Drying and gasification process

a gasification process and gasification technology, applied in the field of gasification process, can solve the problems of large and more expensive boiler plants, large volume of boilers, and inability to make a wide spread difference in the local or global energy market of biomass, and achieve the effect of reducing the surface moisture content of carbonaceous substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

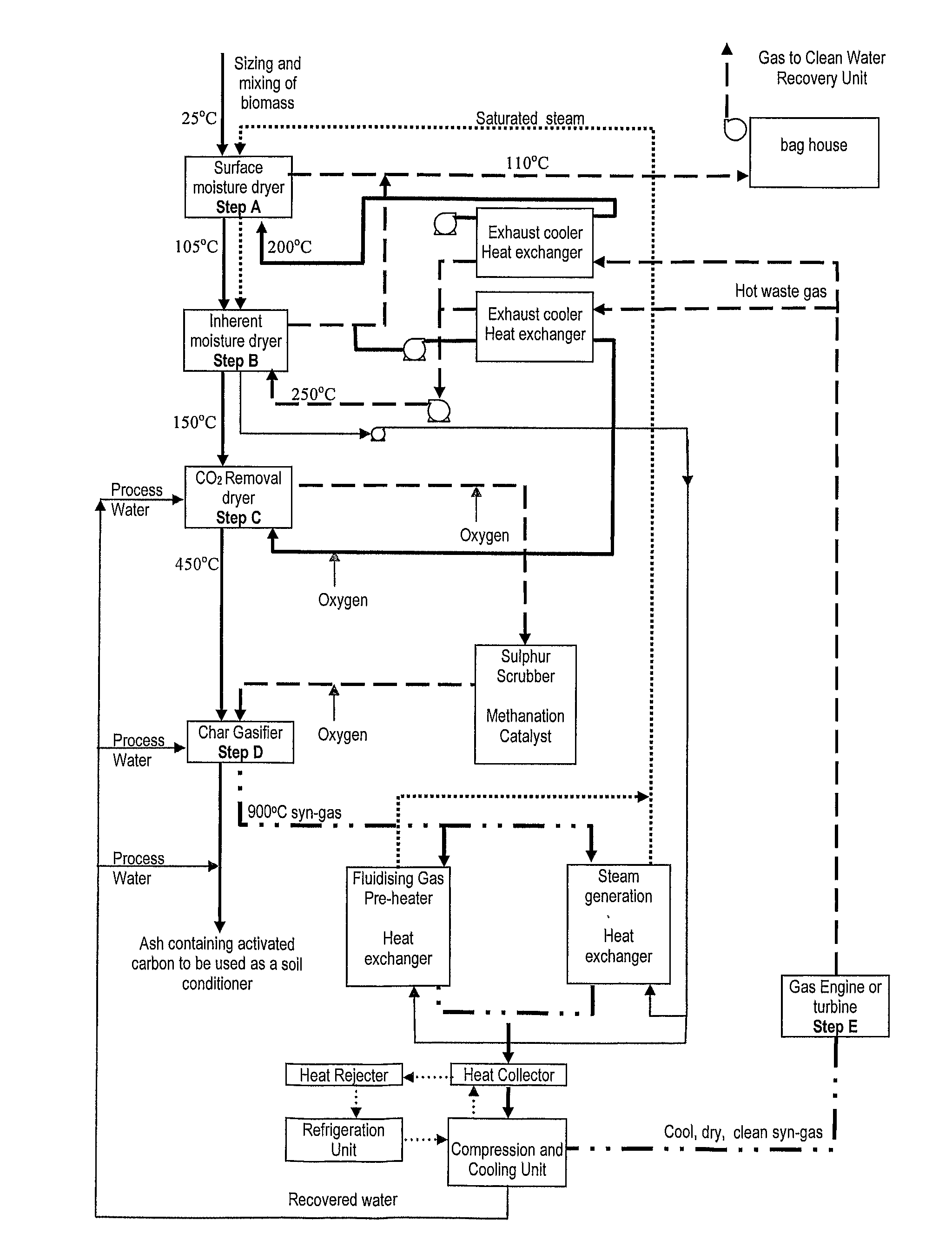

example 1

[0086]Example 1 is for a plant to produce a hot bio-char as a feed to a conventional coal based power station. Referring to FIG. 3, there is shown a process flow diagram in accordance with one embodiment of the present invention. As can be seen, the carbonaceous material proceeds through three process steps which ultimately results in the production of low grade syn-gas.

[0087]In the first process step a) the carbonaceous substance enters a surface moisture dryer where the carbonaceous substance is contacted with a hot gas at a temperature of between 115° C. and 400° C. According to this embodiment, the hot gas is a waste gas from the power station. In addition to the direct contact with the hot gas, the surface moisture dryer also indirectly contacts the carbonaceous substance with steam flowing through steam tubes within the dryer. The action of the steam indirectly contacting the carbonaceous substance slowly heats the substance to between 100° C. and 140° C. resulting in the stea...

example 2

[0100]In the following example, fresh leaves and branches have been mechanically pick up from the ground. The average collection rate is 1.25 tonne per hour over the entire year. This biomass material will be brought to the small central plant where the timber is chipped. The power plant is within 25 km of the farm based sustainable timber production. The fuel composition is:

Total Moisture50.00%w.b.Ash10.80%d.b.Carbon46.10%d.b.Hydrogen5.90%d.b.Nitrogen0.60%d.b.Sulfur0.20%d.b.Oxygen36.40%d.b.Specific Energy18.10MJ / kg d.b (gross)

[0101]This amount of biomass, at its stated composition and if it was used in an open cycle power plant would typically produce about 0.46 MW, (gross). This represents an overall conversion efficiency of 15%. This is below economic size for an open cycle power plant.

[0102]However, if this same biomass was used as a feed source for a plant as outlined in the process diagram FIG. 5, this resource could be used quite effectively. In FIG. 5 the wood waste proceeds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com