Recycling treatment method for phosphate ester fire retardant waste water

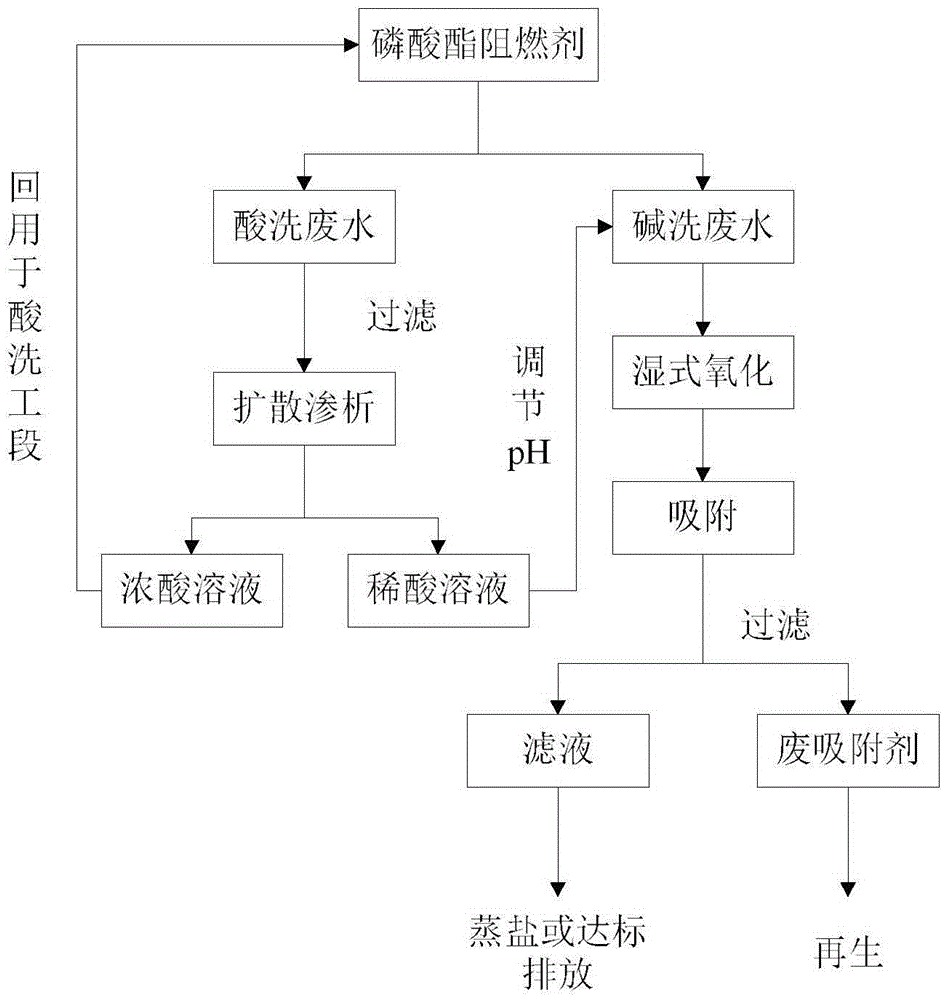

A treatment method and flame retardant technology are applied in the field of resource treatment of phosphate ester flame retardant wastewater, which can solve problems such as difficult sludge treatment, achieve simple and easy-to-understand process and operation, mild reaction conditions, and easy industrialization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The pickling wastewater and alkali washing wastewater produced in the production workshop of flame retardant FR-220, the pickling wastewater mainly contains hydroquinone, phenol, toluene, a small amount of products, PO 4 3- 、H + , Mg 2+ And a little precipitation, the solid content is about 3.9%, the filtered wastewater COD is about 3800mg / L, H + The concentration is about 7.3mol / L, the total phosphorus concentration is about 9570mg / L; the alkali washing wastewater mainly contains toluene, a small amount of products, OH - And a little precipitation, the solid content is about 7.8%, the COD of the filtered wastewater is about 24000mg / L, the pH is 13~14, and the total phosphorus is about 970mg / L.

[0025] 1. Diffusion dialysis: The filtered pickling wastewater is treated by anion exchange membrane diffusion dialysis to obtain a concentrated acid solution (c(H + )=7.9mol / L) and dilute acid solution (c(H + )=0.54mol / L), the concentrated acid solution is reused in the p...

Embodiment 2

[0040] The pickling wastewater and alkali washing wastewater produced in the flame retardant BDP production workshop, the pickling wastewater mainly contains hydroquinone, phenol, toluene, a small amount of products, PO 4 3- 、H + , Mg 2+ And a little precipitation, the filtered wastewater COD is about 4300mg / L, H + The concentration is about 4.6mol / L, and the total phosphorus concentration is about 11660mg / L; the alkali washing wastewater mainly contains toluene, a small amount of products, OH - And a little precipitation, the COD of the filtered wastewater is about 171600mg / L, and the pH is 13~14.

[0041] 1. Diffusion dialysis: The filtered pickling wastewater is treated by anion exchange membrane diffusion dialysis to obtain a concentrated acid solution (c(H + )=5.2mol / L) and dilute acid solution (c(H + )=0.26mol / L), the concentrated acid solution is reused in the pickling section of the phosphate ester flame retardant production process. Anion exchange membrane diffu...

Embodiment 3

[0045] The pickling wastewater produced by the flame retardant FR-220 production workshop is mixed with the alkali washing wastewater produced by the flame retardant BDP production workshop.

[0046] 1. Diffusion dialysis: The filtered FR-220 pickling wastewater is treated by anion exchange membrane diffusion dialysis to obtain a concentrated acid solution (c(H + )=7.9mol / L) and dilute acid solution (c(H + )=0.54mol / L), the concentrated acid solution is reused in the pickling section of the phosphate ester flame retardant production process. Anion exchange membrane diffusion dialysis experimental parameters: number of membranes: 19 pairs; membrane size: 200mm*400mm; pipeline connection: waste acid enters from bottom to top, pure water (recovered acid) flows from top to bottom. The outlet pipe must be higher than the height of the membrane stack to discharge the air inside the membrane stack and avoid short flow.

[0047] 2. Wet oxidation: use the FR-220 dilute acid solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com