Tailing discarding and dissociation integrated coarse grain mineral dissociation device and method

A dissociated, coarse-grained technology, used in solid separation, grain treatment, flotation, etc., can solve the problems of rapid loss of mill lining and grinding media, reduce the selectivity of target minerals, and increase the pollution of new surfaces. Achieve the effect of reducing the contamination of new surfaces, reducing transportation and maintenance costs, and reducing the consumption of sorting chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

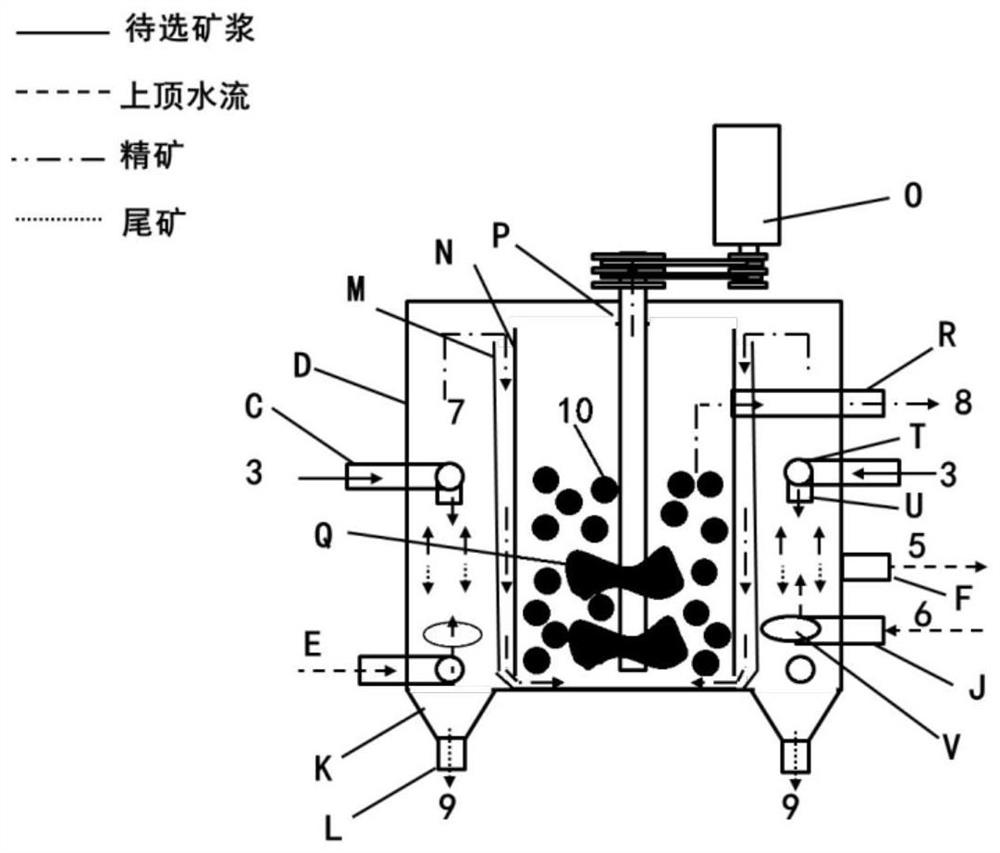

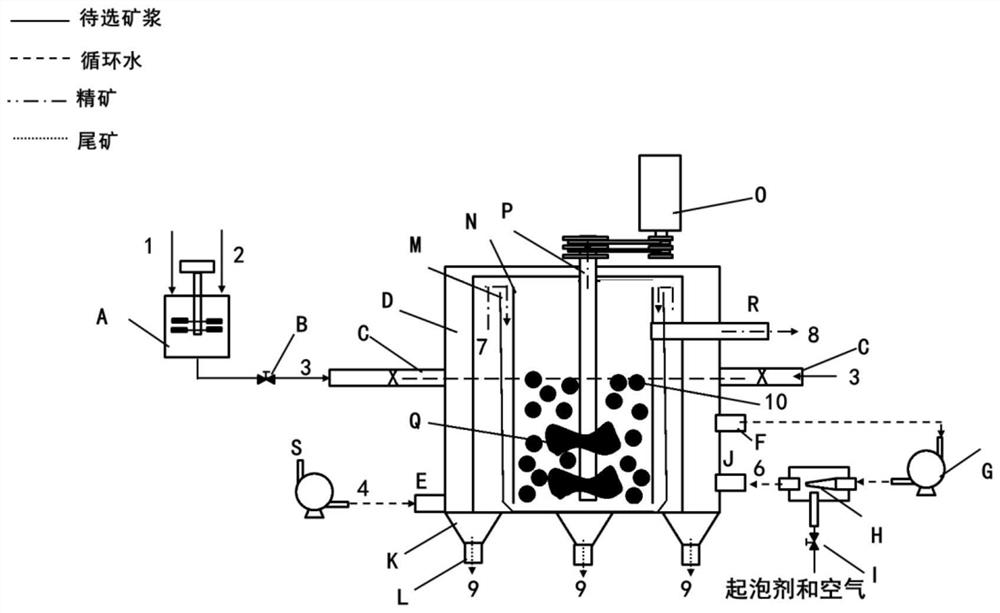

[0025] like figure 1 and figure 2 As shown, the integrated coarse-grained mineral dissociation device for tail throwing and dissociation is characterized in that it includes a mixing tank A and a hydraulic flotation separation unit cylinder, and a pipe is passed between the mixing bucket A and the hydraulic flotation separation unit cylinder. Road connection, the pipeline is equipped with a pipeline valve B;

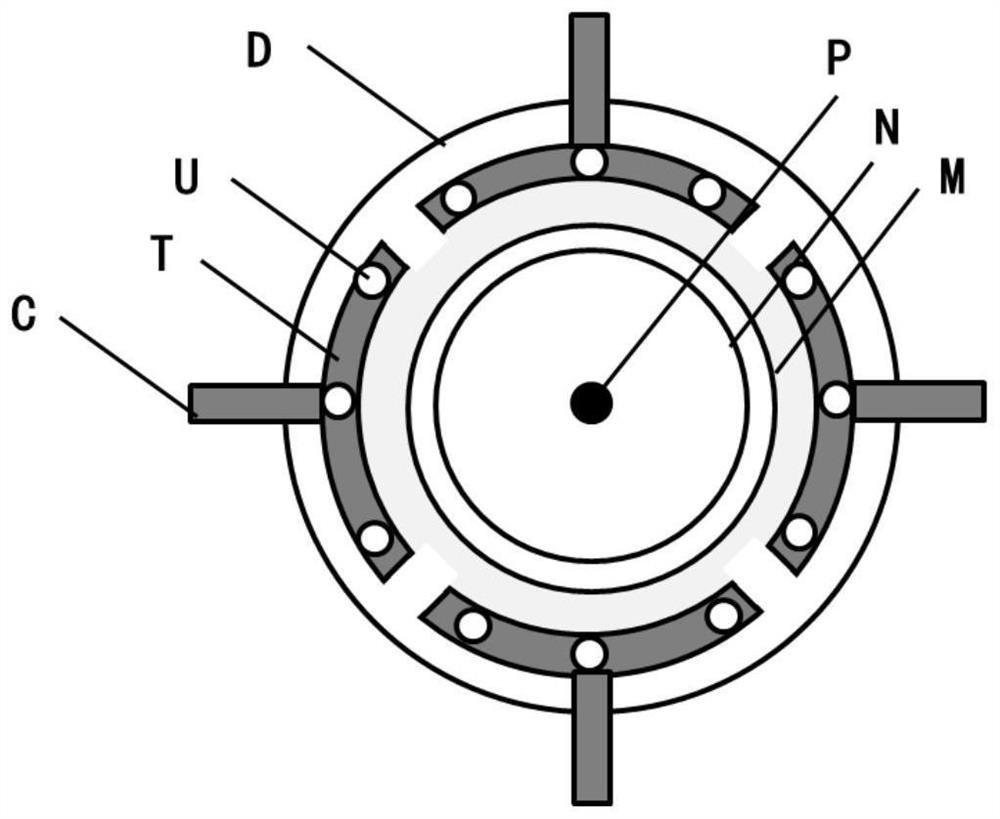

[0026] The hydraulic flotation separation unit cylinder includes a columnar structure hydraulic flotation separation unit outer cylinder body D, and the hydraulic flotation separation unit outer cylinder body D is provided with a hydraulic flotation separation unit inner cylinder body M. The inner cylinder M of the sorting unit is equipped with a columnar structure of the agitating ball mill unit cylinder N, and the separation chamber is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com