Patents

Literature

73results about How to "Improve concentrate quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

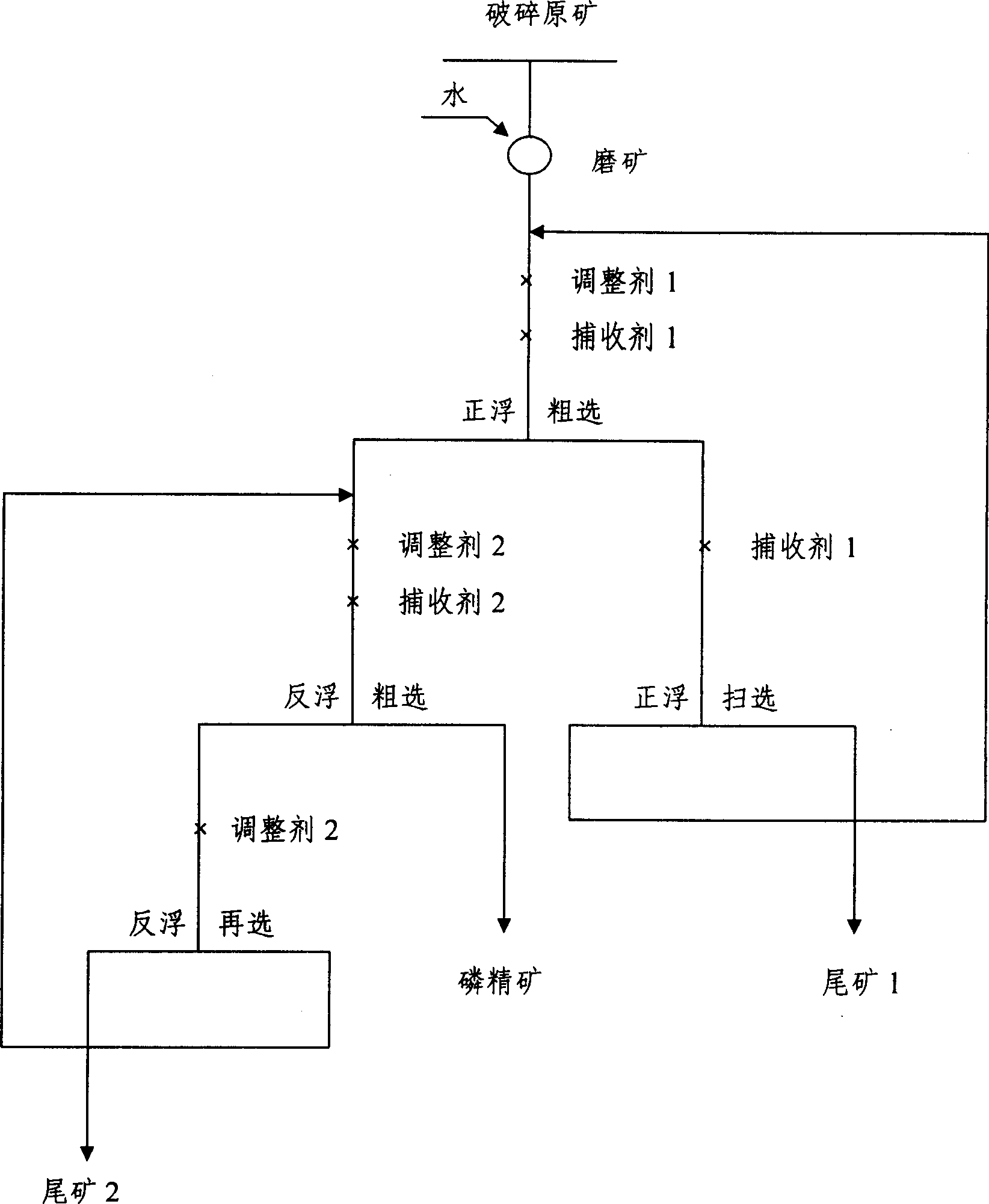

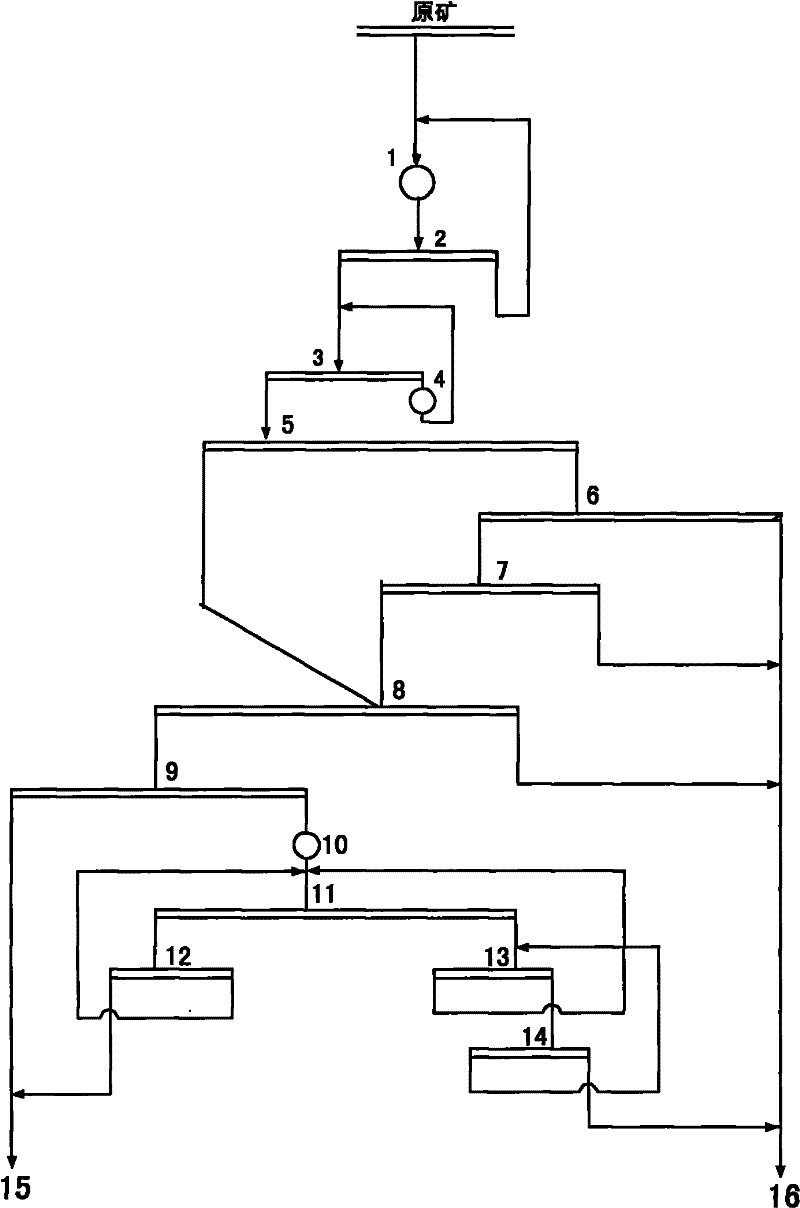

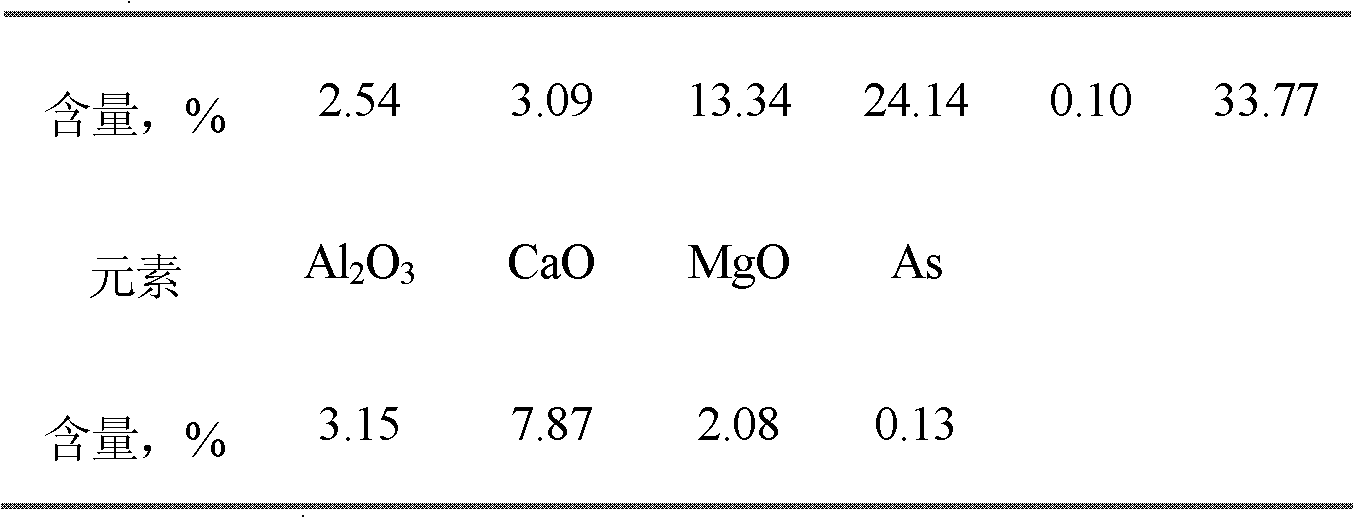

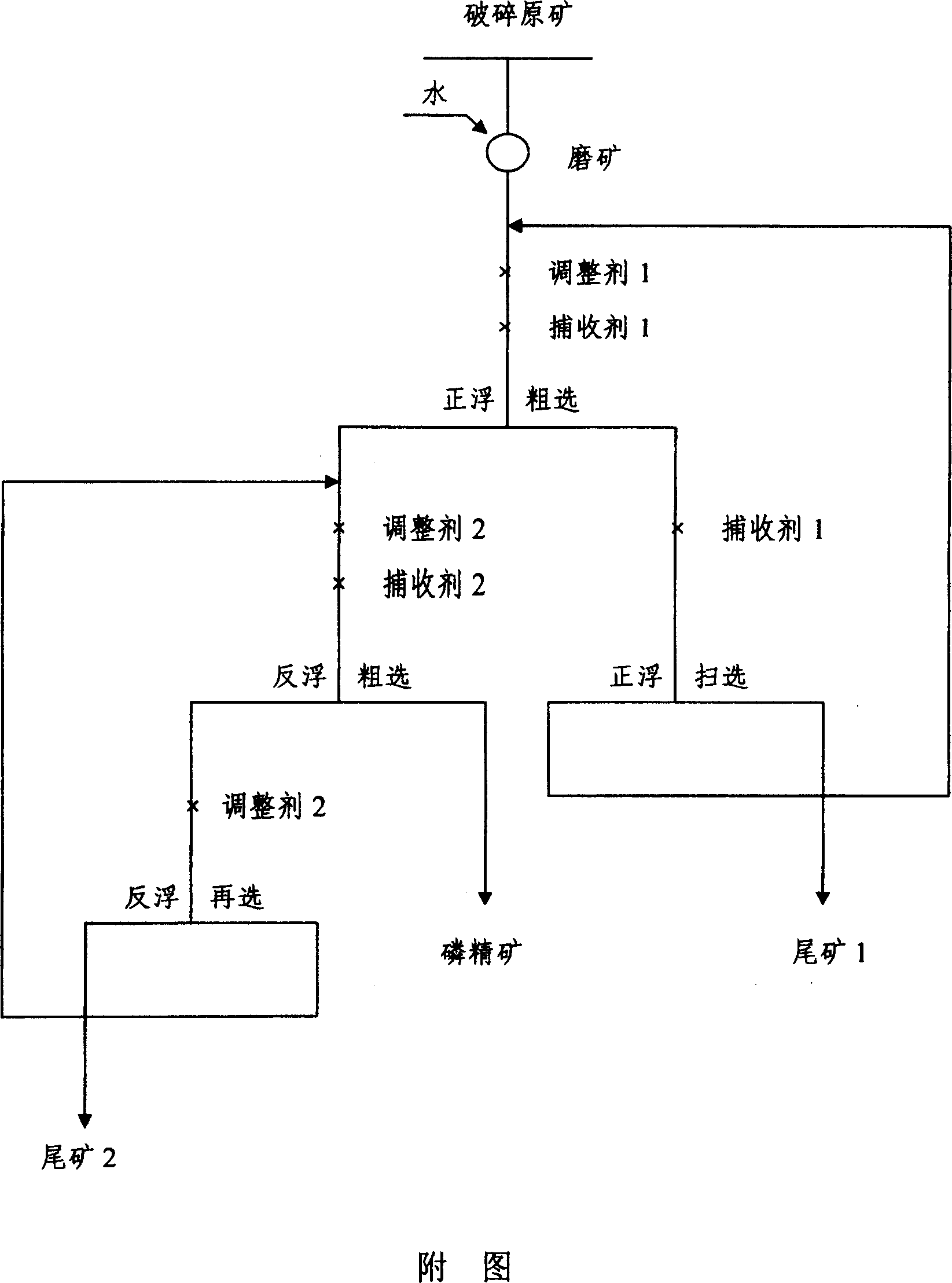

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

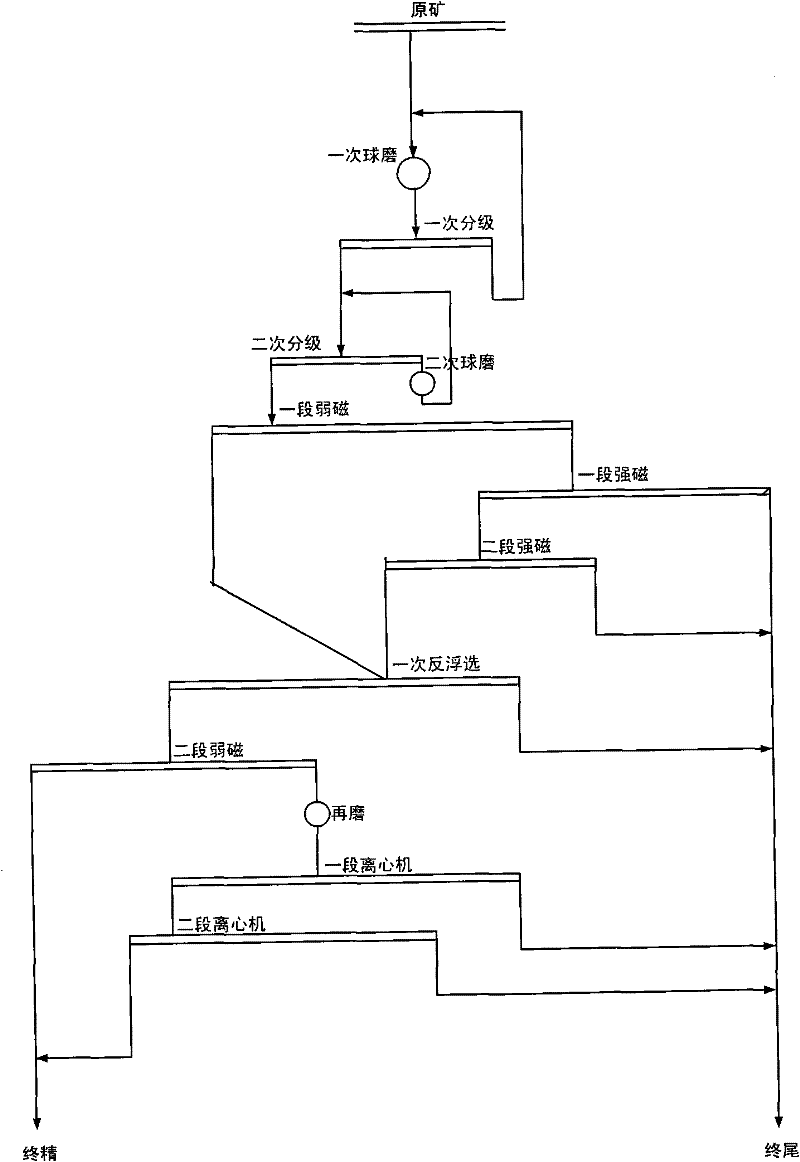

Efficient magnetic separation method for quartz sand

InactiveCN102626668AIncrease production capacityReduce unit energy consumptionWet separationPurification methodsNo production

The invention discloses an efficient purification method for quartz sand. In the method, two-section smashing (rough smashing and fine smashing) and ore milling with a rod mill are adopted, so that the production capacity is increased greatly, unit energy consumption is lowered, and the method is suitable for large-scale production. A method for removing weakly-magnetic minerals and intergrowth quartz with high iron content from quartz sand through advanced ore washing and weakly magnetic-high gradient strongly magnetic combined magnetic separation before ore milling is adopted, so that the purity of quartz sand is increased greatly. The method has the advantages of simple process flow, easiness for operating, low cost, high purification efficiency, stable performance and environmental friendliness of a produced product, no use of any chemical substance in an entire production process, no production of any waste water, waste residues and waste gas, true realization of zero emission, no production of waste and prevention of pollution. The method is not limited by the production scale, various quartz sand products of low, medium and high grades can be produced, the enterprise profit can be maximized, and the method has a wide application prospect on the aspect of purification of quartz sand.

Owner:赣州金环磁选科技装备股份有限公司

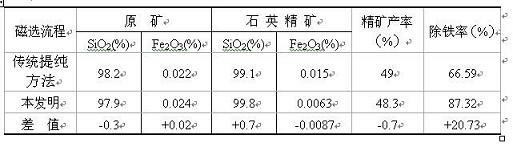

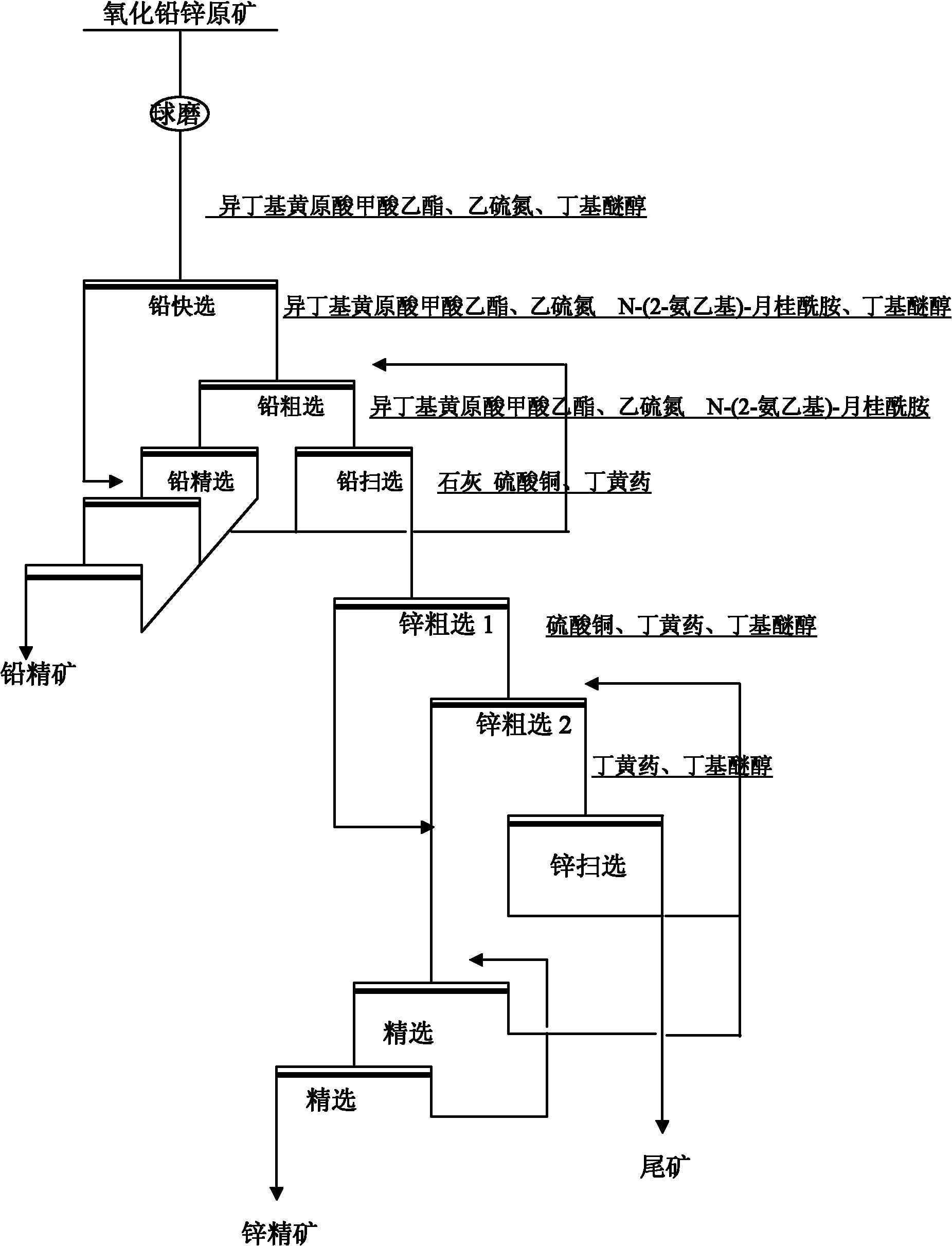

Flotation method for sulfidization-oxidization mixed lead-zinc ore

InactiveCN1704170AHigh recovery rateImprove concentrate qualityFlotationGrain treatmentsLead zincChemistry

The invention relates to a floating method of sulfide-oxide mixing Pb-Zn mine. The lead floating method adopts the flow process of one fast separation, one roughing separation, one sweeping separation and three classifications so that the mine grouting acidity of the full floating process can keep at pHú¥11. The zinc floating method adopts the flow process of one fast separation, one roughing separation, one sweeping separation and two classifications so that the mine grouting acidity of the full floating process can keep at pHú¥12. It can increase the recovery ratio of PbíóZn over 10% when Pb-Zn mine has oxide ratio over 30%.

Owner:黎东明

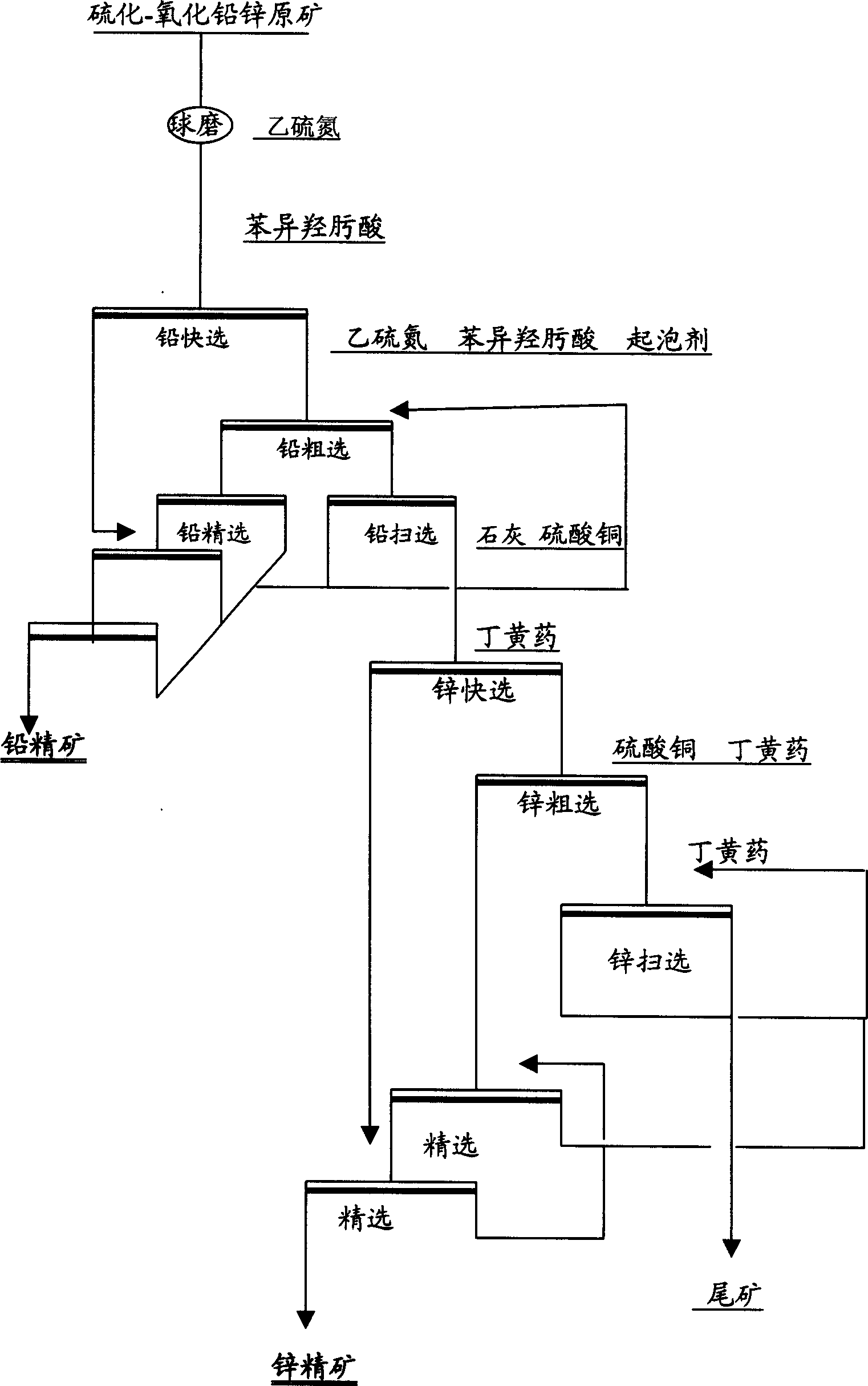

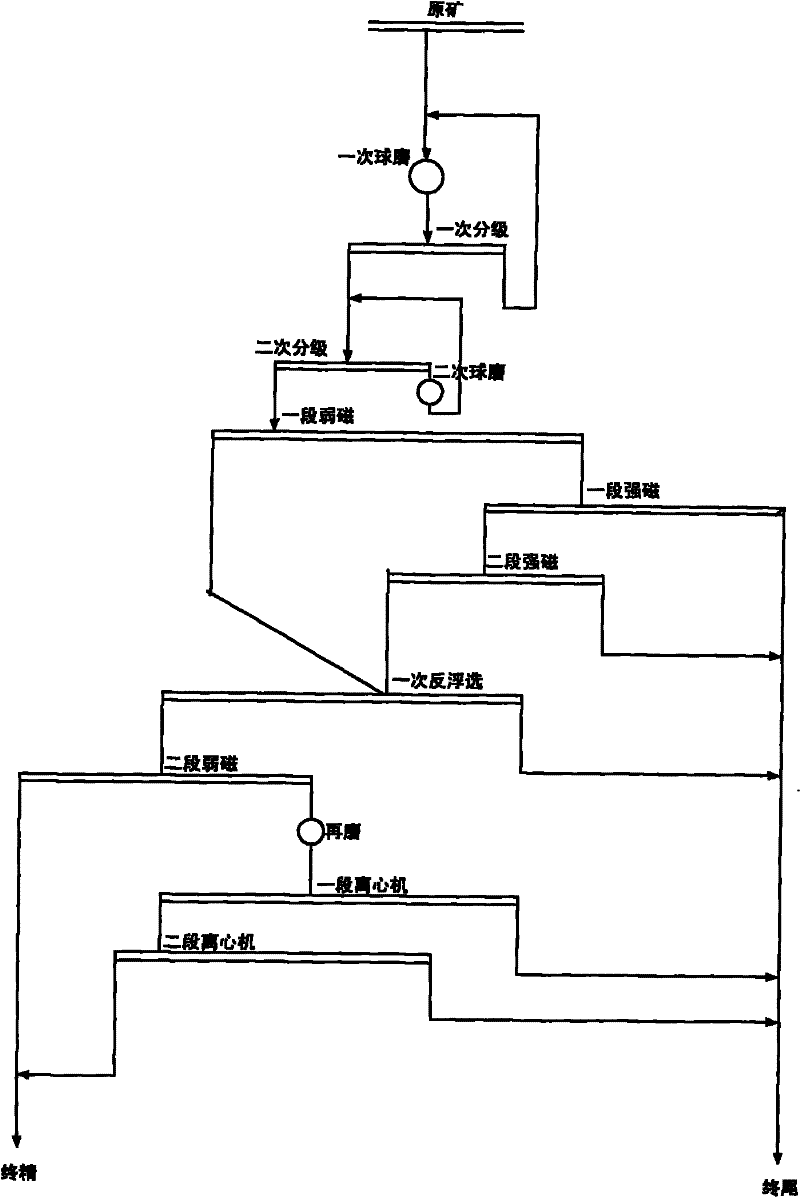

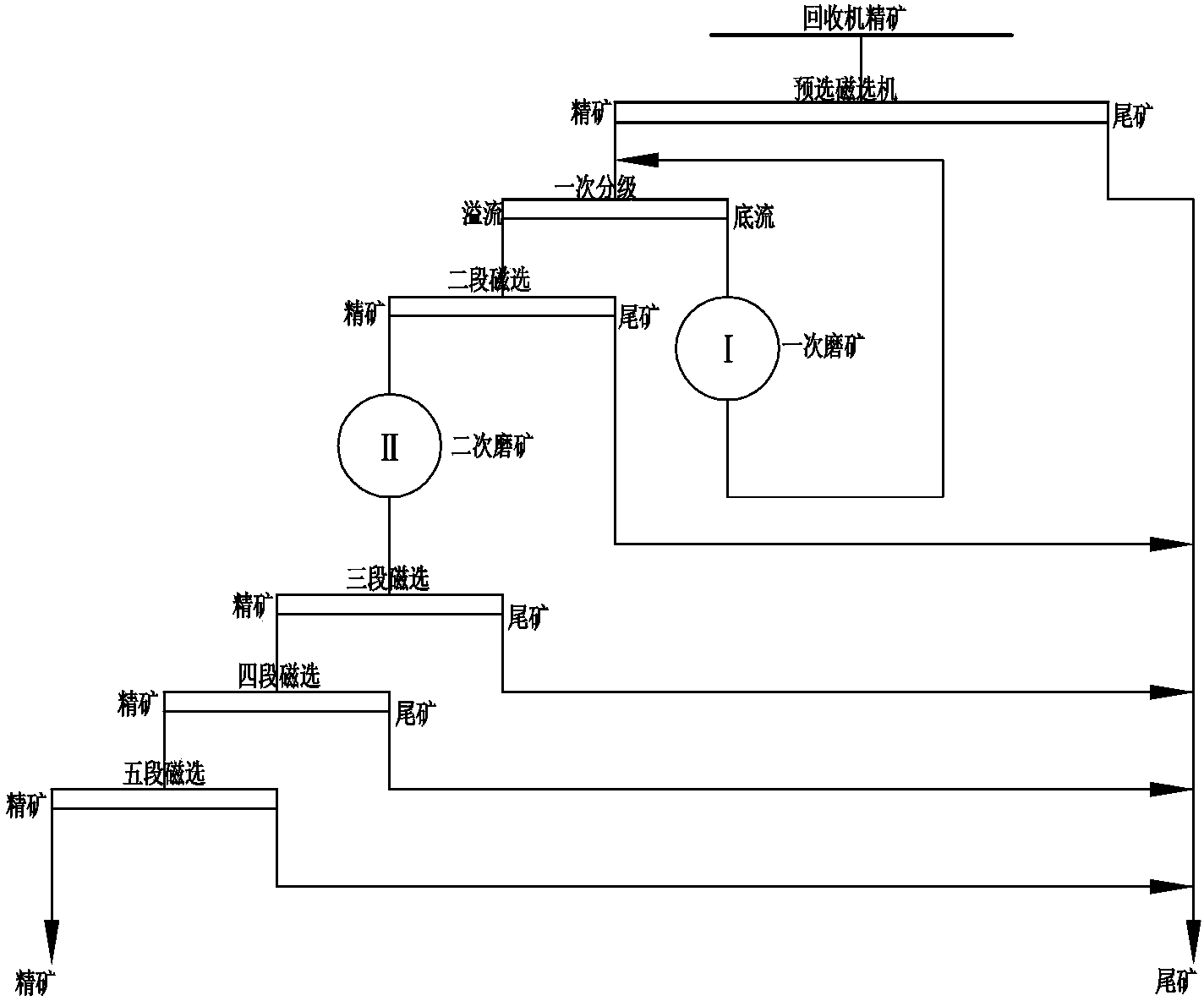

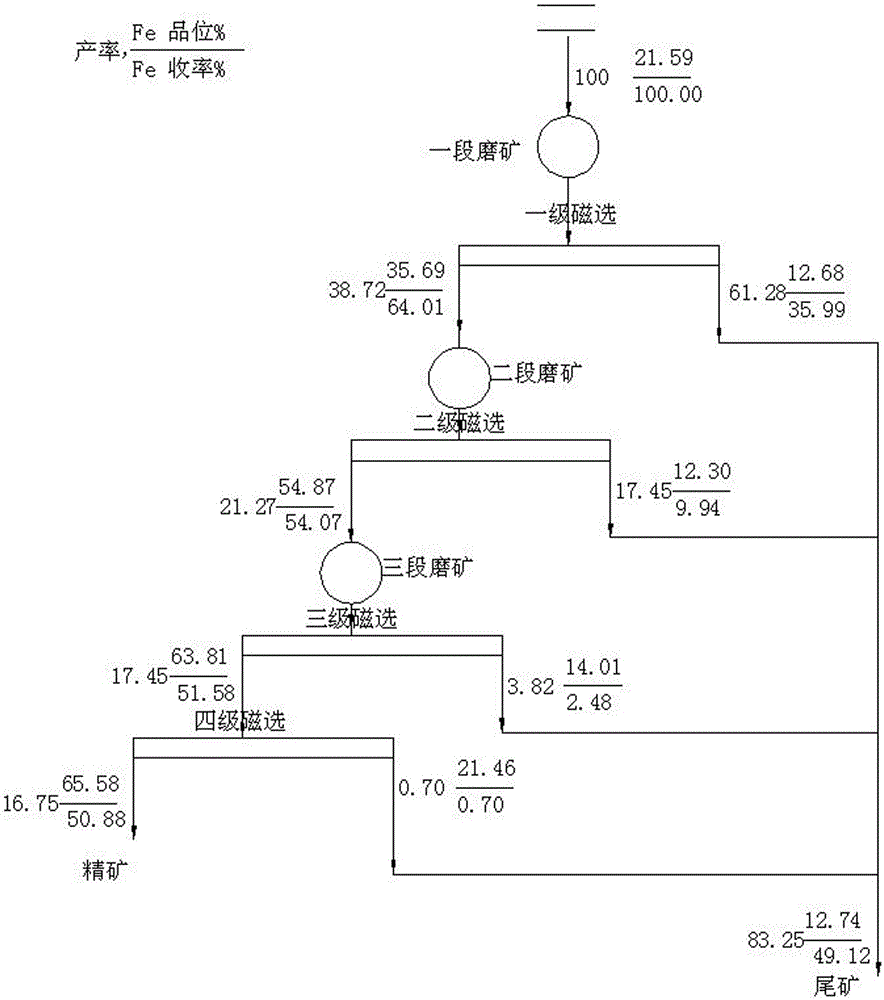

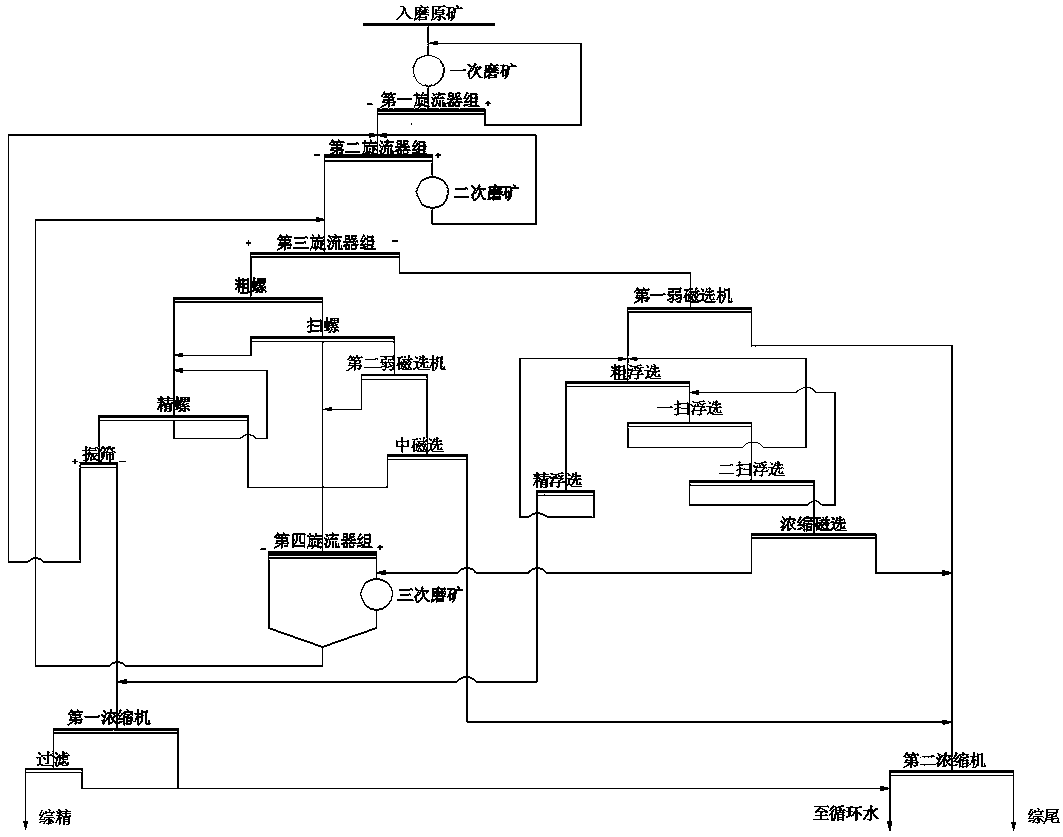

Sorting method of multi-metal lean hematite

ActiveCN102228861AEfficient separationImprove concentrate qualityFlotationWet separationReverse flotationMining industry

The invention belongs to the technical field of ore beneficiation in metallurgical mining industry, and particularly relates to a sorting method of multi-metal lean hematite. The sorting method is characterized by employing a two-stage continuous grinding, magnetic separation, reverse flotation, grinding aging and centrifuge sorting method to separate the iron minerals and other metallic minerals, and comprises the following steps of: carrying out ball milling for the first time and classification for the first time, classification for the second time, ball milling for the second time, first-stage weak magnetic separation, first-stage strong magnetic roughing, first-stage strong magnetic selection, reverse flotation sorting, second-stage magnetic separation, grinding again, centrifuge roughing and centrifuge selection on the multi-metal symbiotic lean hematite, combining the weak magnetic separation concentrate and centrifuge concentrate to obtain final concentrate, and combining second-stage strong magnetic separation tailings, reverse flotation tailings and centrifuge tailings to obtain final tailings. After the introduction of the novel new sorting method, the grade of the raw ore is 30.505%, the grade of the obtained concentrate increases to 64.14% from about 58% and the yield is 28.59%, the recovery rate is 60.13%, and the grade of the tailings is 17.03%.

Owner:ANSTEEL GRP MINING CO LTD

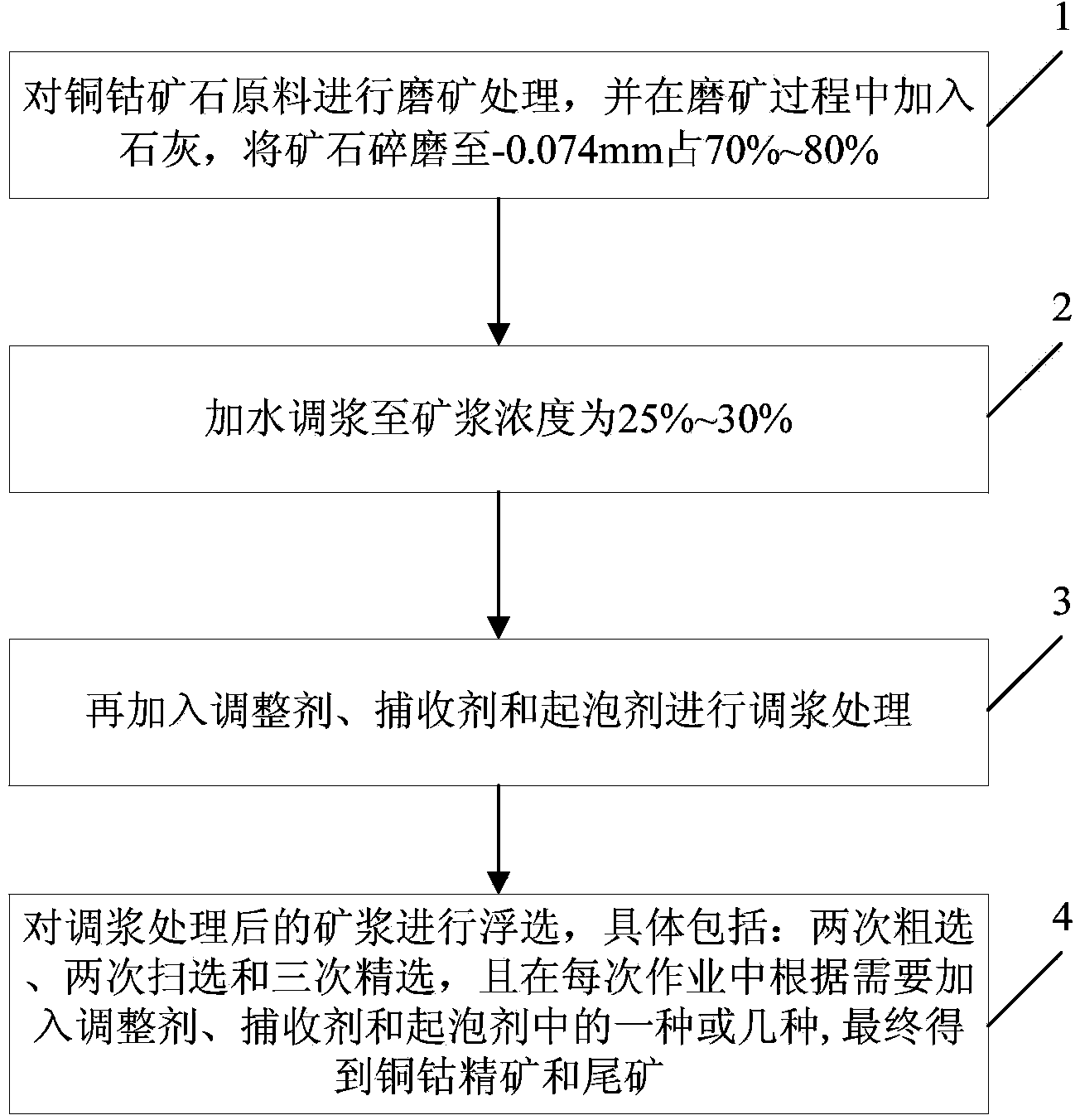

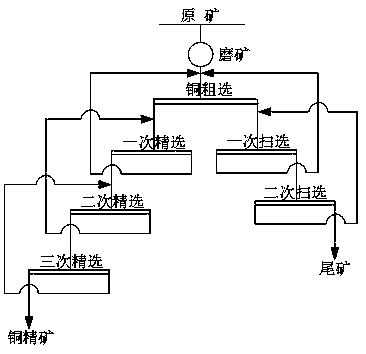

Flotation method for carbonaceous copper-cobalt ore

InactiveCN103480500AImprove concentrate qualityThe method flow is simpleFlotationFoaming agentCopper

The invention discloses a flotation method for carbonaceous copper-cobalt ore. The flotation method includes firstly, performing ore grinding on copper-cobalt core raw materials, adding lime during ore grinding, and grinding the ore until the ore is -0.074mm in size and accounts for 70%-80%; adding water and preparing ore pulp until concentration of the ore pulp reaches 25%-30%; adding a regulating agent, a collecting agent and a foaming agent again for ore pulp preparation; performing flotation, including two-time rougher flotation, two-time scavenging and three-time concentration, on the ore pulp subjected to ore pulp preparation; adding one or more of the regulating agent, the collecting agent and the foaming agent during each operation according to needs to finally obtain copper-cobalt concentrates and tailings. The flotation method is simple in procedure, convenient to control, high in separation efficiency and good in index, and the obtained copper-cobalt concentrates have good quality.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

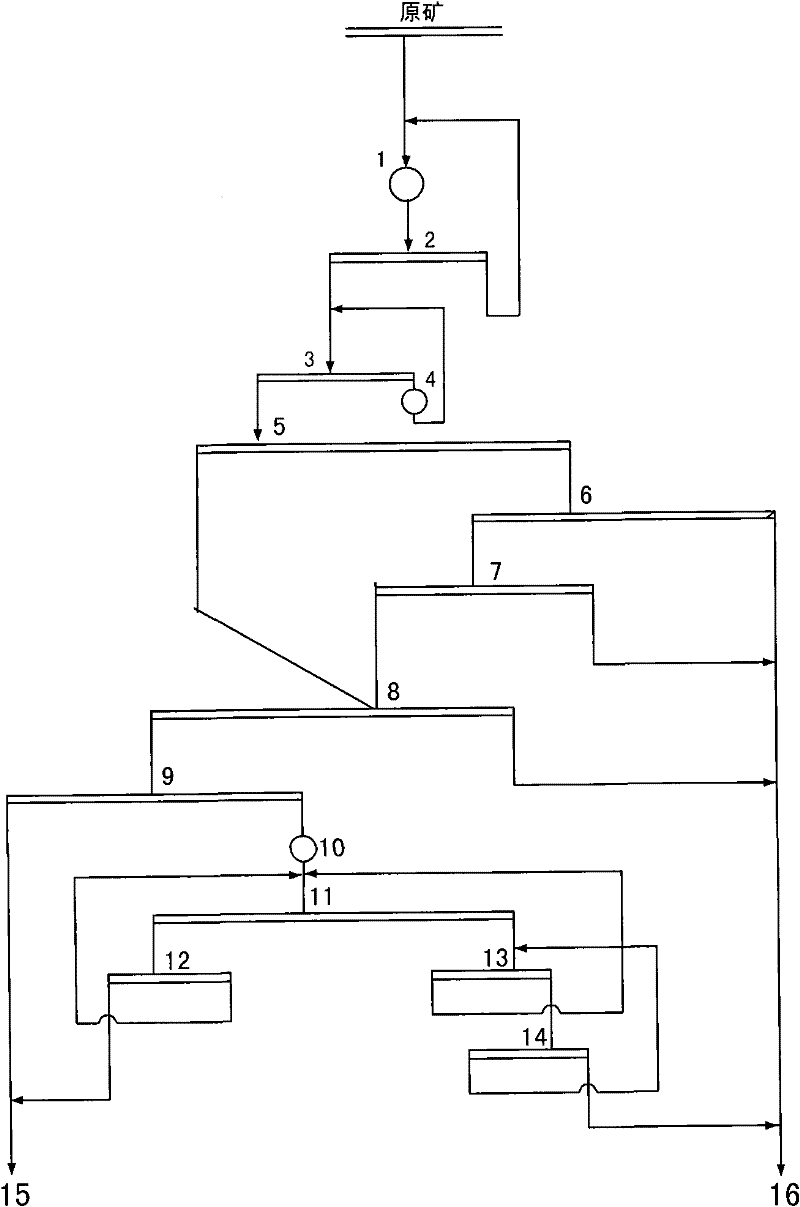

Novel separation process of multi-metal lean hematite

ActiveCN102228863AEfficient separationImprove concentrate gradeFlotationWet separationMetalMetallurgical industry

The invention belongs to the technical field of mineral separation in the metallurgical industry, and in particular relates to a novel separation process of multi-metal lean hematite, which is characterized in that a separation method of two sections of continuous ore grinding, magnetic separation, reverse floatation, regrinding and centrifuging through a centrifugal machine is adopted so that iron minerals and other metal minerals are separated. The novel separation process comprises the following steps of: subjecting primary ball grinding, primary grading, secondary grading, secondary ball grinding, one-section weak magnetic separation, one-section strong magnetic separation, one-section strong magnetic fine separation, reverse floatation operation separation, two-section magnetic separation and regrinding to multi-metal symbiotic lean hematite ores; carrying out one-section rough separation, one-section fine separation, one-section scavenging and two-section scavenging; merging weak magnetic concentrate and secondary reverse floatation concentrate to form final concentrate; and merging two-section strong magnetic tailings and reverse floatation tailings to form final tailings. After the novel separation process is adopted for separation, raw ore grade is 30.505 percent, the concentrate obtained after the separation has better selection indexes such as a grade of 64.14 percent, a yield of 28.59 percent, a metal recovering rate of 60.13 percent, and a tailing grade of 17.03 percent. The grade of the concentrate can be improved from about 58 percent to 64.14 percent.

Owner:ANSTEEL GRP MINING CO LTD

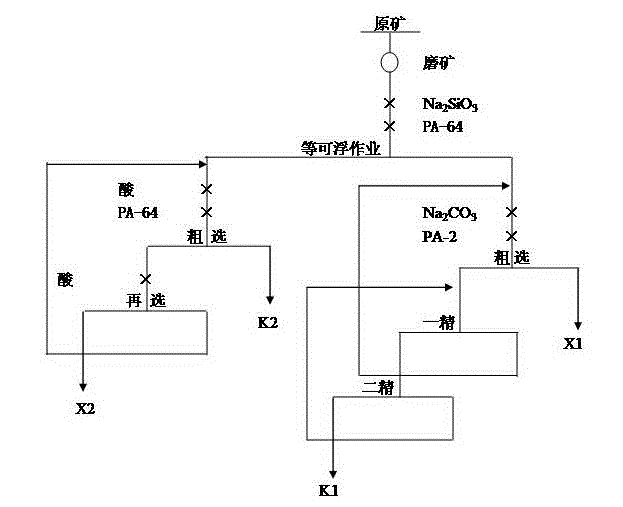

Iso-floatable separation process of siliceous-calcareous collophanite

ActiveCN102744160ARealize beneficiation and enrichmentReduce dosageFlotationCalcium in biologyPhosphorite

The invention relates to an iso-floatable separation process of siliceous-calcareous collophanite, comprising the following steps of: crushing and grinding siliceous-calcareous-based collophanite ores, adding water, mixing size, and then entering iso-floatable operation for the iso-floatable flotation of the siliceous-calcareous-based collophanite ores; enabling flotation froths to flow into a reverse flotation agitating tank, mixing the size, and then entering a reverse flotation system for the reverse flotation of carbonate gangue minerals, wherein products inside a reverse flotation tank are reverse flotation phosphate concentrates; and enabling the products inside an iso-floatable flotation tank to enter a direct flotation agitating tank and materials obtained after size mixing to enter a direct flotation system for direct flotation, wherein direct flotation froth products are direct flotation phosphate concentrates. The iso-floatable separation process sufficiently utilizes the difference of natural floatability of ores and has the advantages of small using amount of flotation reagent, circulation utilization of beneficiation wastewater, high separation efficiency and excellent process index; the obtained phosphate concentrates contain lower MgO content and high concentrate quality; and final product phosphate concentrates are lower in comprehensive cost.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

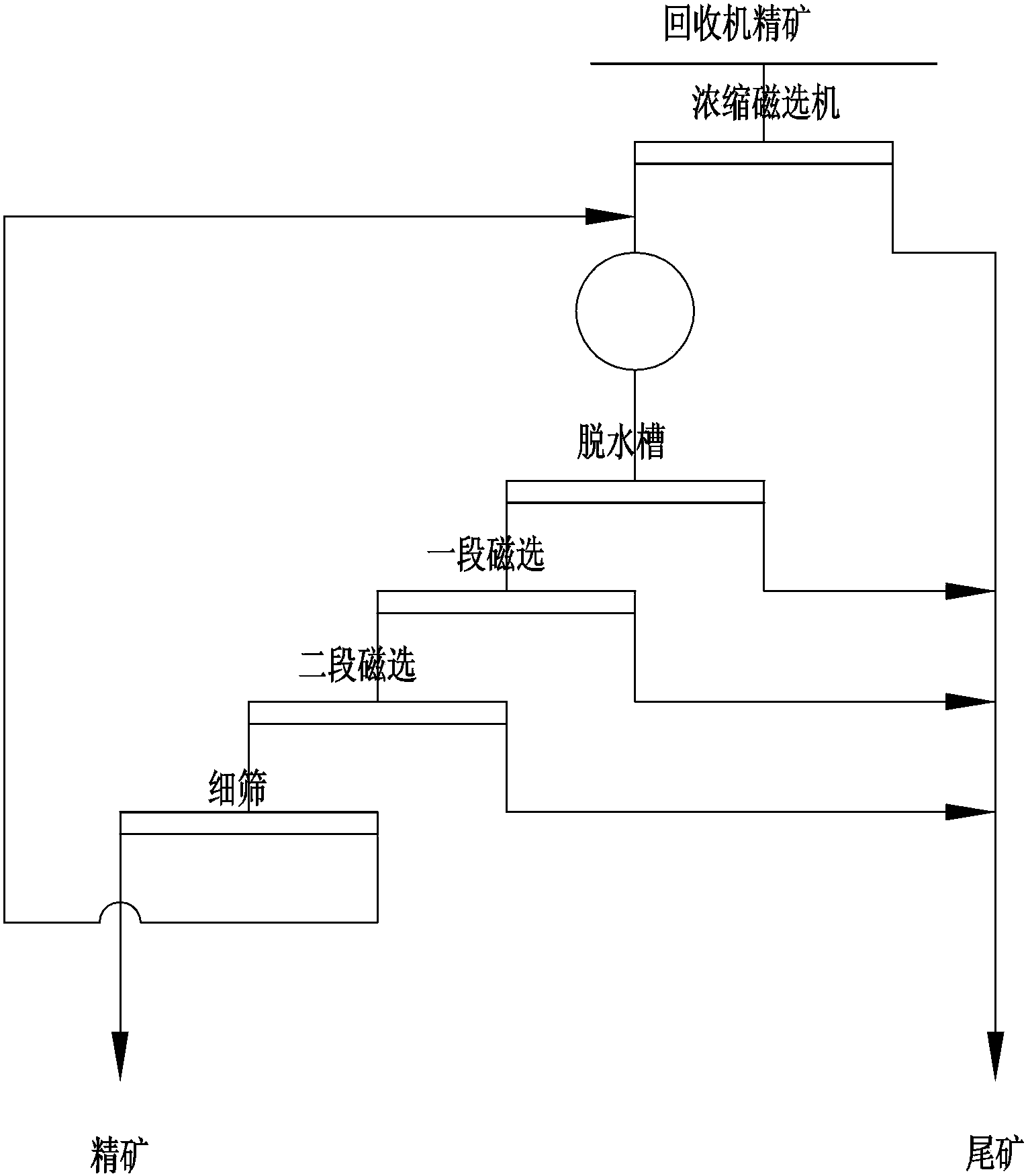

Technology for screening iron ore concentrate from mineral tailing of low-grade ore

ActiveCN103406197AReduce the amount of regrindImprove concentrate qualityMagnetic separationOre concentrateMagnetic separator

The invention relates to a technology for screening iron ore concentrate from mineral tailing of low-grade ore. The invention is characterized by comprising the following steps: recycling crude ore concentrate with grade of 16-20% from mineral tailing of low-grade ore with grade of 8-11% through a disc recycling machine; feeding the crude ore concentrate into a one-section preselection magnetic separator for screening; feeding the ore concentrate from the preselection magnetic separator into a one-time classification; then feeding the overflow of the one-time classification into a two-section magnetic separator, and feeding the underflow of the one-time classification into a section of closed grinding ore formed through one-time ball mill; feeding the ore concentrate passing through the two-section magnetic separator into a two-section tower mill to carry out ore grinding, so as to obtain ore concentrate with graininess of 325-500 meshes with the content of 90%; then feeding the ore concentrate into a three-section magnetic separator, a four-section magnetic separator, and a five-section magnetic separator for machining screen respectively; obtaining the final ore concentrate with the grade of 64.98-67.21%, wherein the preselection magnetic separator mineral tailing, the two-section mineral tailing, the three-section mineral tailing, the four-section mineral tailing, and the five-section mineral tailing are the final mineral tailing in total. The invention has the advantages that the technology can lower the grade of the mineral tailing, and increase metal recovery rate; the grade of the ore concentrate can reach 64.98-67.21%, and is 7-9.5% larger than the grade of the ore concentrate of a conventional reselection technology.

Owner:ANSTEEL GRP MINING CO LTD

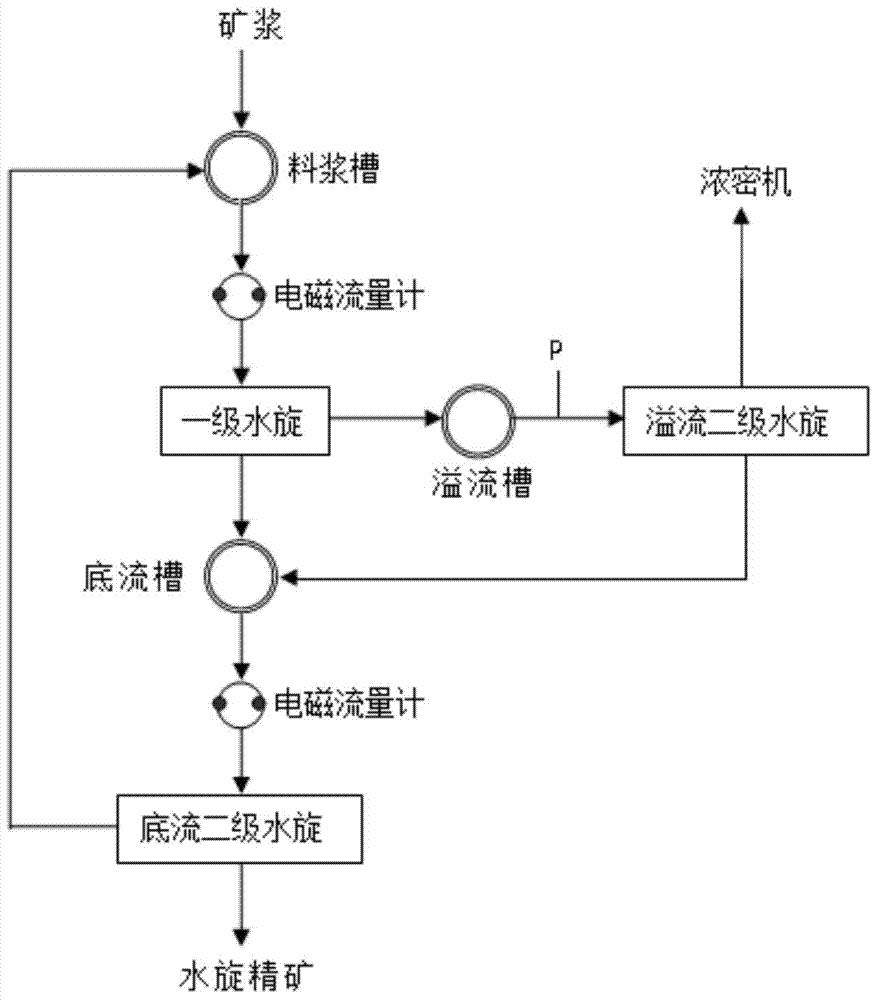

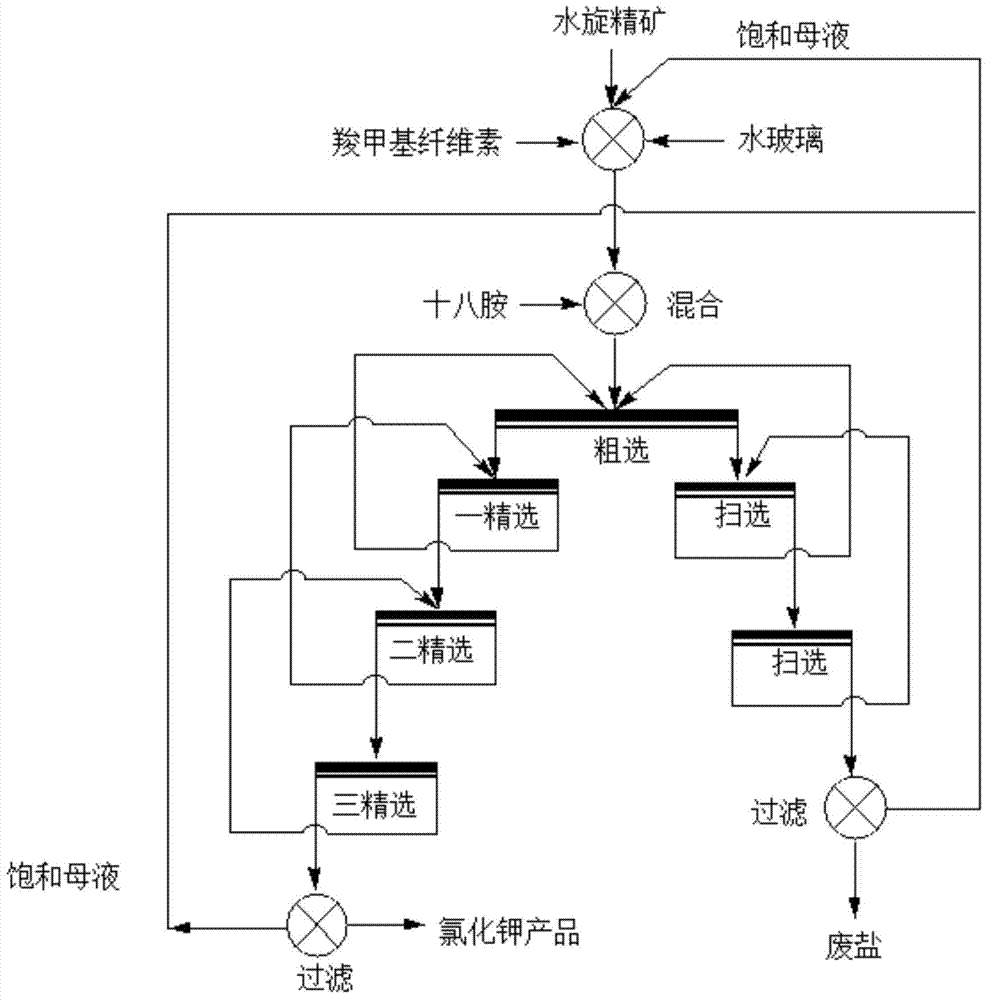

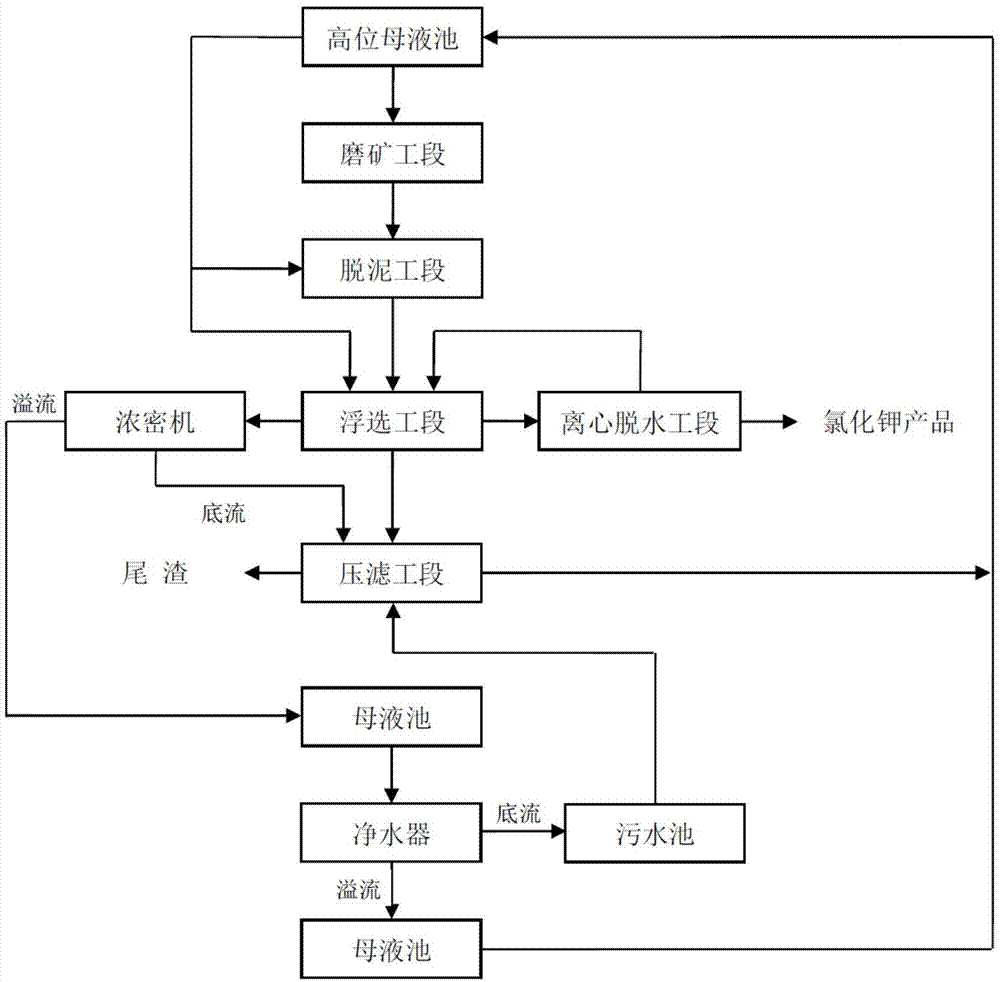

Method for extracting potassium chloride from high-silt-content high-grade feldspar salt mine

InactiveCN103787372AImprove concentrate qualityHigh yieldAlkali metal chloridesSolventEnvironmental resistance

The invention discloses a method for extracting potassium chloride from a high-silt-content high-grade feldspar salt mine. The method comprises the following steps: (1) crushing and grinding the feldspar salt mine to obtain ore particles; (2) mixing the ore particles and a solvent to prepare slurry with the mass concentration of 25-40 percent, and desliming to obtain deslimed concentrate; and (3) preparing 20-30% ore pulp from the deslimed concentrate by using potassium chloride and sodium chloride co-saturated mother liquor, simultaneously adding a slurry inhibitor and a collecting agent, carrying out rough concentration on the ore pulp to obtain rough ore concentrate and concentrate to be swept, and carrying out more than two stages of selection on the rough ore concentrate to obtain selected foams, and dewatering the selected foams to obtain a potassium chloride product. According to the method disclosed by the invention, not only is the problem of waste ore accumulation solved, but also the environment-friendly problem is solved, resources are sufficiently utilized, wastes are turned into treasures, and the economic and social benefits are relatively remarkable.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

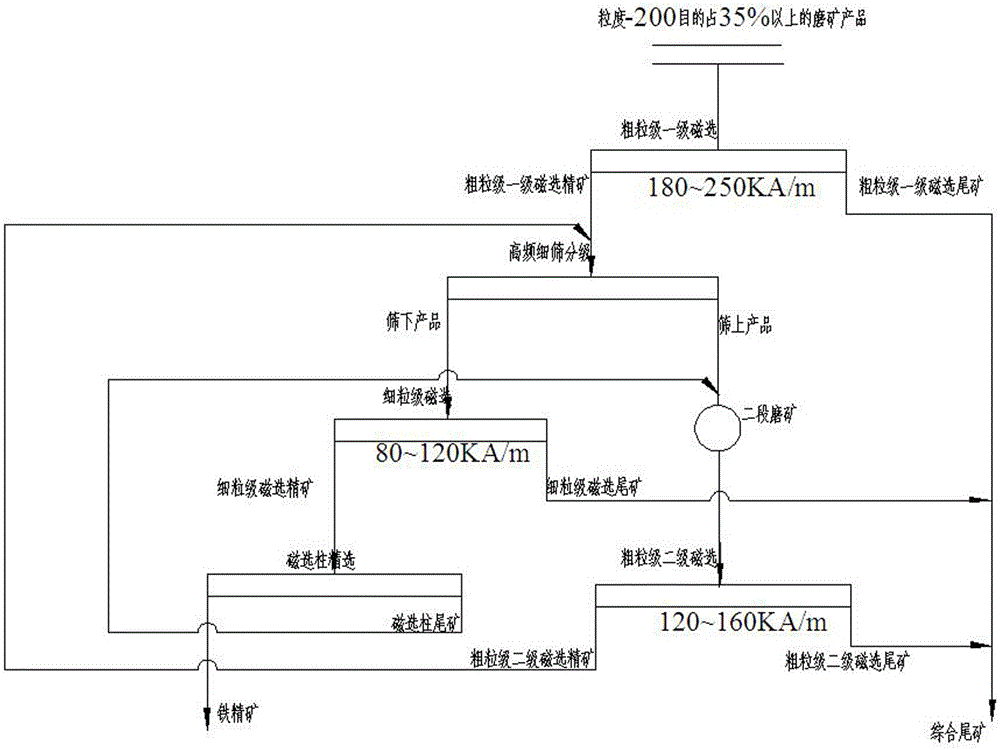

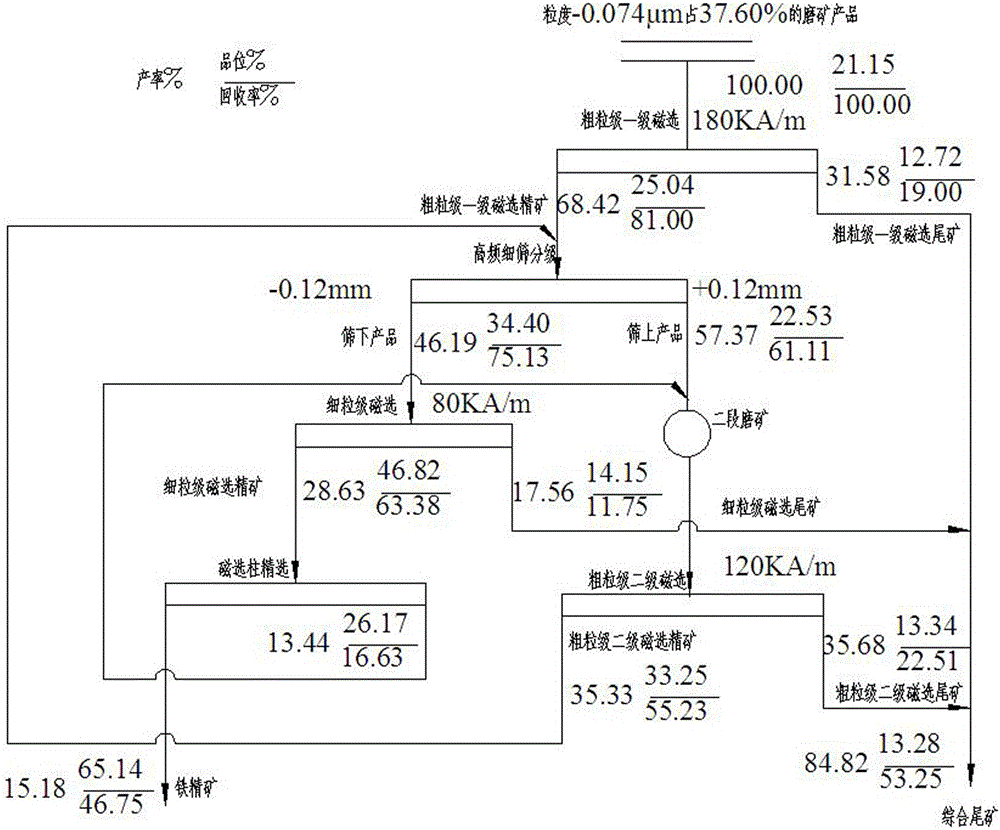

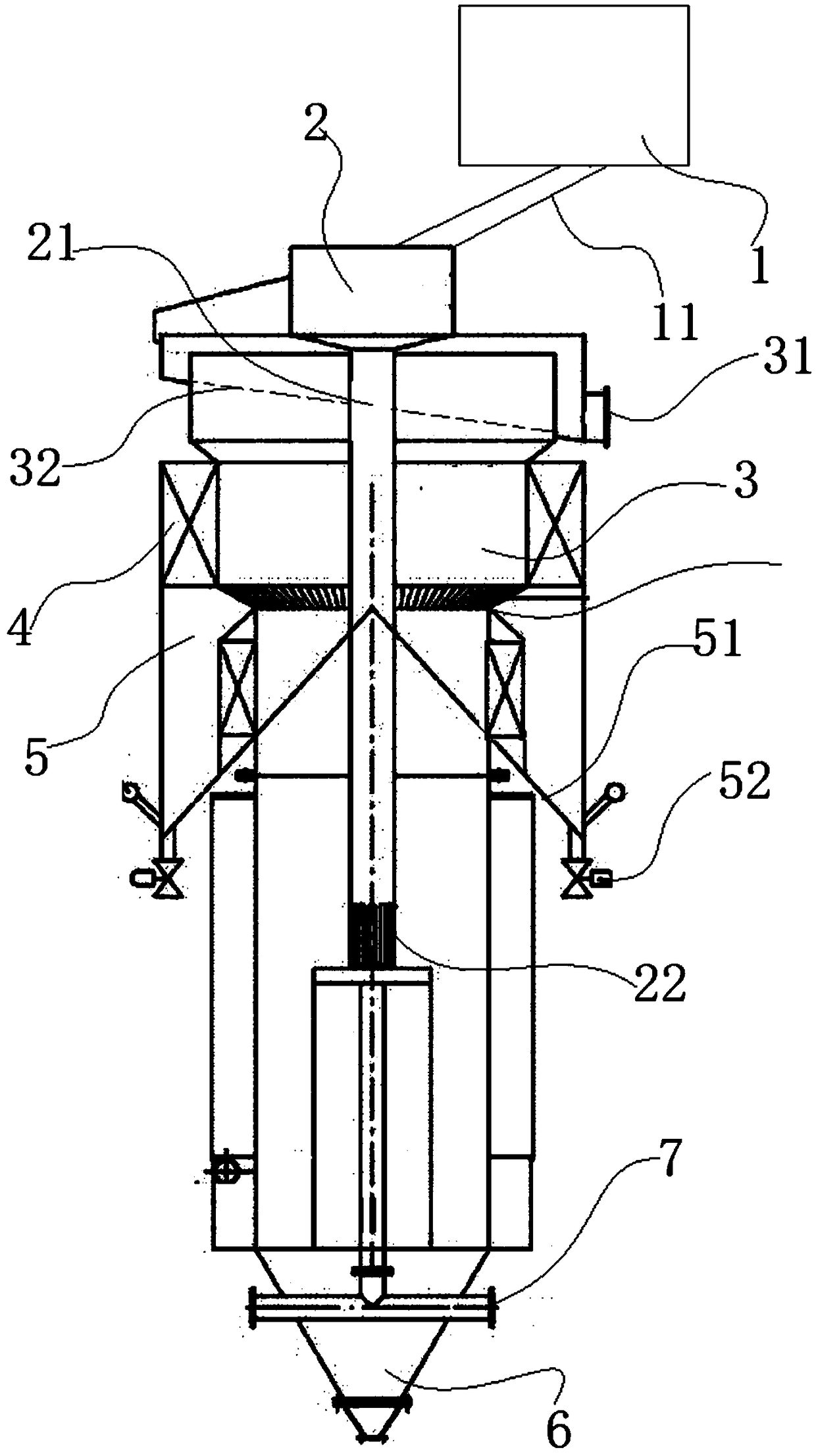

Lean magnetite beneficiation method capable of reducing fineness of grinding ore

ActiveCN104959228AWidely applicable to magnetic separation processStrong process adaptabilityMagnetic separationIronstoneMagnetite

The invention relates to a lean magnetite beneficiation method capable of reducing fineness of grinding ore, which comprises the following process steps: (1) finely grinding crushed lean magnetite ore and then carrying out primary coarse particle magnetic separation; (2) classifying primary coarse particle magnetic separation magnetic concentration by adopting a high frequency fine screen; (3) carrying out secondary ore grinding on oversize products and then carrying out secondary coarse particle magnetic separation; (4) returning secondary coarse particle magnetic separation magnetic concentration to the high frequency fine screen in step (2) to be reclassified, and repeating the operations of steps (2) to (6); (5) carrying out fine magnetic separation on high frequency undersize products; (6) carrying out fine separation on fine magnetic separation magnetic concentration by adopting a magnetic separation column so as to obtain iron ore concentration, returning magnetic separation column tailings to the secondary ore grinding procedure in step (3) and repeating the operations of steps (3) and (4). The granularity of -0.074 micrometers of iron ore concentration separated by the method disclosed by the invention accounts for 35-88%, which is reduced by more than 10% compared with iron ore concentration obtained by a conventional dressing production procedure, iron grade is 65-69%, and iron recovery rate is 45-97%.

Owner:抚顺罕王傲牛矿业股份有限公司

Flotation method of lead-zinic-sulphide ore with high oxygenation efficiency

The invention discloses a select flotation method of lead-zinic-sulphide ore with high oxygenation efficiency. The method comprises the following steps: carrying out first flotation on ore pulp of which the pH value is 11.3-11.5 and the concentration is 30%; adding 10-20g / t of raw ore of isobutyl xanthate ethyl formate and 20-40g / t of raw ore of diethyldithiocarbamate (C2H5)2NCSSK to obtain rough concentrate of lead; carrying out a flow comprising one rough flotation, one scavenging and two concentration on the remained tail ore remained after the first selection flotation to obtain the remained lead ore material; combining with the lead rough concentrate obtained in the first flotation and selecting for one time to form the ultimate lead concentrate; and obtaining zinic concentrate by selecting and floating the tail ore after the lead floatation. The lead-zinic-sulphide ore of which the oxygenation efficiency is 15-20% can obtain Pb grade of 51-52% and the recovery of 80-84% by adopting the invention; and the zinic concentrate grade is 46-50%, the recovery is 84-86%; and compared with the common method, the recovery rates of Pb and Zn are improved by more than 8%.

Owner:CENT SOUTH UNIV +1

Coarse grain reverse floatation magnesium removal method for phosphorus ore

ActiveCN104801418AImprove discharge rateImprove concentrate qualityFlotationWet separationHigh concentrationSlurry

The invention relates to a coarse grain reverse floatation magnesium removal method for phosphorus ore. The method comprises the following steps of crushing and grinding low-grade phosphorus ore, the floatation feeding granularity constitution satisfies the condition that the granularity of -200 meshes is lower than 50 percent according to the weight, transferring the ground phosphorus ore into a floatation machine stirring trough, mixing the ground phosphorus ore with water to form slurry with concentration more than 50 percent, wherein the temperature of the ore slurry is 10 to 30 DEG C, respectively mixing the ore slurry with an adjusting agent inorganic acid and a reverse floatation mixing capturing agent, carrying out the slurry regulation, replenishing fresh water, carrying out the reverse floatation systematic operation, wherein a foam product is reverse floatation tailings, discharging the reverse floatation tailings to be stacked, a product in the trough is low-magnesium phosphorus ore concentrate. The floatation feed is the coarse-particle high-magnesium phosphorus ore, by optimizing the reverse floatation operation and the chemical system, on the premise of regulating the slurry at the high concentration, the coarse-grain magnesium removal effect can be realized by adopting the reverse floatation mixing trapping agent on the basis of high-concentration slurry, the final magnesium content of the concentrate can be reduced, and the concentrate quality can be improved. The method also has the characteristics of simple flow, good sorting effect and high magnesium discharging rate.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Direct and reverse flotation technique for high-magnesium low-grade phosphorus ore coarse grains

The invention relates to a direct and reverse flotation technique for high-magnesium low-grade phosphorus ore coarse grains. The technique comprises the following steps: crushing and grinding high-magnesium low-grade phosphorus ores; transferring into a flotation machine stirring tank and adding water for mixing slurry; keeping the temperature of the ore slurry at 10-30 DEG C, and then respectively adding regulator sodium silicate and inorganic base into the ore slurry; adding a direct flotation collecting agent for mixing the slurry; adding water for performing direct flotation system operation; transferring a direct flotation foam product into a reverse flotation stirring tank, respectively adding the regulator sodium silicate and reverse flotation mixing collecting agent into the reverse flotation stirring tank, and mixing the slurry without adding fresh water; adding fresh water and performing the reverse flotation system operation; discharging and stacking the foam products which are reverse flotation tailings, wherein the products in the tank are low-magnesium phosphorus ore concentrates; concentrating, filtering and drying, thereby acquiring the end products of concentrates. According to the technique, the last magnesium content of the concentrates is reduced and the quality of the concentrates is increased; the process is simple; the energy consumption for ore grinding is low; the dosage of agents is less; the separation effect is good; the discharging rate of magnesium is high; the water quality of concentrate and tailing is improved.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

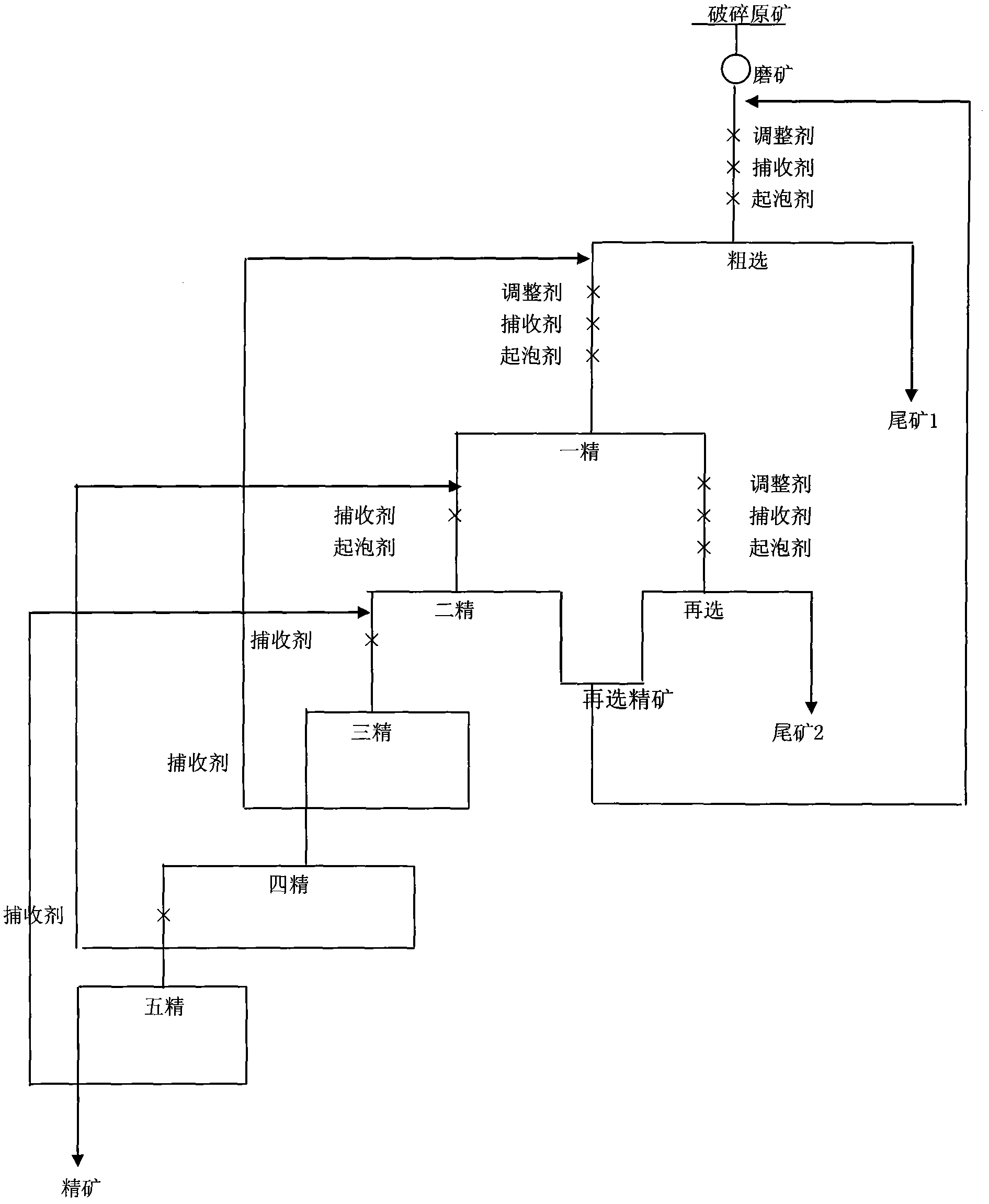

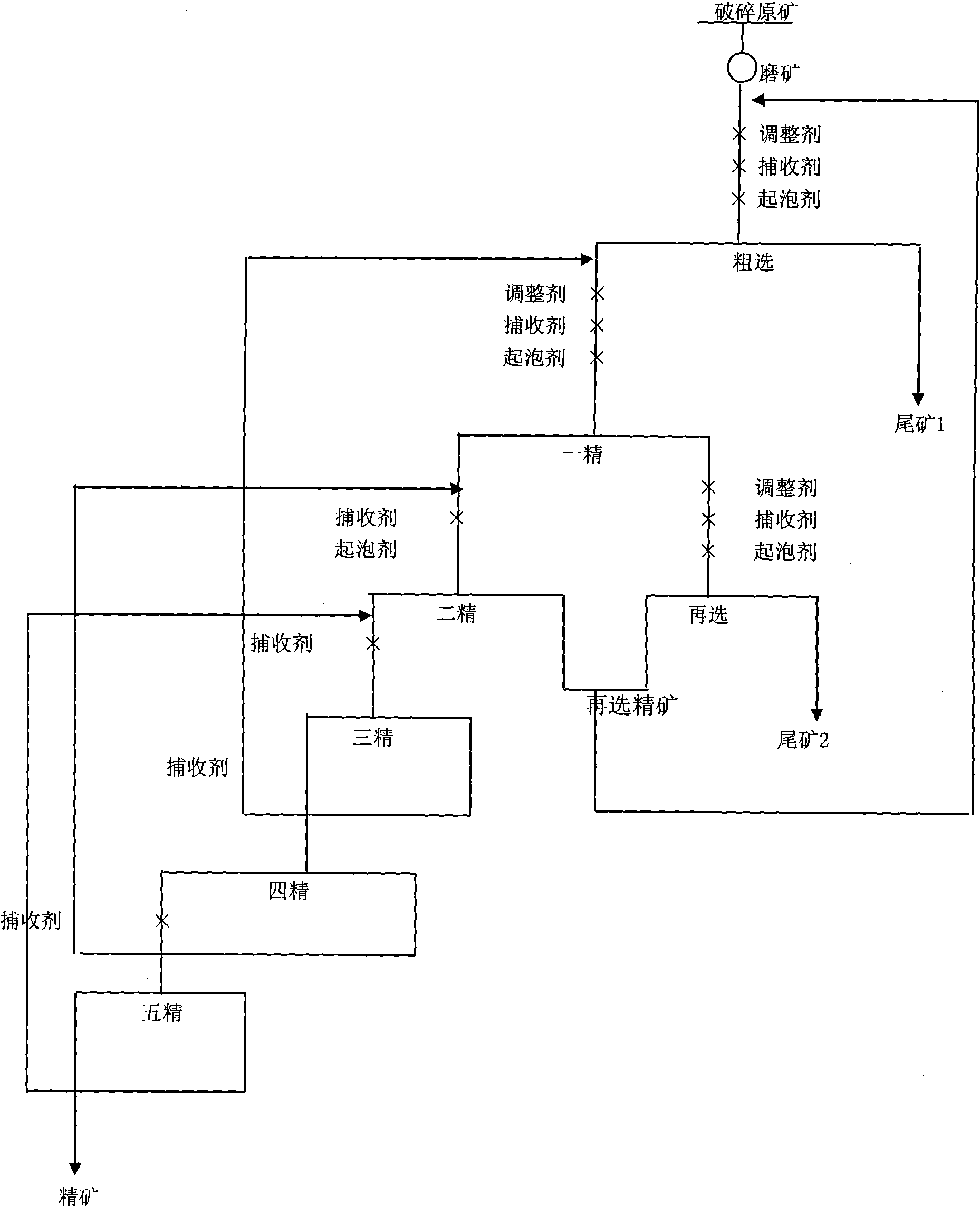

Flotation process for charcoal clay-containing pyrite

ActiveCN101972711ARealize beneficiation and enrichmentEffective dispersionFlotationFoaming agentPyrite

The invention discloses a flotation process for charcoal clay-containing pyrite. The flotation process comprises the following steps of: taking a pyrite ore raw material, crushing and grinding the pyrite ore to dissociate mineral monomer, and then adding water into the ground ore to form ore pulp; after the ore pulp flows into a stirring tank, adding an adjusting agent, a collecting agent and a foaming agent into the ore pulp to condition the pulp respectively; and feeding the pulp conditioned material into a flotation system to perform flotation, wherein the flotation process comprises one-time rough flotation, at least three times of fine flotation and one-time fine middling re-cleaning. One or more of the adjusting agent, the collecting agent and the foaming agent is or are added in each operation as required; and the adjusting agent for flotation is lignin, the collecting agent is mixed xanthate of ethyl xanthate and butyl xanthate, and the foaming agent is No.2 oil. The process successfully realizes ore dressing enrichment of the charcoal clay-containing pyrite, and has the advantages of high separation efficiency, excellent process index, high quality of the obtained pyrite concentrate and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

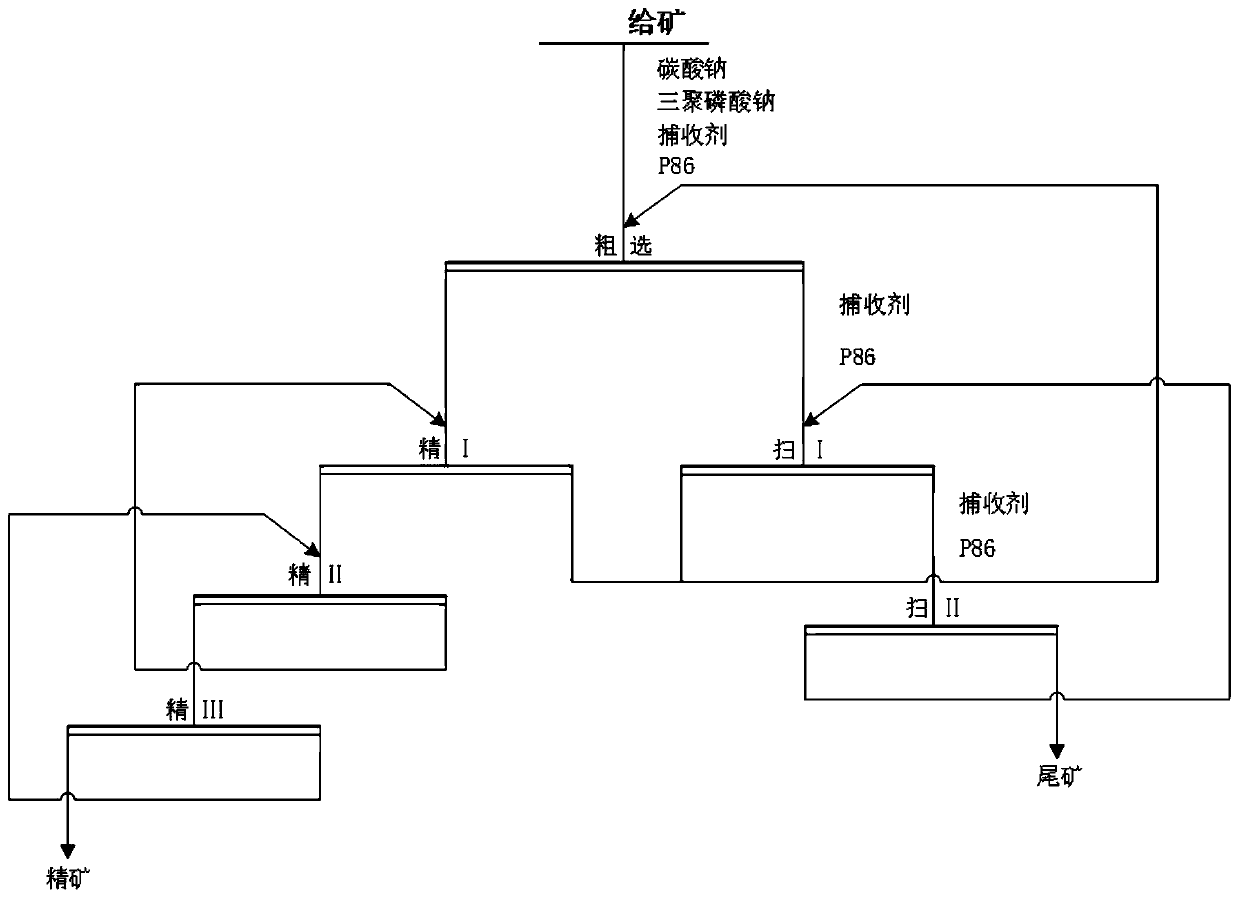

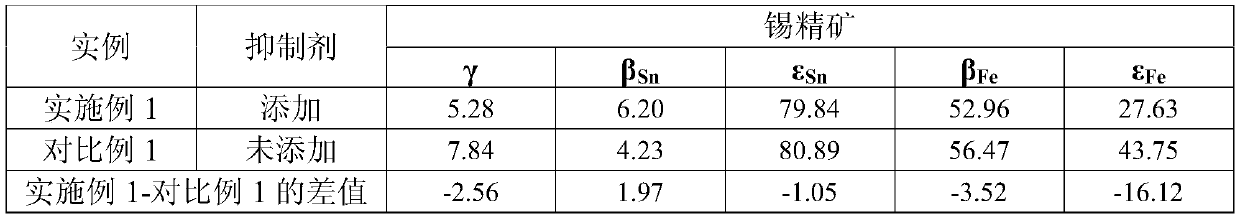

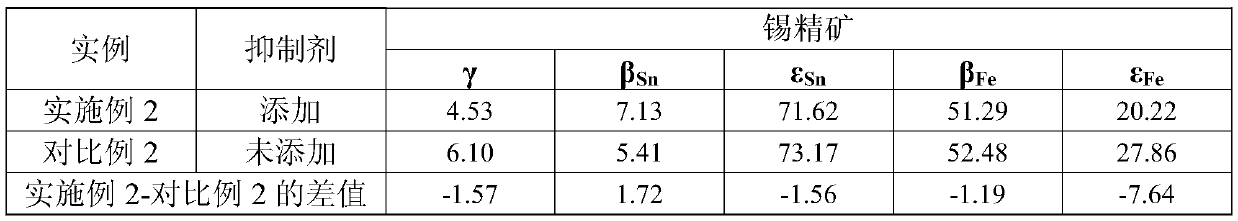

Method for flotation separation of iron oxide ore in cassiterite sulphide slime ore by using combined inhibitor

The invention discloses a method for flotation separation of iron oxide ore in cassiterite sulphide slime ore by using a combined inhibitor. The combined inhibitor is composed of sodium carbonate andsodium tripolyphosphate. The operation of flotation separation of the iron oxide ore in the cassiterite sulphide ore slime ore comprises the following steps: roughing, scavenging and concentrating thecassiterite sulphide ore in sequence; in the roughing process, a sodium carbonate solution is firstly used for adjusting the pH of ore pulp to be 6-8, then a sodium tripolyphosphate solution, a collecting agent salicylhydroxamic acid and an auxiliary collecting agent P86 are added, and cassiterite and iron oxide minerals are separated through roughing, scavenging and concentration. The combined inhibitor has the advantages of being high in selectivity, soluble at normal temperature, non-toxic, harmless, low in dosage, easy in concentrate treatment and the like and can realize effective separation of cassiterite and iron oxide minerals and further improves the quality of tin concentrate.

Owner:云南锡业研究院有限公司

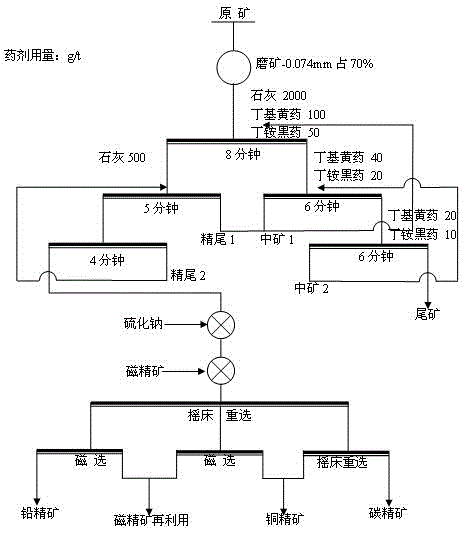

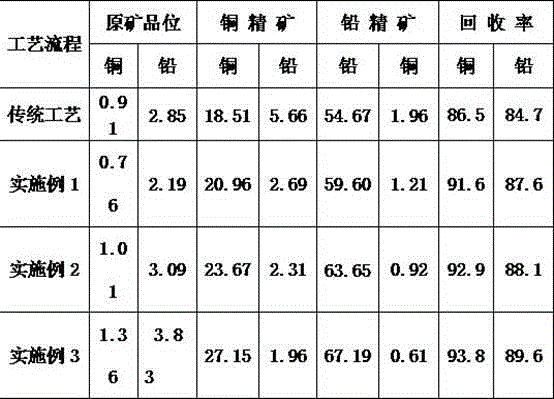

Recovery method for carbon-contained copper and lead ore difficult to separate

ActiveCN104941788ASimple processReduce environmental pollutionFlotationWet separationMagnetic separatorOre concentrate

The invention discloses a recovery method for carbon-contained copper and lead ore difficult to separate. The recovery method includes the following steps that step1, according to smashing and grinding, the raw ore is smashed and ground to be at the size fraction of -0.074 mm by 70-80%; step2, bulk concentrate is obtained through bulk flotation; step3, reagent removal solution is prepared; step4, reagent removal is performed; step5, slurry mixing is performed; step6, shaking table reselection is performed; step7, according to purification, bulk concentrate of lead and magnetite and bulk concentrate of copper and magnetite are placed into a magnetic separator to be separated so as to obtain lead concentrate and copper concentrate, the magnetite can be repeatedly utilized, and bulk concentrate of copper and carbon is placed in a shaking table to be separated to obtain copper concentrate and carbon concentrate. The recovery method has the advantages that a gravity and magnetic levitation combination method is adopted for recovering lead and copper, inhibitor is not needed, environmental pollution is small, economic benefits are high, the lead concentrate and the copper concentrate are high in quality, mutual inclusion is low, and the technology process is simple; the recovery method has great economic benefits and social benefits.

Owner:TONGLING NON FERROUS METAL GROUP CORP

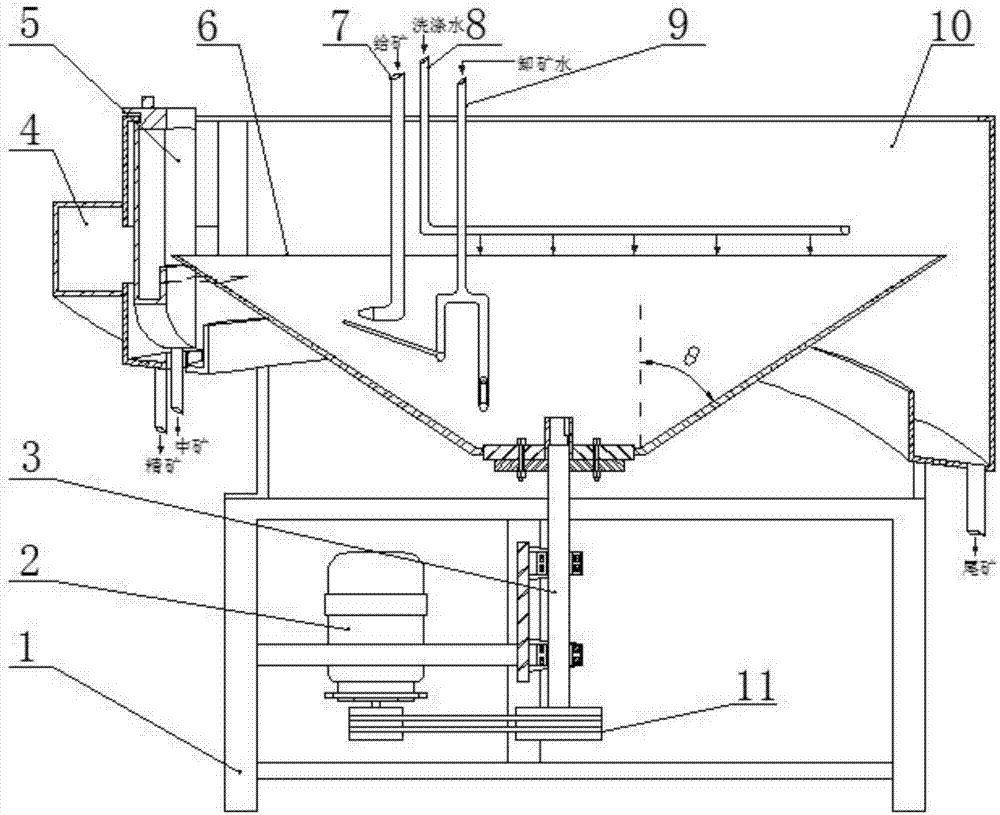

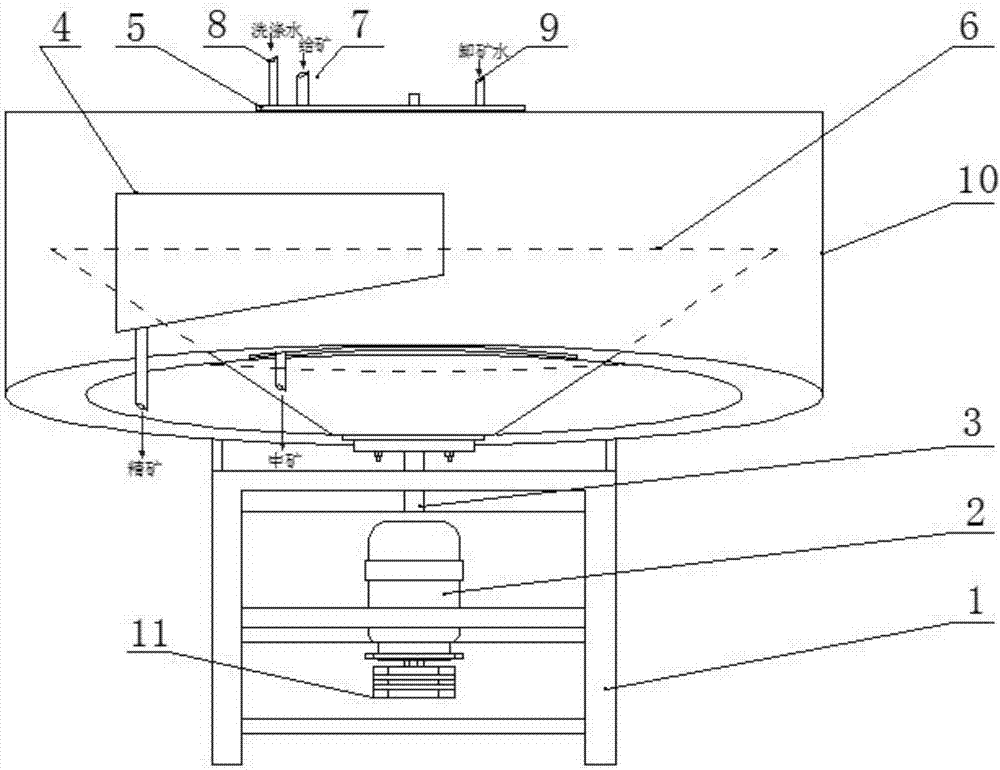

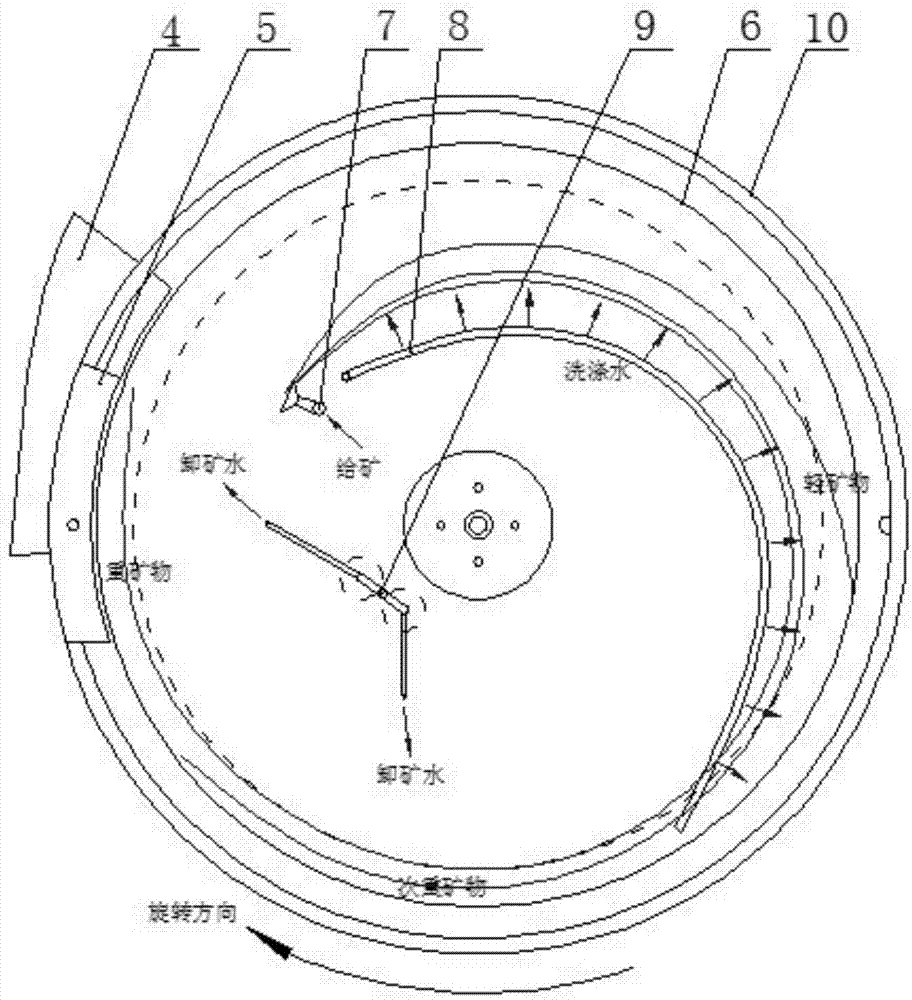

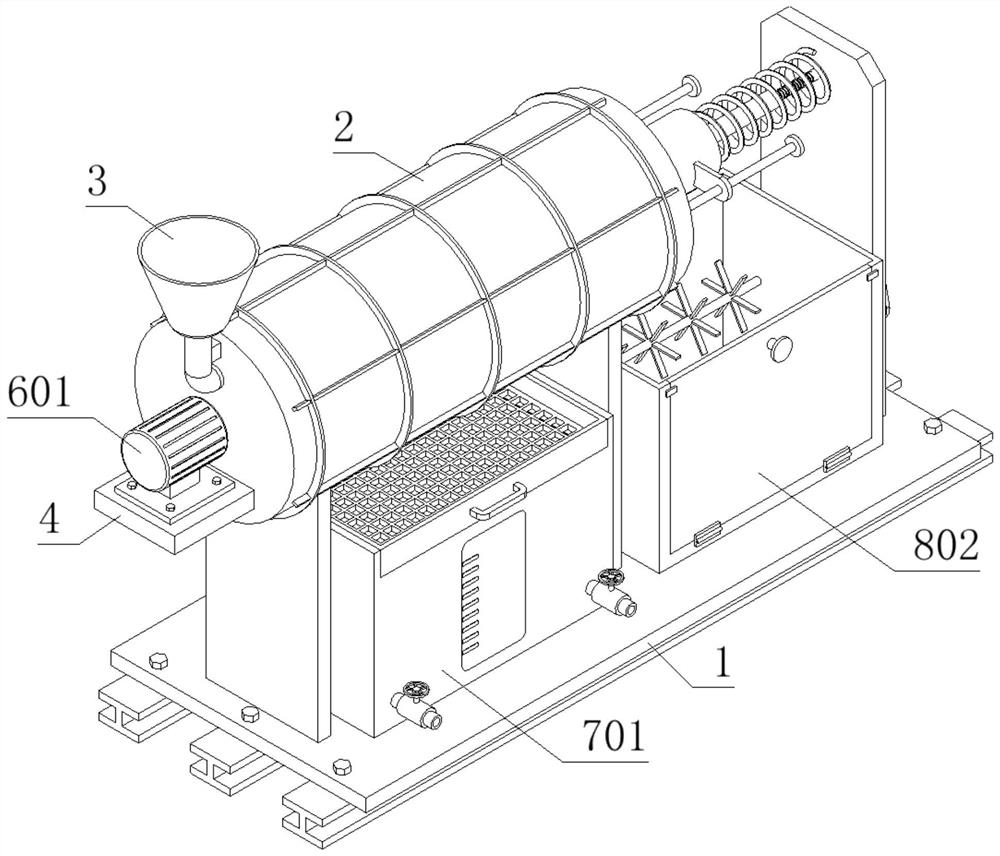

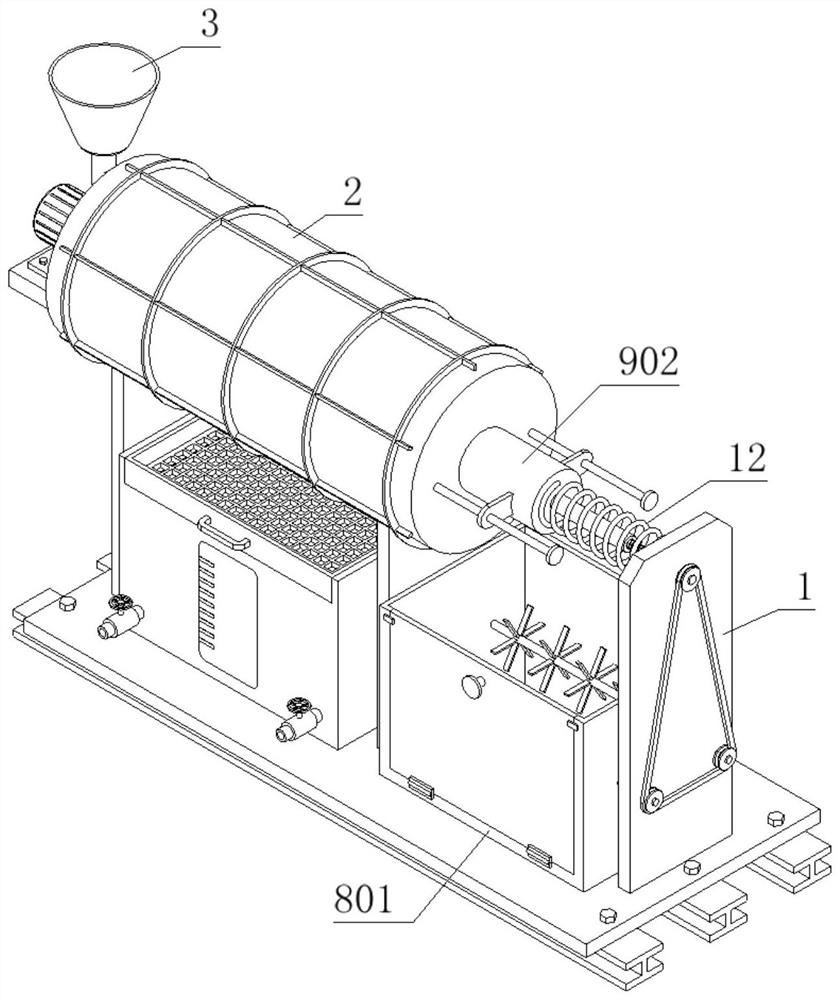

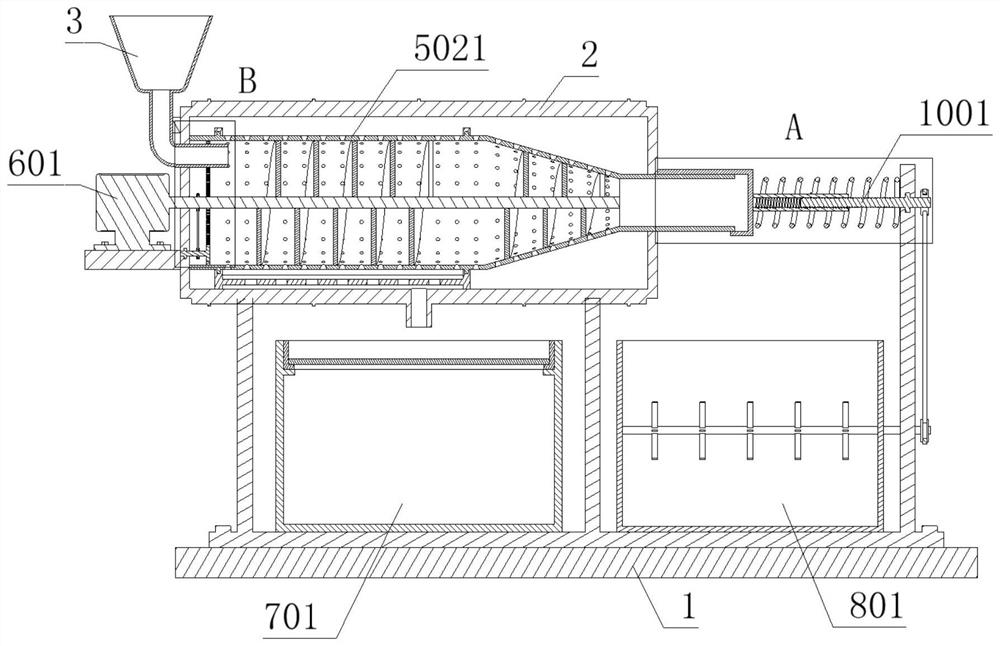

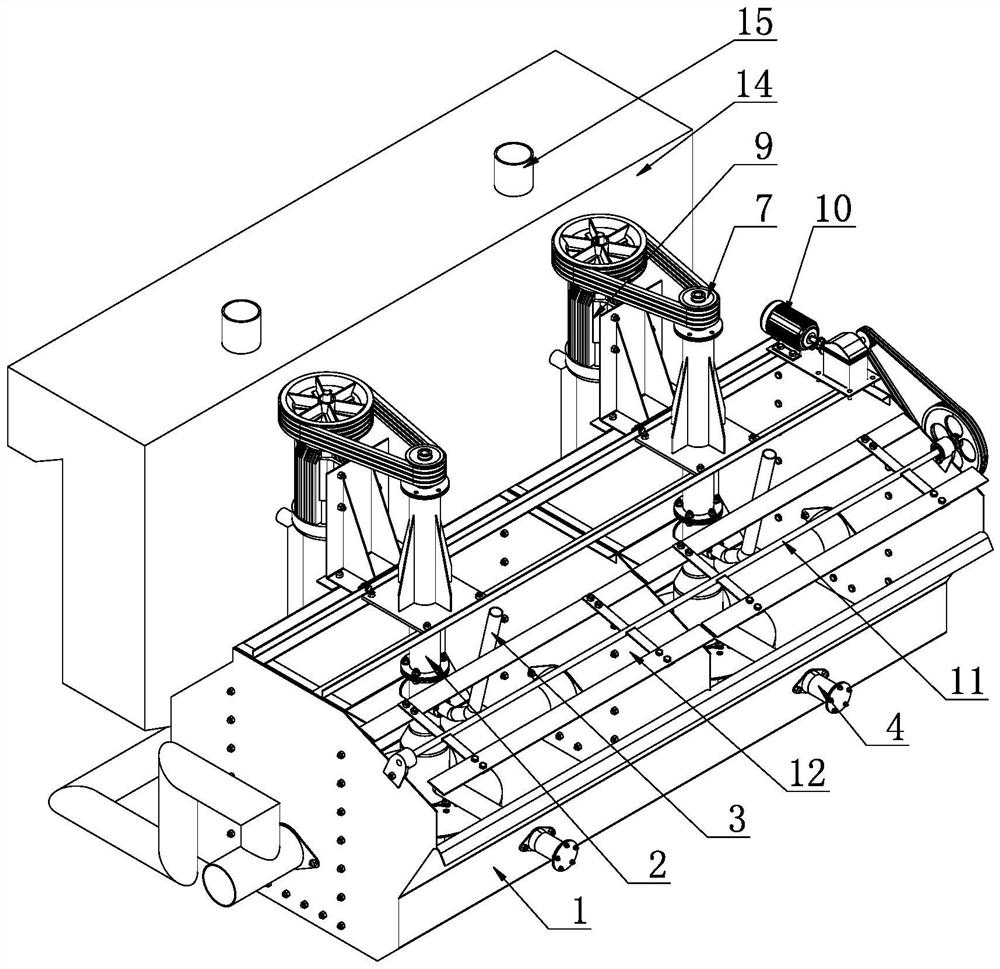

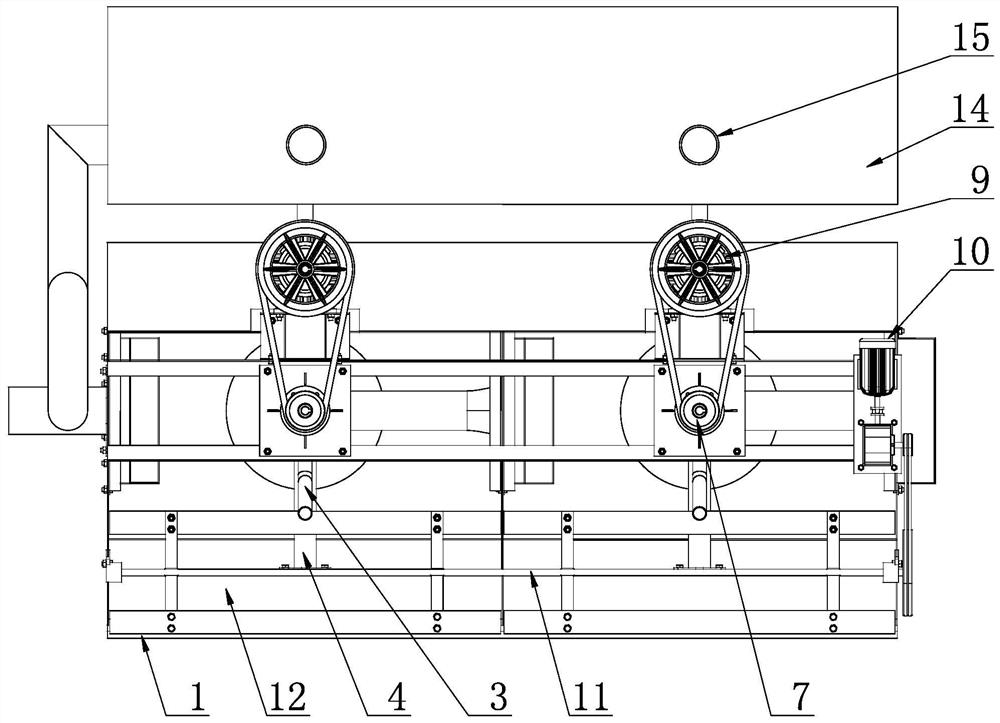

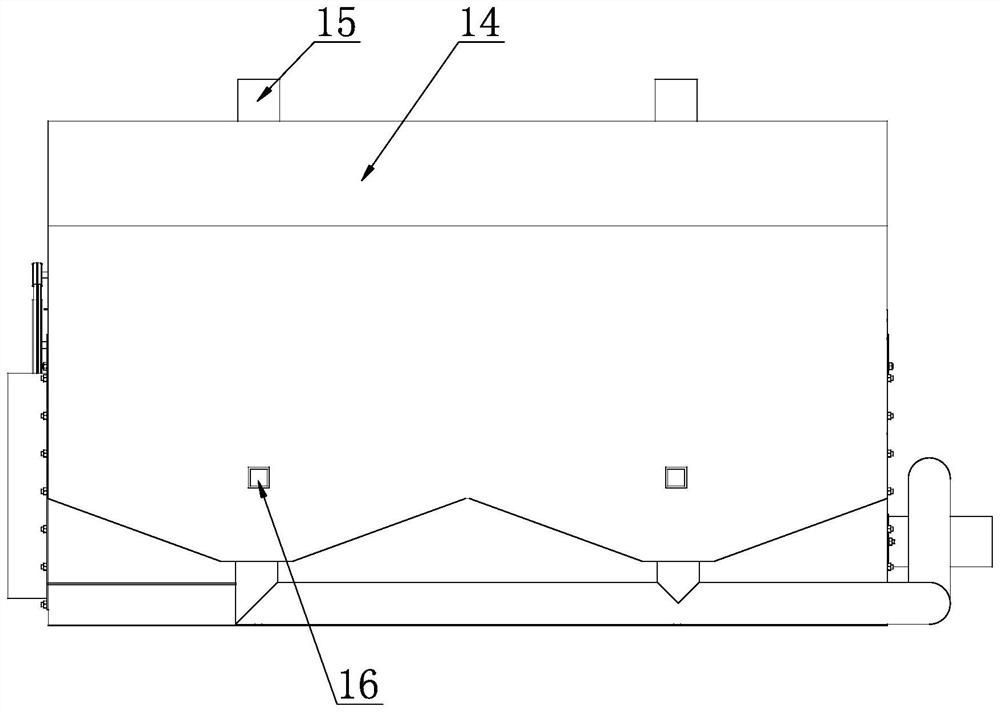

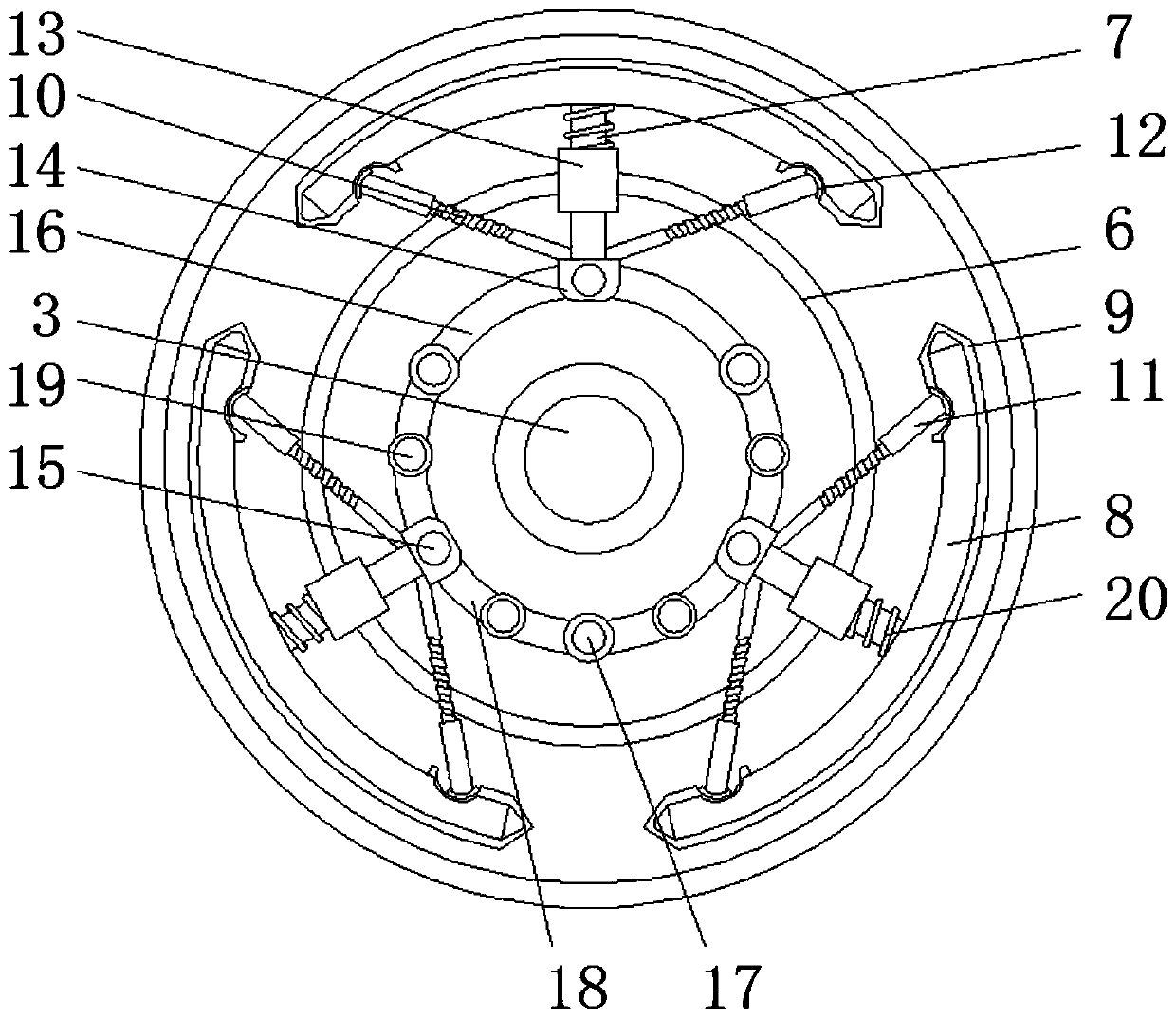

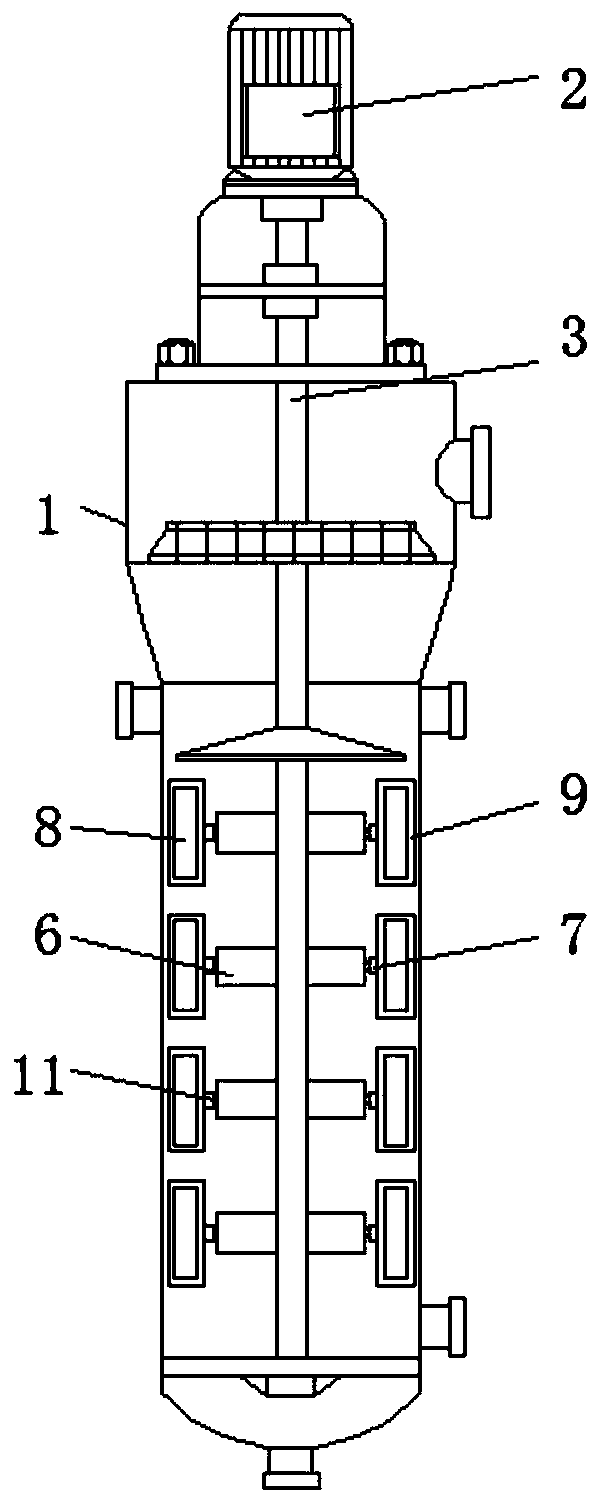

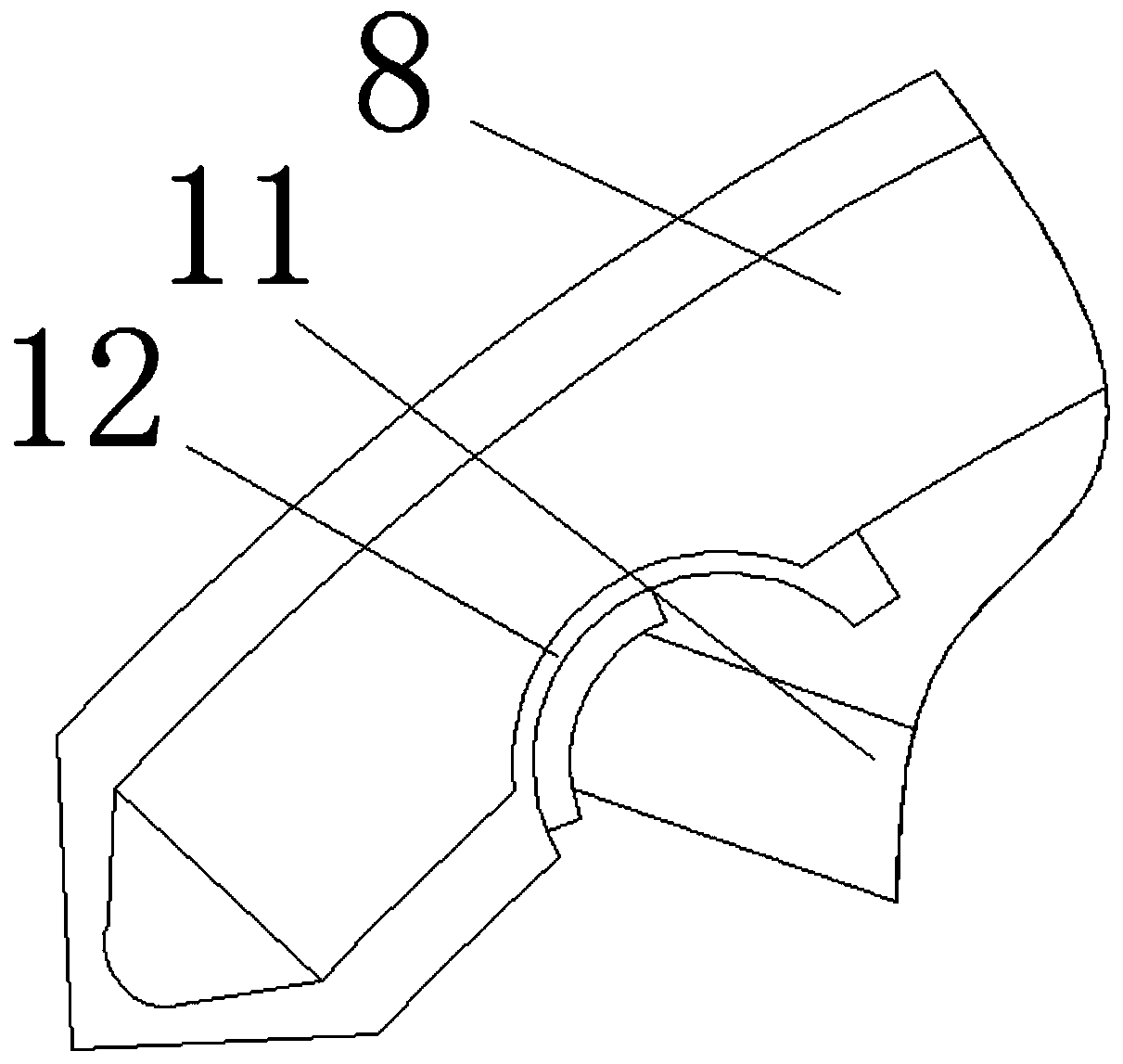

Super-gravity ore separator

The invention discloses a super-gravity ore separator comprising a rack, a motor, a rotating disc main shaft, a concentrate tank, a middling cutting device, a separation rotating disc, an ore feeding device, a washing water device, an ore discharging water pipe, a tailing cover and a belt pulley. The separation rotating disc is of a conic structure and is composed of a base disc, a rotating disc supporting seat and a plurality of rotating disc lining plates. The rotating plate supporting seat is fixedly arranged on the base disc. The base disc is connected with the rotating disc main shaft. The multiple rotating disc lining plates are spliced and fixed on a rotating disc supporting seat. The separation rotating disc is connected with the rotating disc main shaft. The washing water device and the ore discharging water pipe are arranged on the inner wall of the tailing cover. The concentrate tank is arranged on the outer wall of the tailing cover. An opening of the concentrate tank faces one side of the tailing cover. The ore discharging water pipe and the middling cutting device are arranged at the clockwise near end of the concentrate tank. A moving baffle is arranged at the clockwise far end of the concentrate tank. An ore feeding pipe is arranged in the separation rotating disc. The super-gravity ore separator is reasonable in structure and stable in operation and can work continuously, large-scale equipment is easy to realize, and the separation effect is good.

Owner:昆明理工凯吉思科技有限公司

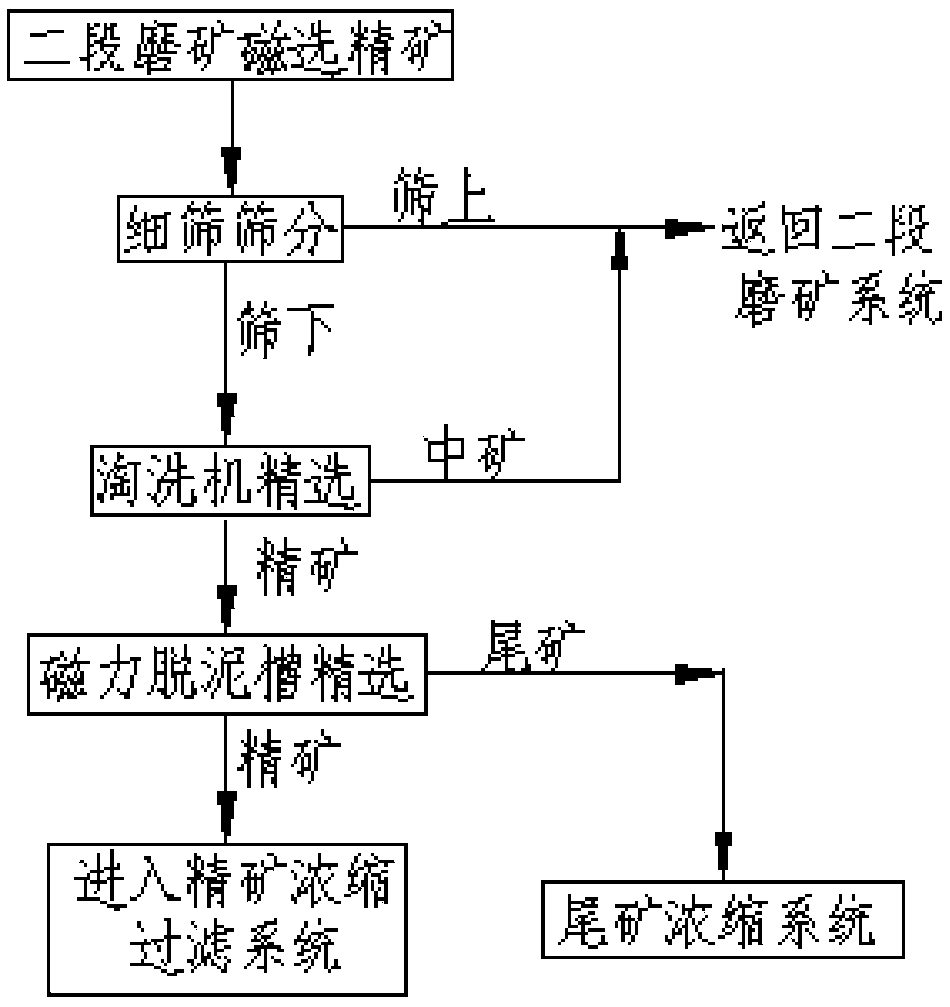

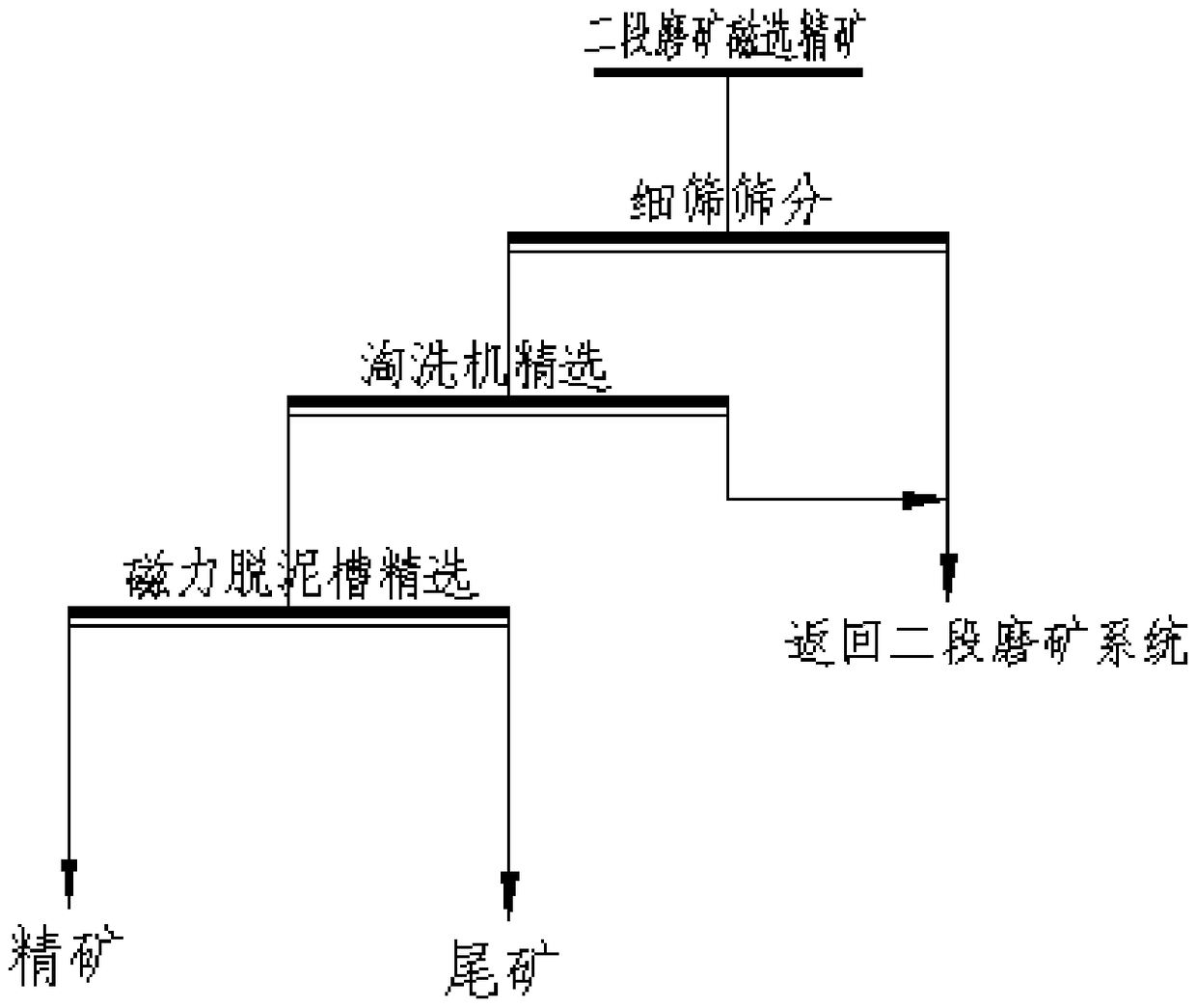

Ore dressing process for reducing content of silicon dioxide in iron ore concentrate

ActiveCN108970800AImprove the grade of all ironReduced silica contentSolid separationLower gradeLow graded

The invention belongs to the technical field of ore dressing and discloses an ore dressing process for reducing the content of silicon dioxide in iron ore concentrate. The ore dressing process includes: step one, crushing, to be more specific, crushing low-grade magnetic iron ore into size smaller than 20mm, and performing high-pressure rolling, superfine grinding and sieving and full-closed wet pre-separation to obtain rough concentrate in size smaller than 3mm; step two, ore grinding and magnetic separation, to be more specific, to be more specific, performing two-stage ore grinding, gradingand low-intensity magnetic separation; step three, fine sieving, to be more specific, feeding the magnetically separated rough concentrate into a fine sieve for sieving, and then returning materialson the sieve to a two-stage grinding system, wherein the sieve mesh size is 0.075-0.1mm; step four, feeding sieved powder into a wash mill, and concentrating to obtain washed concentrate; step five, magnetic desliming, to be more specific, subjecting the washed concentrate to concentration in a magnetic desliming tank to obtain final concentrate, wherein the SiO2 content is reduced to 3.5% or below. After two-stage grinding and low-intensity magnetic separation, two-stage continuous concentration is performed through the wash mill and the magnetic desliming tank, so that the problem of high SiO2 content of the ore concentrate is solved while quality improvement and impurity reduction of the ore concentrate are realized.

Owner:马钢集团设计研究院有限责任公司

Regulating method for zinc oxide flotation froth

The invention discloses a regulating method for zinc oxide flotation froth and belongs to the technical field of beneficiation. The regulating method comprises the following steps that firstly, a combined antifoaming agent is prepared, wherein by weight ratio, tributyl phosphate, dodecanethiol and kerosene are mixed according to the proportion being (20-30):(3-6):(1-2) and are dissolved into waterto be prepared into a solution with the weight concentration being 20%; secondly, the solution prepared in the first step is stirred for 30 min till uniform and stable faint yellow liquid is formed;and thirdly, the prepared combined antifoaming agent is added in the flotation process to adjust froth, the froth amount and the froth structure are controlled in the zinc oxide flotation process by controlling the adding amount of the combined antifoaming agent, ore can be gathered more effectively, and the quality of concentrates is improved.

Owner:GUANGXI UNIV

Selection method for molybdenum and tungsten oxide mixed rough concentrate

InactiveCN102205269AHigh recovery rateImprove concentrate qualityFlotationWet separationOre concentrateMaceral

The invention discloses an ore dressing method for molybdenum and tungsten oxide mixed rough concentrate. The ore dressing method is characterized by comprising the following steps of: 1) grinding raw molybdenum and tungsten oxide ore till the ore with the diameter of 0.074 millimeter accounts for 60 percent, and performing flotation; 2) grading the molybdenum and tungsten rough concentrate obtained in the step 1) according to the grain diameter, wherein the ore with diameter of more than 0.031 millimeter belongs to the rough grain level, and the ore with diameter of less than or equal to 0.031 millimeter belongs to the fine grain level; and 3) heating the rough ore obtained in the step 2) to the temperature of between 90 and 95 DEG C, adding a modifier, and performing flotation to obtain molybdenum and tungsten mixed ore concentrate. By treating the ore grains of different granularity by grading respectively, regulating the reagent system and improving the separation temperature and the like to create a flotation environment adaptive to the rough grain level and treating the ore of the fine grain level by a wet metallurgy process, the separation efficiency is improved, and the recovery rate and the ore concentrate quality of the molybdenum and tungsten oxide mixed ore concentrate are effectively improved.

Owner:中铁资源集团有限公司 +1

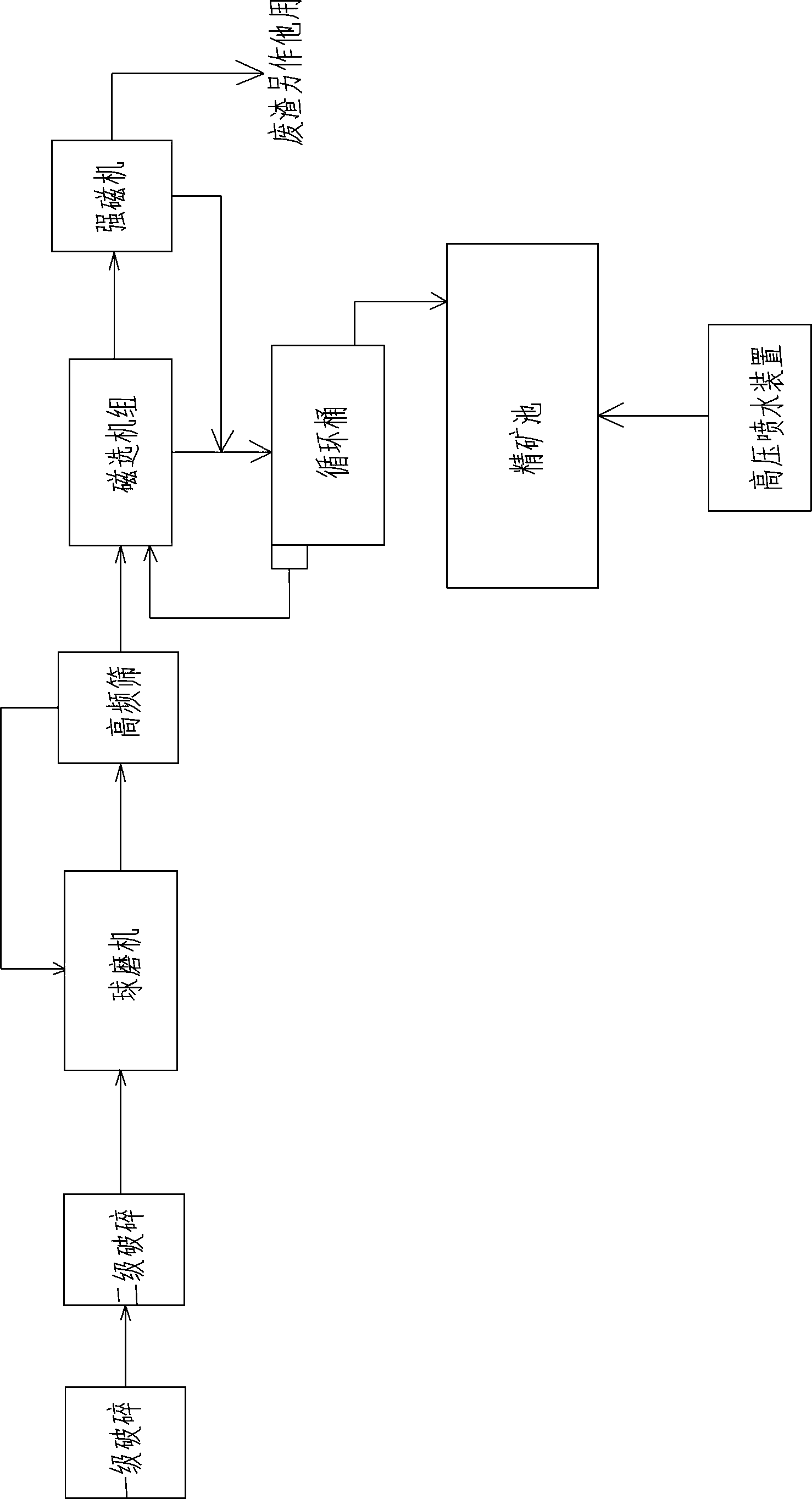

Magnetic iron ore concentrating technology

The invention discloses a magnetic iron ore concentrating technology. The magnetic iron ore concentrating technology includes the steps of fragmenting, ball milling, magnetic separating, high-intensity magnetic separating and stirring and concentrating after entering a circulating barrel. Concentrated ore overflows into an ore concentrate pool, cleaning, impurity removing and ore pressing are performed through a high-pressure water jetting device to obtain ore concentrate, and meanwhile ore which does not overflow into the ore concentrate pool is conveyed through a pumping pipe to a magnetic separation unit again for magnetic separation. The magnetic iron ore concentrating technology is low in cost and energy consumption, simple in process, high in recovery rate and capable of greatly improving the grade of the ore without adding agents.

Owner:何征徽

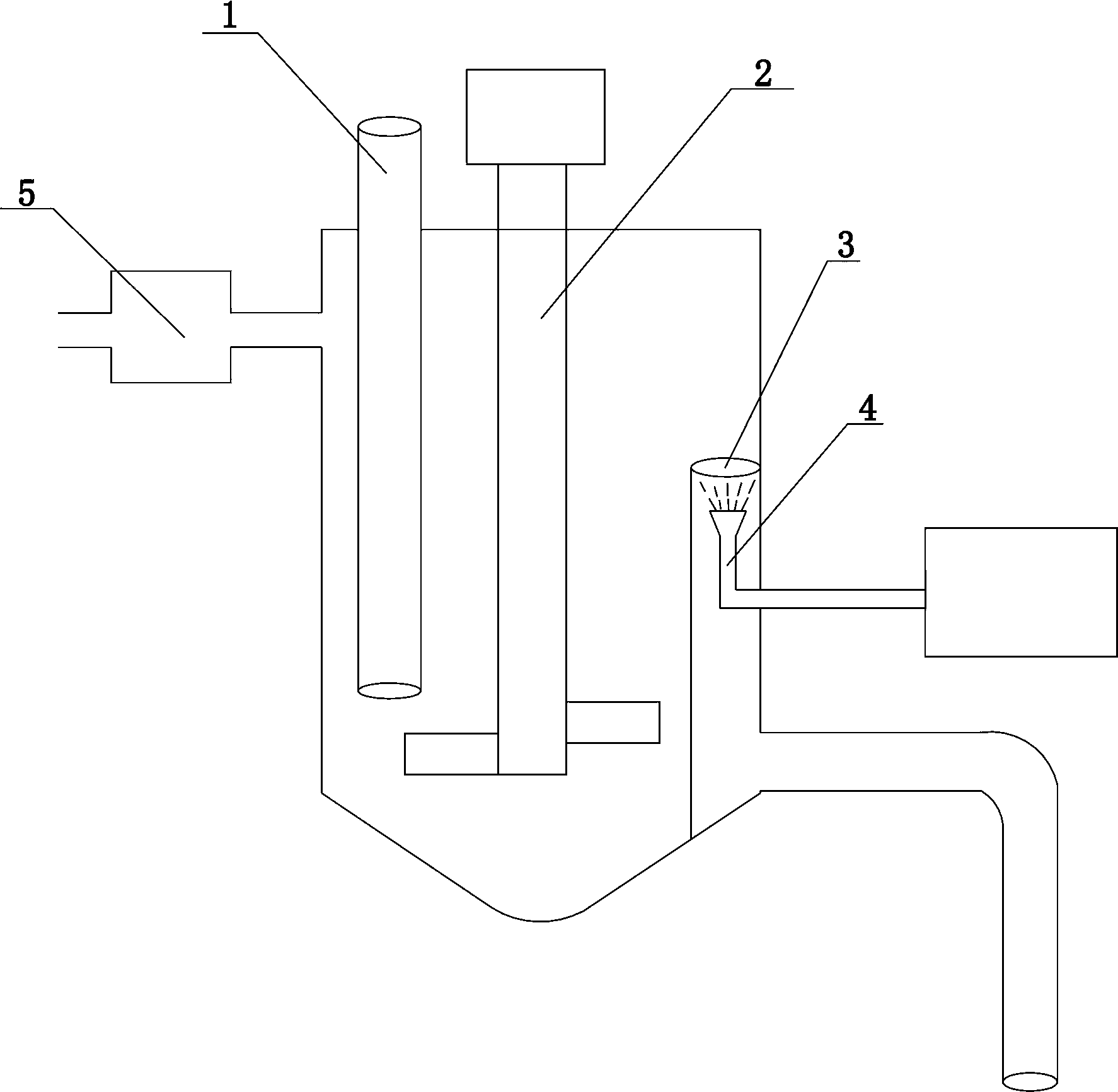

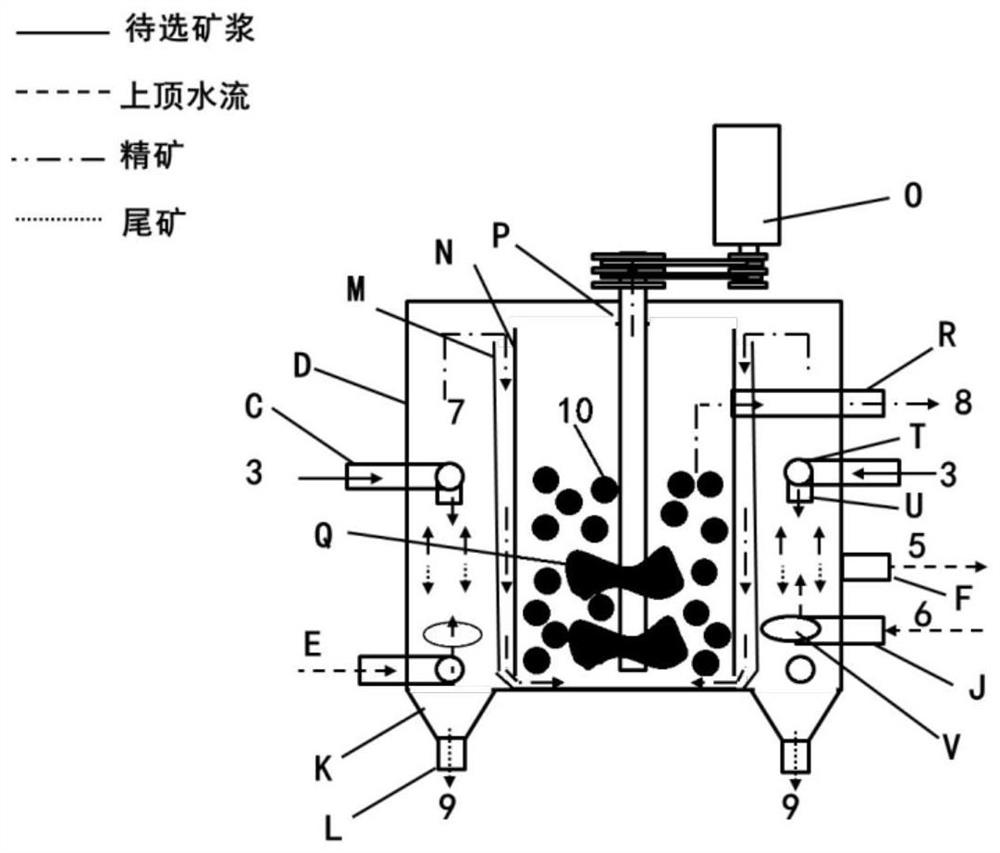

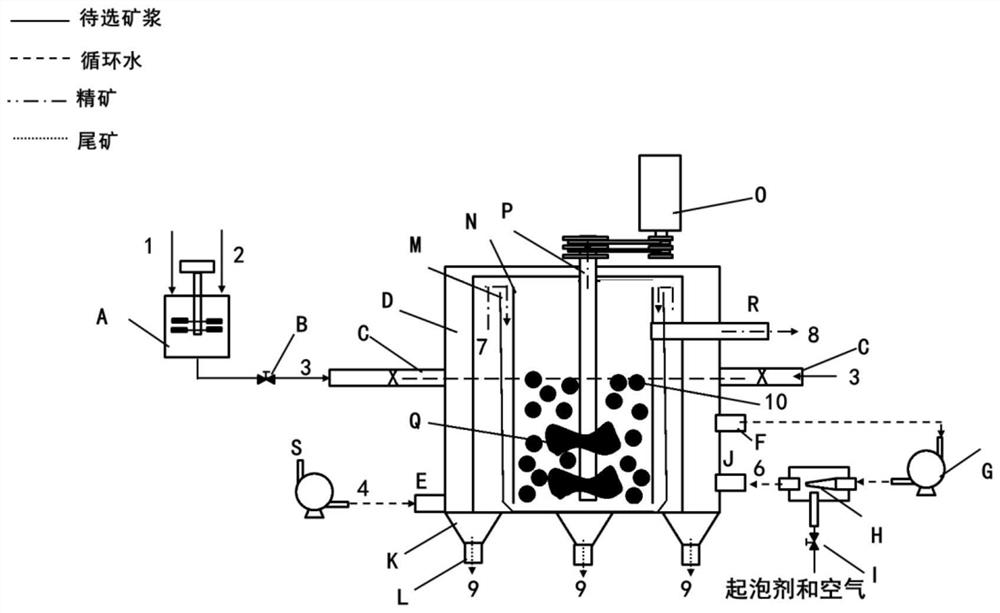

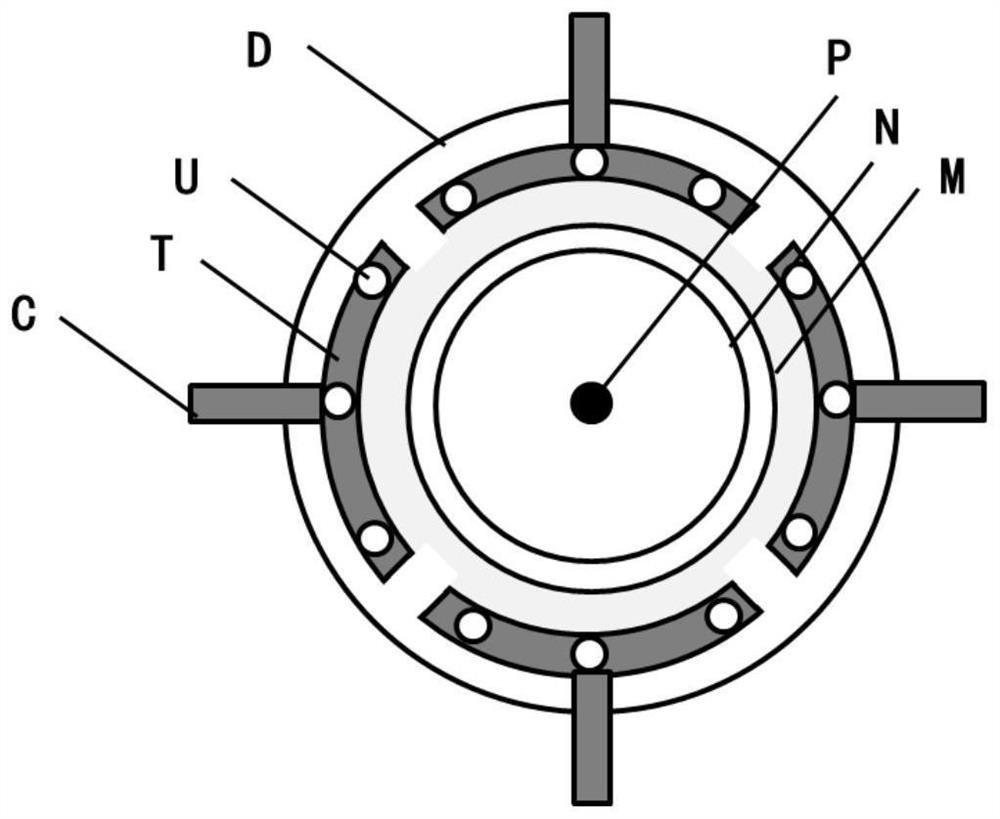

Tailing discarding and dissociation integrated coarse grain mineral dissociation device and method

The invention discloses a tailing discarding and dissociation integrated coarse grain mineral dissociation device and method, which are applicable to the field of mineral separation. The device comprises a hydraulic flotation separation unit and a stirring type ball milling unit, wherein the hydraulic flotation separation unit is located on the outer layer, the stirring type ball milling unit is arranged in the hydraulic flotation separation unit, an interlayer is arranged in the middle to allow concentrate in the hydraulic flotation separation unit to overflow and then feed the concentrate from the bottom of the stirring type ball milling unit. According to the invention, the hydraulic flotation separation unit plays a role in pre-discharging gangue, and a large amount of high-density gangue is discharged, so that the concentrate grade is improved; and the stirring type ball milling unit plays a role in dissociating coarse-grained minerals, releases more concentrates, and has the advantages of being high in ore milling product quality, simplifying the process and reducing new surface pollution.

Owner:CHINA UNIV OF MINING & TECH

Flotation separation process of copper sulfide lead ore

The invention discloses a flotation separation process of copper sulfide lead ore. The copper sulfide lead ore is ground till the mass percent of the partial ore with the particle fineness less than 0.074 mm is 70%-95%; water is added into the ground copper sulfide lead ore to adjust the mass percent concentration of ore pulp to 25-35%; and 200g / t-1500g / t of a combined inhibitor, namely, a mixtureof ferric sulfate and magnesium chloride is added into the ore pulp, and 40g / t-120g / t of a combined collecting agent composed of ethionine ester, O-isooctyl-N-ethyoxyl carbonyl thionocarbamates and 4-terpene alcohol is added to carry out floatation separation. According to the flotation separation process, flotation separation of the copper sulfide lead ore is realized; and the process is simple,low in reagent cost, high in concentrate quality and free of environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

Multi-disc concentration equipment of papermaking system

The invention provides multi-disc concentration equipment for a papermaking system. The multi-disc concentration equipment comprises a base; a cylinder is fixedly mounted at the top of the base, and a mounting plate is fixedly mounted on the left side of the base; a feeding hole is fixedly formed in the left side of the base, and the feeding hole is positioned above the mounting plate; a flow guide device is mounted at the top of the mounting plate, and the right side of the flow guide device is located in a concentration device; a collecting device is installed on the left side of the top of the base, and a receiving device is installed on the right side of the top of the base; and a material baffling device is installed on the right side of the cylinder, and an elastic piece is arranged between the material baffling device and the base. When a motor works, a connecting shaft drives a first belt wheel to rotate, so that a gear drives a gear ring to rotate, a filtering cover slowly rotates, meanwhile, filtered water washes filtering holes in the bottom, self-cleaning of the filtering holes is achieved, and the filtering holes are of a conical structure, so that fine paper pulp blocked in the filtering holes can flow out conveniently, and the filtering holes are prevented from being blocked.

Owner:LONGYOU COUNTY JINLONG PAPER

Video concentration method and device

ActiveCN113365104AImprove video concentration efficiencyImprove video enrichment qualityImage enhancementImage analysisEngineeringComputer graphics (images)

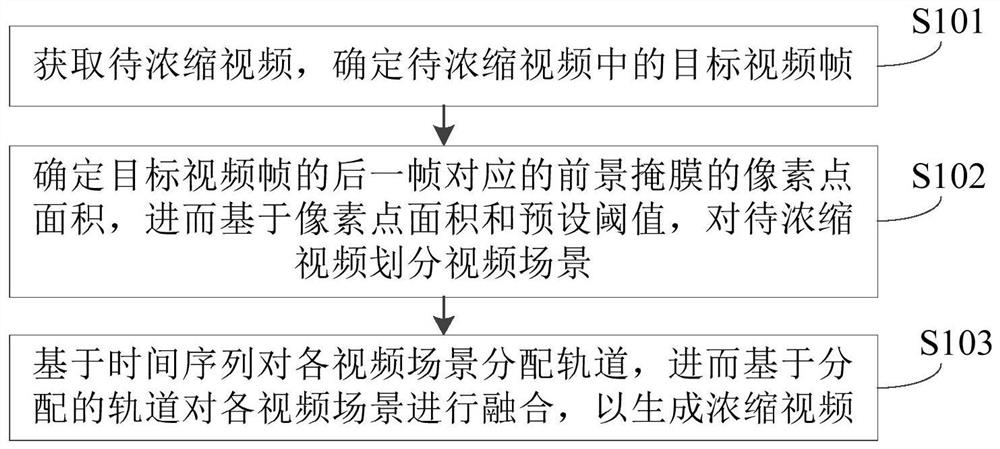

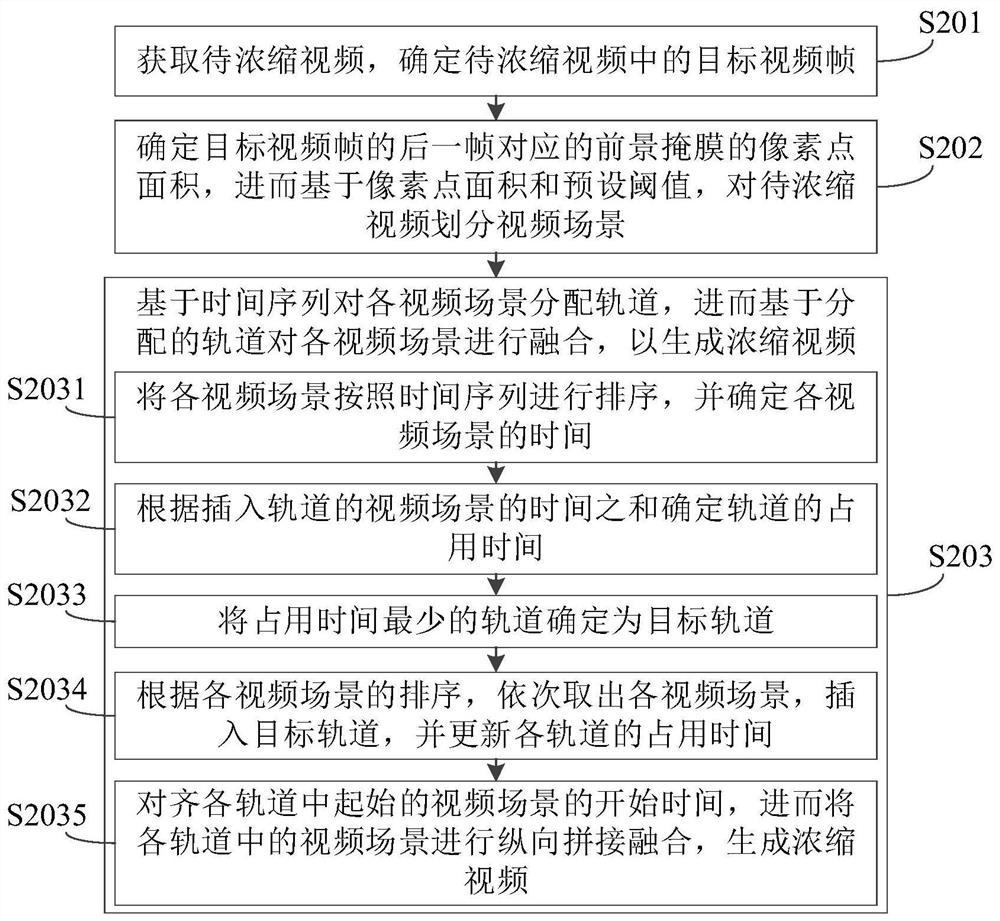

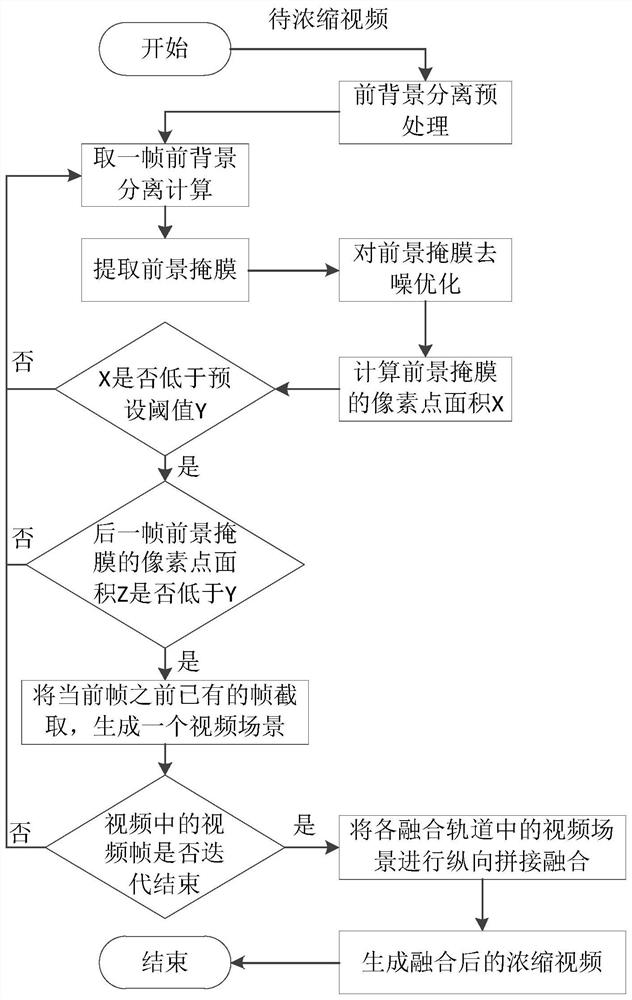

The invention discloses a video concentration method and device, and relates to the technical field of computers, in particular to the technical field of artificial intelligence, one specific embodiment comprises the steps of obtaining a to-be-concentrated video, and determining a target video frame in the to-be-concentrated video; determining the pixel point area of a foreground mask corresponding to the next frame of the target video frame, and dividing the video scene of the to-be-concentrated video based on the pixel point area and a preset threshold value; and allocating a track to each video scene based on the time sequence, and fusing each video scene based on the allocated track to generate a concentrated video. Therefore, the video scenes are divided by judging whether the pixel point area of the foreground in the foreground mask is smaller than the preset threshold value or not, and the video scenes are fused based on the allocated tracks by allocating the tracks to the divided video scenes, so that the video concentration efficiency is improved, and the video concentration quality is improved.

Owner:CHINA CONSTRUCTION BANK

Graphite flotation treatment process and device

The invention relates to a graphite flotation treatment process which comprises the following steps: S1, mixed-mesh roughing; S101, crushing; S102, primary separation; and S103, secondary separation. S2, large scale selection, S201, primary selection of large scales, S202, primary grinding of large scales, S203, secondary selection of large scales, S204, secondary grinding of large scales and S205, tertiary selection of large scales; s3, fine scale selection, S301, primary fine scale selection, S302, primary fine scale grinding, S303, secondary fine scale selection, S304, secondary fine scale grinding and S305, tertiary fine scale selection. The invention discloses a device for a graphite flotation treatment process. The device comprises a grading flotation device, a flotation machine and a flotation column. The invention aims to solve or at least alleviate the problem that a traditional multi-section grinding and floating lengthy process cannot well protect large scales and improve the selectivity of fine scales, and provides a graphite flotation treatment process and device.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

Beneficiation process for mixed ore of magnetite and hematite

InactiveCN109550587ARaise the gradeSave on infrastructure investment costsWet separationSocial benefitsQuality level

The invention relates to a beneficiation process for mixed ore of magnetite and hematite. The beneficiation process comprises the steps that after the raw ore is subjected to staged grinding and coarse and fine grading, the coarse and fine graded and settled sand is subjected to reselecting process to obtain gravity concentrate and tailings, and the coarse and fine graded overflow is subjected toa weak magnetic-anion reversed flotation process to obtain flotation concentrate and the tailings, wherein the comprehensive fine ore are composed of the gravity concentrate and the flotation concentrate. Compared with the staged grinding, coarse and fine grading, gravity concentration, and strong magnetic-anionic reversed flotation process, the quality level of the flotation concentrate can be improved by two percent points, and the quality level of the comprehensive and fine ores can be improved by 1 percent, and meanwhile, the capital investment cost of construction, the construction occupied area and the production operation cost of a strong magnetic machine, a strong magnetic pre-concentration machine, and a flotation pre-concentration machine are reduced, and the energy conservationand consumption reduction are achieved; and due to the amount of dry ore entering the flotation operation is reduced, the dosage of the flotation reagents can also be reduced, so that the environmental pollution can be reduced, the production investment can be reduced, the cost is reduced and the energy is saved under the condition that the earnings are the same, and good economic benefits and social benefits are achieved.

Owner:魏建民

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Scraper type evaporator

ActiveCN111001174AExtend your lifeIncreased durabilityEvaporator accessoriesRotational axisElectric machinery

The invention relates to the technical field of evaporators. The invention discloses a scraper type evaporator. The scraper type evaporatorcomprises a cylinder, a motor, a rotating shaft, a supportingframe and a scraper blade, the motor is installed at the top of the cylinder, the rotating shaft is installed on the motor, the supporting frame is installed on the rotating shaft, the scraper bladeis installed on the supporting frame, a bearing plate is installed on the rotating shaft, a supporting rod is installed on the bearing plate, and an arc-shaped plate located outside the bearing plateis installed at the end of the supporting rod. The arc-shaped plate is matched with an arc-shaped sleeve; rigid contact between the traditional scraper and the inner wall is optimized aselastic contact, when the arc-shaped plate collides with thecylinder; the arc-shaped plate can be retracted instantaneously, so that the diameter of the arc-shaped plate is reduced, the strength of friction betweenthe arc-shaped plate and the cylinder is reduced, the durability of the arc-shaped plate and the cylinder is improved, and meanwhile, through cooperation of a positioning seat, a positioning rod, a positioning plate, the rotating shaft, a sliding plate and a positioning pin, after one arc-shaped plate is collided, all arc-shaped edges can be driven to shrink synchronously.

Owner:济宁市邦达煤化工有限公司

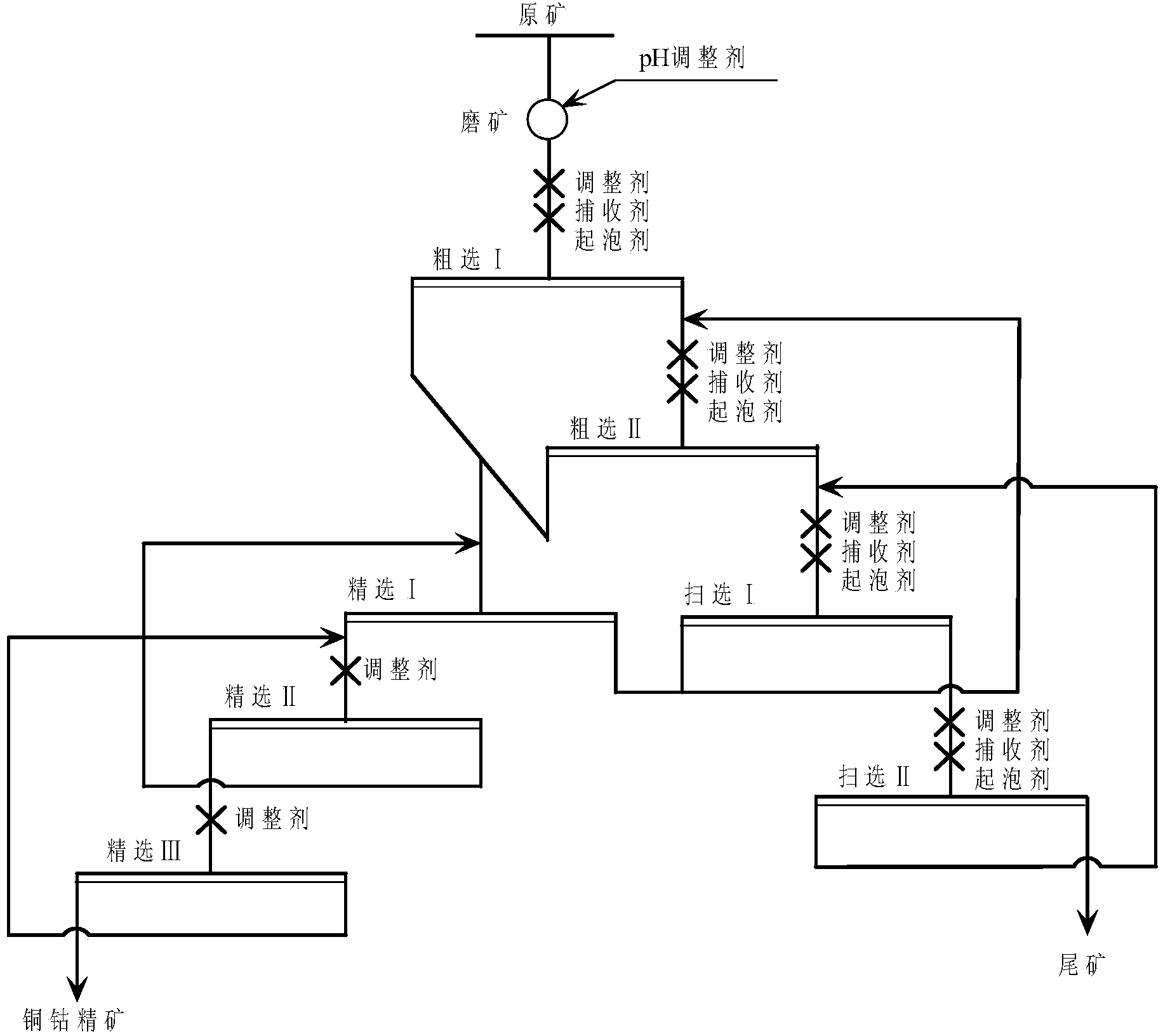

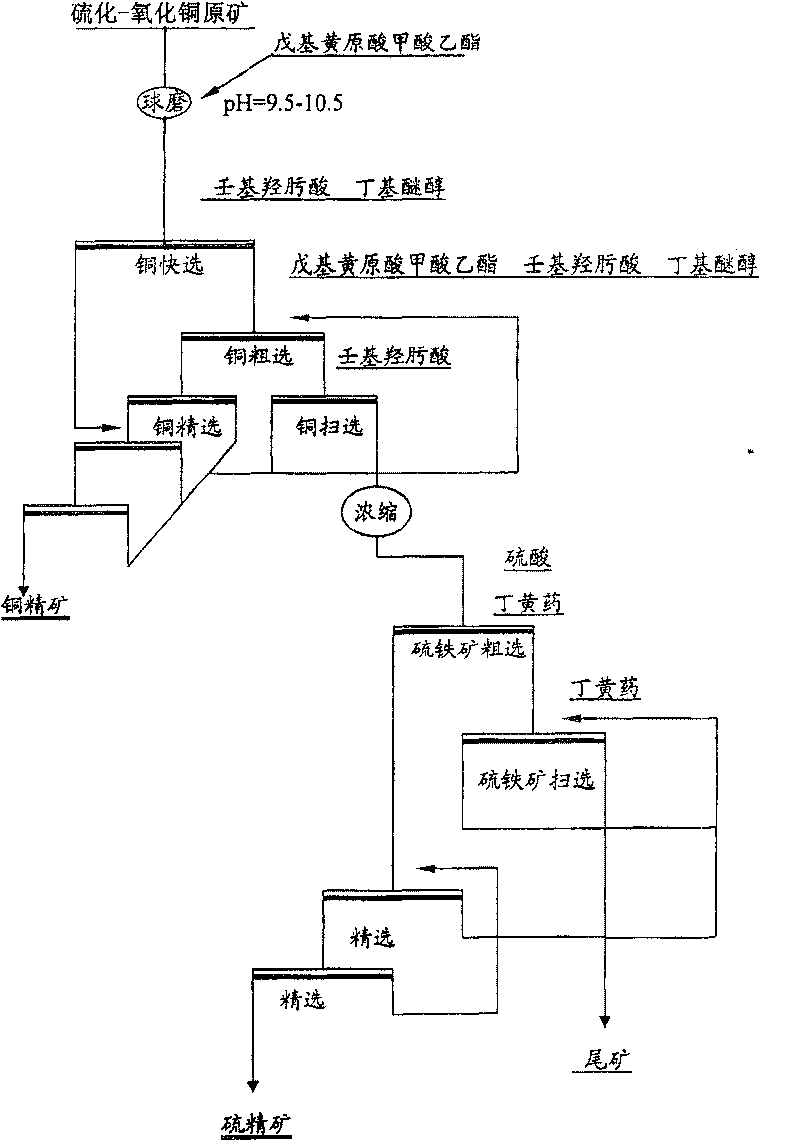

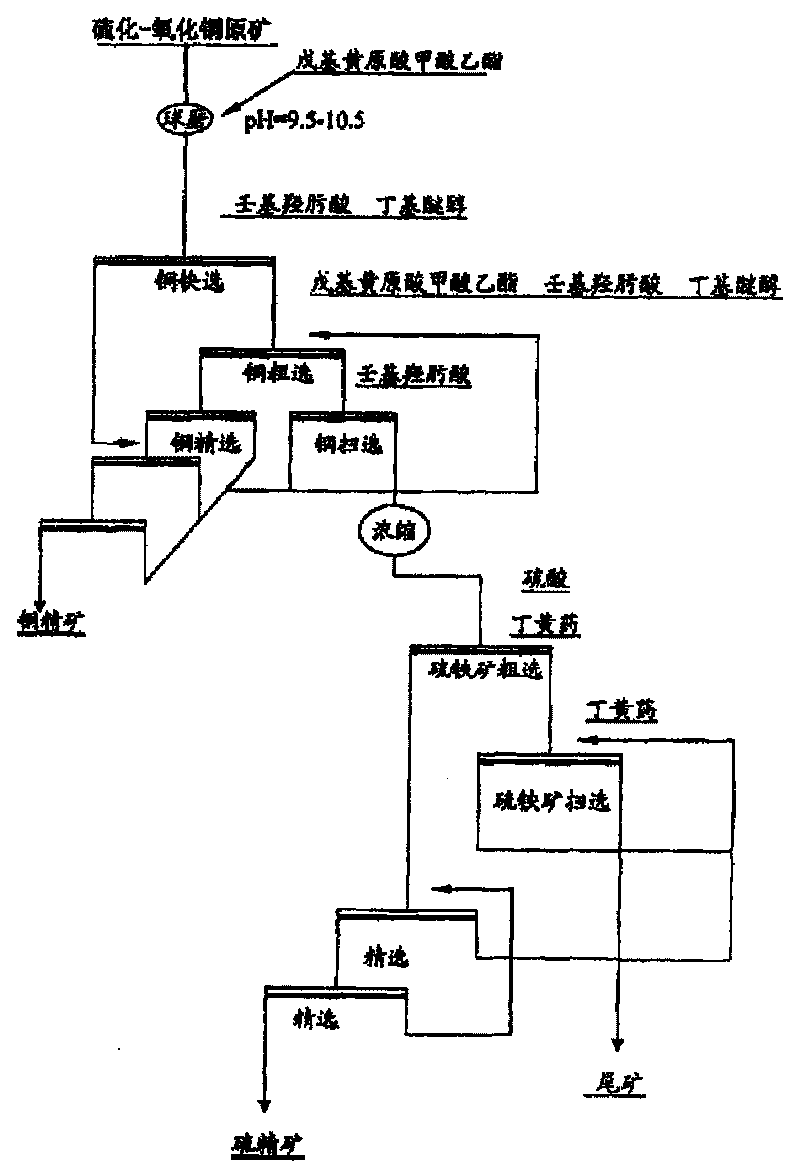

Vulcanization-oxidization mixing copper ore floatation method

InactiveCN101190426BHigh recovery rateImprove concentrate qualityFlotationVulcanizationHydroxamic acid

The invention discloses a sulfurization-oxidation mixed copper mine flotation method, comprising the steps of ore grinding and copper flotation: 20 to 50g / t of pentyl xanthic acid ethyl formate raw ore is added in the grinding process; meanwhile, a pH adjusting agent is added to lead the pH of the mine slurry to keep between 9.5 and 10.5; the invention comprises one time of fast selection, one time of coarse selection, one time of sweeping selection and three times of precise selection; in the fast selection process, 20 to 30g / t of nonyl hydroxamic acid raw ore is added and 20 to 30g / t of frother raw ore is added; in the coarse selection process, 10 to 30g / t of the pentyl xanthic acid ethyl formate raw ore and 10 to 20g / t of the nonyl hydroxamic acid raw ore as well as 10 to 20g / t of thefrother raw ore are added; in the sweeping selection process, 10 to 20g / t of the nonyl hydroxamic acid raw ore is added; the pH of the flotation mine pulp is kept between 9.5 and 10.5 and the copper ore is recovered. Compared with the traditional flotation methods of copper sulphide ore and copper oxide ore, the invention improves the flotation efficiency, reduces flotation equipment and energy loss and increases the copper recovery for more than 10%.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com