Patents

Literature

75 results about "Carbonaceous matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonaceous matter was extracted from ore obtained from Stawell Gold Mine and characterised by microscopic methods and XRD. The carbonaceous matter was predominantly hexagonal crystalline graphite mixed with some minor semi-crystalline graphite or amorphous carbon.

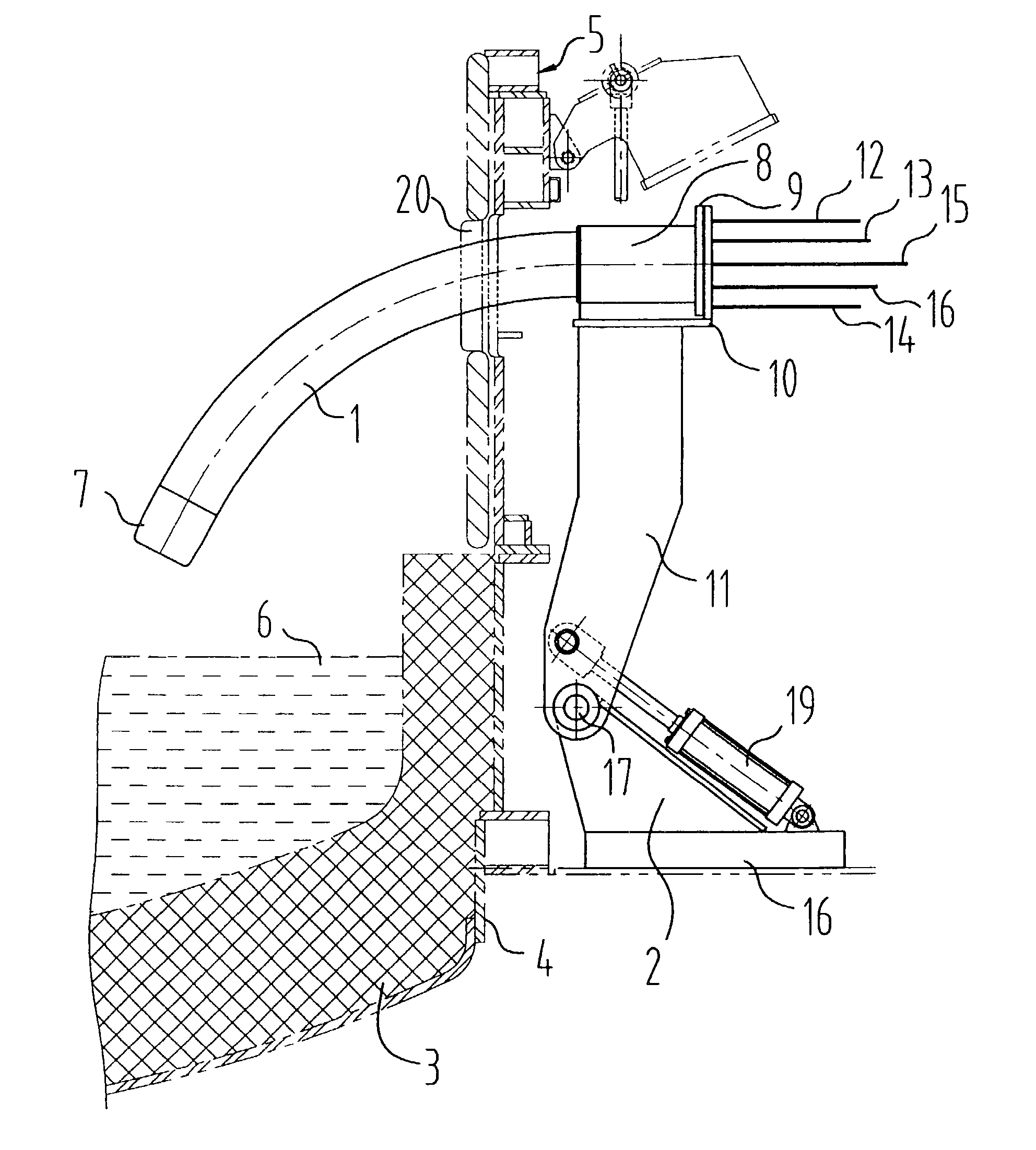

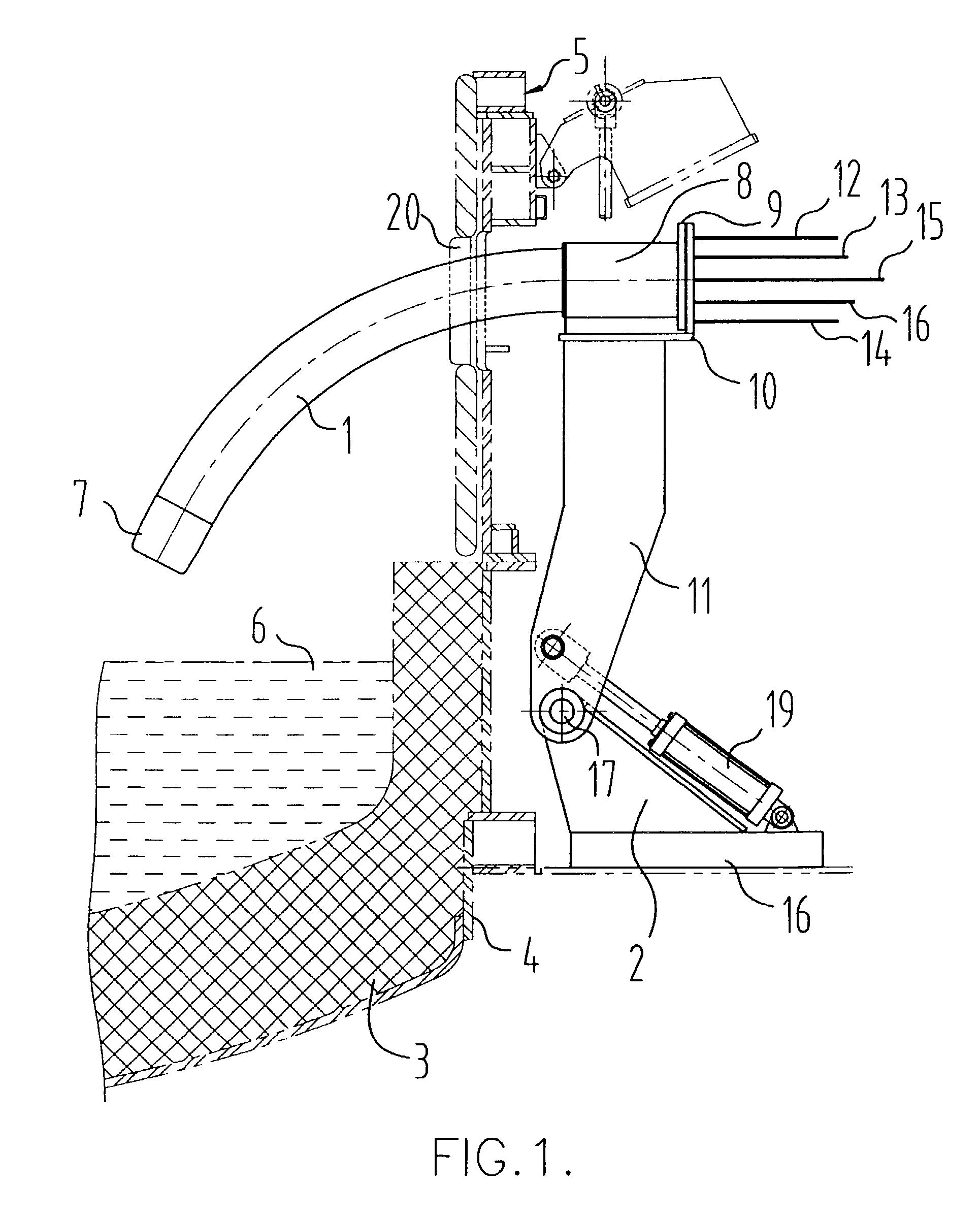

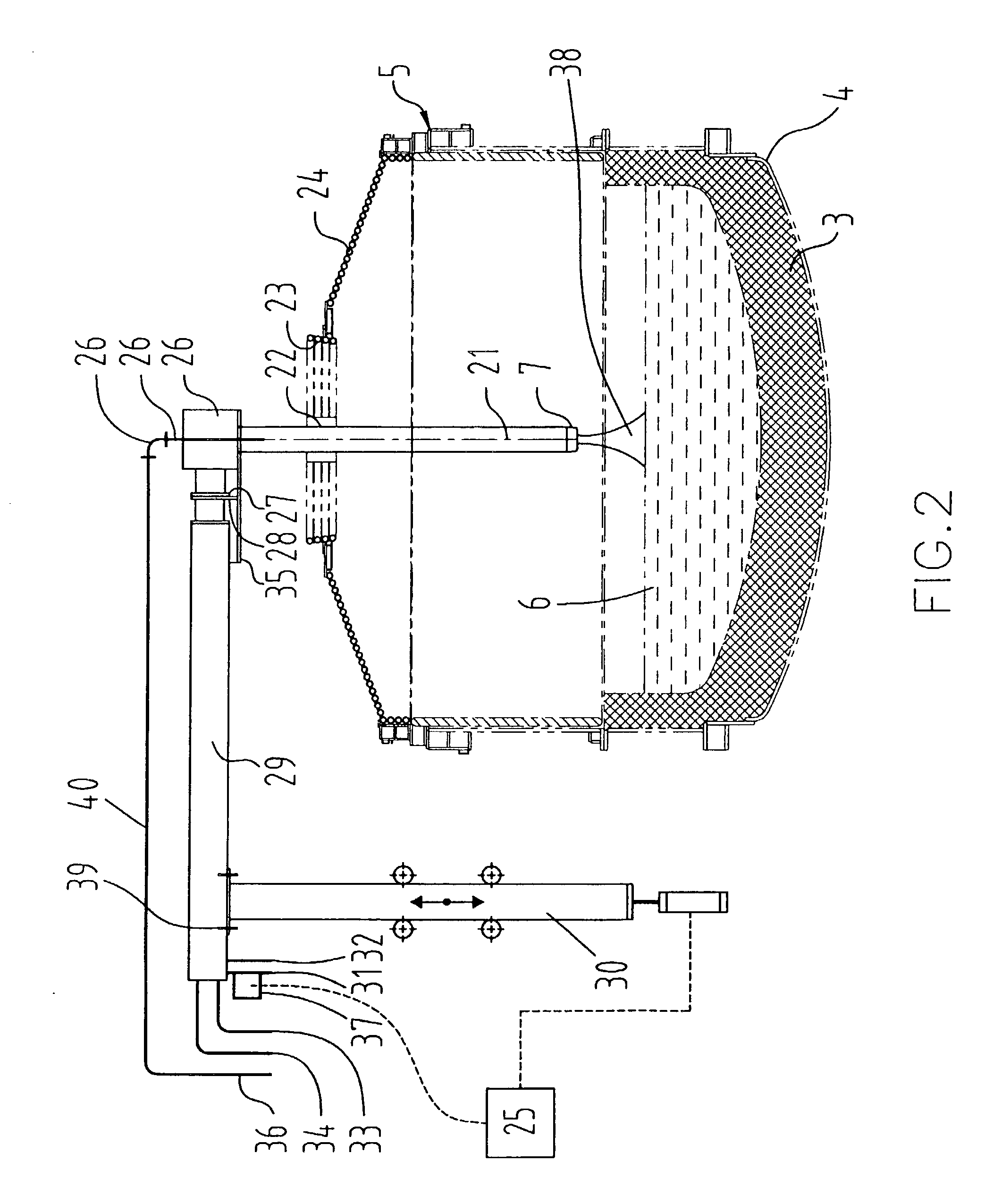

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

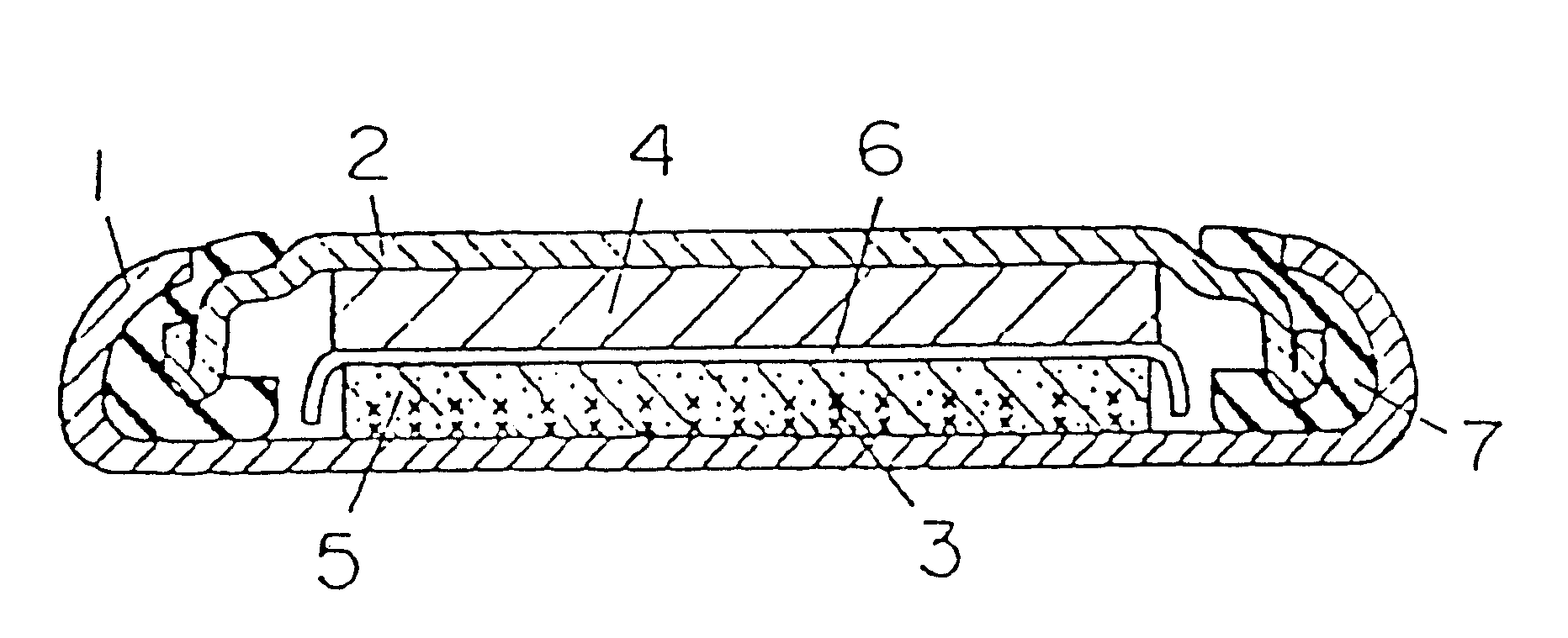

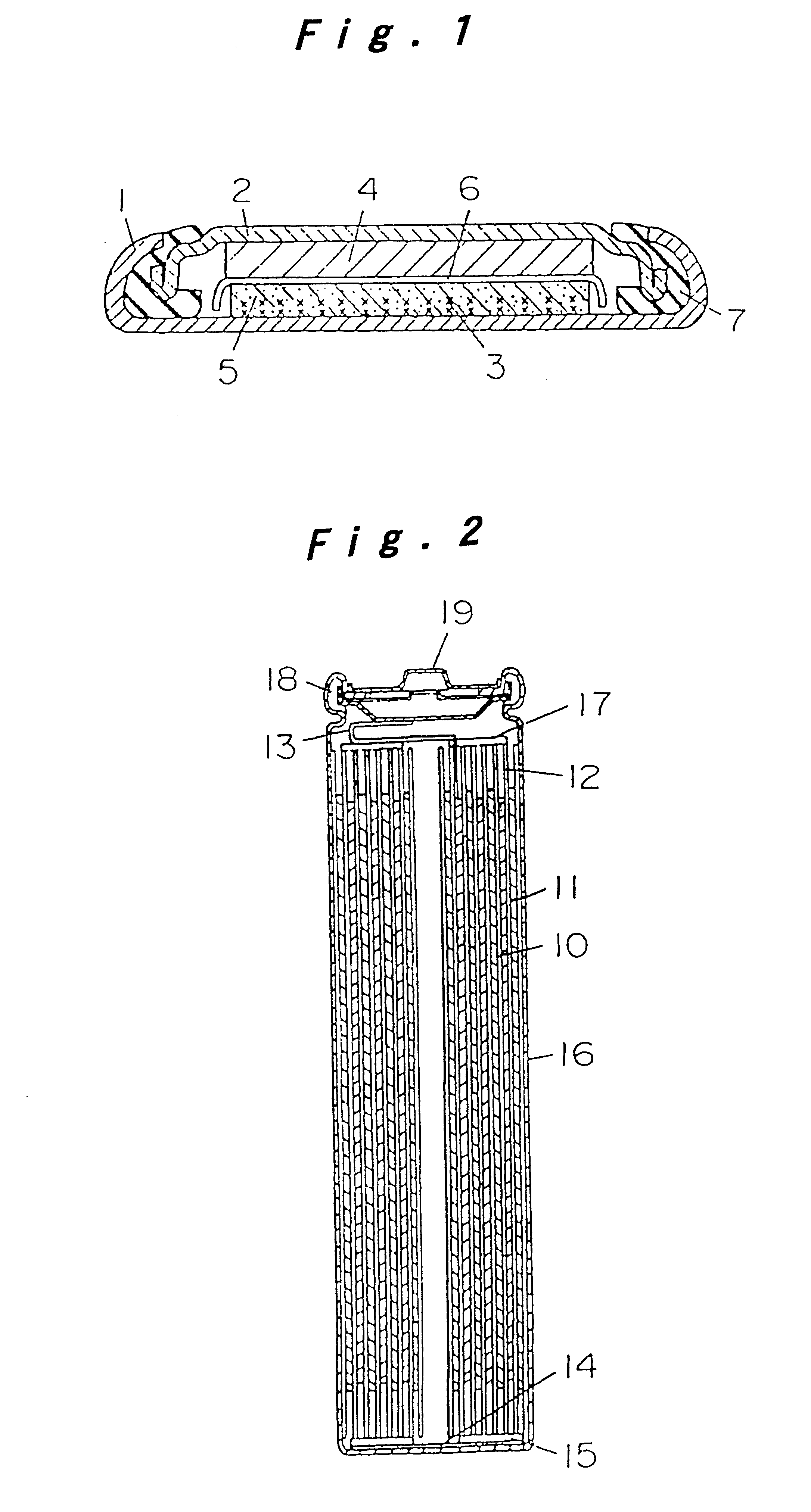

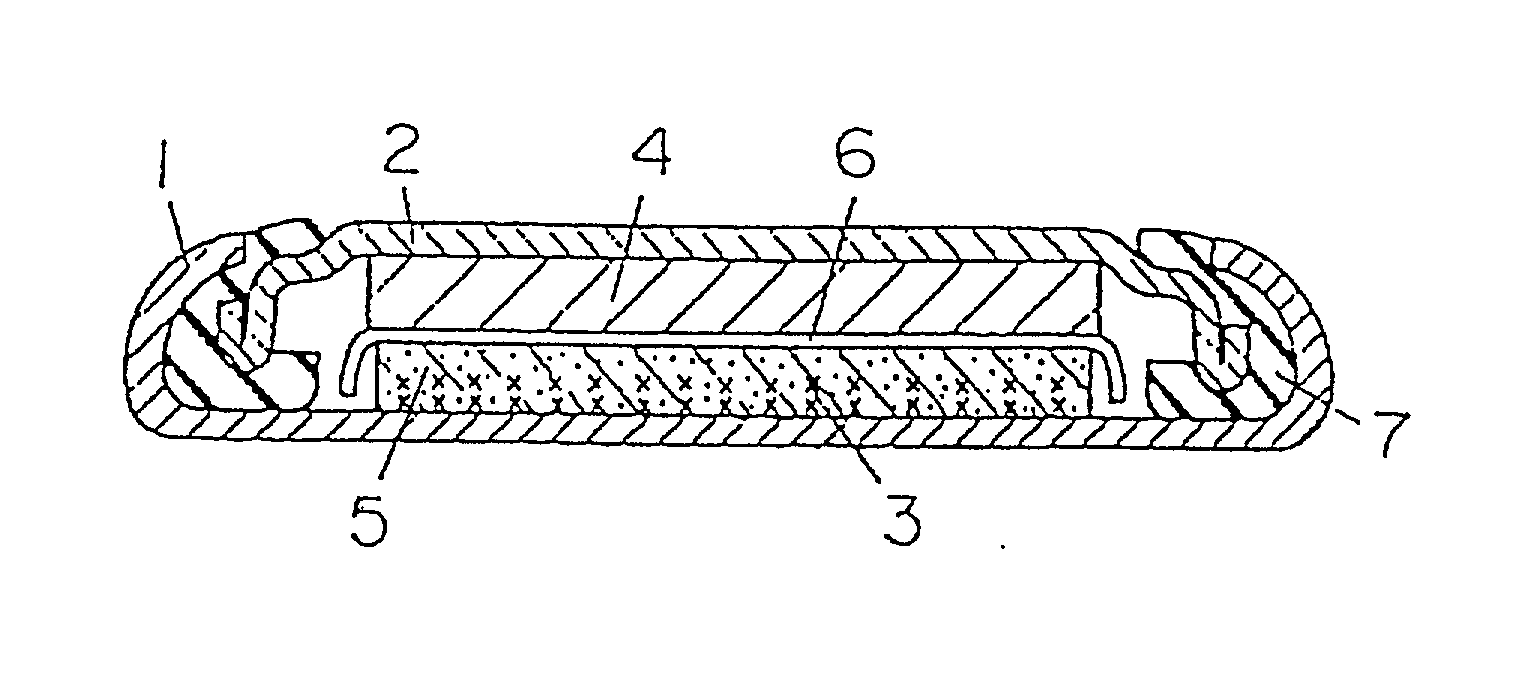

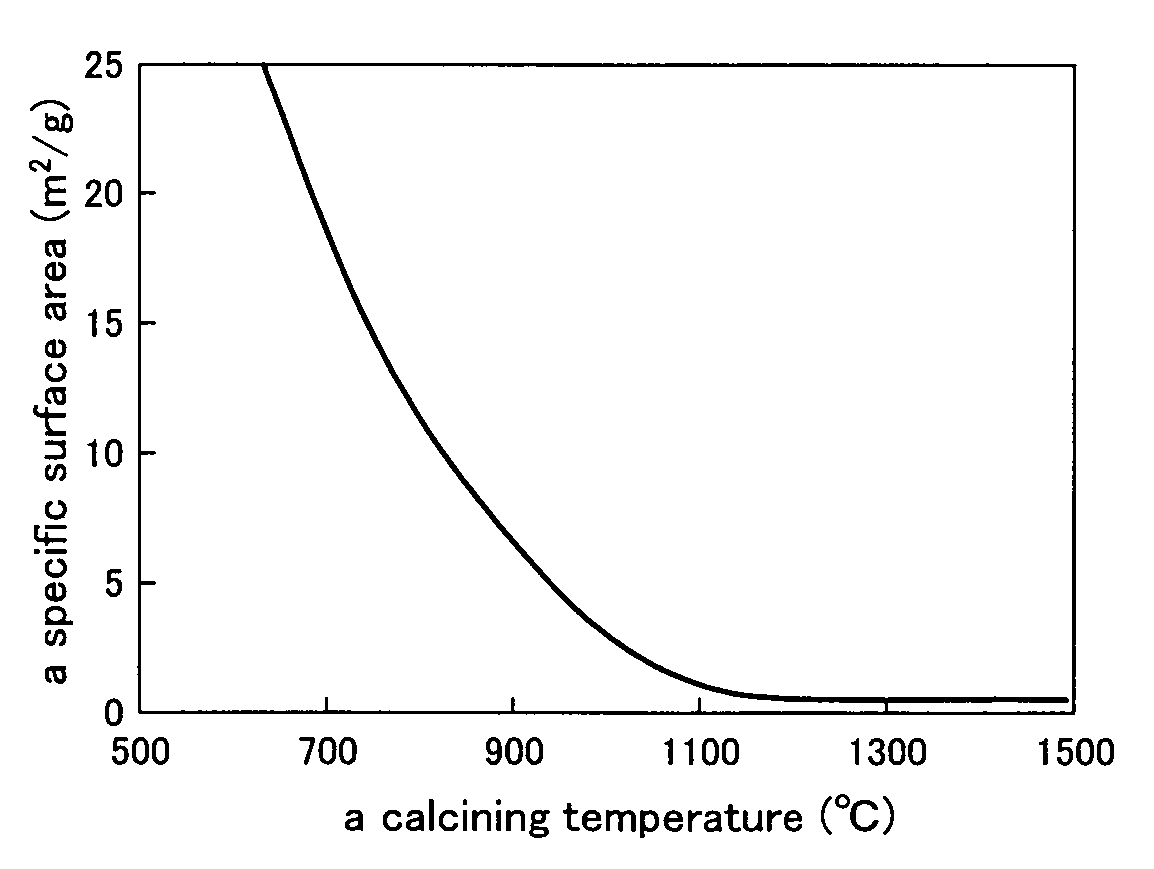

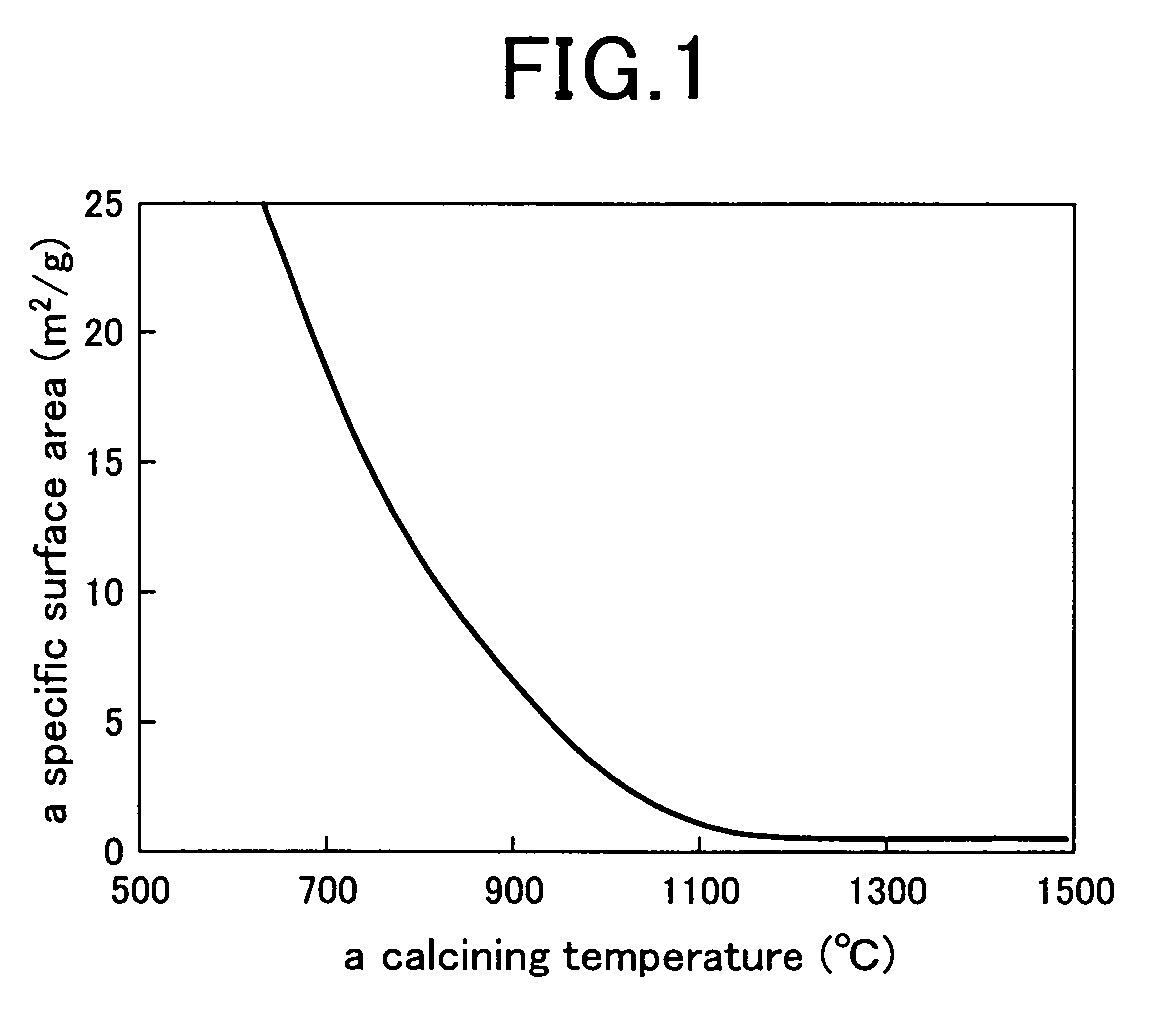

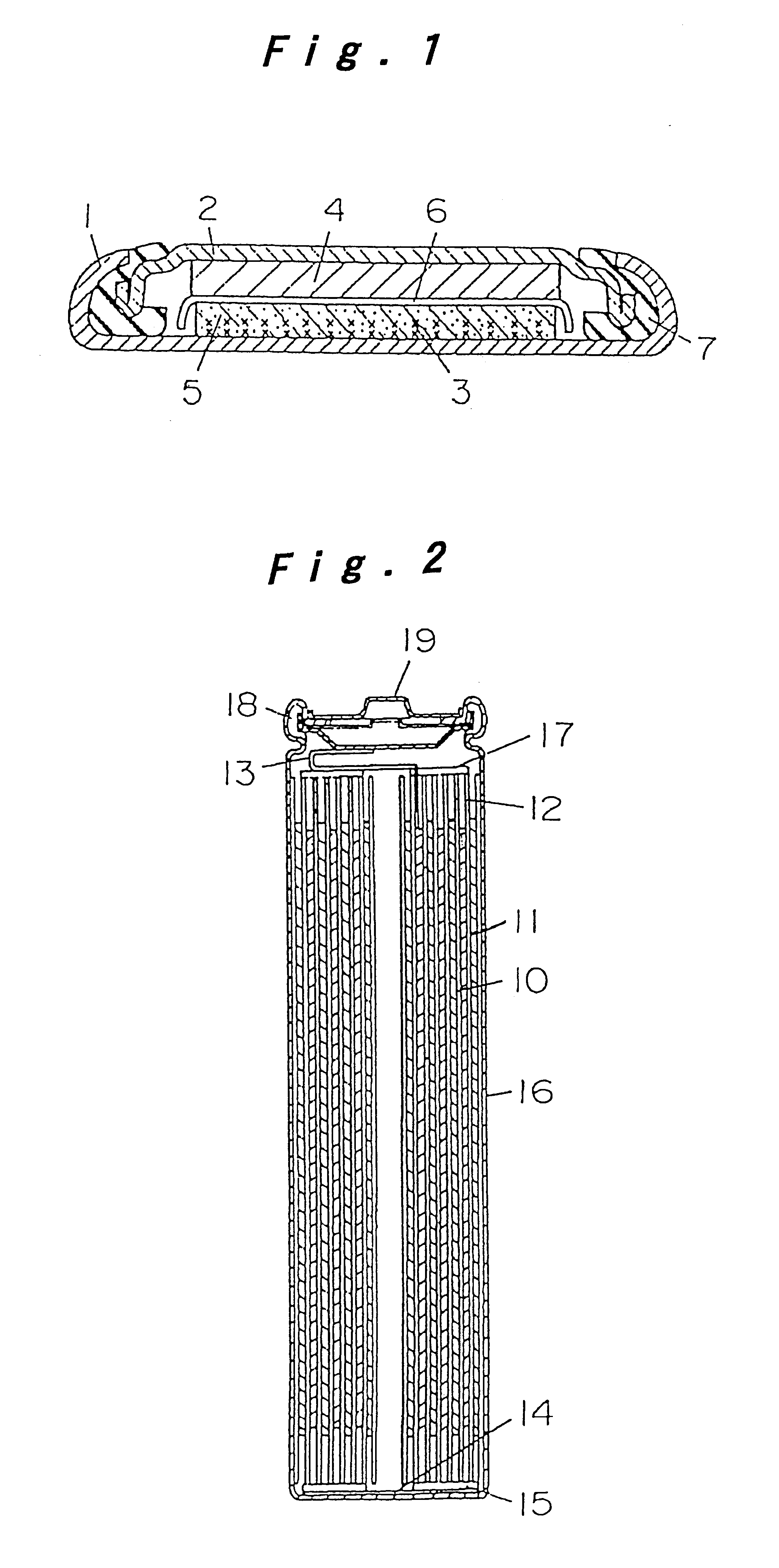

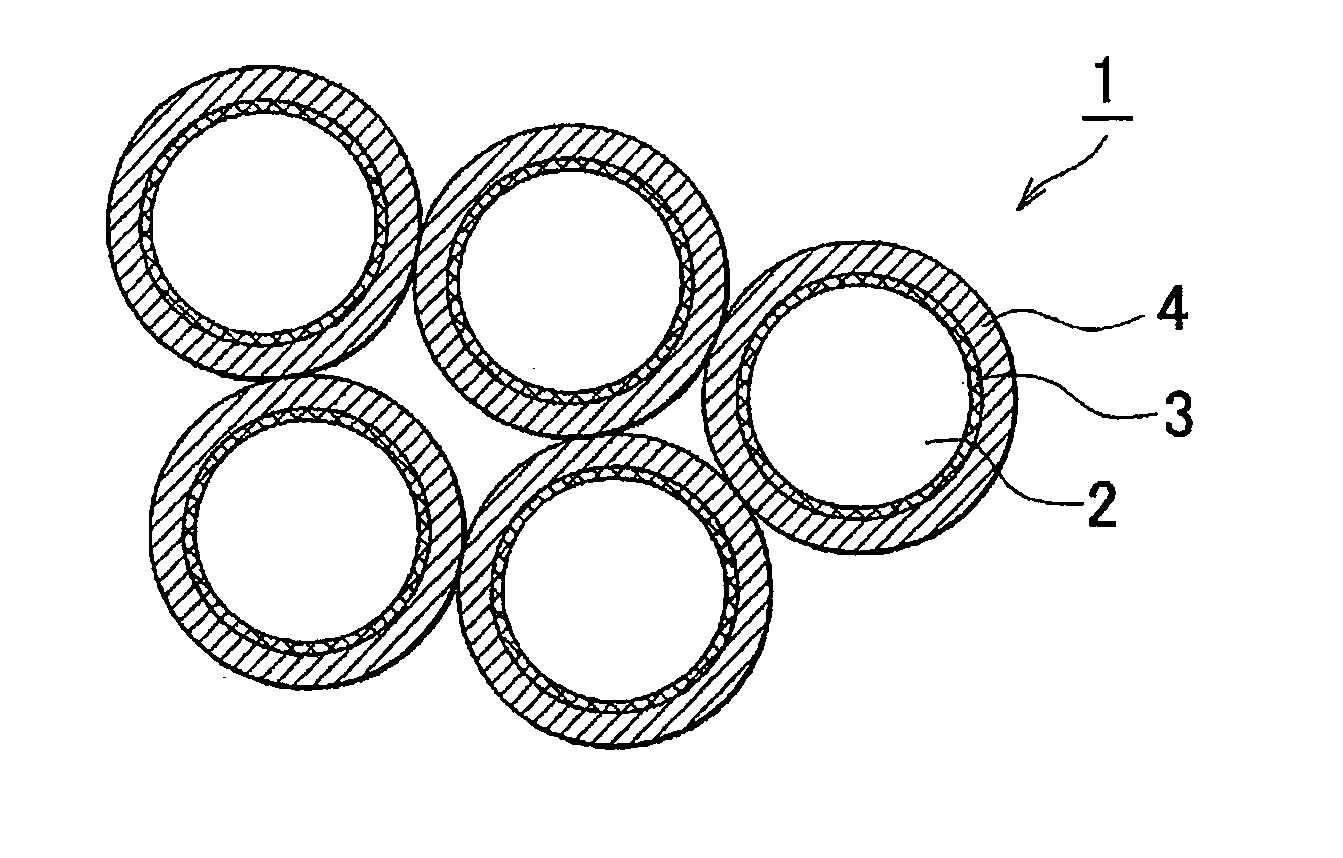

Nonaqueous electrolyte secondary battery comprising carbon particles with a plural-layer structure

InactiveUS6403259B1High specific capacityImprove propertiesElectrode thermal treatmentActive material electrodesX-rayGraphite

Enhancement of the storage property at a high temperature and discharge characteristics at a low temperature of a nonaqueous electrolyte secondary cell is intended. A negative electrode material which is prepared by covering the surface of a nucleus made of a graphite powder with a carbonaceous matter, the graphite powder having a specified plane interval, spectrum value, mean particle size, specific surface area, tapping density, and (110) / (004) X-ray peak intensity ratio, is used in the nonaqueous electrolyte secondary cell.

Owner:PANASONIC CORP +1

Nonaqueous electrolyte secondary cell

InactiveUS20020061445A1High specific capacityImprove propertiesElectrode thermal treatmentLayered productsX-rayGraphite

Enhancement of the storage property at a high temperature and discharge characteristics at a low temperature of a nonaqueous electrolyte secondary cell is intended. A negative electrode material which is prepared by covering the surface of a nucleus made of a graphite powder with a carbonaceous matter, the graphite powder having a specified plane interval, spectrum value, mean particle size, specific surface area, tapping density, and (110) / (004) X-ray peak intensity ratio, is used in the nonaqueous electrolyte secondary cell.

Owner:MITSUBISHI CHEM CORP

Method for preparing graphene

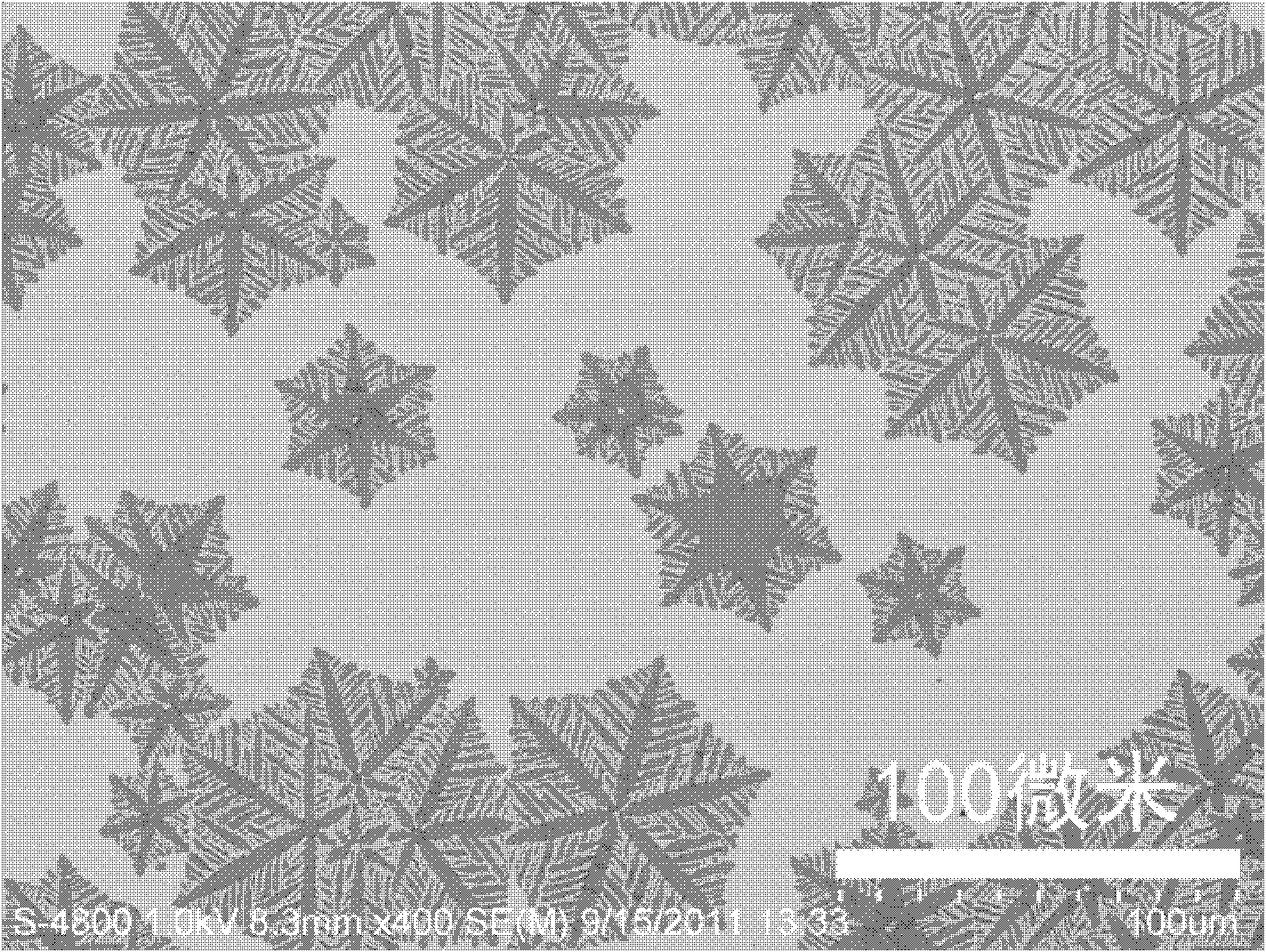

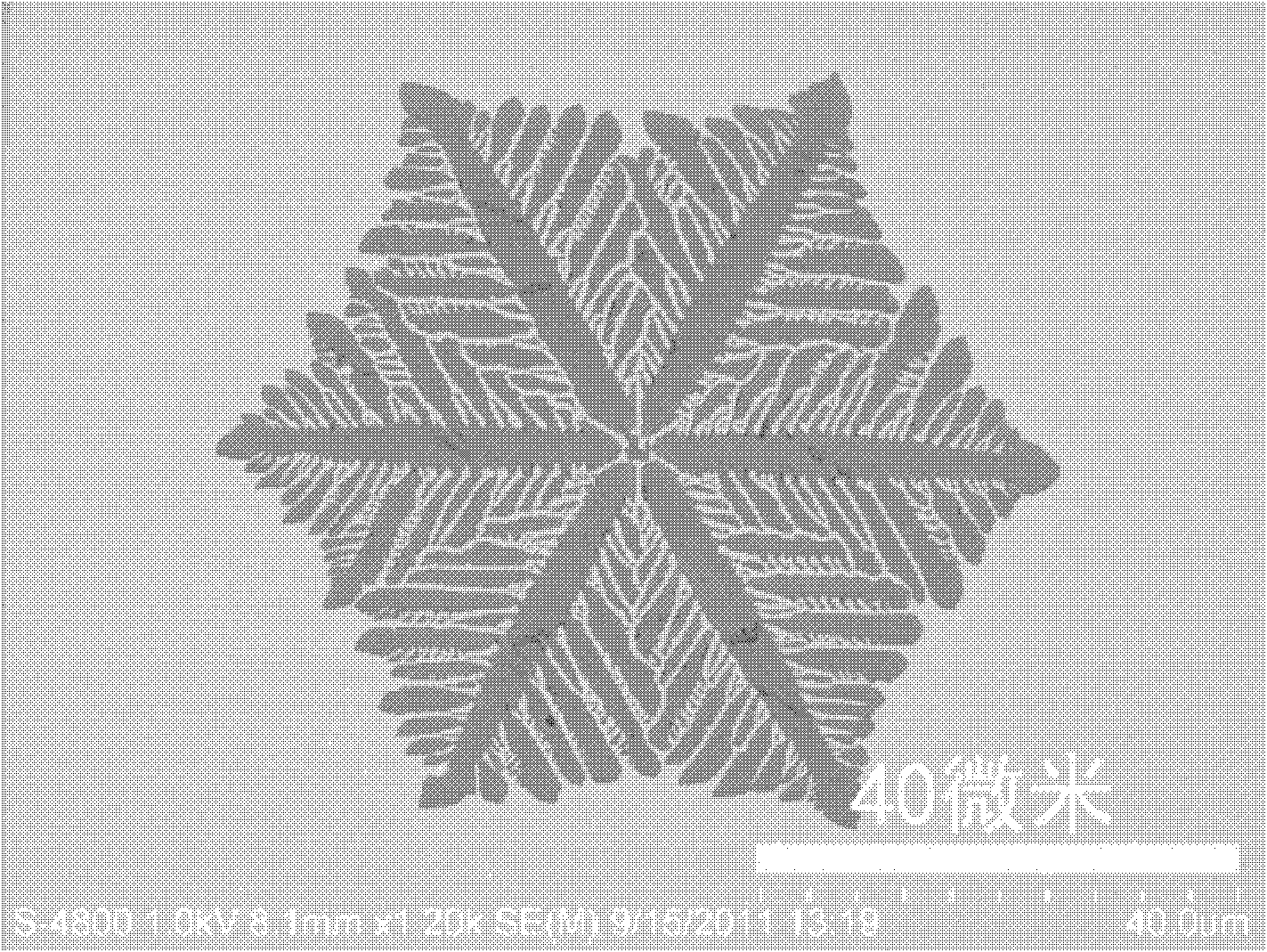

InactiveCN102491315ASimple and fast operationImprove product qualityGrapheneHydrogenConcentration ratio

The invention discloses a method for preparing graphene. The method comprises the following steps of: after heating a substrate loaded with a copper metal layer to a bulk phase melting point and above the bulk phase melting point of copper in the flowing anaerobic and anhydrous atmosphere, introducing a carbon-containing compound into a system to perform chemical vapor deposition to obtain the graphene on the surface of the copper metal layer after the deposition. According to the method, the graphene with various shapes is prepared by introducing inert gases under a liquid state copper catalyst. The method is easy and convenient to operate and high in quality of products, and can be used for large-scale production. The shapes of the graphene can be regulated and controlled by regulating a concentration ratio of the inert gases to carbon-containing substances and hydrogen.

Owner:INST OF CHEM CHINESE ACAD OF SCI

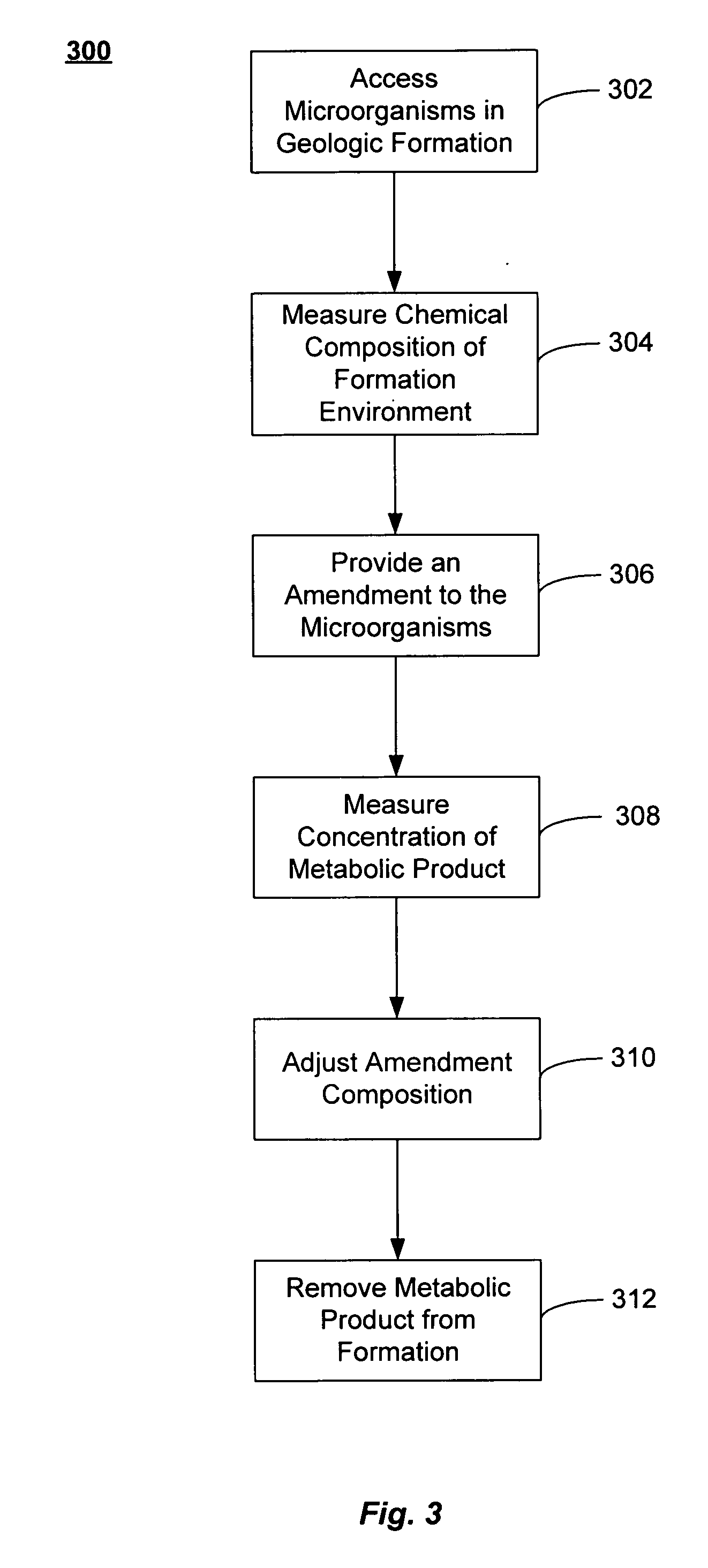

Chemical amendments for the stimulation of biogenic gas generation in deposits of carbonaceous material

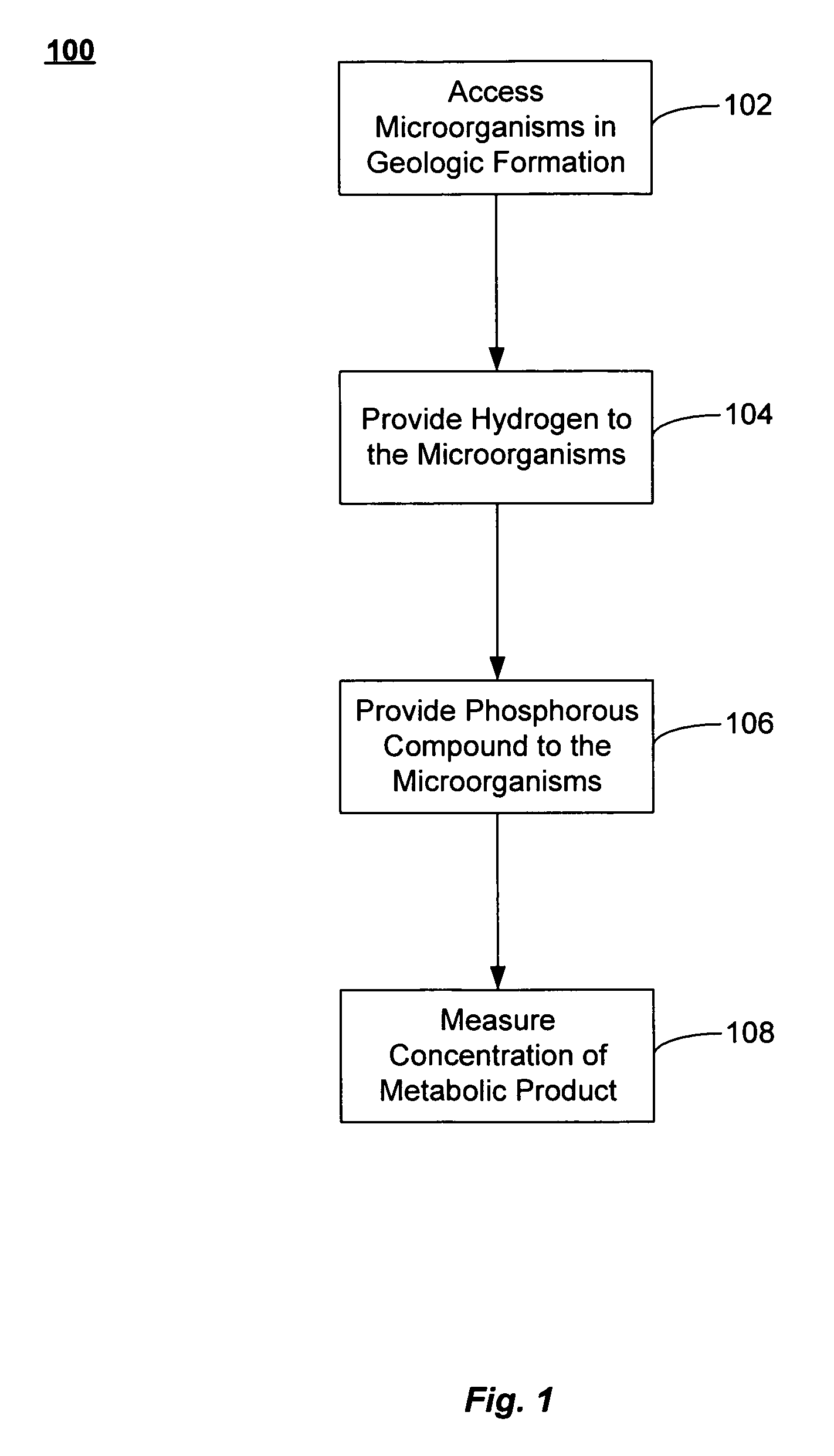

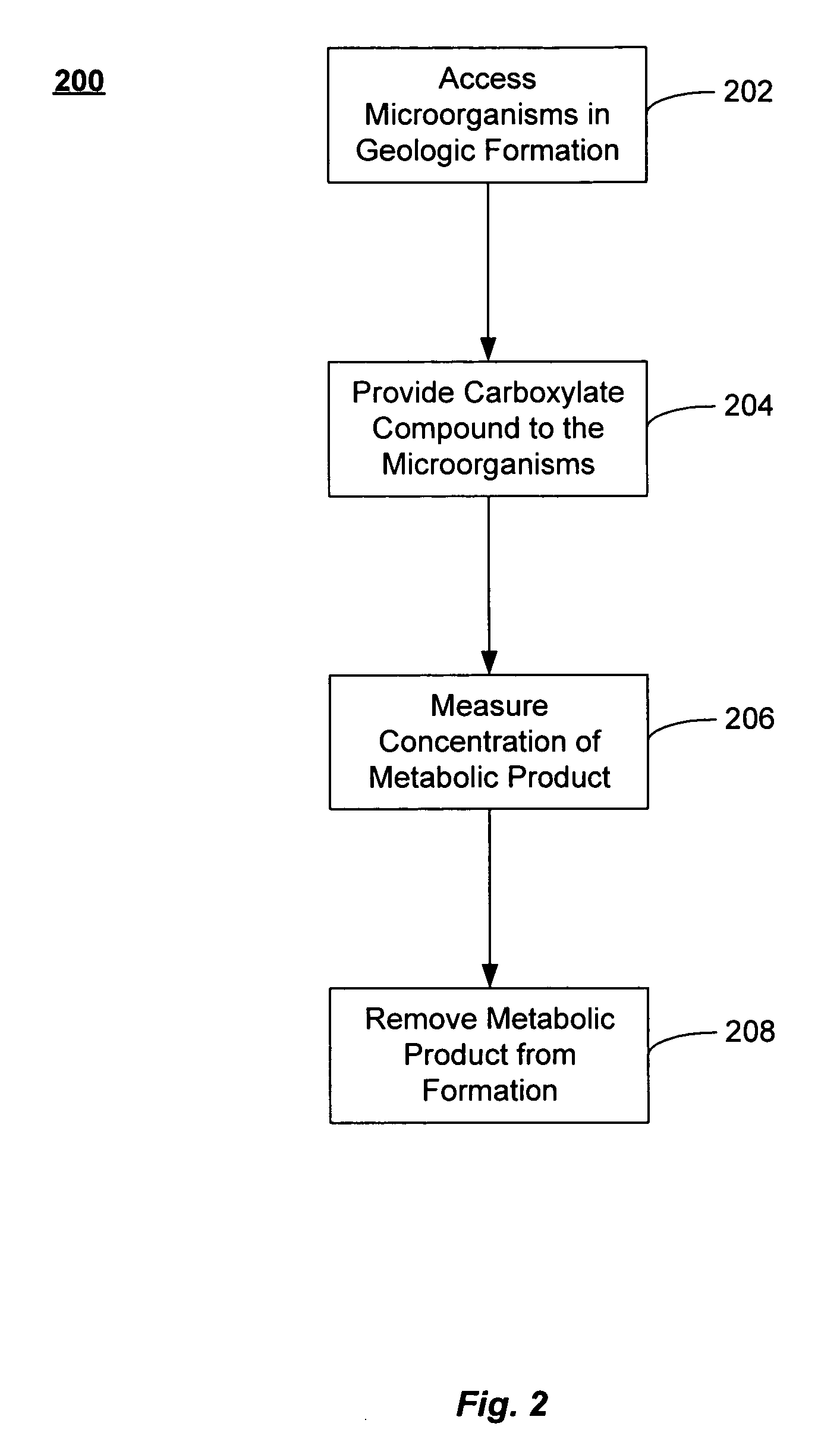

Methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content are described. The methods may include accessing a consortium of microorganisms in a geologic formation that includes a carbonaceous material. They may also include providing hydrogen and one or more phosphorous compounds to the microorganisms. The combination of the hydrogen and phosphorous compounds stimulates the consortium to metabolize the carbonaceous material into the metabolic product with enhanced hydrogen content. Also, methods of stimulating biogenic production of a metabolic product with enhanced hydrogen content by providing a carboxylate compound, such as acetate, to a consortium of microorganisms is described. The carboxylate compound stimulates the consortium to metabolize carbonaceous material in the formation into the metabolic product with enhanced hydrogen content.

Owner:TRANSWORLD TECH

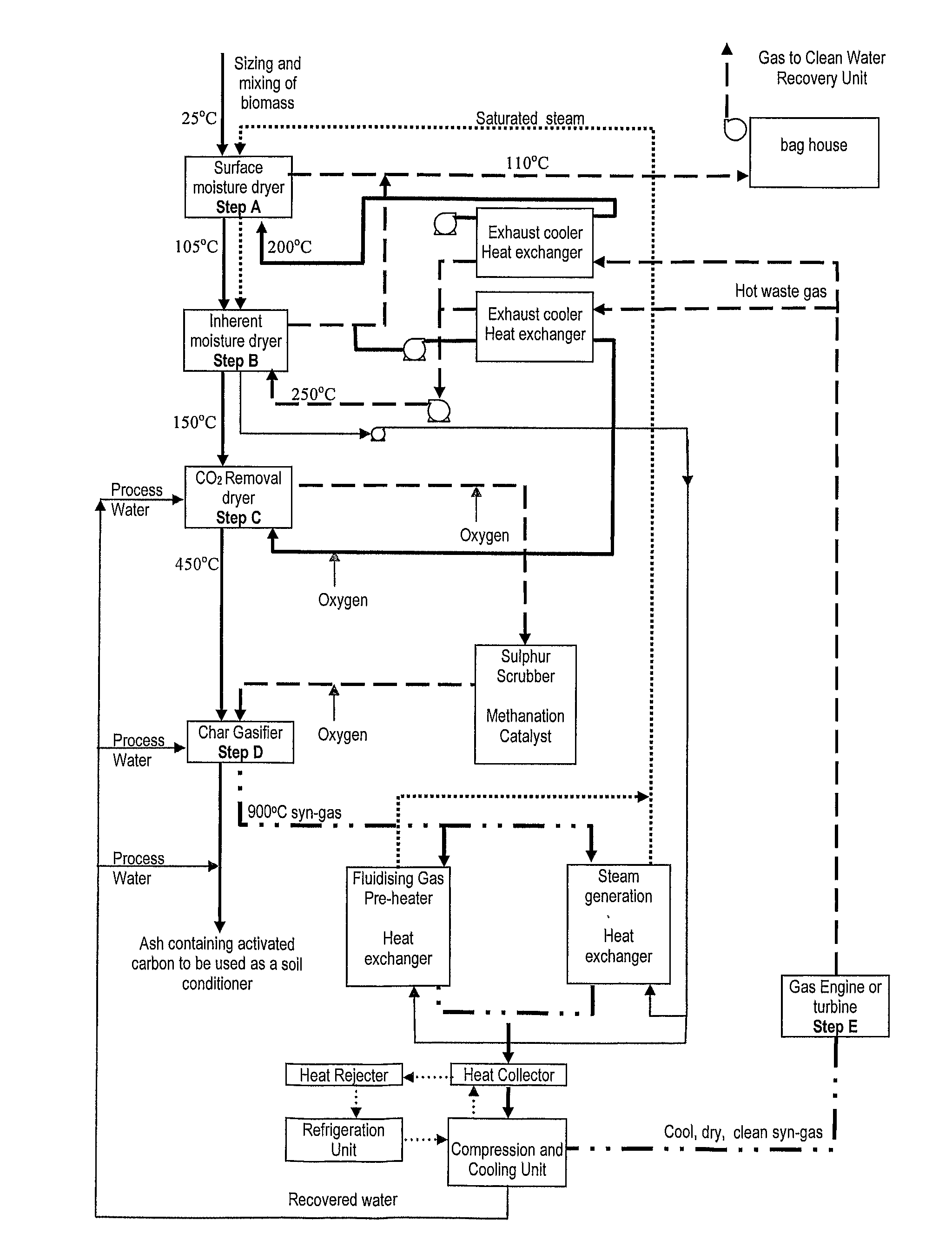

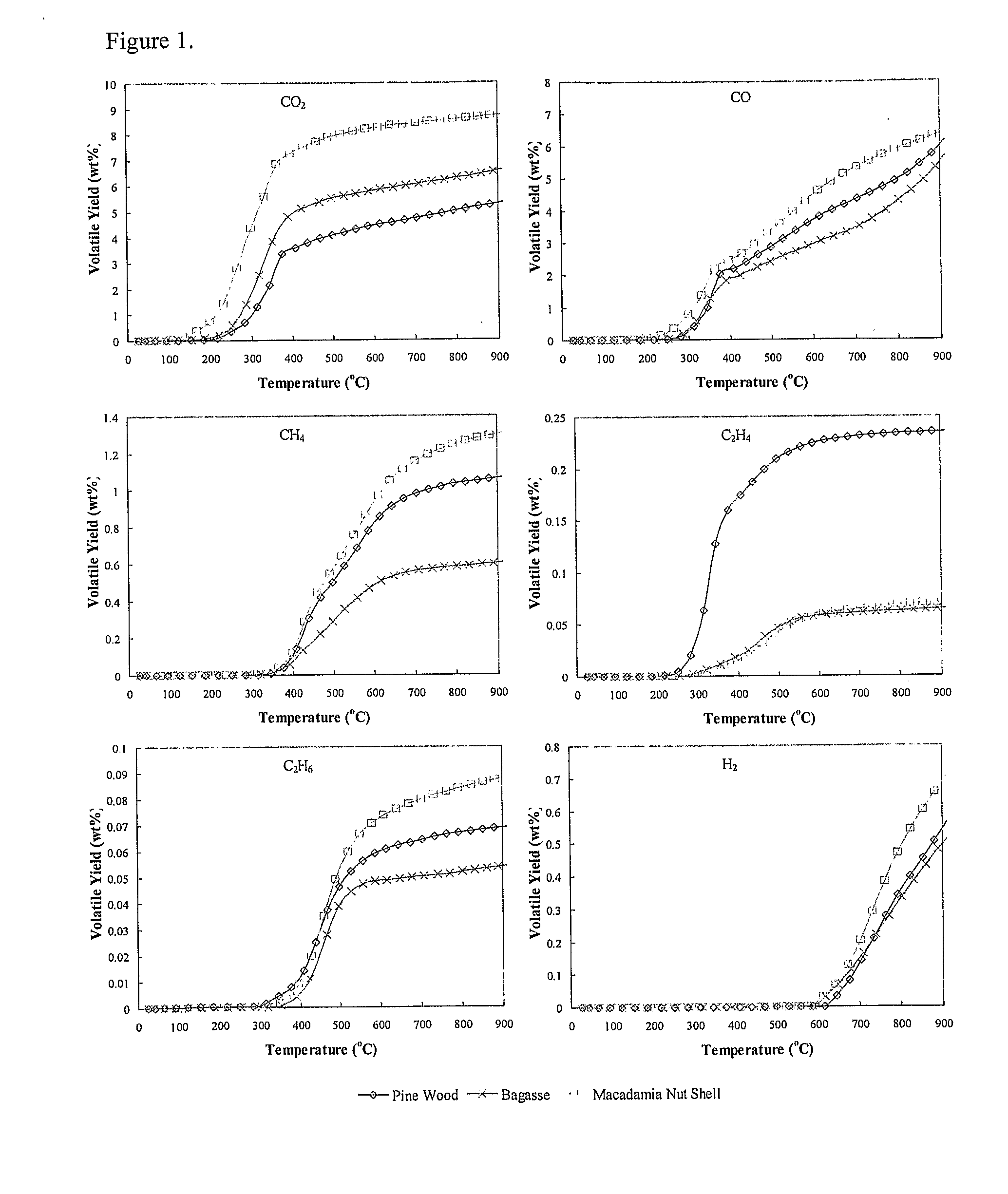

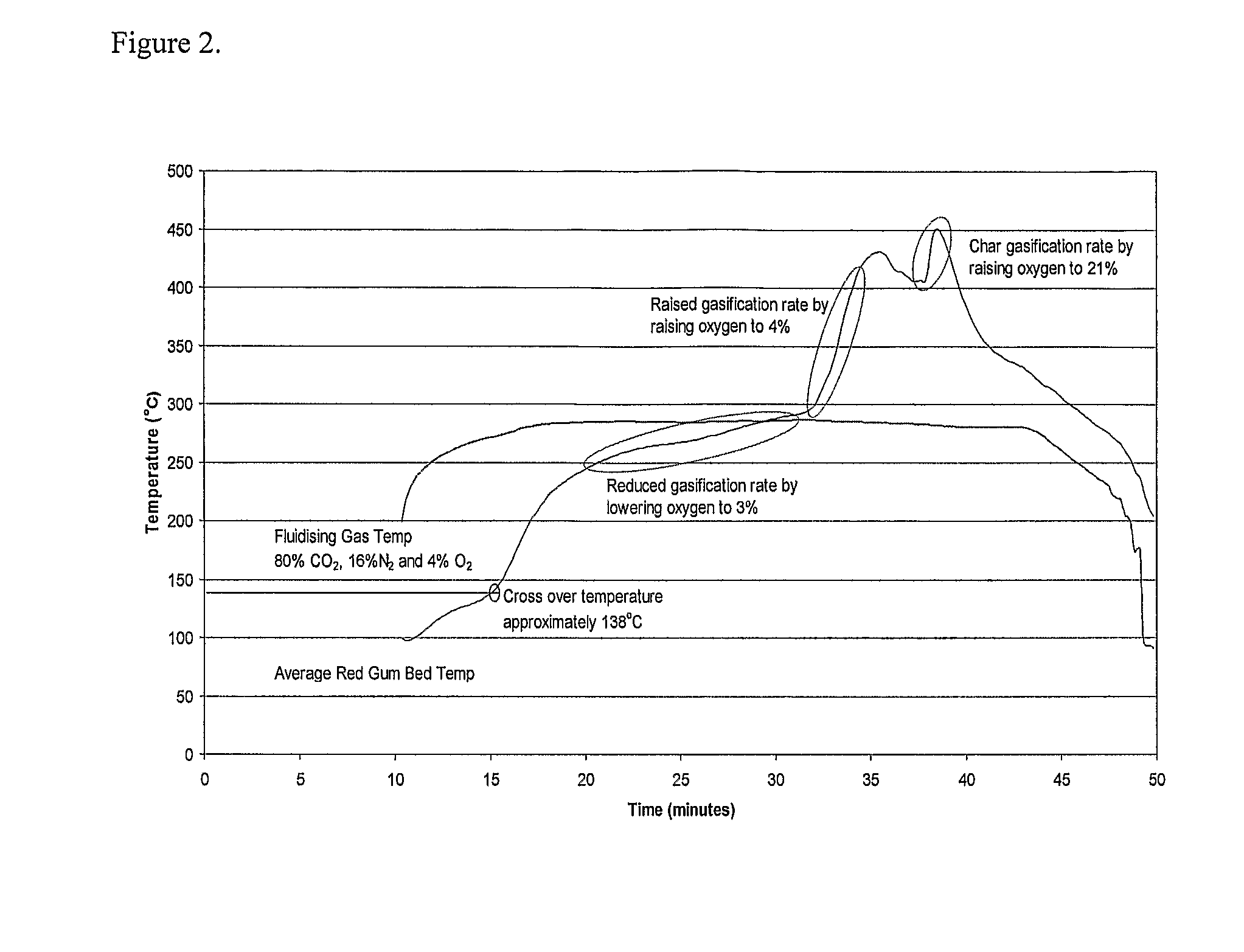

Drying and gasification process

InactiveUS20100115841A1Reduce surface moistureReducing inherent moistureDrying solid materials with heatBiofuelsSyngasSurface moisture

A process for producing syngas from a carbonaceous substance and / or treating a carbonaceous substance, the process including the following steps: a) reducing the surface moisture of the carbonaceous substance; b) reducing the inherent moisture of the carbonaceous substance; and, c) gasifying the carbonaceous substance to produce syngas, wherein at step a) the carbonaceous substance is directly contacted with a hot gas at a temperature of between 50° C. to 250° C., and / or the carbonaceous substance is indirectly contacted with saturated steam at a temperature of between 105° C. and 250° C.

Owner:CORK DAVID

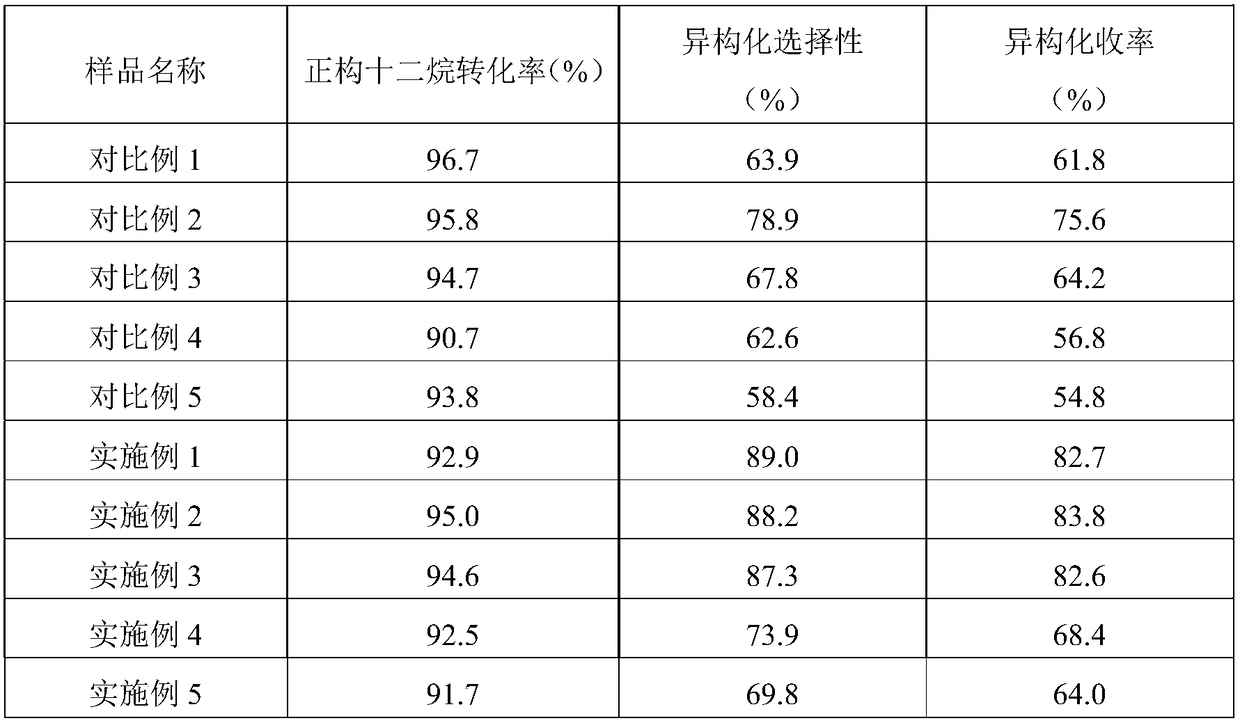

Isomerization catalyst, preparation and application

ActiveCN108126735AHigh selectivityHigh yieldMolecular sieve catalystsHydrocarbon oils refiningAlkaneMolecular sieve

The invention discloses a preparation method and an application of an isomerization catalyst. The method comprises the following specific steps: filling pore channels of a molecular sieve with hydrocarbon compounds firstly, then performing heating treatment to obtain a molecular sieve support with the blocked pore channels of the molecular sieve, supporting metal active components on the support,and performing drying and reduction to obtain the target catalyst. Part of organic matter is transformed into carbonaceous matter to block the pore channels of the molecular sieve by controlling treatment conditions, so that pore volume and pore channel depth of the molecular sieve are regulated. Compared with the prepared catalyst in the prior art, the catalyst prepared with the method has higherisomerization selectivity and isomerization yield in an isomerization reaction of n-alkanes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

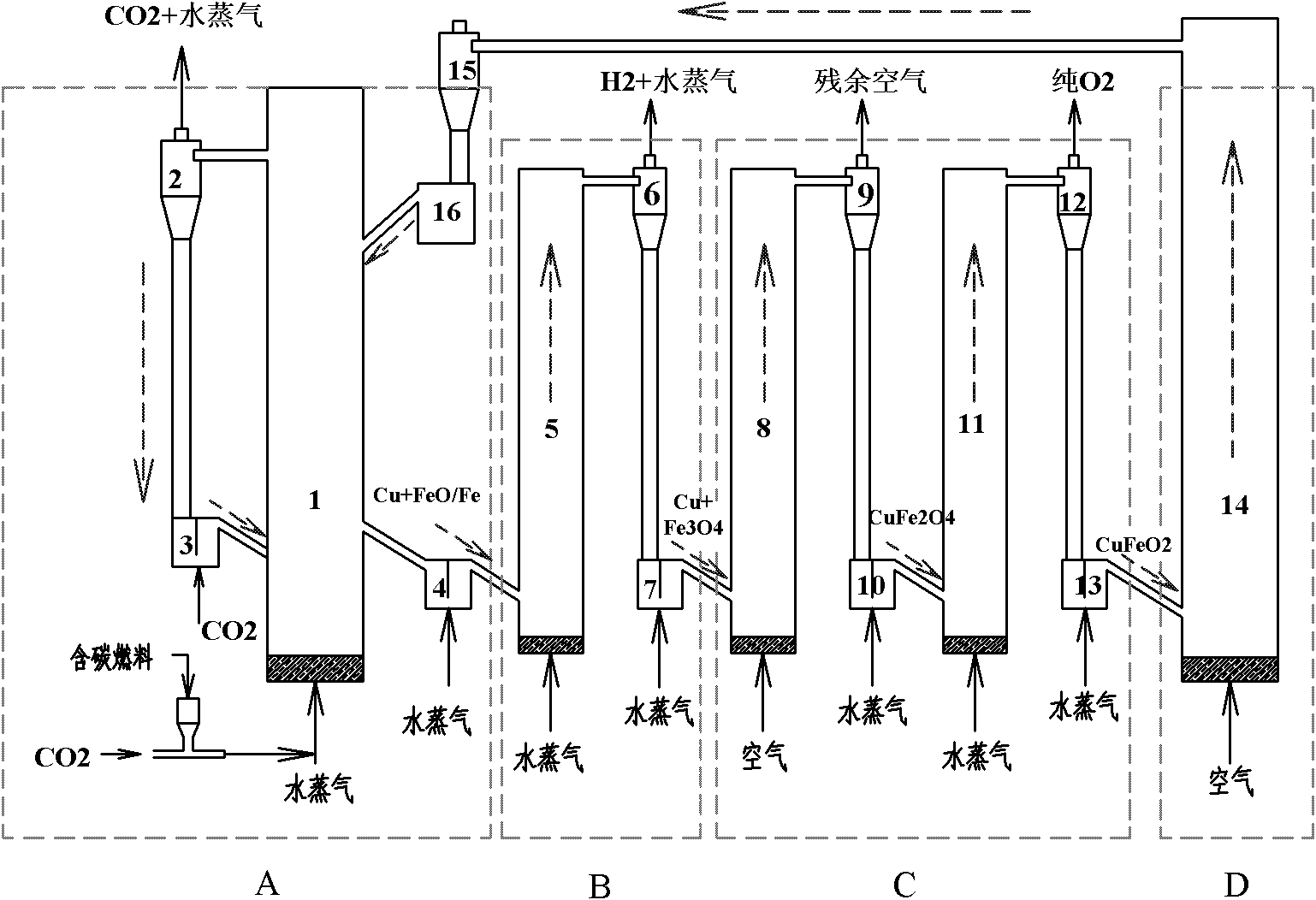

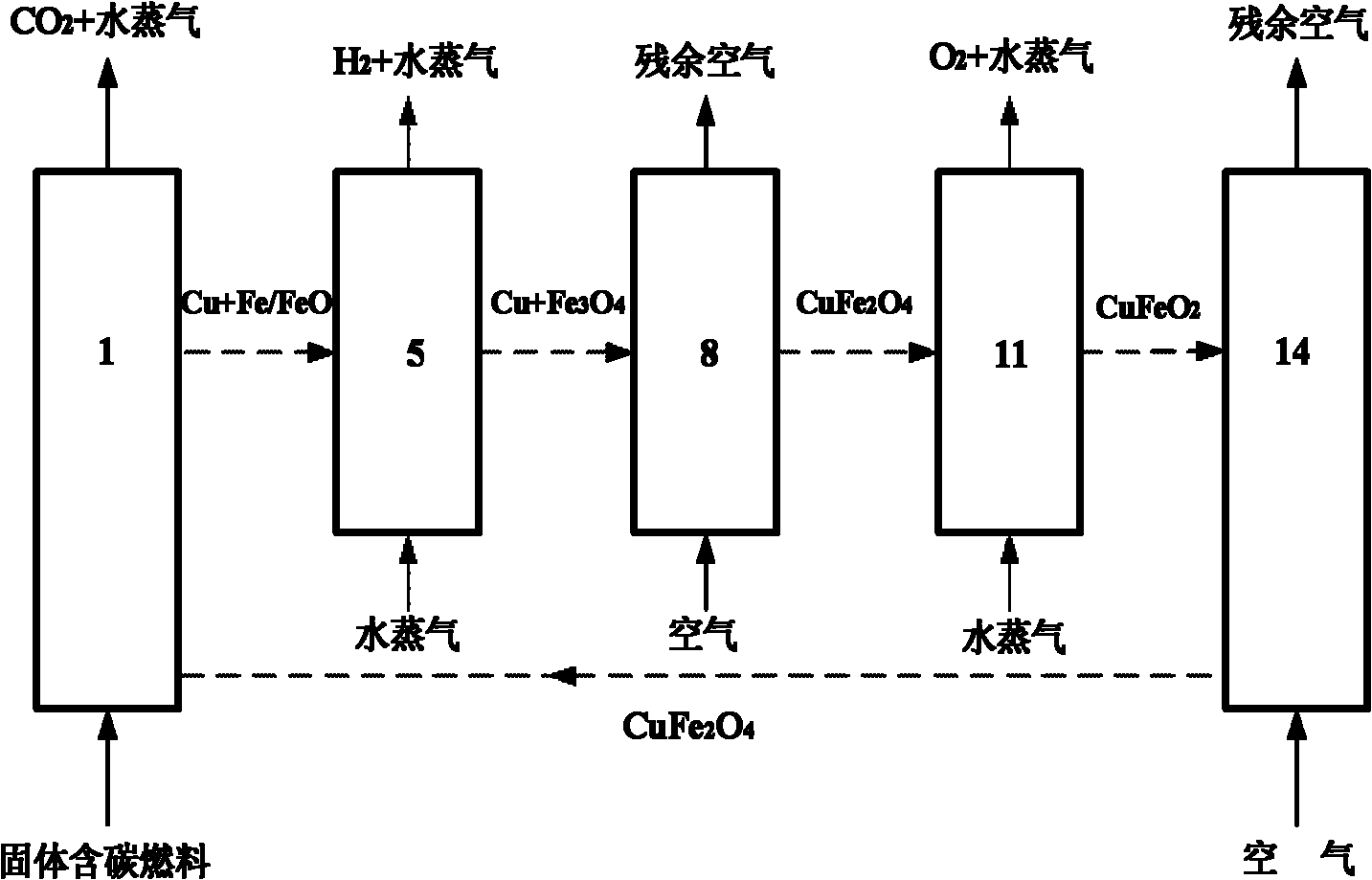

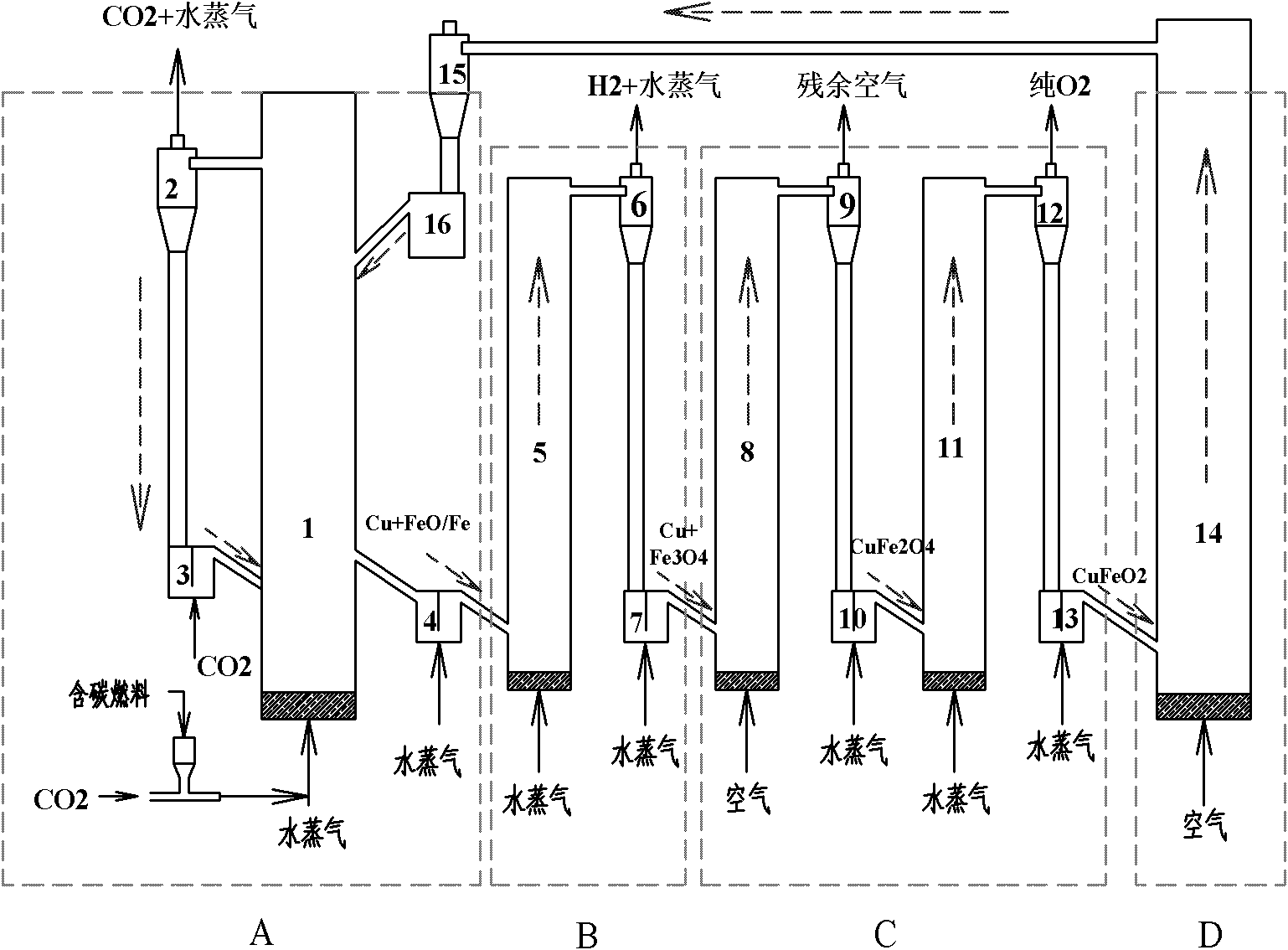

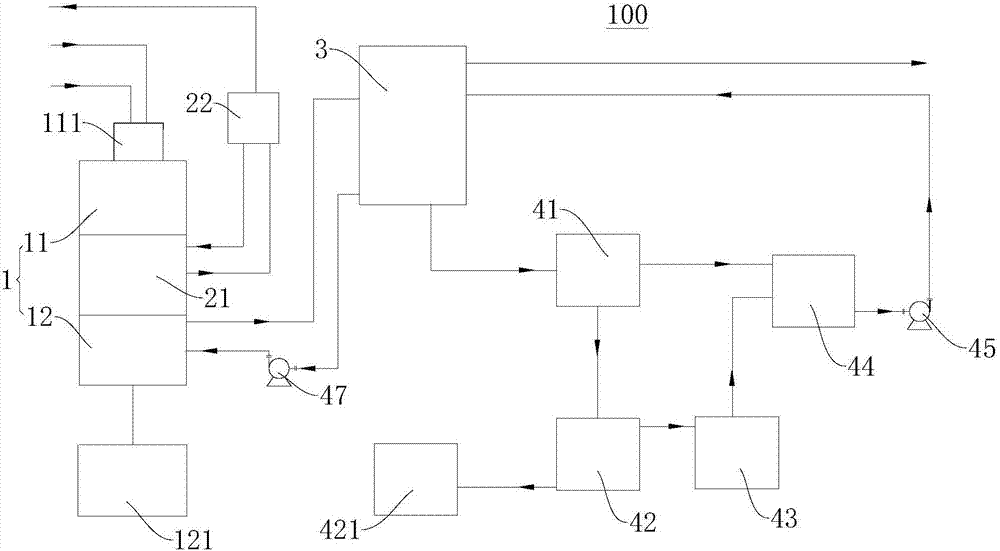

Chain type hydrogen and oxygen production integrated method and device

InactiveCN101870455ALarge reservesWide variety of sourcesHydrogen productionIron compoundsCarbonaceous matterChemistry

The invention provides a chain type hydrogen and oxygen production integrated method, comprising the following steps: CuFe2O4 and solid carbonaceous matters are subjected to reduction reaction to obtain reduction products of Cu, Fe and FeO, wherein the Fe, the FeO and vapour are subjected to oxidation reaction to generate H2 and Fe3O4, and the residual Cu is in oxidation reaction with the Fe3O4 and air to generate CuFe2O4 by oxidation; and the CuFe2O4 is heated and decomposed to generate O2 and CuFeO2, and the CuFeO2 and air are in oxidation reaction to generate CuFe2O4 once again. The invention also provides a device for realizing the method, which comprises the main assemblies of a bubbling fluidized bed reactor, a cyclone separator, a sealing valve and a rapid fluidized bed. The invention can obtain H2 and O2 by chain type continuous preparation, has simple process and low energy consumption, can obtain H2 and O2 with the high purity approximate to 100%, realizes CO2 zero emission in the hydrogen production process and has broad application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

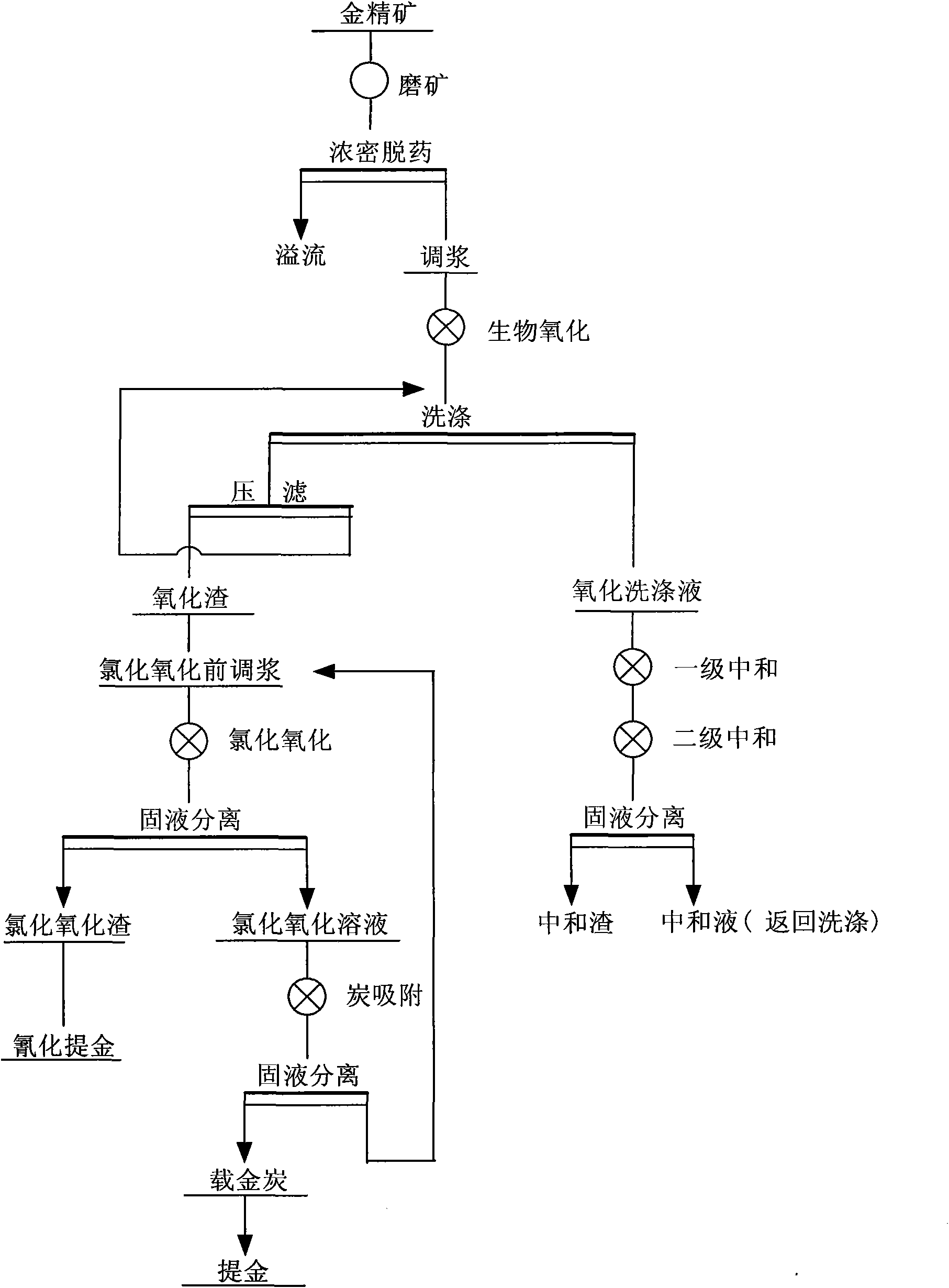

Secondary oxidation pretreatment process for arsenic, sulphur and carbon-containing difficultly treated gold concentrate

InactiveCN102011013ASolve the technical bottlenecks that are not suitable for processing carbon-containing refractory concentratesNo pollution in the processProcess efficiency improvementHypochloriteBiological oxidation

The invention discloses a secondary oxidation pretreatment process for arsenic, sulphur and carbon-containing difficultly treated gold concentrate. The process sequentially comprises the following steps of: grinding concentrate again, removing a reagent, performing biological oxidation, chloridizing and oxidizing and cyaniding to leaching gold. In the process, the gold concentrate is oxidized by a biological oxidation process, and oxidizing slag is treated by using hypochlorite, so that the harmful influence of carbonaceous matter on the cyaniding and gold leaching is reduced greatly by chloridizing and oxidizing; and the process can effectively improve gold recovery rate, and is simple and environmental-friendly.

Owner:CHANGCHUN GOLD RES INST +1

Hydrocarbon-reforming catalyst and a method of manufacturing thereof

Owner:JAPAN PETROLEUM EXPLORATION CO LTD

Nonaqueous electrolyte secondary cell with a plural-layer carbonaceous negative electrode

InactiveUS6723471B2High specific capacityImprove propertiesElectrode thermal treatmentLayered productsX-rayGraphite

Enhancement of the storage property at a high temperature and discharge characteristics at a low temperature of a nonaqueous electrolyte secondary cell is intended. A negative electrode material which is prepared by covering the surface of a nucleus made of a graphite powder with a carbonaceous matter, the graphite powder having a specified plane interval, spectrum value, mean particle size, specific surface area, tapping density, and (110) / (004) X-ray peak intensity ratio, is used in the nonaqueous electrolyte secondary cell.

Owner:MITSUBISHI CHEM CORP

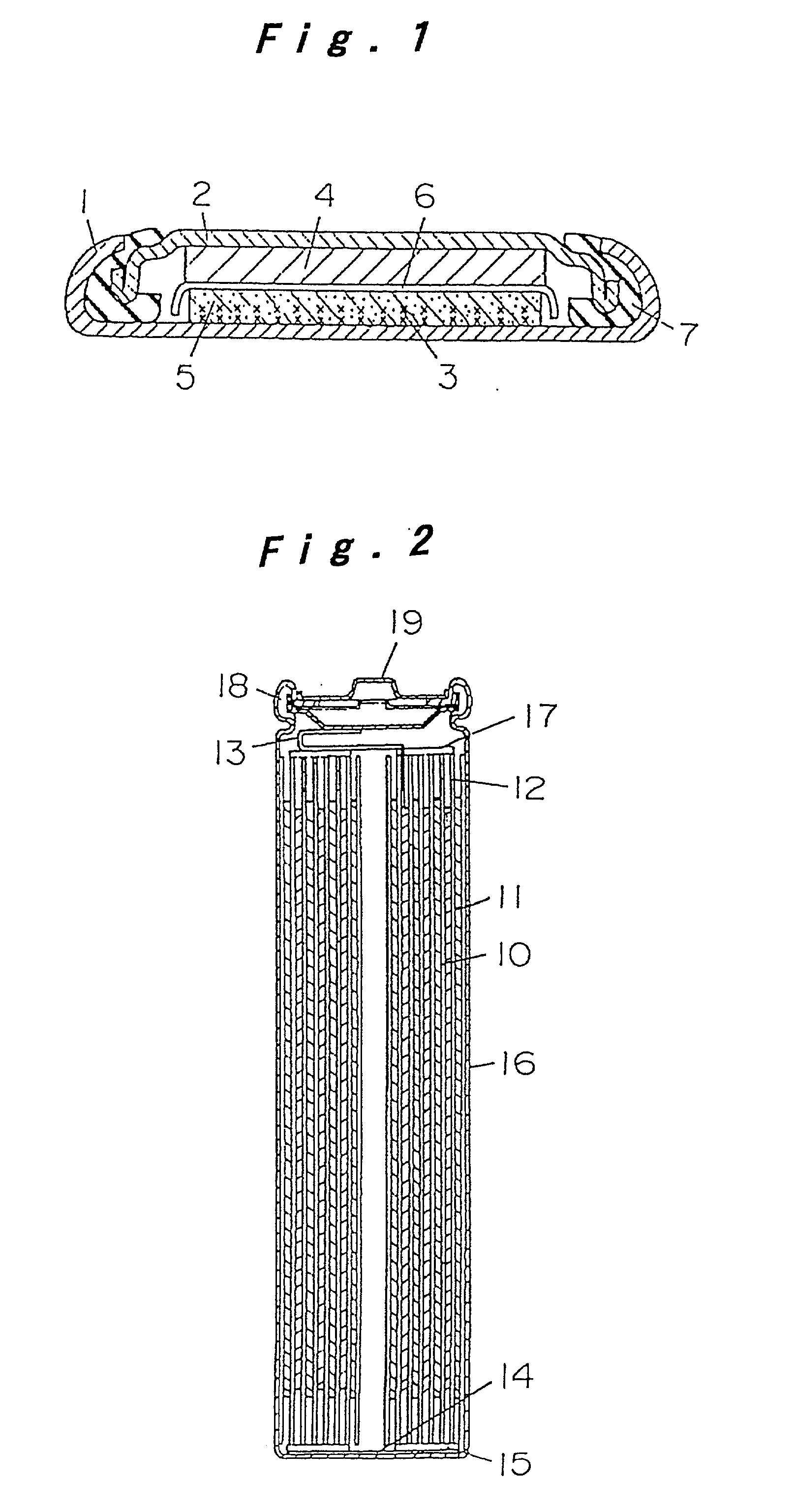

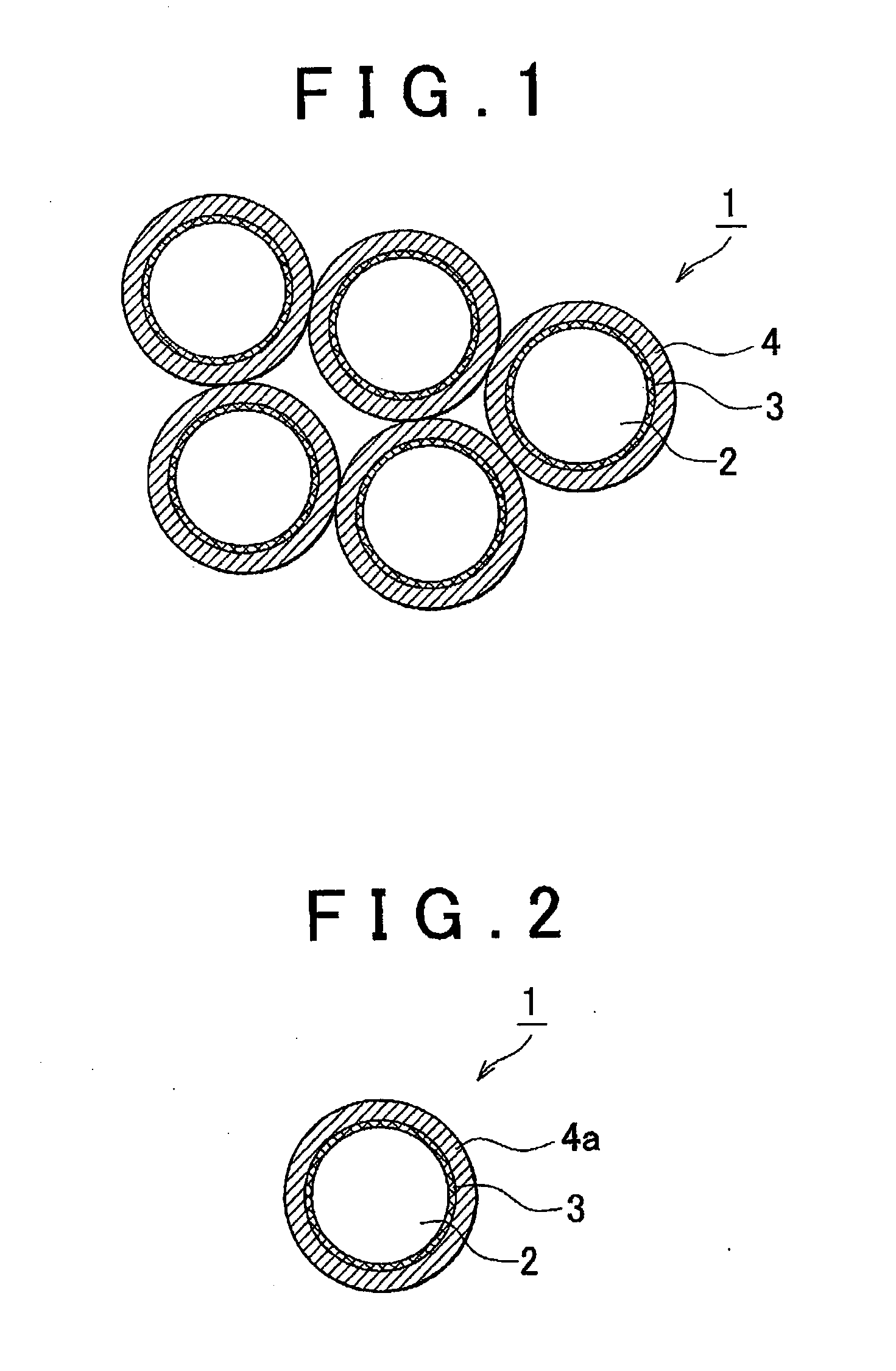

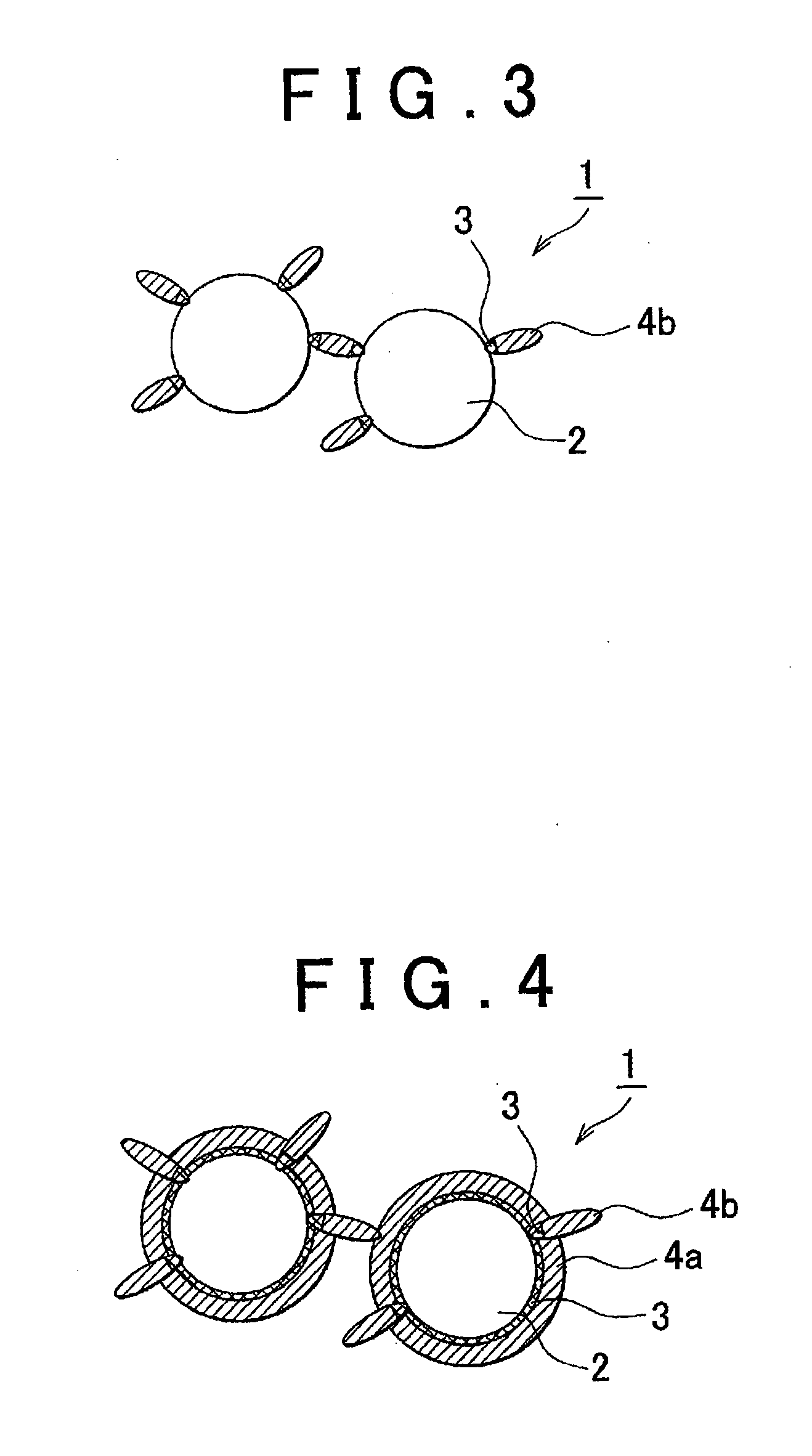

Negative electrode active material, lithium secondary battery using the same, and method of manufacturing negative electrode active material

ActiveUS20100310939A1Avoid crackingExcellent cycle characteristicsElectrode manufacturing processesSecondary cellsLithiumMaterials science

A negative electrode active material characterized in that carbonaceous matter essentially consisting of carbon adheres to the surface of a tin particle essentially consisting of tin, with a mixture phase, in which tin and carbon are mixed, interposed between the carbonaceous matter and the tin particle.

Owner:TOYOTA JIDOSHA KK

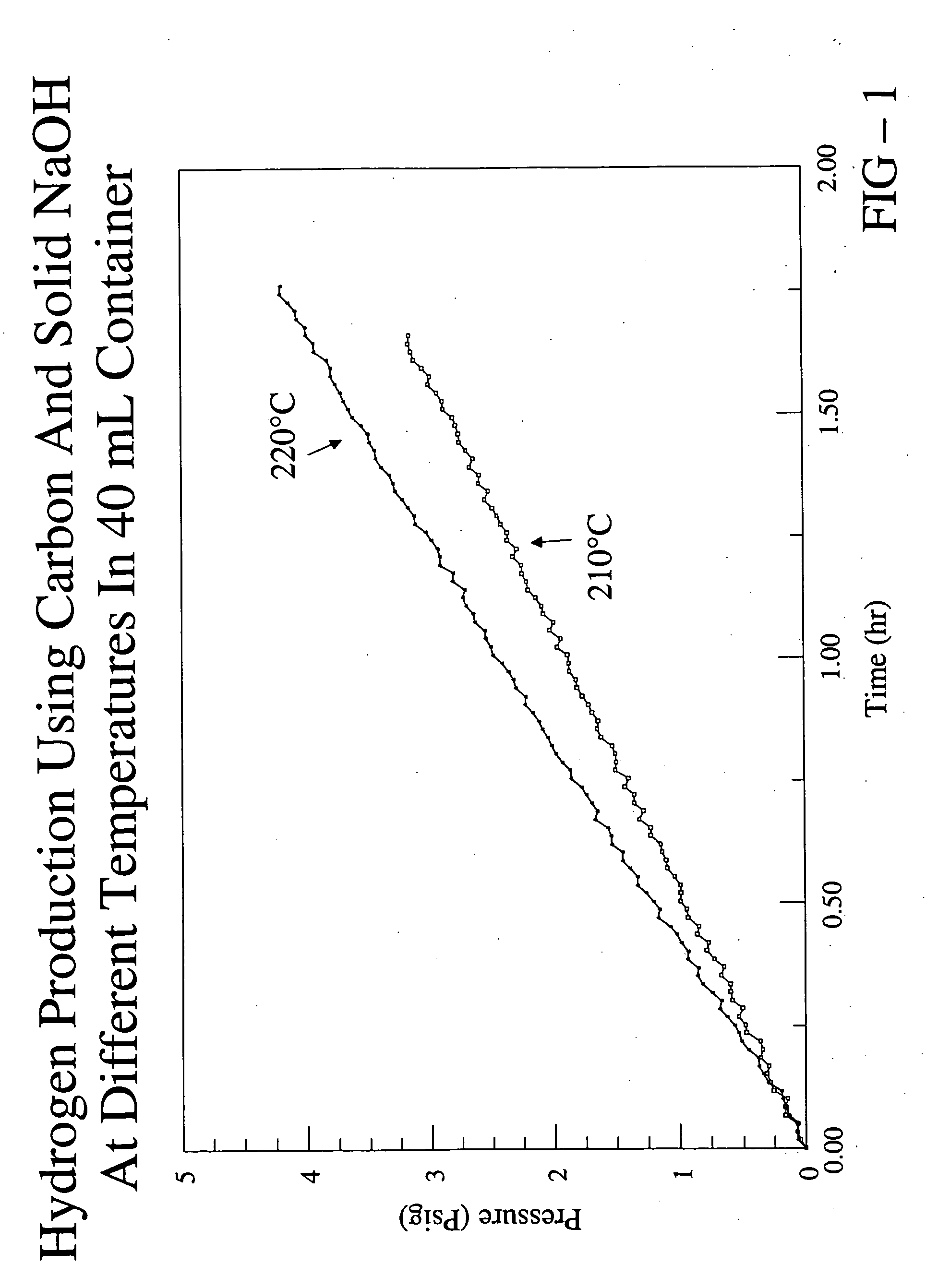

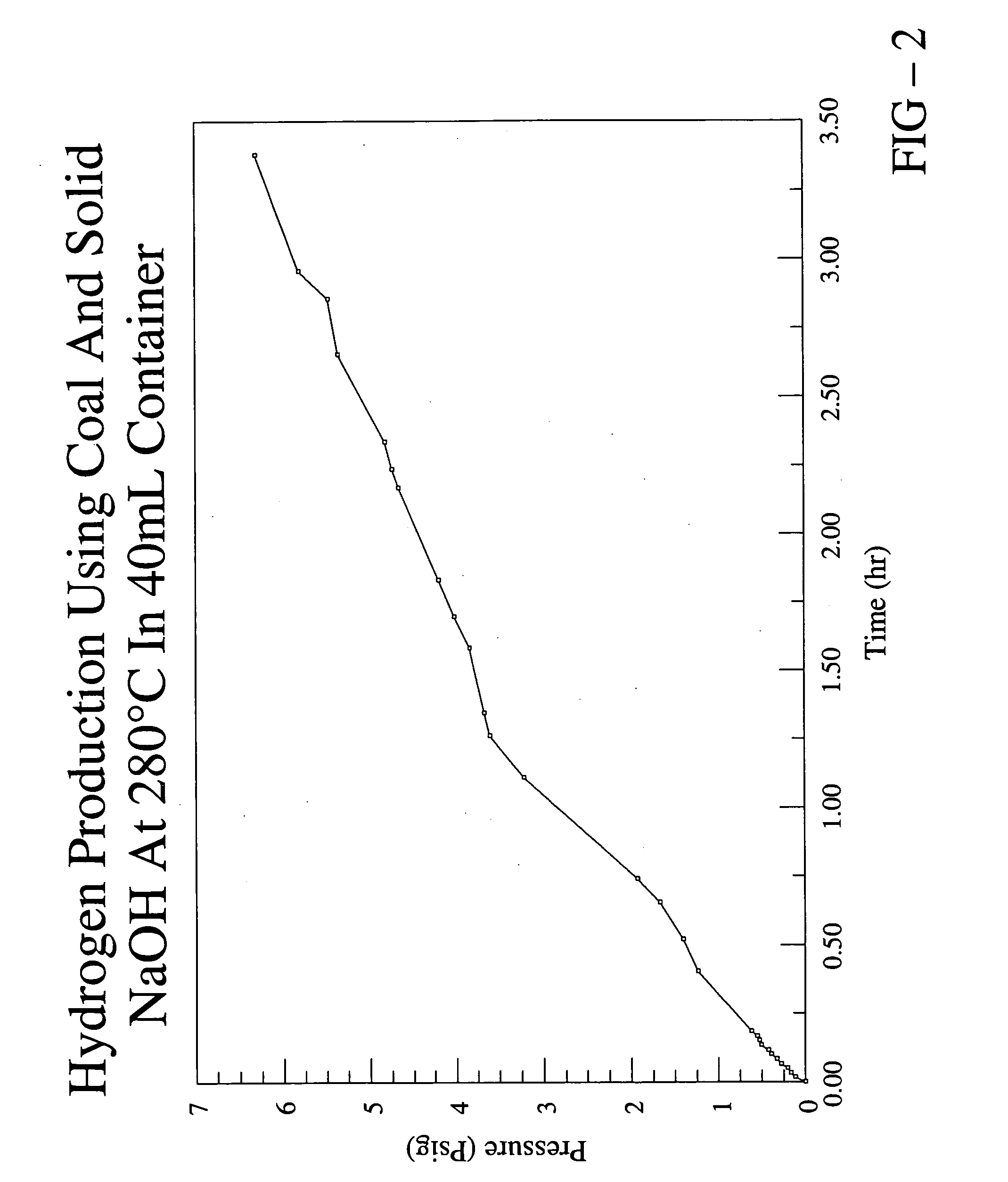

Base-facilitated production of hydrogen from carbonaceous matter

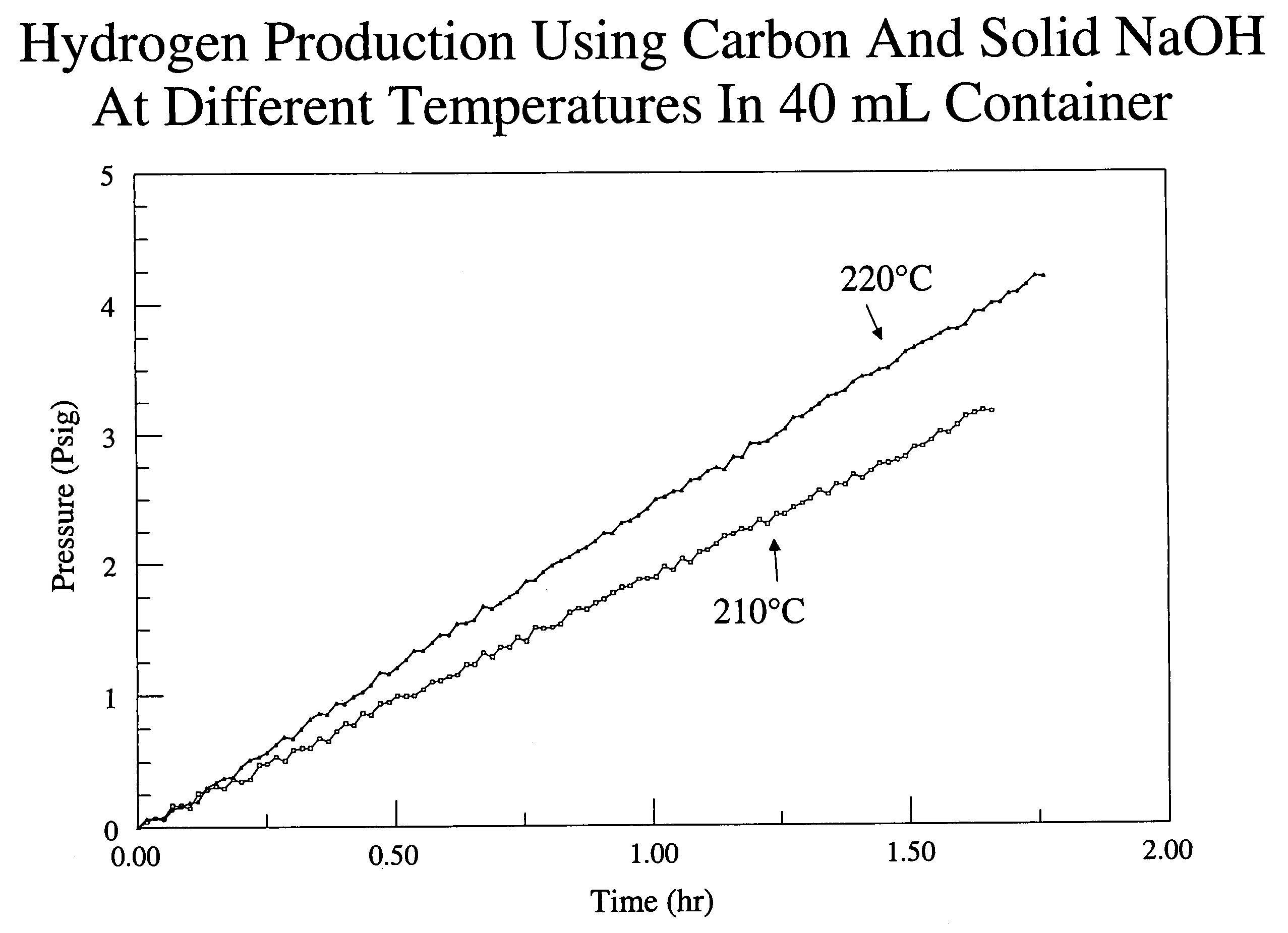

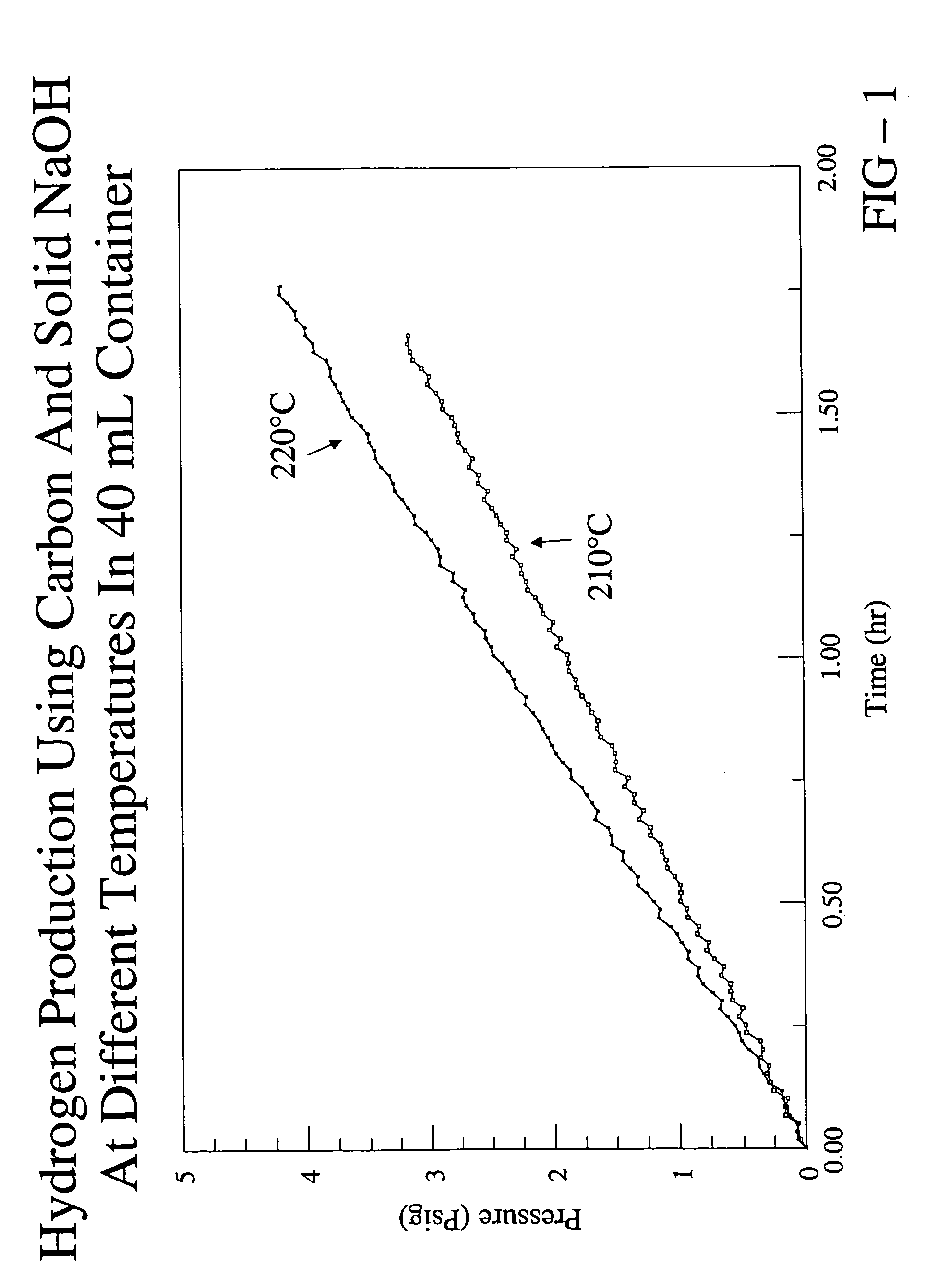

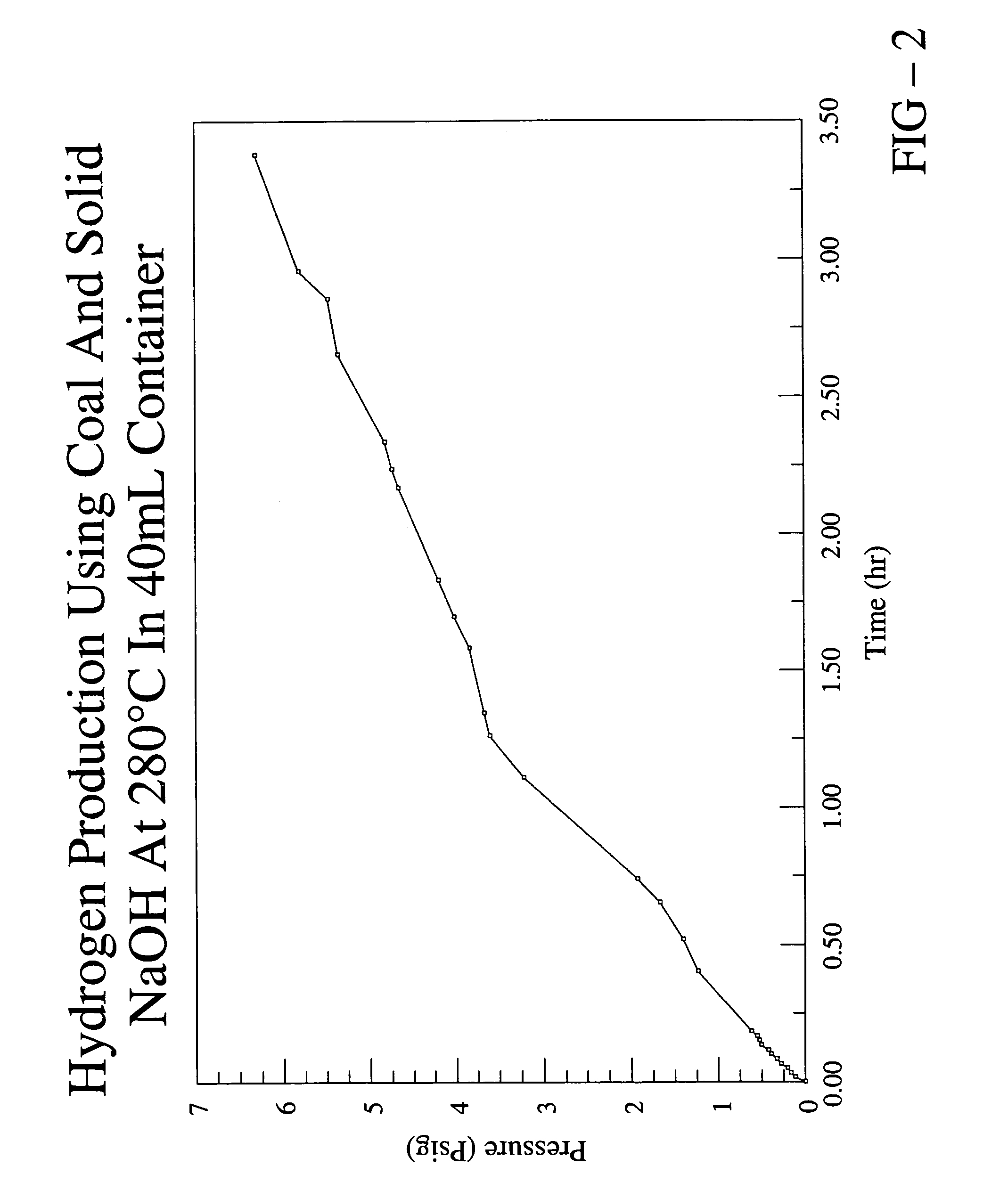

InactiveUS20050163705A1Improve thermodynamic spontaneityFaster rateProductsElectrolysis componentsHydrogenCoal

A base-facilitated process for producing hydrogen. Hydrogen is produced from a reaction of carbonaceous matter with a base and water, preferably through the formation of a bicarbonate or carbonate by-product. The base-facilitated hydrogen-producing reactions are thermodynamically more spontaneous and are able to produce hydrogen gas at less extreme reaction conditions than conventional reformation or gasification reactions of carbonaceous matter. In another embodiment, the instant reactions permit the production of hydrogen from carbonaceous matter without the production of carbon dioxide or carbon monoxide. In a preferred embodiment, the carbonaceous matter is coal or a derivative thereof.

Owner:TACTICAL FUEL CELLS

Ore-dressing process by using carbon-contg. block to reduce lean iron ore for prodn. of magnetite

InactiveCN1861265AWide adaptabilityStrong ability to remove harmful impuritiesMagnetic separationMagnetiteWater cooling

A reductive ore dressing technology for preparing the magnetite concentrate from poor hematitie or poor limonite includes such steps as pulverizing said poor hematite or limonite and carbon contained substance, mixing, cold die pressing to obtain lumps, heating at 280-1200 deg.C for 3-100 min to reduce Fe2O3 to Fe3O4, water cooling, grinding and magnetic separation.

Owner:纪礽辉

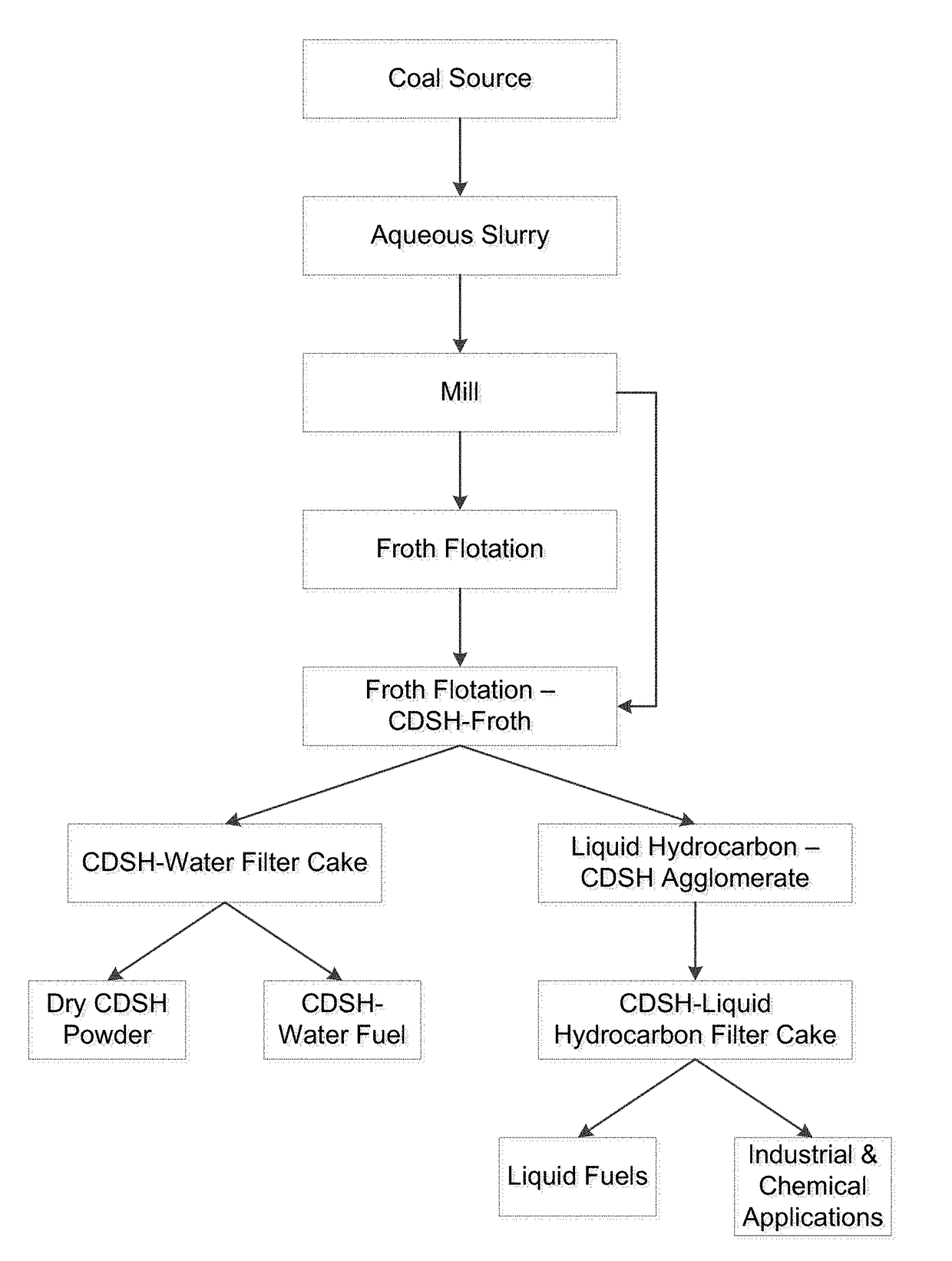

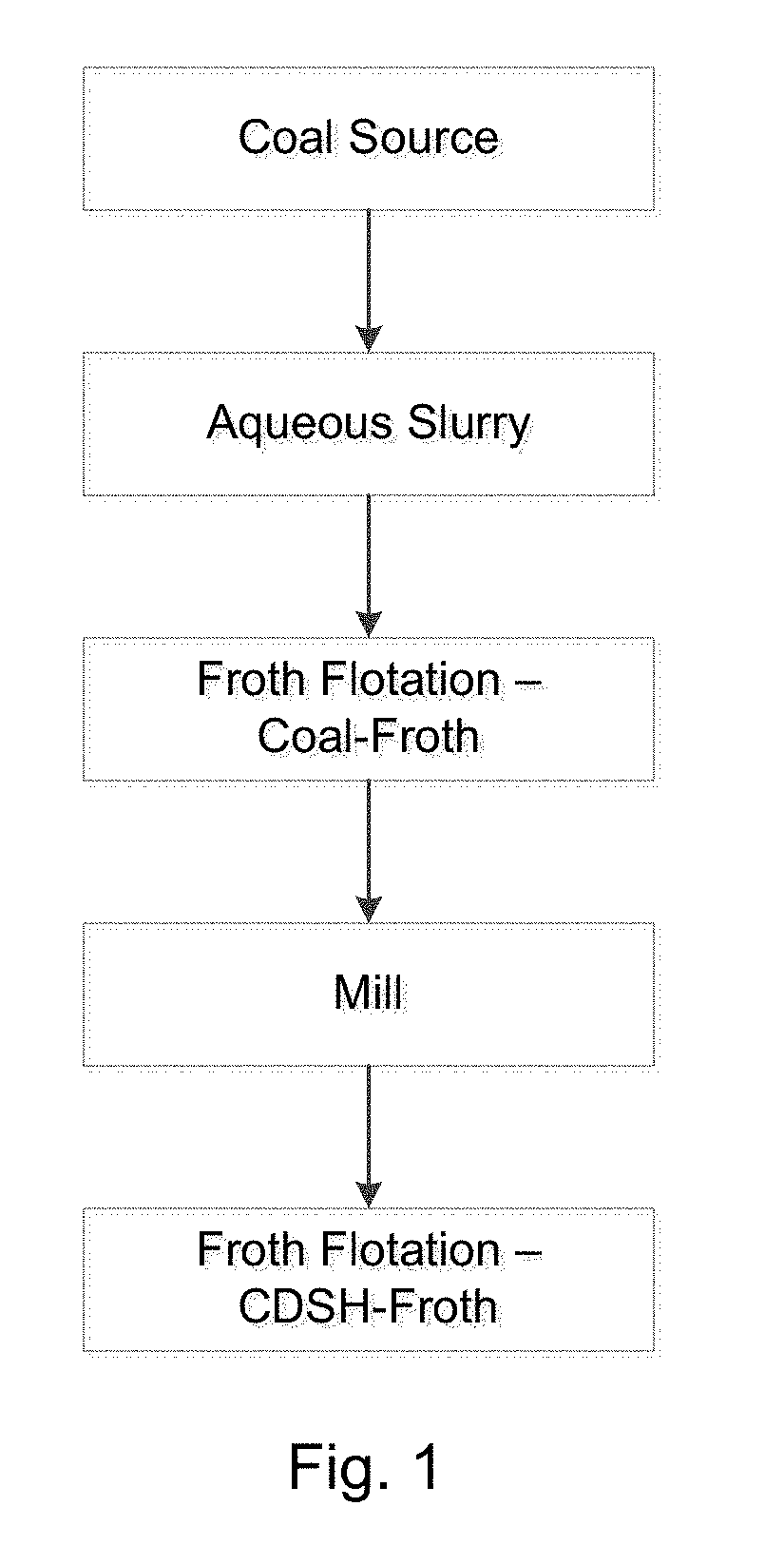

Coal-derived solid hydrocarbon particles

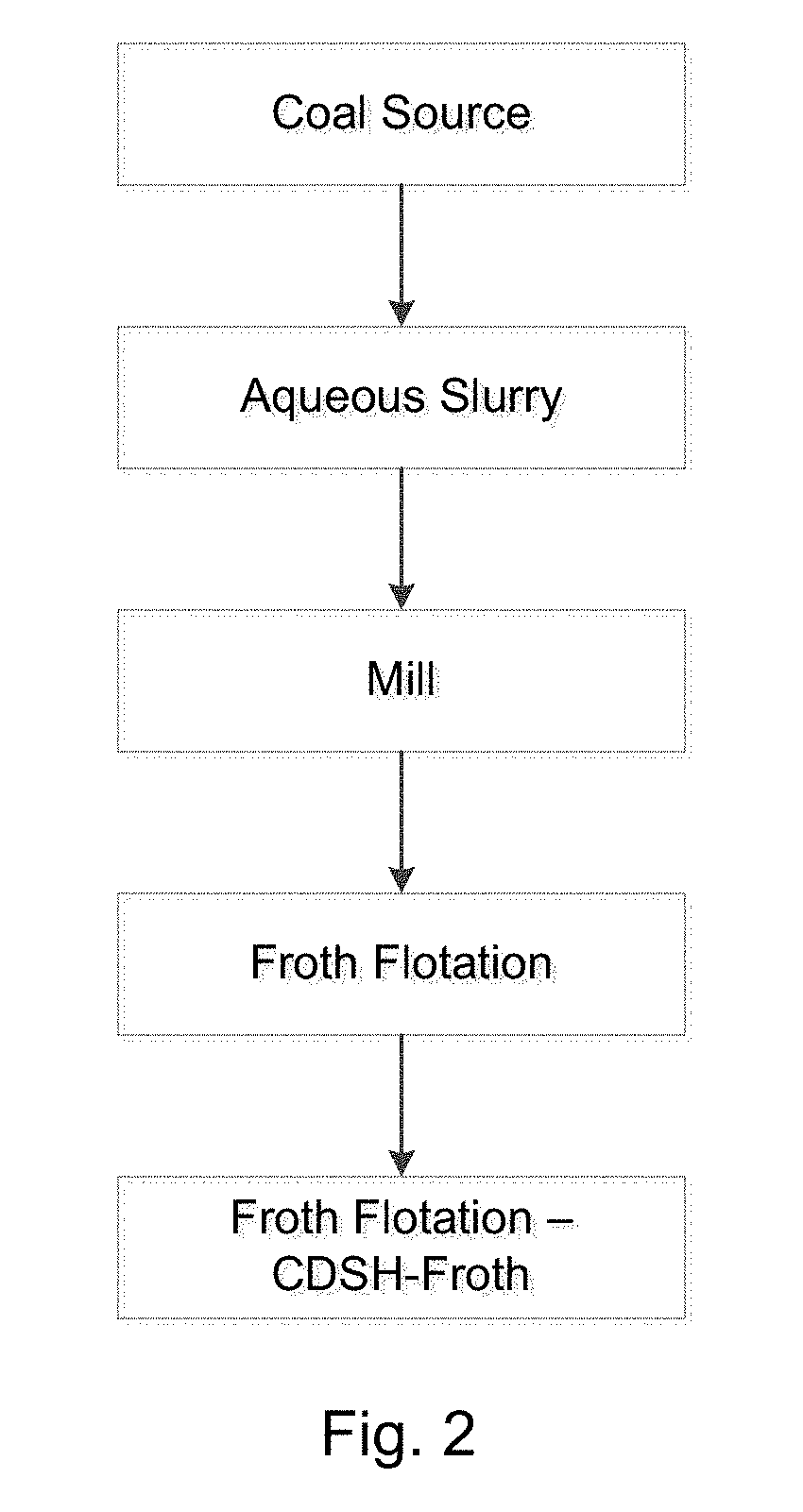

ActiveUS20180134977A1Reduce particle agglomerationPrevent oxidationGaseous fuelsSolid fuelsLiquid hydrocarbonsSolid particle

The coal-derived solid hydrocarbon particles are discrete particles of coal-derived carbonaceous matter having a particle size less than about 10 μm that are substantially free of inherent or entrained mineral matter. The particles of have an average particle size in the range from 1 μm to 8 μm. The particles of coal-derived carbonaceous matter are milled to a size approximately the same as a size of coal-derived mineral matter inherent in the coal source to release inherent coal-derived mineral matter particles such that the particles of carbonaceous matter and the particles of mineral matter are discrete and separable solid particles. Following separation, less than 1.5 wt. % discrete coal-derived mineral matter particles are associated with the discrete particles of coal-derived carbonaceous matter. Particles of coal-derived solid hydrocarbon matter are blended with a gaseous or liquid hydrocarbon fuel to form a two-phase hydrocarbon fuel feedstock.

Owner:EARTH TECH USA

Base-facilitated production of hydrogen from carbonaceous matter

InactiveUS7588676B2Improve thermodynamic spontaneityFaster rateProductsElectrolysis componentsHydrogenCoal

A base-facilitated process for producing hydrogen. Hydrogen is produced from a reaction of carbonaceous matter with a base and water, preferably through the formation of a bicarbonate or carbonate by-product. The base-facilitated hydrogen-producing reactions are thermodynamically more spontaneous and are able to produce hydrogen gas at less extreme reaction conditions than conventional reformation or gasification reactions of carbonaceous matter. In another embodiment, the instant reactions permit the production of hydrogen from carbonaceous matter without the production of carbon dioxide or carbon monoxide. In a preferred embodiment, the carbonaceous matter is coal or a derivative thereof.

Owner:TACTICAL FUEL CELLS

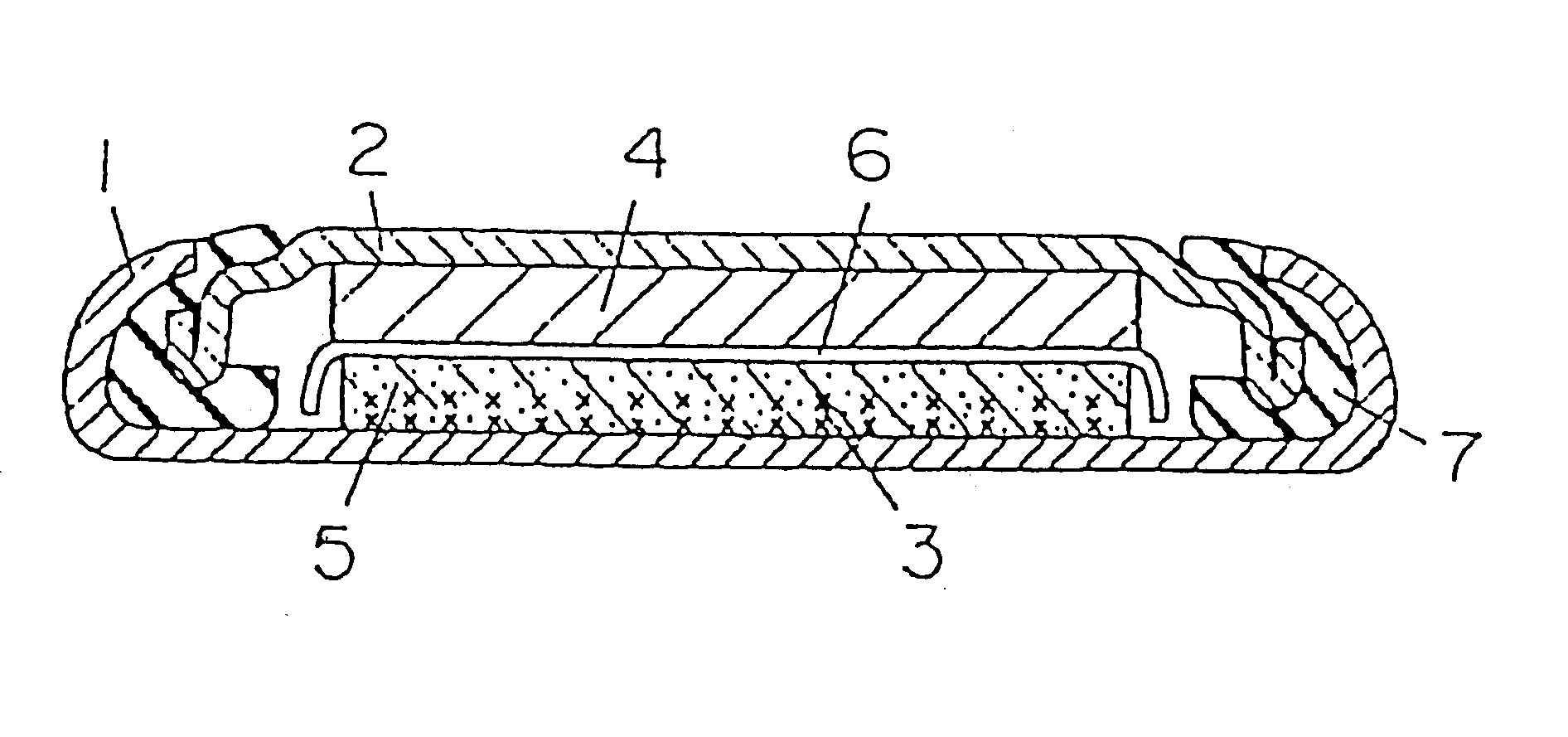

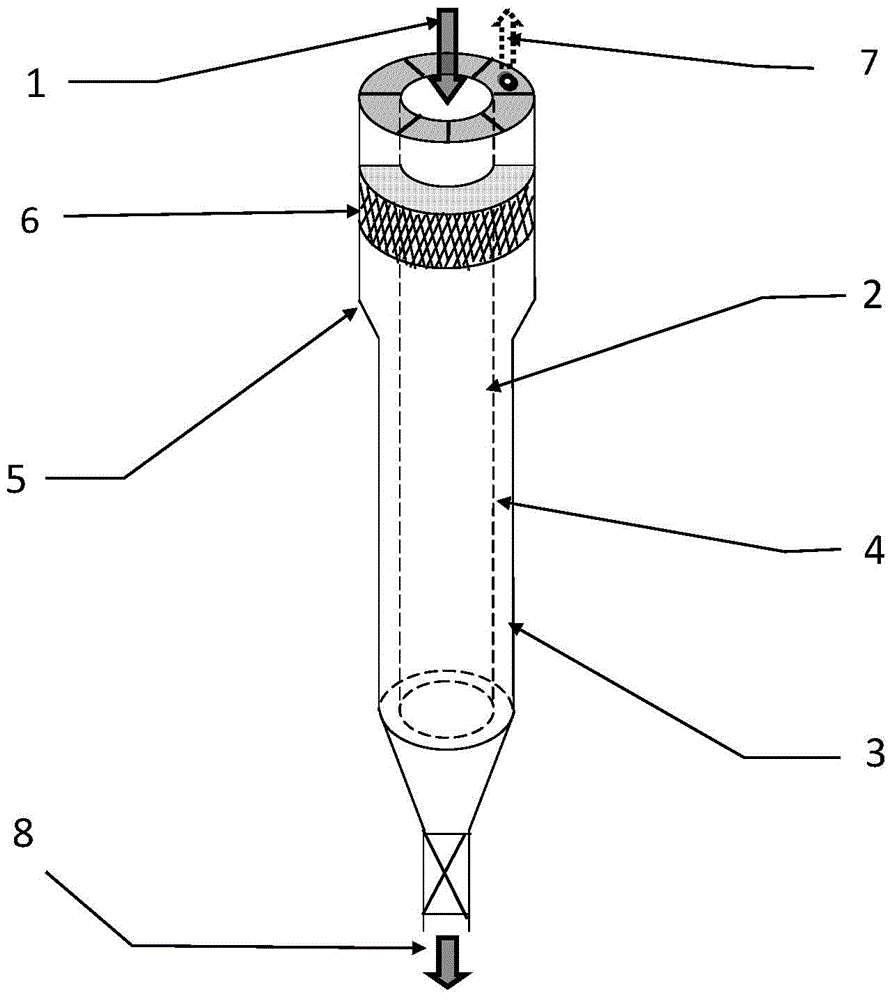

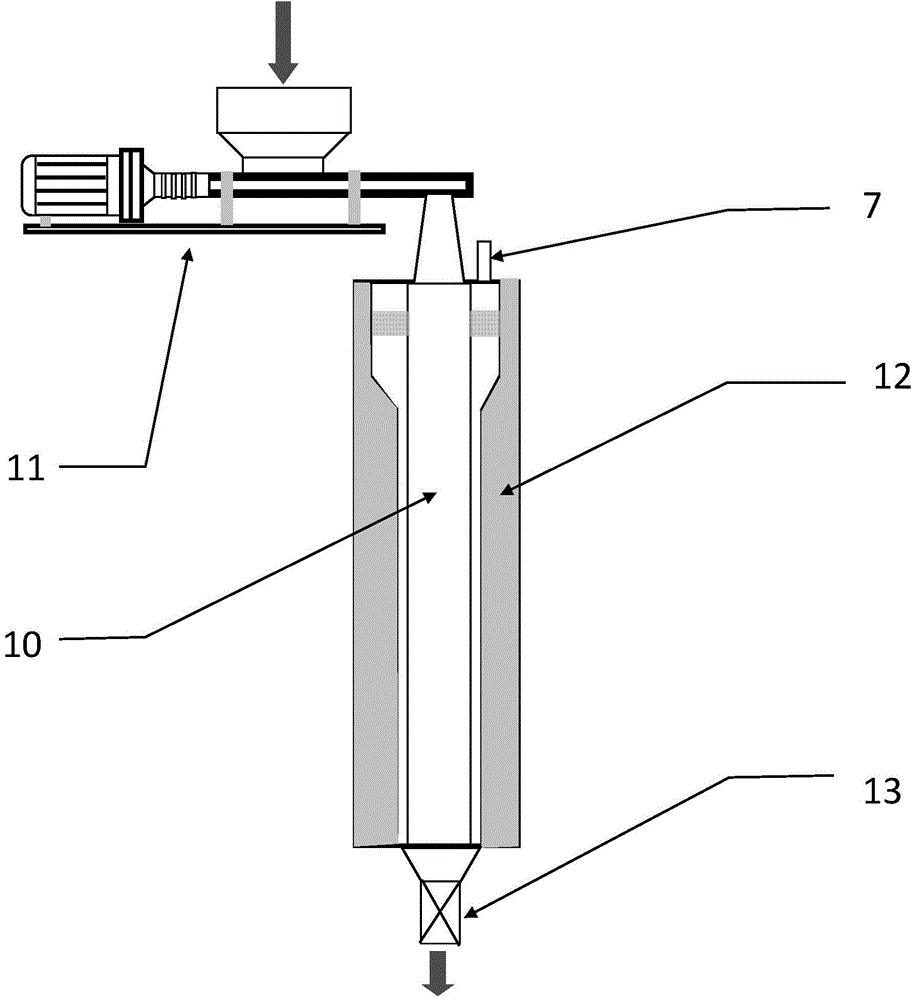

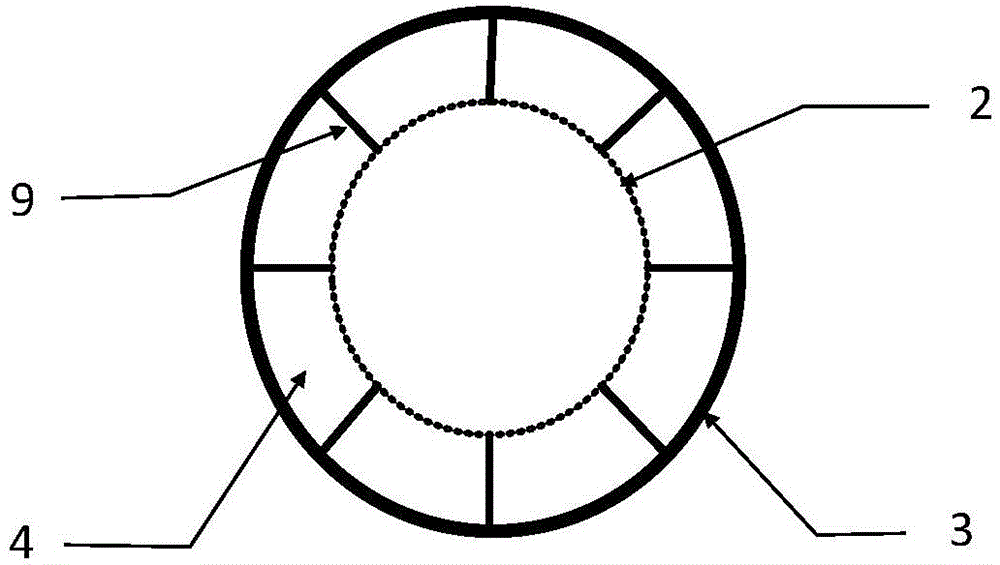

Pyrolysis device for carbonaceous substance

InactiveCN104629775APrevent precipitationImprove separation efficiencyDirect heating destructive distillationBiofuelsCatalytic pyrolysisThree level

The invention relates to a pyrolysis device for a carbonaceous substance. In a pyrolysis process, the device can realize gas-solid separation and catalytic quenching and tempering synchronously. In the existing pyrolysis technology, gas-solid separation equipment of high temperature pyrolysis gas, catalytic quenching and tempering equipment and a pyrolysis device are independent to each other. Under the restriction of temperature drop outside the pyrolysis device, high-boiling point tar precipitates out, and dust cannot be effectively removed, thus causing dust entrainment and catalyst deactivation. And along with tar precipitation and accumulation, the dust also results in equipment and pipeline blockage. The invention is characterized in that the pyrolysis device provided by the invention has a double-layer structure, the pyrolysis gas produced by pyrolysis is subjected to three-level gas-solid separation measures, i.e. filtration by a pyrolysis device inner layer 2, separation by a gas collection chamber's diameter expanding segment 5 and filtration by a filtration layer 6, efficient gas-solid separation is realized in the pyrolysis device, and dust entrainment of oil gas products can be avoided. At the same time, a catalyst can be added into the filtration layer 6 to simplify the catalytic pyrolysis process and realize quenching and tempering of pyrolytic oil gas products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

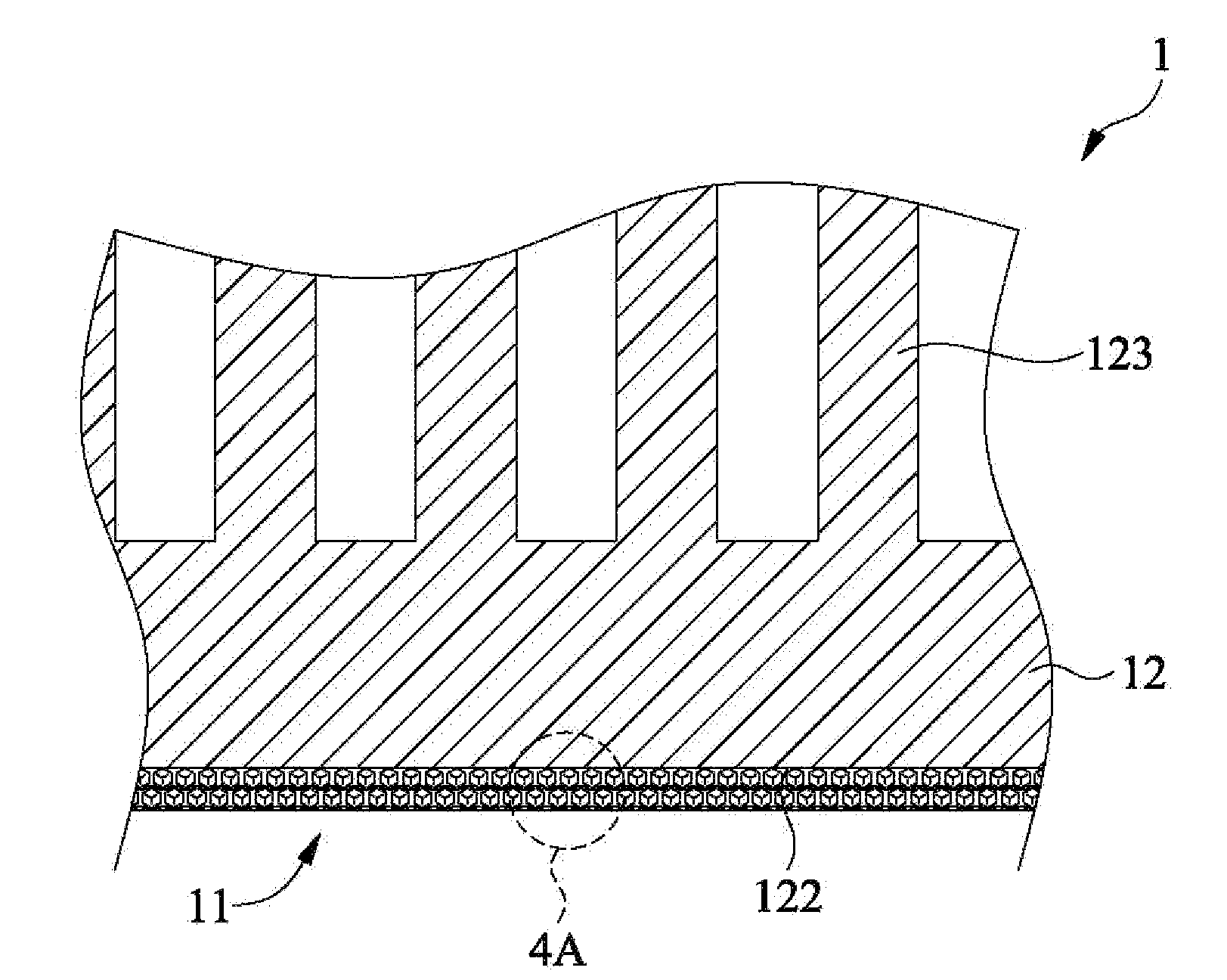

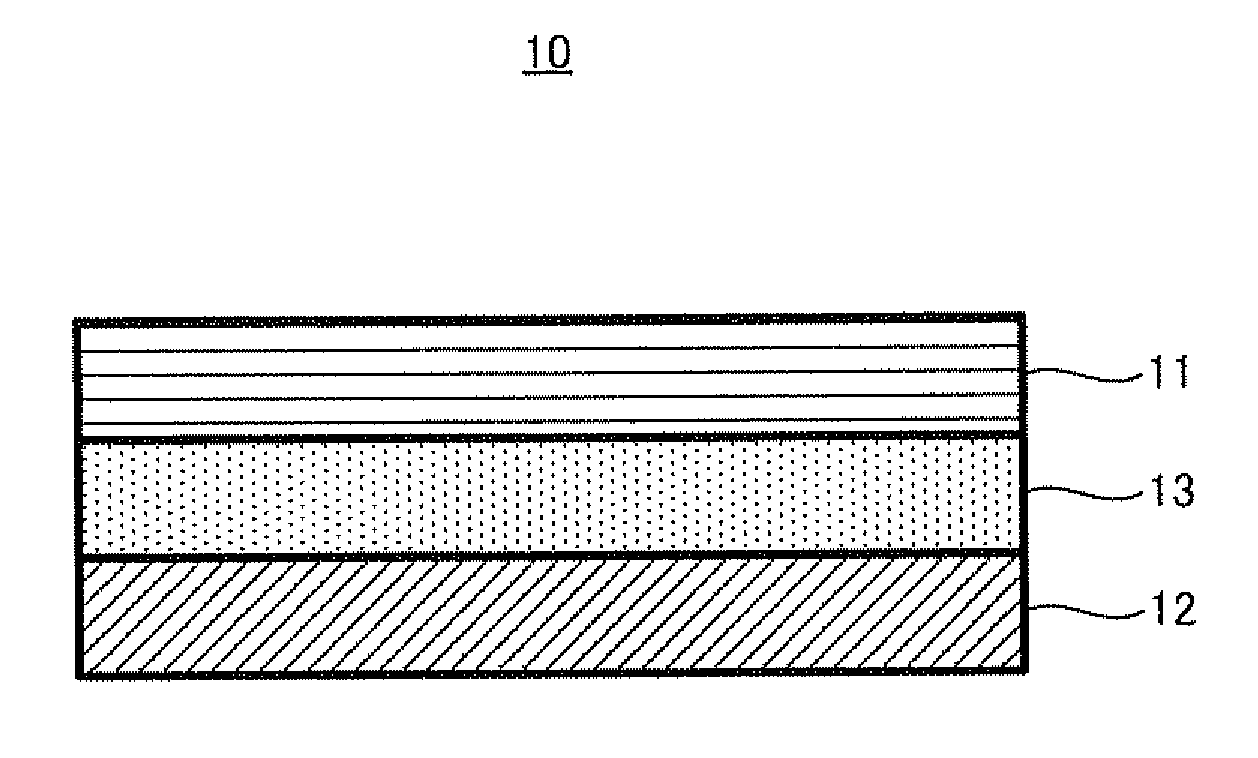

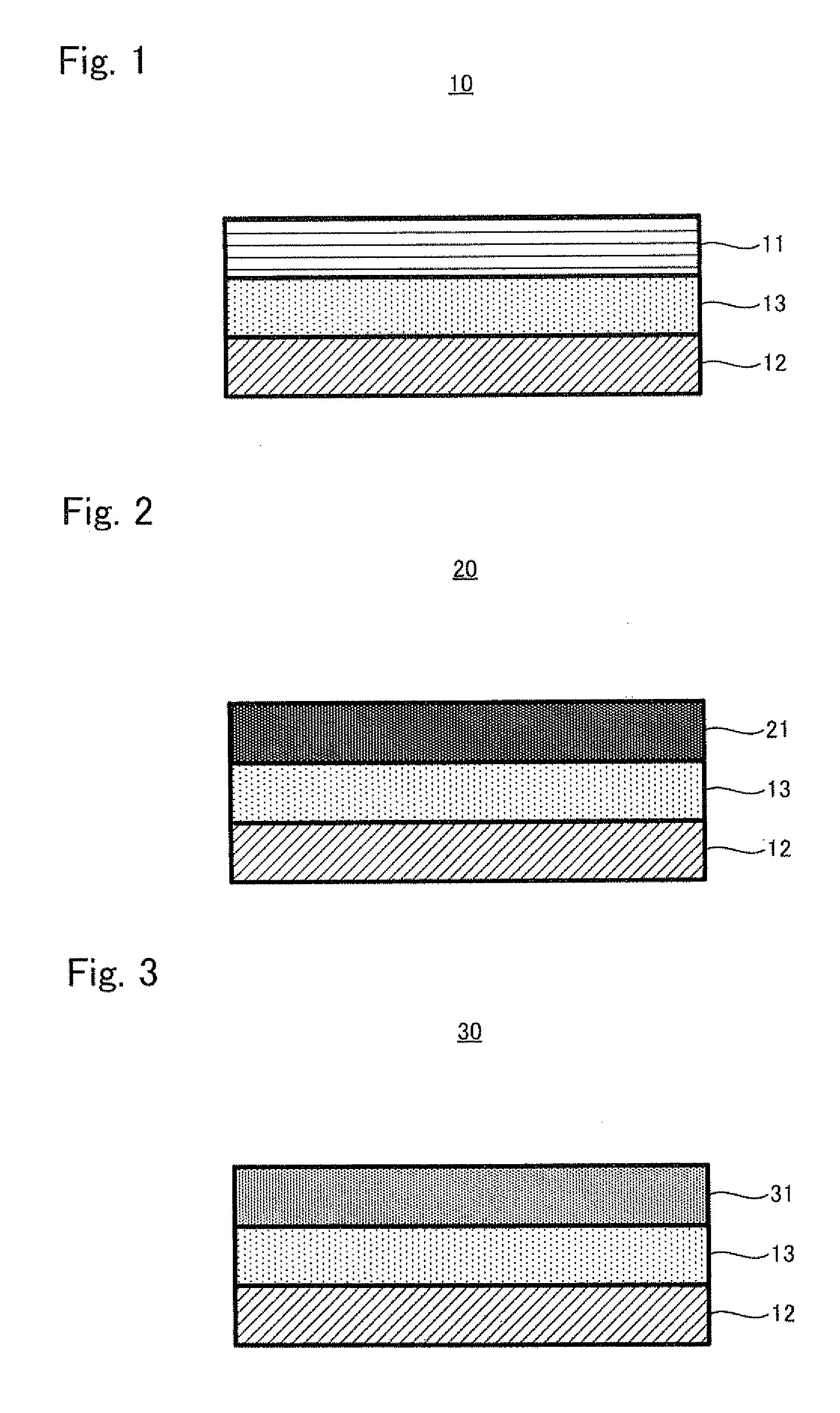

Heat spreader structure and method of manufacturing the same

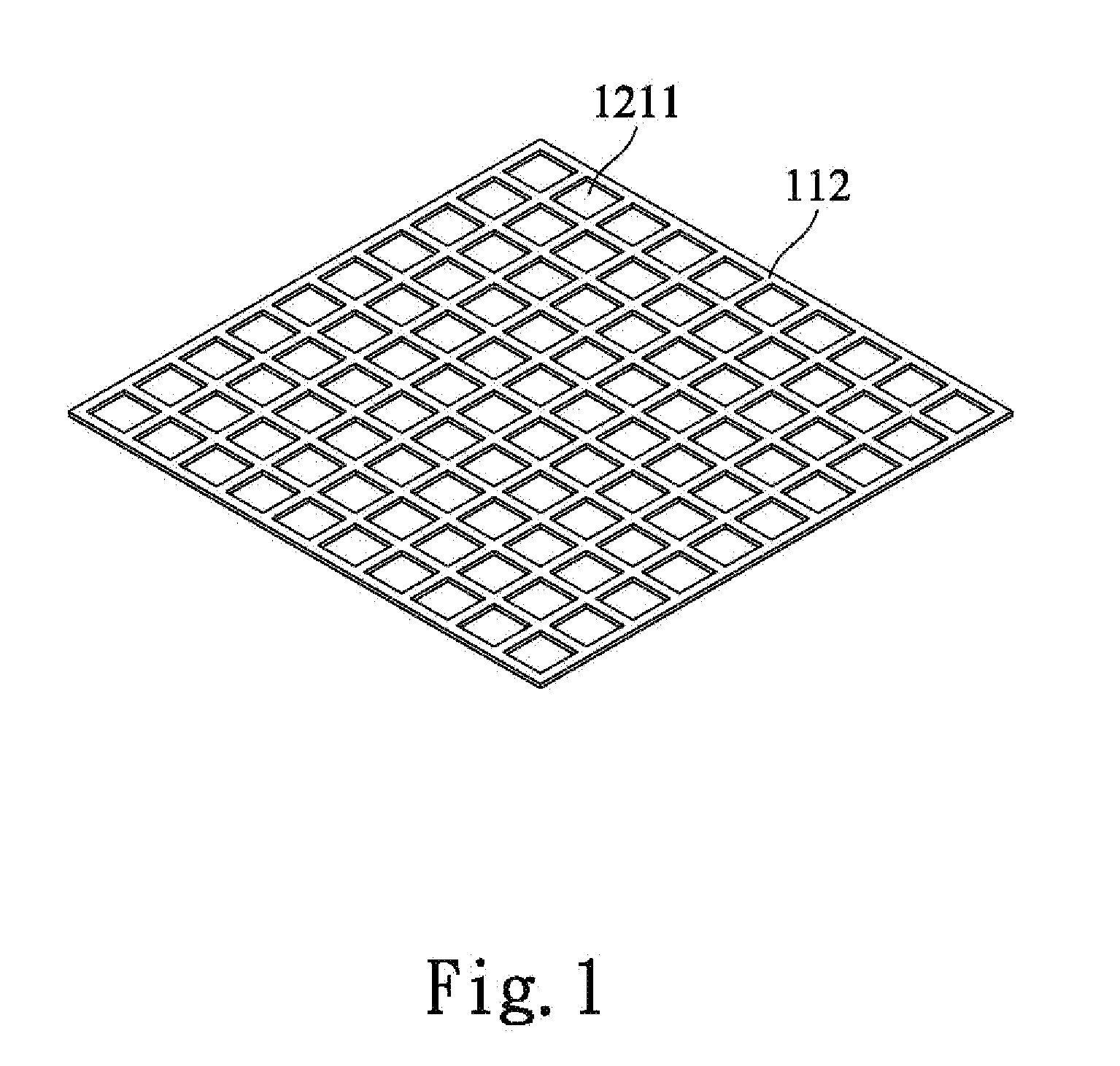

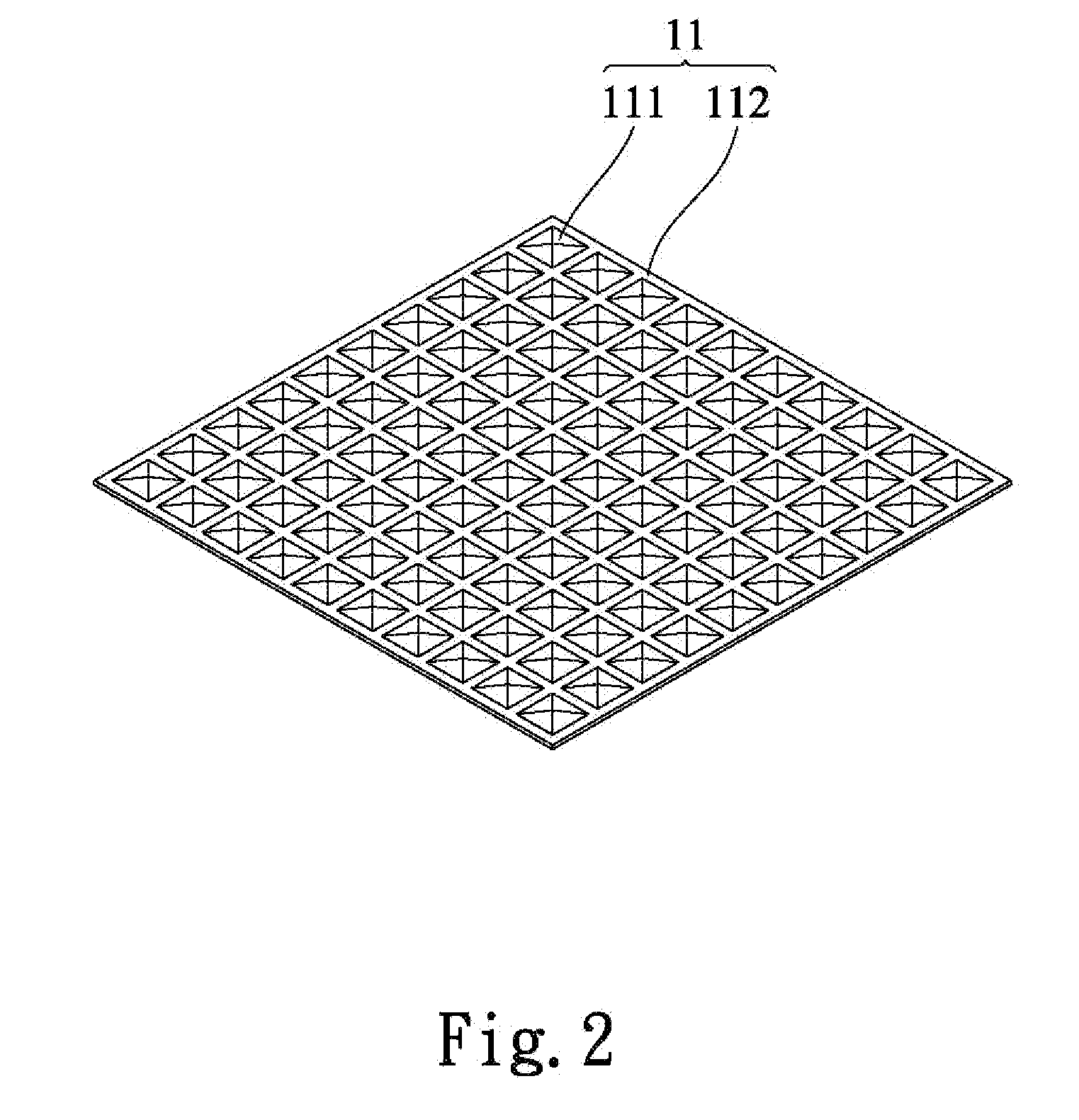

InactiveUS20100319895A1Improve thermal conductivityEqually distributedSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsMetal mesh

A heat spreader structure includes at least one carbonaceous matter-metal composite layer having a plurality of carbonaceous particles and at least one metal-mesh layer having a plurality of meshes. The carbonaceous particles are either separately firmly held inside the meshes of the metal-mesh layer or covered and held in place by the metal-mesh layer. The carbonaceous matter-metal composite layer can be coated on a metal-made body through sintering to ensure good bonding of the carbonaceous particles to the metal-made body and accordingly enhance the heat spreading efficiency of the metal-made body. A method for manufacturing the heat spreader structure is also disclosed.

Owner:CHEN WEI EN +1

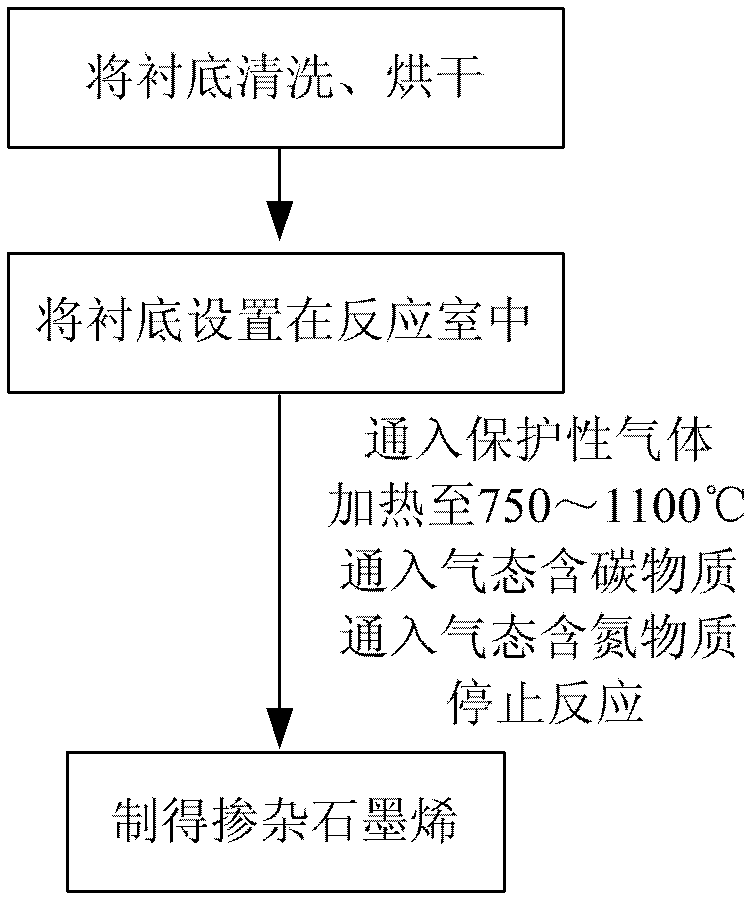

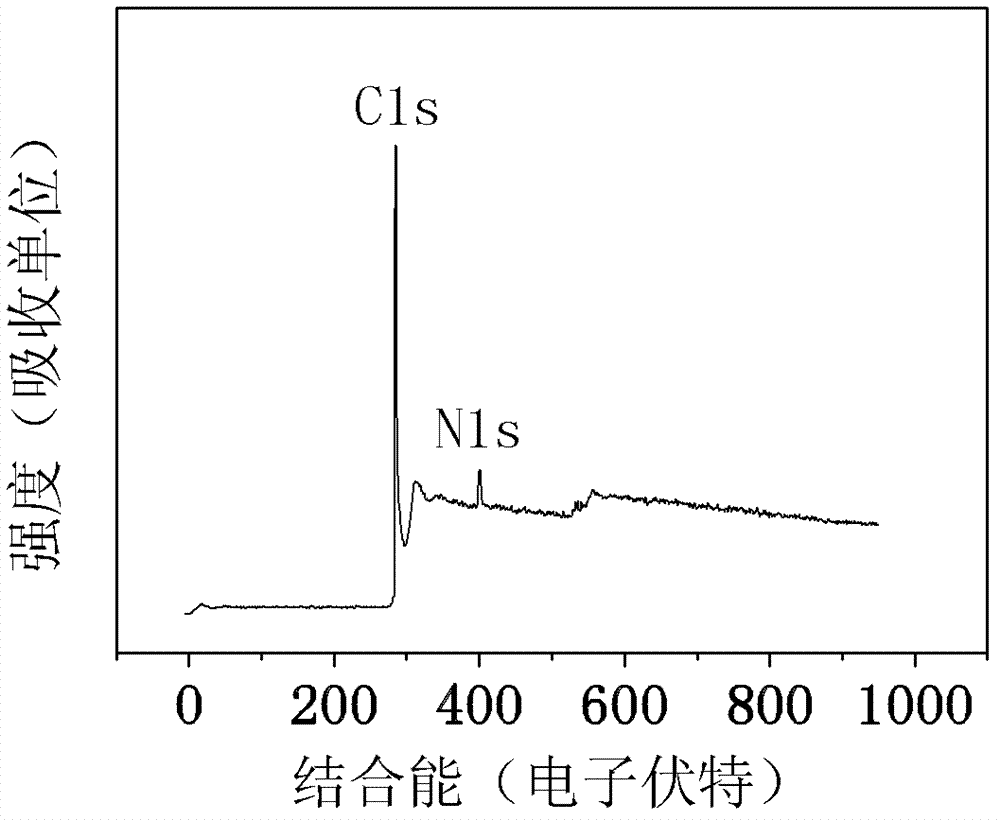

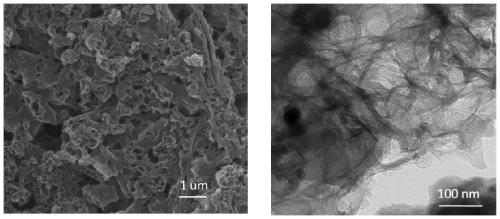

Preparation method of doped graphene

InactiveCN103088312ASimple processSimple equipmentGrapheneChemical vapor deposition coatingDoped grapheneCvd graphene

The invention provides a preparation method of doped graphene. The method comprises the steps of: cleaning a metal substrate and drying it; disposing the dried substrate in a reaction chamber, introducing a protective gas into the reaction chamber, and keeping the gas for 1-60min; then heating the reaction chamber to 750-1100DEG C, introducing a gaseous carbonaceous matter at a gas flow rate of 20-1000sccm and a gaseous nitrogenous matter at a gas flow rate of 10-200sccm to undergo a reaction, with C and N being in an atomic ratio of 2-20:1, and maintaining the reaction for 1-300mins, thus obtaining the doped graphene on the substrate surface. With no need for additional preparation of a catalyst, the method provided in the invention has the characteristics of simple process and equipment, and easy and feasible operation. Compared with other nitrogen doped methods, the product prepared by the method has the advantages of low oxygen content, easily controllable nitrogen content and uniform doping, etc.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of graded porous carbon

PendingCN111285346AReduce productionUniformity is moreCarbon preparation/purificationSolid carbonFoaming agent

The invention discloses a preparation method of graded porous carbon. According to the technical scheme, the preparation method comprises the steps: firstly, adding a foaming agent into a low-melting-point solid carbon-containing substance, and mixing for later use; then under a certain pressure and atmosphere, heating to a temperature T1, and homogenizing for t1; and under a certain pressure andatmosphere, heating to a temperature T2, carrying out a reaction for t2, heating to a temperature T3, carrying out a reaction for t3, cooling to room temperature, cleaning and drying to obtain the graded porous carbon. The basic concept of the invention comprises that a macroporous structure is formed by a foaming technology, the porosity of the carbon material is further increased by utilizing generated reducing gas, and then more micropores and small mesopores are generated by utilizing cracking and intercalation of anode ions under heat treatment to form porous carbon with a micropore-mesopore-macroporous hierarchical pore structure. The method has the advantages of being high in operability, large in aperture adjusting range, accurate in regulation and control and the like.

Owner:ZHENGZHOU UNIV

Method for preparing silicon dioxide micropowder by using pulverized fuel ash extracted aluminum residue as raw material and silicon dioxide micropowder

The invention discloses a method for preparing silicon dioxide micropowder by using pulverized fuel ash extracted aluminum residue as a raw material and the silicon dioxide micropowder. The method for preparing the silicon dioxide micropowder by using the pulverized fuel ash extracted aluminum residue as the raw material comprises the following steps: step one. mixing sodium hydroxide and the pulverized fuel ash extracted aluminum residue, and calcining so as to obtain a calcination material; and step two. adding hydrochloric acid to the calcination material, reacting, filtering and drying so as to obtain the silicon dioxide micropowder. The method is characterized in that sodium silicate and sodium metaaluminate can be formed by mixing and calcining the sodium hydroxide and the pulverized fuel ash extracted aluminum residue; meanwhile, other carbon-containing substances in the pulverized fuel ash extracted aluminum residue can also be converted into carbon oxide so as to be removed; after the hydrochloric acid to the calcination material, aluminium chloride, sodium chloride soluble salt and silicon dioxide precipitates are generated by reaction, so that silicon dioxide is separated out; and the silicon dioxide micropowder with relatively high purity can be obtained by filtration and drying. The method is simple in technological operation, relatively short in operating period and suitable for large-scale recovery and production of large-scale silicon dioxide micropowder.

Owner:CHINA SHENHUA ENERGY CO LTD +1

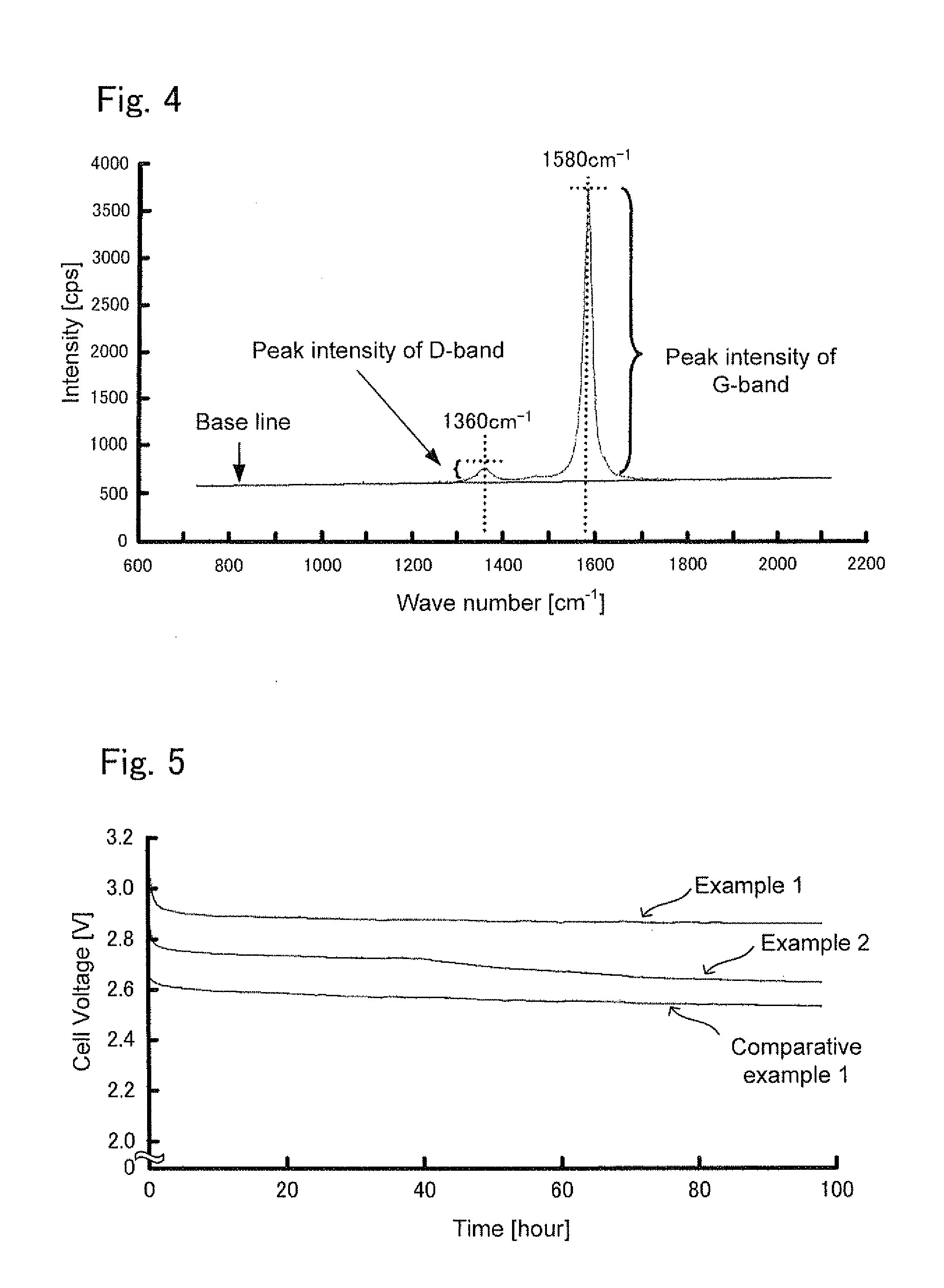

Air battery

An air battery which is capable of improving operating voltage. The air battery includes: an air electrode containing a carbonaceous matter; an anode; and an electrolyte layer containing an electrolyte which conducts ions between the air electrode and the anode, the DIG band ratio X of the carbonaceous matter being 0.058≦X≦0.18.

Owner:TOYOTA JIDOSHA KK

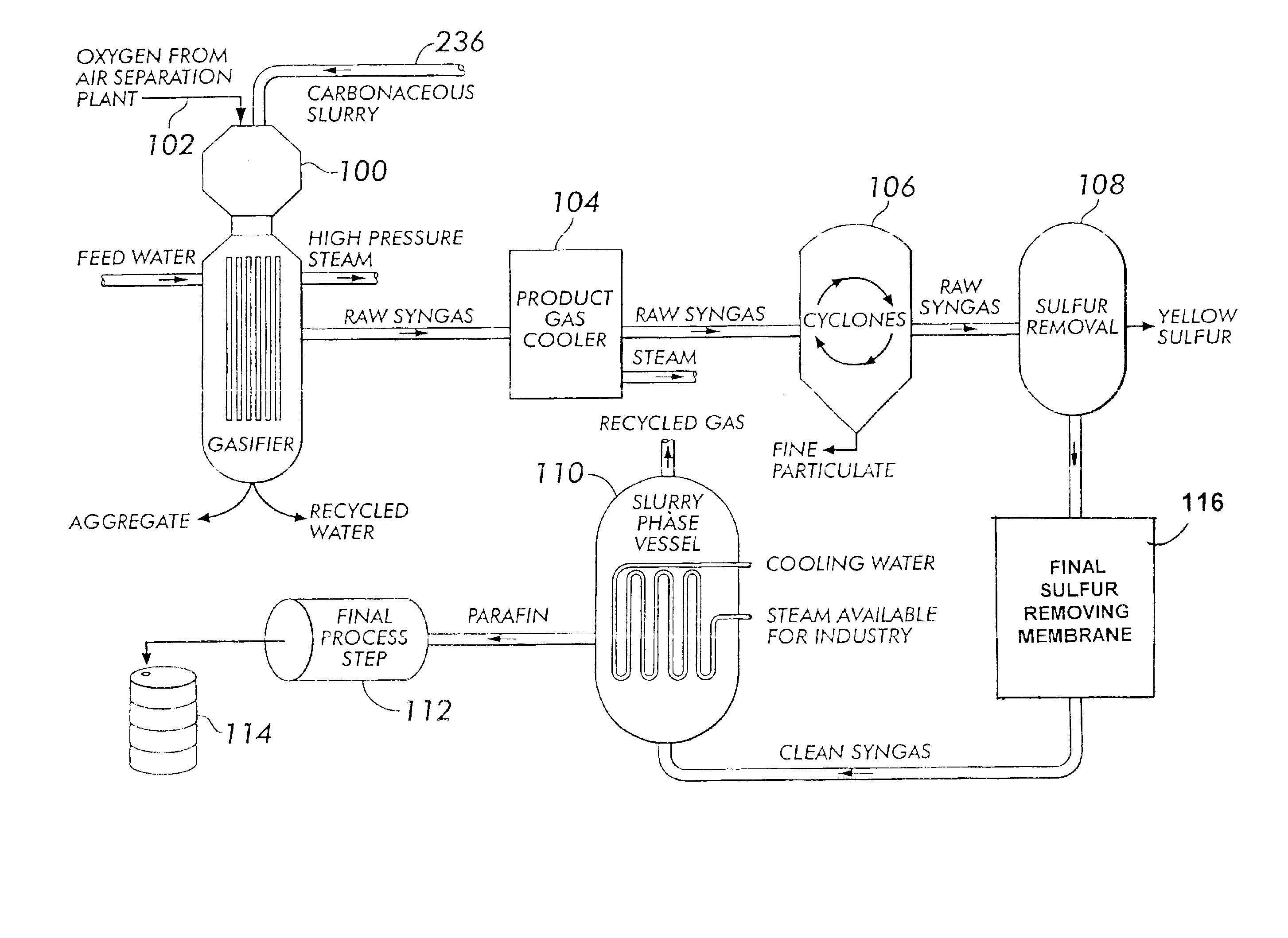

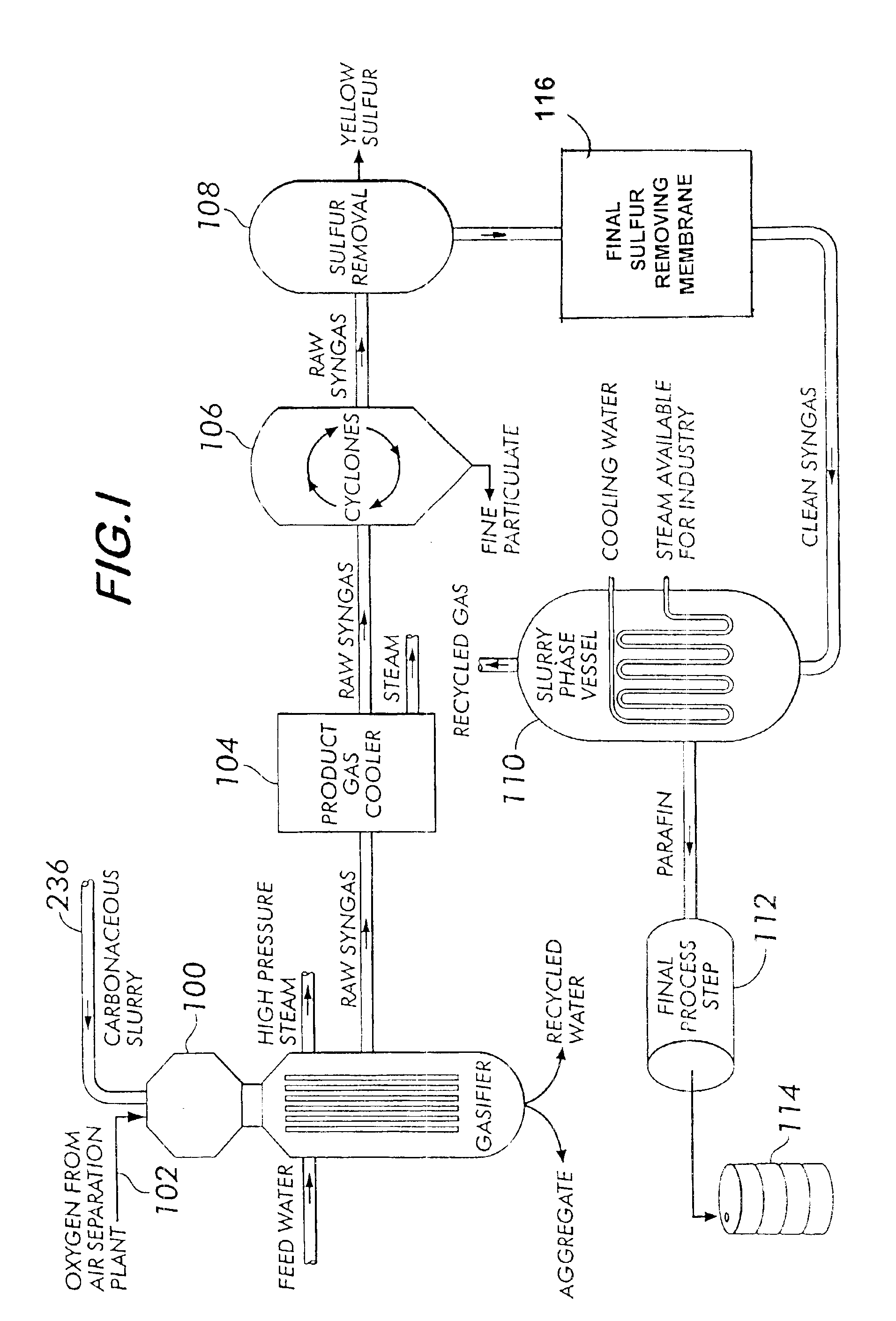

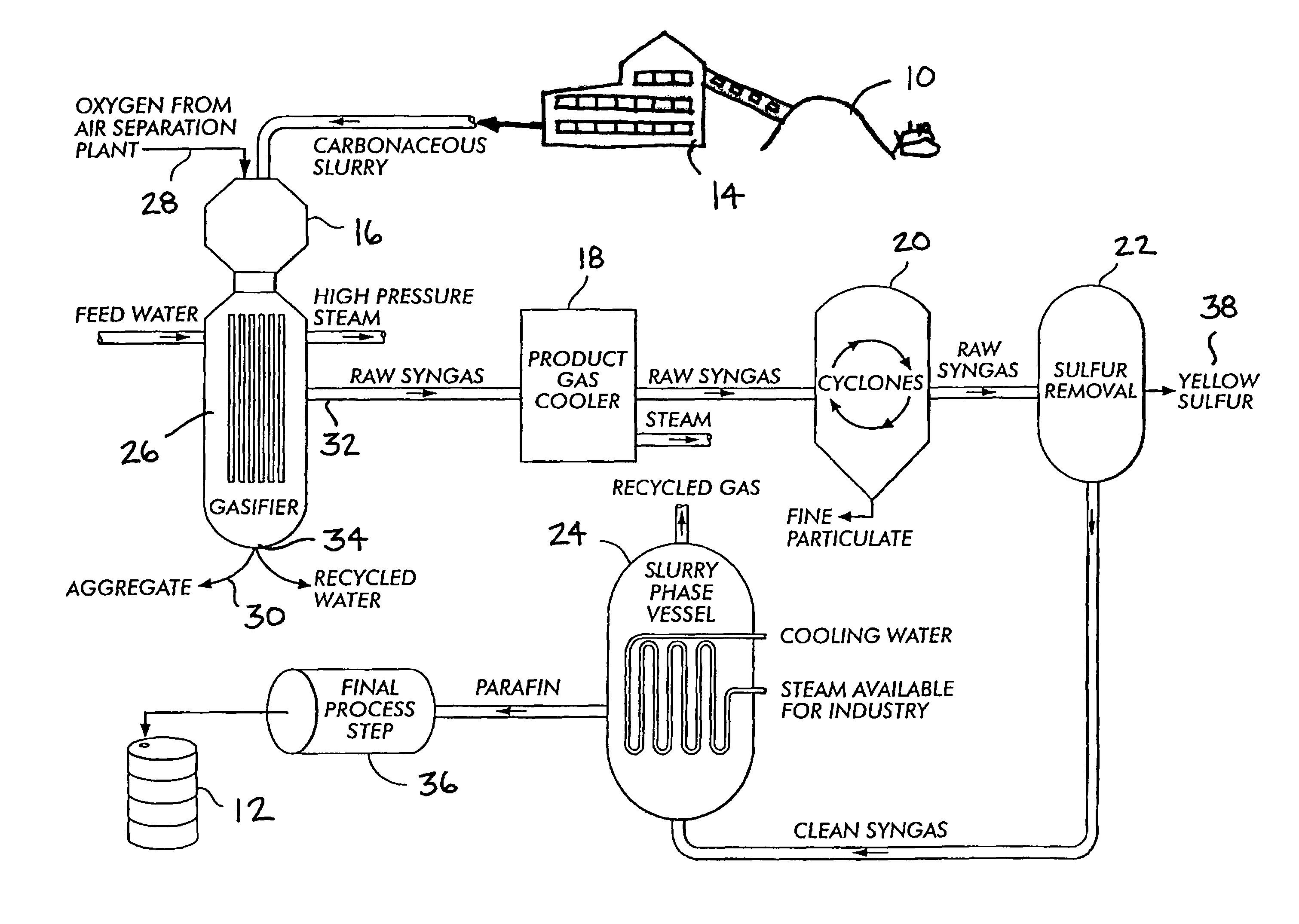

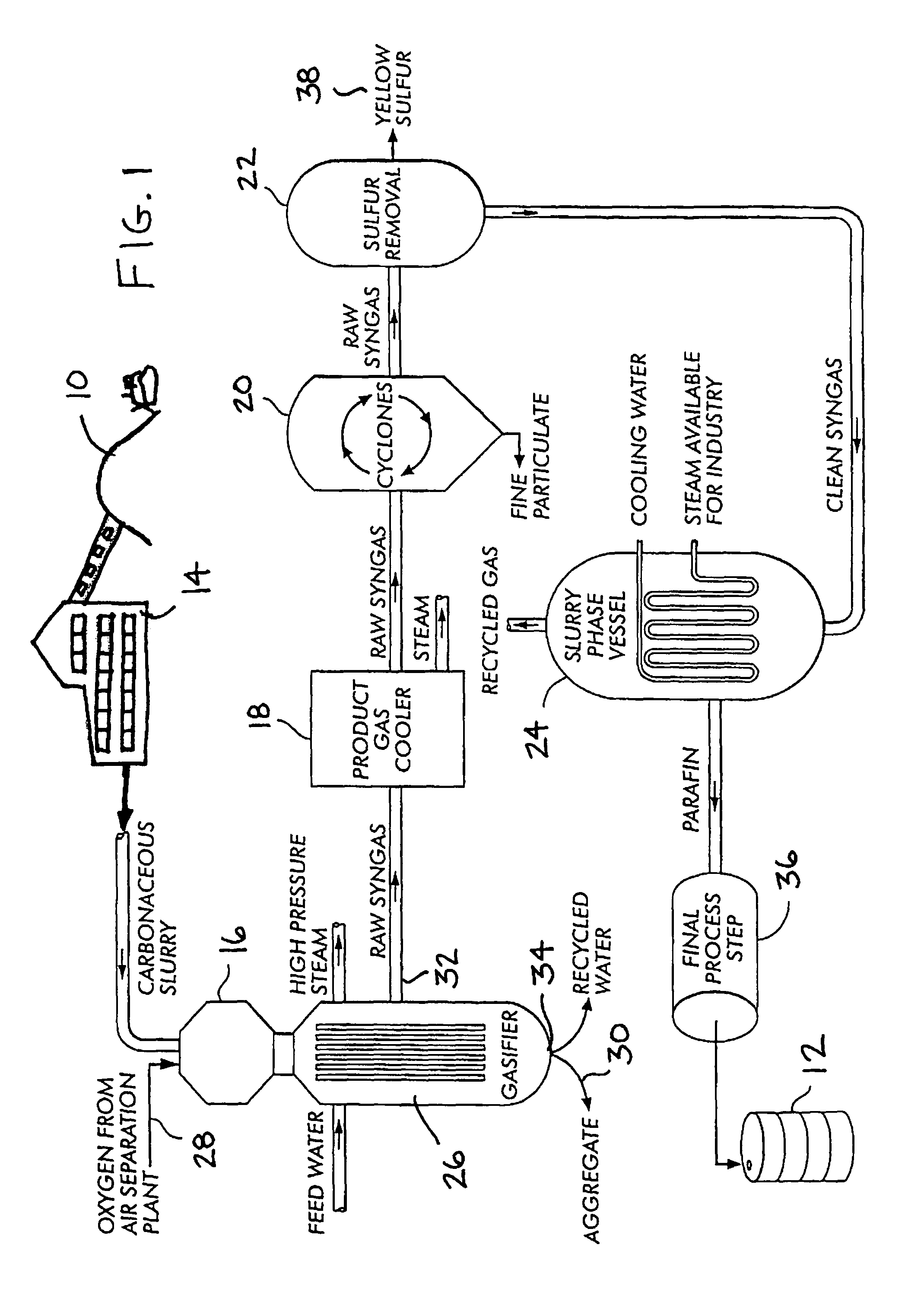

Method for producing ultra clean liquid fuel from coal refuse

InactiveUS6869979B1Efficient productionFree from cleaningOrganic compound preparationOxygen compounds preparation by reductionParaffin waxForming gas

The effective coupling and combination of coal gasification and coal liquefaction techniques to produce ultra clean liquid fuels from carbonaceous matter preferably provided from an abundance of waste coal mining material. The method and apparatus includes a final sulfur washing step utilizing a zinc oxide membrane to remove virtually all sulfur from synthetic gas produced in an entrained flow gasifier before the synthetic gas is permitted to enter a slurry phase vessel having a catalyst used to produce a parafin from which liquid fuel is produced. The liquid fuel is preferably an ultra clean, high cetane, sulfur-free diesel fuel.

Owner:RICH JR JOHN W

Coal gasification equipment having heat recovery function

InactiveCN107033967AAchieve recyclingImprove efficiencyChemical industryWaste water treatment from gaseous effluentsSlagHigh pressure

The invention discloses coal gasification equipment having a heat recovery function. The coal gasification equipment having the heat recovery function comprises a gasifier, a heat recovery device, a scrubber tower and a slag water treatment device, wherein the gasifier is used for combustion gasification of carbonaceous matter; the heat recovery device is connected with the gasifier and used for recovering heat contained in high-temperature high-pressure gas obtained after combustion in the gasifier; the scrubber tower is communicated with the gasifier and used for performing scrubbing dust collection on raw gas; the slag water treatment device is communicated with the scrubber tower and used for concentrating fine slag to recycle slag water. According to the coal gasification equipment having the heat recovery function, the rate of multipurpose utilization of coal can be increased, and energy is saved.

Owner:TSINGHUA UNIV

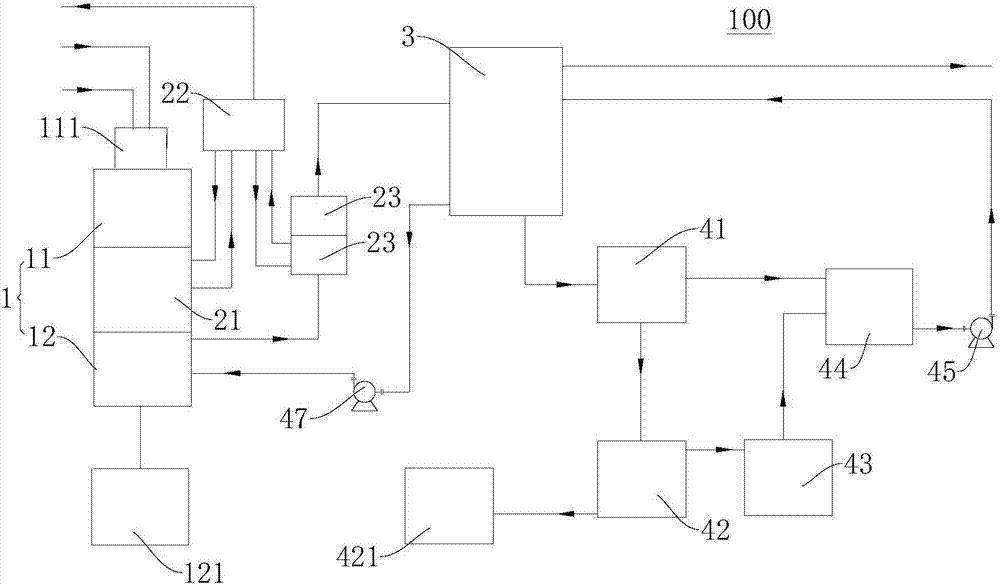

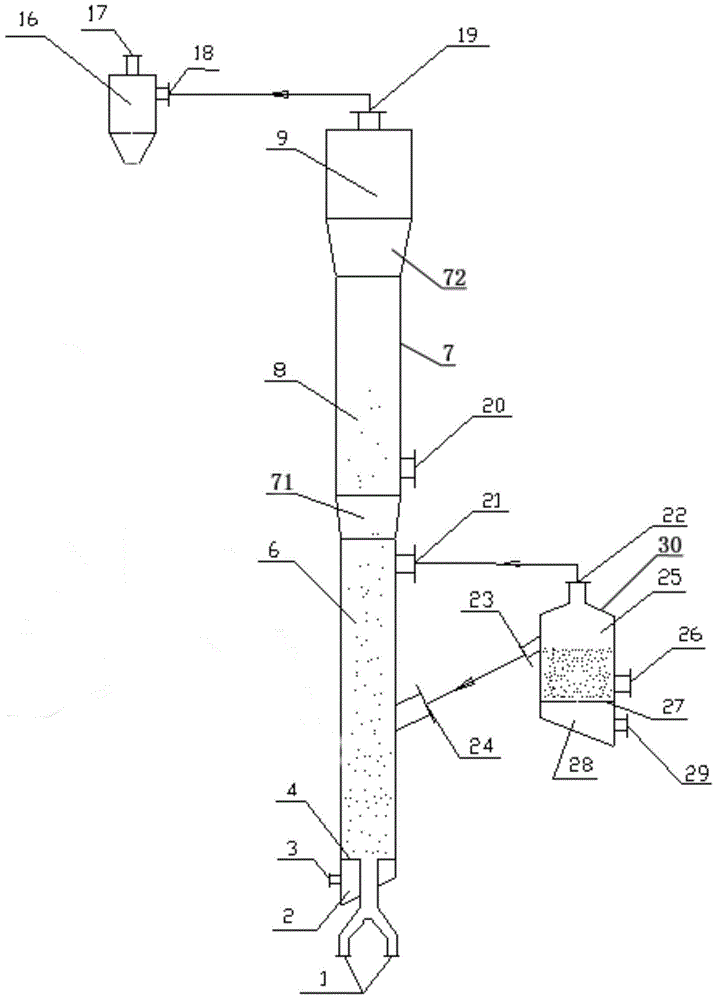

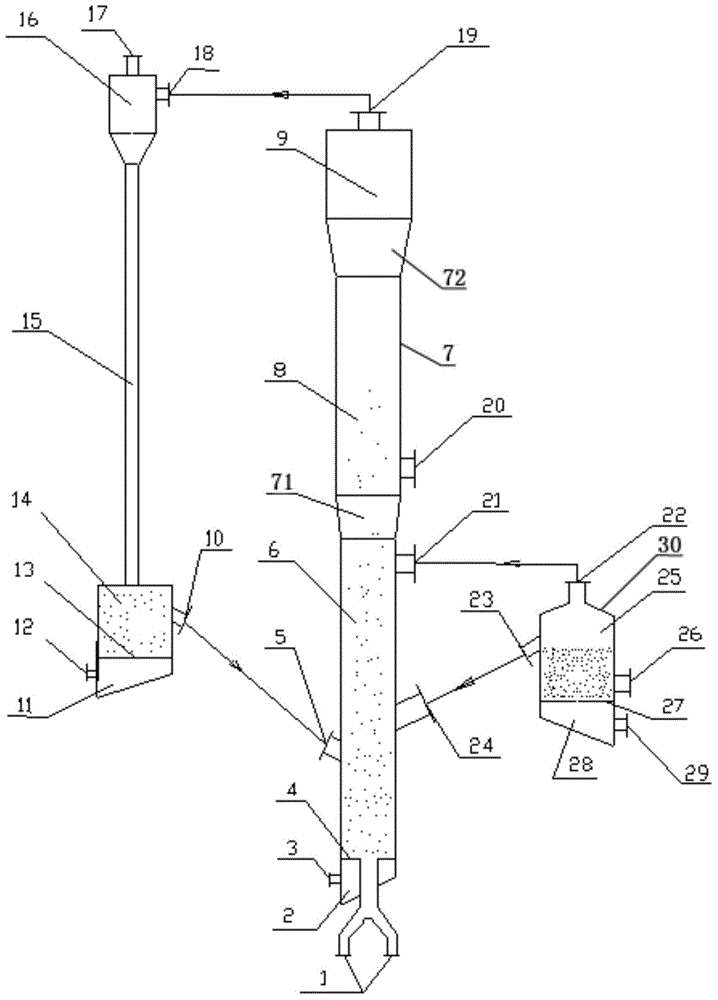

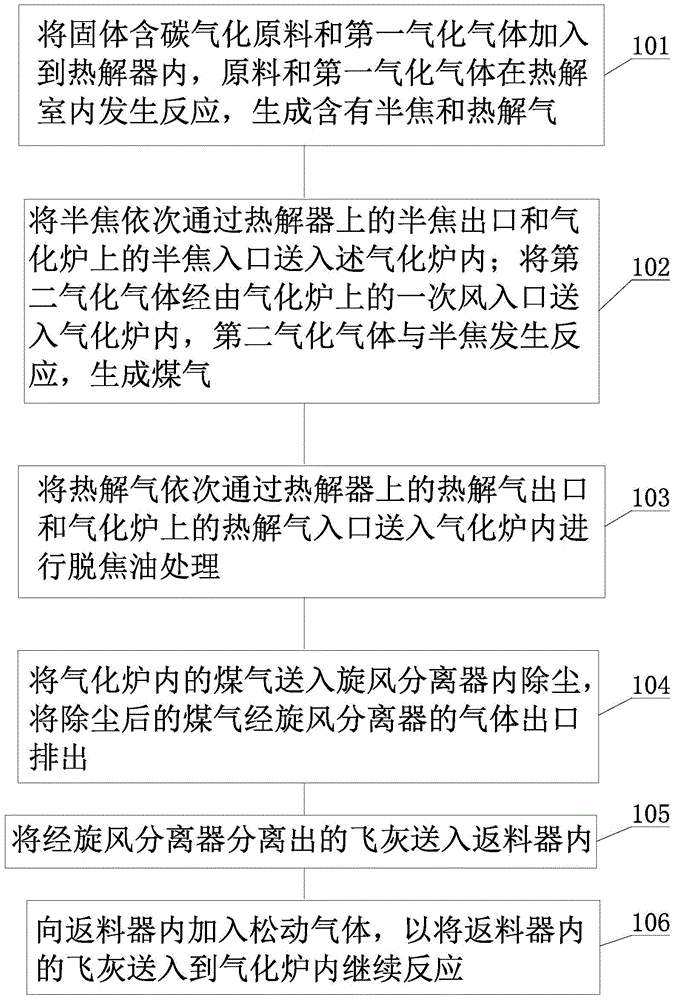

Combined type circulating fluidized bed gasification device and method

InactiveCN105062570AImprove patencyImprove running stabilityGranular/pulverulent flues gasificationFluidized bedSludge

The invention relates to a combined type circulating fluidized bed gasification device and method, and relates to the technical field of fluidized bed gasification. The device and the method are mainly used for gasifying one or more solid carbonaceous matters in organic waste such as gasified coal, petroleum coke, biomass, garbage, sludge and the like or mixtures of the solid carbonaceous matters and other gas and liquid organic matters, higher gasification efficiency is obtained through improvement of raw material adaptability, and clean low-cost fuel gas or synthesis gas is produced. The main technical scheme is that the combined type circulating fluidized bed gasification device comprises a pyrolysis chamber, a gasifying chamber and a cyclone separator which are connected sequentially, wherein a raw material inlet, a pyrolysis gas outlet and a semi-coke outlet are formed in the pyrolysis chamber respectively, and the pyrolysis gas outlet is formed above the semi-coke outlet; a primary air inlet, a pyrolysis gas inlet and a semi-coke inlet are formed in the gasifying chamber, the pyrolysis gas outlet is connected with the pyrolysis gas inlet, and the semi-coke outlet is connected with the semi-coke inlet through an overflow pipe; a gas outlet is formed in the cyclone separator.

Owner:王启花

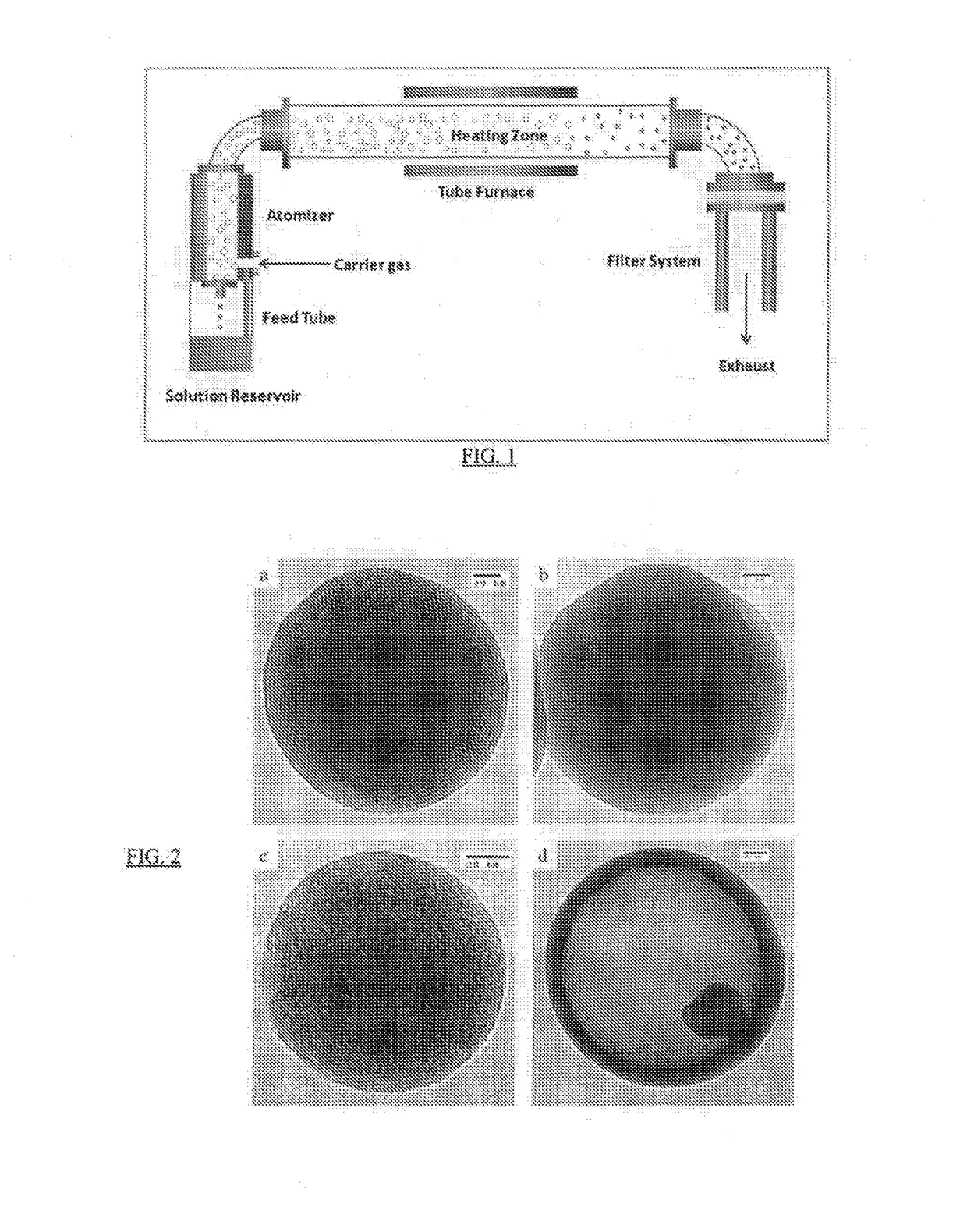

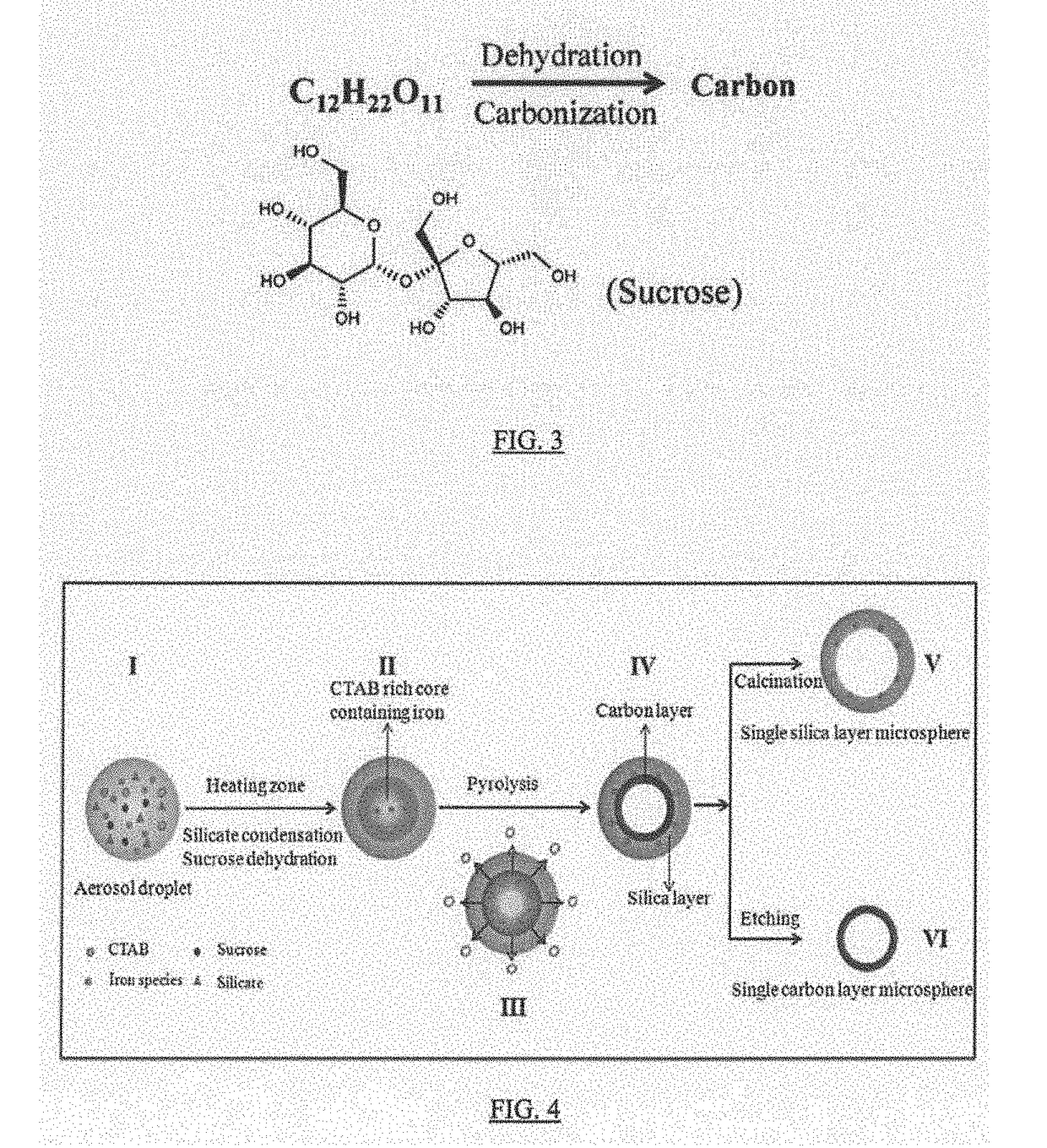

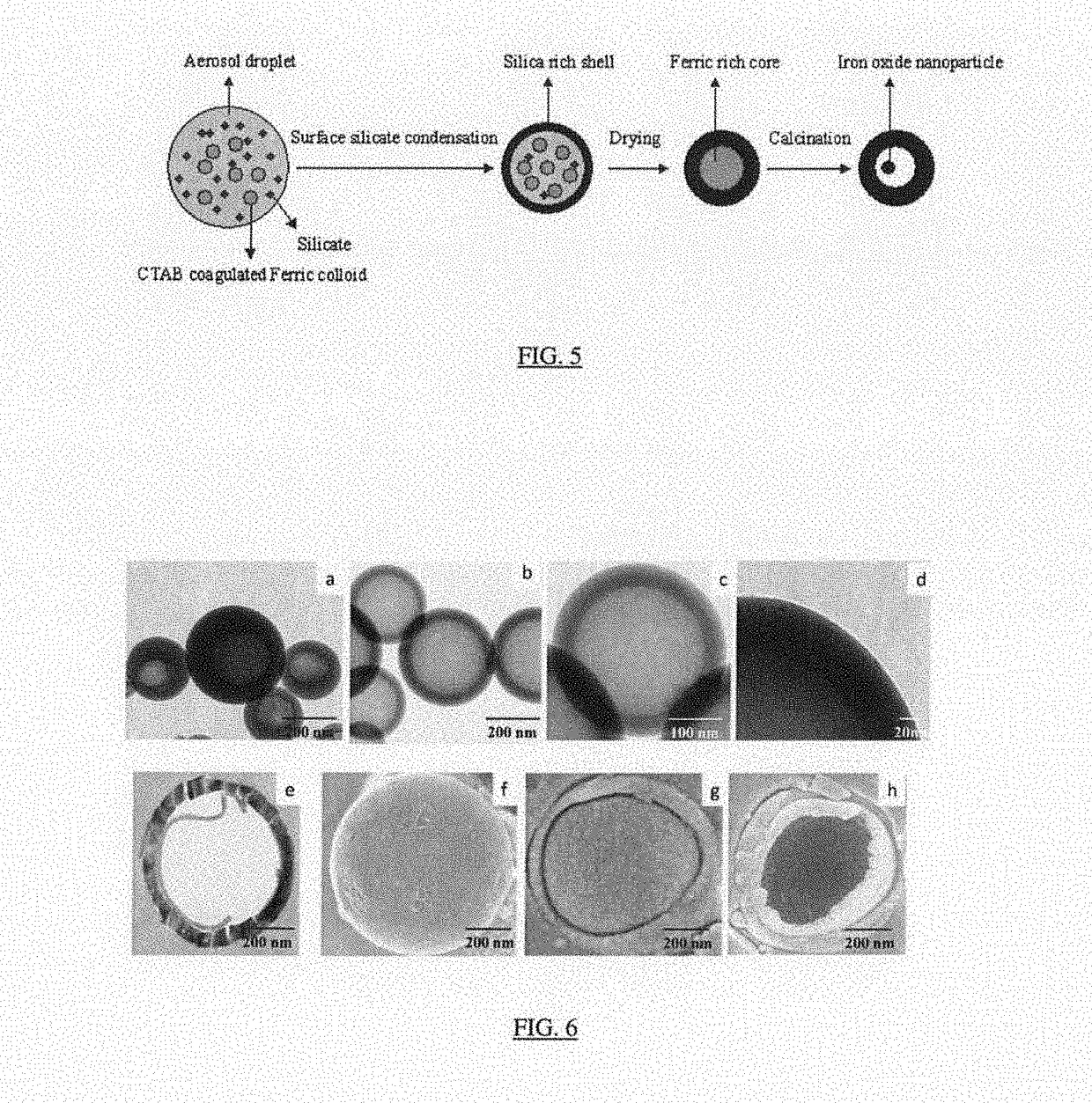

Hollow nanoparticles with hybrid double layers

The present invention discloses the morphology of hollow, double-shelled submicrometer particles generated through a rapid aerosol-based process. The inner shell is an essentially hydrophobic carbon layer of nanoscale dimension (5-20 nm), and the outer shell is a hydrophilic silica layer of approximately 5-40 nm, with the shell thickness being a function of the particle size. The particles are synthesized by exploiting concepts of salt bridging to lock in a surfactant (CTAB) and carbon precursors together with iron species in the interior of a droplet. This deliberate negation of surfactant templating allows a silica shell to form extremely rapidly, sealing in the organic species in the particle interior. Subsequent pyrolysis results in a buildup of internal pressure, forcing carbonaceous species against the silica wall to form an inner shell of carbon. The incorporation of magnetic iron oxide into the shells opens up applications in external stimuli-responsive nanomaterials.

Owner:THE ADMINISTRATORS OF THE TULANE EDUCATIONAL FUND

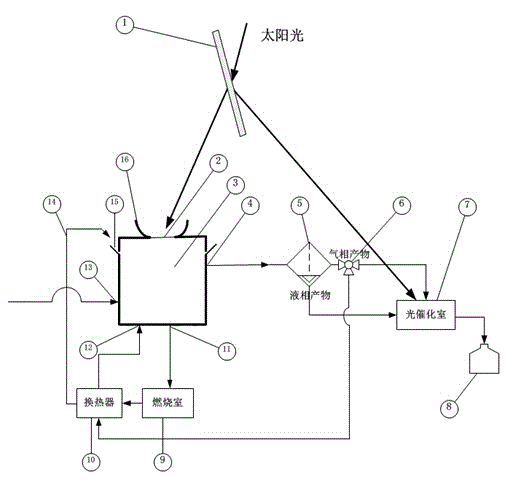

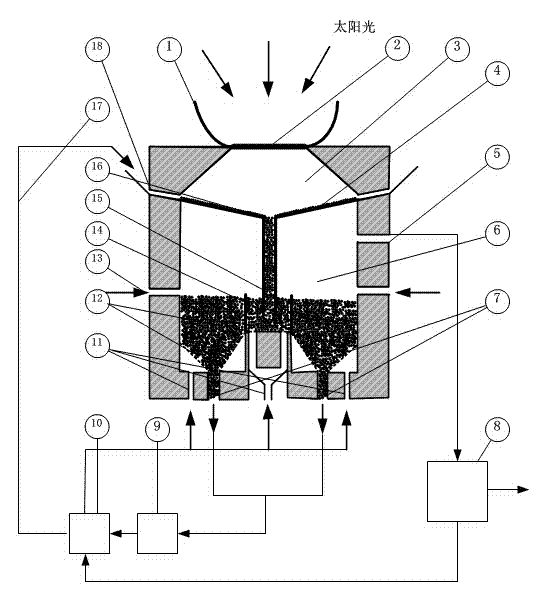

Solar energy-driven carbonaceous matter reaction and reaction product photocatalytic method

ActiveCN104449847AImprove qualityIncrease profitSolar heating energySolar heat devicesBeam splitterGlass cover

The invention relates to a solar energy-driven carbonaceous matter reaction and reaction product photocatalytic method. After sunlight passes through a beam splitter, a beam of light enters into a photocatalytic chamber, and the other beam of light irradiates into a cavity type light absorbing cavity through a glass cover plate; solid particles enter the light absorbing cavity through a particle inlet, and the solid particles and the inner wall of the light absorbing cavity simultaneously absorb the sunlight to convert the sunlight into heat energy; the high-temperature hot particles and a carbonaceous matter entering the light absorbing cavity through a carbonaceous matter inlet are mixed; meanwhile, the carbonaceous matter receives the radiation energy of the light absorbing cavity, and the carbonaceous matter rises in temperature to react; a reaction gaseous product flows into a reaction product catalytic treatment system, and most reaction gas and unsaturated reaction oil are catalyzed in the photocatalytic chamber and then flow to an oil storage tank to be stored. The solid particles are heated by a visible light band and an infrared band to provide heat for the carbonaceous material reaction; the unsaturated reaction oil in the reaction product is photocatalyzed by a UV band to increase the stability of the unsaturated reaction oil.

Owner:ZHEJIANG UNIV

Process for producing clean liquid fuels from coal waste

InactiveUS7988754B1Low melting pointGas modification by gas mixingGasification processes detailsFoundryParaffin wax

The present invention is directed to a process for producing ultra clean liquid fuel from abandoned mine waste. A feedstock is prepared from water and coal mine waste having relatively high ash (non-carbonaceous matter) content. Foundry slag is added to the feedstock as a fluxant to adjust the melting behavior of the ash in the feedstock. Preferably, the fluxant is blast furnace slag provided in a particle size of less than about 150 μm and is provided in an amount sufficient to lower the melting point of the ash in the feedstock by at least about 200° F. The feedstock is admitted with a flow of oxygen into a pressurized chamber of an entrained flow gasifier in which the feedstock and oxygen are heated to produce a synthetic gas from a coal component of the feedstock and molten slag from the ash and fluxant components of the feedstock. The molten slag is of a viscosity to freely flow out of the gasifier through an exit port in the bottom of the gasifier. The synthetic gas can be used to produce paraffin from which ultra clean liquid fuel can be produced.

Owner:RICH JR JOHN W

Composite building humidity-controlling material and preparation method thereof

InactiveCN107876026AHas the ability to absorb and release moisture automaticallyLarge pore volumeOther chemical processesComposite effectClay minerals

The invention relates to a composite building humidity-controlling material and a preparation method thereof, and belongs to the technical field of building materials. The humidity-controlling material is prepared from quaternized chitosan modified sepiolite to be compounded with sierozem, ground calcium carbonate, quartz sand and attapulgite. A great number of detrital impurities such as carbonaceous matters, clay minerals and the like covered on the surface of the sepiolite are removed through acidification and purification, so that most of pore structures appear, the pore volume of the sepiolite is obviously increased, and the moisture absorption and release ability of the sepiolite is enhanced. Meanwhile, chitosan is subjected to quaternization modification, so that the moisture absorption is improved. During the cleaning process of pores of the sepiolite, the pores are filled with the chitosan to produce a composite effect with porous structures of the sepiolite, so that the diffusion performance of water vapor on the surface of the material or inside the material is improved, the capillary condensation of the water vapor inside the material is promoted, and the moisture absorption capacity of the material is increased. The humidity-controlling material has faster moisture absorption and release rate, so that the physical adsorption of the material to moisture is promoted,and the moisture absorption capacity is increased to further enhance the moisture absorption and release ability.

Owner:吴刚

Dual-cavity type solar driven carbonaceous material reaction method and apparatus

ActiveCN104498092AAvoid tightnessAvoid pollutionSolar heating energySolar heat devicesSolar lightGlass cover

The invention discloses a dual-cavity type solar driven carbonaceous material reaction method and apparatus. A focused solar beam irradiates inside a light absorption cavity of a dual-cavity type heat absorption cavity after passing through a glass cover plate; solid particles enter into a separation disk surface of the light absorption cavity through a solid particle inlet; the solid particles and the separation disk surface can be used for absorbing solar light simultaneously, and the solar light is converted into heat energy; high-temperature hot solid particles enter into a downcomer inlet in the center of the light absorption cavity, and a downcomer outlet is connected to a reaction cavity by virtue of a pneumatic box; a preprocessed carbonaceous material is directly conveyed into the reaction cavity by virtue of a spiral conveying pipe and is mixed with hot ceramic particles from the pneumatic box, and the heat energy of the hot ceramic particles is absorbed by the carbonaceous material; meanwhile, the radiation energy of the separation disk surface of the light absorption cavity is absorbed to generate pyrolysis gas; reaction gas enters into a reaction gas product catalysis processing system from the gas outlet of the reaction cavity. The method disclosed by the invention can be used for improving the transfer rate of heat energy; meanwhile, the method can be used for solving the problems of uneven and changeable focus spots, and the service life of the light absorption cavity is prolonged.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com