Patents

Literature

78results about How to "Reduce residual alkali" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

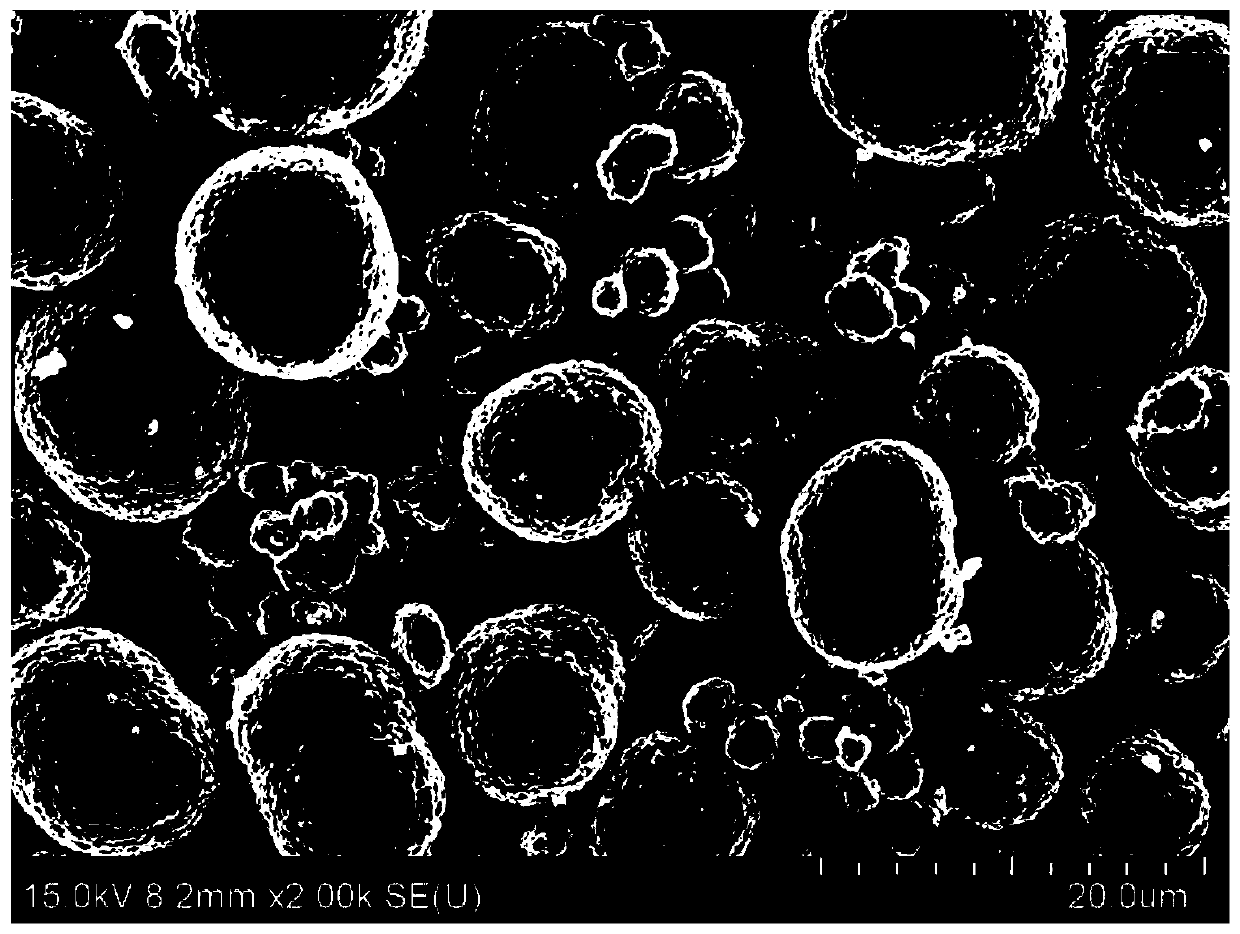

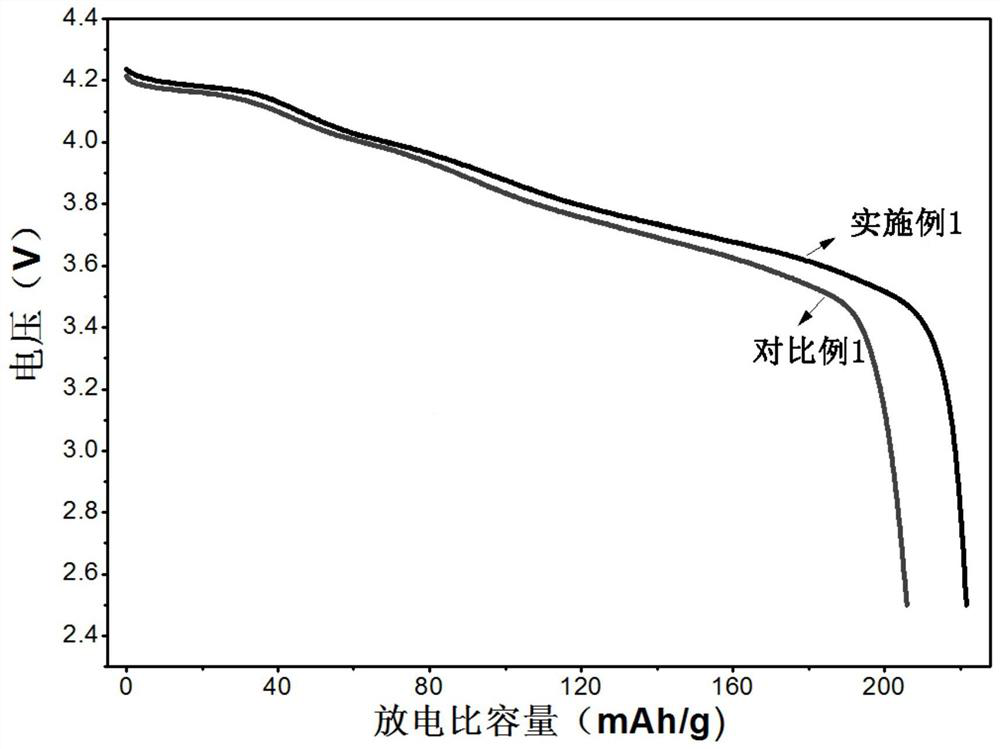

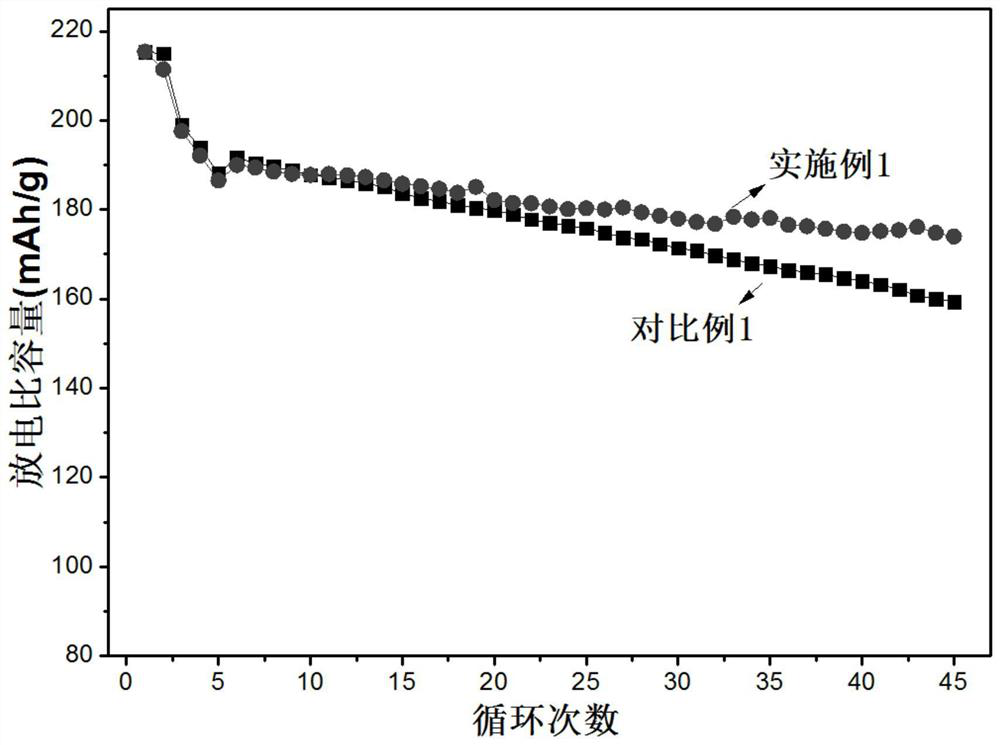

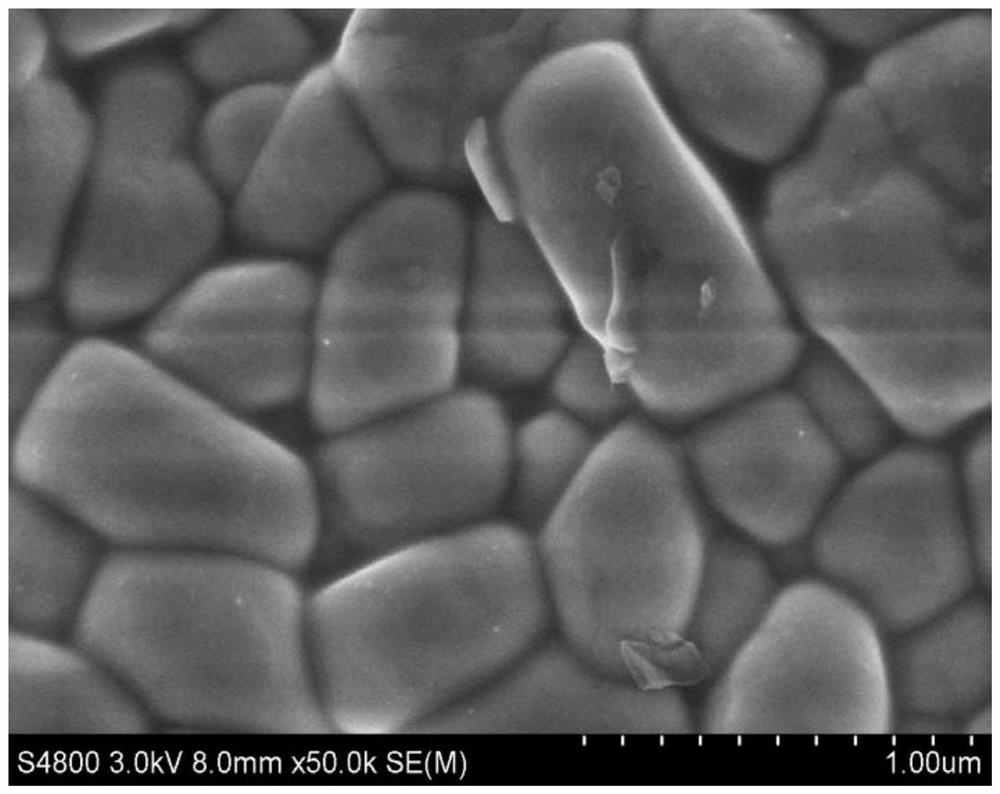

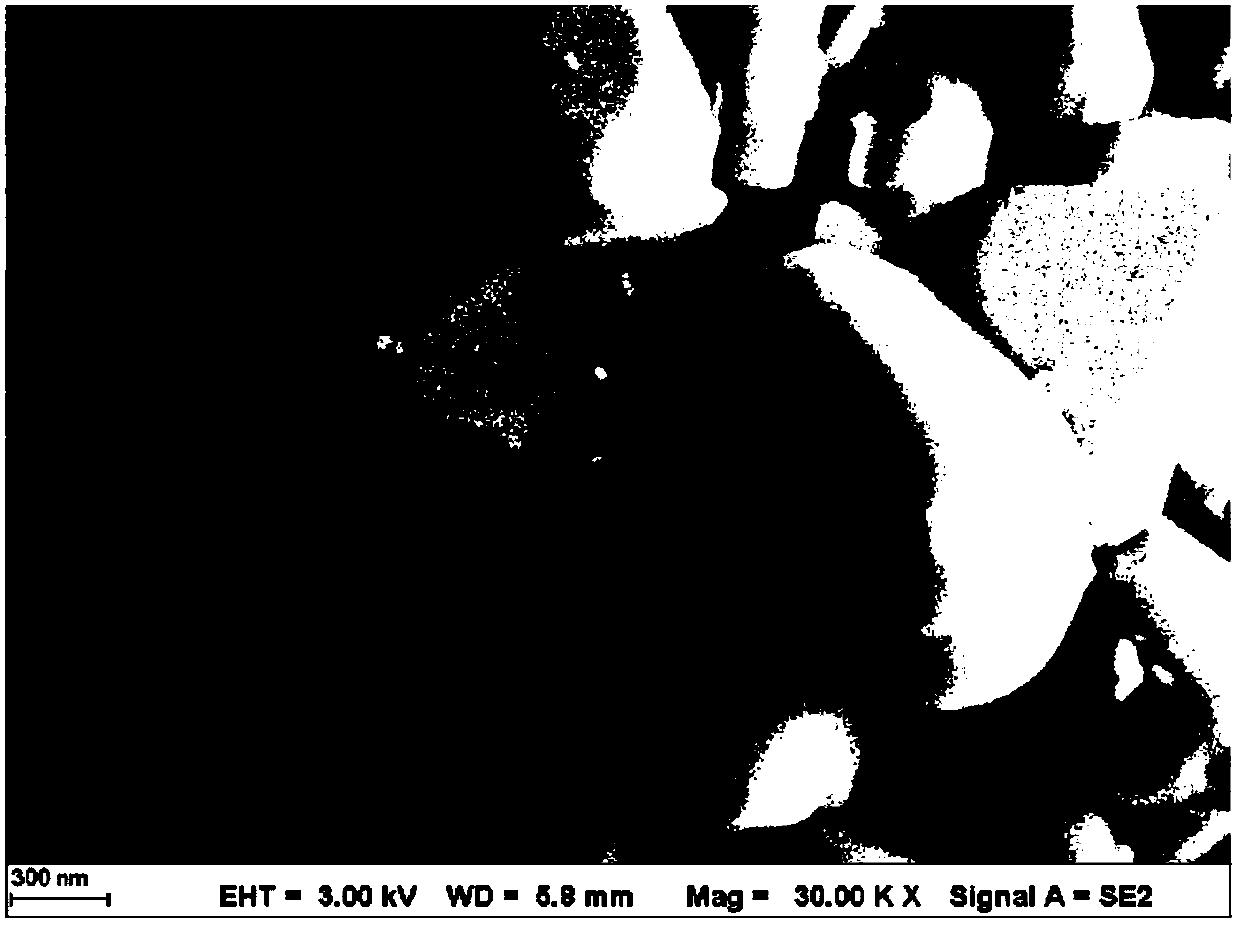

High-compaction and high-stability high-nickel cathode material and preparation method thereof, and lithium ion battery

ActiveCN110010889AImprove powder compactionIncrease the ultimate compaction densitySecondary cellsPositive electrodesHigh energyCerium

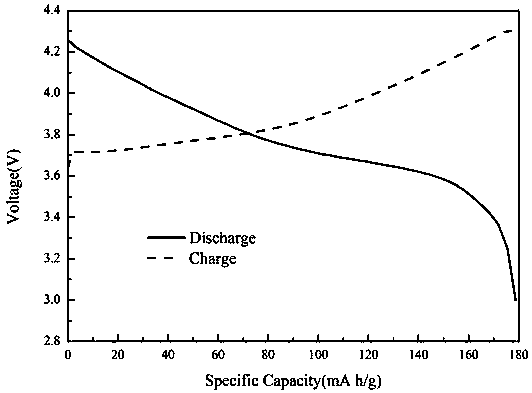

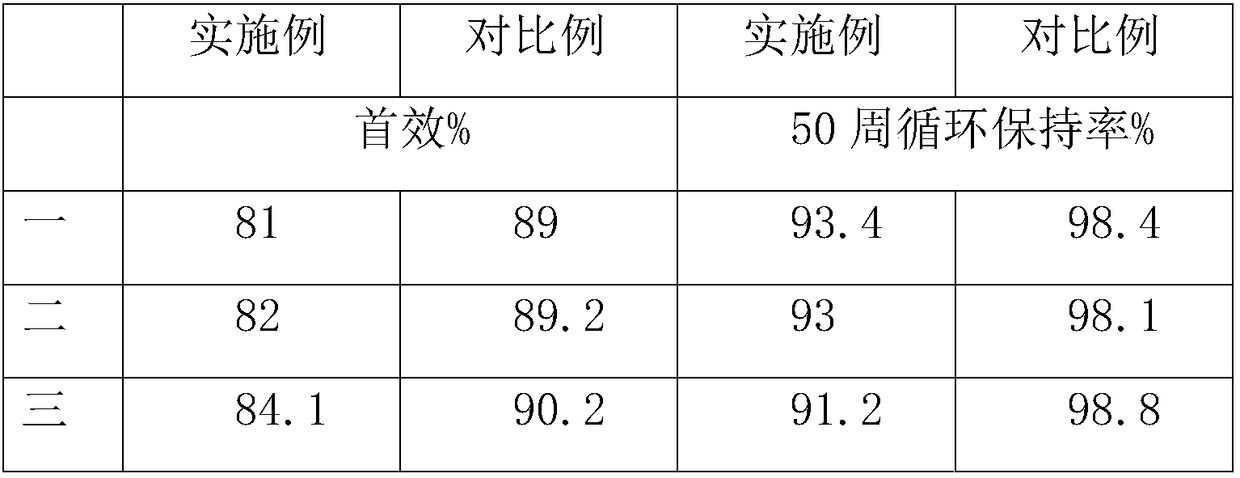

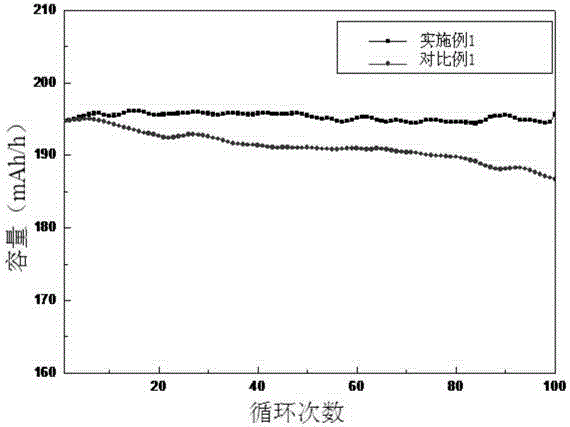

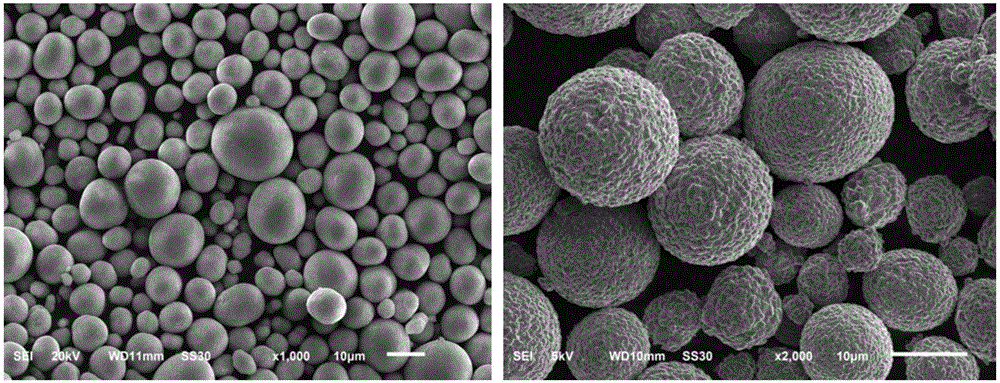

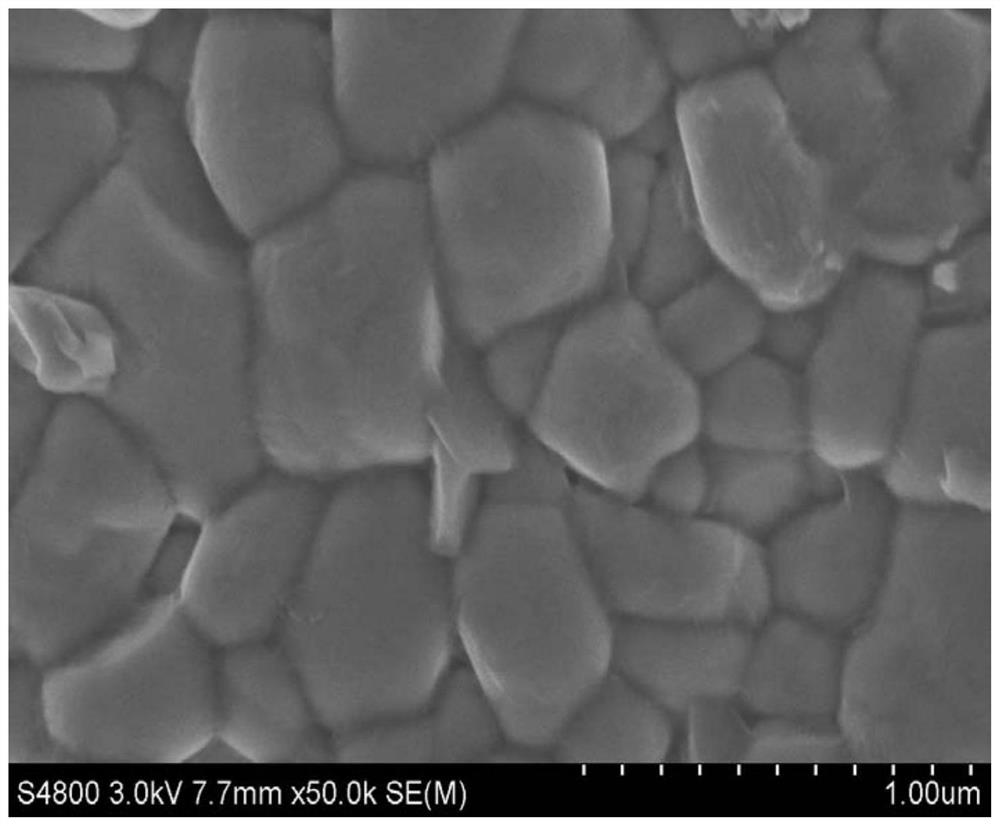

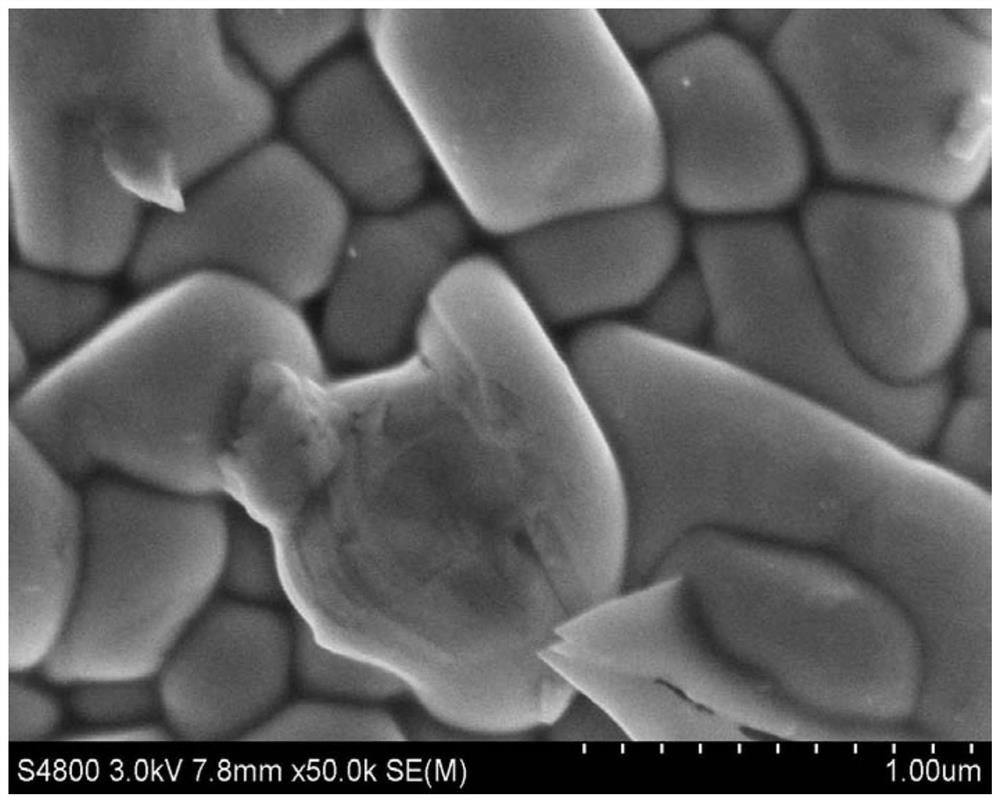

The invention discloses a high-compaction and high-stability high-nickel cathode material and a preparation method thereof, and a lithium ion battery. The high-nickel cathode material comprises a basematerial and a coating layer coating the surface of the base material, the base material is a compound as shown in the formula I: LinNixMyO2, wherein in the formula I, 0.98<n<=1.20, 0.50<x<1.00, 0.00<y<1.00, and 0.00<x+y<=1.00; the base material is consisted of a large-particle substrate and a small-particle substrate; and M is at least one selected from a group consisting of lithium, manganese,aluminum, molybdenum, chromium, vanadium, lanthanum, scandium, cerium, niobium, molybdenum, cobalt, magnesium, zirconium, strontium, yttrium, barium, titanium, fluorine, silicon, boron and phosphorus.The cathode material prepared by the invention has low residual alkali, uniform primary particle coating, primary particle pressure resistance and difficult breakage, so that the prepared lithium ionbattery has high energy density, lower internal resistance and excellent rate capability, safety performance and cycle performance.

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

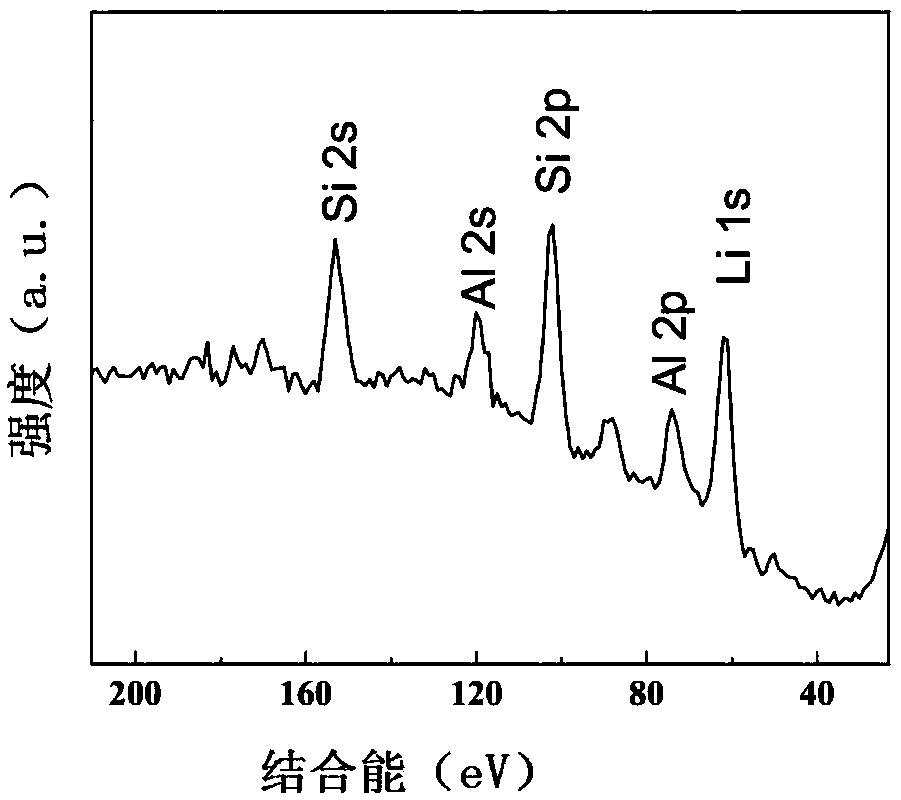

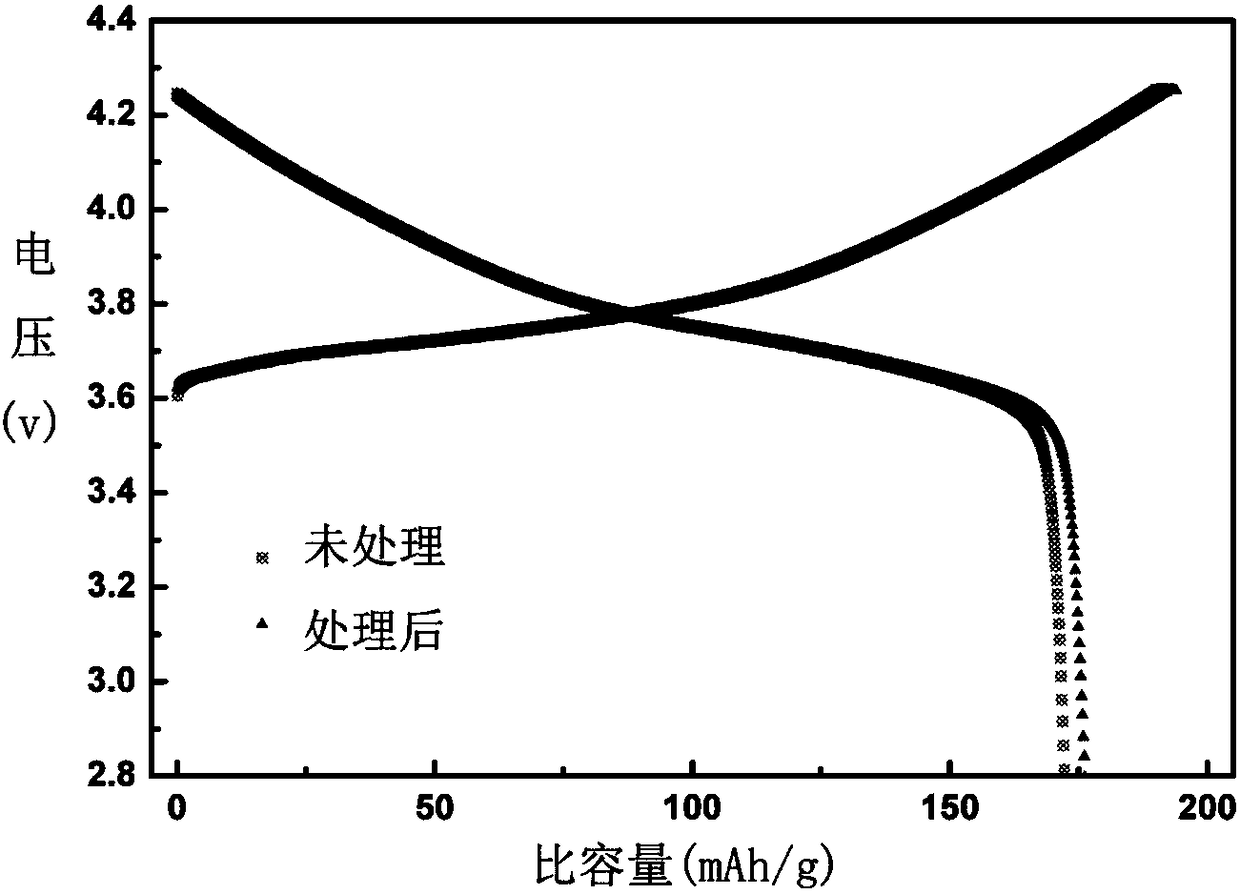

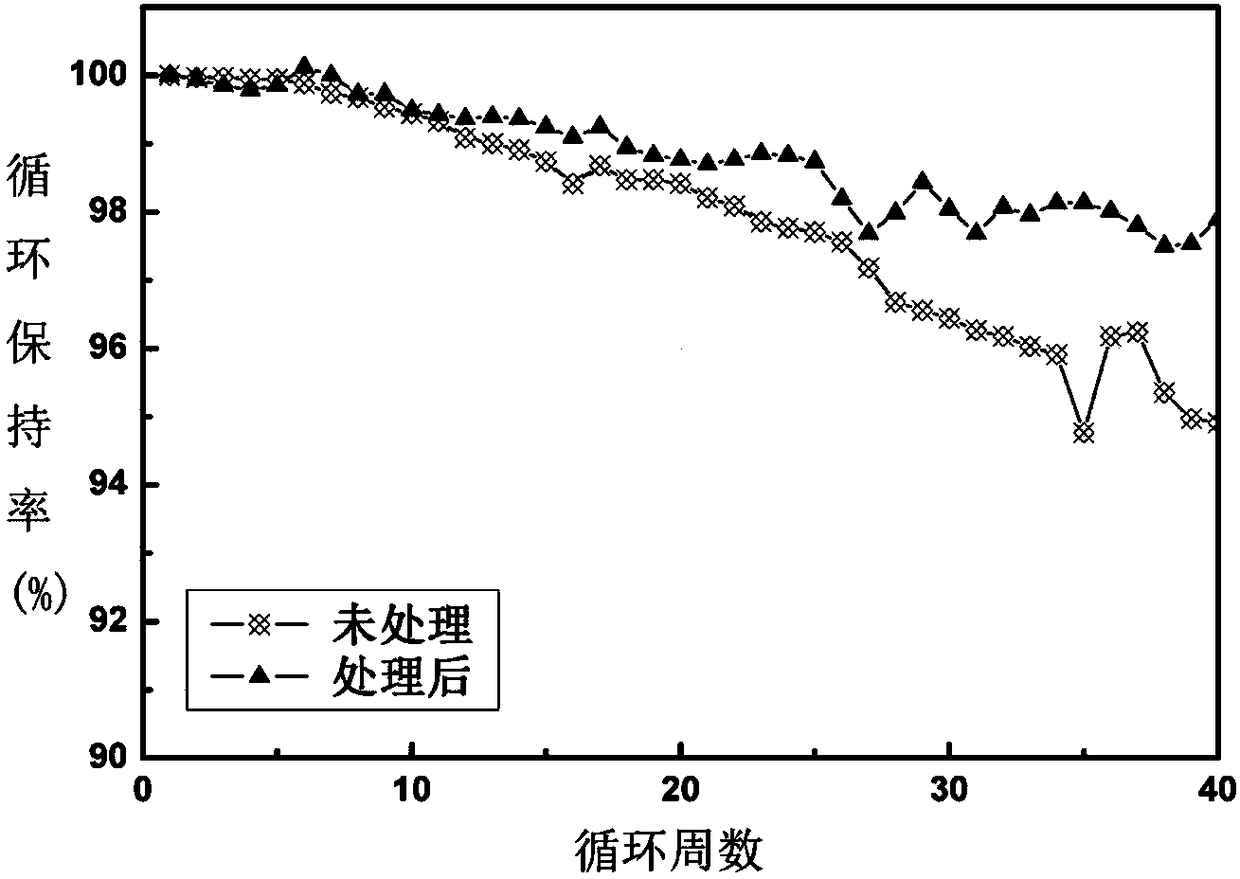

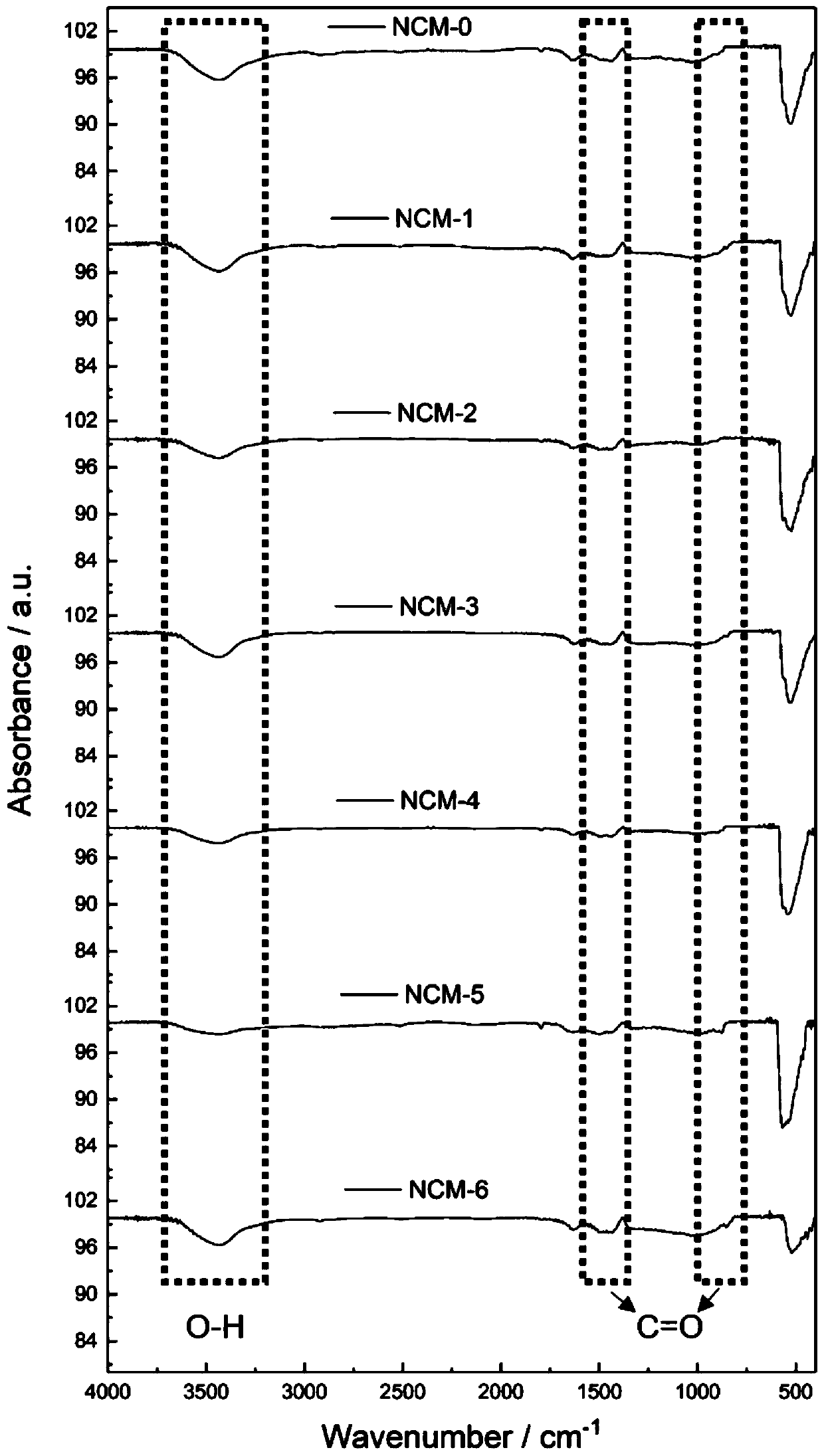

High-nickel material coated with aluminum and lithium silicate on surface and doped with fluorine on surface layer and preparation method

ActiveCN108807931AImprove electronic conductivityReduce residual alkaliCell electrodesElectrical conductorOxygen

The invention discloses a high-nickel material coated with aluminum and lithium silicate on the surface and doped with fluorine on a surface layer. The high-nickel material comprises an aluminum and lithium silicate coating layer and a high-nickel ternary material central layer, wherein the thickness of the coating layer is 1-200 nm, and the coating layer is doped with a fluorine element. In addition, the invention discloses a preparation method of the high-nickel material. The preparation method comprises the steps of mixing, drying and screening, lithium-adding sintering and fluorine-addingthermal treatment. The aluminum and lithium silicate fast-ion conductor material coating layer has good lithium-ion conducting performance, doped fluorine ions replace oxygen in the coating layer or the high-nickel material, accordingly the electronic conductivity of the material is improved, finally the surface of the high-nickel material has better lithium-ion and electronic conductivity properties, and playing of the rate capability of an anode material for lithium ion batteries is facilitated. The preparation method of the high-nickel material is low in cost, the process is simple, and industrialization is easy to achieve.

Owner:余姚市海泰贸易有限公司

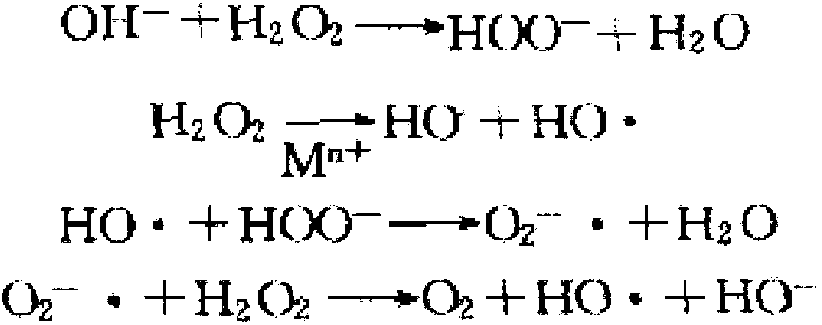

Composite modification method for lithium ion battery positive electrode material

InactiveCN108134069AInhibition of dissolutionInhibit migrationCell electrodesSecondary cellsSolventThermal treatment

The invention discloses a composite modification method for a positive electrode material. The method comprises the following steps: 1) removing impurities from a positive electrode material precursorto obtain a cleaned and impurity-removed positive electrode material precursor; 2) mixing the clean and impurity-removed positive electrode material precursor obtained in step 1) with a lithium source; 3) sintering the above obtained mixture to obtain a positive electrode material matrix; 4) dispersing and dissolving the source substance and the coating aid of a coating material in a solvent to obtain a dispersion system, adding the positive electrode material matrix obtained in step 3) to the dispersion system, performing stirring, then performing solid-liquid separation to obtain a coated solid substance, and finally performing heat treatment to obtain a material having a coating material layer; and 5) washing and drying the material obtained in step 4) to obtain a composite modified lithium ion battery positive electrode material. The high-nickel positive electrode material with a good stability is prepared through the method, and can be washed to effectively reduce residual alkaliwhile keeping the structure stable without causing deterioration of performances.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Preparation method of low-surface-residual-alkali nickel cobalt manganese ternary positive electrode material

The invention relates to a preparation method of a low-surface-residual-alkali nickel cobalt manganese ternary positive electrode material and belongs to the field of chemical energy storage batteries. The preparation method includes that boric acid or citric acid is dissolved in alcohol, so that a certain amount of free-state hydrogen ions are contained in a solution; a nickel cobalt manganese ternary positive electrode material is added then, acid-alkali neutralization reaction between H+ and material surface residual alkali is utilized, and reaction intensity is regulated through stirring time, so that the residual alkali on the surface of the material can be reduced effectively, and pH value of the surface of the material is lowered; an alcohol solution is used for flushing then, so that the surface of the material is ensured to be free of residual borate ions or citrate ions; alcohol molecules probably left on the surface are removed through a two-time calcining method, so that uniformity and stability of the material are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Lithium ion battery positive electrode material and preparation method thereof, and battery

ActiveCN109713284AImprove cycle performanceReduce residual alkaliCell electrodesSecondary cellsPhysical chemistryPyrophosphate

The invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery positive electrode material and a preparation method thereof, and a battery. The method includes the following steps: 1) a precursor of the lithium ion battery positive electrode material is mixed with phosphate, and then low temperature calcination is performed to obtain the precursor havingpyrophosphate or metaphosphate coating layers on the surface; and 2) the precursor is mixed with a lithium salt, and high temperature calcination is performed to obtain the positive electrode material, wherein the temperature of the low temperature calcination is 250-400 DEG C, and the time is 8-12 hours. The positive electrode material prepared by the method includes an active material having ageneral molecular formula of LiaNixCoyMnzO2, and a coating layer of lithium pyrophosphate or lithium metaphosphate, residual alkali of the positive electrode material can be reduced, and cycle stability of the positive electrode material is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Dual-cladding 622-type Ni-Co-Mn ternary positive electrode material and preparation method thereof

InactiveCN107863514AImprove intrinsic electronic conductivityLarge cell parametersCell electrodesSecondary cellsManganeseHeat treated

The invention discloses a dual-cladding 622-type Ni-Co-Mn ternary positive electrode material. The molecular formula of the dual-cladding 622-type Ni-Co-Mn ternary positive electrode material is xMO.yMF.LiNi<0.6>Co<0.2>Mn<0.2>O2, wherein M is Na, Mg or Al, x is more than or equal to 0 but less than or equal to 0.09, and y is more than or equal to 0 but less than or equal to 0.09. The dual-cladding622-type Ni-Co-Mn ternary positive electrode material is implemented according to the following steps of 1) primary coating, in which lithium carbonate, Ni<0.6>Co<0.2>Mn<0.2>(OH)2 and an oxide are sequentially added into a ball-milling tank, and dry ball-milling is performed for 6-18 hours; 2) pre-sintering, in which powder in the step 1) is subjected to thermal processing for 6 hours under a temperature of 700-800 DEG C and then is naturally cooled; 3) washing, in which the powder in the step 2) is cleaned with deionized water and then is cleaned with ethyl alcohol; 4) secondary coating, inwhich the powder in the step 3) is taken out and mixed with a fluoride, and the product is placed in water bath for drying under 90-100 DEG C after ultrasonic treatment for 30 minutes; and 5) secondary sintering, in which the powder in the step 4) is subjected to heat preservation under a temperature of 800-900 DEG C and is naturally cooled to obtain the dual-cladding 622-type Ni-Co-Mn ternary positive electrode material. The method is safe and efficient, and the obtained dual-cladding 622-type Ni-Co-Mn ternary positive electrode material is fine and uniform distribution in particle, has a favorable microstructure and has relatively good electrochemical performance.

Owner:淮安新能源材料技术研究院

Complex enzyme preparation and technique for preparing dissolving pulp by using same

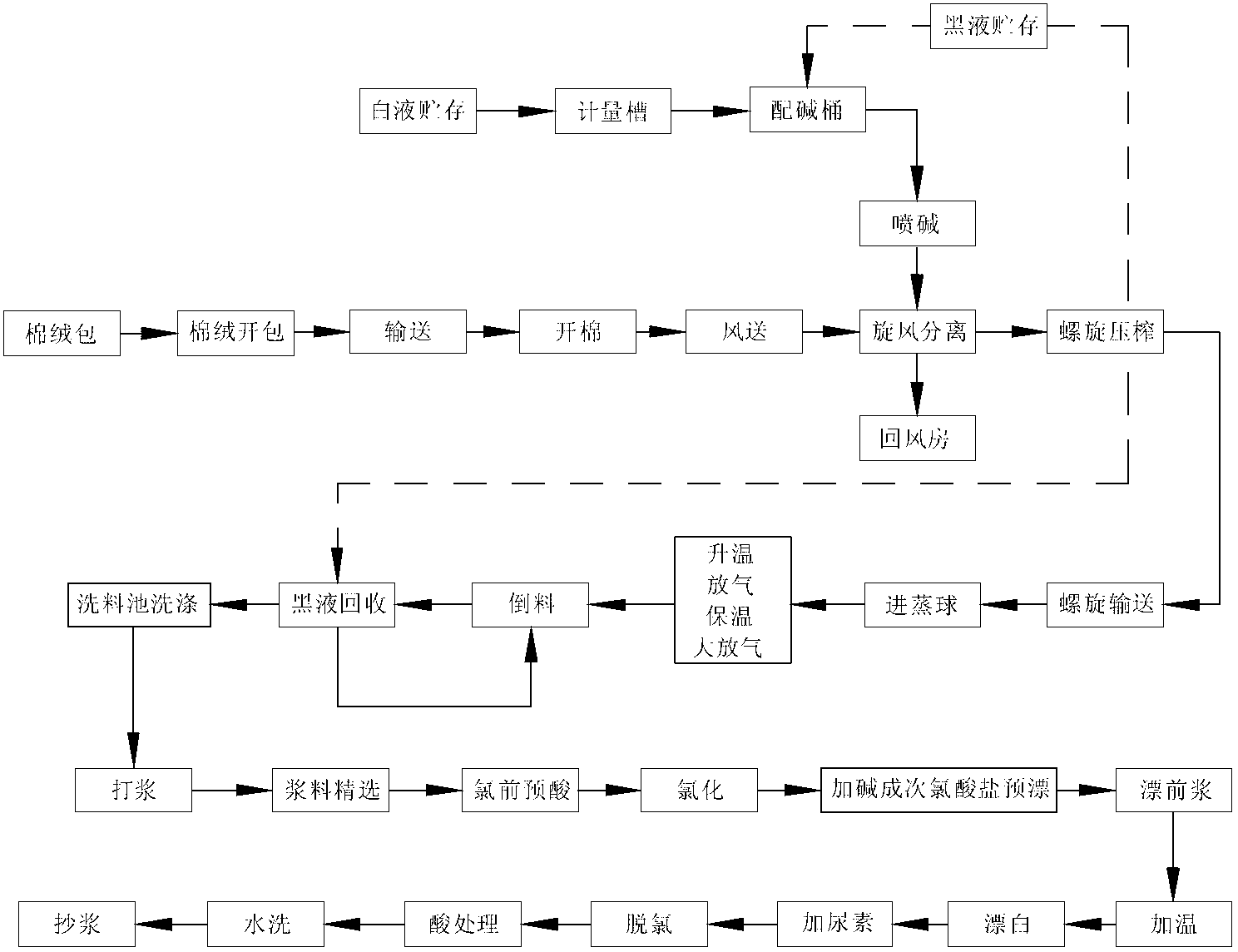

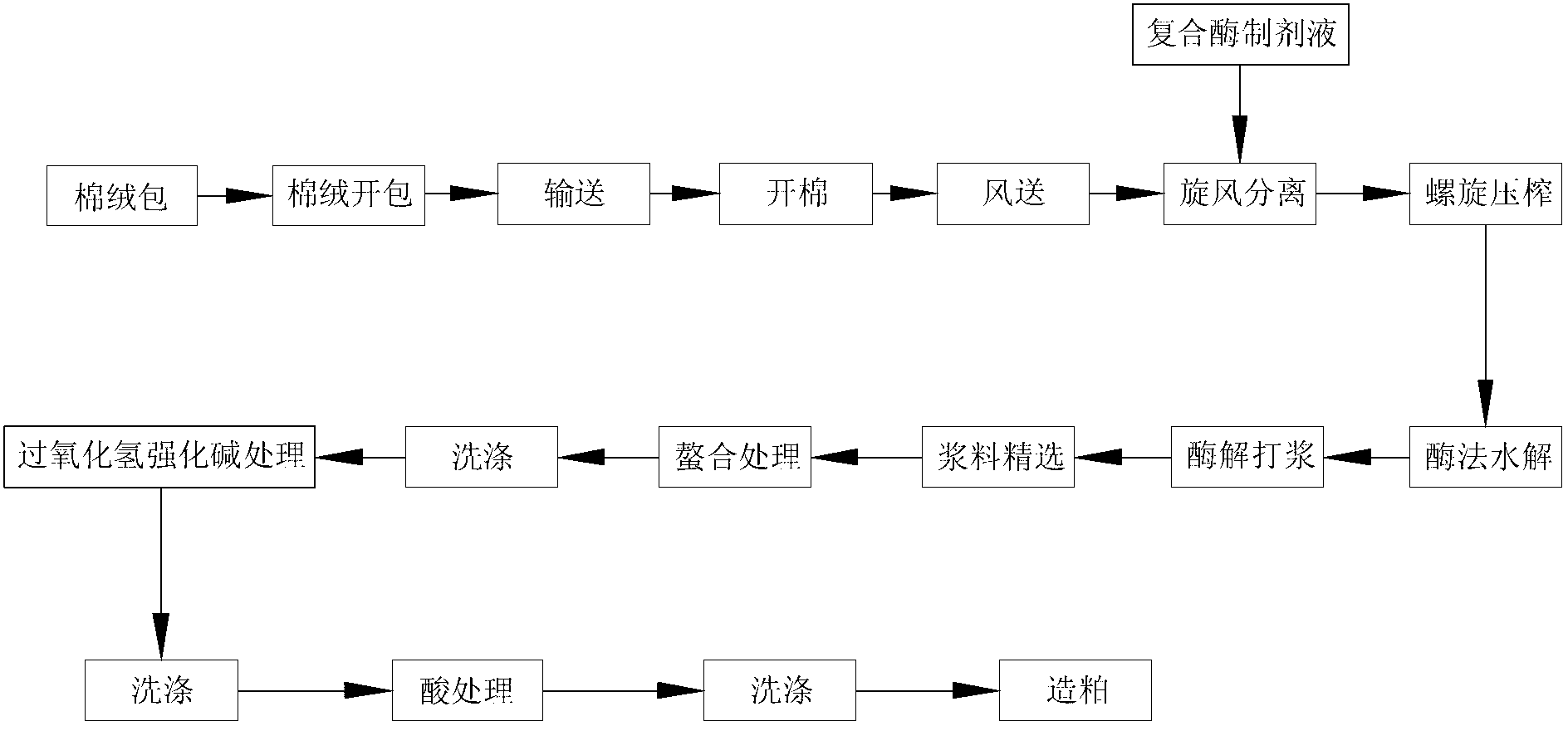

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

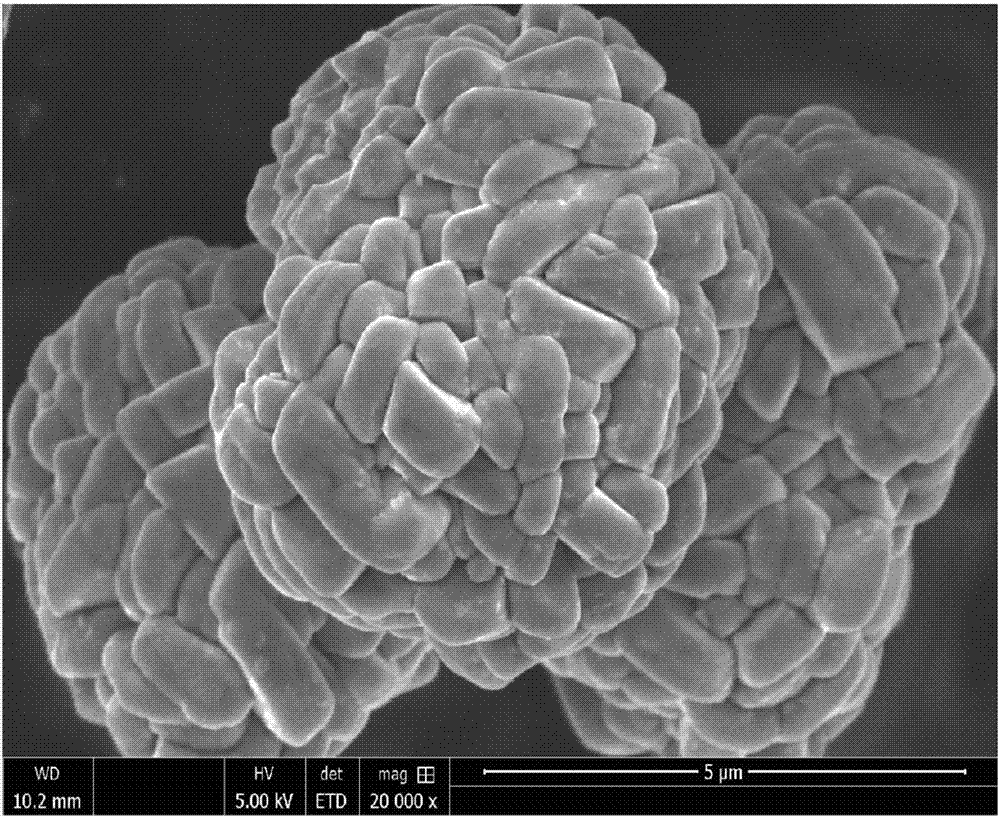

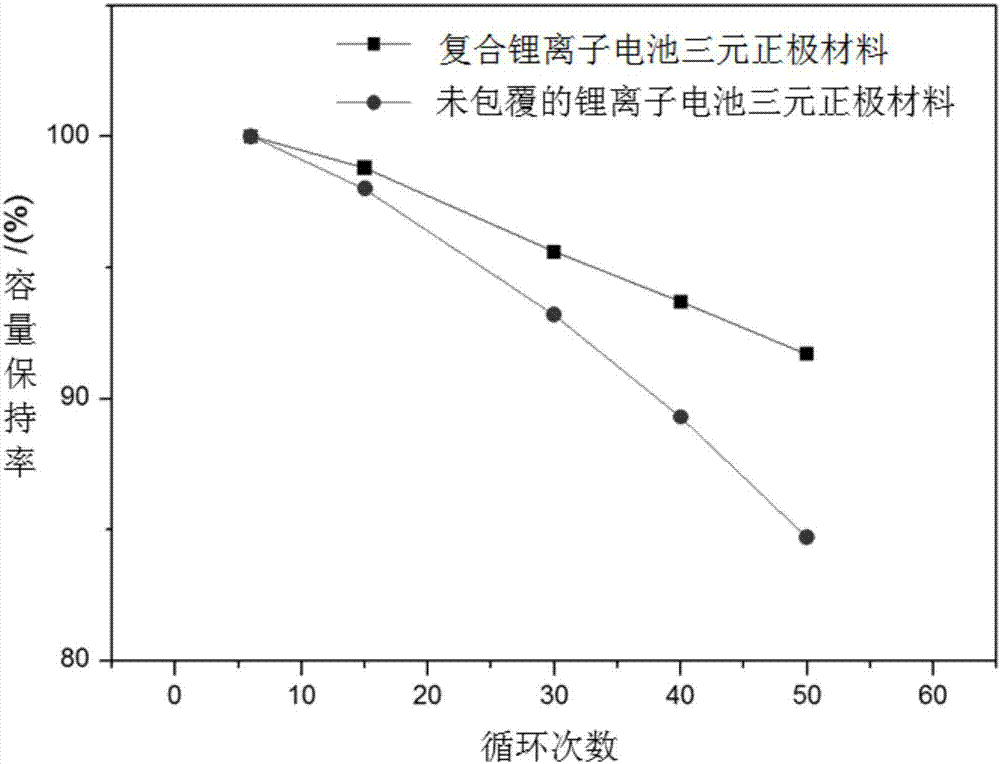

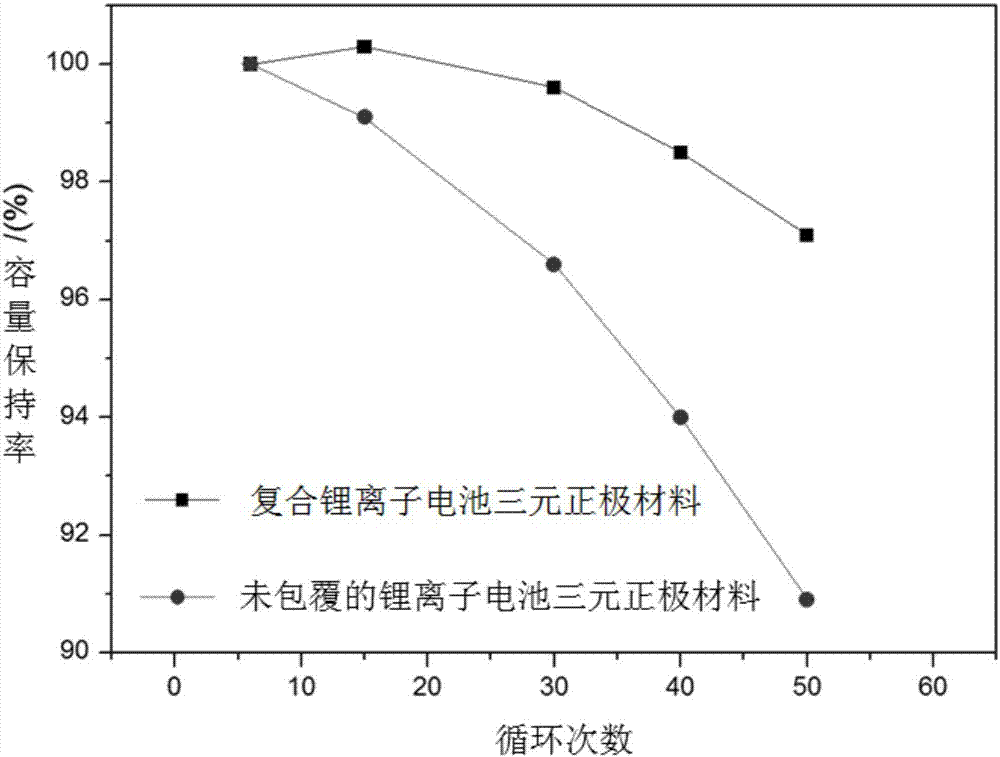

Composite lithium ion battery ternary cathode material and preparation method thereof

ActiveCN107104226AReduce residual alkaliSimple processSecondary cellsPositive electrodesHigh rateManganese

The invention belongs to the technical field of lithium ion batteries, and especially relates to a composite lithium ion battery ternary cathode material and a preparation method thereof. The composite lithium ion battery ternary cathode material includes a Ni-Co-Mn ternary cathode material as a core and a cladding layer that coats the Ni-Co-Mn ternary cathode material. The characteristic general formula of the Ni-Co-Mn ternary cathode material is Li<m>Ni<1-x-y>Mn<x>Co<y>O2, 0.98 <= m <= 1.10, 0.2 <= x <= 0.25 and 0.2 <= y <= 0.25; the cladding layer is composed of Al2O3 and LiAlO2. The composite lithium ion battery ternary cathode material has high volume energy density and has better cycle performance at high temperature and high rate. In the preparation, organic aluminum alcoholate serves as an aluminum source and is firstly uniformly mixed with a cathode material; and then water is added to initiate the reaction to produce the ternary cathode material. The preparation method is simple and low-cost and has good cladding effect.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Double layer clad lithium ion battery cathode material and preparation method thereof

ActiveCN108666534AReduce residual alkaliInhibit side effectsCell electrodesSecondary cellsHigh rateManganese oxide

The invention discloses a double layer clad lithium ion battery cathode material and a preparation method thereof. The cathode material takes a lithium nickel cobalt manganese oxide ternary material as a matrix, and the surface of the matrix is clad with silicon lithium salt cladding and metal oxide cladding. The silicon lithium salt cladding is formed through the following steps: mixing silicon weak acid with the matrix, and carrying out a neutralization reaction on the silicon weak acid and residual alkali on the surface of the matrix to generate a layer of silicon lithium salt with which the matrix is clad. The metal oxide is mixed with the matrix which is clad with the silicon lithium salt, and the matrix is clad with a layer of the metal oxide cladding through physical cladding. The double layer clad lithium ion battery cathode material reduces the amount of the residual alkali on the surface of the lithium nickel cobalt manganese oxide matrix material, and prevents a side reaction of an electrolyte and the matrix material. Furthermore, the cathode material has high rate performance, high specific capacity and good cycle performance. In addition, the method is simple and is easy in operation and large scale production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

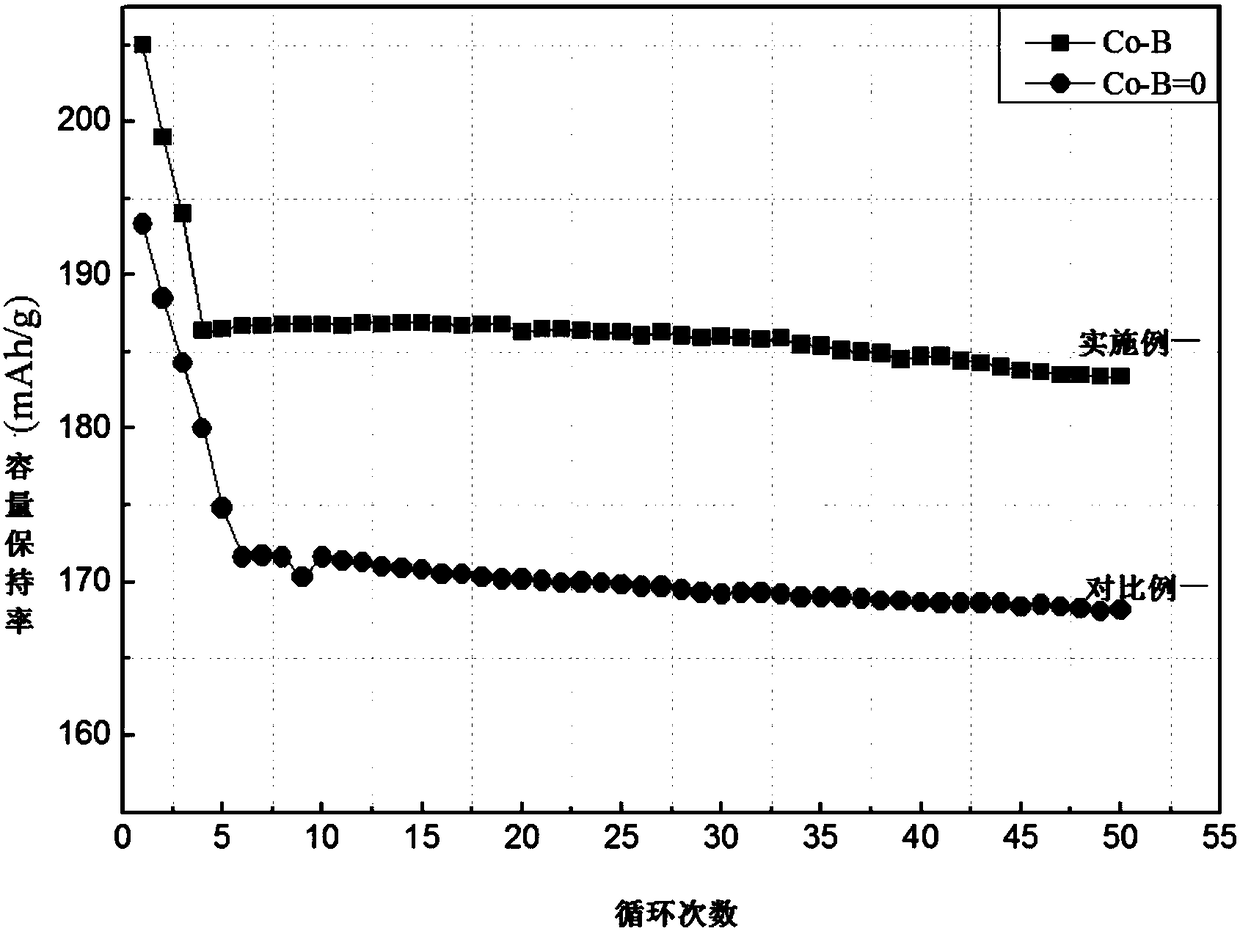

Y/La-doped Co/B co-coated nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

ActiveCN108550802AImprove cycle lifeImprove securityCell electrodesSecondary cellsManganeseSide reaction

The invention belongs to the technical field of lithium batteries, and provides a Y / La-doped Co / B co-coated nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof. According to the present invention, the cycle performance and the safety performance are improved by doping a small amount of Y<3+> ions and La<3+> ions, wherein Y<3+> / La<3+> and Ni<3+> have the same valence state, the doped Y<3+> / La<3+> can enter the metal Ni<3+> position, the Y<3+> / La<3+> does not produce the valence change during the charge and discharge, is electrochemically inert, and doesnot produce the valence state change during the charge and discharge so as not to produce the volume change, such that the Y<3+> / La<3+> can act as the skeleton, stabilize the crystal structure, and improve the cycle life and the safety performance of the material; and under the high voltage, the Co / B co-coated positive electrode material can effectively improve the cycle performance and the electronic conductivity of the battery, reduce the residual alkali, and reduce the flatulence, such that the co-coated nickel-cobalt-manganese ternary positive electrode material can effectively prevent theoccurrence of side reactions so as to improve the cycle performance and the electrochemical performance of the lithium battery.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Method for preparing doped and modified nickel-cobalt lithium aluminate anode materials

ActiveCN106410187AStable structureImprove cycle performanceCell electrodesSecondary cellsCobalt metalNickel salt

The invention provides a method for preparing doped and modified nickel-cobalt lithium aluminate anode materials. The method includes (1), preparing first mixed liquor with nickel salt and cobalt salt; (2), preparing second mixed liquor with aluminum salt, complexing agents and compounds with doped metal elements; (3), combining flow of the first mixed liquor, flow of the second mixed liquor, flow of alkali liquor and flow of ammonia water solution with one another to obtain mixed flow, adding the mixed flow into a reaction kettle, carrying out reaction at the temperatures of 50-80 DEG C for 36-64 h, filtering, washing and drying obtained materials after the reaction is completely carried out so as to obtain doped and modified nickel-cobalt-aluminum precursors; (4), uniformly mixing the doped and modified nickel-cobalt-aluminum precursors and lithium source compounds with one another to obtain mixtures, heating the mixtures in oxygen atmosphere at the speed of 4-10 DEG C / min until the temperatures of the mixtures reach 700-800 DEG C, calcining the mixtures under heat-insulation conditions for 10-20 h, carrying out reaction, then naturally cooling obtained materials until the temperatures of the materials reach the room temperature and smashing and sieving the obtained materials to obtain the doped and modified nickel-cobalt lithium aluminate anode materials. A molar ratio of nickel metal ions to cobalt metal ions to aluminum metal ions in the reaction kettle is 0.80:0.15:0.05. The method has the advantage that the doped metal elements and host elements can be mixed with one another on atomic scales.

Owner:JINGMEN GEM NEW MATERIAL

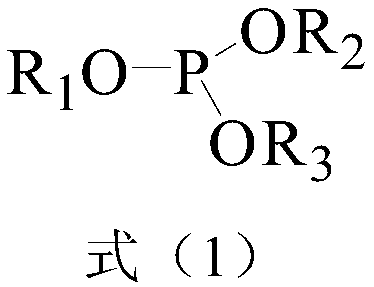

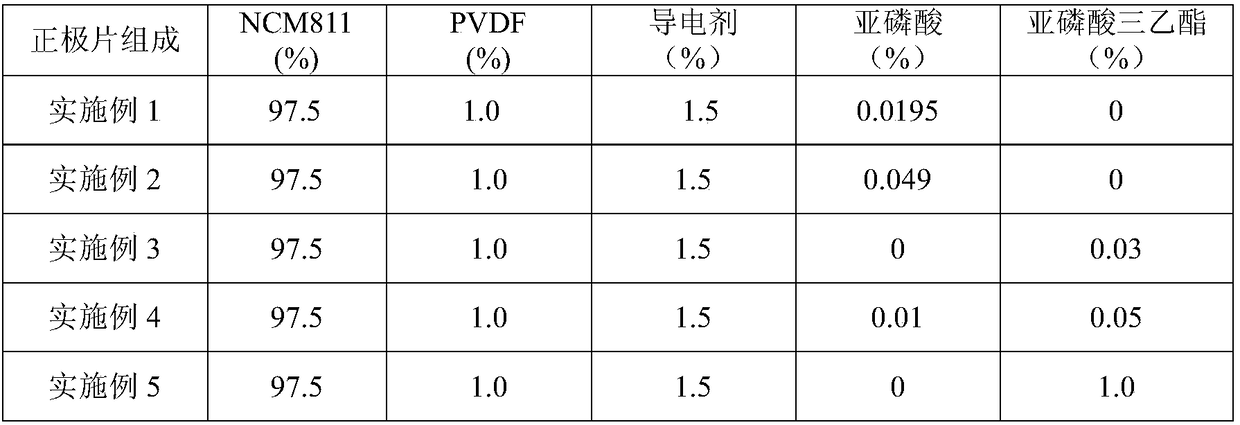

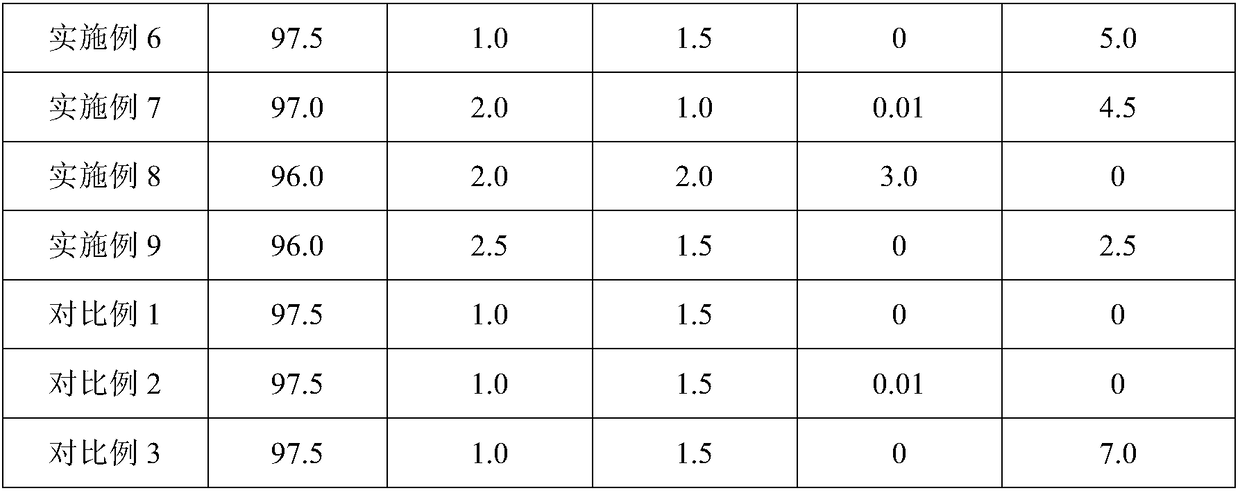

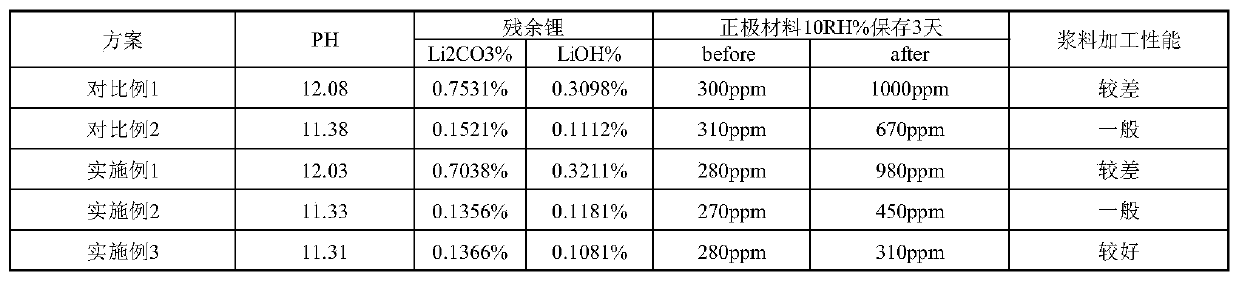

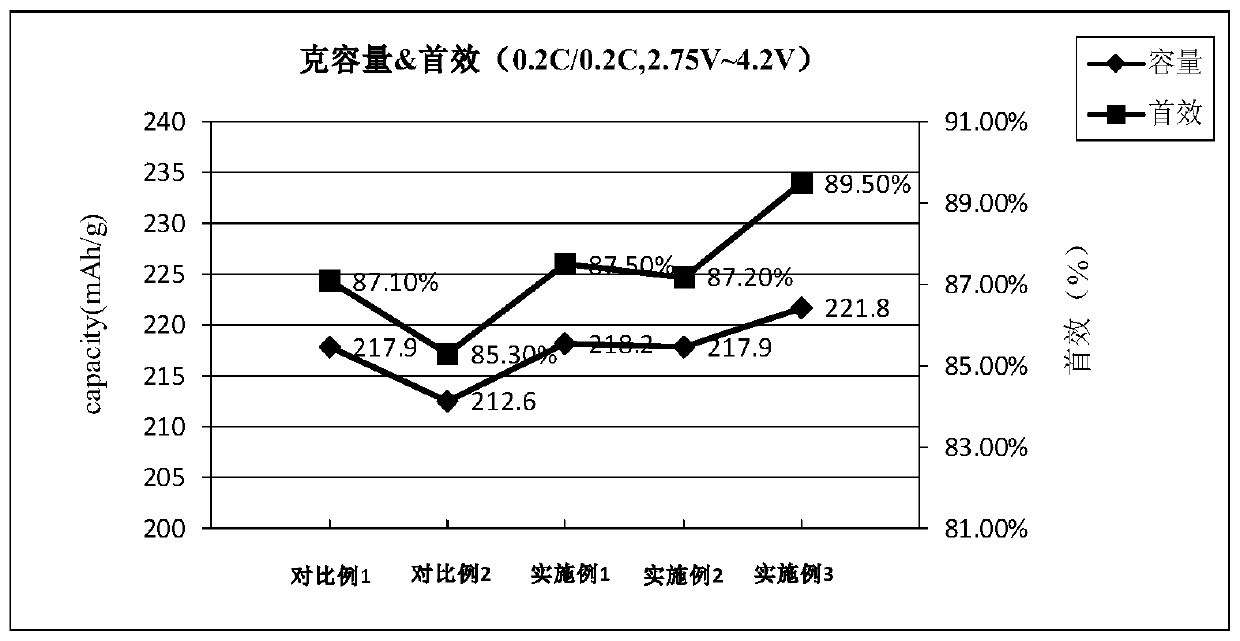

Positive electrode sheet and lithium ion secondary battery with same

ActiveCN108539122APlay a covering roleReduce concentrationCell electrodesSecondary cellsLithiumPhosphorous acid

The invention belongs to the technical field of lithium secondary batteries and discloses a positive electrode sheet preparation method and a lithium ion secondary battery with a positive electrode sheet. Prepared positive electrode sheet paste contains an additive in a molecular formula (1), and the additive can be phosphorous acid or phosphite ester. By adding of the appropriate quantity of phosphorous acid and / or phosphite ester into the positive electrode sheet paste, the problem of powder shedding of the positive electrode sheet can be improved, adhesiveness between a positive electrode sheet coating and an aluminum foil is improved, a positive electrode material particle coating effect is achieved, and accordingly battery gas-producing expansion is remarkably inhibited while batterycycle stability is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Stewing method for preparing bamboo wood dissolving pulp

InactiveCN102337689AIncrease productionQuality improvementPretreatment with water/steamPulping with inorganic basesLiquid wasteBlack liquor

The invention belongs to the technical field of dissolving pulp preparation and relates to a stewing method for preparing bamboo wood dissolving pulp, which comprises the following steps of: (a) introducing vapor to a boiler: preparing bamboo wood raw materials into slice materials, conveying the slice materials to a digester, and introducing low pressure vapor to the digester while conveying theslice materials; (b) vapor heating and pre-hydrolyzing: heating through the vapor after introducing the vapor to the boiler to pre-hydrolyze the slice materials; (c) neutralizing through white liquor: neutralizing the slice materials and vapor condensed water in the digester through the white liquor in a hot white liquor tank; (d) replacing through hot black liquor: replacing the neutralization liquid waste in the digester through the hot black liquor in a hot black liquor tank; (e) heating and stewing in a temperature control manner to prepare virgin pulp of the bamboo wood dissolving pulp; (f) replacing the washing black liquor, washing and cooling the virgin pulp; and (g) discharging at a low temperature. The invention has the advantages of reducing the production cost, increasing the production efficiency, effectively utilizing the stewing heat and improving the yield and the quality of the bamboo wood dissolving pulp.

Owner:CHONGQING LEE & MAN PAPER MFG

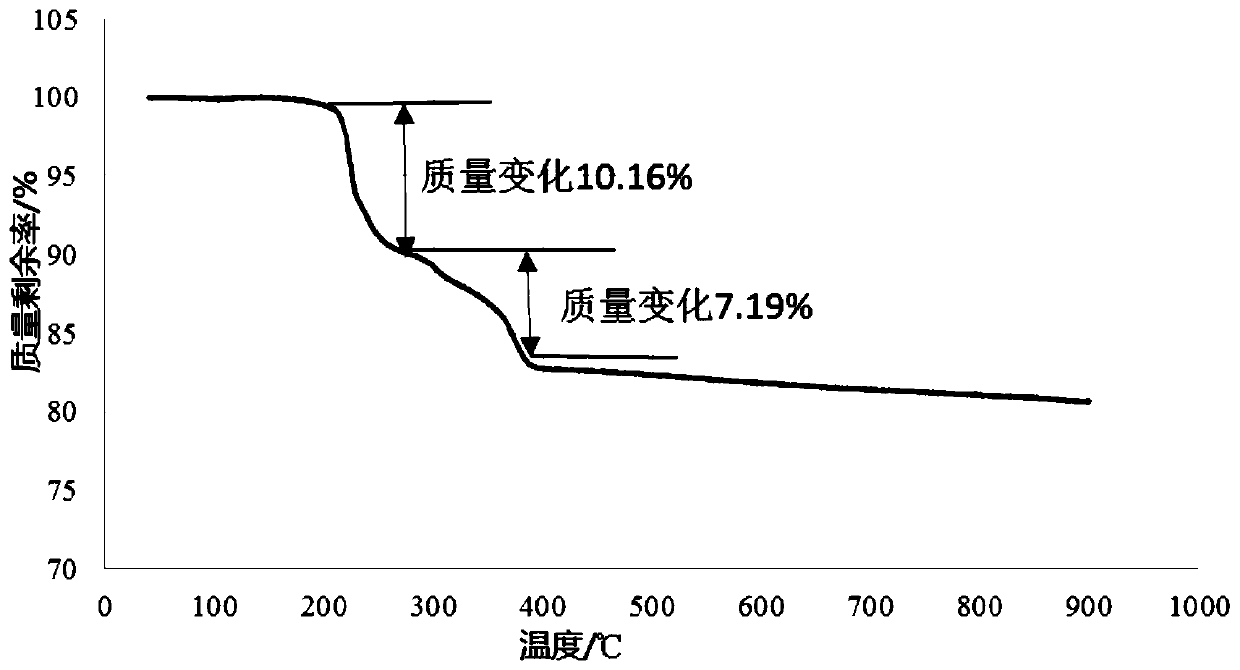

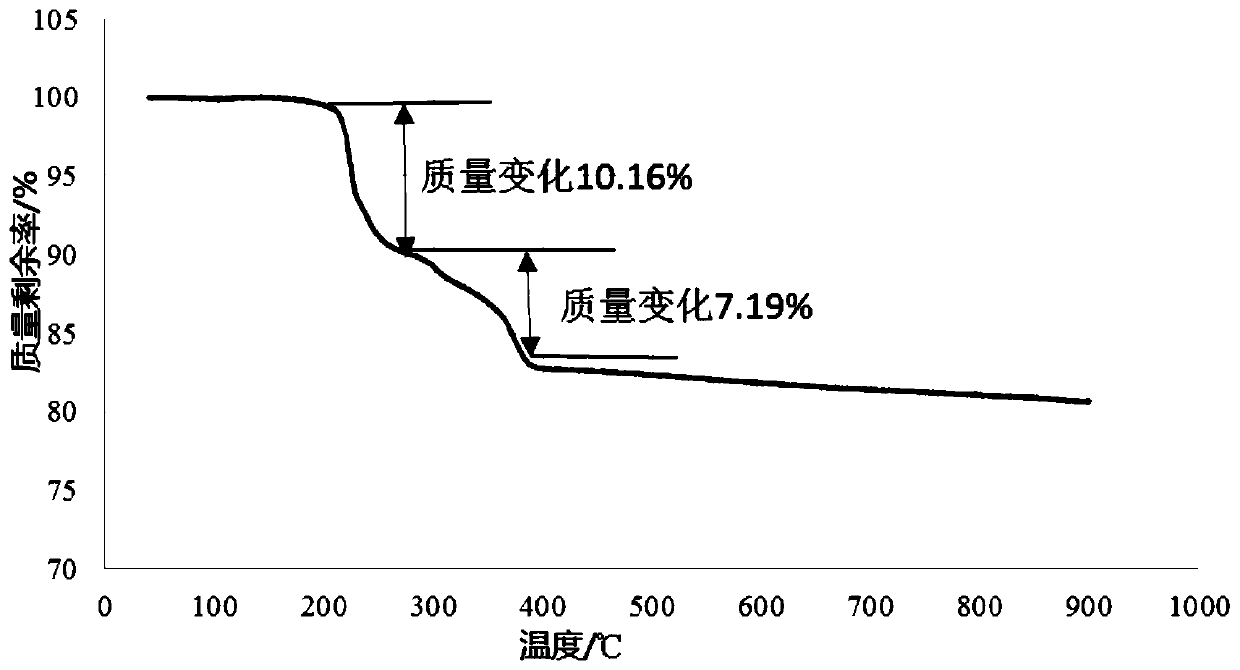

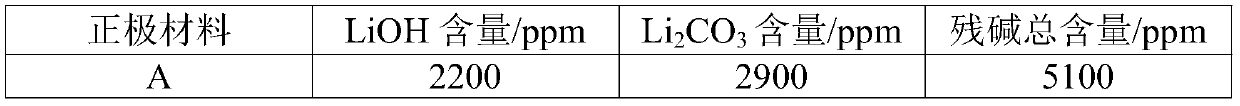

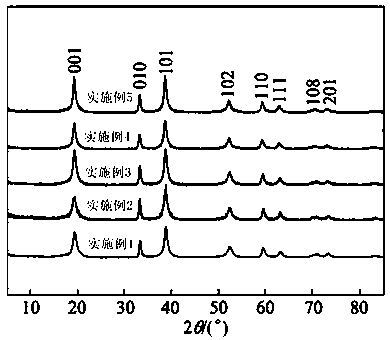

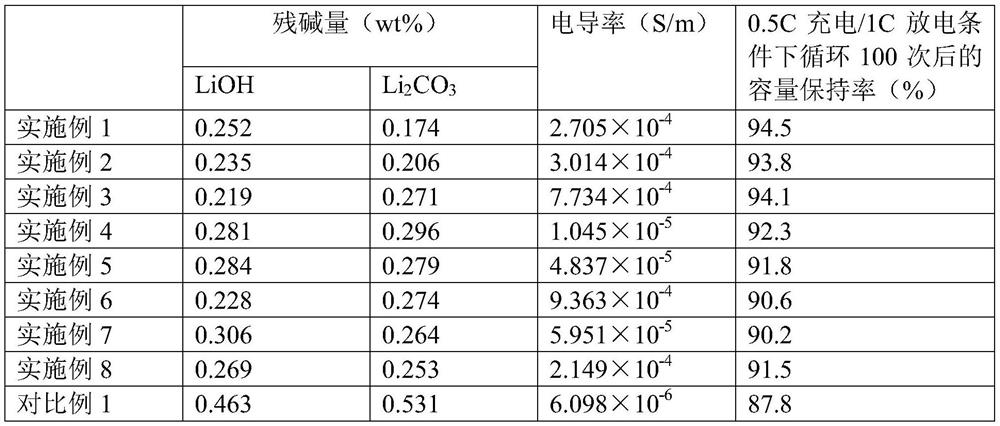

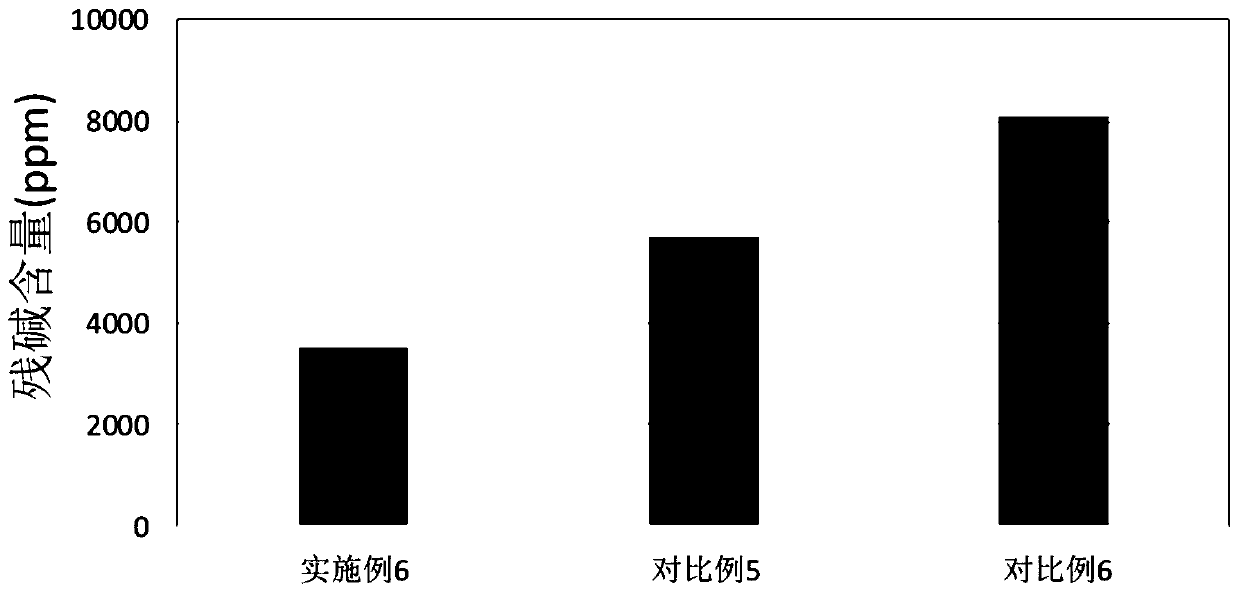

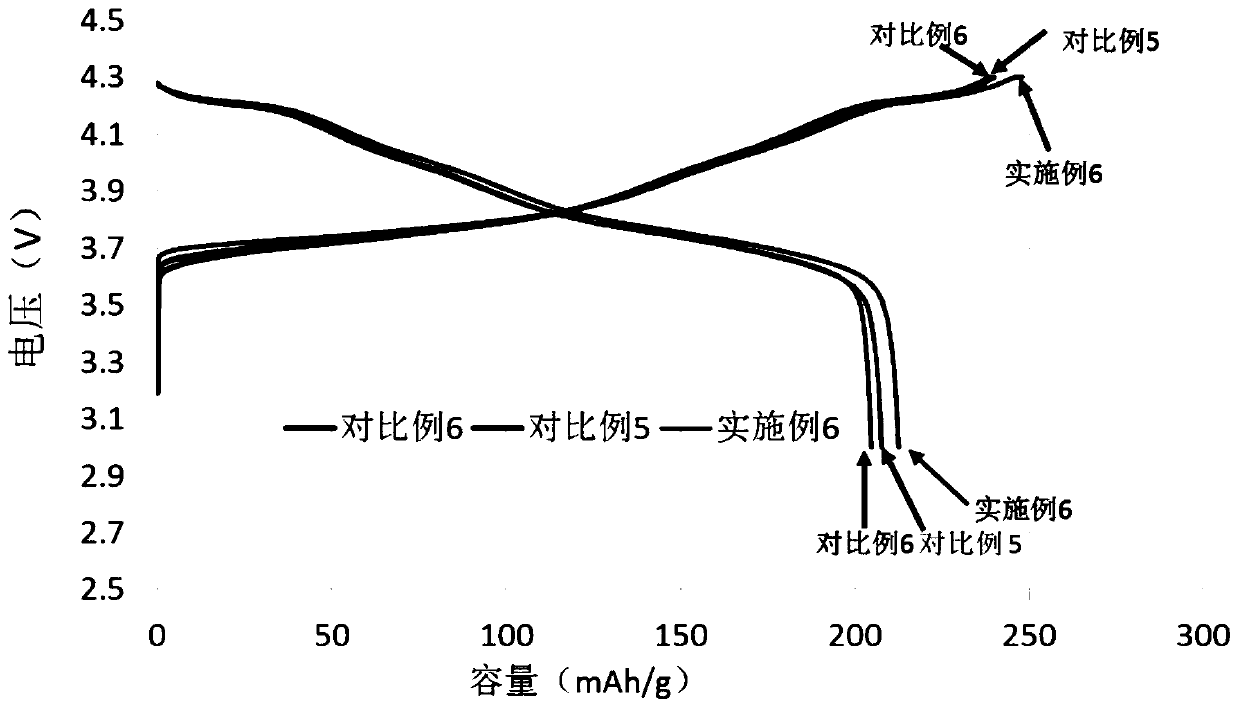

Preparation method of high-nickel positive electrode material

InactiveCN109802123AImprove high temperature stabilityImprove water absorptionCell electrodesSecondary cellsLithium hydroxideLithium carbonate

The invention discloses a preparation method of a high-nickel positive electrode material, which comprises the following steps: uniformly mixing up a Ni-containing hydroxide, a lithium-containing compound and a doping element, and calcining to obtain a base material A after the mixing operation; adding the base material A into a washing solution, controlling the temperature of the washing solution, washing away residual lithium carbonate and lithium hydroxide on the surface, adding a lithium-containing compound into the washing solution, and drying the washed base material to obtain a mixtureB; uniformly mixing the mixture B, a coating element and a lithium-containing compound, calcining, and crushing to obtain the finally modified high-nickel positive electrode material. The high-temperature stability of the nickel material is improved through doping. The residual lithium carbonate and lithium hydroxide on the surface are reduced through washing. The water absorption and processing performance of the material is improved. The damage to the surface of the material during washing can be repaired through coating. The direct contact between the positive electrode material and the electrolyte can be reduced, so that the high-temperature characteristic and long-cycle performance of the battery cell are improved.

Owner:浙江迈纳新材料有限公司

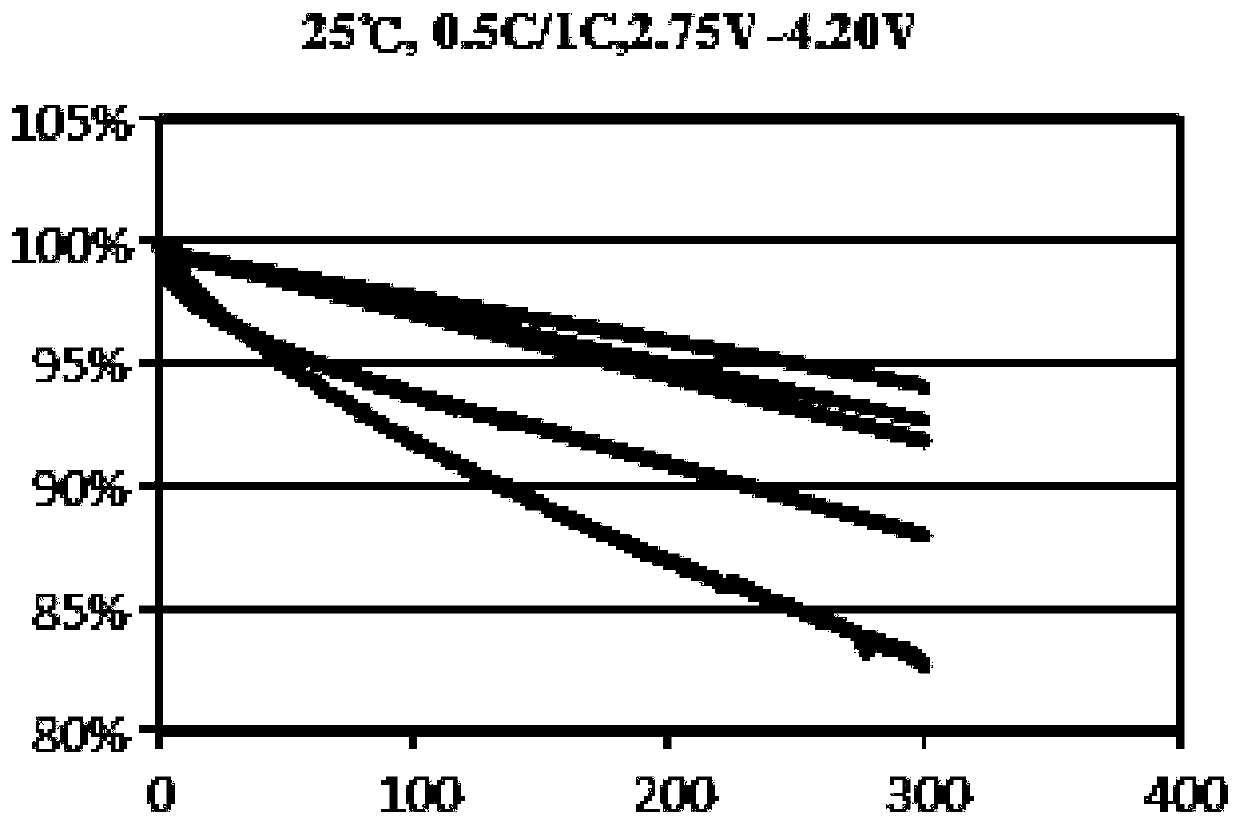

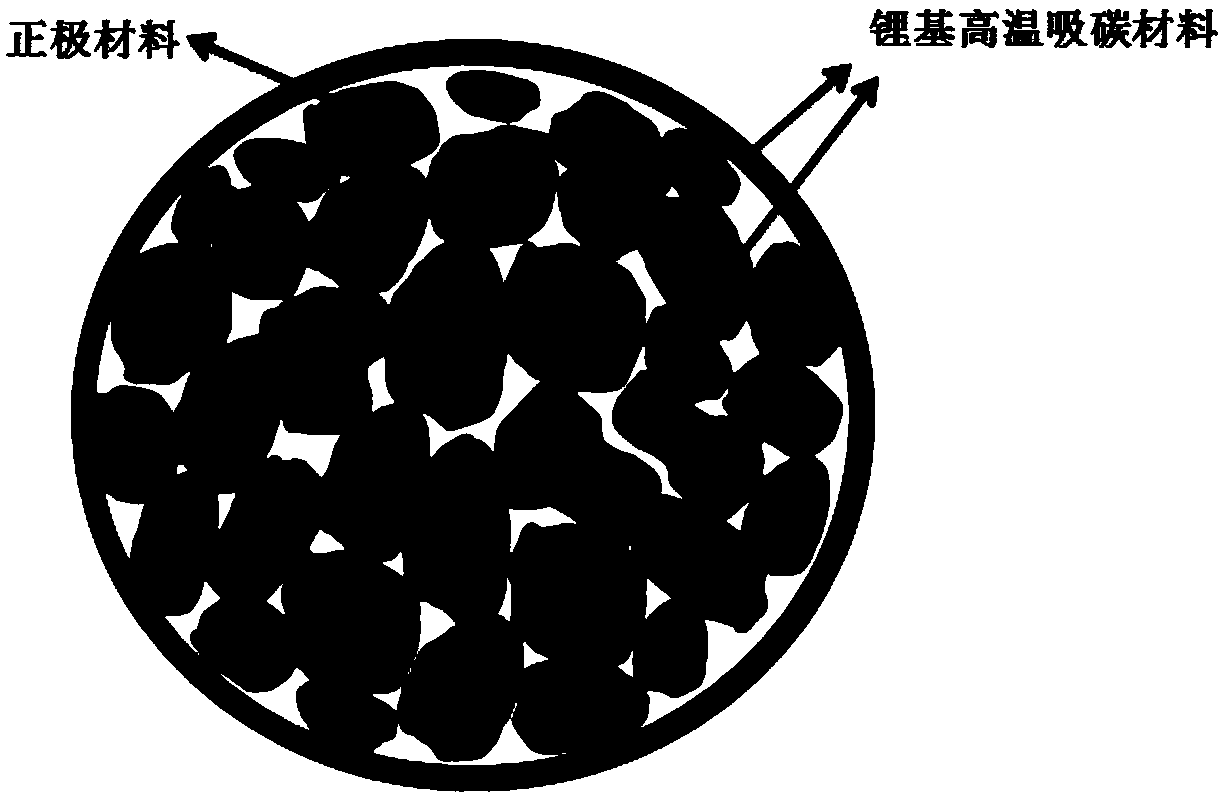

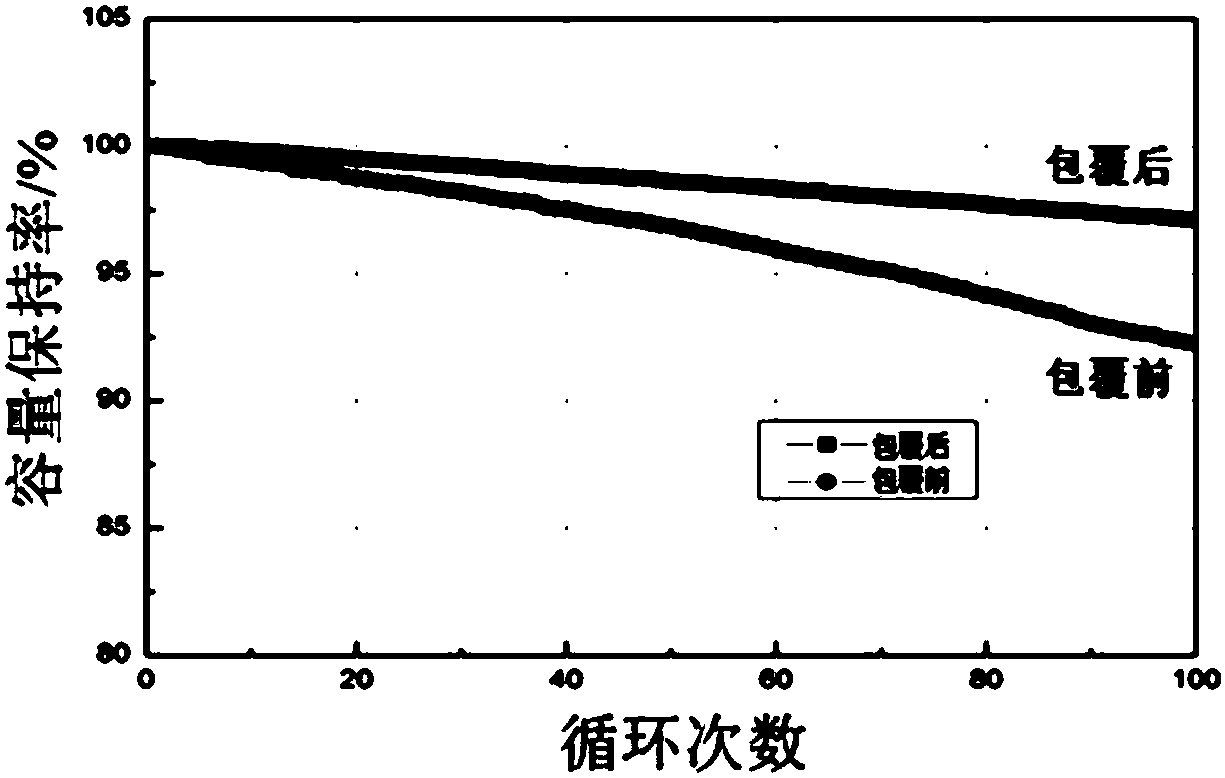

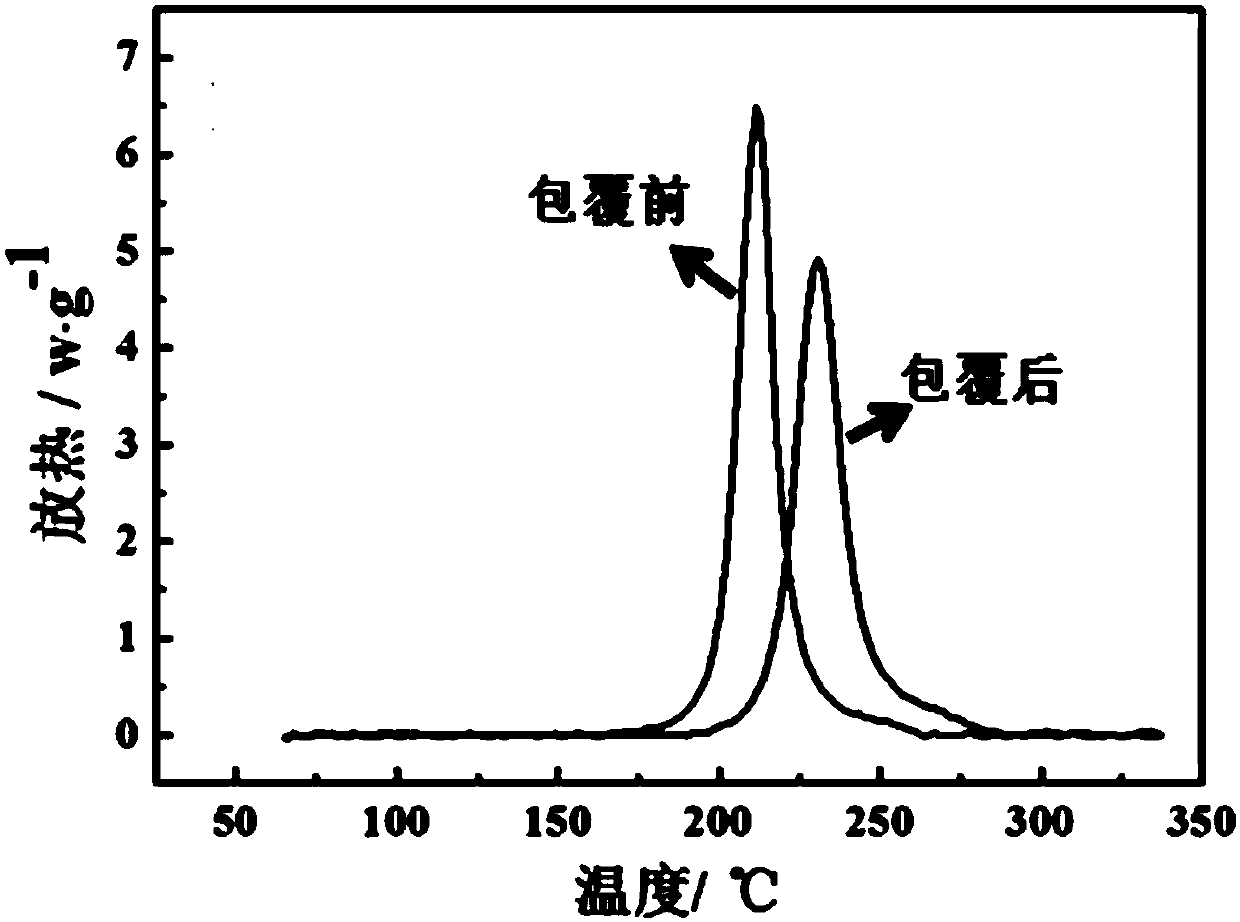

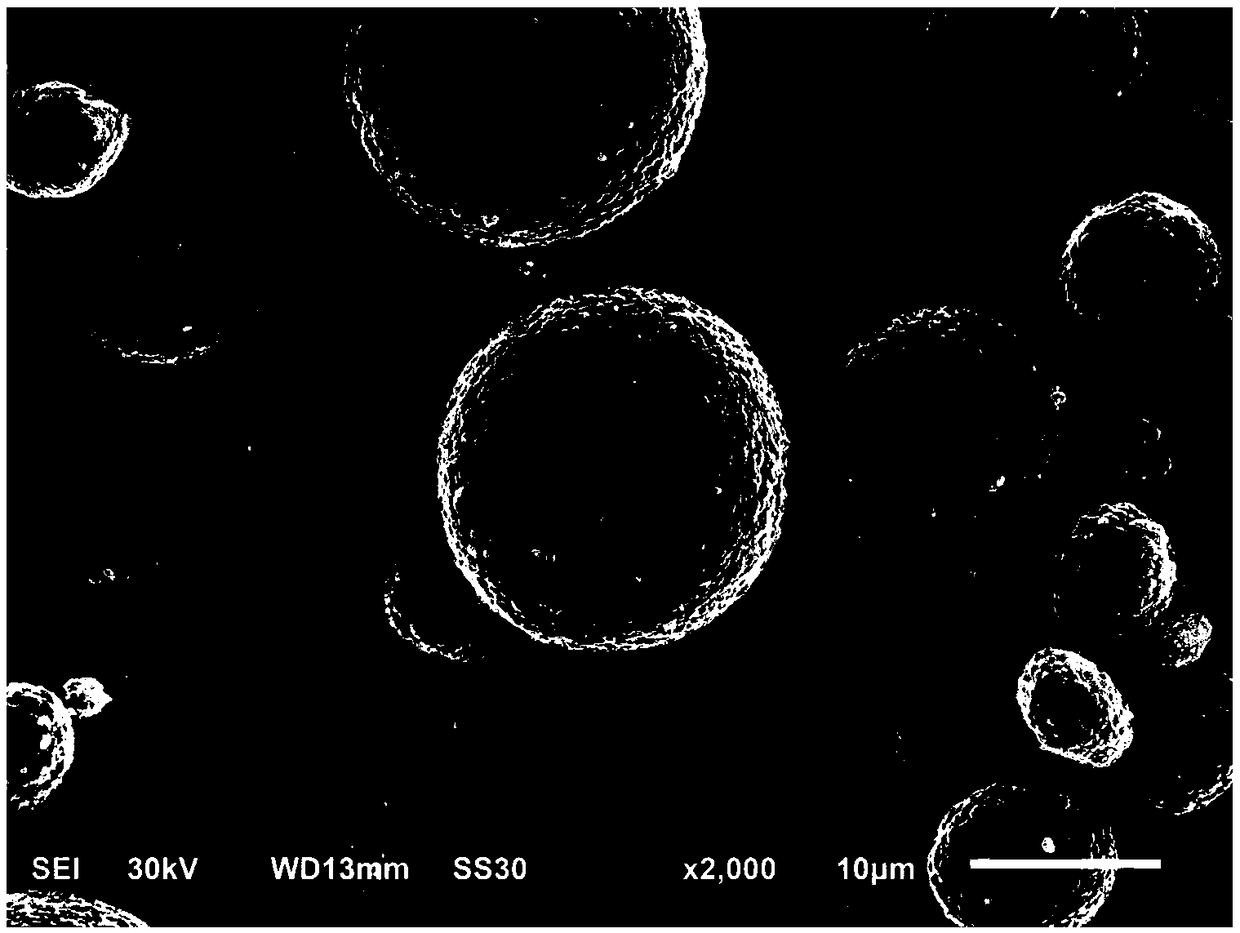

Lithium-based high-temperature carbon-absorbing material-modified positive electrode material and preparation method and application thereof

ActiveCN107681138AImprove securityImprove cycle performanceCell electrodesSecondary cellsLithium-ion batterySide reaction

The invention discloses a lithium-based high-temperature carbon-absorbing material-modified positive electrode material and a preparation method and application thereof in a lithium-ion battery. The lithium-based high-temperature carbon-absorbing material-modified positive electrode material is prepared from a positive electrode material and a lithium-based high-temperature carbon-absorbing material; and specifically, the lithium-based high-temperature carbon-absorbing material coats the positive electrode material to form primary particles, the primary particles are bridged to form secondaryparticles, and the secondary particles are coated to form the modified positive electrode material. The modified positive electrode material is in a multi-layer coating form, the coating effect generated by the structure is excellent and the conductivity is obviously strengthened; and when the modified positive electrode material is applied to the battery, one part of lithium in the lithium-basedhigh-temperature carbon-absorbing material is deintercalated to enter a negative electrode, so that the lithium consumed for generation of an SEI film of the negative electrode is compensated and theutilization rate of the lithium is improved. Volume changes in charge and discharge processes are effectively reduced through multi-coating, formation of microcracks of the positive electrode materialis reduced, meanwhile, side reaction of the positive electrode material and an electrolyte is effectively blocked, and the safety performance and the cycle performance of the material are improved.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Positive electrode material, and preparation method thereof and lithium ion battery

PendingCN112820861AImprove high voltage performanceImprove cycle stabilityCell electrodesSecondary cellsElectrical batteryLithium-ion battery

The invention provides a positive electrode material, and a preparation method thereof and a lithium ion battery. The positive electrode material comprises a substrate and a coating layer coating the substrate, the substrate is a high-nickel ternary material, and the coating layer is a composite oxide coating layer containing Al, Co and Mn. The preparation method comprises the following steps: 1) mixing a matrix precursor with a lithium source, and calcining to obtain a matrix material; (2) mixing an aluminum source, a cobalt source and a manganese source in a dissolving agent, adding a coprecipitator, standing for reaction, and then carrying out solid-liquid separation to obtain a coating material; and 3) mixing the base material and the coating material, and performing heat treatment to obtain the positive electrode material. The positive electrode material provided by the invention can well solve the safety problem and the cycle stability problem of a high-nickel ternary material, reduces the residual alkali amount on the surface of the positive electrode material, and has the advantages of low residual alkali, low mixing degree, high conductivity, high capacity, high cycle efficiency and the like.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Ternary positive electrode material, preparation method thereof and lithium ion battery

PendingCN112864385AReduce the amount of residual alkaliImprove cycle performanceSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention provides a ternary positive electrode material, a preparation method thereof and a lithium ion battery. The ternary positive electrode material comprises a core and a composite coating layer coating the core, the core is a high-nickel ternary material, and the composite coating layer comprises a boron-containing compound and a phosphorus-containing compound. The method comprises the following steps: mixing a boron source, a phosphorus source and a high-nickel ternary material, and sintering in an oxidizing atmosphere to obtain the ternary positive electrode material. According to the ternary positive electrode material provided by the invention, through the high-nickel ternary material core and the composite coating layer including the boron-containing compound and the phosphorus-containing compound, the residual alkali amount is low, and the rate discharge capacity and the cycle performance are good.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Sulfide-coated positive electrode material, preparation method thereof and lithium ion battery

PendingCN112447948AImprove ionic conductivityReduce interface impedanceCell electrodesSecondary cellsInterface impedanceInterfacial impedance

The invention provides a sulfide-coated positive electrode material, a preparation method thereof and a lithium ion battery. The sulfide-coated positive electrode material comprises a lithium-containing positive electrode material and a sulfide coating layer coating the surface of the lithium-containing positive electrode material, and the lithium-containing positive electrode material comprises aternary material. The preparation method comprises the following steps: 1) mixing a lithium-containing positive electrode material with a solvent and reacting with a sulfur source to obtain a positive electrode material with lithium sulfide on the surface; and 2) mixing the positive electrode material with lithium sulfide on the surface with other raw materials, and carrying out heat treatment toobtain the sulfide-coated positive electrode material. The sulfide-coated positive electrode material provided by the invention solves the problems of residual alkali on the surface of a ternary positive electrode material and unstable surface structure, and has the characteristics of good surface structure stability, high ionic conductivity, low interface impedance, low residual alkali and excellent cycling stability.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

High-nickel lithium ion battery positive electrode material, preparation method thereof and lithium ion battery

InactiveCN108987728AReduce residual alkaliImprove cycle performanceCell electrodesSecondary cellsMass ratioLithium-ion battery

The invention provides a positive electrode material of a high-nickel lithium ion battery, a preparation method thereof and a lithium ion battery, wherein, the method comprises the following steps: (1) a metal oxide is coated on the surface of the electrode material by a mixing or spray drying method to obtain a coated electrode material; The mass ratio of metal oxide to electrode material is (0.1-2): 100; (2) adding the coating electrode material obtained in the step (1) into water for stirring, wherein the mass ratio of the coating electrode material to water is (0.5-10): 1; Dehydration anddrying. The invention also provides a high-nickel lithium ion battery positive electrode material prepared by the method and a lithium ion battery using the positive electrode material. The method ofthe invention not only effectively reduces the residual alkali on the surface of the layered high-nickel positive electrode material, but also minimizes the destruction of the surface structure and the cycle performance of the material during the alkali reduction process. The layered high nickel positive electrode material prepared by the method has low residual alkali content, high reversible capacity and excellent cycling performance.

Owner:桑顿新能源科技(长沙)有限公司

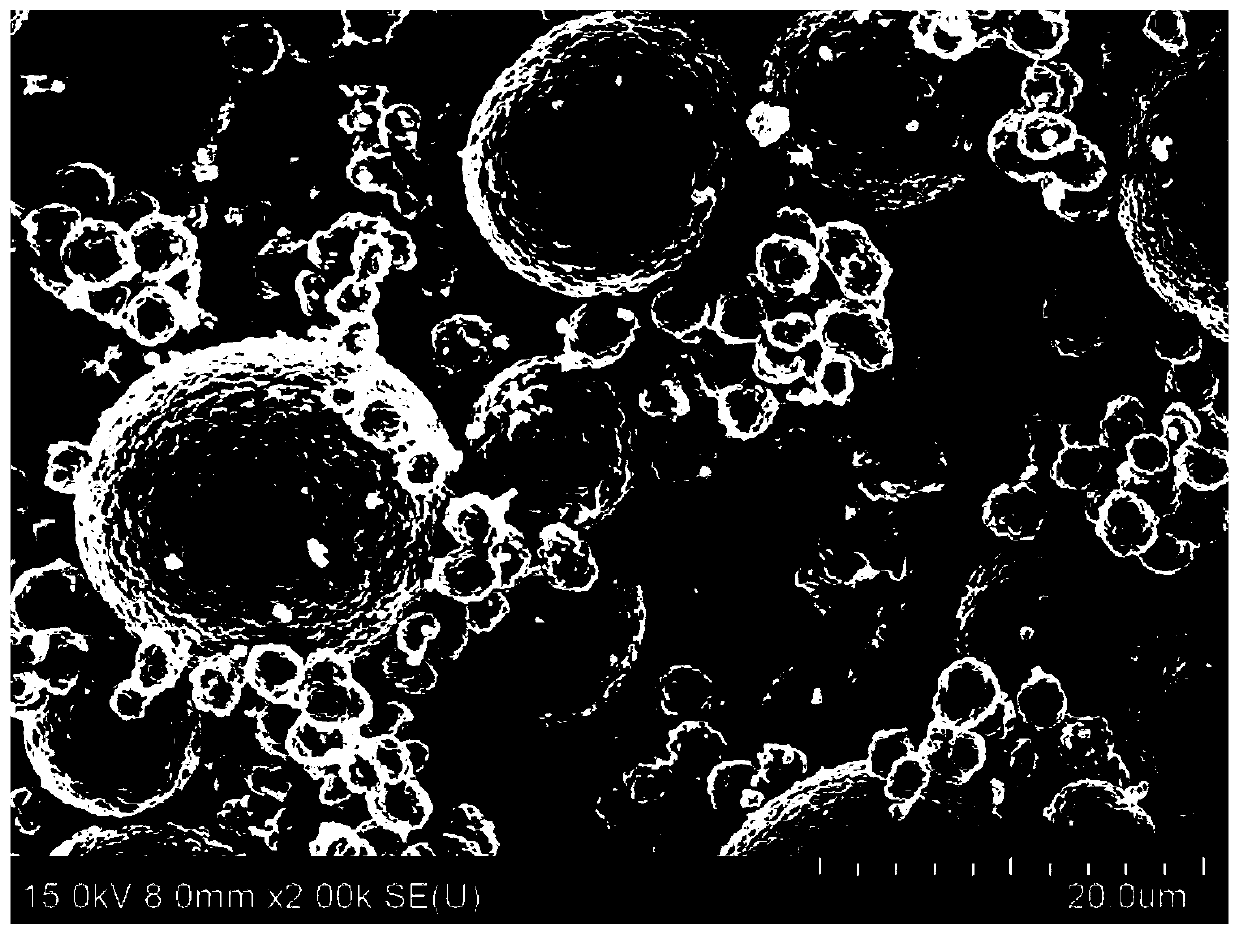

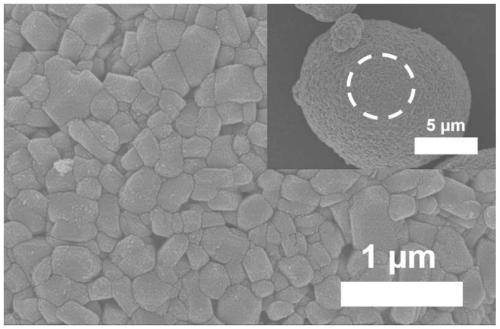

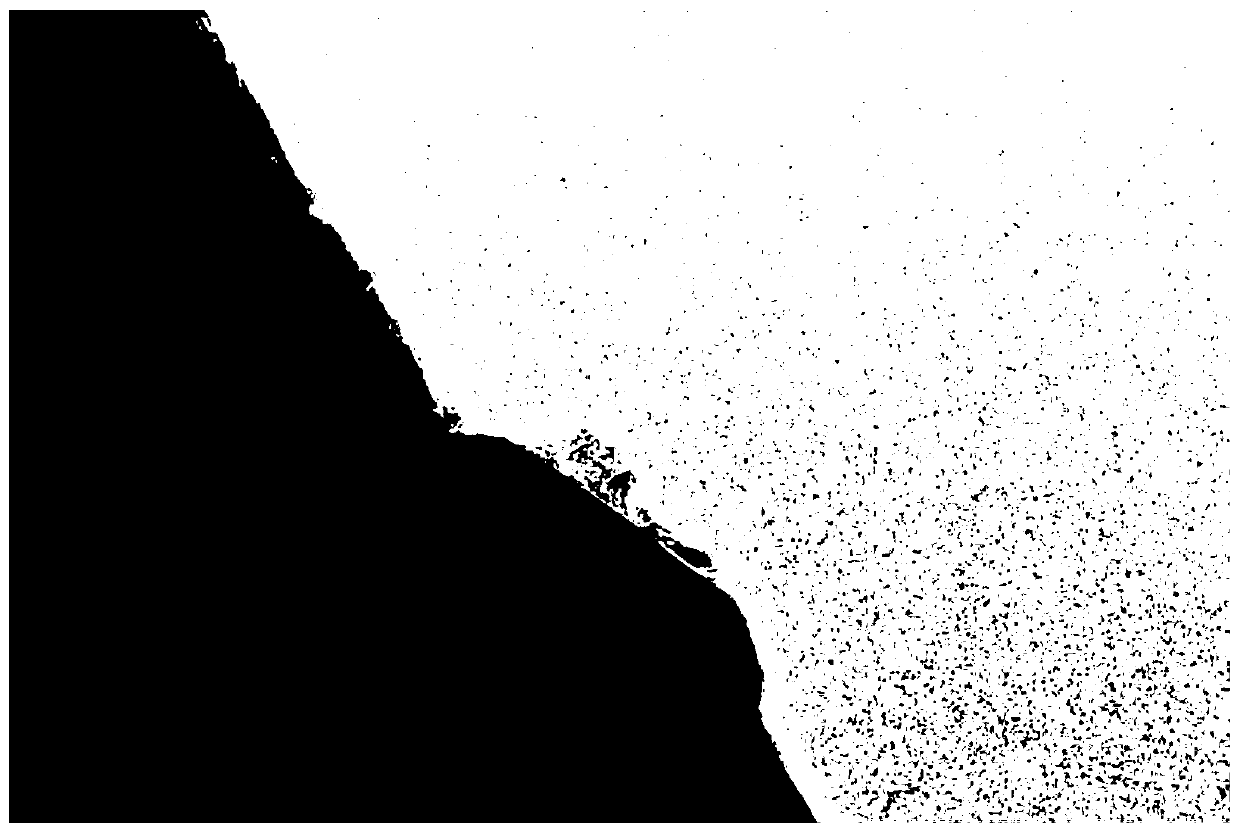

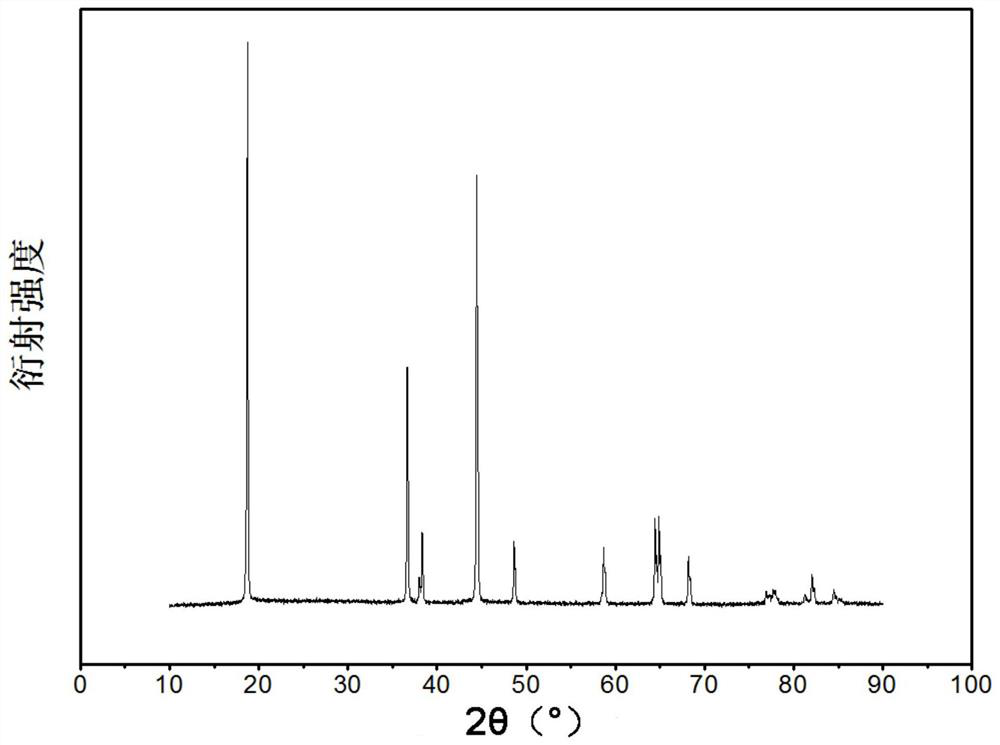

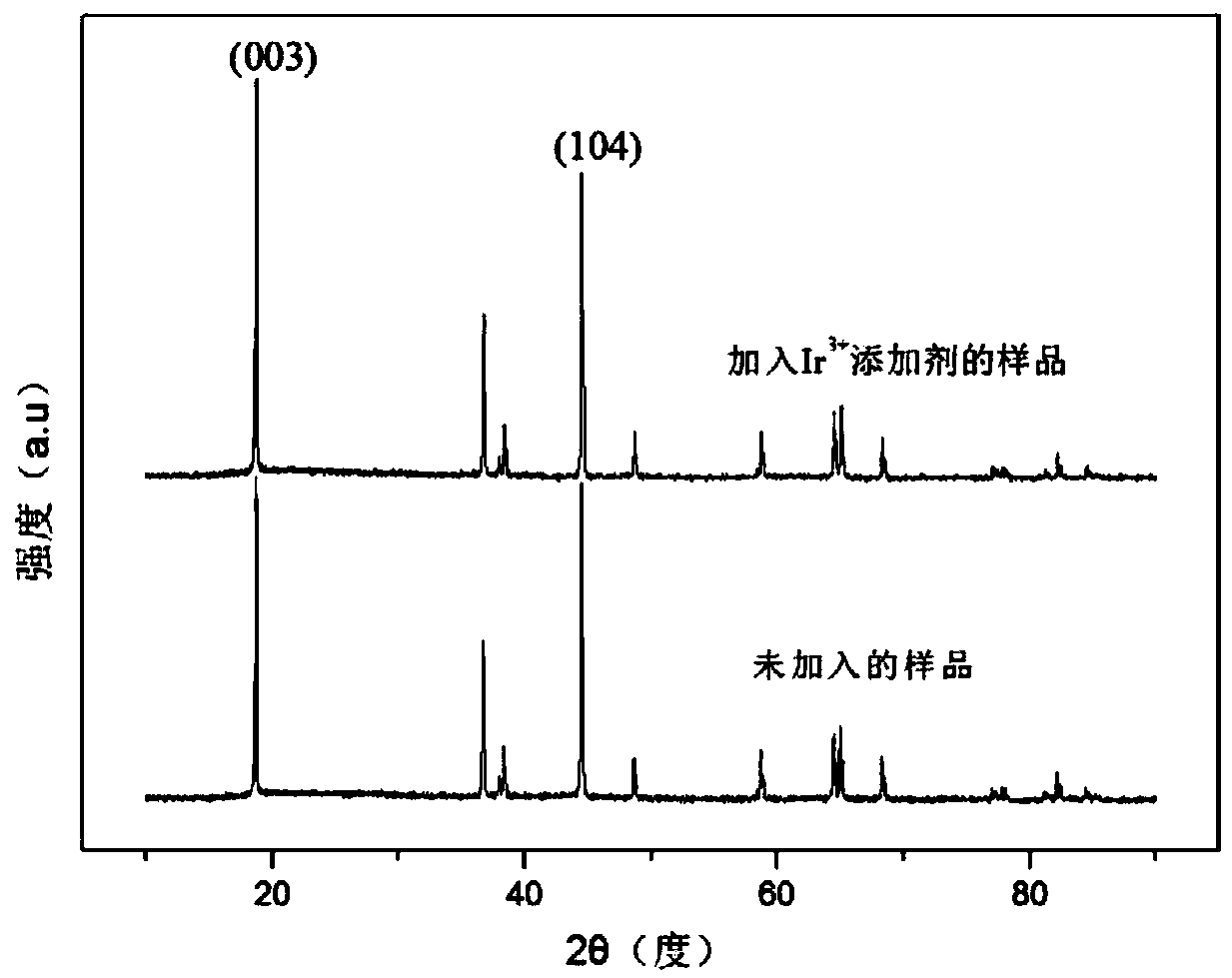

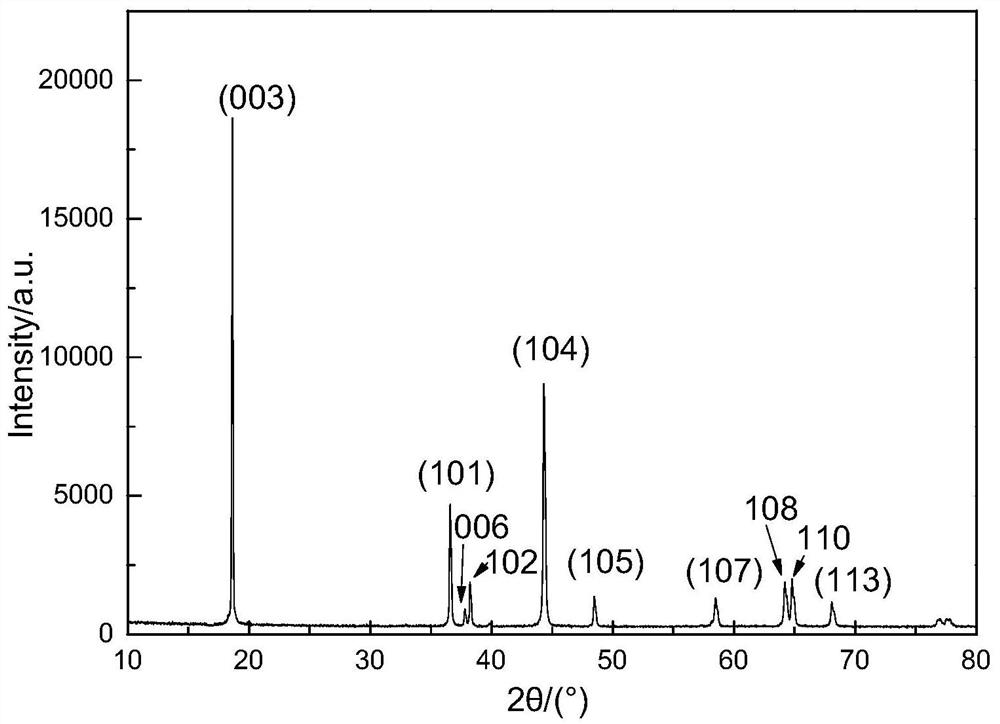

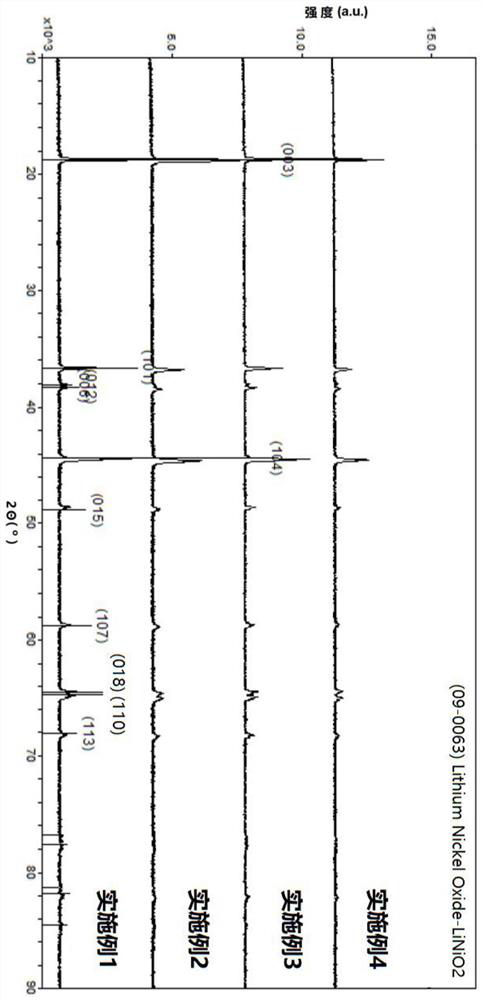

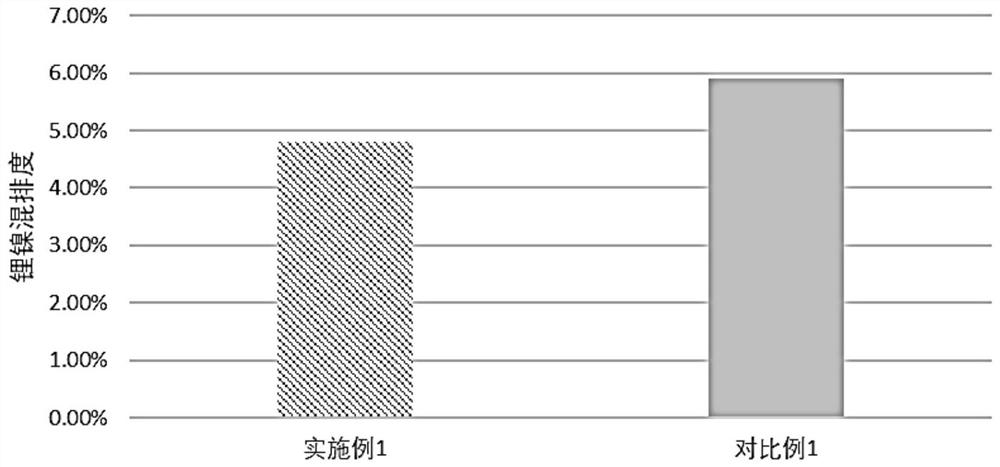

Single crystal ternary positive electrode material with good dispersibility, lithium-nickel mixed arrangement and low residual alkali, and preparation method and application thereof

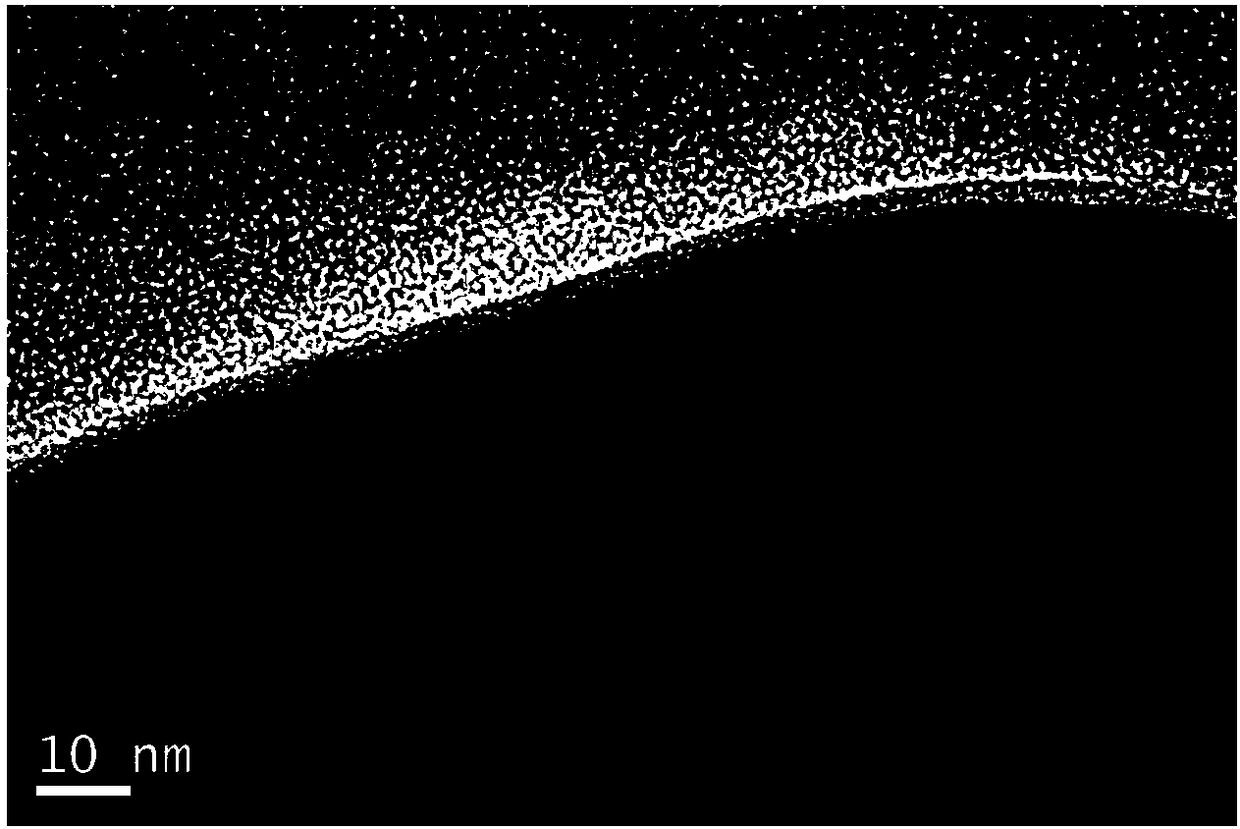

ActiveCN110581259AReduce shufflingPromote formationCell electrodesSecondary cellsTe elementSingle crystal

The invention discloses a single crystal ternary positive electrode material with good dispersibility, lithium-nickel mixed arrangement and low residual alkali, and a preparation method and an application thereof. In the preparation process of the single crystal ternary positive electrode material, the raw materials comprise a cationic additive, and the cationic additive is any one or a combination of at least two of an iridium source, an yttrium source, a tellurium source, an indium source and a gallium source. By adding the cationic additives such as Ir<3+>, Y<3+>, Te<4+>, In<3+> and Ga<3+>,the surface energy of the ternary material can be promoted to be reduced on the one hand, so that the sintering temperature of the material is reduced, and the volatilization of lithium salt is reduced; and on the other hand, the lithium-nickel mixed arrangement can be reduced, the directional growth of the crystal face of the material is controlled, and the adsorption effect and reaction activity of the crystal face and CO2 and H2O in the air are inhibited, so that residual alkali on the surface of the ternary material is reduced, the processing performance of the material is improved, and the rate discharge capacity and cycle performance of the single crystal ternary material are improved.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

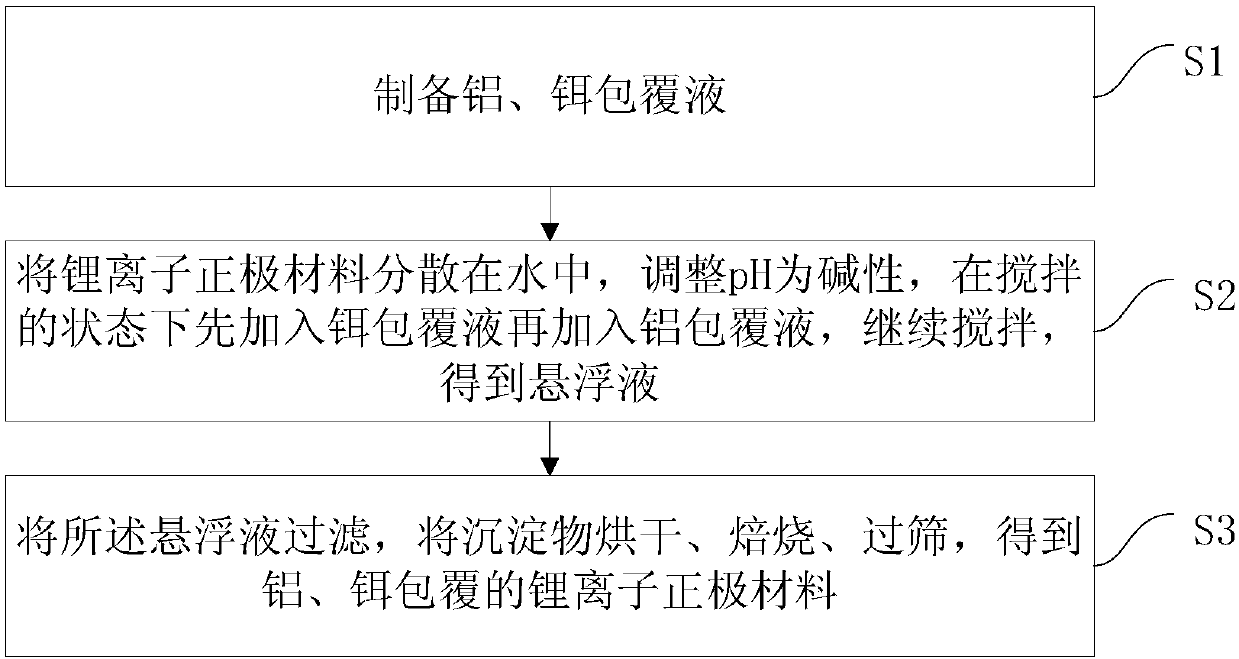

Aluminium and erbium coated high-nickel lithium-ion cathode material and preparation method thereof

ActiveCN107611386AReduce residual alkaliRaise room temperatureCell electrodesSecondary cellsFlatulenceElectrolyte

The invention is applicable to the technical field of a lithium battery, and provides an aluminium and erbium coated high-nickel lithium-ion cathode material and a preparation method thereof. The method comprises the steps of: preparing aluminium and erbium coating liquid; dispersing a lithium-ion cathode material into water, regulating pH into an alkaline state, in a stirring state, firstly adding erbium coating liquid and then adding the aluminium coating liquid, and continuously stirring to obtain suspension; and filtering the suspension, and drying, roasting and sieving precipitates to obtain the aluminium and erbium coated lithium-ion cathode material. According to the method provided by the invention, metal aluminium and erbium ions can be well dissolved in solution and are uniformlycoated on the surface of the cathode material so as to fulfill the aim of integrating washing with coating. Residual alkali of the high-nickel lithium-ion cathode material is efficiently reduced in the aspect of physical and chemical performance, reaction of the cathode material and electrolyte is inhibited, normal temperature and high temperature cycle performance of the high-nickel cathode material are improved, and flatulence is reduced.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

High-voltage nickel-cobalt-manganese ternary precursor and preparation method thereof

ActiveCN113603154AHold capacityImprove high pressure performanceCell electrodesSecondary cellsPhysical chemistryManganese

The invention relates to the field of nickel-cobalt-manganese ternary precursor manufacturing, and in particular, relates to a high-voltage nickel-cobalt-manganese ternary precursor and a preparation method thereof. The preparation method comprises the steps: mixing a nickel-cobalt-manganese ternary metal salt solution, a carbonate solution, a complexing agent solution and a first base solution, carrying out a co-precipitation reaction, and carrying out solid-liquid separation after precipitate reaches a required particle size range to obtain a nickel-cobalt-manganese composite basic carbonate seed crystal; and mixing the nickel-cobalt-manganese ternary metal salt solution, a precipitant solution, the ammonia water solution and a second base solution containing the nickel-cobalt-manganese composite basic carbonate seed crystal, enabling the nickel-cobalt-manganese composite basic carbonate seed crystal to continuously grow, and after the seed crystal reaches the required particle size range, carrying out solid-liquid separation, drying, batch mixing, sieving and demagnetizing to obtain the ternary precursor, wherein the core of the ternary precursor is nickel-cobalt-manganese composite basic carbonate, and the shell of the ternary precursor is nickel-cobalt-manganese composite hydroxide. A battery assembled by a ternary positive electrode material prepared from the precursor shows high discharge capacity, high first coulombic efficiency and excellent rate capability under 4.5 V high cut-off voltage.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

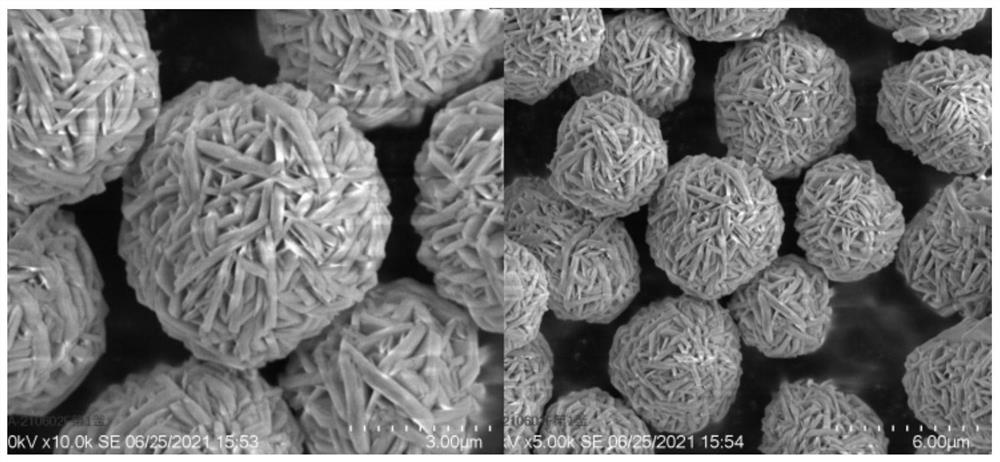

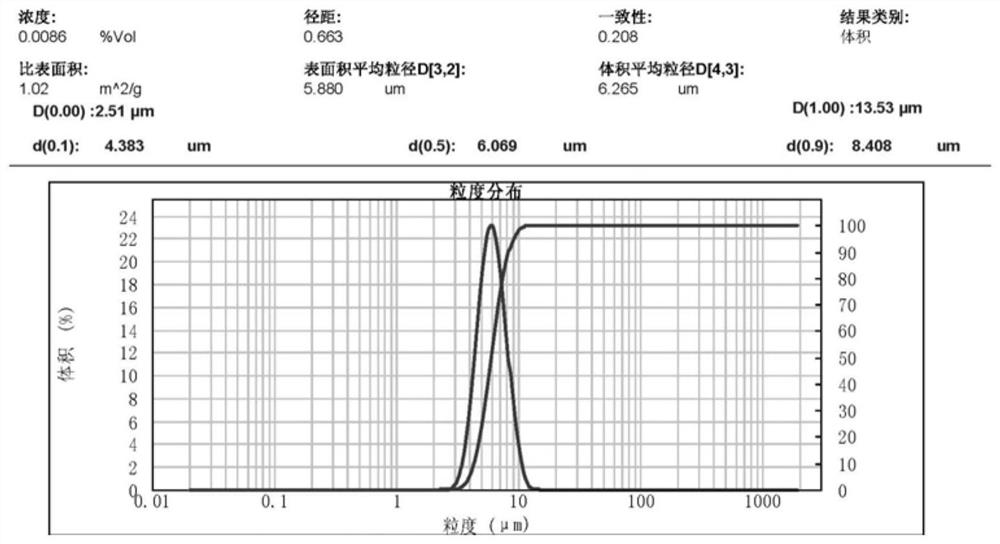

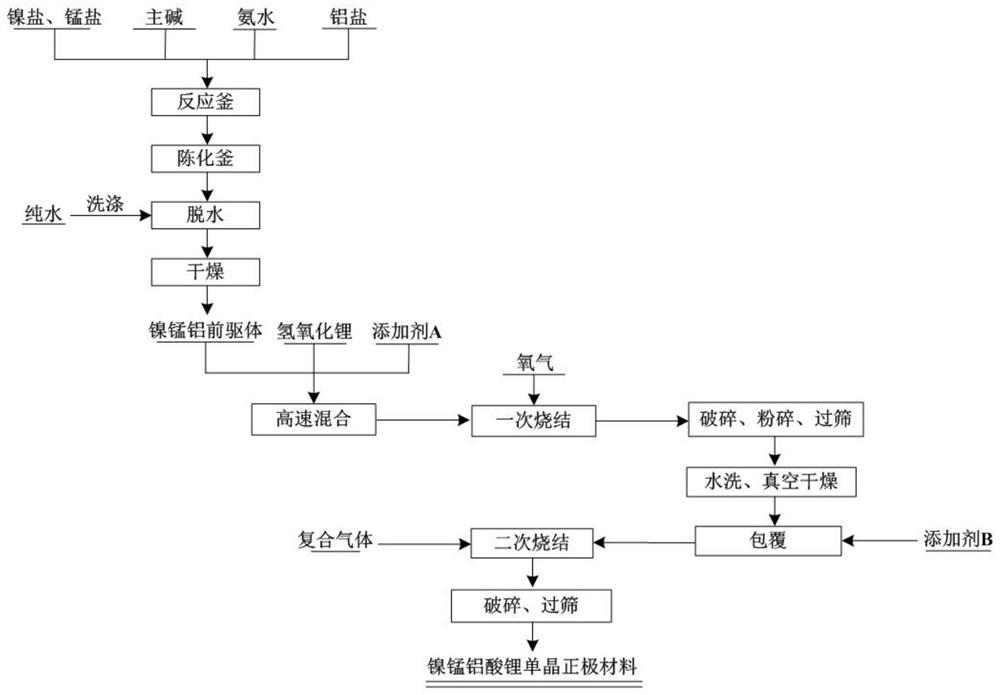

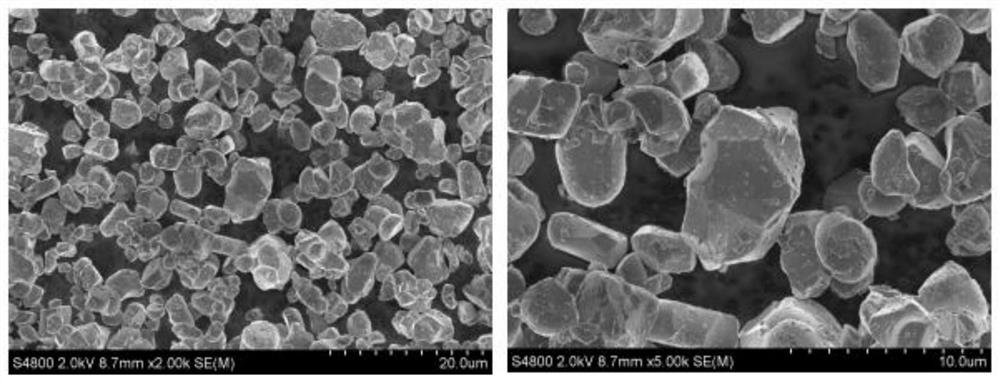

Preparation method of single-crystal lithium nickel manganese aluminate positive electrode material

The invention relates to the field of lithium ion battery positive electrode materials, in particular to a preparation method of a high-capacity ternary material and application of the high-capacity ternary material in a lithium ion battery positive electrode material. The method comprises the following steps: (1) preparing precursor mixed raw stock; (2) preparing a precursor; (3) preparing precursor and lithium source mixed slurry; (4) preparing a ternary material; the ternary material prepared by the method is narrow in particle size distribution, uniform in particle morphology, high in energy density and excellent in electrochemical performance. Compared with the prior art, the material has the advantages that no organic solvent is used, and the influence of the pH value is avoided;andthe operation method has the advantages of simplicity, feasibility, environmental friendliness, low production cost, high yield, excellent electrochemical performance and the like.

Owner:浙江格派钴业新材料有限公司

Washing method of high-nickel positive electrode material and product and application thereof

InactiveCN112186157AImprove thermal stabilityLow costCell electrodesNon-aqueous electrolyte cellsPhosphatePhysical chemistry

The invention relates to a washing method of a high-nickel positive electrode material and a product and application thereof, and the washing method comprises the following steps: mixing the high-nickel positive electrode material with a phosphate solution with the concentration of 0.1-1mol / L, reacting and sintering to obtain the washed high-nickel positive electrode material. In the washing process, phosphate reacts with residual alkali on the surface of the high-nickel positive electrode material to generate lithium phosphate precipitate to be attached to the surface of the high-nickel positive electrode material, a lithium phosphate coating layer is formed through subsequent sintering, and part of lithium phosphate can permeate into the surface layer of the material and deep positions of the surface to fill lattice gaps of the material to modify the surface, so that coating is tighter; therefore, the structural stability and the thermal stability of the positive electrode material are improved, and the dual effects of washing to remove residual alkali and improving the stability of the material are achieved; furthermore, the reaction process of washing can be carried out at normal temperature, the washing process is simple to control, the energy consumption is low, the cost is low, and the washing effect is obviously improved.

Owner:EVE HYPERPOWER BATTERIES INC

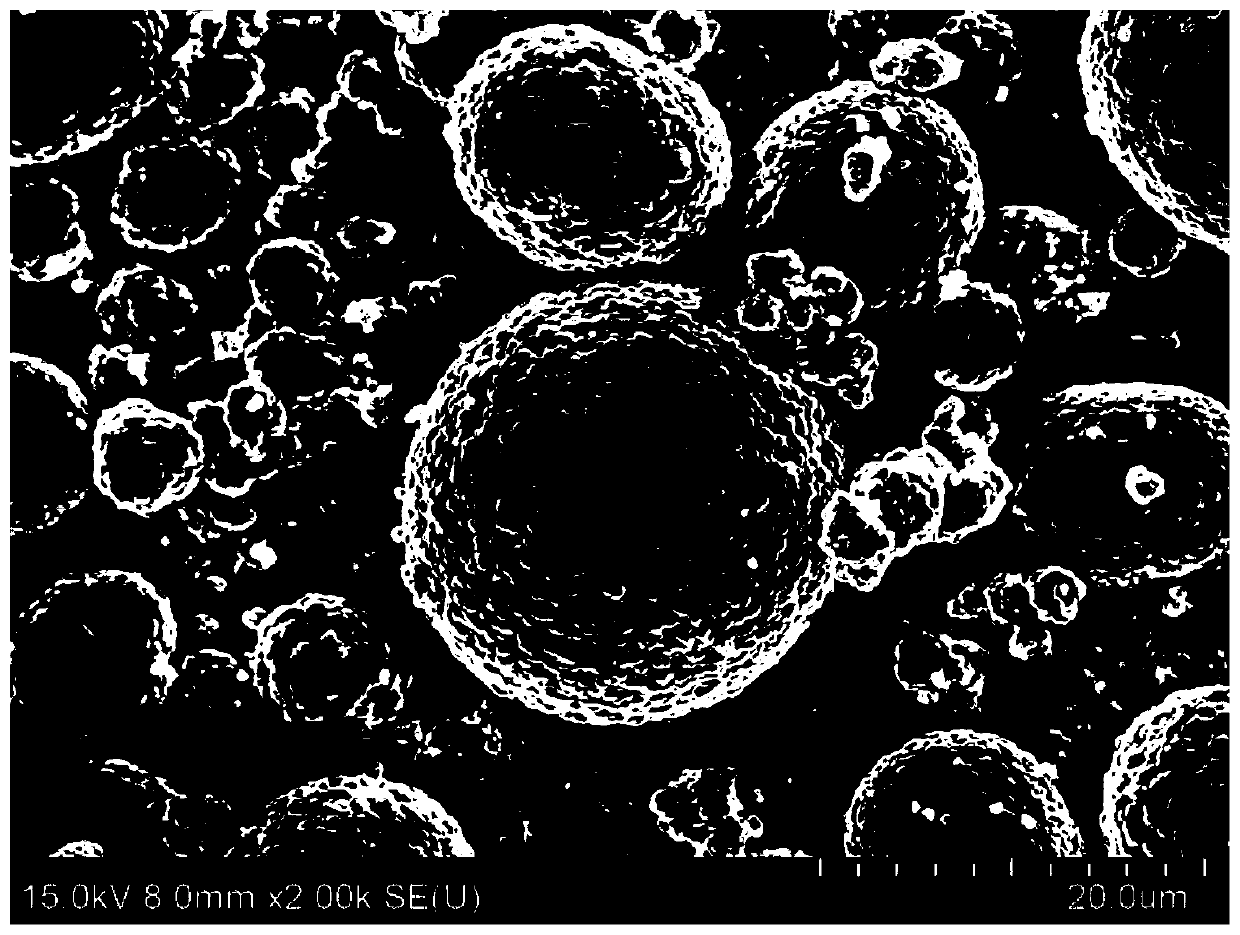

Positive electrode material and preparation method and application thereof

InactiveCN110112393AIncrease energy densityImproved magnification performanceCell electrodesSecondary cellsState of artDecomposition

The invention relates to a positive electrode material and a preparation method and application thereof. The surfaces of a core layer material A composed of secondary spherical particles and a singlecrystal particle core layer material B composed of the secondary spherical particles are coated with a shell layer material to form a material A and a material B respectively, and then the material Aand the material B are mixed, so that the energy density, the rate capability, the high-temperature cycle and the safety performance of the positive electrode material are remarkably improved. The core layer material is coated with the shell layer material, so that the residual alkali of the positive electrode material can be remarkably reduced, the oxidative decomposition of the positive electrode material on the electrolyte is reduced, and the high-temperature cycle and safety performance of the positive electrode material are improved. Compared with the prior art, a lithium ion battery obtained by the invention can achieve very good energy density, cycle performance and safety performance under higher voltage (greater than or equal to 4.2V vs (Li + / Li)). Due to the fact that the charging cut-off voltage is increased, the battery has high energy density, and the requirement of people for thinness of the lithium ion battery can be met.

Owner:东莞维科电池有限公司

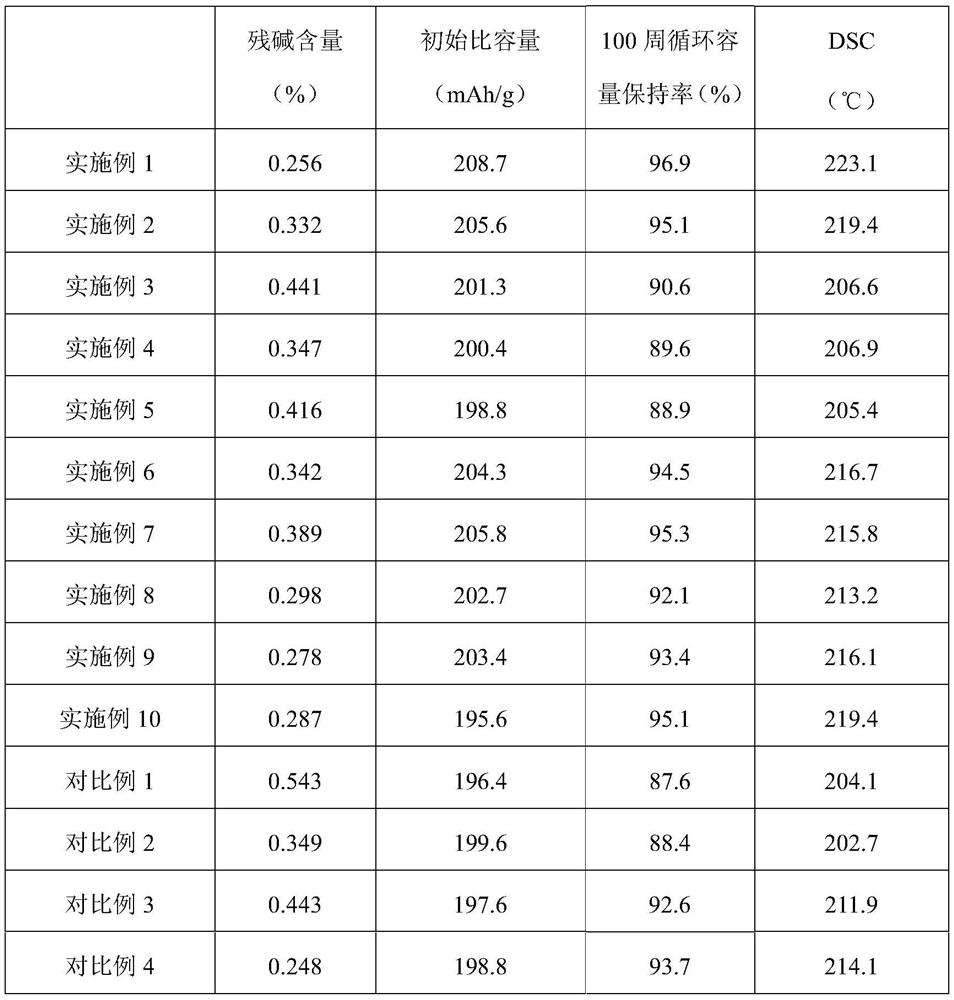

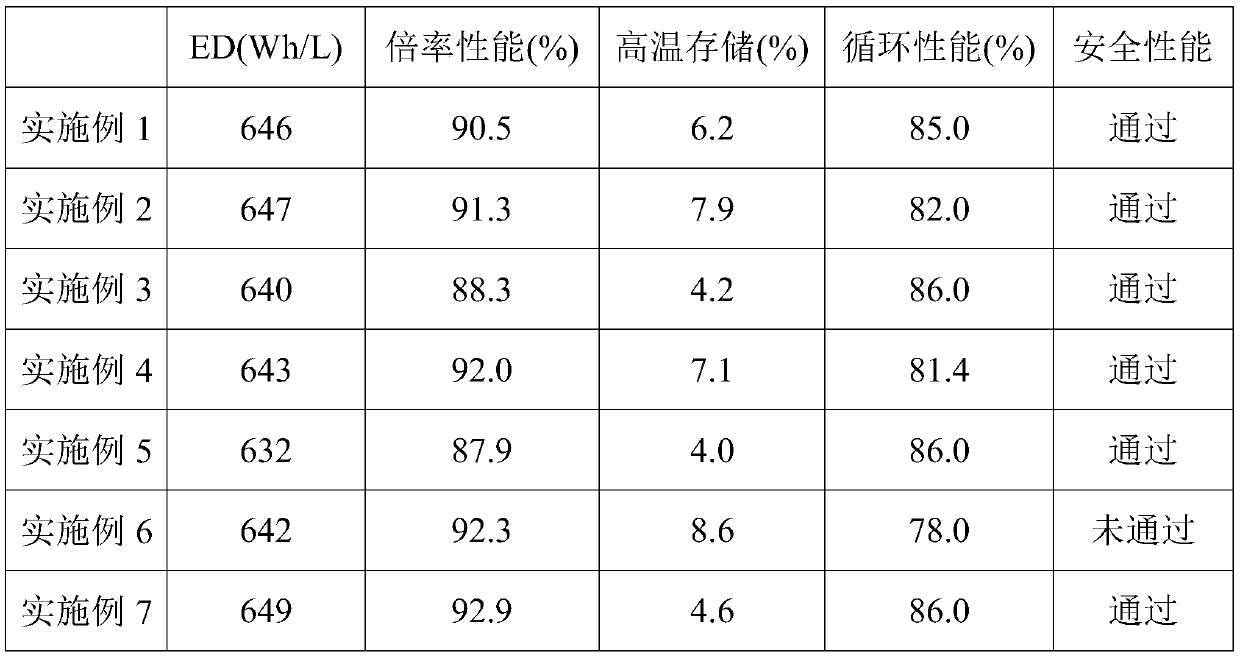

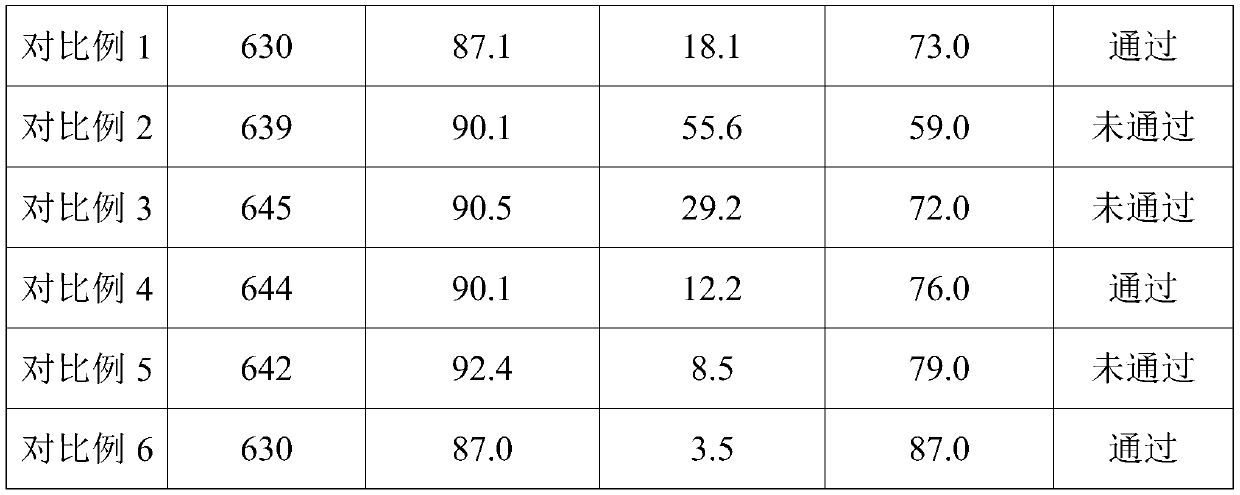

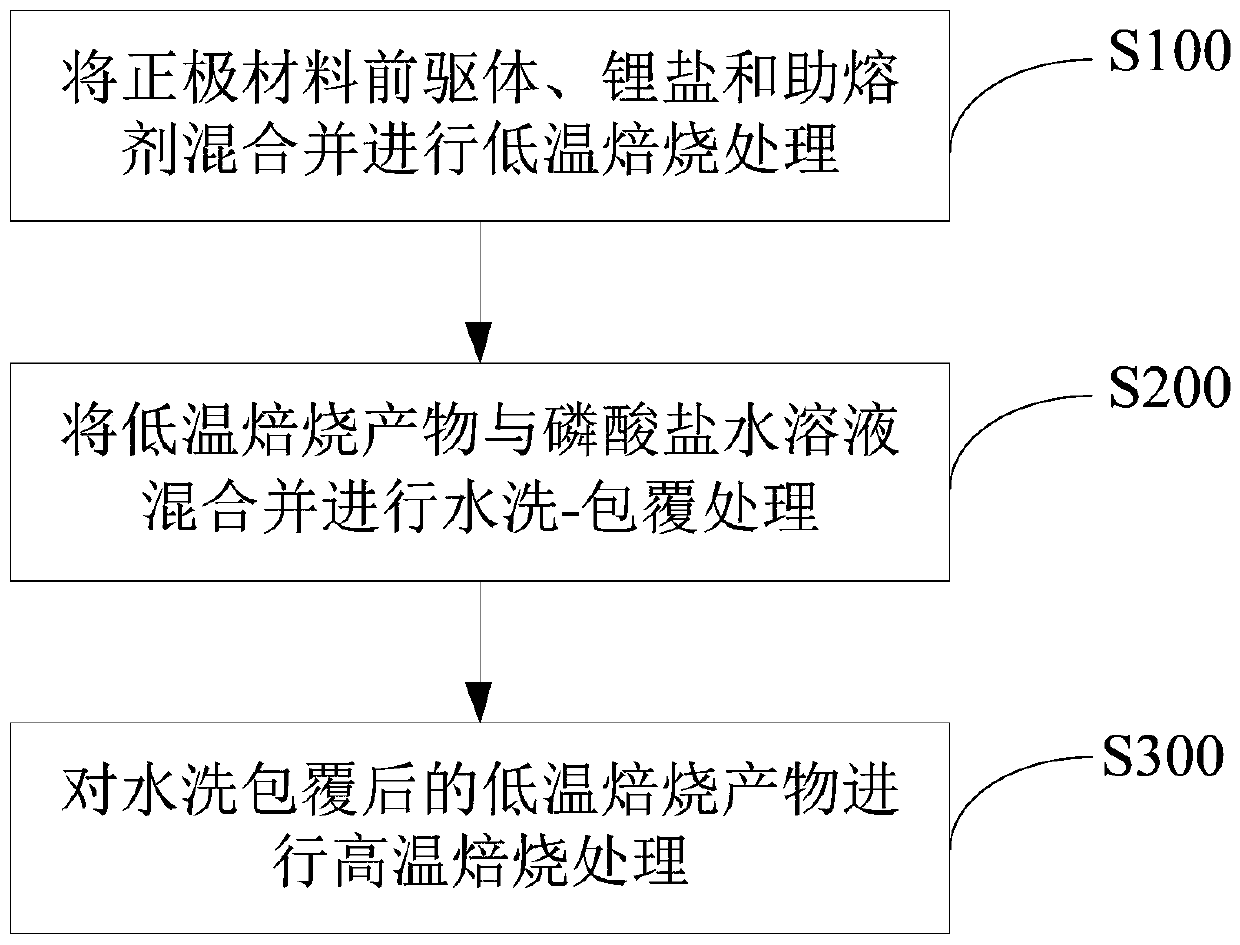

Lithium battery anode material and preparation method and application thereof

InactiveCN109860588AReduce residual alkali contentHigh yieldCell electrodesSecondary cellsOperabilityAqueous solution

The invention discloses a lithium battery positive electrode material and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a positive electrode material precursor, lithium salt and a fluxing agent, and carrying out low-temperature roasting treatment to obtain a low-temperature roasted product; (2) mixing the low-temperature roasted product with phosphate aqueous solution, and performing water washing-coating treatment to obtain a low-temperature roasting product after water washing-coating; (3) carrying out high-temperature roastingtreatment of the low-temperature roasted product after water washing-coating to obtain the positive electrode material. The method is strong in operability, high in preparation efficiency and low incost, and the prepared positive electrode material is high in yield, relatively uniform in coating, low in material residual alkali content, good in cycling stability and long in cycling service life.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

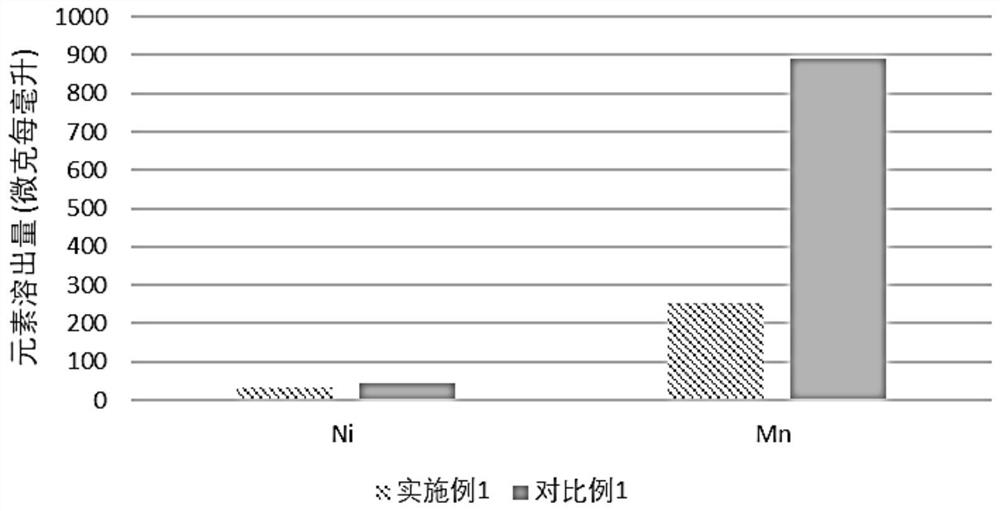

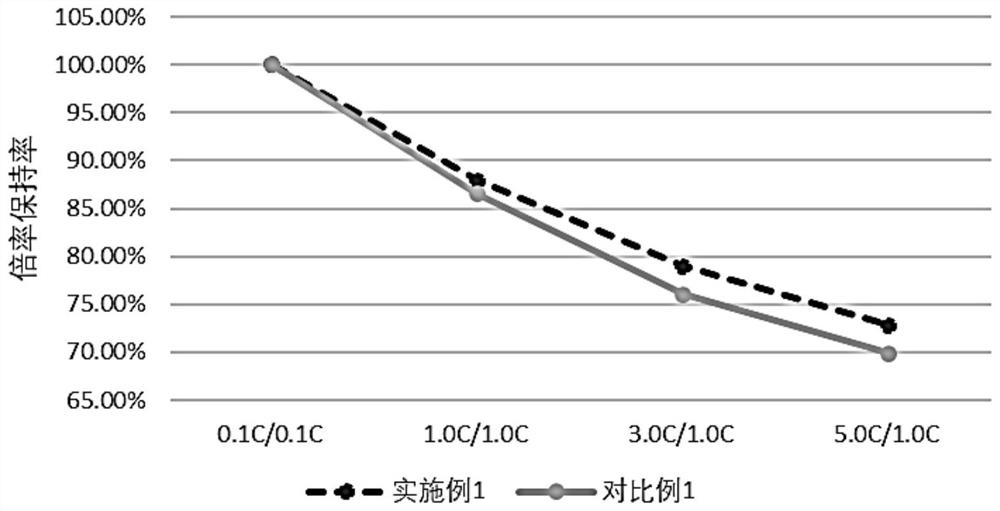

Lithium ion secondary battery cathode material and preparation method thereof

PendingCN112490444AImprove structural orderImprove conductivityCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention provides a lithium ion secondary battery cathode material and a preparation method thereof, belongs to the technical field of lithium ion batteries, and aims to effectively improve Li / Nimixed arrangement caused by a low-cobalt material in a sintering process by reasonably designing doped coating elements and utilizing a synergistic effect or further reaction among the elements. According to the invention, the rate capability of the low-cobalt material is improved, meanwhile, element dissolution is reduced, the cycle performance is improved, the technical effect which cannot be brought by doping and coating of a single element is overcome, and the problems of poor dynamic performance and poor element dissolution and cycle performance of the low-cobalt material are improved.

Owner:BEIJING TAIFENG XIANXING NEW ENERGY TECH CO LTD +2

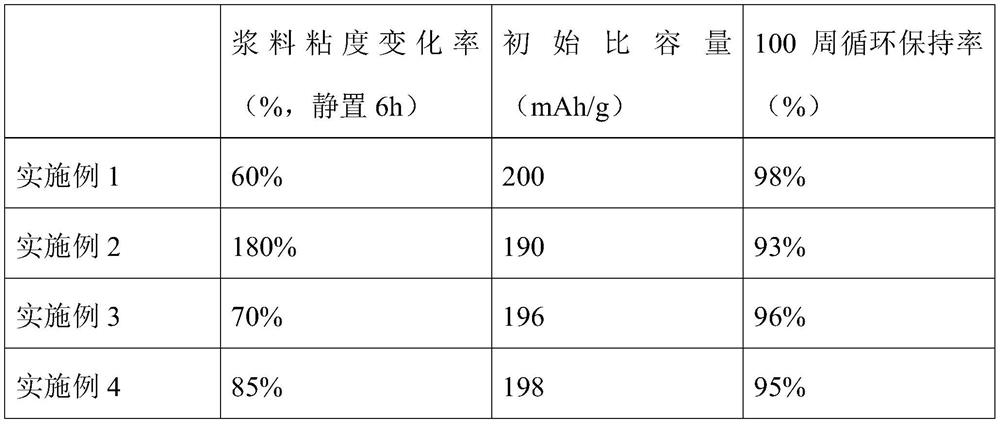

Positive electrode slurry and application thereof

ActiveCN112510192AEasy to operateEasy to industrializePositive electrodesSecondary cells servicing/maintenanceOXALIC ACID DIHYDRATEElectrical battery

The invention relates to a positive electrode slurry and an application thereof, the positive electrode slurry comprises a high-nickel positive electrode material and an additive, and the additive comprises at least one of LiPF6, boric acid, oxalic acid, citric acid, tartaric acid, tetraethyl silicate, LiPO2F2 and HPF6; the additive can react with residual alkali on the surface of a high-nickel positive electrode material to reduce the alkalinity of positive electrode slurry and improve the stability and processability of the positive electrode slurry, so that the gas production of a battery prepared from the additive in the use process is reduced, the safety of the battery is improved, the application of the waterless high-nickel positive electrode material is facilitated, and the cost ofthe battery is reduced; meanwhile, the preparation process of the positive electrode slurry is simple to operate, and industrialization is easy to realize.

Owner:EVE ENERGY CO LTD

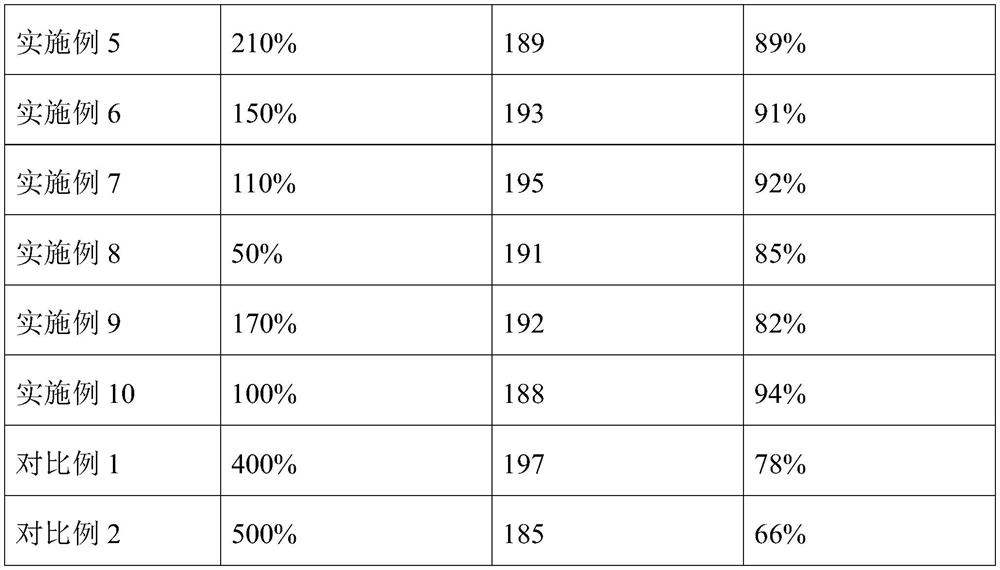

Method for extracting rubidium from fly ash

ActiveCN110229964AReduce pollutionReduce alkali consumptionProcess efficiency improvementPregnant leach solutionResource utilization

The invention provides a method for extracting rubidium from fly ash. The method comprises the following steps that a leaching agent is used for leaching the fly ash, solid-liquid separation is carried out, and leaching slag and leaching liquid with the pH value being 11-13.5 are obtained; sodium carbonate and the leaching liquid are mixed, solid-liquid separation is carried out after precipitation is completely carried out, and precipitation slag and precipitation liquid are obtained; an extraction agent is used for extracting the precipitation liquid, liquid dividing is carried out, and a rubidium-containing organic phase and a first aqueous phase are obtained; the rubidium-containing organic phase is washed to obtain an extraction phase and a second aqueous phase; and a reverse extraction agent is used for conducting reverse extraction on the extraction phase, liquid separating is carried out, and a rubidium-containing concentrated solution and a reverse extraction organic phase areobtained. According to the method, the fly ash is leached, the pH value of the leaching liquid does not need to be adjusted, and the alkali consumption is reduced; by selecting the specific leachingagent and the specific extraction agent, adding the sodium carbonate in the leaching liquid and conducting washing extraction on the organic phases, the rubidium extracting ratio is 52.57%, and the rubidium and potassium separation coefficient is 22, the fly ash resource utilization additional value is increased, and a new idea is provided for comprehensive utilization of the fly ash.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A modified nickel-cobalt-manganese ternary cathode material and a preparation method thereof

ActiveCN109244446ALow equipment requirementsLow reaction conditionsCell electrodesSecondary cellsNiobiumManganese

The invention provides a preparation method of a modified nickel-cobalt-manganese ternary cathode material, comprising the following steps: 1) preparation of the modified nickel-cobalt-manganese and 2) preparation of the niobium doped nickel-cobalt-manganese ternary cathode material. The invention also discloses a modified nickel-cobalt-manganese ternary cathode material prepared according to thepreparation method of the modified nickel-cobalt-manganese ternary cathode material and a lithium ion battery using the modified nickel-cobalt-manganese ternary cathode material as the cathode material. Compared with the traditional Ni-Co-Mn ternary cathode material in the prior art, the modified Ni-Co-Mn ternary cathode material prepared by the invention has the advantages of lower production cost, higher gram capacity, higher cycle stability and energy density, more excellent electrochemical performance, longer cycle service life, higher first charge-discharge efficiency, and safer and environmentally friendly use.

Owner:ZHEJIANG WELLY ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com