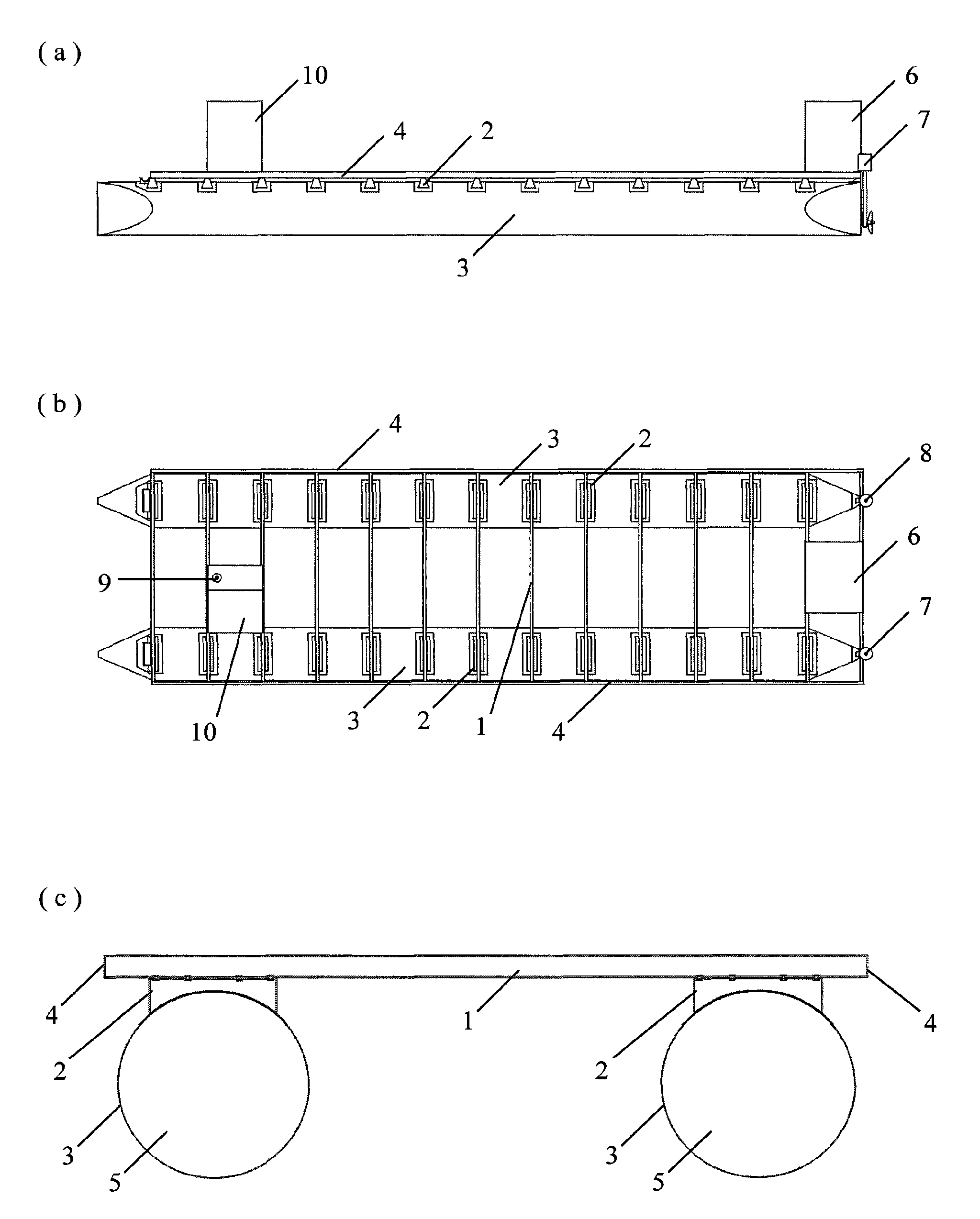

Large simulated type water-surface blue-green algae removing device

A bionic and blue-green algae technology, which is applied in the cleaning of open water, water conservancy projects, construction, etc., can solve the problems of high energy consumption, low efficiency, and inability to meet the needs of blue-green algae disaster control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention carries out operation and uses according to the following steps:

[0043] (1) Start the diesel generator set.

[0044] (2) Start the frequency-modulated electric pulper and the universal water jet propeller, and drive the device away from the dock.

[0045] (3) Start the electric pulper and drive the device into the working water area.

[0046] (4) Shut down the propulsion system and enter a static state.

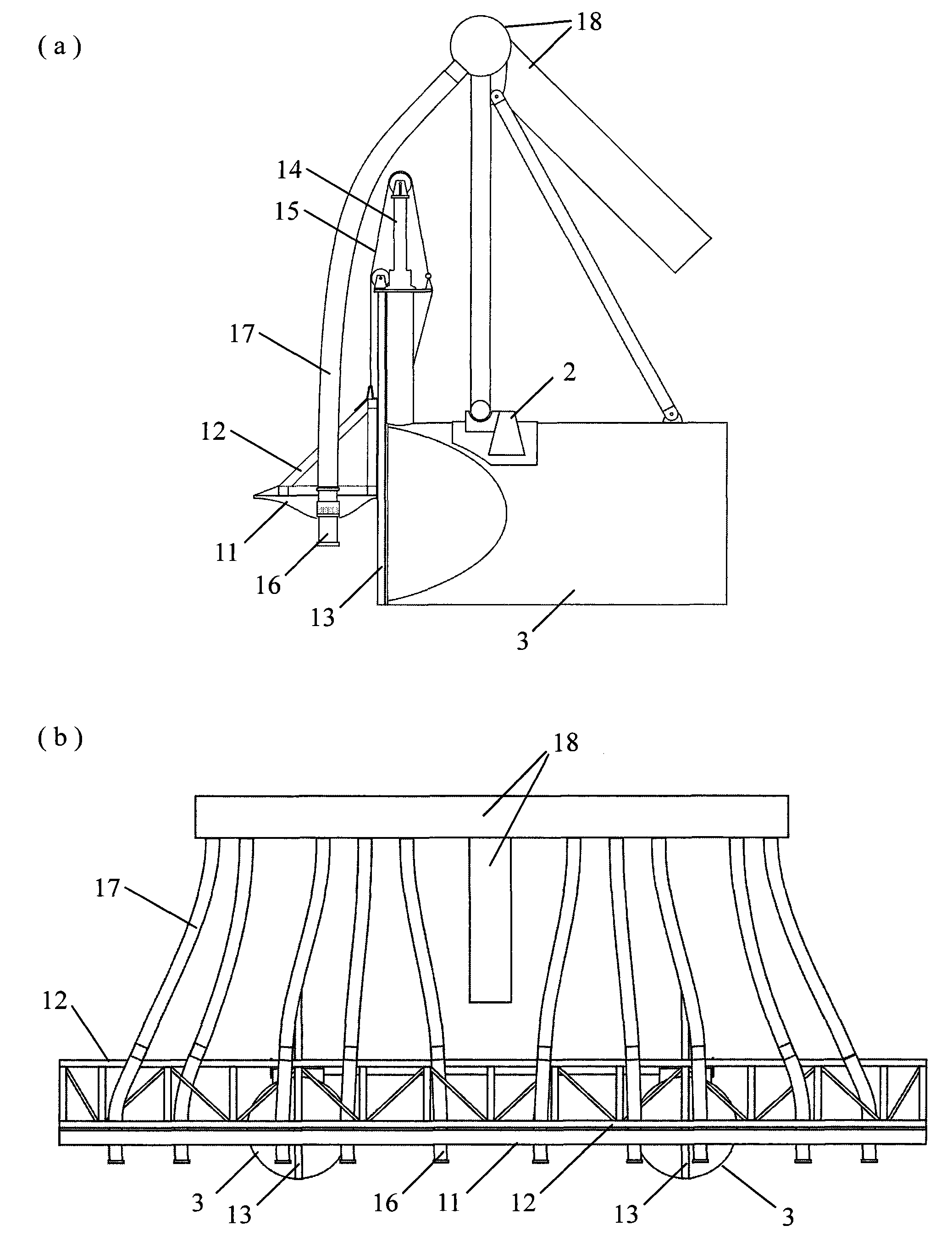

[0047] (5) Start the synchronous electric screw elevator to make the separation shovel drop to the working position.

[0048] (6) Start 10 water pumps and vibrating screens in turn to enter the working state.

[0049] (7) Adjust the separation shovel to an appropriate working height.

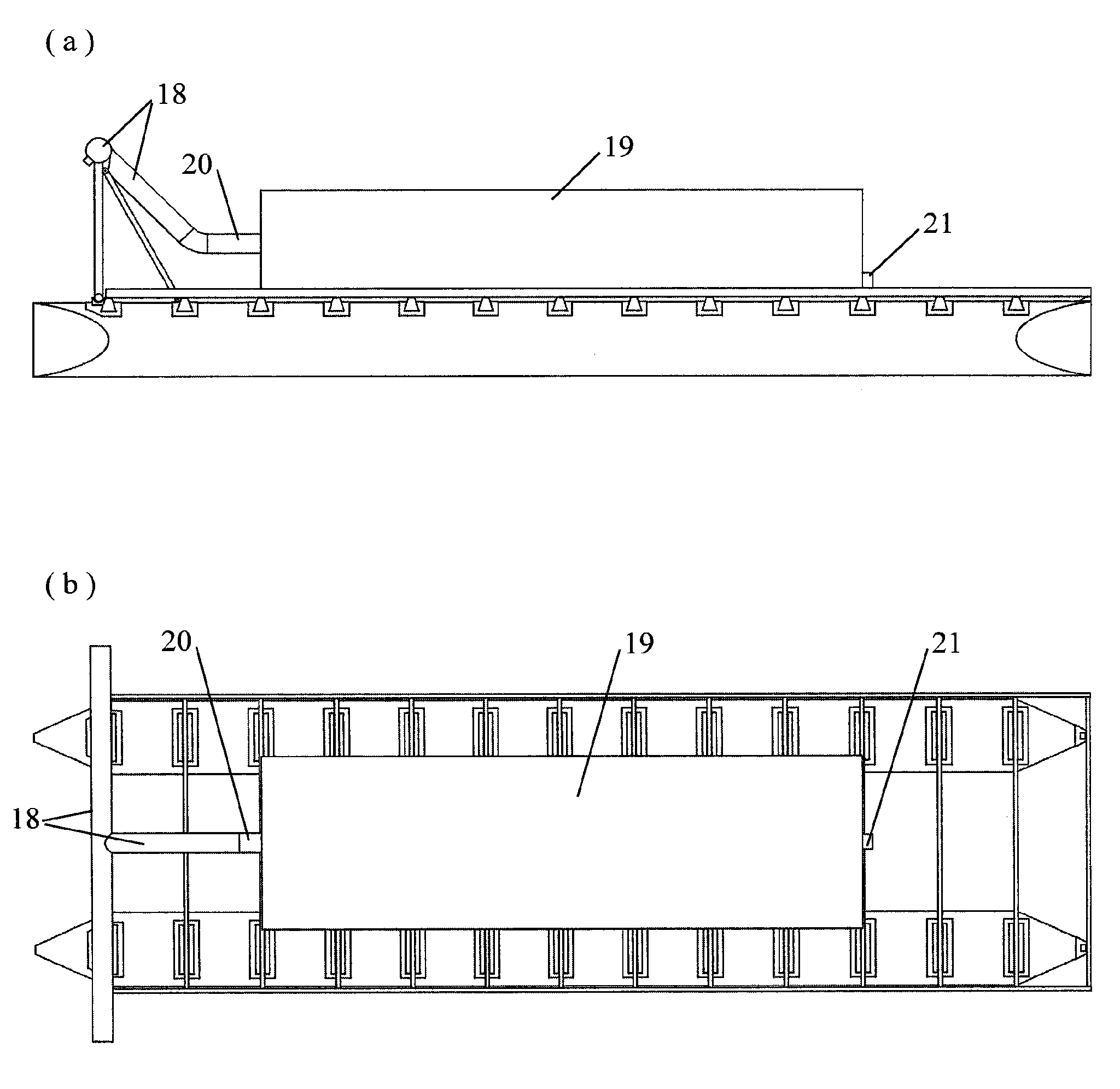

[0050] (8) Start the frequency-modulated electric pulper and the universal water jet propulsion, and operate according to the predetermined route and speed.

[0051] (9) If necessary, pump the algae slurry in the buffer pool to the accompanying transport ship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com