Patents

Literature

373results about How to "Reduce unit energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

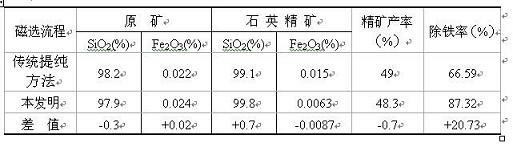

Efficient magnetic separation method for quartz sand

InactiveCN102626668AIncrease production capacityReduce unit energy consumptionWet separationPurification methodsNo production

The invention discloses an efficient purification method for quartz sand. In the method, two-section smashing (rough smashing and fine smashing) and ore milling with a rod mill are adopted, so that the production capacity is increased greatly, unit energy consumption is lowered, and the method is suitable for large-scale production. A method for removing weakly-magnetic minerals and intergrowth quartz with high iron content from quartz sand through advanced ore washing and weakly magnetic-high gradient strongly magnetic combined magnetic separation before ore milling is adopted, so that the purity of quartz sand is increased greatly. The method has the advantages of simple process flow, easiness for operating, low cost, high purification efficiency, stable performance and environmental friendliness of a produced product, no use of any chemical substance in an entire production process, no production of any waste water, waste residues and waste gas, true realization of zero emission, no production of waste and prevention of pollution. The method is not limited by the production scale, various quartz sand products of low, medium and high grades can be produced, the enterprise profit can be maximized, and the method has a wide application prospect on the aspect of purification of quartz sand.

Owner:赣州金环磁选科技装备股份有限公司

Method for processing oil sludge

The invention relates to a method for processing oil sludge, and is suitable for processing ground crude oil in oil field, and a whole technology does not impacted by the loading. According to the existence state of oil, sand and water in oil-containing sludge, by the steps of heating, adding drug, homogenizing, aerating, depositing and centrifuging at high speed, the existence distribution state of oil, sand and water can be changed, the sand-in-oil phenomenon in the original oil sludge is gradually changed to sand-in-water, and the inclusion viscosity of the crude oil to sediment is reduced. Through settlement, oil sludge can be separated before entering into a centrifuge, the loading of the high speed centrifuge is reduced, processing amount of a device is increased, and the unit energy consumption is reduced. The separated sediment surface as well as the internal oil content are reduced to the lowest limitation. The unit treatment process parameter can be freely adjusted according to the oil-containing sludge processing requirement, the method has certain adaption capability; the process is simple and smooth, the operation and management are convenient, recovered crude oil and processed sediment can reach the standard in a stable manner, and a system employs the combination of automatic mode and manual operation.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

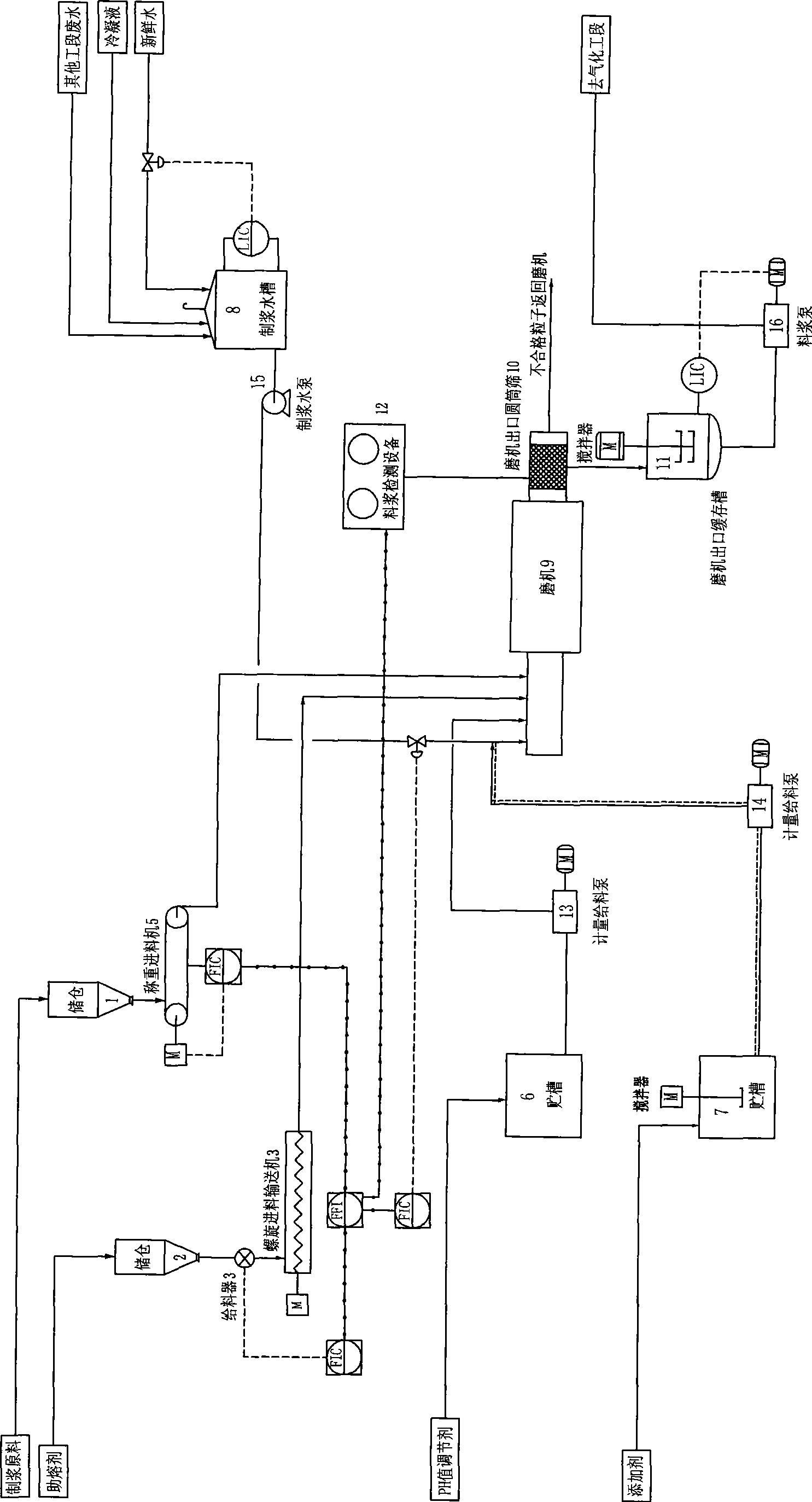

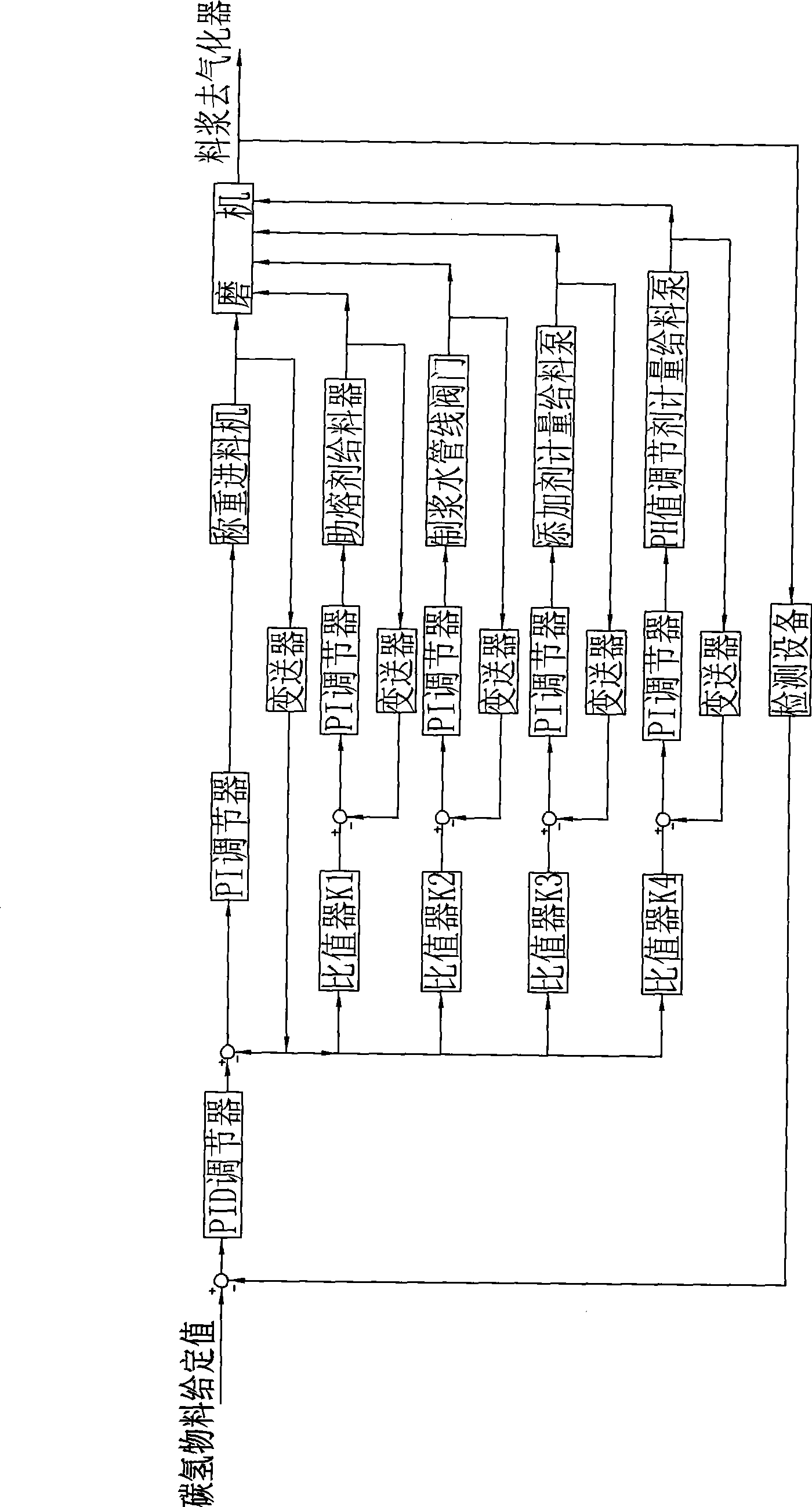

Preparation method of multi-component slurry for production of synthesis gas and multi-component slurry obtained by said method

ActiveCN101362966AIncrease concentrationQuality improvementCombustible gas productionSyngasMetallurgy

The invention relates to a preparation method of multi-element slurry used for producing synthesis gas and also relates to the multi-element slurry by adopting the method. The method comprises the steps as follows: material containing carbon and hydrogen, additive, pH regulator and fluxing agent are adjusted by given values; all material feeding lines are provided with a detecting and measuring device respectively so as to carry out the online detection of the material feeding quantity, send the detected signals to a control system and reset all material feeding quantities in combination with characteristics such as consistency, composition and the like of the grinder slurry till the prepared slurry meets the requirement of a synthesis gas production system. The multi-element slurry prepared by the method achieves the conditions of 58-70wt% of consistency of fixed matter, less than 1500mPa.s of viscosity, less than 200 mesh of granularity and 30-60wt% of grains, the quality is stable, the conveying and gasifying are easy to be carried out and the method has obvious economical benefits.

Owner:XIAN ORIGIN CHEM TECH

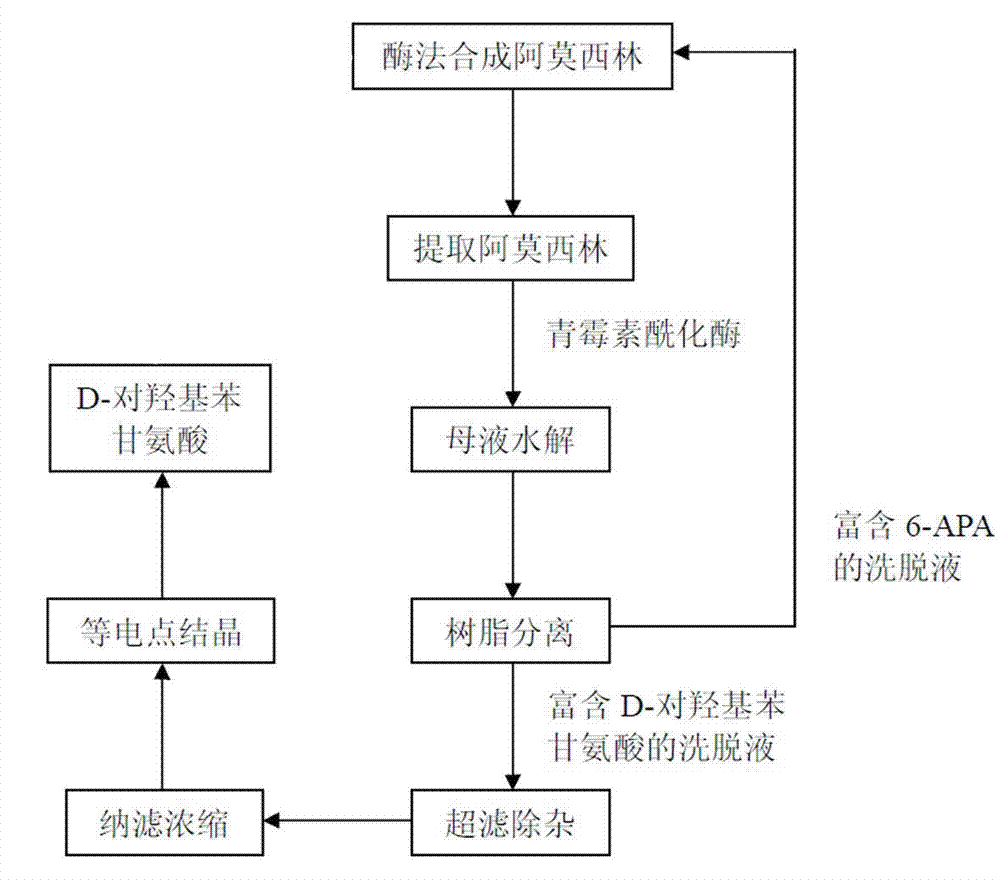

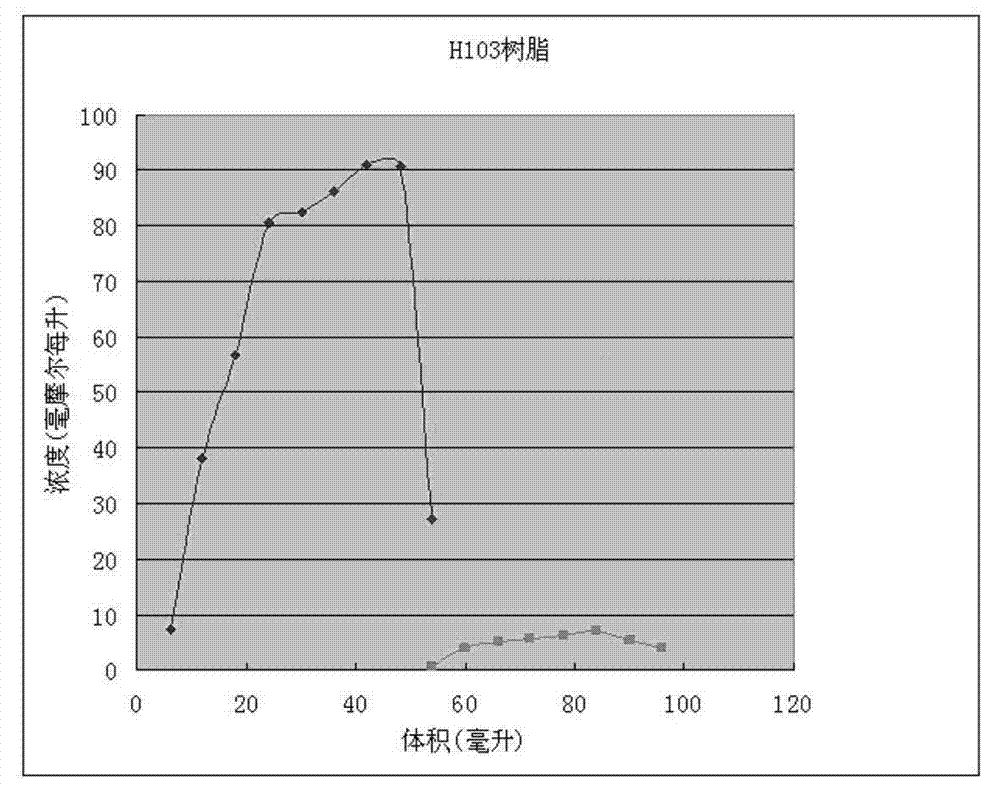

Method for recycling active ingredients in amoxicillin mother liquor synthesized by enzymatic method

ActiveCN102816803AAvoid adverse reactionsRelieve pressureOrganic compound preparationChemical industryBULK ACTIVE INGREDIENTP-hydroxyphenylglycine

The invention discloses a method for recycling active ingredients in the amoxicillin mother liquor synthesized by an enzymatic method. The method includes synthesizing the amoxicillin mother liquor by the enzymatic method; separating the amoxicillin mother liquor through a macro-porous resin column, eluting the separated amoxicillin mother liquor by deionized water, and collecting an eluant rich in D-4-Hydroxyphenylglycine and an eluant rich in 6-amino penicillanic acid (APA) respectively; filtering the eluant rich in D-4-Hydroxyphenylglycine with Daltonian ultrafiltration membranes with a cutoff molecular weight of 150 to 200; performing nanofiltration concentration on the Daltonian ultrafiltration membranes for the filtered liquor with the cutoff molecular weight of 150 to 200, and standing, crystallizing and filtering the concentrated liquor to obtain solids, and drying the solids to obtain the D-4-Hydroxyphenylglycine. According to the method, the technological design is reasonable, the operation is convenient, the recycling effect is good, and energy is saved and the environment is protected.

Owner:NORTH CHINA PHARM GRP SEMISYNTECH CO LTD

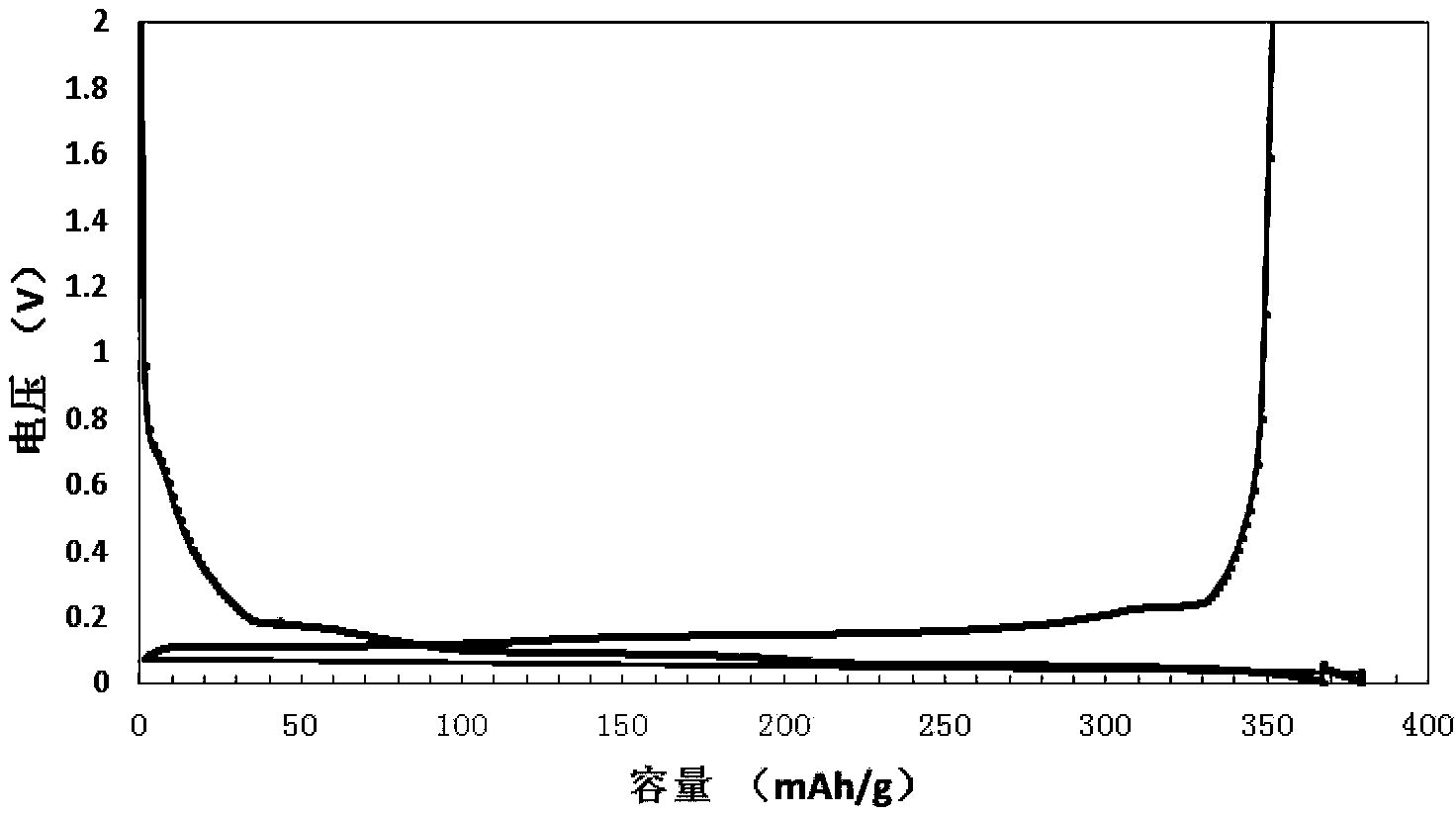

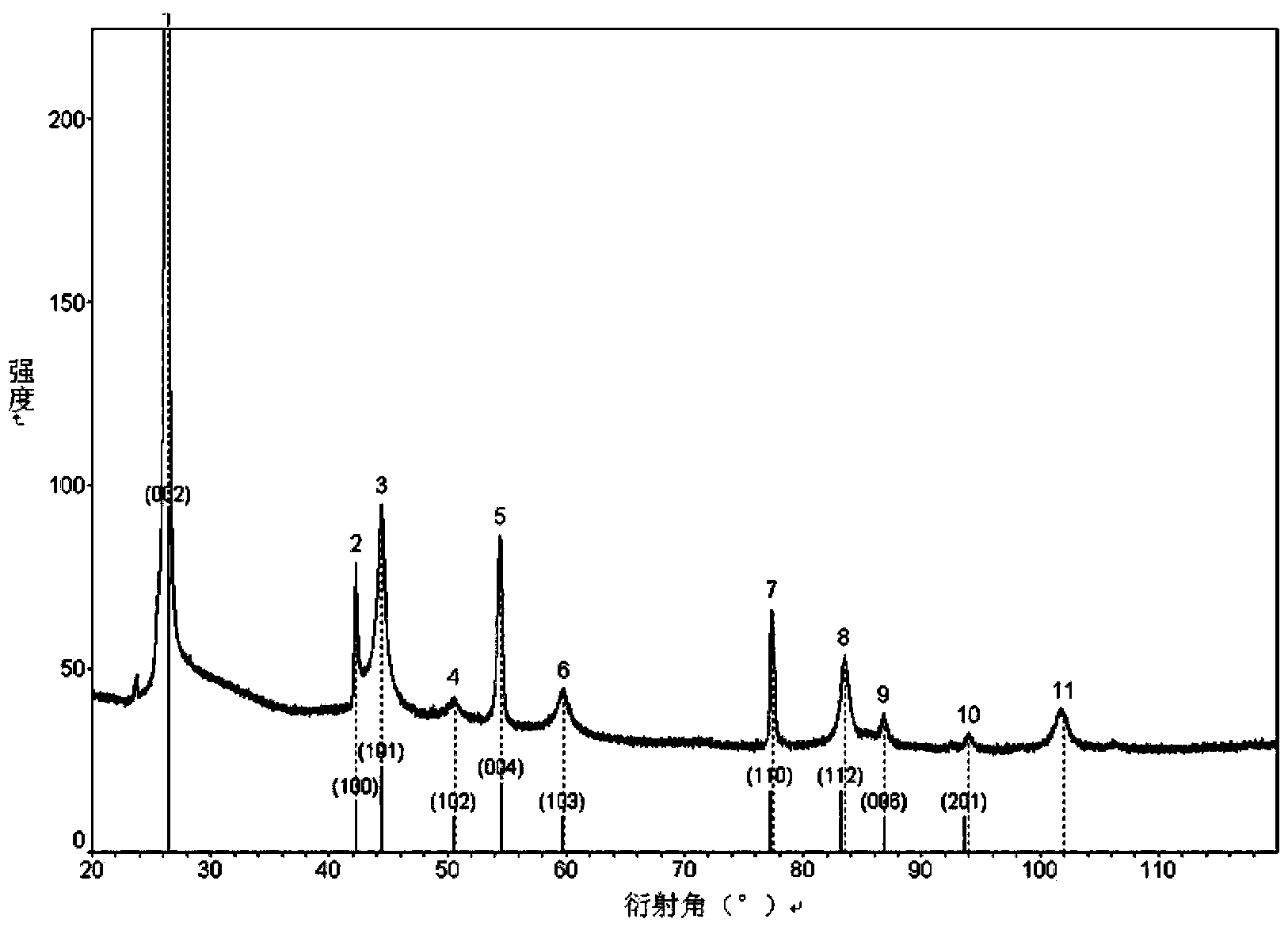

Lithium battery negative electrode material and preparation method thereof

InactiveCN103855369AIncrease energy densityHigh liquid absorptionNegative electrodesLi-accumulatorsNanotechnologyElectrode material

The invention discloses a lithium battery negative electrode material and a preparation method thereof. The preparation method of the lithium battery negative electrode material comprises the following steps of heating and stirring a mixture of carbon powder, a binder and a catalyst, pressing and molding, carbonizing, and graphitizing the mixture. The prepared lithium battery negative electrode material is high in graphitization degree, good in isotropic property, high in energy density, good in cycling property and low in preparation cost; the preparation process combining the molding graphitization and catalytic graphitization is also applicable to the graphitization process of other powder materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

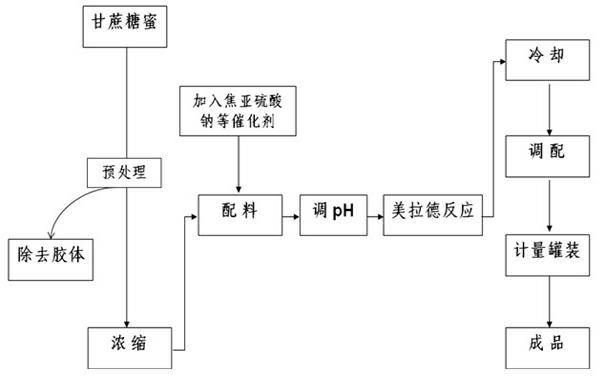

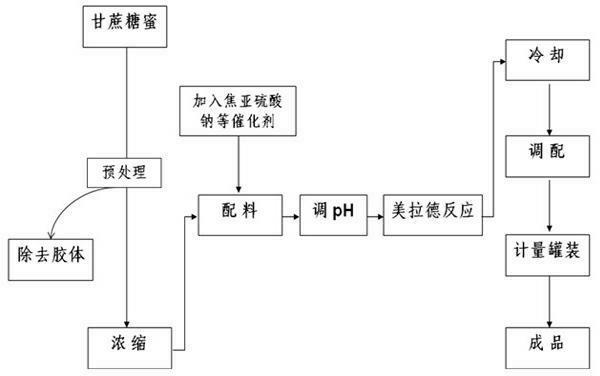

Method for producing high color ratio double-strength caramel using cane molasses

The invention provides a method for producing high color ratio double-strength caramel using cane molasses, which includes: a, pretreating cane molasses to remove gum, and filtering the molasses solution after neutralizing PH value; b, concentrating the pretreated molasses till the molasses accounts for 60%-80% of total molasses in weight percentage; c, adding solid catalysts, namely sodium pyrosulfite and ammonium bicarbonate; d, adding phosphoric acid to adjust the PH value to 5.5; e, heating and controlling temperature, and performing Maillard reaction; f, cooling caramel; g, blending, metering, and canning to obtain the finished product. The method overcomes a plurality of technical bottlenecks, and implements production of the high color ratio double-strength caramel using the cane molasses to replace white granulated sugar or glucose as material, and accordingly material cost is reduced greatly, and the molasses is turned into wealth. The color ratio of the double-strength caramel can be up to 120000EBC, and liquid catalysts such as traditional liquid ammonia, liquid sulfur dioxide and the like are replaced with the solid catalysts such as the sodium pyrosulfite and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

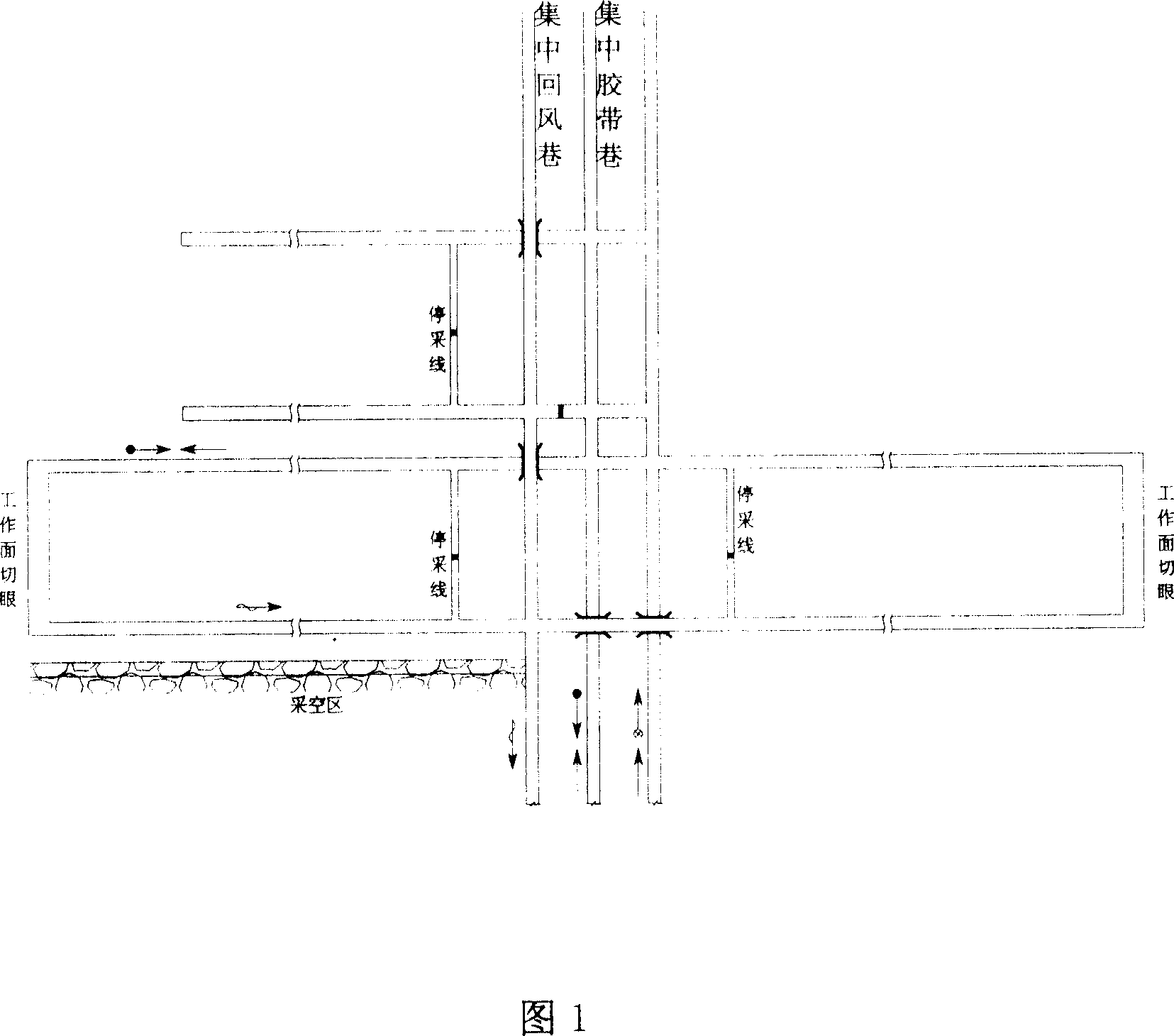

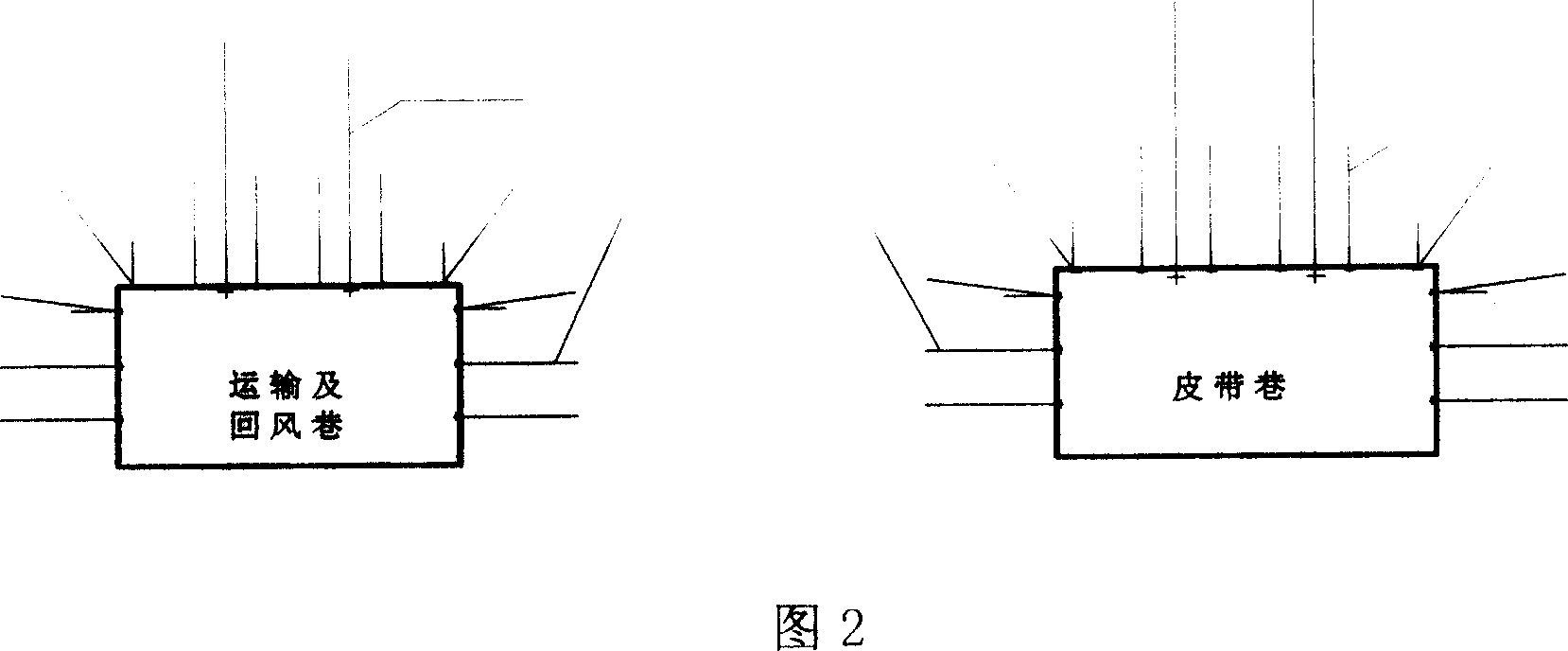

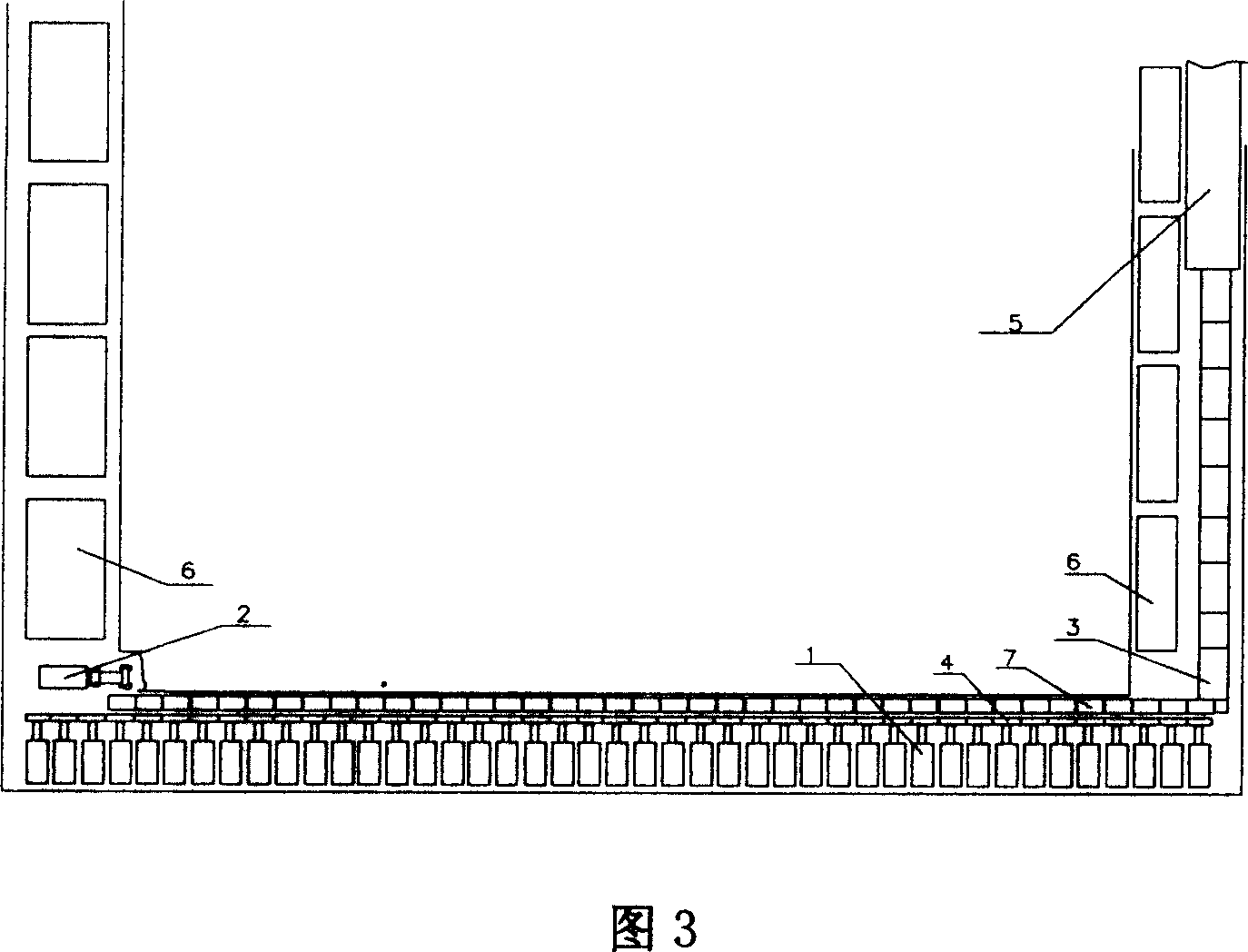

Full-seam cutting, retreating, separate moving and full-caving comprehensive mechanized coal mining method and equipment

ActiveCN1932240ALarge air volumeImprove support strengthUnderground miningSurface miningIt equipmentTransport system

The present invention provides a full-seam mining retreating separately-moving full-span comprehensive mechanized coal-cutting method and its equipment. It is mainly characterized by that it adopts full-seam mining support form, utilizes crawler-type single-drum shearer to cut coal and utilizes the separate movement of coal-cutting equipment coal-conveying equipment and supporting equipment and transporting system to implement coal-cutting operation. Besides, said invention also provides the concrete steps of said mechanized coal-cutting method.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

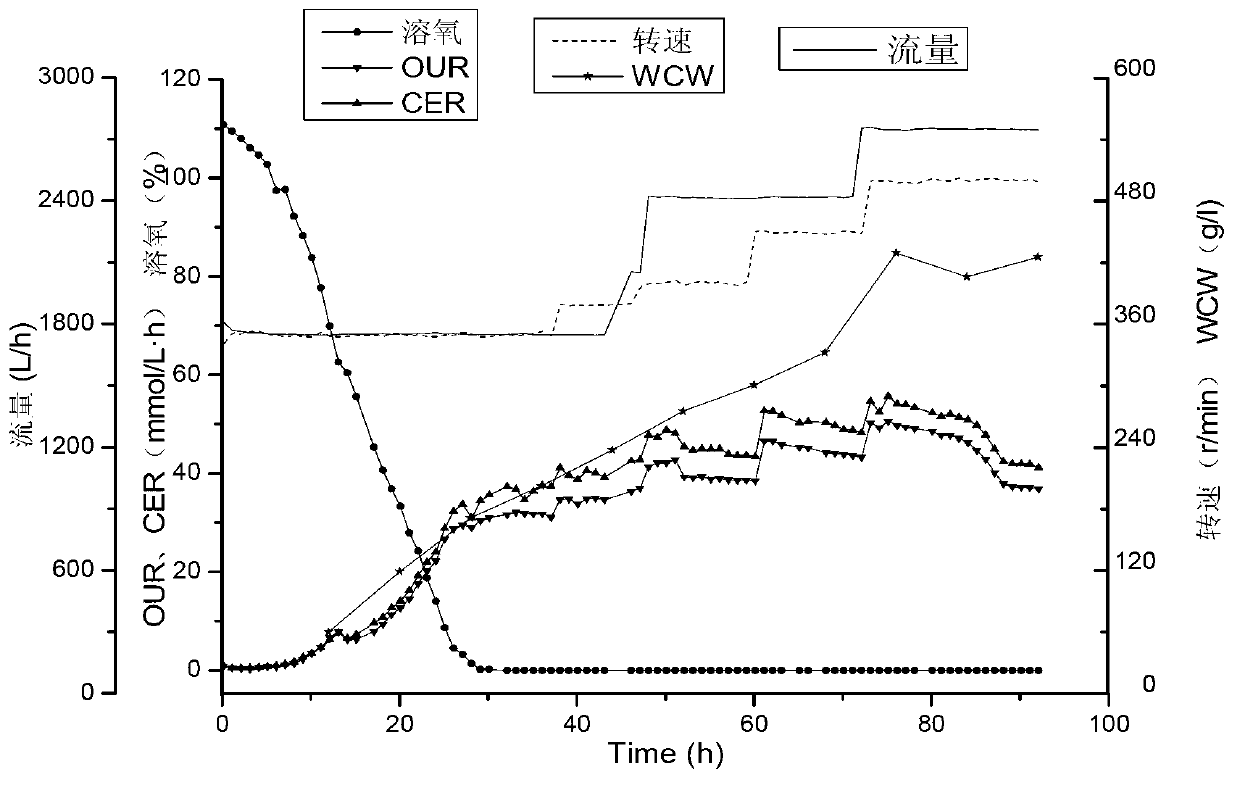

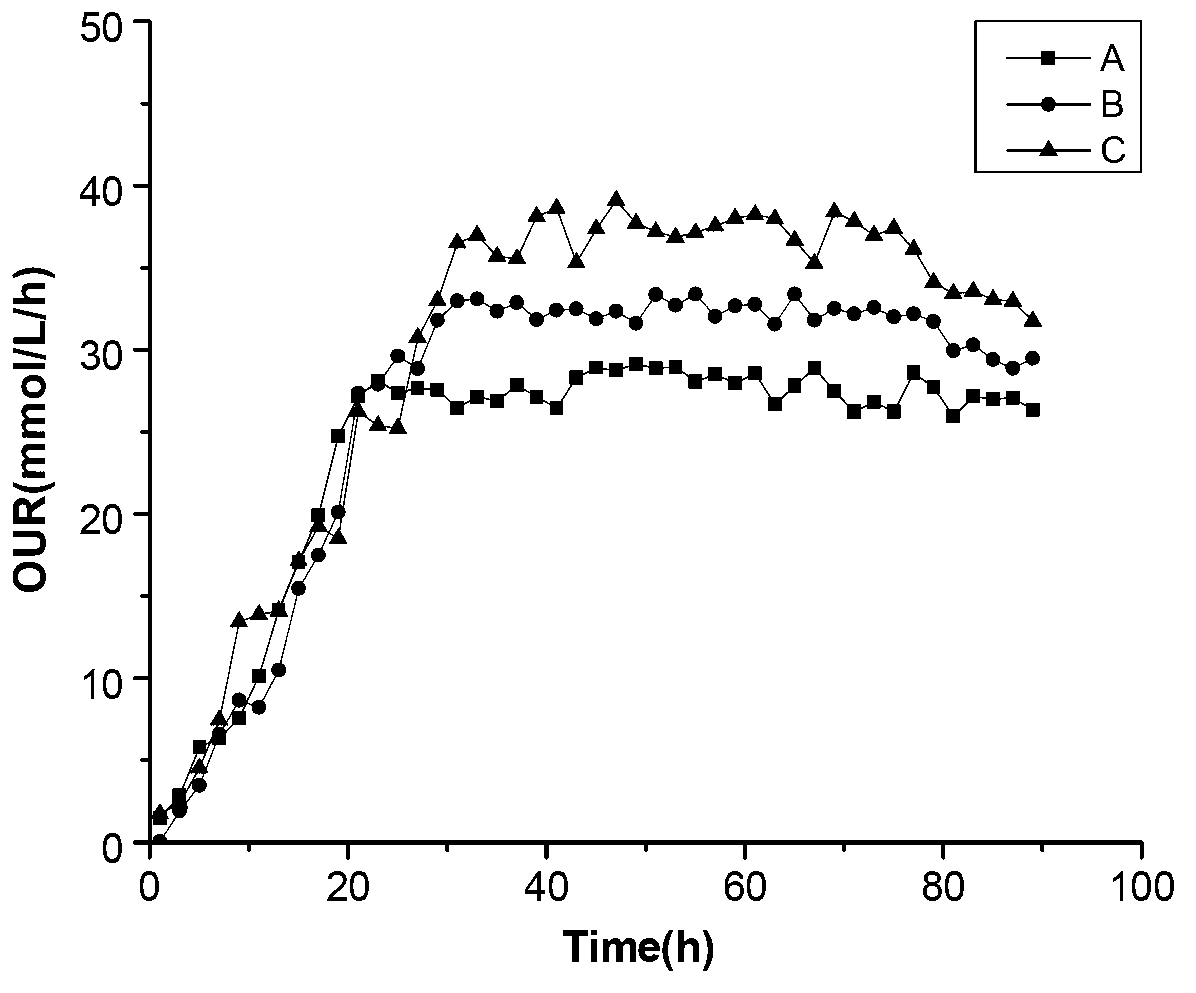

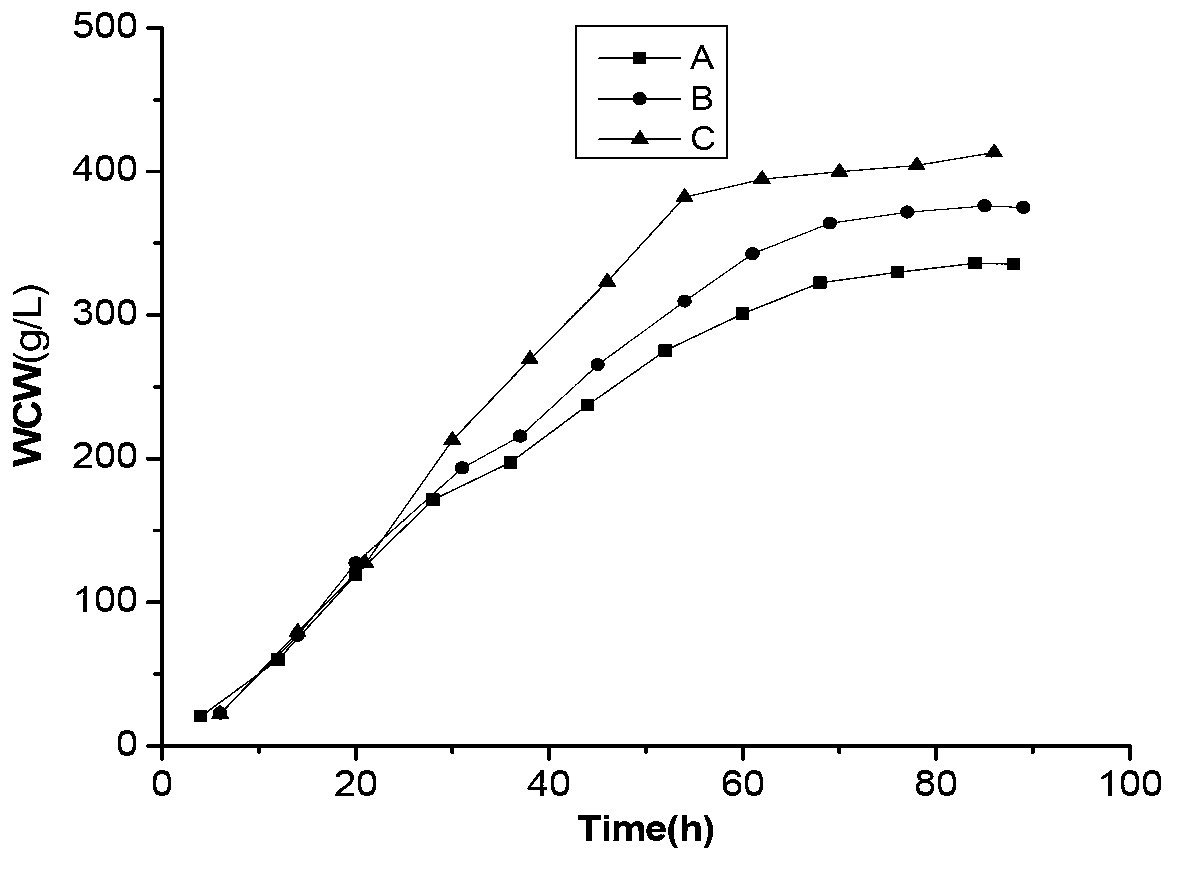

Novel process for fermenting coenzyme Q10 based on online oxygen consumption rate control

ActiveCN102876743AHigh yieldReduce wasteMicroorganism based processesFermentationOperabilityFermentation

The invention provides a novel process for fermenting coenzyme Q10 based on online oxygen consumption rate control. Oxygen consumption rate is controlled at 30-150mmol / L*h during fermentation of coenzyme Q10 strain production, so that growth of thallus and starting and accumulation of coenzyme Q10 synthesis are promoted. Yield of coenzyme Q10 is evidently increased, unit energy consumption is lowered, and production cost is lowered greatly. The novel process is simple to control, high in operability, energy-saving and the like.

Owner:SHANGYU NHU BIOCHEM IND +1

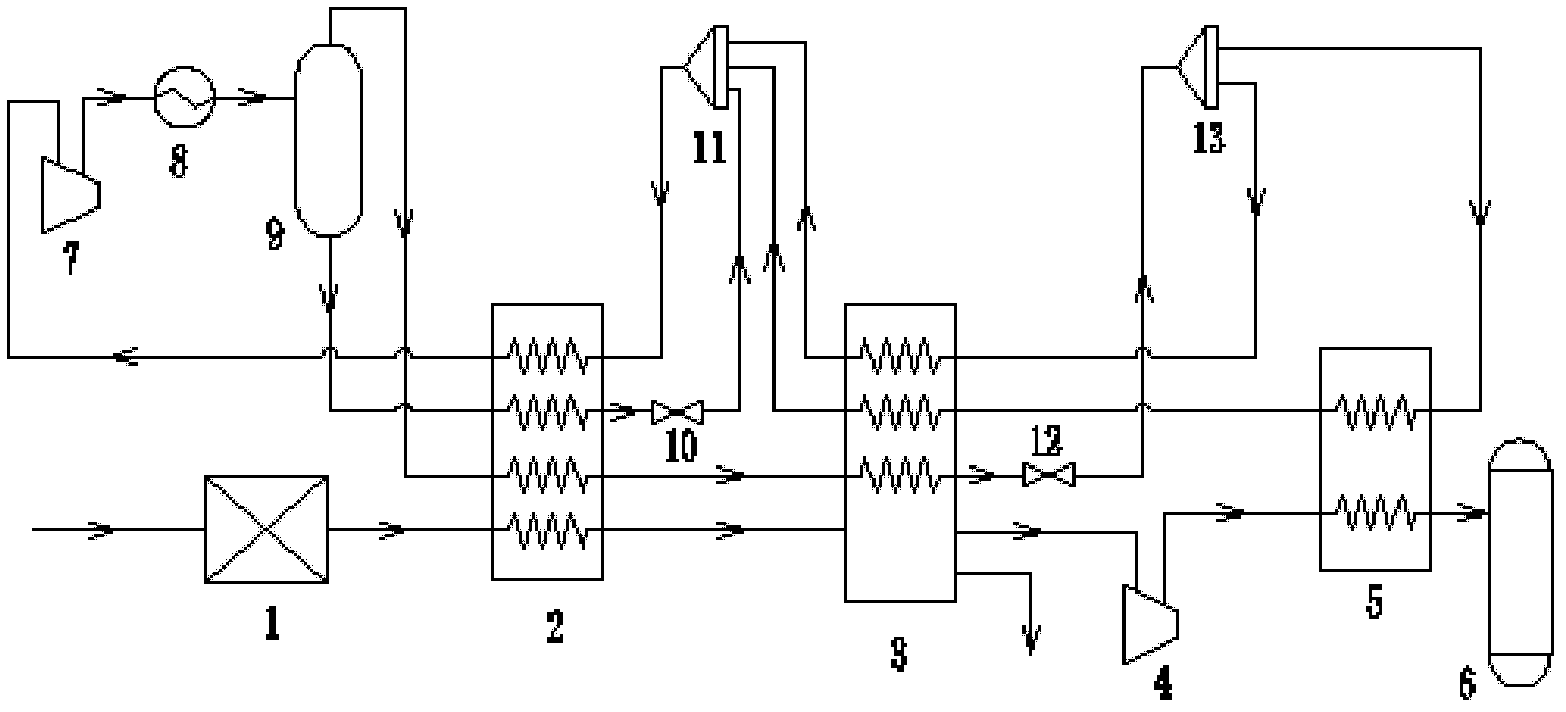

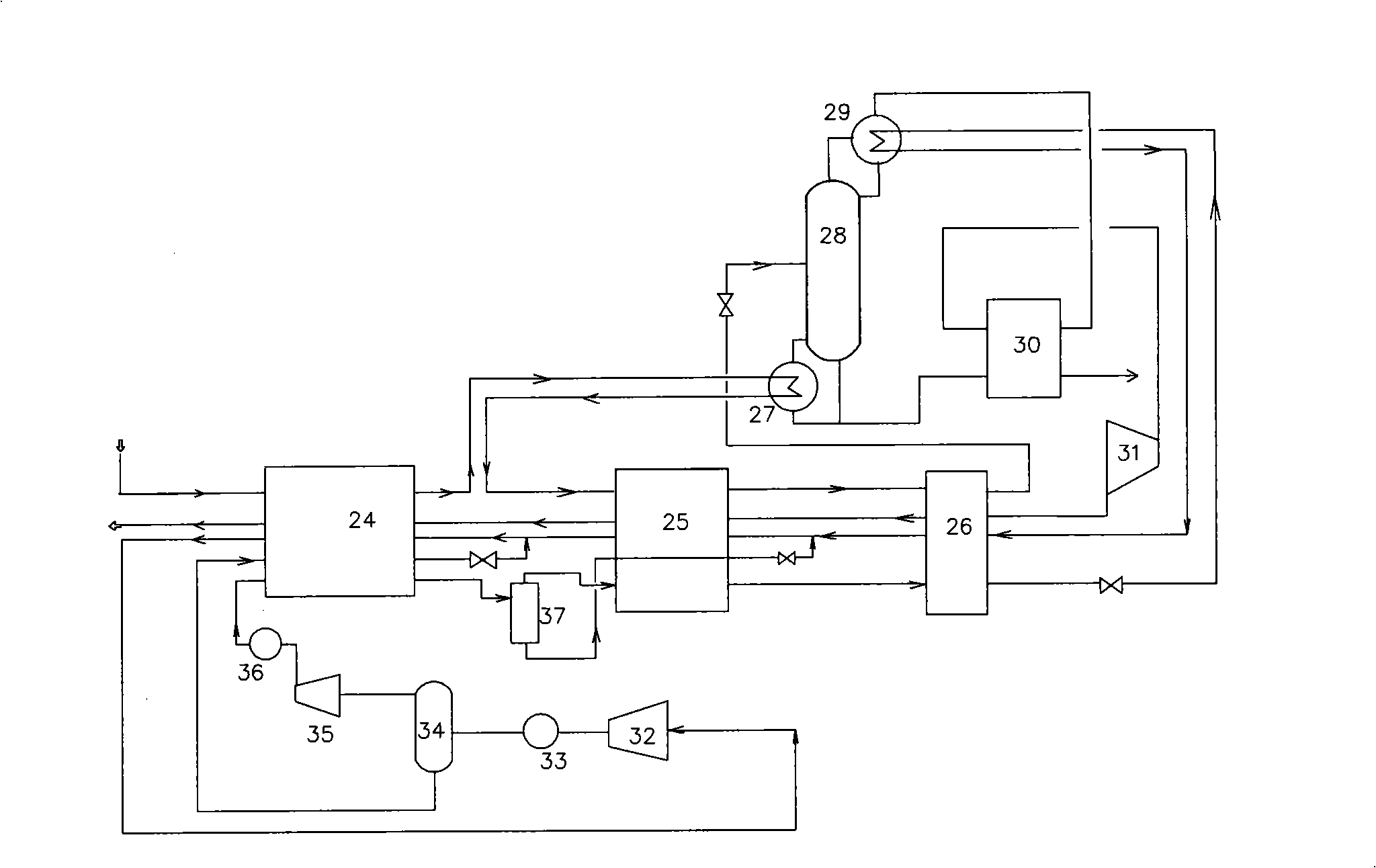

Mixed refrigerant circulation natural gas zone pressure liquefaction technology with sublimation removal of CO2

InactiveCN102620523AImprove toleranceReduce unit energy consumptionSolidificationLiquefactionEngineeringHigh pressure

The invention relates to mixed refrigerant circulation natural gas zone pressure liquefaction technology with sublimation removal of CO2. In the liquefaction process, natural gas maintains a gas state and is pre-cooled, and then enters a crystallizer to be continuously cooled, and the content of CO2 is reduced to 0.5% while solid dry ice is separated through sublimation. Next the natural gas enters a low temperature compressor for pressurization, then enters a liquefaction device, is liquefied under high pressure, and enters a storage tank for storage under. The cold energy required by the liquefaction process is provided by an independent mixed refrigerant circulation refrigeration system. Compared with the prior art, the mixed refrigerant circulation natural gas zone pressure liquefaction technology with sublimation removal of CO2 omits a CO2 pre-treatment device which occupies large area in the conventional natural gas liquefaction process, can greatly reduce investment cost that an offshore platform with high manufacture cost performs natural gas liquefaction, simultaneously, the energy consumption of refrigeration circulation is also reduced by liquefying the natural gas at high temperature.

Owner:SHANGHAI JIAO TONG UNIV

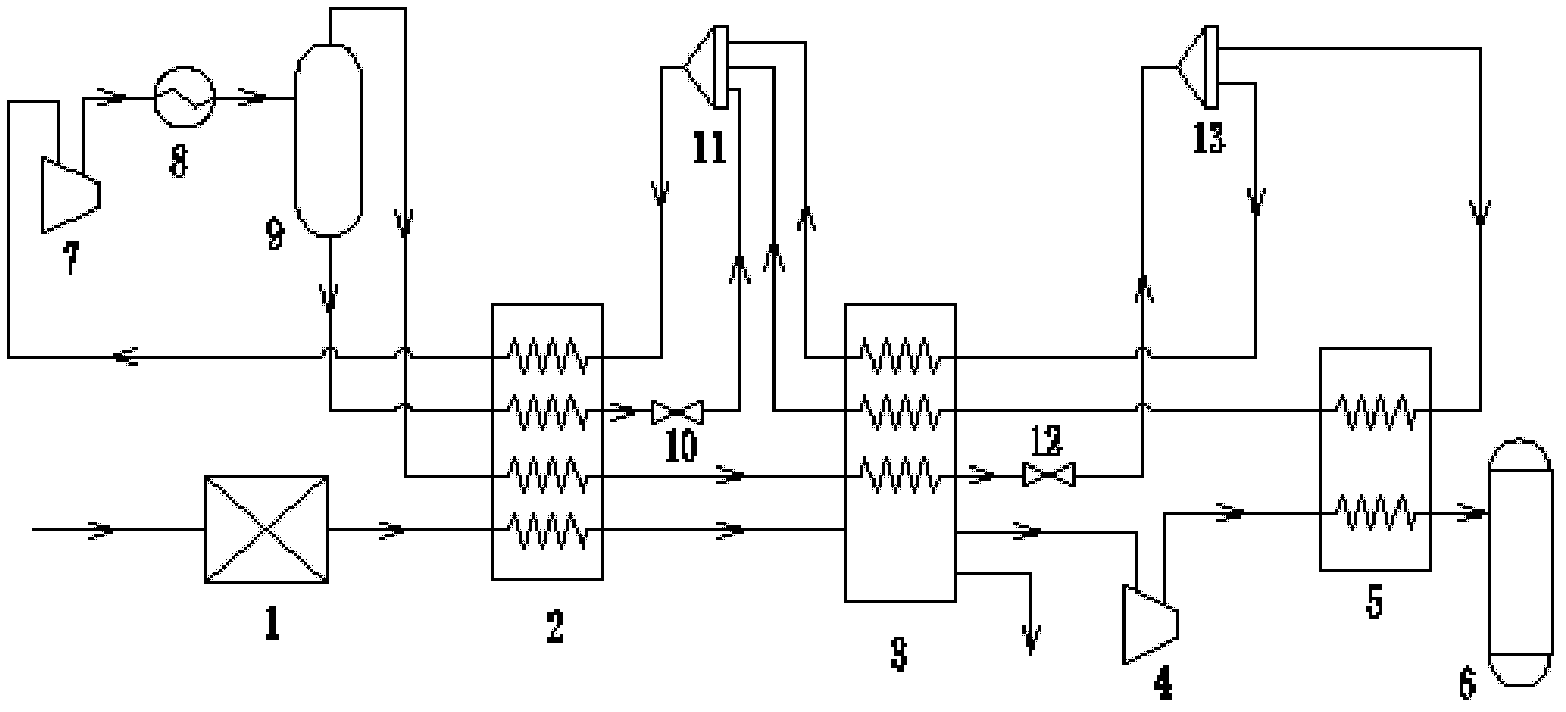

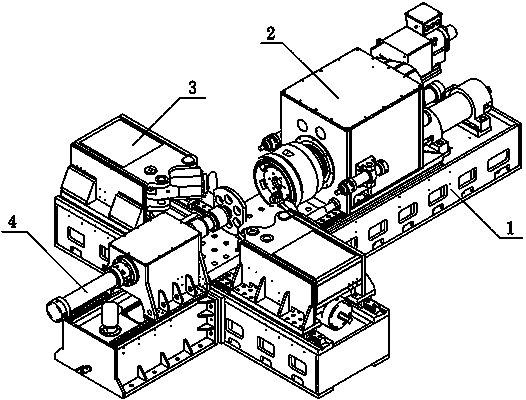

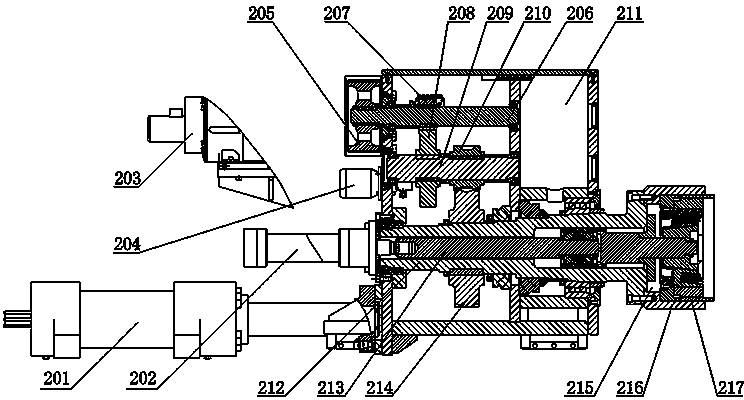

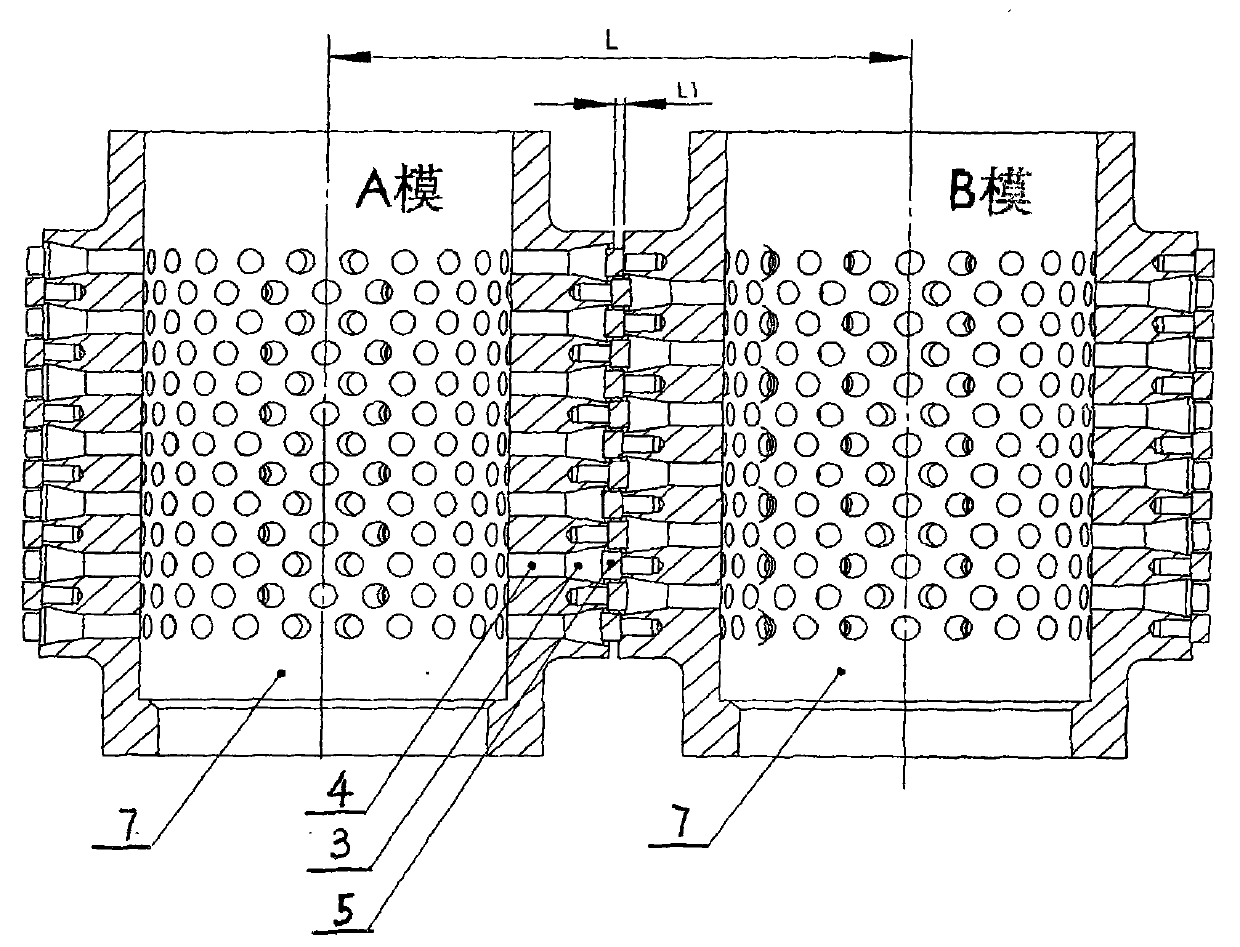

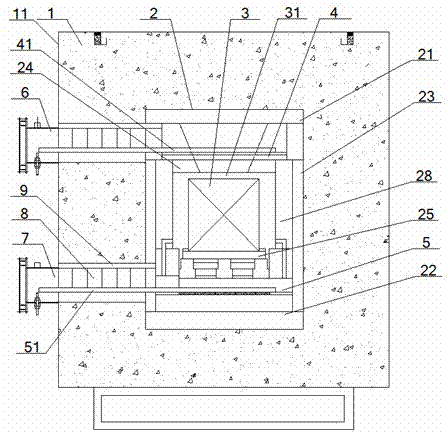

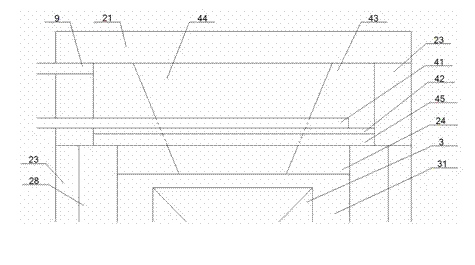

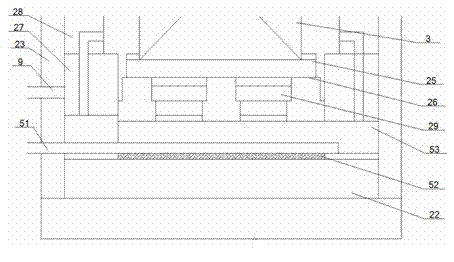

Special numerical-control spinning forming machine for hub parts of engineering vehicle

ActiveCN103433345ASolve UtilizationIncrease profitMetal-working apparatusSpinningStructural engineering

The invention relates to a special numerical-control spinning forming machine for hub parts of an engineering vehicle. The special numerical-control spinning forming machine comprises a lathe bed (1), a main shaft component (2), two spinning roller components (3) and a tail jacking component (4), wherein the lathe bed (1) is of a cross shape structure, the main shaft component (2) and the tail jacking component (4) are longitudinally mounted on the lathe bed (1), and the two spinning roller components (3) are transversely and symmetrically mounted on the lathe bed (1); the main shaft component (2) carries out rotary input by utilizing a main shaft motor, the spinning roller components (3) are of double-sliding-block symmetrical structures, each spinning roller head (314) is provided with four fixed mounting angles and can be regulated and mounted according to a process, and the tail jacking component (4) is in rigid connection with a main shaft tank so as to realize longitudinal synchronous feed. The special numerical-control spinning forming machine has the advantages that the strong spinning and flaring-flanging forming of cylinder-shaped and cone-shaped revolved body type parts can be realized, the spinning forming of annular thin-wall wheel hub parts with abnormal-shape curved buses can be realized, the energy and the materials are saved, and the automation degree and the working efficiency are high.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

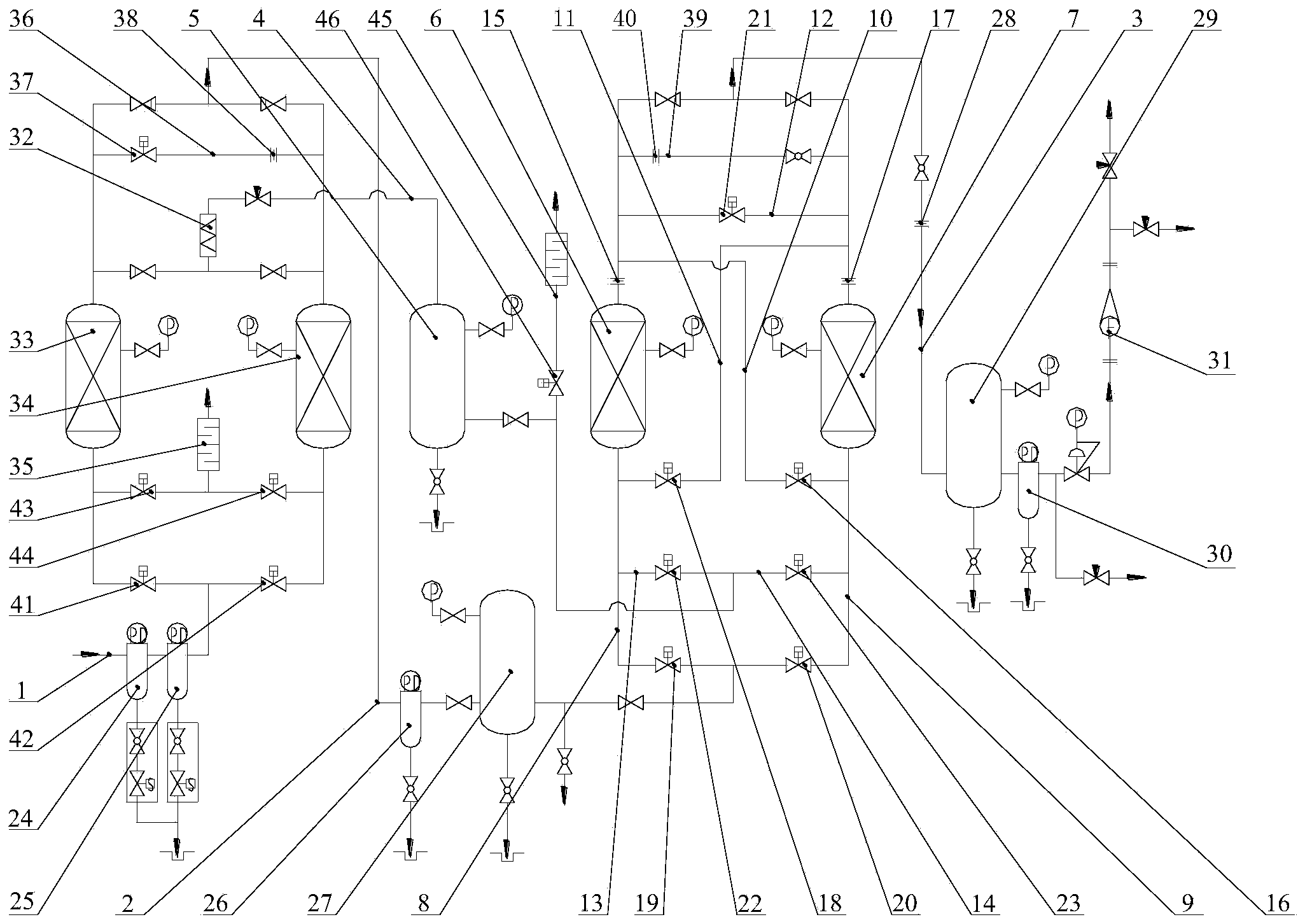

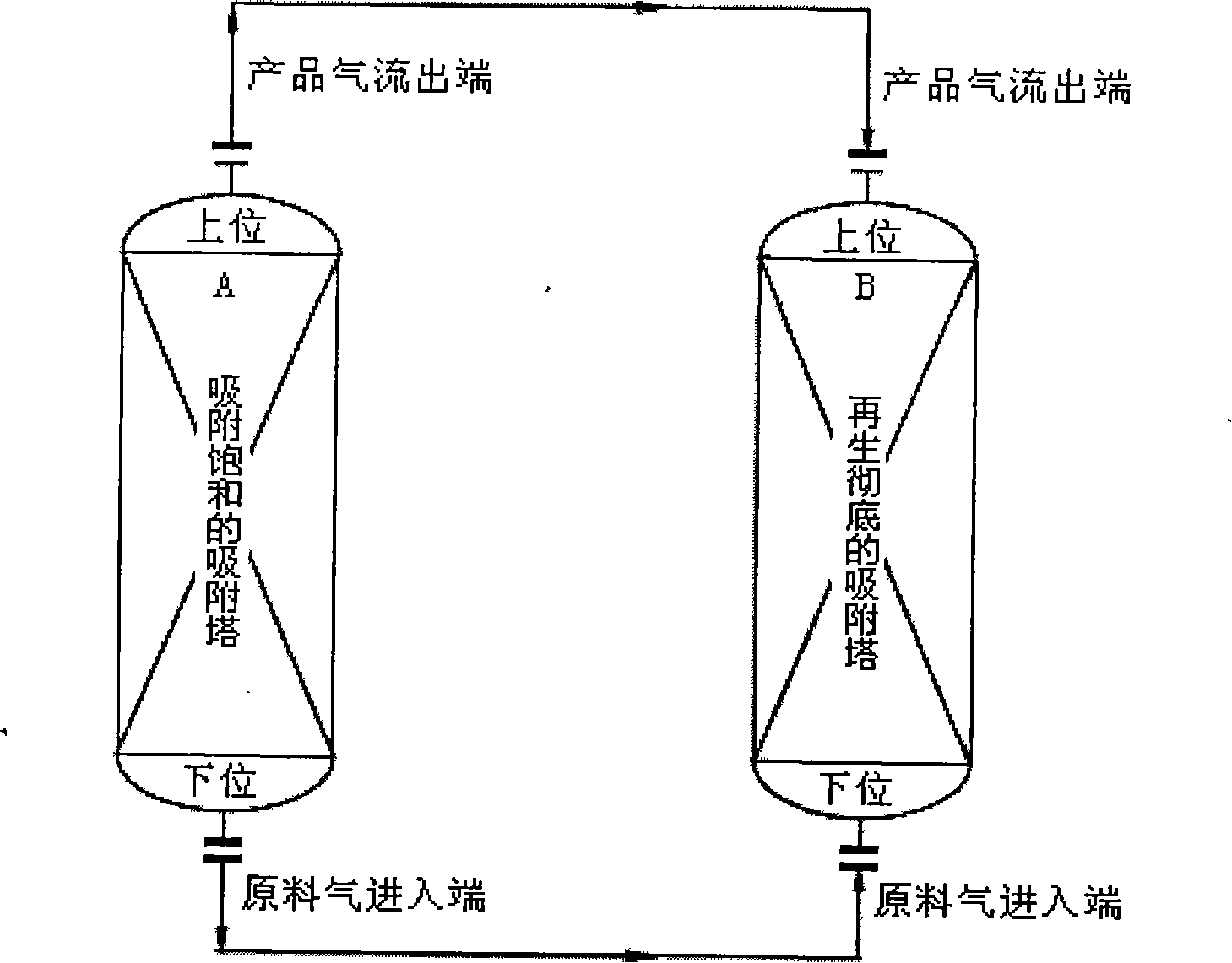

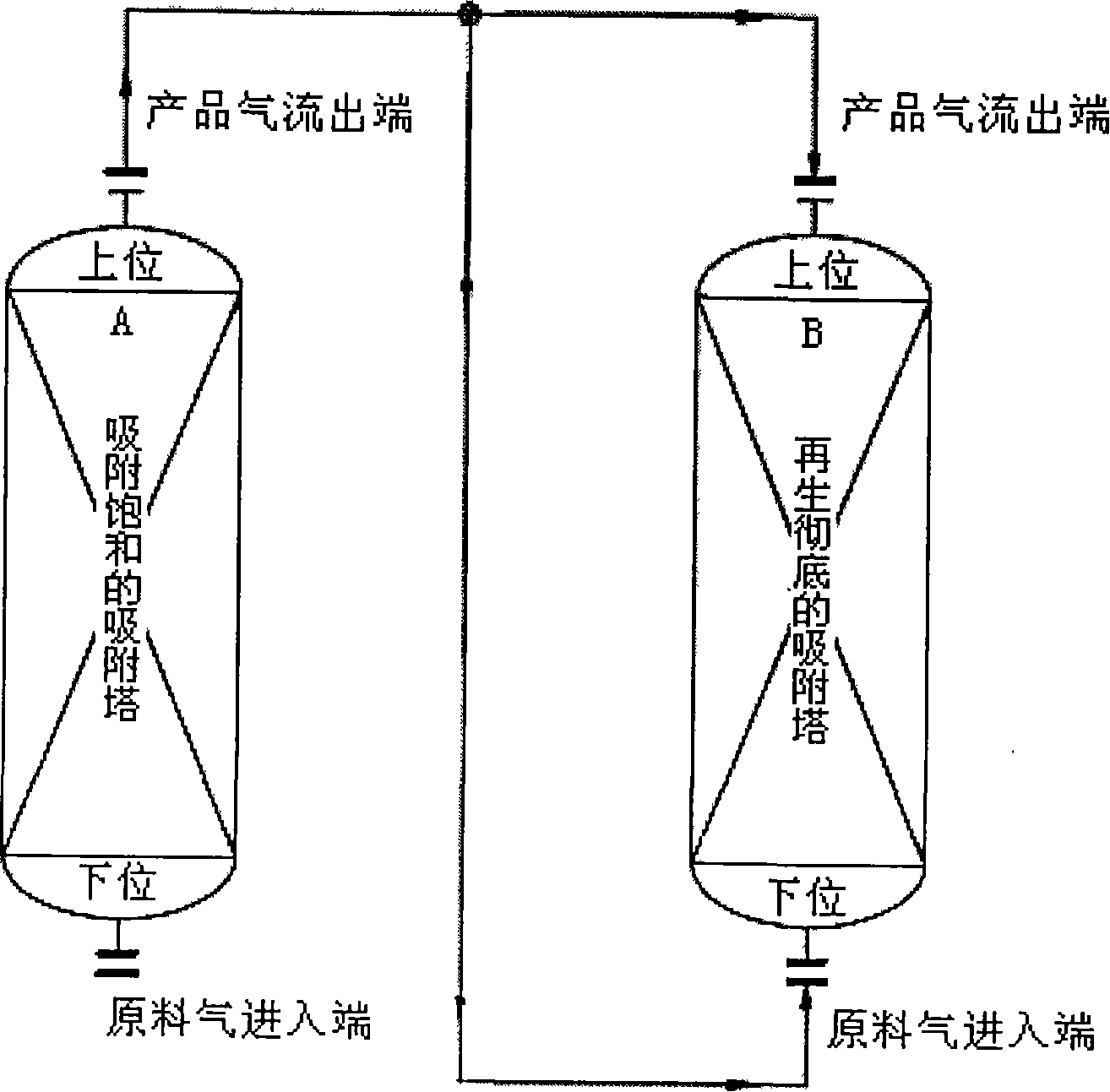

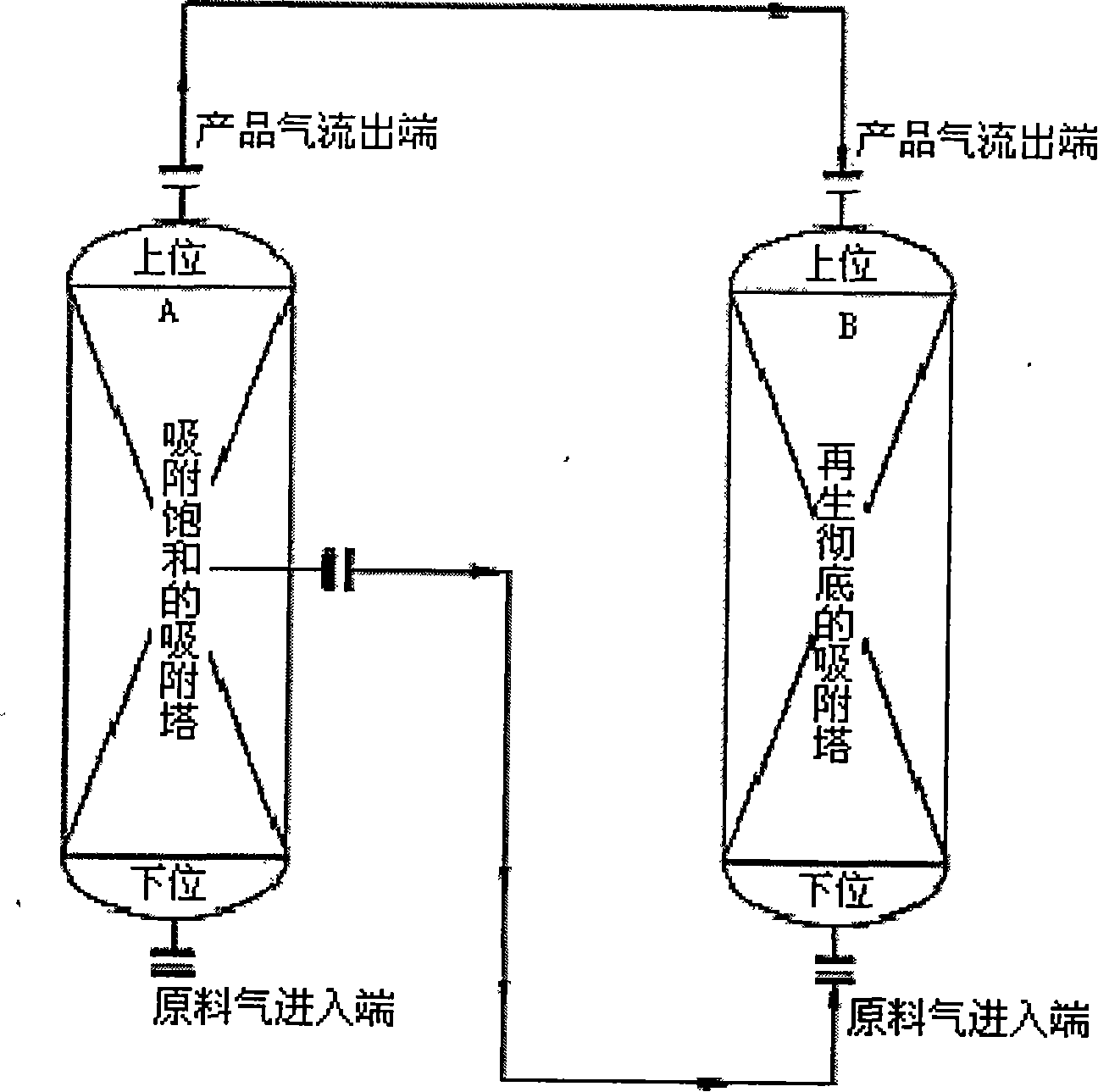

Pressure swing adsorption oxygen generating equipment and method

ActiveCN104340961AEfficient use ofIncrease profitDispersed particle separationSpecific gas purification/separationLow speedProcess engineering

The invention provides pressure swing adsorption oxygen generating equipment and method. The equipment comprises an intake pipeline, a heat regenerative adsorption type dryer, a gas conveying pipeline, a pressure swing adsorption oxygen generating host, a finished gas output pipeline, a regenerating pipeline and an exhaust gas recovery tank, wherein an inlet of the heat regenerative adsorption type dryer is connected with the intake pipeline, and an outlet of the heat regenerative adsorption type dryer is connected with the gas conveying pipeline; an inlet of the pressure swing adsorption oxygen generating host is connected with the gas conveying pipeline, and an outlet of the pressure swing adsorption oxygen generating host is connected with the finished gas output pipeline; the pressure swing adsorption oxygen generating host also comprises a first adsorption tower and a second adsorption tower, and an outlet of the first adsorption tower is connected with an inlet of the second adsorption tower through a third pipeline; an outlet of the second adsorption tower is connected with an inlet of the first adsorption tower through a fourth pipeline, and the exhaust gas recovery tank is arranged on the regenerating pipeline. By adopting an exhaust recovery device, a seven-valve two-step non-equipotential voltage-sharing process, and a low-speed voltage-sharing control technology, the unit energy consumption of oxygen generation can be substantially reduced, and the air utilization rate and the equipment reliability are improved.

Owner:WUHAN HENGYETONG GAS EQUIP

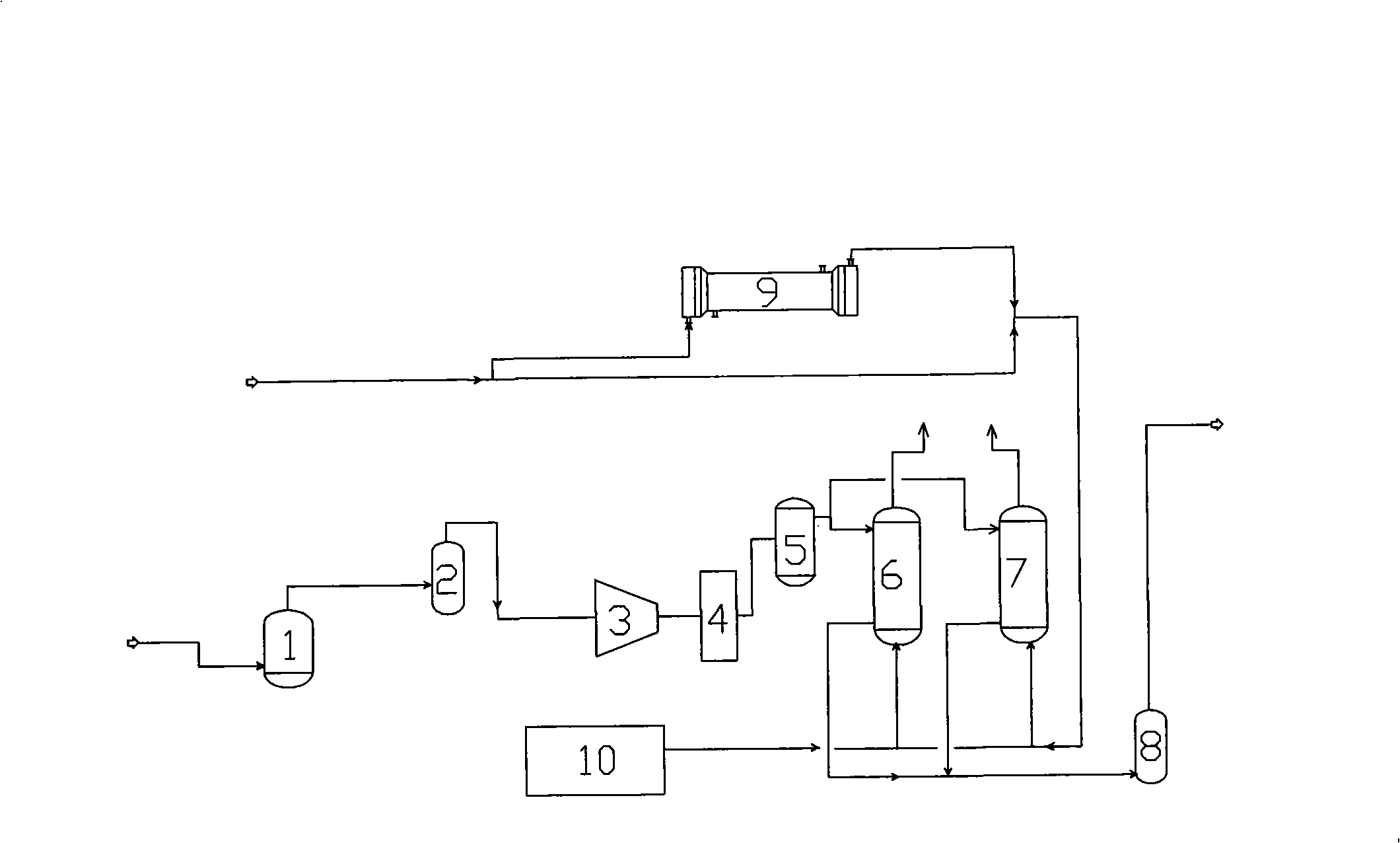

Air backheating type mine gas separation and liquefaction method and apparatus

InactiveCN101270952AIncrease costImprove energy consumptionSolidificationLiquefactionNitrogenEngineering

The invention relates to a mine gas separation liquefaction method and a device. The technical proposal of the method is that raw mine gas is compressed and purified, the impurities are removed to produce compressed purified mine gas; the compressed purified mine gas is inlet into a heat exchanger to be cooled to below 82.5 degree centigrade below zero; the cooled mine gas is inlet into the middle part of a fractionating tower, wherein the bottom part of the fractionating tower is provided with an evaporator, the top is provided with a condenser; the top of the fractionating tower produces low temperature air of high purity, while the bottom of the fractionating tower produces high purity liquefied natural gas; the low temperature air separated at the top of the fractionating tower is inlet into the heat exchanger to be used as the cold energy source. The method and the device of the invention avoids production process of nitrogen at low temperatures and adopts the method of air recycling, thereby the structure is simple, the cost and the energy consumption are reduced, and the device and the method are more conducive to wide popularization.

Owner:北京国能时代能源科技发展有限公司 +1

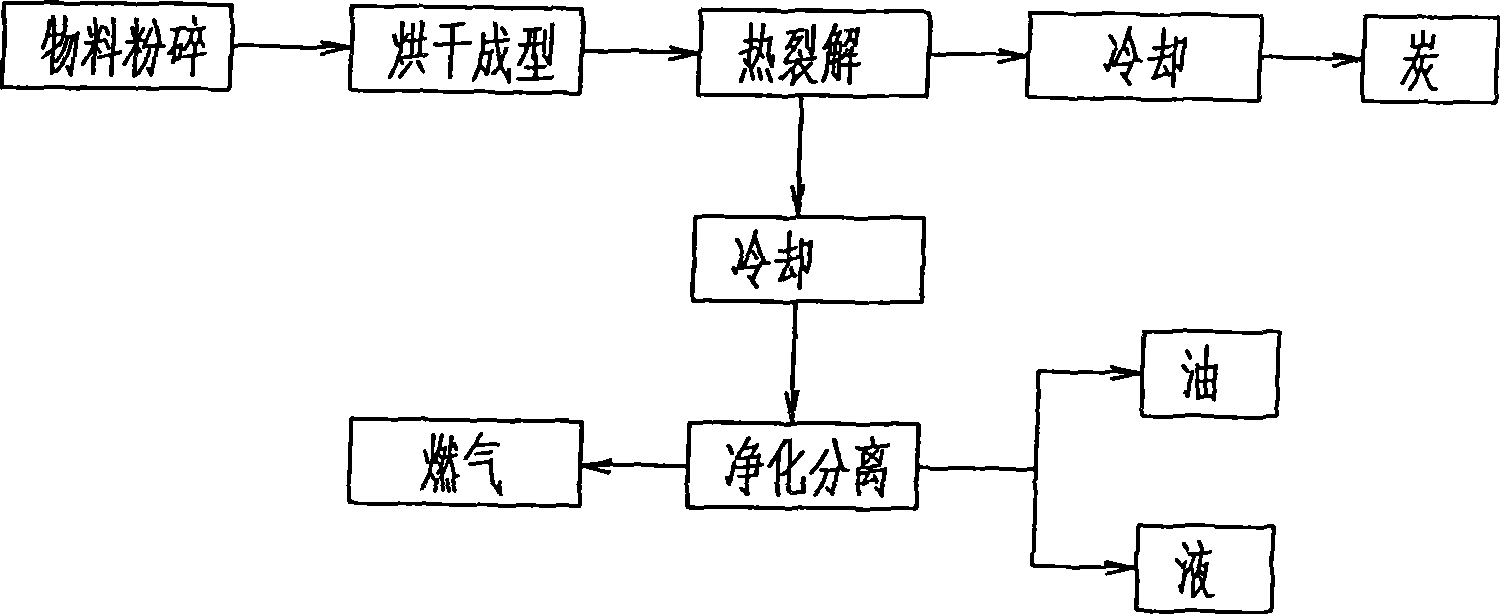

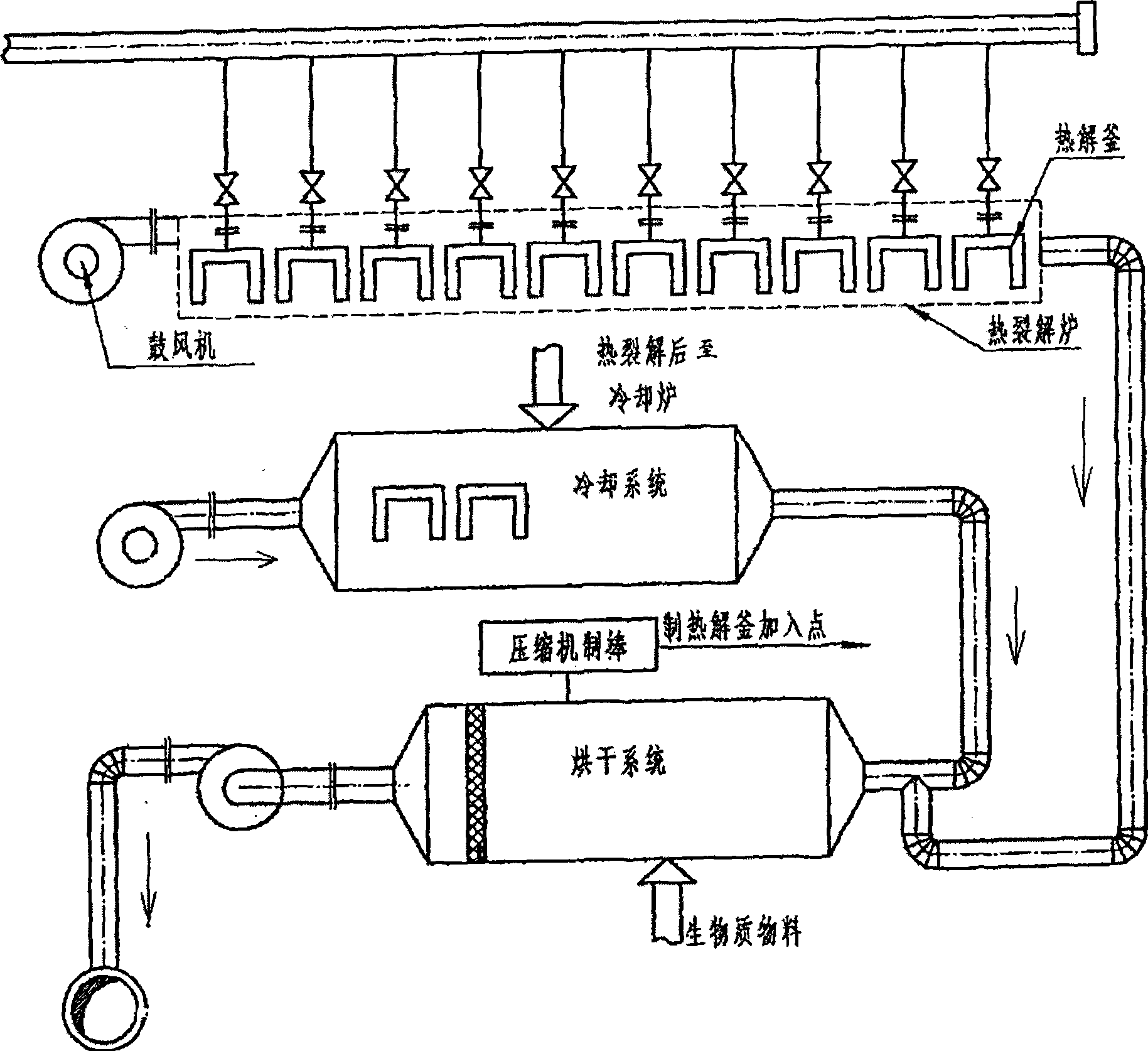

Method for preparing carbon, gas, oil and solution in scale by thermally cracking biomass material

InactiveCN101372624AImprove comprehensive heat utilization efficiencyReduce unit energy consumptionBiofuelsEnergy inputBiomassProcess engineering

The invention discloses a method for large-scale preparation of carbon, gas, oil and liquid by thermal cracking of biomass materials; the method includes the following production steps: material pulverization-drying and molding-thermal cracking-cooling and separation; in the invention, waste heat in a cooling system and a thermal cracking system is induced into a drying and molding system for drying materials, biomass fuel gas obtained by cooling and separation is burned to provide heat for thermal cracking, surplus biomass fuel gas is stored and used as industrial or domestic fuel. In thermal cracking, a plurality of thermal cracking reactors are taken as one batch to form one row which is positioned in a thermal cracking furnace. The method can raise comprehensive heat utilization efficiency of the system, greatly reduce unit energy consumption of products, improve the operating efficiency of the system, achieve outstanding energy-saving effect, shorten molding time of products, reduce heat emission and effectively control thermal pollution, thus achieving significant environmental production benefits. The method can realize large-scale production and has the capacity of treating tens of thousands of tons of raw materials every year.

Owner:熊晓明

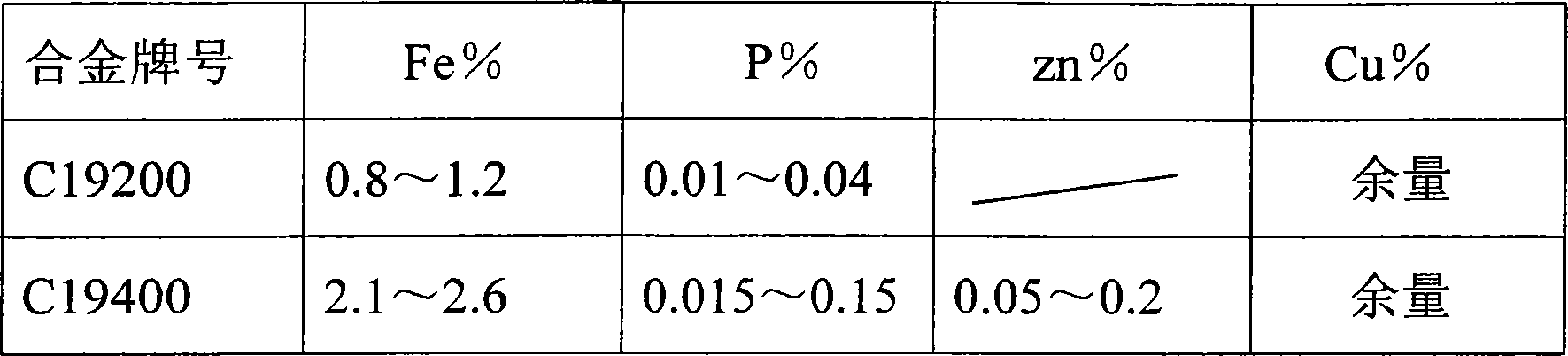

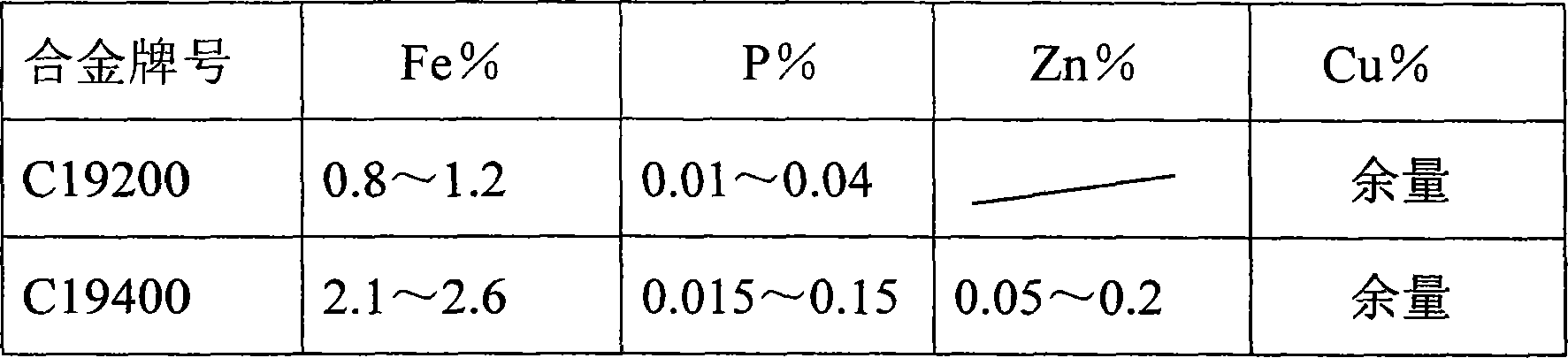

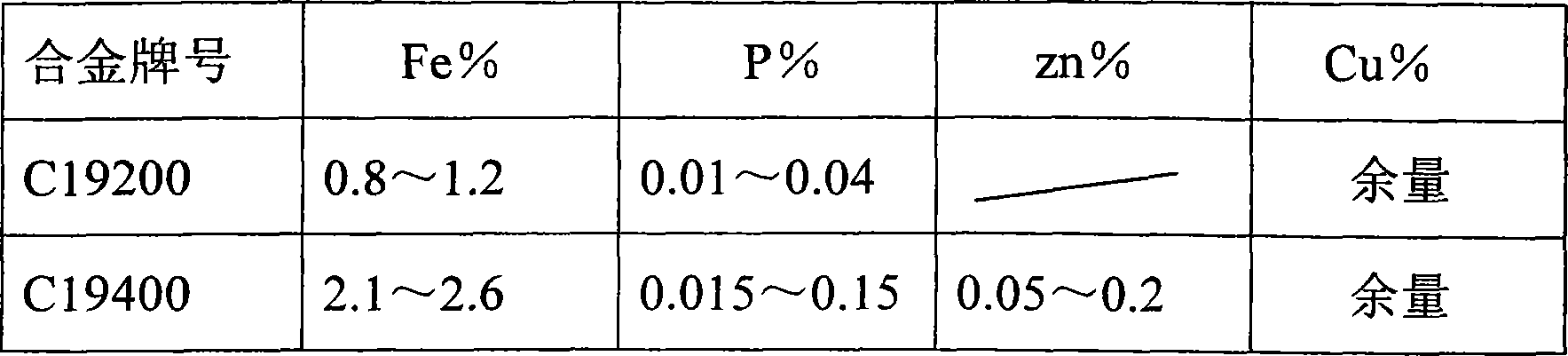

Producing method of lead frame cuprum alloy strip with high strength and conductivity

The invention relates to a production method of a high-strength and high conductive lead frame copper alloy strip material. The main process steps comprises: batching and up melt casting; the material in the step 1 is added into a subsurface flow continuous furnace according to the formula for up melt casting; a crystallizer adopts the graphite material and dry carbon black is taken as covering agent which has the layer thickness of 80-120mm and the melt casting temperature is ranging from 1158-1218 DEG C; the extrusion is carried out continuously; a copper rod which is achieved in the step 2 is straightened and is heated to the temperature of 300-400 DEG C in an induction heating furnace; the copper rod then directly enters an extrusion concave groove; finally, a flat strip blank with the size of 12mm multiplied by 200mm is formed out of a die cavity and directly enters a cooling area which is provided with alcohol to be cooled below the temperature of 70 DEG C; the flat strip blank is coiled into coiled belts by a coiler and then handled to the next process. The method of the invention has the advantages of simple and convenient process, low investment expense, small land occupying, short construction period of the project, small unit energy consumption, low operation cost, and high yield of the products.

Owner:江阴华电新材料有限公司

Method for blasting plant biomass walls with oxygen

InactiveCN102206928ADecompose thoroughlyBreak down evenlyRaw material divisionProcess engineeringOxygen

The invention discloses a method for blasting plant biomass walls with oxygen, comprising the following steps of: firstly, adding ethanol, hydrogen peroxide with concentration of 30% and water to crushed plant biomass, mixing the materials to oxidize and soak the materials, and conveying the oxidized and soaked materials to an oxygen blasting tank via a feeding port of the oxygen blasting tank; secondly, sealing the feeding port of the oxygen blasting tank, regulating the temperature of the gas in the oxygen blast tank at 80-150 DEG C and the pressure within 1-4 MPa by conveying pressure air to the oxygen blasting tank, preserving heat and keeping pressure for 20-200 seconds to soak the plant biomass into ethanol, hydrogen peroxide with concentration of 30%, steam and water; and finally, completely opening the discharge port of the oxygen blasting tank within 3 seconds to reduce the pressure in the oxygen blasting tank to the normal pressure. The invention aims to provide the method for blasting plant biomass walls with oxygen, which can be used for completely and uniformly decomposing the plant biomass and realizing industrialization production and has high production efficiency.

Owner:BEIJING ZHONGNUO DERUI IND TECH

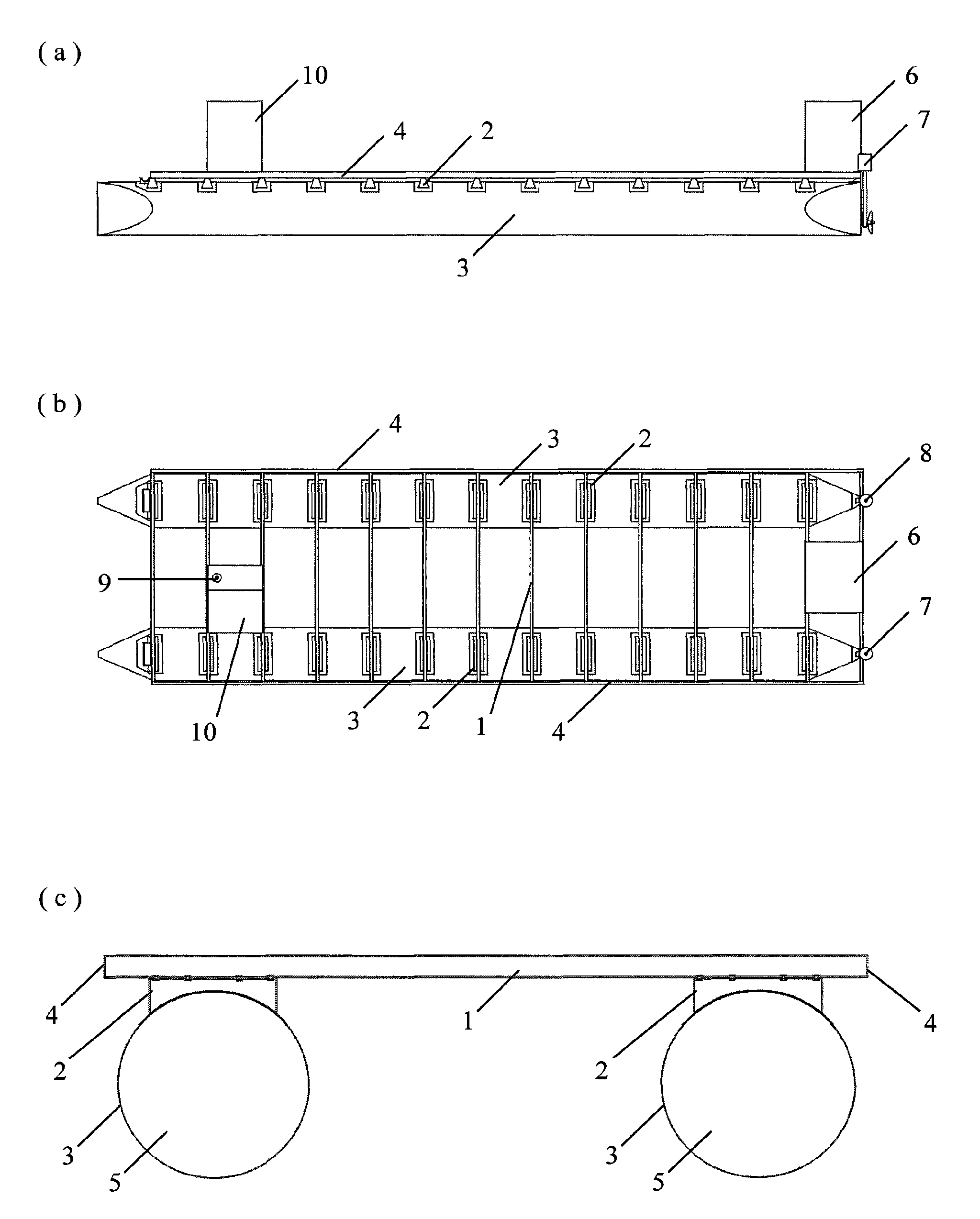

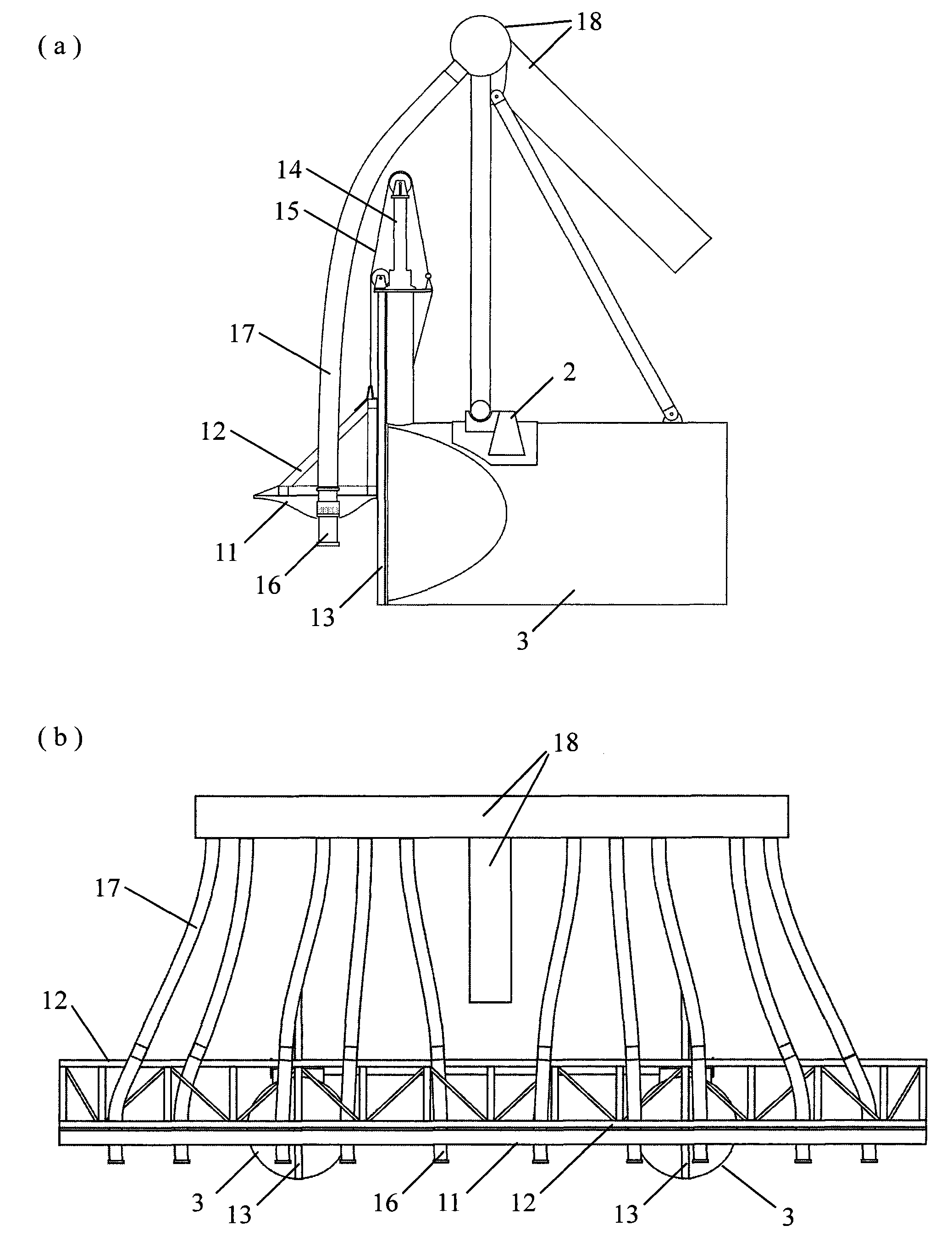

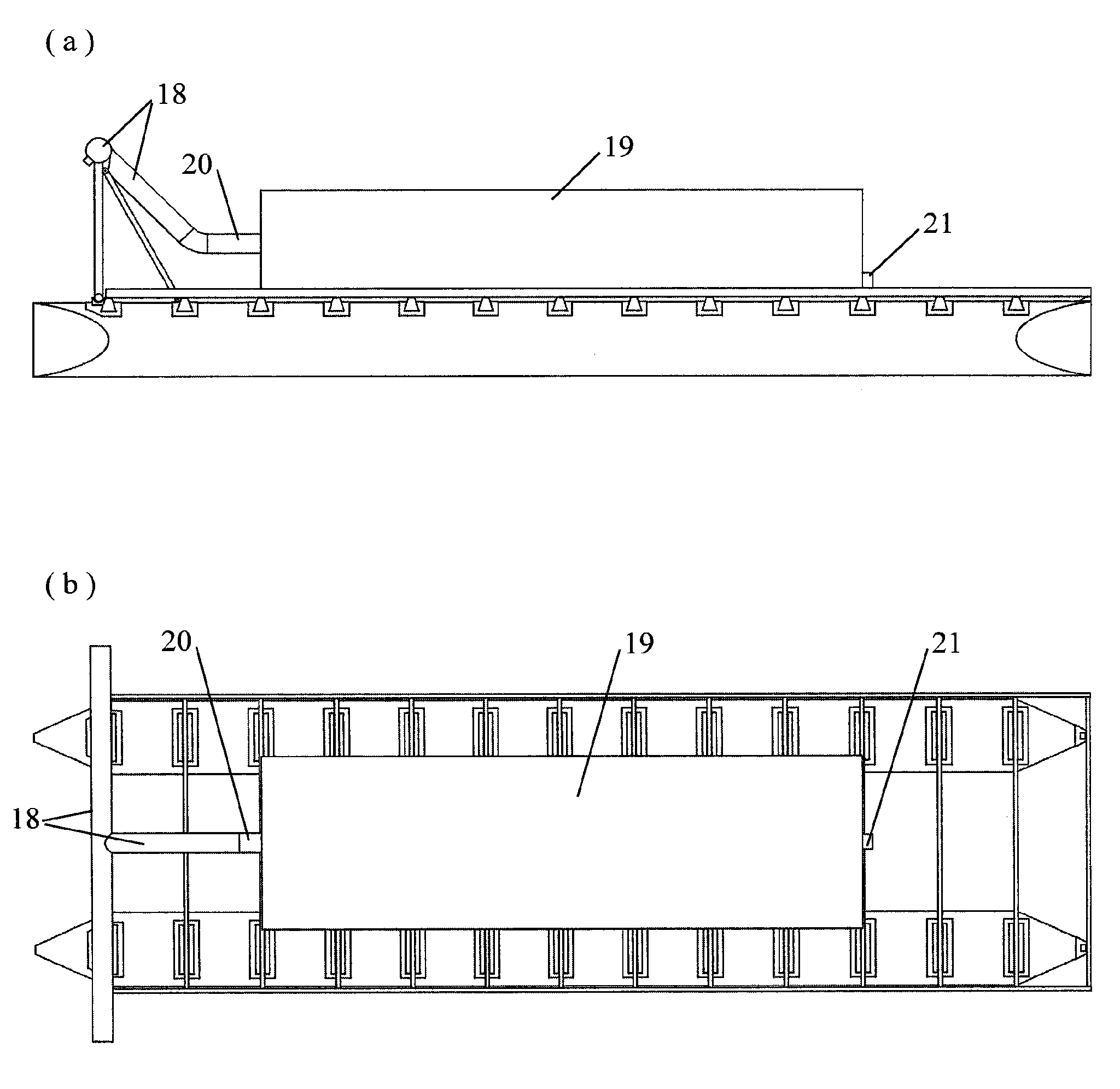

Large simulated type water-surface blue-green algae removing device

The invention relates to a large water-surface blue-green algae removing device researched by the principle of simulating chub to filter-feed plankton. The large water-surface blue-green algae removing device adopts a 21m*6m power platform as a carrier and a 50KW diesel generator unit as power; a separating shovel with the width of 10m is arranged at the front end so as to separate surface water rich in blue-green algae when in process, ten branch pump-pipe systems are used for absorbing algae water from the separating shovel, the algae water is conveyed to the algae water to a 600m<2> gill type filter for primary filtration, and then concentrated by a shaking sieve, and a 3m<3> buffer pool stores the algae slurry temporarily; a rear 11KW electric slurry hanging machine provides non-operation drive, a rear 5.5KW frequency-modulation electric slurry hanging machine provides operation drive, and a front 2.2KW spraying propeller provides auxiliary steering power. The width of the operation is 10m, the maximum operation speed is 5km / h, and the capability for absorbing and filtering algae is 1000m<3> / h. The technology can be used for removing the blue-green algae on the lake in a scale manner and has the advantages of high efficiency and low energy consumption.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

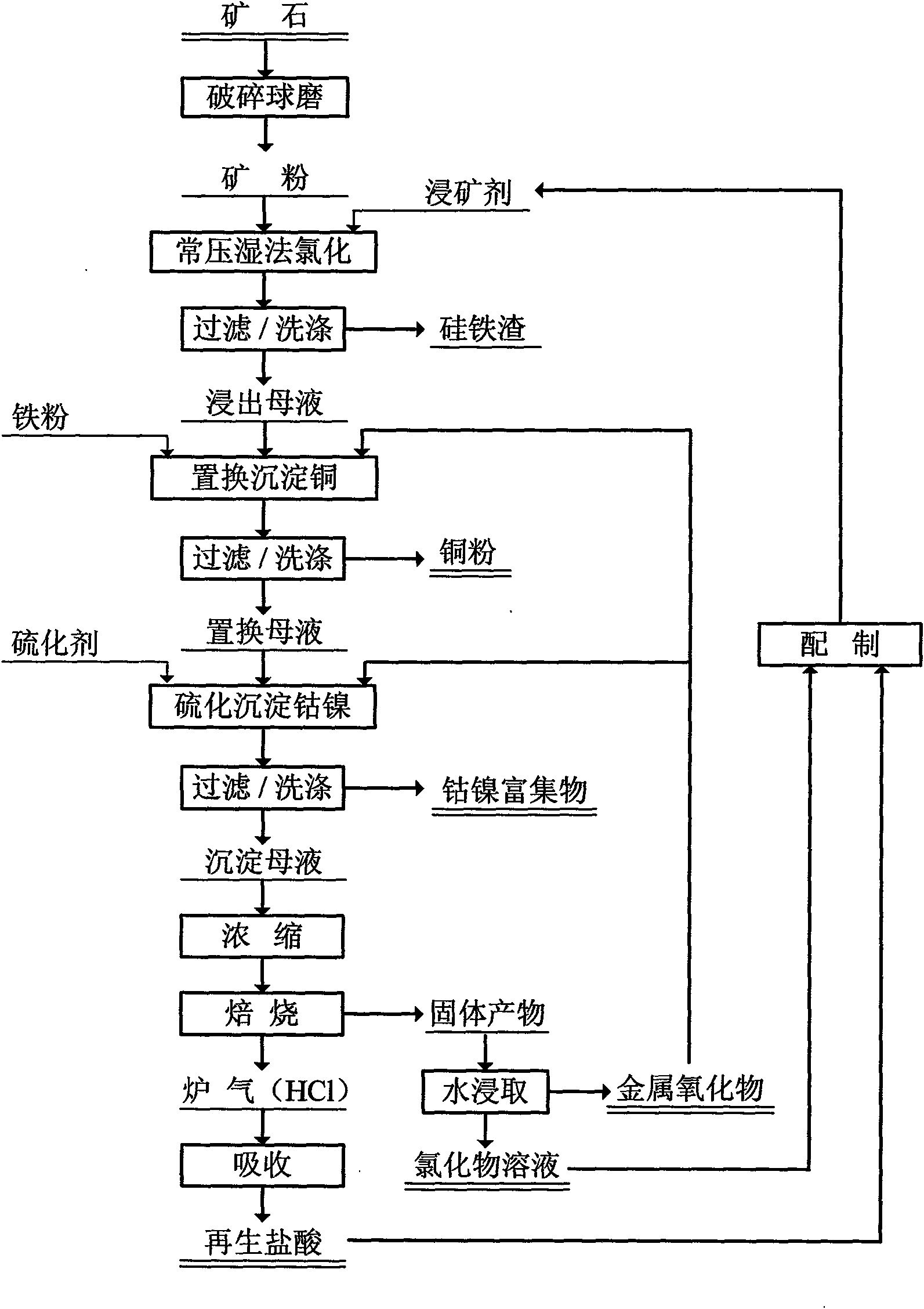

Method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore

ActiveCN101575673AImprove leaching ratePromote circulationProcess efficiency improvementSlurrySulfide

The invention provides a method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore, which uses low-grade complex mixed copper-cobalt ore (sulfide and oxide) as a raw material to extract an intermediate product of the copper and cobalt-nickel by adopting process flows of crushing and grinding ore into slurry, leaching the slurry with acidic villaumite by a wet method, extracting copper powder by reduction and replacement, vulcanizing and depositing nickel (cobalt), concentrating, drying, baking and hydrolyzing deposited mother solution at low temperature and the like. The method comprises main technical points that metallic elements in the mixed copper-cobalt ore are dissolved and leached by the acidic villaumite under normal pressure; copper in leaching liquor is reduced and deposited by a reducing agent; the cobalt and nickel are deposited by a vulcanizing agent to obtain the intermediate product; the mother solution is concentrated, dried, baked and hydrolyzed at low temperature after cobalt-nickel deposition to obtain metal oxide, metal oxychloride and hydrogen chloride containing iron, magnesium and the like; hydrogen chloride is reclaimed to obtain hydrochloric acid, and baked solid is leached into water to obtain chloride solution; and the hydrochloric acid and the chloride solution are used for leaching of ore slurry. The method comprehensively reclaims the copper, the cobalt-nickel and the like, and has the characteristics of high leaching rate of the copper and the cobalt-nickel, less energy consumption, low cost, closed circulation of chlorine (hydrochloric acid), less investment of project engineering and the like. The whole process is concise, clean and environment-friendly. The method is particularly applicable to large-scale industrial production.

Owner:福建常青新能源科技有限公司

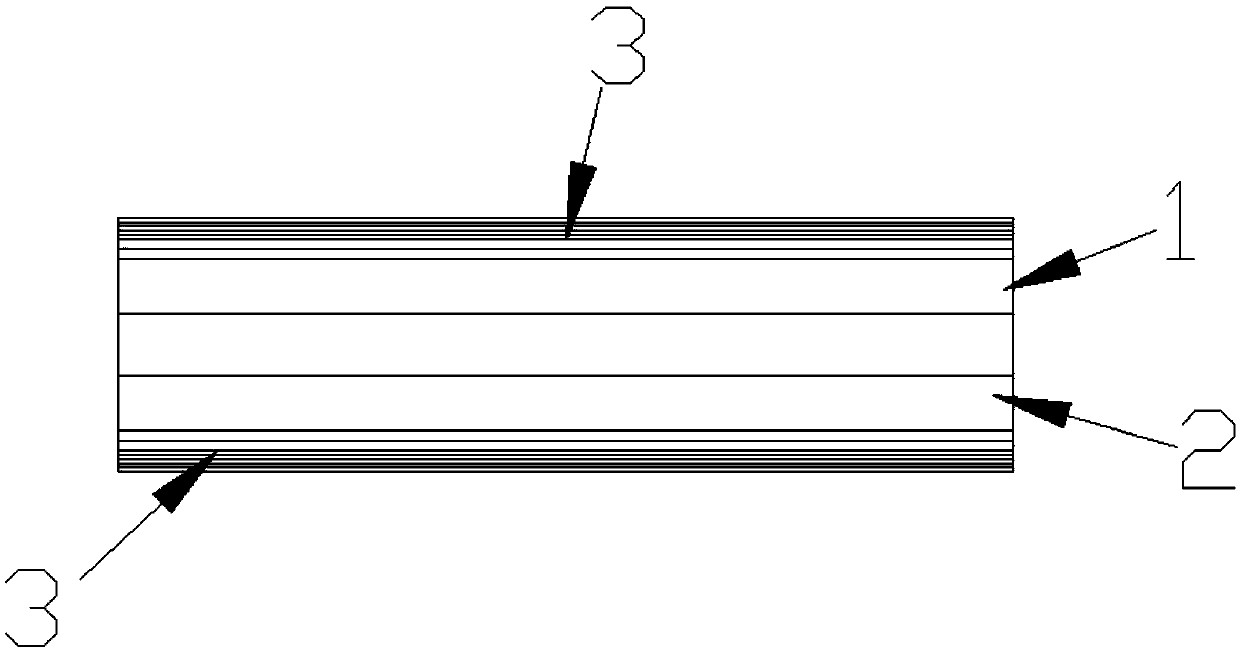

Laminated glass and preparation process thereof

ActiveCN109572109ALess impuritiesLower iron levelsSynthetic resin layered productsGlass/slag layered productsTransmittanceHigh pressure

The invention discloses laminated glass, comprising an upper super-white coated glass layer, SGP (SentryGlas Plus) film and a lower super-white coated glass layer. The invention also discloses a preparation method of the laminated glass, comprising the steps of providing a raw sheet, cutting, polishing edge, washing, tempering, coating, washing, laminating, pressing primarily, vacuumizing, heatingand pressurizing in a high-pressure kettle, holding the temperature and pressure in the high-pressure kettle, lowering the temperature and pressure in the high-pressure kettle, removing from the kettle, trimming and dressing, finishing, packaging, and allowing the finished glass to leave a factory. The heating mode is modified to a mode with a heating tube and a convection fan, so that heating uniformity of glass is improved, glass heating efficiency is improved, SGP laminated glass has better visible light transmittance and strength, production time of the SGP laminated glass is shortened, and energy consumption is lowered.

Owner:JIANGYIN MUXIANG ENERGY SAVING DECORATION MATER

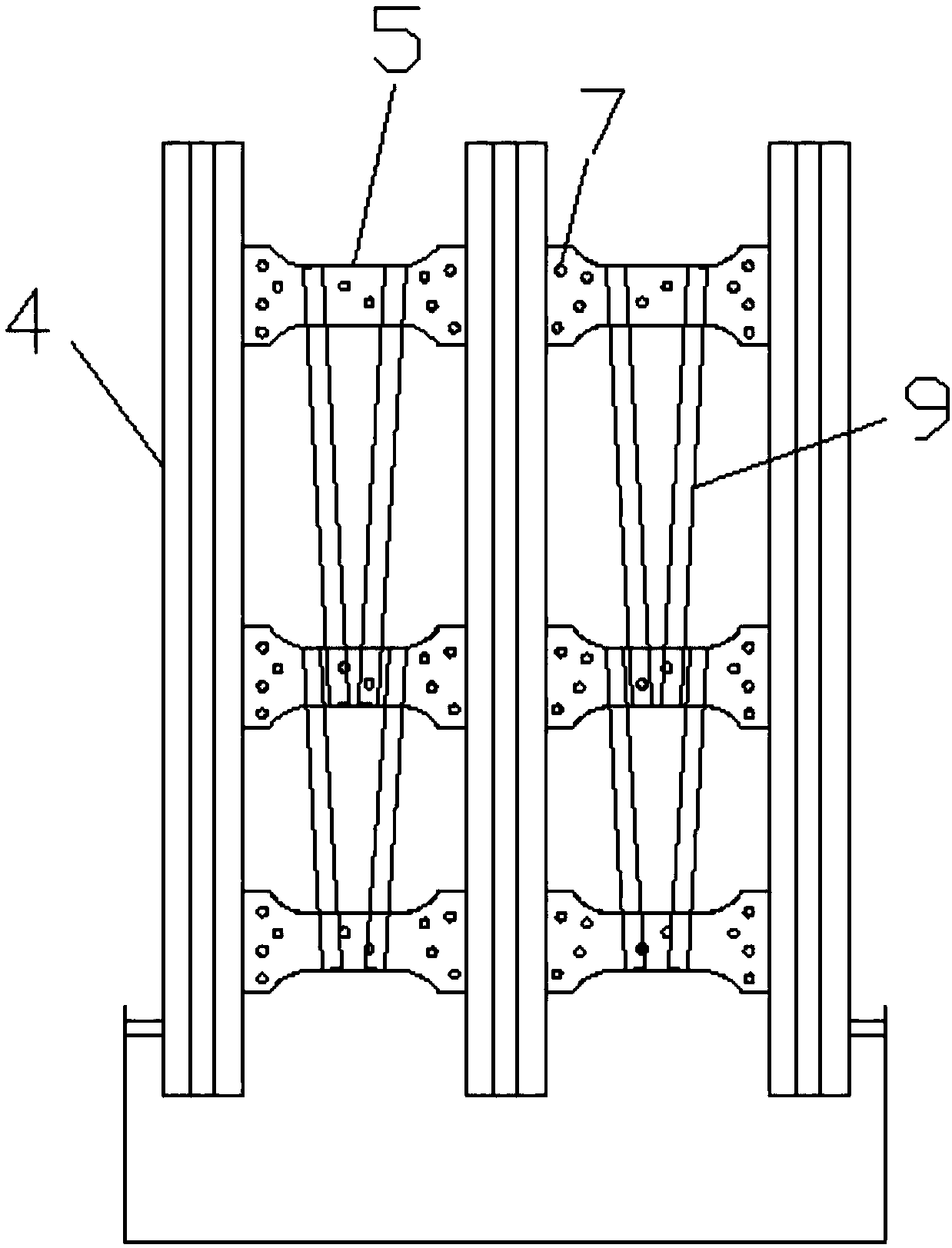

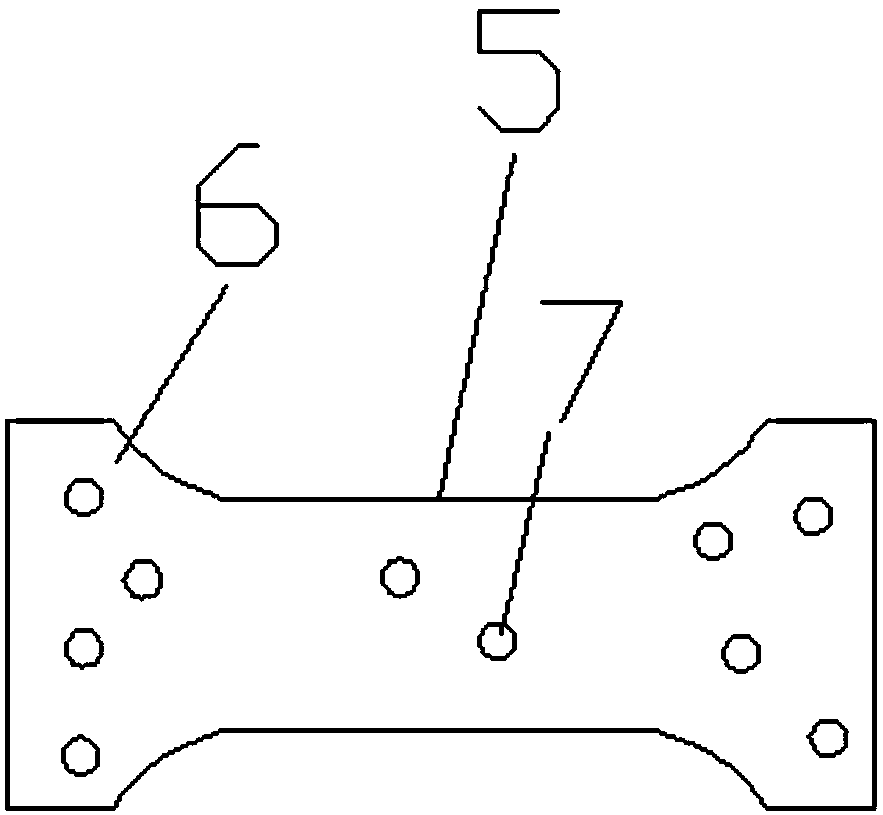

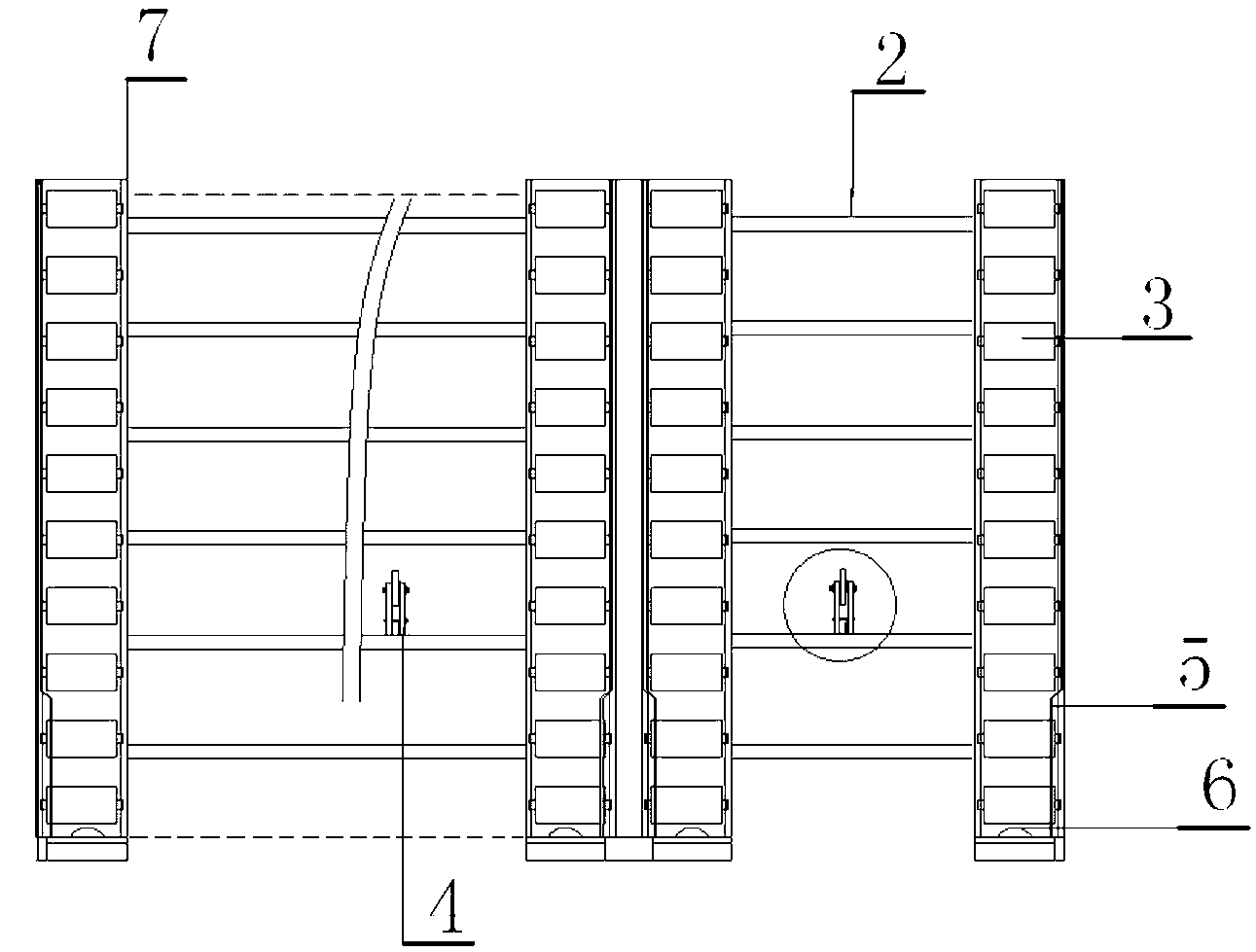

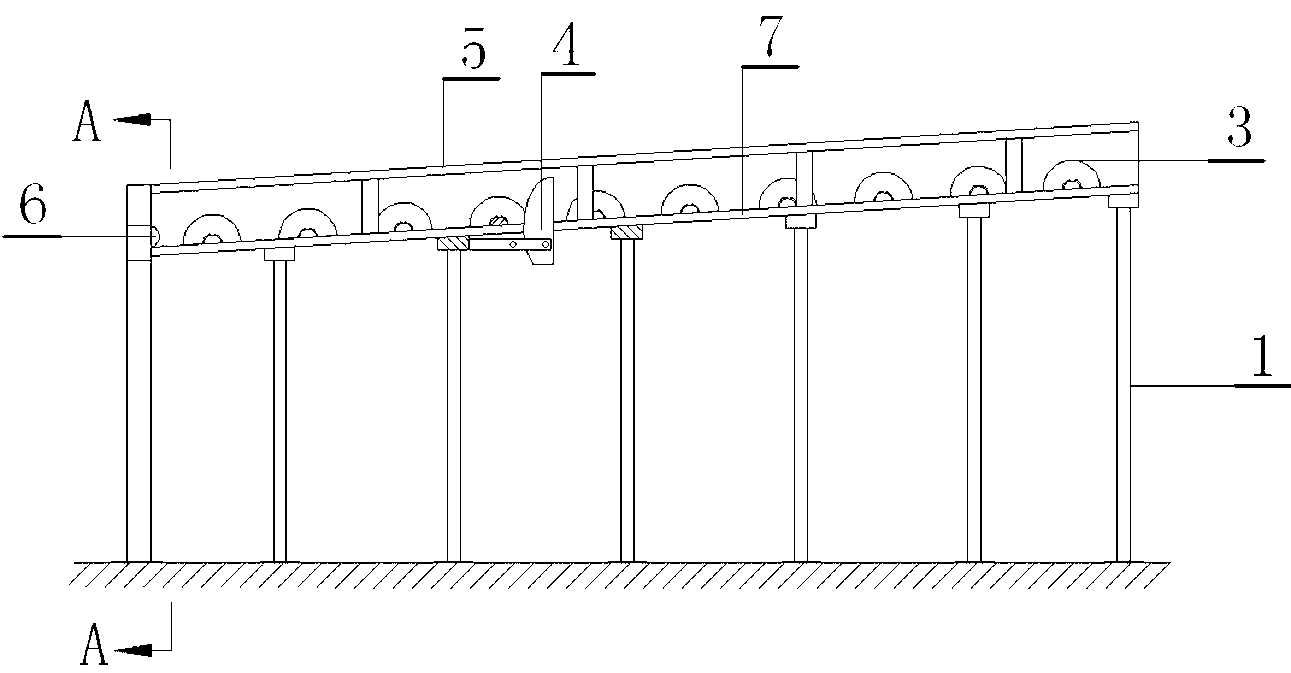

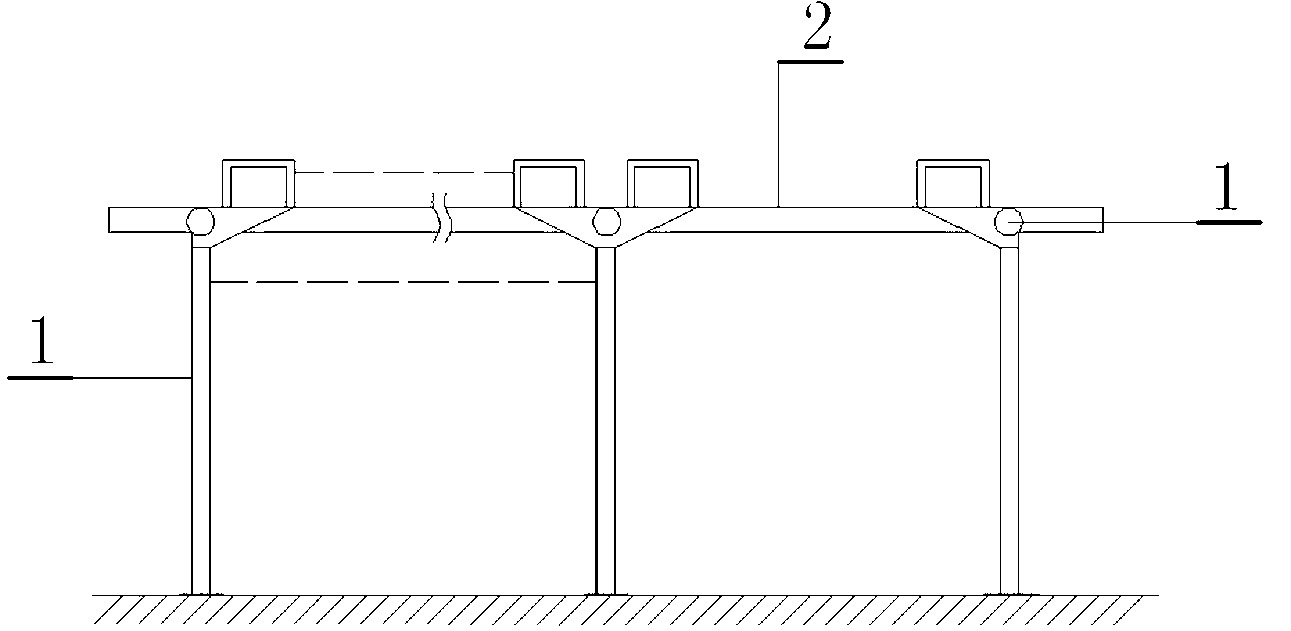

Gravity drive-in self-moving intensive warehouse rack allowing for convenient delivery

InactiveCN103057886AReduce unit energy consumptionLow costStorage devicesLogistics managementMechanical engineering

The invention discloses a gravity drive-in self-moving intensive warehouse rack allowing for convenient delivery. The gravity drive-in self-moving intensive warehouse rack allowing for convenient delivery comprises a vertical frame and beams. The beams are disposed on the vertical frame. Conveying rails are correspondingly disposed at two ends of the beams. The conveying rails incline down to a discharge end. The inclining rail design of the rack allows for automatic movement by gravity of goods to help delivery. Automatic goods stoppers disposed on the beams of the rack can automatically stop the goods from sliding off during storage. The automatic goods stoppers are locked during delivery, upper goods slide to the positions of the lower goods to wait for delivery since the lower goods are removed, the rest can be done in the same manner, and accordingly automatic movement and delivery of goods by gravity are achieved. The gravity drive-in self-moving intensive warehouse rack allowing for convenient delivery is simple in structure, simple to mount, laborsaving, higher in warehouse capacity utilization rate and higher in warehouse storage capacity, and meets the requirement of modern enterprises for low cost, low loss and high efficiency on management of logistics supply chains.

Owner:高士甲

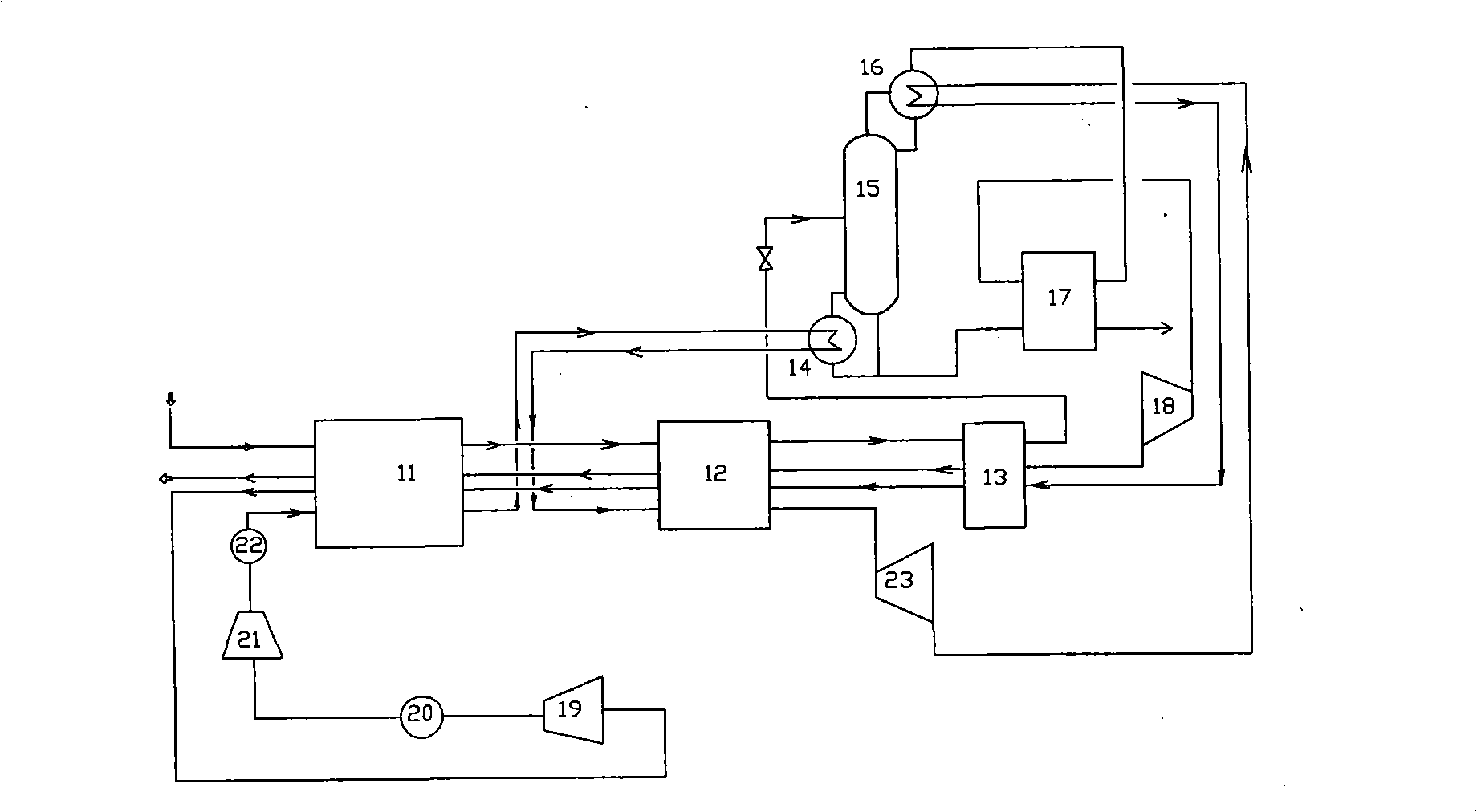

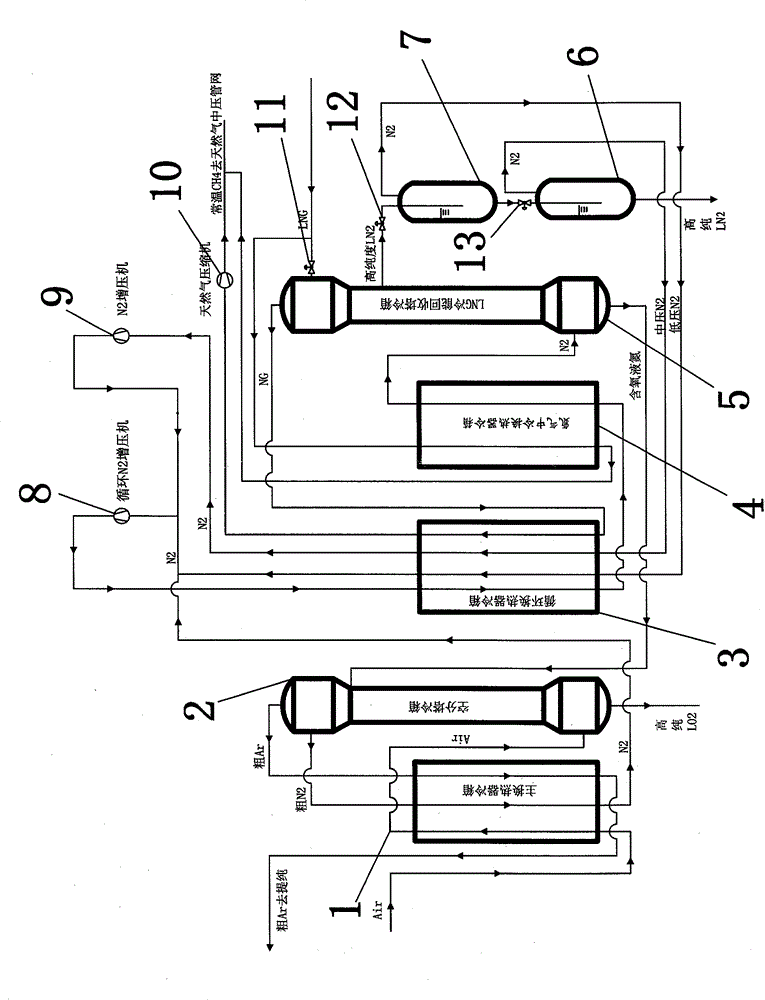

Method for air separation production on liquid oxygen and liquid nitrogen through LNG (Liquefied Natural Gas) cold energy

InactiveCN104807289AFull and efficient useLow stress levelSolidificationLiquefactionEnergy recoveryHigh pressure

The invention provides a method for air separation production on the liquid oxygen and the liquid nitrogen through the LNG (Liquefied Natural Gas) cold energy. According to the all-liquid air separation method, the investment is less, the energy-saving rate is high, the energy consumption is low, the cold loss is small, the output of the liquid nitrogen and the liquid oxygen is large, and the production cost can be greatly reduced. According to the technical scheme, the implementation steps of the method includes that the raw nitrogen from an air separation tower cold box is reheated through a main heat exchanger cold box to join the medium-pressure and low-temperature nitrogen separated through a gas and liquid separation tank to be reheated through a circulating heat exchanger cold box, the reheated low-pressure and low-temperature nitrogen is reheated through the circulating heat exchanger cold box, and the medium-pressure and normal-temperature nitrogen boosted through a nitrogen booster enters a circulating nitrogen booster to be boosted into the high-pressure nitrogen; the high-pressure nitrogen is precooled through the circulating heat exchanger cold box; the precooled high-pressure nitrogen is fed into the air separation tower cold box to serve as an air separation cold source, the high-purity and high-pressure liquid nitrogen is obtained at the bottom of an upper tower of an LNG cold energy recovery tower cold box, the high-pressure liquid nitrogen is throttled through a throttling valve to obtain the medium-pressure liquid nitrogen and the medium-pressure nitrogen, and the medium-pressure liquid nitrogen and the medium-pressure nitrogen are throttled through the throttling valve to obtain a low-pressure liquid nitrogen product and the low-pressure nitrogen.

Owner:刘继福

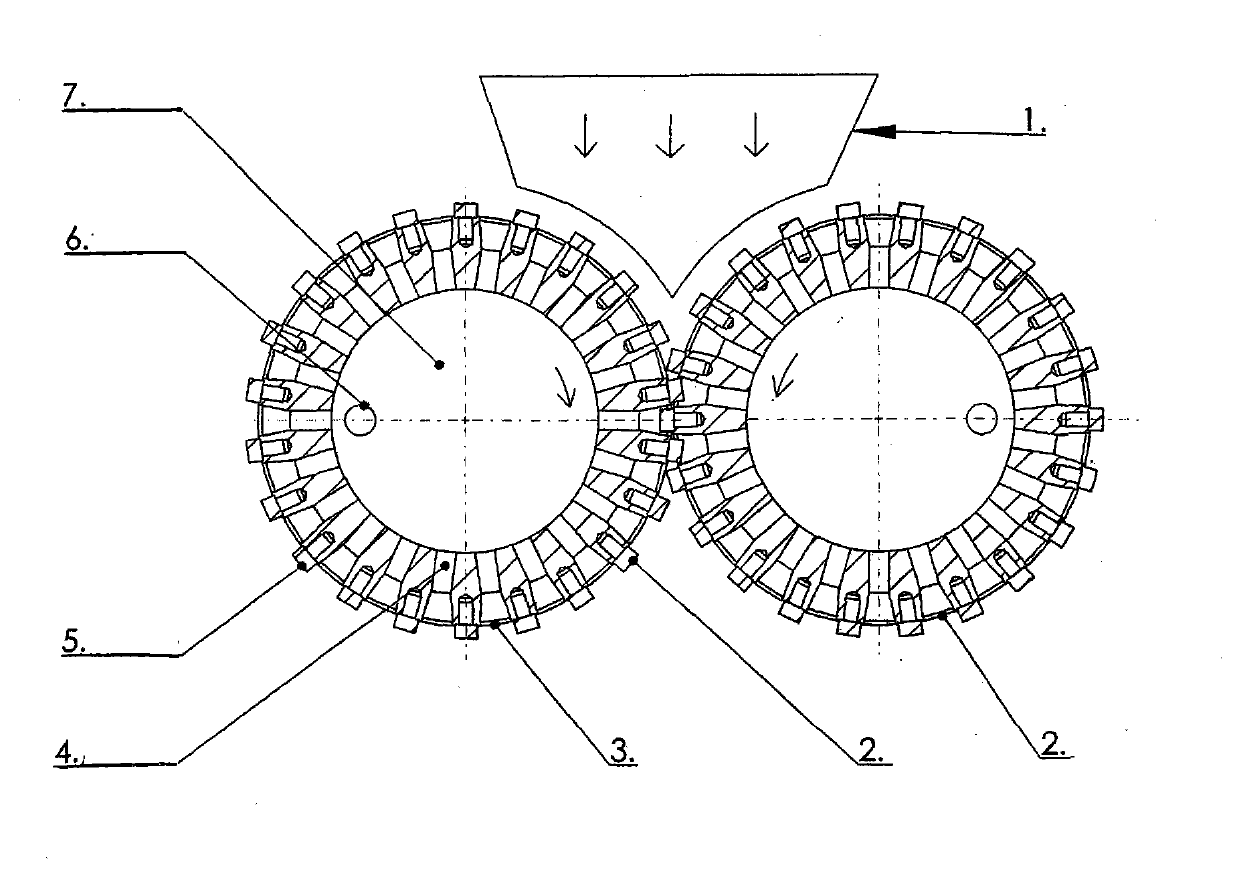

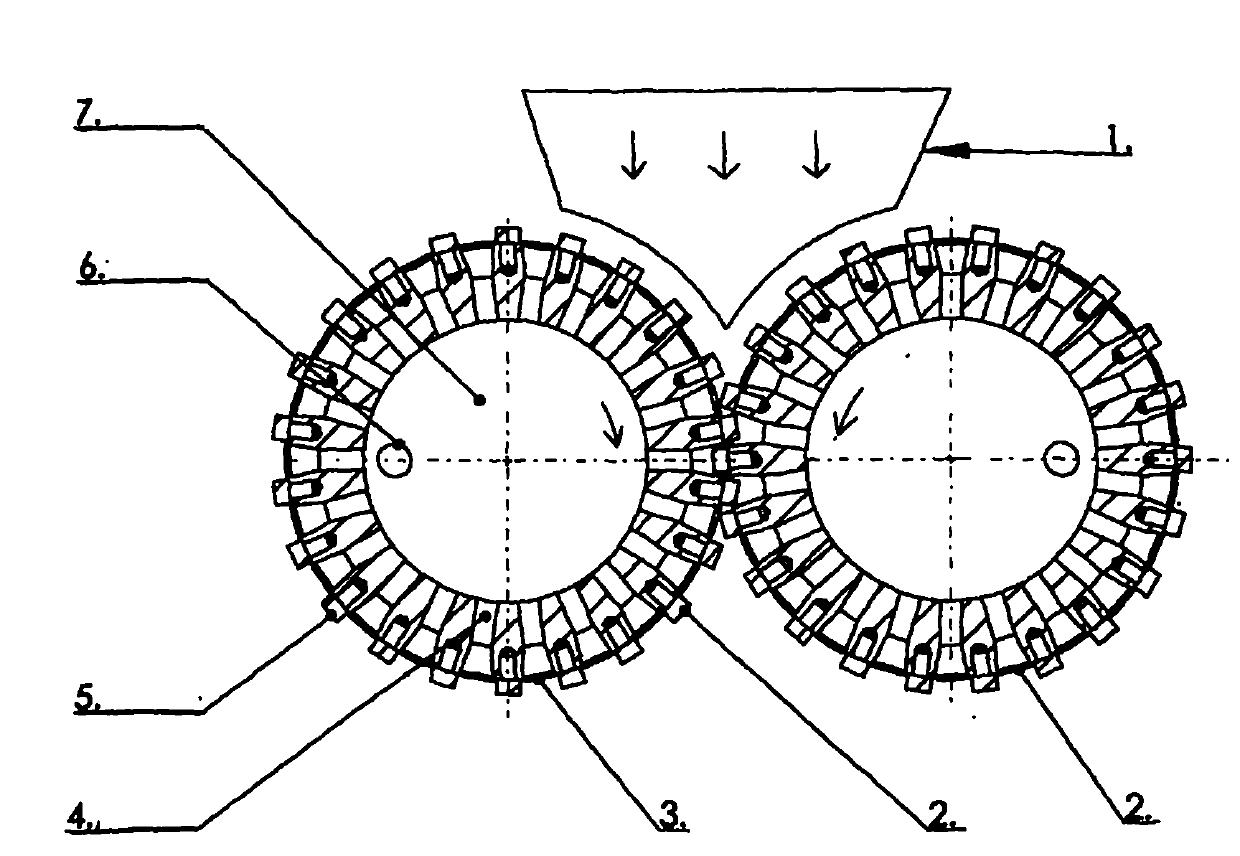

Biomass straw granulator

InactiveCN101947419AIncrease the forced mutual extrusion functionLow pellet priceGranulation by pressingShaping pressEngineeringMechanical engineering

The invention discloses a biomass straw granulator. The biomass straw granulator consists of rolling moulds; each rolling mould is uniformly provided with material extruding heads and shaped orifices; the material extruding heads are staggered with the shaped orifices; compression holes are formed on the heads of the shaped orifices; a discharging cavity is formed in the middle of the rolling mould; a cutter is arranged in the discharging cavity; and an extrusion head of a roller extends to the shaped orifice of the other roller, and an extrusion head of the other roller extends to the shaped orifice of the roller. The biomass straw granulator has the advantages of energy conservation, consumption reduction and improvement on work efficiency.

Owner:TIANJIN TESIDA BIOMASS ENERGY MACHINERY

Method for preparing fish bone chondroitin sulfate

InactiveCN102898541AShorten the production cycleReduce unit energy consumptionChemistryEnzymatic hydrolysis

The invention discloses a method for preparing chondroitin sulfate from fish bone, which comprises the following steps of: pretreating fish bone, subjecting the fish bone to steam explosion treatment, carrying out the enzymatic hydrolysis of the fish bone, removing impurities, carrying out centrifugal separation, settling the solution, washing the sedimentation and drying the product. The method disclosed by the invention is simple, low in production cost, short in production period, mild in reaction conditions and high in equipment utilization rate. The average yield of the method is 8.7%, and the chondroitin sulfate content of the obtained product is 92.1% on average. The method well addresses the utilization of fish bone in fish processing, thereby improving the added value of leftovers from aquatic product processing and the comprehensive utilization rate of fresh water fish.

Owner:宜昌湘宜水产品有限公司

Energy-saving and environmentally-friendly kiln body and vanadium-nitrogen alloy high-temperature sintering kiln adopting energy-saving and environmentally-friendly kiln body

ActiveCN102853670ASave powerImprove distributionFurnace componentsFurnace typesFiberThermal insulation

An energy-saving and environmentally-friendly kiln body comprises a thermal insulation fire-proof layer, a calcining chamber, a graphite crucible, horizontal heating chambers and a sealing box, wherein the graphite crucible and the thermal insulation fire-proof layer are respectively arranged inside and outside the calcining chamber; the upper horizontal heating chamber and the lower horizontal heating chamber are respectively arranged above and under the graphite crucible; an upper horizontal heating body and a lower horizontal heating body that correspond to each other are horizontally arranged in the upper horizontal heating chamber and the lower horizontal heating chamber; one end of each horizontal heating body is arranged in each heating chamber, and the other end of the horizontal heating body passes through a side wall, the thermal insulation fire-proof layer and a furnace shell in sequence and then extends into the sealing box; high-temperature fibers are filled in gaps between the heating bodies and plug bricks; and a gas inlet port and a copper electrode are arranged on the sealing box. In a vanadium-nitrogen alloy high-temperature sintering kiln adopting the energy-saving and environmentally-friendly kiln body, a low-temperature segment, a transition segment and a high-temperature segment adopt different manufacturing materials and different heating bodies so as to adapt to calcining processes. According to the design, the unit energy consumption is lower, and the operation conditions are better; in addition, the process atmosphere and the calcining effect in the kiln are better, and the service life of the kiln is longer.

Owner:湖北晶洋科技有限公司

Voltage transformation adsorption method for circulation valuable gas

ActiveCN101249370AModified PSA methodImprove energy efficiencyDispersed particle separationAbsorption columnPower equipment

The invention belongs to the technology field of separation of gaseous mixture, in particular relates to a pressure swing absorption method for circulating valuable gases. The method comprises the following steps that: at least a primary or a secondary surge tank is arranged in an absorption system; the absorption system is provided with at least one absorption column which can be arranged in a parallel way; at least one absorption column is involved in absorption steps and other absorption columns are involved in out-of-phase operation such as regeneration and so on; valuable gases are circulated and reclaimed to the middle surge tank or a raw gas storage container from the product end of the absorption columns for pressure equalization in grades, thus not only effectively recycling kinetic energy of components and gases which are difficult to be absorbed, reducing the energy consumption and the cost required by power equipment, but also improving the stability of the system. In addition, the system can be expanded infinitely by adopting unsymmetrical operation mode.

Owner:上海穗杉实业股份有限公司

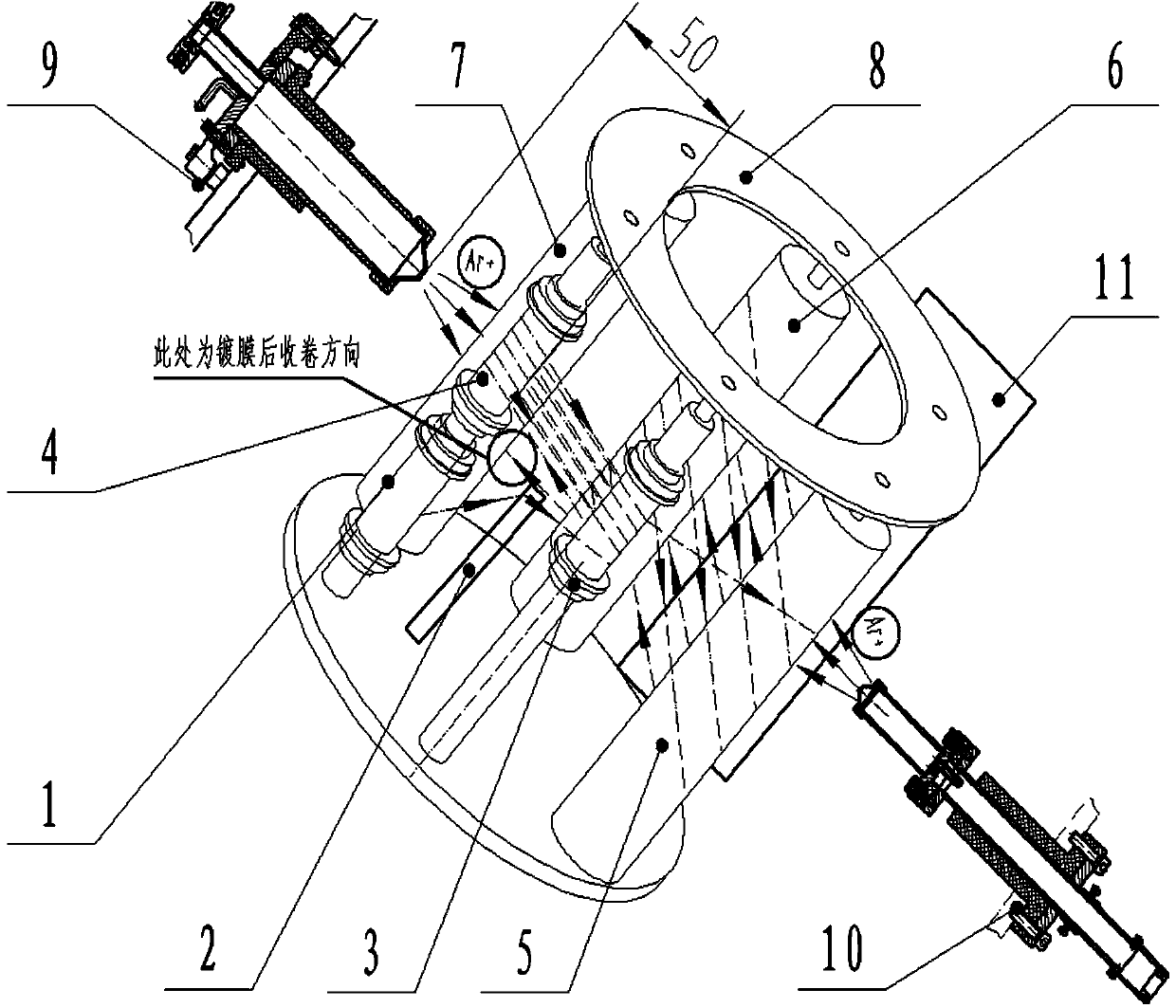

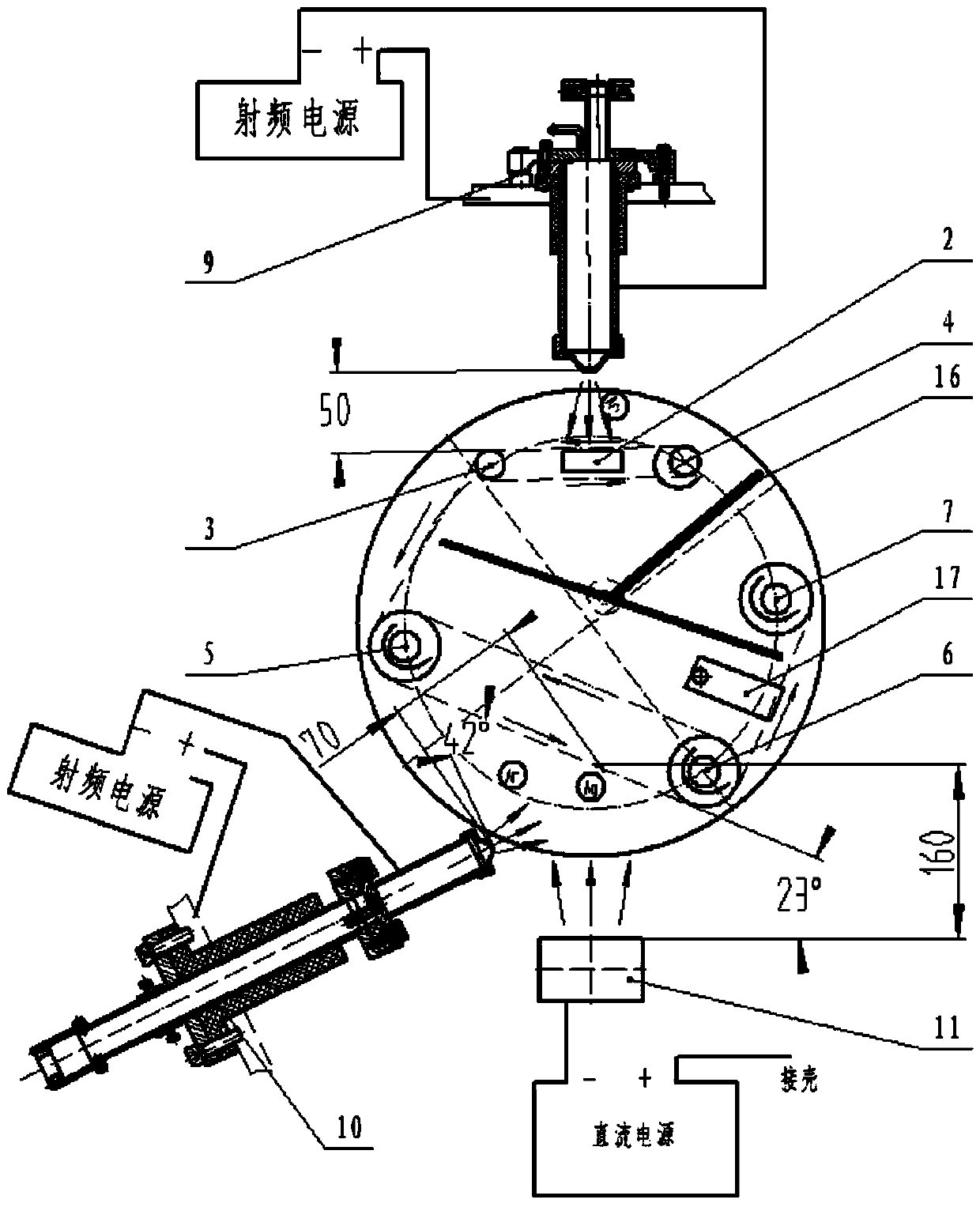

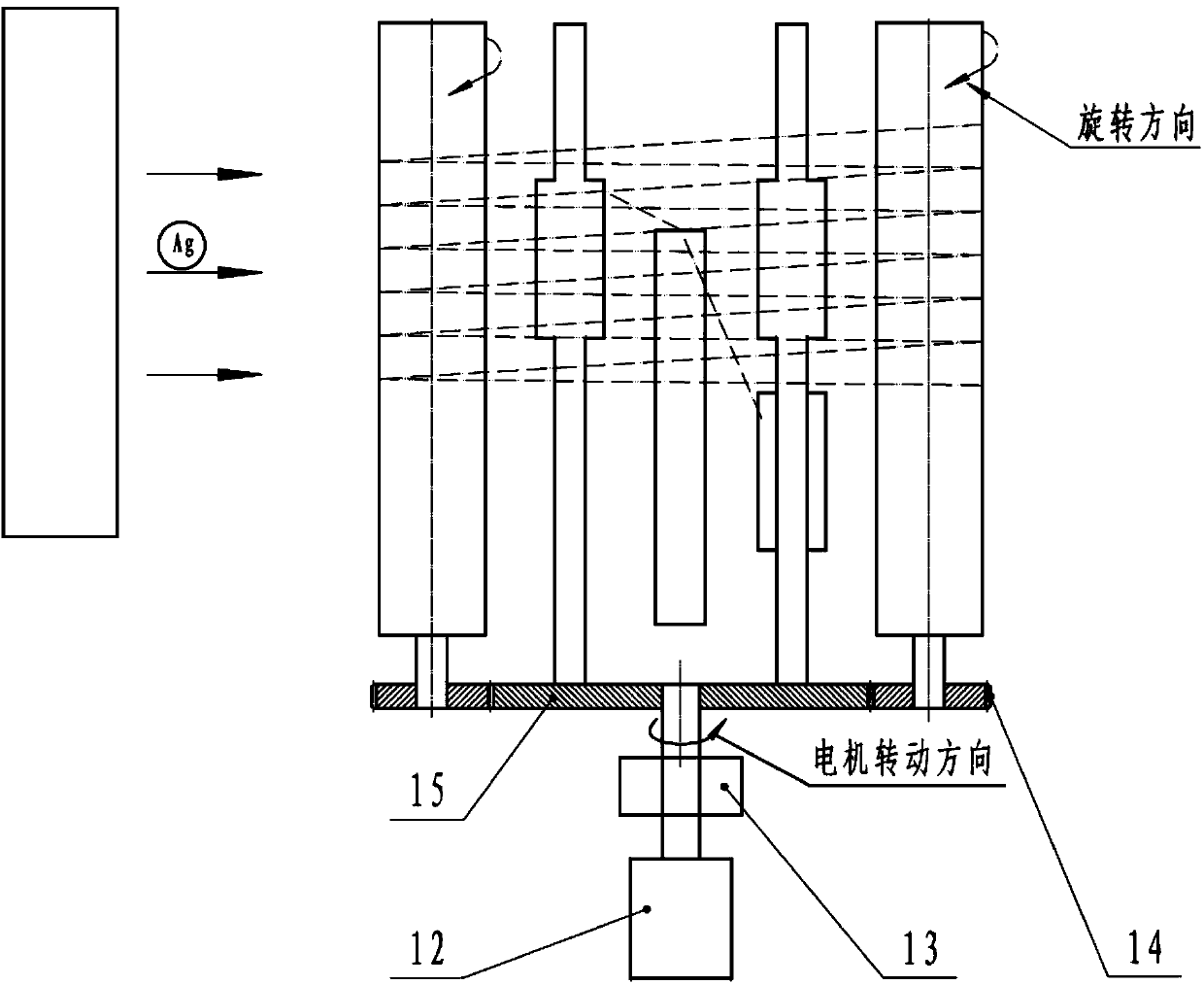

Device and method for continuously coating fiber with metallic conductive function film through magnetron sputtering

The invention discloses a device and a method for continuously coating a fiber with a metallic conductive function film through magnetron sputtering, and belongs to the field of vacuum film coating. The method comprises the following steps: winding fiber filaments around an unwinding device; putting the unwinding device into a vacuum chamber for filament moving; cleaning and roughening the fiber filaments unwound by the unwinding device through a plasma cleaning device repeatedly in parallel; performing film coating on the cleaned fiber filaments through an auxiliary plasma film coating device and a rectangular magnetron sputtering target repeatedly in parallel; winding the film-coated fiber filaments around a winding device so as to complete film coating. During cleaning and surface roughening through the plasma cleaning device, introduced gas is mixed gas of oxygen and argon, oily substances on the fiber are decomposed, and meanwhile, the surface of the fiber is roughened to increase the adhesion force of the film. The auxiliary plasma film coating device is used for increasing the adhesion force of the film through ion bombardment. According to the device and the method, the defects of pollution, high operation cost, poor adhesion force and the like in the prior art are overcome. The device and the method have the advantages of uniform coating, impurity elimination, high adhesion force and the like.

Owner:BEIJING UNIV OF TECH

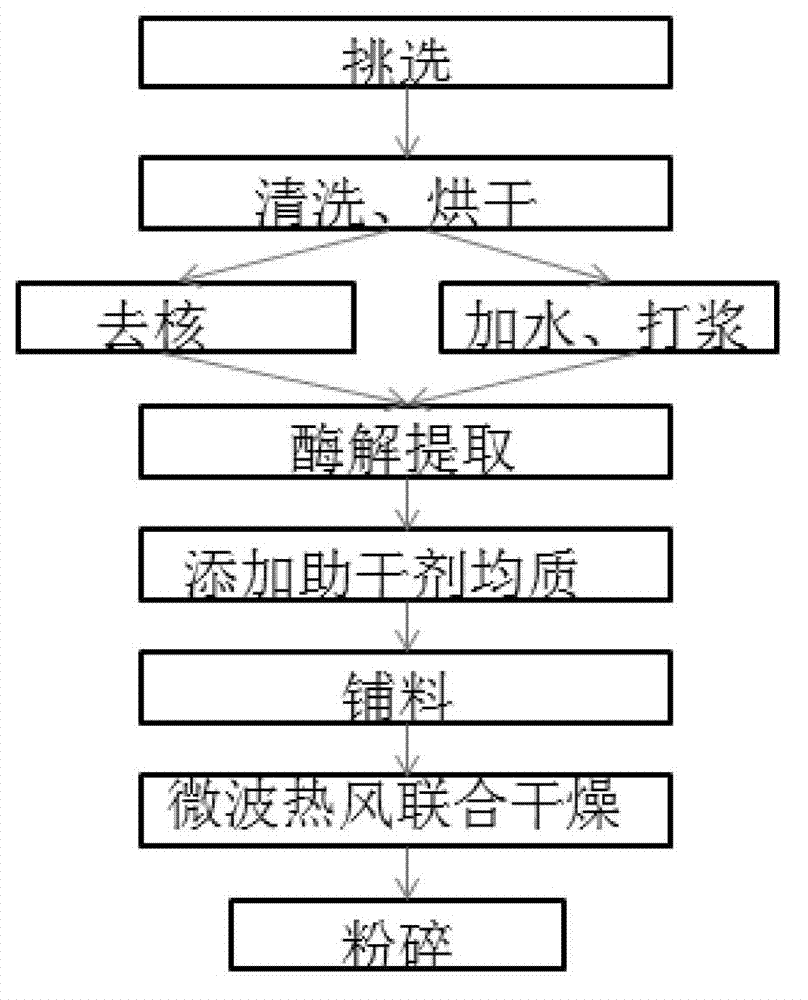

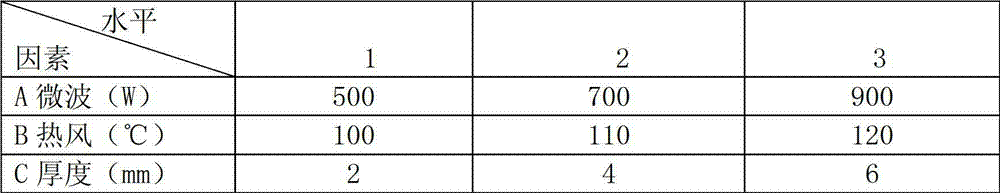

Preparation method of Cangzhou golden silk jujube powder

InactiveCN102948701AMicrowave sterilization has strong penetrating powerStrong sterilization penetrationFood preparationWater bathsPectinase

The invention relates to a preparation method of Cangzhou golden silk jujube powder. The preparation method comprises the steps of: selecting high-quality golden silk jujubes, cleaning the golden silk jujubes with clean water, and drying surfaces of the golden silk jujubes; slicing the golden silk jujubes, removing kernels of the golden silk jujubes, placing the golden silk jujubes into a container, adding pure water with the mass of 5-7 times of the mass of jujube flesh, and preparing pulp with a beating machine; adding pectinase with the mass of 0.14 percent of the mass of the jujube flesh, heating for 40 min in a water bath kettle with the water temperature of 40 DEG C; performing enzymatic extraction through ultrasonic waves after water bathing enzymolysis; adding drying additives and auxiliary drying additives into jujube pulp after enzymolysis, wherein the mass ratio of the main drying additive maltodextrin and the jujube pulp is 6:4, the auxiliary drying additives consists of mixture of soy isolate protein, beta-cyclodextrin, soluble starch and lecithin, and the amounts of the soy isolate protein, beta-cyclodextrin, soluble starch and lecithin are respectively 2.5 percent, 15 percent, 15 percent and 3 percent of the mass of the jujube flesh; and then making the mixture homogeneous with a homomixer. The homogenized matter is placed in a flat plate with the spreading thickness of 2-6mm, dried by microwaves of the power of 500-700W until the water content of a sample is 0.2, then dried in a blast drying box with the temperature of 100-120 DEG C, and finally pulverized with a mortar or crushed by a crushing machine into powder.

Owner:SHANGHAI OCEAN UNIV

Oilfield oil sludge treatment method

InactiveCN104230132AReduce inclusion viscosityEasy to separateWaste water treatment from quariesSludge treatmentOrganic solventOil sludge

The invention provides an oilfield oil sludge treatment method. Oil sludge is fed into a homogeneous agitation tank at the speed of 4 m<3> / h by a screw feeder and jetted by pressurized hot water at the temperature of 65-80 DEG C, the ratio of oil sludge to water is (1:4)-(1:6), then the mixture is heated to 80-95 DEG C, agents comprising, by concentration, 0.5%-1.2% w / w of a demulsifying agent, 1.0%-2.0% w / w of a gel breaker and 10%-15% w / w of an organic solvent are added and stirred for 60-90 min at the speed of 20-30 r / min, a floating oil liquid is drained, a product is input into a horizontal spiral separating machine for separation at the rotating speed of 2,800-3,000 r / min, the oil liquid after separation enters a trapezoidal sedimentation tank, after natural setting is performed for 4 h under the condition of 85 DEG C, an upper layer oil liquid is recovered, precipitate that does not meet the draining standard is subjected to secondary heating, agent adding, stirring, washing and deoiling disposal, the sand content in oil after final treatment is 0.5%-0.8%, the oil content in silt and sand is 0.3%-2.0%, and the water content in oil is 0.5%-2.0%.

Owner:克拉玛依市华隆润洁生态环境科技有限公司 +1

Acrylic emulsion, preparation method and application thereof

ActiveCN102382235ASimple processing methodImprove performanceFibre treatmentPolymer scienceFunctional monomer

The invention relates to the field of materials, and specifically discloses an acrylic emulsion, a preparation method and application thereof. The acrylic emulsion comprises the following raw material in parts by weight: 35%swung dash45% of acrylate monomer, 7%swung dash10% of functional monomer, 1.0%swung dash2.5% of emulsifier, 0.2%swung dash0.6% of initiating agent and 42%swung dash55% of water; and the preparation method is a semicontinuous starvation feeding method. The prepared acrylic emulsion has high solid content, can be used for textile coating, and has good handfeel, high low temperature resistance and good fastness on cloth; and the preparation method is environmental friendly.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

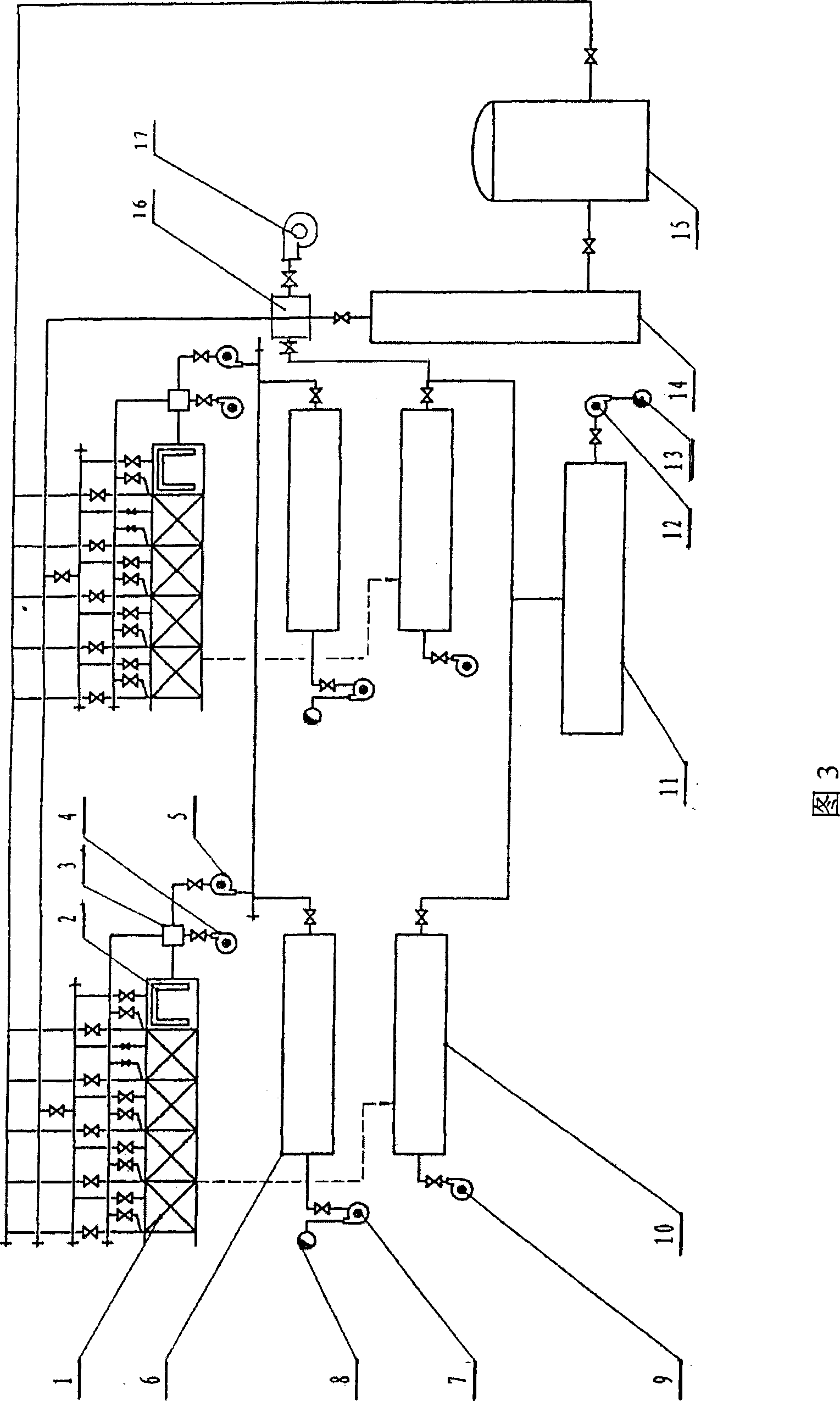

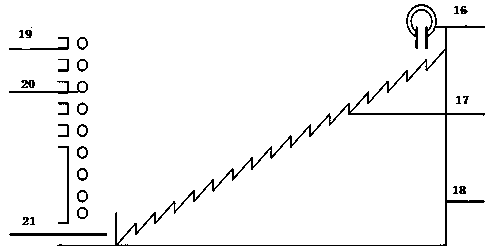

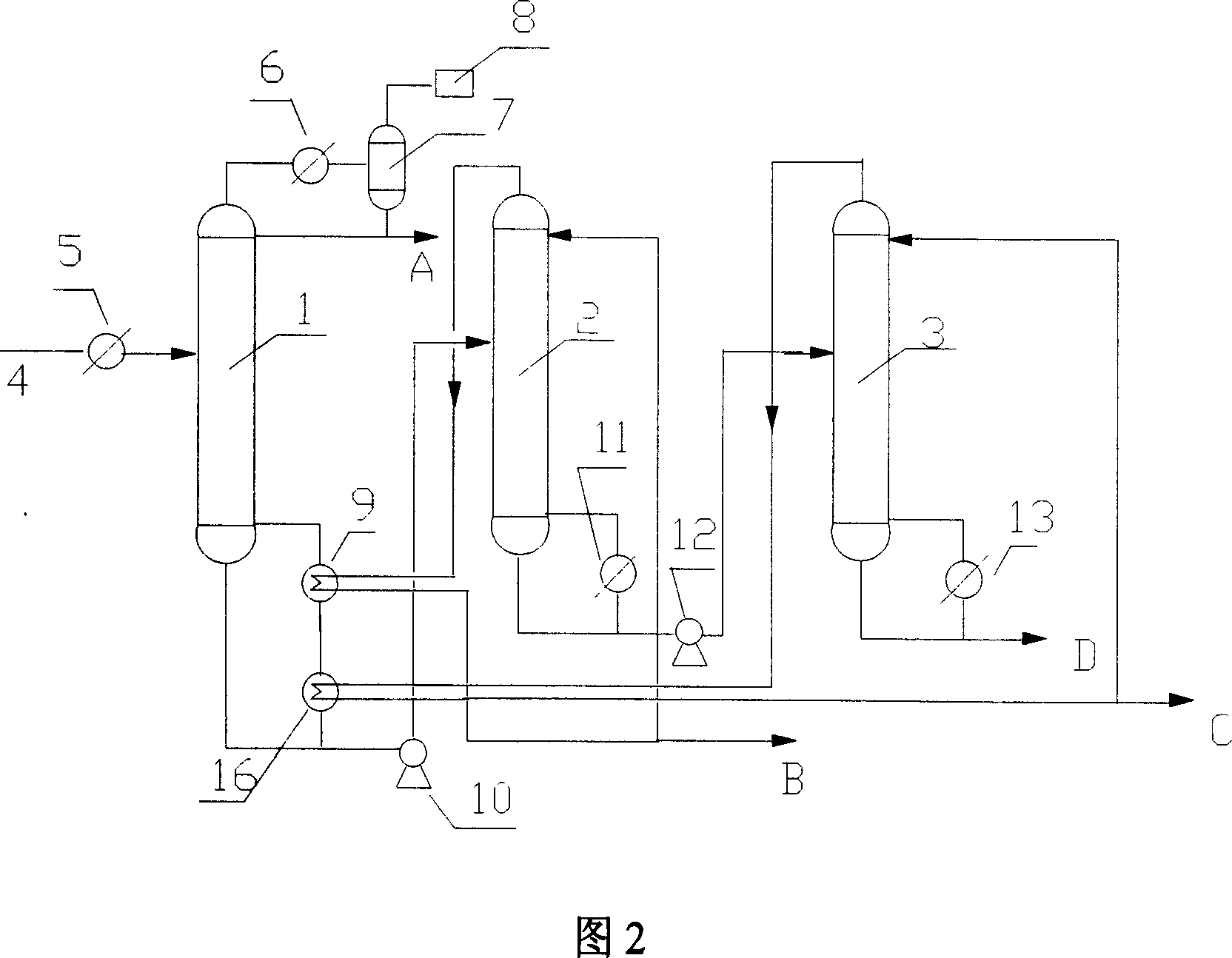

Serial trimethyl benzene separating apparatus and method

InactiveCN1974500AReduce unit energy consumptionRealize Thermal CouplingDistillation purification/separationFractional distillationRefluxReboiler

The present invention relates to serial trimethyl benzene separating apparatus and method. The serial trimethyl benzene separating apparatus includes a pre-separating tower, a sym-trimethyl benzene tower and an unsym-trimethyl benzene tower, and features the condensator on the pre-separating tower connected to the outlet of the pre-separating tower, the reflux accumulator connected to the condensator and one vacuum unit, the reboiler in the bottom of the pre-separating tower connected between the outlet and the inlet of the sym-trimethyl benzene tower. The present invention adopts a serial three-tower process, can produce unsym-trimethyl benzene in purity over 99 % and sym-trimethyl benzene in purity over 35 % simultaneously in the yield over 90 % and power consumption 30 %-40 % lower than one normal pressure process.

Owner:TIANJIN UNIV

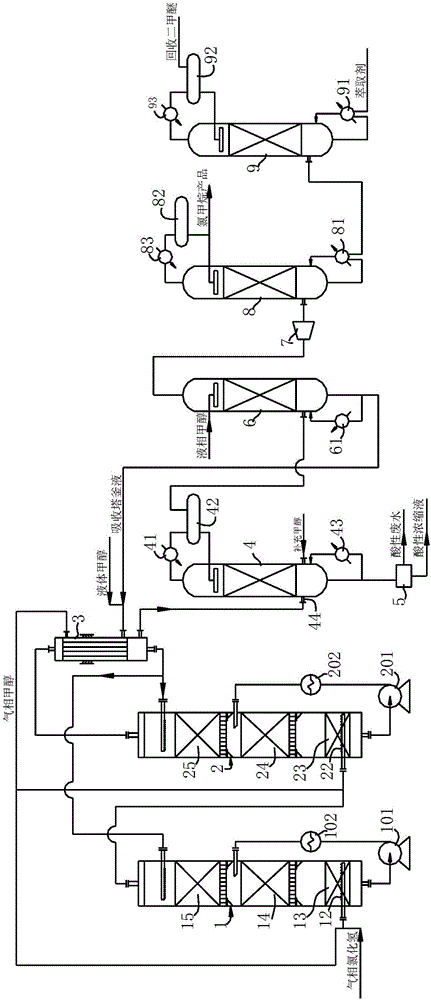

Cleaner production method for synthetizing chloromethane

ActiveCN106748632AWide pressure rangeReduce unit energy consumptionHalogenated hydrocarbon separation/purificationChemistryEther

The present invention discloses a cleaner production method for synthetizing chloromethane. The method comprises the steps: 1), synthetizing chloromethane: synthetizing crude chloromethane from gas-phase hydrogen chloride and gas-phase methanol; 2), recovering waste heat: performing heat exchange on the crude chloromethane by a heat exchange device and liquid methanol, cooling and discharging, wherein liquid methanol is heated by the heat exchange device to form gas-phase methanol which enters the step 1) as a raw material to react; 3), deacidifying by a deacidifying tower: deacidifying the crude chloromethane; 4), refining in an absorption tower; 5), pressurizing, extracting, rectifying and removing ether; and 6) performing diluted acid solution membrane concentration. In the method, the pressure application ranges of the hydrogen chloride and the methanol are relatively wide, and the content of HCl in diluted acid solution is greatly reduced; the methanol is used as a washing solution, other secondary wastes can not be generated; raw materials, such as the methanol and HCl, are utilized to the greatest extent; the unit energy consumption of CH3Cl is greatly reduced, the unit energy consumption of a product, namely CH3Cl is reduced by more than 20% compared with that in an industrialized unit in the prior art.

Owner:南通科恩化工技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com