Method for systemically improving efficiency of low-grade bauxite Bayer-method process

A low-grade bauxite and Bayer process technology, applied in alumina/aluminum hydroxide and other directions, can solve the problem of high alkali consumption, and achieve the effects of low alkali consumption, low ore consumption and high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

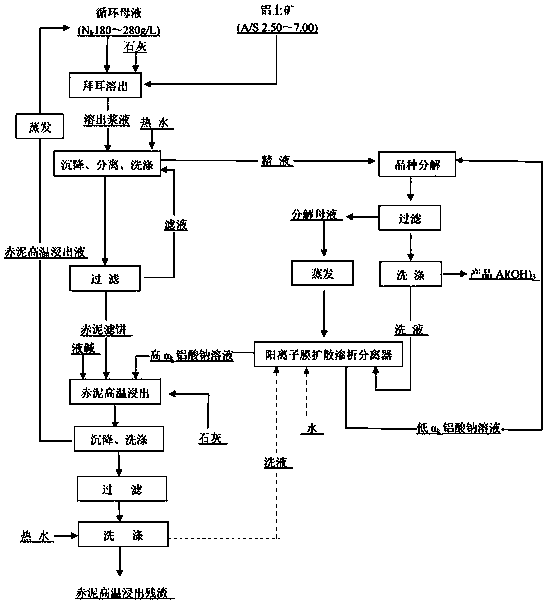

Method used

Image

Examples

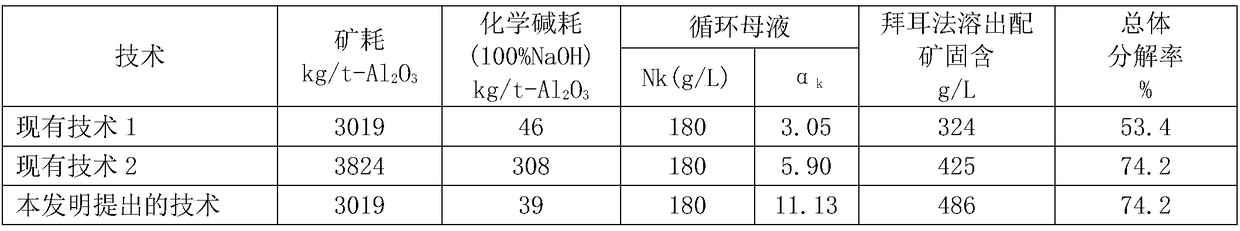

Embodiment 1

[0043] Al in Bauxite 1 2 o 3 Content is 61.58%, SiO 2 The content is 12.89%, Fe 2 o 3 The content is 4.85%, the A / S is 4.77, and the caustic alkali concentration N k 280g / L, α k The 5.90% circulating mother liquor dissolves bauxite 1 to obtain a stripping slurry, and the stripping liquid α k It is 1.42, the amount of lime added is 6%, the dissolution temperature is 250°C, the dissolution time is 120min, the A / S of the dissolved red mud is 1.01, and the N / S of the dissolved red mud is 0.60. The stripping slurry is sequentially subjected to dilution, sedimentation, separation and fine filtration to obtain α k It is the Bayer method semen of 1.47, and the semen is obtained through the treatment processes such as seed crystal decomposition process and solid-liquid separation under conventional Bayer method seed separation conditions to obtain the decomposition product aluminum hydroxide and decomposition mother liquor. N can be obtained after the mother liquor is evaporated...

Embodiment 2

[0045] Al in Bauxite 1 2 o 3 Content is 61.58%, SiO 2 The content is 12.89%, Fe 2 o 3 The content is 4.85%, the A / S is 4.77, and the caustic alkali concentration N k 275g / L, α k 5.19 The circulating mother liquor dissolves bauxite 1 to obtain the stripping slurry, and the stripping liquid α k It is 1.42, the amount of lime added is 10%, the dissolution temperature is 280°C, the dissolution time is 20min, the A / S of the dissolved red mud is 1.10, and the N / S of the dissolved red mud is 0.45. The red mud slurry is sequentially diluted, settled, separated and finely filtered to obtain α k It is the Bayer method semen of 1.47, and the semen is obtained through the treatment processes such as seed crystal decomposition process and solid-liquid separation under conventional Bayer method seed separation conditions to obtain the decomposition product aluminum hydroxide and decomposition mother liquor. The mother liquor is evaporated and concentrated to obtain N k 320g / L, α ...

Embodiment 3

[0047] Al in Bauxite 2 2 o 3 Content is 43.58%, SiO 2 The content is 16.89%, Fe 2 o 3 The content is 9.85%, the A / S is 2.58, and the caustic concentration N k 180g / L, α k The circulating mother liquor of 9.55% dissolves the bauxite 2 to obtain the stripping slurry, and the stripping liquid α k 1.42, lime addition 12%, dissolution temperature 270°C, dissolution time 50min, dissolution red mud A / S 1.20, dissolution red mud N / S 0.30. The red mud slurry is sequentially diluted, settled, separated and finely filtered to obtain α k It is the Bayer method semen of 1.47, and the semen is obtained through the treatment processes such as seed crystal decomposition process and solid-liquid separation under conventional Bayer method seed separation conditions to obtain the decomposition product aluminum hydroxide and decomposition mother liquor. The mother liquor is evaporated and concentrated to obtain N k 140g / L, α k 3.02 evaporation mother liquor, the evaporation mother liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com