A method for improving seed decomposition rate and cycle efficiency in alumina production

A cycle efficiency, alumina technology, applied in chemical instruments and methods, alkali metal aluminate/alumina/aluminum hydroxide preparation, inorganic chemistry, etc., can solve the problem of low effective heat energy, weak dissolution ability, and high unit energy consumption problems, to achieve the effect of increasing the output rate, increasing the αk value, and improving the efficiency of the alkali cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

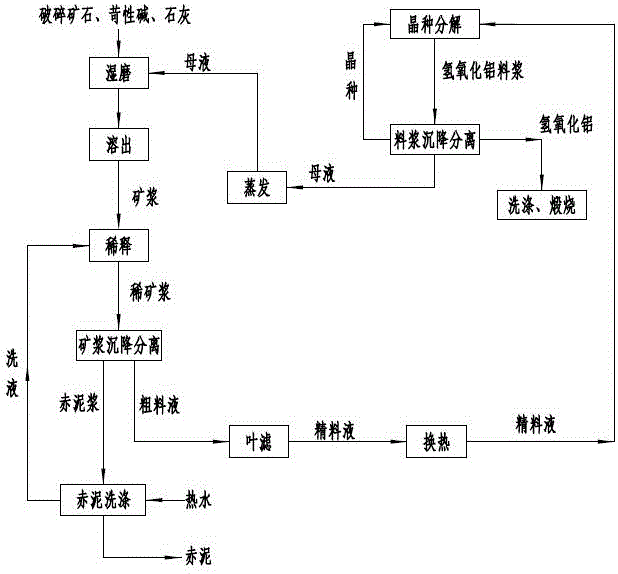

Problems solved by technology

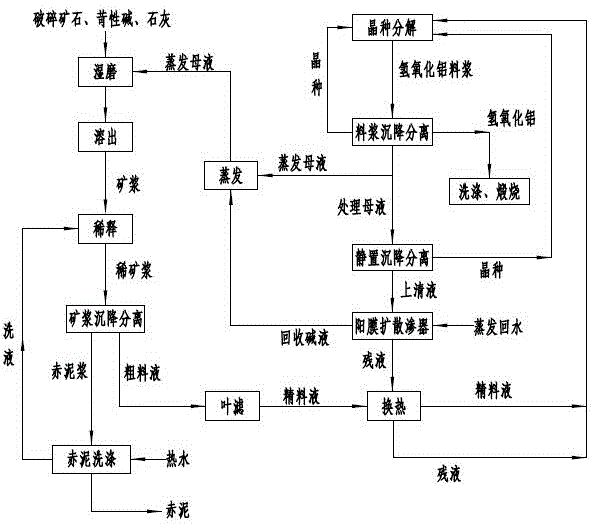

Method used

Image

Examples

Embodiment 1

[0033] The ore used in the dissolution of this embodiment is diaspore, and the sodium hydroxide slurry produced in the seed crystal decomposition process has a value of αk of the mother liquor obtained through the slurry sedimentation and separation process at about 3.1, wherein the caustic alkali content is expressed as Na 2 O is about 155g / L, the content of aluminum is Al 2 o 3 Calculated as about 80g / L. The method for improving the decomposition rate and cycle efficiency of alumina production comprises the following steps:

[0034] (1) Divide the mother liquor obtained by settling and separating the aluminum hydroxide slurry in the seed crystal decomposition process in the alumina production process into two parts, one part is the evaporated mother liquor accounting for 80% of the total, and the other part is the treated mother liquor accounting for 20% of the total %; the evaporated mother liquor is sent to the evaporation process for evaporation and concentration, and ...

Embodiment 2

[0039] The ore used in the dissolution of this embodiment is diaspore, and the sodium hydroxide slurry produced in the seed crystal decomposition process has a value of αk of the mother liquor obtained through the slurry sedimentation and separation process at about 3.1, wherein the caustic alkali content is expressed as Na 2 O is about 155g / L, the content of aluminum is Al 2 o 3 Calculated as about 80g / L. The method for improving the decomposition rate and cycle efficiency of alumina production comprises the following steps:

[0040] (1) Divide the mother liquor obtained by settling and separating the aluminum hydroxide slurry in the seed crystal decomposition process in the alumina production process into two parts, one part is the evaporated mother liquor accounting for 70% of the total, and the other part is the treated mother liquor accounting for 30% of the total %; the evaporated mother liquor is sent to the evaporation process for evaporation and concentration, and ...

Embodiment 3

[0045] The ore used in the dissolution of this embodiment is diaspore, and the sodium hydroxide slurry produced in the seed crystal decomposition process has a value of αk of the mother liquor obtained through the slurry sedimentation and separation process at about 3.1, wherein the caustic alkali content is expressed as Na 2 O is about 155g / L, the content of aluminum is Al 2 o 3 Calculated as about 80g / L. The method for improving the decomposition rate and cycle efficiency of alumina production comprises the following steps:

[0046] (1) Divide the mother liquor obtained by settling and separating the aluminum hydroxide slurry in the seed crystal decomposition process in the alumina production process into two parts, one part is the evaporated mother liquor accounting for 60% of the total, and the other part is the treated mother liquor accounting for 40% of the total %; the evaporated mother liquor is sent to the mother liquor evaporation process for evaporation and conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com