Patents

Literature

39 results about "Membrane diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diffusion Through a Membrane. Diffusion is the net movement of particles (atoms, molecules, or ions) from a highly concentrated region to a region of low concentration.

Treatments for contaminant reduction in lactoferrin preparations and lactoferrin containing compositions

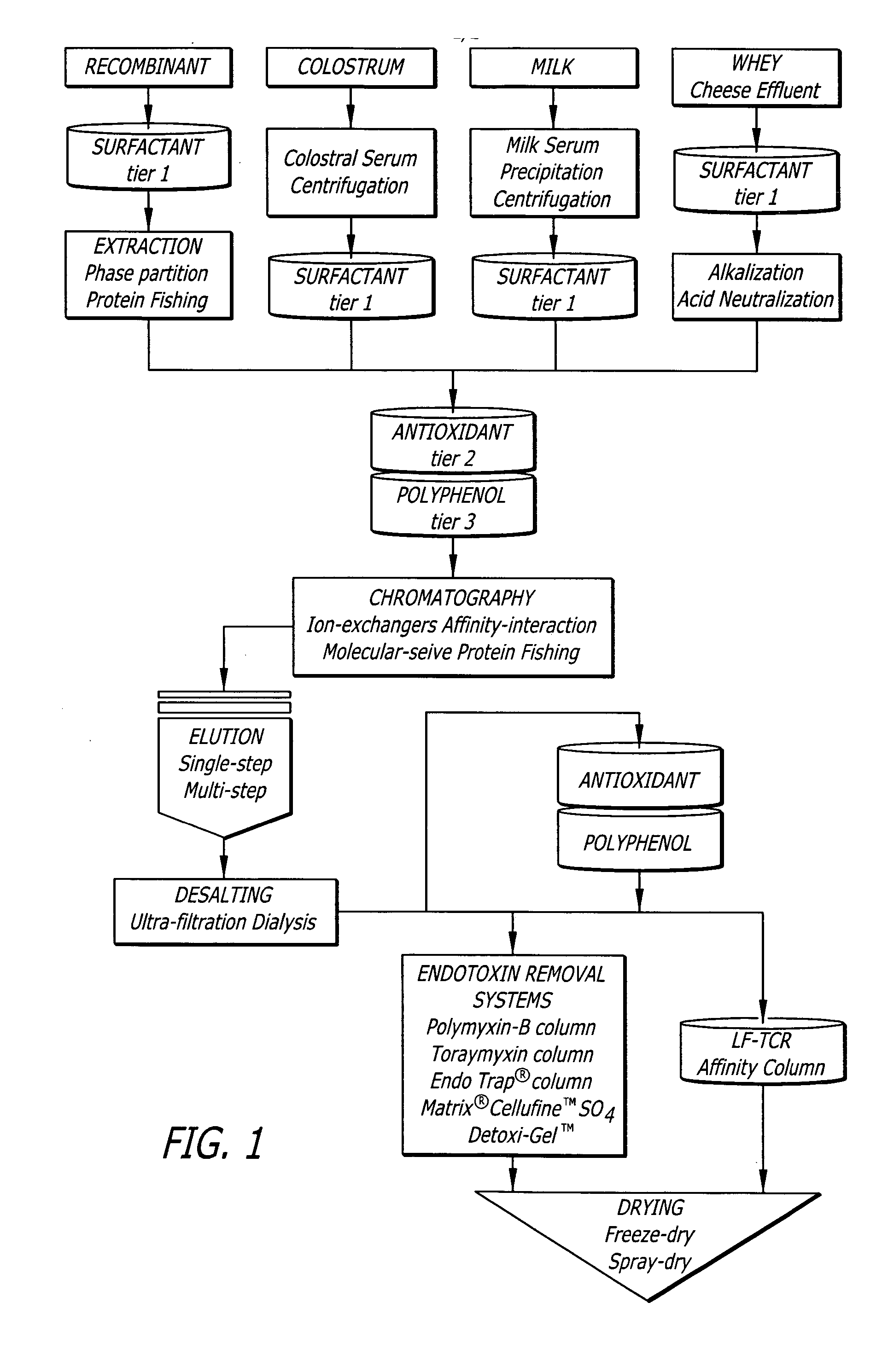

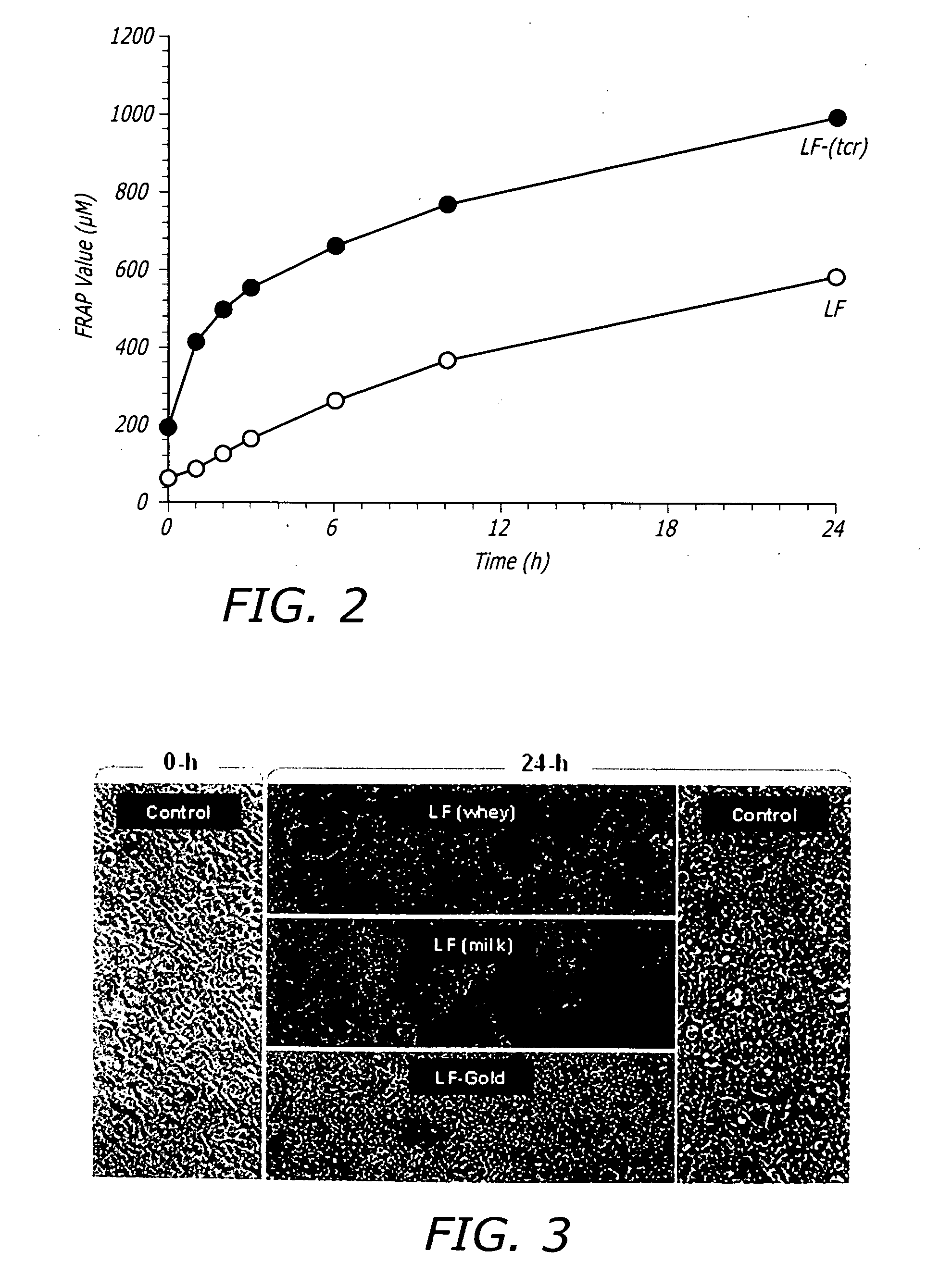

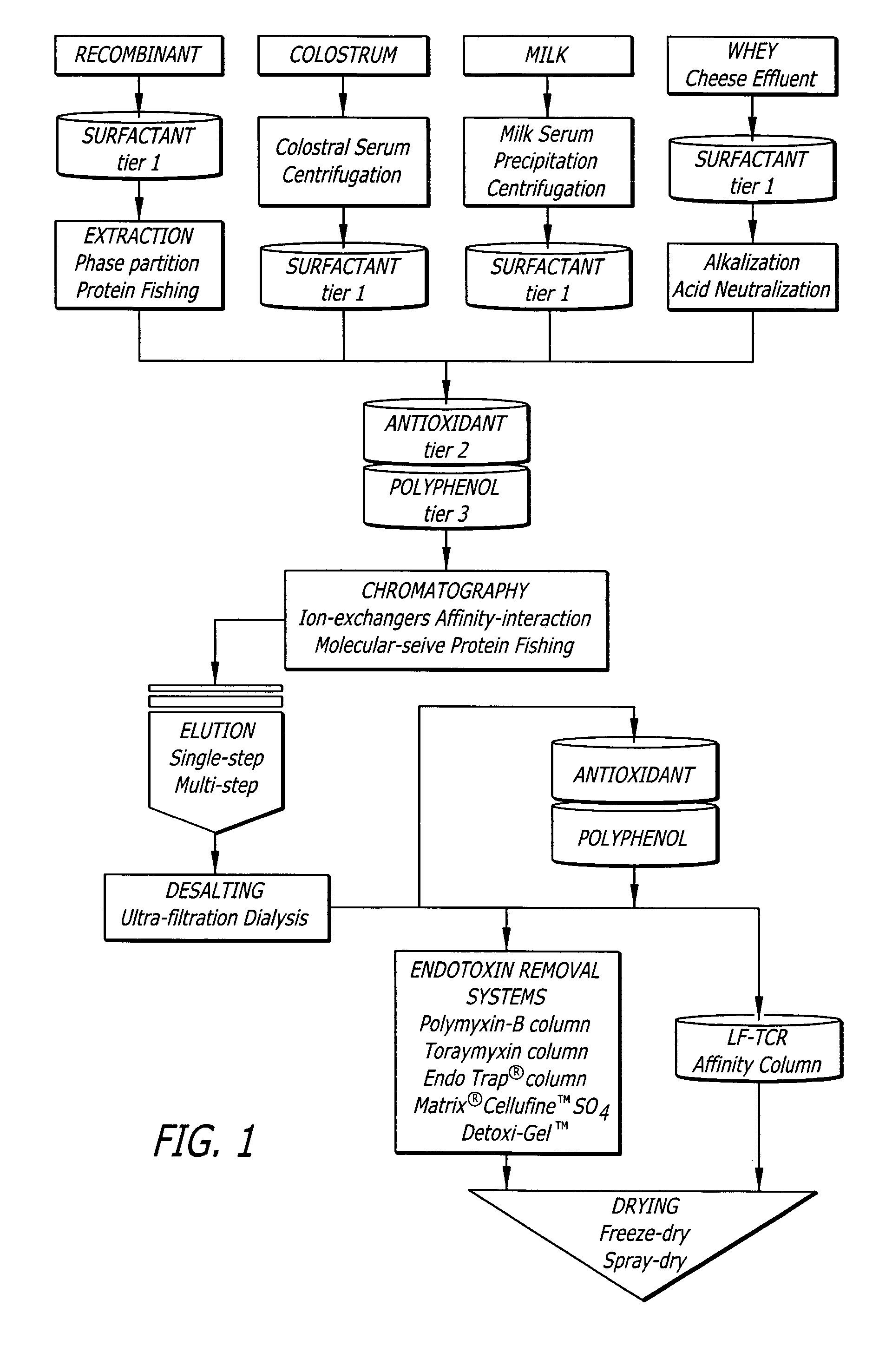

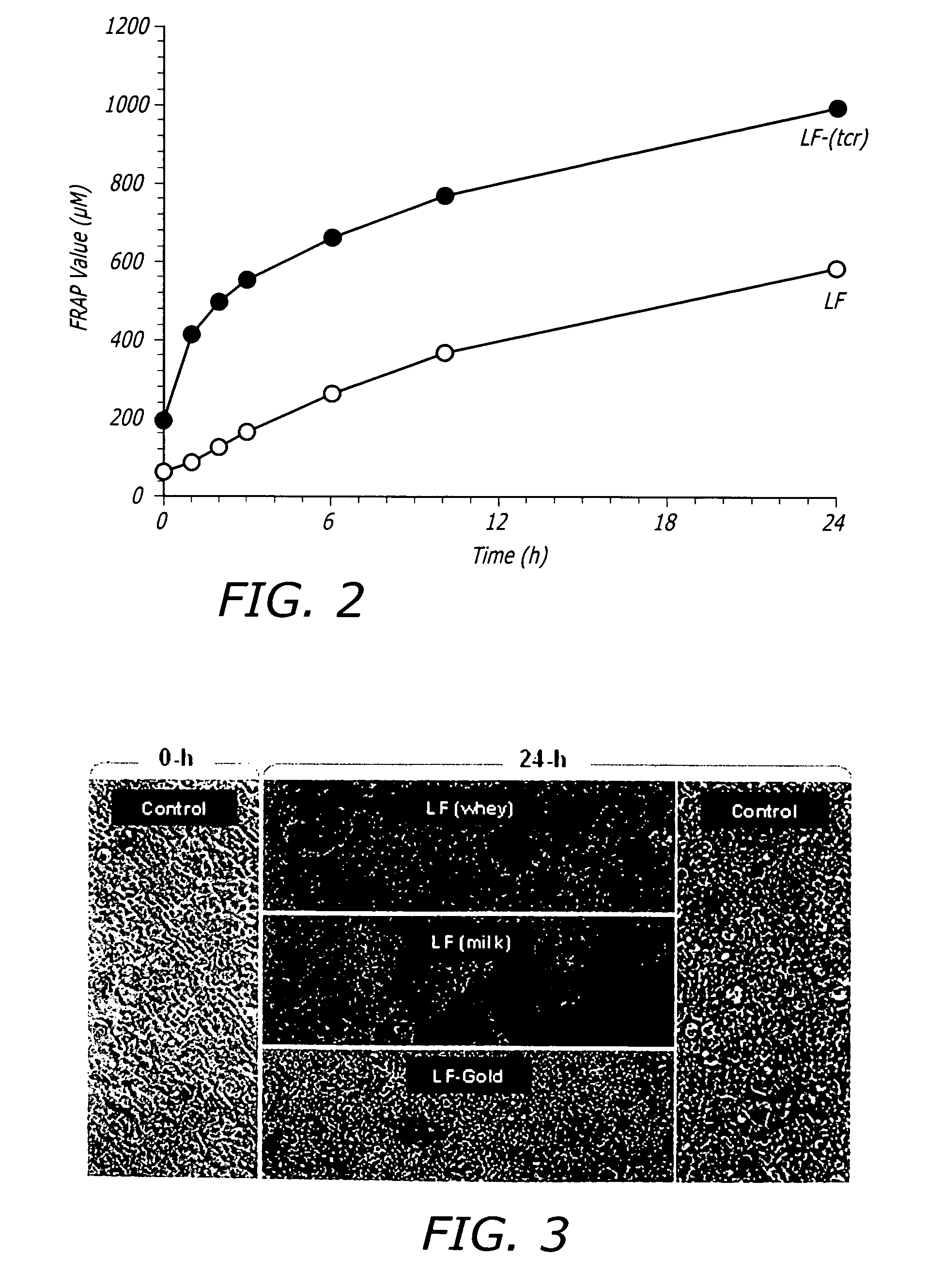

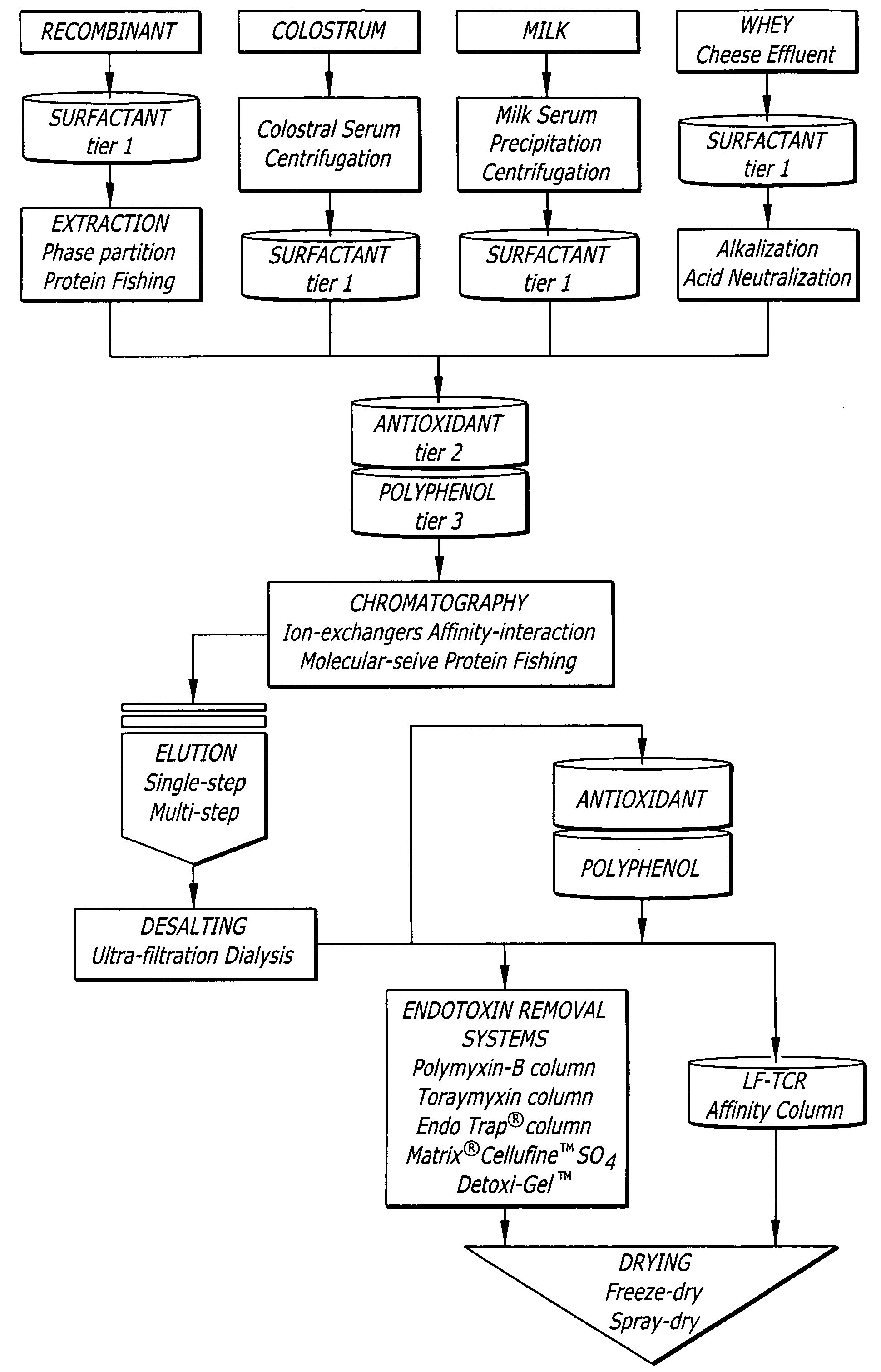

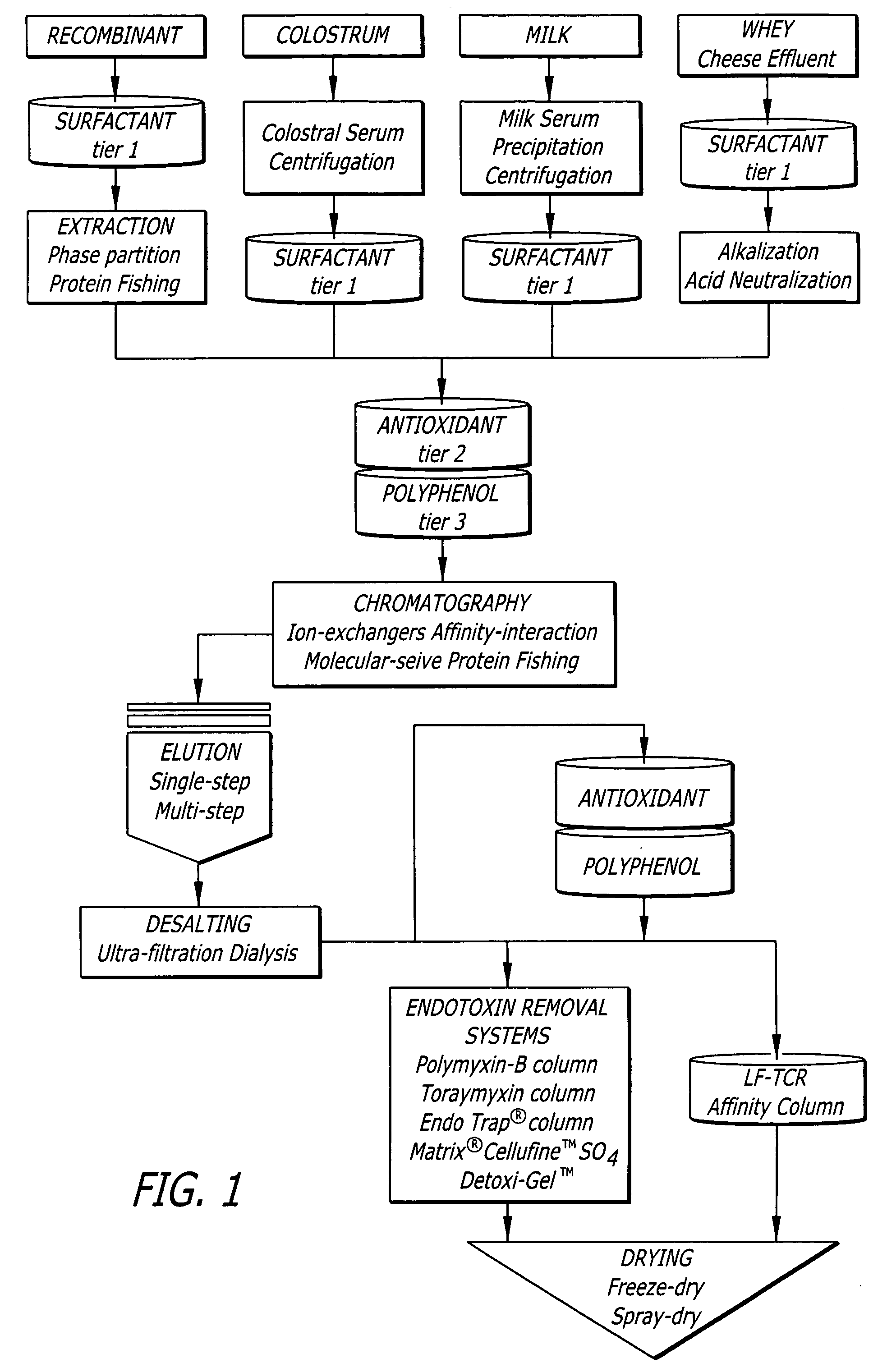

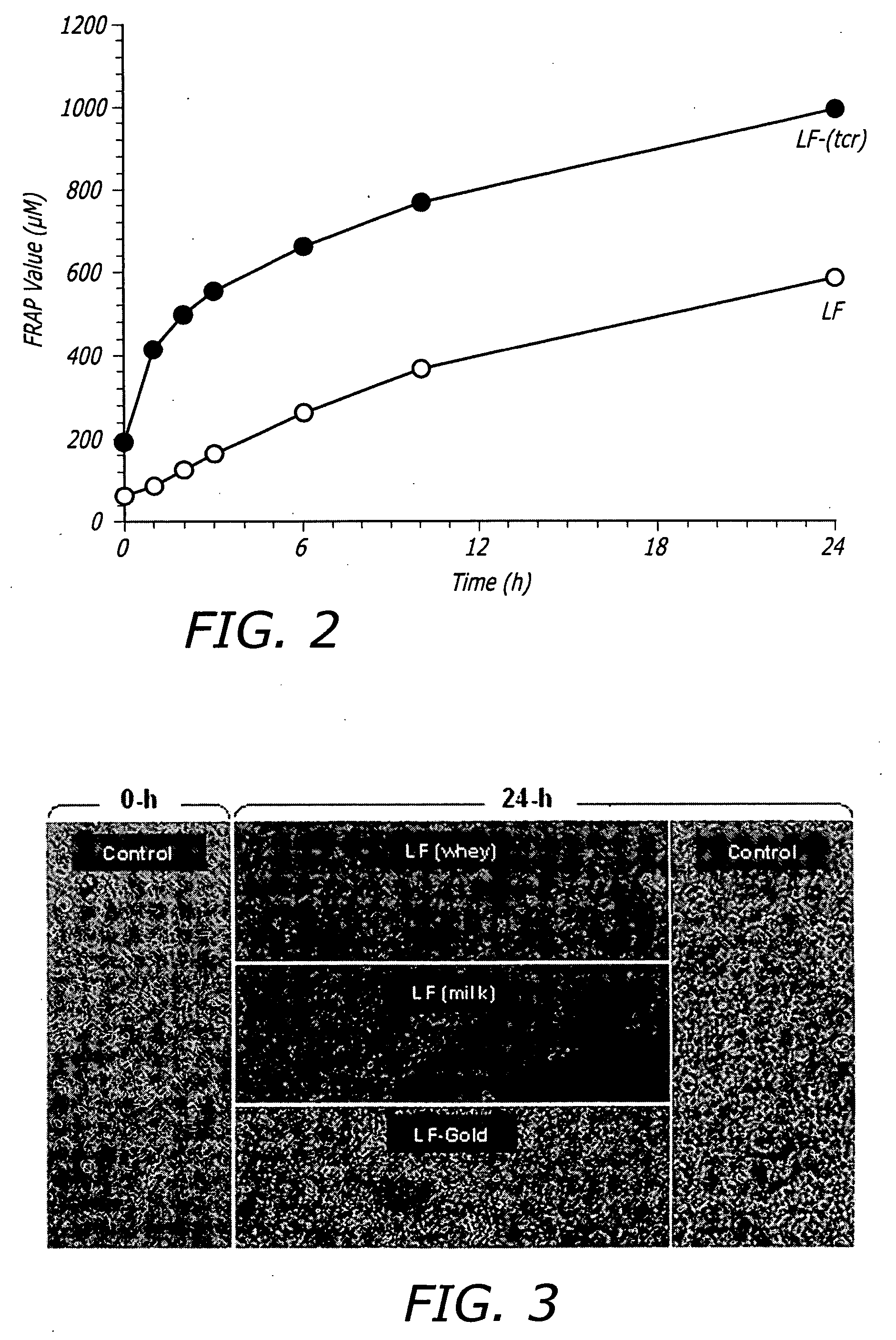

A method of preparing an ultra-cleansed lactoferrin preparation, termed treatment for contaminant reduction (TCR) is provided which includes the steps of treating commercial lactoferrin preparation with at least one each of surfactants, antioxidants and polyphenols to form purified lactoferrin (LF-TCR) and drying the LF-TCR. Additionally a therapeutic lactoferrin composition is provided which contains LF-TCR and optionally surfactants, antioxidants, polyphenols, tissue / membrane diffusion facilitating agents and anionic compounds. The therapeutic lactoferrin composition can additionally contain bioactive agents, dietary supplements, nutraceuticals / functional foods, prophylactic agents, therapeutic agents and probiotic lactic acid bacteria.

Owner:NAIDU LP

Treatments for contaminant reduction in lactoferrin preparations and lactoferrin containing compositions

A method of preparing an ultra-cleansed lactoferrin preparation, termed treatment for contaminant reduction (TCR) is provided which includes the steps of treating commercial lactoferrin preparation with at least one each of surfactants, antioxidants and polyphenols to form purified lactoferrin (LF-TCR) and drying the LF-TCR. Additionally a therapeutic lactoferrin composition is provided which contains LF-TCR and optionally surfactants, antioxidants, polyphenols, tissue / membrane diffusion facilitating agents and anionic compounds. The therapeutic lactoferrin composition can additionally contain bioactive agents, dietary supplements, nutraceuticals / functional foods, prophylactic agents, therapeutic agents and probiotic lactic acid bacteria.

Owner:NAIDU LP

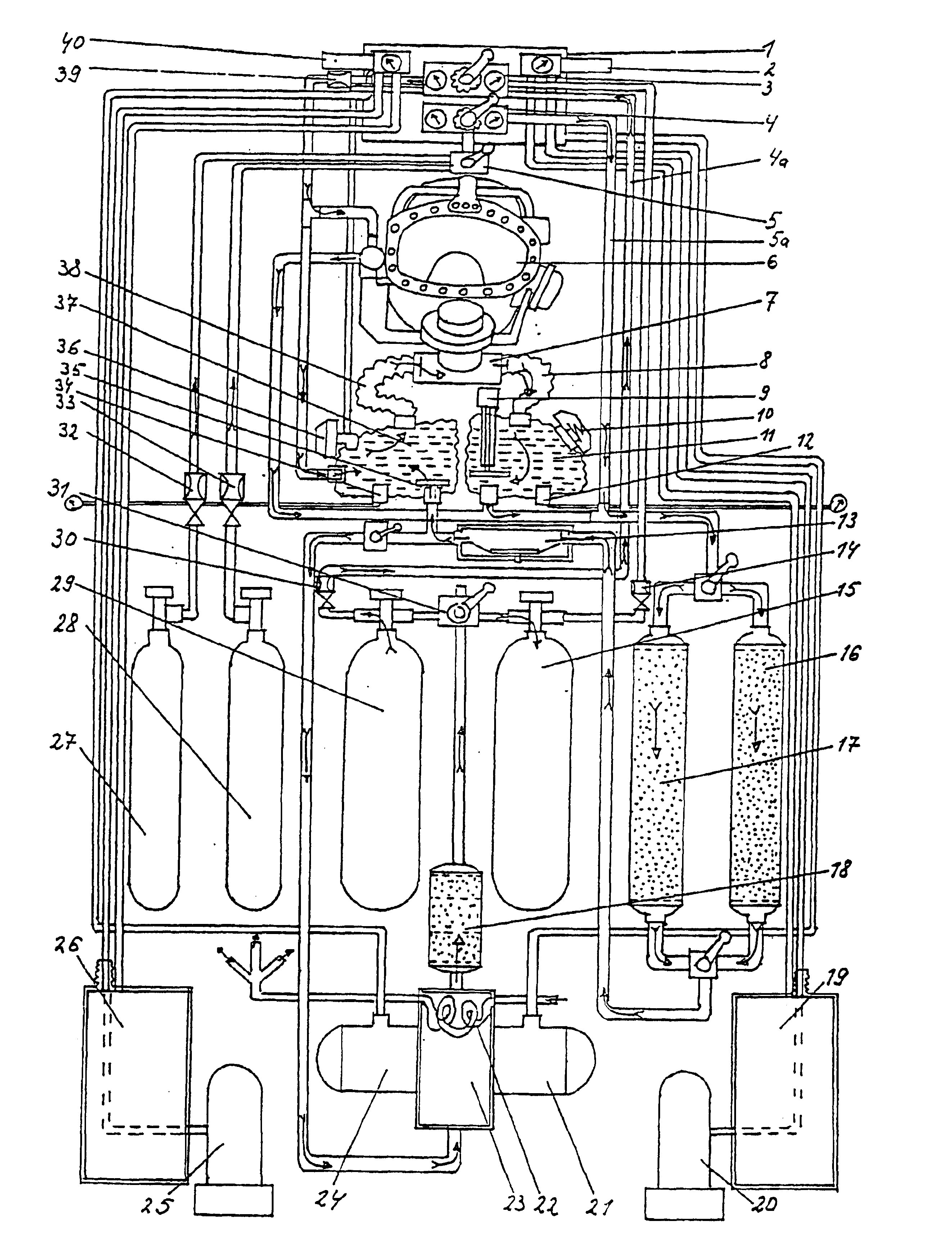

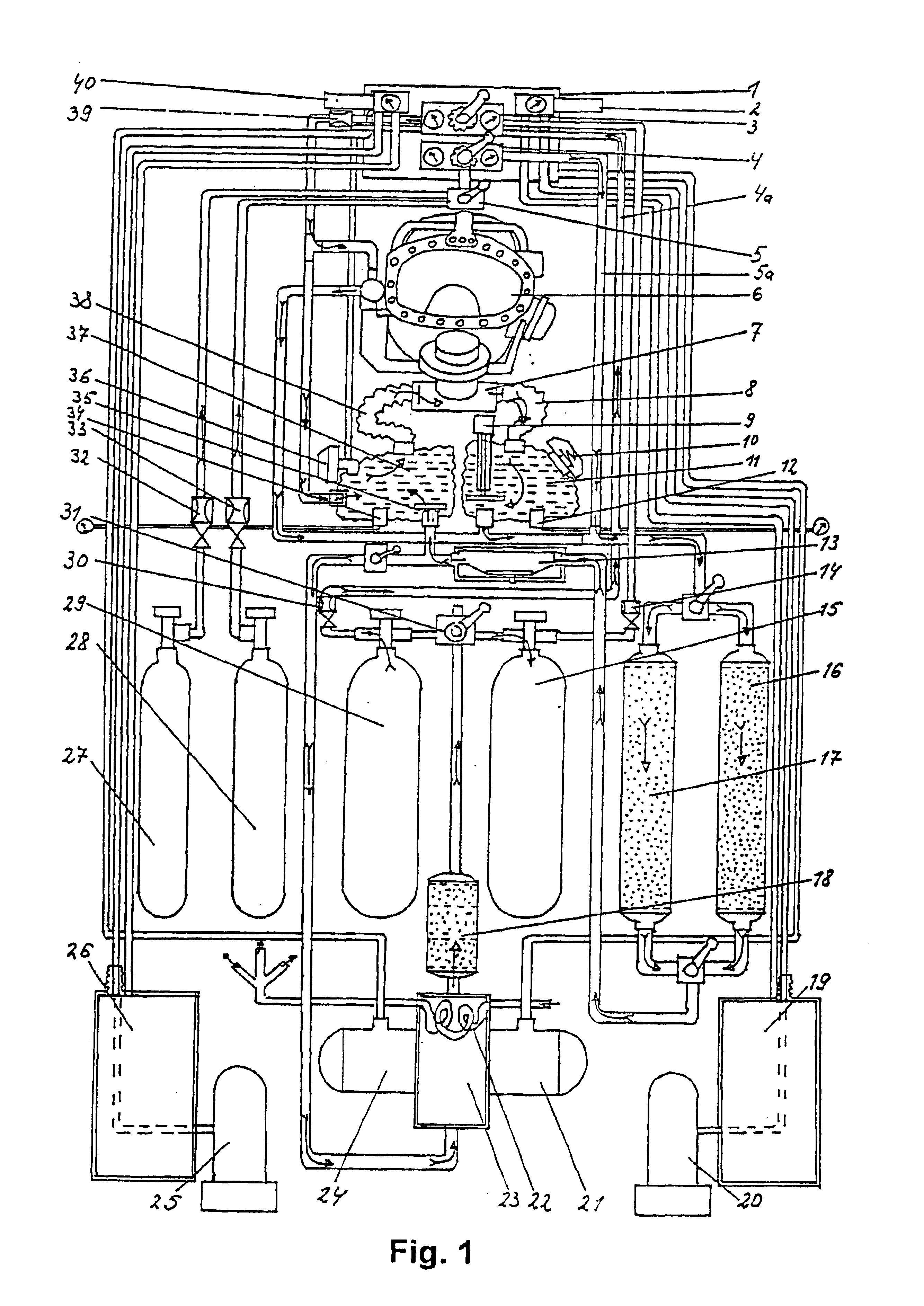

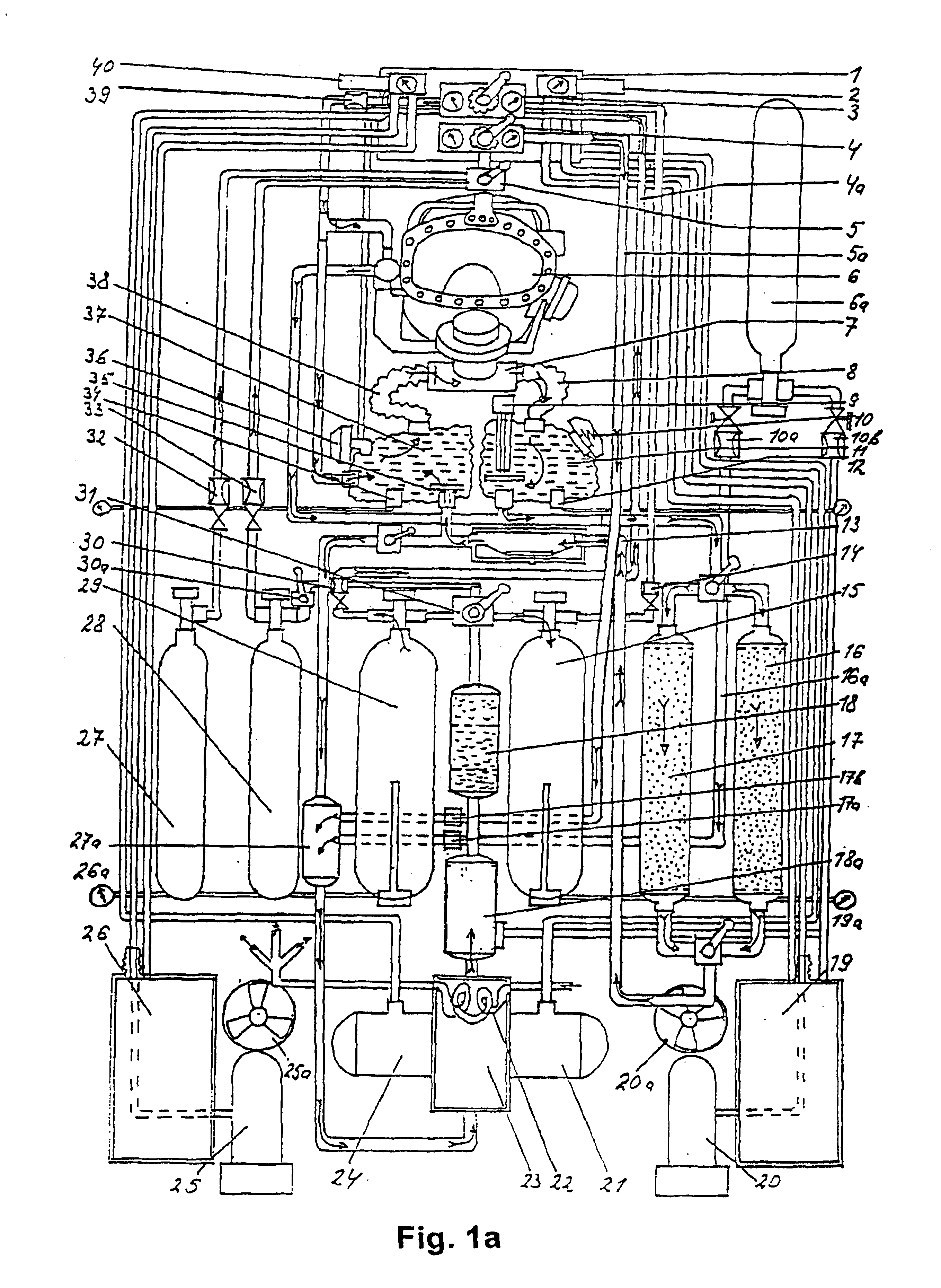

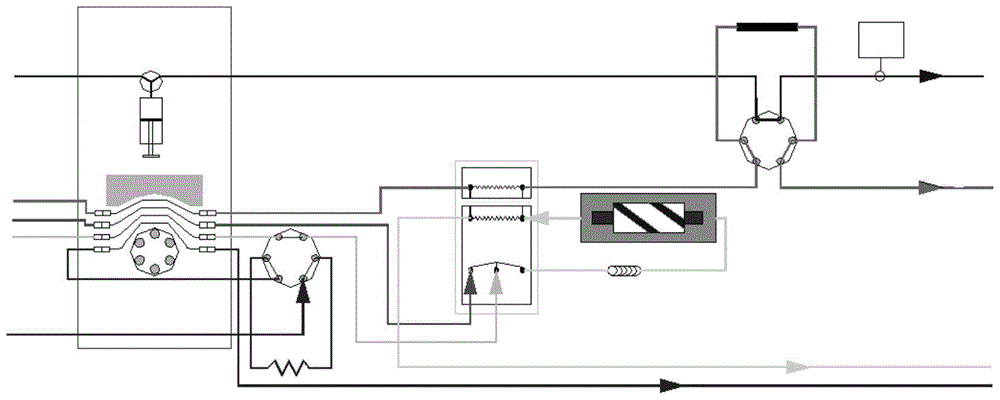

Method and device for the autonomous production, preparation, and supply of breathing gas to divers at extreme depths

InactiveUS6895961B1Enhances diving securityLong supplyRespiratorsGas treatmentAbsorption filterMembrane diffusion

The invention relates to a fully closed circuit-pendulum-storage system wherein a given amount of a ready to breathe gas mixture made of various inert gases including hydrogen and oxygen is continuously conveyed between two highly pressurized gas containers. Initially, the required breathing gas leaves the pressurized gas container and reaches the circuit at a constant dosage according to the overdosing principle. The circuit consists of an inhalation bag, a diving helmet, an exhalation bag and a single or double pack CO2 absorption filter. At a depth of 0-100 m a mixture of oxygen, nitrogen and helium is used as a breathing gas. At a depth of 100-700 m a given amount of hydrogen is mixed therewith according to the wishes of the diver, whereby the oxygen content should not exceed 3 vol. %. When the diver emerges from a depth of over 100 m, the hydrogen is removed from the breathing gas and from the circuit by means of palladium membrane diffusion or catalytic water conversion. The removal of hydrogen is controlled by hydrogen detectors. At this point only, the oxygen content can exceed 3 vol %.

Owner:TODOROV GUEORGUI

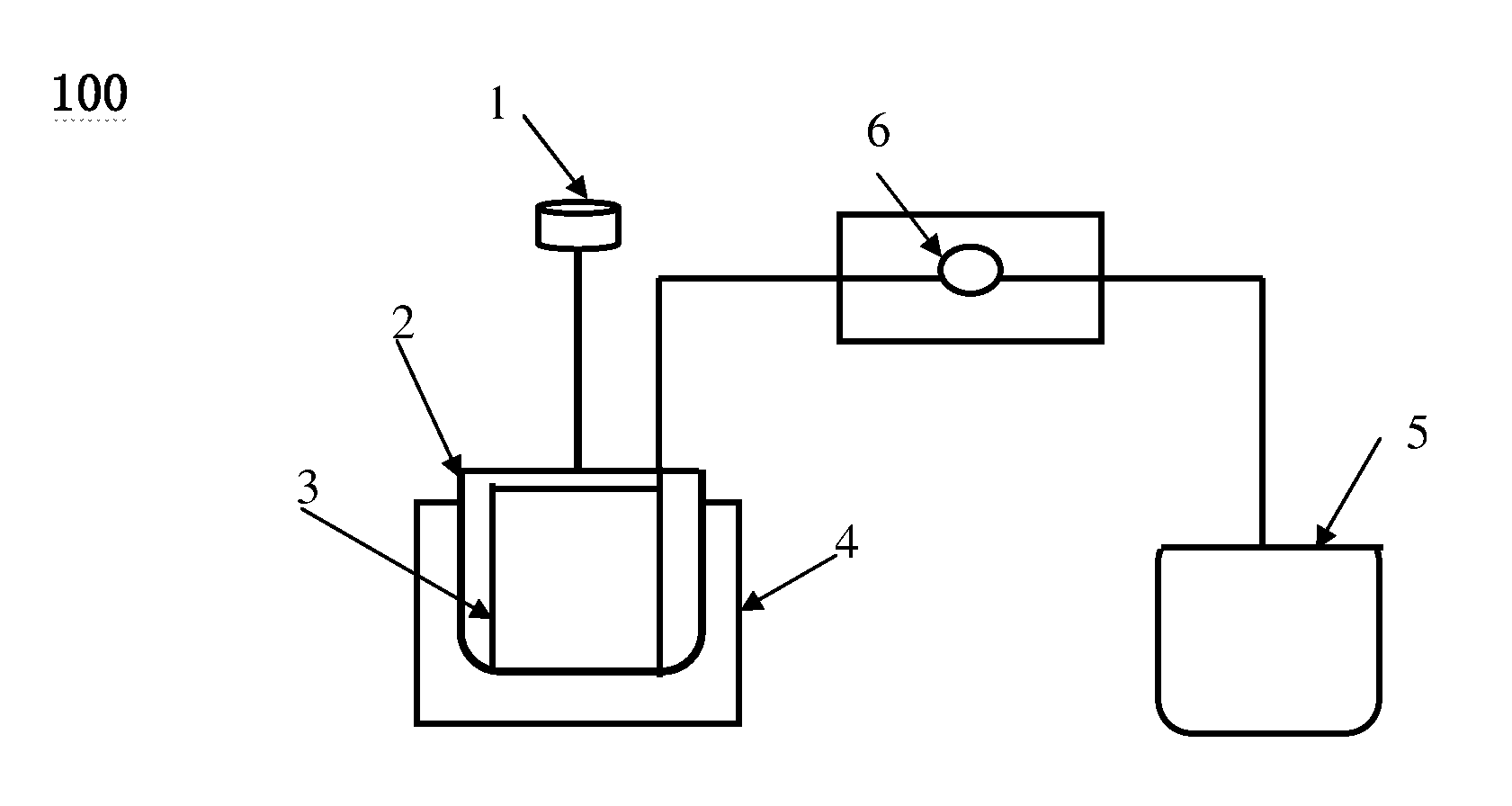

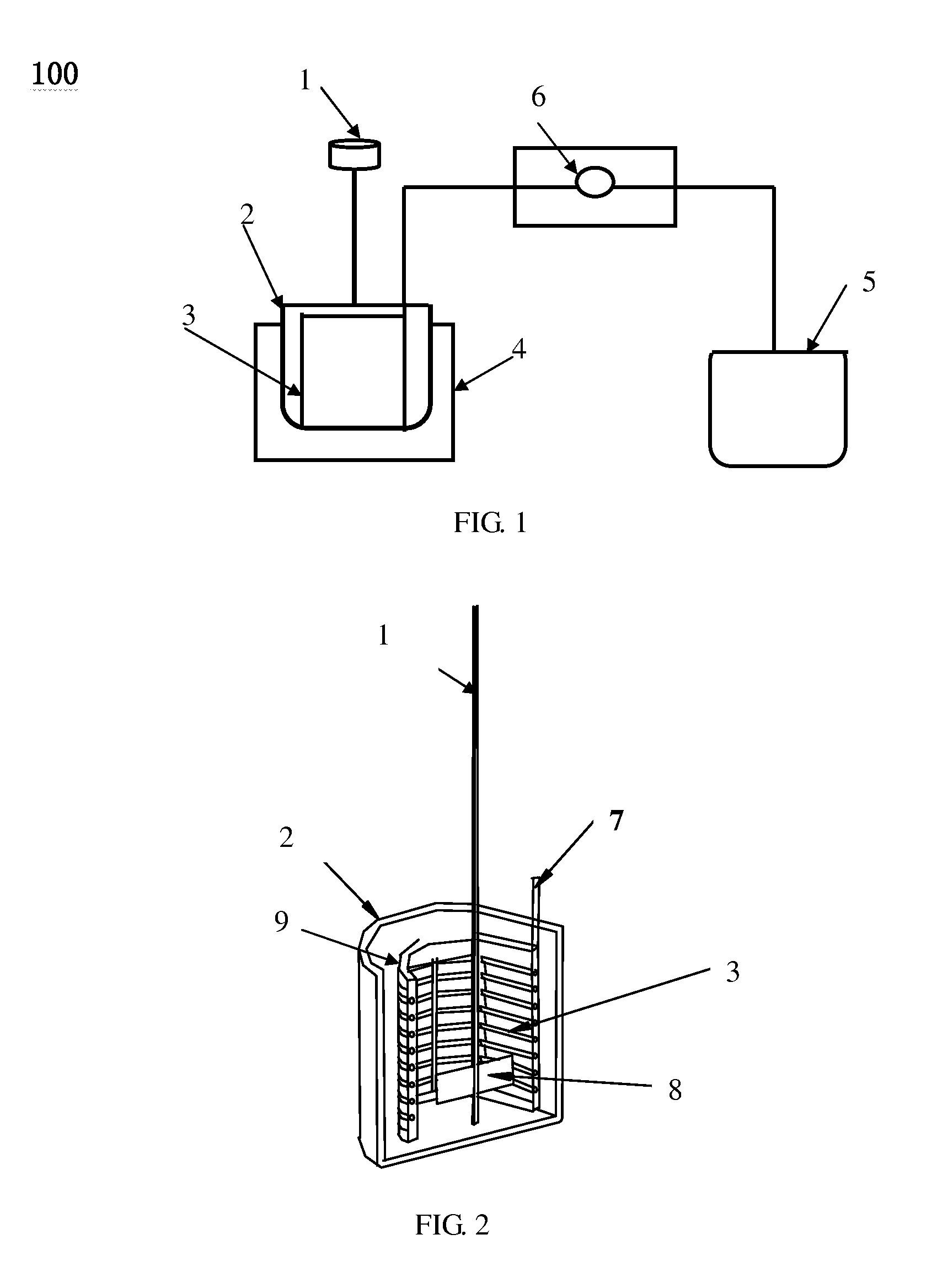

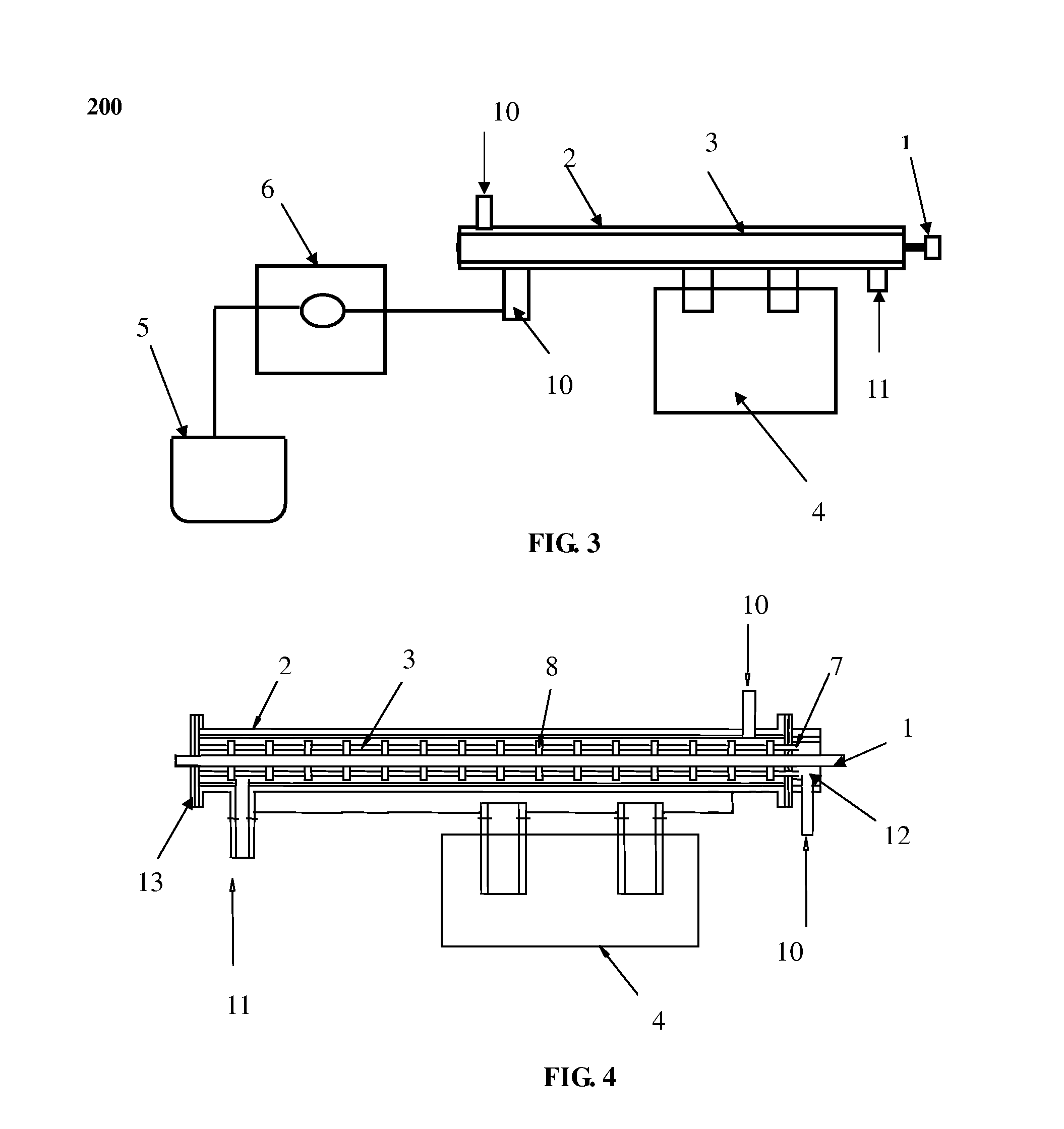

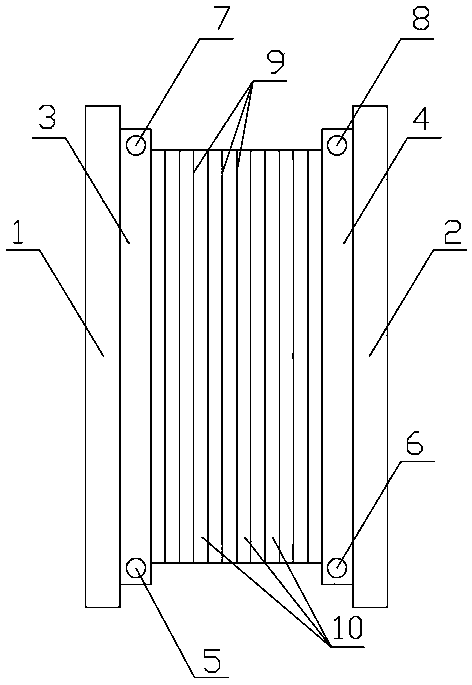

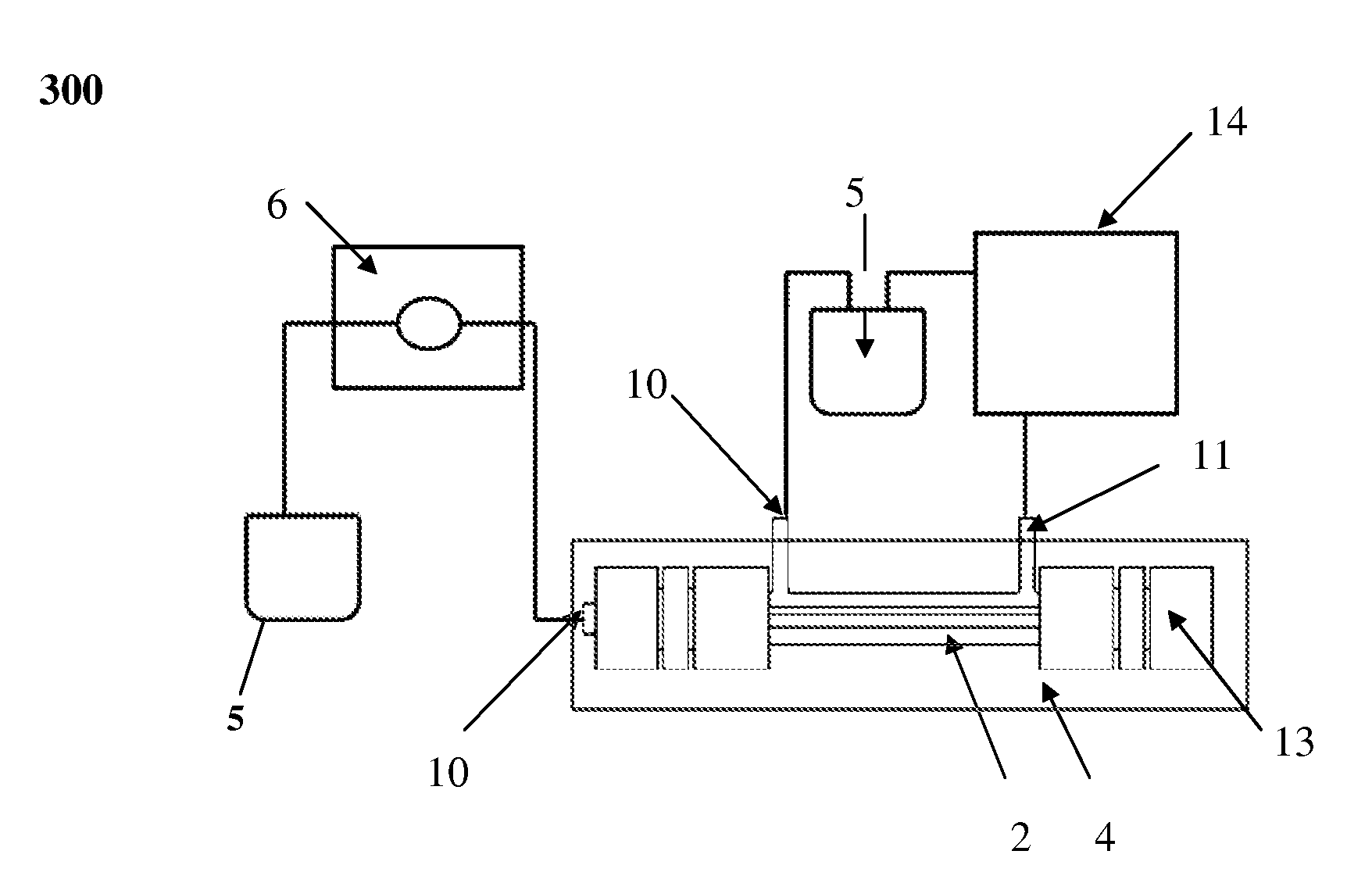

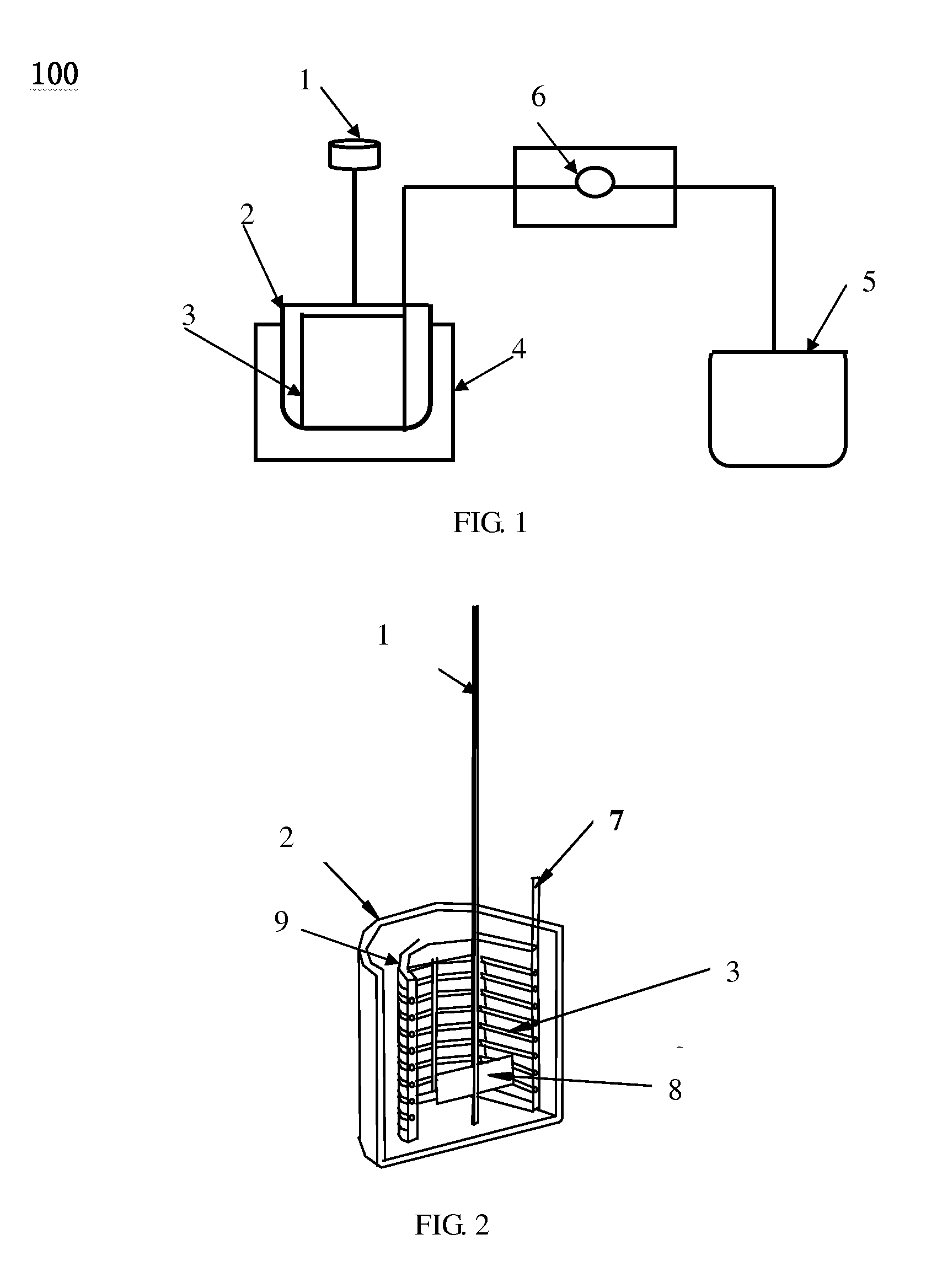

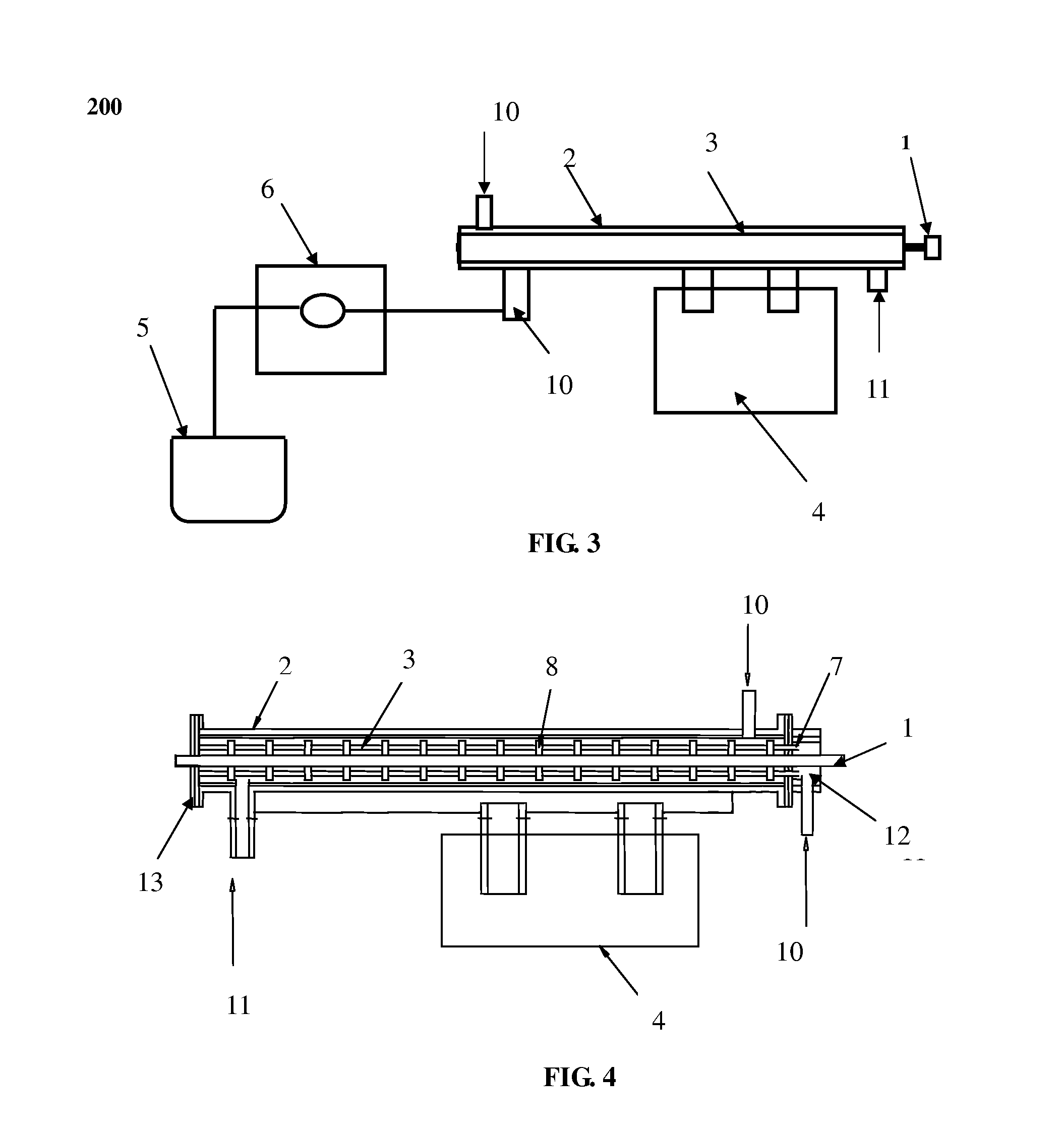

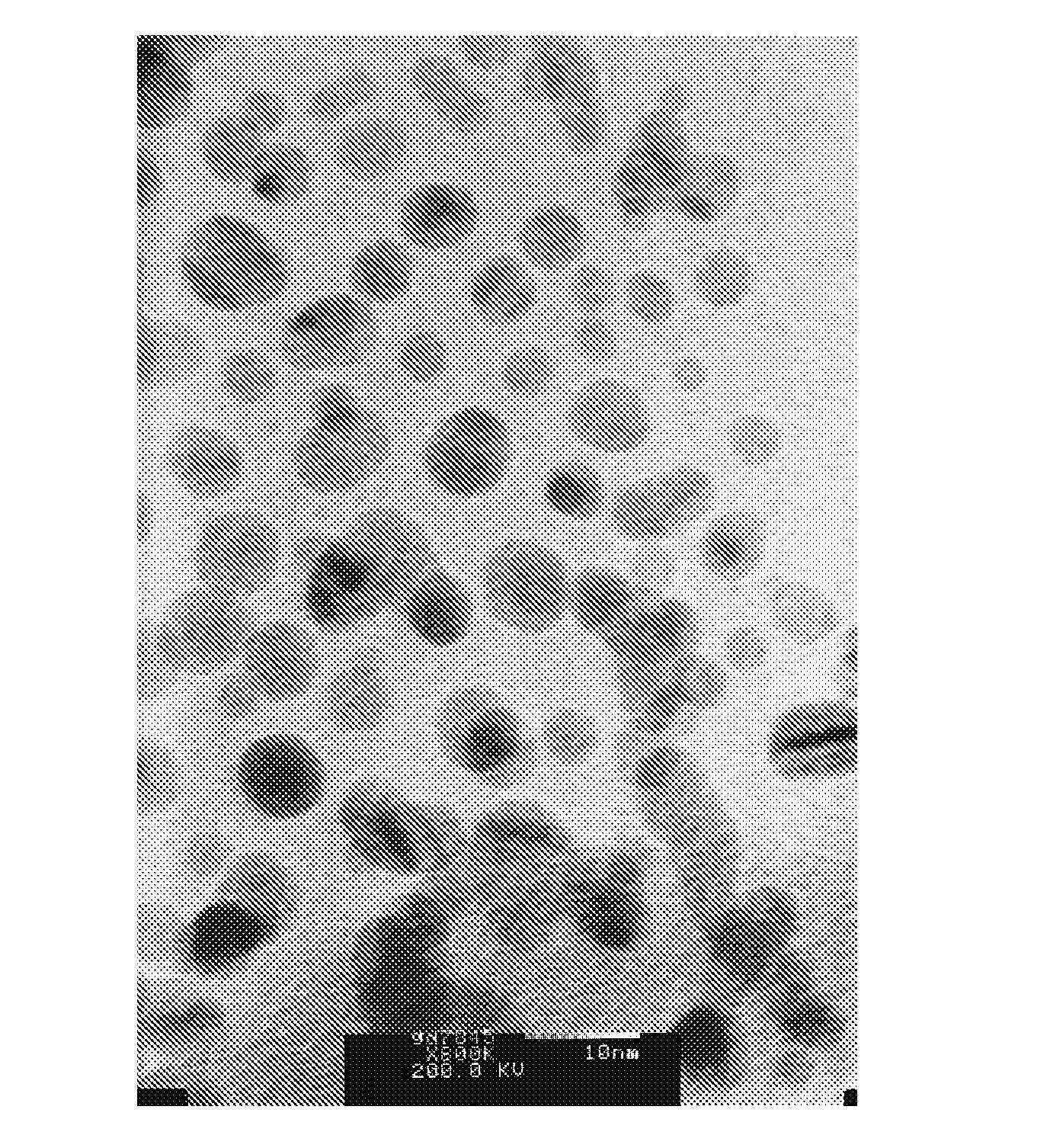

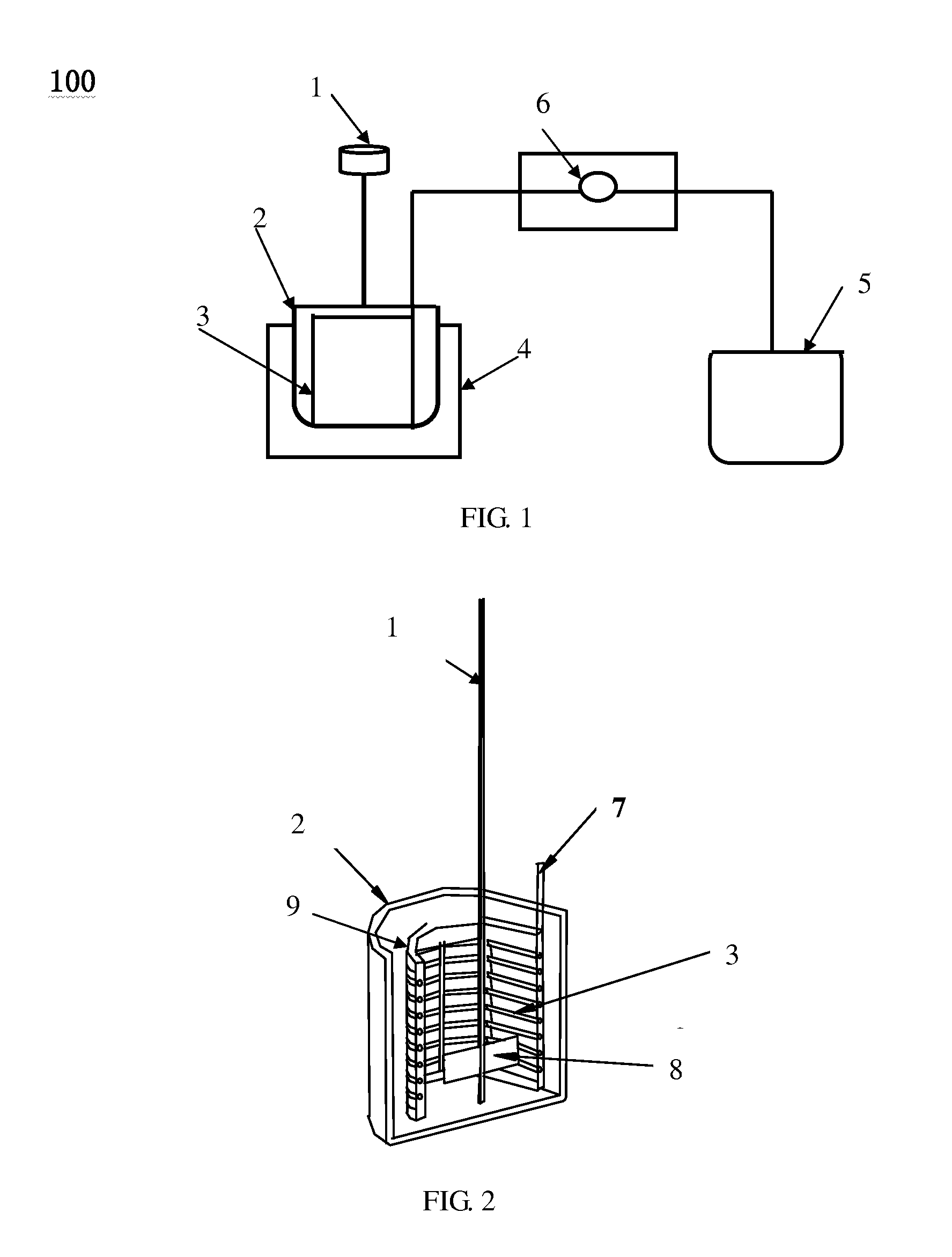

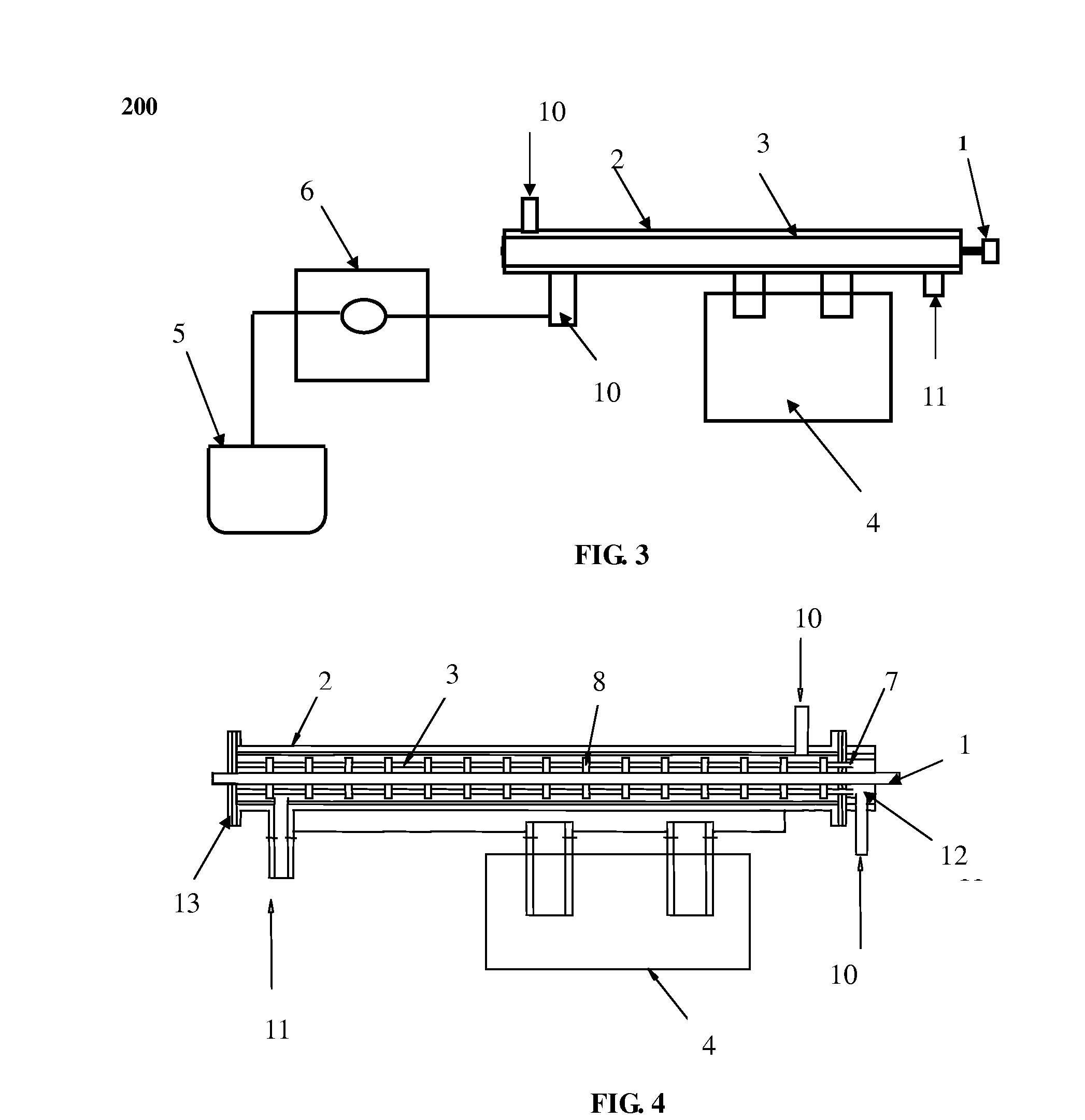

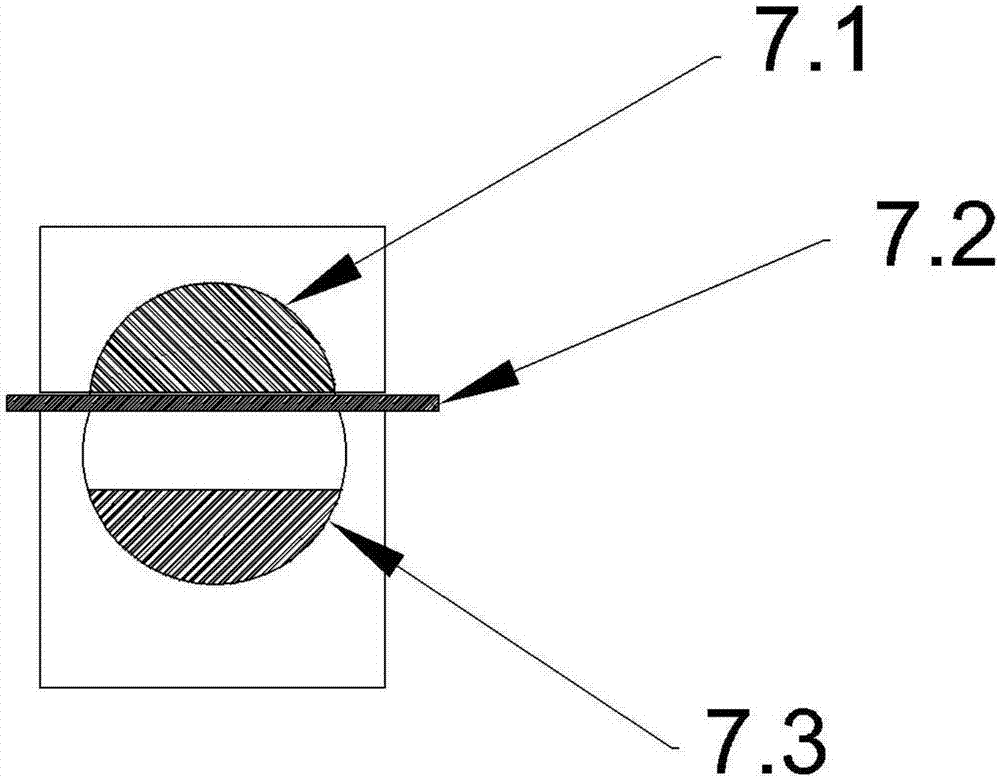

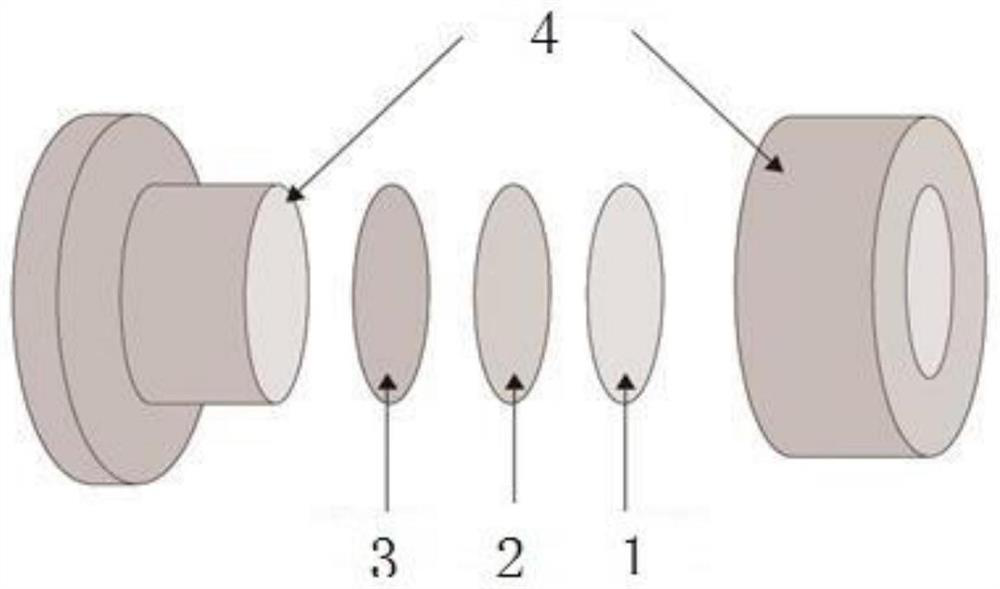

Apparatus and process for metal oxides and metal nanoparticles synthesis

InactiveUS8133441B2Increase productionMembranesSemi-permeable membranesPhysical approachCompound (substance)

The present invention provides an approach to control the generation and grow of nanocrystal with membrane diffusion method and related apparatuses to produce inorganic oxide nanopowders and metal nanoparticles. With this method, the size and size distribution of inorganic oxide nanopowders and metal nanoparticles can be tuned. It overcomes the shortcomings possessed by the common chemical and physical method of preparing nanoparticles.

Owner:BEIJING UNIV OF TECH

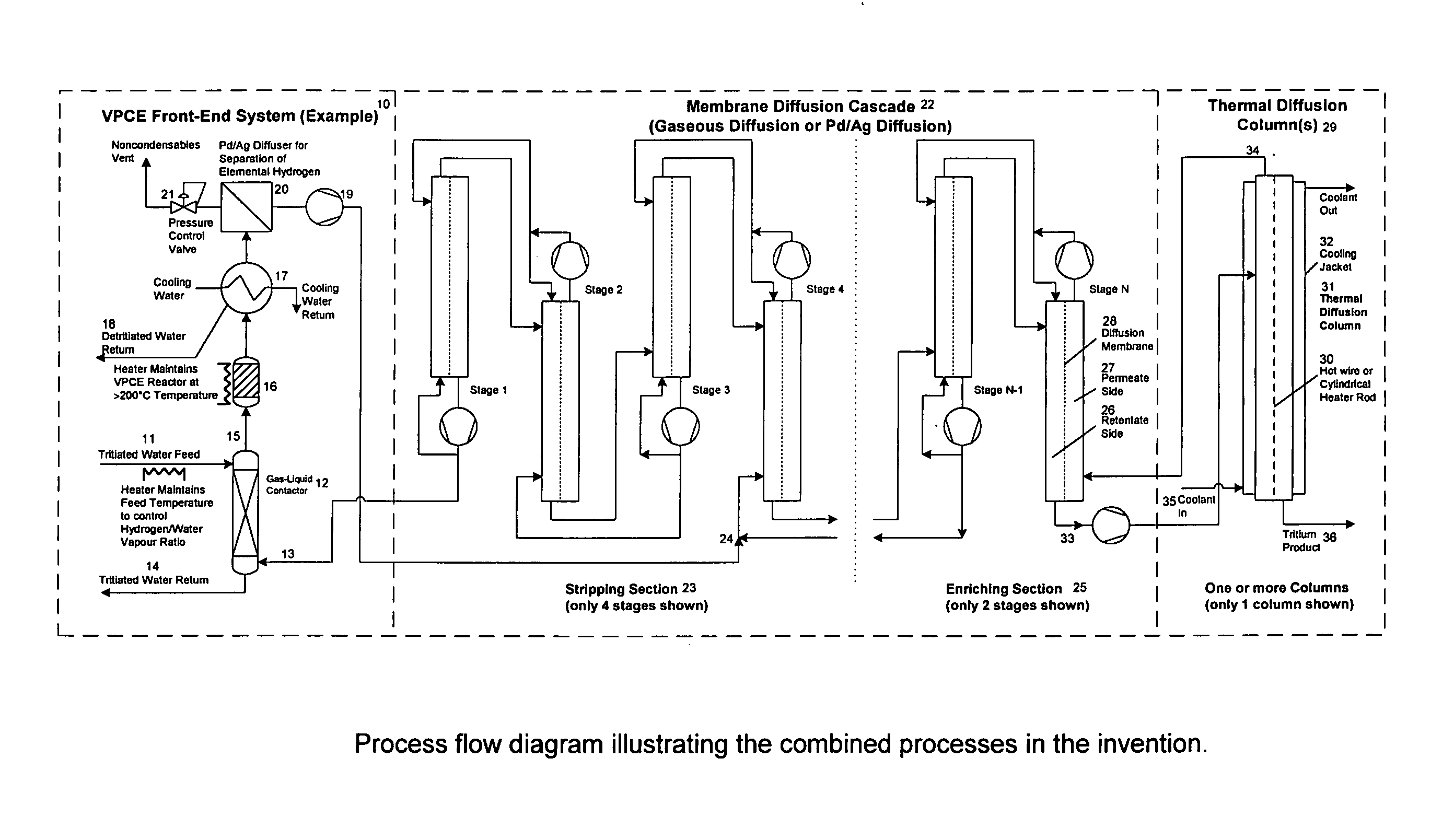

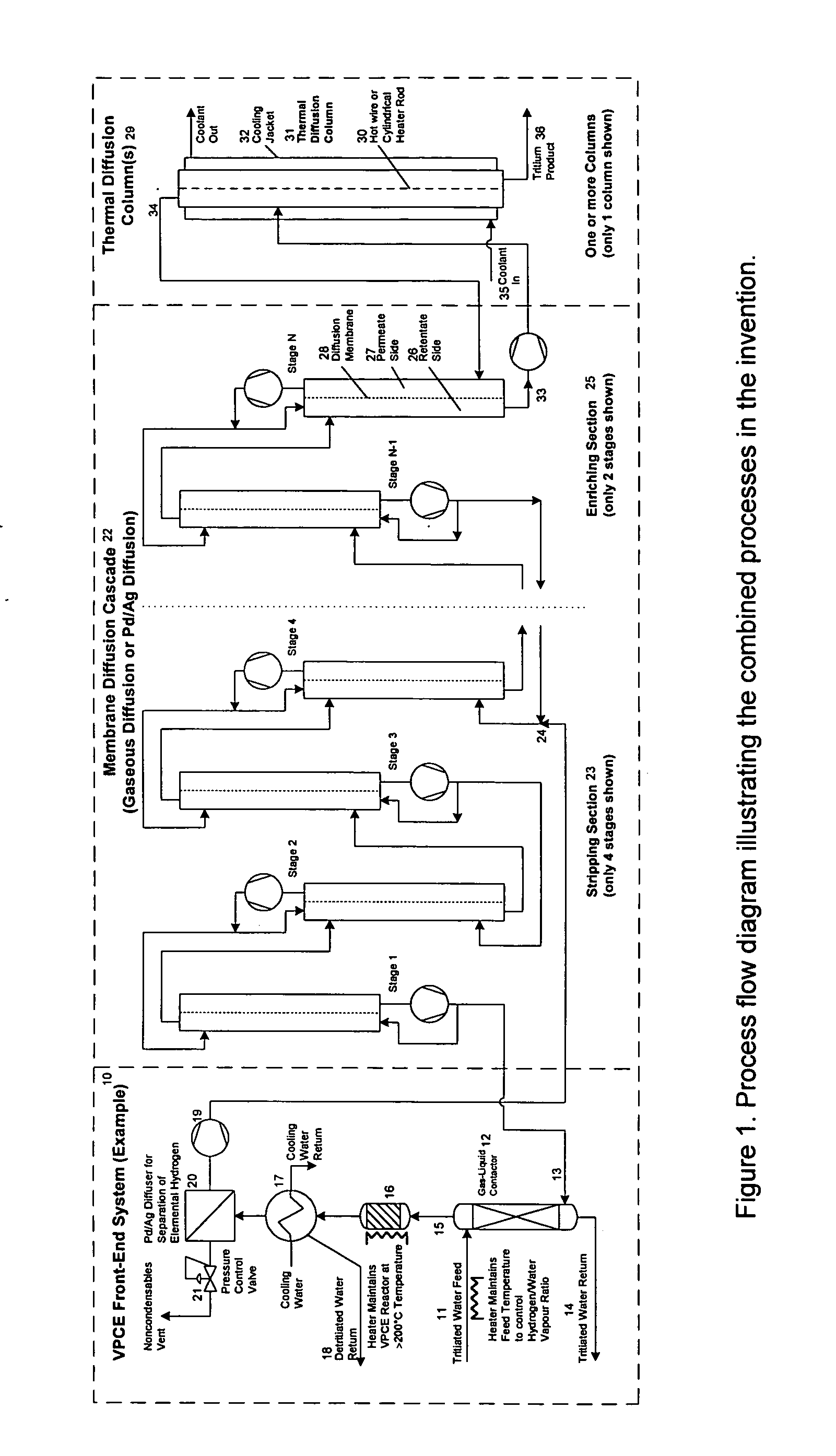

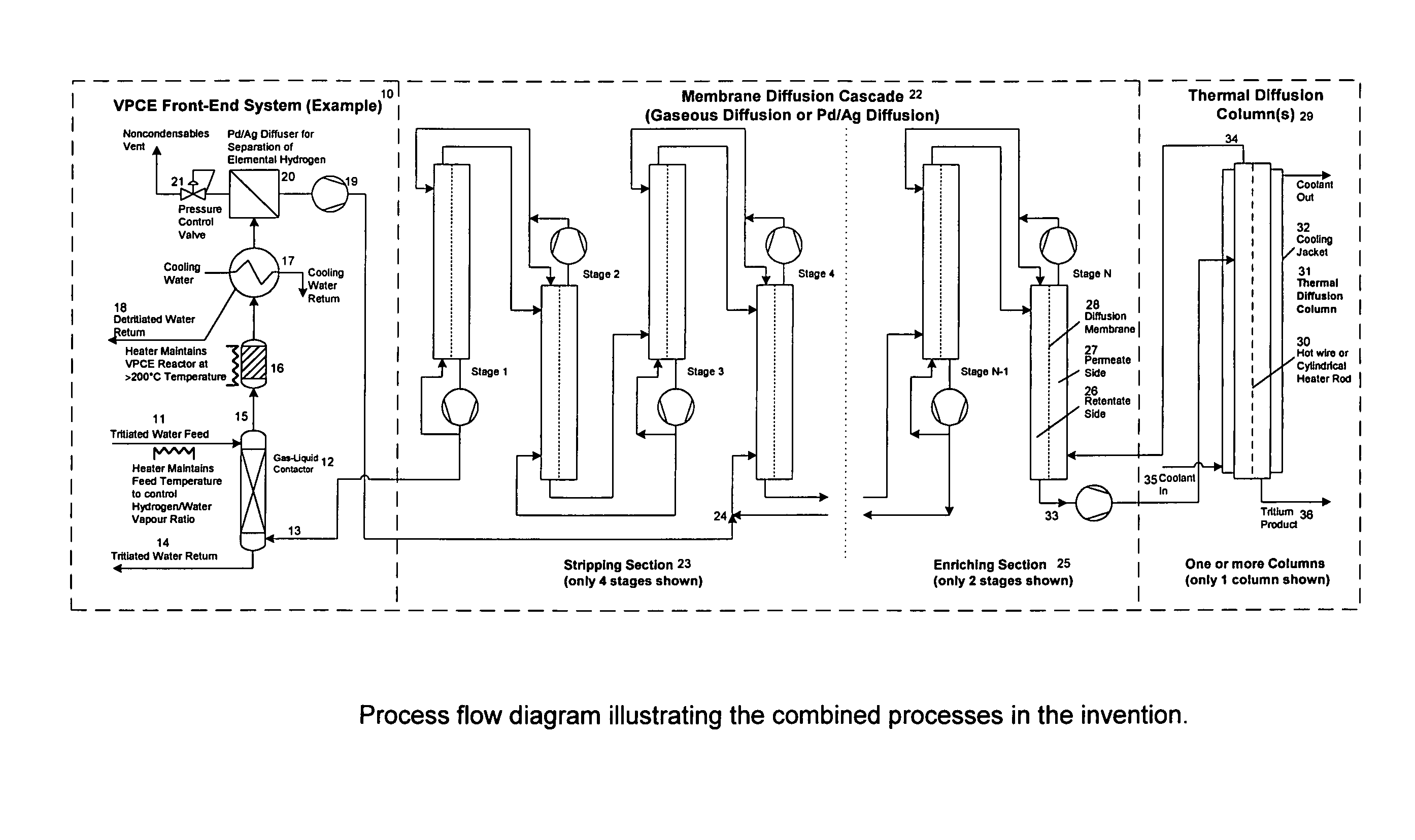

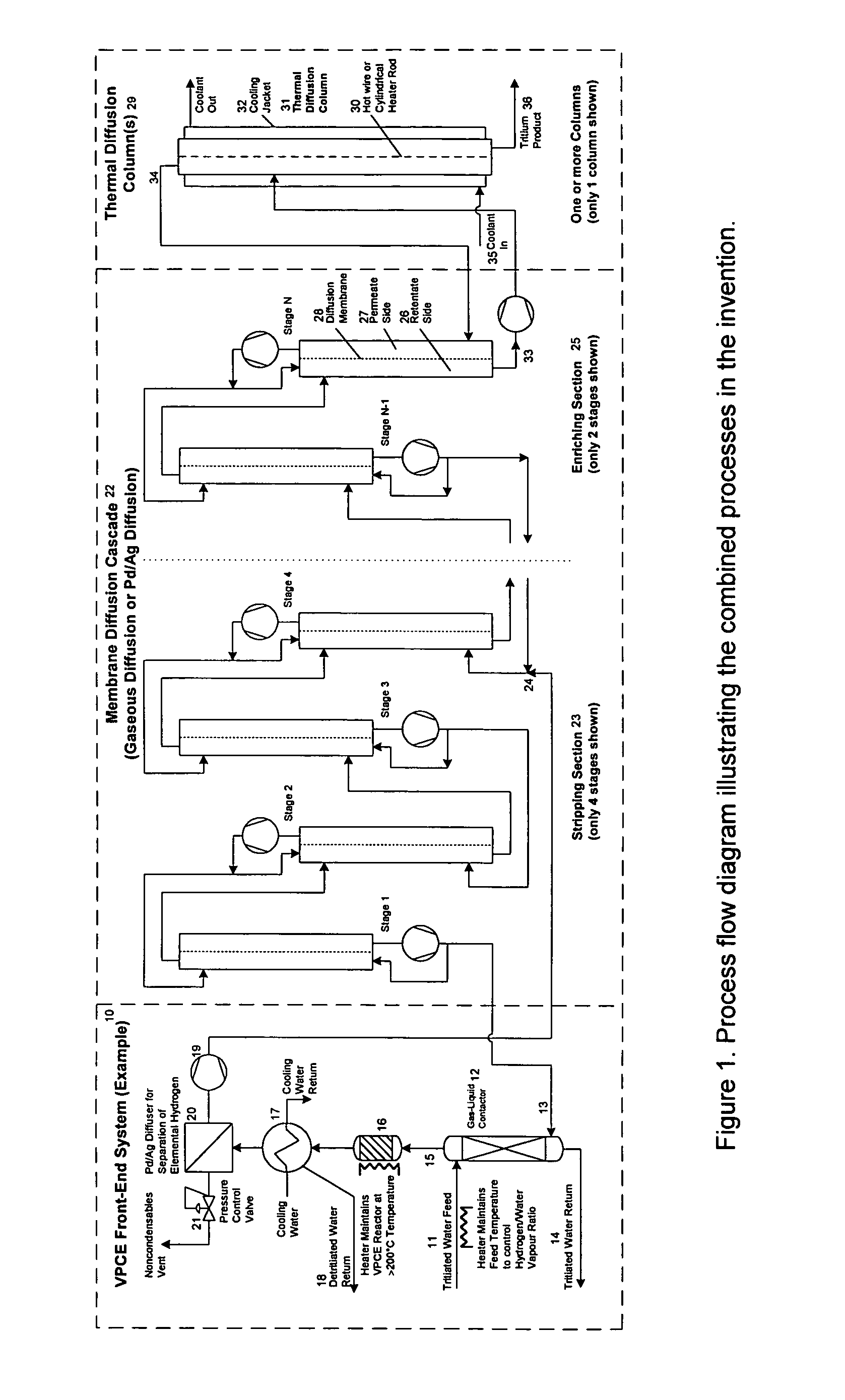

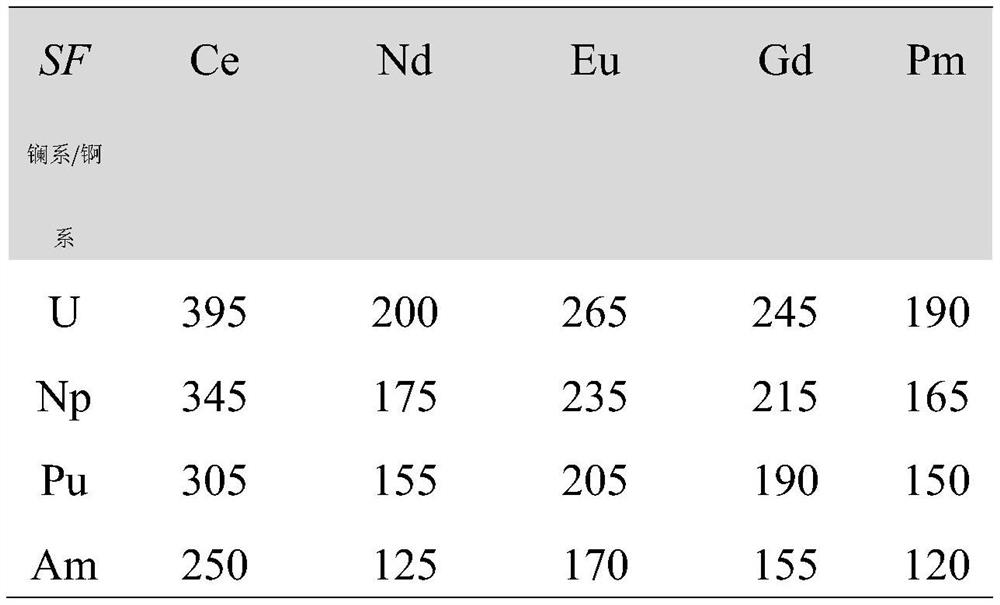

Process for tritium removal from water by transfer of tritium from water to an elemental hydrogen stream, followed by membrane diffusion tritium stripping and enrichment, and final tritium enrichment by thermal diffusion

ActiveUS20100239481A1Economical and simpleSimpler to start-up and shutdown and operateTransuranic element compoundsRadium compoundsDiffusionMembrane diffusion

A diffusion based process for tritium removal from water by tritium transfer from water to an elemental hydrogen stream, followed by a membrane diffusion cascade for tritium stripping and enrichment, and final tritium enrichment by one or more thermal diffusion columns. The combination of process steps takes advantage of membrane diffusion's large throughput capability at low tritium concentration with the simplicity of thermal diffusion for small throughput final tritium enrichment. The membrane diffusion stages use supported or unsupported microporous or hydrogen permeable metal membranes (such as Pd / Ag alloy). The diffusion process is compatible with any front-end process to transfer tritium from tritiated water to elemental hydrogen. The process may be designed and operated at low pressure, with small gas inventory, and no inherent overpressure hazard.

Owner:BWXT NUCLEAR ENERGY CANADA INC

Treatments for contaminant reduction in lactoferrin preparations and lactoferrin-containing compositions

A method of preparing an ultra-cleansed lactoferrin preparation, termed treatment for contaminant reduction (TCR) is provided which includes the steps of treating commercial lactoferrin preparation with at least one each of surfactants, antioxidants and polyphenols to form purified lactoferrin (LF-TCR) and drying the LF-TCR. Additionally a therapeutic lactoferrin composition is provided which contains LF-TCR and optionally surfactants, antioxidants, polyphenols, tissue / membrane diffusion facilitating agents and anionic compounds. The therapeutic lactoferrin composition can additionally contain bioactive agents, dietary supplements, nutraceuticals / functional foods, prophylactic agents, therapeutic agents and probiotic lactic acid bacteria.

Owner:NAIDU LP

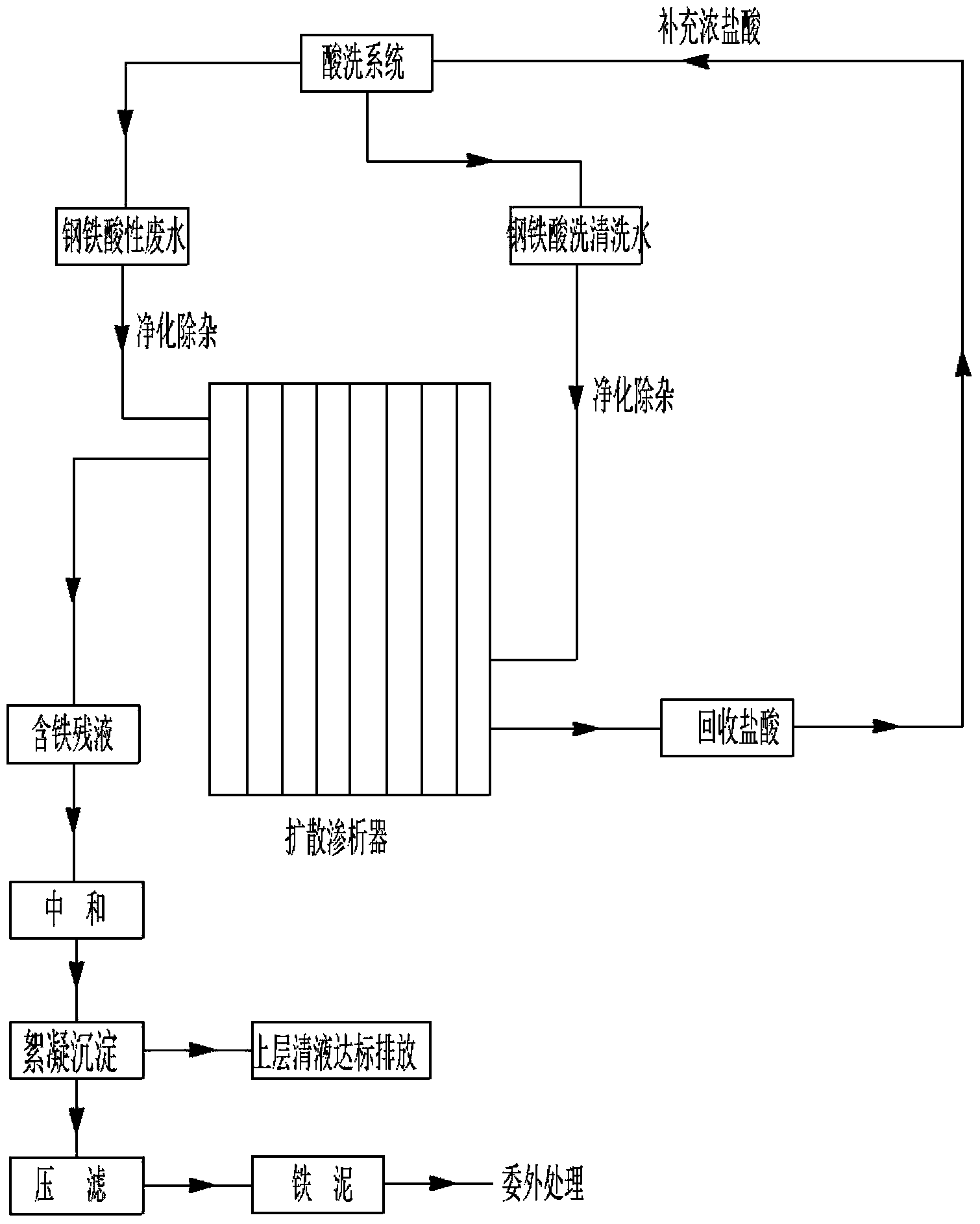

Disposal method for iron and steel pickling waste water containing hydrochloric acids

InactiveCN104291499ARealize resource reuse and recyclingEmission reductionWaste water treatment from metallurgical processWater/sewage treatment by ion-exchangeFiltrationAcid washing

The invention discloses a disposal method for iron and steel pickling waste water containing hydrochloric acids. Through the adoption of the method disclosed by the invention, not only can the hydrochloric acids be recovered for cyclic utilization, so that the optimal allocation of sources is realized, but also the problem of environmental pollution is solved, the discharge of pollutants is reduced, and the method has the advantages of low production cost, simple technology and the like. The method comprises the following steps: spent acid solutions after purification and impurity removal and pickling cleaning water flow through the internal part of an anion exchange membrane diffusion dialyzator at the same time, so that the spent acid solutions flowing out of the internal part of the anion exchange membrane diffusion dialyzator are changed into raffinate containing iron with a low content of hydrochloric acids, and the cleaning water flowing out of the internal part of the anion exchange membrane diffusion dialyzator is changed into recovered acids containing a large quantity of hydrochloric acids, an extremely small quantity of iron ions and an extremely small quantity of ferrous ions; then the recovered acids are returned to an iron and steel pickling workshop section for cyclic utilization, and are continuously used for pickling; the raffinate containing the iron is led to a waste water collecting pond for neutralizing treatment and pressure filtration treatment, and iron mud and filtrate which reaches a discharge standard are obtained.

Owner:昆山市千灯三废净化有限公司

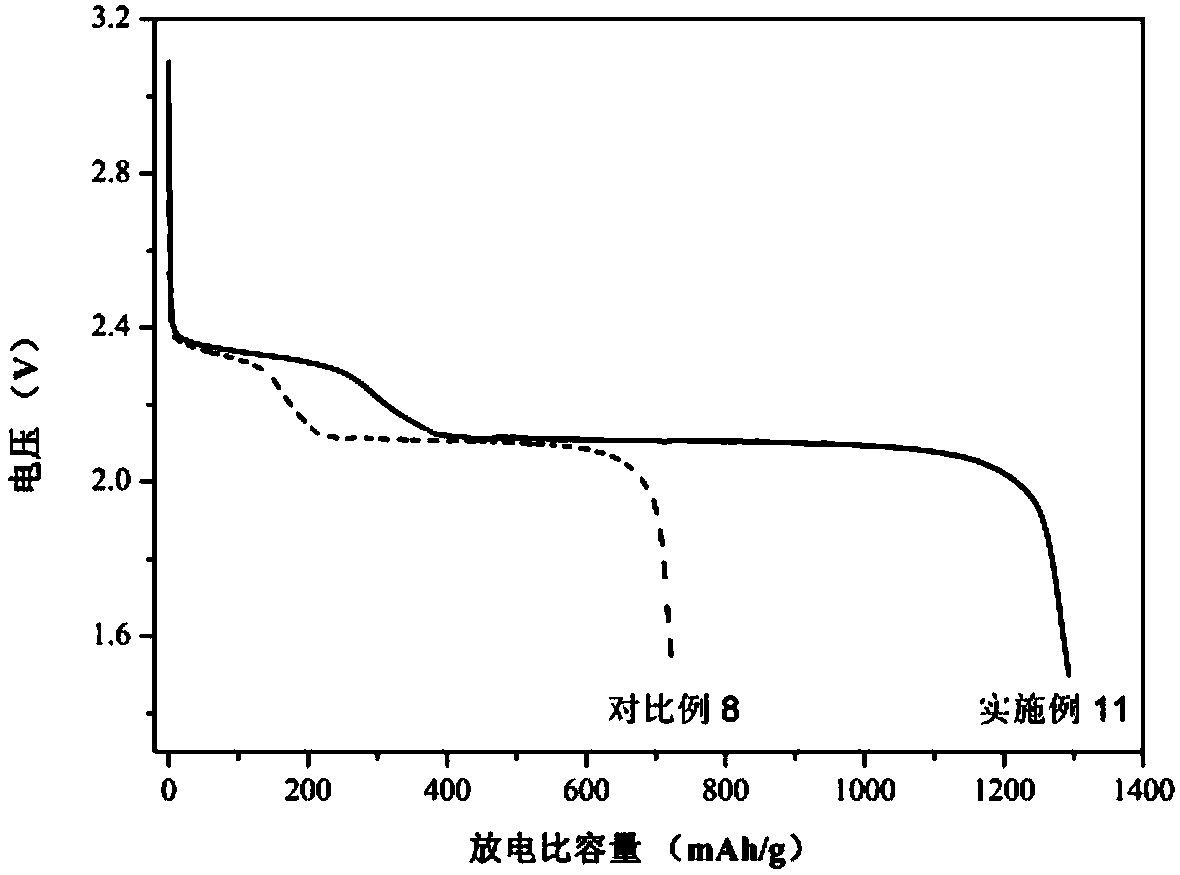

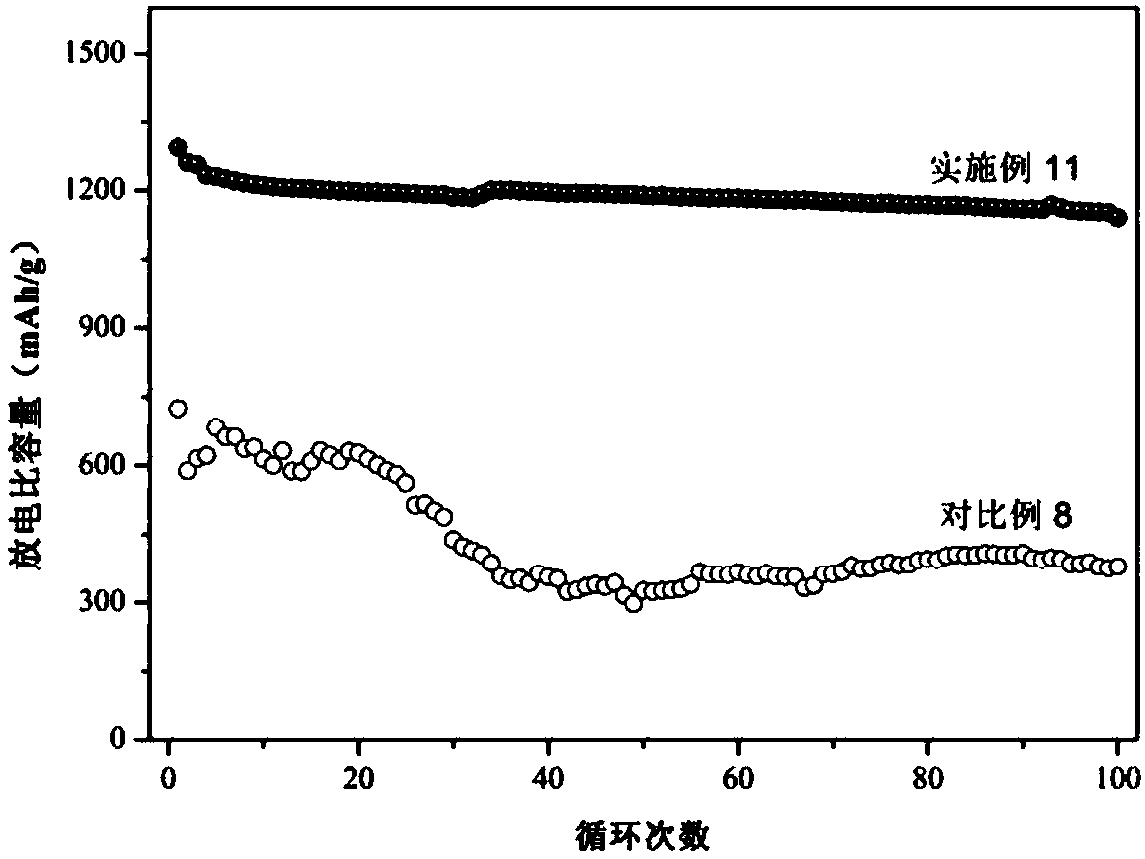

Lithium-sulfur battery diaphragm and preparation method thereof as well as lithium-sulfur battery and preparation method thereof

ActiveCN108565386AImprove cycle performanceInhibition of the "shuttle effect"Final product manufactureCarbon preparation/purificationLithium–sulfur batteryConductive coating

The invention provides a lithium-sulfur battery diaphragm and a preparation method thereof as well as a lithium-sulfur battery and a preparation method thereof and relates to the technical field of diaphragms. The lithium-sulfur battery diaphragm comprises a support membrane, and the support membrane is compounded with a nitrogen-doped carbon adsorption-conductive coating. The preparation method of the lithium-sulfur battery diaphragm comprises the following steps: coating the support membrane with the nitrogen-doped carbon adsorption-conductive coating, and drying the nitrogen-doped carbon adsorption-conductive coating to obtain the lithium-sulfur battery diaphragm. The lithium-sulfur battery diaphragm relieves the technical problems that a traditional diaphragm basically has no blockingeffect on multiple sulfur ions and can not block polysulfide dissolution and shuttling phenomena; and by compounding the nitrogen-doped carbon adsorption-conductive coating on the support membrane, the polysulfide can be adsorbed to the diaphragm to perform high-conductivity conversion, thereby inhibiting the shuttling effect of polysulfide, reducing the interface reaction resistance, effectivelyrecovering the dissolved sulfur at the interface between the anode and the diaphragm, increasing the utilization ratio of active substances of the anode, and limiting trans-membrane diffusion of polysulfide so as to enhance the cycle performance of the lithium-sulfur battery.

Owner:GREAT POWER BATTRY ZHUHAI

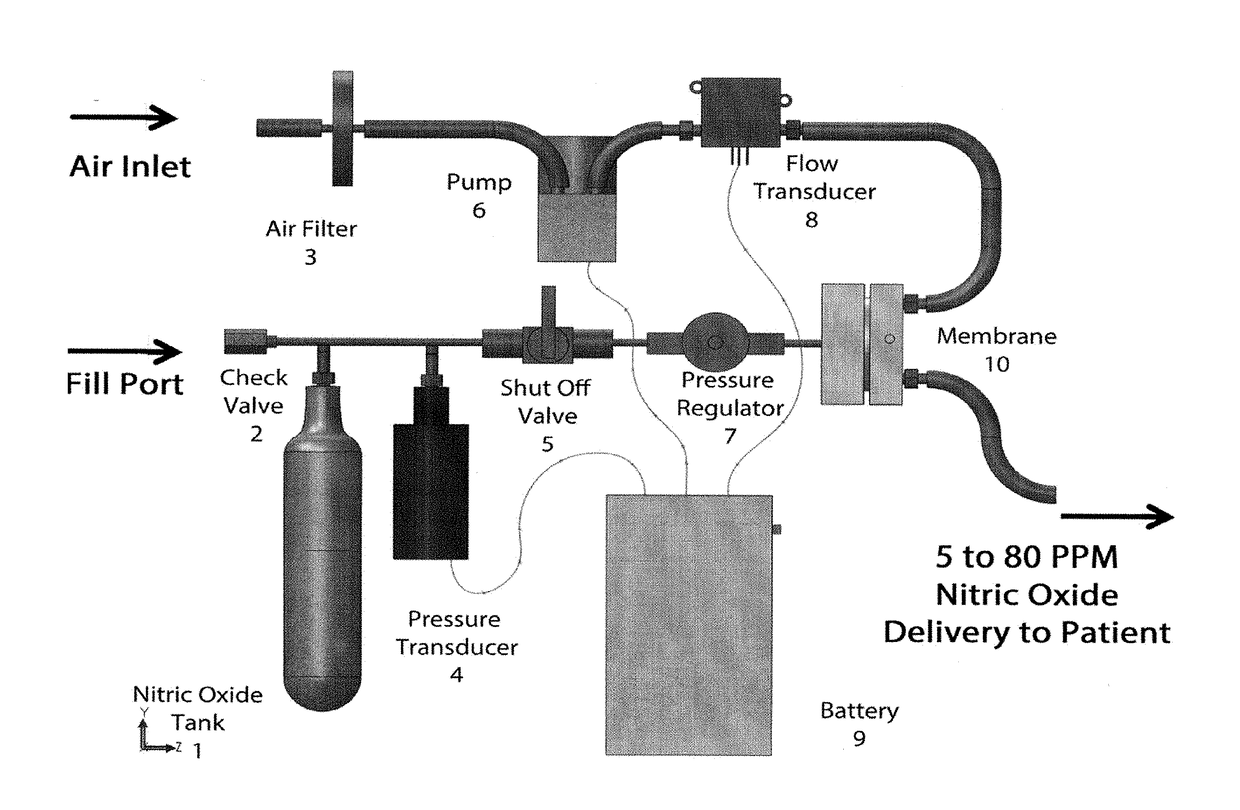

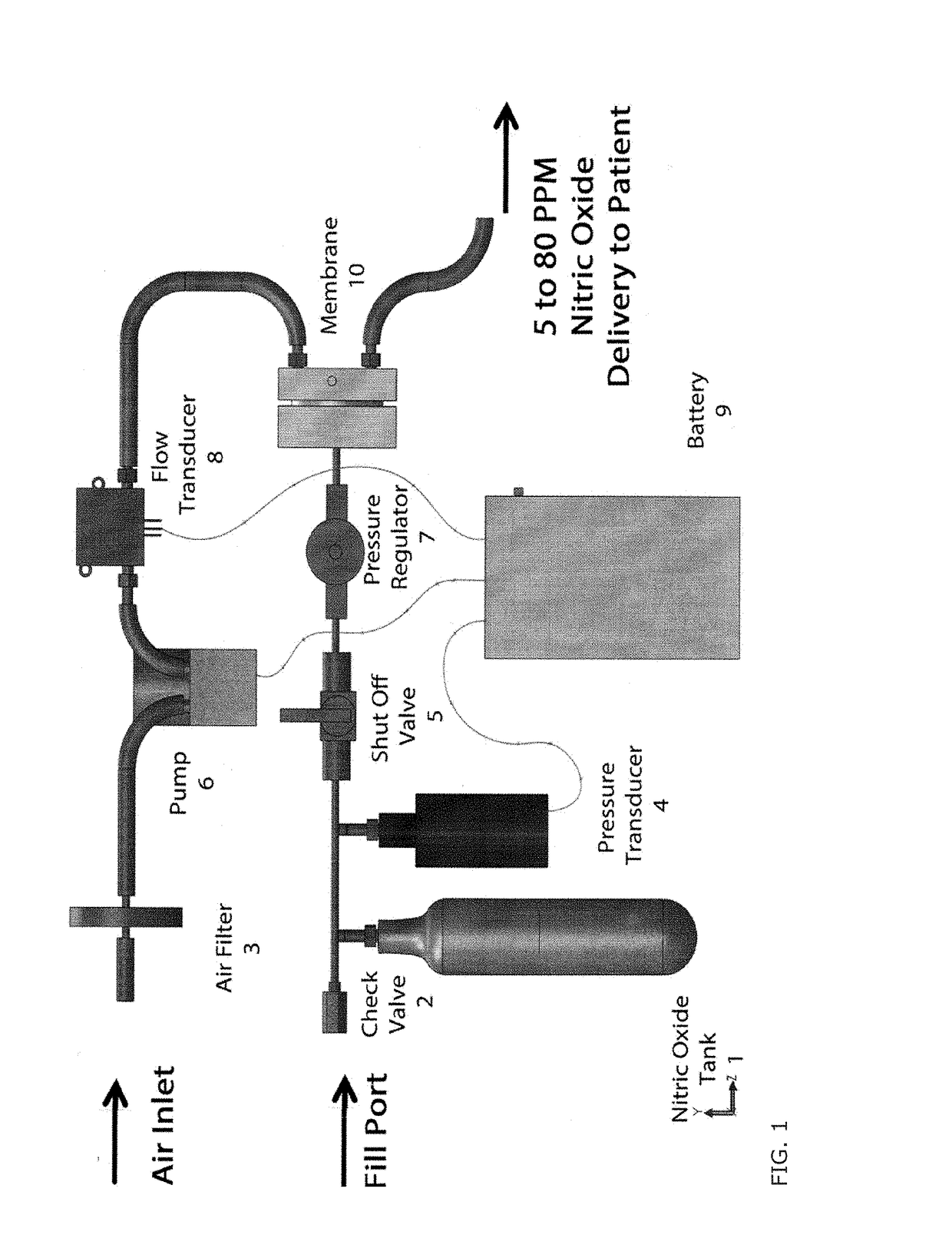

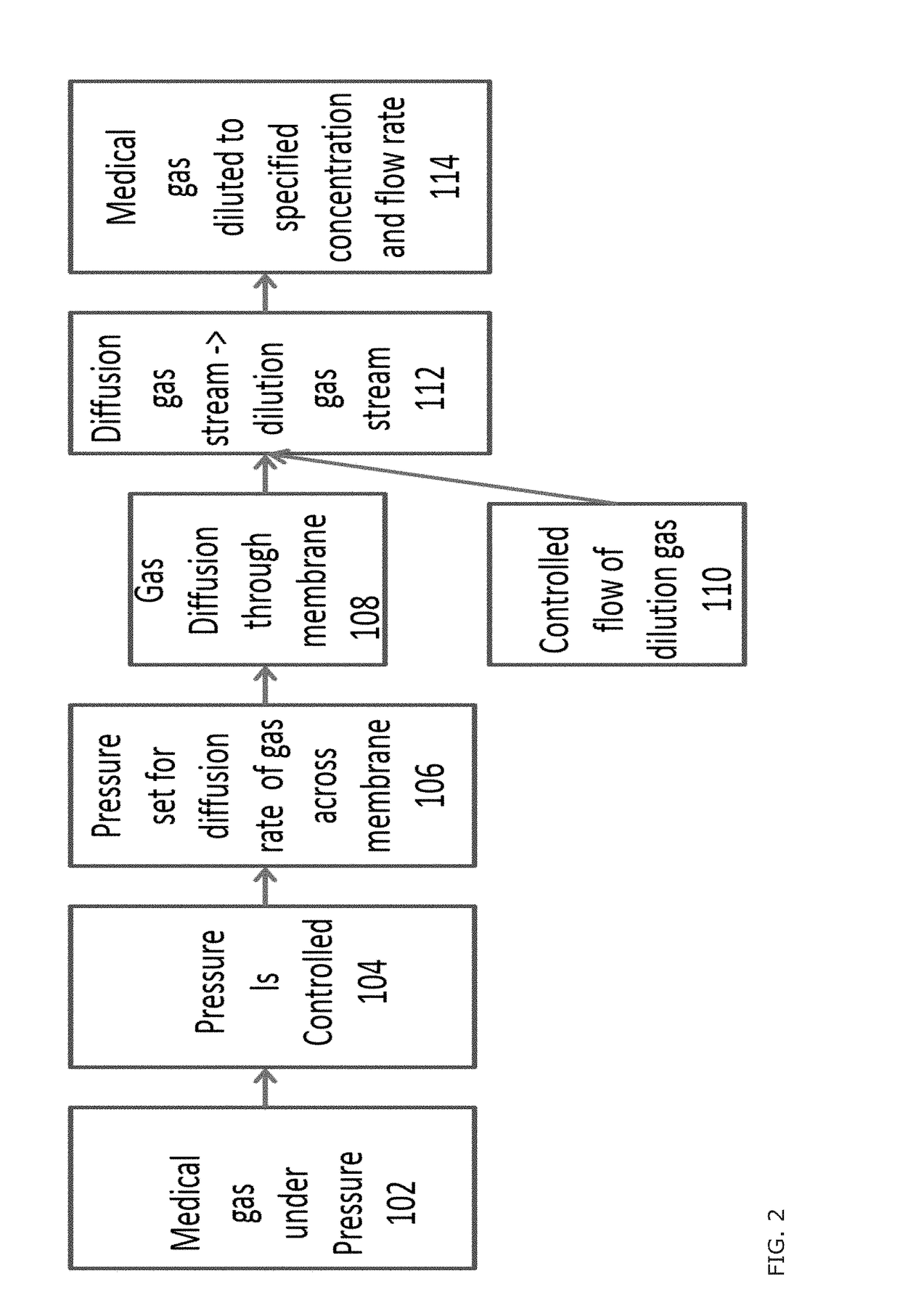

Controlled delivery of medical gases using diffusion membranes

A delivery system utilizing a diffusion membrane that regulates the concentration of medical gases that are administered to a patient. A storage vessel contains a neat or pure medical gas under pressure that is in fluid communication with a diffusion membrane. The medical gas is then dispensed at a specified rate by diffusion across a membrane into a carrier gas. The concentration is kept constant by regulating the pressure and carrier gas flow. Typical applications are for inhaled gases that are used in patient treatment and care.

Owner:NU MED PLUS

Process for tritium removal from water by transfer of tritium from water to an elemental hydrogen stream, followed by membrane diffusion tritium stripping and enrichment, and final tritium enrichment by thermal diffusion

ActiveUS7815890B2Economical and simpleSimpler to start-up and shutdown and operateIsotope separationHydrogen isotopesDiffusionMembrane diffusion

A diffusion based process for tritium removal from water by tritium transfer from water to an elemental hydrogen stream, followed by a membrane diffusion cascade for tritium stripping and enrichment, and final tritium enrichment by one or more thermal diffusion columns. The combination of process steps takes advantage of membrane diffusion's large throughput capability at low tritium concentration with the simplicity of thermal diffusion for small throughput final tritium enrichment. The membrane diffusion stages use supported or unsupported microporous or hydrogen permeable metal membranes (such as Pd / Ag alloy). The diffusion process is compatible with any front-end process to transfer tritium from tritiated water to elemental hydrogen. The process may be designed and operated at low pressure, with small gas inventory, and no inherent overpressure hazard.

Owner:BWXT NUCLEAR ENERGY CANADA INC

In-situ sampling method of phosphorus in soil

The invention discloses an in-situ sampling method of phosphorus in soil. The method comprises the following steps of: drilling a sampling hole in a land parcel by using a sampling device; inserting a casing pipe; pulling the casing pipe out during sampling; inserting a dialysis bag into the sampling hole; adding deionized water; extracting remaining water from the dialysis bag 24-36 hours later;taking the dialysis bag out; putting the sampling device into the sampling hole; putting a sampling assisting device into the sampling device; injecting water into the sampling assisting device; making the sampling device contact with a soil section; taking the sampling device out 36-48 hours later; and detecting to make sure that the content of phosphorus in soil is between 0.001 mg / L and 1 mg / L. In the process of the method, a flexible support is formed by using a membrane diffusion gradient technical device and a water sac, so that the method is suitable for field sampling and device adaptability is wider; a pretreating device is adopted, so that the method is suitable for droughty soil environment and sampling is simplified; meanwhile, the influence of a large amount of irrigation on leaching can be avoided; and iron and aluminum oxides are taken as a precipitated phase, so that higher adaptability is achieved compared with a single iron oxide and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

Method for recycling nitric acid and copper from waste water generated in production of printed circuit board

InactiveCN103265094AAvoid corrosionIncreased concentration of nitric acidPhotography auxillary processesWater/sewage treatment by ion-exchangeWastewaterWater flow

The invention discloses a method for recycling nitric acid and copper from waste water generated in production of a printed circuit board. The method comprises the following steps that: (1) waste water generated in production of the printed circuit board and water flow through an inner cavity of an anion-exchange membrane diffusion dialysis apparatus at the same time, the flow speed of the waste water and the water is controlled, so that the waste water flowing out of the anion-exchange membrane diffusion dialysis apparatus is turned into raffinate with 0.05-0.2mol / L of nitric acid, the water flowing out of the anion-exchange membrane diffusion dialysis apparatus is turned into recycled liquid with a large quantity of nitric acid and little copper ions, and the recycled liquid returns back to a step of copper peeling in the production of the printed circuit board to be recycled; and (2) the raffinate is guided into an electrolytic cell for electrolysis, so that the copper in waste water is recycled. According to the method, the nitric acid is recycled, and the electrolysis recovery efficiency of copper is improved; and the discharged waste water contaminating the environment is reduced, the resource is recycled and the energy consumption is also lowered.

Owner:SHANDONG TIANWEI MEMBRANE TECH

Alkali recovery process for paper-making black liquid

InactiveCN103074796AReduce pollutionReduce energy consumptionRegeneration of alkali lyeMembrane diffusionEnergy consumption

The invention discloses an alkali recovery process for paper-making black liquid. The alkali recovery process for the paper-making black liquid comprises the following steps: filtering the paper-making black liquid to remove solid impurities; allowing the paper-making black liquid and water to flow through an inner cavity of a cation exchange membrane diffusion dialyzer; and controlling the flow rate of the paper-making black liquid and the water, so that the NaOH content of the paper-making liquid flowing out of the cation exchange membrane diffusion dialyzer is 25 to 35 g / L. The process is low in energy consumption, high in efficiency and low in environmental pollution, and can bring the benefits of saving resources and reducing the production cost.

Owner:SHANDONG TIANWEI MEMBRANE TECH

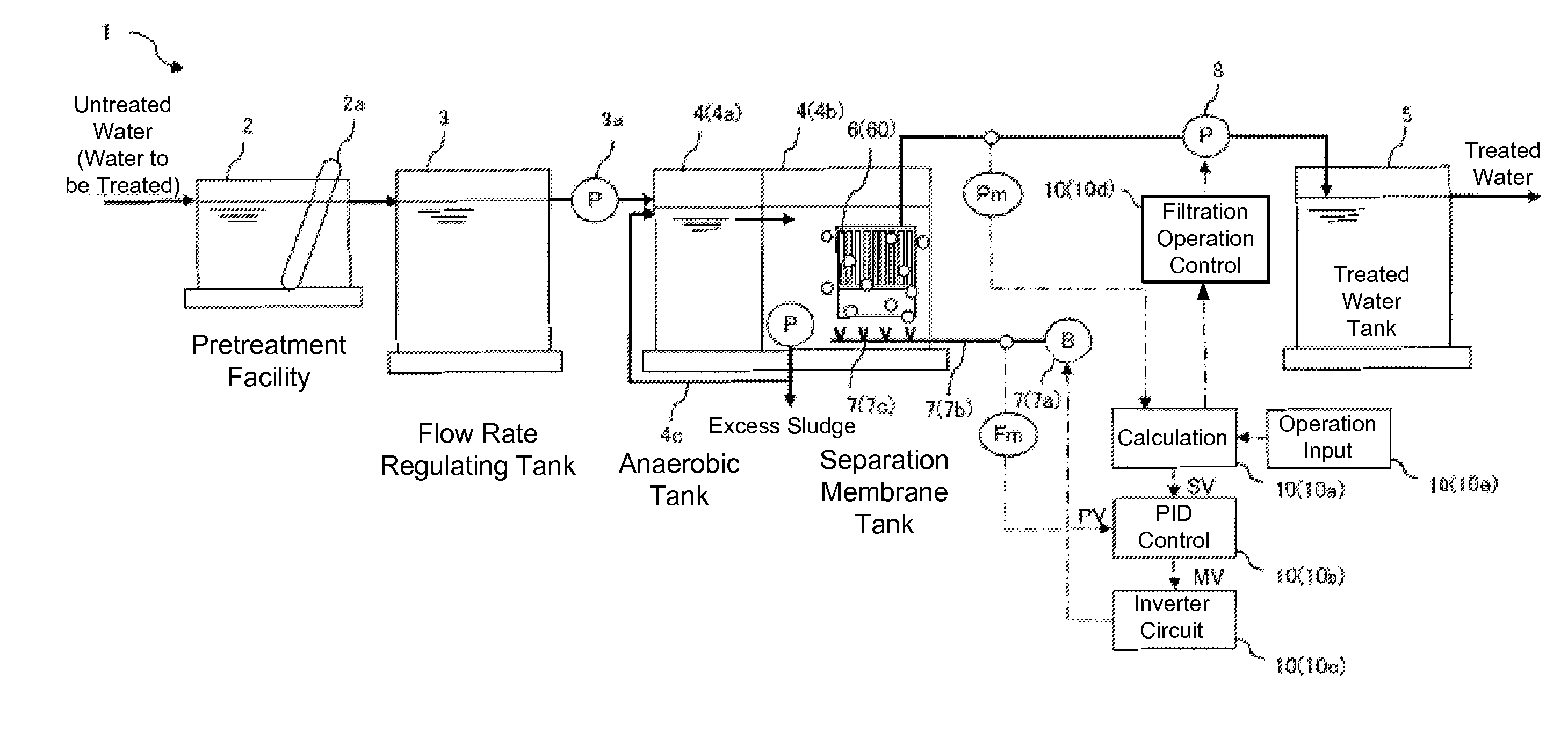

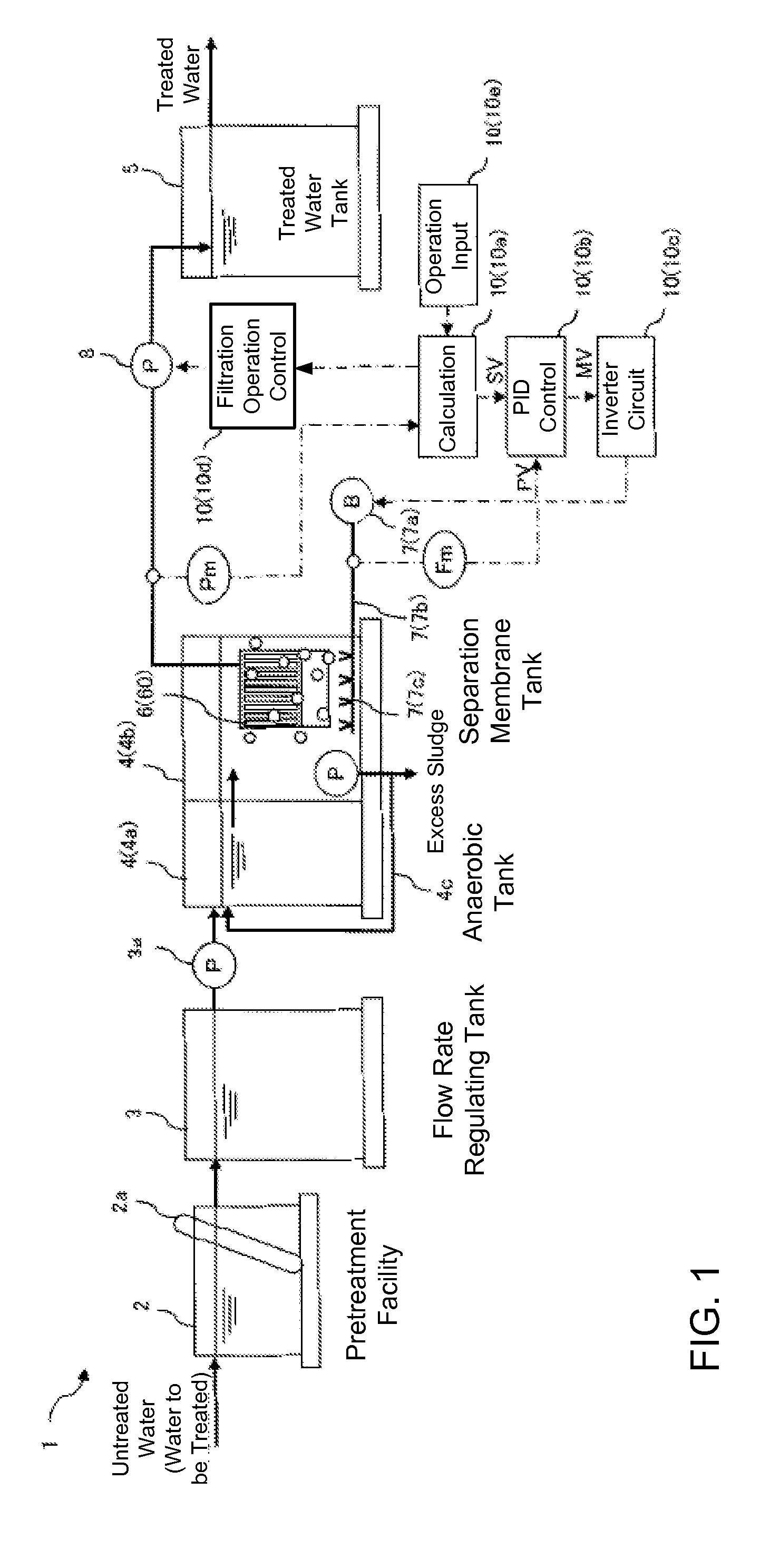

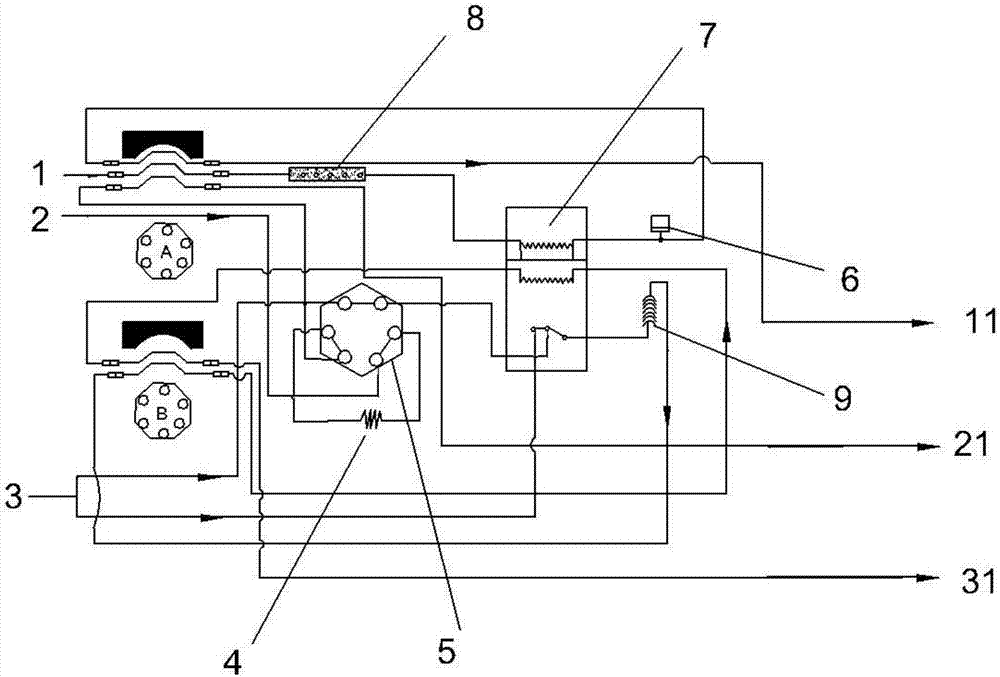

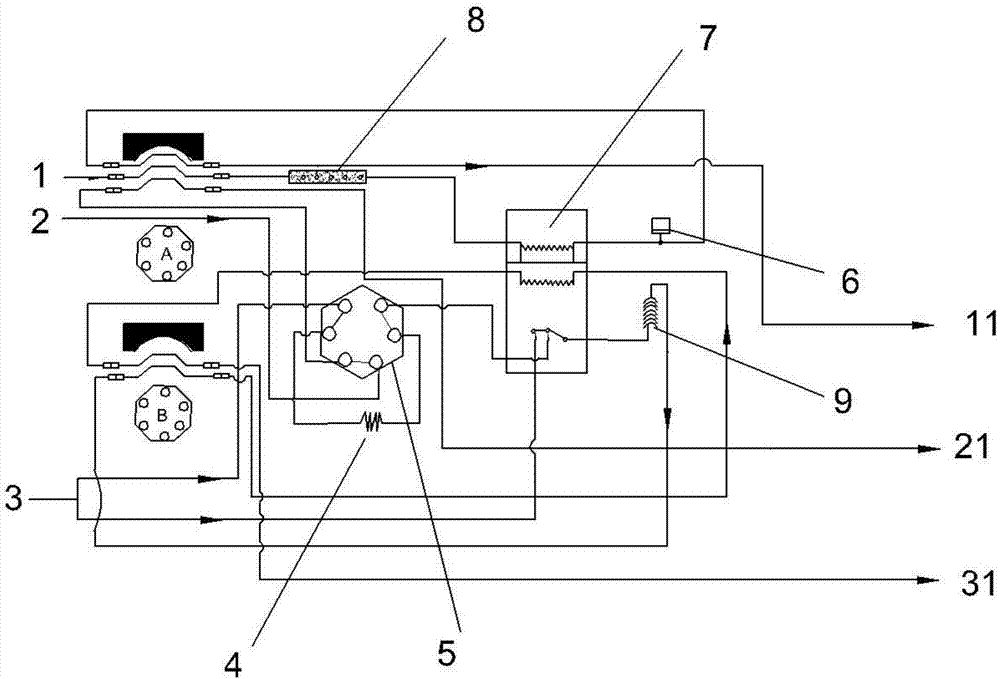

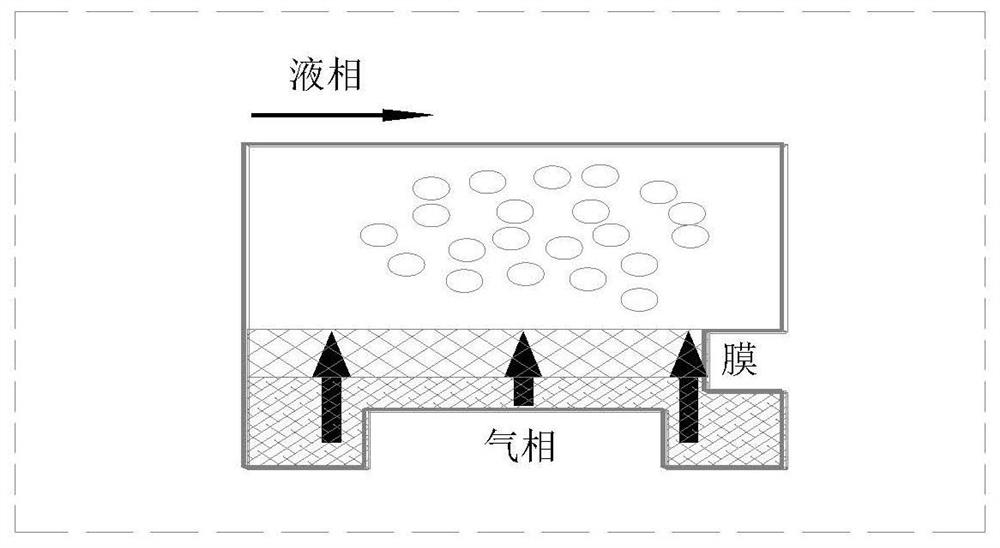

Operating method for membrane separation device and membrane separation device

ActiveUS20150021266A1Increases target valueReducing value of targetBiological treatment regulationBiological treatment apparatusChemical physicsMembrane diffusion

A membrane separation device includes a separation membrane immersed in water to be treated and an air diffusion device positioned below the separation membrane, and provides treated water that has permeated through the separation membrane while diffusing air from the air diffusion device towards the separation membrane. A target value setting step sets a target value of an amount of diffusion air diffused from the air diffusion device based on a transmembrane pressure difference, and the air diffusion device is controlled such that the amount of the diffusion air becomes the target value. In the target value setting step, an absolute value of a change or a rate of change in the target value for increasing the amount of the air diffusion is set greater than an absolute value of a change or a rate of change in the target value for decreasing the amount of the air diffusion.

Owner:KUBOTA LTD

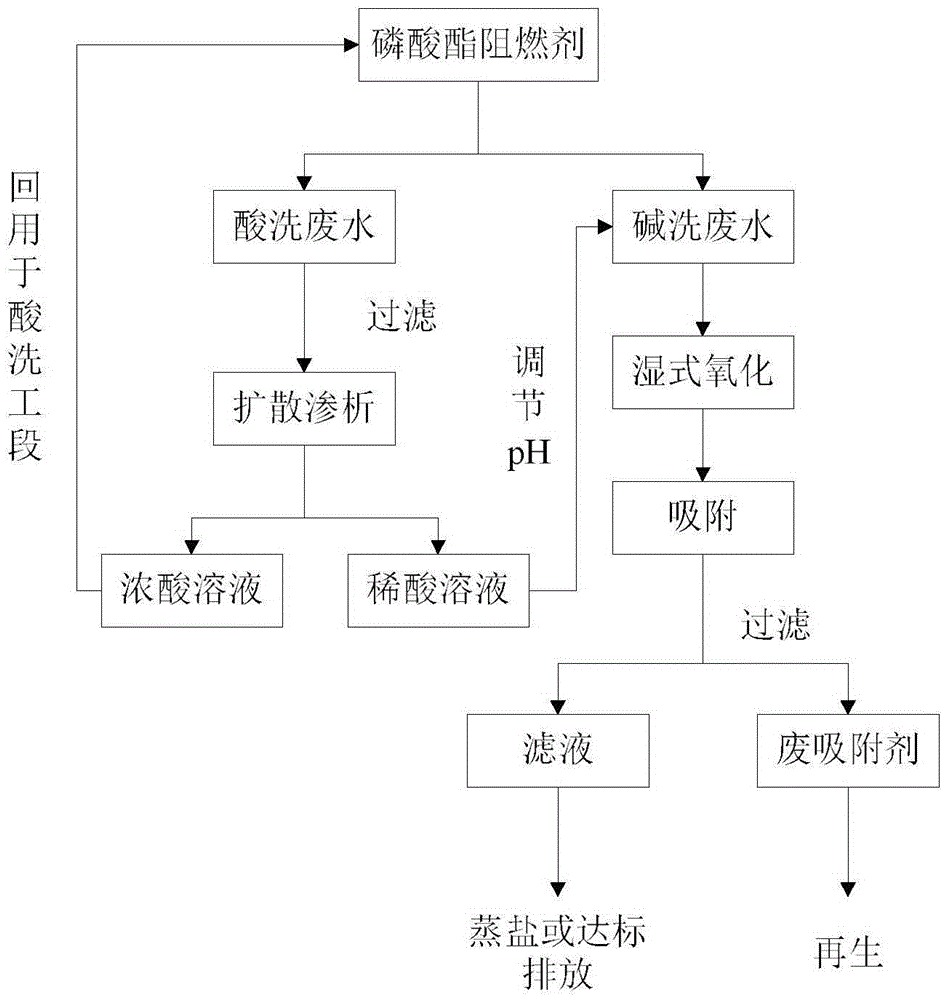

Recycling treatment method for phosphate ester fire retardant waste water

ActiveCN105540915AThe process is simple and easy to understandEasy to understand and operateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSorbentPhosphate

The invention provides a recycling treatment method for phosphate ester fire retardant waste water. The phosphate ester fire retardant waste water comprises pickling waste water and alkaline waste water. The recycling treatment method is characterized by comprising the following steps: 1, diffusion dialysis: a step of subjecting the pickling waste water having undergone filtering to anion-exchange membrane diffusion dialysis so as to obtain a concentrated acid solution and a weak acid solution, wherein the concentrated acid solution is recycled and reused in the pickling procedure of a fire retardant production process; 2, wet oxidation: a step of adjusting the pH value of the alkaline waste water having undergone filtering to 3 to 11 by using the weak acid solution obtained in the step 1 and then carrying out wet oxidation on the alkaline waste water so as to obtain treatment fluid; and 3, adsorption: a step of adding an adsorbent in the treatment fluid obtained in the step 2, carrying out a stirring reaction, then carrying out filtering so as to obtain a filtrate and evaporating salt from the filtrate or directly discharging the filtrate having reached the standard. The method provided by the invention employs a combination of diffusion dialysis and wet oxidation for treatment of the phosphate ester fire retardant waste water, so the waste water is discharged after having reached the standard, acid in the pickling waste water is recycled, and production cost for the fire retardant is reduced.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

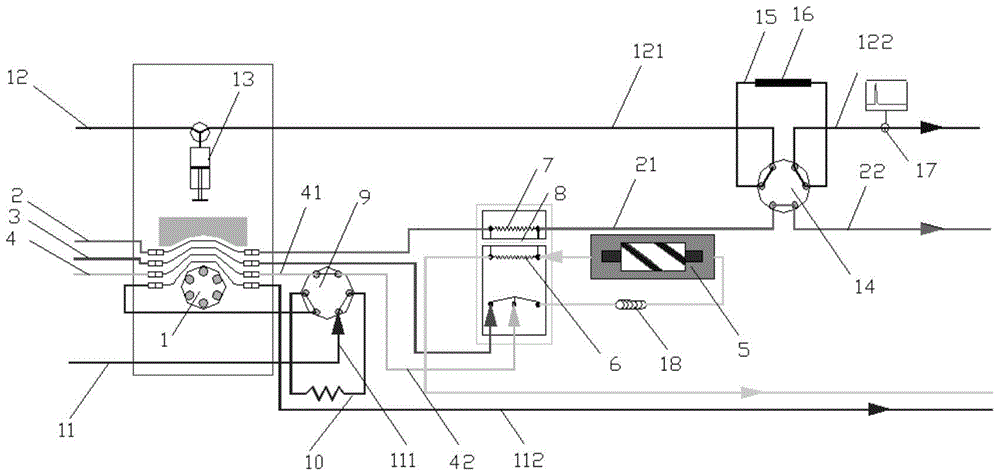

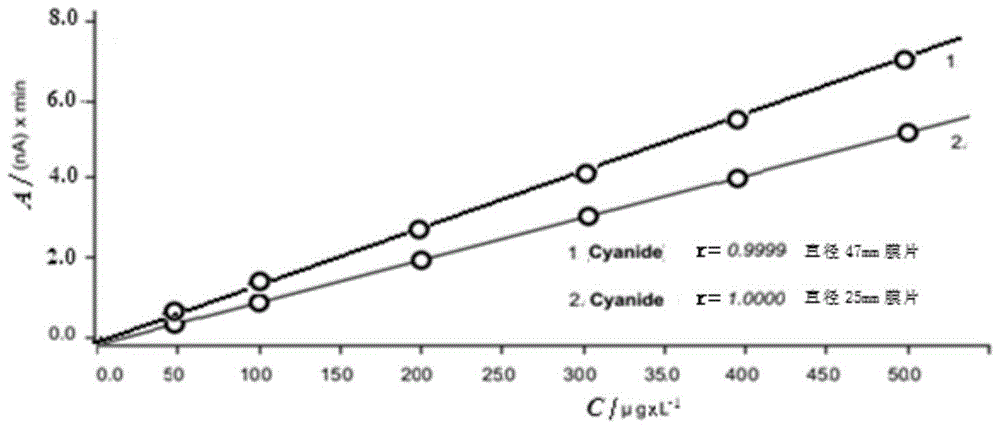

Apparatus and method for distillation-free non-color-development detection of trace-amount releasable cyanogens and total cyanogens in water solution

ActiveCN105738431AReduce the use effectReduce storagePreparing sample for investigationMaterial electrochemical variablesPeristaltic pumpDistillation

The invention discloses a device and method for non-distillation-free and non-chromogenic detection of trace amounts of easily-released cyanide and total cyanide in an aqueous solution. The device includes a peristaltic pump, an alkali solution pump tube, an acid solution pump tube, an aqueous solution pump tube, a washing device, and a detection device. The method includes filtering the sample solution, mixing it with an acidic solution, mixing it fully in the mixing tube, and transporting it to the photolysis device for photolysis, so that the different forms of cyanide are converted into simple hydrogen cyanide, and the sulfide is converted into hydrogen sulfide. The alkali chamber of the membrane diffusion separator flows through the low-pressure enrichment column, and the cyanide retained in the low-pressure enrichment column is washed by the eluent in the injection pump, enters the ampere pool, and is detected by DC amperometry. The operating conditions of the present invention are mild , high selectivity, long service life of hydrophobic membrane, safety and environmental protection, high recovery rate and no human error, it can measure easily released cyanide or total cyanide in wastewater within 10 minutes.

Owner:CHINA PETROLEUM & CHEM CORP

Post-processing method for squeezed alkali liquid in diffusion dialysis recycling viscose manufacture

The invention relates to a post-processing method for squeezed alkali liquid in diffusion dialysis recycling viscose manufacture, and belongs to the technical field of viscose manufacture. The post-processing method comprises the following steps: performing filtration preprocessing for the squeezed alkali liquid; then performing cation exchange membrane diffusion dialysis processing; post-processing the recycling liquid with low hemicelluloses content and residue liquid with high hemicelluloses content both obtained through separation, wherein the post-processing refers to concentrating or attenuating the recycling liquid with low hemicelluloses content to retrieve alkali liquid, and neutralizing the residue liquid with high hemicelluloses content to obtain the hemicelluloses. The preprocessing technology aims at the diffusion dialysis technology for recycling the viscose squeezed liquid, and adopts filtration preprocessing method to process the squeezed alkali liquid; the preprocessing technology performs post-processing for the recycling liquid with low hemicelluloses content and the residue liquid with high hemicelluloses content respectively, the obtained recycling liquid, through concentration or attenuation, can be used in the alkali-requiring process in the viscose manufacture, and meet the alkali-requiring index requirement of the process.

Owner:YIBIN HIEST FIBER +2

Apparatus and process for metal oxides and metal nanoparticles synthesis

InactiveUS20100025224A1Increase productionSemi-permeable membranesMembranesMembrane diffusionNanocrystal

The present invention provides an approach to control the generation and grow of nanocrystal with membrane diffusion method and related apparatuses to produce inorganic oxide nanopowders and metal nanoparticles. With this method, the size and size distribution of inorganic oxide nanopowders and metal nanoparticles can be tuned. It overcomes the shortcomings possessed by the common chemical and physical method of preparing nanoparticles.

Owner:BEIJING UNIV OF TECH

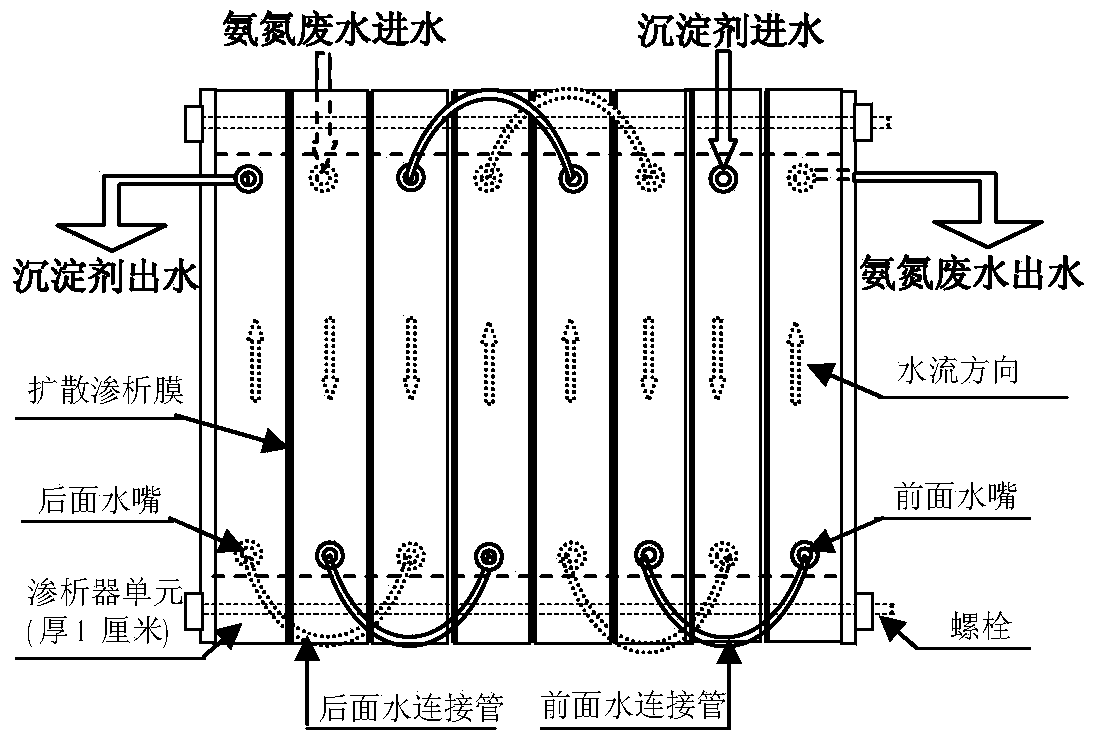

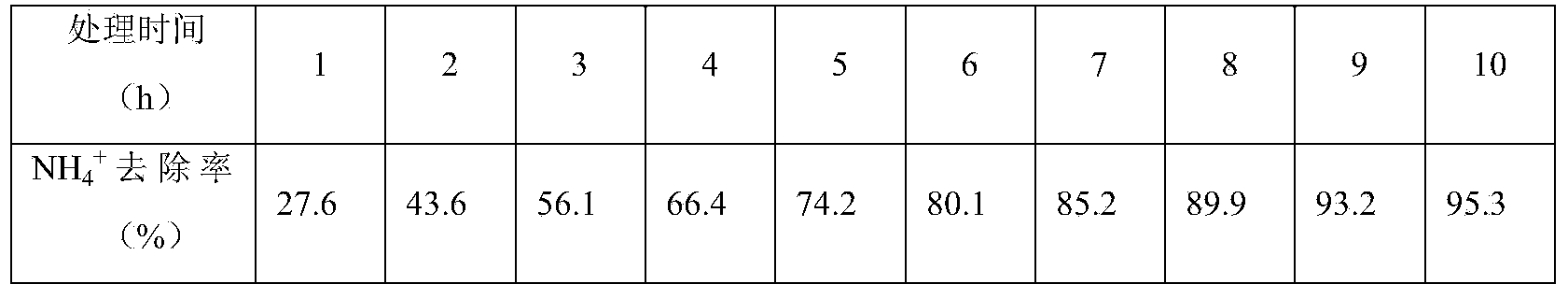

Device and method for recycling ammonia nitrogen from coking wastewater

InactiveCN103831022AGood chemical stabilityChemically resistantDialysisWater/sewage treatment bu osmosis/dialysisHigh concentrationMembrane diffusion

The invention provides a diffusion dialysis device for recycling NH4<+> from coking wastewater, and a method for treating the coking wastewater and other high-concentration ammonia nitrogen wastewater and recycling the NH4<+> by using the device. The economic feasibility and technical feasibility of the treatment method are fully considered, the high-concentration NH4<+> in the coking wastewater is subjected to the combined technology of membrane diffusion dialysis separation and sodium tetraphenylborate selective precipitation, the aim of removing and recycling NH4<+> from the coking wastewater containing high-concentration ammonia nitrogen and other high-concentration ammonia nitrogen wastewater is achieved, the removal rate of the NH4<+> can be over 95 percent, and the recycling rate of the NH4<+> can be over 90 percent.

Owner:SHANXI UNIV

Sulfuric acid recovery technique in process of producing cystine by adopting sulfuric acid method

InactiveCN103264995AReduce consumptionReduce processing difficultySulfur-trioxide/sulfuric-acidHydrolysateMembrane diffusion

The invention discloses a sulfuric acid recovery technique in the process of producing cystine by adopting a sulfuric acid method. The sulfuric acid recovery technique comprises the steps of: (1) simultaneously flowing hydrolysate and water through an anion-exchange membrane diffusion dialyzer, controlling the flow velocity of the hydrolysate and water so that the pH value of the hydrolysate flowing out is 1-1.5 and the water flowing out becomes acid liquor; and (2) flowing the hydrolysate and water out to simultaneously flow through an electrodialyzer, so that the pH value of the hydrolysate flowing out from a desalting chamber of the electrodialyzer is 3-4 through controlling the electrified voltage and the flow rate of the hydrolysate and water, wherein the hydrolystae flows in cystine production procedure, and the water flowing out from a concentration chamber of the electrodialyzer becomes diluted acid liquor which is used for replacing the water in the step (1), thus realizing the recovery cycle of sulfuric acid. The technique is simple and easy for steps, the consumption of alkali and liquid ammonia in cystine production can be reduced, the raw materials can be saved, the production cost can be lowered, the content of salt in waste water can be decreased, and the treating difficulty and treatment cost of waste water can be lowered.

Owner:SHANDONG TIANWEI MEMBRANE TECH

Apparatus and process for metal oxides and metal nanoparticles synthesis

ActiveUS20110286904A1Increase productionSemi-permeable membranesMembranesMembrane diffusionNanocrystal

The present invention provides an approach to control the generation and grow of nanocrystal with membrane diffusion method and related apparatuses to produce inorganic oxide nanopowders and metal nanoparticles. With this method, the size and size distribution of inorganic oxide nanopowders and metal nanoparticles can be tuned. It overcomes the shortcomings possessed by the common chemical and physical method of preparing nanoparticles.

Owner:BEIJING UNIV OF TECH

Method for directly detecting ammonia in wastewater by non-contact gas film diffusion-electric conductance

InactiveCN107340319AImprove detection limitExtended service lifeMaterial resistancePeristaltic pumpDistillation

The invention discloses a method for directly detecting ammonia in wastewater by non-contact gas membrane diffusion-electric conductance. The method comprises the steps that a sample solution is sucked by a peristaltic pump A, a quantitative loop is filled with the sample solution, after a six-way valve is switched, a peristaltic pump B drives and sucks an alkaline solution to make the alkaline solution sufficiently mixed with the sample solution, ammonia in the sample solution is all transformed into ammonia gas, then the ammonia gas enters a sample solution cavity channel of a membrane diffusion unit, and a certain proportion of the ammonia gas is not in contact with a hydrophobic membrane, diffuses into a received solution cavity channel on the other side and turns into ammonium ions. Through a 'flow stop' or 'flowing' dialysis mode, a received solution which contains the ammonium ions enters the received solution cavity channel of the membrane diffusion unit and flows through a conductance cell, and an electrical conductivity detector directly measures the ammonia content according to the conductivity change of the solution. Compared with the prior art, the method has the advantages that the method has high selectivity, does not need distillation and color rendering, and is good in sample adaptability, wide in linearity range and long in service life of membranes, no toxic reagent is used, and the ammonia in sewage or recycled water can be directly determined within 5 minutes.

Owner:CHINA PETROLEUM & CHEM CORP

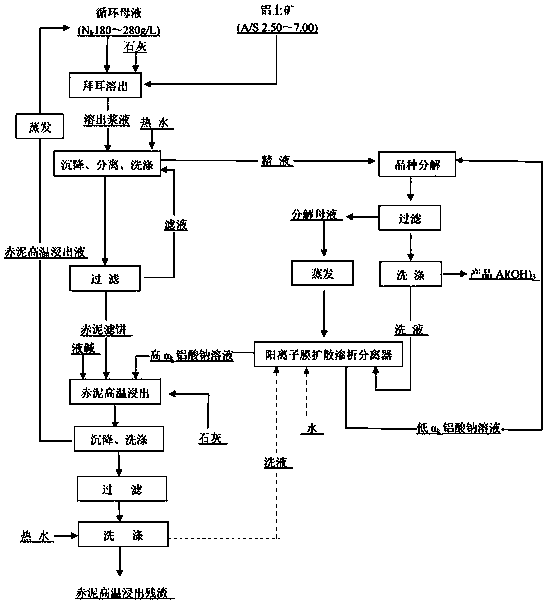

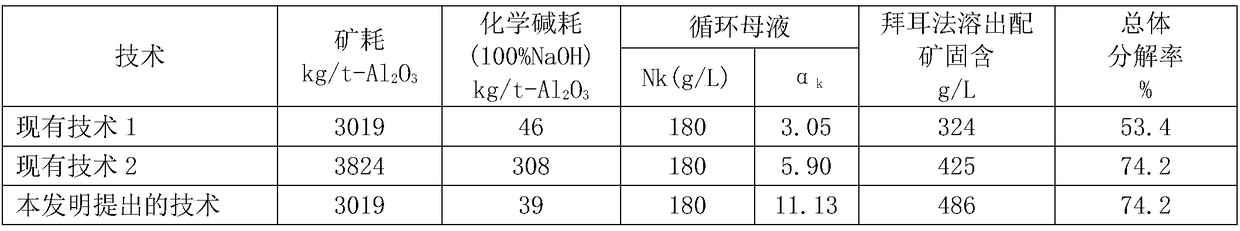

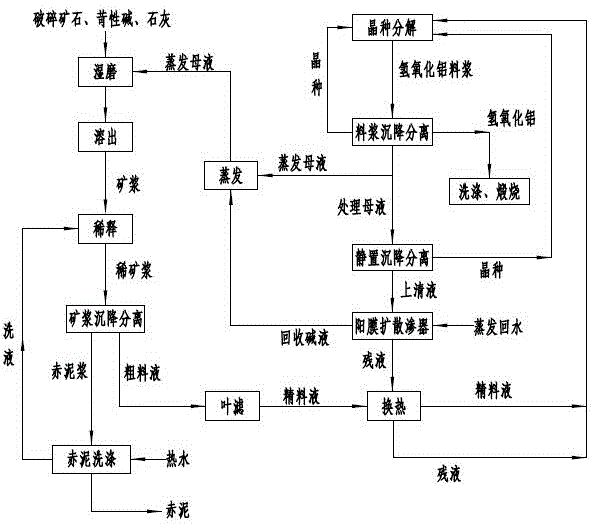

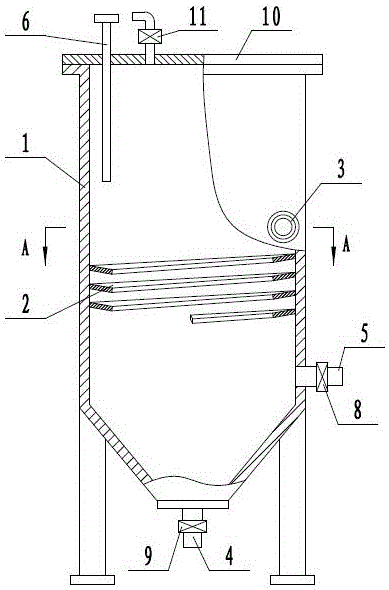

Method for systemically improving efficiency of low-grade bauxite Bayer-method process

InactiveCN108862340AImprove decomposition rateImprove efficiencyAluminium oxides/hydroxidesRed mudDecomposition

The invention discloses a method for systemically improving the efficiency of a low-grade bauxite Bayer-method process and relates to improvement of a technology of producing aluminum oxide through aBayer method. The method is characterized in that a main technological process comprises the following steps: 1) dissolving out bauxite by utilizing a circulating mother solution; 2) treating a Bayerseed precipitation steaming mother solution by utilizing a cationic membrane diffusion dialysis separator to obtain a low-alphak sodium aluminate solution and a high-alphak sodium aluminate solution;conveying the low-alphak sodium aluminate solution into a Bayer seed precipitation procedure, and carrying out secondary crystal seed decomposition; 3) mixing the high-alphak sodium aluminate solutionof step 2), supplemented liquid alkali, lime and a Bayer red mud filter cake to prepare alkaline red mud; carrying out leaching treatment on the alkaline red mud at room temperature to obtain red mudhigh-temperature leaching residues and red mud high-temperature leaching liquid. The method is suitable for treating middle-grade and low-grade bauxite with the A / S of 2.50 to 7.00 and has the advantages of high efficiency of a production process, low ore consumption and low alkali consumption; the A / S of the discharged high-temperature leaching residues is 0.50 to 0.90, the N / S is less than or equal to 0.15 and the total decomposition rate of a seed precipitation process is greater than or equal to 68 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

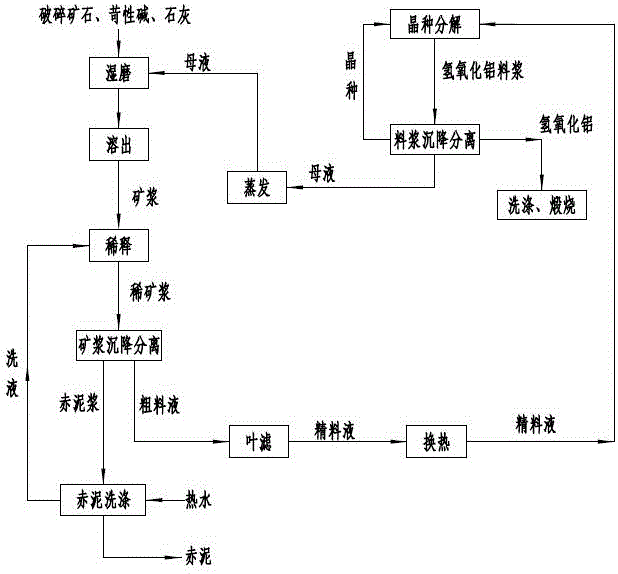

A method for improving seed decomposition rate and cycle efficiency in alumina production

ActiveCN105836771BHigh primary cycle decomposition rateIncrease productivityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionEvaporation

The invention discloses a method for improving the seed decomposition rate and cycle efficiency in alumina production. The method comprises the steps of: (1) subjecting a aluminum hydroxide slurry to settling separation, and separating an obtained mother solution into an evaporation mother liquor and a treatment mother liquor, letting the evaporation mother liquor enter an evaporation process to perform evaporation concentration, and subjecting the treatment mother liquor to standing treatment, and then carrying out solid-liquid separation to obtain a supernatant and aluminum hydroxide; (2) sending the supernatant and evaporation return water into a cation membrane diffusion dialyzer to conduct countercurrent exchange so as to obtain raffinate and recovered alkali liquid; and (3) sending the raffinate back to the seed decomposition process to conduct further decomposition, sending the recovered alkali liquid into an evaporation process to perform evaporation concentration, then sending the concentration product to a wet grinding process and mixing the product with ores. The method has the characteristics of high alkali cycle efficiency, high mother solution primary circulation decomposition rate, high alumina output rate, and low alumina production unit energy consumption.

Owner:SHANDONG TIANWEI MEMBRANE TECH

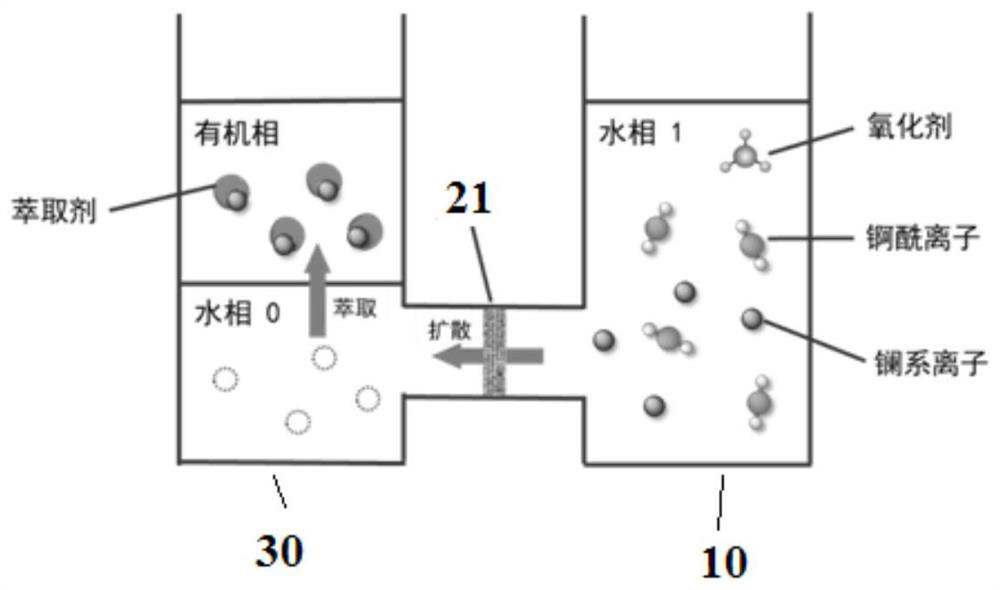

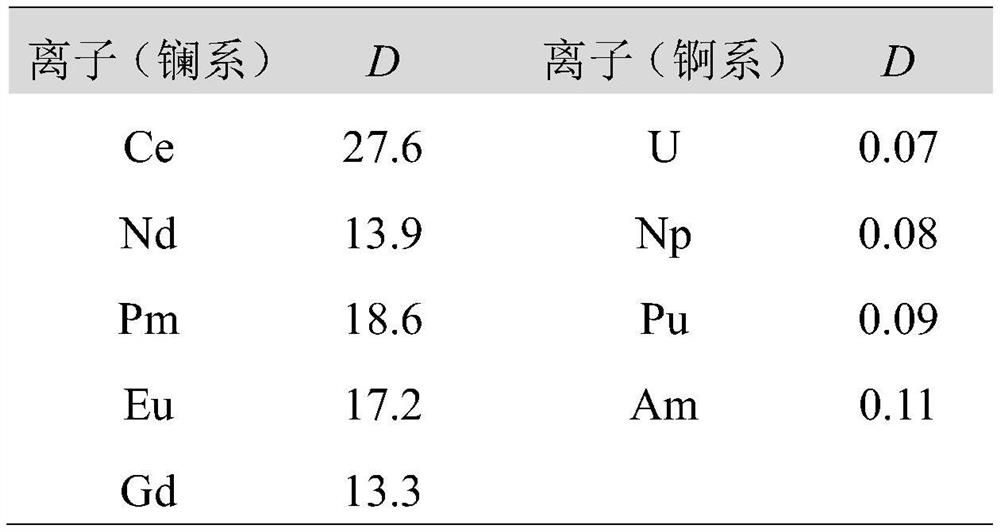

Lanthanum actinide group separation system and method based on oxidation, screening and extraction coupling

ActiveCN114107667AAchieving long-term shape constancyStable separationProcess efficiency improvementMembrane diffusionLanthanum

The invention discloses a lanthanum actinide group separation system and a lanthanum actinide group separation method based on oxidation, screening and extraction coupling. The system comprises a feed liquid area, a permeation area and a separation membrane for separating the feed liquid area from the permeation area, the actinide ions are oxidized into actinide ions by adopting an oxidizing agent in the feed liquid area, the oxidizing agent and the actinide ions in the feed liquid area are intercepted in the feed liquid area by a separation membrane, and the lanthanide ions in the feed liquid area continuously penetrate through the separation membrane to be diffused into a water phase in the permeation area and are extracted into an organic phase by an extracting agent; meanwhile, the organic phase in the permeation area cannot diffuse to the feed liquid area. According to the invention, the three different modules of oxidation, screening and extraction are effectively combined, and the separation of lanthanum and actinide elements is efficiently and stably realized in a manner of coupling and linking the three modules of oxidation, screening and extraction.

Owner:TSINGHUA UNIV

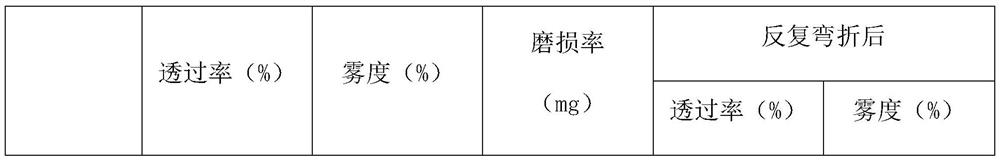

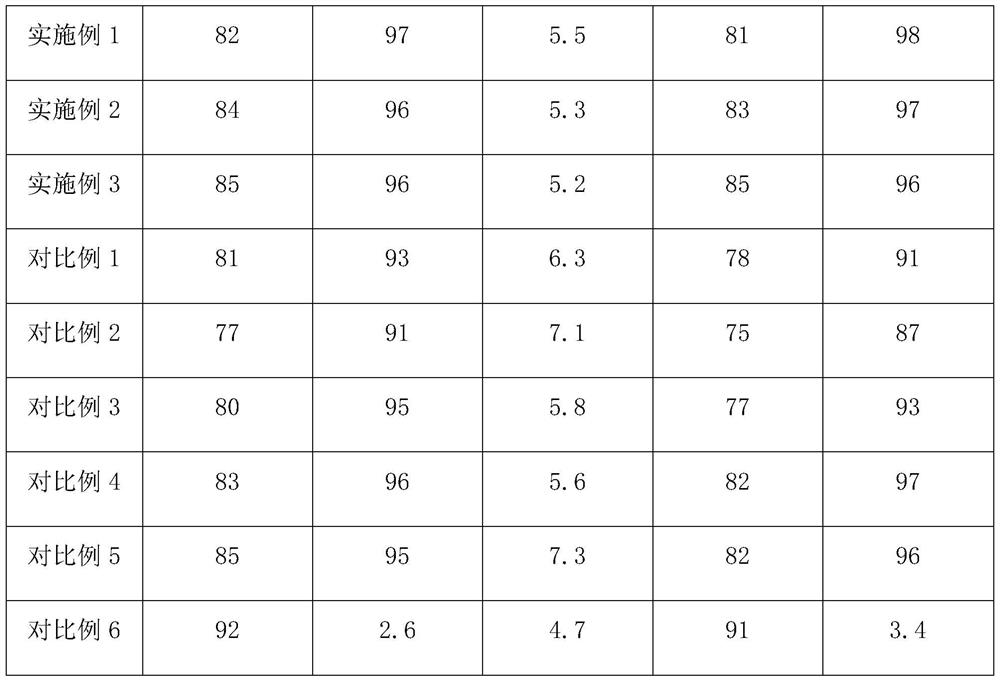

Wear-resistant flexible diffusion film and preparation process thereof

InactiveCN113736114AImprove transmittanceHigh hazeDiffusing elementsPolyurea/polyurethane coatingsMicrosphereMembrane diffusion

The invention discloses a wear-resistant flexible diffusion film and a preparation process thereof. The preparation process comprises the following steps: (1) preparing diffusion particles: preparing silicon dioxide microspheres from a silicon source and ammonia water; injecting zinc ions to prepare modified silicon dioxide microspheres; adding urea, sodium tartrate and vinyl trimethoxy silane, and reacting; adding polyethylene and an initiator, and reacting; (2) preparing the film body: reacting hydroxyl-terminated polybutadiene with glyoxylic acid, and reacting with m-phenylenediamine to prepare modified polybutadiene; reacting with diffusion particles and maleic anhydride, coating and stretching; and (3) preparing the diffusion film: coating the surface of the diffusion film body with the coating, compounding the coating surface with the base film, and curing. According to the arrangement of the diffusion film and the preparation process thereof, the layer structure of the base film and the diffusion film body is formed, the base film and the diffusion film body are bonded and filled through the coating, relative refraction exists between every two films, light refraction can be effectively increased, backscattering can be effectively reduced, and the transmittance and haze of the prepared diffusion film are improved.

Owner:YILIKIM NEW MATERIALS CO LTD

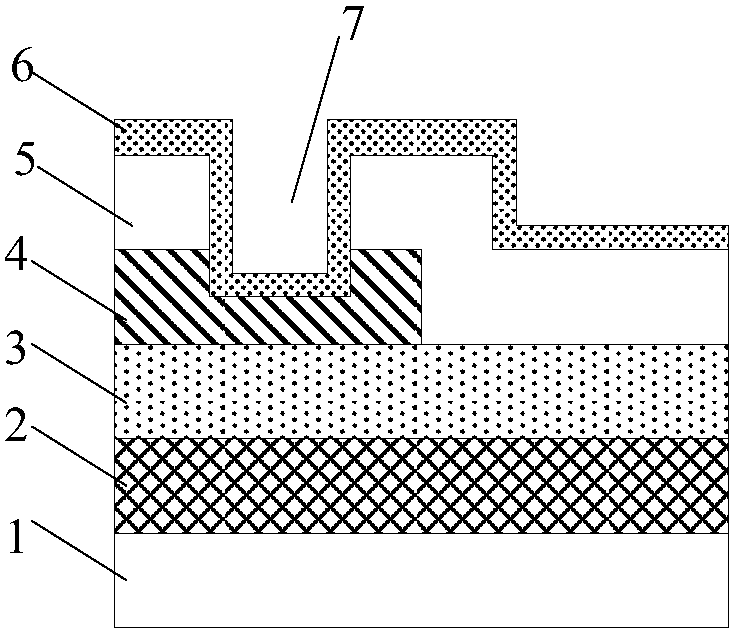

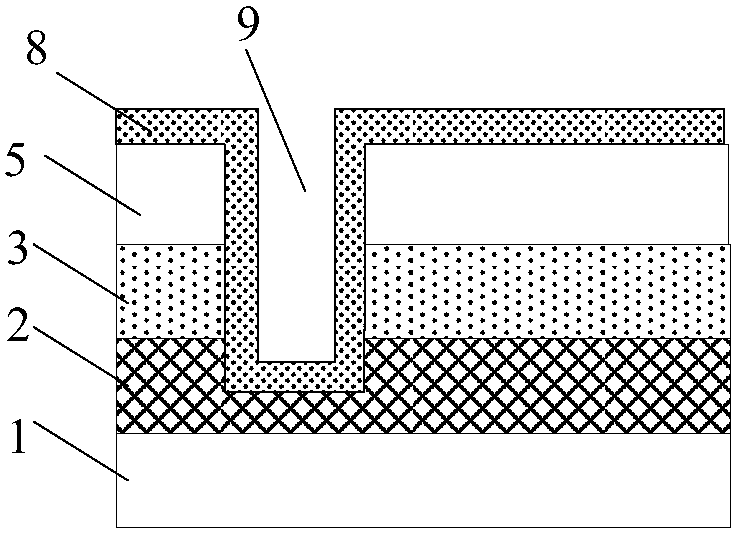

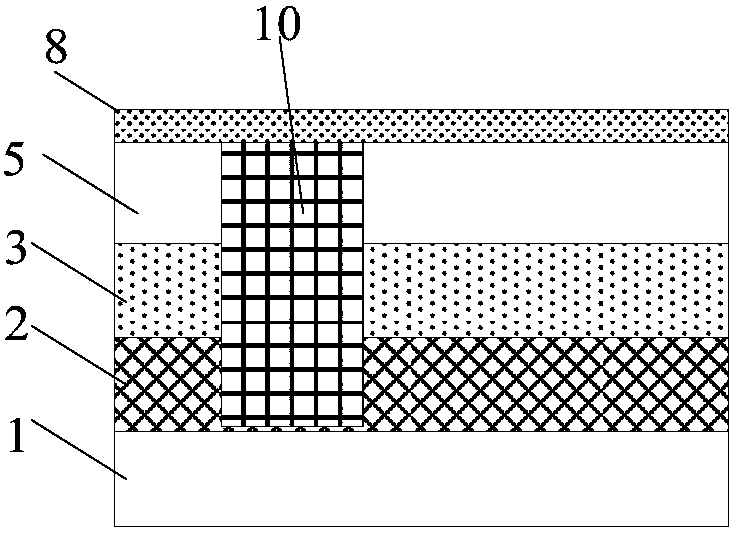

Array substrate, manufacturing method thereof, and display device

ActiveCN105552024BAchieve planarizationAvoid dentsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMembrane diffusion

The invention provides an array substrate, a manufacturing method thereof, and a display device, belonging to the field of display technology. Wherein, the array substrate includes a first conductive pattern, an insulating layer covering the first conductive pattern, and a second conductive pattern on the insulating layer, and the insulating layer includes a A via hole of the second conductive pattern is formed, and a conductive column connected to the first conductive pattern and the second conductive pattern is formed in the via hole. The technical solution of the present invention can solve the mura defect caused by the uneven diffusion of the alignment film at the via hole, and improve the display effect of the display device.

Owner:BOE TECH GRP CO LTD +1

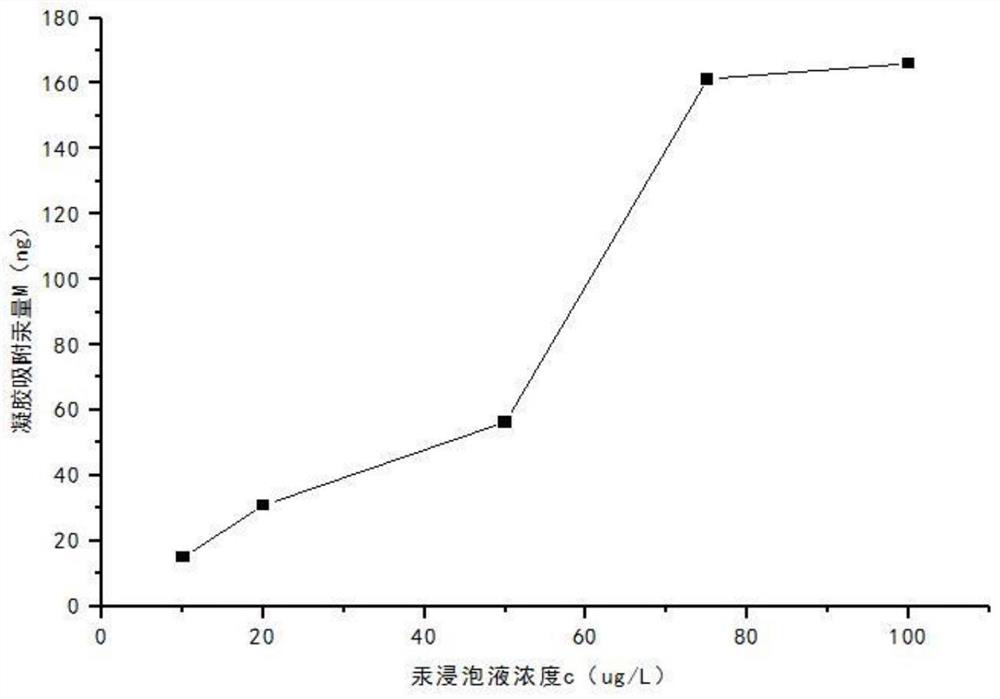

Mercury bio-availability determination device and determination method

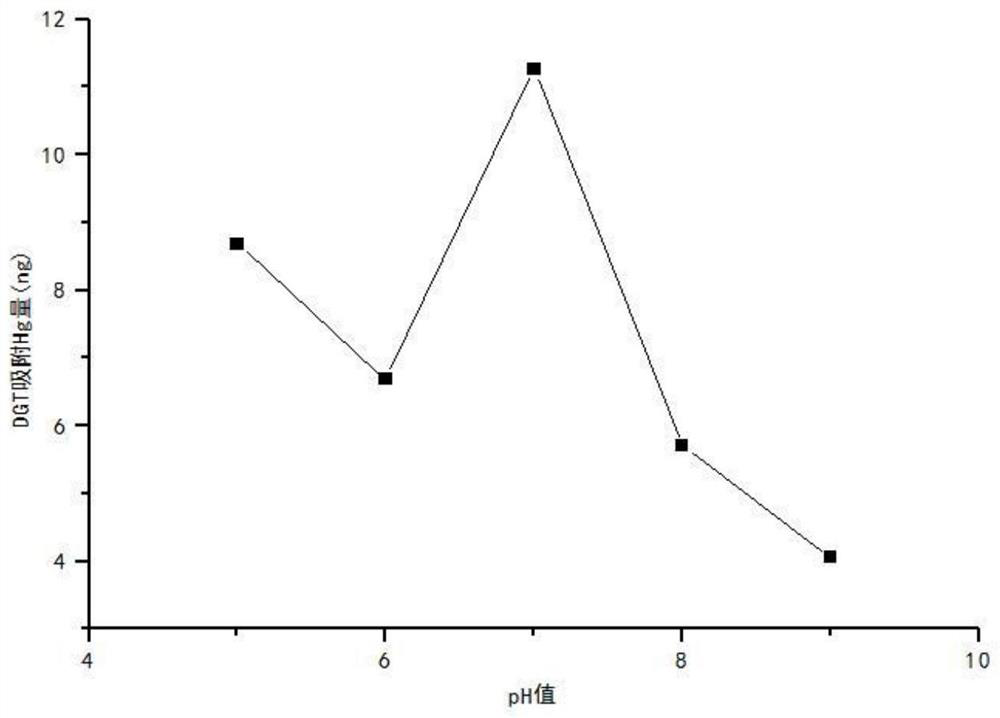

PendingCN114646575AThe preparation method is simple and easyRaw materials are easy to getFluorescence/phosphorescenceDiffusion analysisMembrane diffusionSilica gel

The invention discloses a mercury bioavailability measuring device and method, and relates to the technical field of metal pollution detection, the mercury bioavailability measuring device comprises a filter membrane, a diffusion membrane, an adsorption membrane and a plastic shell for fixing the filter membrane, the diffusion membrane and the adsorption membrane, the filter membrane is a glass fiber filter membrane, the diffusion membrane is a membrane made of agarose gel with the mass percent of 1.5%, and the adsorption membrane is a membrane made of silica gel. According to the invention, the novel gel assembled DGT device is self-researched, the manufacturing method of the DGT device is simple in process, the raw materials are easy to obtain, the cost is low, and a basis is provided for DGT production localization; meanwhile, by researching the application conditions and effects of the DGT device, a scientific basis is expected to be provided for mercury pollution risk evaluation and pollution abatement.

Owner:HENAN AGRICULTURAL UNIVERSITY

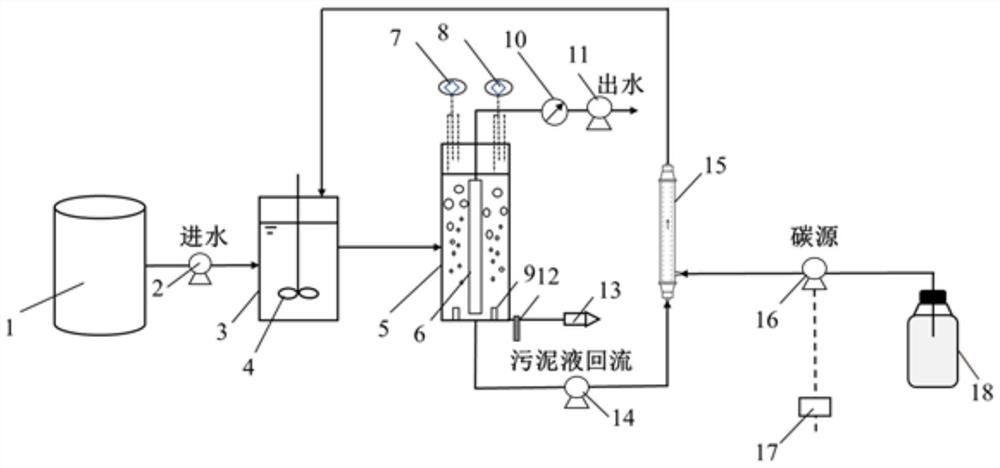

Enhanced denitrification method and device

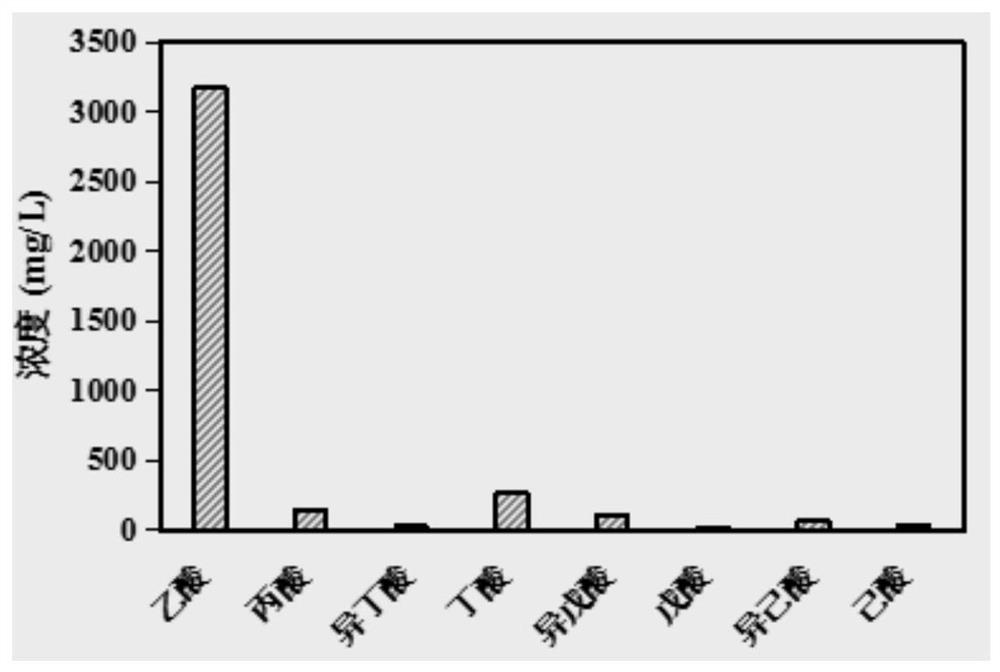

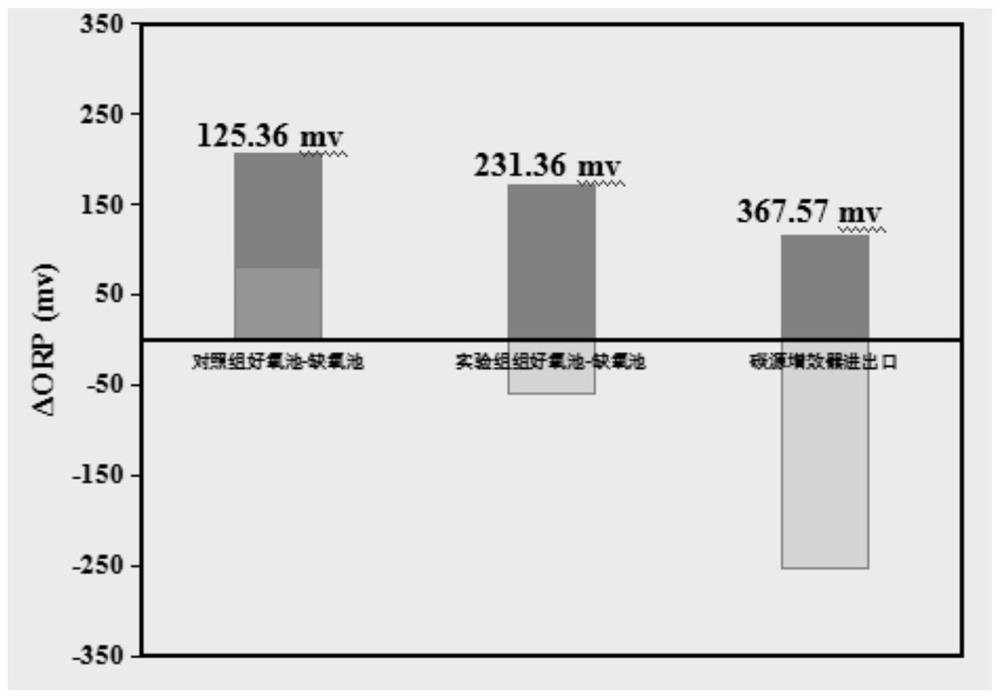

ActiveCN114716015APromotes the denitrification processHas sustained release propertiesWater contaminantsBiological treatment apparatusVolatile fatty acidsMembrane diffusion

The invention discloses an enhanced denitrification method and device, and belongs to the technical field of wastewater treatment. The enhanced denitrification device comprises an anoxic tank, an aerobic tank and a carbon source multiplier which are connected in sequence, and the output end of the carbon source multiplier is connected with the anoxic tank; a plurality of membrane contactors are fixed in the carbon source multiplier, the membrane contactors are of hollow structures, and gaps exist between the membrane contactors and a shell of the carbon source multiplier; when the device disclosed by the invention is used for denitrification, a macromolecular carbon source can be added in the denitrification process, the macromolecular carbon source is hydrolyzed into volatile fatty acid by utilizing hydrolysis zymophyte existing in a gap between the carbon source multiplier and the membrane contactor, and then the volatile fatty acid is diffused and permeated into a hollow structure of the membrane contactor through the membrane; as a small molecular carbon source which can be efficiently utilized by denitrifying bacteria, the denitrification process is promoted.

Owner:SUN YAT SEN UNIV

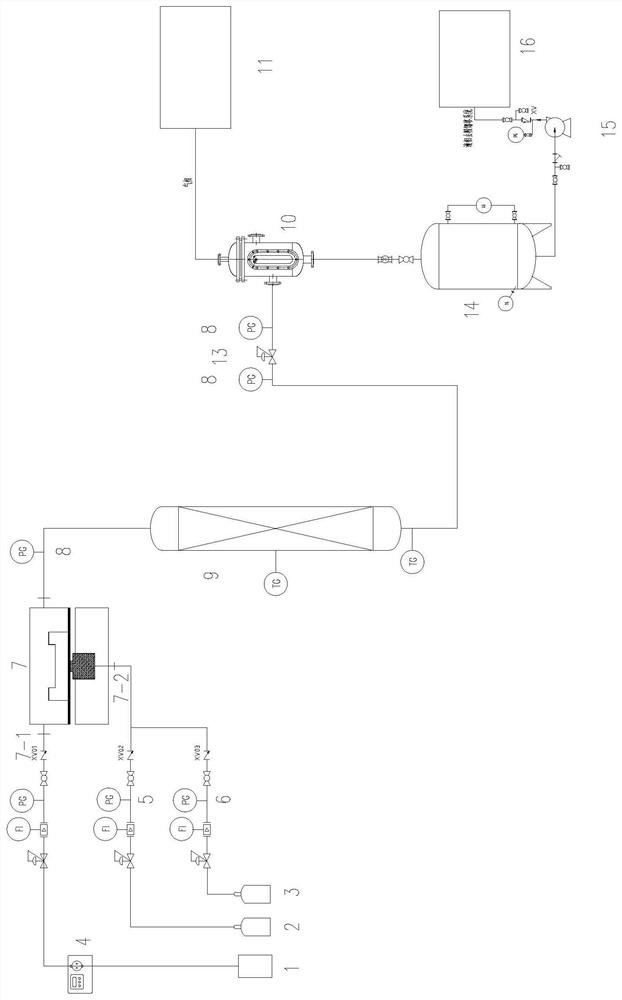

Production equipment and method for synthesizing 3-aminopropanol through continuous hydrogenation

PendingCN111991827ALow reaction temperatureRelieve pressureOrganic compound preparationDistillation separationPropanolPtru catalyst

The invention relates to a synthetic method of 3-aminopropanol, in particular to production equipment and method for synthesizing 3-aminopropanol through continuous hydrogenation, and belongs to the technical field of chemical organic synthesis. The equipment mainly comprises a membrane diffusion module, a packed bed reactor and a gas-liquid separation device which are connected in sequence; the top end of the gas-liquid separation device is connected with an ammonia gas absorption device; a bottom outlet of the gas-liquid separation device is connected with a liquid phase collection device, and the liquid phase collection device is connected with a rectifying tower pipeline; the membrane diffusion module is provided with a liquid phase inlet and a gas phase inlet; a 3-hydroxypropionitrilestorage tank is connected with the liquid phase inlet; and a hydrogen steel cylinder and an ammonia gas steel cylinder are connected with a gas phase inlet through branch pipelines respectively. Themethod and the device disclosed by the invention are low in cost, high in total yield, good in safety and environment-friendly. In the absence of a solvent, a supported nickel-based catalyst and ammonia gas are used as co-catalysts, and hydrogen is introduced to reduce cyano groups, so that the defects of temperature runaway and low productivity of a kettle type reaction device are avoided, and the process route is economic, safe, green and environment-friendly,.

Owner:BROTHER ENTERPRISES HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com