Lithium ion battery positive electrode material and preparation method thereof, and battery

A technology for lithium-ion batteries and positive electrode materials, which can be used in battery electrodes, secondary batteries, circuits, etc., and can solve problems such as limited performance of positive electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

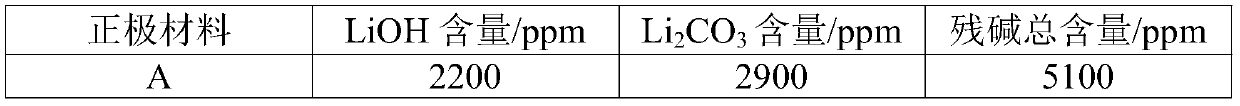

Embodiment 1

[0044] 1) Add 0.08g of LiH 2 PO 4 Dissolved in 10mL of water to make a solution, then 10g of Ni 0.88 mn 0.12 (OH) 2 Adding it to the above solution, stirring under magnetic force until the solution is evaporated to dryness, and roasting the obtained material at 300°C for 10 hours to obtain a precursor with a coating layer;

[0045] 2) The precursor with coating layer obtained in step 1) was mixed with LiOH at a mass ratio of 100:48, and then calcined at 830° C. for 10 h to obtain positive electrode material A.

[0046] The positive electrode material A includes the positive active component LiNi 0.88 mn 0.12 o 2 and Li 2 h 2 P 2 o 7 cladding. The positive electrode material A is subjected to XRD test, and there is Li with a 2θ of 23° in the obtained spectrum. 2 h 2 P 2 o 7 Characteristic peaks. The thickness of the coating layer is 5nm, and the content of the active component in the positive electrode material is 99% by weight.

Embodiment 2

[0048] 1) Add 0.05g of (NH 4 ) 2 HPO 4 Dissolved in 10mL of water to make a solution, then 10g of Ni 0.88 mn 0.12 (OH) 2 Adding it to the above solution, stirring under magnetic force until the solution is evaporated to dryness, and roasting the obtained material at 260° C. for 8 hours to obtain a precursor with a coating layer;

[0049] 2) Combine the precursor with coating obtained in step 1) with Li 2 CO 2 Mix according to the mass ratio of 100:45, and then bake at 800° C. for 10 h to obtain positive electrode material B.

[0050] The positive electrode material B includes the positive active component LiNi 0.88 mn 0.12 o 2 and Li 2 h 2 P 2 o 7 cladding. The positive electrode material B is subjected to XRD test, and there is Li with a 2θ of 23° in the obtained spectrum 2 h 2 P 2 o 7 Characteristic peaks. The thickness of the coating layer is 7nm, and the content of the active component in the positive electrode material is 98.7% by weight.

Embodiment 3

[0052] Carry out according to the method of Example 1, the difference is that the temperature for calcination in step 1) is 370° C. to obtain positive electrode material C.

[0053] The positive electrode material C includes the positive active component LiNi 0.88 mn 0.12 o 2 and LiPO 3 cladding. The positive electrode material C was tested by XRD, and the obtained spectrum contained LiPO with a 2θ of 22° 3 Characteristic peaks. The thickness of the coating layer is 6nm, and the content of the active component in the positive electrode material is 99% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com