Patents

Literature

185results about "Radium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for radioisotope recovery and system for implementing same

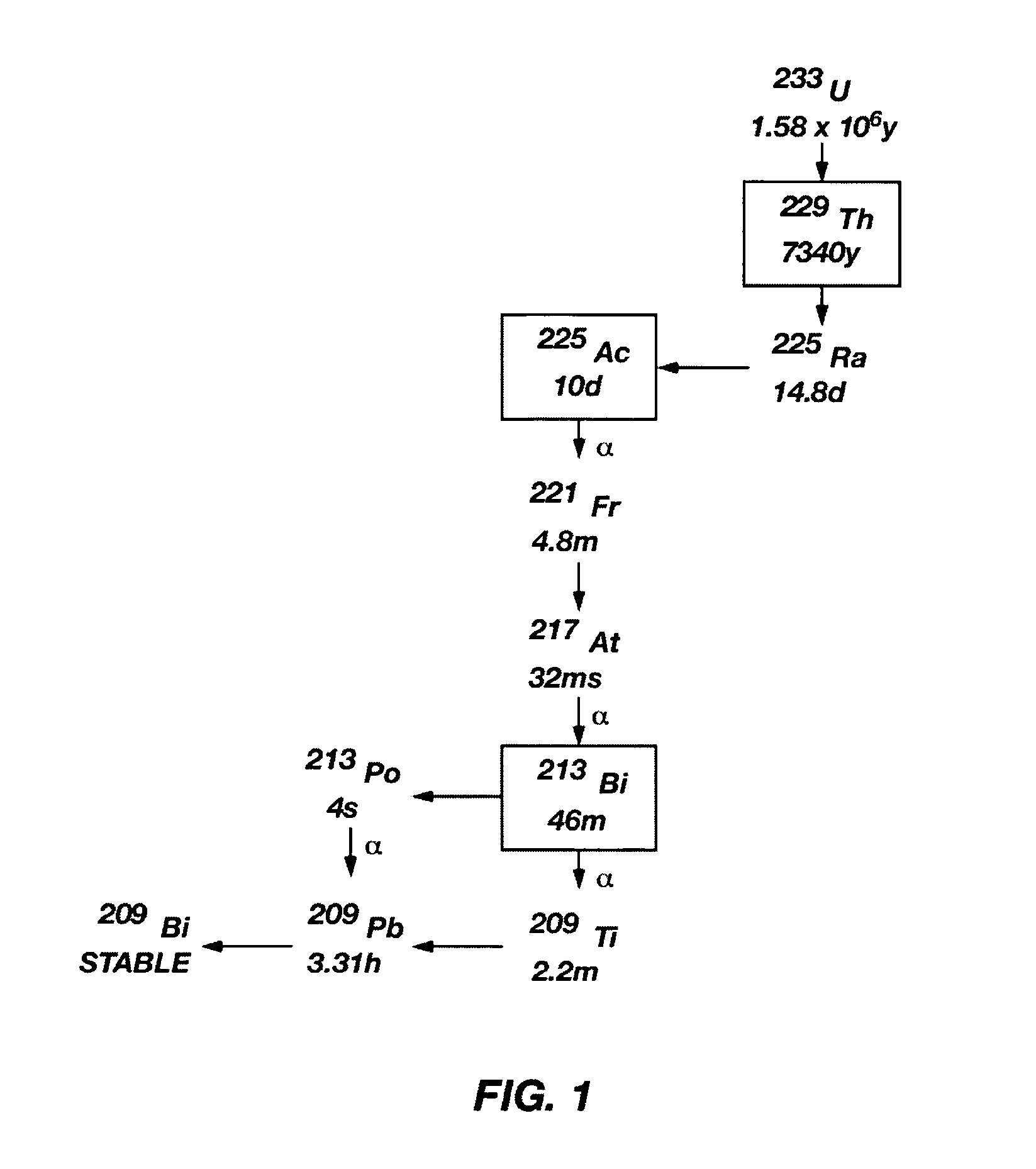

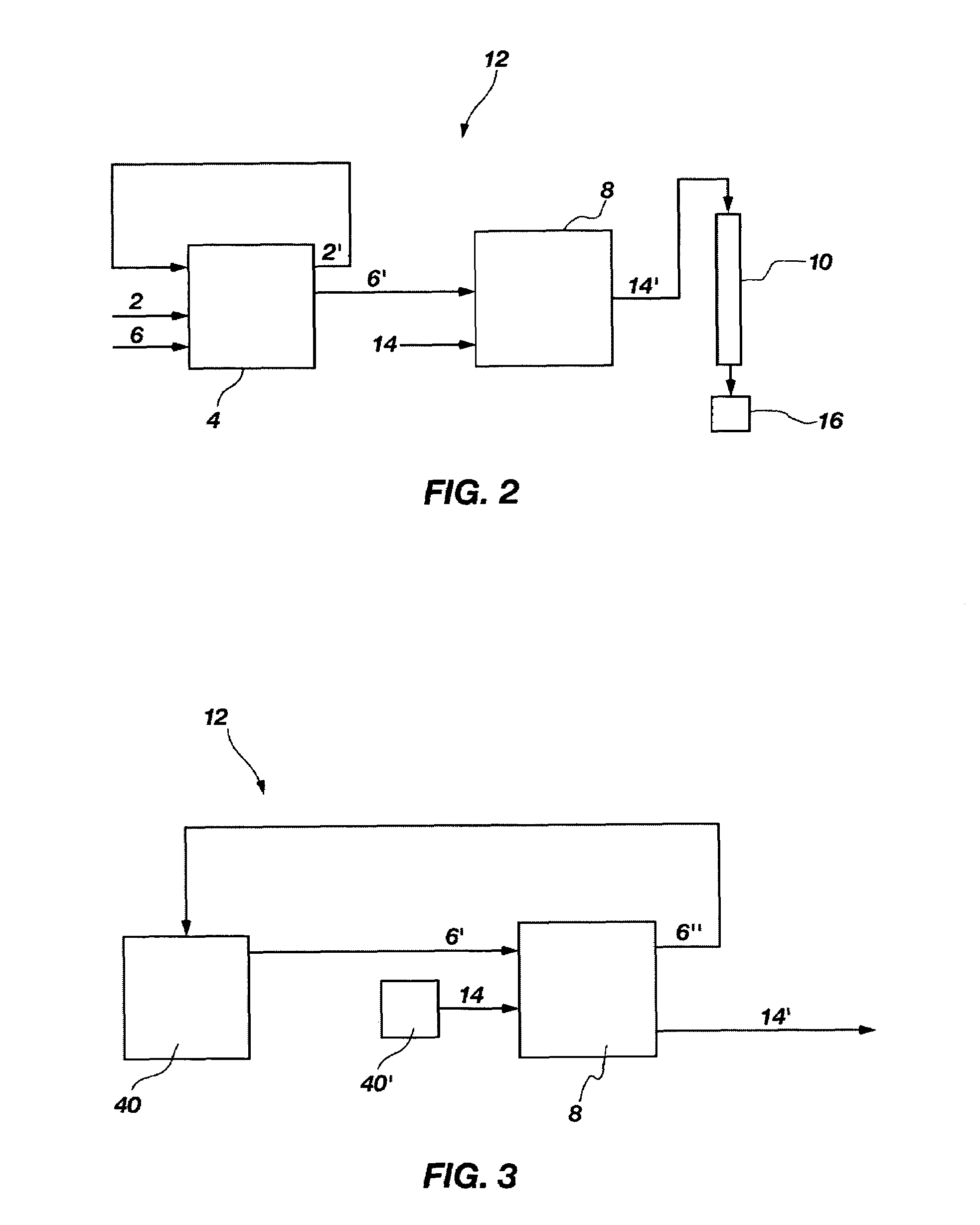

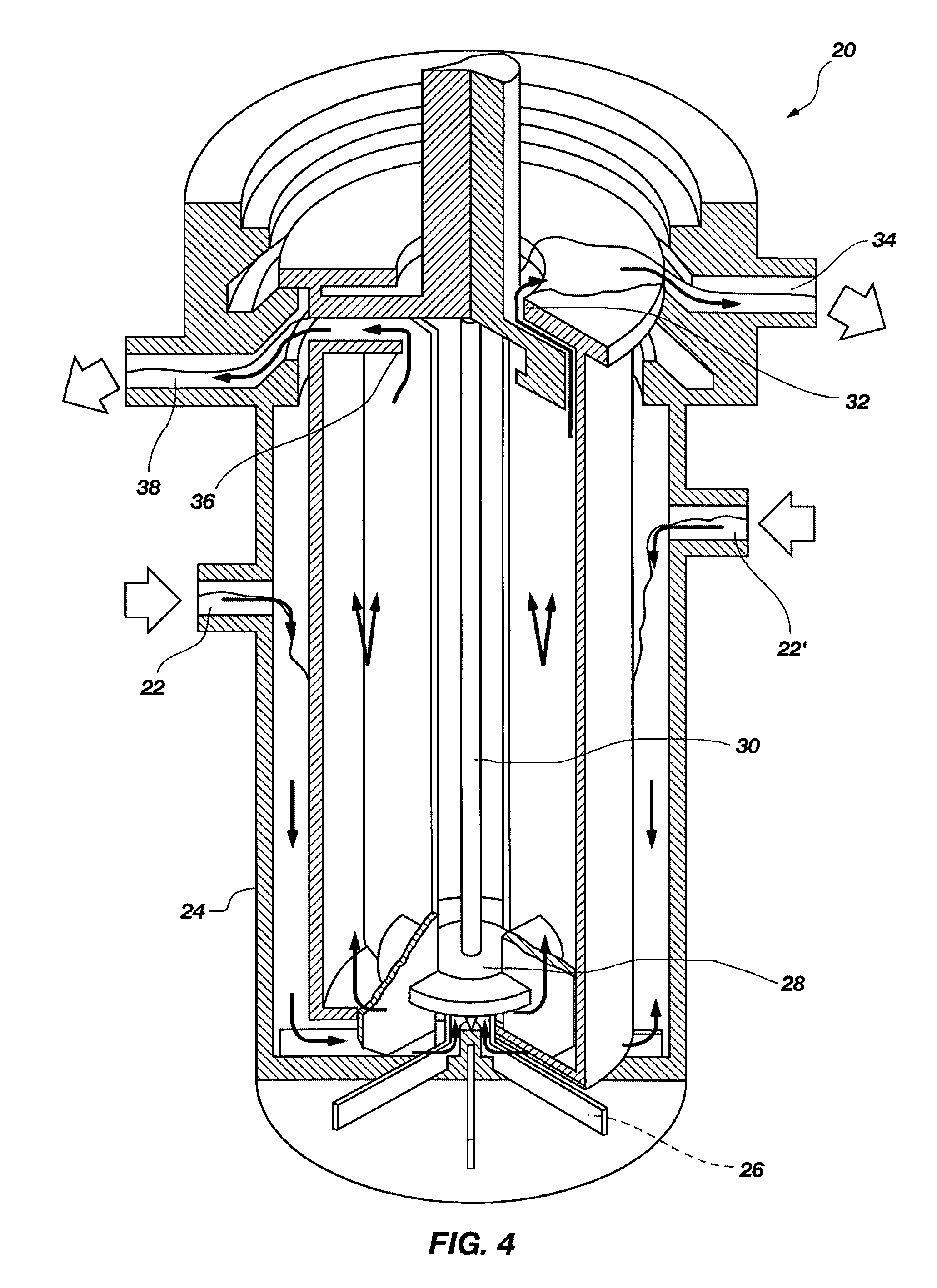

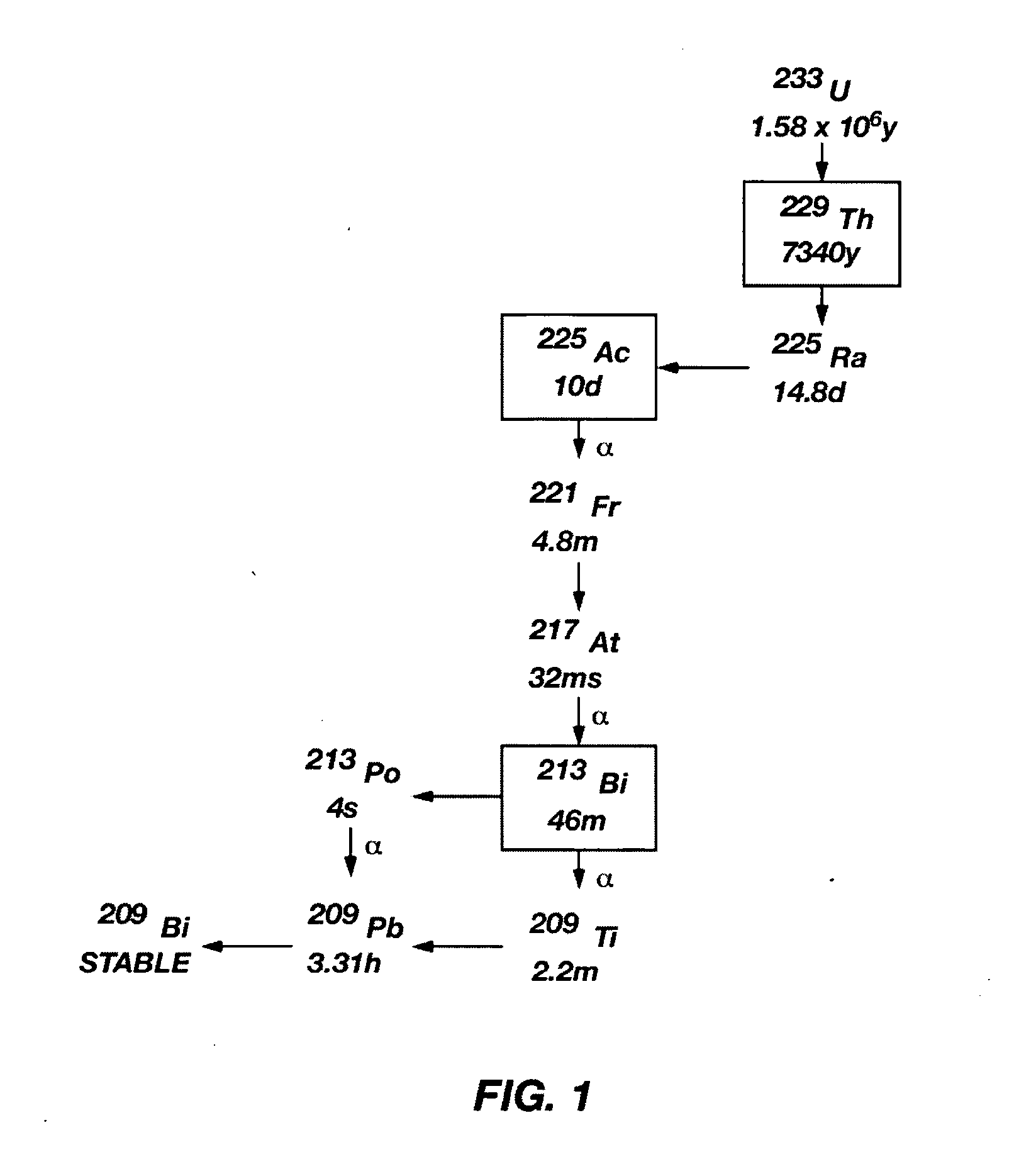

A method of recovering daughter isotopes from a radioisotope mixture. The method comprises providing a radioisotope mixture solution comprising at least one parent isotope. The at least one parent isotope is extracted into an organic phase, which comprises an extractant and a solvent. The organic phase is substantially continuously contacted with an aqueous phase to extract at least one daughter isotope into the aqueous phase. The aqueous phase is separated from the organic phase, such as by using an annular centrifugal contactor. The at least one daughter isotope is purified from the aqueous phase, such as by ion exchange chromatography or extraction chromatography. The at least one daughter isotope may include actinium-225, radium-225, bismuth-213, or mixtures thereof. A liquid-liquid extraction system for recovering at least one daughter isotope from a source material is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

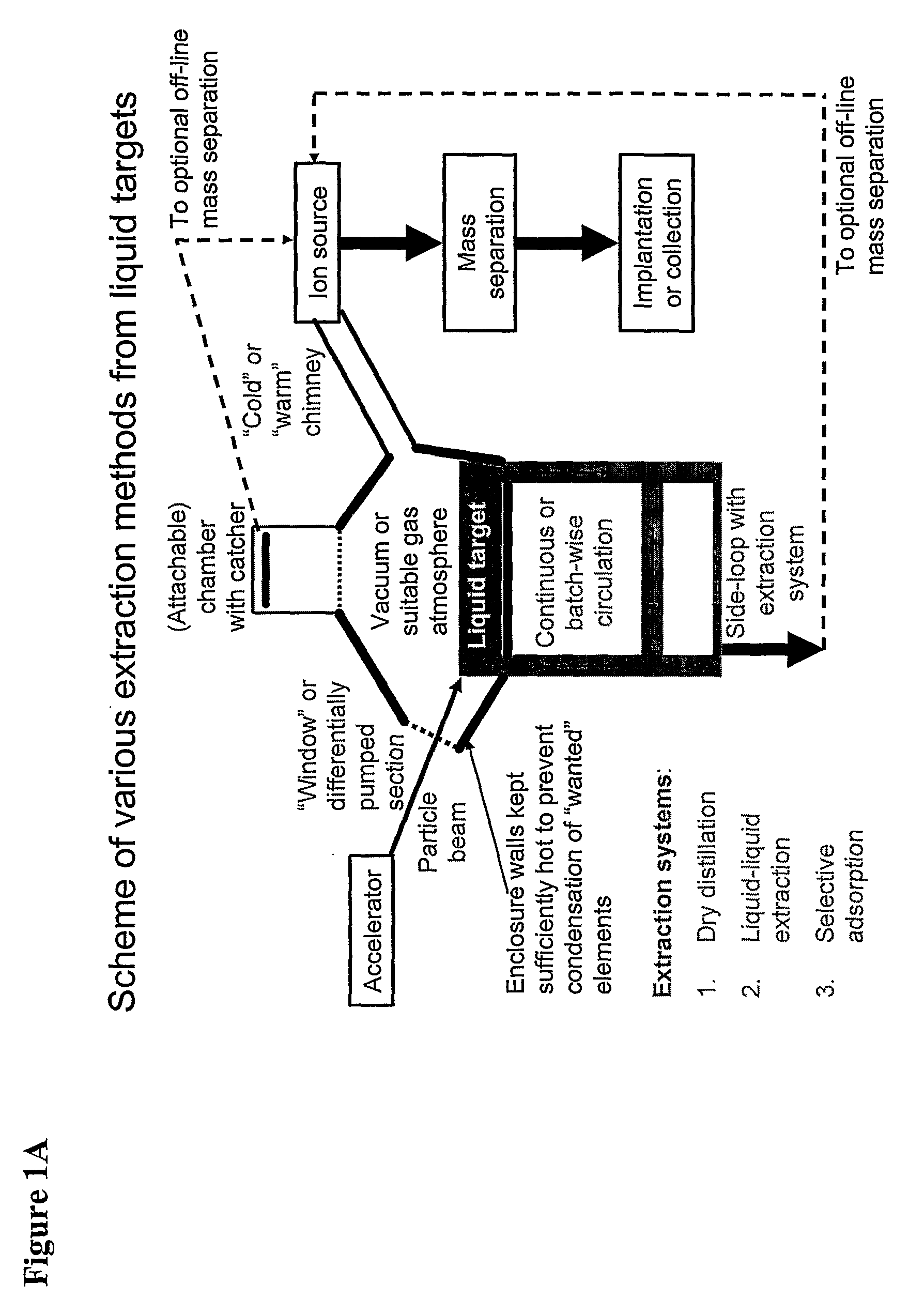

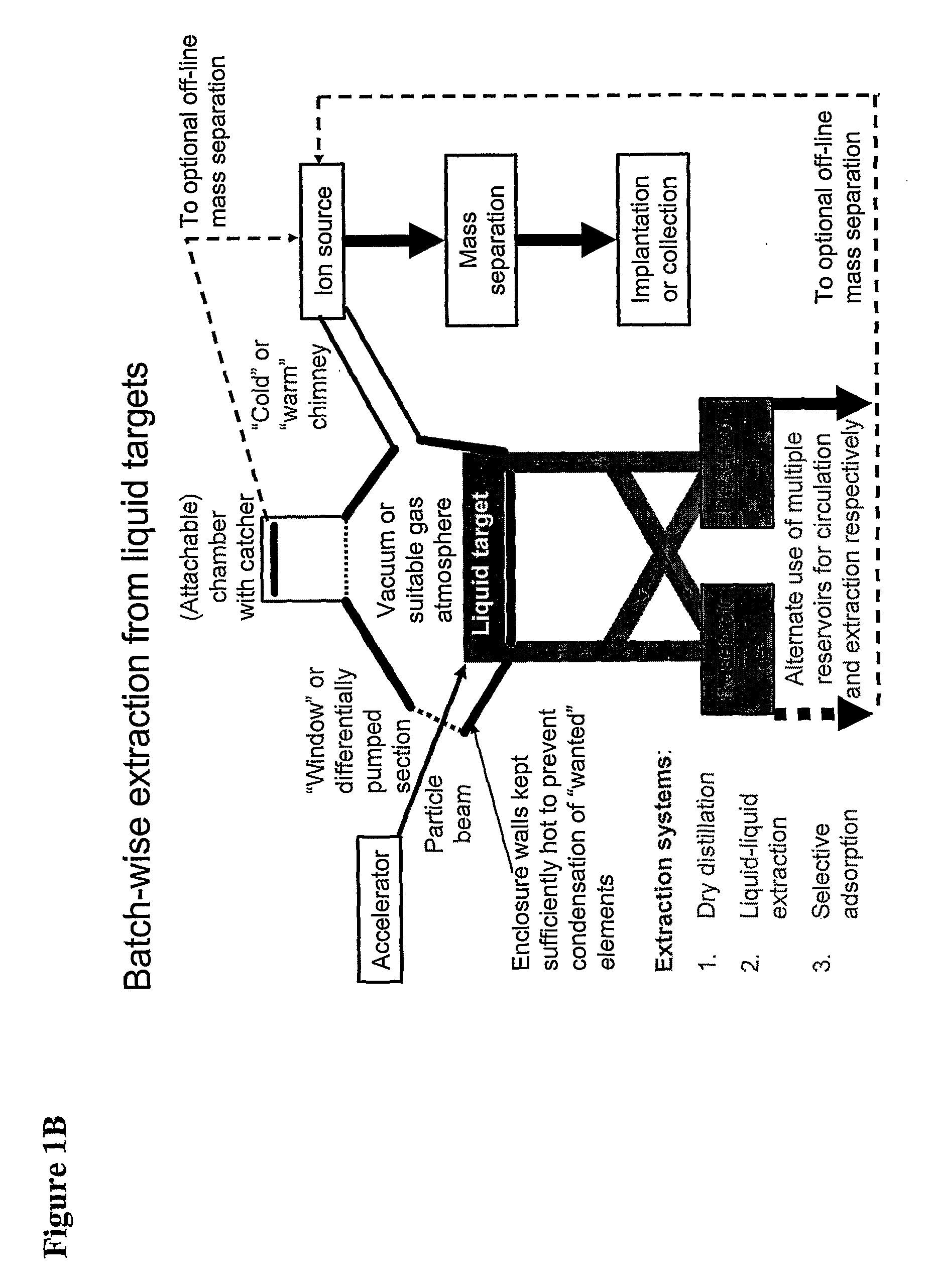

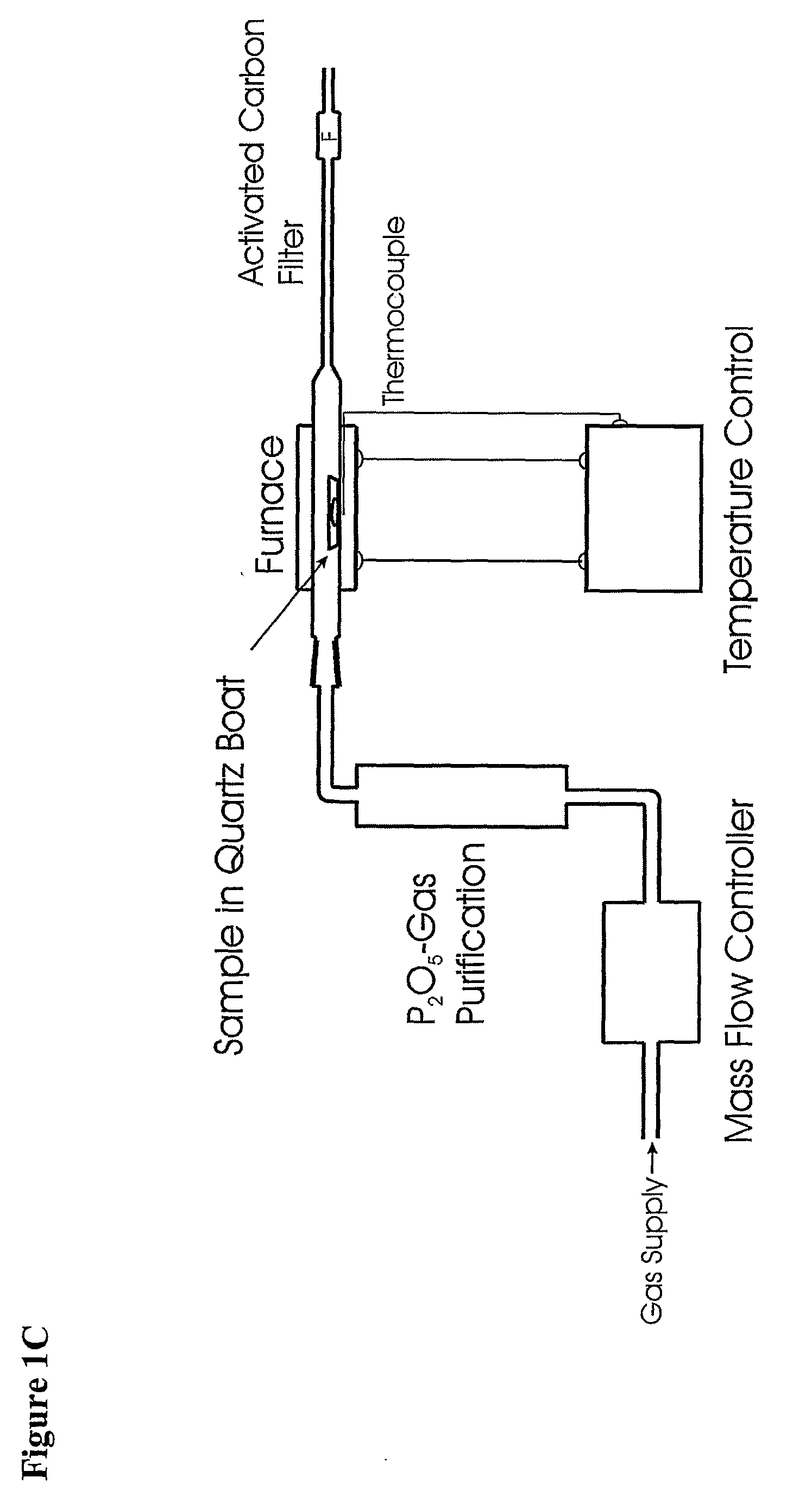

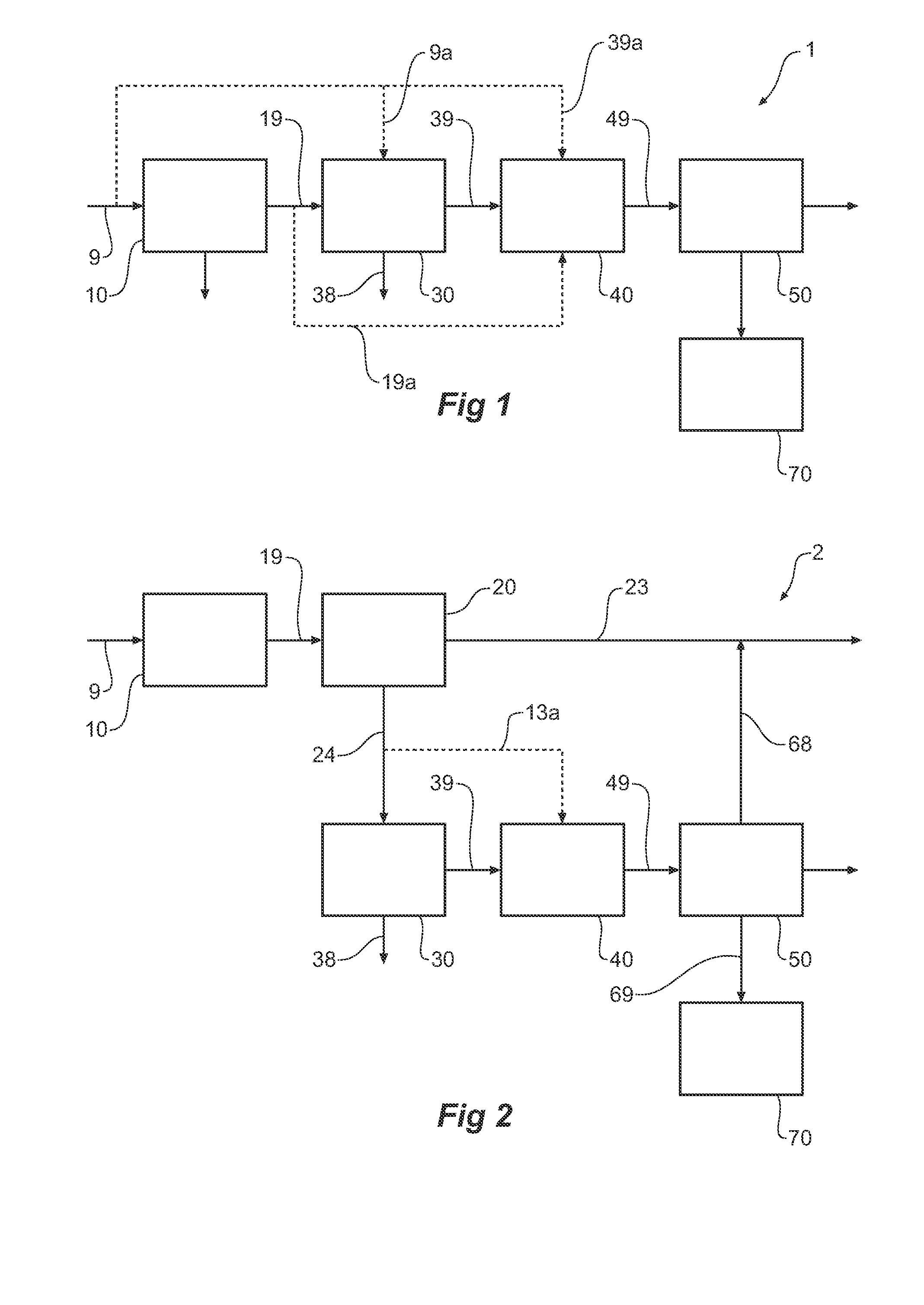

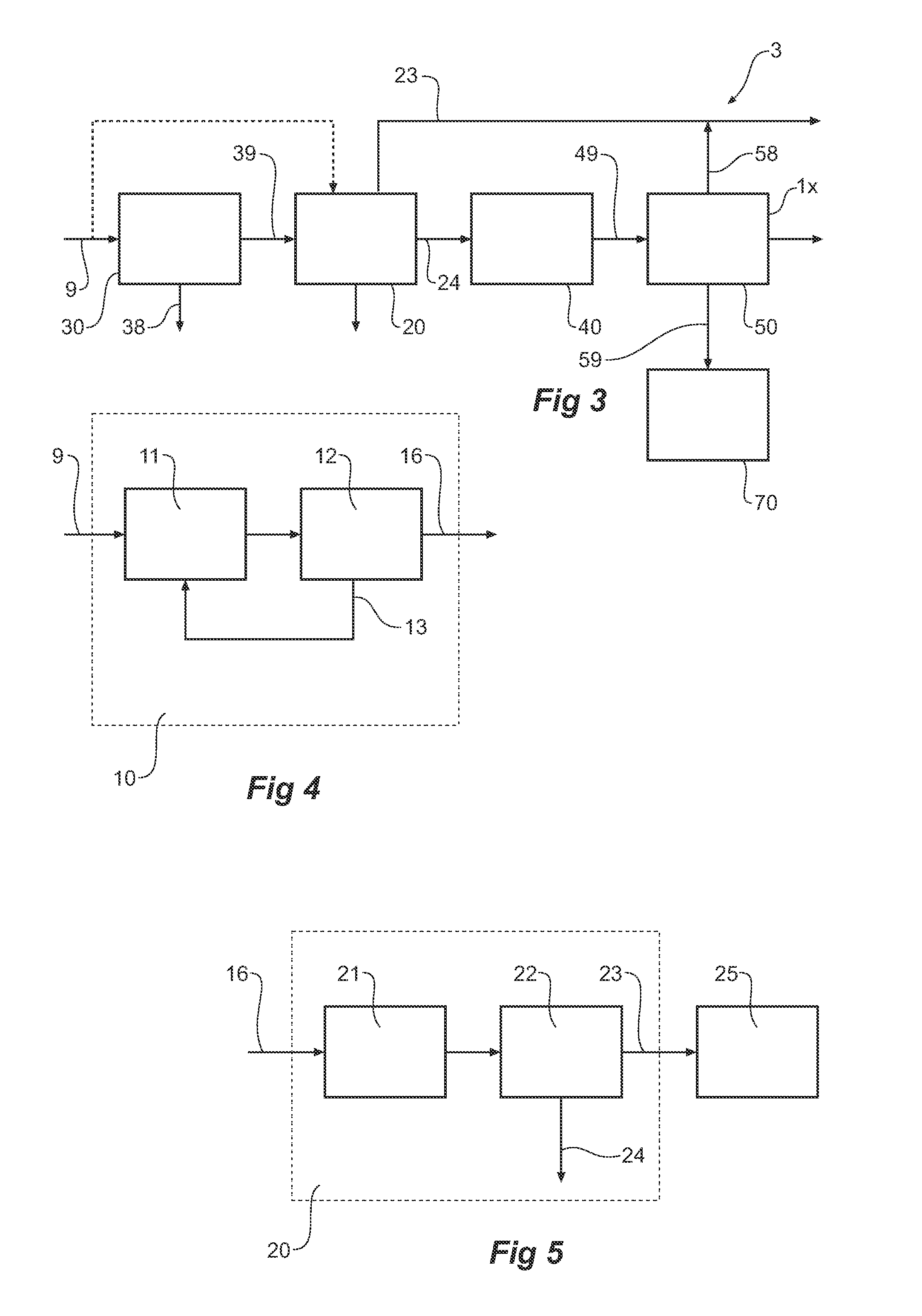

Method for Production of Radioisotope Preparations and Their Use in Life Science, Research, Medical Application and Industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimised individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

Process for the preparation of metal carbides having a large specific surface from activated carbon foams

InactiveUS6217841B1Easy accessPhysical/chemical process catalystsTransuranic element compoundsActivated carbonCarbide

The invention relates to a silicon carbide or metal carbide foam to be used as a catalyst or catalyst support for the chemical or petrochemical industry or for silencers, as well as the process for producing the same.The foam is in the form of a three-dimensional network of interconnected cages, whose edge length is between 50 and 500 micrometres, whose density is between 0.03 and 0.1 g / cm3 and whose BET surface is between 20 and 100 m2 / g. The carbide foam contains no more than 0.1% by weight residual metal and the size of the carbide crystallites is between 40 and 400 Angstroms.The production process consists of starting with a carbon foam, increasing its specific surface by an activation treatment using carbon dioxide and then contacting the thus activated foam with a volatile compound of the metal, whose carbide it is wished to obtain.

Owner:CENT NAT DE LA RECHERCHE SCI

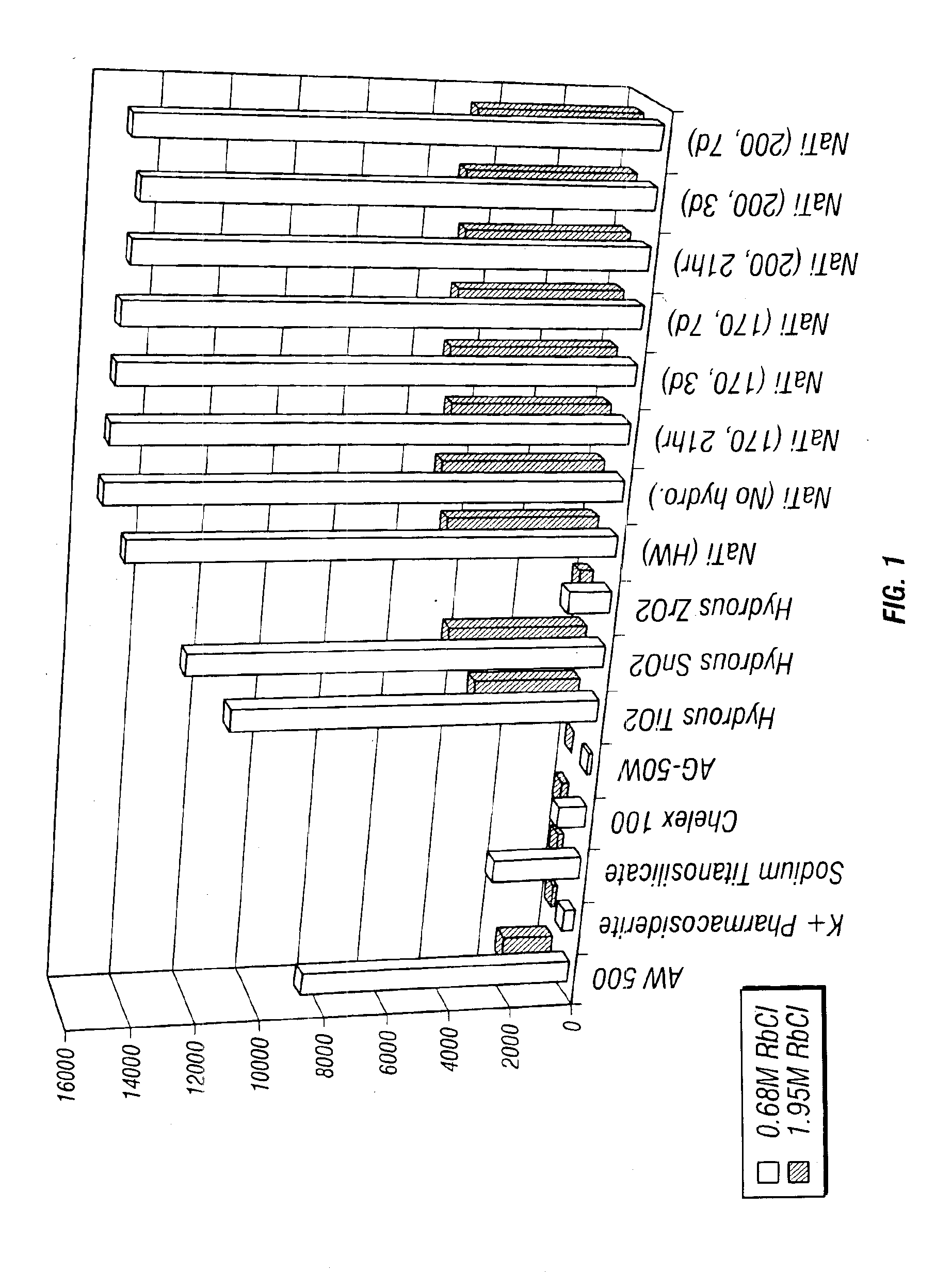

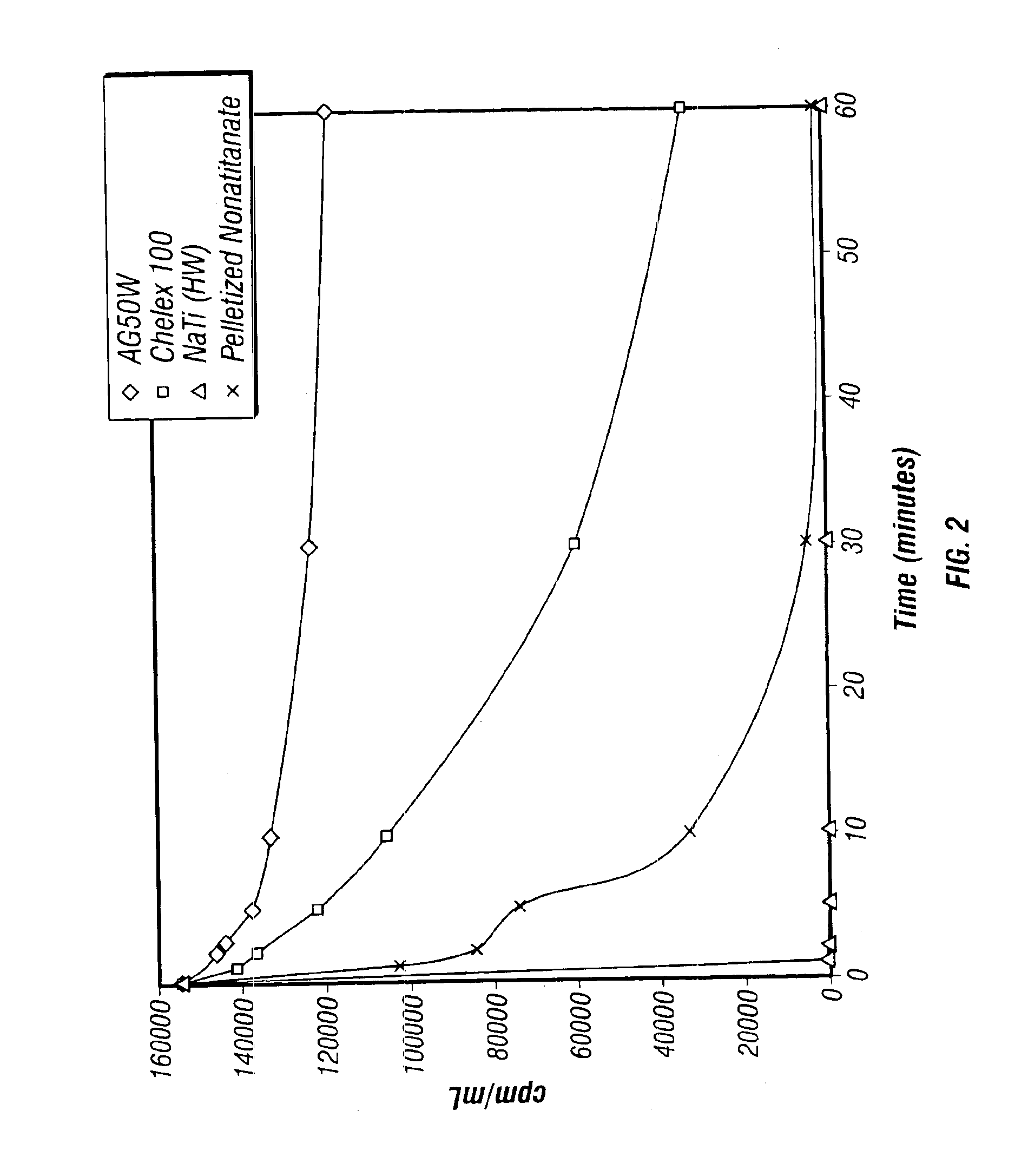

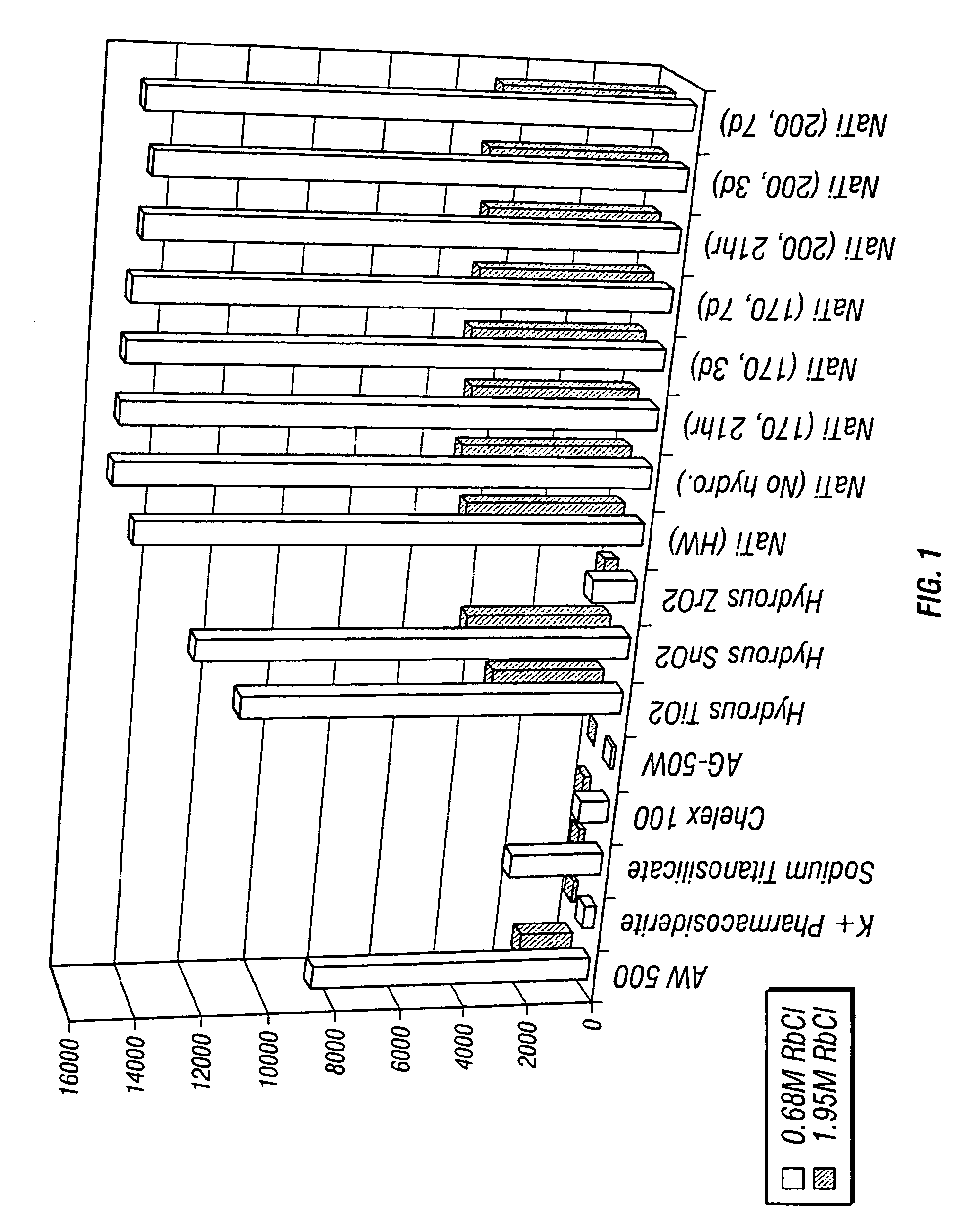

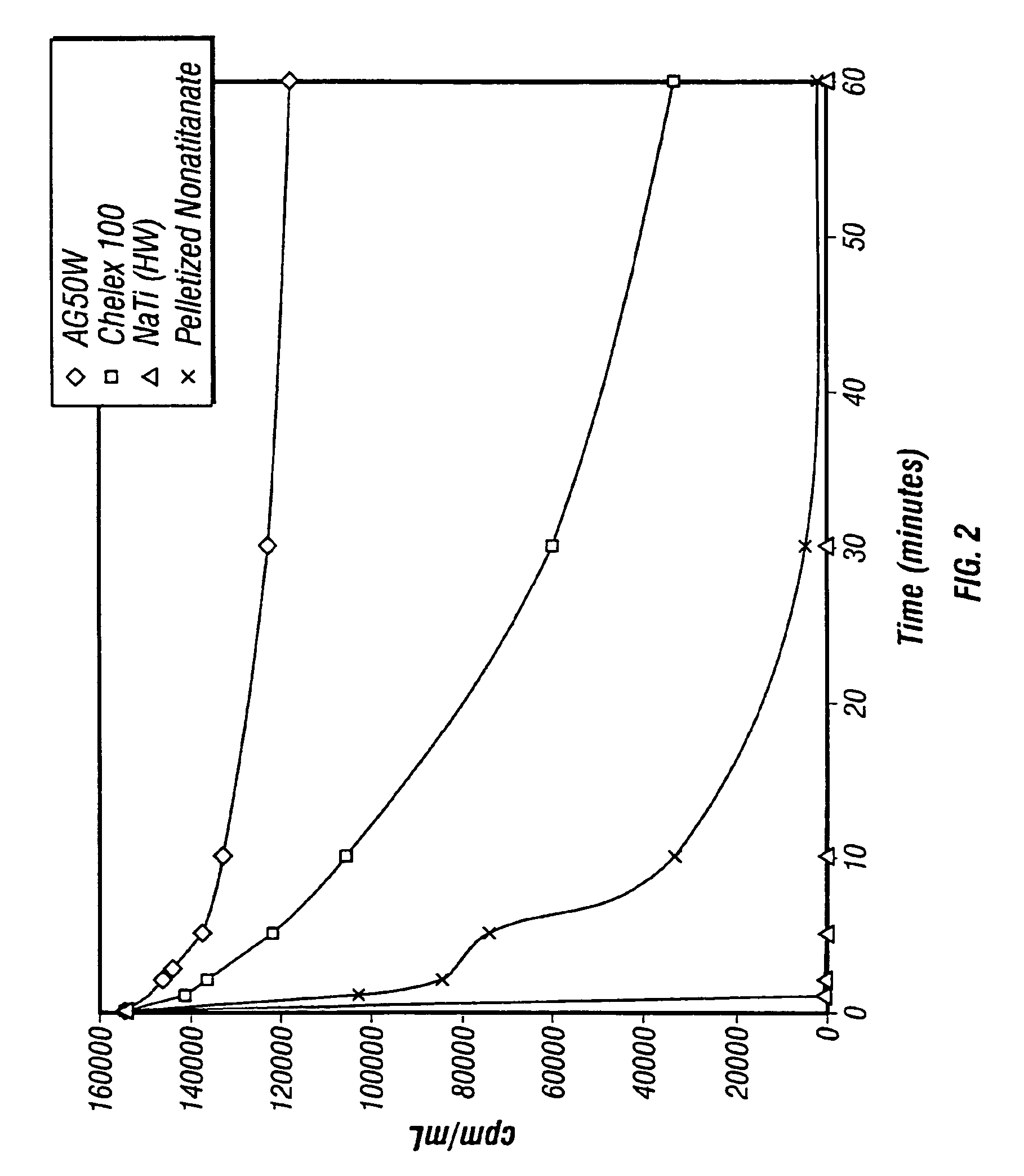

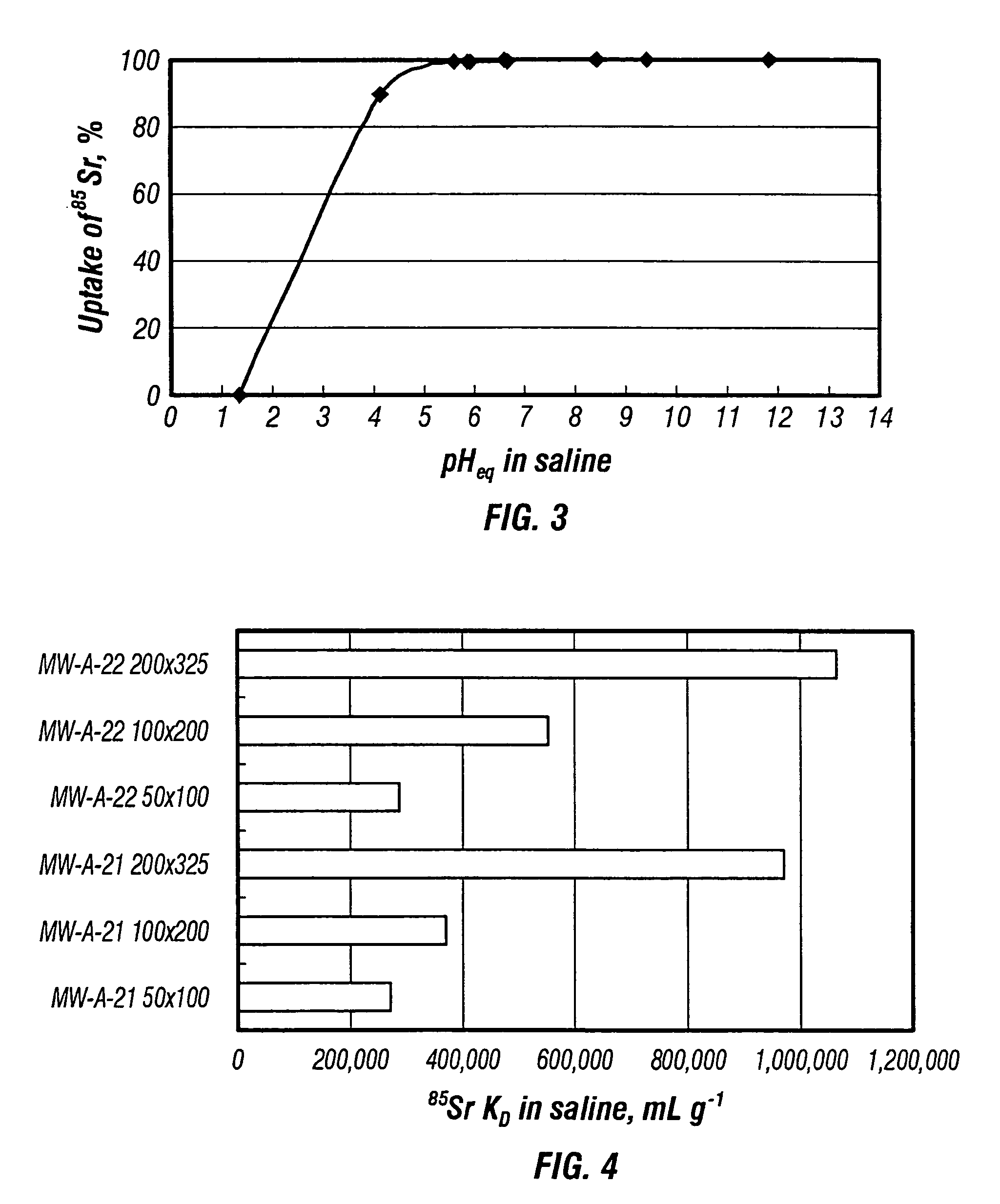

Rubidlum-82 generator based on sodium nonatitanate support, and improved separation methods for the recovery of strontium-82 from irradiated targets

InactiveUS6908598B2Effective recoveryOther chemical processesTransuranic element compoundsLow affinityRubidium

Sodium nonatitanate compositions, a method using the composition for recovery of 82Sr from irradiated targets, and a method using the composition for generating 82Rb. The sodium nonatitanate materials of the invention are highly selective at separating strontium from solutions derived from the dissolution of irradiated target materials, thus reducing target processing times. The compositions also have a very low affinity for rubidium, making it an ideal material for use as a 82Rb generator. Sodium nonatitanate materials of this type both improve the recovery of 82Sr and provide a safer, more effective 82Rb generator system.

Owner:LYNNTECH

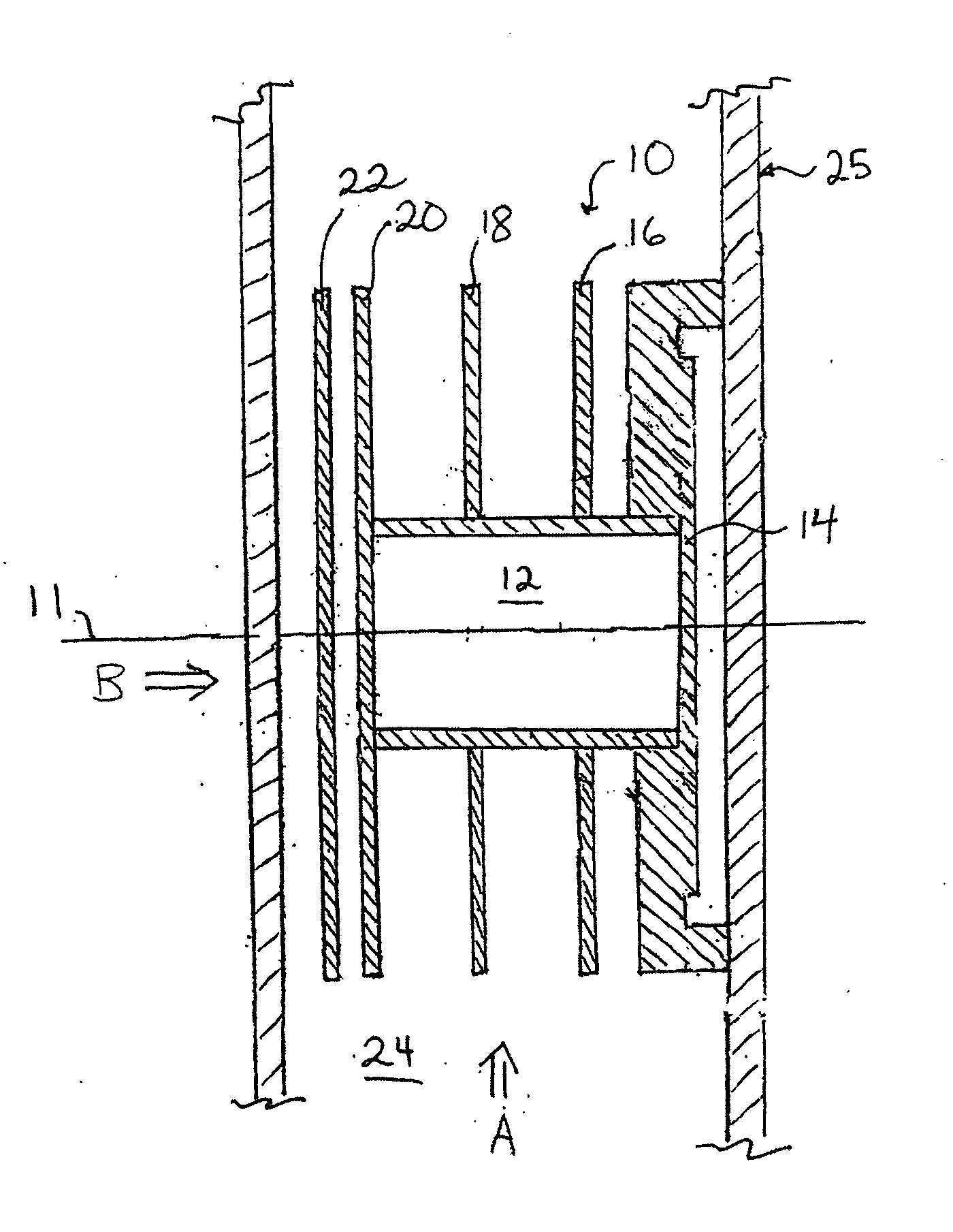

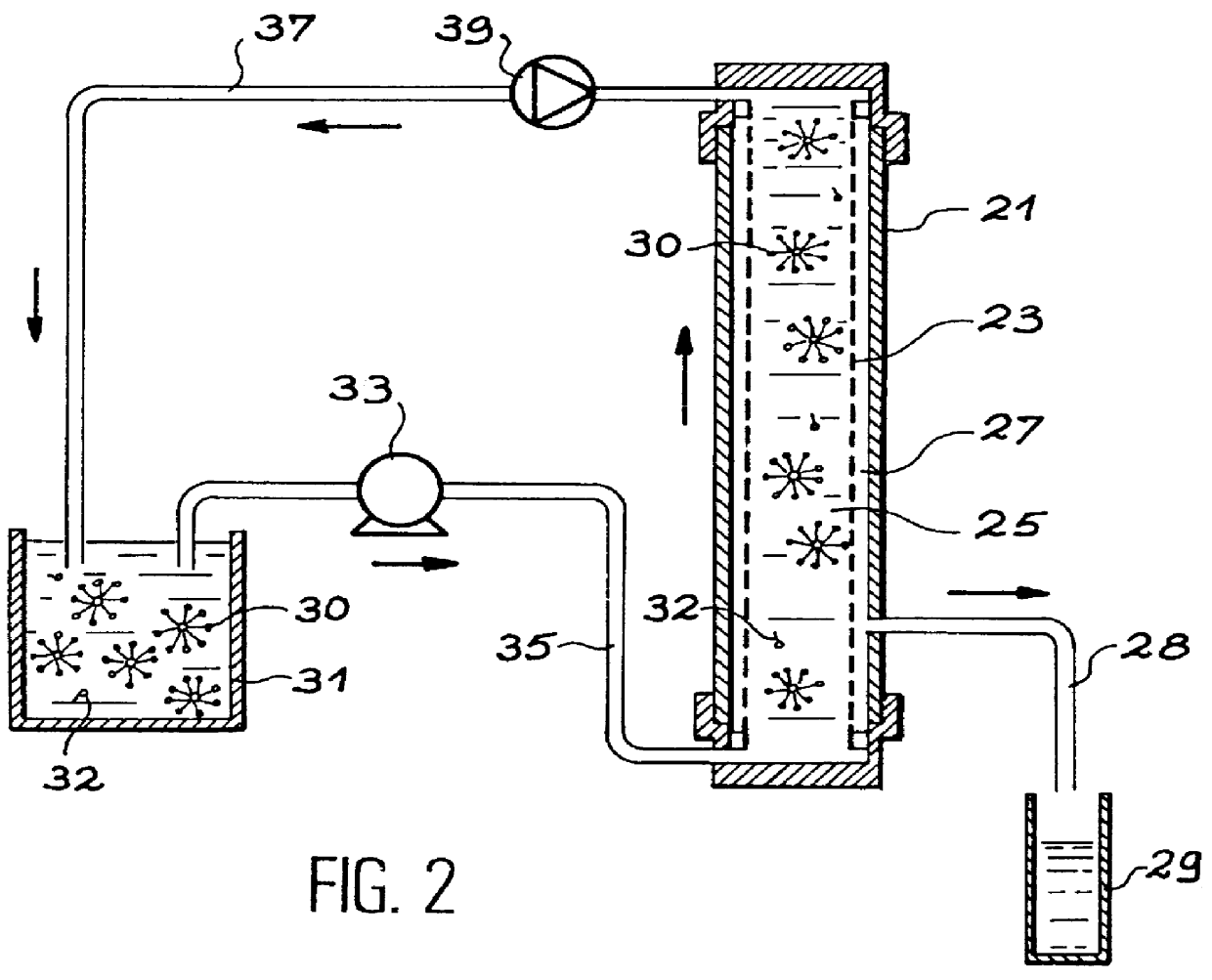

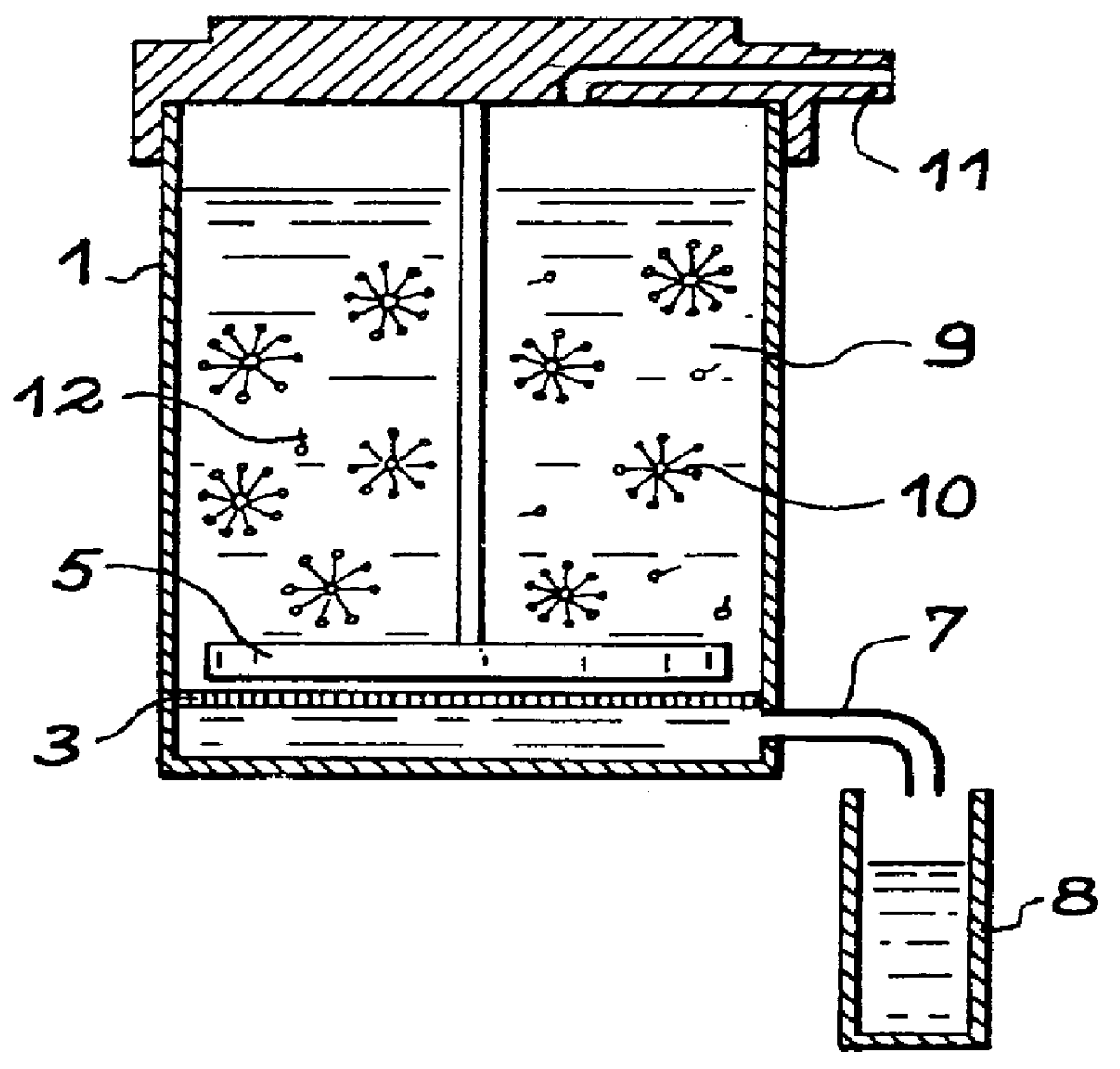

Systems and Methods for Radioisotope Generation

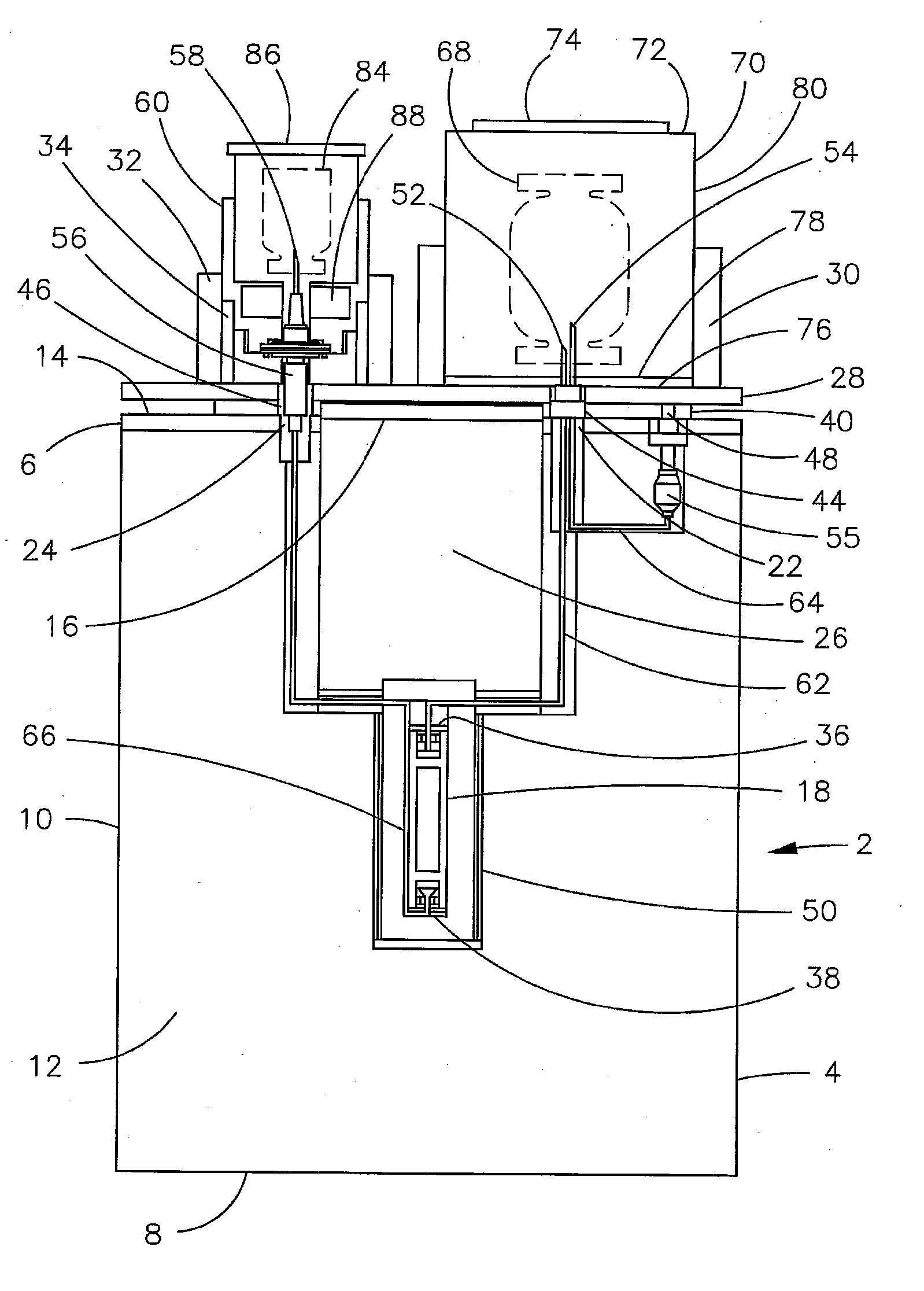

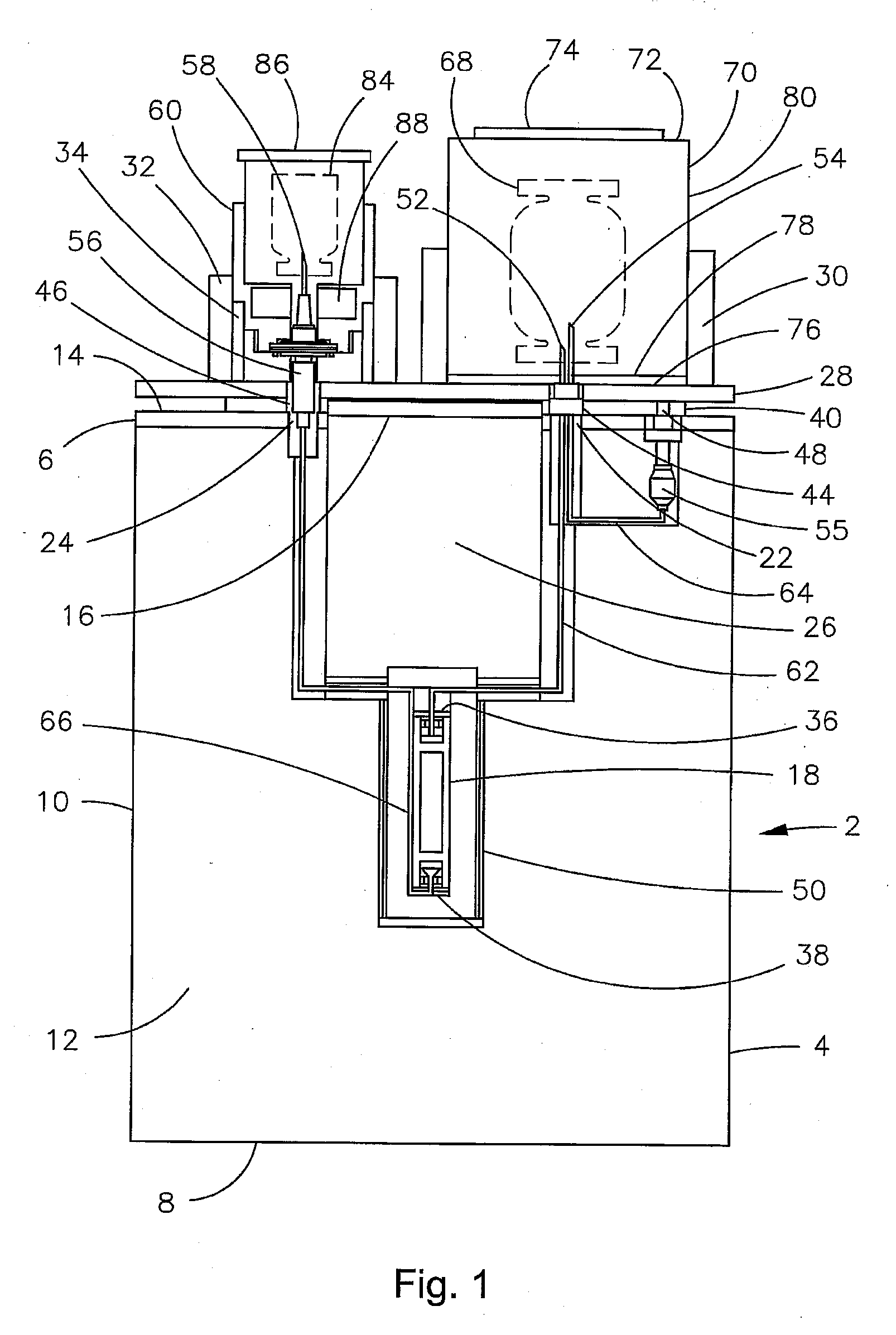

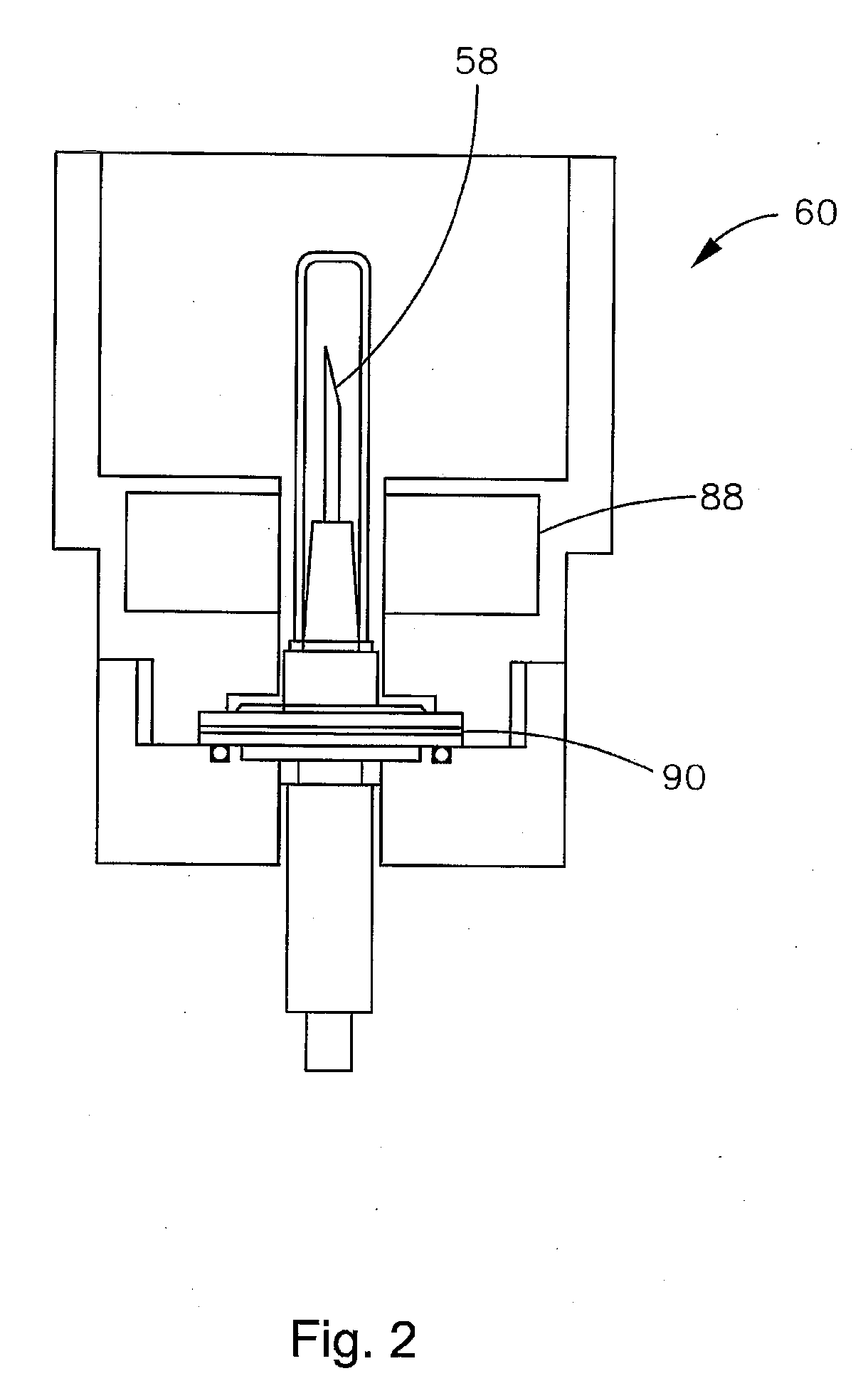

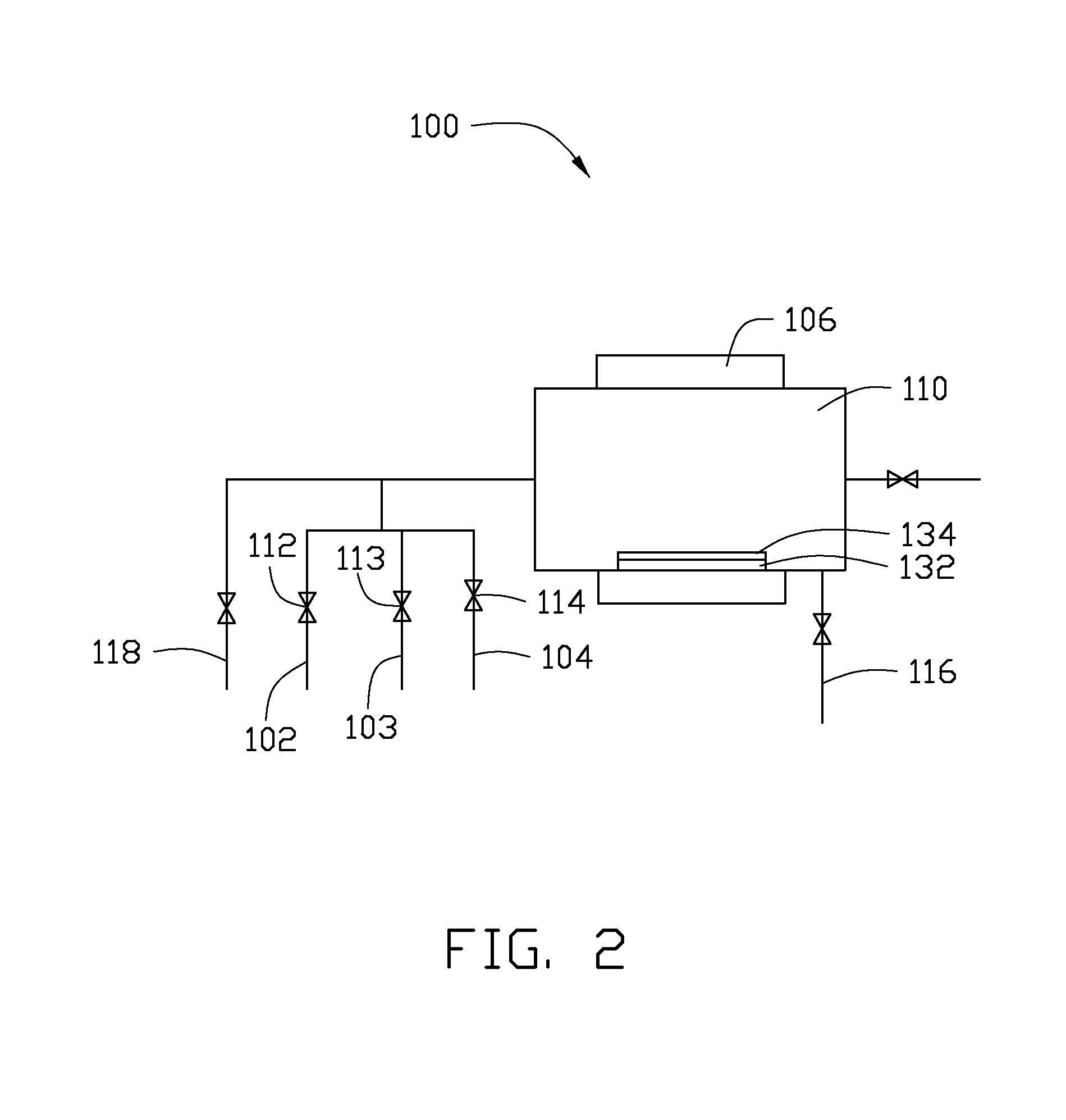

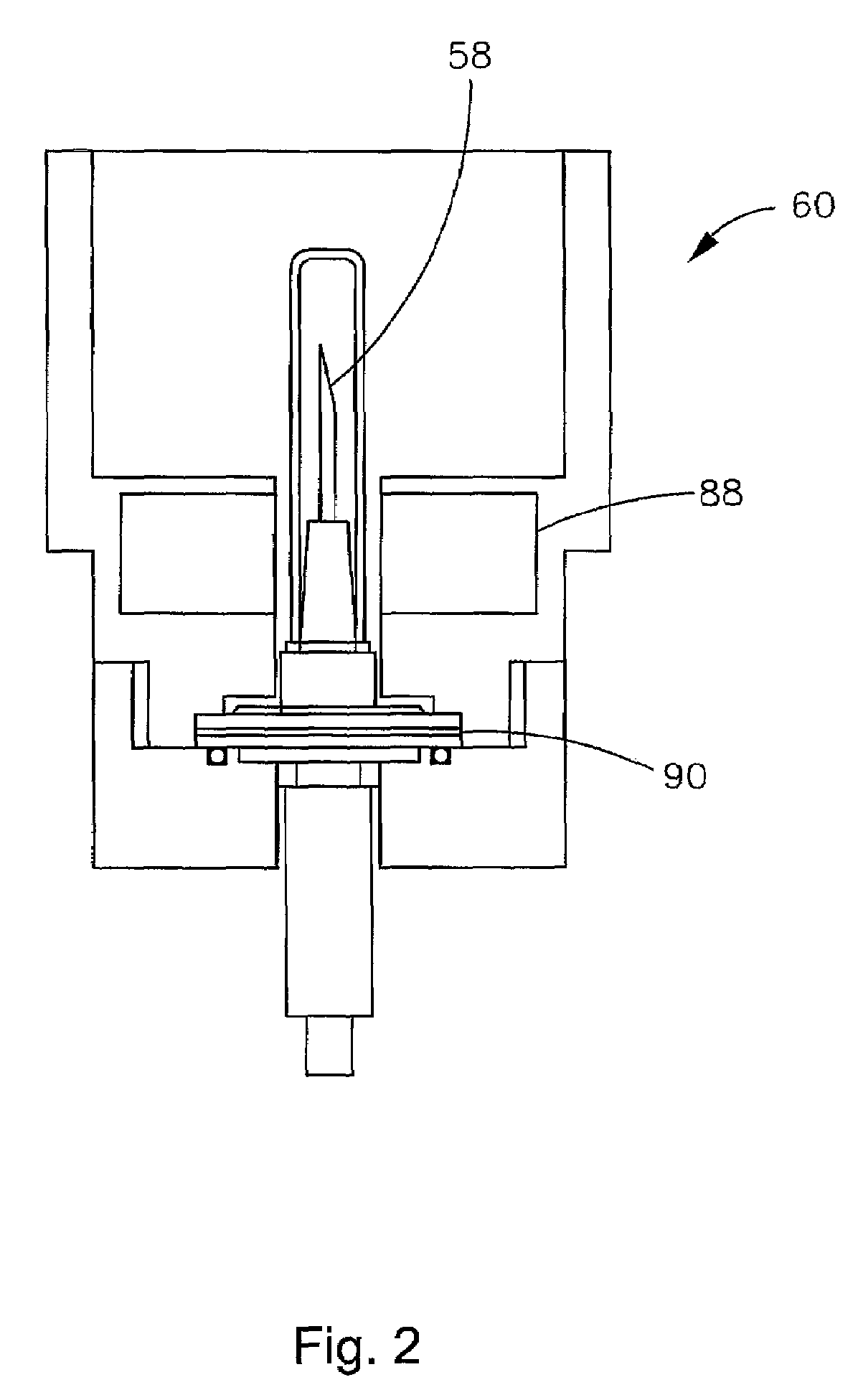

ActiveUS20080093564A1Isotope delivery systemsTransuranic element compoundsEngineeringChromatographic column

Systems and methods are disclosed for producing customized, predictable and reproducible supplies of radioisotopes using, for example, a reactor housing that is fabricated from a radioactive shielding material and has both an internal volume and a surface that comprises an entry port and an exit port, a chromatographic column that is positioned within said internal volume such that a first end of said column is in fluid communication with said entry port and a second end of said column is in fluid communication with said exit port, and a changeable filter module that is disposed external to said reactor housing and in fluid communication with said exit port.

Owner:JUBILANT DRAXIMAGE

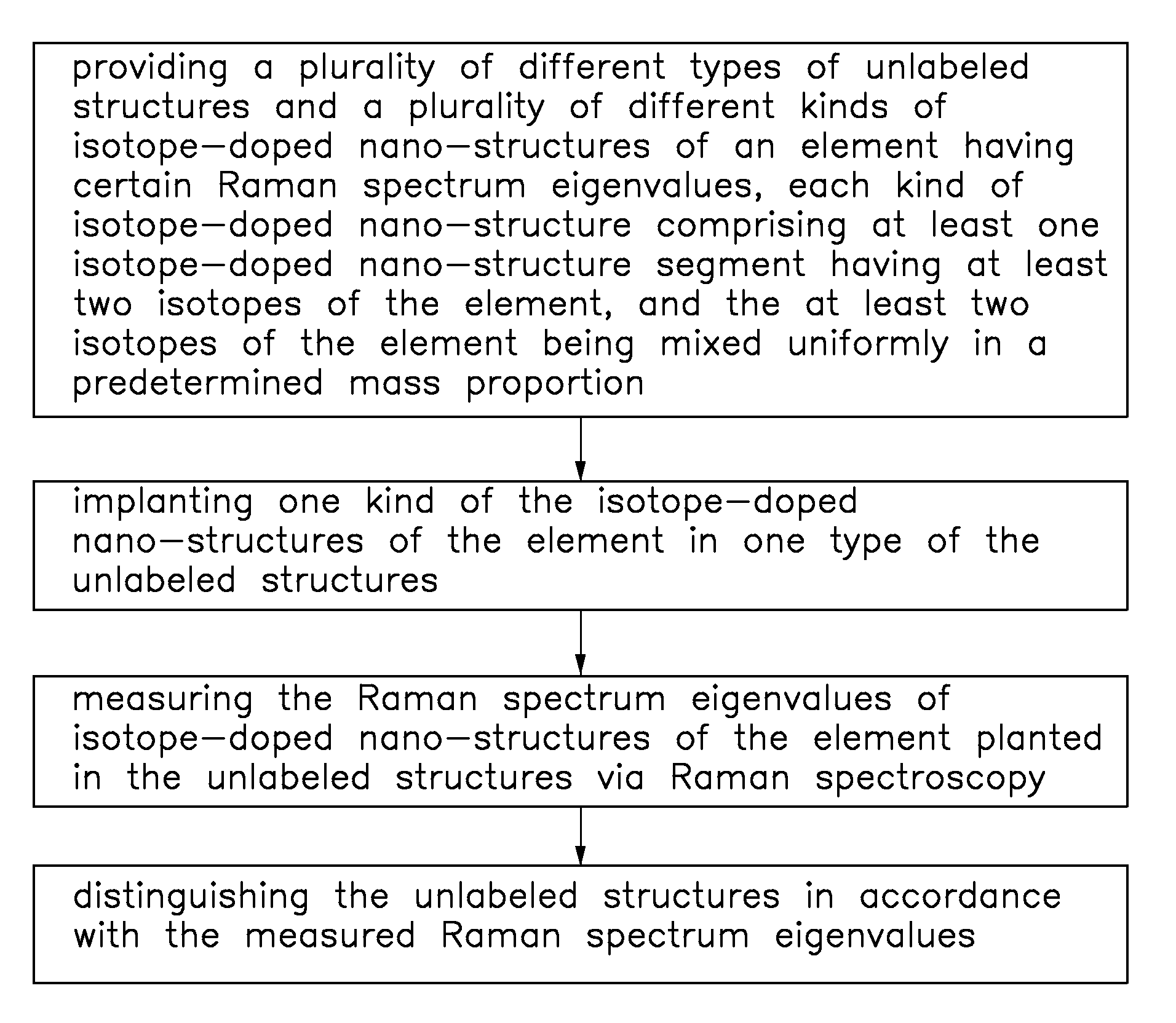

Isotope-doped nano-material, method for making the same, and labeling method using the same

An isotope-doped nano-structure of an element is provided. The isotope-doped nano-structure includes at least one isotope-doped nano-structure segment having at least two isotopes of the element, and the at least two isotopes of the element are mixed uniformly in a certain proportion. The present disclosure also provides a method for making the isotope-doped nano-structures, and a labeling method using the isotope-doped nano-structures.

Owner:TSINGHUA UNIV +1

Rubidium-82 generator based on sodium nonatitanate support, and improved separation methods for the recovery of strontium-82 from irradiated targets

InactiveUS7476377B2Effective recoveryTransuranic element compoundsOther chemical processesLow affinityRubidium

Sodium nonatitanate compositions, a method using the composition for recovery of 82Sr from irradiated targets, and a method using the composition for generating 82Rb. The sodium nonatitanate materials of the invention are highly selective at separating strontium from solutions derived from the dissolution of irradiated target materials, thus reducing target processing times. The compositions also have a very low affinity for rubidium, making it an ideal material for use as a 82Rb generator. Sodium nonatitanate materials of this type both improve the recovery of 82Sr and provide a safer, more effective 82Rb generator system.

Owner:LYNNTECH

Process for extracting and separating thorium and extracting rare earth chloride from sulfuric and phosphoric mixed acid system

InactiveCN1394971AReduce radioactive contaminationReduce negative impactRadium compoundsRare earth metal compoundsKeroseneFractionation

The present invention belongs to a process for extracting and separating thorium from sulfo-phosphoric mixed acid and extracting rare earth chloride. Said process adopts primary amine added mixed alcohol as extracting agent, and makes direct fractionation of rare earth slurry to extract thorium, and the thorium content in the separated rare earth slurry is ThO2 / REO is less than or equal to 5X10 to the minus sixth. Said invention utilizes the thorium being in organic phase and adopts countercurrent reextraction process by means of nitric acid to obtain thorium nitrate product, its purity is 99%, and thorium recovery is up to 99%. Said invention adopts magnesium oxide precipitation method to remove the iron and phosphorus in the rare earth reffinate, uses ammoniated P507-kerosene to extract organic phase.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

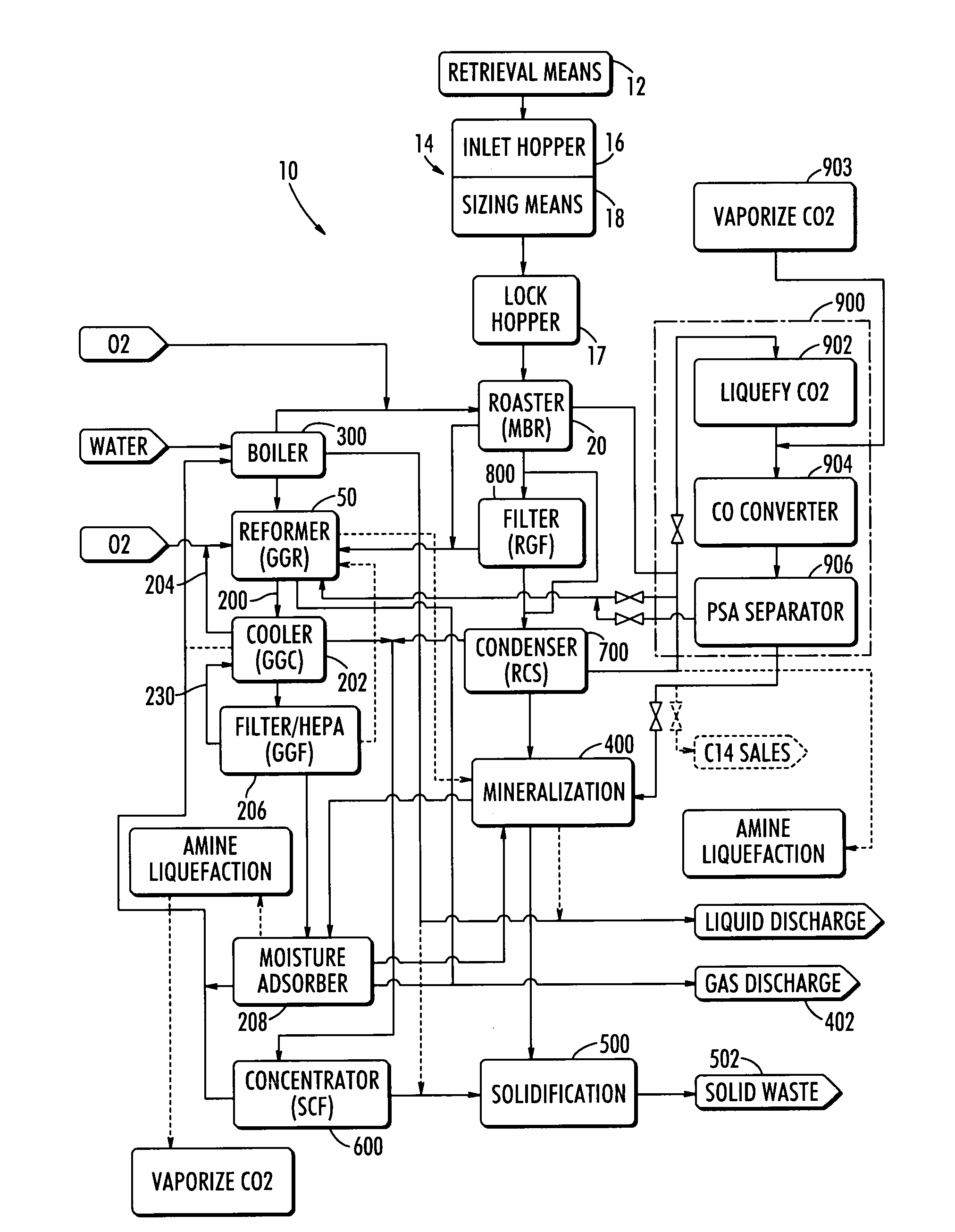

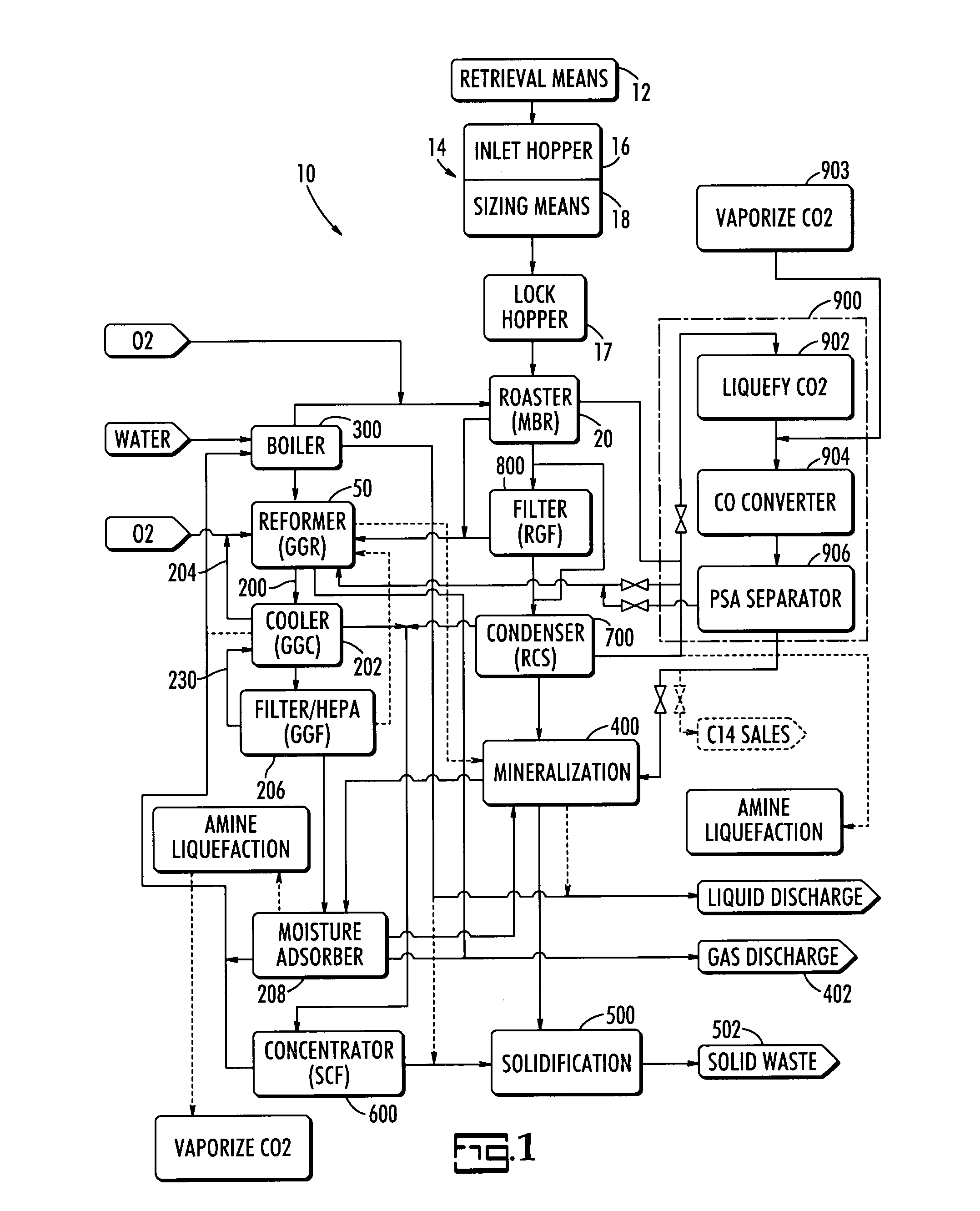

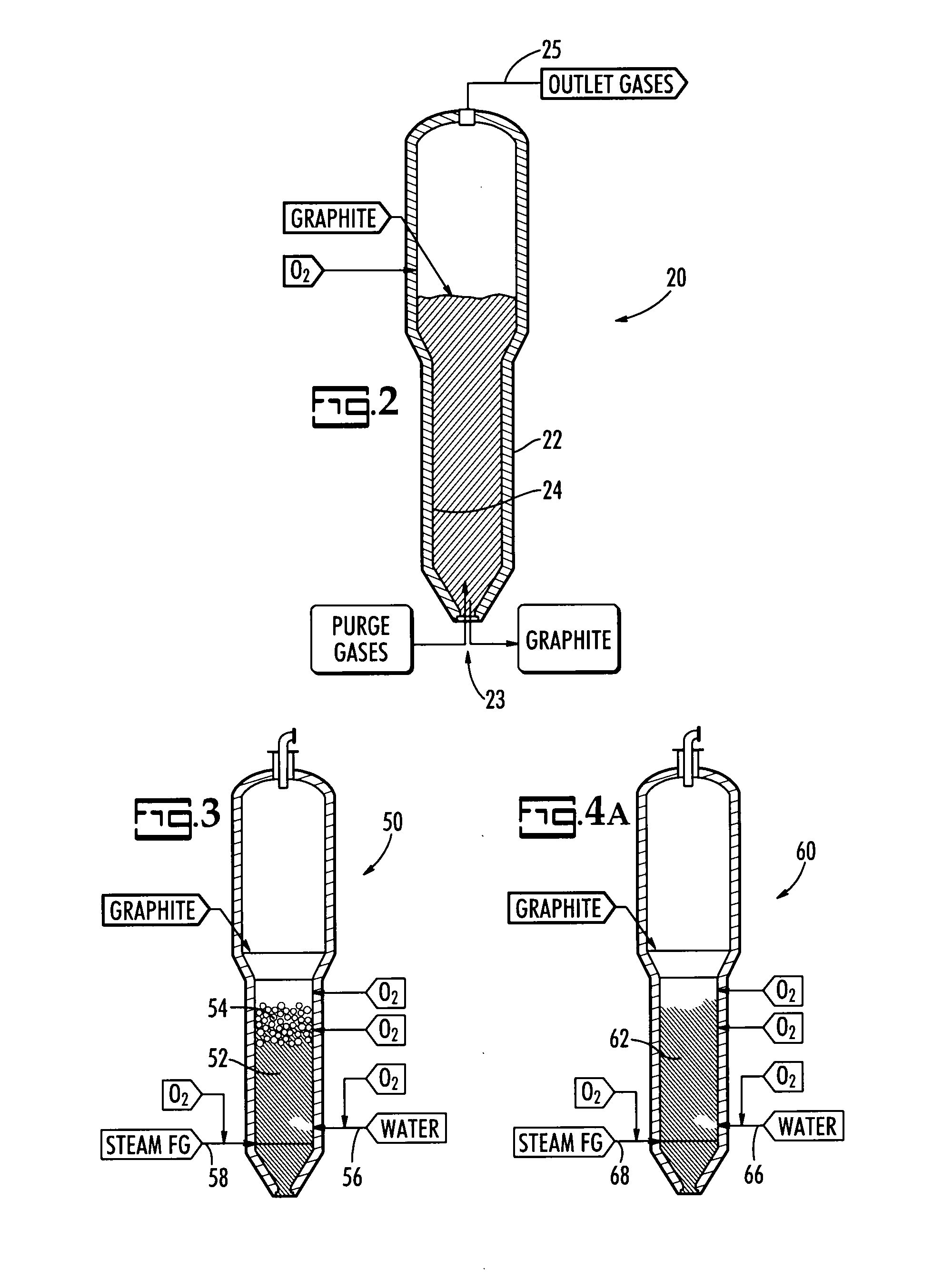

Steam reforming process system for graphite destruction and capture of radionuclides

InactiveUS20080181835A1Step is made and efficientAvoid excessive dischargeTransuranic element compoundsRadium compoundsProcess systemsSteam reforming

A system for the treatment and recycling of graphite containing radionuclides including a two stage method that employes a thermal roaster that is operatively connected to a steam reformer. In the first stage, radioactive graphite is roasted or heated to volatize a first amount of radionuclides contained in the graphite. In the second stage, the roasted graphite is reacted with steam or gases containing water vapor so that a second amount of radionuclides is removed. Optionally, the present system also processes the radionuclides to enable their disposal.

Owner:STUDSVIK INC

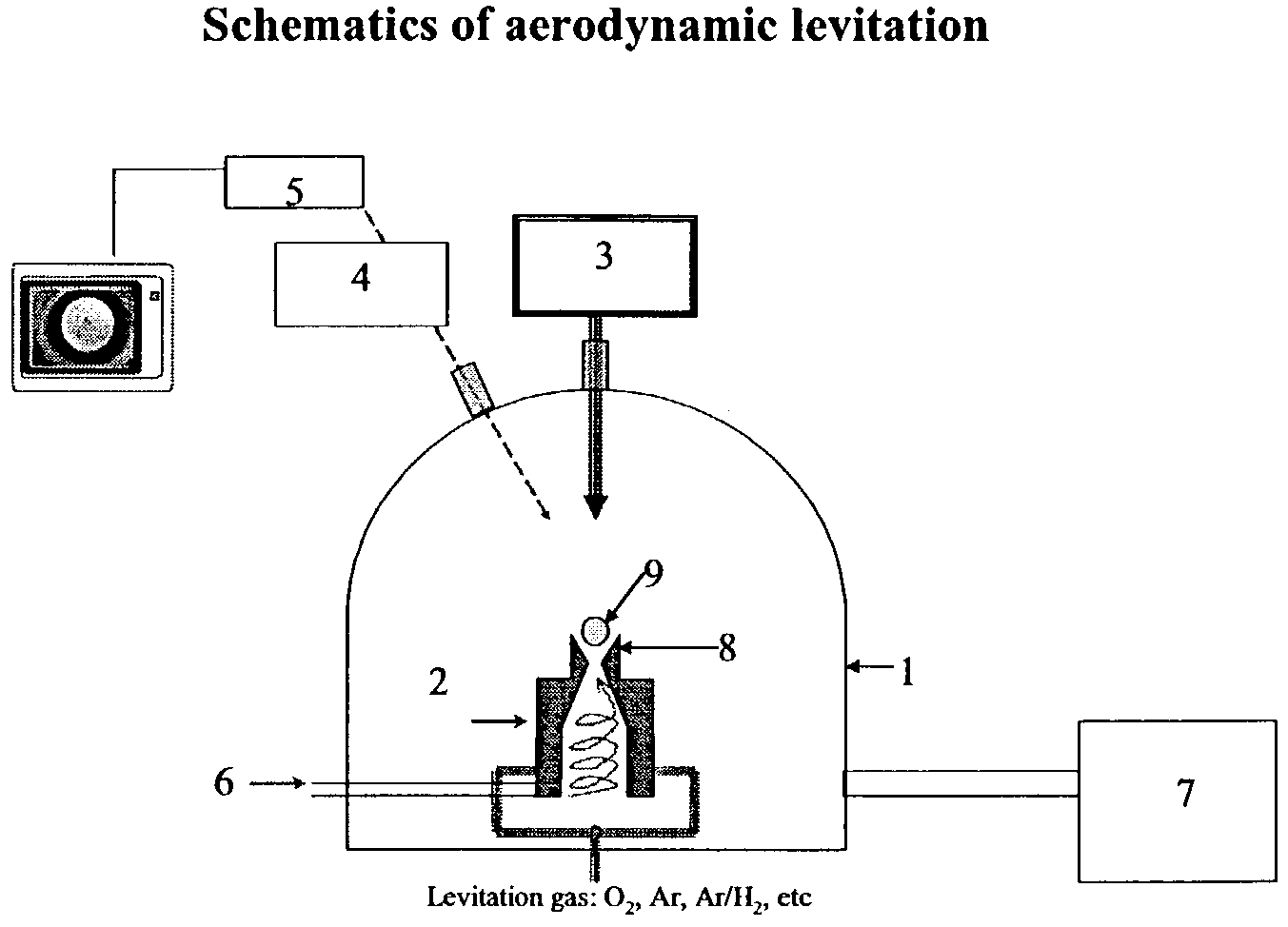

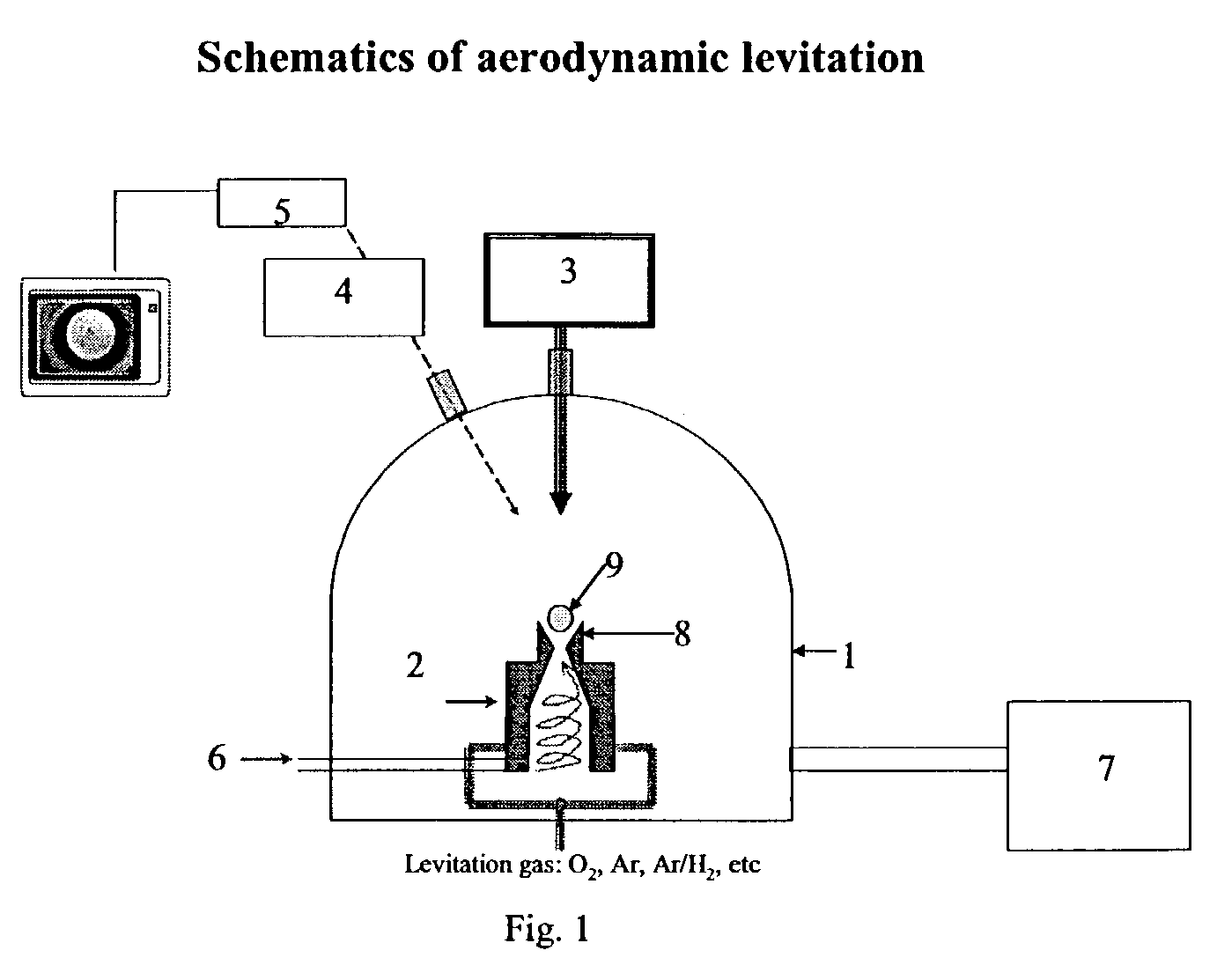

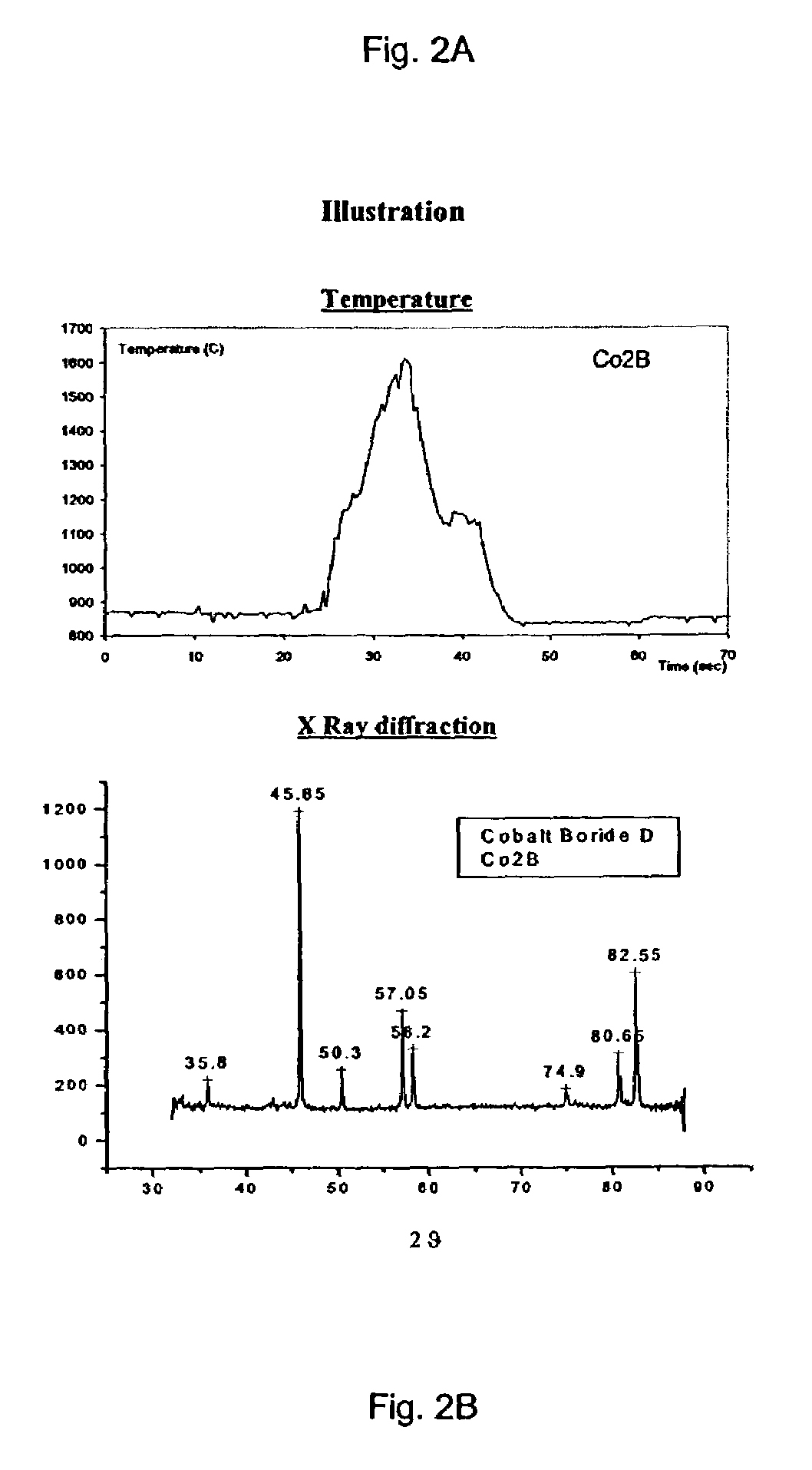

Method for synthesizing extremely high-temperature melting materials

The invention relates to a method of synthesizing high-temperature melting materials. More specifically the invention relates to a containerless method of synthesizing very high temperature melting materials such as borides, carbides and transition-metal, lanthanide and actinide oxides, using an Aerodynamic Levitator and a laser. The object of the invention is to provide a method for synthesizing extremely high-temperature melting materials that are otherwise difficult to produce, without the use of containers, allowing the manipulation of the phase (amorphous / crystalline / metastable) and permitting changes of the environment such as different gaseous compositions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Methods for making and processing metal targets for producing Cu-67 radioisotope for medical applications

ActiveUS20100028234A1Improve productivitySimple methodBacterial antigen ingredientsTransuranic element compoundsHigh energyCompound (substance)

The present invention provides a method for producing Cu67 radioisotope suitable for use in medical applications. The method comprises irradiating a metallic zinc-68 (Zn68) target with a high energy gamma ray beam. After irradiation, the Cu67 is isolated from the Zn68 by any suitable method (e.g., chemical and / or physical separation). In a preferred embodiment, the Cu67 is isolated by sublimation of the zinc (e.g., at about 500-700° C. under reduced pressure) to afford a copper residue containing Cu67. The Cu67 can be further purified by chemical means (i.e., dissolution in acid, followed by ion exchange).

Owner:UCHICAGO ARGONNE LLC

Systems and methods for radioisotope generation

Owner:JUBILANT DRAXIMAGE

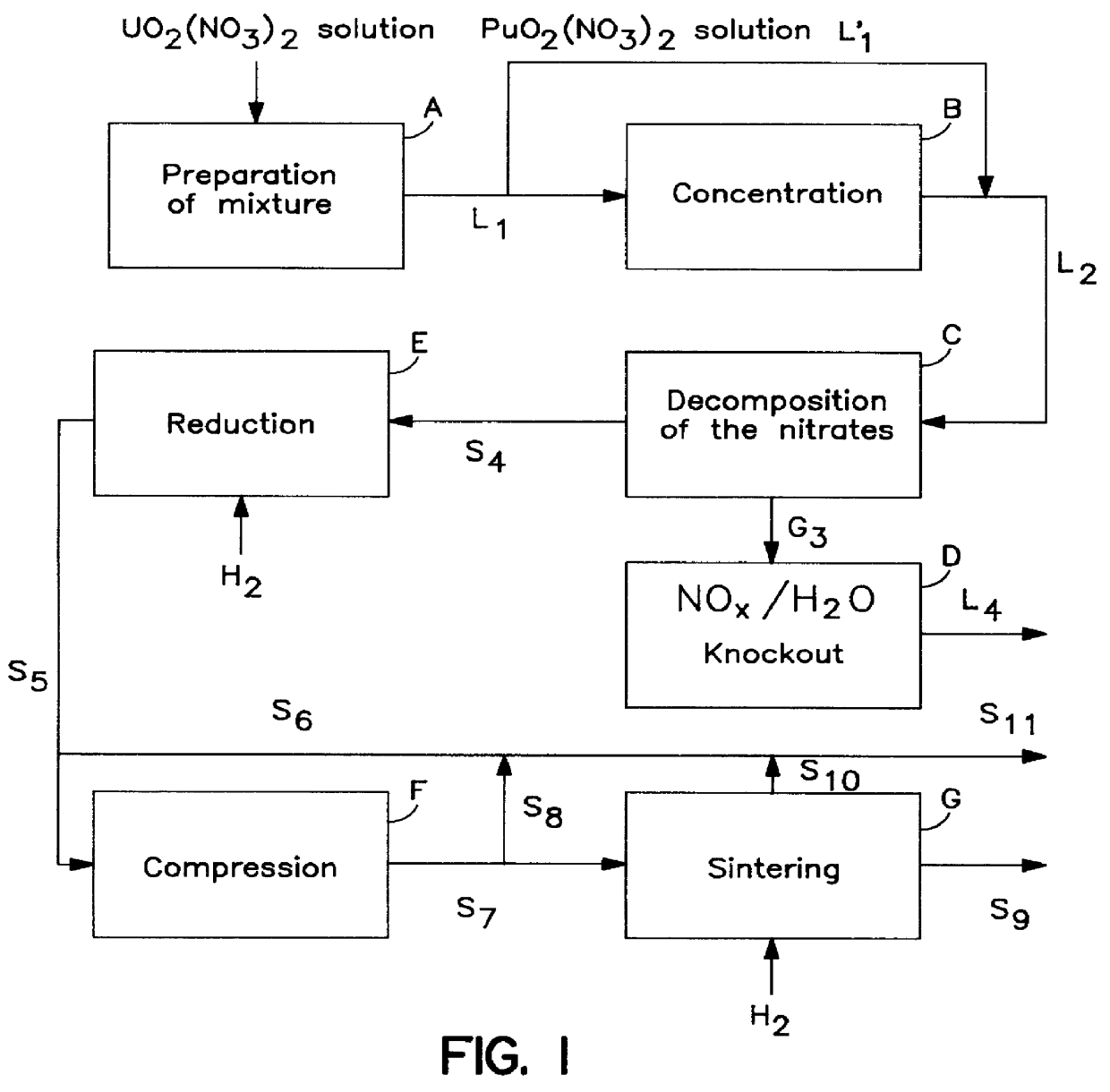

Method for preparing a mixture of powdered metal oxides from nitrates thereof in the nuclear industry

InactiveUS6110437AEasy to recycleImprove responseOxygen/ozone/oxide/hydroxideTransuranic element compoundsPowder mixtureNitrate

PCT No. PCT / FR96 / 01993 Sec. 371 Date Mar. 2, 1999 Sec. 102(e) Date Mar. 2, 1999 PCT Filed Dec. 12, 1996 PCT Pub. No. WO97 / 21629 PCT Pub. Date Jun. 19, 1997A thermal decomposition method useful in the nuclear industry for preparing a powdered mixture of metal oxides having suitable reactivity from nitrates thereof in the form of an aqueous solution or a mixture of solids. According to the method, the solution or the mixture of solids is thermomechanically contacted with a gaseous fluid in the contact area of a reaction chamber, said gaseous fluid being fed into the reaction chamber at the same time as the solution or mixture at a temperature no lower than the decomposition temperature of the nitrates, and having a mechanical energy high enough to generate a fine spray of the solution or a fine dispersion of the solid mixture, and instantly decompose the nitrates. The resulting oxide mixtures may be used to prepare nuclear fuels.

Owner:COMURHEX

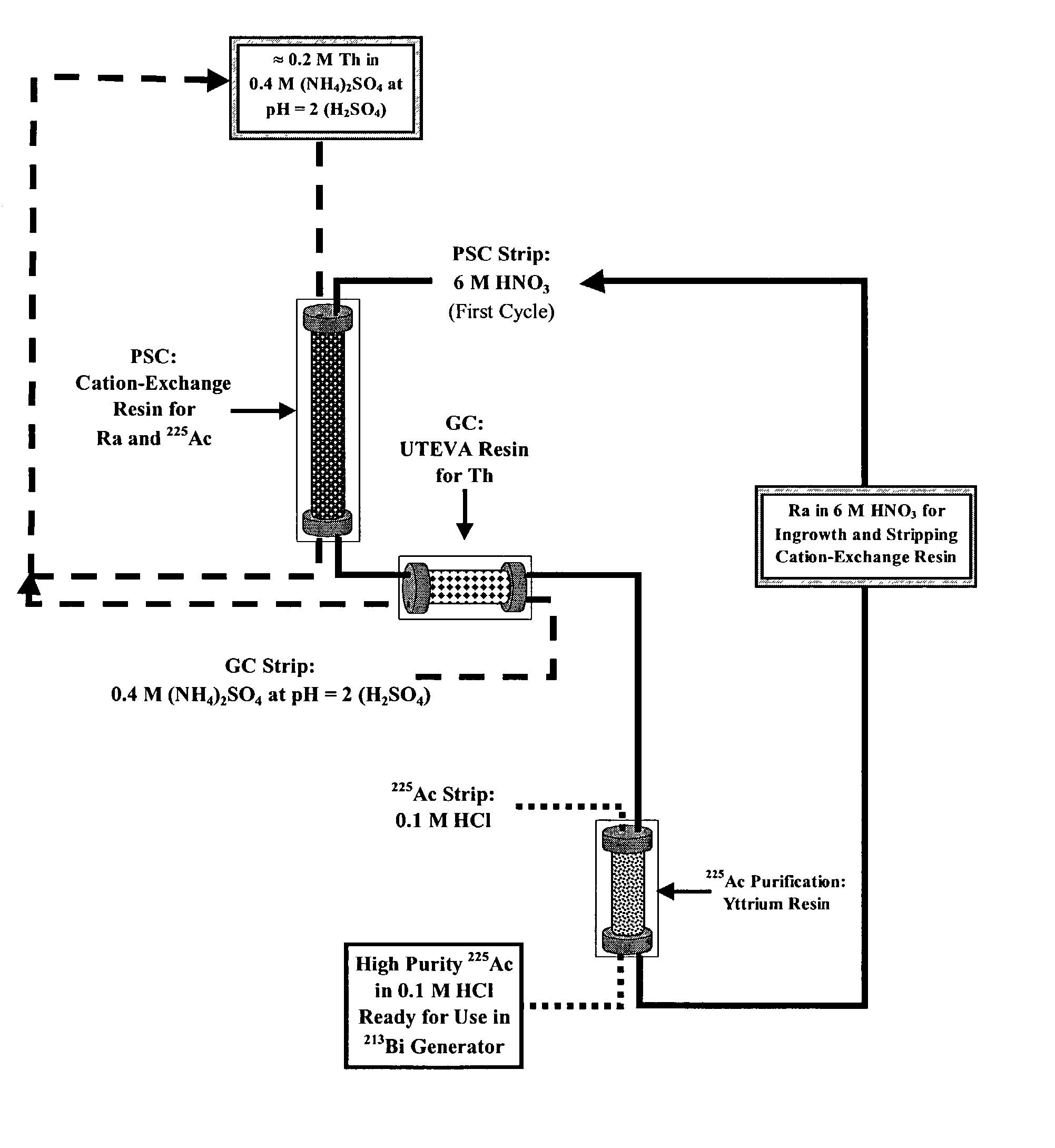

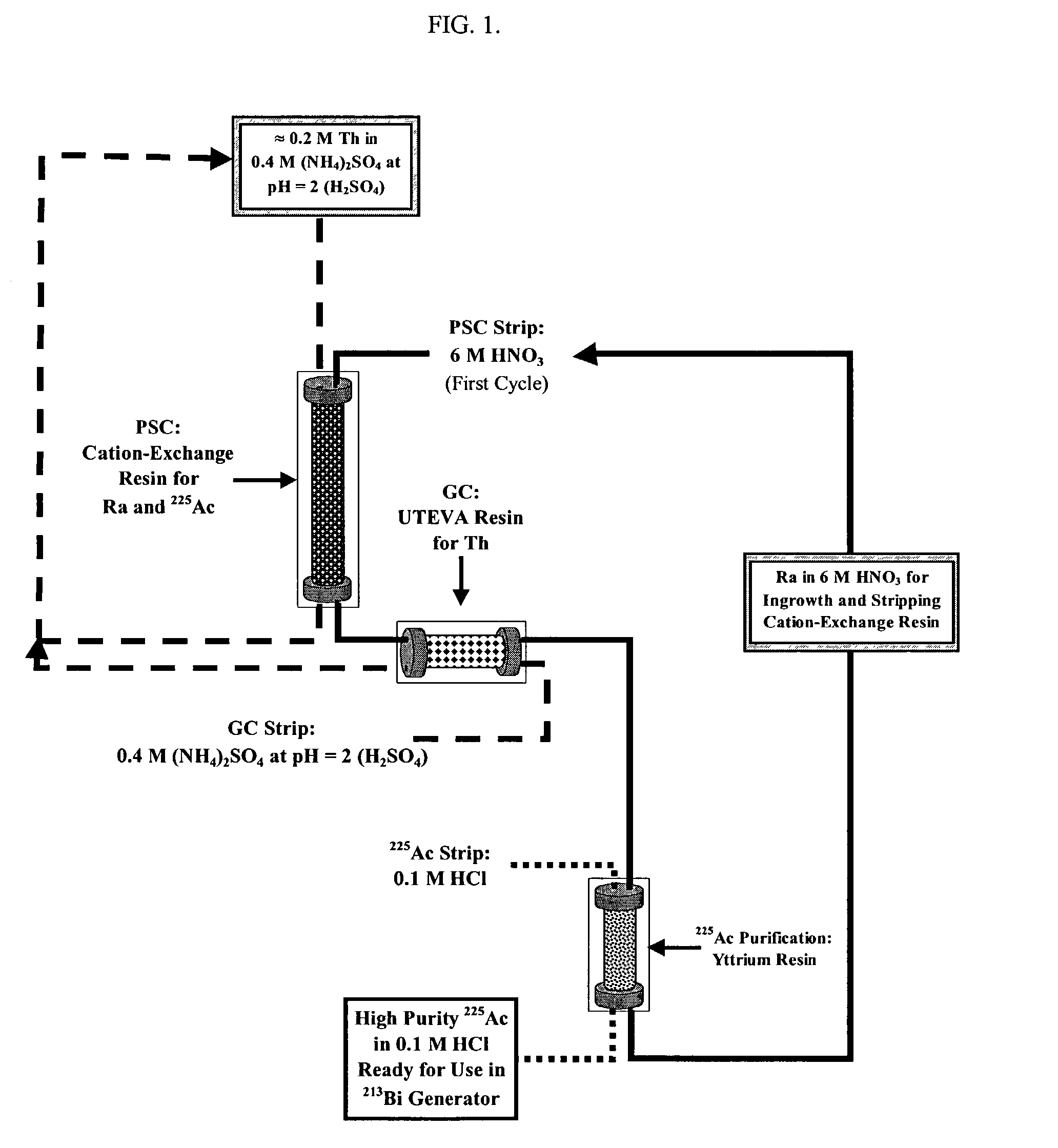

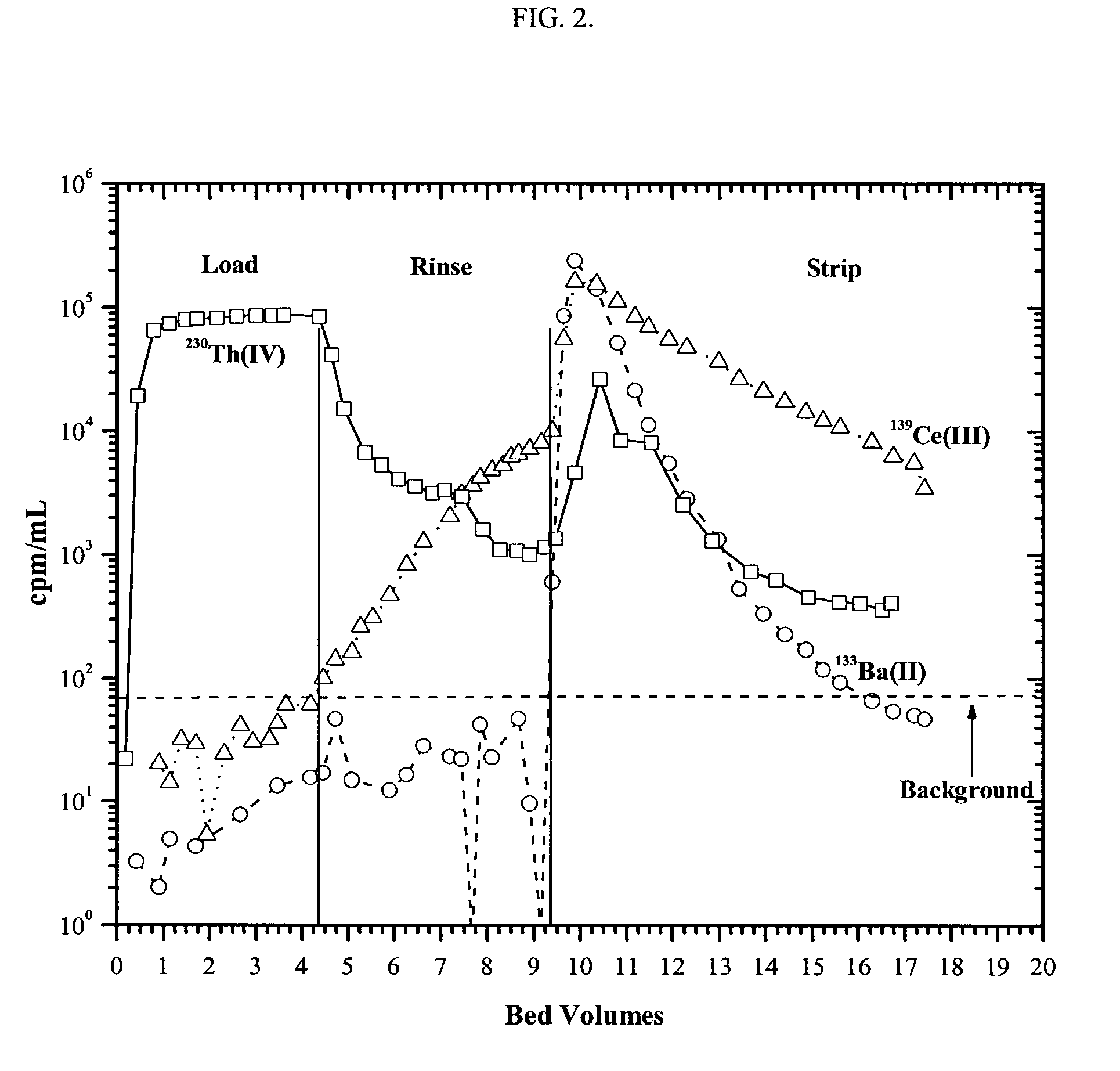

Multicolumn selectivity inversion generator for production of high purity actinium for use in therapeutic nuclear medicine

InactiveUS7087206B2Separation efficiency is highSmall volumeIsotope delivery systemsTransuranic element compoundsActiniumRadiation damage

A multicolumn selectivity inversion generator separation method has been developed in which actinium ions, a desired daughter radionuclide, are selectively extracted from a solution of the thorium parent and daughter radionuclides by a primary separation column, stripped, and passed through a second guard column that retains any parent or other daughter interferents, while the desired daughter actinium ions and radium ions elute. This separation method minimizes the effects of radiation damage to the separation material and permits the reliable production of radionuclides of high chemical and radionuclidic purity for use in diagnostic or therapeutic nuclear medicine.

Owner:PG RES FOUND

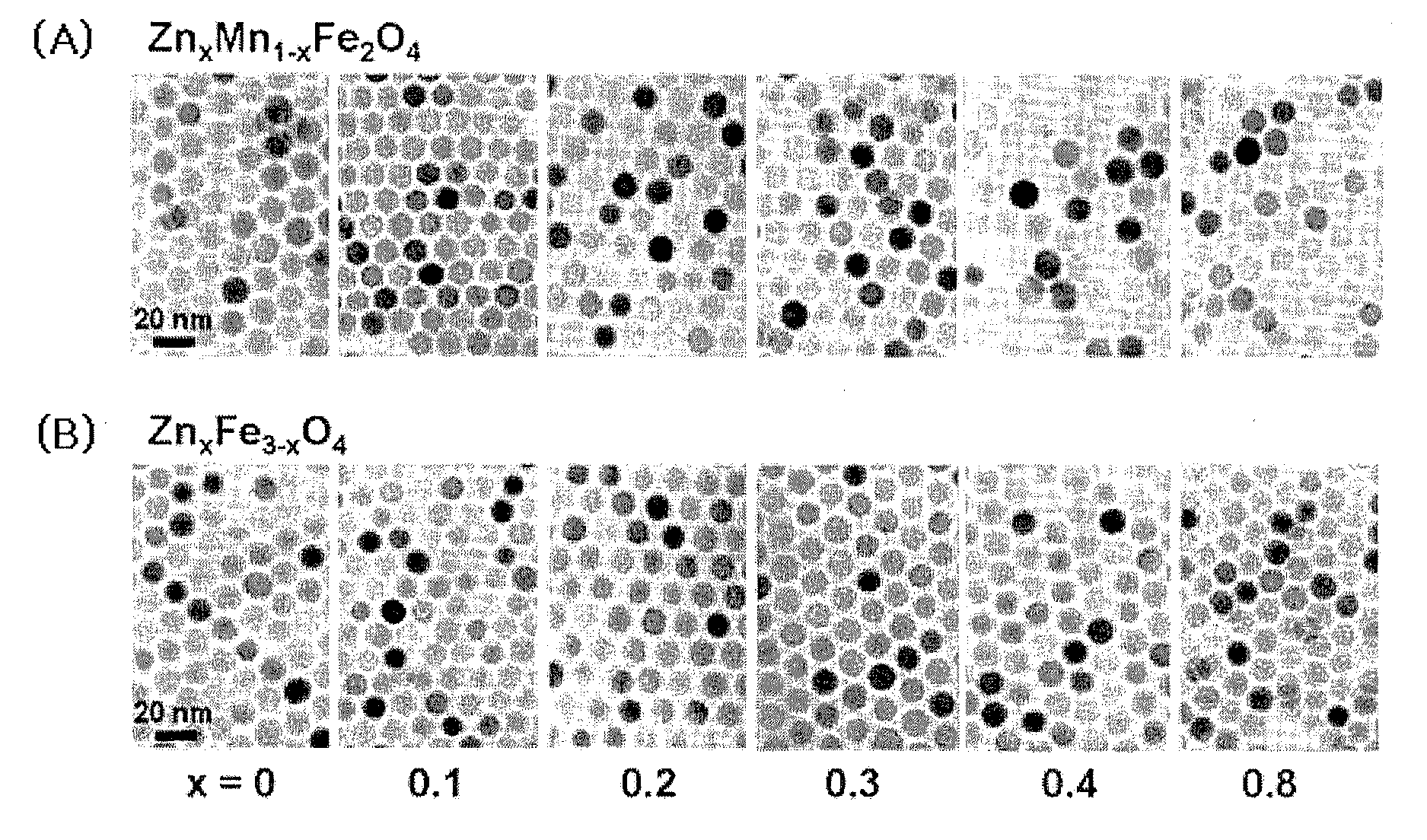

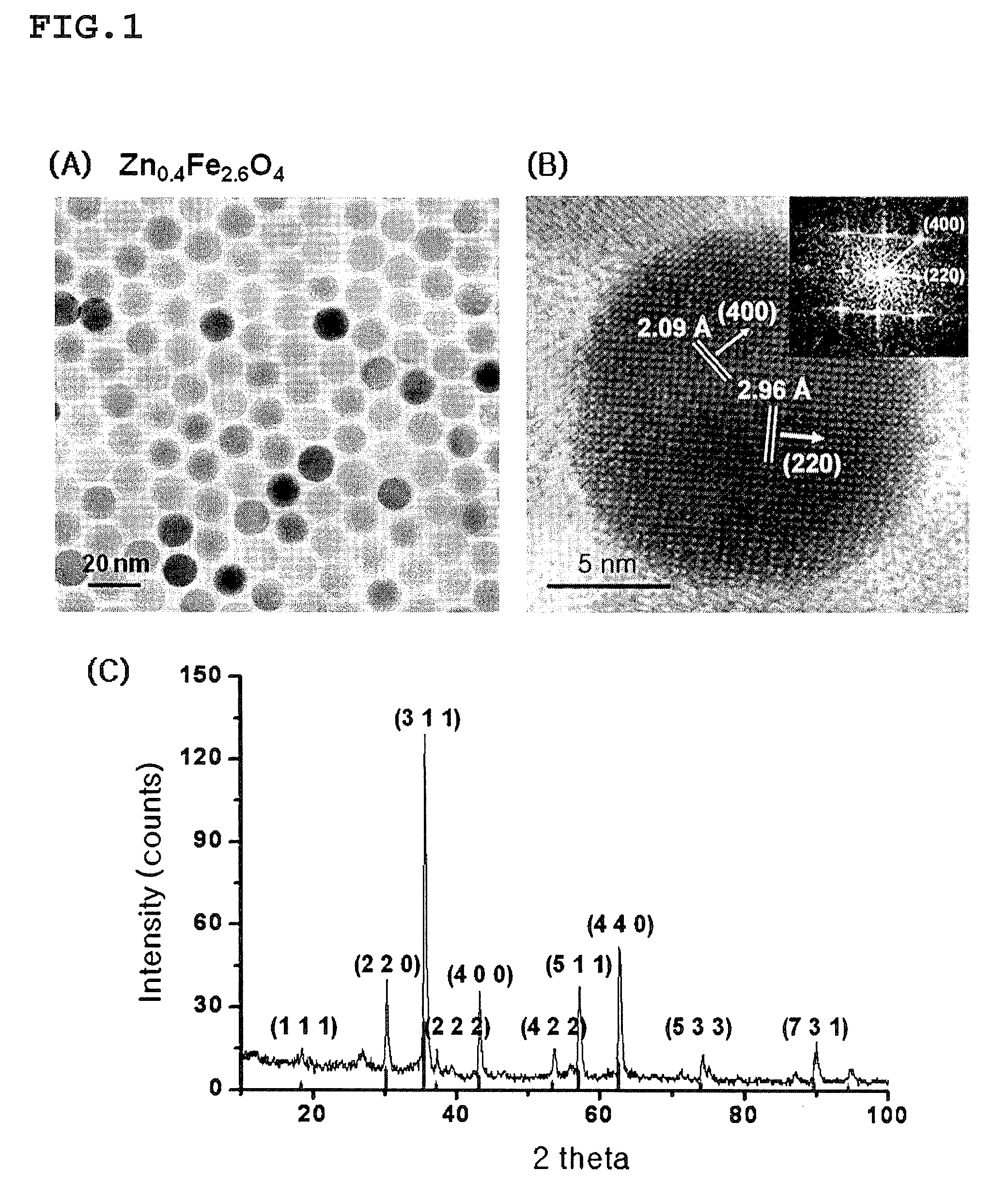

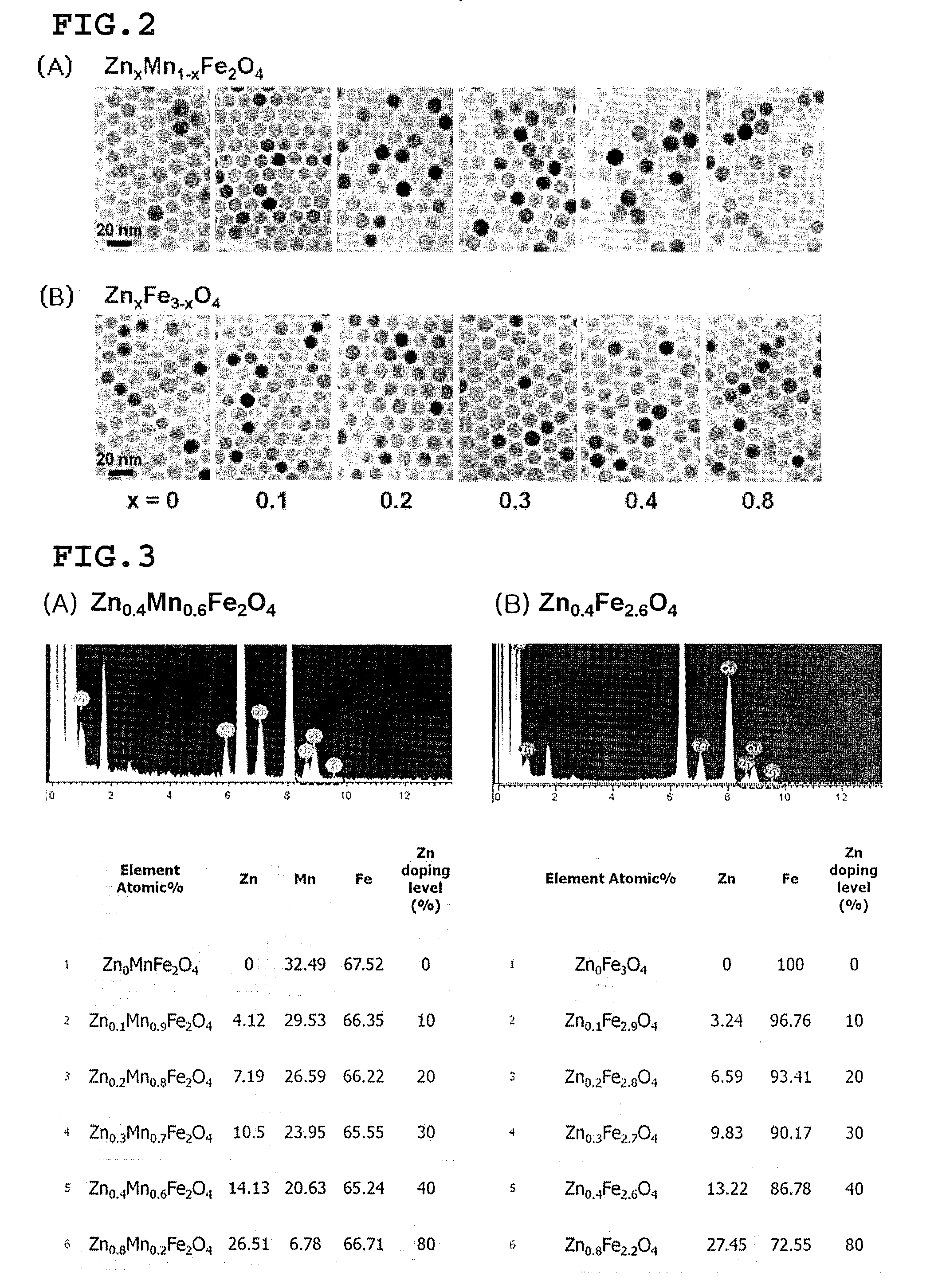

Magnetic resonance imaging contrast agents comprising zinc-containing magnetic metal oxide nanoparticles

ActiveUS20100143263A1Improve magnetic propertiesLow cytotoxicityBiocideNanomagnetismMRI contrast agentMetal oxide nanoparticles

The present invention relates to an MRI contrast agent that includes zinc-containing water-soluble metal oxide nanoparticles and has an improved contrast effect. The zinc-containing water-soluble metal oxide nanoparticles are characterized by addition of zinc to a matrix comprising the metal oxide nanoparticles or by substitution of metal in the matrix, resulting in the improved contrast effect of MRI. In addition, the zinc-containing metal oxide nanoparticles of the present invention include the MRI contrast agent t having hybrid structures of “zinc-containing metal oxide nanoparticle—biologically / chemically active material” in which the nanoparticle is conjugated with a bioactive material such as proteins, antibodies, and chemical materials.

Owner:INVENTERA PHARM INC

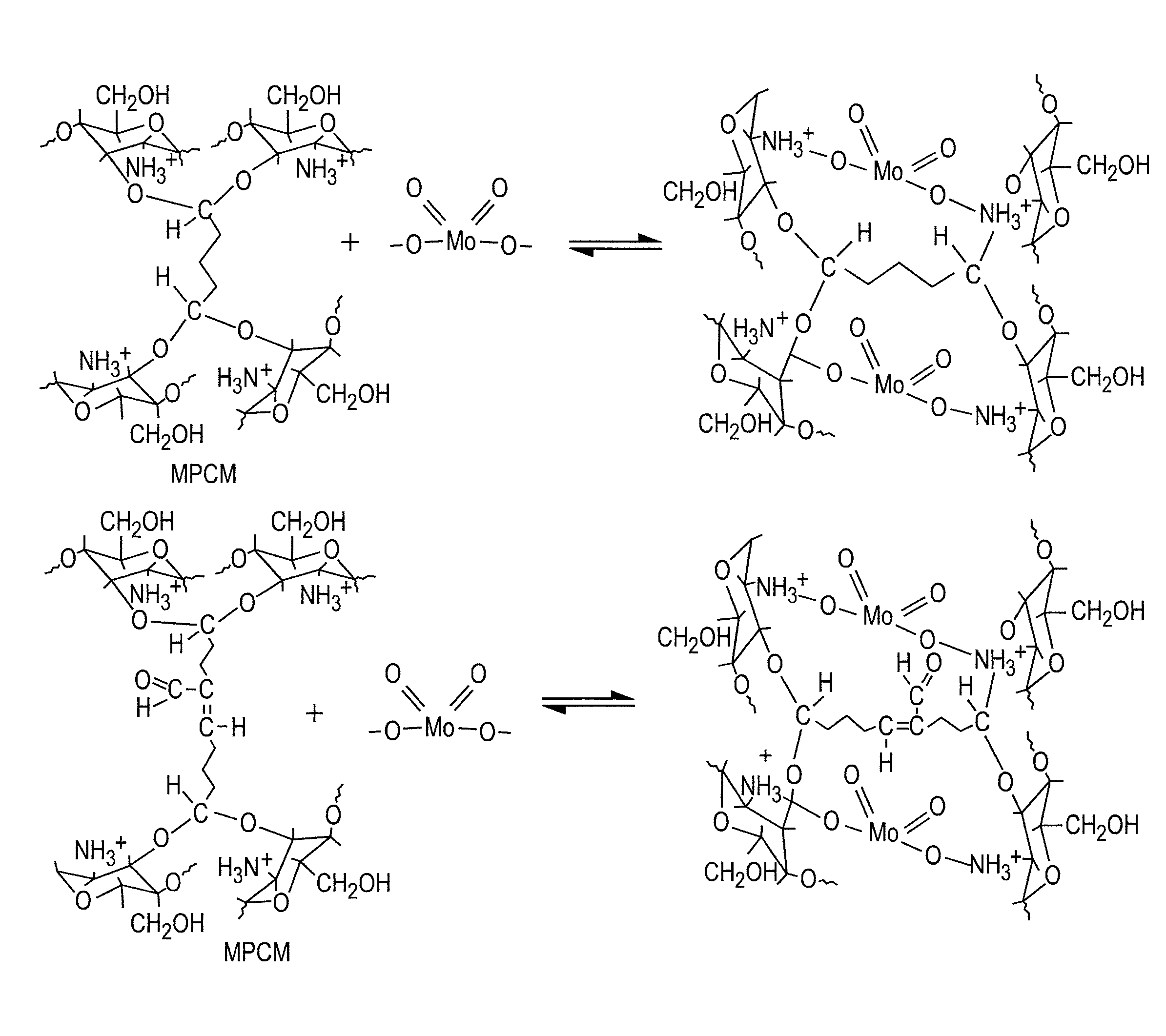

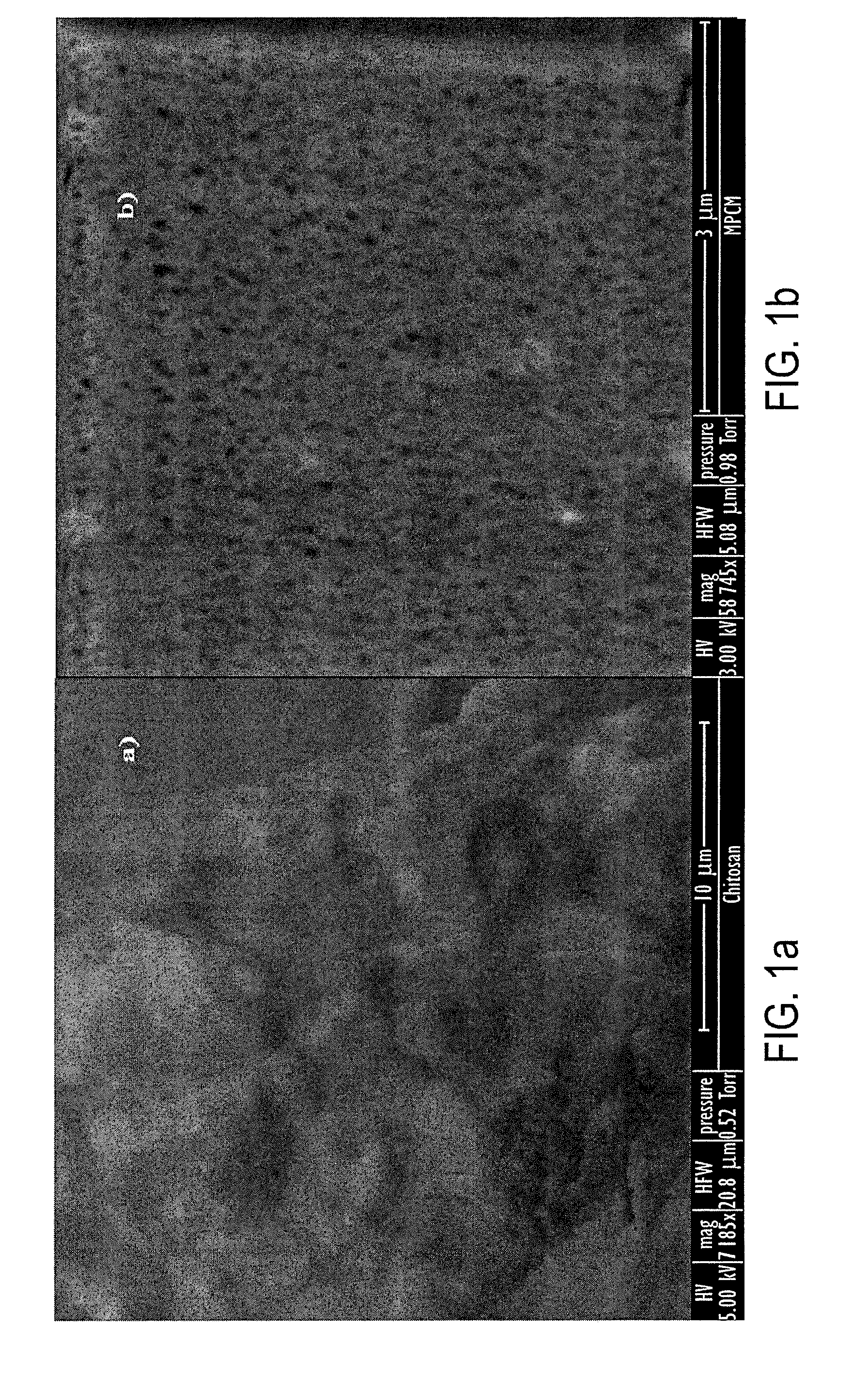

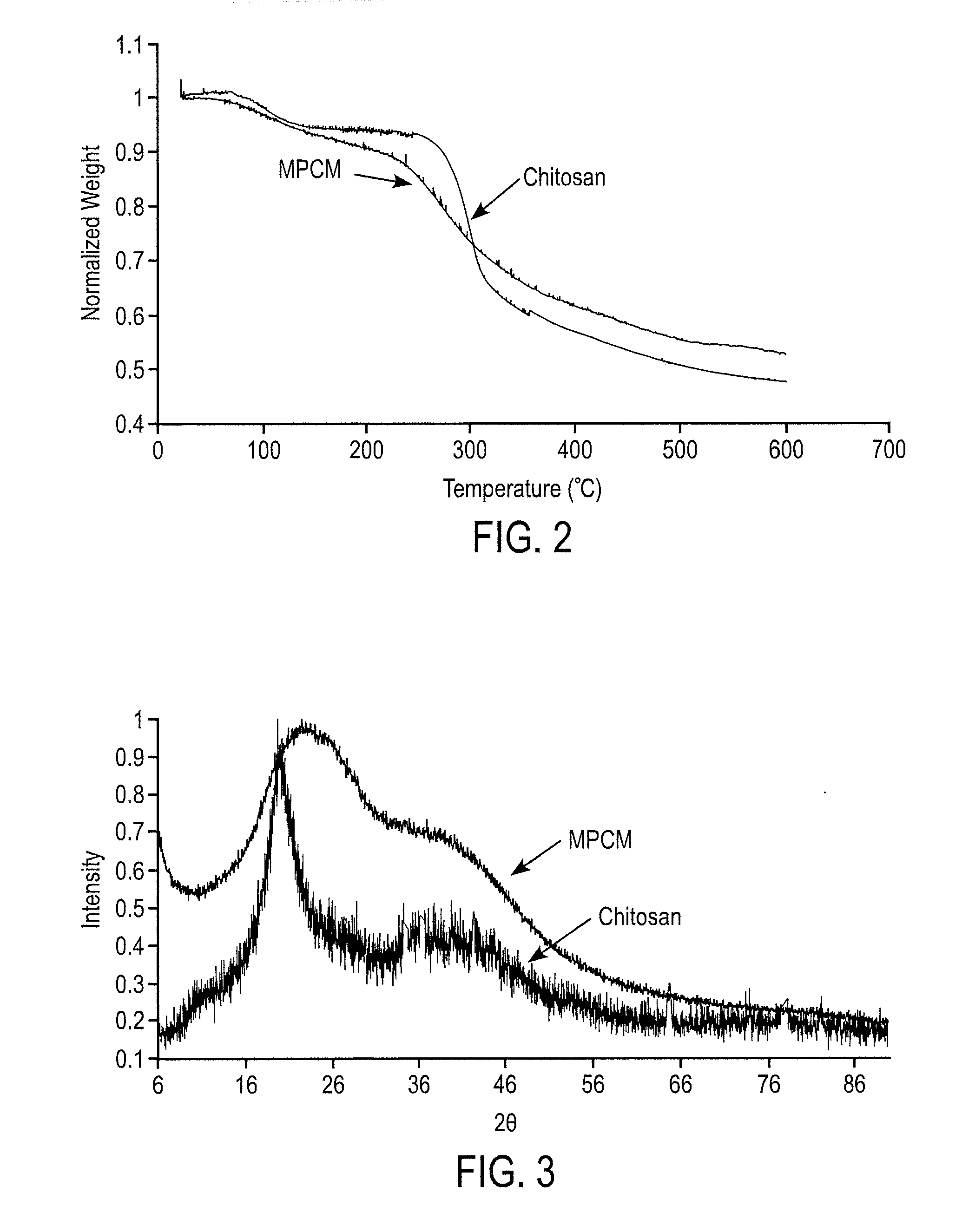

Preparation of chitosan-based microporous composite material and its applications

ActiveUS20130039822A1The material is lowCostTransuranic element compoundsRadium compoundsCrosslinked chitosanSorbent

Microporous glutaraldehyde-crosslinked chitosan sorbents, methods of making and using them, and a generator for the radioisotope 99Mo containing the sorbents.

Owner:PERMA FIX ENVIRONMENTAL SERVICES

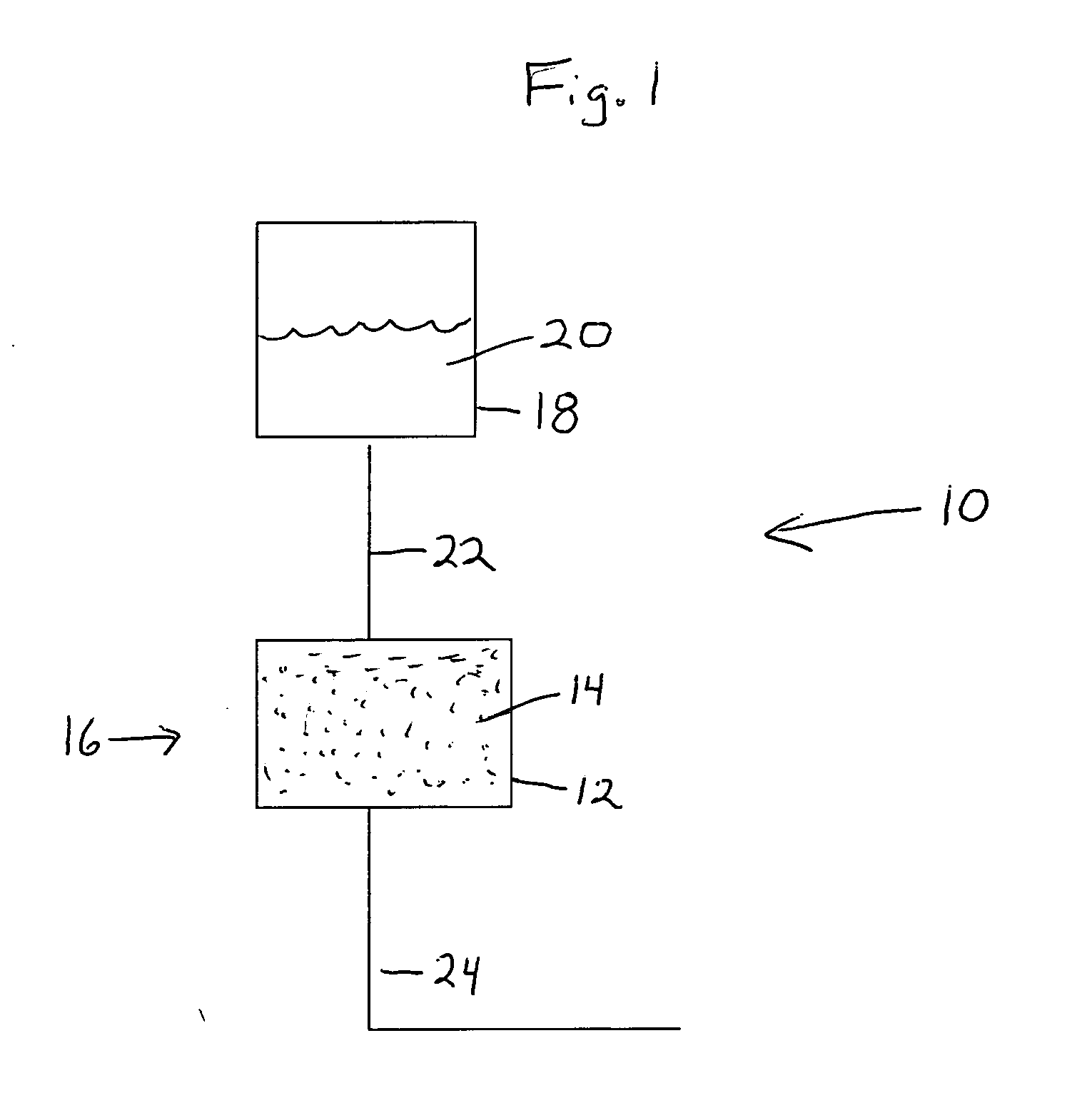

Process for radioisotope recovery and system for implementing same

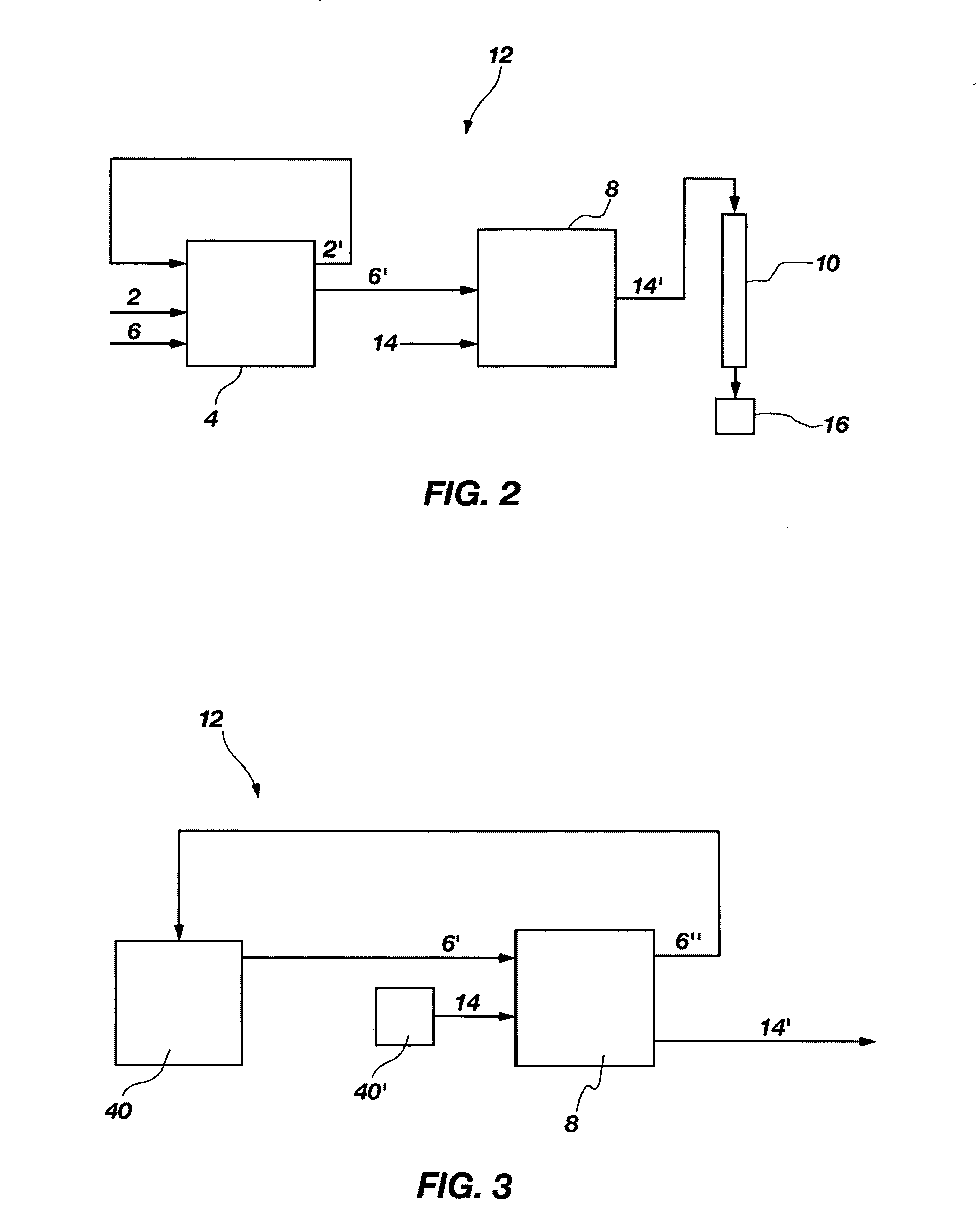

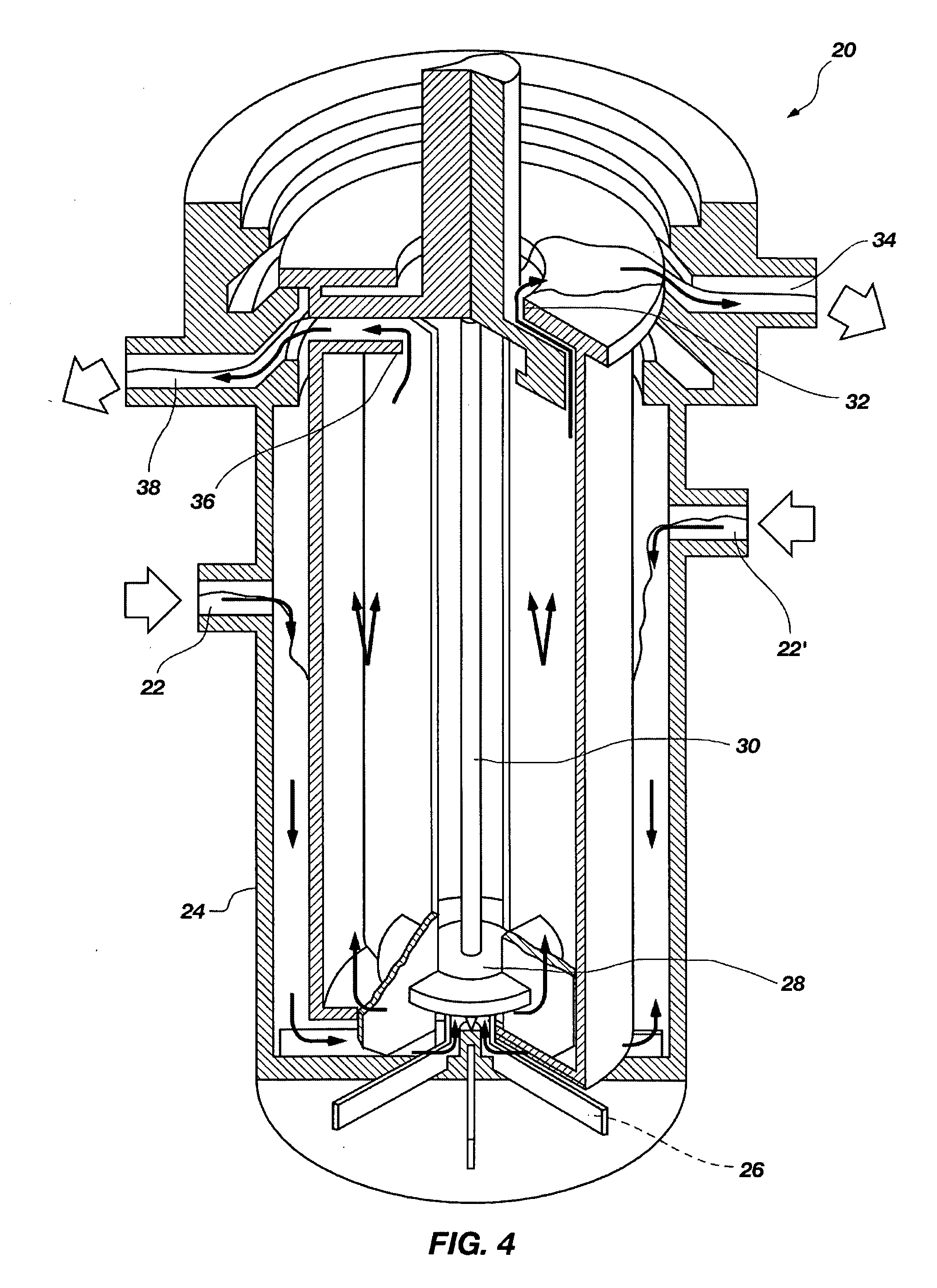

InactiveUS20060153760A1Sure easySolvent extractionTransuranic element compoundsSource materialIon exchange

A method of recovering daughter isotopes from a radioisotope mixture. The method comprises providing a radioisotope mixture solution comprising at least one parent isotope. The at least one parent isotope is extracted into an organic phase, which comprises an extractant and a solvent. The organic phase is substantially continuously contacted with an aqueous phase to extract at least one daughter isotope into the aqueous phase. The aqueous phase is separated from the organic phase, such as by using an annular centrifugal contactor. The at least one daughter isotope is purified from the aqueous phase, such as by ion exchange chromatography or extraction chromatography. The at least one daughter isotope may include actinium-225, radium-225, bismuth-213, or mixtures thereof. A liquid-liquid extraction system for recovering at least one daughter isotope from a source material is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

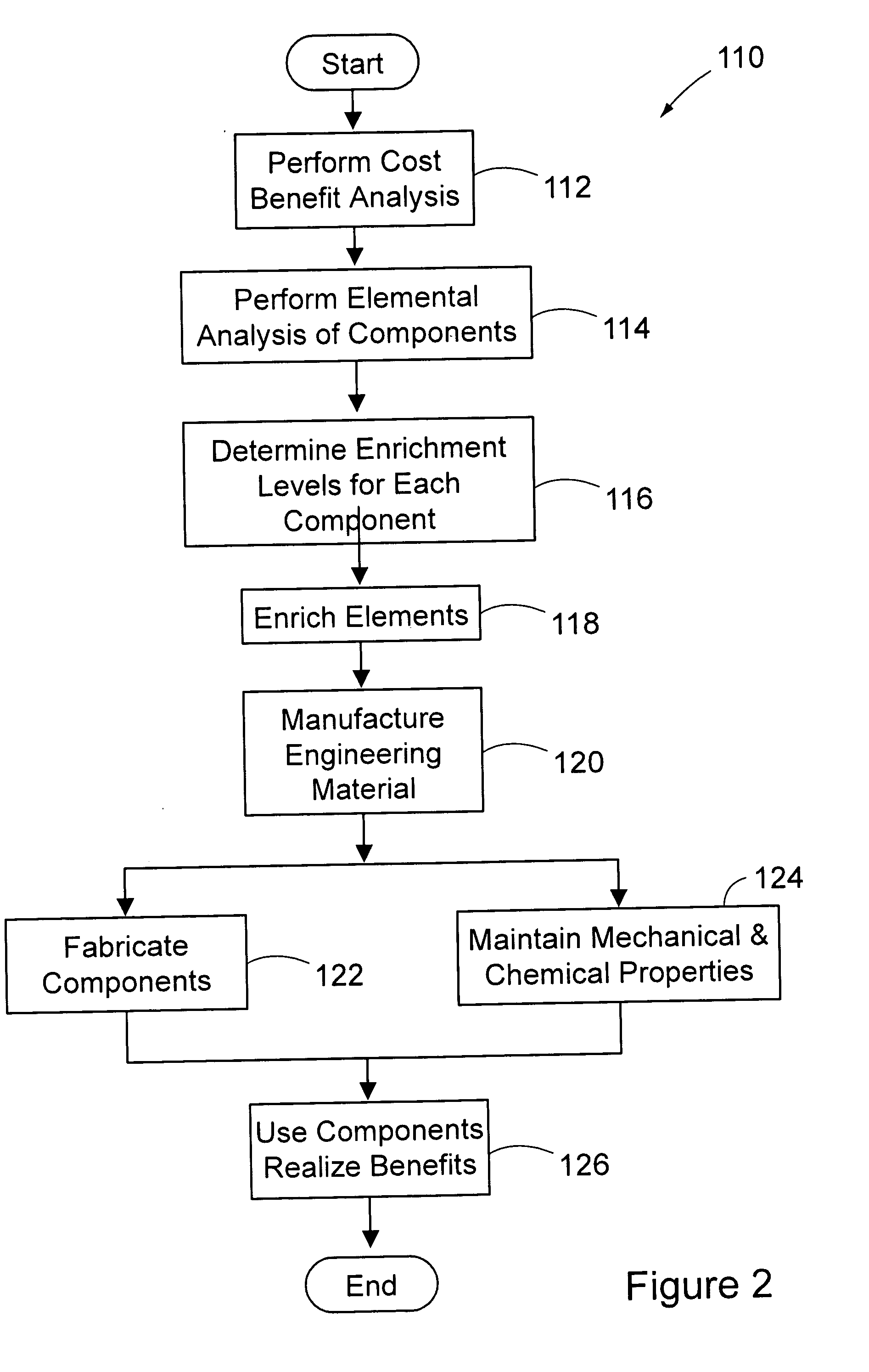

Isotopic lightening

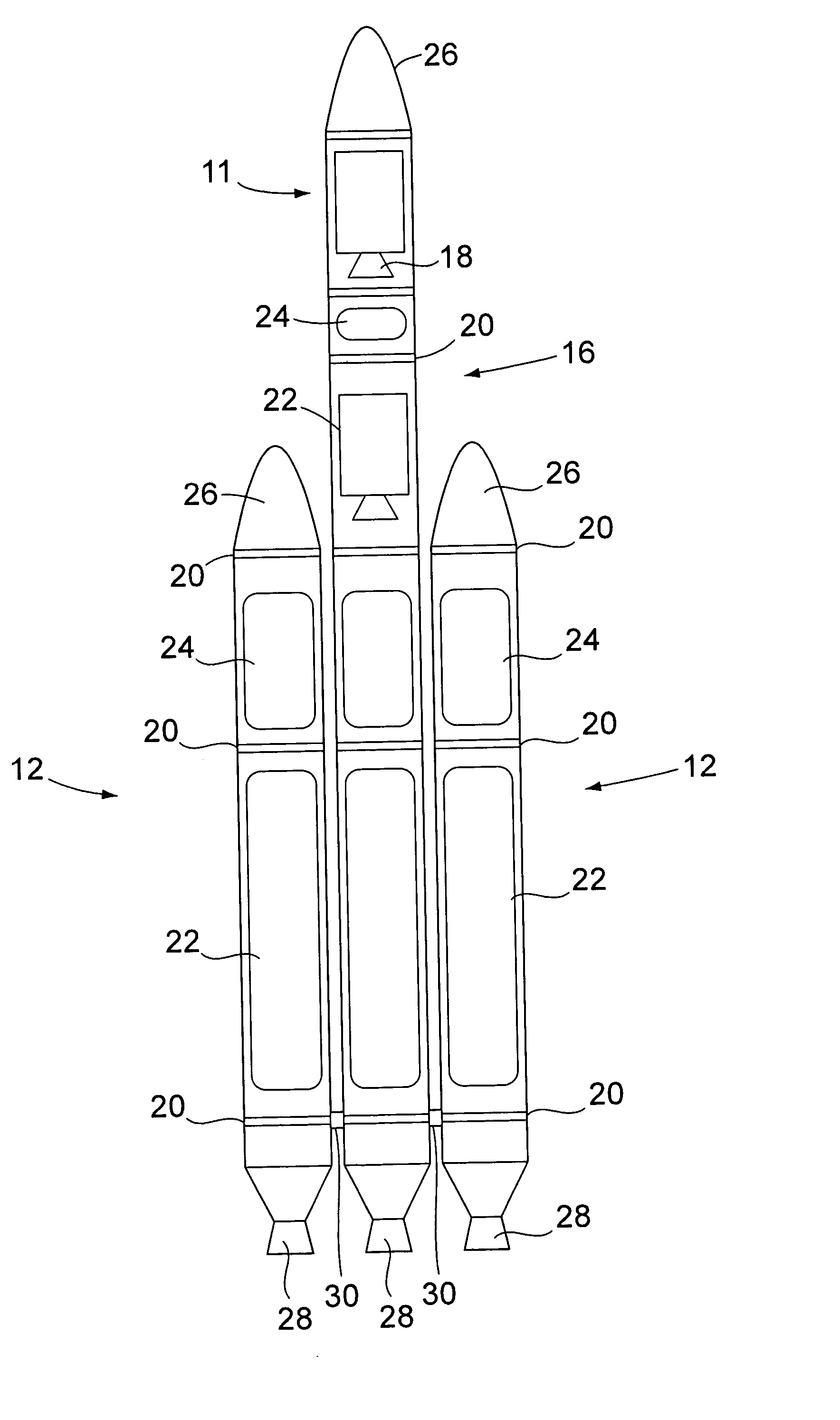

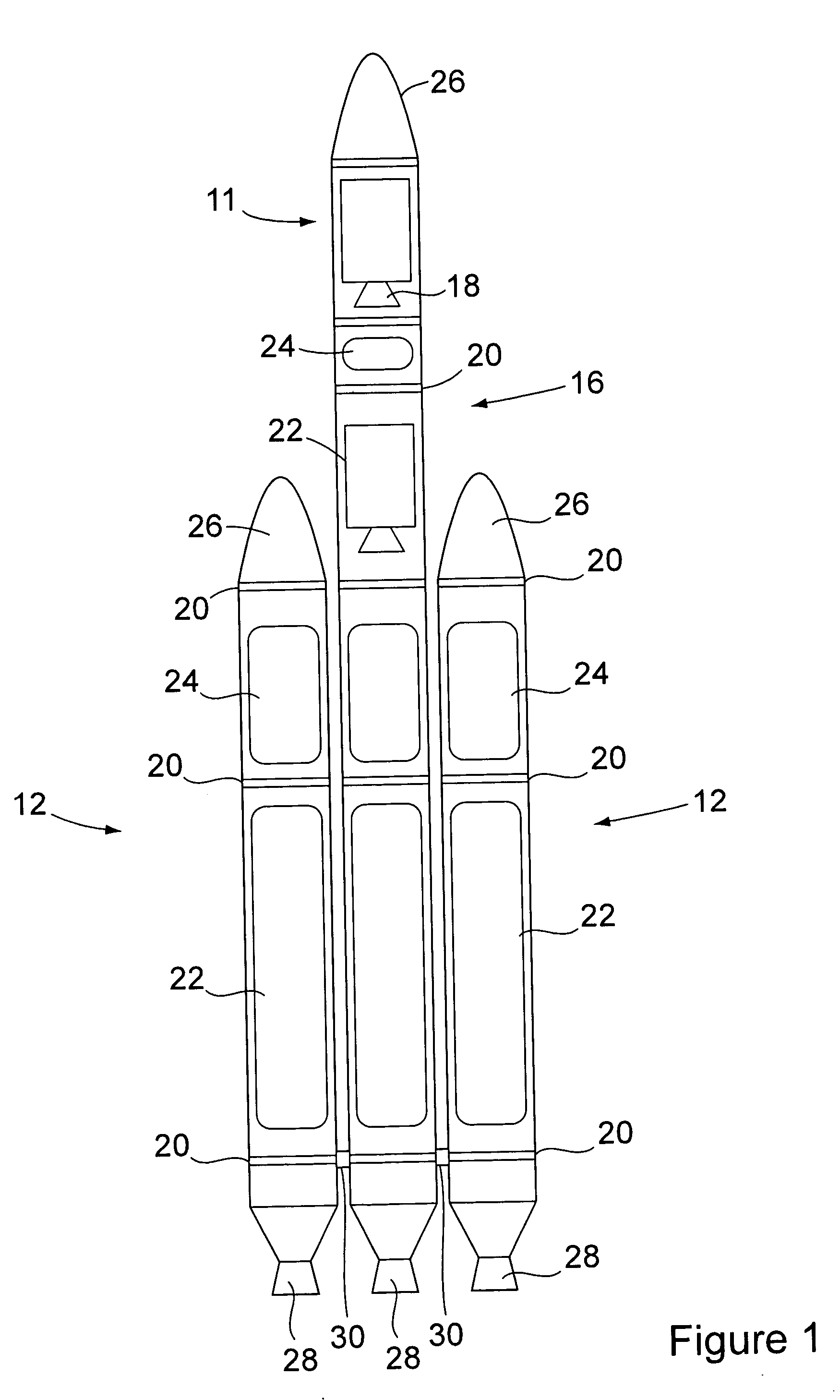

ActiveUS20060102464A1Low densityLight weightTransuranic element compoundsLaunch systemsLithiumHydrogen

A method of manufacturing a component. In a preferred embodiment, the method includes enriching an element with an isotope and using the enriched element as a material of the component. A property of the first isotope being the same as a property of a second isotope and is preferably a mechanical, chemical, or electrical property. A second element can also be used as a material of the component, for instance, where the material is an alloy or a composite material. Further, the first isotope can be a lighter isotope of the element. Lightweight components may be manufactured using the method such that mobile platforms (e.g. spacecraft) can be assembled from the component(s). In other exemplary embodiments, the element can be hydrogen, lithium, boron, magnesium, titanium, or iron. Additionally, the component may carry a load. Components including isotopically enriched elements are also provided.

Owner:THE BOEING CO

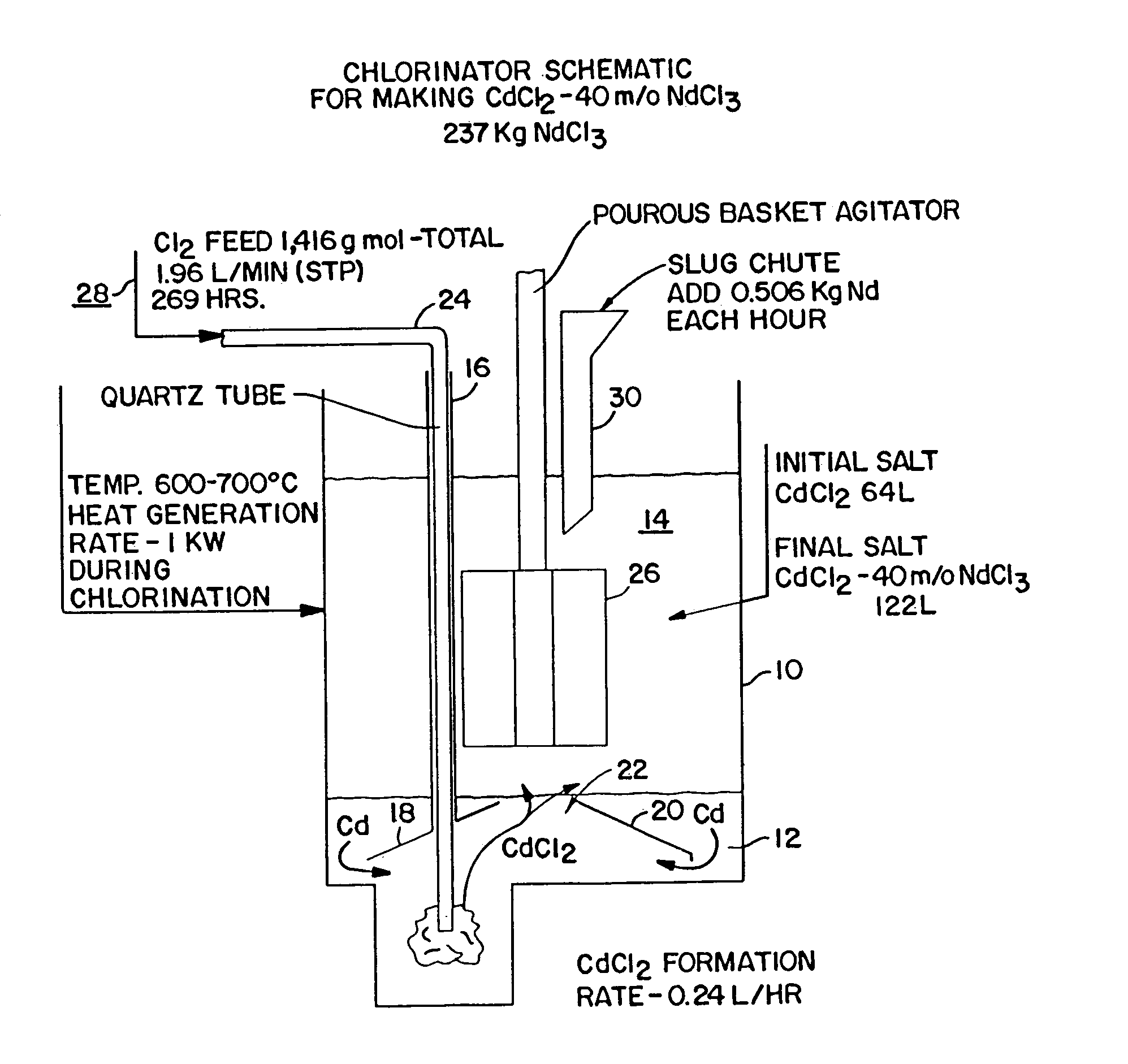

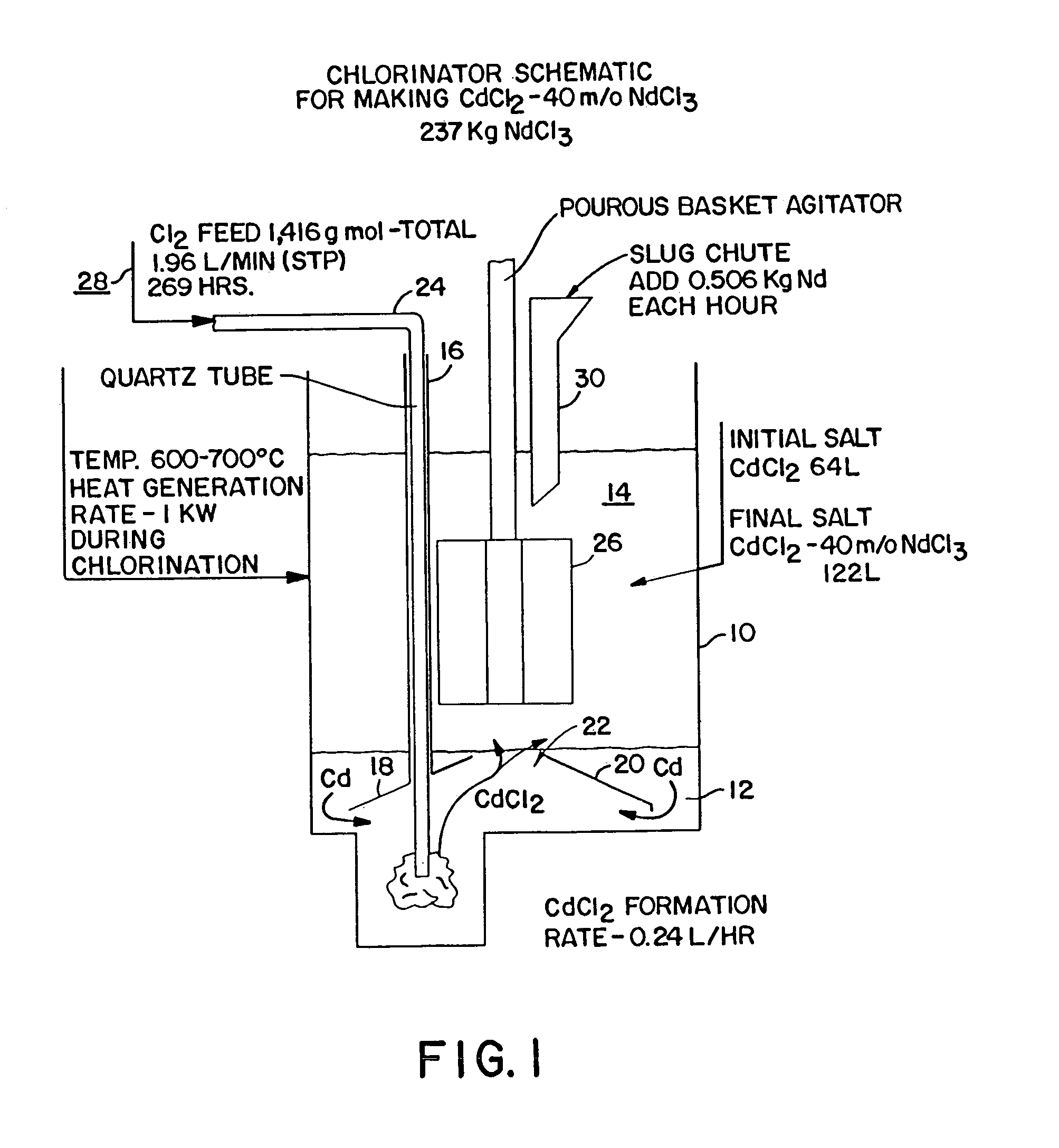

Apparatus and method for making metal chloride salt product

InactiveUS7217402B1Low densityRare earth metal chloridesChloride preparationMetal chlorideDistillation

A method of producing metal chlorides is disclosed in which chlorine gas is introduced into liquid Cd. CdCl2 salt is floating on the liquid Cd and as more liquid CdCl2 is formed it separates from the liquid Cd metal and dissolves in the salt. The salt with the CdCl2 dissolved therein contacts a metal which reacts with CdCl2 to form a metal chloride, forming a mixture of metal chloride and CdCl2. After separation of bulk Cd from the salt, by gravitational means, the metal chloride is obtained by distillation which removes CdCl2 and any Cd dissolved in the metal chloride.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

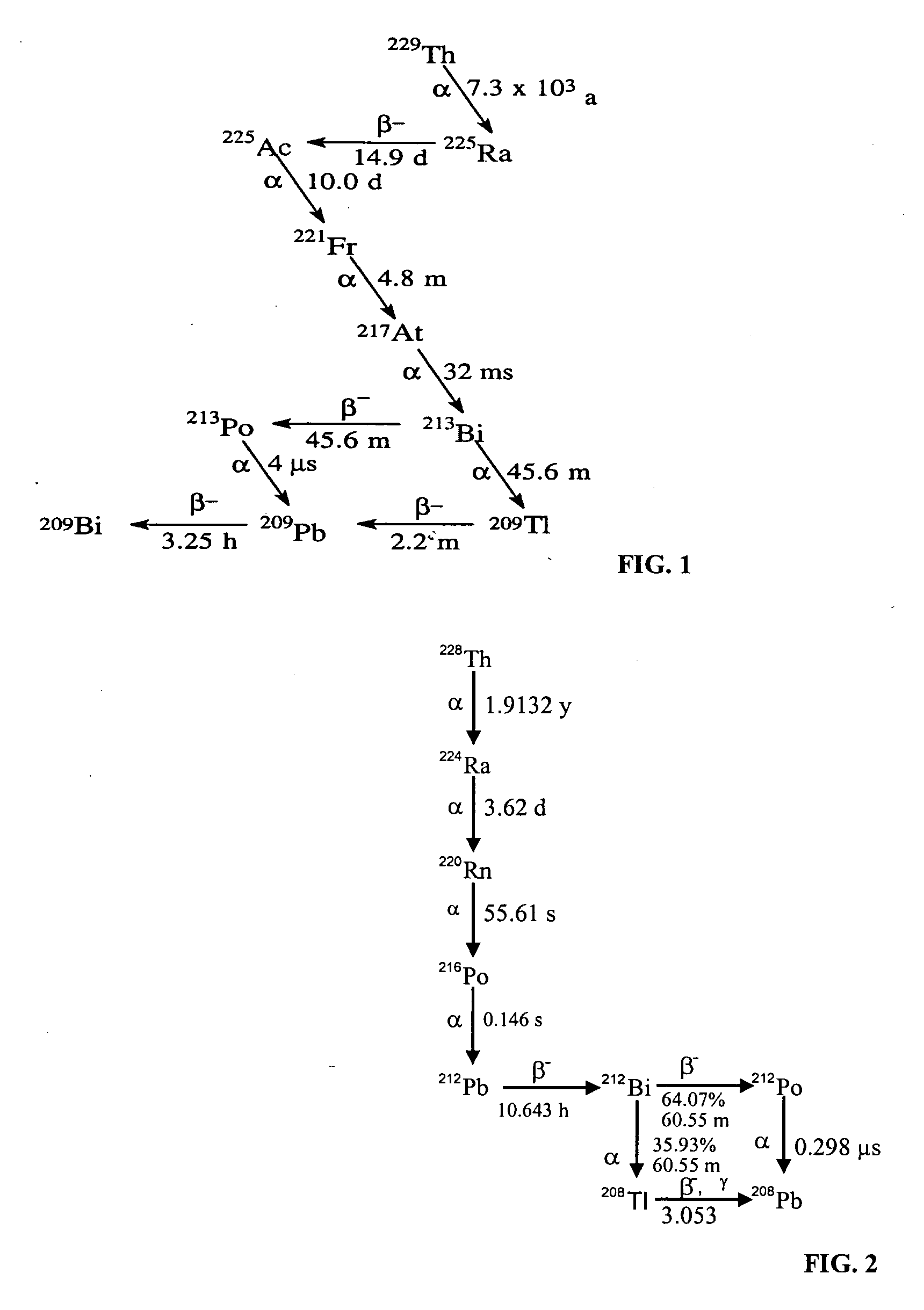

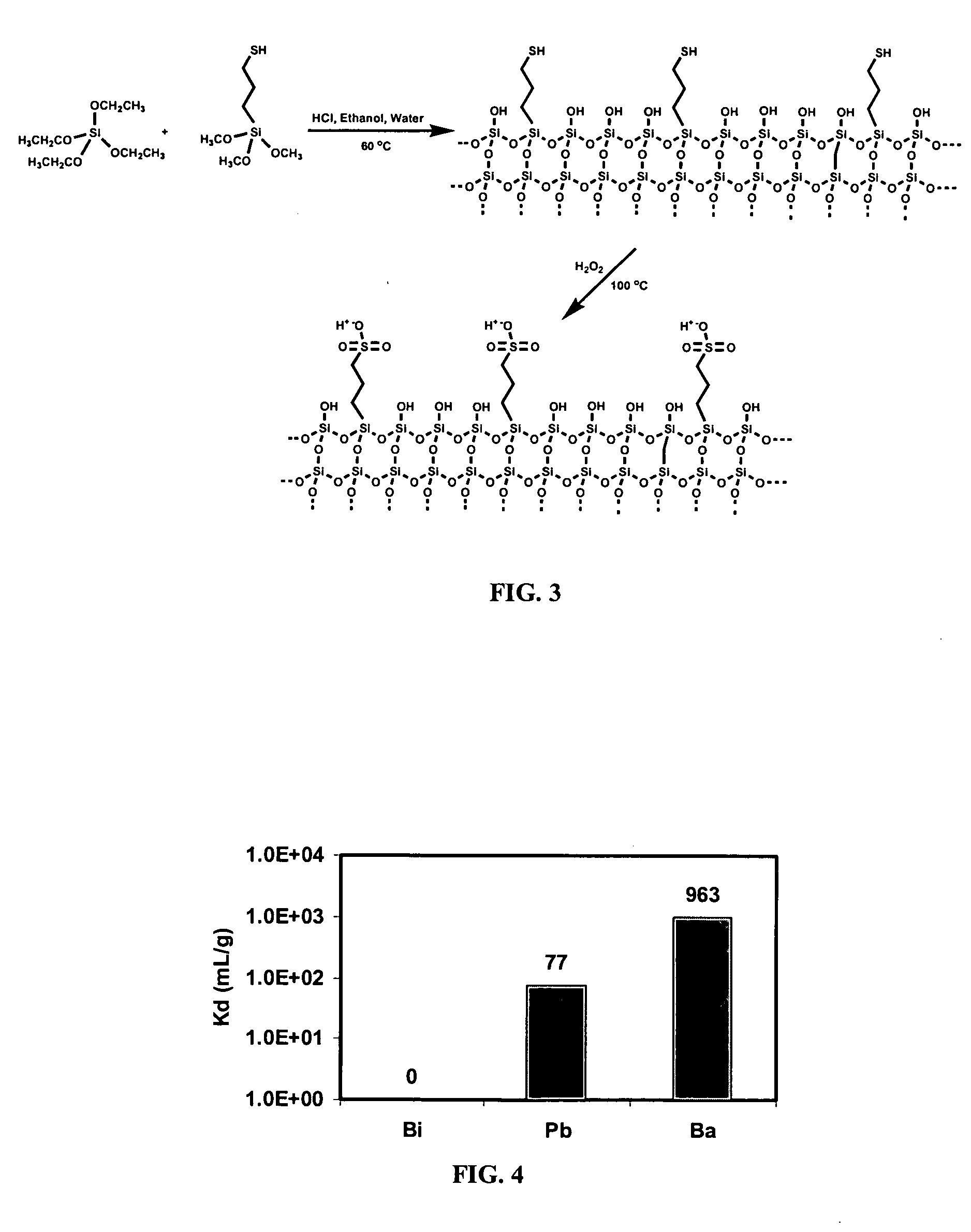

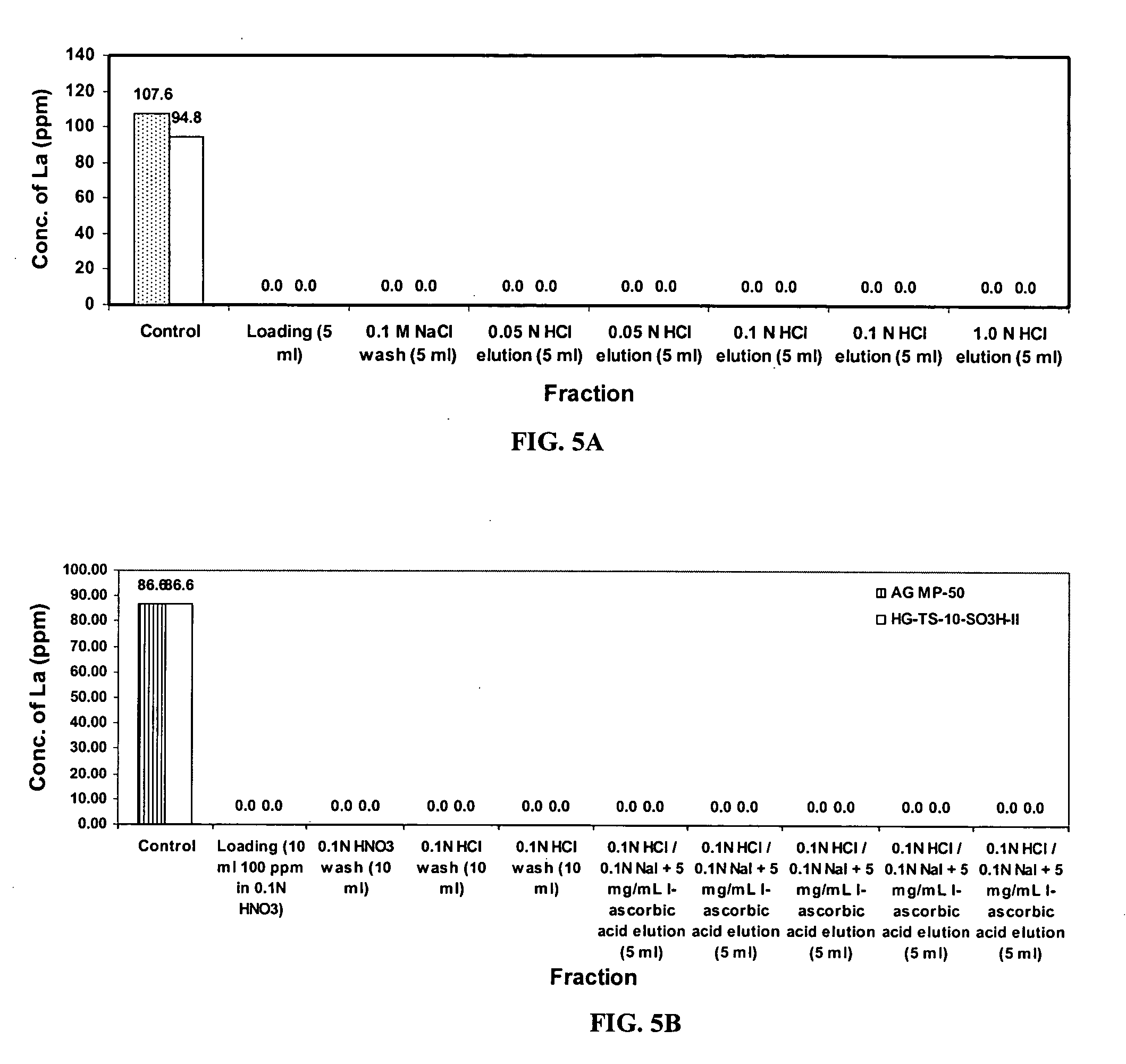

212Bi or 213Bi Generator from supported parent isotope

The invention includes a radionuclide generator having an ion exchange sorbent that comprises oxygen-containing functional groups grafted by organic linking groups to an inorganic oxygen-linked network and a parent isotope. For 212Bi or 213Bi generators, the parent isotope may be 224Ra, 225Ra or 225Ac. The surface area of the sorbent is preferably less than about 10 m2 / g and more preferably less than about 1 m2 / g. The exchange sorbent may be formed of any covalently bonded inorganic oxide that is capable of forming oxygen-linked networks. The oxidized functional groups may include sulfonato groups, may include moieties selected from —SO3H, —SO3Na, —SO3K, —SO3Li, —SO3NH4 or may include moieties selected from —PO(OX)2 or —COOX, wherein X is selected from H, Na, K or NH4 or combinations thereof. A 213Bi or 212Bi generator process includes eluting 213Bi or 212Bi with an aqueous solvent that includes 225Ac or 225Ra or 224Ra on the above support medium.

Owner:GALI HARIPRASAD +1

Method for separating metals by micellar ultrafiltration that can be used to process radioactive waste

The present invention relates to a method for separating metals by micellar ultrafiltration, that can be used to process radioactive waste. This process consists of adding to the aqueous solution a complexing anionic surfactant having the formula: M+=cation, for example NA+m=1 or 2 R=aliphatic group of at least eight carbon atoms, and optionally a nonionic surfactant such as Triton X-100 or Brij 35 to produce micelles (10) in the solution, and subsequently of filtering the solution through an ultrafiltration membrane (3) to retain the previously formed micelles.

Owner:COGEMA SA

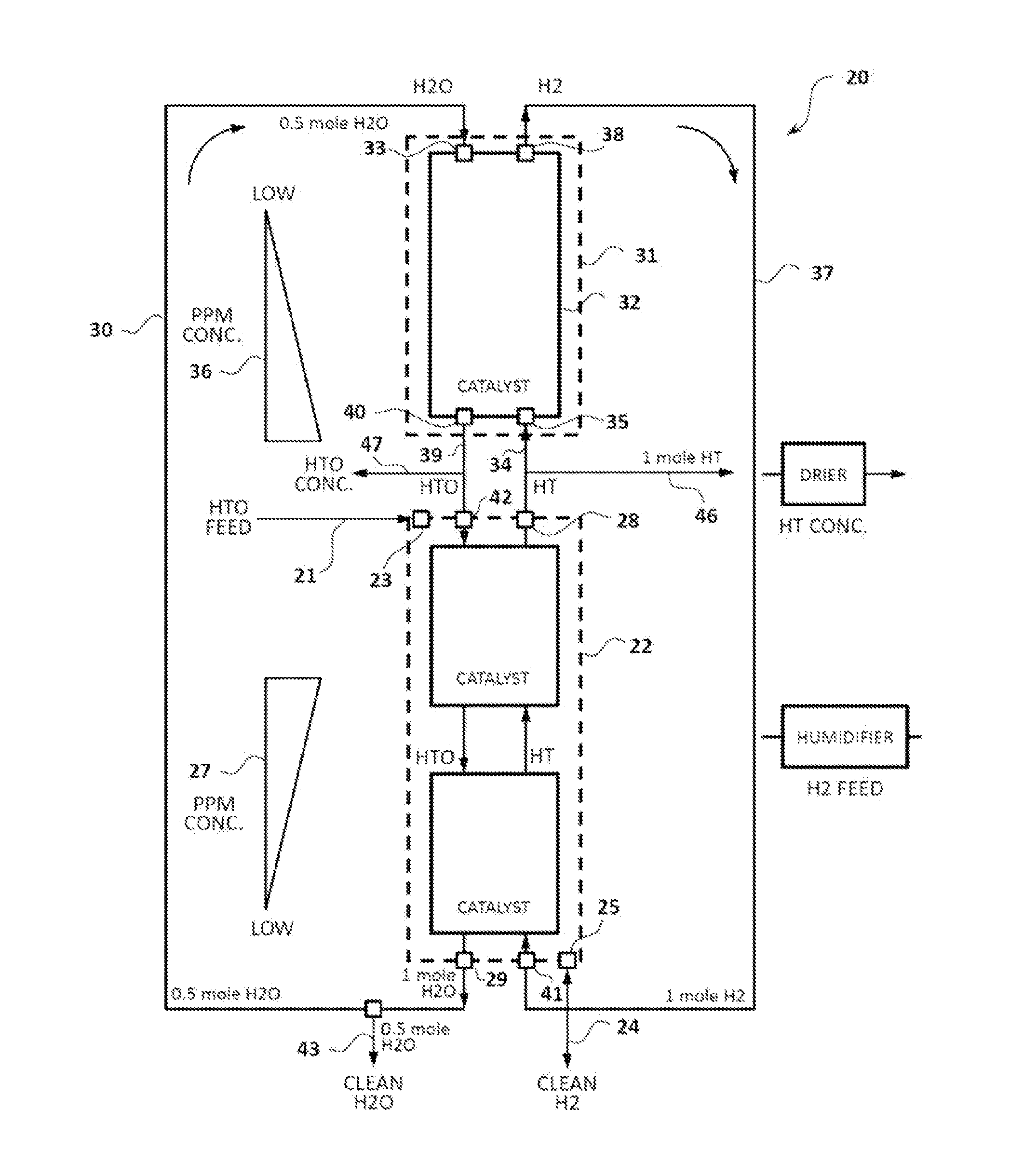

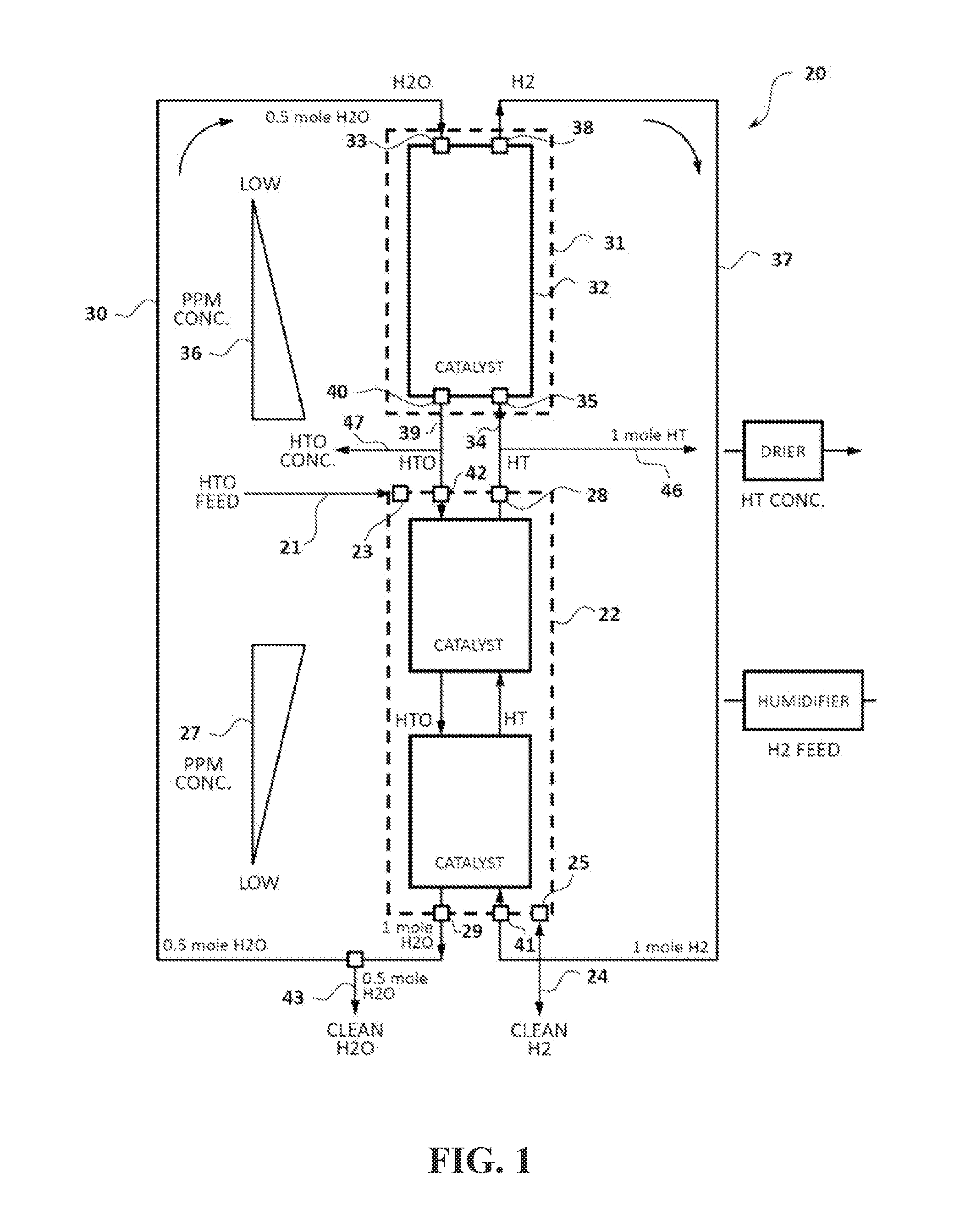

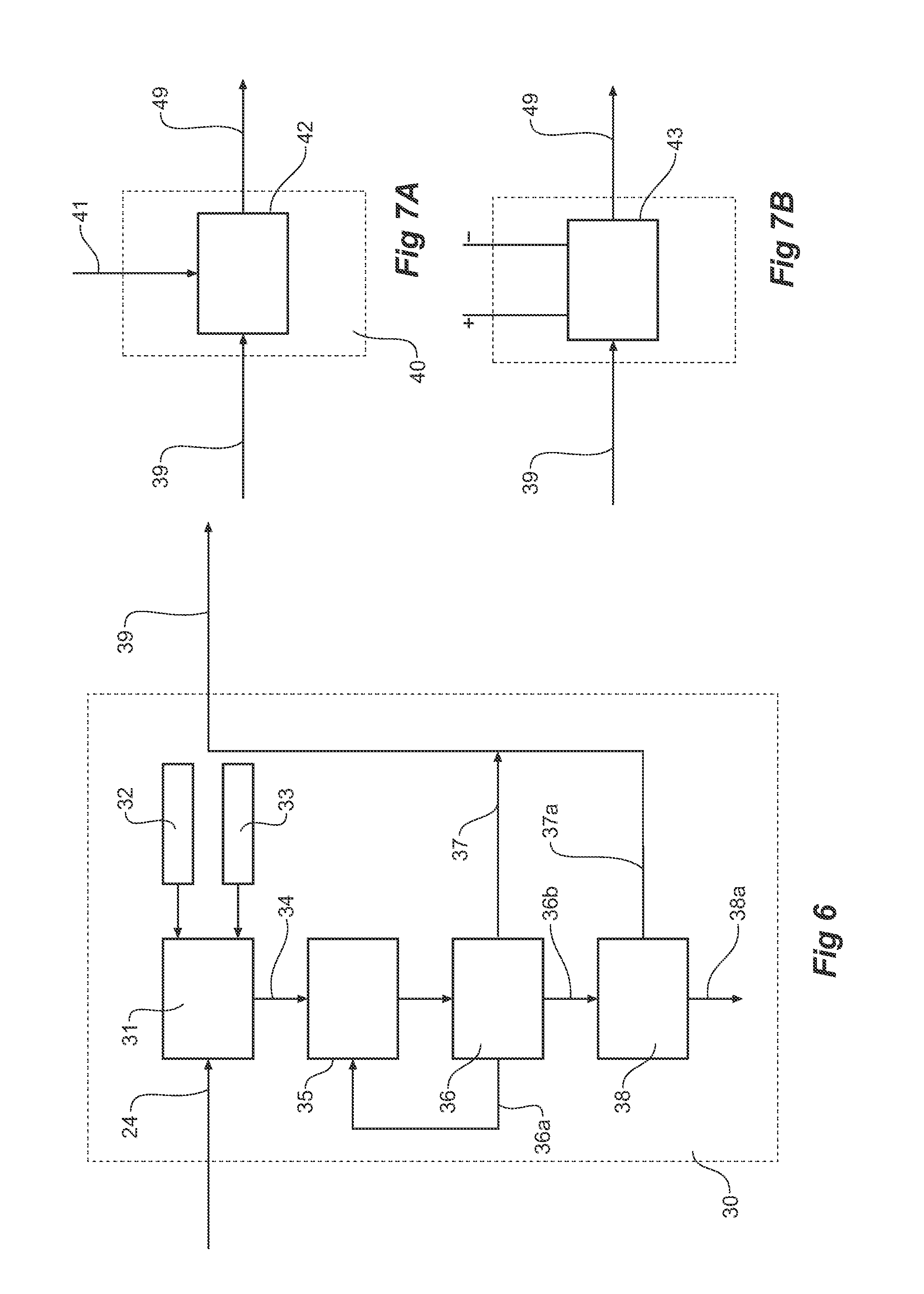

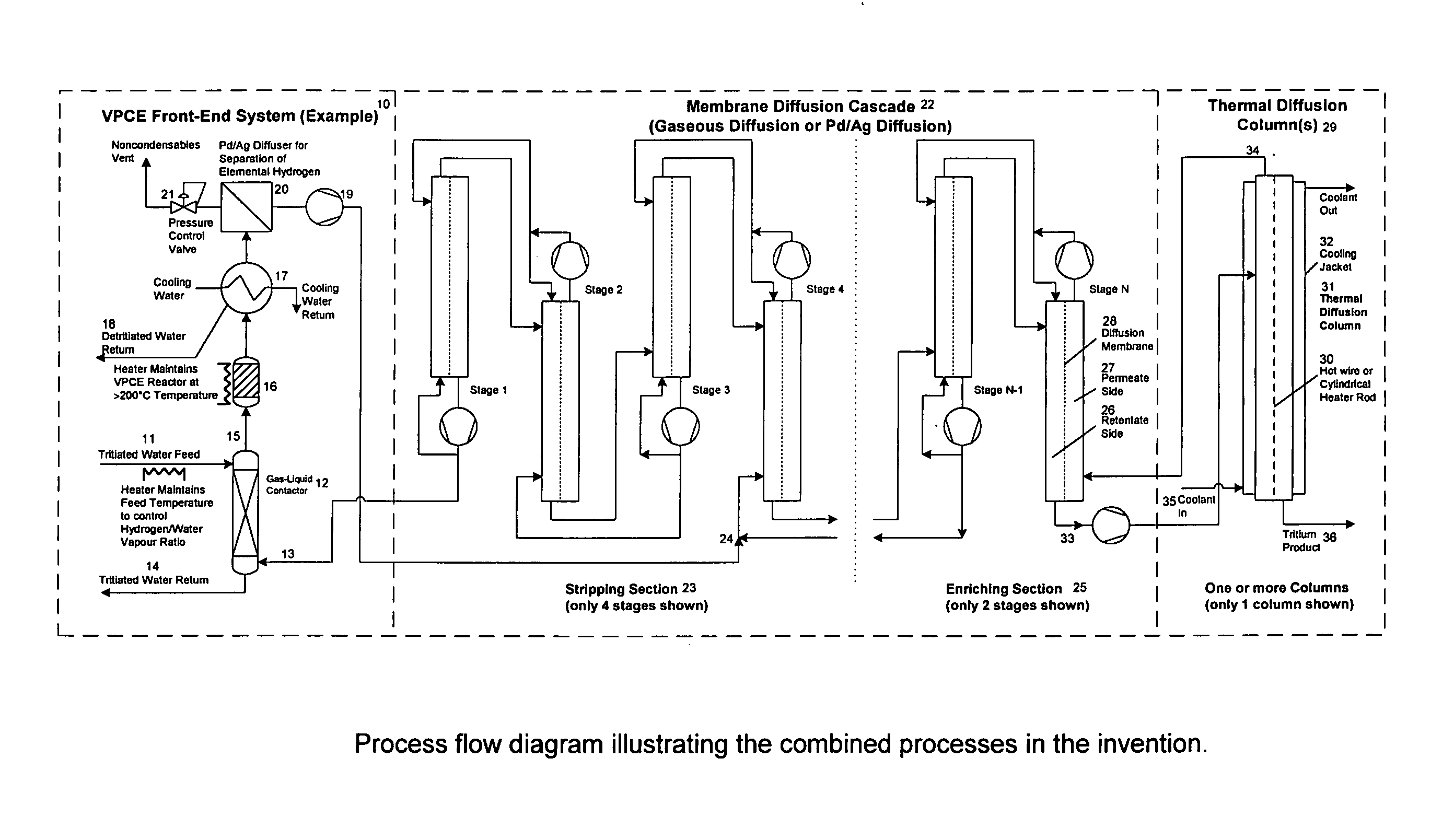

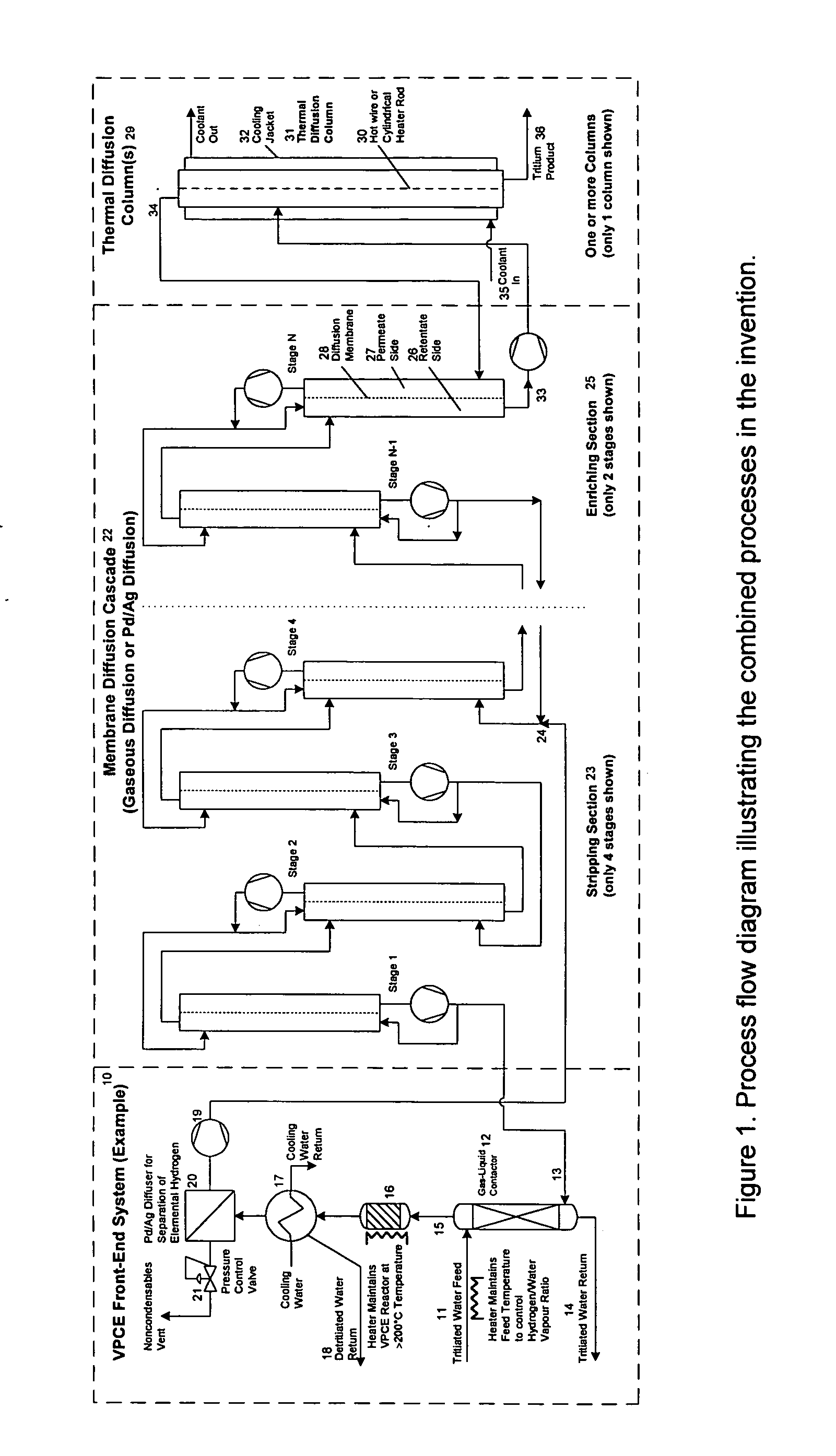

Balanced closed loop continuous extraction process for hydrogen isotopes

ActiveUS20140356270A1Valid conversionRapidly and economically extractTransuranic element compoundsNuclear energy generationWaste streamClosed loop

A system and method for tritium separation systems using a mixed bed catalytic exchange process in a Liquid Phase Catalytic Exchange / Closed Loop Continuous Process (LPCE / CLCP) system, that operates as a low temperature and low pressure continuous balanced process, designed to rapidly, economically and safely extract and isolate isotope specific products without generating unwanted products in the form of new waste streams.

Owner:KURION

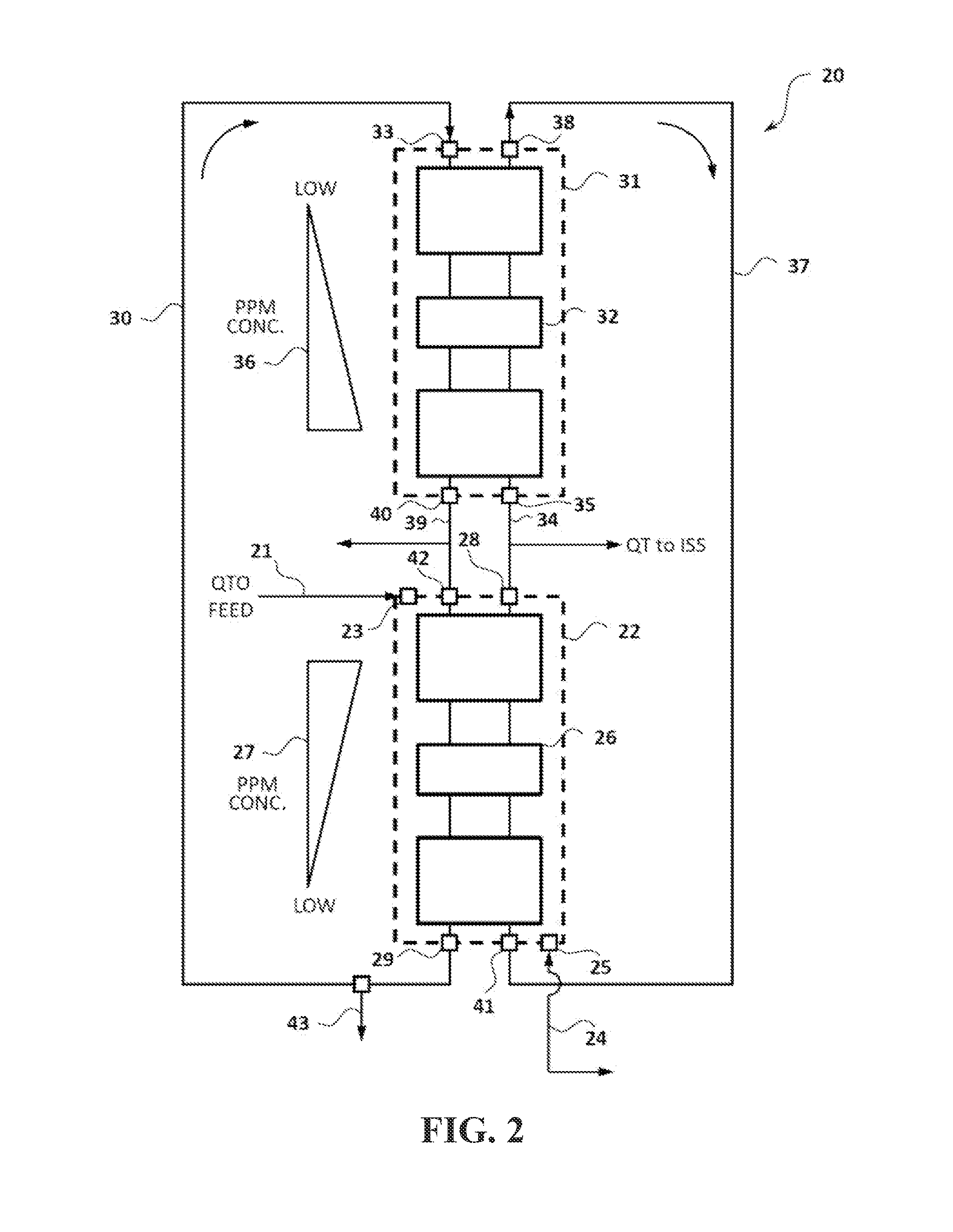

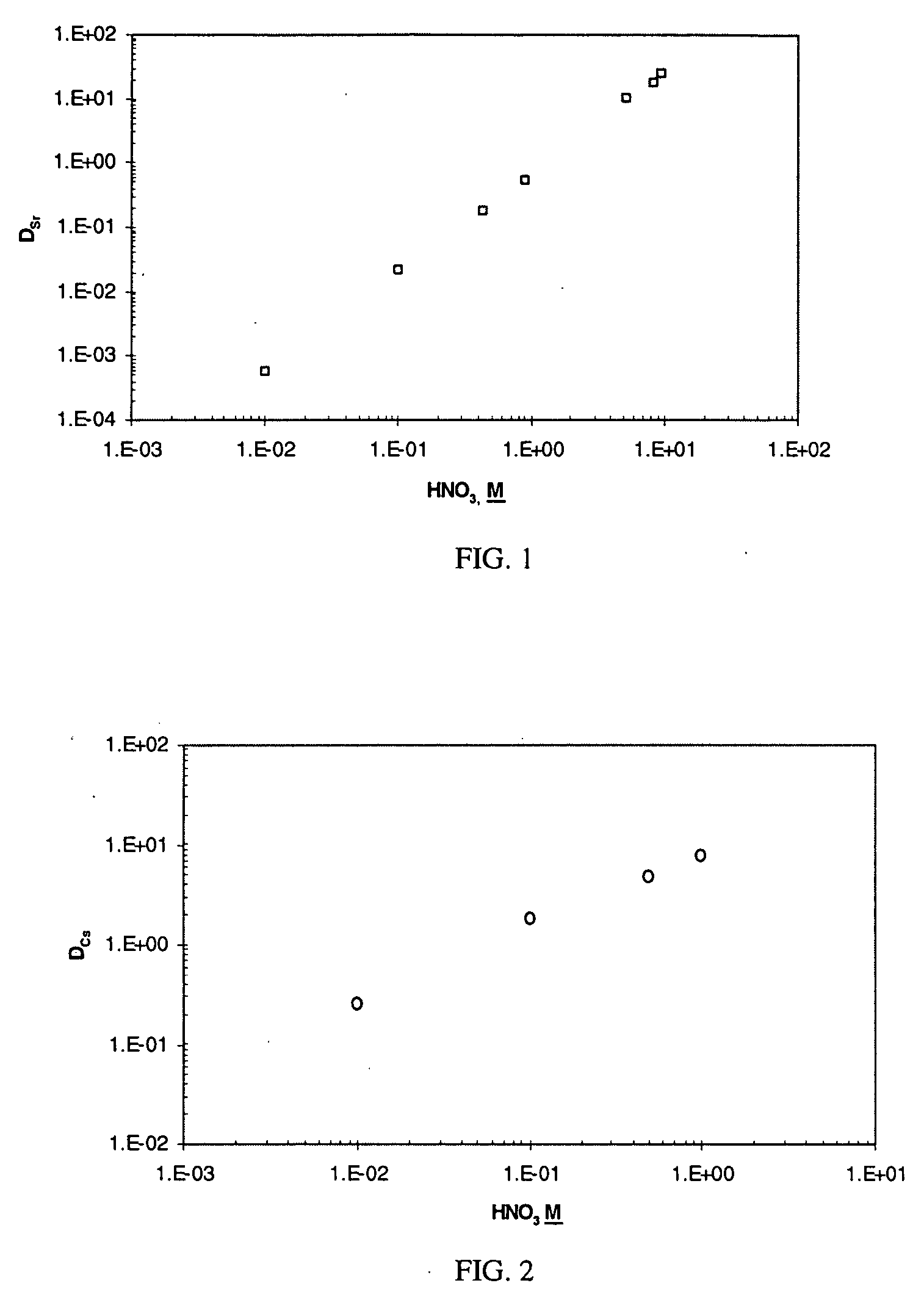

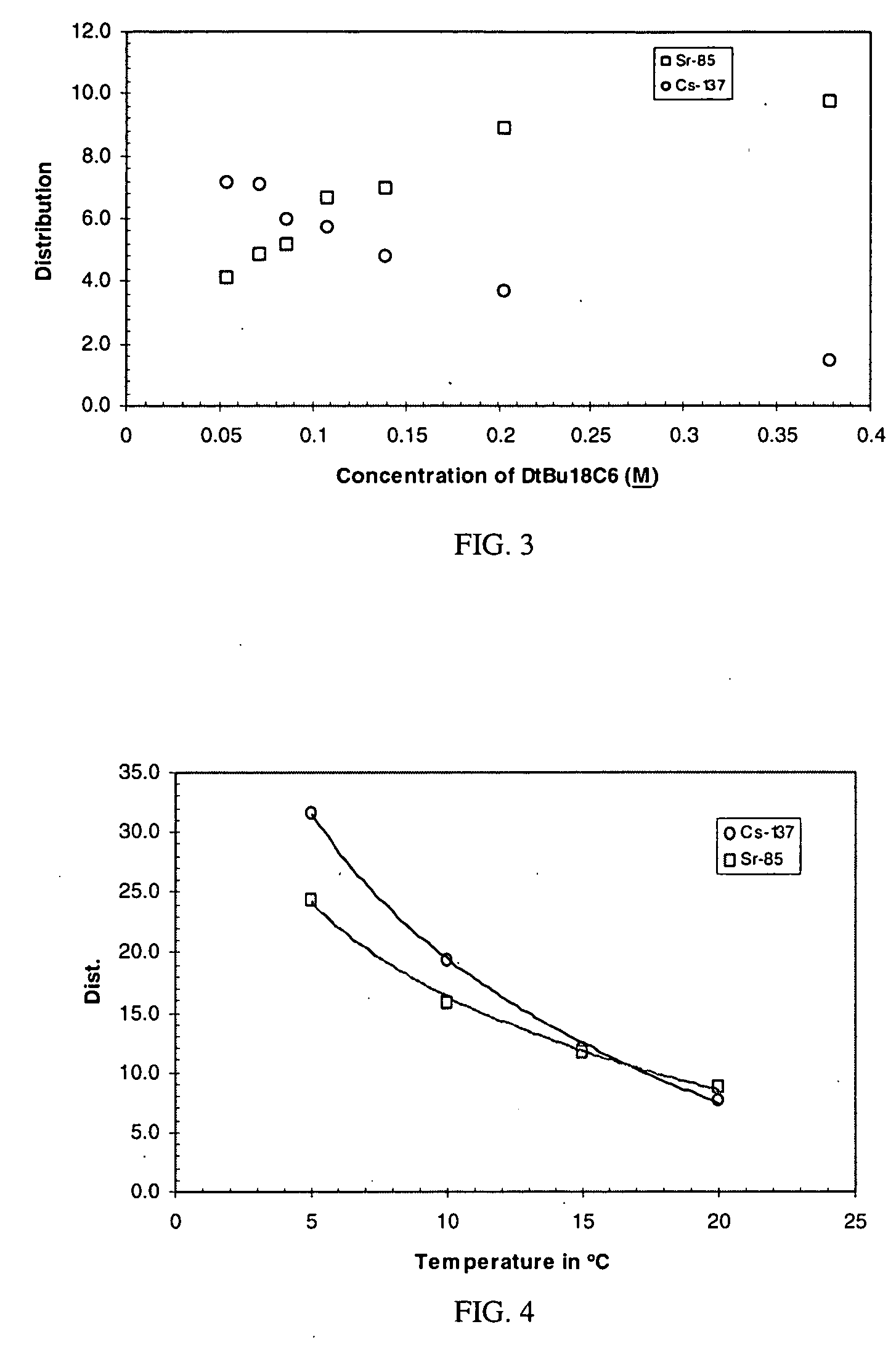

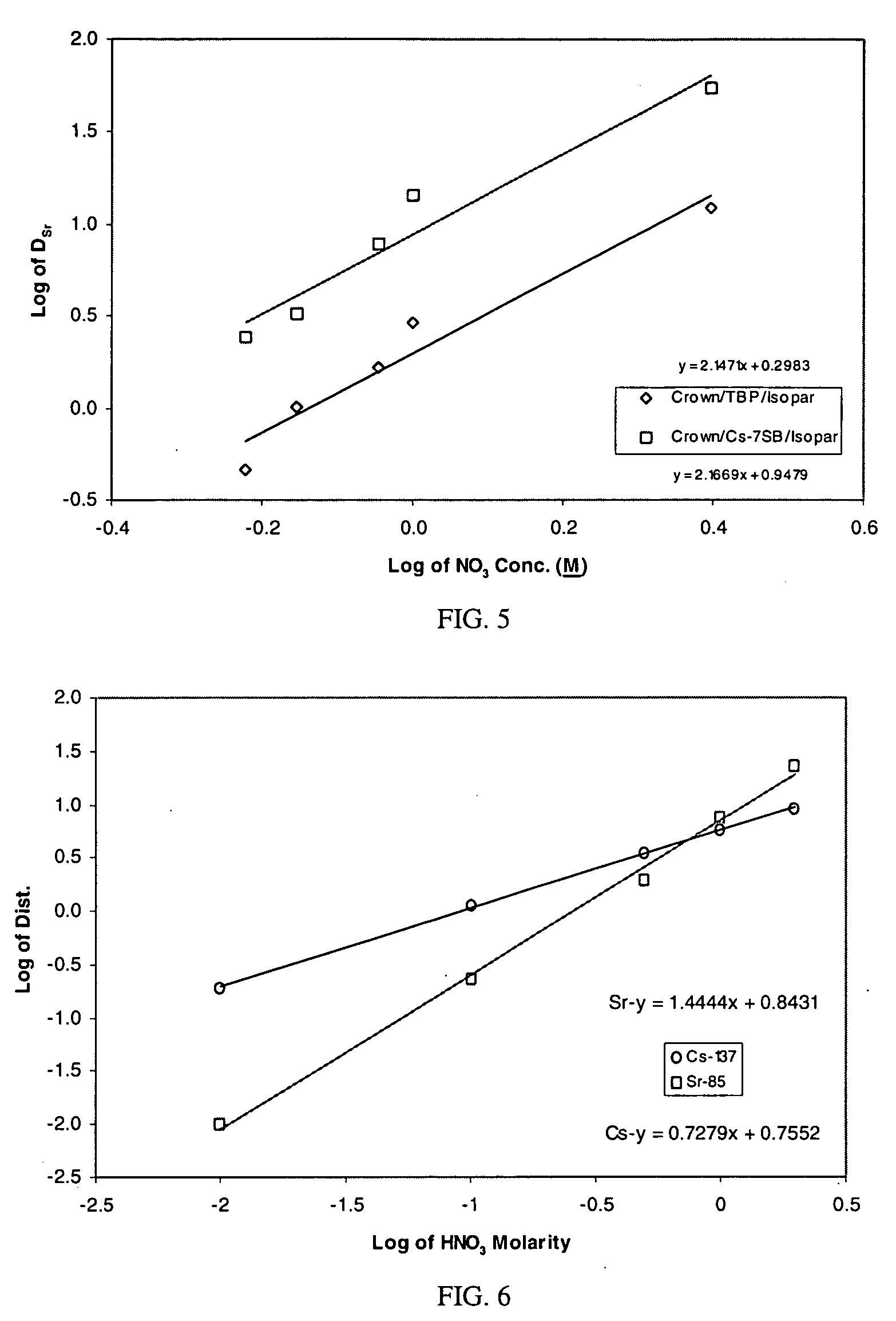

Cesium and strontium extraction using a mixed extractant solvent including crown ether and calixarene extractants

A mixed extractant solvent including calix[4]arene-bis-(tert-octylbenzo)-crown-6 (“BOBCalixC6”), 4′,4′,(5′)-di-(t-butyldicyclo-hexano)-18-crown-6 (“DtBu18C6”), and at least one modifier dissolved in a diluent. The mixed extractant solvent may be used to remove cesium and strontium from an acidic solution. The DtBu18C6 may be present from approximately 0.01 M to approximately 0.4M, such as from approximately 0.086 M to approximately 0.108 M. The modifier may be 1-(2,2,3,3-tetrafluoropropoxy)-3-(4-sec-butylphenoxy)-2-propanol (“Cs-7SB”) and may be present from approximately 0.01M to approximately 0.8M. In one embodiment, the mixed extractant solvent includes approximately 0.15M DtBu18C6, approximately 0.007M BOBCalixC6, and approximately 0.75M Cs-7SB modifier dissolved in an isoparaffinic hydrocarbon diluent. The mixed extractant solvent may form an organic phase in an extraction system that also includes an aqueous phase. Methods of extracting cesium and strontium as well as strontium alone are also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

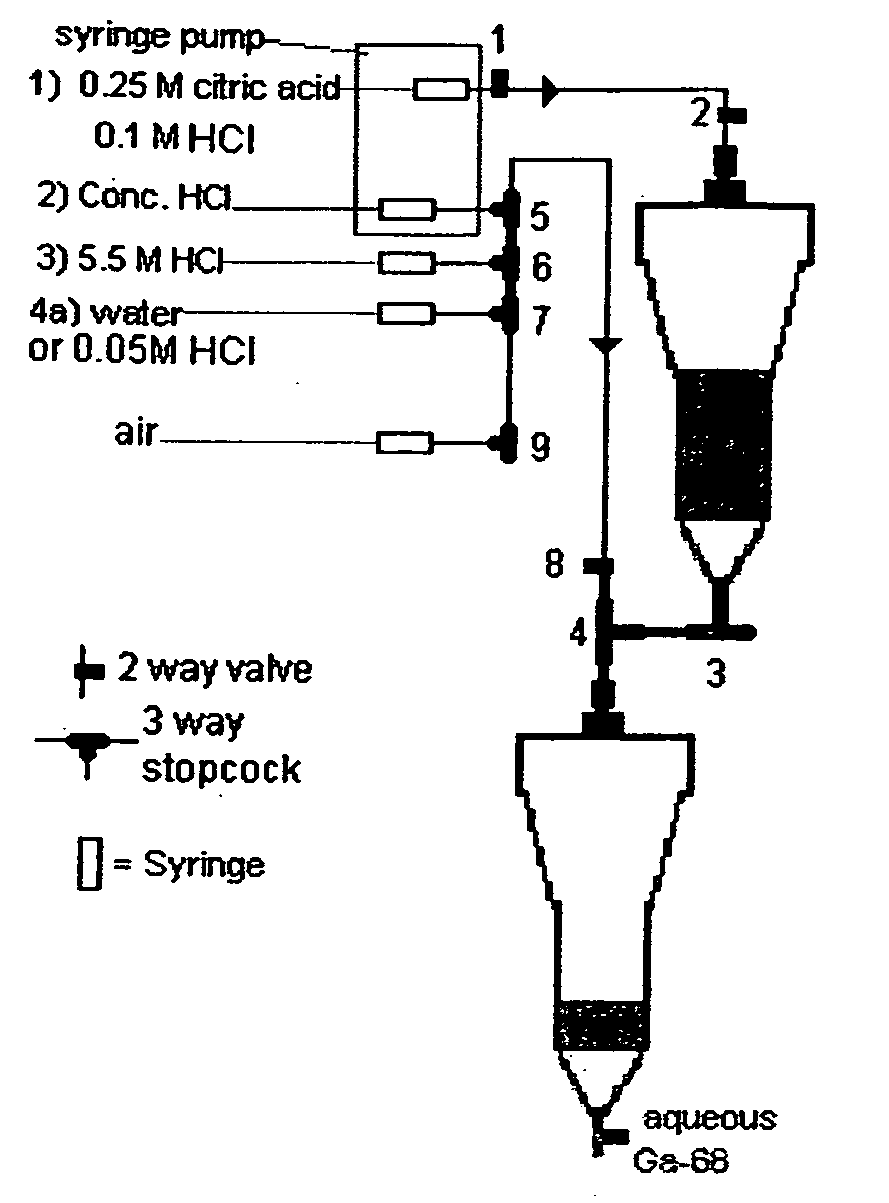

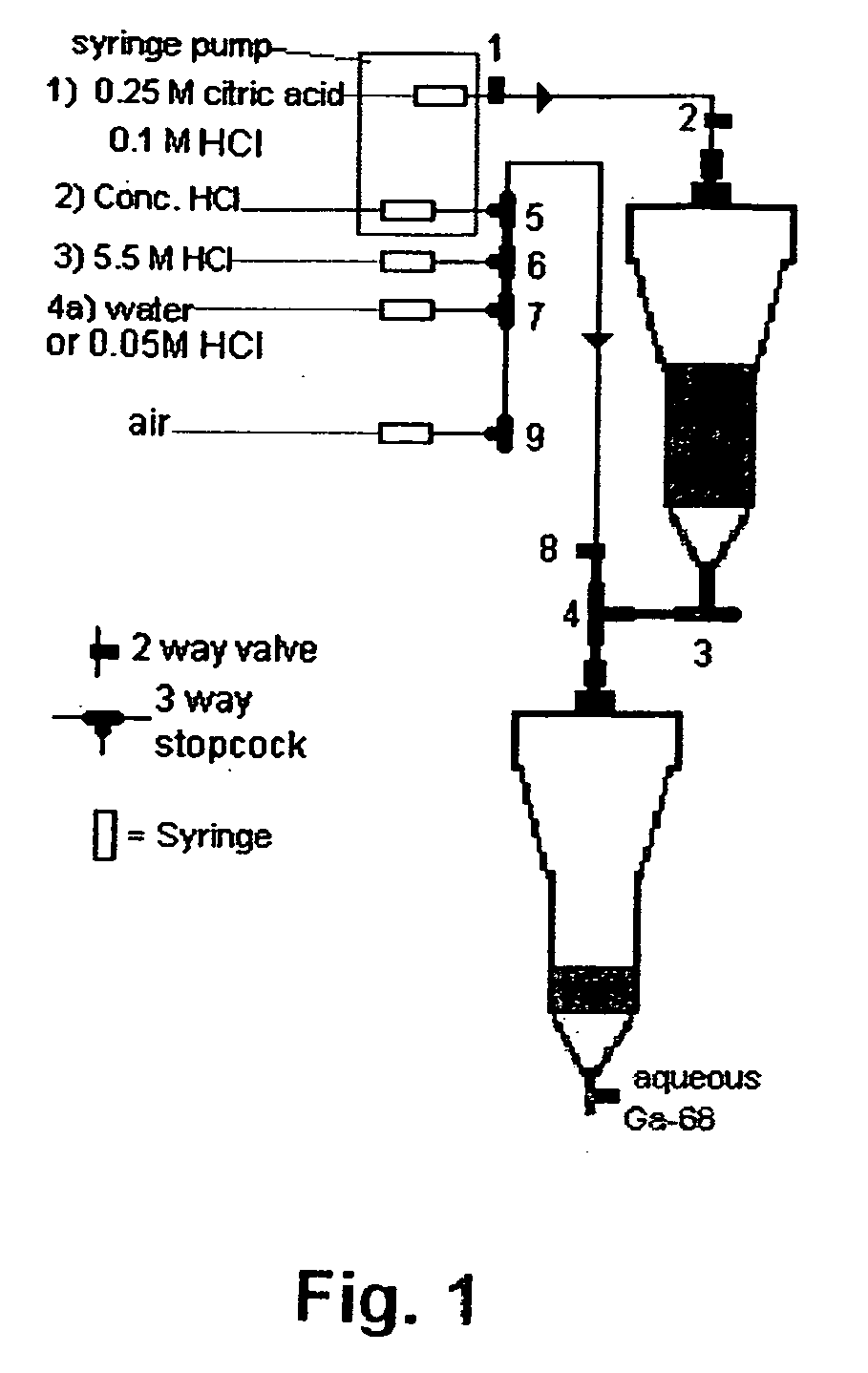

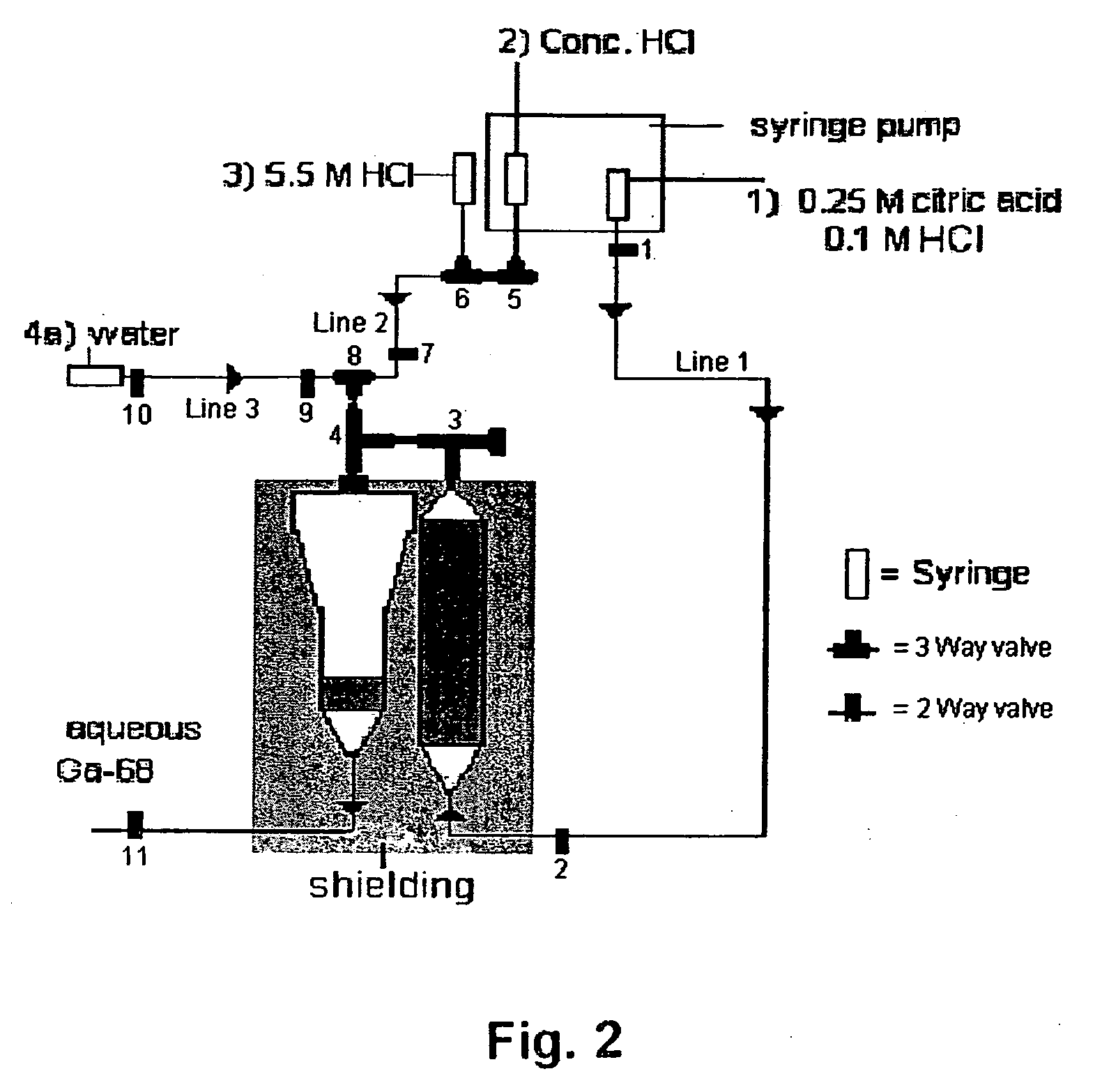

Separation of germanium-68 from gallium-68

InactiveUS20070207075A1High specific activitySpecific isotope recoveryTransuranic element compoundsCarboxylic acidGallium alloy

A method for separating germanium-68 from gallium-68 using an anion exchange resin and a chelating / complexing agent containing a plurality of carboxylic acid groups and at least three carbon atoms to the first solution is disclosed together with a generator apparatus for providing a source of gallium-68.

Owner:LOS ALAMOS NATIONAL SECURITY

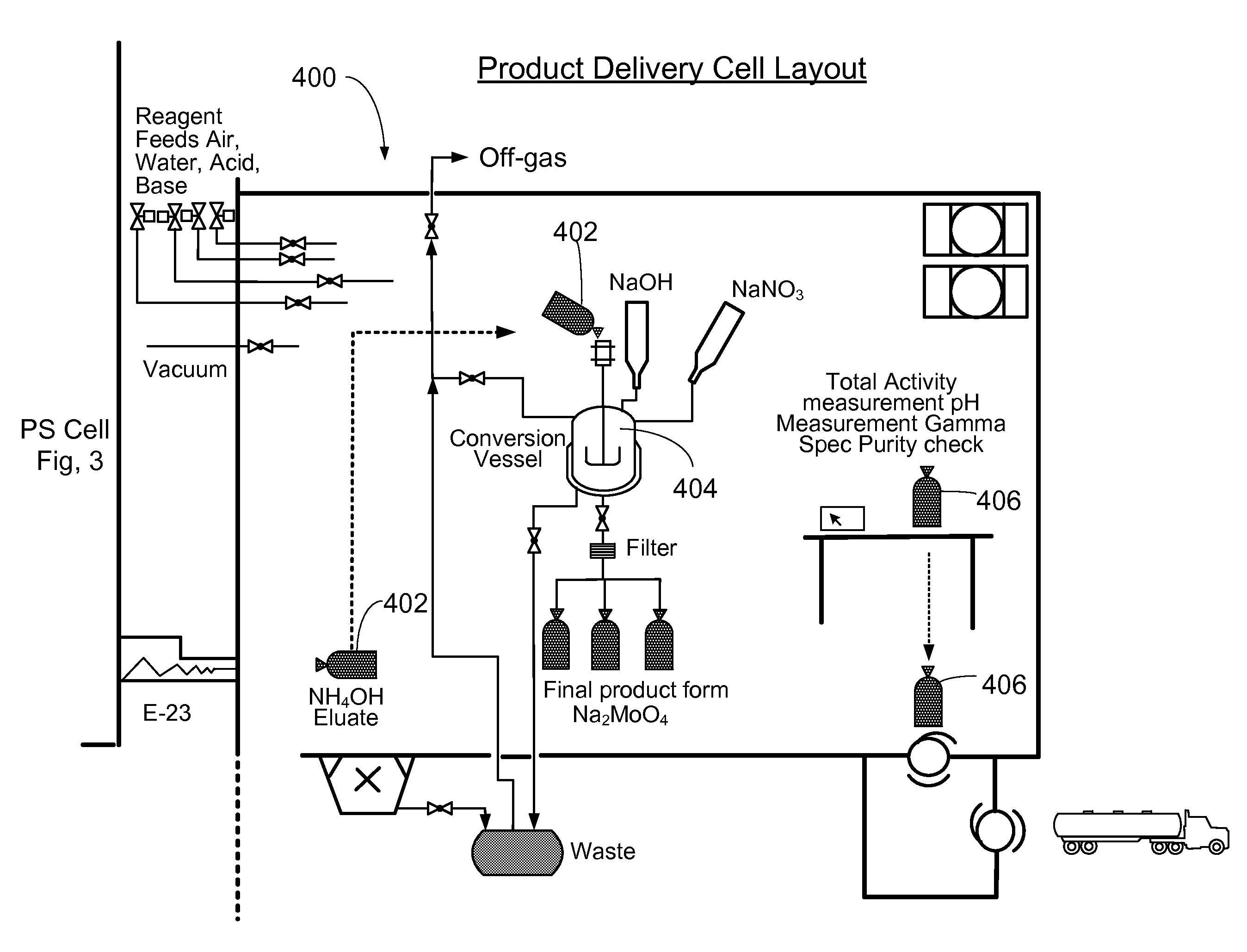

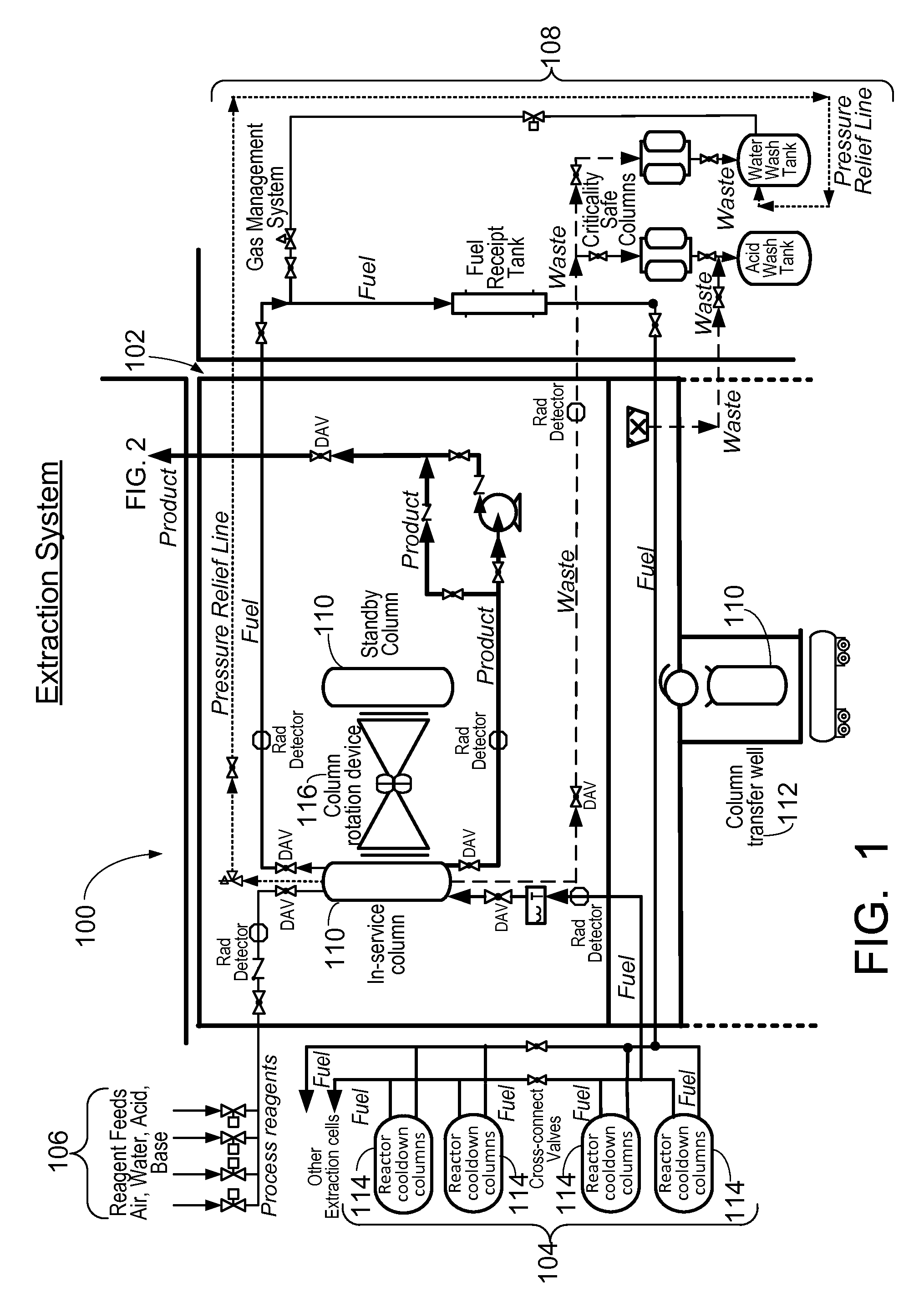

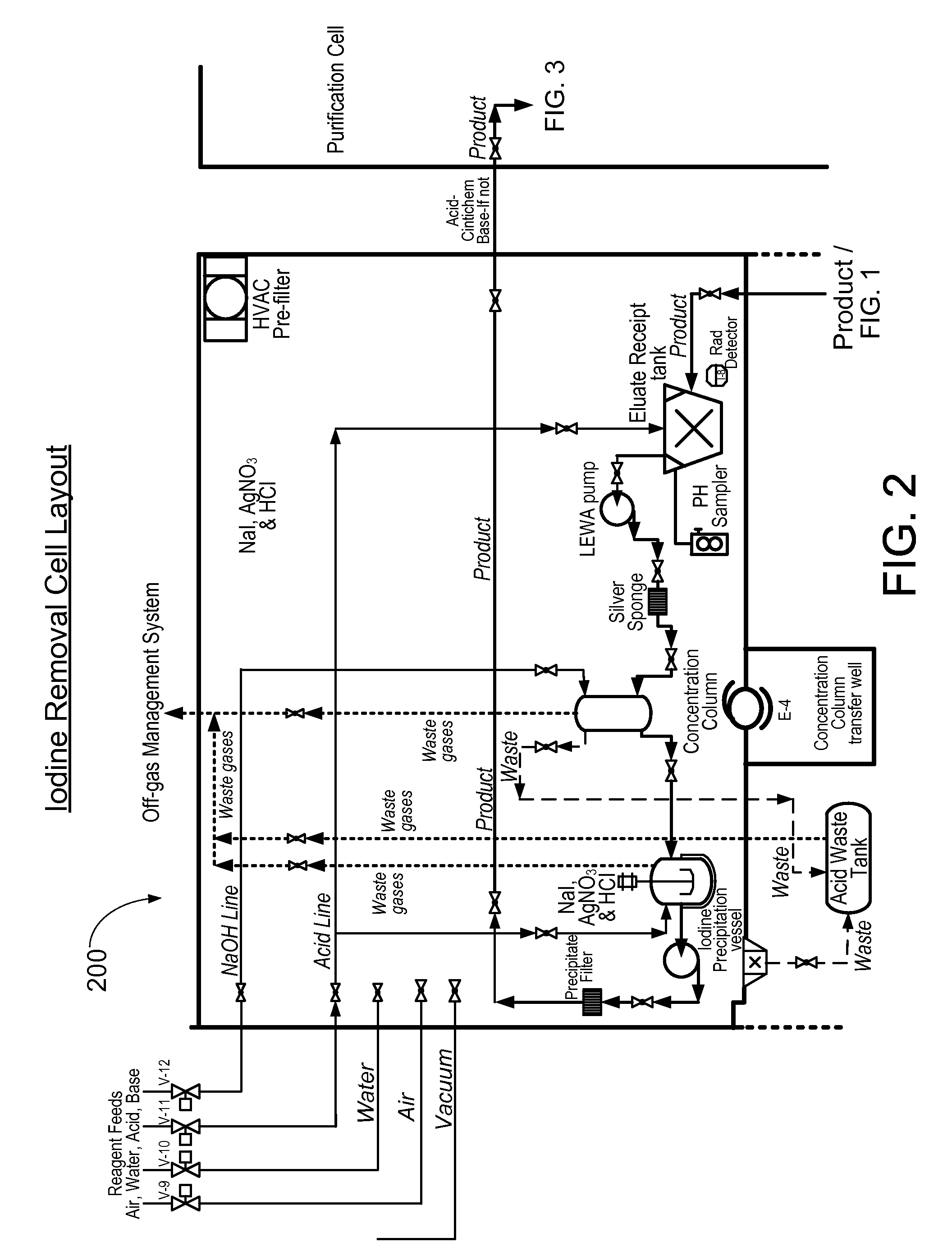

Method and apparatus for the extraction and processing of molybdenum-99

ActiveUS20110206579A1Reduce the amount requiredTransuranic element compoundsSolid sorbent liquid separationSorbentIodine

A method for the extraction and purification of molybdenum, the method comprising the steps of: transferring an irradiated fuel solution to an extraction system, the irradiated fuel solution comprising iodine and molybdenum and other fission products, the extraction system comprising at least one sorbent column; passing the irradiated fuel solution upwards through the at least one sorbent-containing extraction column; directing the irradiated fuel solution towards a fuel management system by means of at least one discharge alignment valve; directing the extraction column eluate towards an iodine removal system; removing the iodine from the extraction column eluate; purifying the extraction column eluate; and collecting the purified eluate. Also disclosed is an apparatus for accomplishing the aforementioned method.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

Extraction of uranium from wet-process phosphoric acid

ActiveUS20100028226A1Lower iron levelsReduced valencyCobalt ammonia complexesPhotography auxillary processesFiltrationIon exchange

A process for the extraction of uranium compounds from wet-process phosphoric acid includes lowering the iron concentration of the wet-process phosphoric acid and reducing the valency of any remaining ferric iron in the wet-process phosphoric acid to ferrous iron, and then extracting uranium compounds from the wet-process phosphoric acid. The process can include separating a side stream from a feed stream of wet-process phosphoric acid, wherein the side stream has a greater concentration of the uranium compounds than the feed stream by filtration. Extracting uranium compounds from the wet-process phosphoric acid can be by ion exchange process or by solvent extraction.

Owner:URTEK

Process for tritium removal from water by transfer of tritium from water to an elemental hydrogen stream, followed by membrane diffusion tritium stripping and enrichment, and final tritium enrichment by thermal diffusion

ActiveUS20100239481A1Economical and simpleSimpler to start-up and shutdown and operateTransuranic element compoundsRadium compoundsDiffusionMembrane diffusion

A diffusion based process for tritium removal from water by tritium transfer from water to an elemental hydrogen stream, followed by a membrane diffusion cascade for tritium stripping and enrichment, and final tritium enrichment by one or more thermal diffusion columns. The combination of process steps takes advantage of membrane diffusion's large throughput capability at low tritium concentration with the simplicity of thermal diffusion for small throughput final tritium enrichment. The membrane diffusion stages use supported or unsupported microporous or hydrogen permeable metal membranes (such as Pd / Ag alloy). The diffusion process is compatible with any front-end process to transfer tritium from tritiated water to elemental hydrogen. The process may be designed and operated at low pressure, with small gas inventory, and no inherent overpressure hazard.

Owner:BWXT NUCLEAR ENERGY CANADA INC

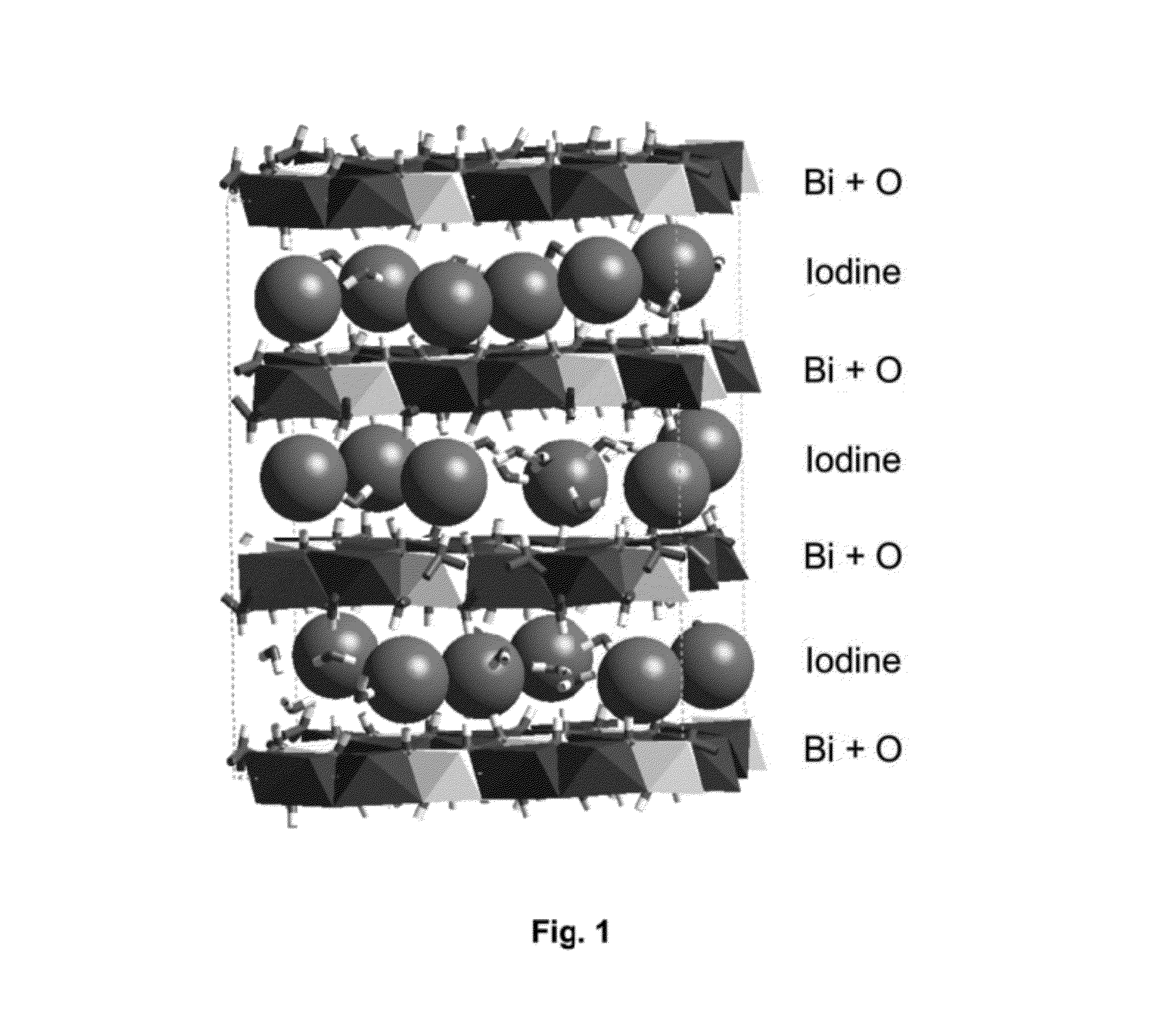

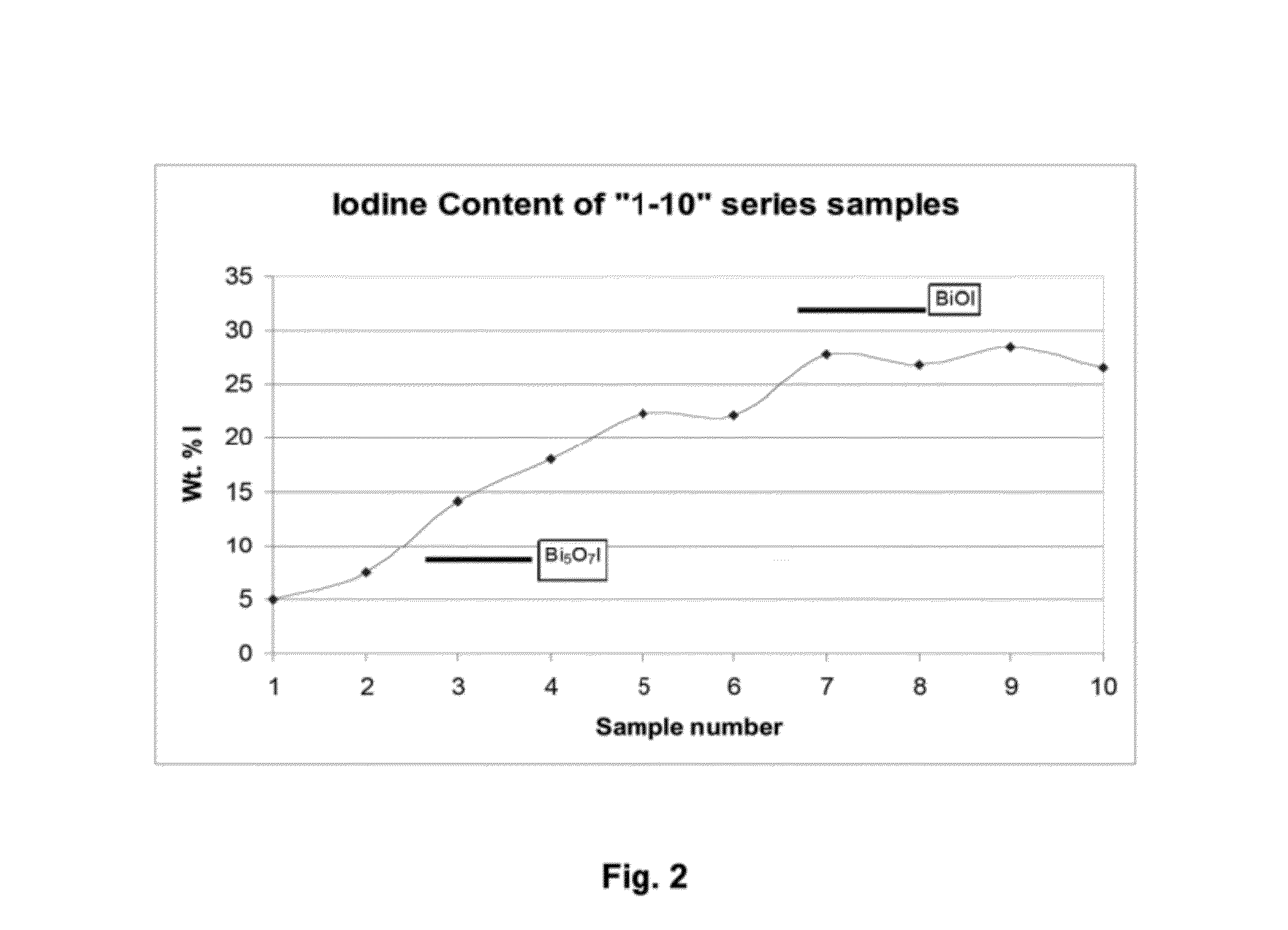

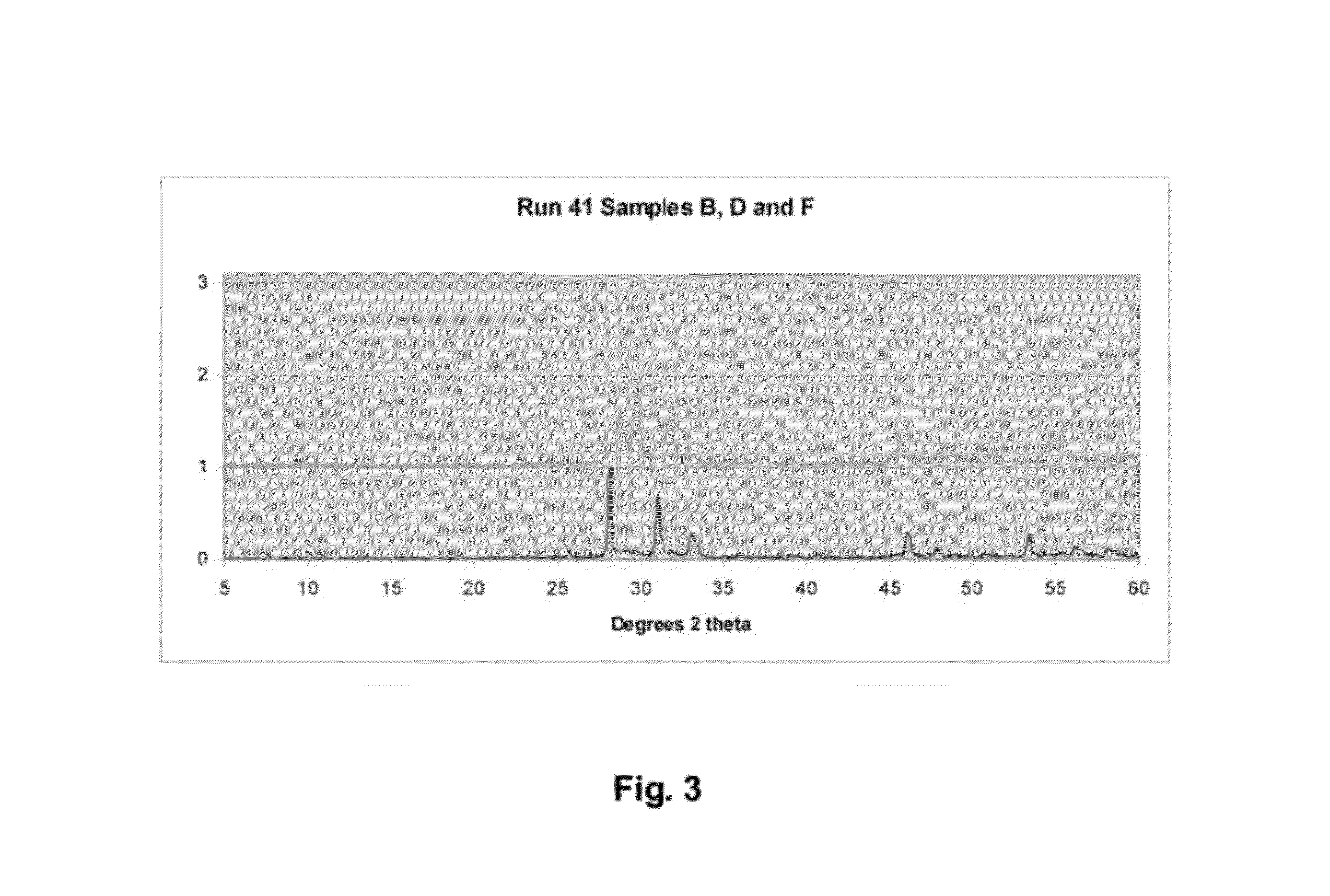

Mixed-layered bismuth-oxygen-iodine materials for capture and waste disposal of radioactive iodine

ActiveUS8383021B1Transuranic element compoundsSolid waste disposalSolubilityWaste Isolation Pilot Plant

Materials and methods of synthesizing mixed-layered bismuth oxy-iodine materials, which can be synthesized in the presence of aqueous radioactive iodine species found in caustic solutions (e.g. NaOH or KOH). This technology provides a one-step process for both iodine sequestration and storage from nuclear fuel cycles. It results in materials that will be durable for repository conditions much like those found in Waste Isolation Pilot Plant (WIPP) and estimated for Yucca Mountain (YMP). By controlled reactant concentrations, optimized compositions of these mixed-layered bismuth oxy-iodine inorganic materials are produced that have both a high iodine weight percentage and a low solubility in groundwater environments.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

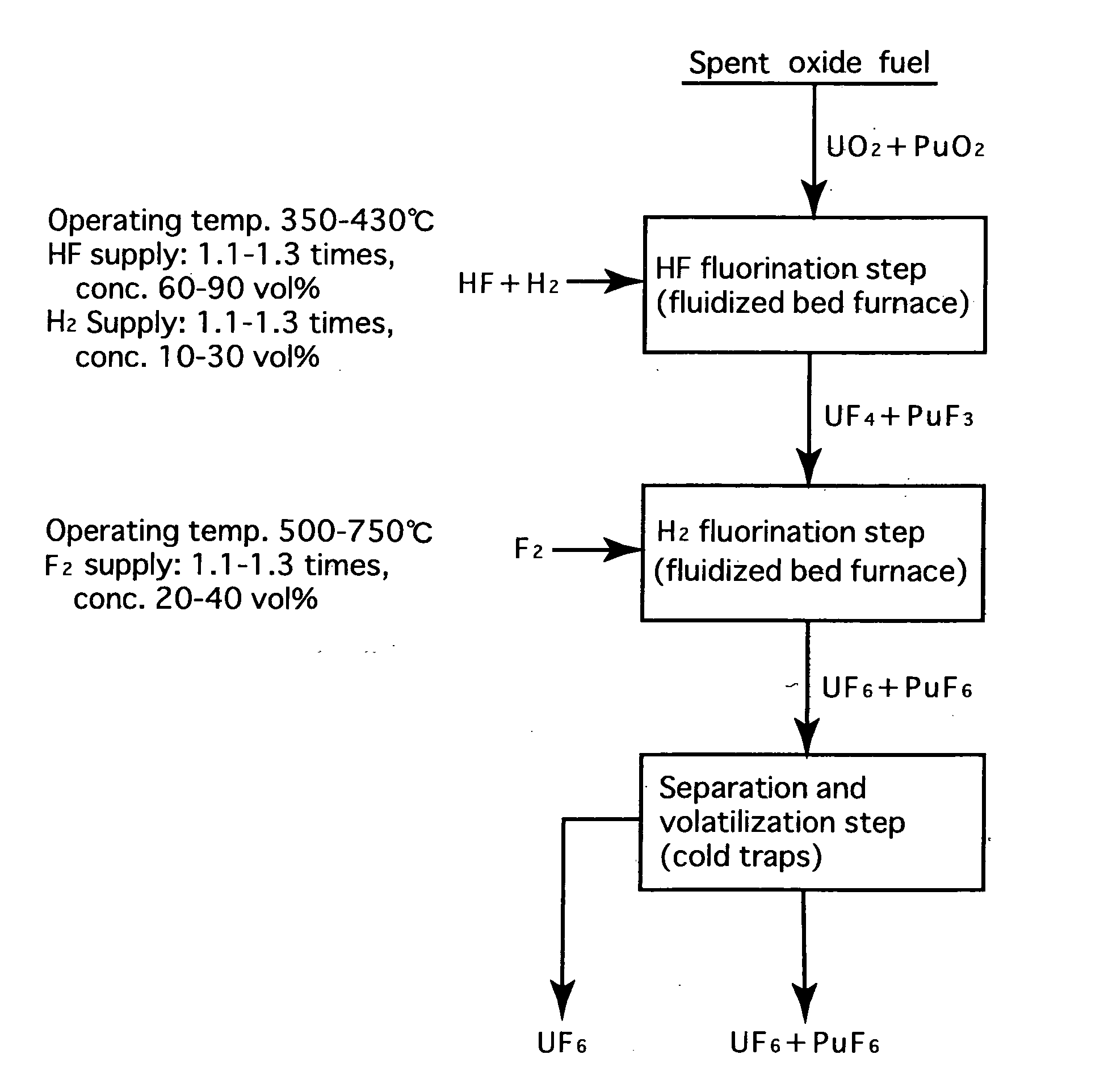

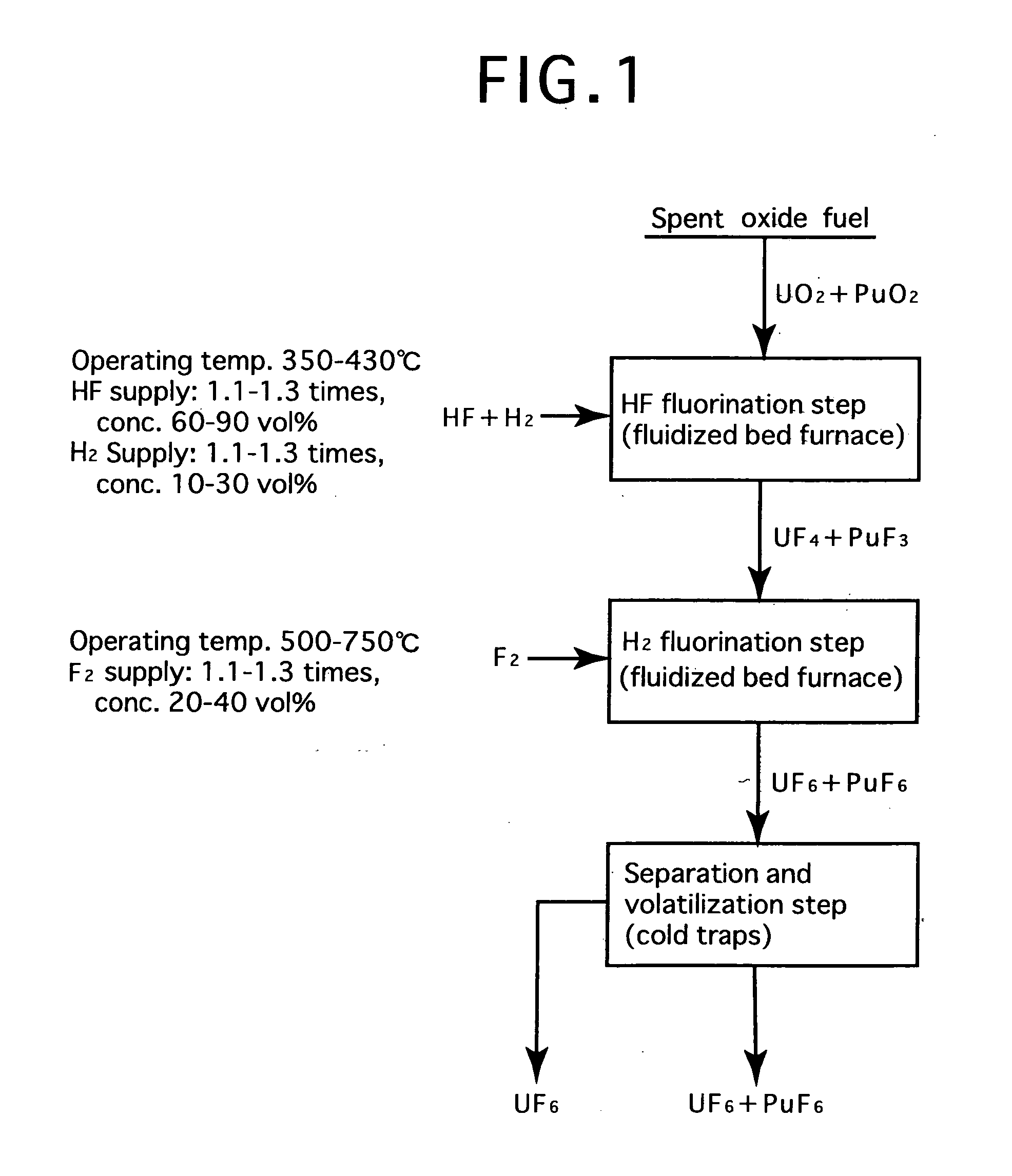

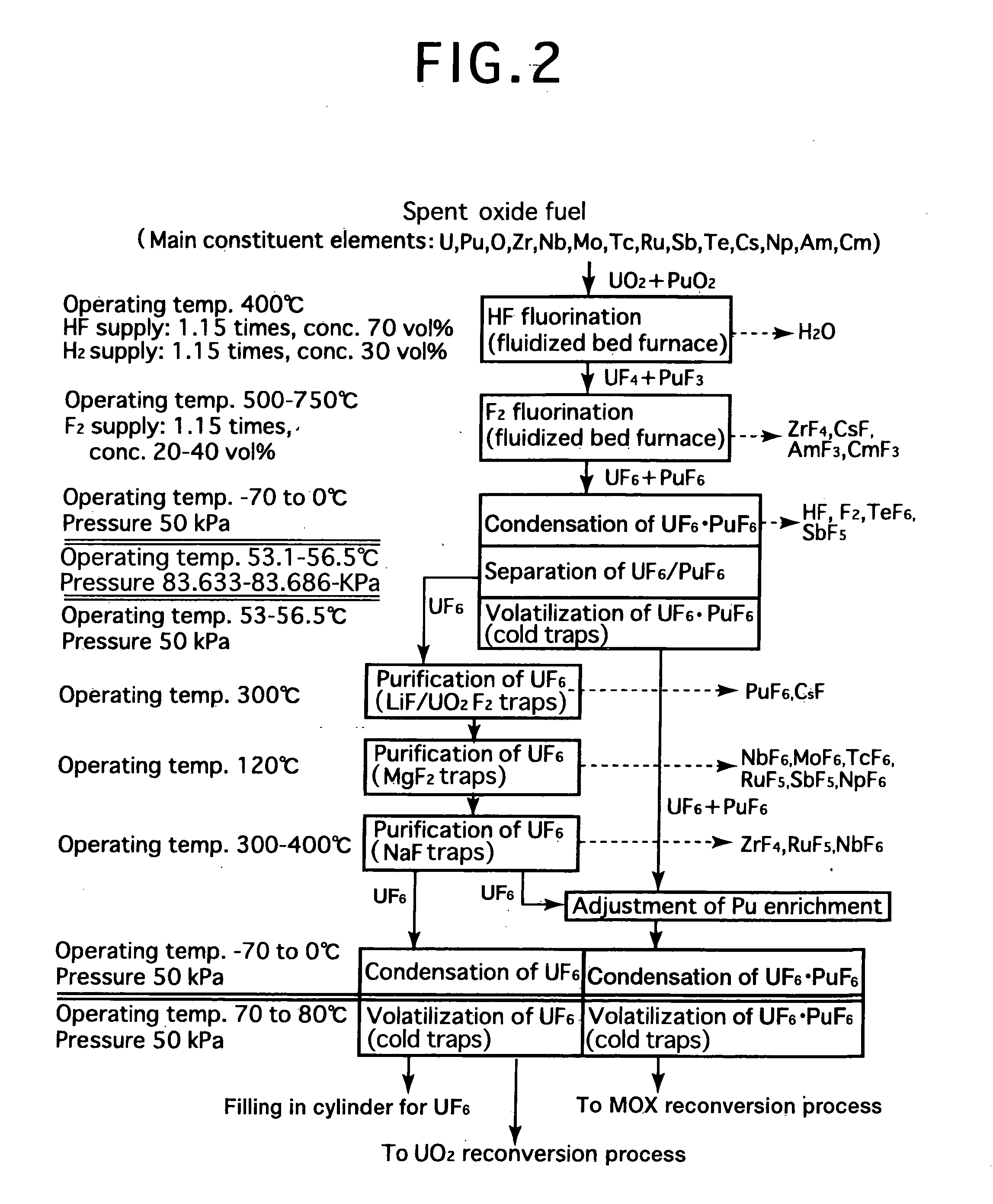

Reprocessing method by fluoride volatility process using fractional distillation

InactiveUS20060057042A1Increase ratingsRaise the ratioPlutonium compoundsUranium fluoridesHydrogen fluorideHydrogen

Fluorine or a fluorine compound is subjected to a reaction with a spent oxide fuel to produce fluorides of uranium and plutonium, and recovering the fluorides using a difference in volatility behavior. The method includes steps of: subjecting a mixture of UO2 and PuO2 with hydrogen fluoride mixed with hydrogen to HF-fluorinate uranium and plutonium into UF4 and PuF3; subjecting UF4 and PuF3 with a fluorine gas to F2-fluorinate uranium and plutonium into UF6 and PuF6; and fractionating UF6 and PuF6 using a difference in phase change of obtained UF6and PuF6, removing a part of UF6, and volatilizing the remaining UF6 and PuF6 at the same time. By such a reprocessing method, PuF4 hard to undergo a reaction is prevented from being formed as an intermediate fluoride, the material of a reactor is hard to be corroded, and a consumption of expensive fluorine gas is reduced.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

Method for the chemical separation of GE-68 from its daughter Ga-68

InactiveUS20090001283A1Specific isotope recoveryMaterial analysis using wave/particle radiationCITRATE ESTERTetrachloride

The present invention is directed to a generator apparatus for separating a daughter gallium-68 radioisotope substantially free of impurities from a parent gernanium-68 radioisotope, including a first resin-containing column containing parent gernanium-68 radioisotope and daughter gallium-68 radioisotope, a source of first eluent connected to said first resin-containing column for separating daughter gallium-68 radioisotope from the first resin-containing column, said first eluent including citrate whereby the separated gallium is in the form of gallium citrate, a mixing space connected to said first resin-containing column for admixing a source of hydrochloric acid with said separated gallium citrate whereby gallium citrate is converted to gallium tetrachloride, a second resin-containing column for retention of gallium-68 tetrachloride, and, a source of second eluent connected to said second resin-containing column for eluting the daughter gallium-68 radioisotope from said second resin-containing column.

Owner:LOS ALAMOS NATIONAL SECURITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com