Flotation method for carbonaceous copper-cobalt ore

A carbonaceous material, copper-cobalt technology, applied in flotation, solid separation, etc., can solve the problems of large specific surface area, poor sortability, fine carbonaceous mineral particles, etc., and achieve high separation efficiency, easy control, and flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

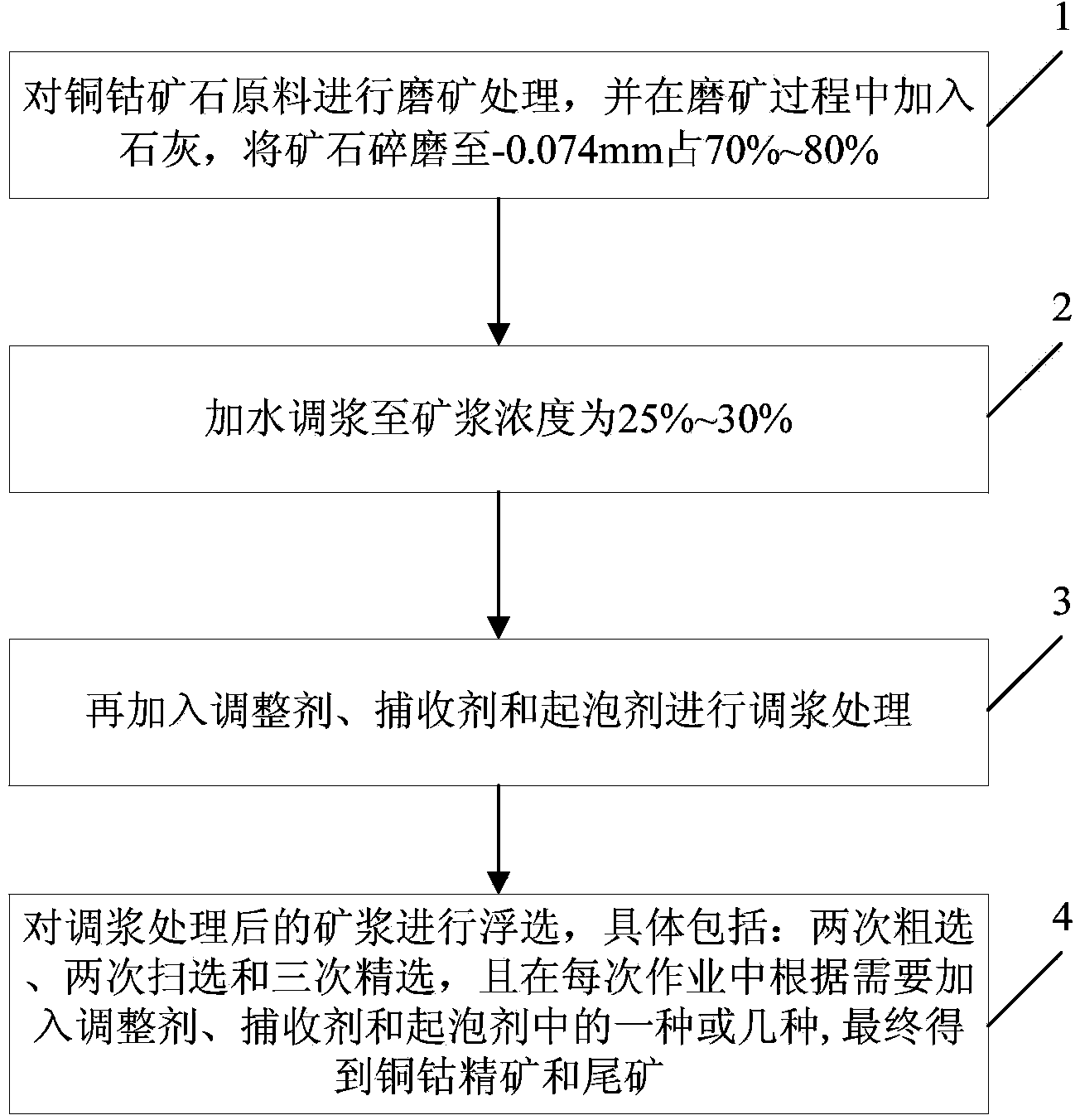

[0041] 1) Grinding the copper-cobalt ore raw materials, adding lime during the grinding process, grinding the ore to -0.074mm, accounting for 75%, and the amount of lime is 600g / t;

[0042] 2) Add water to adjust the pulp until the pulp concentration is 27.5%, and the pH value of the pulp is 10.0-11.0;

[0043] 3) Add conditioner, collector and foaming agent to adjust the slurry, the conditioner is sodium lignosulfonate, the dosage is 300-500g / t, the collector is butyl xanthate, the dosage is 60-130g / t , the foaming agent is pine alcohol oil, the dosage is 50-100g / t;

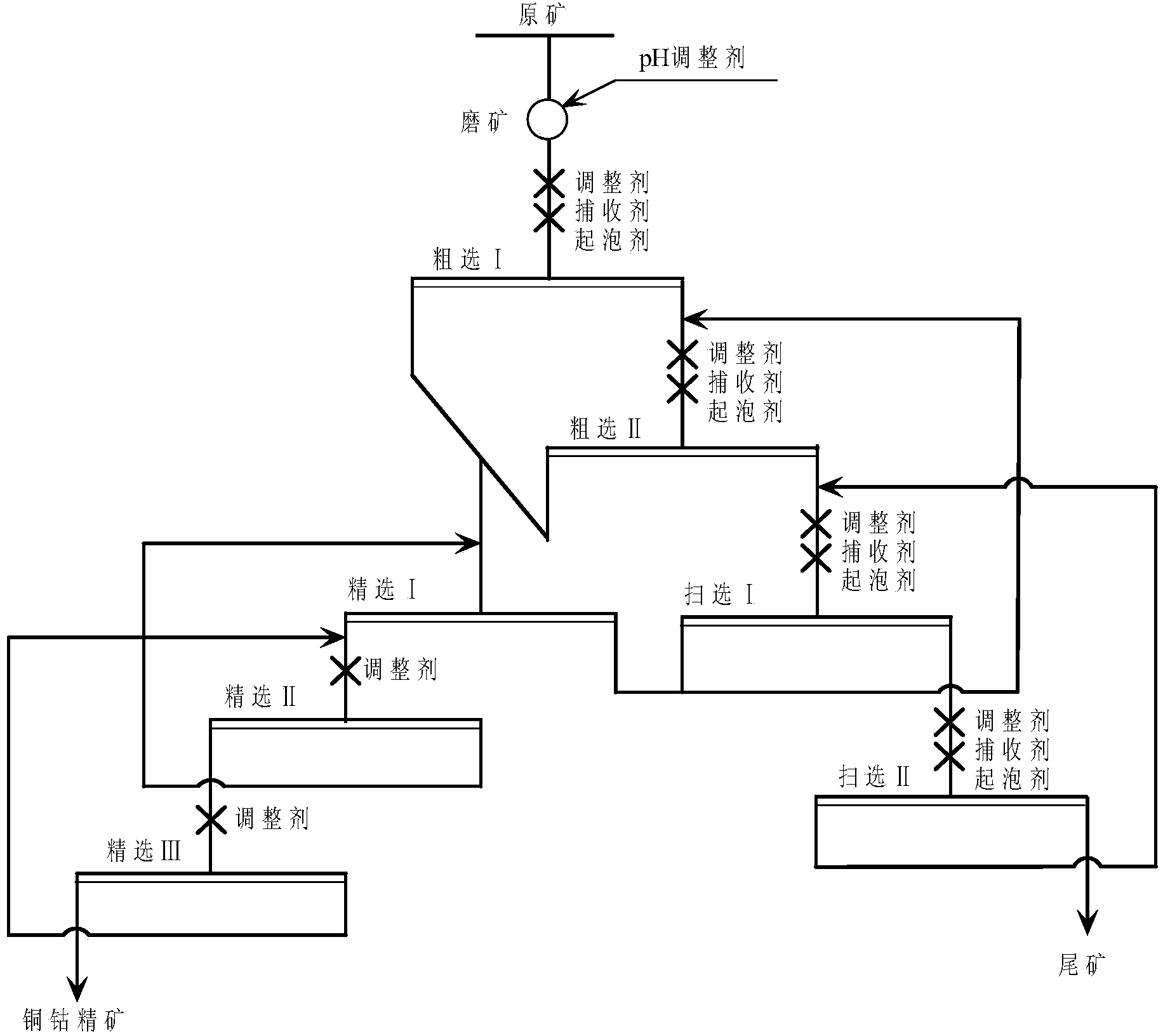

[0044] 4) Flotation is carried out after pulping, and the flotation method is two times of roughing, two times of sweeping, and three times of fine selection; each operation is added with one or more of regulators, collectors and foaming agents as needed ;

[0045] 5) During flotation, the foam products of the first rough selection and the foam products of the second rough selection are combined for selection,...

Embodiment 2

[0048] 1) Grinding the copper-cobalt ore raw materials, adding lime during the grinding process, grinding the ore to -0.074mm, accounting for 70%, and the amount of lime is 500g / t;

[0049] 2) Add water to adjust the pulp until the pulp concentration is 27.5%, and the pH value of the pulp is 10.0-11.0;

[0050] 3) Add conditioner, collector and foaming agent to make slurry, conditioner is lignin, dosage is 300-500g / t, collector is butyl xanthate, dosage is 60-130g / t, foaming The agent is pine alcohol oil, the dosage is 50-100g / t;

[0051] 4) Flotation is carried out after pulping, and the flotation method is two times of roughing, two times of sweeping, and three times of fine selection; each operation is added with one or more of regulators, collectors and foaming agents as needed ;

[0052] 5) During flotation, the foam products of the first rough selection and the foam products of the second rough selection are combined for selection, and the products in the tank of the f...

Embodiment 3

[0055]1) Grinding the copper-cobalt ore raw materials, adding lime during the grinding process, grinding the ore to -0.074mm, accounting for 80%, and the amount of lime is 800g / t;

[0056] 2) Add water to adjust the pulp until the pulp concentration is 27.5%, and the pH value of the pulp is 10.5-11.0;

[0057] 3) Add conditioner, collector and foaming agent to adjust the slurry, the conditioner is potassium lignosulfonate, the dosage is 300-500g / t, the collector is butyl xanthate, the dosage is 60-130g / t , the foaming agent is pine alcohol oil, the dosage is 50-100g / t;

[0058] 4) Flotation is carried out after pulping, and the flotation method is two times of roughing, two times of sweeping, and three times of fine selection; each operation is added with one or more of regulators, collectors and foaming agents as needed ;

[0059] 5) During flotation, the foam products of the first rough selection and the foam products of the second rough selection are combined for selectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com