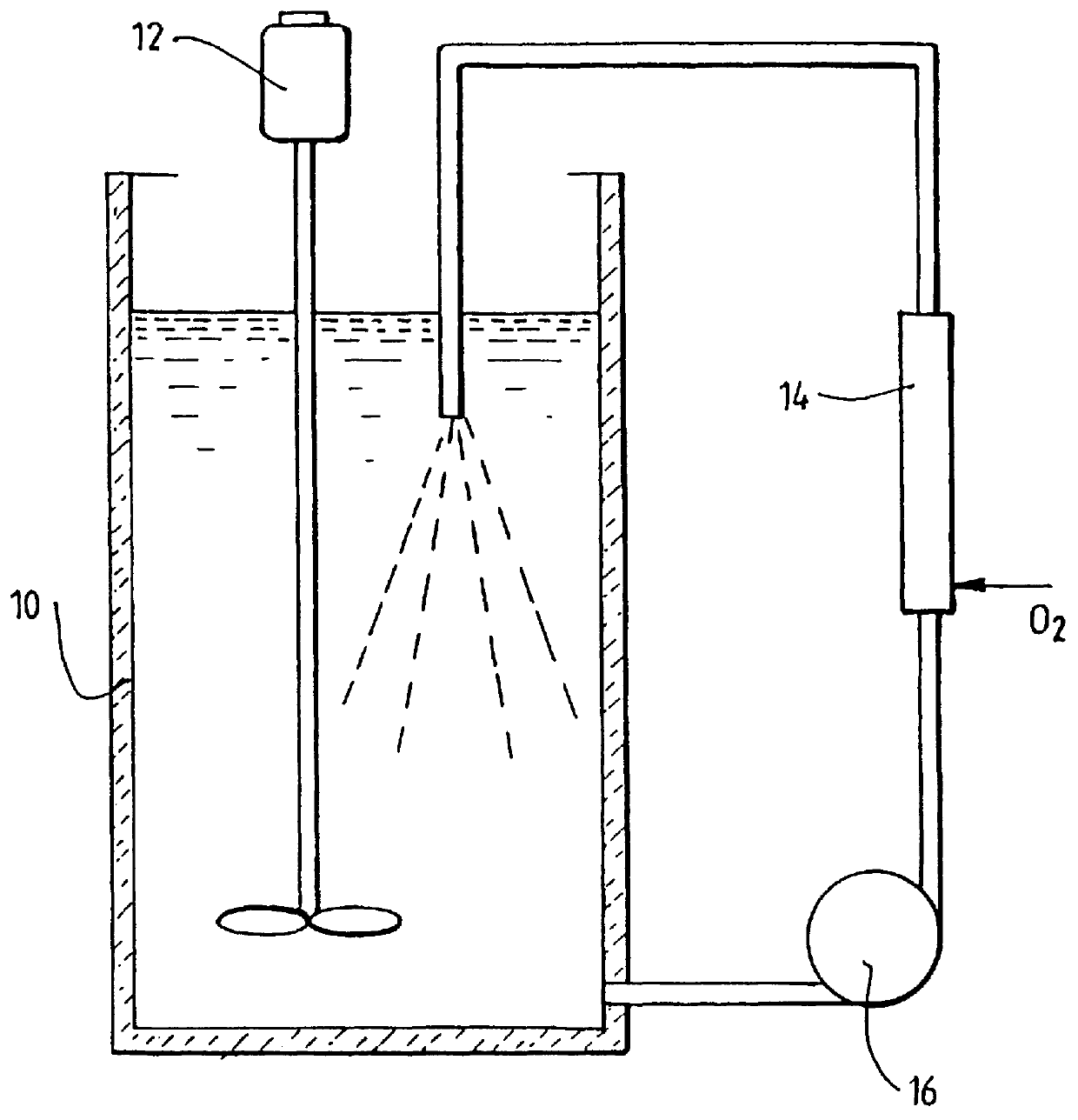

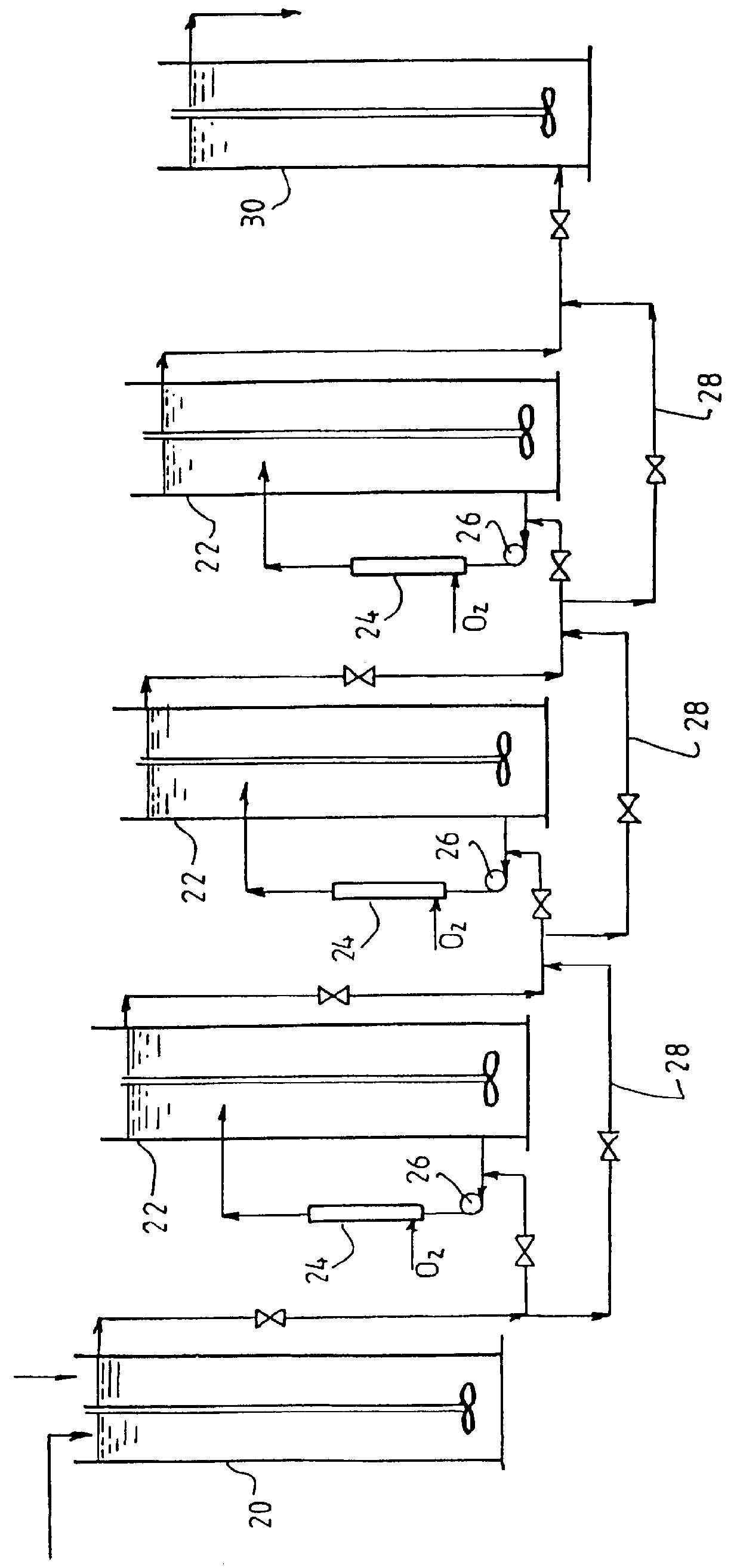

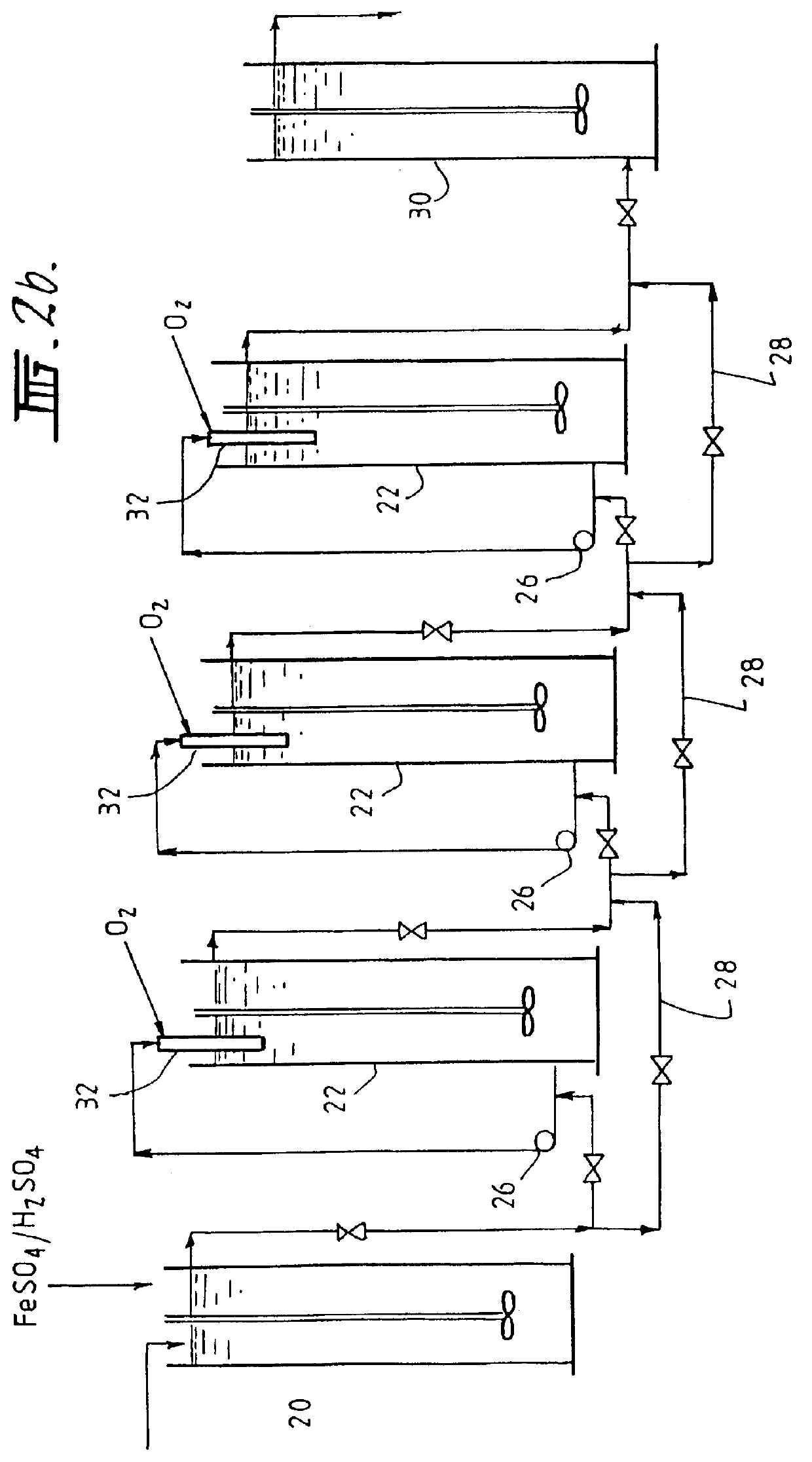

Leaching of mineral ores

A process for oxidation of ferrous ions in solution, and more particularly a process for improved base metal and / or uranium leaching from ores, concentrates or tailings using ferric ion as an oxidizing agent. A reaction vessel (10) holds a ferrous ion-containing solution, for example, a copper sulphide leach slurry or concentrate. An agitator (12) may be provided to promote leaching of the base metal into solution. Some of the ferrous ion-containing solution is drawn off from the reaction vessel (10) and pumped through an in-line mixer (14) via a feed pump (16). Oxygen is injected into the reactor (14) to facilitate oxidation of the ferrous sulphate to form ferric sulphate. The ferric ion-containing solution is then recirculated back to the reaction vessel (10) where the ferric ions are reused in the dissolution of copper sulphide into soluble copper sulphate. The two processes of ferrous oxidation and metal leaching can be conducted either simultaneously or sequentially to effect recovery of copper, other base metals or uranium from ores, concentrates or tailings.

Owner:ATOMAER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com