Graphite flotation treatment process and device

A treatment process and flotation device technology, applied in flotation, solid separation, etc., can solve the problem of not being able to better protect the selectivity of large scales and fine scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

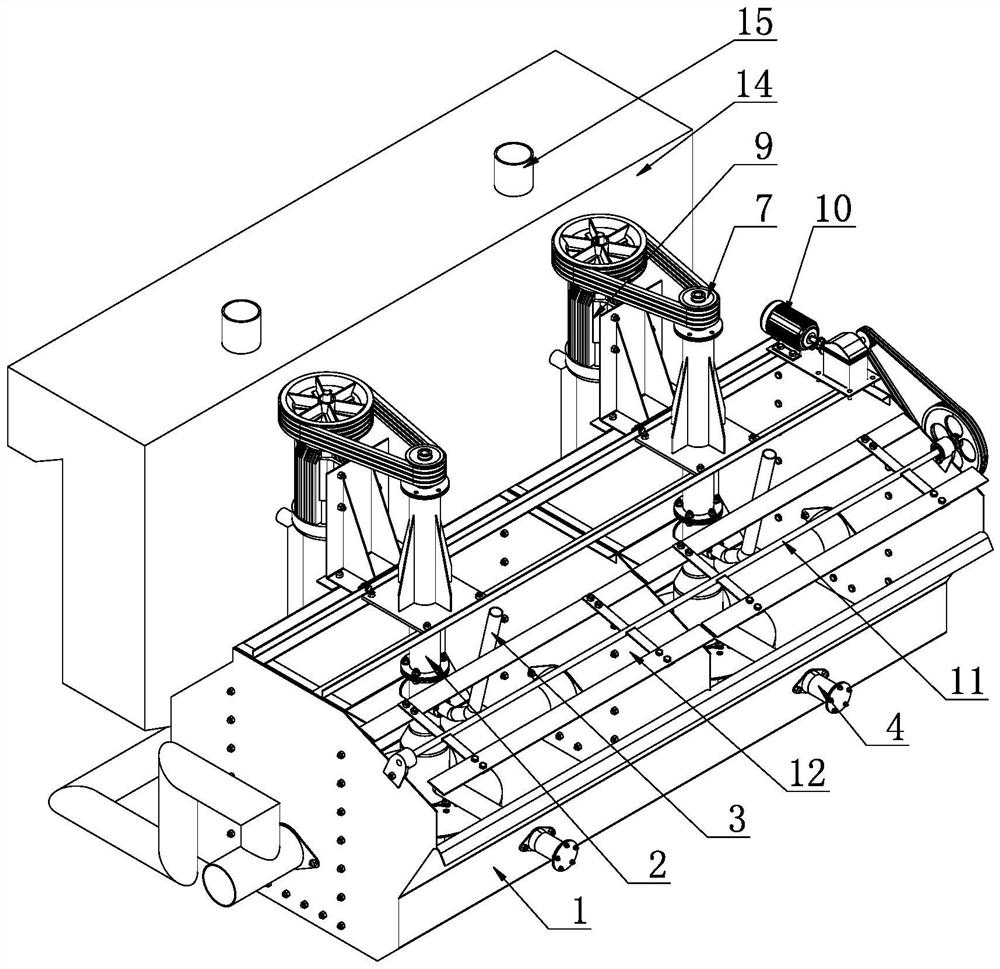

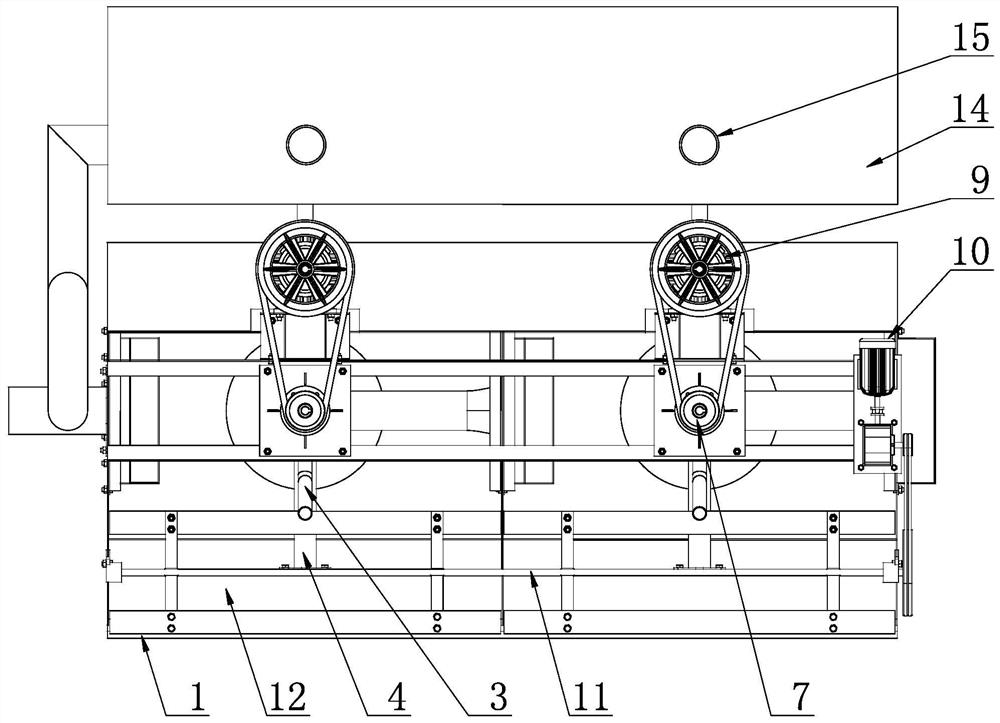

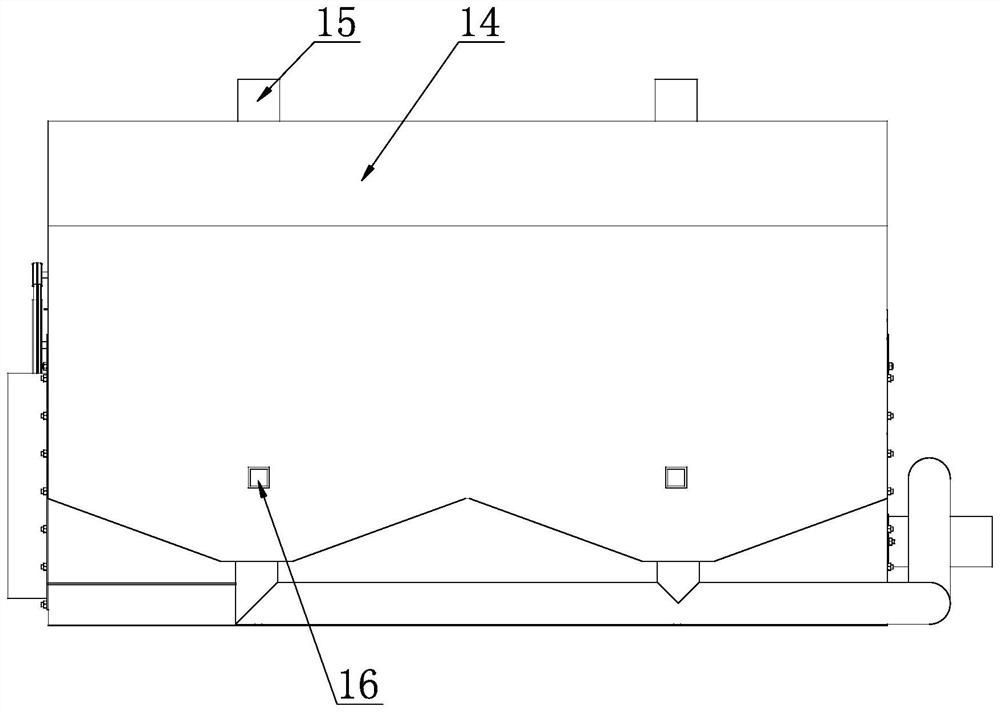

[0065] Such as Figure 1-12 Shown, a kind of graphite flotation treatment process comprises the following steps:

[0066] S1, rough selection of mixed items;

[0067] S101, crushing, transporting the raw graphite ore to a roller mill for crushing and then transporting it to a grading device for grading, controlling the -180 μm product in the grading overflow to reach 70-75%, and the fixed carbon content of the scavenging tailings is less than 1%;

[0068] S102, a sorting, the product obtained in step S101 is input into the classification flotation device, and a part of large flake graphite and a part of fine flake graphite are floated;

[0069] S103, secondary separation, input the remaining product of large flake graphite in step S102 into the classification flotation device again, and float a part of large flake graphite and a part of fine flake graphite, and the remaining product is tailings;

[0070] S2, selection of large scales;

[0071] S201, the large flakes are sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com