Special numerical-control spinning forming machine for hub parts of engineering vehicle

A technology of engineering vehicles and spinning forming, which is applied in the direction of metal processing equipment, etc., can solve the problems of easy shaking of workpieces, low degree of automation, and unfavorable production efficiency, so as to reduce unit energy consumption, improve automation degree, and improve material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

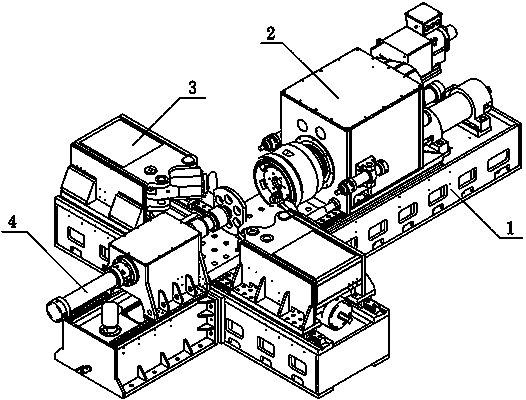

[0025] Such as figure 1 As shown, the CNC spinning forming machine for engineering vehicle wheel hub parts includes a bed 1, a main shaft part 2, two spinning wheel parts 3 and a tail top part 4. The bed 1 is in the shape of a "ten" and the main shaft part 2 The tail top part 4 is installed longitudinally on the bed 1, and the two rotary wheel parts 3 are installed laterally and symmetrically on the bed 1;

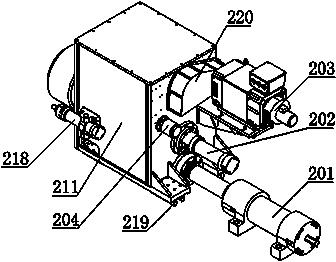

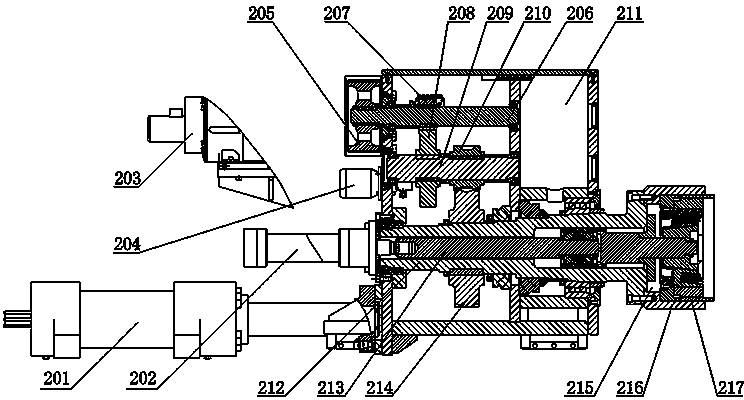

[0026] Such as figure 2 , image 3 with Figure 4As shown, the main shaft part 2 includes a main shaft housing 211, a main shaft 212, a longitudinal oil cylinder 201, a tensioning oil cylinder 202, a main shaft motor 203, a mold assembly 215 and an external material return cylinder 218, and the bottom of the main shaft housing 211 is provided with a heavy-duty slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com