Voltage transformation adsorption method for circulation valuable gas

A technology of pressure swing adsorption and gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of not fully considering the gas flow direction and reducing system instability, so as to maintain system stability and improve operation. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This implementation example takes a single adsorption tower as an example Figure 10 The embodiments described in illustrate the invention in more detail:

[0074] In the single adsorption tower, the zeolite molecular sieve adsorbent is used to separate the air into high-purity difficult-to-adsorb oxygen products, and nitrogen gas, which is an easily adsorbable component of the by-product gas, is discharged. After the raw material air passes through the one-way check valve 6, it enters the raw material gas balance tank 1 and mixes with the recovered valuable gas (pressure release gas of the adsorption tower). When the pressure of the raw material gas balance tank 1 increases due to the clearance gas, Feed air will not pass through check valve 6, but when the pressure of the residual air in feed gas balance tank 1 decreases, the air will start to pass through control valve 7 and mix with the remaining residual gas in feed gas balance tank 1, including After the raw mate...

Embodiment 2

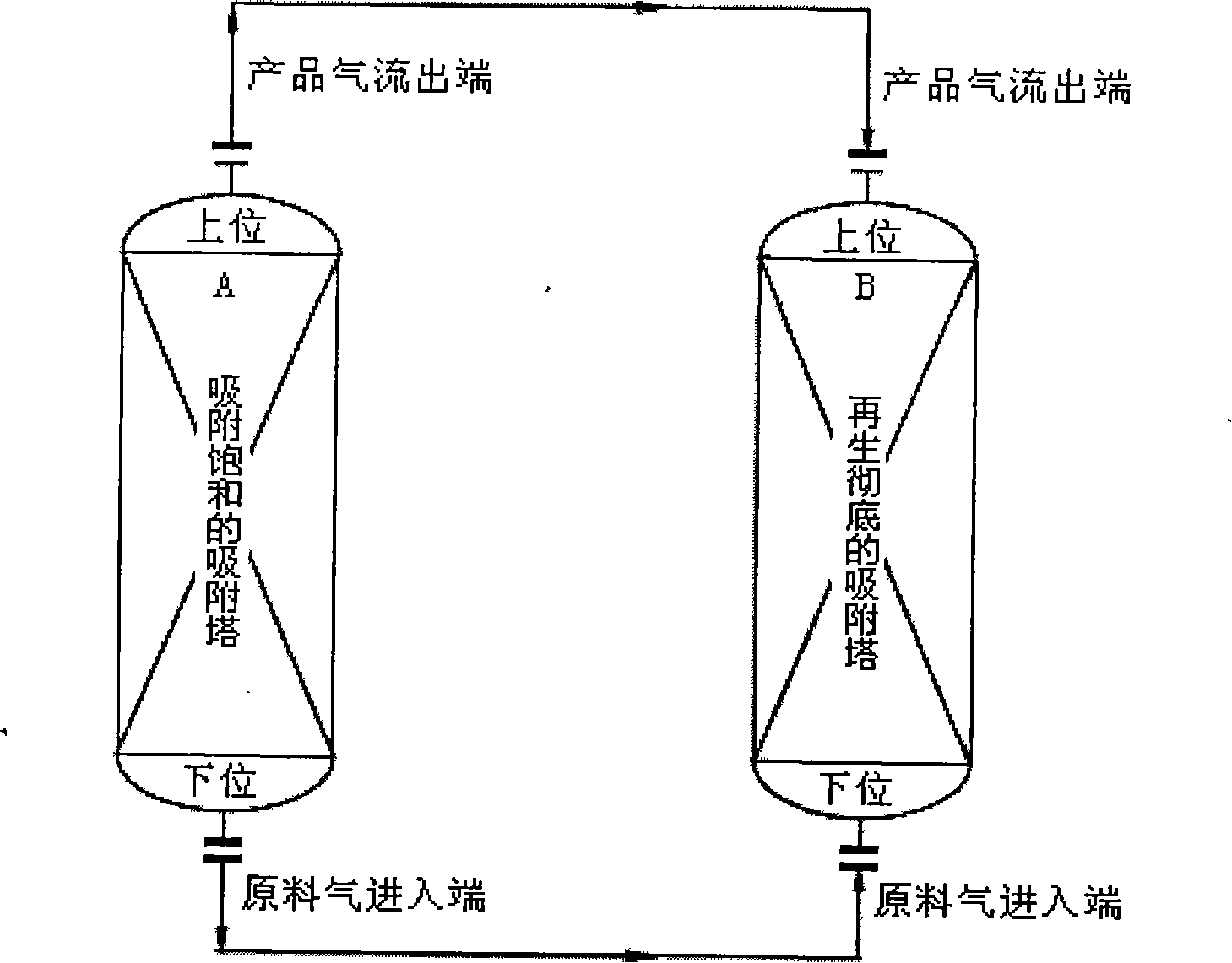

[0076] This implementation example takes two adsorption towers as an example Figure 11 The embodiment described in illustrates in more detail the preferred pressure swing adsorption system of a plurality of adsorption towers of the present invention:

[0077] In two parallel adsorption towers, the zeolite molecular sieve adsorbent is used to separate the air into high-purity difficult-to-adsorb oxygen products, and discharge nitrogen as the easily adsorbable component of the by-product gas. After the raw material air passes through the one-way check valve 6, it enters the raw gas balance tank 1 and mixes with the recovered valuable gas (pressure release gas of the adsorption tower). When the pressure in the raw gas balance tank 1 rises due to the clearance gas, The feed air will not pass through the check valve 6, but when the pressure of the clearance air in the feed balance tank 1 decreases, the air will start to pass through the check valve 6 and mix with the remaining cle...

Embodiment 3

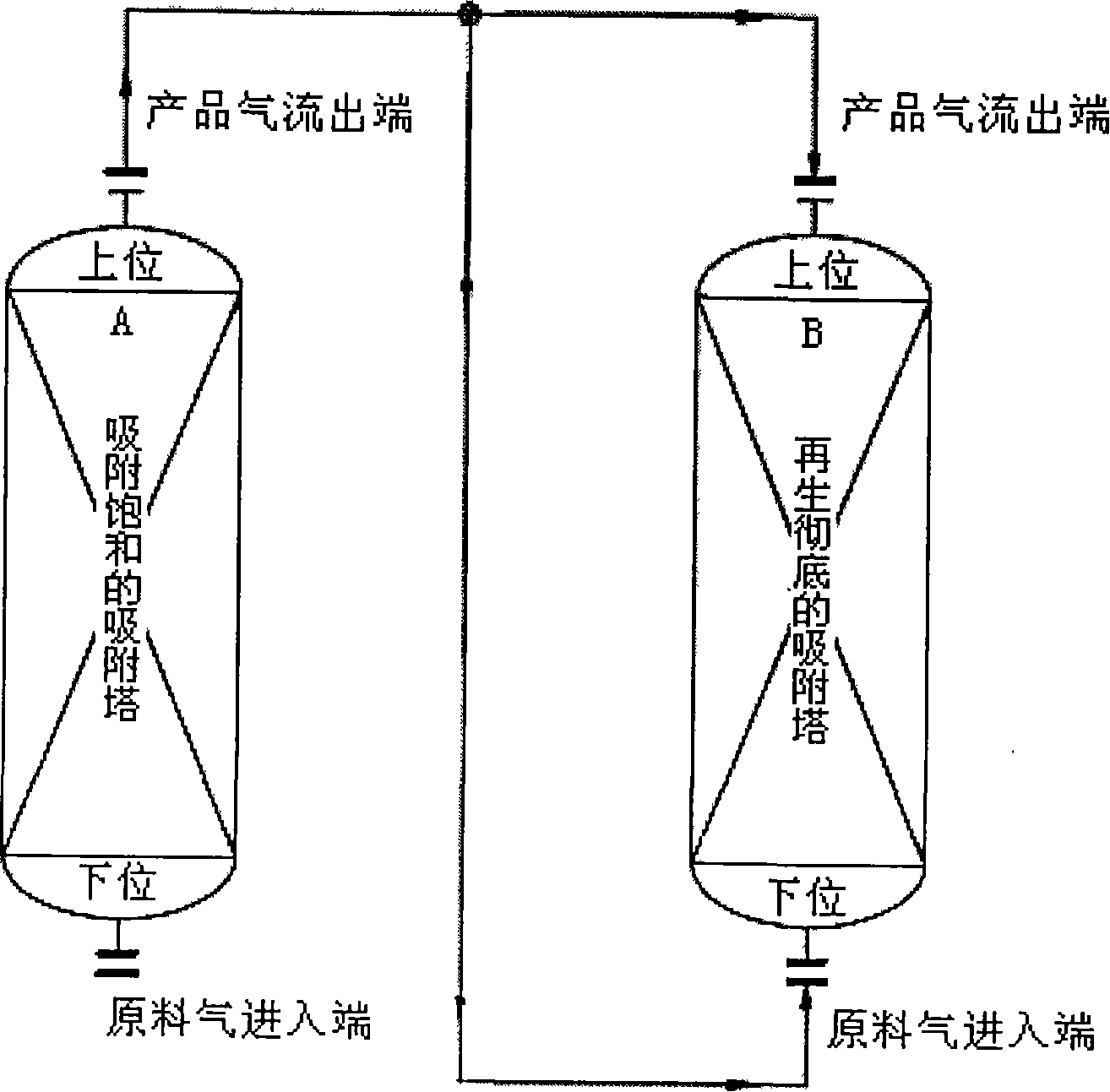

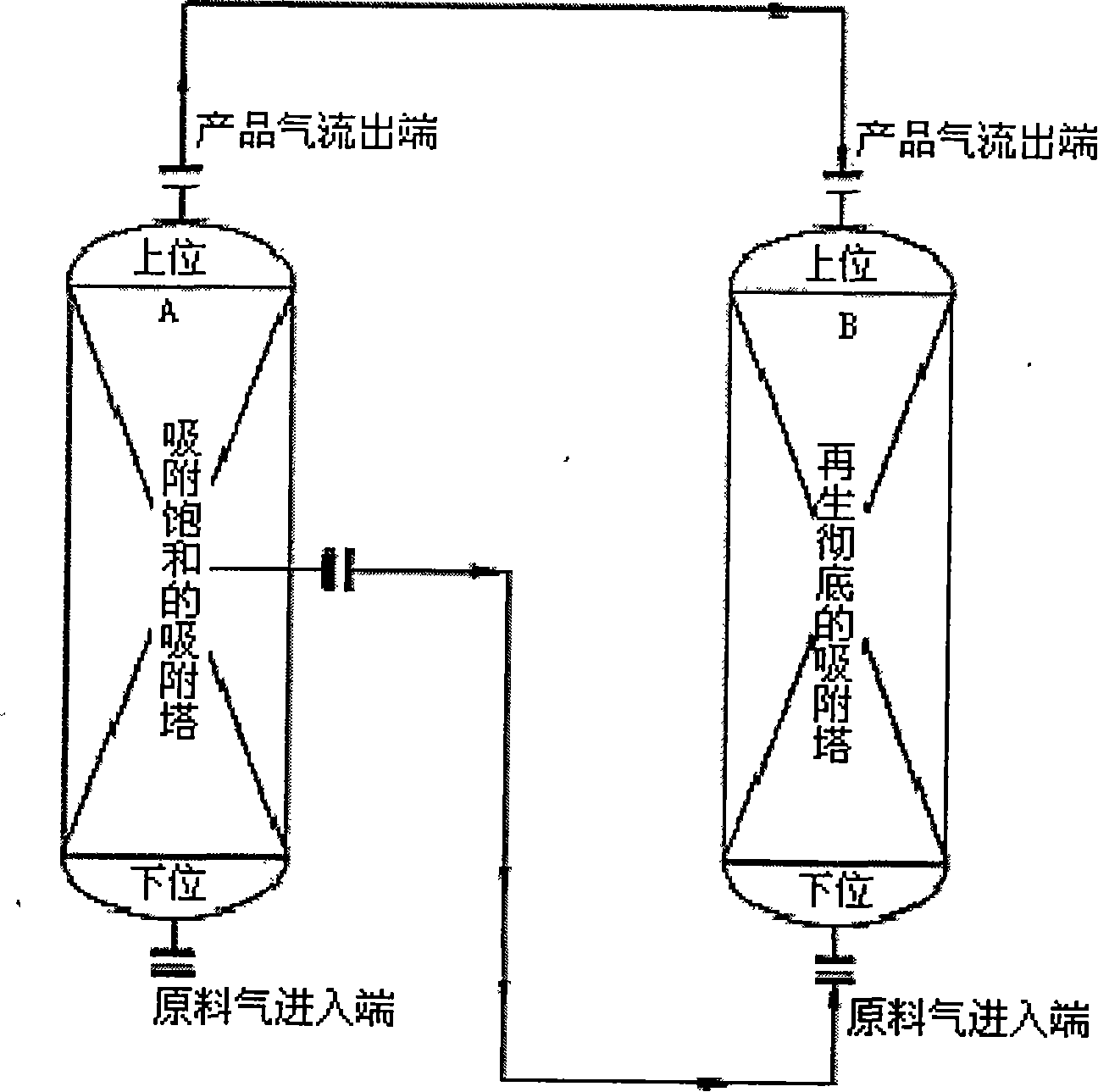

[0079] This implementation example takes two adsorption towers as an example Figure 12 The embodiment described in illustrates in more detail the preferred pressure swing adsorption system of a plurality of adsorption towers of the present invention:

[0080] In two parallel adsorption towers, the zeolite molecular sieve adsorbent is used to separate the air into high-purity difficult-to-adsorb oxygen products, and discharge nitrogen as the easily adsorbable component of the by-product gas. After the raw material air passes through the one-way check valve 6, it enters the raw gas balance tank 1 and mixes with the recovered valuable gas (pressure release gas of the adsorption tower). When the pressure in the raw gas balance tank 1 rises due to the clearance gas, Feed air will not pass through check valve 6, but when the pressure of the residual air in feed balance tank 1 decreases, the air will start to pass through valve 6 and mix with the remaining residual gas in feed balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com