Vulcanization-oxidization mixing copper ore floatation method

A mixed copper ore and mineral flotation technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of copper concentrate, large consumption of beneficiation reagents, poor economic benefits, etc., and achieve reduction of flotation equipment and energy consumption , Improve the recovery rate and the quality of the concentrate, and the effect of improving the copper recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

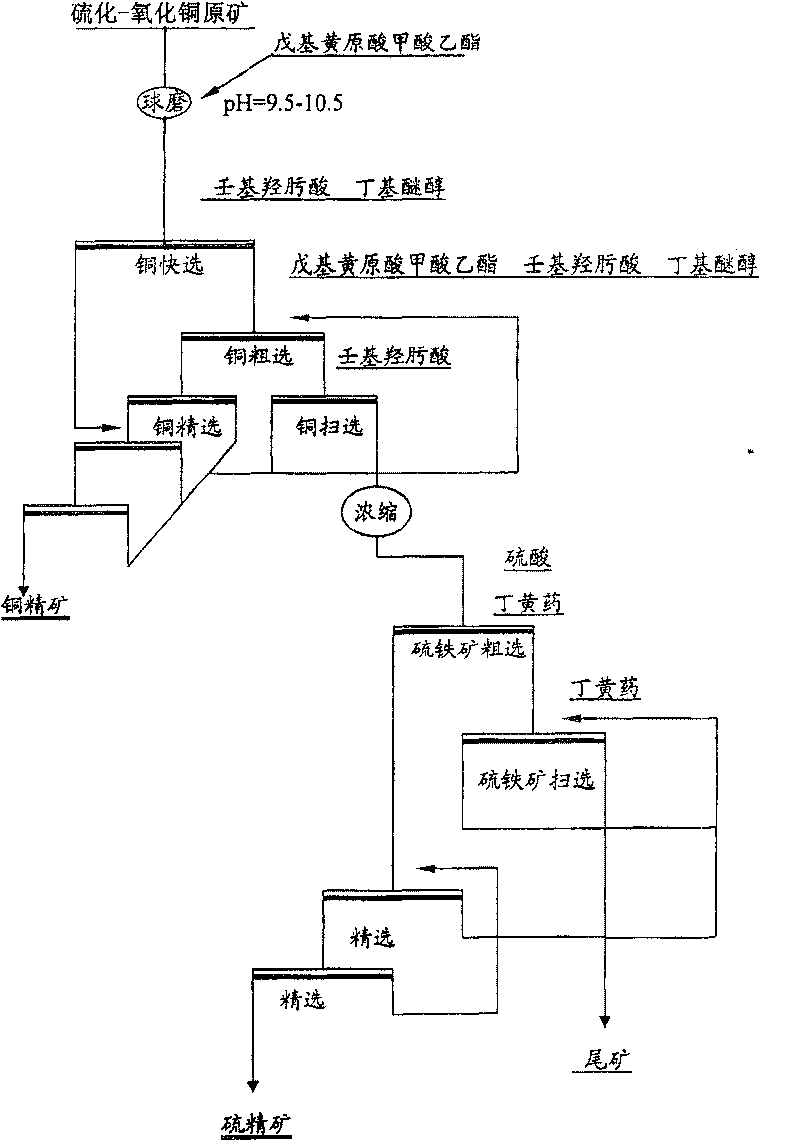

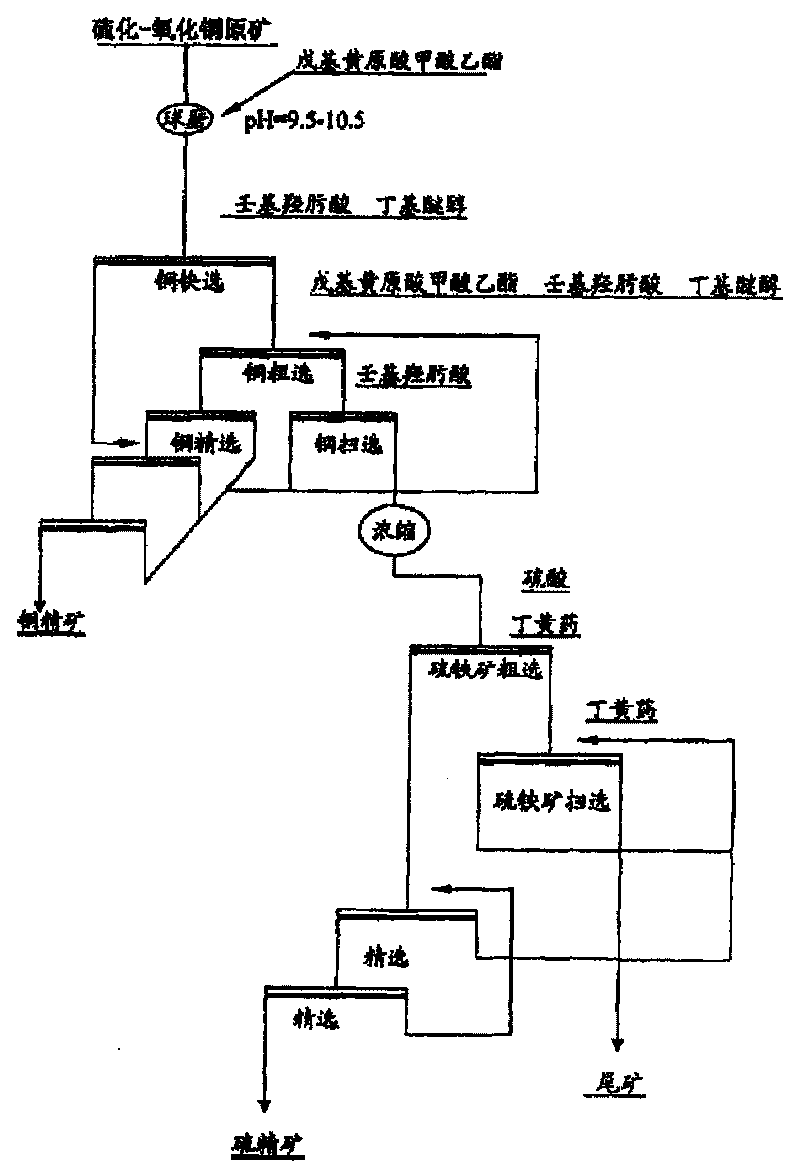

[0016] Using a copper mine in Hunan that contains 0.91% Cu and 11.65% S in the raw ore, the phase analysis of copper minerals shows that 26.5% of the copper minerals exist in the form of copper oxide, and the rest are copper sulfide minerals. Mainly mine. Other minerals are mainly pyrite, pyrrhotite, magnetite, etc., and gangue minerals are mainly quartz, calcite, etc. The mineral is ball-milled with a wet ball mill so that the particle size of the product is -0.074mm and accounts for about 80%. figure 1 As shown, ethyl amyl xanthate formate is added during the grinding process, and the addition amount is 28g / t raw ore, and the pH of the grinding system is controlled at pH 10. Grinding products go directly to flotation without desliming. Flotation includes one fast separation, one rough separation, one sweep and three selections. During fast separation, 20g / t raw ore of nonylhydroxamic acid and 20g / t raw ore of foaming agent are added; during rough separation, amyl hydroxami...

Embodiment 2

[0018] Using a copper mine in Yunnan that contains 1.12% Cu and 12.77% S in the original ore, the phase analysis of copper minerals shows that 27.3% of the copper minerals exist in the form of copper oxide, and the rest are copper sulfide minerals. Mainly mine. Other minerals are mainly pyrite, arsenopyrite, magnetite, etc., and main gangue minerals are mainly quartz, calcite, etc. The mineral is ball milled with a wet ball mill so that the particle size of the product is -0.074mm and accounts for about 74%. figure 1 As shown, ethyl amyl xanthate formate is added during the grinding process, the addition amount is 40g / t raw ore, and the pH of the grinding system is controlled at pH 9.8. Grinding products go directly to flotation without desliming. Flotation includes one fast separation, one rough separation, one sweep and three selections. During the fast separation, 30g / t raw ore of nonylhydroxamic acid and 28g / t raw ore of foaming agent are added; during the rough separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com